Page 1

High Efficiency Commercial Gas Water Heater

USE & CARE MANUAL

WITH INSTALLATION INSTRUCTIONS FOR THE CONTRACTOR

This Use & Care Manual covers the following model numbers:

HE55-100N HE119-130N HE55-199LP

HE55-130N HE119-160N HE80-130LP

HE55-160N HE119-199N HE80-160LP

HE55-199N

HE80-130N

HE80-160N HE55-130LP HE119-160LP

HE80-199N HE55-160LP HE119-199LP

—————–

HE55-100LP HE119-130LP

HE80-199LP

n

Recognize this symbol as an indication of

important Safety Information!

Do Not Destroy this Manual. Please read carefully

and keep in a safe place for Future Reference.

n

n NOTICE

This water heater is designed for use in a commercial application. The installation and maintenance of it

should be performed by qualified, licensed service personnel.

n WARNING

Read and review this entire manual with special emphasis on the Venting and Operation Sections prior to

any installation work.

n CALIFORNIA PROPOSITION 65 WARNING

This product contains chemicals known to the State of California to cause cancer, birth defects and other

reproductive harm.

n WARNING

If the information in these instructions are not followed exactly, a fire or explosion may result causing

property damage, personal injury or death.

FOR YOUR SAFETY!

n

— Do not store or use gasoline or other flammable

vapors or liquids or other combustible materials in

the vicinity of this or any other appliance. To do so

may result in an explosion or fire

— WHAT TO DO IF YOU SMELL GAS

Do not try to light any appliance.

•

Do not touch any electrical switch; do not use any

•

phone in your building.

Immediately call your gas supplier from a neighbor’s

•

phone. Follow the gas supplier’s instructions.

If you cannot reach your gas supplier, call the fire

•

department.

Do not return to your building until authorized by

•

the gas supplier or fire department.

— Improper installation, adjustment, alteration, service

or maintenance can cause injury, property damage

or death. Refer to this manual. Installation and

service must be performed by a qualified installer,

service agency or gas supplier.

Printed in the USA AP15135 (5/09)

1

Page 2

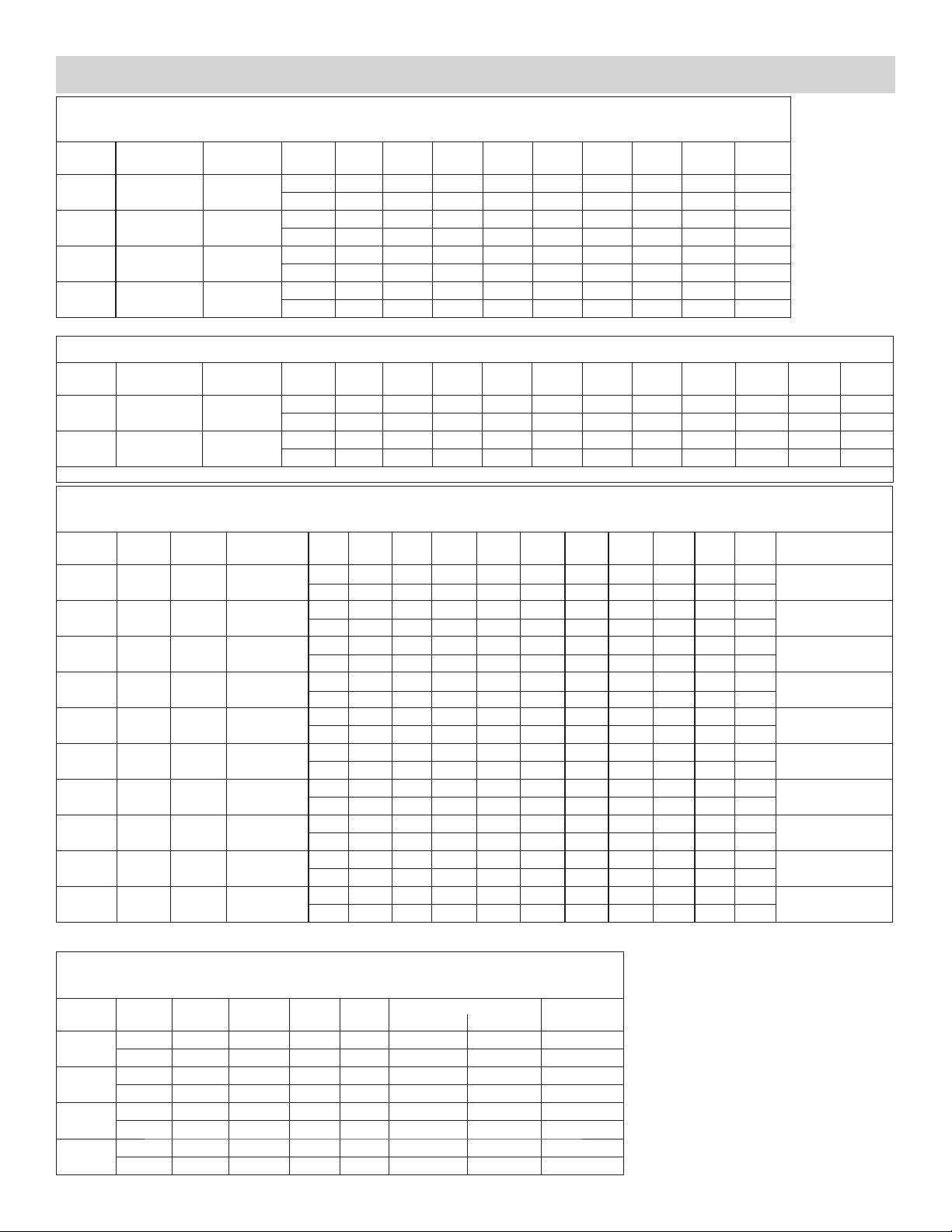

SPECIFICATIONS

RECOVERY CAPACITIES

Recovery in U.S. Gallons/Hr. (GPH) and Liters/Hr. (LPH) at Various Temperature Rises

MODEL

NUMBER

HE55-100 100,000 95%

HE55-130

HE80-130

HE119-130

HE80-160

HE119-160

HE80-199

HE119-199

Recovery rating is based on thermal efficiencies obtained in Intertek testing laboratory.

BOOSTER MODELS

MODEL

NUMBER

HE55-160 160,000 95%

HE55-199 199,000 95%

All models exceed the minimum energy efficiency requirements of current ASHRAE 90.1 requirements.

INPUT (BTU/HR)

NAT. & LP

130,000 95%

160,000 95%

199,000 95%

INPUT (BTU/HR)

NAT. & LP

THERMAL

EFFICIENCY

THERMAL

EFFICIENCY

UNITS

GPH 288 230 192 165 144 128 115 105 96

LPH 1090 872 726 623 545 484 436 396

GPH 374 299 249 214 187 166 150 136 125

LPH 1417

GPH

LPH 1744

GPH 573 458 382

LPH 2169

Recovery in U.S. Gallons/Hr. (GPH) and Liters/Hr. (LPH)

UNITS

GPH 461 368 307 263 230 205 184 167 154 142 132

LPH 1744 1395 1

GPH 573

LPH 2169 1735 1446 1239 1084 964 867 789 723 667 620

40°F

(22.2°C)

40°F

(22.2°C)

MAXIMUM DELIVERY

In U.S. Gallons and Liters (Includes useable storage and recovery for indicated times)

MODEL

NUMBER

HE55-100

HE55-130

HE80-130

HE119-130

HE55-160

HE80-160

HE1

HE55-199

HE80-199

HE1

All models have a maximum setpoint of 160°F with the exception of the HE55-160 and HE55-199 booster models. The HE55-160 and HE55-199 have a maximum setpoint of 180°F.

* NOTE: The 180º F models are shipped with all necessary components for an approved installation (see Booster Installation Kit for component list on Page 7.)

19-160

19-199

GALLONS/

LITERS

55

208

55

208

80

303

119

450

55

208

80

303

119

450

55

208

80

303

119

450

MAX

SETPOINT

160º

71ºC

160º

71ºC

160º

71ºC

160º

71ºC

180º*

82ºC

160º

71ºC

160º

71ºC

180º*

82ºC

160º

71ºC

160º

71ºC

INPUT (BTU/HR)

NAT. & LP

100,000

130,000

130,000

130,000

160,000

160,000

160,000

199,000

199,000

199,000

TEMP.

RISE UNITS 5 MIN.

100°F GAL. 48 58 67 77 96 125 154 269 388

37.7°C LTR. 182 219 255 291 364 473 582 1019 1455

100°F GAL. 51 63 76 88 1

37.7°C

100°F

33.7°C

100°F GAL. 96 108 121 133 158 196 233 383

33.7°C LTR. 363 410 457 504 599 750 882 1449 2015

100°F GAL. 54 69 85 100 131 177 223 407 591

37.7°C

100°F

37.7°C L

100°F GAL. 99 114 129 145 175 221 268

37.7°C L

100°F

37.7°C L

100°F

37.7°C L

100°F GAL. 102 121 141 160 198 255 312 542

37.7°C L

DIMENSIONAL INFORMATION

All dimensions shown in English and Metric

MODEL WATER CONNECTIONS APPROX

NUMBER UNITS HEIGHT WIDTH DEPTH VENT

HE55-100

HE55-130

HE55-160

HE55-199

HE80-130

HE80-160

HE80-199

HE1

19-130

HE119-160

HE119-199

All models require a 120V power source.

* 130,000 Btu models are certified to be installed with 2" venting.

inches 52 23 1/2 32

mm 1321 597 813 51 25 25 79 kgs

inches 52

mm 1321 597 813 76 25 25 79 kgs

inches 72 23 1/2 32 3* 1-1/2 1-1/2 235 lbs.

mm 1854 597 813 76 38 38 106 kgs

inches 73 27 36 3* 1-1/2 1-1/2 405 lbs.

mm 1854

23 1/2 32 3 1 1 175 lbs.

686 914 76 38 38 184 kgs

50°F

(27.8°C)

1

461 368 307 263 230 205 184 167 154

1395 1

1735 1446 1239 1084 964 867 789 723

50°F

(27.8°C)

458 382 327 286 255 229 208 191 176 164

LTR. 193 240 288 335 430 571 713 1281 1848

GAL. 68 81 93 106 131 168 206 355 505

LTR. 259 306 354 401 495 637 779 1345 1912

L

TR. 204 262 320 379 495 670 844 1542 2241

GAL.

TR. 270 328 386 444 561 735 909 1607 2304

TR. 373 432 490 548 664 838 1013 1710 2408

GAL. 57 77 96 115 153 210 268 497

TR. 218 291 363 435 580 797 1014 1883 2751

GAL. 75 94 113 132 171 228 285 514

TR. 284 357 429 501 646 863 1079 1947 2814

TR. 338 460 532 604 749 966 1183 2050 2918

60°F

(33.3°C)

133 944 809 708 630 567 515 472

60°F

(33.3°C)

10

MIN.

87

71

70°F

(38.9°C)

162 996 872 775 697 634 581

327 286 255 229 208 191

70°F

(38.9°C)

162 996 872 775 697 634 581 536 498

15

MIN.

102 117

80°F

(44.4°C)

80°F

(44.4°C)

20

MIN.

90°F

(50.0°C)

90°F

(50.0°C)

30

MIN.

13 151 188 338 488

148

100°F

(55.6°C)

100°F

(55.6°C)

45

MIN. 1 HR. 2 HR. 3 HR.

194

240

110°F

(61.1°C)

110°F

(61.1°C)

424

452 636

120°F

(66.7°C)

363

120°F

(66.7°C)

532

609

726

743

771

0" CLEARANCE TO

INLET OUTLET

2 1 1 175 lbs.

SHIPPING WT.

COMBUSTIBLES ON ALL

ADVANTAGEPLUS

UNITS, HOWEVER, A 24"

(61 cm) CONTROL PANEL

SERVICE CLEARANCE IS

RECOMMENDED.

2

130°F

(72.2°C)

MIN. TO RECOVER

CONTENTS

140°F

(77.8°C)

29

22

32

48

18

26

39

14

21

31

Page 3

TABLE OF CONTENTS

Part 1: General Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Part 2: Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

A. Local Installation Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

B. Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Temperature And Pressure Relief Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

C.

D. Expansion Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

E. Domestic Water Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

F. Special Instructions For Booster Installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

G. Lighting and Operating Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

H. Electrical Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

I. Gas Connection

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-10

Part 3: Venting, Combustion Air & Condensate Removal . . . . . . . . . . . . . . . . 11-16

A. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

B. Approved Materials For Exhaust Vent And Intake Air Vent . . . . . . . . . . . . . . . . . . . . 11

C. Exhaust Vent And Intake Air Vent Pipe Location . . . . . . . . . . . . . . . . . . . . . . . . . . 11-13

D. Exhaust Vent

E. Longer Vent Runs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

F. Exhaust V

Very Important Set-up Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

G.

Concentric Vent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

H.

And Intake Air Vent Sizing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

ent And Intake Air Pipe Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-15

Part 4: Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-19

A. Overall Appliance And Control Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

B. Status Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

C. Test Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17-18

D. Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

E. Shutdown Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

F. Prevent Combustion

G. Corrosive Contaminants And Sour

H. Condensate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Air Contamination

ces Products To

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Avoid. . . . . . . . . . . . . . . . . . . . . 19

Part 5: Components Of The AdvantagePlus . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-23

Service Parts, Wiring Diagram and How to Obtain Service . . . . . . . . . . . . . . . . . . . .20-22

Most Common AdvantagePlus Installation Concerns. . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Part 6: Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-25

3

Page 4

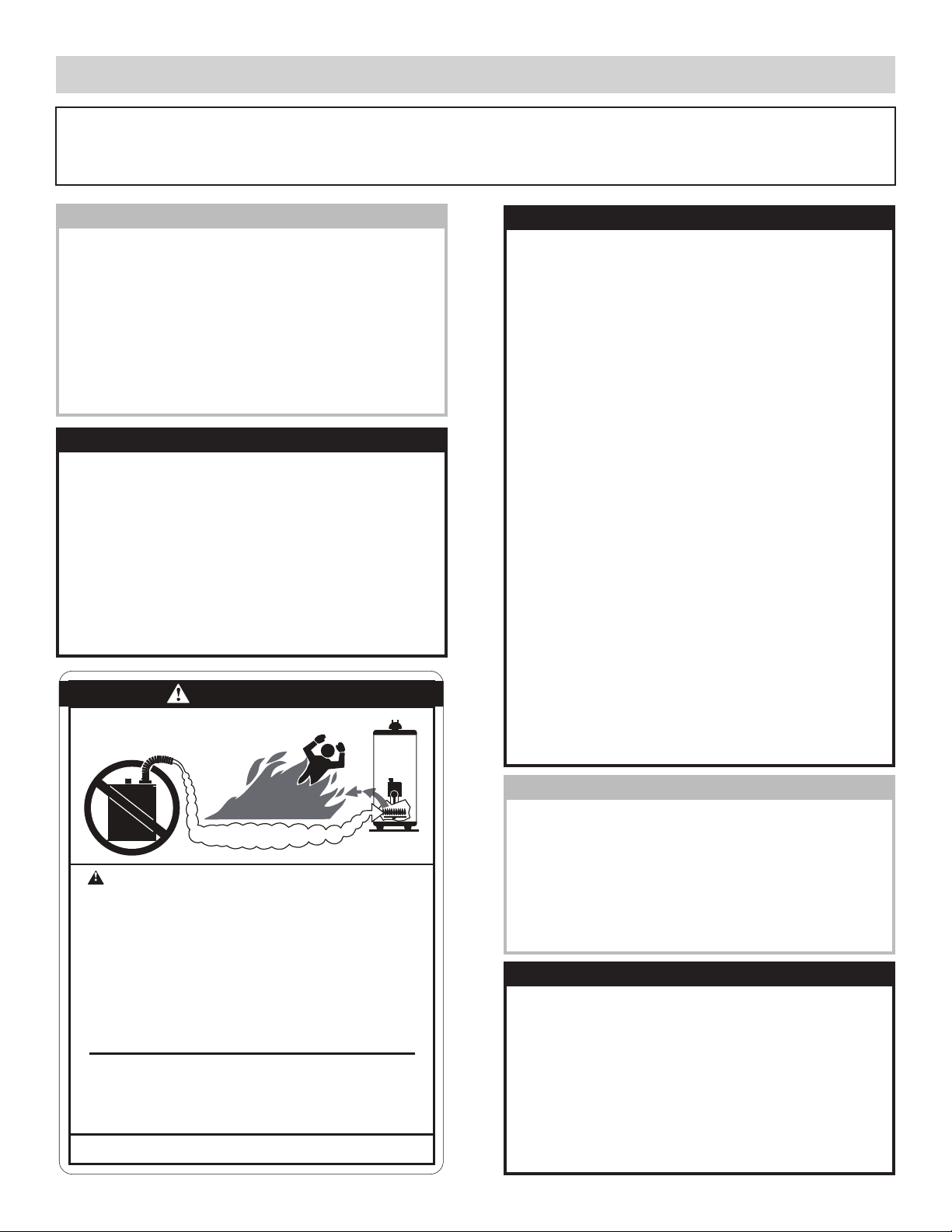

D A N G E R

FLAM MAB LES

Flammable Vapors

Vapors from flammable

liquids will explode and

catch fire causing death or

severe burns.

Do not use or store flammable

products such as gasoline,

solvents or

adhesives in the

same room or

area near the

water heater.

Ke

ep flammable products:

1. far away f

rom heater,

2. in approve

d containers,

3. tightly closed and

4. out of chi

ldren's reach.

Water heater has a main

burner and

pilot flame.

The pilot fl

ame:

1. which can come on at

any time and

2

. will igni

te flammable

vapors.

Vapors:

1

. cannot be

seen,

2. are heavi

er than air,

3. go a long way on the

floor and

4

. can be ca

rried from

other rooms

to the pilot

f

lame by air currents.

Installation

:

Do not insta

ll water heater

where flammable products will

be stored or used unless the

main burner

and pilot flames

are at least 18" above the

floor. This

will reduce, but not

eliminate, t

he risk of vapors

being ignite

d by the main

burner or pilot flame.

Read and fol

low water heater warnings and instructions.Ifowners

manual is mi

ssing, contact the retailer or manufacturer.

PART 1: GENERAL SAFETY PRECAUTIONS

Be sure to read and understand the entire Use & Care Manual before attempting to install or operate this water heater.

Pay particular attention to the following General Safety Precautions. Failure to follow these warnings could result in a fire

or explosion, causing property damage, bodily injury or death. Should you have any problems understanding the instructions in this manual, STOP, and get help from a qualified installer or service technician or the gas supplier.

n WARNING

Gasoline, as well as other flammable materials and

liquids (adhesives, solvents, etc.), and the vapors

they produce, are extremely dangerous. DO NOT

handle, use or store gasoline or other flammable

or combustible materials anywhere near or in the

vicinity of a water heater. Be sure to read and follow

the warning label pictured below and other labels on

the water heater, as well as the warnings printed in

this manual. Failure to do so can result in property

damage, bodily injury, or death.

n DANGER

Failure to install and properly vent the water heater

to the outdoors as outlined in the Venting Section

of this manual can result in unsafe operation of the

water heater. To avoid the risk of fire, explosion, or

asphyxiation from carbon monoxide, never operate

this water heater unless it is properly vented and has

an adequate air supply for proper operation. Be sure

to inspect the vent system for proper installation at

initial start-up and at least annually thereafter. Refer

to maintenance section of this manual for more

information regarding vent system inspections.

n DANGER

LIQUEFIED PETROLEUM MODELS

-Propane, or LP gas, must be used with great caution.

· It is heavier than air and will collect first in lower

areas making it hard to detect at nose level.

· Make sure to look and smell for LP leaks before

attempting

to check all gas fittings and connections. Bubbling at

a connection indicates a leak that must be corrected.

When smelling to detect an LP leak, be sure to sniff

near the floor.

· Gas detectors are recommended in LP applications

and their installation should be in accordance with

the manufacturer’s recommendations and/or local

laws, rules, regulations or customs.

· It is recommended that more than one method be

used to detect leaks in LP applications.

IF LP GAS IS PRESENT OR SUSPECTED:

· DO NOT attempt to find the cause yourself;

· DO NOT try to light any appliance;

· DO NOT touch any electrical switch;

· DO NOT use any phone in your building.

· Leave the house immediately and make

family and pets leave also.

· Leave the doors open for ventilation and contact

the gas supplier, a qualified service agency or the

fire department.

· Keep the area clear until the service call has been

made, the leak is corrected, and a qualified agency

has determined the area to be safe.

to light appliance. Use a soapy solution

sure your

n WARNING

Both LP and natural gas have an odorant added to

help detection. Some people may not physically be

able to smell or recognize this odorant. If unsure

or unfamiliar about the smell associated with LP or

natural gas, ask the gas supplier. Other conditions,

such as “Odorant Fade”, which causes the odorant

to “fade”, or diminish in intensity can also hide or

camouflage a gas leak.

n DANGER

Water heaters utilizing Liquefied Petroleum gas (LP)

are different from natural gas models. A natural gas

heater will not function safely on LP gas and vice

versa. No attempt should ever be made to convert a

heater from natural gas to LP gas. To avoid possible

equipment damage, personal injury or fire: DO

NOT connect this water heater to a fuel type not in

accordance with unit rating plate. Propane gas for

propane units. Natural gas for natural gas units.

These units are not certified for any other type fuel.

4

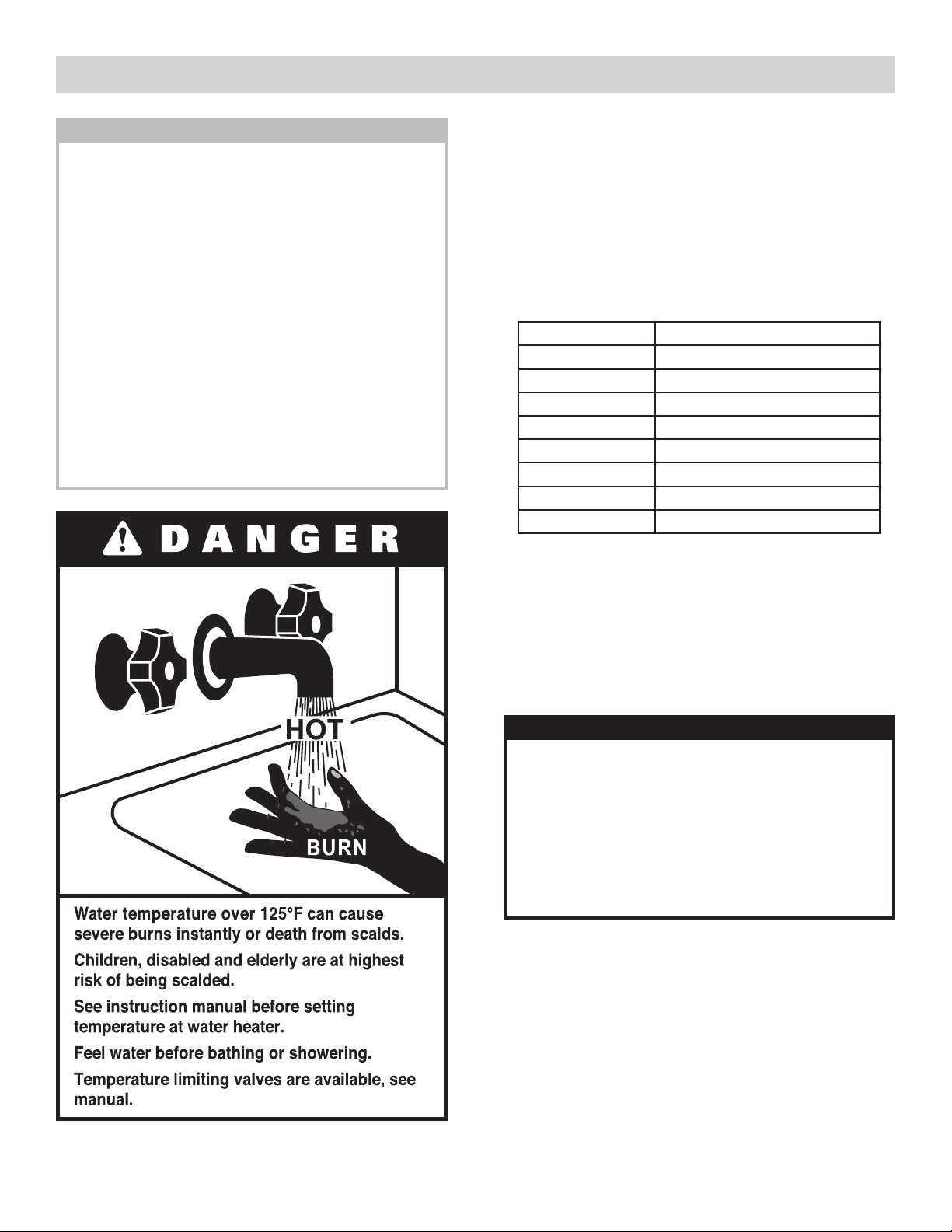

Page 5

PART 1: GENERAL SAFETY PRECAUTIONS cont’d

n WARNING

LP appliances should not be installed below-grade

(for example, in a basement) if such installation is

prohibited by federal, state and/or local laws, rules,

regulations, or customs.

To meet commercial water use needs, the thermostat on this water heater is adjustable up to 160°F

(71°C) (Booster models have a maximum setpoint

of 180°F (82°C). However, water temperatures over

125° F (52°C) can cause severe burns instantly or

death from scalds. This is the preferred starting

point for setting the controls for supplying general purpose hot water.

Safety and energy conservation are factors to be

considered when setting the water temperature

on the thermostat. The most energy efficient

operation will result when the temperature setting

is the lowest that satisfies the needs consistent

with the application.

Maximum water temperatures occur just after burner has

shut off. To find temperature of the water being delivered, turn on a hot water faucet and place a thermometer in the hot water stream and read the thermometer.

The following chart details the relationship of water temperature and time with regard to scald injury and may be

used as a guide in determining the safest water temperature for your applications.

TIME / TEMPERATURE RELATIONSHIPS IN SCALDS

Temperature Time to Produce Serious Burn

120°F (49°C) More than 5 minutes

125°F (52°C) 1½ to 2 minutes

130°F (54°C) About 30 seconds

135°F (57°C) About 10 seconds

140°F (60°C) Less than 5 seconds

145°F (63°C) Less than 3 seconds

150°F (66°C) About 1½ seconds

155°F (68°C) About 1 second

Table courtesy of Shrines Burn Institute

The temperature of the water in the heater can be regulated by setting the temperature on the electronic thermostat. To comply with safety regulations, the thermostat

was set at its lowest setting before the water heater was

shipped from the factory. See the section titled SET

POINT ADJUSTMENT PROCEDURE to set the electronic thermostat.

n DANGER

There is a Hot Water SCALD Potential if the

thermostat is set too high.

NOTE: When this water heater is supplying

general purpose hot water requirements for use by

individuals, a thermostatically controlled mixing

valve for reducing point of use water temperatures

is recommended to reduce the risk of scald injury.

Contact a licensed plumber or the local plumbing

authority for further information.

5

Page 6

PART 2: INSTALLATION

n WARNING

Read and review this entire manual with special

emphasis on the Venting Sections and Operation

Sections prior to any installation work.

A. LOCAL INSTALLATION REGULATIONS

This water heater must be installed in accordance with

these instructions, local codes, utility company requirements, and/or in the absence of local codes, the latest

edition of the National Fuel Gas Code ANSI 223.1 in the

United States or CAN/CSA B149.1 installation code in

Canada.

The water heater must be located or protected so it is

not subject to physical damage, for example, by moving

objects, area flooding, etc.

n CAUTION

The water heater should not be located in an area

where leakage of the tank or connections will result in

damage to the area adjacent to it or to lower floors of

the structure. When such areas cannot be avoided, it

is recommended that a suitable catch pan, adequately

drained, be installed under the water heater.

NOTE: Auxiliary catch pan installation MUST conform to the applicable local codes

B. LOCATION

removed. This water heater must not be located near

flammable liquids such as gasoline, adhesives,

solvents, paint thinners, butane, liquefied propane,

etc. as the controls of this appliance could ignite

those vapors, causing an explosion.

C.

TEMPERATURE AND PRESSURE RELIEF VALVE

A new combination temperature and pressure relief valve,

complying with the Standard for Relief Valves and

Automatic Gas Shutoff Devices for Hot Water Supply

Systems, ANSI Z21.22 or Standard CSA 4.4, must be

installed in the opening provided on the water heater at

the time of installation. No valve is to be placed between

the relief valve and the water heater. For circulating tank

installation, the separate storage tank(s) must have

similar protection. The pressure rating of the relief valve

must not exceed the maximum working pressure as

marked on the front of the water heater. The Btu/h rating

of the relief valve must equal or exceed the Btu/h input of

the water heater as noted on its rating plate. Connect the

outlet of the relief valve to a suitable open drain. The

discharge line must pitch downward from the valve to

allow complete draining (by gravity) of the relief valve and

discharge line, and must be no smaller than the outlet of

the relief valve. The end of the discharge line should not

be threaded or concealed and should be protected from

freezing. No valve of any type, restriction or reducer

coupling should be installed in the discharge line. In the

U.S., local codes shall govern the installation of relief

valves. In Canada, use CAN/CSA B149.1.

Choose a

the piping system, along with consideration to vent pipe

length. As the length of vent pipe increases, the firing

rate of the appliance decreases. You must also locate

the AdvantagePlus where it will not be exposed to below

freezing temperatures. Additionally, you will need to

place the water heater so that the controls, drain, inlet/

outlet, and gas valve are easily accessed. This appliance

must not be installed outdoors, as it is certified as an

indoor appliance, and must be kept vertical and on a

level surface. Also, care must be exercised when

choosing the location of this appliance where leakage

from the relief valve, leakage from related piping, or leakage from the tank or connections, will not result in damage to the surrounding areas or to the lower floors of the

building. A water heater should always be located in

an area with a floor drain or installed in an adequately drained catch pan suitable for water heaters.

Proper clearance must be provided around the

AdvantagePlus as follows: Sides, bottom, top, and back

are 0" (zero clearance). Front of the appliance needs 24"

(61 cm) service clearance minimum. This front service

may be achieved by a non-rated or combustible door or

access panel; providing the 24" (61 cm) service clearance

is achieved when the door is opened or panel is

location for your water heater centralized to

D. EXPANSION TANK

A potable hot water expansion tank may be required to

offset the water expansion as the water is heated. In

most city plumbing systems, the water meter has a no

return or back flow device built into the system to prevent

back flowing of water back into city mains. Back flow preventers may be found on all incoming water supplies.

Under these circumstances, you will need a hot water

expansion tank listed for potable water use. The expansion tank should be located on the cold inlet piping close

to the water heater. The expansion tank must be suit-

able for hot potable water.

n WARNING

The manufacturer’s warranty does not cover any

damage or defect caused by installation or attachment or use of any special attachments such as energy saving devices (other than those authorized by the

manufacturer) into, onto, or in conjunction with the

water heater. The use of such unauthorized devices may

shorten the life of the water heater and may endanger

life and property. The manufacturer disclaims any

responsibility for such loss or injury resulting from

the use of such unauthorized devices.

6

Page 7

E. DOMESTIC WATER CONNECTIONS

The water connections must be installed in accordance with all national and local plumbing codes, or

any prevailing standard. NEVER USE DIELECTRIC

UNIONS OR GALVANIZED STEEL FITTINGS ON

ADVANTAGEPLUS CONNECTIONS. The inlet and out-

let connections are 1" on the 55 gallon models and 11/2" on the 80 and 119 gallon models. On the cold inlet,

install a 1" brass tee on the 55 gallon models, or a 1-1/2"

brass tee on the 80 and 119 gallon models. On the run

of the 1" brass tee install, with pipe sealant, compound a

1" brass drain cock or it’s equivalent (not supplied). Into

the branch of the 1" or 1-1/2" brass tee install a copper

male adapter to match with the copper plumbing system.

For convenience, you may install a shut off valve and a

union in the cold inlet piping to ease servicing in the future. If there is a back flow preventer, or any type of a

check valve in the system, then you must install an additional tee for a suitable potable thermal expansion tank.

(See section on Expansion Tank.) In the hot outlet connection, (top left), install a suitable adapter to match the

copper tubing of the plumbing system. A thermal trap or

heat trap loop may be installed here to provide additional

energy savings and prevent thermal siphoning of domestic hot water. If required, a domestic hot water tempering/anti-scald valve should be installed into the hot water

line to prevent the maximum outlet water temperature

from exceeding 125°F (52°C) to prevent scald injury.

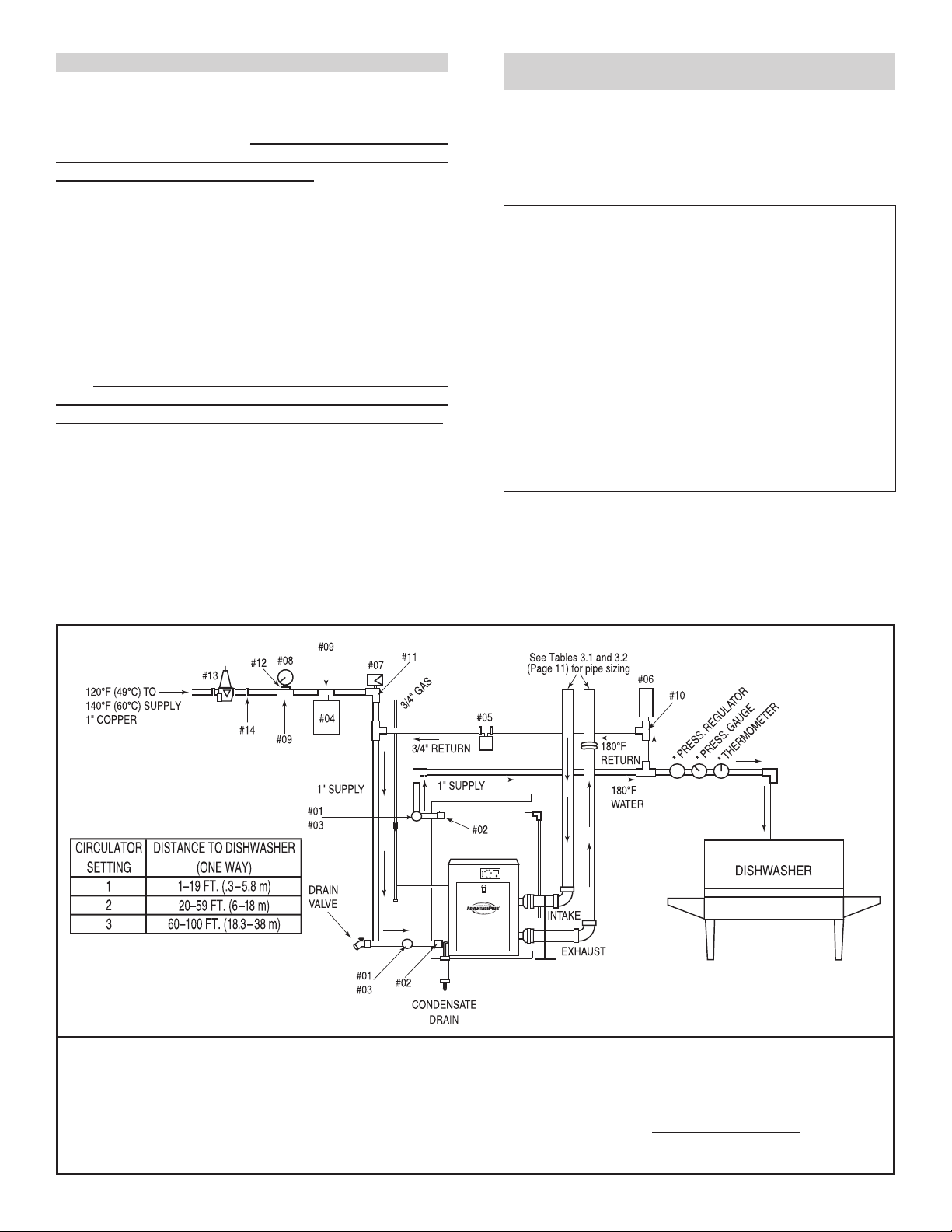

F. SPECIAL INSTRUCTIONS FOR BOOSTER

INSTALLATIONS

All booster heaters are supplied with the “Booster

Installation" kit. In order to maintain proper temperature,

this kit must be correctly installed. The Booster kit contains the following list of parts:

#01 - Nibco Tee - 1"x 1"x 1/2" (2 pcs.)

#02 - Female Adapter - 1" (2 pcs.)

#03 - Dial Thermometer (2 pcs.)

#04 - Expansion Tank - 4-1/2 Gal.

#05 - Grundfos 3 Speed Pump w/ Check Valve

#06 - Nibco 1.2" x 12" Fitting Air Chamber

#07 - Vacuum Relief Valve

#08 - Pressure Gauge - 0 - 200 PSI

#09 - Nibco Tee 712R - 1"x 1" x 3/4" (2 pcs.)

#10 - Nibco Tee 714RR - 1"x 1/2"x 1"

#11 - Nibco Tee - 1"x 1/2"x 1" Copper

#12 - Reducing Coupling

#13 - Pressure Reducing Valve

#14 - Nibco Male Adapter - 1"

See the following drawing for a typical “Booster” installation. Please note that those items marked with an asterisk in the drawing are not included with the Booster kit,

but are items that should be installed in a typical dishwasher package.

The booster heater is equipped with a circulating pump to provide the

minimum water flow in the booster and maintain a uniform water temperature in the tank.

booster to the dishwasher, and the length of time between washes, it

may be necessary to run an empty rack to purge the supply line of

water that has cooled below 180ºF (82ºC). For this reason it is best to

locate the booster as close as possible to the dishwasher. The circulator

is equipped with

Depending on the physical distance from the

three speeds to increase flow rate and reduce

heat loss. Reference the “Distance” chart to determine the appropriate

circulator speed setting.

All piping should be

perature loss on the

sulation is recommended. Under no

booster be installed without a circulating pump.

installed with suitable pipe insulation to avoid tem-

re-circulation line. A minimum of 1" thick pipe in-

circumstances should the the

7

Page 8

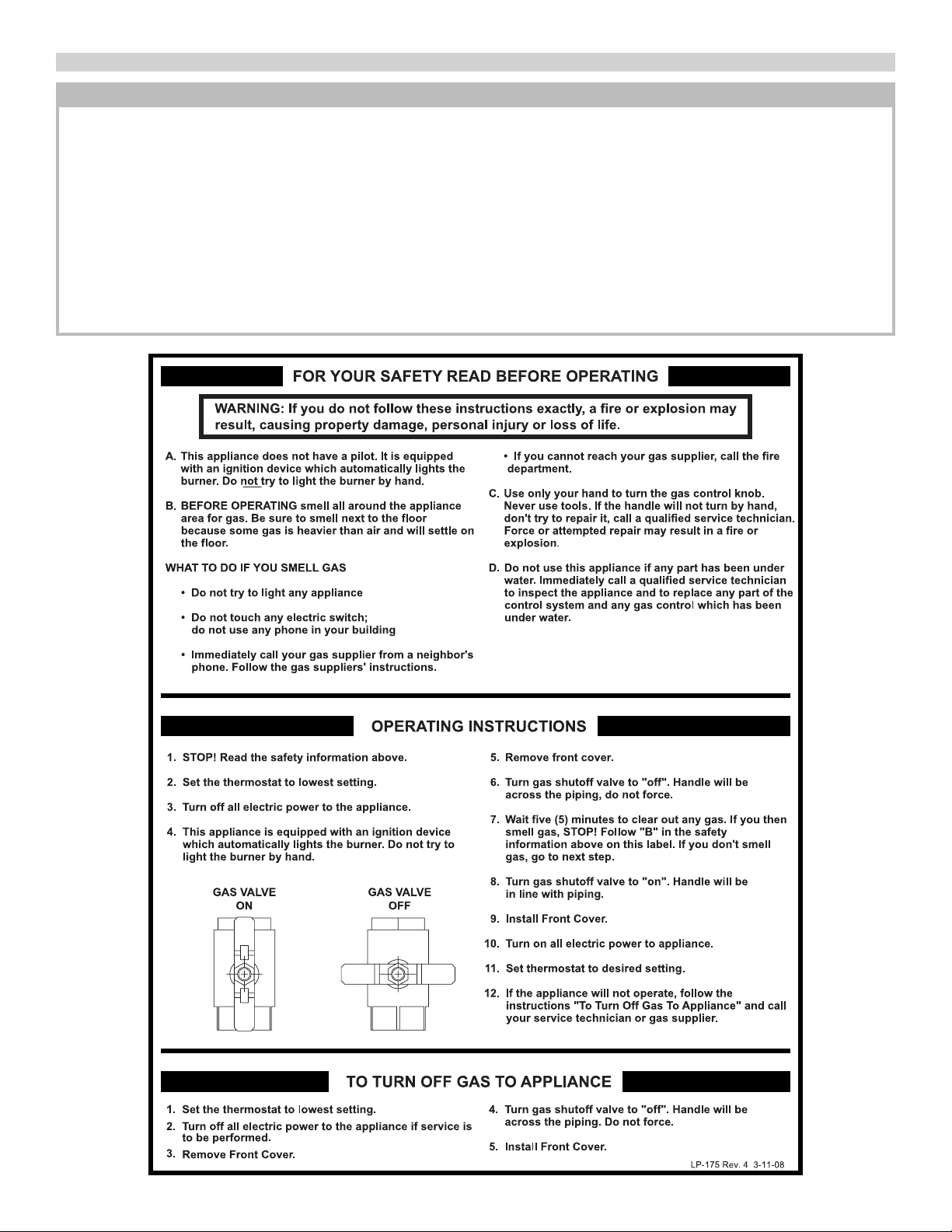

G. LIGHTING AND OPERATING INSTRUCTIONS

n WARNING

If the information in this manual is not followed

exactly, a fire or explosion may result causing

property damage, personal injury or loss of life.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch: do not

use any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas

supplier’s instructions.

Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any other

appliance.

• If you cannot reach your gas supplier,

call the fire department. Installation and

service must be performed by a qualified

installer, service agency or the gas

supplier.

8

Page 9

n WARNING

Tank MUST be full of water before power is turned

on. Heat exchanger coil WILL BE DAMAGED if energized even for a short time while the tank is dry. The

water heater’s warranty does not cover damage or

failure resulting from operation with an empty or partially empty tank. (Reference is made to the limited

warranty for complete terms and conditions)

H. ELECTRICAL CONNECTION

The electrical connection for the AdvantagePlus is on the

left side of the combustion shroud. There is a 1/2" knockout location for electrical connection. All electrical wiring

must be performed by a qualified licensed electrician,

and in accordance with National Electrical Code and

Canadian Electrical Code, or to the applicable local

codes and standards. The electrical requirements are

for standard 120 volts, 60 Hz., 10 amp service. It is

recommended that an electrical disconnect switch be

placed near the water heater, and that the connection to

the AdvantagePlus be made using 3/8" extra-flex, or 3/8"

greenfield (or equivalent). This unit must be wired with

#14 AWG, and fused for no more than 15 amps. It is

of extreme importance that this unit be properly

grounded and be connected with proper polarity!

Ground the water heater by connecting the green wire in

the electrical access compartment directly to the main

building ground system. It is very important that the

building system ground is inspected by a qualified

electrician prior to making this connection. Once all

connections have been made, the electrical access may

be closed. It is very important that the electrical power is

not turned on until gas and venting connections are

completed and the tank is full of water.

I. GAS CONNECTION

Refer to the below table to size the supply piping to

minimize pressure drop between meter or regulator

and unit. In Canada, use table found in CAN/CSA

B149.1

Maximum Capacity of Pipe in Cubic Feet of Gas per

Hour for Gas Pressures of 0.5 psi or Less and a

Pressure Drop of 0.3 Inch water Column

Gas Table

(Nominal

Iron Pipe Internal Length of Pipe (Feet)

Size Diameter

(inches) (inches) 10 20 30 40 50 60 70

3/4 .824 278 190 152 130 115 105 96 BTU’S

1 1.049 520 350 285 245 215 195 180 PER

1 1/4 1.380

1 1/2 1.610 1,600 1,100 890 760 670 610 560 x1,000

(Nominal

Iron Pipe Internal Length of Pipe (Feet)

Size Diameter

(inches) (inches) 80 90 100 125 150 175 200

3/4 .824

1 1.049 170 160 150 130 120 110 100 PER

1 1/4

1 1/2 1.610 530 490 460 410 380 350 320 x1,000

1,050 730 590 500 440 400 370

90 84 79 72 64 59 55 BTU’S

1.380 350 320 305 275 250 225 210

HOUR

}

HOUR

}

It is recommended that a soapy solution be used to detect

leaks. Bubbles will appear on the pipe to indicate a leak is

present. The gas piping must be sized for the proper flow

and length of pipe, to avoid excessive pressure drop. Both

the gas meter and the gas regulator must be properly

sized for the total gas load. If you experience a pressure

drop greater than 1” WC, the meter, regulator or gas

line is undersized or in need of service. You can attach

a manometer to the incoming gas drip leg, by removing

the cap and installing the manometer. The gas pressure

must remain between 3.5” WC and 14” WC during standby (static) mode and while in operating (dynamic) mode

at full output. If an in-line regulator is used, it must be

a minimum of 10 feet from the AdvantagePlus. It is

very important that the gas line is properly purged by

the installer, gas supplier or utility. Failure to properly

purge the lines or improper line sizing, will result in

ignition failure. This problem is especially noticeable in

NEW LP installations and also in empty tank situations.

This can also occur when a utility company shuts off

service to an area to provide maintenance to their lines.

The gas valve must not be replaced with a conventional

gas valve under any circumstances. As an additional

safety feature in the AdvantagePlus water heater, the gas

valve in this appliance has a flanged connection to the

swirl plate and blower.

Gas supply shall not exceed a maximum inlet pressure

of 14" water column (350 mm), 1/2 pound pressure (3.4

kPa), between 3.5” WC and 14” WC (natural and

propane). The entire piping system, gas meter, and regulator must be sized properly to prevent a pressure drop

greater than 0.5" of water column as stated in the

National Fuel Gas Code. Gas pressure information is

listed on the rating plate. It is very important that you

are connected only to the type of gas noted on the

rating plate; “LP” or propane gas or “Nat” natural

gas. All gas connections must be approved by the local

gas supplier or utility in addition to the governing

authority prior to turning

the gas supply on. The nipple

provided for the inlet gas connection is 1/2", and it is

mandatory that a 3/4" to 1/2" reducing bushing (provided)

is used, threaded into the branch of a 3/4" tee, and a drip

leg fabricated, as per the National Fuel Gas Code and in

Canada refer to CAN/CSA B149.1.

You must ensure that the entire gas line to the reducing bushing connection at the AdvantagePlus is no

smaller than 3/4".

n CAUTION

THE USE OF FLEXIBLE GAS CONNECTORS IS

NOT RECOMMENDED. HOWEVER, IF USED, IT IS

IMPERATIVE THAT THEY ARE SIZED CORRECTLY.

FLEXIBLE GAS CONNECTORS MUST HAVE A MINIMUM

ID OF 3/4". A MINIMUM 3/4" ID MUST BE MAINTAINED TO

AVOID RESTRICTION OF GAS FLOW! NEVER REDUCE

THE GAS SUPPLY LINE BELOW 3/4"! In Canada, refer

to CAN/CSA B149.1 for approved connections.

9

Page 10

Once all the inspections have been performed, the piping

system must be leak tested. If the leak test pressure is

higher than the maximum permissible inlet pressure, you

must isolate the AdvantagePlus from the gas line before

testing. In order to do this, you must disconnect the

union and cap the inlet gas line. In the event the gas

valve is exposed to a pressure greater than 1/2 PSI, 14"

water column, the gas valve must be replaced.

Failure to follow all precautions could result in fire,

explosion or death! It is recommended that a soapy

solution be used to detect leaks. Bubbles will appear and

indicate a leak is present. The gas piping must be sized

for the proper flow and length of pipe to avoid unacceptable pressure drop. Both the gas meter and the gas regulator must be properly sized for the total gas load. If you

experience a pressure drop greater than 1" W.C., the

meter or regulator or gas line may be undersized or in

need of service. On the inlet side of the gas valve, there

is a 1/8" NPT plug. This plug can be removed to attach a

manometer. You can attach a meter to the incoming gas

drip leg by removing the cap and installing the meter. The

gas pressure must remain between 3.5" and 14" of water

column during stand-by and unit running heat cycle. If

an in-line regulator is used, it must be a minimum of 10

feet from the AdvantagePlus. It is very important that

the gas line is properly purged by the installer, gas

supplier or utility. Failure to properly purge the lines

or improper line sizing, will result in ignition failure

of the AdvantagePlus. The gas valve is a special

gas valve which has a Pressure Augmented Regulator

feature, as well as negative outlet pressure. This valve

must not be replaced with a conventional valve under any

circumstances. Make sure valve is in the “OFF” position

prior to turning gas supply on. As an additional safety

feature, this valve has a left hand thread on the outlet end,

and a special tamper resistant electrical connector.

n WARNING

Never use open flame to test for gas leaks, as

bodily injury or property damage could result.

n WARNING

DO NOT exceed input shown on water heater

rating label.

10

Page 11

PART 3: VENTING, COMBUSTION AIR & CONDENSATE REMOVAL

n WARNING

This vent system will operate with a positive pressure

in the flue gas vent pipe. Do not connect vent

connectors serving appliances vented by natural

draft into any portion of mechanical draft systems

operating under positive pressure.

Follow the venting instructions below carefully.

Failure to do so may result in severe personal injury,

death, or substantial property damage.

A. GENERAL

1. Install the water heater venting system in accordance

with these instructions and with the National Fuel

Gas Code, ANSI Z223.1/NFPA 54, CAN/CGA B149.1,

and/or applicable provisions of local building codes.

2. This water heater is a direct vent appliance and is

listed as a Category IV appliance with Underwriters

Laboratories, Inc. VENT AND INTAKE AIR VENT

B. APPROVED MATERIALS FOR EXHAUST VENT

AND INTAKE AIR VENT

Table 3-1

APPROVED PLASTIC EXHAUST VENTING MATERIAL

MATERIAL STANDARDS FOR INSTALLATION IN:

UNITED STATES CANADA

PVC SCHEDULE 40 / 80 ANSI /ASTM D1785 ULC-S636

PVC -DWV

CPVC SCHEDULE 40 / 80 ANSI /ASTM F441 ULC-S636

*Note: Cellular Foam Core Pipe

can only be used on INT

piping.

Table 3-2

AKE

APPROVED PLASTIC INTAKE VENTING MATERIAL

MATERIAL STANDARDS FOR INSTALLATION IN:

PVC SCHEDULE 40 / 80 ANSI /ASTM D1785

CPVC SCHEDULE 40 / 80 ANSI /ASTM F441

PVC DWV

PVC-CELLULAR FOAM

CORE*

*Note: Cellular Foam Core Pipe

can only be used on INT

piping.

Table 3-3

AKE

APPROVED PLASTIC CONDENSATE PIPING MATERIAL

MATERIAL STANDARDS FOR INSTALLATION IN:

PVC SCHEDULE 40 / 80 ANSI /ASTM D1785

ANSI /ASTM D2665 ULC-S636

UNITED STATES AND CANADA

ANSI /ASTM D2665

U.L. LISTED

UNITED STATES AND CANADA

Table 3-4

APPROVED PIPE CEMENT AND PRIMER FOR PLASTIC PIPE

MATERIAL STANDARDS FOR INSTALLATION IN:

CEMENT AND PRIMER UNITED STATES CANADA

CPVC ANSI/ASTM F493

PVC ANSI/ASTM D2564

ULC-S636 approved

primer and adhesive

system, for ULC-S636

pipe and fittings

n WARNING

Do not use Foam Core Pipe in any portion of the

exhaust piping from this water heater. Use of Foam

Core Pipe may result in severe personal injury, death,

or substantial property damage.

C. EXHAUST VENT AND INTAKE AIR VENT PIPE

LOCATION

1. Determine exhaust vent location:

n WARNING

Both exhaust and intake air vents must exit from the

same side of the building to assure correct appliance

operation.

a. The vent piping for this water heater is approved

for zero clearance to combustible construction.

b. See illustration within this section of clearances

for location of exit terminals of direct-vent venting

systems.

c. This water heater vent system shall terminate at

least 3 feet (0.9 m) above any forced air intake

located within 10 ft (3 m). Note: this does not

apply to the combustion air intake of this directvent appliance.

d. Provide a minimum of 1 foot distance from any

door, operable window, or gravity intake into any

building.

e. Provide a minimum of 1 foot clearance from

the bottom of the exhaust above the expected

snow accumulation level. Snow removal may be

necessary to maintain clearance.

f. Provide 4 feet horizontal clearance from

electrical meters, gas meters, gas regulators,

relief equipment, exhaust fans and inlets. In no

case shall the exit terminal be above or below

the aforementioned equipment unless the 4 foot

horizontal distance is maintained.

g. When adjacent to a public walkway, locate exit

terminal at least 7 feet above grade.

11

h. Do not locate the exhaust directly under roof

overhangs to prevent icicles from forming.

Page 12

i. Provide 4 feet clearance from the inside corner

of vertical walls, chimneys, etc., as well as

horizontal corners created by roof overhangs.

2. Determine air intake vent location.

a. Provide 1 foot clearance from the bottom of the

intake air vent and the level of maximum snow

accumulation. Snow removal may be necessary

to maintain clearances.

b. Do not locate intake air vent in a parking area

where machinery may damage the pipe.

c. When venting with a two pipe system, maximum

distance between intake air vent and exhaust

vent is 6 feet (1.8 m). Minimum distance between

exhaust vent and intake air vent on single water

heater is 8” (0.2 m) center-to-center. Minimum

distance between exhaust vents and intake air

vents on multiple water heaters is 8” (0.2 m)

center-to-center.

d. You must place support brackets on vent piping.

The first bracket must be within 1 foot of the

appliance and the balance at 4 foot intervals on

the vent pipe.

12

Page 13

Location of exit terminals of mechanical draft and direct-vent v

(Reference: National Fuel Gas Code ANSI Z223.1/NFPA 54 2002). In Canada, refer to CAN/CSA B149.1 for vent terminal location

enting systems.

Fig. 3-1 Multiple Vents

Fig. 3-2 Multiple Vent Spacing*

*Note: Exhaust must extend out 1 foot. There should be no more than 2 vents and 2 intakes then a space of 36" to the next set of vents.

*Note: There must be a minimum of 36" spacing between every 2 kit grouping.

Multiple Series Vents

Fig. 3-3 Multiple Stainless Steel Horizontal Vent Kit Installation – Front View

13

Page 14

D. EXHAUST VENT AND INTAKE AIR VENT SIZING

E. LONGER VENT RUNS

1. The exhaust and intake vent size is 2" for the HE100

and HE130 and 3" for the HE199.

2. The total combined equivalent length of exhaust vent

and intake air pipe should not exceed 85 feet.

a. The equivalent length of elbows, tees, and other

fittings are listed in the Friction Loss Table 3-5.

Table 3-5

FRICTION LOSS EQUIVALENT IN PIPING AND FITTINGS

FITTINGS OR PIPING EQUIVALENT FEET

2" (5 cm) 3" (7.6 cm) 4" (10 cm)

90 DEGREE ELBOW* 5' (1.5 m) 5' (1.5 m) 3' (.92 m)

45 DEGREE ELBOW 3' (.92 m) 3' (.92 m) 1' (.31 m)

COUPLING 0' 0' 0'

AIR INLET

STRAIGHT PIPE 1' (.31 m) 1' (.31 m) 1' (.31 m)

CONCENTRIC VENT KIT SP12161

V1100 3" VENT KIT SP12162 N/A 1

-

*Friction loss for long radius elbow is 1 foot less

TEE 0' 0' 0'

N/A 3' (.92 m) N/A

' (.31m) N/A

b. For example: If the exhaust vent has two 90°

elbows and 10 feet of PVC pipe we will calculate:

Exhaust Vent Pipe Equivalent Length = (2×5)+10=20 feet

(.61m×1.5m)+3m=6.1m

Further, if the intake air vent pipe has two 90°

elbows, one 45° elbow and 10 feet of PVC pipe,

the following calculation applies:

Intake Air Vent Pipe Equivalent Length = (2×5)+3+10=23 feet

(.61m×1.5m)+.92m+3m=7m

Finally, if a concentric vent kit is used we find:

1. The maximum combined equivalent length can be

extended by increasing the diameter of both exhaust

vent and intake air vent pipe equally. However, the

transitions should begin a minimum of 15 equivalent

feet from the water heater.

a. The maximum equivalent length for the

increased diameter vent pipes is 125 feet.

b. Transitions should always be made in vertical

sections of pipe to prevent the condensate from

pooling in the vent pipe.

Table 3-6: Vent Run Transition

Vent

Connection

2" (5 cm) 3" × 2" (7.6 cm × 5 cm) 3" (7.6 cm)

3" (7.6 cm) 4" × 3" (10 cm

Reducing

Coupling

× 7.6 cm) 4" (10 cm)

Vent

Transition

c. If the transition occurs at a distance greater than

15 equivalent feet from the water heater, the

maximum equivalent length will be reduced. See

Table 3-7.

Table 3-7: Vent Termination Kits

Transition

Point

(ft from

water heater)

15 (4.58 m) 30 (9.1 m) 95 (29 m) 125 (38 m)

20 (6 m) 40 (12.2 m) 77-1/2 (23.6

25 (7.6 m) 50 (15.2 m) 60-1/2 (18.4 m) 110-1/2 (33.7 m)

30 (9.1 m) 60 (18.2 m) 43 (13.1 m) 103 (31.4 m)

35 (10.7 m) 70 (21.3 m) 26 (7.92 m) 96 (29.2 m)

40 (12.2 m) 80 (24.3 m) 8-1/2 (2.6 m) 88-1/2 (27 m)

None 85 (27

TEL = Total Equivalent Length

TEL of

Standard

2” Vent

Pipe (ft)

m) 0 85 (26 m)

TEL of

Oversized

2”, 3” or 4”

Vent Pipe (ft)

m) 117-1/2 (35.9 m)

Maximum TEL

of all

Vent Pipe (ft)

F. EXHAUST VENT AND INTAKE AIR PIPE

INSTALLATION

Total Combined Equivalent Length = 20+23+3=46 feet

.61m+7m+.92m=14m

Therefore, the total combined equivalent length

is 46 feet which is well below the maximum of 85

feet.

c. The intake air vent pipe and the exhaust vent are

intended to penetrate the same wall or roof of the

building.

d. Effort should be made to keep a minimum

difference in equivalent length between the

intake air vent pipe and the exhaust vent.

3. The minimum combined equivalent length is 16

equivalent feet.

1. Use only solid PVC or CPVC for exhaust vent pipe.

FOAM CORE PIPING, as well as PVC and CPVC,

can be used for the intake vent pipe. Refer to chart

Section 3B, Page 11.

2. Remove all burrs and debris from joints and fittings.

3. All joints must be properly cleaned, primed, and

cemented. Use only cement and primer approved

for use with the pipe material. Cement must conform

to ASTM D2564 for PVC and ASTM F493 for CPVC

pipe.

n WARNING

All joints of positive pressure vent systems must be

sealed completely to prevent leakage of flue products

into the living space.

14

Page 15

4. Horizontal lengths of exhaust vent must slope back

towards the water heater not less than ¼” per foot

to allow condensate to drain from the vent pipe. If

the exhaust pipe must be piped around an obstacle

that results in the creation of a low point, condensate

will collect in this low point and form a blockage. This

condensate must be drained away using a fieldinstalled condensate drain assembly as shown. (See

page 19)

5. All piping must be fully supported. Use pipe hangers

at a minimum of 4 foot (1.2 m) intervals to prevent

sagging of the pipe where condensate may form.

COMBUSTION SETTINGS

HIGH FIRING RATES AND LOW FIRING RATES ON

ALL MODELS

Natural Gas Propane LP

low high low high

Carbon

Monoxide

(CO%)

Carbon

Dioxide

(CO2%)

0–10

ppm

8½% –

9½%

0 ppm–

20 ppm

8½% –

9½%

0–10

ppm

9½% –

10½%

0 ppm–

20 ppm

9½% –

10½%

6. Do not use the water heater to support any piping.

7. A screened straight coupling is provided with the water

heater for use as an outside exhaust termination.

G. VERY IMPORTANT SET-UP INSTRUCTIONS!

IF YOU HAVE A COMBUSTION ANALYZER, THE FOLLOWING RATINGS WILL BE VERY HELPFUL IN SETTING UP YOUR ADVANTAGEPLUS:

FAN SPEEDS

BTU IGNITION MIN MAX

100,000 3000 2000 5400

130,000 3000 2000 6950

199,000 3000 2000 8500

15

Page 16

LP-301-L Rev. 3/30/09

H. CONCENTRIC VENT

Note:

Spacing for multiple series of concentric vents should be the same as Multiple Vertical Vent in Fig. 3-3, P. 13.

16

Page 17

PART 4: OPERATION

A. OVERALL APPLIANCE AND CONTROL

OPERATION

To adjust temperature of the stored water press and hold

{S3} for 2 seconds. The first item is: |DU|: Water

Temperature Set Point – factory set at 119ºF, adjustable

down by pressing {S1} key to 70ºF and adjustable up by

pressing the {S2} key up to 159ºF. The {S3} key is then

pressed again momentarily to display |DH|, the differential

which is factory set at 7ºF and adjustable down to 1ºF by

pressing the {S1} key and up to 18ºF by pressing the {S2}

key. The {S3} key is pressed again momentarily to

display

the choice of Fahrenheit “F” factory default or Celcius by

pressing the {S1} key. When finished, press the {S3} key

one final time to place unit back into operation. The

control automatically re-starts if no key is pressed for 2

minutes.

B. STATUS MENU

Installers are also able to check the current status of the

AdvantagePlus parameters by pressing {S4/RESET} key

for 3 seconds. Once activated, the display will show |d1|

alternating value of the actual upper supply tank

temperature. Actual values are displayed for each

function. To view the next value simply press the {S/4} key

to go to the next displayed value. Listed below are the

values which can be displayed. These values cannot be

changed. To exit this menu, simply press {S3/Program}

key to resume normal operation.

Function Value

d1 — Actual Temperature from upper tank sensor

d2 — Actual Temperature from lower tank sensor

d3 — |0| (Not used)

d4 — |308| (Not used)

d5 — |nc| (Not used)

d6 — Actual Fan speed multiplied by 10

(Example: If fan speed displayed is

|410| RPM x 10 = 4100 actual fan speed)

Function Value

d7 — Actual Ionization current read from Flame

Rectification probe

d8 — |0| (Not used)

d9 — |1| (Not used)

d10 — Actual Status bus communication

|co| = connected, |nc| = not connected

d11 — |32| (Not used)

d12 — Power On Hours (Example:Hours x 1000

Ex. 0.1 = 100 hrs. or 1.0 = 1000 hrs.

d13 — Total Water Heating Hours (TW – Hrs. x 1000)

d14 — |0| (Not used)

d15 — Passed Ignition Attempts (Passed ignition x

1000)

C. TEST MODE

This function is intended to simplify the gas valve

adjustment if needed. Listed below are the recommended

limits on each Water Heater and the Combustion

Settings. Automatic modulation does not take place

when the controller is in Test mode, only temperature

limitation based on the AdvantagePlus set point. The

user will be allowed to increase or decrease the fan

speed by pressing in either the {S1/–} or {S2/+} keys.

To activate the Test mode simply press the {S2/+} and

{S3/Program} key together for 1 second. Once activated,

you will see in the display |Ser| and the actual fan speed.

The measurement of the combustion levels should

always be taken at the highest and lowest fan speed.

After 10 minutes, the Test mode stops automatically. To

exit Test Mode press {S1/–} and {S2/+} key together for 1

second.

FOR YOUR OWN SAFETY READ

BEFORE OPERATING

1. This appliance does not have pilot. It is equipped

with an ignition device which automatically lights the

burner. Do not try to light the burner by hand.

2. BEFORE OPERATING smell all around the appliance

area for gas. Be sure to smell next to the floor because

some gas is heavier than air and will settle on the

floor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any

phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas suppliers’

instructions.

• If you cannot reach your gas supplier, call the fire

department.

17

Page 18

3. Turn on gas shutoff valve (located inside of the down

near burner) so that the handle is aligned with the gas

pipe. If the handle will not turn by hand, don’t try to

repair it, call a qualified service technician. Force or

attempted repair may result in a fire or explosion.

4. Do not use this appliance if any part has been under

water. Immediately call a qualified service technician

to inspect the appliance and to replace any part of the

control system and any gas control which has been

under water.

5. The AdvantagePlus shall be installed so the gas

ignition system components are protected from

water (dripping, spraying, rain, etc.) during appliance

operation and service (circulator replacement,

condensate trap, control replacement, etc.)

D. OPERATING INSTRUCTIONS

If you smell gas, STOP. Follow listed safety instructions

above. If you do not smell gas, follow the next steps.

to any programming operations.

The control system requires no periodic maintenance

under normal conditions. However, in unusually dirty or

dusty conditions, periodic vacuuming of the cover to

maintain visibility of the display and indicators is recommended.

E. SHUTDOWN PROCEDURE

If the burner is operating, lower the set point value to

70°F (21°C) and wait for the burner to shut off. Continue

to wait for the combustion blower to stop so all latent

combustion gases are purged from the system. This

should take a maximum of 40 to 90 seconds, then

n WARNING

Should overheating occur or the gas supply fail to

shut off, turn off the manual gas control valve to

the appliance.

1. Turn on all electric power to appliance. Make sure

tank is full with cold water and purge all piping. To

assure adequate purging, open all hot water faucets.

2. Adjust the temperature setpoint of the appliance if

desired. The factory default setting is 119° (48°C). If

changes are ncessary follow “Overall Appliance and

Control Operation” in this section.

3. If the appliance fails to start, refer to the Troubleshooting section in the back of this manual.

n WARNING

When this water heater is supplying general purpose

hot water requirements for individuals, a thermostatically controlled mixing valve for reducing point of

use water temperature is recommended. Contact a

licensed plumber or the local plumbing authority for

further instructions.

The three digit LED display will illustrate actual water

temperature within the tank under normal operating conditions. However, this display is also used to indicate the

temperature set point when in the programming mode.

The controller has a temperature set point range of 70°F

(21°C) to 159°F

maximum set point of 180°F [82°C]), with a factory

setting of 120°F (49°C).

(70.5°C) (Booster models have a

n WARNING

DO NOT use this appliance if any part has been under

water. Immediately call a qualified service technician

to inspect the appliance and to replace the water

heater if the control system or any gas control which

has been under water.

disconnect the electrical supply. If the burner is not operating, disconnect the electrical supply.

F. PREVENT COMBUSTION AIR CONTAMINATION

Install intake air piping for the AdvantagePlus Water

n WARNING

You must pipe outside air to the water heater air

intake. Ensure that the intake air will not contain

any of the contaminants below. Contaminated air

will damage the water heater, resulting in possible

severe personal injury, death or substantial property

damage. For example, do not pipe intake air vent

near a swimming pool. Also avoid areas subject to

exhaust fumes from laundry facilities. These areas

will always contain contaminants.

Heater as described in the Venting section. Do not

terminate exhaust in locations that can allow

contamination of intake air.

NOTE: Power must be applied to the controller prior

n CAUTION

In unusually dirty or dusty conditions, care must be

taken to keep appliance door in place. Failure to do

so VOIDS WARRANTY!

18

Page 19

G. CORROSIVE CONTAMINANTS AND SOURCES

PRODUCTS TO AVOID

Spray cans containing fluorocarbons

Permanent wave solutions

Chlorinated waxes/cleaners

Chlorine-based swimming pool chemicals

Calcium chloride used for thawing

Sodium chloride used for water softening

Refrigerant leaks

Paint or varnish removers

Hydrochloric acid/muriatic acid

Cements and glues

Antistatic fabric softeners used in clothes dryers

Chlorine-type bleaches, detergents, and cleaning solvents

found in household laundry rooms

Adhesives used to fasten building products and other

similar products

AREAS LIKELY TO HAVE CONTAMINANTS

Dry cleaning/laundry areas and establishments

Swimming pools

Metal fabrication plants

Beauty shops

Refrigeration repair shops

Photo processing plants

Auto body shops

Plastic manufacturing plants

Furniture refinishing areas and establishments

New building construction

Remodeling areas

Garages and workshops

n DANGER

Do not install the AdvantagePlus into a common

vent with any other appliance. This will cause flue

gas spillage or appliance malfunction, resulting in

possible severe personal injury, death or substantial

property damage.

H. CONDENSATE

This is a condensing high efficiency appliance, therefore

this unit has a condensate removal system. Condensate

is nothing more than water vapor, derived from the combustion products, similar to an automobile when it is initially started. This condensate does have a low pH and

should be treated with a condensate filter. This filter contains either lime crystals or marble crystals, which will

neutralize the condensate. The outlet of the filter is sized

for 5/8" (1.6 cm) ID (inside diameter) plastic tubing. It is

very important that the condensate line is sloped away

from and down to a suitable inside drain. If the

condensate outlet on the AdvantagePlus is lower than

the drain, you must use a condensate removal pump. It

is also very important that the condensate line is not

exposed to freezing temperatures, or any other type of

blockage. Plastic tubing should be the only material used

for the condensate line. Steel, brass, copper, or other

metals will be subject to corrosion and deterioration. A

second vent may be necessary to prevent condensate

line vacuum lock if a long horizontal run is used. Also an

increase to 1" (2.5 cm) tubing may be necessary.

NOTE: Always check local codes for proper

evacuation of condensate.

Notes:

1. CONDENSATE LINE MUST BE PITCHED AT LEAST 1/4" PER FOOT (0.64 cm per 0.3 m)TO PROPERLY DRAIN. IF THIS CANNOT BE DONE OR A VERY LONG LENGTH OF

CONDENSATE HOSE IS USED YOU MUST INCREASE THE CONDENSATE LINE TO A MINIMUM OF 1" (2.5 CM) ID AND PLACE A TEE IN THE LINE AFTER THE

CONDENSATE NEUTRALIZER TO PROPERLY REDUCE VACUUM LOCK IN THE DRAIN LINE.

2. PLASTIC PIPE SHOULD BE THE ONLY MATERIAL USED FOR THE CONDENSATE LINE. STEEL, BRASS, COPPER OR OTHERS WILL BE SUBJECT TO CORROSION OR

DETERIORATION.

3. IT IS ALSO VERY IMPORTANT THAT THE CONDENSATE LINE IS NOT EXPOSED TO FREEZING TEMPERATURES, OR ANY OTHER TYPE OF BLOCKAGE.

19

Page 20

20

Page 21

LP-301-D Rev. 3/30/09

21

Page 22

HOW TO OBTAIN SERVICE ASSISTANCE

Should you have any questions about your new water heater, or if

it requires adjustment, or routine maintenance, it is suggested that

you first contact your installer, plumbing contractor or previously

agreed upon service agency. In the event that the firm has moved,

or is unavailable, refer to the telephone directory commercial

listings or local utility for qualified service assistance.

Should your problem not be resolved to your complete satisfaction,

you should then contact the Manufacturer’s National Service

Department at the following address:

In the United States:

RHEEM MANUF

ACTURING COMPANY

1241 Carwood Ct.

Montgomery

, AL 361

17

In Canada:

Rheem Canada Ltd

125 Edgeware Road, Unit 1

Bramptom, ON

0P5

L6Y

You may also obain technical assistance by calling

1-800-432-8373.

When contacting the manufacturer, the following

information should

be made available:

Model and serial number

1.

of the water heater as shown on

the

rating plate attached to the jacket of the water heater.

2. Address where the water heater is located and can be seen.

3. Name and address of installer and any service agency who performed service on the water heater.

4. Date of original installation and dates any service work was performed.

5. Details of the problems as you can best describe them.

List of people, with dates, who have been contacted regarding

6.

your problem.

22

Page 23

MOST COMMON ADVANTAGEPLUS INSTALLATION CONCERNS

VENTING:

VENT LENGTH TOO LONG - OVER 85' (26 m)

VENTING NOT PITCHED PROPERLY - CONDENSATE BUILD UP IN VENT

EXHAUST GAS RE-CIRCULATION - VENT TERMINALS NOT USED, WRONG FITTINGS USED, SIGHT PROBLEMS

BUSH IN FRONT OF VENT TERMINAL

INSIDE CORNER OF BUILDING FOR VENT LOCATION

OVERHANG WITH VENT UNDERNEATH

COMPOUND ROOF PITCH, OR ABOVE ROOF FIRE WALL

ADDITIONAL FITTINGS INSTALLED INTO TERMINALS

VENT SIZED FROM 3" TO 4" BY USING BUSHINGS - INSTEAD OF REDUCING COUPLING OR REDUCING ELBOW

VENT CHANGED FROM 3" TO 4" - WITHOUT GOING REQUIRED 15' (4.6 m) ON BOTH INTAKE AND EXHAUST

VENTING NOT CLEANED AND GLUED TOGETHER FOR PRESSURE TIGHT JOINTS

INTAKE AIR CONTAINING EXHAUST FROM ANOTHER VENT OR APPLIANCE

GAS SUPPLY:

GAS PRESSURE TOO LOW - NEED 3.5" WC (0.87 kPa) GAS PRESSURE UP TO 14" WC (3.5 kPa) GAS PRESSURE

GAS METER TOO LOW IN CAPACITY

GAS REGULATOR NOT SIZED PROPERLY - TOO LOW IN CAPACITY

GAS PIPE TOO SMALL - 3/4" MINIMUM GAS SUPPLY SIZE

GAS REGULATOR TOO CLOSE TO APPLIANCE - NEED 10' OF PIPE FOR EVERY 200,000 BTU’S PER HOUR

GAS REGULATOR WITH LONG VENT OR BLEED VENT ORIFICE - REGULATOR SLOW TO RESPOND

GAS METER RESTRICTION, OR IN NEED OF REPAIR/REPLACEMENT

GAS SUPPLY PRESSURE DROPS BELOW 3.5" WC (0.87 kPa) WHEN APPLIANCE FIRES

ELECTRICAL:

APPLIANCE NOT GROUNDED

ELECTRICAL POLARITY REVERSED - FLAME WILL LIGHT BUT GO BACK OUT IN 4-6 SECONDS VOLTAGE TOO LOW OR TOO HIGH

APPLIANCE CYCLES, BUT NO IGNITION - REMOVE ANY CORROSION FROM SPARK ELECTRODE AND RECTIFIER. CHECK GAP

SPACING ON SPARK ELECTRODE. SHOULD BE 1/4" SPACING.

PLUMBING: DIELECTRIC UNIONS INSTALLED - RUSTY WATER

CONDENSA

BURNER:

GAS VALVE:

TE:

CONDENSATE LINE NOT

CONDENSA

CONDENSA

CONDENSATE TRAP PLUGGED

EXTREMEL

RED BURNER DECK AS SEEN THROUGH VIEW PORT - GAS VALVE NEEDS ADJUSTMENT

PUFFING ON IGNITION LOUD POP

HUFF

RUNNING GREAT BUT INTERMITTENTLY HUFFING OR POPPING - CHECK FOR RE-CIRCULATION UNDER VENTING

IT IS IMPORTANT TO NOTE FOR MAINTENANCE PURPOSES: THE THREAD ON THE END OF THIS GAS VALVE AND NIPPLE IS A

LEFT HAND THREAD.

TE LINE NOT

TE PUMP

Y LOUD BANG ON IGNITION - BURNER FAILED OR END CAP OFF

ON IGNITION,

AND PUFF DURING OPERA

PITCHED TO DRAIN

DRAINING DUE TO LONG RUN WITHOUT

WORKING

NOT

ADJUST

GAS VALVE

THEN RUNNING SMOOTH -

TION - ADJUST GAS VALVE

SEALING ADVANTAGEPLUS AS PER N.S.F. STANDARD

NUMBER 5

TO SEAL THE BASE OF BOOSTER TO THE FLOOR TO

PREVENT SEE PAGE UNDERNEATH, PER N.S.F.

STANDARD #5 - APPLY A 3/8" BEAD OF RTV SILICONE

(AS SHOWN HERE), COMPLETELY AROUND TANK.

ADJUST

VENT

GAS VALVE

23

Page 24

PART 6: TROUBLESHOOTING

Table 6-1: 926 Control Board Error Codes

Code Description Remedy

1. Try reset, if F00 repeats, create a demand for hot water (n DANGER: use caution to prevent burn

injury) If water is above 194°F (90°C) test upper and lower temperature sensor with an ohmmeter.

High temperature switch

F00

¢

F01

¢

F02

¢

F03

¢

F05

¢

F06

¢

F09

¢

F10

¢

F11

¢

F13

¢

NOTE: IF YOU REPLACE A PART

limit exceeded

(194°F [90°C])

Vent temperature limit

exceeded

Interrupted or shorted

upper temperature sensor

Interrupted or shorted

lower temperature sensor

Upper temperature sensor

exceeds 194°F (90°C)

Lower temperature sensor

exceeds 194°F (90°C)

No flame detected – The

unit will make three

attempts at ignition before

the control goes into this

lockout condition. Will

reset in 1 hour.

Loss of Flame Signal –

The unit will relight 4 times

before the control goes

into this lockout condition.

Will reset in 1 hour.

False Flame Signal – The

water heater will lock out if

it senses a flame signal

when there should be

none present.

Combustion Fan Speed

Incorrect – The water

heater will lock out if it

senses that the fan speed

is less than 70% of

expected rate for more

than 60 seconds.

LEAST THREE OR FOUR TIMES TO ASSURE THE FAULT HAS BEEN RESOLVED.

(Refer to resistance chart, this section.) Replace bad sensor. If water is below 194° (90°C) test high

temperature switch and wiring with ohmmeter. Switch should be closed at this point, if not, replace switch.

2. If unit did reset successfully, let the unit run and go into the status menu to check the upper and lower

temperature sensor. If either reading displayed does not make sense, check appropriate sensor with

ohmmeter. (Refer to resistance chart this section.) Replace bad sensor. Do an OHMs reading on both

sensors to check continuity.

1. Inspect all flue piping. If the flue is damaged or shows signs of overheating then repair or replace the flue

parts as necessary before proceeding.

2. If the flue piping system is intact, not damaged and there is no sign of the flue overheating such as

discoloration or melting, then push the red reset button on the flue switch.

3. Be sure the unit is connected to a water supply and full of water.

4. Push the RESET button on the unit control panel. The appliance should light. If the appliance lights

proceed to step 5. If the appliance does not light and the display again begins to flash F01, inspect the

wiring to the flue switch, repairing or replacing as necessary. If the wiring is intact, replace the fl

using care to mount the new flue switch in the same position and mounting holes as the old one. If the

display flashes a code other than F01, follow the troubleshooting guide for that code.

5. Observe operation for 5 minutes. Place the probe of an exhaust analyzer into the flue system within 6

feet of the unit appliance. The exhaust temperature should not rise above 190°F (88°C) after several

minutes of operation.

6. If the flue temperature is below 190°F (88°C) and the appliance again goes into lockout displaying F01,

replace the flue switch using care to mount the new flue switch in the same position and mounting holes

as the old one. If the display flashes a code other than F01, follow the troubleshooting guide for that code.

7. If the flue temperature increases to over 190°F (88°C), Consult the AdvantagePlus factory for further

assistance.

Check the electrical connection to the appropriate temperature sensor, if connection is okay, replace bad

sensor.

If water in tank is not greater than 190°F (88°C), check wiring and repair if faulty. If the wiring is okay, check

appropriate sensor with ohmmeter and compare to reading in resitance chart. If reading does not agree with

water temperature, replace bad sensor.

1. Watch the igniter through the observation window provided.

2. f there is no spark, check the spark electrode for the proper ¼” (0.64 cm) gap.

3. Remove any corrosion from the spark electrode and flame rectifier probe.

4. If there is a spark but no flame, check the gas supply to the water heater.

5. If there is a fl

6. Check any flue blockage or condensate blocks.

1. Monitor the gas pressure to the unit while in operation.

2. Assure that the flame is stable when lit.

3. Check to see if the green light on the display module is out while the water heater is running.

4. If the green light doesn’t come on or goes off during operation check the flame signal on the status menu.

5. If the signal reads less than 1 microampere, clean the flame rectifier probe.

If the flame rectifier probe continues to read low, replace it.

6.

1. Turn the gas off to the unit at the service valve.

2. If the flame signal is still present replace the igniter.

3. If the flame signal is not

4. If there is no power to the gas valve, remove the valve and check for obstruction in the valve seat or

replace the gas valve.

5. Turn the gas on at the service valve after corrective action is taken.

1. Check the combustion air fan wiring.

2. Replace the combustion air fan.

3. Replace the control board.

TO REMEDY A FAULT, IT IS RECOMMENDED THAT YOU CYCLE THE UNIT AT

ame, check the flame sensor.

ue switch

present after turning off the gas supply, check the gas valve electrical connection.

24

Page 25

Table 6-2: AdvantagePlus

Resistance Table for Supply

Temperature Sensor

High/Low Temp.

Sensor Temp.

32°F (0ºC) 32550

41°F (5ºC) 25340

50°F (10ºC) 19870

59°F (15ºC) 15700

68°F (20ºC) 12490

77°F (25ºC) 10000

86°F (30ºC) 8059

95°F (35ºC) 6535

104°F (40ºC) 5330

13°F (45ºC) 4372

1

122°F (50ºC) 3605

131°F (55ºC) 2989

140°F (60ºC) 2490

149°F (65ºC) 2084

158°F (70ºC) 1753

167°F (75ºC) 1481

176°F (80ºC) 1256

185°F (85ºC) 1070

194°F (90ºC) 915

202°F (95ºC) 786

212°F (100ºC) 667

Resistance

(ohms)

ble 6-3: 926 Control Board Error Codes

a

T

Code Description Duration Corrective Action

Combustion Fan

E13

¢

E14

¢

LE0

¢

FLU

¢

LOU

¢

Speed Low. The

combustion air fan

speed less than

70% of expected.

Combustion Fan

Speed High. The

combustion air fan

speed is more than

130% of expected.

Water level in tank

is low

Blocked Vent

Pressure Switch

Open

24 VAC low

60 Sec.

60 Sec.

Until

Corrected

Until

Corrected

Until

Corrected

1. Check the combustion air fan wiring.

Replace the combustion air fan.

2.

3. Replace the control board.

1. Check the combustion air fan wiring.

Replace the combustion air fan.

2.

3. Replace the control board.

1. Be sure all air is bled from system.

2. Inspect low level switch and wiring for

damage and repair as necessary.

1. Assure that the vent is not blocked

2. Check the blocked vent pressure

switch operation by applying a jumper.

(If the switch is not functioning properly,

replace it.)

1. Check line voltage. Must be between

100-128 VAC.

2. If available, connect PC and using

AdvantagePlus service software check

the 24 VAC supply display in the lower

left corner of the screen. The number

displayed here must be greater than

128 and should be greater than 250.

Use this as a troubleshooting guide as

you follow the steps below.

3. Remove 10 pin Molex connector from

customer connection board. If LOU

code clears, then the problem is with

external sensor wiring. Examine

external sensor wiring for shorts to

ground repairing as necessary. If LOU

code is still present and the boiler is so

equipped, disconnect high gas

pressure switch, then low gas pressure

switch, then UL 353 low water cutoff in

this order one at a time to see if LOU

code clears. Replace faulty part. Check

low voltage wire harness in boiler for

shorts to ground.

4. If LOU only occurs when burner tries to

light, check gas valve for excessive

current draw.

5. If LOU is present with the low voltage

harness disconnected from the 926

control board, replace the 926 control

board.

25

Page 26

N O T E S

26

Page 27

N O T E S

27

Page 28

Loading...

Loading...