Rudd RHKA-HM2417JA Installation Manual

FORM NO. H11-523 REV. 7

Supersedes Form No. H11-523 Rev. 6

AIR HANDLERS

AIR HANDLERS

RHKA- SERIES

featuring R-22 Refrigerant

RHKL- SERIES

featuring Earth-Friendly

R-410A Refrigerant

Features

■ Includes an energy efficient GE

®

ECM®Motor, which in

most applications, enhances the SEER rating of the outdoor unit. It also slowly ramps its speed up for quiet operation and enhanced customer satisfaction.

■ Versatile 4-way convertible design for upflow, downflow,

horizontal left and horizontal right applications.

■ Nominal airflow up to 1.0" external static pressure.

■ Factory-installed high efficiency indoor coil.

■ Sturdy cabinet construction with 1.0 inch [25.4 mm] of

foil faced insulation for excellent sound and insulating

characteristics.

■ Field-installed auxiliary electric heater kits provide exact

heat for indoor comfort. Kits include circuit breakers which

meet U.L. and cUL requirements for service disconnect.

■ Dip switch settings for selectable, customized cooling air-

flow over a wide variety of applications.

■ On-demand dehumidification terminal that adjusts airflow

to help control humidity for unsurpassed comfort in cooling mode.

■ External filter required.

earth friendly refrigerant

2 Rheem Heating, Cooling and Water Heating

RHKA- AND RHKL- Series

■ Quiet, efficient ECM motor technology providing nominal airflow

up to 1.0 inch [25 kPa] of external static pressure.

■ Interface board with dip switches conveniently located in the

blower compartment allows for precise, field selectable airflow

to meet the requirements of particular applications.

■ Selectable continuous fan “on” options.

■ The most compact unit design available.

■ Attractive pre-painted cabinet exterior.

■ Rugged steel cabinet construction, designed for added

strength and versatility.

■ 1.0" foil faced insulation mechanically retained in blower

compartment.

■ Four leg rubber insulated motor mount.

■ Field-installed auxiliary heater kit includes circuit breakers that

meet UL and cUL requirements as a service disconnect switch.

■ Blower housing with integrated controls, motor and blower.

Slide out design for service and maintenance convenience.

■ Field convertible for vertical upflow, vertical downflow, horizon-

tal left hand or right hand air supply.

■ Combustible floor base accessory available when required for

downflow installations on combustible floors.

■ Indoor coil design provides low air side pressure drop, high

performance and extremely compact size. All coils come with

PVC condensate elbow standard.

■ Coils are constructed of aluminum fins bonded to internally

grooved copper tubing.

■ Molded polymer corrosion resistant condensate drain pan is

provided on all indoor coils.

■ Supply duct flanges provided as standard on air handler

cabinet.

■ Provisions for field electrical connections available from either

side or top of the air handler cabinet.

■ Connection point for high voltage wiring is inside the air han-

dler cabinet. Low voltage connection is made on the outside of

the air handler cabinet.

■ Concentric knockouts are provided for power connection to

cabinet. Installer may pull desired hole size up to 2 inches

[51 mm] for 1

1

/2 inch [38 mm] conduit.

■ Internal checked TX valves are used on the Heat Pump indoor

coil for more quiet refrigerant metering.

■ Front refrigerant and drain connections.

[ ] Designates Metric Conversions

Engineering Features

GENERAL TERMS OF LIMITED WARRANTY

Rheem will furnish a replacement for any part of this product

which fails in normal use and service within the applicable

periods stated, in accordance with the terms of the limited

warranty.

For Complete Details of the Limited Warranty, Including Applicable Terms

and Conditions, See Your Local Installer or Contact the Manufacturer for

a Copy.

Indoor Coil leaks caused by

factory defects ..........................................Five (5) Years

Electric Heating Element..............................Five (5) Years

Any Other Part* ............................................Five (5) Years

*In addition, a ten-year conditional parts warranty applies when the

RHKL air handler is matched with a JEZ or JEC condensing unit or

heat pump.

Rheem Heating, Cooling and Water Heating 3

RHKA—HM2417JA

Design Variation

A = 1st Design

Voltage

J = 208/240/1/60

Cabinet Size

17 = 17.5" [431.8 mm] (600-1200 CFM)

21 = 21" [533.4 mm] (1400-1600 CFM)

24 = 24.5" [609.6 mm] (1600-1800 CFM)

Capacity

24 = 18,000/24,000 BTUH

[5.27 to 7.03 kW]

36 = 30,000/36,000 BTUH

[8.79 to 10.55 kW]

48 = 42,000/48,000 BTUH

[12.31 to 14.06 kW]

60 = 60,000 BTUH

[17.58 kW]

HM = A/C or HP, Multi-Position

(Upflow & Horizontal Left is the factory configuration)

Refrigerant

A = R-22

L = R-410A

K = Premium

Classification

H = Air Handler

Rheem

MODEL NUMBER DATA

Coil Specifications/Airflow Pressure Drop

[ ] Designates Metric Conversions

AVAILABLE MODELS

R-22 MODELS R-410A MODELS

RHKA-HM2417JA RHKL-HM2417JA

RHKA-HM3617JA RHKL-HM3617JA

RHKA-HM4821JA RHKL-HM4821JA

RHKA-HM4824JA RHKL-HM4824JA

RHKA-HM6024JA RHKL-HM6024JA

4 Rheem Heating, Cooling and Water Heating

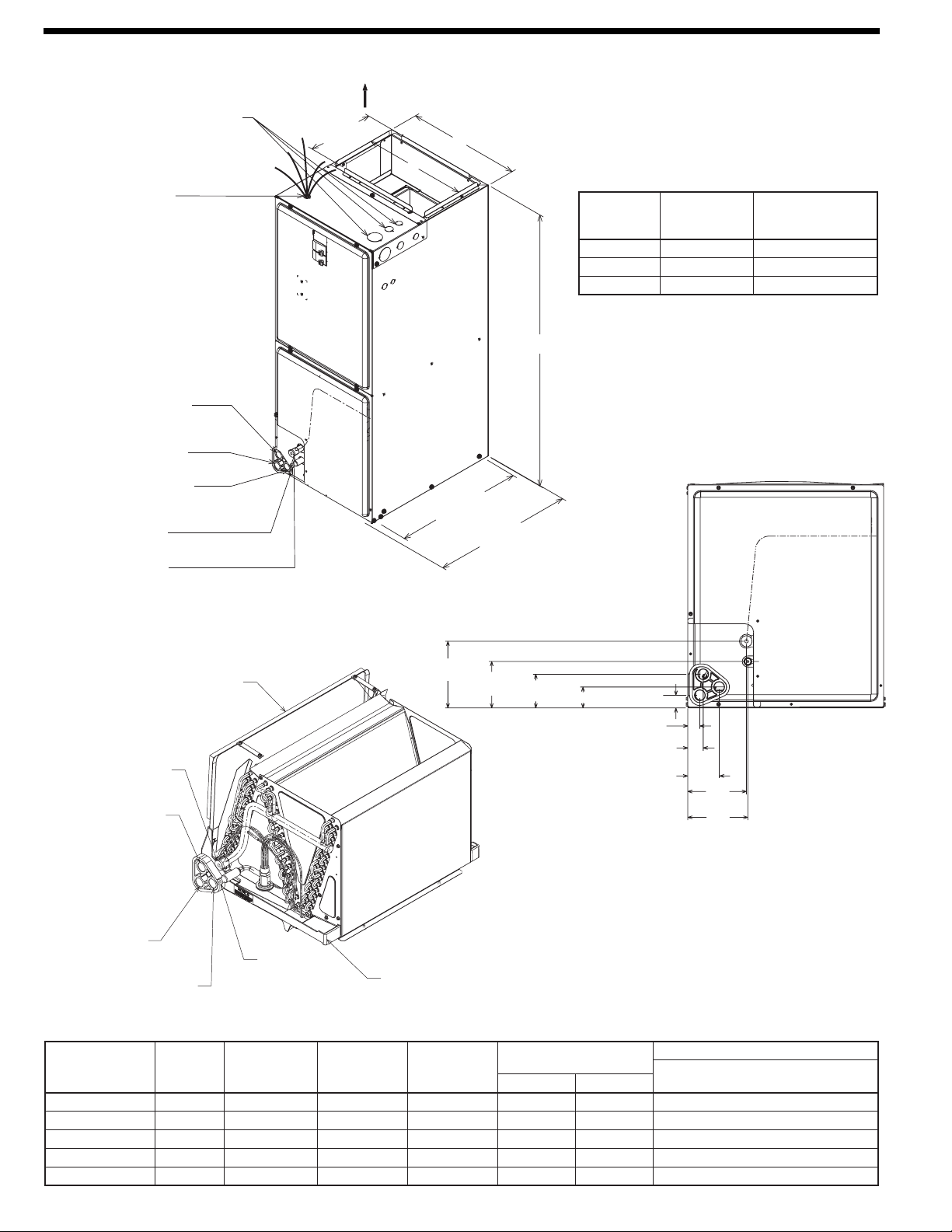

Unit Dimensions

Unit Dimensions & Weights

[ ] Designates Metric Conversions

( ) Designates Unit with Double Coil Cabinet

UPFLOW UNIT SHOWN:

UNIT MAY BE INSTALLED UPFLOW,

DOWNFLOW, HORIZONTAL RIGHT

OR LEFT AIR SUPPLY.

Return Air Opening Dimensions

ELECTRICAL CONNECTIONS

MAY EXIT TOP OR EITHER SIDE

7

HIGH VOLTAGE CONNECTION

3

/32 [27.8 mm], 131/32 [50 mm] DIA.

1

KNOCKOUTS. IF LARGER REQUIRED,

PULL HOLE SIZE REQUIRED UP TO 2 [50.8 mm] DIA.

1

/2 [38.1 mm] CONDUIT

FOR 1

LOW VOLTAGE CONNECTION

5

/8 [15.9 mm] AND 7/8 [22.2 mm] KNOCKOUT

(OUTSIDE OF CABINET)

AUXILIARY DRAIN CONNECTION

3

/4 [19.1 mm] FEMALE PIPE THREAD (NPT)

HORIZONTAL APPLICATION ONLY

PRIMARY DRAIN CONNECTION

3

/4 [19.1 mm] FEMALE PIPE THREAD (NPT)

AUXILIARY DRAIN CONNECTION

3

/4 [19.1 mm] FEMALE PIPE THREAD (NPT)

UPFLOW/DOWNFLOW APPLICATION ONLY

LIQUID LINE CONNECTION

COPPER (SWEAT)

VAPOR LINE CONNECTION

COPPER (SWEAT)

DOWNFLOW APPLICATION AND HORIZONTAL RIGHT

INDOOR COIL AND COIL DOOR ROTATES 180°

/8 [22.2 mm],

SUPPLY AIR

105/16

[262 mm]

A

19

RETURN AIR

NOTE: 24 CLEARANCE REQUIRED IN FRONT OF

UNIT FOR FILTER AND COIL MAINTENANCE.

W

1

/2 [495 mm]

OPENING

11

/16

21

[551 mm]

Model

Cabinet Size

17 16 191/2

21 191/2 191/2

24 23 191/2

H

Opening Width

Return Air

(Inches)

Return Air Opening

Depth/Length

(Inches)

HORIZONTAL ADAPTER KIT

VAPOR LINE

CONNECTION

AUXILIARY HORIZONTAL

DRAIN CONNECTION

515/16

[151 mm]

1

/8

4

[105 mm]

31/16

[76 mm]

3

1

/16 [48 mm]

1

1

/8 [29 mm]

1

/16

1

[27 mm]

1

[35 mm]

2

[71 mm]

3

/8

13

/16

51/4

[133 mm]

53/8

[136 mm]

PRIMARY DRAIN

CONNECTION

AUXILIARY UPFLOW/DOWNFLOW

DRAIN CONNECTION

LIQUID LINE

CONNECTION

VERTICAL DRAIN PAN

Nominal Cooling

Capacity

Tons

11/2 & 2

21/2 & 3

31/2 & 4 21 191/2 [495] 1400 [661] 1600 [755] 150/166 [68/75]

4 24 231/2 [584] 1600 [755] — 162/180 [73/81]

5 24 231/2 [584] — 1800 [850] 181/198 [82/90]

Model

Cabinet

Size

17

17

Unit

Width

“W” In. [mm]

171/2 [445]

171/2 [445]

211/2 [533]

241/2 [622]

241/2 [622]

Unit

Height

“H” In. [mm]

421/2 [1080]

421/2 [1080]

501/2 [1282]

551/2 [1410]

551/2 [1410]

Supply

Duct

“A” In. [mm]

161/2 [406]

161/2 [406]

CFM (Nom.) [L/s]

Lo Hi

600 [283] 800 [378] 82/96 [37/44]

1000 [472] 1200 [566] 92/106 [37/48]

Air Flow

Unit Weight/Shipping Weight (Lbs.) [kg]

Unit With

Coil (Max. KW)

Loading...

Loading...