Page 1

21

RSS, RSR and RSH Series Laminator

OWNER'S MANUAL

Royal Sovereign International Inc.

www.royalsovereign.com

Read all instructions carefully before use.

For any Customer Support needs please choose the

Customer Support tab on www.royalsovereign.com

RS International Australia PTY. LTD.

30 Prime Drive, Seven Hills, NSW 2147, Australia

TEL : +61) 2-9674-2127

FAX : +61) 2-9674-2027

E-mail : salesaust@royalsovereign.com

CORPORATE HEADQUARTERS

Royal Sovereign International Inc.

2 Volvo Drive, Rockleigh, NJ 07647 U.S.A.

TEL : +1) 800-397-1025 FAX : +1) 201-750-1022

E-mail : info@royalsovereign.com

Royal Sovereign Inc.

<Oversea Sales Office>

1001, World Meridian II, 426-5, Gasan-dong,

Geumcheon-gu, Seoul, 153-759, KOREA

TEL : +82)2-2025-8800 FAX : +82)2-2025-8830

E-mail : sales@royalsovereign.com

RS Canada Inc.

164 Oakdale Road, Toronto, Ontario M3N 2S5

CANADA

TEL : +1) 416-741-8400 FAX : +1) 416-741-8185

E-mail : info@royalsovereign.com

RS Holland B.V.

Planetenweg 75 2132HM Hoofddorp, The Netherlands.

TEL : +31) 23-5626620, +31) 23-5654451

FAX : +31) 23-5654565

E-mail : purchaseorder@royalsovereign.com

18. W ARRANTY

Royal Sovereign International warrants the equipment sold is free from defects in

material and workmanship for a period of One (1) year for Parts and Labor from the date

of installation, excluding lamination rollers which are warranted for Six (6) months. This

warranty is extended only to the original purchaser. This warranty is the only warranty

made by Royal Sovereign International and cannot be modified or amended. Royal

Sovereign’s sole and exclusive liability and the customer’s sole and exclusive remedy

under this warranty shall be, at Royal Sovereign’s option, to repair or replace any such

defective part or product. These remedies are only available if Royal Sovereign’s

examination of the product discloses to Royal Sovereign’s satisfaction that such defects

actually exist and were not caused by misuse, neglect, attempt to repair, unauthorized

alternation or modification, incorrect line voltage, fire, accident, flood or other hazard.

All warranty claims must be filed through the authorized Royal Sovereign dealer or

reseller through which the equipment was originally purchased. Model, serial number

and date of delivery are required for all claims.

The warranty made herein is in lieu of all other warranties, expressed or implied,

including any warranty or merchantability or fitness for a particular purpose. Royal

Sovereign will not be liable for personal damage or personal injury (unless primarily

caused by its negligence), loss of profit, or other incidental or consequential damages

arising out of the use or inability to use this equipment.

This warranty specifically does not cover damage to laminating rollers caused by knives,

razor blades, or any sharp objects or abrasives, or failure caused by adhesives, or

damage caused by lifting, tilting or improper use of the machine. Warranty repair or

replacement by Royal Sovereign or its authorized Reseller(s) does not extend the

warranty beyond the initial one year period from the date of installation. Unauthorized

customer alterations will void this warranty.

LIMITED WARRANTY

Page 2

RSS, RSR, RSH Series

21

TABLE OF CONTENTS

1. INTRODUCTION

TOPIC PAGE

1. Introduction.......................................................................................................... 2

2. Safety Precautions............................................................................................... 2

3. Installation ............................................................................................................ 3

4. Included with Laminator.......................................................................................4

5. Product Identification.............................................................................................5

6. Control Panel........................................................................................................ 6

7. Speed and Temperature Settings ....................................................................... 8

8. Roller Nip Settings................................................................................................ 8

9. Using Foot Pedal and Remote Control................................................................ 9

10. Using Cross Cutter ............................................................................................ 9

11. Using Slitter...................................................................................................... 10

12. Loading Film

12.1. Installation of the core plugs................................................................... 11

12.2. Installation of the auto grip...................................................................... 12

13. Threading Film

13.1. Laminating and Encapsulation................................................................ 13

13.2. Decaling .................................................................................................. 15

13.3. Mounting ................................................................................................. 16

14. Installation of the Front Feed and Rear Rewind Options................................ 18

15. Maintenance..................................................................................................... 19

16. Troubleshooting ............................................................................................... 19

17. Specifications...................................................................................................20

18. Warranty........................................................................................................... 21

Thank you for choosing a Royal Sovereign laminator. It has been designed and

manufactured to provide years of continuous service. For complete operating and

maintenance information please read this manual thoroughly. Upon receipt of your

laminator, please inspect the box, the machine and all other contents for shipping

damage. Damage should be brought to the immediate attention of the delivering carrier

(See page 4 for list of shipment elements).

2. SAFETY PRECAUTIONS

Failure to comply with any of the following safety procedures could result in serious injury.

Please read the instructions carefully and keep for future reference.

1. Only a licensed electrician should install wiring and outlet for the laminator.

2. Ensure the unit is plugged into a properly grounded outlet with the correct voltage.

3. Keep hands and clothing (i.e. Neckties) away from rollers. The rollers have pinch points

that can trap body parts or clothing and cause serious injury.

4. Keep flammable and wet objects away from the machine.

5. Place machine on a level surface.

6. Avoid excessive sunlight, humidity and extreme temperatures.

7. Ensure the unit is turned off, cooled, and unplugged from the outlet prior to moving

and/or repairing.

8. Keep out of reach of children.

9. Only Royal Sovereign authorized maintenance and service technicians should make

repairs.

10. Do not attempt to laminate items that exceed total recommended material thickness

for the unit.

11. When cleaning the machine, don't use flammable sprays or materials.

12. Do not touch the rollers when they are hot or place foreign objects inside the machine.

13. Do not cover the surface of the machine until the machine has completely cooled.

Page 3

RSS, RSR, RSH Series

43

3. INSTALLATION

Note: The laminator should be installed by a trained service technician.

ELECTRICAL REQUIREMENTS

The laminator comes fully assembled, except for the feed table and paper guide to avoid

shipping damage. Upon arrival, thoroughly inspect the unit. It is imperative that any

shipping damage is reported and a claim is filed with the delivering carrier immediately

upon receipt.

The laminator should be located in an area with adequate work space for feeding graphics

and lamination materials.

Avoid placing the laminator in a dusty area or near sources of extreme heat or cold.

Once the laminator is in place, lock the casters into position(“ON” position). Always unlock

the casters (“OFF” position) when moving to a different location.

4. INCLUDED WITH LAMINATOR

Thoroughly inspect the parts and the unit. It is imperative that any missing parts are

reported and a claim is filed with the reseller immediately upon receipt of shipment.

Royal Sovereign recommends that a licensed electrician ensures proper power to your

laminator in accordance with electrical codes in your area.

The laminator should have a dedicated power line.

MODEL

RSS-685 / RSS-1050 /

RSR-685 RSR-1050 RSH-1050 RSH-1650

RSS-685N RSS-1050N

Power supply AC 200 ~ 220V, AC 230 ~ 240V, 50/60HZ Single phase

Part Name

Laminator

Owner's Manual

3´´(76mm) / 2" (57mm) Core Plugs

Core - Bolts

Dust Cover

Spare Motor Fuse - FUSE(50T)

6.3A

Spare Main Power Fuse - FUSE(65TS)

15A / 20A(only RSH-1650)

Roll film Samples

8 - 1/4"Hexa head Bolt (M6

@?hf

/Xe@??W.?h

V/X?@?W.Y?h

?V/?@?.Yhe

W.?/X?he

?W.Y?V/Xhe

?.Y?eV/he

20mm)

8 - Spring Washer(

?@h

J5h

?O&Hh

O2@@@@@?O@g

W2@0M??W@@@@g

?W&(M?e?7<I'@g

?7@Hf?@eN@g

J@5?fJ5e?@g

7@H?f7Hhe

@@g@?he

@@f?J5?he

@@f?7H?he

@@f?@hf

3@L?eJ5hf

N@1?e7Hhf

?3@Le@?fW.g

?V')KC5?e?O.Yg

V4@@Y??O20Y?g

?@@@@0M?h

J(M?hf

7Hhg

@?hg

6.1)

(Included with option only)

Front Feeder and Rear Rewinder Kit

(Included with option only)

1

1

6/6

6

1

1

1

2

10/10

2/2

Quantity Picture

12 - 3/16"screw (M5

@?hf

/Xe@??W.?h

V/X?@?W.Y?h

?V/?@?.Yhe

W.?/X?he

?W.Y?V/Xhe

?.Y?eV/he

10mm).

12 - Spring Washer(

?@h

J5h

?O&Hh

O2@@@@@?O@g

W2@0M??W@@@@g

?W&(M?e?7<I'@g

?7@Hf?@eN@g

J@5?fJ5e?@g

7@H?f7Hhe

@@g@?he

@@f?J5?he

@@f?7H?he

@@f?@hf

3@L?eJ5hf

N@1?e7Hhf

?3@Le@?fW.g

?V')KC5?e?O.Yg

V4@@Y??O20Y?g

?@@@@0M?h

J(M?hf

7Hhg

@?hg

5.1)

(Included with option only)

12/12

230V UL 220V EU 240V UK

3´´(76mm) / 2" (57mm) Auto Grip

(Included with US only )

L-wrench (2.5)

(Included with US only )

6/6

1

Page 4

RSS, RSR, RSH Series

65

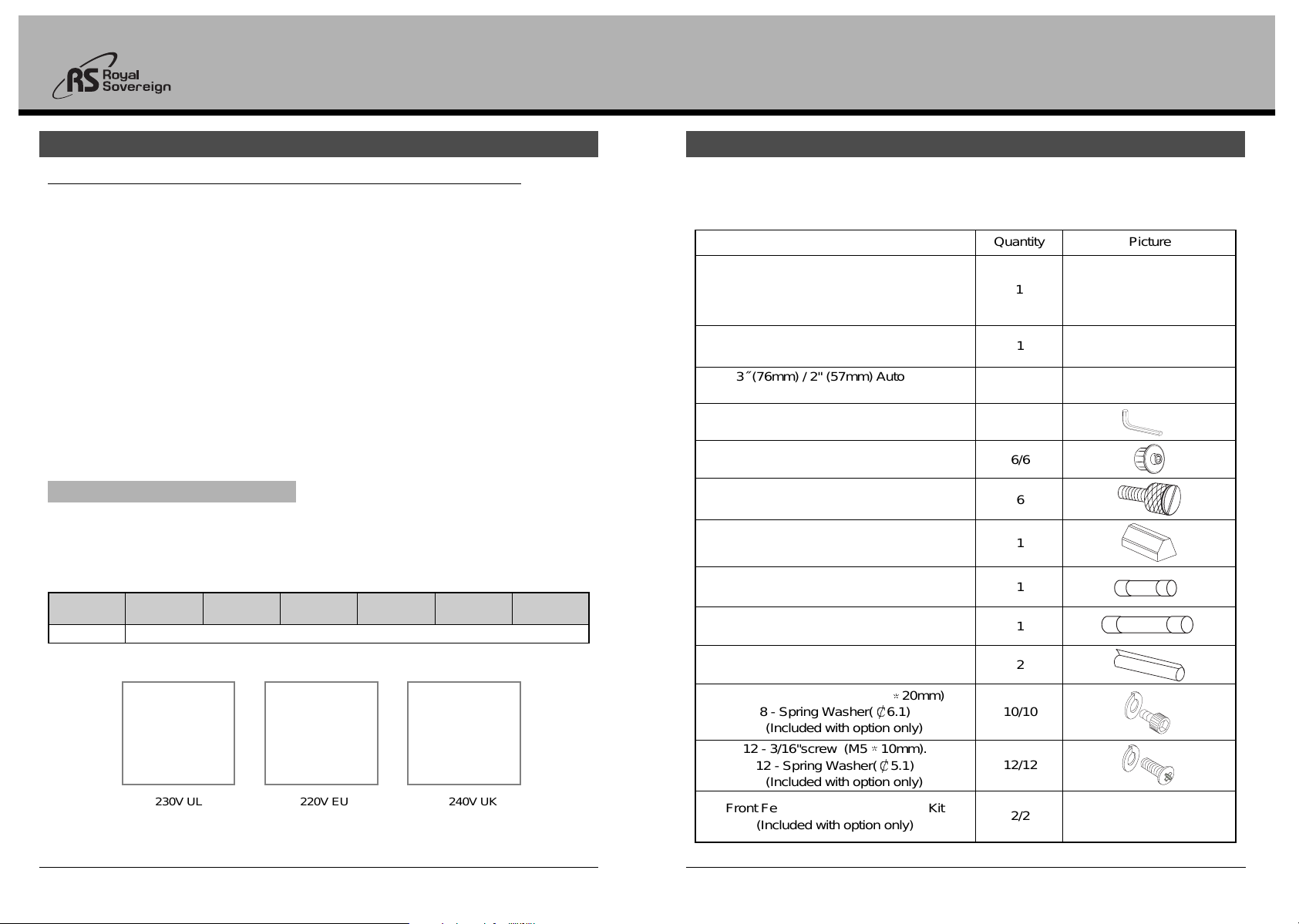

5. PRODUCT IDENTIFICATION 6. CONTROL PANEL

1 15

2

3

4

5

6

7

8

14

13

10

9

12

11

No. PART NAME

RSS-685/ RSS-1050/

RSR-685 RSR-1050 RSH-1050 RSH-1650

RSS-685N RSS-1050N

1 FILM ALIGNMENT KNOB O O O O O X

2 EMERGENCY SWITCH O O O O O O

3 SAFETY COVER O O O O O O

4 FRAME-PAPER GUIDE O O O O O O

5 FEED TABLE O O O O O O

HOT ROLLER X X X X O O

6 ROLLING SHOE X X O O X X

HOT SHOE O O X X X X

7 ASSEMBLY STAND O O O O O O

8 REMOTE CONTROL O O O O O O

9 FOOT PEDAL O O O O O O

10

TENSION CONTROL KNOBS

OOOOOO

11 PRESSURE LEVER O O O O O O

12 CONTROL PANEL O O O O O O

13 UPPER IDLE BAR O O O O O O

14 TAKE-UP SWITCH O O O O O O

15

RELEASE LINER TAKE UP

OOOOOO

16 TEMPERATURE DISPLAY

?

?

?

?

?

?

?

?

?

?

?

?

W2@6X?hg?

?W.M?I/Xhg?

?7H?eN1hg?

?@f?@hg?

?3L?eJ5hg?

?V/K?O.Yhg?

V4@0Y?hg?

?

?

?

?

?

?

?

?

?

?

?

?

?

?

C

/

?W2@6Xhg

?7<?I/X?hf

?@e?N1?hf

?@f@?hf

?@e?J5?hf

?3=?O.Y?hf

?V4@0Yhg

F

?

?

?

?

?

?

?

?

?

?

?

?

W2@6X?hg?

?W.M?I/Xhg?

?7H?eN1hg?

?@f?@hg?

?3L?eJ5hg?

?V/K?O.Yhg?

V4@0Y?hg?

?

?

?

?

?

?

?

?

?

?

?

?

?

?

C

/

?W2@6Xhg

?7<?I/X?hf

?@e?N1?hf

?@f@?hf

?@e?J5?hf

?3=?O.Y?hf

?V4@0Yhg

F

?

?

?

?

?

?

?

?

?

?

?

?

W2@6X?hg?

?W.M?I/Xhg?

?7H?eN1hg?

?@f?@hg?

?3L?eJ5hg?

?V/K?O.Yhg?

V4@0Y?hg?

?

?

?

?

?

?

?

?

?

?

?

?

?

?

C

&

?W2@6Xhg

?7<?I/X?hf

?@e?N1?hf

?@f@?hf

?@e?J5?hf

?3=?O.Y?hf

?V4@0Yhg

F

?

?

?

?

?

?

?

?

?

?

?

?

W2@6X?hg?

?W.M?I/Xhg?

?7H?eN1hg?

?@f?@hg?

?3L?eJ5hg?

?V/K?O.Yhg?

V4@0Y?hg?

?

?

?

?

?

?

?

?

?

?

?

?

?

?

C

&

?W2@6Xhg

?7<?I/X?hf

?@e?N1?hf

?@f@?hf

?@e?J5?hf

?3=?O.Y?hf

?V4@0Yhg

F

?

?

?

?

?

?

?

?

?

?

?

?

W2@6X?hg?

?W.M?I/Xhg?

?7H?eN1hg?

?@f?@hg?

?3L?eJ5hg?

?V/K?O.Yhg?

V4@0Y?hg?

?

?

?

?

?

?

?

?

?

?

?

?

?

?

C

&

?W2@6Xhg

?7<?I/X?hf

?@e?N1?hf

?@f@?hf

?@e?J5?hf

?3=?O.Y?hf

?V4@0Yhg

F

?

?

?

?

?

?

?

?

?

?

?

?

W2@6X?hg?

?W.M?I/Xhg?

?7H?eN1hg?

?@f?@hg?

?3L?eJ5hg?

?V/K?O.Yhg?

V4@0Y?hg?

?

?

?

?

?

?

?

?

?

?

?

?

?

?

C

&

?W2@6Xhg

?7<?I/X?hf

?@e?N1?hf

?@f@?hf

?@e?J5?hf

?3=?O.Y?hf

?V4@0Yhg

F

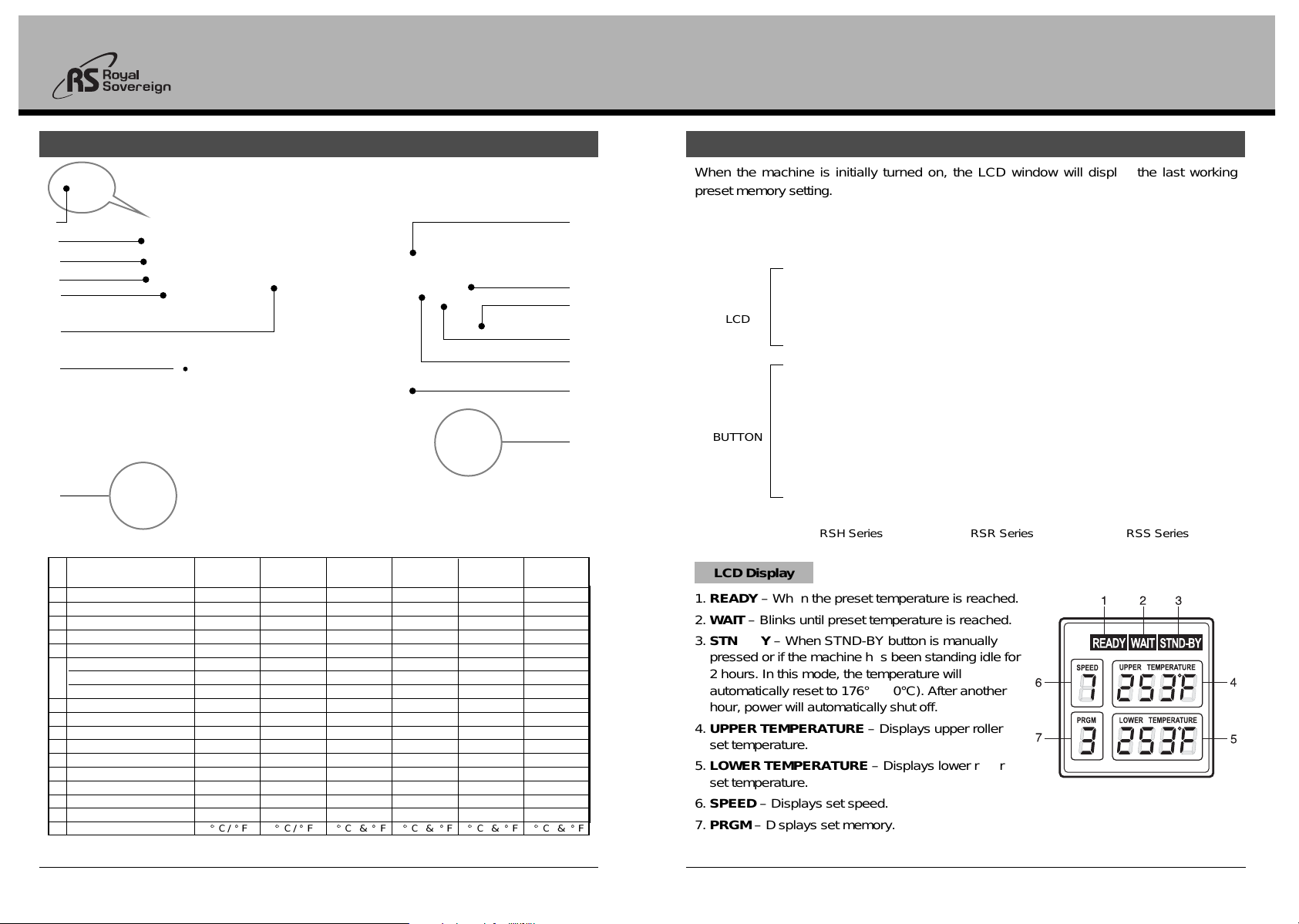

When the machine is initially turned on, the LCD window will display the last working

preset memory setting.

LCD Display

1. READY – When the preset temperature is reached.

2. WAIT – Blinks until preset temperature is reached.

3. STND-BY – When STND-BY button is manually

pressed or if the machine has been standing idle for

2 hours. In this mode, the temperature will

automatically reset to 176°F (80°C). After another

hour, power will automatically shut off.

4. UPPER TEMPERATURE – Displays upper roller

set temperature.

5. LOWER TEMPERATURE – Displays lower roller

set temperature.

6. SPEED – Displays set speed.

7. PRGM – Displays set memory.

LCD

BUTTON

RSH Series RSR Series RSS Series

Page 5

RSS, RSR, RSH Series

87

Control Buttons

1. UPPER: To change upper roller temperature by

pressing button, then up or down arrow.

(range 32~320°F or 0~160°C)

2. LOWER: To change lower roller temperature by

pressing button, then up or down arrow.

(range 32~320°F or 0~160°C)

3. SPEED: To change speed of the rollers by

pressing button, then up or down arrow.

(range 1 through 9)

4. MEMORY: To recall or change presets.

To recall the settings, press MEMORY then up or

down arrow. To save the settings, set desired

temperatures and speeds then press the

MEMORY button twice.

(stores up to 9 different settings)

5. C/HOT: To change the mode from hot to cold or

cold to hot lamination. In cold mode, the speed defaults to 2

(speed 1~4 settings) and stand-by function is disabled.

6. T-CHECK: To check current upper and lower roller

temperatures. Display automatically returns to the previous

settings after 5 blinks.

7. ST/BY: To change to stand-by mode (temperature will

automatically reset to 176°F (80°C). While in this mode, all the buttons on the control

panel are disabled. Press ST/BY mode button to resume normal operation.

NOTE:

Auto stand by mode and auto power off mode

-Stand by mode: If no activity is made within 2 hours after each use the machine will

automatically switch into stand by mode.

-Auto power off mode: If the machine is in stand by mode and no activity is made for 60

minutes the machine will automatically power off.

-If any activity is made while in stand by or auto power off mode the machine will return

to it's previous stage.

8. REV: To reverse the rollers. Must press and hold the button to activate.

9. STOP: To stop the rollers from turning.

10. RUN: To start the rollers.

11. RESET: To reset the substrate and length counters (Excluding RSR/ RSS series).

Press and hold RESET button for 2 seconds.

12. FAN: To activate the cooling fans.

13. MEAS: To display the substrate and length counters (Excluding RSR /RSS series).

Press button again to return to previous screen.

7. SPEED AND TEMPERATURE SETTINGS

8. ROLLER NIP SETTING

Speed (Ft/min, M/min)

SPEED #

RSS-1050/685

RSR-1050/685 RSH-1650/1050

RSS-1050N/685N

1 3.3(1.0) 2.6(0.8) 1.3(0.4)

2 4.6(1.4) 3.9(1.2) 1.9(0.6)

3 5.9(1.8) 5.2(1.6) 2.6(0.8)

4 7.2(2.2) 6.6(2.0) 3.3(1.0)

5 8.8(2.7) 7.9(2.4) 3.9(1.2)

6 10.5(3.2) 9.2(2.8) 4.6(1.4)

7 13.1(4.0) 10.5(3.2) 5.2(1.6)

8 16.4(5.0) 11.8(3.6) 5.9(1.8)

9 19.7(6.0) 13.1(4.0) 6.6(2.0)

No. Inches

Metric

(mm)

1 Lamination Lamination

2 1/25" 1

3 3/16 ~1/4" 5-7

4 3/8 ~1/2" 10-13

5

RSH Series Only

3/5" 15

NOTE: If you don't want to laminate,

please place the pressure lever to the

"Open position(NO.5)."

Page 6

RSS, RSR, RSH Series

109

9. USING FOOT PEDAL AND REMOTE CONTROL

10. USING CROSS CUTTER

USING FOOT PEDAL

Place the foot pedal on the floor in front of the machine.

Once all correct settings are displayed, you may use the

foot pedal to operate the laminator for “Hands Free

Operation.” To activate the machine, press the foot pedal

once and then release. Repeat to stop the rollers.

The cross cutter is located on the rear exit table of the machine.

1. After lamination, move the cutter approximately to the

center of the completed application at the desired point

of detachment (Figure 1).

2. Grasp film with one hand, press the cutter

downward into the application and slide it first to one

end of the application, then to the other end to

complete the cut (Figure 2 & 3).

USING REMOTE CONTROL

Located on the left hand side of the rear of the laminator, to

use press:

1. RUN: To activate the rollers.

2. STOP: To stop the rollers from turning.

3. REV: To reverse the rollers. Press and hold the button

(useful for jams or misfed media).

12 3

Figure 1

1 1. USING SLITTER

Only the RSR & RSS series have slitters included

1. Adjust the left and/or right slitters by loosening the

slitter adjuster knob (located between the front and

rear rollers.) (Figure 1)

2. Activate the slitter by turning the slitter knob (located

on the left side of the machine) clockwise. (Figure 2)

3. Once you activate the slitter then you can begin

lamination. (Figure 3)

4. To deactivate the slitter turn the slitter knob

counterclockwise. (Figure 4)

NOTE:

When the slitter becomes dull break off the

blade. Loosen the screw to pull down a new blade.

Once the new blade is down tighten the screw.

(Figure.5 )

Figure 2

Figure 3

CAUTION

When the slitters are not in use please keep the slitters positioned at the

far left and right side to avoid injury.

Figure 1

Figure 2

Figure 3

Figure 4

Figure 5

Page 7

RSS, RSR, RSH Series

1211

12. LOADING FILM

Royal Sovereign films are wound with the adhesive side facing the inside of the roll

(adhesive in).

1. Remove the upper and lower film shafts from the

machine and load the films (do not tighten the core

screws at this time). Note the direction of the

adhesives on the lower and upper films

(Figure 1 & 2).

Figure 1

Figure 2

Figure 3

Figure 5

Figure 4

1. Adjust the auto grip to fit to the film and tighten the

auto grip screw (Figure 1 & 2).

2. Remove the upper and lower film shafts from the

machine and load the films (Center the upper and

lower films on the shaft). Note the direction of the

adhesives on the lower and upper films

(Figure 3 & 4).

3. Load the upper and lower film shafts on the

machine (Figure 5 & 6).

Figure 1

Figure 2

Figure 3

Figure 4

Figure 6

Figure 5

Loading films to upper and lower film shafts:

(See page 5 for assistance with parts identification.)

2. Center the upper roll on the shaft, and then tighten

the upper bolt core screws (Figure 3).

3. Load the upper and lower film shafts on the

machine (Figure 4 & 5).

12.1 Installation of the core plugs

12.2 Installation of the auto grip

Page 8

RSS, RSR, RSH Series

14

10. Reinstall the Front Table, the Paper Guide, and

close the Safety Cover.

11. Adjust the nip setting to 1/8´´ (3mm).

12. Insert and push the leader board on each end until

board reaches the front nip point.

13. Push the Run button.

14. Push the leader board between the pair of main

rollers (Figure 4).

15. Press the Run button and adjust the supply roll

tension knobs by rotating clockwise or

counterclockwise. Turn it until the supply roll films

have some resistance (the tension varies

depending on the film thickness; the thicker the film

the more tension is required) (Figure 5).

16. Press Stop button when the leader board has

completely exited the rear of the unit.

17. Use the Cross Cutter to cut the leader board from

the web (see page 9).

18. Peel off the film from the board for reuse.

19. Set the roller nip setting to the appropriate position

for the lamination or encapsulation application.

Figure 5

Figure 4

13. THREADING FILM

Figure 1

Figure 2

Figure 3

13.1 Lamination and Encapsulation

RSH Series RSR Series RSS Series

Thermal Lamination

1. Turn the power switch on (“I” position). Power switch is

located in the rear of the unit on the left side.

2. Complete the steps on “Loading films to upper and

lower film shafts” - Page 11

3. Set the rollers temperature to the recommended film

temperature.

4. Remove the Paper Guide and the Front Table.

5. Pull down the upper film over the Safety Cover to the

lower film; align and center the lower film to upper film

and tighten the two lower bolt core screws (Figure 1).

6. Rewind the upper film until the film aligns with the Safety

Cover.

7. Thread the film over the Upper Idle Bar and underneath

the Safety Cover until the film rests on the upper roller

(Figure 2).

8. Carefully pull up the laminate from the lower roll around

the back side of the lower idler (Caution: lower roller may

be hot).

9. Tape the lower film to the upper film that is resting on the

main roller (Figure 3).

13

Page 9

RSS, RSR, RSH Series

16

Figure 1

1. Lay the decaled image face down on a flat surface.

Carefully peel back and put a crease along the edge of the

release liner (Approximately 1 inch or 25mm, Figure 1).

2. With the image facing up, align the image onto the board.

Press firmly from the center out (Figure 2).

3. Adjust the pressure lever to ensure the proper opening

(Figure 3).

4. Flip the image over the upper roller and hold on to the

release liner (Figure 4).

5. Press the foot pedal once, and then let it go while slowly

pulling the release liner as the board enters the main roller

nip (Figure 5).

Press the foot pedal once again when the board has

completely exited from the rear of the unit.

Trim the board if necessary.

Figure 2

Figure 3

Figure 4

Figure 5

13.3 Mounting

15

1. Follow the steps in the “Loading Film” procedure by loading the upper shaft with

pressure sensitive film, e.g. (Royal Print-Pro Film) and lower shaft with pressure

sensitive mounting adhesive films, e.g. (Royal Sovereign White-Mount or ClearMount).

2. Pull the upper laminate under the upper idle bar and separate the release liner from

the laminate.

3. Tape the release liner to the Take-Up Paper Core and allow the laminate to hang

over the main rollers.

4. Pull up the mounting adhesive and tack it to the laminate hanging over the rollers (do

not use the Lower Idle Bar).

5. Reinstall the Front Table and the Paper Guide and close the Safety Cover.

6. Turn on the upper take-up motor.

7. Adjust the nip setting to 1/8´´(3mm).

8. Insert and push the leader board until board reaches the nip point.

9. Press the Run button and adjust the supply roll tension knobs by rotating clockwise or

counterclockwise. Turn it until the supply roll films have some resistance (the tension

varies depending on the thickness of a film, the thicker the film the more tension is

required).

10. Press Stop button when the leader board has completely exited the rear of the unit.

11. Use the Cross Cutter to cut the leader board from the web (see page 9).

12. Set the roller nip setting to the appropriate position for the lamination application.

<RSH Series> <RSR Series> <RSS Series>

13.2 Decaling

Page 10

RSS, RSR, RSH Series

1817

NOTE: Below options are to be installed by an authorized

RS reseller.(These options are available for the RSH-1650.)

4. Disassemble the power switch bracket and place the left

rewinder outside of the frame; fasten with round head

3/16"(M5) screws (included in the option kit). Then,

reinstall the power switch bracket (Figure 7).

5. Install the right rewinder on the outside of the frame and

connect the motor wire connector to the rear wire

(Figures 8 & 9).

6. Reinstall the rear cover.

7. Reinstall the side covers.

8. Reinstall the lever knob and screw.

Figure 7

Figure 8

Figure 9

Installation of the Front Feeder Option (Includes 2 brackets,

one spindle, and mounting hardware).

1. Install the Front Feeder to the inside of the front frames

using four 1/4"(M6) hexagon bolts on each side (Figure 1).

Installing the Rear Rewinder Option (Includes motorized

winder, bracket, one spindle, and mounting hardware).

1. Remove the left and right covers by using a Phillips

screwdriver (four screws on each side cover)

(Figures 2 & 3).

2. Remove the lever knob screw and lever (Figure 4).

3. Remove the rear cover by removing all

12 screws (4 top, 4 bottom, and 2 on

each side) (Figure 5 & 6).

14. INSTALLATION OF FRONT FEEDER AND REAR

REWINDER OPTIONS

Figure 1

Figure 2 Figure 3

Figure 4

Figure 6Figure 5

Page 11

RSS, RSR, RSH Series

2019

17. SPECIFICATIONS

RSS-685 / 685N RSS-1050 / 1050N

AC 200, 220~240V

50/60Hz

2000W 3000W

685mm / 27" 1050mm / 41"

25 ~ 250mic / 1~10mil

6 m/min / 19.7 ft/min

10 min

Hot Shoe

DC geared

160°C / 320°F

9 settings

4 Roller

2.25", 3" [Auto grip 2.25", 3" (only us)]

1 Blower 2 Blower

Yes

Yes

Yes

Yes

Yes

13mm / 0.5"

Motor

Yes

Yes

Yes

1070 x 650 x 1210 (mm) 1400 x 650 x 1210 (mm)

42" x 25.5" x 47.5" 55" x 25.5" x 47.5"

129kg / 285lbs 163kg / 360lbs

1260 x 900 x 1460 (mm) 1560 x 900 x 1460 (mm)

49.5" x 35.5" x 57.5" 61.5" x 35.5" x 57.5"

237kg / 523lbs 262kg / 578lbs

RSR-685 RSR-1050

AC 200, 220~240V

50/60Hz

2000W 300W

685mm / 27" 1050mm /41"

25 ~ 250mic / 1~10mil

4 m/min / 13.1 ft/min

15 min

Rolling Shoe

DC geared

160°C / 320°F

9 settings

4 Roller

2.25", 3" [Auto grip 2.25", 3" (only us)]

1 Blower 2 Blower

Yes

Yes

Yes

Yes

Yes

13mm / 0.5"

Motor

Yes

Yes

Yes

1070 x 650 x 1210 (mm) 1400 x 650 x 1210 (mm)

42" x 25.5" x 47.5" 55" x 25.5" x 47.5"

123kg / 271lbs 157kg / 346lbs

1260 x 900 x 1460 (mm) 1560 x 900 x 1460 (mm)

49.5" x 35.5" x 57.5" 61.5" x 35.5" x 57.5"

231kg / 509lbs

256kg / 565lbs

Description

Power supply

Power consumption

Max laminating width

Film thickness

Max laminating speed

Ready time

Heating method

Driving motor

Max. temperature control

Speed control

Transport type

Film core size

Cooling system

Side cutter

Cross cutter

Film alignment

Hot lamination

Cold lamination

Mounting thickness

Take up system

Paper counter

Length measurement

Reverse

Remote control

Foot pedal

Unit dimensions

(w x d x h)

Unit weight

Carton dimensions

(w x d x h)

Carton weight

RSH-1050 RSH-1650

AC 200,220~240V

50/60Hz

3000W 3300W

1050mm / 41" 1650mm / 65"

25 ~ 250mic / 1~10mil

Hot : 2 m/min / 6.6 ft/min

Cold : 1 m/min / 3.3 ft/min

25 min 40 min

Hot roller

DC geared

160°C / 320°F

9

settings

4 Roller

2.25", 3" [Auto grip 2.25", 3" (only us)]

2 Blower 3 Blower

No

Yes

Yes No

Yes

Yes

15(mm) / 0.6"

Motor

Yes

Yes

Yes

Yes

Yes

1400 x 650 x 1210 (mm) 1960 x 650 x 1210 (mm)

55" x 25.5" x 47.5" 77" x 25.5" x 47.5"

166kg / 366lbs 269kg / 593lbs

1560 x 900 x 1460 (mm) 2190 x 900 x 1460 (mm)

61.5" x 35.5" x 57.5" 86" x 35.5" x 57.5"

265kg / 584lbs 394kg / 869lbs

15. MAINTENANCE

16. TROUBLESHOOTING

Cleaning the Body of the laminaor

1. To clean the machine body, dampen a cloth with water only and gently wipe the

machine clean.

Removing Adhesive Build Up

1. Remove the film from the laminator.

2. Use a damp (water only) cloth and a rubber gum eraser to remove the adhesive on the

Teflon (metal) and silicone rollers.

NOTE:

Rub firmly but do not scrub the rollers vigorously as this may scratch the

surface. Do not use sharp metal objects, steel wool, or abrasives, as these may also

damage the rollers.

Symptom Cause Possible Solution

Machine will not turn

on:

a. Power plug is not plugged in.

b. Power switch is in “0” (Off) position.

c. Tripped circuit breaker.

d. Blown main power fuse.

a. Plug the power cord into appropriate

outlet.

b. Put the power switch to the “I” (On)

position.

c. Reset the circuit breaker.

d. Replace the fuse.

There is power, but the

rollers are not turning

after the “RUN” button

is pressed:

a. Emergency switch(es) is (are) engaged.

b. Safety cover is not closed.

c. Paper guide is not installed correctly.

d. Blown motor fuse.

a. Disengage the emergency switch(es).

b. Close the safety cover to active the

safety switch.

c. Properly install the paper guide so that

the micro switch is activated.

d. Replace the motor fuse.

The unit is not heating

up:

a. The machine is in “COLD” mode.

b. Set temperature is lower than the room

temperature.

a. Switch to “HOT” mode.

b. Raise the temperature according to the

recommended film temperature.

Curled lamination:

a. Upward curl.

b. Downward curl.

a. Loosen the top roll film tension.

b. Loosen the bottom roll film tension.

Unclear lamination:

a. The main roller temperatures are too

low and/or lamination speed is too fast.

a. Raise the roller temperatures and/or

lower the lamination speed.

Loading...

Loading...