Page 1

Xtreme High-Input Gas Commercial Water Heaters

Available in 90 Gallon Tank-Type Models

!

550,000 BTU/Hr. thru 715,000 BTU/Hr.

Xtreme Gas Commercial Water Heaters are specifically designed to

minimize the difficulty of replacing failed water heaters and are versatile for

new installations. These products are designed for applications requiring

large quantities of hot water.

Construction Features:

GX90-550 and

GX90-640 Comply

With SCAQMD

Rule 11 46.2 for

Low NOxEmissions

Small

Jacket Diameters

• Space saving tank design –

maximizes installation adaptability

by offering models with front side

and rear side inlet/outlet water

connections. Short heights and

small jacket diameters result in

greater installation flexibility.

• Patented multi-flue tank design

– proprietary steel formulation,

patented multi-flue design, and

two coats of high temperature

porcelain enamel to maximize

corrosion resistance result in a

superior heat exchanger design.

• Low profile automatic flue

damper –

low profile design minimizes overall product height. Heavy duty vent

hood supports are designed to

withstand rigors of installation.

• Specialized burner

assembly –

each model features five premix

burners mounted into a metal face

plate and sealed with a Viton

gasket. Patented “quick release”

manifold for easier service.

• Spark-To-Pilot ignition system –

Standard on all models. Provides

reliable and energy saving ignition

sequencing by igniting the pilot

only when the thermostat calls

for heat.

™

• System Sentinel

diagnostic system –

Our exclusive diagnostic system,

with glowing LED lights, verifies

system operation sequence

by sequence.

• Full port, full flow brass drain

valve

LED

Short Floor-to-Vent

Heights

Multiple Water

Connection Options

(On Selected

Models)

Certifications and Ratings:

• Efficiency – these models have been tested according to ANSI test

procedures, and exceed the thermal efficiency and standby loss

requirements of current ASHRAE standards (Part of the Federally

mandated Energy Policy Act (EPact)). Also exceeds energy efficiency

codes of all states.

• Safety and construction – These products are design certified by U.L.:

a) For operation at 180°F. b) To meet all safety and construction

requirements of ANSI Z21.10.3-2001 c) As an automatic storage or

instantaneous water heater. d) As an automatic circulating tank water

heater. e) For operation on combustible floors and in alcove installations.

CERTIFIED FOR A 150 PSI MAXIMUM WORKING PRESSURE

(160 PSI FOR ASME MODELS).

Continued next page.

Page 2

treme Gas continued.

X

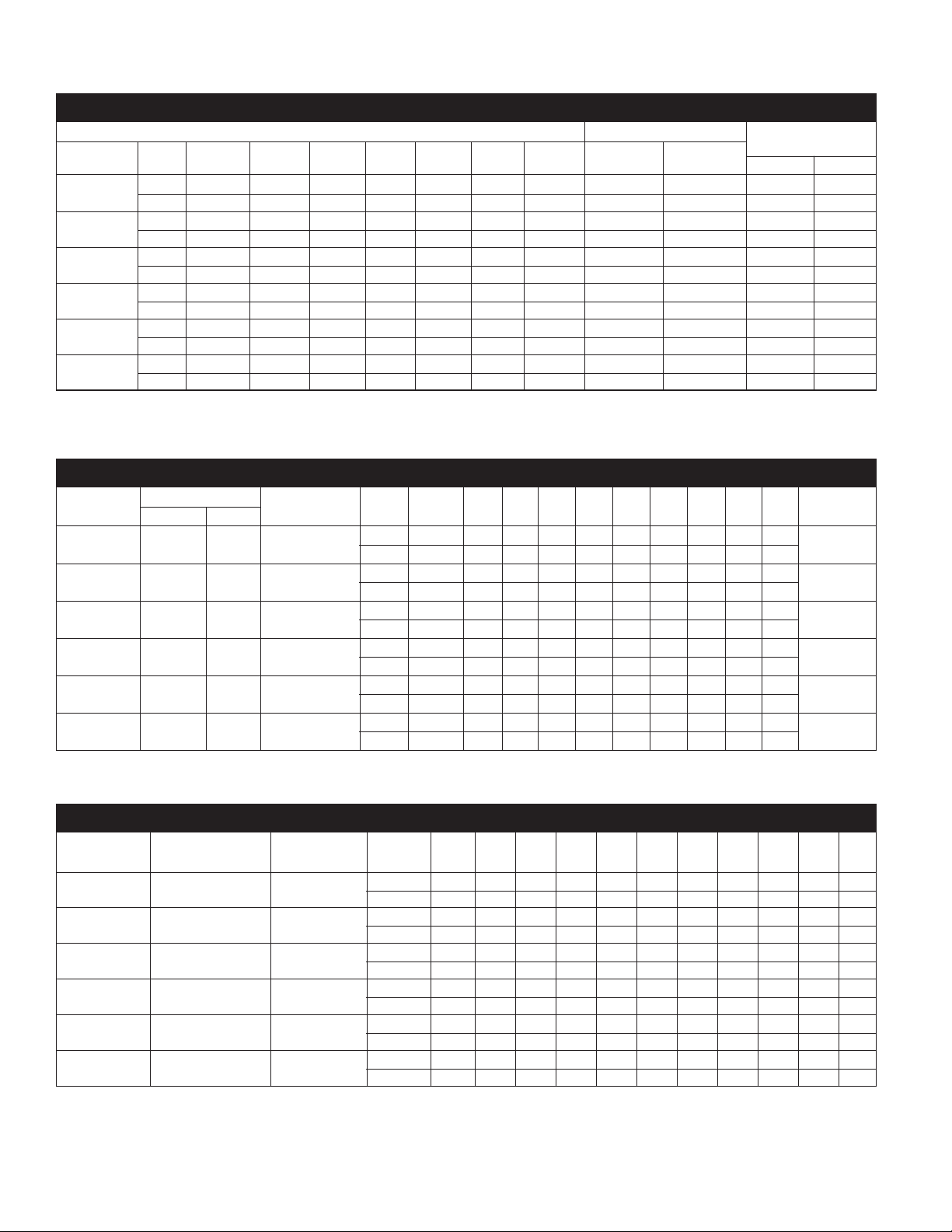

DIMENSIONAL INFORMATION All Dimensions Shown in English and Metric.

WATER CONNECTIONS APPROXIMATE

MODEL FRONT REAR

NUMBER UNITS ABCDEFG SIDE SIDE STD. ASME

GX90-550(A) inches 74.5 68 30 25 10 59 12 2905 945

mm 1892 1727 768 635 254 1509 25.4 51 51 905 945

GX90-640(A) inches 74.5 68 30 25 10 59 12 2905 945

mm 1892 1727 768 635 254 1509 25.4 51 51 905 945

GX90-715(A) inches 74.5 68 30 25 10 59 12 2905 945

mm 1892 1727 768 635 254 1509 25.4 51 51 905 945

GX90-500(A) inches 74.5 68 30 25 10 59 12 2905 945

mm 1892 1727 768 635 254 1509 25.4 51 51 905 945

GX90-600(A) inches 74.5 68 30 25 10 59 12 2905 945

mm 1892 1727 768 635 254 1509 25.4 51 51 905 945

GX90-680(A) inches 74.5 68 30 25 10 59 12 2905 945

mm 1892 1727 768 635 254 1509 25.4 51 51 905 945

All Models Require a 120V Power Source. (A) Suffix Indicates ASME Tank Construction Available.

SHIPPING WEIGHT

MAXIMUM DELIVERY In U.S. Gallons and Liters. (Includes useable storage and recovery for indicated times.)

MODEL TANK CAPACITY INPUT BTU/HR. TEMP. 5 10 15 20 30 45 60 120 180 Min. to Rec.

NUMBER

GX90-550(A) 90 341 550,000 NAT 100°F GAL 107 152 196 241 330 463 596 1130 1663 10

GX90-640(A) 90 341 640,000 NAT 100°F GAL. 115 166 218 270 373 529 684 1304 1925 9

GX90-715(A) 90 341 715,000 NAT 100°F GAL. 121 179 236 294 410 583 756 1450 2143 8

GX90-500(A) 90 341 500,000 LP 100°F GAL. 103 144 184 225 305 427 548 1033 1518 11

L.P. 37.7°C LTR. 391 544 697 850 1156 1615 2073 3909 5744

GX90-600(A) 90 341 600,000 LP 100°F GAL. 112 160 209 257 354 499 645 1227 1809 9

L.P. 37.7°C LTR. 422 606 789 972 1340 1890 2441 4643 6845

GX90-680(A) 90 341 680,000 LP 100°F GAL. 118 173 228 283 393 558 722 1382 2041 8

L.P. 37.7°C LTR. 446 654 862 1070 1486 2110 2886 5230 7726

GALLONS

LITERS NAT. &L.P. RISE UNITS Min. Min. Min. Min. Min. Min. Min. Min. Min. Contents

37.7°C LTR. 407 575 743 911 1248 1752 2257 4276 6294

37.7°C LTR. 434 630 826 1022 1413 2000 2587 4936 7285

37.7°C LTR. 457 676 894 1113 1551 2207 2863 5487 8111

RECOVERY CAPACITIES Recovery in U.S. Gallons/Hr. (GPH) and Liters/Hr. (LPH) at Various Temperature Rises.

MODEL INPUT BTU/HR. THERMAL 40°F 50°F 60°F 70°F 80°F 90°F 100°F 110°F 120°F 130°F 140°F

NUMBER NATURAL & L.P. EFFICIENCY UNITS

GX90-550(A) 550,000 NAT 80% GPH 1333 1067 889 762 667 593 533 485 444 410 381

LPH 5047 4037 3364 2884 2523 2243 2019 1835 1682 1553 1442

GX90-640(A) 640,000 NAT 80% GPH 1551 1241 1034 887 776 690 621 564 517 477 443

LPH 5873 4698 3915 3356 2936 2610 2349 2135 1958 1807 1678

GX90-715(A) 715,000 NAT 80% GPH 1733 1387 1156 991 867 770 693 630 578 533 495

LPH 6561 5249 4374 3749 3280 2916 2624 2386 2187 2019 1875

GX90-500(A) 500,000 LP 80% GPH 1212 970 808 693 606 539 485 441 404 373 346

L.P.

LPH 4588 3670 3059 2622 2294 2039 1835 1668 1529 1412 1311

GX90-600(A) 600,000 LP 80% GPH 1455 1164 970 831 727 647 582 529 485 448 416

L.P.

LPH 5506 4404 3670 3146 2753 2447 2202 2002 1835 1694 1573

GX90-680(A) 680,000 LP 80% GPH 1649 1319 1099 942 824 733 659 599 550 507 471

L.P.

LPH 6240 4992 4160 3565 3120 2773 2496 2269 2080 1920 1783

Recovery ratings are based on thermal efficiencies obtained in a CSA certified laboratory. Recovery rate shown on the rating

plate (80%) Thermal Efficiency in accordance with ANSIZ21.10.3 labeling requirements. (A) indicates available ASME model.

22°C 28°C 33°C 39°C 45°C 50°C 56°C 61°C 67°C 72°C 78°C

Page 3

E

C

G

FDBA

OUTLET

FRONT SIDE

INLET

FRONT SIDE

SYSTEM

SENTINEL

T&P

treme Gas continued.

X

DIMENSIONAL DIAGRAM

CLEARANCES TO

COMBUSTIBLES

MODEL

NUMBER UNITS SIDE REAR TOP

GX90-550 inches

mm

GX90-640 inches

mm

GX90-715 inches

mm

GX90-500 inches

mm

GX90-600 inches

mm

GX90-680 inches

mm

Allow a minimum of 18" (457mm) front clearance

for servicing.

2.5 Amps.

4412

102 102 305

4412

102 102 305

4412

102 102 305

4412

102 102 305

4412

102 102 305

4412

102 102 305

Page 4

treme Gas continued.

X

Other Features:

• Insulation – sag and moisture proof fiberglass

insulation surrounds the storage tank to

minimize heat loss.

• Anode rods – patented design utilizes multiple

magnesium rods to ensure long life and

corrosion resistance.

• Temperature and pressure relief valve –

AGA/ASME rated and factory installed.

• Hand-hole cleanout – for removal of lime/

sediment deposits.

• Manual reset high limit – all

models are factory

equipped with a manual reset high limit to meet the

code requirements of many states.

• Gas control system –

fully adjustable thermostat

from 100°F to 180°F, 24 volt combination gas valve

includes main gas pressure regulation,

On-Off manual valve, 120/24 volt transformer, and

high limit temperature cut-out.

•

Round premix burners – precision burners are

formed from high chromium stainless steel.

Recommended Specifications (for trade reference only)

Water

of __________ Btu/hr. and a recovery rate of _____________ GPH at a 100°F temperature rise when tested and

certified at ____________ thermal efficiency. Water heater(s) shall have a storage capacity of 90 gallons. Water

heater(s) shall have the U.L. seal of certification and supplied with a factory installed AGA/ASME rated temperature

and pressure relief valve. Tank(s) shall be furnished with a tube bundle having a double coating of high temperature porcelain enamel and furnished with magnesium anode rods rigidly supported. Water heater(s) shall meet or

exceed the thermal efficiency and standby loss requirements of current ASHRAE standards. Tanks shall have a

working pressure rating of 150 psi, and shall be completely factory assembled, including a pressure regulator

properly adjusted for operation on ___________ gas with chromium stainless steel burners. Controls will be

arranged for safety shutoff in event of pilot failure. Water heater(s) shall have front and rear side inlet/outlet water

connections. Water heater(s) shall be covered by a three year limited warranty against tank leaks.

heater(s) shall be XTREME model ________________, manufactured by RHEEM-RUUD, having gas input

Add “A” for ASME construction

Water heater(s) shall be constructed in accordance with the requirements of the ASME Boiler and Pressure Vessel

Code, Section IV Part HLW.

Limited Warranty

This product features a three year limited warranty against tank leaks. Please refer to Commercial

Warranty Information Certificate for complete warranty information.

In keeping with its policy of continuous progress and product improvement, Rheem-Ruud reserves the right to make changes without notice.

Rheem Water Heating • 101 Bell Road, Montgomery, Alabama 36117-4305 • www.rheem.com

Rheem Canada Ltd./Ltée • 125 Edgeware Road, Unit 1, Brampton, Ontario L6Y 0P5

P R I N T E D IN U .S .A 0 2 / 1 0 WP F O R M NO . R R1 02 C -1 5 Re v. 5

Loading...

Loading...