Page 1

FORM NO. H11-521 REV. 5

Supersedes Form No. H11-521 Rev. 4

AIR HANDLERS

RBHM- SERIES

AIR HANDLERS

AND FAN COIL UNIT

Features

■ Versatile 3-way convertible design for upflow, horizontal

left and horizontal right.

■ Available from the factory in upflow and horizontal left

configurations.

■ Nominal airflow up to 1.0" external static pressure.

■ Standard factory installed high-efficiency coils.

■ The blower box is made of sturdy double wall construc-

tion with .5 inch [12.7 mm] of foil faced insulation for

excellent sound and insulating characteristics.

■ Designed for use with exterior high-static filters.

■ Circuit breaker (standard on units with more than 11 kW)

meets U.L. and cUL requirements for service disconnect.

■ Factory installed electric heat provides exact heat for

indoor comfort over a variety of applications.

■ Dip switch settings for selectable, customized cooling air-

flow over a wide variety of applications.

■ On-demand dehumidification-terminal that adjusts airflow to

help control humidity for unsurpassed comfort in cooling mode.

Page 2

2 Rheem Heating, Cooling and Water Heating

RBHM- Series

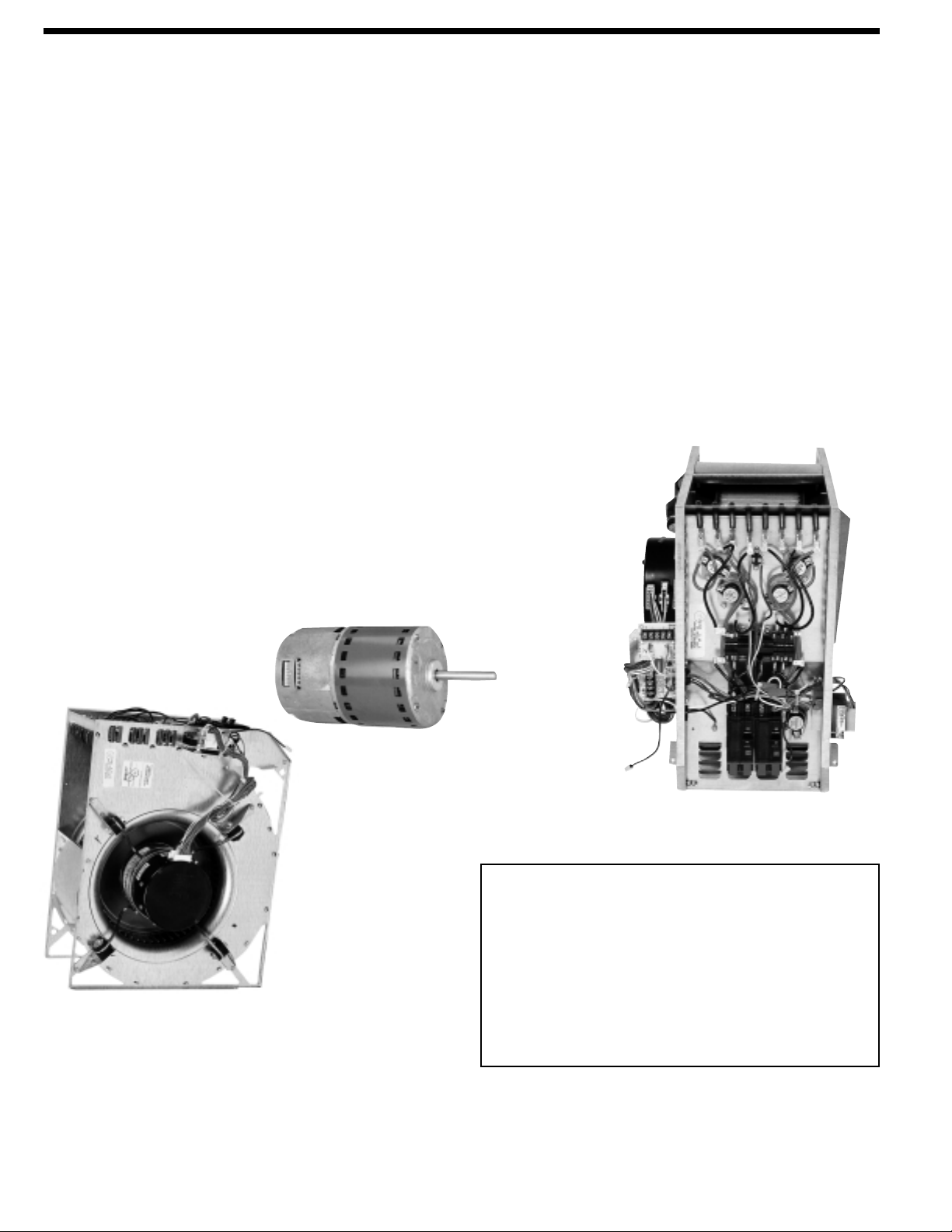

■ Quiet, energy efficient ECM motor technology providing nomi-

nal airflow to 1.0 inch [25 kPa] of external static pressure.

■ Interface board with dip switches conveniently located in the

blower compartment allows for precise, field selectable airflow

to meet the requirements of particular applications.

■ Selectable continuous fan “on” options.

■ Attractive pre-painted cabinet exterior.

■ The blower box has rugged double wall steel cabinet construc-

tion, designed for added strength and versatility.

■ .5" foil faced insulation mechanically retained in blower

compartment.

■ Four leg, rubber insulated wire motor mount.

■ Circuit breakers standard on 1-phase models above 11 kW

and optional on models with 11 kW or less.

■ Models supplied with circuit breakers meet UL and CUL

requirements as a service disconnect switch.

■ Provisions for field electrical connections from either side of air

handler cabinet.

■ Tab lock blower housing with integrated electric heaters, con-

trols, motor and blower. Slide out design for service and maintenance convenience.

[ ] Designates Metric Conversions

■ Exclusive dependable Incoloy sheath type electric heating

elements located in the blower housing provide mixed warm

air.

■ Field convertible for vertical upflow, horizontal left hand or right

hand air supply.

■ Indoor coil design provides low air side pressure drop and

high performance. All coils come with PVC condensate elbow

standard.

■ All indoor coils have copper tubing and aluminum fins.

■ Molded polymer corrosion resistant condensate drain pan is

provided on all indoor coils.

■ Both supply and return duct flanges provided as standard on

air handler cabinet.

■ Connection points for both high voltage and low voltage control

wiring inside air handler cabinet.

■ Concentric knockouts are provided for power connection to

cabinet. Installer may pull desired hole size up to 2 inches

[51 mm] for 1

1

/2 inch [38 mm] conduit.

■ Front refrigerant and drain connections.

Engineering Features

BLOWER

SECTION

ECM

MOTOR

GENERAL TERMS OF

LIMITED WARRANTY

Rheem will furnish a replacement for any part of this

product which fails in normal use and service within the

applicable periods stated, in accordance with the terms of

the limited warranty.

Limited Parts Warranty ........................................10 years.*

For Complete Details of the Limited Warranty, Including

Applicable Terms and Conditions, See Your Local Installer or

Contact the Manufacturer for a Copy.

Page 3

Rheem Heating, Cooling and Water Heating 3

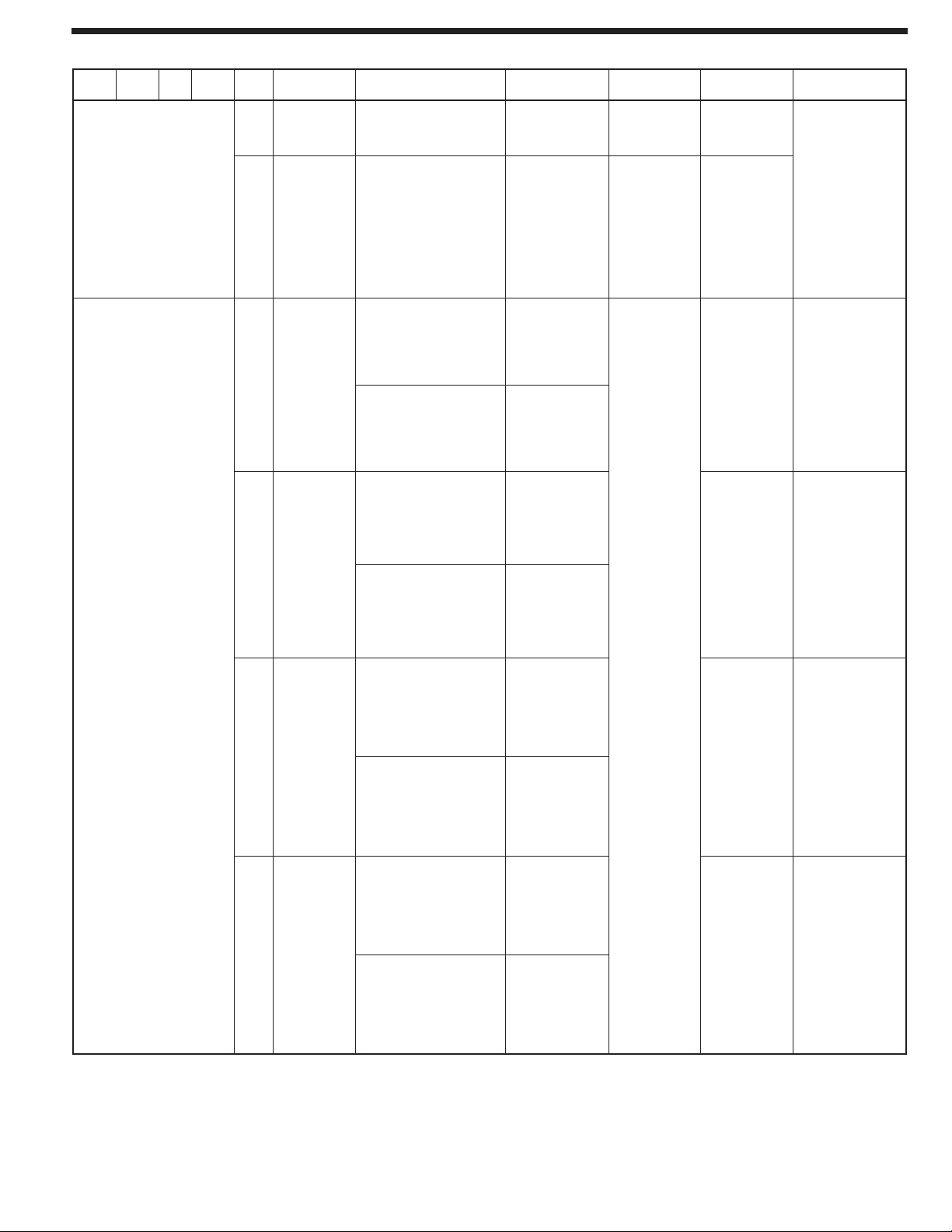

Model Identification

NOTES: 1) RBHM Air Handler cannot be ordered without coil.

2) Electrical heat designation: set electric heat data for actual heater kW represented by number above.

3) Electric heater BTUH = (heater watts + motor watts) x 3.412 (See airflow table for motor watts).

4)

†

Air Handlers with A-Coils do not come with a factory installed air filter. External filter rack or other means of filtration is required.

[ ] Designates Metric Conversions

R B H M 17 J 11 S M Q

Rheem Blower

Unit

Type

Unit

H = Air

Handler

Design

Series

Cab.

Width

17

24

25

26

Electrical

Designations

J = 208/240V,

1PH, 60HZ

Electrical Heat (KW) Designation

See Electrical Heat Data for

Actual KW at 208 Volts.

00 = No Heat

06 = 4.9 kW

07 = 7.0 kW

11 = 10.0 kW

14 = 14.0 kW

Control

Designation

N = No Circuit

Breakers Single

Supply Circuit

S = Circuit Breaker(s)

Single Supply

Circuit

Airflow

Direction

M = Multiposition

Coil

Code

Additional

Inform.

1) Motor H.P. [W]

2) Blower CFM [L/s]

1st/2nd Stage

3) Blower Wheel

Dia./Width [mm]

4) Filter Size

Width/Length [mm]

5) Outdoor

Unit Size

17 =

17.5"

24 =

24.5"

25 =

24.5"

00, 06, 07, 11

J

N

Q = RCQD-2417AS

06, 07, 11 S

00, 07, 11 N

J

R = RCQD-3624AS

07, 11, 14 S

1) 1/3 H.P. [249]

2) 600/800 CFM

[283/378]

29

13

32 x 3

/

3) 11

[302 x 96]

†

4) N/A

5) -024

1) 1/2 H.P. [373]

2) 900/1200 CFM

[425/566]

29

3) 11

/32 x 71/8

[302 x 181]

†

4) N/A

5) -036

16

/

M = Multiposition

00, 11 N

J

S= RCQD-4824AS

11, 14, 18 S

1) 3/4 H.P. [559]

2) 1200/1600 CFM

[566/755]

29

3) 11

/32 x 91/2

[302 x 241]

†

4) N/A

5) -048

11 N

26 =

24.5"

J

11, 14, 18, 21 S

1) 1 H.P.

2) 1275/1700 CFM

[602/802]

T= RCQD-6024AS

29

3) 11

[302 x 241]

4) N/A

/32 x 91/2

†

5) -060

Page 4

4 Rheem Heating, Cooling and Water Heating

Unit Dimensions

Unit Dimensions & Weights

[ ] Designates Metric Conversions

( ) Designates Unit with Double Coil Cabinet

AIRFLOW

FRONT VIEW

SIDE VIEW

3

/4 [19 mm] DUCT FLANGE

SUPPLIED ON RETURN AND

SUPPLY DUCT OPENING

HIGH VOLTAGE CONNECTION

7

/8 [22 mm], 13/32 [28 mm] DIA.

CONCENTRIC KNOCK OUTS. IF

LARGER REQUIRED, PULL HOLE

SIZE REQ'D UP TO 2 [51 mm] DIA.

FOR 11/2 [38 mm] CONDUIT

LOW VOLTAGE CONNECTION

1

/2 [12.5 mm] KNOCK OUT

UPFLOW UNIT SHOWN:

UNIT MAY BE INSTALLED UPFLOW,

HORIZONTAL RIGHT OR LEFT HAND

AIR SUPPLY.

A

18

[457 mm]

171/2

[445 mm]

28

[711 mm]

AIRFLOW

DIRECTION

1

/2

45

[1156 mm]

HORIZONTAL DRAIN

KNOCKOUT RIGHT AIRFLOW

PRIMARY HORIZONTAL

DRAIN LEFT AIRFLOW

AUXILIARY HORIZONTAL

DRAIN LEFT AIRFLOW

BOTTOM IMAGE

RETURN AIR OPENING

22

[559 mm]

20

[508 mm]

W

W-1

[25 mm]

AUXILIARY VERTICAL DRAIN

PRIMARY VERTICAL DRAIN

3

1

/4

[44 mm]

Model Number

RBHM-

(with RCQD coil)

17

24 241/2 [622] 113/4 [298] 720 190/199 [86/90]

25

Unit

Width

“W” In. [mm]

171/2 [445] 79/16 [192]

241/2 [622] 113/4 [298]

241/2 [622] 113/4 [298]

Supply

Duct

“A” In. [mm]

Nominal Coil Airflow Stage

1st 2nd

ODD ODD

450 136/143 [62/65]

960 1280 196/205 [89/93]

1050 1350 197/206 [89/93]

Normal

600

900

1200

1275 170026

600

960

Normal

800

1200

1600

Unit Weight/Shipping

Weight (Lbs.) [kg]

Unit With

Coil (Max. KW)

Page 5

Rheem Heating, Cooling and Water Heating 5

Airflow Performance

Airflow performance data is based on cooling performance

with dry coil and filter in place. Select performance table for

appropriate unit size, voltage and number of electric heaters to

be used. Make sure external static applied to unit allows operation within the minimum and maximum limits shown in table

below for both cooling and electric heat operation. For optimum

blower performance, operate the unit in the .2" to .5" in. W.C.

external static range. In general, the indoor motor speed tap

should be as shown in table for the appropriate cooling capacity shown. Always check to make sure proper motor speed tap

is connected as units are shipped from the factory connected

for high speed operation.

Airflow Performance Data

IMPORTANT: Observe airflow operating limits. Do not operate above 1.0 in. W.C. system external static.

[ ] Designates Metric Conversions

Model

Cabinet

RBHM17

RBHM24

Size

2 ton

-17

3 ton

-24

Electric

Heaters

3 (Max.)

None

3 (Max.)

None

Blower Motor

Thermostat

Volts

208

230

208

230

208

230

208

230

Input

Y1

Y2

Y1

Y2

Y1

Y2

Y1

Y2

Y1

Y2

Y1

Y2

Y1

Y2

Y1

Y2

0.1 [.02] 0.2 [.05] 0.3 [.07] 0.4 [.10] 0.5 [.12] 0.6 [.15] 0.7 [.17] 0.8 [.20] 0.9 [.23] 1.0 [.25]

585 [276] 588 [278] 589 [278] 590 [278] 589 [278] 588 [278] 585 [276] 582 [275] 577 [272] 572 [270]

CFM

RPM 552 610 667 725 782 840 898 955 1013 1070

WATTS 59 76 93 110 127 144 161 179 197 214

CFM

792 [374] 795 [375] 797 [376] 798 [377] 797 [376] 795 [375] 791 [373] 786 [371] 779 [368] 771 [364]

RPM 684 731 777 824 870 917 963 1009 1056

WATTS 135 156 177 197 218 238 259 279 299 319

CFM

585 [276] 590 [278] 593 [280] 595 [281] 595 [281] 594 [280] 592 [279] 589 [278] 585 [276] 579 [273]

RPM 557 615 673 731 788 846 904 961 1019

WATTS 67 82 98 114 131 148 166 184 203 222

CFM

786 [371] 790 [373] 793 [374] 795 [375] 795 [375] 794 [375] 792 [374] 788 [372] 783 [370] 777 [367]

RPM 664 713 762 811 861 910 959 1009 1058

WATTS

CFM

RPM 549 605 660 716 772 828

WATTS

CFM

RPM 681 724 768 812 855 899 943 986 1030

WATTS 136 156 175 194 213 232 251 270 288 307

CFM

RPM 545 601 657 712 768 824 879 935 991

WATTS 55 74 93 111 129 146 163 179 195 210

CFM

RPM 677

WATTS

CFM

RPM 496 551 607 663 718 774

WATTS

CFM

RPM 544 598 653 707 762 816 871 925 980

WATTS 115 154 192 229 264 298

CFM

RPM 489 547 604 661 719 776 833 890 948

WATTS 74 98 122 147 172 198 223 249 275 301

CFM

RPM 550

WATTS 124 162 198 234

CFM

RPM

WATTS

CFM

RPM 514 564 614 664 714 764 813 863 913

WATTS 126 153 180 207 235 263 292 321 351 381

CFM

RPM 448 503 559 614 670 725 780 836 891

WATTS 63 83 104 126 149 172 196 222 247 274

CFM

RPM

WATTS 124 151 177 205

131 151 172 193 214 236 258 281 304 328

606 [286] 609 [287] 611 [288] 611 [288] 609 [287] 606 [286] 602 [284] 596 [281] 589 [278] 580 [274]

60 77 95 112 129 146 163 179 196 212

819 [387] 821 [387] 822 [388] 821 [387] 819 [387]

613 [289] 614 [290] 614 [290] 613 [289] 611 [288] 608 [287] 605 [286] 600 [283] 595 [281] 589 [278]

819 [387] 821 [387] 823 [388] 822 [388]

139 156 173 191

870 [411] 876 [413] 881 [416] 883 [417] 883 [417] 881 [416] 877 [414] 871 [411] 863 [407] 852 [402]

71 95 119 143 167 191 215 239 264 288

1147 [541] 1163 [549] 1175 [555] 1183 [558] 1187 [560]

867 [409] 874 [412] 880 [415] 884 [417] 886 [418] 885 [418] 883 [417] 879 [415] 872 [412] 864 [408]

1139 [538] 1158 [547] 1172 [553] 1182 [558]

880 [415] 888 [419] 895 [422] 900 [425] 903 [426] 906 [428] 906 [428] 905 [427] 903 [426] 899 [424]

451 506

65 87 108 129 151 172 194 215 236 258

1127 [532] 1151 [543] 1171 [553] 1186 [560] 1196 [564]

881 [416] 891 [421] 899 [424] 906 [428] 911 [430] 914 [431] 916 [432] 916 [432] 914 [431] 910 [429]

1134 [535] 1158 [547] 1178 [556] 1194 [564]

509

721

604

559

CFM [L/s] (Watts)/External Static Pressure—Inches W.C. [kPa]

765

657

560

610

809 853 897 941 985 1029

710 764 817 870 924 977

615 670 725

660 711 761 812 862 913

1102

1077

1107

884

815 [385] 809 [382] 802 [379] 793 [374] 782 [369]

821 [387] 817 [386] 812 [383] 806 [380] 798 [377] 789 [372]

210

1189 [561] 1191 [562] 1189 [561] 1184 [559] 1174 [554] 1160 [547]

269

1205 [569] 1212 [572] 1214 [573] 1213 [572] 1206 [569] 1196 [564]

233

230 249 270 291 313

829

1187 [560] 1183 [558] 1175 [555] 1163 [549] 1148 [542]

331 362 391 419

302 334 365 395 424

779

1202 [567] 1204 [568] 1201 [567] 1194 [564] 1183 [558]

262 292 323 354 386

940 996

885 941

834 889

1052

1074

1046

1073

996

1034

1005

1030

944

963

947

964

Page 6

6 Rheem Heating, Cooling and Water Heating

Airflow Performance Data

IMPORTANT: Observe airflow operating limits. Do not operate above 1.0 in. W.C. system external static.

[ ] Designates Metric Conversions

Model

Size

4 ton

-25

5 ton

-26

Electric

Heaters

6 (Max.)

None

6 (Max.)

None

Cabinet

RBHM25

RBHM26

Blower Motor

Thermostat

Volts

208

230

208

230

208

230

208

230

Input

Y1

WATTS

Y2

WATTS 235 286 333 378 420 460

Y1

WATTS 126 162 196 230 264 296 328 359 389 419

Y2

WATTS 241 287 332 376

Y1

WATTS

Y2

WATTS 220 252 284 318 352 386 421 457 494 531

Y1

WATTS 117 140 165 191 217 245 274 303 334 365

Y2

WATTS 216 250 285 321

Y1

WATTS

Y2

WATTS 303 339 376 414 451 488

Y1

WATTS 161 186 212 241 271 303 337 372 409 448

Y2

WATTS 311 350 389 426

Y1

WATTS

Y2

WATTS 288 316 346 375 406 437 469 502 536 570

Y1

WATTS 133 158 184 211 239 267 296 325 356 387

Y2

WATTS 287 318 349 380

0.1 [.02] 0.2 [.05] 0.3 [.07] 0.4 [.10] 0.5 [.12] 0.6 [.15] 0.7 [.17] 0.8 [.20] 0.9 [.23] 1.0 [.25]

CFM

1182 [558] 1184 [559] 1184 [559] 1181 [557] 1177 [555] 1170 [552] 1160 [547] 1149 [542] 1134 [535] 1118 [528]

RPM 545 599 653 708 762 816

CFM

RPM 634 680 726 772 818 864 910 956 1002

CFM

RPM 546 600 654 709 763 818 872 926 981

CFM

RPM 630

CFM

RPM

CFM

RPM 578 621 664 707 750 792 835 878 921

CFM

RPM 480 532 584 636 688 740 792 844 896

CFM

RPM

CFM

RPM 543 598 652 706 761 815

CFM

RPM 659 701 744 786 829 871 914 957 999

CFM

RPM 540 595 649 704 758 813 867 922 976

CFM

RPM 669

CFM

RPM

CFM

RPM 630 668 705 742 780 817 854 892 929

CFM

RPM 505 555 605 654 704 754 804 854 903

CFM

RPM

133 162 193 223 255 286 319 352 385 419

1554 [733] 1567 [740] 1576 [744] 1583 [747] 1586 [749]

1186 [560] 1190 [562] 1191 [562] 1190 [562] 1185 [559] 1179 [556] 1169 [552] 1157 [546] 1143 [539] 1125 [531]

1566 [739] 1579 [745] 1588 [749] 1595 [753]

1200 [566] 1202 [567] 1204 [568] 1204 [568] 1204 [568] 1203 [568] 1201 [567] 1198 [565] 1195 [564] 1191 [562]

478

117 139 162 186 212 240 269 299 331 364

1558 [735] 1571 [741] 1581 [746] 1590 [750] 1597 [754]

1202 [567] 1205 [569] 1207 [570] 1207 [570] 1207 [570] 1206 [569] 1204 [568] 1201 [567] 1197 [565] 1192 [563]

1566 [739] 1575 [743] 1583 [747] 1590 [750]

583

1276 [602] 1278 [603] 1276 [602] 1272 [600] 1264 [597] 1252 [591] 1238 [584] 1220 [576] 1198 [565] 1174 [554]

144 173 203 233 265 298 331 366 402 439

1707 [806] 1706 [805] 1704 [804] 1699 [802] 1693 [799]

1289 [608] 1288 [608] 1284 [606] 1277 [603] 1268 [598] 1255 [592] 1240 [585] 1223 [577] 1202 [567] 1179 [556]

1707 [806] 1706 [805] 1704 [804] 1700 [802]

1287 [607] 1285 [606] 1282 [605] 1279 [604] 1276 [602] 1273 [601] 1269 [599] 1266 [597] 1262 [596] 1258 [594]

496 547

130 152 176 202 229 258 289 321 356 391

1692 [800] 1695 [800] 1697 [801] 1699 [802] 1699 [802]

1294 [611] 1291 [609] 1288 [608] 1285 [606] 1281 [605] 1278 [603] 1274 [601] 1270 [599] 1266 [597] 1261 [595]

1699 [802] 1703 [804] 1705 [805] 1706 [805]

615

676

530

625

710

655

CFM [L/s] (Watts)/External Static Pressure—Inches W.C. [kPa]

722

582

668

751

597

695

769 815 861 907 954 1000

633 685 737

711 753 796 839 881 924

793 834 876 917 959 1000

648 699 750

735 775 815 855 895 935

871

1586 [749] 1583 [747] 1577 [744] 1568 [740] 1556 [734]

496 530 562 591

1598 [754] 1598 [754] 1595 [753] 1589 [750] 1579 [745] 1567 [740]

418

1596 [753] 1602 [756] 1607 [758] 1611 [760] 1614 [762] 1616 [763]

356

1695 [800] 1689 [797] 1682 [794] 1674 [790] 1664 [785] 1653 [780]

464

1706 [805] 1705 [805] 1703 [804] 1700 [802] 1696 [800] 1691 [798]

412

458 497 534 571 605

789

1602 [756] 1604 [757] 1605 [757] 1604 [757] 1601 [756]

393 429 467 504 543

869

1685 [795] 1674 [790] 1662 [784] 1648 [778] 1632 [770]

526 564 602 640

501 537 573 608 643

801

1698 [801] 1696 [800] 1693 [799] 1689 [797] 1683 [794]

443 474 505 536 567

925 979

841 893

924 978

851 902

1033

1048

1035

1046

945

964

948

967

1032

1042

1031

1042

953

966

953

976

Page 7

Rheem Heating, Cooling and Water Heating 7

Blower Motor Electrical Data

Electric Heat Electrical Data

*Unit shipped from factory wired for single supply circuit. Unit may be field converted to multiple supply circuit.

[ ] Designates Metric Conversions

Model

Size/Elec.

Designation

17J 208/230 1 601/3 [249] 300-1100 3.0/2.8 4/4 15

24J 208/230 1 601/2 [373] 300-1100 5.0/4.3 7/6 15

25J 208/230 1 603/4 [559] 300-1100 6.6/5.9 9/8 15

26J 208/230 1 601 [746] 300-1100 9.4/9.1 12/12 15

Voltage Phase HertzHP [W] RPM

Circuit

Amps.

Minimum

Circuit

Ampacity

Model

Elec./KW

Designation

17J06 1/60 Single Circuit 2/2.5 3.7/4.9 20.6/23.2 26/29 30/30

17J07 1/60 Single Circuit 2/3.5 5.3/7.0 28.2/32.0 36/40 40/40

17J11 1/60 Single Circuit 3/3.5 7.9/10.5 40.8/46.6 51/59 60/60

24J07 1/60 Single Circuit 2/3.5 5.3/7.0 30.2/33.5 38/42 40/45

24J11 1/60 Single Circuit 3/3.5 7.9/10.5 42.8/48.1 54/61 60/70

24J14 1/60

25J11 1/60 Single Circuit 3/3.5 7.9/10.5 44.4/49.7 56/63 60/70

25J14 1/60

25J18 1/60

26J11 1/60 Single Circuit 3/3.5 7.9/10.5 47.2/52.9 59/67 60/70

26J14 1/60

26J18 1/60

26J21 1/60

PH/HZ

Type Supply Circuit

Single Circuit

Multiple Circuit*

Single Circuit 4/3.5 10.5/14.0 55.4/62.7 70/79 70/80

Multiple Ckt. 1

Multiple Ckt. 2

Single Circuit 4/3.5 10.5/14.0 57.0/64.3 72/81 80/90

Multiple Ckt. 1

Multiple Ckt. 2

Single Circuit 5/3.5 13.1/17.5 69.6/78.9 87/99 90/100

Multiple Ckt. 1

Multiple Ckt. 2

Single Circuit 4/3.5 10.5/14.0 59.8/67.5 75/85 80/90

Multiple Ckt. 1

Multiple Ckt. 2

Single Circuit 5/3.5 13.1/17.5 72.4/82.1 91/103 100/110

Multiple Ckt. 1

Multiple Ckt. 2

Single Circuit 6/3.5 15.8/21.0 85.0/96.7 107/121 110/125

Multiple Ckt. 1

Multiple Ckt. 2

Heater

No./KW

@ 240V

2/3.5 5.3/7.0 30.2/33.5 38/42 40/45

2/3.5 5.3/7.0 25.2/29.2 32/37 35/40

2/3.5

2/3.5

2/3.5 5.3/7.0 31.8/35.1 40/44 40/45

3/3.5 7.9/10.5 37.8/43.8 48/55 50/60

2/3.5

2/3.5

2/3.5 5.3/7.0 34.6/38.3 44/48 45/50

3/3.5 7.9/10.5 37.8/43.8 48/55 50/60

3/3.5 7.9/10.5 47.2/52.9 59/67 60/70

3/3.5 7.9/10.5 37.8/43.8 48/55 50/60

Heater KW

208/240V

5.3/7.0 31.8/35.1 40/44 40/45

5.3/7.0 25.2/29.2 32/37 35/40

5.3/7.0 34.6/38.3 44/48 45/50

5.3/7.0 25.2/29.2 32/37 35/40

Circuit

Amps.

Minimum

Circuit

Ampacity

Maximum

Circuit

Protector

Maximum

Circuit

Protector

Model PH Maximum KW HP CFM

RBHM-17 1/60 11 1/3 500

RBHM-24 1/60 14 1/2 1000

RBHM-25 1/60 18 3/4 1400

RBHM-26 1/60 21 1 1600

Electric Heat Backup CFM Tube 1

Page 8

Copper Wire Size—AWG. (3% Voltage Drop)

ACCESSORIES—KITS—PARTS

• Filter Bases

Model Filter

Cabinet Size Filter Size In. [mm] Width Part Number

-17 16 x 20 [406 x 508] 1" or 2" 54-1620-E3

-24 25 x 20 [635 x 508] 1" or 2" 54-2025-E3

-25 25 x 20 [635 x 508] 1" or 2" 54-2025-E3

-26 25 x 20 [635 x 508] 1" or 2" 54-2025-E3

[ ] Designates Metric Conversions

Combustible Floor Base for Downflow Installations

Before proceeding with installation, refer

to installation instructions packaged

with each model, as well as complying

with all Federal, State, Provincial, and

Local codes, regulations, and practices.

Rheem Heating,

Cooling and

Water Heating

P.O. Box 17010, Fort Smith, AR 72917

“In keeping with its policy of continuous progress and product improvement, Rheem reserves the right to make changes without notice.”

PRINTED IN U.S.A. 11-09 DC FORM NO. H11-521 REV. 5

Supersedes Form No. H11-521 Rev. 4

S

U

P

P

L

Y

W

I

R

E

200 [61] 12 10 8 8 8 6 6 6 4 4 3 3 2 2 1 0 00

L

E

150 [46] 12 10 10 10 8 8 6 6 6 4 4 3 3 2 1 0 00

N

100 [30] 14 12 10 10 8 8 8 6 6 4 4 3 3 2 1 0 00

G

50 [15] 14 12 10 10 8 8 8 6 6 4 4 3 3 2 1 0 00

T

H

F

E

E

T

[m]

15 20 25 30 35 40 45 50 60 70 80 90 100 110 125 150 175

SUPPLY CIRCUIT AMPACITY

NOTE: Wire based on copper conductors 75°C minimum rating.

For more than 3 conductors in a raceway or cable,

see N.E.C. for derating the ampacity of each conductor.

Loading...

Loading...