Page 1

FORM NO. H11-533 REV. 1

Supersedes Form No. H11-533

AIR HANDLERS

AIR HANDLERS

RHBL- High Efficiency X-13 (ECM)

featuring Industry Standard

R-410A Refrigerant

RHAL- Standard Efficiency – PSC

featuring Industry Standard

R-410A Refrigerant

Features/Accessories

■

Front or Bottom Return

■

Flow Check Piston for cooling or heat pump operation

■

Wall-hanging brackets

■

Built in Filter Rack

■

Suitable for R-410A or R-22 Refrigerants (RHAL Only)

■

AHRI Certified

■

UL Certified

■

Molex Plug Connections for field installed heater kits

■

Dual Voltage Direct Drive Blower with multi-speed motor

■

Thermoplastic Drain Pan with bottom primary and

secondary connections

■

Optional Decorative Grill for front return applications

■

Optional Factory Installed Condensate Float Switch which

shuts off the outdoor unit in event the condensate pan

becomes clogged

Page 2

2 Rheem Heating, Cooling and Water Heating

Engineering Features

GENERAL TERMS OF LIMITED WARRANTY

Rheem will furnish a replacement for any part of this product

which fails in normal use and service within the applicable

periods stated, in accordance with the terms of the limited

warranty.

Conditional Parts* (Registration Required)........Ten (10) Years

*For Complete Details of the Limited Warranty, Including Applicable

Terms and Conditions, See Your Local Installer or Contact the

Manufacturer for a Copy.

RHAL/RHBL- Series

■

The most compact unit design available, all standard heat air

handler models only 36" [915 mm].

■

Rugged wall steel cabinet construction, designed for added

strength and versatility.

■

1.0" foil faced insulation for excellent thermal and sound

performance.

■

Four leg blower motor mount.

■

Traditional open wire element design for heat applications.

■

Indoor coil design provides low air side pressure drop, high

performance and extremely compact size.

[ ] Designates Metric Conversions

■

Coils are constructed of aluminum fins and internally grooved

copper tubing.

■

Molded polymer corrosion resistant condensate drain pan is

provided for all indoor coils.

■

Connection point for high voltage wiring is inside the air handler

cabinet. Low voltage connection is made on the outside of the

air handler cabinet.

■

Concentric knockouts are provided for power connection to

cabinet. Installer may pull desired hole size up to 1

3

/8 inch

inches [35 mm] for

7

/8 inch [22 mm] conduit.

Page 3

Rheem Heating, Cooling and Water Heating 3

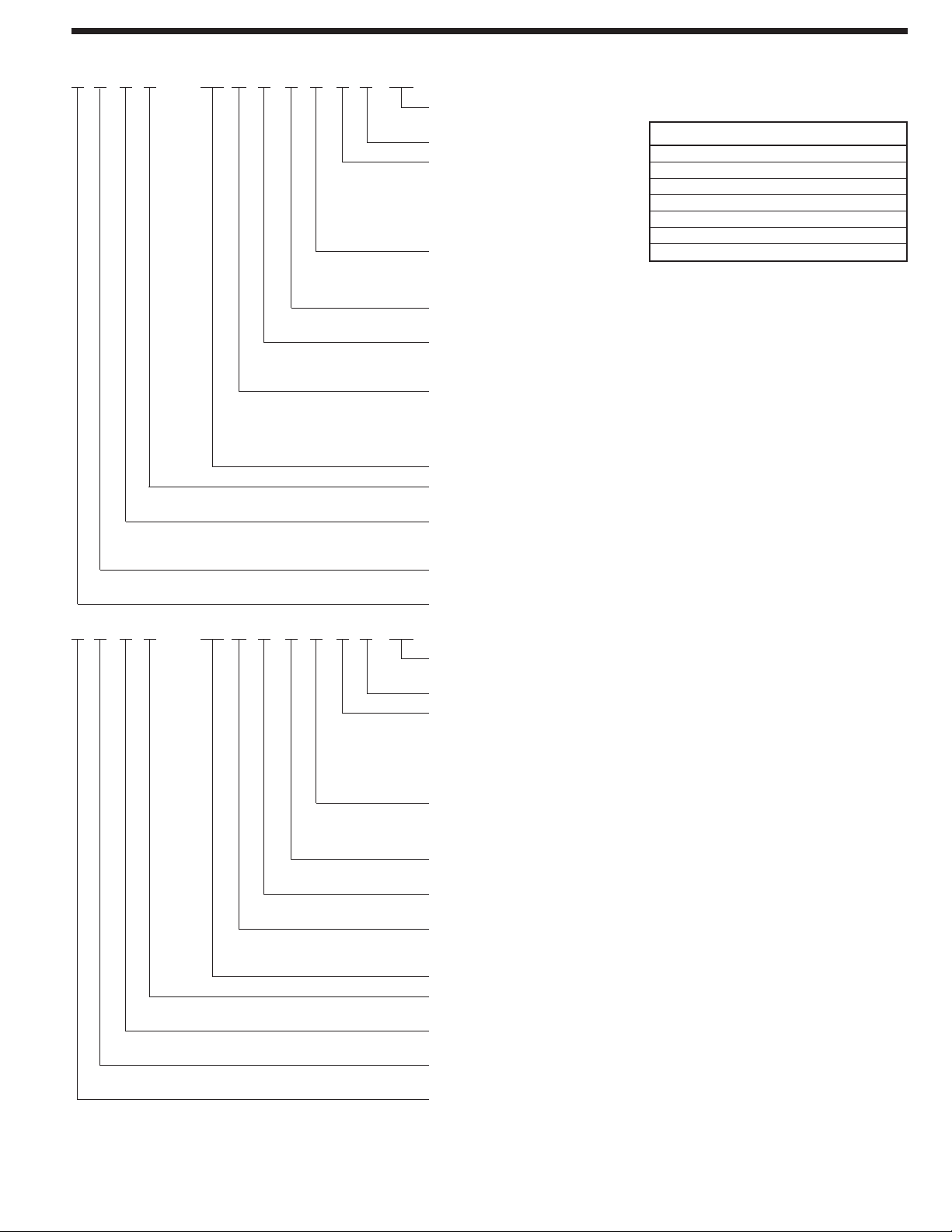

R H A L — FR 24 P J N 00 A 000

Options

417 = Float Switch

Design Variation

Electric Heat

00 = NO HEAT

03 = 3 kW

05 = 5 kW

08 = 8 kW

10 = 10 kW

Disconnect Configuration

N = None

B = Breaker

Voltage

J = 208/240/1/60

Metering

P = Piston (R22 or R410A)

T = TXV (R410A)

Capacity

18 = 18,000 BTU/H [5.30 kW]

24 = 24,000 BTU/H [7.03 kW]

30 = 30,000 BTU/H [8.80 kW]

36 = 36,000 BTU/H [10.6 kW]

FR = Front Return

Refrigerant

L = 410A

Front Return/Wall Mount

A = PSC Motor –

Standard Efficiency

Classification

H = Air Handler

Rheem

Model Identification

Available Models at J Voltage

RHAL-FR18PJ

RHAL-FR24PJ

RHAL-FR30PJ

RHAL-FR36PJ

RHAL-FR36TJ

RHBL-FR24TJ

RHBL-FR36TJ

• Supply circuit protective devices may be fuses or

“HACR” type circuit breakers.

• Largest motor load is included in single circuit.

• If non-standard fuse size is specified, use the next

larger fuse size.

• J Voltage (230V) single-phase air handler is

designed to be used with single or three phase

230 volt power. In the case of connecting 3-phase

power to the air handler terminal block, bring

only two leads to the terminal block. Cap, insulate and fully secure the third lead.

• The air handlers are shipped from the factory with

the proper indoor coil installed, and cannot be

ordered without a coil.

R H B L — FR 24 T J N 00 A 000

Options

417 = Float Switch

Design Variation

Electric Heat

00 = NO HEAT

03 = 3 kW

05 = 5 kW

08 = 8 kW

10 = 10 kW

Disconnect Configuration

N = None

B = Breaker

Voltage

J = 208/240/1/60

Metering

T = TXV (R410A only)

Capacity

24 = 24,000 BTU/H [7.03 kW]

36 = 36,000 BTU/H [10.6 kW]

FR = Front Return

Refrigerant

L = 410A

Front Return/Wall Mount

B = X13 (ECM) Motor – High Efficiency

Classification

H = Air Handler

Rheem

[ ] Designates Metric Conversions

Page 4

4 Rheem Heating, Cooling and Water Heating

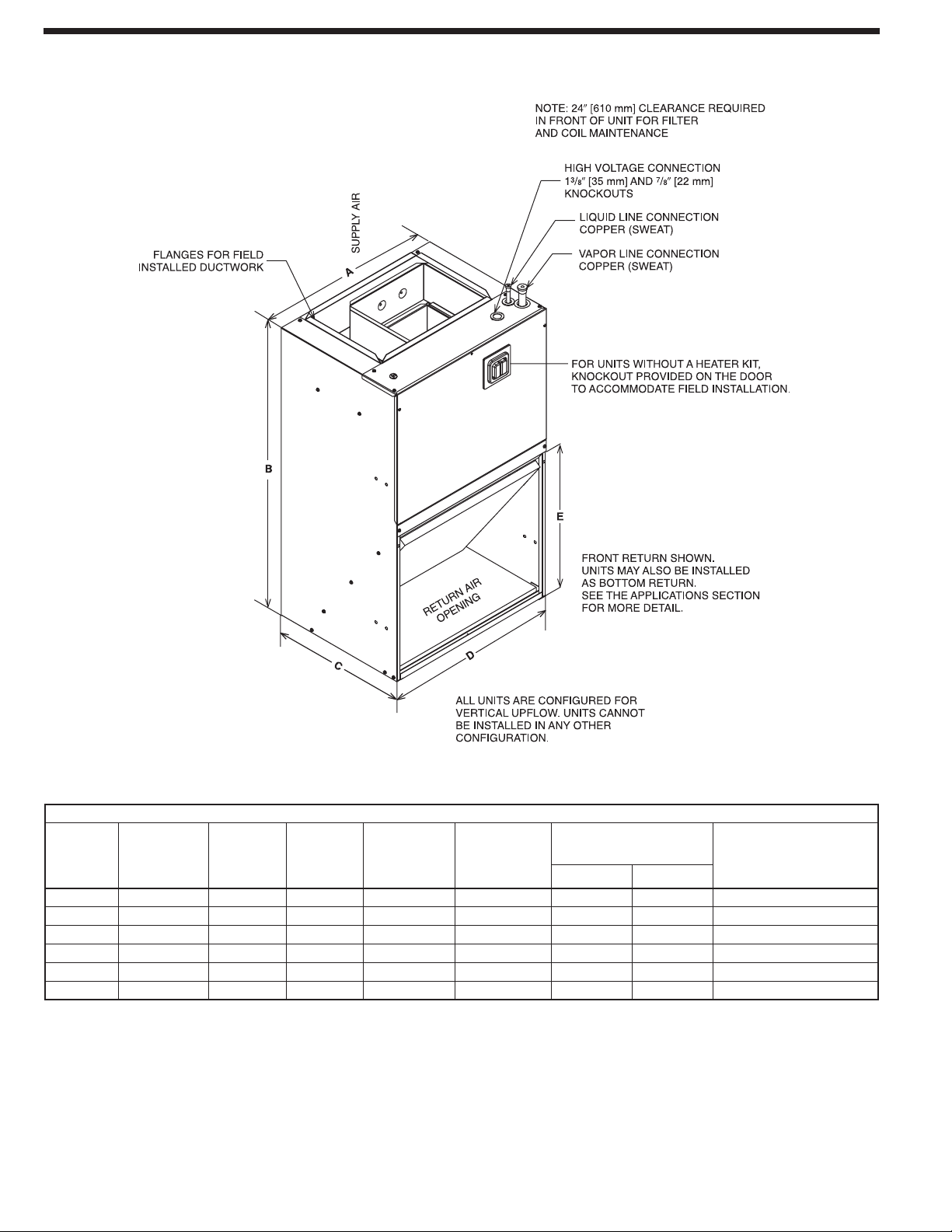

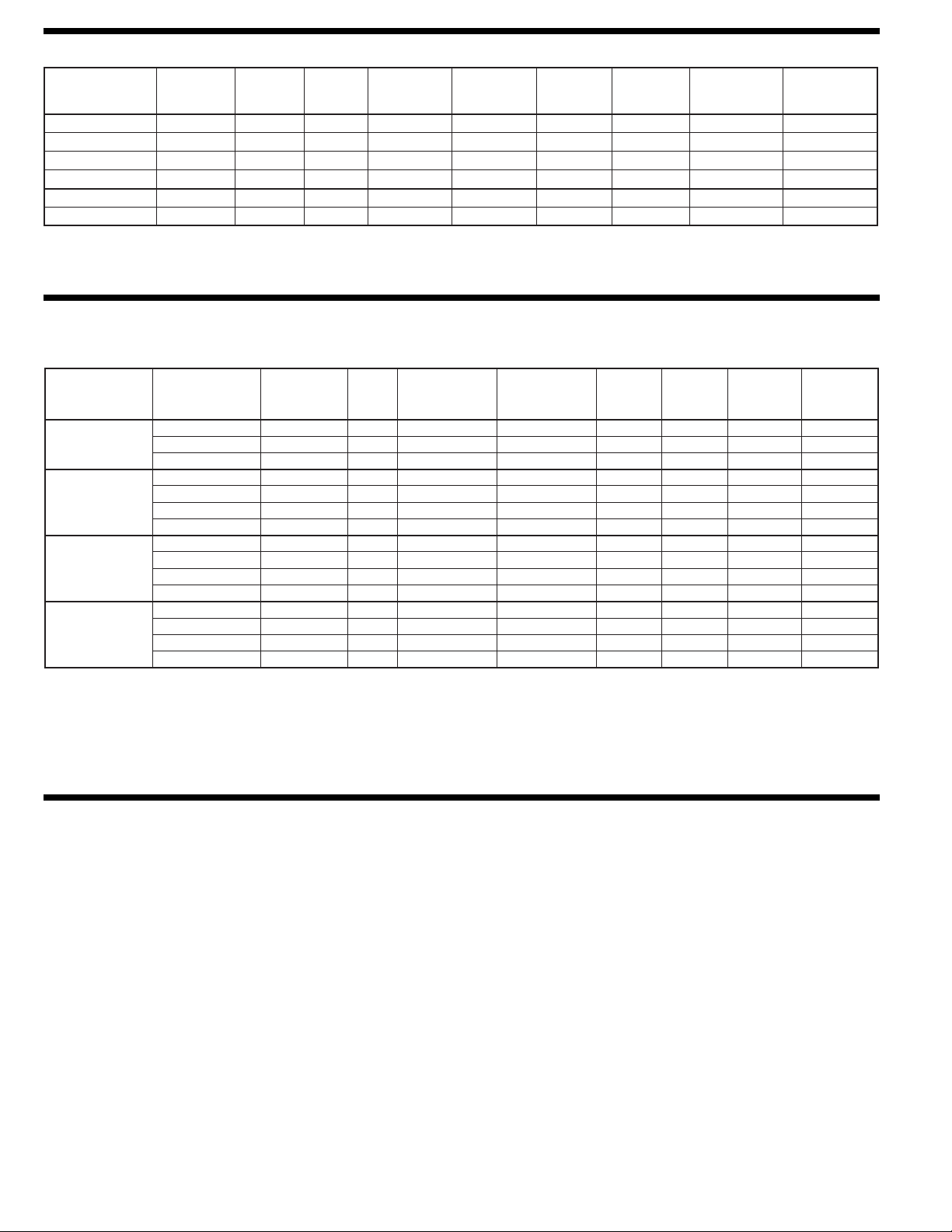

Unit Dimensions

Unit Dimensions & Weights

[ ] Designates Metric Conversions

Dimensional Data

Model

RHAL-18 20 [508] 600 [283] — 80 [36] / 90 [41]

RHAL-24 20 [508] 800 [378] — 80 [36] / 90 [41]

RHAL-30 23 [584.2] 1000 [472] — 95 [43] / 105 [48]

RHBL-24 20 [508] 600 [283] 800 [378] 95 [43] / 105 [48]

RHBL-36 23 [584.2] 1000 [472] 1200 [566] 95 [43] / 105 [48]

(A) Unit

Width

In. [mm]

211/2 [546.1]

211/2 [546.1]

241/2 [609.6]

241/2 [609.6] 36 [914.4]RHAL-36 23 [584.2] 1200 [566] — 95 [43] / 105 [48]

211/2 [546.1]

241/2 [609.6]

(B) Unit

Height

In. [mm]

36 [914.4]

36 [914.4]

36 [914.4]

36 [914.4]

36 [914.4]

(C) Unit

Depth

In. [mm]

17 [431.8]

17 [431.8]

21 [533.4]

21 [533.4]

17 [431.8]

21 [533.4]

(D) Return

Air Opening

Width

In. [mm]

(E) Return

Air Opening

Height

In. [mm]

177/16 [442.9]

177/16 [442.9]

213/88 [542.9]

213/88 [542.9]

177/16 [442.9]

213/88 [542.9]

Air Flow

CFM (Nom.) [L/s]

Low High

Unit Weight/

Shipping Weight (Lbs.) [kg]

Page 5

Rheem Heating, Cooling and Water Heating 5

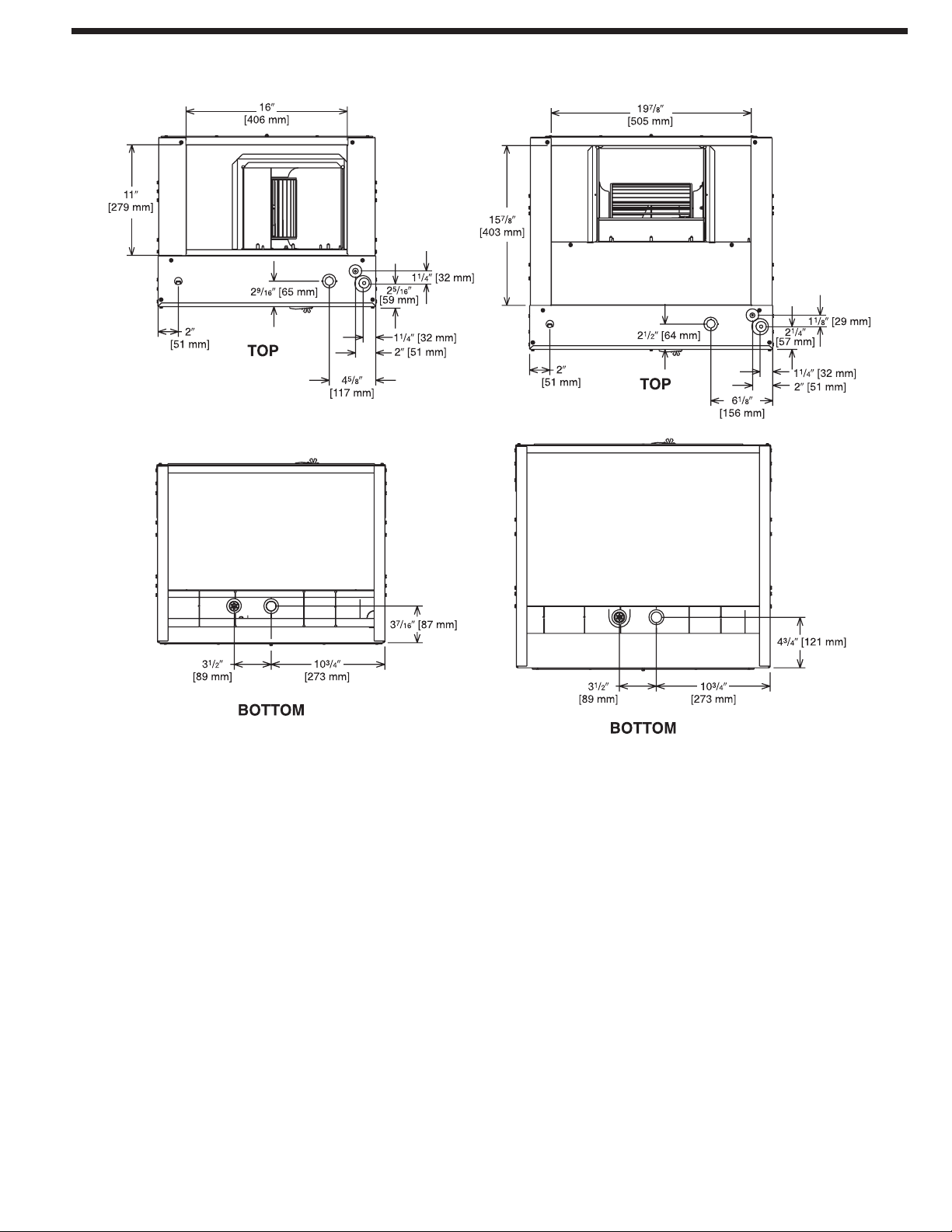

Unit Dimensions

[ ] Designates Metric Conversions

11/2 & 2 TON [5.28 & 7.03 kW] MODELS 21/2 & 3 TON [8.79 & 10.6 kW] MODELS

Page 6

6 Rheem Heating, Cooling and Water Heating

Airflow Performance

Airflow performance data is based on cooling performance

with a coil and filter in place. Select performance table for

appropriate unit size, voltage and number of electric heaters to

be used. Make sure external static applied to unit allows operation within the minimum and maximum limits shown in table

below for both cooling and electric heat operation. For optimum

blower performance, operate the unit in the .3 [8 mm] to .7

inches [18 mm] W.C. external static range. Units with coils

should be applied with a minimum of .1 inch [3 mm] W.C.

external static range.

Airflow Operating Limits

[ ] Designates Metric Conversions

Cooling BTUH x 1,000

Cooling Tons Nominal

Heat Pump or Air Conditioning

Maximum Heat/Cool CFM [L/s]

(37.5 CFM [18 L/s]/1,000 BTUH)

(450 CFM [212 L/s]/Ton Nominal)

Heat Pump or Air Conditioning

Nominal Heat/Cool CFM [L/s]

(33.3 CFM [16 L/s]/1,000 BTUH)

(400 CFM [189 L/s]/Ton Nominal)

Heat Pump or Air Conditioning

Minimum Heat/Cool CFM [L/s]

(30.0 CFM [14 L/s]/1,255 BTUH)

(360 CFM [170 L/s]/Ton Nominal)

Maximum kW Electric Heating

& Minimum Electric Heat CFM [L/s]

Maximum Electric Heat Rise °F [°C] 54 [12] 44 [7] 44 [7] 44 [7]

-18

1.5

675

[319]

600

[283]

540

[255]

8

450 [212]

-24

2

900

[425]

800

[378]

720

[340]

10

690 [326]

-30

2.5

1125

[531]

1000

[472]

900

[425]

10

808 [381]

-36

3

1350

[637]

1200

[566]

1080

[510]

10

976 [461]

Page 7

Rheem Heating, Cooling and Water Heating 7

208V/240V Airflow Performance Data—RHAL (PSC Motor)

Notes: • All 208/240V PSC motors have voltage taps for 208 and 240 volts.

• All 208/240V PSC motors are shipped on high speed and 240 volts.

• If the application external static is less than 0.5" WC, adjust the motor speed to the low static speed as described below:

• Unplug the black motor wire off the relay on the control board and plug in the red motor wire.

• Replace the cap on the black motor wire.

• Voltage change (208/240V motors):

• Move the orange lead to transformer 208V tap from 240V tap. Replace the wire cap on 240V tap.

• Unplug the purple motor wire off the transformer and plug in the yellow motor wire.

• Replace the cap on the purple motor wire.

• The above airflow table lists the airflow information for air handlers with maximum heater allowed for each model.

[ ] Designates Metric Conversions

Nominal

Cooling

Capacity

Tons

1.5

2

2.5

3

Manufacturer

Recommended

Air-Flow Range

(Min/Max) CFM

850/450 CFM

[401/212 L/s]

1016/690 CFM

[479/326 L/s]

1190/808 CFM

[562/381 L/s]

1330/976 CFM

[628/461 L/s]

Blower Size/

Motor

HP [W]

# of Speeds

10x6

1/5 HP [149]

2 Speed

Dual Voltage

10x6

1/5 HP [149]

2 Speed

Dual Voltage

10x8

1/4 HP [186]

2 Speed

Dual Voltage

10x8

1/3 HP [186]

2 Speed

Dual Voltage

Motor

Speed

From

Factory

High

High

High

High

Motor

Speed

High

Low

High

Low

High

Low

High

Low

0.1 [.02] 0.2 [.05] 0.3 [.07] 0.4 [.10] 0.5 [.12] 0.6 [.15] 0.7 [.17]

CFM 850 [260] 807 [271] 763 [283] 723 [283] 644 [295] 568 [295] 538 [295]

RPM 948 970 989 1003 1021 1037 1046

Watts 269 262 252 245 238 226 221

CFM 642 [271] 606 [260] 575 [366] 521 [366] 450 [366] — —

RPM 766 798 817 864 912 — —

Watts

CFM 1016 [389] 966 [389] 927 [389] 885 [389]

RPM 1083

Watts 380 365 360 349 338 328 311

CFM 830 [425] 805 [425] 772 [425] 735 [425] 690 [425] — —

RPM

Watts 270 262 253 244 235 — —

CFM 1190 [566] 1116 [566] 1058 [578] 997 [578] 927 [566] 851 [566] 762 [566]

RPM 900 927 950 974 997 1018 1038

Watts 374 361 346 331 320 307 290

CFM 1034 [566] 983 [555] 931 [555] 868 [566] 808 [578] — —

RPM 836 860 892 921 944 — —

Watts

CFM 1330 [566] 1262 [566] 1184 [767] 1066 [779] 968 [779] 871 [779] —

RPM 1029 1047 1060 1082 1095 1104 —

Watts 478 456 437 403 376 355 —

CFM 1189 [791] 1135 [779] 1054 [779] 976 [767] — — —

RPM 958 984 1012 1037 — — —

Watts 402 385 362 341 — — —

175 170 168 158 149 — —

932 950 974 994 1014 —

300 291 281 269 260 — —

External Static Pressure-Inches W.C. [kPa]

1090

1096

1101 1109 1114 1121

PSC CFM wet coil with filter and heaters

834 [413] 780 [425] 718 [425]

—

Page 8

8 Rheem Heating, Cooling and Water Heating

208V/240V Airflow Performance Data—RHBL (X-13 (ECM) Motor)

Notes: X-13 motor speed changes.

All X-13 motors have 5 speed taps. Speed tap 1 is for continuous fan. Speed tap 2 (low static) and speed tap 3 (high static) are for lower tonnage. Speed tap

4 (low static) and speed tap 5 (high static) are for higher tonnage.

X-13 air handlers are always shipped from factory at speed tap 5. To change to 1.5-ton or 2.5-ton airflow, move the blue wire to speed tap 2 or 3 on the

X-13 motor. The low static speed tap 2 (lower tonnage) and 4 (higher tonnage) are used for external static below 0.5" WC. The high static speed tap 3 (lower

tonnage) and 5 (higher tonnage) are used for external static exceeding 0.5" WC. Move the blue wire to the appropriate speed tap as required by the

application needs.

• The airflow for continuous fan (speed tap 1) is 50% of the speed tap 4 airflow.

• The above airflow table lists the airflow information for air handlers with maximum heater allowed for each model.

[ ] Designates Metric Conversions

Nominal

Cooling

Capacity

Tons

1.5

2

2.5

3

Manufacturer

Recommended

Air-Flow Range

(Min/Max) CFM

827/474 CFM

[390/224 L/s]

977/708 CFM

[461/334 L/s]

1170/897 CFM

[552/423 L/s]

1316/1049 CFM

[621/495 L/s]

Blower Size/

Motor

HP [W]

# of Speeds

10x6

1/3 HP [249]

2 Speed

Dual Voltage

10x6

1/3 HP [249]

2 Speed

Dual Voltage

10x8

1/2 HP [373]

2 Speed

Dual Voltage

10x8

1/2 HP [373]

2 Speed

Dual Voltage

Motor

Speed

From

Factory

5

5

5

5

5

5

5

5

Motor

Speed

3

2

5

4

3

2

5

4

0.1 [.02] 0.2 [.05] 0.3 [.07] 0.4 [.10] 0.5 [.12] 0.6 [.15] 0.7 [.17]

CFM 827 [390] 804 [379] 779 [368] 740 [349] 708 [334] 659 [311] 608 [287]

RPM 1020 1035 1068 1095 1119 1138 1147

Watts 198 207 206 204 211 205 189

CFM 599 [283] 578 [273] 544 [257] 509 [240] 474 [224] — —

RPM 832 875 905 935 963 — —

Watts

CFM 977 [461] 930 [439] 898 [424] 850 [401]

RPM 1120

Watts 294 271 266 257 239 231 214

CFM 811 [383] 785 [370] 759 [358] 726 [343] 708 [334] — —

RPM

Watts 177 186 182 188 189 — —

CFM 1170 [552] 1127 [532] 1085 [512] 1048 [495] 1012 [478] 973 [459] 943 [445]

RPM 886 921 958 986 1022 1053 1083

Watts 267 275 287 290 301 305 315

CFM 1053 [497] 1003 [473] 969 [457] 928 [438] 897 [423] — —

RPM 835 864 903 933 973 — —

Watts

CFM 1316 [621] 1275 [602] 1229 [580] 1191 [562] 1151 [543] 1093 [516] 1039 [490]

RPM 974 1006 1036 1063 1098 1120 1131

Watts 365 378 383 390 399 393 377

CFM 1208 [570] 1172 [553] 1125 [531] 1087 [513] 1049 [495] — —

RPM 906 938 968 1002 1030 — —

Watts 284 299 306 315 322 — —

95 96 108 102 112 — —

982 1008 1026 1050 1081 —

212 216 227 232 242 — —

External Static Pressure-Inches W.C. [kPa]

1132

1136

1141 1146 1153 1160

801 [378] 746 [352] 687 [324]

X-13 CFM wet coil with filter and heaters

—

Page 9

Rheem Heating, Cooling and Water Heating 9

Piston Sizing Chart

Indoor Unit Factory Piston

RHAL-FR18PJ 0.047

RHAL-FR24PJ 0.053

RHAL-FR30PJ 0.061

RHAL-FR36PJ 0.065

SEER Rating

OD Unit

13 1.5 R410a 0.047

14 1.5 R410a 0.049

13 1.5 R22 0.049

12 1.5 R22 0.051

10 1.5 R22 0.053

13 2 R410a 0.053

14 2 R410a 0.057

13 2 R22 0.057

12 2 R22 0.061

10 2 R22 0.063

13 2.5 R410a 0.061

14 2.5 R410a 0.063

13 2.5 R22 0.065

12 2.5 R22 0.065

10 2.5 R22 0.065

13 3 R410a 0.065

14 3 R410a 0.068

13 3 R22 0.069

12 3 R22 0.070

10 3 R22 0.070

Nominal Tons Refrigerant Orifice Size

Page 10

10 Rheem Heating, Cooling and Water Heating

RHAL/RHBL Electrical Data – Blower Motor Only – No Electric Heat

*Blower motors are all single phase motors.

RHAL/RHBL Electrical Data – with Electric Heat

Installation of the U.L. Listed original equipment manufacturer provided heater kits listed in the table below is recommended for all

auxiliary heating requirements.

• Electric heater BTUH - (heater watts + motor watts) x 3.414 (see airflow table for motor watts.)

• Supply circuit protective devices may be fused or “HACR” type circuit breakers.

• If non-standard fuse size is specified, use next size larger standard fuse size.

• Largest motor load is included in single circuit or circuit 1 of multiple circuits.

• No electrical heating elements are permitted to be used with A Voltage (115V) air handler.

• J voltage (230V) single phase air handler is designed to be used with single or three phase

230 volt electric heaters. In the case of connecting 3 phase power to air handler terminal block

without the heater, bring only two leads to terminal block, cap, insulate and fully secure the

third lead.

• Do not use 480 volts electrical heaters on 230 volts air handler.

Electrical Wiring:

Power Wiring

• Field wiring must comply with the National Electrical Code

(C.E.C. in Canada) and any applicable local ordinance.

• Supply wiring must be 75°C minimum copper conductors only.

• See electrical data for product Ampacity rating and Circuit

Protector requirement.

Grounding

• This product must be sufficiently grounded in accordance with

National Electrical Code (C.E.C. in Canada) and any applicable

local ordinance.

• A grounding lug is provided.

Model/Nominal

Cooling Tons

RHAL18 208/230 1 60 1/5 [149] 1075 2 1.5 3 15

RHAL24 208/230 1 60 1/5 [149] 1075 2 1.5 3 15

RHAL30 208/230 1 60 1/4 [186] 1075 2 2.5 4 15

RHAL36 208/230 1 60 1/3 [249] 1075 2 2.5 4 15

RHBL24 208/230 1 60 1/3 [249] 300-1100 4 1.6 3 15

RHBL36 208/230 1 60 1/2 [373] 300-1100 4 2.7 4 15

Voltage Phase Hertz HP [W] RPM Speeds

Circuit

Amps.

Minimum

Circuit

Ampacity

Maximum

Circuit

Protector

Cooling

Capacity Tons

RHAL

18

RHAL/RHBL

24

RHAL

30

RHAL/RHBL

36

Model

No.

RXHJ-21B/T03J

RXHJ-21B/T05J

RXHJ-21B/T08J

RXHJ-21B/T03J 2.25/3.0 1/60 1-3.0 Single 10.8/12.5 1.5 16/18 20/20

RXHJ-21B/T05J 3.6/4.8 1/60 1-4.8 Single 17.3/20.0 1.5 24/27 25/30

RXHJ-21B/T08J 5.4/7.2 1/60 2-3.6 Single 26.0/30.0 1.5 35/40 35/40

RXHJ-21B/T10J 7.2/9.6 1/60 2-4.8 Single 34.6/40.0 1.5 46/52 50/60

RXHJ-24B/T03J 2.25/3.0 1/60 1-3.0 Single 10.8/12.5 2.5 17/19 20/20

RXHJ-24B/T05J 3.6/4.8 1/60 1-4.8 Single 17.3/20.0 2.5 25/29 25/30

RXHJ-24B/T08J 5.4/7.2 1/60 2-3.6 Single 26.0/30.0 2.5 36/41 40/45

RXHJ-24B/T10J 7.2/9.6 1/60 2-4.8 Single 34.6/40.0 2.5 47/54 50/60

RXHJ-24B/T03J 2.25/3.0 1/60 1-3.0 Single 10.8/12.5 2.5 17/19 20/20

RXHJ-24B/T05J 3.6/4.8 1/60 1-4.8 Single 17.3/20.0 2.5 25/29 25/30

RXHJ-24B/T08J 5.4/7.2 1/60 2-3.6 Single 26.0/30.0 2.5 36/41 40/45

RXHJ-24B/T10J 7.2/9.6 1/60 2-4.8 Single 34.6/40.0 2.5 47/54 50/60

Heater

kW

(208/240V)

2.25/3.0 1/60 1-3.0 Single 10.8/12.5 1.5 20/20

3.6/4.8 1/60 1-4.8 Single 17.3/20.0 1.5 25/30

5.4/7.2 1/60 2-3.6 Single 26.0/30.0 1.5 35/40

PH/Hz

No. Elements -

kW Per

Type Supply

Circuit

Circuit

Amps.

Motor

Ampacity

Minimum

Circuit

Ampacity

16/18

24/27

35/40

Maximum

Protection

Circuit

Page 11

Rheem Heating, Cooling and Water Heating 11

16.0 Accessories-Kits-Parts

• Drain Pan Over Flow Switch RXHK-A01 is used to detect condensate drain blockage and will shut down the outdoor unit in order to

prevent structural damage to the surrounding structures of the air handler.

• Louvered Cabinet Grill RXHK- is used as decorative grill which covers the return air opening of the front return air handler.

• Decorative Wall Grill RXHK-D01 is used in applications where the air handler is installed in a closet or interior wall and allows

adequate return air back to the unit.

• Bottom Return Conversion Kit RXHK- is used to divert the return air from the factory standard front return to a bottom return.

[ ] Designates Metric Conversions

Accessory Number

RXHK-B01

RXHK-B02

Indoor Unit

RHAL-FR18

RHAL-FR24

RHBL-FR24

RHAL-FR30

RHAL-FR36

RHBL-FR36

Accessory Number

RXHK-C01

RXHK-C02

Indoor Unit

RHAL-FR18

RHAL-FR24

RHBL-FR24

RHAL-FR30

RHAL-FR36

RHBL-FR36

Page 12

Before proceeding with installation, refer

to installation instructions packaged

with each model, as well as complying

with all Federal, State, Provincial, and

Local codes, regulations, and practices.

Rheem Heating,

Cooling and

Water Heating

P.O. Box 17010, Fort Smith, AR 72917

“In keeping with its policy of continuous progress and product improvement, Rheem reserves the right to make changes without notice.”

PRINTED IN U.S.A. 7-10 DC FORM NO. H11-533 REV. 1

Supersedes Form No. H11-533

Loading...

Loading...