Page 1

FORM NO. H11-524 REV. 8

Supersedes Form No. H11-524 Rev. 7

AIR HANDLERS

AIR HANDLERS

RHLL- High Efficiency

featuring Industry Standard

R-410A Refrigerant

RHSL- Standard Efficiency

featuring Industry Standard

R-410A Refrigerant

Features

■

RHLA/RHLL feature GE’s new X-13 (ECM) motor which

provides enhanced SEER performance with most Rheem

outdoor units.

■

11/2 ton [5.3 kW] through 5 ton [17.6 kW] models are

between 42

1

/2 to 551/2 inches [1080 to 1410 mm] tall and 22

inches [559 mm] deep.

■

Versatile 4-way convertible design for upflow, downflow,

horizontal left and horizontal right applications.

■

Factory-installed high efficiency indoor coil.

■

All models meet or exceed 330 to 400 CFM [156 to 189 L/s]

per ton at .3 inches [.7 kPa] of external static pressure.

■

Enhanced airflow up to .7" external static pressure.

■

Sturdy construction with 1.0 inch [.24 kPa] of reinforced foil

faced jacket insulation for excellent thermal and sound

insulation.

■

Field-installed auxiliary electric heater kits provide exact

heat for indoor comfort. Kits include circuit breakers which

meet UL and cUL requirements for service disconnect.

Page 2

2 Rheem Heating, Cooling and Water Heating

Engineering Features

GENERAL TERMS OF LIMITED WARRANTY

Rheem will furnish a replacement for any part of this product

which fails in normal use and service within the applicable

periods stated, in accordance with the terms of the limited

warranty.

Conditional Parts (Registration Required) .........Ten (10) Years

For Complete Details of the Limited Warranty, Including

Applicable Terms and Conditions, See Your Local Installer or

Contact the Manufacturer for a Copy.

RHLL/RHSL- Series

■

The most compact unit design available, all standard heat air

handler models only 42

1

/2 to 551/2 inches [1079 to 1409 mm] high.

■

Attractive pre-painted cabinet exterior.

■

Rugged wall steel cabinet construction, designed for added

strength and versatility.

■

1.0" foil faced insulation mechanically retained in blower

compartment for excellent thermal and sound performance.

■

Four leg blower motor mount.

■

Blower housing with controls, motor and blower. Slide out

design for service and maintenance convenience.

■

Traditional open wire element design for heat applications.

■

Field convertible for vertical downflow, horizontal left hand or

right hand air supply.

■

3 combustible floor base accessories fit all model sizes when

required for downflow installations on combustible floors.

■

Indoor coil design provides low air side pressure drop, high

performance and extremely compact size.

[ ] Designates Metric Conversions

■

Expansion valve on indoor coil provides for operation with air

conditioning or heat pump using the same coil.

■

Coils are constructed of aluminum fins bonded to internally

grooved copper tubing.

■

Molded polymer corrosion resistant condensate drain pan is

provided on all indoor coils.

■

Supply duct flanges provided as standard on air handler cabinet.

■

Provisions for field electrical, connections available from either

side or top of the air handler cabinet.

■

Connection point for high voltage wiring is inside the air handler

cabinet. Low voltage connection is made on the outside of the

air handler cabinet.

■

Concentric knockouts are provided for power connection to

cabinet. Installer may pull desired hole size up to 2 inches

[51 mm] for 1

1

/2 inch [38 mm] conduit.

■

Front refrigerant and drain connections.

Page 3

Rheem Heating, Cooling and Water Heating 3

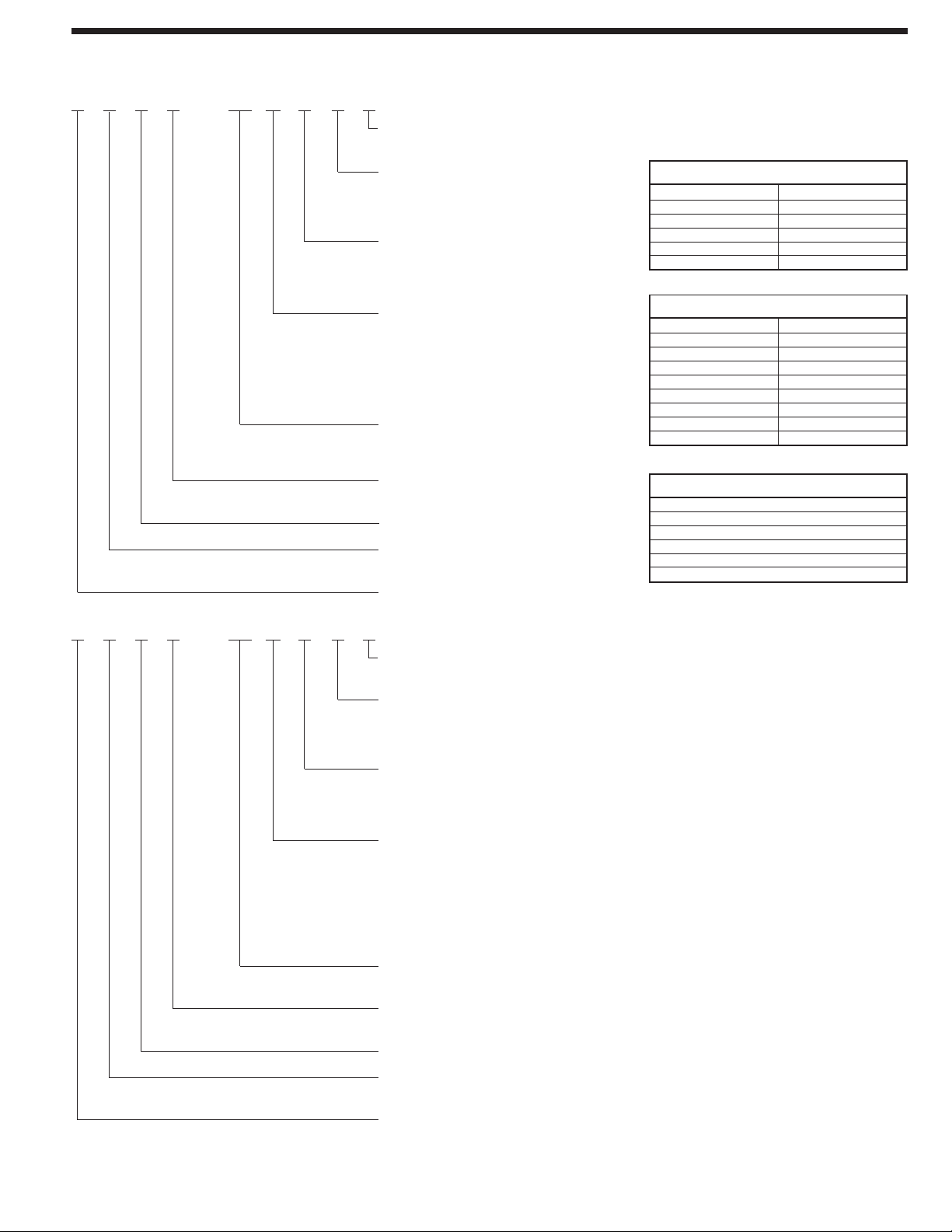

RHSL—HM1817JA

Design Variation

A = 1st Design

Voltage

A = 115/1/60

D = 480V-3-60

J = 208/240/1/60

Cabinet Size

17 = 17.5" [431.8 mm] (600-1200 CFM)

21 = 21" [533.4 mm] (1200-1600 CFM)

24 = 24.5" [609.6 mm] (1600-1800 CFM)

Capacity

18 = 18,000 BTU/H [5.27 kW]

24 = 24,000 BTU/H [7.03 kW]

30 = 30,000 BTU/H [8.79 kW]

36 = 36,000 BTU/H [10.55 kW]

42 = 42,000 BTU/H [12.31 kW]

48 = 48,000 BTU/H [14.06 kW]

60 = 60,000 BTU/H [17.58 kW]

HM = A/C or HP, Multi-Position

(Vertical Upflow/Horizontal Left is the factory configuration)

Refrigerant

L = R-410A

S = Standard Model (PSC Motor)

Classification

H = Air Handler

Rheem

[ ] Designates Metric Conversions

RHLL—HM2417J A

Design Variation

A = 1st Design

Voltage

A = 115/1/60

J = 208/240/1/60

D = 460/3/60

Cabinet Size

17 = 17.5" [431.8 mm] (600-1200 CFM)

21 = 21" [533.4 mm] (1400-1600 CFM)

24 = 24.5" [609.6 mm] (1600-1800 CFM)

Capacity

24 = 18,000/24,000 BTU/H [5.27/7.03 kW]

36 = 30,000/36,000 BTU/H [8.79/10.55 kW]

38 = 30,000/36,000/42,000 BTU/H

[8.79/10.55/12.31 kW]

48 = 42,000/48,000 BTU/H [12.31/14.06 kW]

60 = 60,000 BTU/H [17.58 kW]

HM = A/C or HP Multi-Position

(Vertical Upflow/Horizontal Left is the

factory configuration)

Refrigerant

L = R-410A

L = High Efficiency (X-13 (ECM) Motor)

Classification

H = Air Handler

Rheem

Model Identification

Available Models at 115V A Voltage

RHSL-HM1817AA

RHSL-HM2417AA

RHSL-HM3017AA

RHSL-HM3617AA

RHSL-HM4221AA

RHSL-HM4821AA

RHLL-HM2417AA

RHLL-HM3617AA

RHLL-HM4821AA

RHLL-HM4824AA

RHLL-HM6024AA

RHLL-HM3821AA

Available Models at D Voltage

RHSL-HM3617DA

RHSL-HM4221DA

RHSL-HM4821DA

RHSL-HM4824DA

RHLL-HM6024DA

RHSL-HM6024DA

Available Models at 218V J Voltage

RHSL-HM1817JA

RHSL-HM2417JA

RHSL-HM3017JA

RHSL-HM3617JA

RHSL-HM3621JA

RHSL-HM4221JA

RHSL-HM4821JA

RHSL-HM4824JA

RHSL-HM6024JA*

RHLL-HM2417JA

RHLL-HM3617JA

RHLL-HM4821JA

RHLL-HM4824JA

RHLL-HM6024JA

RHLL-HM3821JA

• Supply circuit protective devices may be fuses or

“HACR” type circuit breakers.

• Largest motor load is included in single circuit

and multiple circuit.

• If non-standard fuse size is specified, use the next

larger fuse size.

• J Voltage (230V) single-phase air handler is

designed to be used with single or three phase

230 volt power. In the case of connecting 3-phase

power to the air handler terminal block, bring

only two leads to the terminal block. Cap, insulate and fully secure the third lead.

• The air handlers are shipped from the factory with

the proper indoor coil installed, and cannot be

ordered without a coil.

• The air handlers do not have an internal filter

rack. An external filter rack or other means of

filtration is required.

Page 4

4 Rheem Heating, Cooling and Water Heating

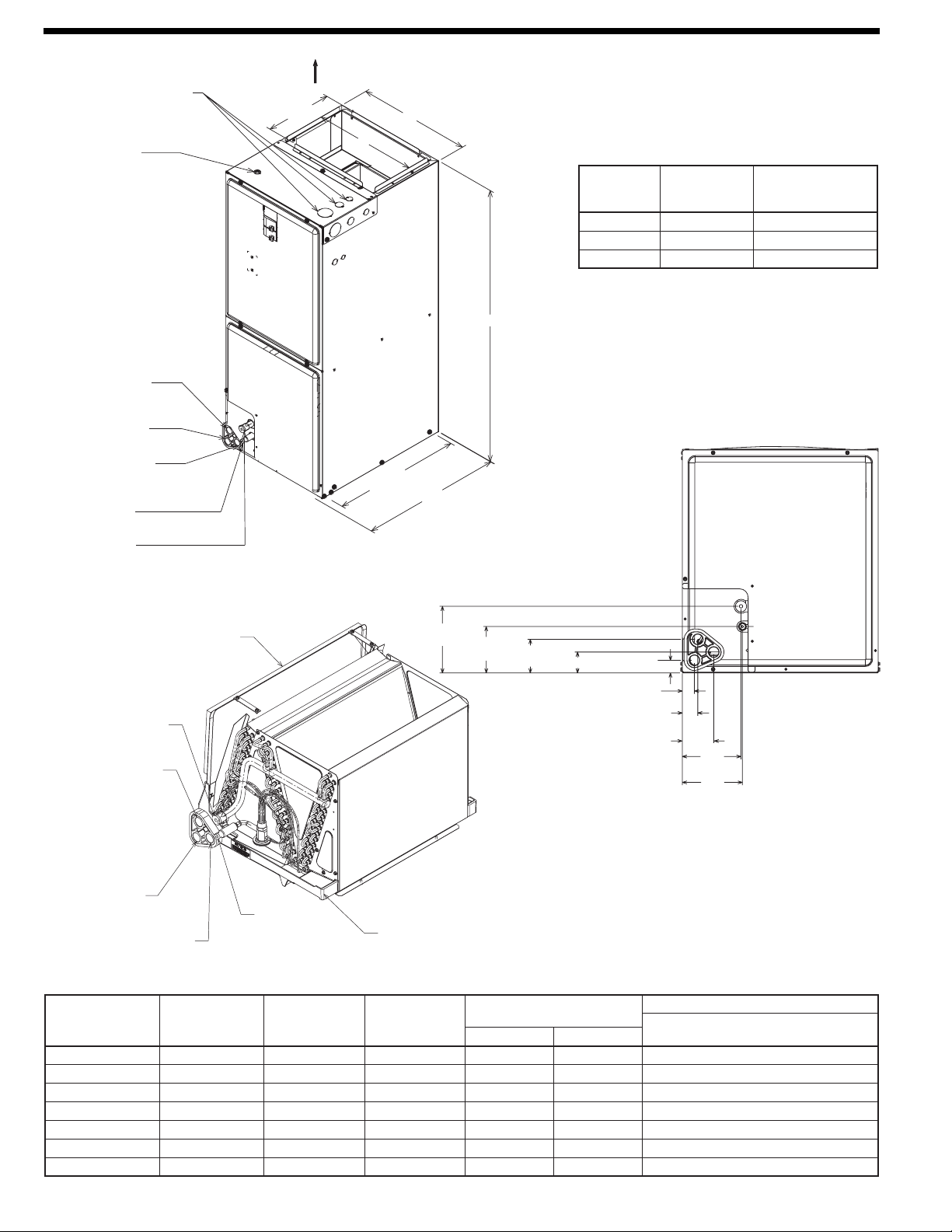

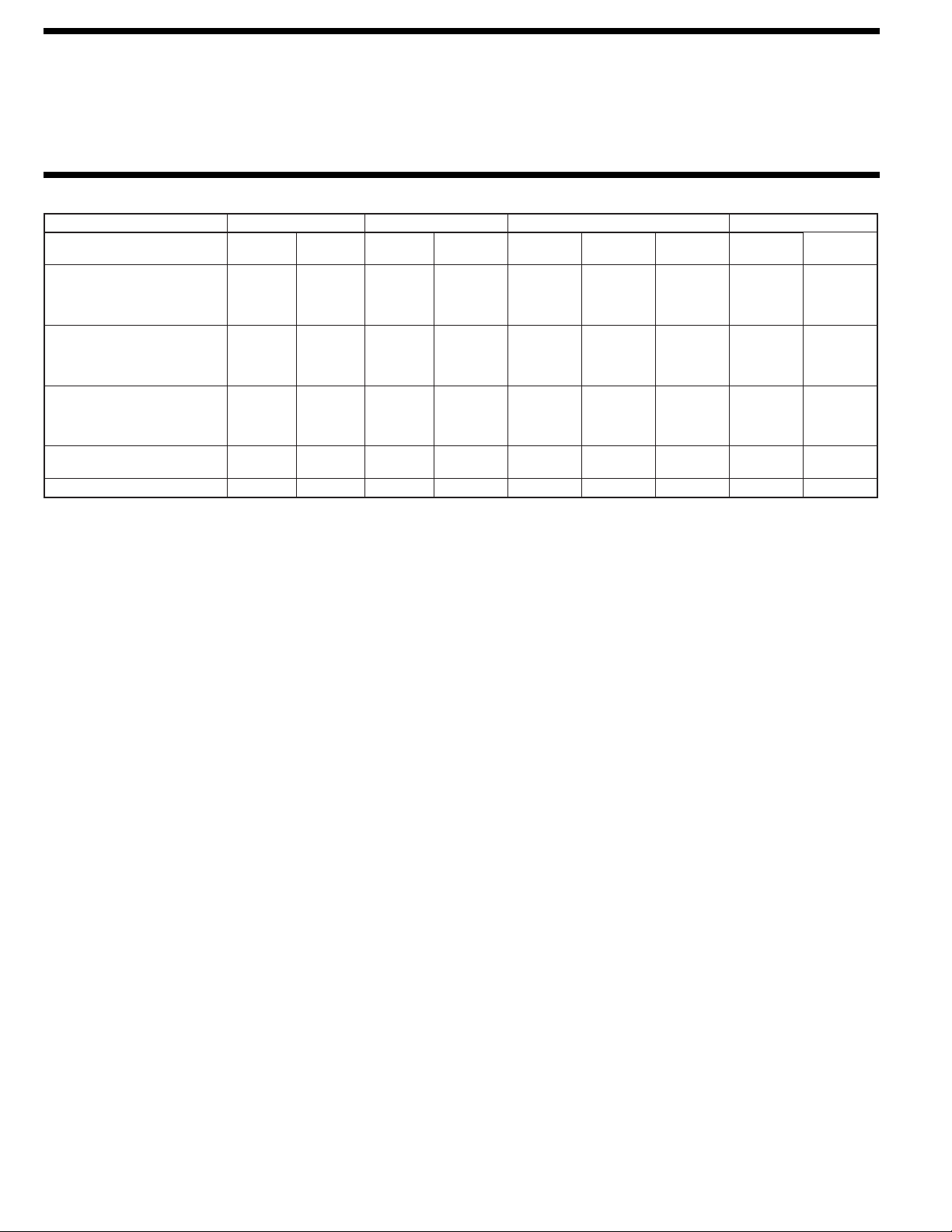

Return Air Opening Dimensions

Unit Dimensions

[ ] Designates Metric Conversions

( ) Designates Unit with Double Coil Cabinet

Unit Dimensions & Weights

ELECTRICAL CONNECTIONS

MAY EXIT TOP OR EITHER SIDE

HIGH VOLTAGE CONNECTION

3

/32 [27.8 mm], 131/32 [50 mm] DIA. KNOCKOUTS.

1

LOW VOLTAGE CONNECTION

5

/8 [15.9 mm] AND 7/8 [22.2 mm] KNOCKOUT

AUXILIARY DRAIN CONNECTION

3

/4 [19.1 mm] FEMALE PIPE THREAD (NPT)

HORIZONTAL APPLICATION ONLY

PRIMARY DRAIN CONNECTION

3

/4 [19.1 mm] FEMALE PIPE THREAD (NPT)

AUXILIARY DRAIN CONNECTION

3

/4 [19.1 mm] FEMALE PIPE THREAD (NPT)

UPFLOW/DOWNFLOW APPLICATION ONLY

LIQUID LINE CONNECTION

COPPER (SWEAT)

VAPOR LINE CONNECTION

COPPER (SWEAT)

7

/8 [22.2 mm],

SUPPLY AIR

5

10

/16

[262 mm]

A

191/2 [495 mm]

RETURN AIR

OPENING

UPFLOW UNIT SHOWN:

UNIT MAY BE INSTALLED UPFLOW, DOWNFLOW,

HORIZONTAL RIGHT OR LEFT AIR SUPPLY.

NOTE: 24 CLEARANCE REQUIRED IN FRONT OF

UNIT FOR FILTER AND COIL MAINTENANCE.

W

H

11

/16

21

[551 mm]

Model

Cabinet Size

Return Air

Opening Width

(Inches)

17 157/8 193/4

21 193/8 193/4

24 227/8 193/4

Return Air Opening

Depth/Length

(Inches)

HORIZONTAL ADAPTER KIT

VAPOR LINE

CONNECTION

AUXILIARY HORIZONTAL

DRAIN CONNECTION

515/16

[151 mm]

1

/8

4

[105 mm]

31/16

[76 mm]

3

1

/16 [48 mm]

1

1

/8 [29 mm]

1

/16

1

[27 mm]

1

[35 mm]

2

[71 mm]

3

/8

13

/16

51/4

[133 mm]

53/8

[136 mm]

PRIMARY DRAIN

CONNECTION

AUXILIARY UPFLOW/DOWNFLOW

DRAIN CONNECTION

LIQUID LINE

CONNECTION

VERTICAL DRAIN PAN

Model

Size

RHLL & RHSL

1817/2417 161/2 [406] 600 [283] 800 [378] 82/96 [37/44]

3017/3617

3621 191/2 [495] 1200 [566] — 97/112 [44/51]

Unit

Width

“W” In. [mm]

171/2 [445]

171/2 [445]

211/2 [533]

Unit

Height

“H” In. [mm]

421/2 [1080]

421/2 [1080]

421/2 [1080]

Supply

Duct

“A” In. [mm]

161/2 [406]

1000 [472] 1200 [566] 92/106 [37/48]

Air Flow

CFM (Nom.) [L/s]

Lo Hi

3821 191/2 [495] 1000 [472] 1200 [566] 150/166 [68/75]211/2 [533] 501/2 [1282]

4221/4821

4824

6024

211/2 [533] 501/2 [1282]

241/2 [622]

241/2 [622]

551/2 [1410]

551/2 [1410]

191/2 [495]

231/2 [584]

231/2 [584]

1400 [661] 1600 [755] 150/166 [68/75]

1600 [755] — 162/180 [73/81]

— 1800 [850] 181/198 [82/90]

Unit Weight/Shipping Weight (Lbs.) [kg]

Unit With

Coil (Max. KW)

Page 5

Rheem Heating, Cooling and Water Heating 5

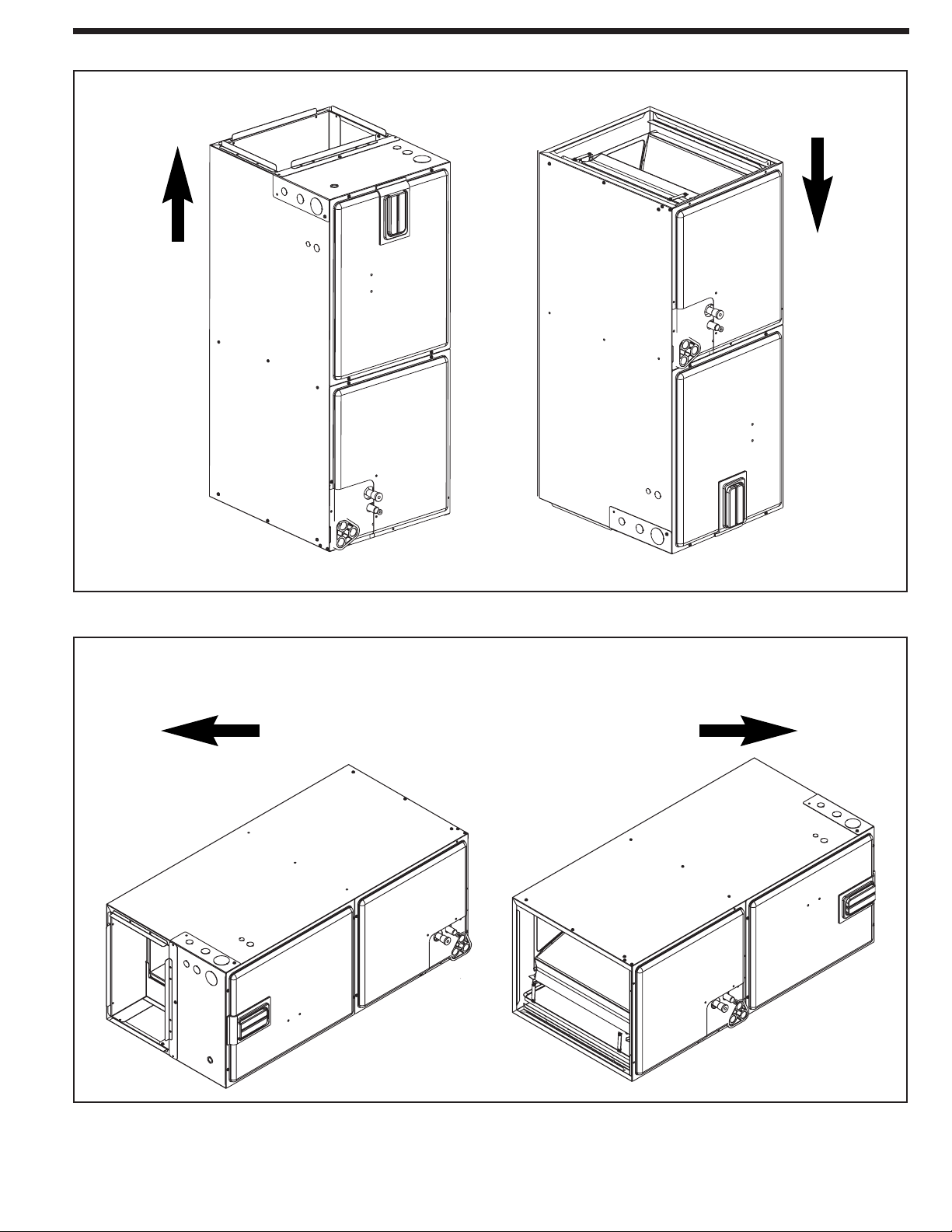

UPFLOW DOWNFLOW

Airflow Directions

HORIZONTAL RIGHT

HAND AIRFLOW

HORIZONTAL LEFT

HAND AIRFLOW

Page 6

6 Rheem Heating, Cooling and Water Heating

Airflow Performance

Airflow performance data is based on cooling performance

with a coil and no filter in place. Select performance table for

appropriate unit size, voltage and number of electric heaters to

be used. Make sure external static applied to unit allows operation within the minimum and maximum limits shown in table

below for both cooling and electric heat operation. For optimum

blower performance, operate the unit in the .3 [8 mm] to .7

inches [18 mm] W.C. external static range. Units with coils

should be applied with a minimum of .1 inch [3 mm] W.C.

external static range.

Airflow Operating Limits

[ ] Designates Metric Conversions

Model Cabinet Size 17 17/21

Cooling BTUH x 1,000

Cooling Tons Nominal

Heat Pump or Air Conditioning

Maximum Heat/Cool CFM [L/s]

(37.5 CFM [18 L/s]/1,000 BTUH)

(450 CFM [212 L/s]/Ton Nominal)

Heat Pump or Air Conditioning

Nominal Heat/Cool CFM [L/s]

(33.3 CFM [16 L/s]/1,000 BTUH)

(400 CFM [189 L/s]/Ton Nominal)

Heat Pump or Air Conditioning

Minimum Heat/Cool CFM [L/s]

(30.0 CFM [14 L/s]/1,200 BTUH)

(360 CFM [170 L/s]/Ton Nominal)

Maximum kW Electric Heating

& Minimum Electric Heat CFM [L/s]13487 [230]13617 [291]18814 [384]181054 [497]

Maximum Electric Heat Rise °F [°C] 80 [26.7] 63 [17.2] 66 [18.9] 51 [10.6] 49 [9.4] 50 [10] 50 [10]

-018

1.5

675

[319]

600

[283]

540

[255]

-024

2

900

[425]

800

[378]

720

[340]

-030

2.5

1125

[531]

1000

[472]

900

[425]

-036

3

1350

[637]

1200

[566]

1080

[510]

-038

3.5

1350

[637]

1200

[566]

1080

[510]

18

1042 [492]

21

-042

3.5

1575

[743]

1400

[661]

1260

[595]

20

1171 [553]251502 [709]251502 [709]

-048

4

1800

[850]

1600

[755]

1440

[680]

-048

4

1800

[850]

1600

[755]

1440

[680]

24

-060

5

1930

[911]

1800

[850]

1620

[765]

30

1666 [786]

54 [12.2]52 [11.1]

Page 7

Rheem Heating, Cooling and Water Heating 7

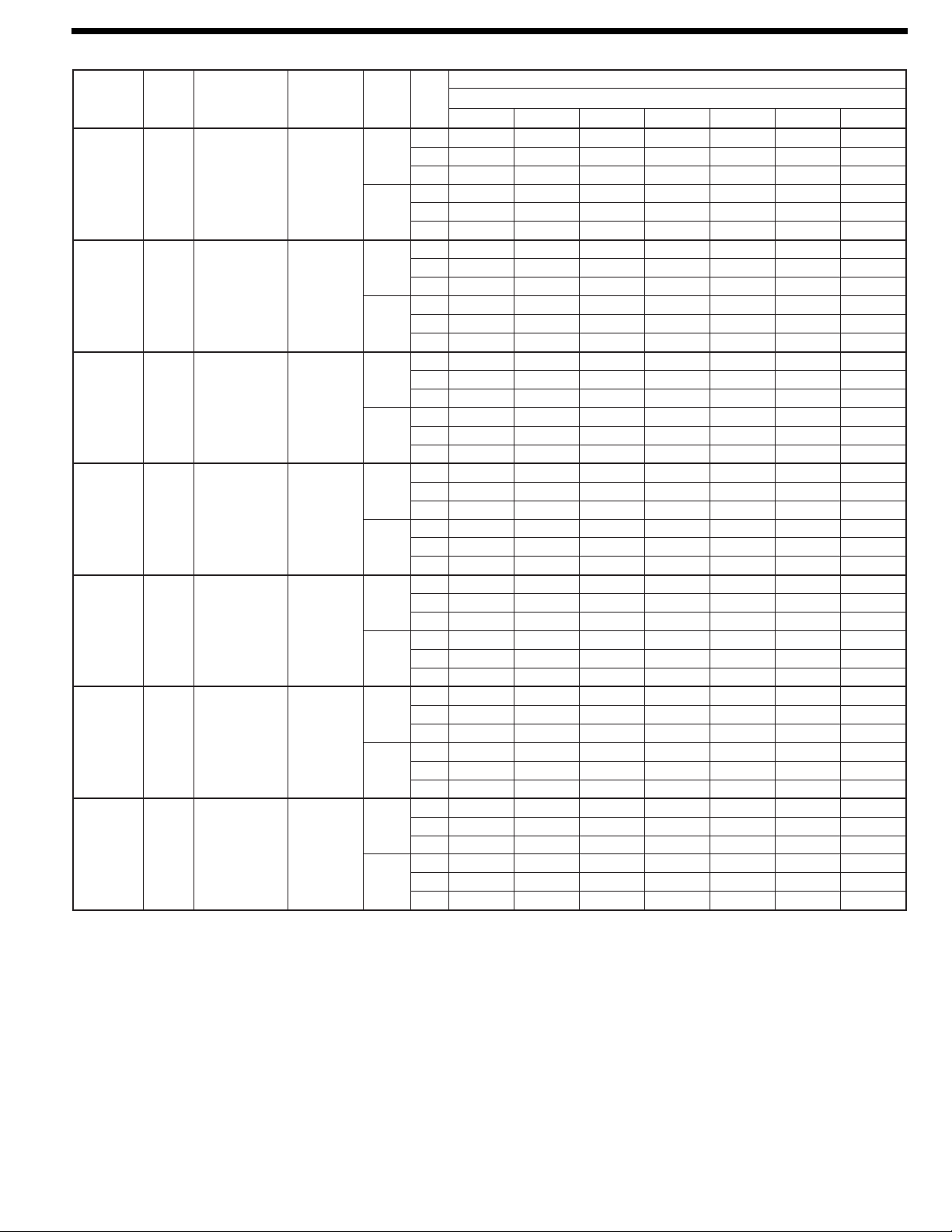

240V Airflow Performance Data—RHSL (PSC Motor)

Notes: • All 208/240V PSC motors have voltage taps for 208 and 240 volts.

• All 208/240V PSC motors are shipped on high speed and 240 volts.

• If the application external static is less than 0.5" WC, adjust the motor speed to the low static speed as described below:

• Unplug the black motor wire off the relay on the control board and plug in the red motor wire.

• Replace the cap on the black motor wire.

• Voltage change (208/240V motors):

• Move the orange lead to transformer 208V tap from 240V tap. Replace the wire cap on 240V tap.

• Unplug the purple motor wire off the transformer and plug in the yellow motor wire.

• Replace the cap on the purple motor wire.

• The above airflow table lists the airflow information for air handlers without heater and air handler with maximum heater allowed for each model.

• The following formula can be used to calculate the approximate airflow, if a smaller (N kW) than the maximum heater kit is installed.

Approximate Airflow = Airflow without heater - (Airflow without heater - Airflow with maximum heater) x (N kW/maximum heater kW)

[ ] Designates Metric Conversions

Model

No.

RHSL

-1817

No Heater

-1817

with 13 kW

Heater

-2417

No Heater

-2417

with 13 kW

Heater

-3017

No Heater

-3017

with 18 kW

Heater

-3617/-3621

No Heater

Motor

Speed

from

Factory

High

240V

High

240V

High

240V

High

240V

High

240V

High

240V

High

240V

Manufacturer

Recommended

Air-Flow Range

(Min/Max) CFM

517/711 CFM

[244/336 L/s]

487/661 CFM

[230/312 L/s]

647/888 CFM

[305/419 L/s]

617/838 CFM

[291/395 L/s]

864/1004 CFM

[408/474 L/s]

814/904 CFM

[384/427 L/s]

1104/1248 CFM

[521/589 L/s]

Blower Size/

Motor

HP [W]

# of Speed

10x6

1/5 HP [149]

2 Speed

10x6

1/5 HP [149]

2 Speed

10x6

1/5 HP [149]

2 Speed

10x6

1/5 HP [149]

2 Speed

10x8

1/4 HP [186]

2 Speed

10x8

1/4 HP [186]

2 Speed

10x8

1/3 HP [249]

2 Speed

Motor

Speed

Low

High

Low

High

Low

High

Low

High

Low

High

Low

High

Low

High

0.1 [.02] 0.2 [.05] 0.3 [.07] 0.4 [.10] 0.5 [.12] 0.6 [.15] 0.7 [.17]

CFM 668 [315] 637 [301] 595 [281] 560 [264] 517 [244] — —

RPM 541 596 657 706 761 — —

Watts 180 171 166 161 109 — —

CFM — — — — 711 [336] 662 [312] 614 [290]

RPM — — — — 812 853 890

Watts — — — — 243 227 210

CFM 638 [301] 607 [286] 565 [267] 530 [250]

RPM 571

Watts 171 162 157 152 146 — —

CFM — — — — 661 [312] 612 [289] 564 [266]

RPM

Watts — — — — 232 216 199

CFM 817 [386] 779 [368] 757 [357] 693 [327] 647 [305] — —

RPM 616 667 715 770 808 — —

Watts 239 230 221 206 205 — —

CFM — — — — 888 [419] 828 [391] 774 [365]

RPM — — — — 875 908 958

Watts — — — — 331 313 301

CFM 787 [371] 749 [353] 727 [343] 663 [313] 617 [291] — —

RPM 646 697 745 800 838 — —

Watts 230 221 212 197 187 — —

CFM — — — — 838 [395] 778 [367] 724 [342]

RPM — — — — 900 933 983

Watts

CFM 1022 [482] 987 [466] 940 [444] 903 [426] 864 [408] — —

RPM 700 754 794 633 870 — —

Watts 344 313 302 309 288 — —

CFM — — — — 1004 [474] 951 [449] 883 [417]

RPM — — — —

Watts

CFM 972 [459] 937 [442] 890 [420] 853 [403] 814 [384] — —

RPM 750 804 844 883 920 — —

Watts 324 293 282 274 268 — —

CFM — — — — 904 [427] 851 [402] 783 [370]

RPM — — — — 949 978 1000

Watts

CFM 1229 [580] 1201 [567] 1170 [552] 1141 [538] 1104 [521] — —

RPM 788 833 872 909 951 — —

Watts 466 462 427 406 395 — —

CFM — — — — 1248 [589] 1194 [563] 1133 [535]

RPM — — — — 1008 1028 1042

Watts — — — — 488 475 454

— — — — 837 878

— — — — 320 302 290

— — — — 364 352 344

— — — — 334 322 314

External Static Pressure—Inches W.C. [kPa]

487 [230] — —

626

687

736 791 — —

924

PSC CFM [L/s] Air Delivery/RPM/Watts—240 Volts

915

953 975

Page 8

8 Rheem Heating, Cooling and Water Heating

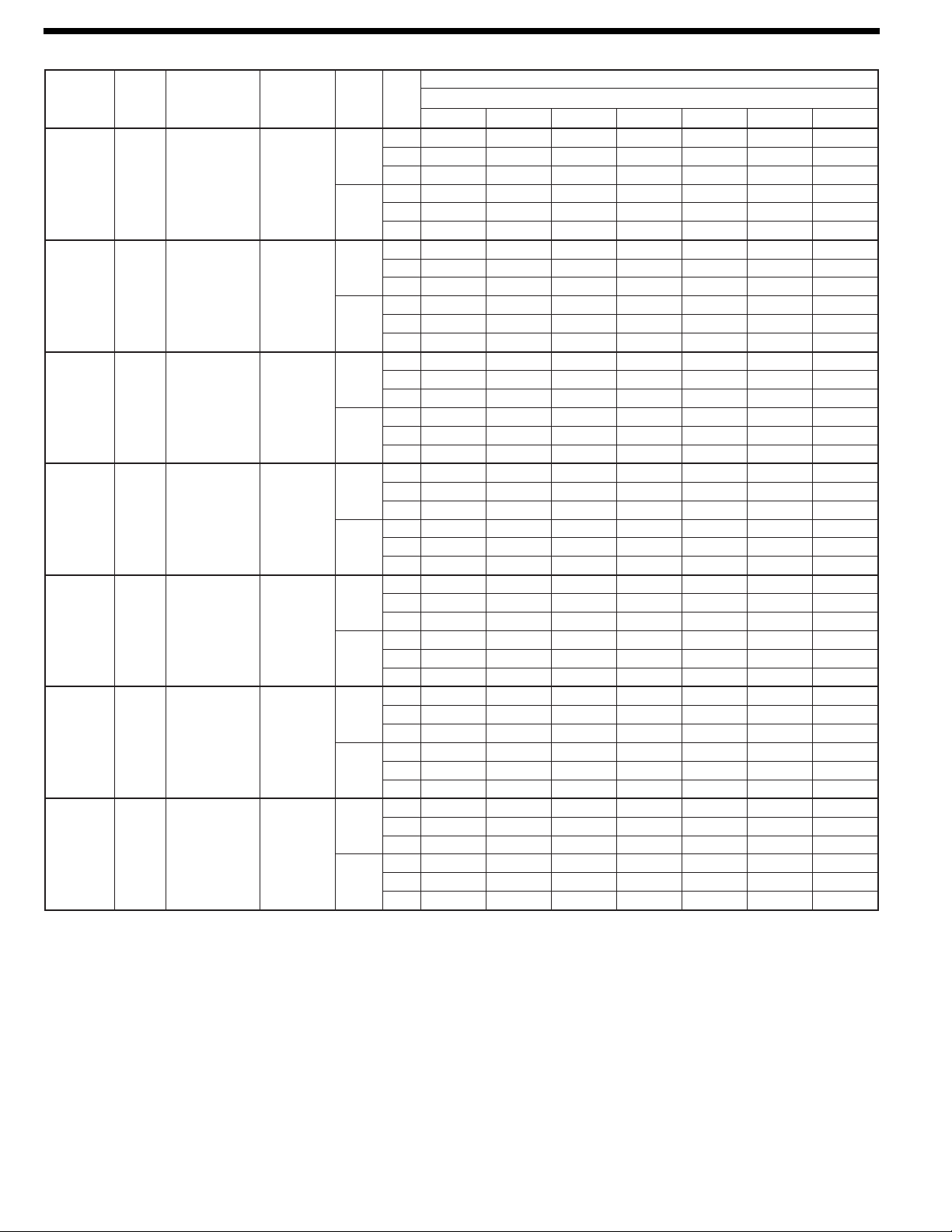

240V Airflow Performance Data—RHSL (PSC Motor) (con’t.)

Notes: • All 208/240V PSC motors have voltage taps for 208 and 240 volts.

• All 208/240V PSC motors are shipped on high speed and 240 volts.

• If the application external static is less than 0.5" WC, adjust the motor speed to the low static speed as described below:

• Unplug the black motor wire off the relay on the control board and plug in the red motor wire.

• Replace the cap on the black motor wire.

• Voltage change (208/240V motors):

• Move the orange lead to transformer 208V tap from 240V tap. Replace the wire cap on 240V tap.

• Unplug the purple motor wire off the transformer and plug in the yellow motor wire.

• Replace the cap on the purple motor wire.

• The above airflow table lists the airflow information for air handlers without heater and air handler with maximum heater allowed for each model.

• The following formula can be used to calculate the approximate airflow, if a smaller (N kW) than the maximum heater kit is installed.

Approximate Airflow = Airflow without heater - (Airflow without heater - Airflow with maximum heater) x (N kW/maximum heater kW)

[ ] Designates Metric Conversions

Model

No.

RHSL

-3617/3621

with 18 kW

Heater

-4221

No Heater

-4221

with 20 kW

Heater

-4821/-4824

No Heater

-4821/-4824

with 25 kW

Heater

-6024

No Heater

-6024

with 30 kW

Heater

Motor

Speed

from

Factory

High

240V

High

240V

High

240V

High

240V

High

240V

High

240V

High

240V

Manufacturer

Recommended

Air-Flow Range

(Min/Max) CFM

1054/1148 CFM

[497/542 L/s]

1241/1537 CFM

[586/725 L/s]

1225/1500 CFM

[553/678 L/s]

1572/1824 CFM

[742/861 L/s]

1225/1500 CFM

[709/814 L/s]

1766/1965 CFM

[833/927 L/s]

1225/1500 CFM

[709/814 L/s]

Blower Size/

Motor

HP [W]

# of Speed

10x8

1/3 HP [249]

2 Speed

10x10

1/2 HP [373]

2 Speed

10x10

1/2 HP [373]

2 Speed

10x10

3/4 HP [559]

2 Speed

10x10

3/4 HP [559]

2 Speed

11x11

3/4 HP [559]

2 Speed

11x11

3/4 HP [559]

2 Speed

Motor

Speed

Low

High

Low

High

Low

High

Low

High

Low

High

Low

High

Low

High

0.1 [.02] 0.2 [.05] 0.3 [.07] 0.4 [.10] 0.5 [.12] 0.6 [.15] 0.7 [.17]

CFM 1179 [556] 1151 [543] 1120 [529] 1091 [515] 1054 [497] — —

RPM 838 883 922 959 1001 — —

Watts 446 442 407 386 375 — —

CFM — — — — 1148 [542] 1094 [516] 1033 [487]

RPM — — — — 1033 1053 1067

Watts — — — — 458 445 424

CFM 1526 [720] 1474 [696] 1427 [673] 1307 [617]

RPM 834

Watts 560 549 535 476 462 — —

CFM — — — — 1537 [725] 1418 [669] 1334 [630]

RPM

Watts — — — — 860 835 820

CFM 1456 [687] 1404 [663] 1357 [640] 1237 [584] 1171 [553] — —

RPM 886 906

Watts 542 524 505 468 431 — —

CFM

RPM — — — — 1080 1090 1105

Watts — — — — 840 800 785

CFM 1741 [822] 1719 [811] 1667 [787] 1628 [768] 1572 [742] — —

RPM 878 920 950 981 1007 — —

Watts 785 757 707 667 641 — —

CFM — — — — 1824 [861] 1767 [834] 1653 [780]

RPM — — — — 1102 1112 1121

Watts

CFM 1671 [789] 1649 [778] 1597 [754] 1558 [735] 1502 [709] — —

RPM 945 965 995 1025 1050 — —

Watts 715 685 650 630 610 — —

CFM — — — — 1724 [814] 1667 [787] 1553 [733]

RPM — — —

Watts

CFM 1944 [917] 1912 [902] 1860 [878] 1813 [856] 1766 [833] — —

RPM 764 803 838 865 889 — —

Watts 779 763 747 729 708 — —

CFM — — — — 1965 [927] 1908 [900] 1854 [875]

RPM — — — — 943 967 977

Watts

CFM 1844 [870] 1812 [855] 1760 [831] 1713 [808] 1666 [786] — —

RPM

Watts 745 729 713 696 678

CFM — —

RPM — —

Watts — — — — 788 766 744

— — — — 1072 1077

— — — — 1437 [678] 1318 [622] 1234 [582]

— — — — 871 830 770

— — — — 810 780 730

— — — — 828 799 795

839

External Static Pressure—Inches W.C. [kPa]

1241 [586] — —

870

865 890 913

902

925 959 992

—

— — 987 1001 1014

948 968 — —

—

— 1865 [880] 1808 [853] 1754 [828]

1116

935 —

PSC CFM [L/s] Air Delivery/RPM/Watts—240 Volts

— —

1119 1130

— —

1085

—

Page 9

115V/208V/480V Airflow Performance Data—RHSL (PSC Motor)

Notes:• All 208/240V PSC motors have voltage taps for 208 and 240 volts.

• All 208/240V PSC motors are shipped on high speed and 240 volts.

• All 115V PSC motors are shipped on high speed.

• If the application external static is less than 0.5" WC, adjust the

motor speed to the low static speed as described below:

• Unplug the black motor wire off the relay on the control board and

plug in the red motor wire.

• Replace the cap on the black motor wire.

• Voltage change (208/240V motors):

• Move the orange lead to transformer 208V tap from 240V tap.

Replace the wire cap on 240V tap.

• Unplug the purple motor wire off the transformer and plug in the

yellow motor wire.

• Replace the cap on the purple motor wire.

• All 480V PSC motors are shipped on high speed.

• If the application external static is less than 0.5" WC, adjust the

motor speed to the low static speed as described below for 3-ton

through 4-ton air handlers.

• Unplug the black motor wire off the relay and remove the cap from

the red motor wire.

• Plug the red motor wire to the relay and connect the black motor

wire with the yellow motor wire.

• For 5-ton air handler, unplug the black motor wire off the relay and

plug in the red motor wire, then cap the black motor wire. There is

no yellow motor wire on 5-ton air handler.

WARNING: Do not connect red motor wire with yellow motor wire in any

circumstance on 480V PSC motors. Connecting red motor wire with yellow

motor wire will result in permanent motor damage.

• The above airflow table lists the airflow information for air handlers

without heater and air handler with maximum heater allowed for each

model.

• The following formula can be used to calculate the approximate airflow, if a

smaller (N kW) than the maximum heater kit is installed. Approximate

Airflow = Airflow without heater - (Airflow without heater - Airflow with

maximum heater) x (N kW/maximum heater kW)

[ ] Designates Metric Conversions

Rheem Heating, Cooling and Water Heating 9

Model

No.

RHSL

-1817

No Heater

-1817

with 13 kW

Heater

-2417

No Heater

-2417

with 13 kW

Heater

-3017

No Heater

-3017

with 18 kW

Heater

-3617/-3621

No Heater

Motor

Speed

from

Factory

High

High

High

High

High

High

High

Manufacturer

Recommended

Air-Flow Range

(Min/Max) CFM

523/705 CFM

[247/333 L/s]

487/661 CFM

[230/312 L/s]

647/888 CFM

[305/419 L/s]

617/838 CFM

[291/395 L/s]

864/1004 CFM

[408/474 L/s]

814/904 CFM

[384/427 L/s]

1104/1248 CFM

[521/589 L/s]

Blower Size/

Motor

HP [W]

# of Speed

10x6

1/5 HP [149]

2 Speed

10x6

1/5 HP [149]

2 Speed

10x6

1/5 HP [149]

2 Speed

10x6

1/5 HP [149]

2 Speed

10x8

1/4 HP [186]

2 Speed

10x8

1/4 HP [186]

2 Speed

10x8

1/3 HP [249]

2 Speed

Motor

Speed

Low

High

Low

High

Low

High

Low

High

Low

High

Low

High

Low

High

0.1 [.02] 0.2 [.05] 0.3 [.07] 0.4 [.10] 0.5 [.12] 0.6 [.15] 0.7 [.17]

CFM 681 [321] 636 [300] 606 [286] 567 [268] 523 [247] — —

RPM 541 601 670 714 768 — —

Watts 193 181 173 164 157 — —

CFM — — — — 705 [333] 650 [307] 599 [283]

RPM — — — — 815 861 989

Watts — — — — 239 227 204

CFM 651 [307] 606 [286] 576 [272] 537 [253] 493 [233] — —

RPM 571 631 700 744 798 — —

Watts 184 172 164 155 148 — —

CFM — — — — 655 [309] 600 [283] 549 [259]

RPM — — — — 840 886 1014

Watts — — — — 228 216 193

CFM 875 [413] 806 [380] 787 [371] 739 [349] 682 [322] — —

RPM 648 700 745 794 827 — —

Watts 259 255 243 234 227 — —

CFM — — — — 897 [423] 851 [402] 765 [361]

RPM — — — — 906 925 955

Watts — — — — 332 318 306

CFM 845 [399] 776 [366] 757 [357] 709 [335] 652 [308] — —

RPM 678 730 775 824 857 — —

Watts 250 246 234 225 218 — —

CFM — — — — 847 [400] 801 [378] 715 [337]

RPM — — — — 931 950 980

Watts

CFM 1038 [490] 1010 [477] 976 [461] 925 [437] 883 [417] — —

RPM 721 771 799 848 880 — —

Watts 325 314 303 290 286 — —

CFM — — — — 1015 [479] 963 [454] 890 [420]

RPM — — — — 928 955 974

Watts

CFM 988 [466] 960 [453] 926 [437] 875 [413] 833 [393] — —

RPM 771 821 849 898 930 — —

Watts 305 294 283 270 266 — —

CFM — — — — 915 [432] 863 [407] 790 [373]

RPM — — — — 953 980 999

Watts

CFM 1201 [567] 1170 [552] 1141 [538] 1104 [521] 1062 [501] — —

RPM 833 872 909 951 965 — —

Watts 462 427 406 396 385 — —

CFM — — — — 1194 [563] 1134 [535] 1078 [509]

RPM — — — — 1024 1042 1060

Watts — — — — 475 454 417

— — — — 321 307 295

— — — — 356 341 329

— — — — 326 311 299

External Static Pressure—Inches W.C. [kPa]

PSC CFM [L/s] Air Delivery/RPM/Watts—115/208/480 Volts

Page 10

10 Rheem Heating, Cooling and Water Heating

115V/208V/480V Airflow Performance Data—RHSL (PSC Motor) (con’t.)

Notes:• All 208/240V PSC motors have voltage taps for 208 and 240 volts.

• All 208/240V PSC motors are shipped on high speed and 240 volts.

• All 115V PSC motors are shipped on high speed.

• If the application external static is less than 0.5" WC, adjust the

motor speed to the low static speed as described below:

• Unplug the black motor wire off the relay on the control board and

plug in the red motor wire.

• Replace the cap on the black motor wire.

• Voltage change (208/240V motors):

• Move the orange lead to transformer 208V tap from 240V tap.

Replace the wire cap on 240V tap.

• Unplug the purple motor wire off the transformer and plug in the

yellow motor wire.

• Replace the cap on the purple motor wire.

• All 480V PSC motors are shipped on high speed.

• If the application external static is less than 0.5" WC, adjust the

motor speed to the low static speed as described below for 3-ton

through 4-ton air handlers.

• Unplug the black motor wire off the relay and remove the cap from

the red motor wire.

• Plug the red motor wire to the relay and connect the black motor

wire with the yellow motor wire.

• For 5-ton air handler, unplug the black motor wire off the relay and

plug in the red motor wire, then cap the black motor wire. There is

no yellow motor wire on 5-ton air handler.

WARNING: Do not connect red motor wire with yellow motor wire in any

circumstance on 480V PSC motors. Connecting red motor wire with yellow

motor wire will result in permanent motor damage.

• The above airflow table lists the airflow information for air handlers

without heater and air handler with maximum heater allowed for each

model.

• The following formula can be used to calculate the approximate airflow, if a

smaller (N kW) than the maximum heater kit is installed. Approximate

Airflow = Airflow without heater - (Airflow without heater - Airflow with

maximum heater) x (N kW/maximum heater kW)

[ ] Designates Metric Conversions

Model

No.

RHSL

-3617/3621

with 18 kW

Heater

-4221

No Heater

-4221

with 20 kW

Heater

-4821/-4824

No Heater

-4821/-4824

with 25 kW

Heater

-6024

No Heater

-6024

with 30 kW

Heater

Motor

Speed

from

Factory

High

High

High

High

High

High

High

Manufacturer

Recommended

Air-Flow Range

(Min/Max) CFM

1054/1148 CFM

[497/542 L/s]

1241/1537 CFM

[580/725 L/s]

1225/1500 CFM

[538/667 L/s]

1512/1824 CFM

[742/801 L/s]

1225/1500 CFM

[695/796 L/s]

1766/1965 CFM

[833/927 L/s]

1225/1500 CFM

[695/796 L/s]

Blower Size/

Motor

HP [W]

# of Speed

10x8

1/3 HP [249]

2 Speed

10x10

1/2 HP [373]

2 Speed

10x10

1/2 HP [373]

2 Speed

10x10

3/4 HP [559]

2 Speed

10x10

3/4 HP [559]

2 Speed

11x11

3/4 HP [559]

2 Speed

11x11

3/4 HP [559]

2 Speed

Motor

Speed

Low

High

Low

High

Low

High

Low

High

Low

High

Low

High

Low

High

0.1 [.02] 0.2 [.05] 0.3 [.07] 0.4 [.10] 0.5 [.12] 0.6 [.15] 0.7 [.17]

CFM 1151 [543] 1120 [529] 1091 [515] 1054 [497] 1012 [478] — —

RPM 883 922 959 1001 1015 — —

Watts 442 407 386 376 365 — —

CFM — — — — 1094 [516] 1034 [488] 978 [462]

RPM — — — — 1049 1067 1085

Watts — — — — 445 424 387

CFM 1493 [705] 1449 [684] 1363 [643] 1287 [607]

RPM 822

Watts 540 519 506 484 459 — —

CFM — — — — 1514 [714] 1411 [666] 1315 [621]

RPM

Watts — — — — 710 702 677

CFM 1423 [672] 1379 [651] 1293 [610] 1217 [574] 1141 [538] — —

RPM 870 882

Watts 514 508 490 461 431 — —

CFM

RPM — — — — 1067 1080 1094

Watts — — — — 700 678 665

CFM 1711 [807] 1689 [797] 1637 [773] 1598 [754] 1542 [728] — —

RPM 863 905 935 966 992 — —

Watts 765 737 687 647 621 — —

CFM — — — — 1787 [843] 1679 [792] 1575 [743]

RPM — — — — 1089 1098 1110

Watts

CFM 1641 [774] 1619 [764] 1567 [739] 1528 [721] 1472 [695] — —

RPM 930 950 985 1015 1041 — —

Watts 700 660 630 600 580 — —

CFM — — — — 1687 [796] 1579 [745] 1475 [696]

RPM — — —

Watts

CFM 1866 [881] 1833 [865] 1806 [852] 1772 [836] 1710 [807] — —

RPM 764 803 824 856 886 — —

Watts 778 756 733 715 701 — —

CFM — — — — 1967 [928] 1916 [904] 1863 [879]

RPM — — — — 948 959 991

Watts

CFM 1796 [848] 1763 [832] 1736 [819] 1702 [803] 1640 [774] — —

RPM

Watts 735 718 705 695 678

CFM — —

RPM — —

Watts — — — — 818 795 780

— — — — 1061 1069

— — — — 1414 [667] 1311 [619] 1215 [573]

— — — — 695 665 630

— — — — 670 635 615

— — — — 850 827 816

828

External Static Pressure—Inches W.C. [kPa]

1211 [571] — —

858

860 878 890

885

925 957 992

—

— — 989 1005 1020

931 958 — —

—

— 1867 [881] 1816 [857] 1763 [832]

1095

1001 —

PSC CFM [L/s] Air Delivery/RPM/Watts—115/208/480V Volts

1078

— —

1107 1120

—

— —

Page 11

Rheem Heating, Cooling and Water Heating 11

115V/208V/240V/460V Airflow Performance Data—RHLL (X-13 (ECM) Motor)

Notes: X-13 (ECM) motor speed changes.

All X-13 (ECM) motors have 5 speed tabs. Speed tab 1 is for continuous fan. Speed tab 2 (low static) and Speed tab 3 (high static) are for lower tonnage.

Speed tab 4 (low static) and Speed tab 5 (high static) are for higher tonnage.

X-13 (ECM) air handlers are always shipped from factory at Speed tab 5, except for -4824, which is set at Speed tab 3. For instance, RHLL-HM2417JA is

always shipped at high static 2-ton airflow (Speed tab 5). To change to 1.5-ton airflow, move the blue wire to Speed tab 2 or 3 on the X-13 (ECM) motor.

The low static Speed tab 2 (lower tonnage) and 4 (higher tonnage) are used for external static below 0.5" WC. The high static Speed tab 3 (lower tonnage)

and 5 (higher tonnage) are used for external static exceeding 0.5" WC. Move the blue wire to the appropriate Speed tab as required by the application needs.

• The airflow for continuous fan (Speed tab 1) is always set at 50% of the Speed tab 4.

• The above airflow table lists the airflow information for air handlers without heater and air handler with maximum heater allowed for each model.

• The following formula can be used to calculate the approximate airflow, if a smaller (N kW) than the maximum heater kit is installed.

Approximate Airflow = Airflow without heater – (Airflow without heater – Airflow with maximum heater) x (N kW/maximum heater kW)

[ ] Designates Metric Conversions

Blower Size/

Motor

HP [W]

# of Speed

10x6

1/3 HP [249]

5 Speed

10x6

1/3 HP [249]

5 Speed

10x6

1/3 HP [249]

5 Speed

10x6

1/3 HP [249]

5 Speed

10x8

1/2 HP [373]

5 Speed

10x8

1/2 HP [373]

5 Speed

10x8

1/2 HP [373]

5 Speed

10x8

1/2 HP [373]

5 Speed

Motor

Speed

2

3

2

3

4

5

4

5

2

3

2

3

4

5

4

5

0.1 [.02] 0.2 [.05] 0.3 [.07] 0.4 [.10] 0.5 [.12] 0.6 [.15] 0.7 [.17]

CFM 689 [325] 644 [304] 602 [284] 563 [266] 509 [240] — —

RPM 580 633 683 728 781 — —

Watts 66 84 86 88 91 — —

CFM — — — — 681 [321] 644 [304] 603 [285]

RPM — — — — 835 879 916

Watts — — — — 136 143 152

CFM 670 [316] 625 [295] 583 [275] 544 [257]

RPM 608

Watts 75 93 95 47 100 — —

CFM — — — — 666 [314] 629 [297] 588 [277]

RPM

Watts — — — — 144 151 160

CFM 875 [413] 839 [396] 804 [379] 762 [360] 730 [345] — —

RPM 679 724

Watts 121 131 135 142 143 — —

CFM

RPM — — — — 904 940 970

Watts — — — — 203 215 228

CFM 856 [404] 820 [387] 785 [370] 743 [351] 711 [336] — —

RPM 707 752 793 838 880 — —

Watts 130 140 144 151 152 — —

CFM — — — — 837 [395] 803 [379] 776 [366]

RPM — — — — 924 960 990

Watts — — — — 211 223 288

CFM 1093 [516] 1050 [496] 1017 [480] 977 [461] 935 [441] — —

RPM 671 725 764 809 852 — —

Watts 153 168 174 180 188 — —

CFM — — — — 1084 [512] 1040 [491] 1001 [472]

RPM — — —

Watts

CFM 1068 [504] 1025 [484] 992 [468] 952 [449] 910 [429] — —

RPM 711 765 804 849 892 — —

Watts 164 179 185 191 199 — —

CFM — — — — 1059 [500] 1015 [479] 976 [461]

RPM — — — — 936 976 1011

Watts

CFM 1270 [599] 1237 [584] 1199 [566] 1165 [550] 1130 [533] — —

RPM

Watts 237 249 259 268 277

CFM — —

RPM — —

Watts

CFM 1245 [588] 1212 [572] 1174 [554] 1140 [538] 1105 [521] — —

RPM 815 856 886 922 966 — —

Watts 248 260 270 279 288 — —

CFM — — — — 1250 [590] 1219 [575] 1186 [560]

RPM — — — — 1003 1039 1069

Watts — — — — 349 359 374

— — — — 855 899

— — — — 862 [407] 828 [391] 801 [378]

— — — — 249 257 261

— — — — 260 268 272

775

— — — — 338 348 363

External Static Pressure—Inches W.C. [kPa]

490 [231] — —

661

816 846 882

711

765 810 852

—

— — 963 999 1029

756 809 — —

—

— 1275 [602] 1244 [587] 1211 [571]

896

926 —

X-13 CFM [L/s] Air Delivery/RPM/Watts—115/208/240 Volts

936

— —

936 971

—

— —

5

5

5

5

5

5

5

5

Manufacturer

Recommended

Air-Flow Range

(Min/Max) CFM

509/681 CFM

[240/321 L/s]

490/666 CFM

[231/314 L/s]

730/651 CFM

[345/307 L/s]

711/626CFM

[336/295 L/s]

935/1084 CFM

[441/512 L/s]

910/1059 CFM

[429/500 L/s]

1130/1275 CFM

[533/602 L/s]

1105/1250 CFM

[521/590 L/s]

Model

No.

RHLL

-2417

No Heater

-2417

with 13 kW

Heater

-2417

No Heater

-2417

with 13 kW

Heater

-3617

No Heater

-3617

with 18 kW

Heater

-3617

No Heater

-3617

with 18 kW

Heater

Tonnage

Application

1.5 Ton

1.5 Ton

2 Ton

2 Ton

2.5 Ton

2.5 Ton

3 Ton

3 Ton

Motor

Speed

From

Factory

Page 12

12 Rheem Heating, Cooling and Water Heating

115V/208V/240V/460V Airflow Performance Data—RHLL (X-13 (ECM) Motor) (con’t.)

Notes: X-13 (ECM) motor speed changes.

All X-13 (ECM) motors have 5 speed tabs. Speed tab 1 is for continuous fan. Speed tab 2 (low static) and Speed tab 3 (high static) are for lower tonnage.

Speed tab 4 (low static) and Speed tab 5 (high static) are for higher tonnage.

X-13 (ECM) air handlers are always shipped from factory at Speed tab 5, except for -4824, which is set at Speed tab 3. For instance, RHLL-HM2417JA is

always shipped at high static 2-ton airflow (Speed tab 5). To change to 1.5-ton airflow, move the blue wire to Speed tab 2 or 3 on the X-13 (ECM) motor.

The low static Speed tab 2 (lower tonnage) and 4 (higher tonnage) are used for external static below 0.5" WC. The high static Speed tab 3 (lower tonnage)

and 5 (higher tonnage) are used for external static exceeding 0.5" WC. Move the blue wire to the appropriate Speed tab as required by the application needs.

• The airflow for continuous fan (Speed tab 1) is always set at 50% of the Speed tab 4.

• The above airflow table lists the airflow information for air handlers without heater and air handler with maximum heater allowed for each model.

• The following formula can be used to calculate the approximate airflow, if a smaller (N kW) than the maximum heater kit is installed.

Approximate Airflow = Airflow without heater – (Airflow without heater – Airflow with maximum heater) x (N kW/maximum heater kW)

[ ] Designates Metric Conversions

Blower Size/

Motor

HP [W]

# of Speed

10x10

3/4 HP [559]

5 Speed

10x10

3/4 HP [559]

5 Speed

10x10

3/4 HP [559]

5 Speed

10x10

3/4 HP [559]

5 Speed

Motor

Speed

2

3

2

3

4

5

4

5

0.1 [.02] 0.2 [.05] 0.3 [.07] 0.4 [.10] 0.5 [.12] 0.6 [.15] 0.7 [.17]

CFM 1073 [506] 1016 [479] 963 [454] 906 [428] 854 [403] — —

RPM 637

Watts 130 142 153 165 176 — —

CFM — — — — 1103 1059 1000

RPM

Watts — — — — 262 271 285

CFM 1044 [493] 988 [466] 936 [442] 880 [415] 828 [391] — —

RPM 678 734 791 844 883 — —

Watts 141 155 158 171 182 — —

CFM — — — — 1016 961 904

RPM — — — — 939 968 1015

Watts — — — — 233 243 265

CFM 1264 [597] 1223 [577] 1171 [553] 1112 [525] 1070 [505] — —

RPM 724 761 814 868 900 — —

Watts 198 208 222 237 245 — —

CFM — — — — 1288 1244 1200

RPM — — — — 974 1012 1044

Watts — — — — 345 362 371

CFM 1233 [582] 1193 [563] 1142 [539] 1084 [512] 1042 [492] — —

RPM 759 794 845 915 933 — —

Watts 219 215 227 251 261

CFM — — — — 1257 1213 1169

RPM — — — — 1020 1023 1054

Watts — — — — 355 368 376

— — — — 917 957 1001

External Static Pressure—Inches W.C. [kPa]

692

746

801 847 — —

PSC CFM [L/s] Air Delivery/RPM/Watts—115/208/240 Volts

4

4

4

4

Manufacturer

Recommended

Air-Flow Range

(Min/Max) CFM

854/1103 CFM

[403/521 L/s]

828/1016 CFM

[391/479 L/s]

1070/1288 CFM

[505/608 L/s]

1042/1257 CFM

[492/593 L/s]

Model

No.

RHLL

-3821

No Heater

-3821

with 18 kW

Heater

-3821

No Heater

-3821

with 18 kW

Heater

Tonnage

Application

2.5 Ton

2.5 Ton

3 Ton

3 Ton

Motor

Speed

From

Factory

Page 13

Rheem Heating, Cooling and Water Heating 13

115V/208V/240V/460V Airflow Performance Data—RHLL (X-13 (ECM) Motor) (con’t.)

Notes: X-13 (ECM) motor speed changes.

All X-13 (ECM) motors have 5 speed tabs. Speed tab 1 is for continuous fan. Speed tab 2 (low static) and Speed tab 3 (high static) are for lower tonnage.

Speed tab 4 (low static) and Speed tab 5 (high static) are for higher tonnage.

X-13 (ECM) air handlers are always shipped from factory at Speed tab 5, except for -4824, which is set at Speed tab 3. For instance, RHLL-HM2417JA is

always shipped at high static 2-ton airflow (Speed tab 5). To change to 1.5-ton airflow, move the blue wire to Speed tab 2 or 3 on the X-13 (ECM) motor.

The low static Speed tab 2 (lower tonnage) and 4 (higher tonnage) are used for external static below 0.5" WC. The high static Speed tab 3 (lower tonnage)

and 5 (higher tonnage) are used for external static exceeding 0.5" WC. Move the blue wire to the appropriate Speed tab as required by the application needs.

• The airflow for continuous fan (Speed tab 1) is always set at 50% of the Speed tab 4.

• The above airflow table lists the airflow information for air handlers without heater and air handler with maximum heater allowed for each model.

• The following formula can be used to calculate the approximate airflow, if a smaller (N kW) than the maximum heater kit is installed.

Approximate Airflow = Airflow without heater – (Airflow without heater – Airflow with maximum heater) x (N kW/maximum heater kW)

[ ] Designates Metric Conversions

Blower Size/

Motor

HP [W]

# of Speed

10x10

3/4 HP [559]

5 Speed

10x10

3/4 HP [559]

5 Speed

10x10

3/4 HP [559]

5 Speed

10x10

3/4 HP [559]

2 Speed

11x11

3/4 HP [559]

5 Speed

11x11

3/4 HP [559]

5 Speed

11x11

3/4 HP [559]

5 Speed

11x11

3/4 HP [559]

5 Speed

Motor

Speed

2

3

2

3

4

5

4

5

2

3

2

3

2

3

2

3

0.1 [.02] 0.2 [.05] 0.3 [.07] 0.4 [.10] 0.5 [.12] 0.6 [.15] 0.7 [.17]

CFM 1473 [695] 1442 [681] 1401 [661] 1373 [648] 1337 [631] — —

RPM 781 825 867 905 949 — —

Watts 257 271 303 307 315 — —

CFM — — — — 1447 [683] 1433 [676] 1402 [662]

RPM — — — — 987 1034 1065

Watts

CFM 1433 [676] 1402 [662] 1361 [642] 1333 [629] 1297 [612] — —

RPM

Watts 277 295 313 319 325

CFM — —

RPM — —

Watts

CFM 1665 [786] 1631 [770] 1601 [756] 1572 [742] 1535 [724] — —

RPM 853 893 934 968 1015 — —

Watts 351 387 401 406 422 — —

CFM — — — — 1654 [781] 1624 [766] 1563 [738]

RPM — — — — 1036 1078 1095

Watts

CFM 1625 [767] 1591 [751] 1561 [737] 1532 [723] 1495 [706] — —

RPM 894 932 970 1020 1052 — —

Watts 389 400 410 430 450 — —

CFM — — — — 1614 [762] 1584 [748] 1523 [719]

RPM — — — — 1085 1090 1105

Watts — — — — 514 520 530

CFM 1748 [825] 1669 [788] 1639 [773] 1599 [755] 1545 [729] — —

RPM 660

Watts 297 311 326 340 353 — —

CFM — — — — 1732 [817] 1683 [794] 1630 [769]

RPM

Watts — — — — 448 467 480

CFM 1708 [806] 1629 [769] 1599 [755] 1559 [736] 1505 [710] — —

RPM 680 736

Watts 305 330 341 350 361 — —

CFM

RPM — — — — 865 890 1014

Watts — — — — 460 470 481

CFM 1705 [800] 1661 [703] 1632 [770] 1572 [741] 1517 [915] — —

RPM 663 701 741 782 819 — —

Watts 292 309 321 343 357 — —

CFM — — — — 1699 [500] 1646 [776] 1601 [725]

RPM — — — — 857 895 920

Watts — — — — 447 466 473

CFM 1665 [995] 1621 [965] 1592 [751] 1532 [723] 1477 [697] — —

RPM 701 739 779 820 857 — —

Watts 313 330 342 364 378 — —

CFM — — — — 1657 [787] 1606 [759] 1561 [735]

RPM — — —

Watts — — — — 968 487 494

— — — — 394 406 405

831

— — — — 350 364 377

— — — — 500 513 523

— — — — 840 872 899

— — — — 1692 [798] 1643 [775] 1590 [750]

External Static Pressure—Inches W.C. [kPa]

875 919 954

698

—

— — 1011 1046 1080

734

760 790 820

— 1333 [629] 1300 [613] 1267 [598]

762 795 — —

— 895 933 958

989 —

PSC CFM [L/s] Air Delivery/RPM/Watts—115/208/240 Volts

—

— —

— —

5

5

5

5

3

3

5

5

Manufacturer

Recommended

Air-Flow Range

(Min/Max) CFM

1337/1447 CFM

[631/683 L/s]

1297/1333 CFM

[612/629 L/s]

1535/1654 CFM

[724/781 L/s]

1495/1614 CFM

[706/762 L/s]

1545/1732 CFM

[729/817 L/s]

1505/1692 CFM

[710/798 L/s]

1517/1699 CFM

[715/800 L/s]

1477/1655 CFM

[687/785 L/s]

Model

No.

RHLL

-4821

No Heater

-4821

with 20 kW

Heater

-4821

No Heater

-4821

with 25 kW

Heater

-4824

No Heater

-4824

with 25 kW

Heater

-6024

No Heater

-6024

with 30 kW

Heater

Tonnage

Application

3.5 Ton

3.5 Ton

4 Ton

4 Ton

4 Ton

4 Ton

5 Ton

5 Ton

Motor

Speed

From

Factory

Page 14

14 Rheem Heating, Cooling and Water Heating

115V/208V/240V/460V Airflow Performance Data—RHLL (X-13 (ECM) Motor) (con’t.)

Notes: X-13 (ECM) motor speed changes.

All X-13 (ECM) motors have 5 speed tabs. Speed tab 1 is for continuous fan. Speed tab 2 (low static) and Speed tab 3 (high static) are for lower tonnage.

Speed tab 4 (low static) and Speed tab 5 (high static) are for higher tonnage.

X-13 (ECM) air handlers are always shipped from factory at Speed tab 5, except for -4824, which is set at Speed tab 3. For instance, RHLL-HM2417JA is

always shipped at high static 2-ton airflow (Speed tab 5). To change to 1.5-ton airflow, move the blue wire to Speed tab 2 or 3 on the X-13 (ECM) motor.

The low static Speed tab 2 (lower tonnage) and 4 (higher tonnage) are used for external static below 0.5" WC. The high static Speed tab 3 (lower tonnage)

and 5 (higher tonnage) are used for external static exceeding 0.5" WC. Move the blue wire to the appropriate Speed tab as required by the application needs.

• The airflow for continuous fan (Speed tab 1) is always set at 50% of the Speed tab 4.

• The above airflow table lists the airflow information for air handlers without heater and air handler with maximum heater allowed for each model.

• The following formula can be used to calculate the approximate airflow, if a smaller (N kW) than the maximum heater kit is installed.

Approximate Airflow = Airflow without heater – (Airflow without heater – Airflow with maximum heater) x (N kW/maximum heater kW)

[ ] Designates Metric Conversions

Blower Size/

Motor

HP [W]

# of Speed

11x11

3/4 HP [559]

5 Speed

11x11

3/4 HP [559]

5 Speed

Motor

Speed

4

5

4

5

0.1 [.02] 0.2 [.05] 0.3 [.07] 0.4 [.10] 0.5 [.12] 0.6 [.15] 0.7 [.17]

CFM 1902 [898] 1862 [879] 1809 [854] 1781 [840] 1739 [821] — —

RPM 712 749 787 815 856 — —

Watts 389 409 419 432 459 — —

CFM — — — — 1905 [899] 1866 [881] 1832 [865]

RPM — — — — 894 924 950

Watts — — — — 565 570 592

CFM 1862 [879] 1822 [860] 1769 [835] 1741 [822] 1699 [802] — —

RPM 750 790 810 850 880 — —

Watts 410 420 430 455 479 — —

CFM — — — — 1865 [880] 1826 [862] 1792 [846]

RPM — — — — 920 945 970

Watts — — — — 565 587 610

X-13 CFM [L/s] Air Delivery/RPM/Watts—115/208/240 Volts

External Static Pressure—Inches W.C. [kPa]

5

5

Manufacturer

Recommended

Air-Flow Range

(Min/Max) CFM

1739/1905 CFM

[821/899 L/s]

1699/1865 CFM

[802/880 L/s]

Model

No.

RHLL

-6024

No Heater

-6024

with 30 kW

Heater

Tonnage

Application

5 Ton

5 Ton

Motor

Speed

From

Factory

Page 15

Rheem Heating, Cooling and Water Heating 15

RHSL Electrical Data – Blower Motor Only – No Electric Heat

RHLL Electrical Data – Blower Motor Only – No Electric Heat

* Blower motors are all single phase motors.

* Blower motors are all single phase motors.

[ ] Designates Metric Conversions

Model

RHLL

1317

2417 1/5 [149] 1075 2 3.8 5.0 15

3017 1/4 [186] 1075 2 4.7 6.0 15

3617 1/3 [249] 1075 2 6.1 8.0 15

4221 1/2 [373] 1075 2 7.9 10.0 15

4821 3/4 [559] 1075 2 8.4 11.0 15

1817

2417 1/5 [149] 1075 2 1.7 3.0 15

3017 1/4 [186] 1075 2 2.5 4.0 15

3617/5621 1/3 [249] 1075 2 2.5 4.0 15

4221 1/2 [373] 1075 2 5.2 7.0 15

4821/4824 3/4 [559] 1075 2 5.2 7.0 15

6024 208/240 3 60 3/4 [559] 1075 2 5.2 7.0 15

3617

4221 1/3 [249] 1075 2 2.1 3.0 15

4821/4824 3/4 [559] 1075 2 2.2 3.0 15

6024 480 3 60 3/4 [559] 1075 2 2.2 3.0 15

Voltage

115 1 60

208/240 1 & 3 60

480 3 60

Application

Phase*

Hertz HP [W] RPM Speeds

1/5 [149] 1075 2 2.3 3.0 15

1/5 [149] 1075 2 1.7 3.0 15

1/3 [249] 1075 2 1.4 2.0 15

Circuit

Amps.

Minimum

Circuit

Ampacity

Model

RHLL

2417

3617/3621 1/2 [373] 300-1100 4 2.7 4.0 15

3821/4821/4824 3/4 [559] 300-1100 4 3.8 5.0 15

6024 3/4 [559] 300-1100 4 4.6 6.0 15

2417

3117/3621 1/2 [373] 300-1100 4 6.8 9.0 15

3821/4821/4824 3/4 [559] 300-1100 4 8.4 11.0 15

6024 3/4 [559] 300-1100 4 8.4 11.0 15

6024 3/4 [559] 300-1100 4 3.2 4.0 15460 3 60

Voltage

208/240 1 & 3 60

115 1 60

Application

Phase*

Hertz HP [W] RPM Speeds

1/3 [249] 300-1100 4 1.6 2.0 15

1/3 [249] 300-1100 4 4.8 6.0 15

Circuit

Amps.

Minimum

Circuit

Ampacity

Maximum

Circuit

Protector

Maximum

Circuit

Protector

Page 16

16 Rheem Heating, Cooling and Water Heating

RHSL Electrical Data – with Electric Heat

Installation of the U.L. Listed original equipment manufacturer provided heater kits listed in the table below is recommended for all

auxiliary heating requirements.

➀ This does not include “D Voltage”. D Voltage = 480 Volts.

• Supply circuit protective devices may be fused or “HACR” type circuit breakers.

• If non-standard fuse size is specified, use next size larger standard fuse size.

• If the kit is listed under both single and multiple circuits, the kit is shipped from factory as

multiple circuits. For single phase application, Jumper bar kit RXBJ-A21 and RXBJ-A31 can be

used to convert multiple circuits to a single supply circuit. Refer to Accessory Section for details.

• Largest motor load is included in single circuit or circuit 1 of multiple circuit.

• Heater loads are balanced on 3 PH. models with 3 or 6 heaters only.

• Electric heater BTUH - (heater watts + motor watts) x 3.414 (see airflow table for motor watts.)

• No electrical heating elements are permitted to be used with “A” voltage (115V) air handler.

• J voltage (208/240V) single phase air handler is designed to be used with single or three phase

208/240V volt electric heaters. In the case of connecting 3 phase power to air handler terminal

block without the heater, bring only two leads to terminal block. Cap, insulate and fully secure

the third lead.

• Do not use 480V electrical heaters on 208/240V air handlers.

• Do not use 208/240V electrical heaters on 480V air handlers.

Model

RHSL

1817

2417

Heater

Model

No.

RXBH-1724A03J

RXBH-1724A05J

RXBH-1724A07J

RXBH-1724A10J 7.2/9.6 1/60 2 - 4.8 SINGLE 34.6/40.0 1.7 46/53 50/60

RXBH-1724A13J 9.4/12.5 1/60 3-4.17 SINGLE 45.1/52.1 1.7 59/68 60/70

RXBH-1724A13J

Heater

kW

(208/240V ➀)

PH/Hz

No. Elements -

kW Per

2.25/3.0 1/60 1 - 3.0 SINGLE 10.8/12.5 1.7 20/20

3.6/4.8 1/60 1 - 4.8 SINGLE 17.3/20.0 1.7 25/30

5.4/7.2 1/60 2 - 3.6 SINGLE 26.0/30.0 1.7 35/40

3.1/4.2 1/60 1-4.17 MULTIPLE CKT 1 15.0/17.4 1.7 21/24 25/25

6.3/8.3 1/60 2-4.17 MULTIPLE CKT 2 30.1/34.7 0 38/44 40/45

RXBH-1724A07C 5.4/7.2 3/60 3 - 2.4 SINGLE 15.0/17.3 1.7 21/24 25/25

RXBH-1724A10C 7.2/9.6 3/60 3 - 3.2 SINGLE 20.0/23.1 1.7 28/31 30/35

RXBH-1724A13C 9.4/12.5 3/60 3 - 4.17 SINGLE 26.1/30.1 1.7 35/40 35/40

RXBH-1724A03J 2.25/3.0 1/60 1 - 3.0 SINGLE 10.8/12.5 2.5 17/19 20/20

RXBH-1724A05J 3.6/4.8 1/60 1 - 4.8 SINGLE 17.3/20.0 2.5 25/29 25/30

RXBH-1724A07J 5.4/7.2 1/60 2 - 3.6 SINGLE 26.0/30.0 2.5 36/41 40/45

RXBH-1724A10J 7.2/9.6 1/60 2 - 4.8 SINGLE 34.6/40.0 2.5 47/54 50/60

RXBH-1724A13J 9.4/12.5 1/60 3-4.17 SINGLE 45.1/52.1 2.5 60/69 60/70

RXBH-1724A13J

3.1/4.2 1/60 1-4.17 MULTIPLE CKT 1 15.0/17.4 2.5 22/25 25/25

6.3/8.3 1/60 2-4.17 MULTIPLE CKT 2 30.1/34.7 0 38/44 40/45

RXBH-1724A15J 10.8/14.4 1/60 3-4.8 SINGLE 51.9/60.0 2.5 68/79 70/80

RXBH-1724A15J

3.6/4.8 1/60 1 - 4.8 MULTIPLE CKT 1 17.3/20.0 2.5 25/29 25/30

7.2/9.6 1/60 2 - 4.8 MULTIPLE CKT 2 34.6/40.0 0 44/50 45/50

RXBH-1724A18J 12.8/17.0 1/60 3-5.68 SINGLE 61.6/70.8 2.5 81/92 90/100

RHSL

3017

3617

RXBH-1724A18J

RXBH-1724A07C 5.4/7.2 3/60 3 - 2.4 SINGLE 15.0/17.3 2.5 22/25 25/25

4.3/5.7 1/60 1-5.68 MULTIPLE CKT 1 20.5/23.6 2.5 29/33 30/35

8.5/11.3 1/60 2 - 5.68 MULTIPLE CKT 2 41.1/47.2 0 52/59 60/60

RXBH-1724A10C 7.2/9.6 3/60 3 - 3.2 SINGLE 20.0/23.1 2.5 29/32 30/35

RXBH-1724A13C 9.4/12.5 3/60 3 - 4.17 SINGLE 26.1/30.1 2.5 36/41 40/45

RXBH-1724A15C 10.8/14.4 3/60 3 - 4.8 SINGLE 30.0/34.6 2.5 41/47 45/50

RXBH-1724A18C 12.8/17.0 3/60 3-5.68 SINGLE 35.5/41.0 2.5 48/55 50/60

RXBH-17A07D 7.2 3/60 2-3.6 SINGLE 8.7 1.4 13 15

RXBH-17A10D 9.6 3/60 3 - 3.2 SINGLE 11.6 1.4 17 20

RXBH-17A15D 14.4 3/60 3 - 4.8 SINGLE 17.3 1.4 24 25

RXBH-17A18D 17 3/60 3 - 5.68 SINGLE 20.4 1.4 28 30

RXBH-1724B05J 3.6/4.8 1/60 1 - 4.8 SINGLE 17.3/20.0 3.8 27/30 30/30

RXBH-1724B07J 5.4/7.2 1/60 2 - 3.6 SINGLE 26.0/30.0 3.8 38/48 40/45

RXBH-1724B10J 7.2/9.6 1/60 2 - 4.8 SINGLE 34.6/40.0 3.8 48/55 50/60

Circuit

Circuit

Amps.

Motor

Ampacity

Minimum

Circuit

Ampacity

Maximum

Circuit

Protection

16/18

24/28

35/40

Page 17

Rheem Heating, Cooling and Water Heating 17

RHSL Electrical Data – with Electric Heat (con’t.)

Installation of the U.L. Listed original equipment manufacturer provided heater kits listed in the table below is recommended for all

auxiliary heating requirements.

➀ This does not include “D Voltage”. D Voltage = 480 Volts.

* Values only. No single point kit available.

• Supply circuit protective devices may be fused or “HACR” type circuit breakers.

• If non-standard fuse size is specified, use next size larger standard fuse size.

• If the kit is listed under both single and multiple circuits, the kit is shipped from factory as

multiple circuits. For single phase application, Jumper bar kit RXBJ-A21 and RXBJ-A31 can be

used to convert multiple circuits to a single supply circuit. Refer to Accessory Section for details.

• Largest motor load is included in single circuit or circuit 1 of multiple circuit.

• Heater loads are balanced on 3 PH. models with 3 or 6 heaters only.

• Electric heater BTUH - (heater watts + motor watts) x 3.414 (see airflow table for motor watts.)

• No electrical heating elements are permitted to be used with “A” voltage (115V) air handler.

• J voltage (208/240V) single phase air handler is designed to be used with single or three phase

208/240V electric heaters. In the case of connecting 3 phase power to air handler terminal block

without the heater, bring only two leads to terminal block. Cap, insulate and fully secure the

third lead.

• Do not use 480V electrical heaters on 208/240V air handlers.

• Do not use 208/240V electrical heaters on 480V air handlers.

Model

Heater

Model

No.

Heater

kW

(208/240V ➀)

PH/Hz

No. Elements -

kW Per

RXBH-1724A05J 3.6/4.8 1/60 1 - 4.8 SINGLE 17.3/20.0 2.5 25/29 25/30

RXBH-1724A07J 5.4/7.2 1/60 2 - 3.6 SINGLE 26.0/30.0 2.5 36/41 40/45

RXBH-1724A10J 7.2/9.6 1/60 2 - 4.8 SINGLE 34.6/40.0 2.5 47/54 50/60

RXBH-1724A15J 10.8/14.4 1/60 3-4.8 SINGLE 51.9/60.0 2.5 68/79 70/80

RXBH-1724A15J

3.6/4.8 1/60 1 - 4.8 MULTIPLE CKT 1 17.3/20.0 2.5 25/29 25/30

7.2/9.6 1/60 2 - 4.8 MULTIPLE CKT 2 34.6/40.0 0 44/50 45/50

RXBH-1724A18J 12.8/17.0 1/60 4-4.26 SINGLE 61.6/70.8 2.5 81/92 90/100

RHSL

3621

RXBH-1724A18J

RXBH-1724A07C 5.4/7.2 3/60 3 - 2.4 SINGLE 15.0/17.3 2.5 22/25 25/25

6.4/8.5 1/60 2 - 4.26 MULTIPLE CKT 1 30.8/35.4 2.5 42/48 45/50

6.4/8.5 1/60 2 - 4.26 MULTIPLE CKT 2 30.8/35.4 0 39/45 40/45

RXBH-1724A10C 7.2/9.6 3/60 3 - 3.2 SINGLE 20.0/23.1 2.5 29/32 30/35

RXBH-1724A15C 10.8/14.4 3/60 3 - 4.8 SINGLE 30.0/34.6 2.5 41/47 45/50

RXBH-1724A18C 12.8/17.0 3/60 3-5.68 SINGLE 35.5/41.0 2.5 48/55 50/60

RXBH-24A07D 7.2 3/60 2-3.6 SINGLE 8.7 1.4 13 15

RXBH-24A10D 9.6 3/60 3 - 3.2 SINGLE 11.6 1.4 17 20

RXBH-24A15D 14.4 3/60 3 - 4.8 SINGLE 17.3 1.4 24 25

RXBH-24A18D 17 3/60 3 - 5.68 SINGLE 20.4 1.4 28 30

RXBH-1724A05J 3.6/4.8 1/60 1 - 4.8 SINGLE 17.3/20.0 5.2 29/32 30/35

RXBH-1724A07J 5.4/7.2 1/60 2 - 3.6 SINGLE 26.0/30.0 5.2 39/44 40/45

RXBH-1724A10J 7.2/9.6 1/60 2 - 4.8 SINGLE 34.6/40.0 5.2 50/57 50/60

RXBH-1724A15J 10.8/14.4 1/60 3-4.8 SINGLE 51.9/60.0 5.2 72/82 80/90

RXBH-1724A15J

3.6/4.8 1/60 1 - 4.8 MULTIPLE CKT 1 17.3/20.0 5.2 29/32 30/35

7.2/9.6 1/60 2 - 4.8 MULTIPLE CKT 2 34.6/40.0 0.0 44/50 45/50

RXBH-1724A18J 12.8/17 1/60 4-4.26 SINGLE 61.6/70.8 5.2 84/95 90/100

RXBH-1724A18J

6.4/8.5 1/60 2 - 4.26 MULTIPLE CKT 1 30.8/35.4 5.2 45/51 45/60

6.4/8.5 1/60 2 - 4.26 MULTIPLE CKT 2 30.8/35.4 0.0 39/45 40/45

RXBH-1724A20J 14.4/19.2 1/60 4-4.8 SINGLE 69.2/80 5.2 93/107 100/110

RXBH-24A20J

7.2/9.6 1/60 2 - 4.8 MULTIPLE CKT 1 34.6/40.0 5.2 50/57 50/60

7.2/9.6 1/60 2 - 4.8 MULTIPLE CKT 2 34.6/40.0 0.0 44/50 45/50

RXBH-24A25J 18.0/24.0 1/60 6-4.0 SINGLE 86.4/99.9 5.2 115/132 125/150

6.0/8.0 1/60 2 - 4.0 MULTIPLE CKT 1 28.8/33.3 5.2 42/49 45/50

6.0/8.0 1/60 2 - 4.0 MULTIPLE CKT 2 28.8/33.3 0.0 36/42 40/45

6.0/8.0 1/60 2 - 4.0 MULTIPLE CKT 3 28.8/33.3 0.0 36/42 40/45

RHSL

4221

4821

4824

RXBH-24A25J

(4-ton only)

RXBH-2417A07C 5.4/7.2 3/60 3 - 2.4 SINGLE 15.0/17.3 5.2 26/29 30/30

RXBH-2417A10C 7.2/9.6 3/60 3 - 3.2 SINGLE 20.0/23.1 5.2 32/36 35/40

RXBH-2417A15C 10.8/14.4 3/60 3 - 4.8 SINGLE 30.0/34.6 5.2 44/50 45/50

RXBH-2417A18C 12.8/17.0 3/60 3-2.84 SINGLE 35.6/41.0 5.2 51/58 60/60

RXBH-24A20C* 14.4/19.2 3/60 3-3.2 SINGLE 40.0/46.2 5.2 58/65 60/70

RXBH-24A20C

7.2/9.6 3/60 3 - 3.2 MULTIPLE CKT 1 20.0/23.1 5.2 32/36 35/40

7.2/9.6 3/60 3 - 3.2 MULTIPLE CKT 2 20.0/23.1 0.0 25/29 25/30

RXBH-24A25C* 18.0/24.0 3/60 6-4.0 SINGLE 50.0/57.8 5.2 64/79 70/80

RXBH-24A25C

(4-ton only)

9.0/12.0 3/60 3 - 4.0 MULTIPLE CKT 1 25.0/28.9 5.2 38/43 40/45

9.0/12.0 3/60 3 - 4.0 MULTIPLE CKT 2 25.0/28.9 0.0 32/37 35/40

RXBH-24A07D 7.2 3/60 2-3.6 SINGLE 8.7 2.2 14 15

RXBH-24A10D 9.6 3/60 3 - 3.2 SINGLE 11.6 2.2 18 20

RXBH-24A15D 14.4 3/60 3 - 4.8 SINGLE 17.3 2.2 25 25

RXBH-24A18D 17 3/60 3 - 5.68 SINGLE 20.4 2.2 29 30

RXBH-24A20D 19.2 3/60 6 - 3.2 SINGLE 23.2 2.2 32 35

RXBH-24A25D

(4-ton only)

24.0 3/60 6 - 4.0 SINGLE 28.8 2.2 39 40

Circuit

Circuit

Amps.

Motor

Ampacity

Minimum

Circuit

Ampacity

Maximum

Circuit

Protection

Page 18

18 Rheem Heating, Cooling and Water Heating

RHSL Electrical Data – with Electric Heat (con’t.)

Installation of the U.L. Listed original equipment manufacturer provided heater kits listed in the table below is recommended for all

auxiliary heating requirements.

➀ This does not include “D Voltage”. D Voltage = 480 Volts.

• Supply circuit protective devices may be fused or “HACR” type circuit breakers.

• If non-standard fuse size is specified, use next size larger standard fuse size.

• If the kit is listed under both single and multiple circuits, the kit is shipped from factory as

multiple circuits. For single phase application, Jumper bar kit RXBJ-A21 and RXBJ-A31 can be

used to convert multiple circuits to a single supply circuit. Refer to Accessory Section for details.

• Largest motor load is included in single circuit or circuit 1 of multiple circuit.

• Heater loads are balanced on 3 PH. models with 3 or 6 heaters only.

• Electric heater BTUH - (heater watts + motor watts) x 3.414 (see airflow table for motor watts.)

• No electrical heating elements are permitted to be used with “A” voltage (115V) air handler.

• J voltage (208/240V) single phase air handler is designed to be used with single or three phase

208/240V volt electric heaters. In the case of connecting 3 phase power to air handler terminal

block without the heater, bring only two leads to terminal block. Cap, insulate and fully secure

the third lead.

• Do not use 480V electrical heaters on 208/240V air handlers.

• Do not use 208/240V electrical heaters on 480V air handlers.

Model

Heater

Model

No.

Heater

kW

(208/240V ➀)

PH/Hz

No. Elements -

kW Per

RXBH-1724A07C 5.4/7.2 3/60 3 - 2.4 SINGLE 15.0/17.3 5.2 26/29 30/30

RXBH-1724A10C 7.2/9.6 3/60 3 - 3.2 SINGLE 20.0/23.1 5.2 32/36 35/40

RXBH-1724A15C 10.8/14.4 3/60 3 - 4.8 SINGLE 30.0/34.6 5.2 44/50 45/50

RXBH-1724A18C 12.8/17.0 3/60 3-2.84 SINGLE 35.6/41.0 5.2 51/58 60/60

RXBH-24A20C* 14.4/19.2 3/60 3-3.2 SINGLE 40.0/46.2 5.2 57/65 60/70

RXBH-24A20C

7.2/9.6 3/60 3 - 3.2 MULTIPLE CKT 1 20.0/23.1 5.2 32/36 35/40

7.2/9.6 3/60 3 - 3.2 MULTIPLE CKT 2 20.0/23.1 0 25/29 25/30

RXBH-24A25C* 18.0/24.0 3/60 6-4.0 SINGLE 50.0/57.8 5.2 69/79 70/80

9.0/12.0 3/60 3 - 4.0 MULTIPLE CKT 1 25.0/28.9 5.2 38/93 40/45

9.0/12.0 3/60 3 - 4.0 MULTIPLE CKT 2 25.0/28.9 0 32/37 35/40

10.8/14.4 3/60 3 - 4.8 MULTIPLE CKT 1 30.0/34.7 5.2 44/50 45/50

10.8/14.4 3/60 3 - 4.8 MULTIPLE CKT 2 30.0/34.7 0 38/44 40/45

RHSL

6024

RXBH-24A25C

RXBH-24A30C* 21.6/28.8 3/60 6-4.8 SINGLE 60.0/69.4 5.2 82/94 90/100

RXBH-24A30C

RXBH-24A07D 7.2 3/60 2-3.6 SINGLE 8.7 2.2 14 15

RXBH-24A10D 9.6 3/60 3 - 3.2 SINGLE 11.6 2.2 18 20

RXBH-24A15D 14.4 3/60 3 - 4.8 SINGLE 17.3 2.2 25 25

RXBH-24A18D 17 3/60 3 - 5.68 SINGLE 20.4 2.2 29 30

RXBH-24A20D 19.2 3/60 6 - 3.2 SINGLE 23.2 2.2 32 35

RXBH-24A25D 24.0 3/60 6 - 4.0 SINGLE 28.8 2.2 39 40

RXBH-24A30D* 28.8 3/60 6 - 4.8 SINGLE 34.6 2.2 46 50

Circuit

Circuit

Amps.

Motor

Ampacity

Minimum

Circuit

Ampacity

Maximum

Circuit

Protection

Page 19

Rheem Heating, Cooling and Water Heating 19

RHLL Electrical Data – with Electric Heat

Installation of the U.L. Listed original equipment manufacturer provided heater kits listed in the table below is recommended for all

auxiliary heating requirements.

* Values only. No single point kit available.

• Supply circuit protective devices may be fused or “HACR” type circuit breakers.

• If non-standard fuse size is specified, use next size larger standard fuse size.

• If the kit is listed under both single and multiple circuits, the kit is shipped from factory as

multiple circuits. For single phase application, Jumper bar kit RXBJ-A21 and RXBJ-A31 can be

used to convert multiple circuits to a single supply circuit. Refer to Accessory Section for details.

• Largest motor load is included in single circuit or circuit 1 of multiple circuit.

• Heater loads are balanced on 3 PH. models with 3 or 6 heaters only.

• Electric heater BTUH - (heater watts + motor watts) x 3.414 (see airflow table for motor watts.)

• No electrical heating elements are permitted to be used with “A” voltage (115V) air handler.

• J voltage (208/240V) single phase air handler is designed to be used with single or three phase

208/240V volt electric heaters. In the case of connecting 3 phase power to air handler terminal

block without the heater, bring only two leads to terminal block. Cap, insulate and fully secure

the third lead.

• Do not use 480V electrical heaters on 208/240V air handlers.

• Do not use 208/240V electrical heaters on 480V air handlers.

Model

Heater

Model

No.

Heater

KW

208/240V

PH/HZ

Elements -

RXBH-1724B03J/RXBH-17A03J 2.25/3.0 1/60 1 - 3.0 SINGLE 10.8/12.5 16/181.6 20/20

RXBH-1724B05J/RXBH-17A05J 3.6/4.8 1/60 1 - 4.8 SINGLE 17.3/20.0 1.6 24/27 25/30

RXBH-1724B07J/RXBH-17A07J 5.4/7.2 1/60 2 - 3.6 SINGLE 26.0/30.0 1.6 35/40 35/40

RXBH-1724B10J/RXBH-17A10J 7.2/9.6 1/60 2 - 4.8 SINGLE 34.6/40.0 1.6 46/52 50/60

RHLL

2417

RXBH-1724A13J 9.4/12.5 1/60 3-4.17 SINGLE 45.1/52.1 1.6 59/68 60/70

RXBH-1724A13J

3.1/4.2 1/60 1-4.17 MULTIPLE CKT 1 15.0/17.4 1.6 21/24 25/25

6.3/8.3 1/60 2-4.17 MULTIPLE CKT 2 30.1/34.7 0 38/44 40/45

RXBH-1724A07C 5.4/7.2 3/60 3 - 2.4 SINGLE 15.0/17.3 1.6 21/24 25/25

RXBH-1724A10C 7.2/9.6 3/60 3 - 3.2 SINGLE 20.0/23.1 1.6 27/31 30/35

RXBH-1724A13C 9.4/12.5 3/60 3 - 4.17 SINGLE 26.1/30.1 1.6 35/40 35/40

RXBH-1724A03J 2.25/3.0 1/60 1 - 3.0 SINGLE 10.8/12.5 2.7 17/19 20/20

RXBH-1724A05J 3.6/4.8 1/60 1 - 4.8 SINGLE 17.3/20.0 2.7 25/29 25/30

RXBH-1724A07J 5.4/7.2 1/60 2 - 3.6 SINGLE 26.0/30.0 2.7 36/41 40/45

RXBH-1724A10J 7.2/9.6 1/60 2 - 4.8 SINGLE 34.6/40.0 2.7 47/54 50/60

RXBH-1724A13J 9.4/12.5 1/60 3-4.17 SINGLE 45.1/52.1 2.7 60/69 60/70

RXBH-1724A13J

3.1/4.2 1/60 1-4.17 MULTIPLE CKT 1 15.0/17.4 2.7 23/26 25/30

6.3/8.3 1/60 2-4.17 MULTIPLE CKT 2 30.1/34.7 0 38/44 40/45

RXBH-1724A15J 10.8/14.4 1/60 3-4.8 SINGLE 51.9/60.0 2.7 69/79 70/80

RHLL

3617

RXBH-1724A15J

3.6/4.8 1/60 1 - 4.8 MULTIPLE CKT 1 17.3/20.0 2.7 25/29 25/30

7.2/9.6 1/60 2 - 4.8 MULTIPLE CKT 2 34.6/40.0 0 44/50 45/50

RXBH-1724A18J 12.8/17.0 1/60 3-5.68 SINGLE 61.6/70.8 2.7 81/92 90/100

RXBH-1724A18J

4.3/5.7 1/60 1-5.68 MULTIPLE CKT 1 20.5/23.6 2.7 29/33 30/35

8.5/11.3 1/60 2 - 5.68 MULTIPLE CKT 2 41.1/47.2 0 52/59 60/60

RXBH-1724A07C 5.4/7.2 3/60 3 - 2.4 SINGLE 15.0/17.3 2.7 23/25 25/25

RXBH-1724A10C 7.2/9.6 3/60 3 - 3.2 SINGLE 20.0/23.1 2.7 29/33 30/35

RXBH-1724A13C 9.4/12.5 3/60 3 - 4.17 SINGLE 26.1/30.1 2.7 36/41 40/45

RXBH-1724A15C 10.8/14.4 3/60 3 - 4.8 SINGLE 30.0/34.6 2.7 41/47 45/50

RXBH-1724A18C 12.8/17.0 3/60 3-5.68 SINGLE 35.5/41.0 2.7 48/55 50/60

RXBH-1724B05J/RXBH-24A05J 3.6/4.8 1/60 1 - 4.8 SINGLE 17.3/20.0 3.8 27/30 30/30

RXBH-1724B07J/RXBH-24A07J 5.4/7.2 1/60 2 - 3.6 SINGLE 26.0/30.0 3.8 38/43 40/45

RXBH-1724B10J/RXBH-24A10J 7.2/9.6 1/60 2 - 4.8 SINGLE 34.6/40.0 3.8 48/55 50/60

RXBH-1724A15J 10.8/14.4 1/60 3-4.8 SINGLE 51.9/60.0 3.8 70/80 70/80

RXBH-1724A15J

3.6/4.8 1/60 1 - 4.8 MULTIPLE CKT 1 17.3/20.0 3.8 27/30 30/30

7.2/9.6 1/60 2 - 4.8 MULTIPLE CKT 2 34.6/40.0 0.0 44/50 45/50

RXBH-1724A18J 12.8/17 1/60 4-4.26 SINGLE 61.6/70.8 3.8 82/94 90/100

RXBH-1724A18J

6.4/8.5 1/60 2 - 4.26 MULTIPLE CKT 1 30.8/35.4 3.8 44/49 45/50

6.4/8.5 1/60 2 - 4.26 MULTIPLE CKT 2 30.8/35.4 0.0 39/45 40/45

RXBH-24A20J 14.4/19.2 1/60 4-4.8 SINGLE 69.2/80 3.8 92/105 100/110

7.2/9.6 1/60 2 - 4.8 MULTIPLE CKT 1 34.6/40.0 3.8 48/55 50/60

7.2/9.6 1/60 2 - 4.8 MULTIPLE CKT 2 34.6/40.0 0.0 44/50 45/50

6.0/8.0 1/60 2 - 4.0 MULTIPLE CKT 1 28.8/33.3 3.8 41/47 45/50

6.0/8.0 1/60 2 - 4.0 MULTIPLE CKT 2 28.8/33.3 0.0 36/42 40/45

6.0/8.0 1/60 2 - 4.0 MULTIPLE CKT 3 28.8/33.3 0.0 36/42 40/45

RHLL

4821

RXBH-24A20J

RXBH-24A25J 18.0/24.0 1/60 6-4.0 SINGLE 86.4/99.9 3.8 113/130 125/150

RXBH-24A25J

(4-ton only)

RXBH-1724A07C 5.4/7.2 3/60 3 - 2.4 SINGLE 15.0/17.3 3.8 24/27 25/30

RXBH-1724A10C 7.2/9.6 3/60 3 - 3.2 SINGLE 20.0/23.1 3.8 30/34 30/35

RXBH-1724A15C 10.8/14.4 3/60 3 - 4.8 SINGLE 30.0/34.6 3.8 43/48 45/50

RXBH-1724A18C 12.8/17.0 3/60 3-2.84 SINGLE 35.6/41.0 3.8 50/56 50/60

RXBH-24A20C* 14.4/19.2 3/60 3-3.2 SINGLE 40.0/46.2 3.8 55/63 60/70

RXBH-24A20C

7.2/9.6 3/60 3 - 3.2 MULTIPLE CKT 1 20.0/23.1 3.8 30/34 30/35

7.2/9.6 3/60 3 - 3.2 MULTIPLE CKT 2 20.0/23.1 0.0 25/29 25/30

RXBH-24A25C* 18.0/24.0 3/60 6-4.0 SINGLE 50.0/57.8 3.8 68/77 70/80

RXBH-24A25C

(4-ton only)

9.0/12.0 3/60 3 - 4.0 MULTIPLE CKT 1 25.0/28.9 3.8 36/41 40/45

9.0/12.0 3/60 3 - 4.0 MULTIPLE CKT 2 25.0/28.9 0.0 32/37 35/40

No.

KW Per

Type Supply Circuit

Single Circuit

Circuit Amps.

Multiple Circuit

Motor

Ampacity

Minimum

Circuit

Ampacity

Maximum

Circuit

Protection

Page 20

20 Rheem Heating, Cooling and Water Heating

RHLL Electrical Data – with Electric Heat (con’t.)

Installation of the U.L. Listed original equipment manufacturer provided heater kits listed in the table below is recommended for all

auxiliary heating requirements.

* Values only. No single point kit available.

• Supply circuit protective devices may be fused or “HACR” type circuit breakers.

• If non-standard fuse size is specified, use next size larger standard fuse size.

• If the kit is listed under both single and multiple circuits, the kit is shipped from factory as

multiple circuits. For single phase application, Jumper bar kit RXBJ-A21 and RXBJ-A31 can be

used to convert multiple circuits to a single supply circuit. Refer to Accessory Section for details.

• Largest motor load is included in single circuit or circuit 1 of multiple circuit.

• Heater loads are balanced on 3 PH. models with 3 or 6 heaters only.

• Electric heater BTUH - (heater watts + motor watts) x 3.414 (see airflow table for motor watts.)

• No electrical heating elements are permitted to be used with “A” voltage (115V) air handler.

• J voltage (208/240V) single phase air handler is designed to be used with single or three phase

208/240V electric heaters. In the case of connecting 3 phase power to air handler terminal block

without the heater, bring only two leads to terminal block. Cap, insulate and fully secure the

third lead.

• Do not use 480V electrical heaters on 208/240V air handlers.

• Do not use 208/240V electrical heaters on 480V air handlers.

Model

Heater

Model

No.

Heater

KW

208/240V

PH/HZ

Elements -

KW Per

RXBH-1724B05J/RXBH-24A05J 3.6/4.8 1/60 1 - 4.8 SINGLE 17.3/20.0 3.8 27/30 30/30

RXBH-1724B07J/RXBH-24A07J 5.4/7.2 1/60 2 - 3.6 SINGLE 26.0/30.0 3.8 38/43 40/45

RXBH-1724B10J/RXBH-24A10J 7.2/9.6 1/60 2 - 4.8 SINGLE 34.6/40.0 3.8 48/55 50/60

10.8/14.4 1/60 3 - 4.8 SINGLE 51.9/60.0 3.8 70/80 70/80

RHLL

3621

3821

RXBH-1724A15J

RXBH-1724A18J

3.6/4.8 1/60 1 - 4.8 MULTIPLE CKT 1 17.3/20.0 3.8 27/30 30/30

7.2/9.6 1/60 2 - 4.8 MULTIPLE CKT 2 34.6/40.0 0.0 44/50 45/50

12.8/17 1/60 4 - 4.26 SINGLE 61.6/70.8 3.8 82/94 90/100

6.4/8.5 1/60 2 - 4.26 MULTIPLE CKT 1 30.8/35.4 3.8 44/49 45/50

6.4/8.5 1/60 2 - 4.26 MULTIPLE CKT 2 30.8/35.4 0.0 39/45 40/45

RXBH-1724A07C 5.4/7.2 3/60 3 - 2.4 SINGLE 15.0/17.3 3.8 24/27 25/30

RXBH-1724A10C 7.2/9.6 3/60 3 - 3.2 SINGLE 20.0/23.1 3.8 30/34 30/35

RXBH-1724A15C 10.8/14.4 3/60 3 - 4.8 SINGLE 30.0/34.6 3.8 43/48 45/50

RXBH-1724A18C 12.8/17.0 3/60 3 - 2.84 SINGLE 35.6/41.0 3.8 50/56 50/60

RXBH-172405J 3.6/4.8 1/60 1 - 4.8 SINGLE 17.3/20.0 3.8 27/30 30/30

RXBH-172407J 5.4/7.2 1/60 2 - 3.6 SINGLE 26.0/30.0 4.6 39/44 40/45

RXBH-172410J 7.2/9.6 1/60 2 - 4.8 SINGLE 34.6/40.0 4.6 49/56 50/60

RXBH-172415J 10.8/14.4 1/60 3 - 4.8 SINGLE 51.9/60.0 4.6 71/81 80/90

RXBH-172415J 3.6/4.8 1/60 1 - 4.8 MULTIPLE CKT 1 17.3/20.0 4.6 28/31 30/35

RXBH-172415J

3.6/4.8 1/60 1 - 4.8 MULTIPLE CKT 1 17.3/20.0 4.6 28/31 30/35

7.2/9.6 1/60 2 - 4.8 MULTIPLE CKT 2 34.6/40.0 0 44/50 45/50

RXBH-172418J 12.8/17 1/60 4 - 4.26 SINGLE 61.6/70.8 4.6 83/95 90/100

RXBH-172418J

6.4/8.5 1/60 2 - 4.26 MULTIPLE CKT 1 30.8/35.4 4.6 45/50 45/50

6.4/8.5 1/60 2 - 4.26 MULTIPLE CKT 2 30.8/35.4 0 39/45 40/45

RXBH-24A20J 14.4/19.2 1/60 4 - 4.8 SINGLE 69.2/80 4.6 93/106 100/110

RXBH-24A20J

7.2/9.6 1/60 2 - 4.8 MULTIPLE CKT 1 34.6/40.0 4.6 49/56 50/60

7.2/9.6 1/60 2 - 4.8 MULTIPLE CKT 2 34.6/40.0 0 44/50 45/50

RXBH-24A25J 18.0/24.0 1/60 6 - 4.0 SINGLE 86.4/99.9 4.6 114/131 125/150

RHLL

4824

6024

RXBH-24A25J

RXBH-24A30J 21.6/28.8 1/60 6 - 4.8 SINGLE 103.8/120. 4.6 136/156 150/175

RXBH-24A30J

(5-ton only)

6.0/8.0 1/60 2 - 4.0 MULTIPLE CKT 1 28.8/33.3 4.6 42/48 45/50

6.0/8.0 1/60 2 - 4.0 MULTIPLE CKT 2 28.8/33.3 0 36/42 40/45

6.0/8.0 1/60 2 - 4.0 MULTIPLE CKT 3 28.8/33.3 0 36/42 40/45

7.2/9.6 1/60 2 - 4.8 MULTIPLE CKT 1 34.6/40.0 4.6 49/56 50/60

7.2/9.6 1/60 2 - 4.8 MULTIPLE CKT 2 34.6/40.0 0 44/50 45/50

7.2/9.6 1/60 2 - 4.8 MULTIPLE CKT 3 34.6/40.0 0 44/50 45/50

RXBH-172407C 5.4/7.2 3/60 3 - 2.4 SINGLE 15.0/17.3 4.6 25/28 25/30

RXBH-172410C 7.2/9.6 3/60 3 - 3.2 SINGLE 20.0/23.1 4.6 31/35 35/35

RXBH-172415C 10.8/14.4 3/60 3 - 4.8 SINGLE 30.0/34.6 4.6 44/49 45/50

RXBH-172418C 12.8/17.0 3/60 3 - 2.84 SINGLE 35.6/41.0 4.6 51/57 60/60

RXBH-24A20C* 14.4/19.2 3/60 3 - 3.2 SINGLE 40.0/46.2 4.6 56/64 60/70

RXBH-24A20C

7.2/9.6 3/60 3 - 3.2 MULTIPLE CKT 1 20.0/23.1 4.6 31/35 35/35

7.2/9.6 3/60 3 - 3.2 MULTIPLE CKT 2 20.0/23.1 0 25/29 25/30

RXBH-24A25C* 18.0/24.0 3/60 6 - 4.0 SINGLE 50.0/57.8 4.6 69/78 70/80

RXBH-24A25C

9.0/12.0 3/60 3 - 4.0 MULTIPLE CKT 1 25.0/28.9 4.6 37/42 40/45

9.0/12.0 3/60 3 - 4.0 MULTIPLE CKT 2 25.0/28.9 0 32/37 35/40

RXBH-24A30C* 21.6/28.8 3/60 6 - 4.8 SINGLE 60.0/69.4 4.6 81/93 90/100