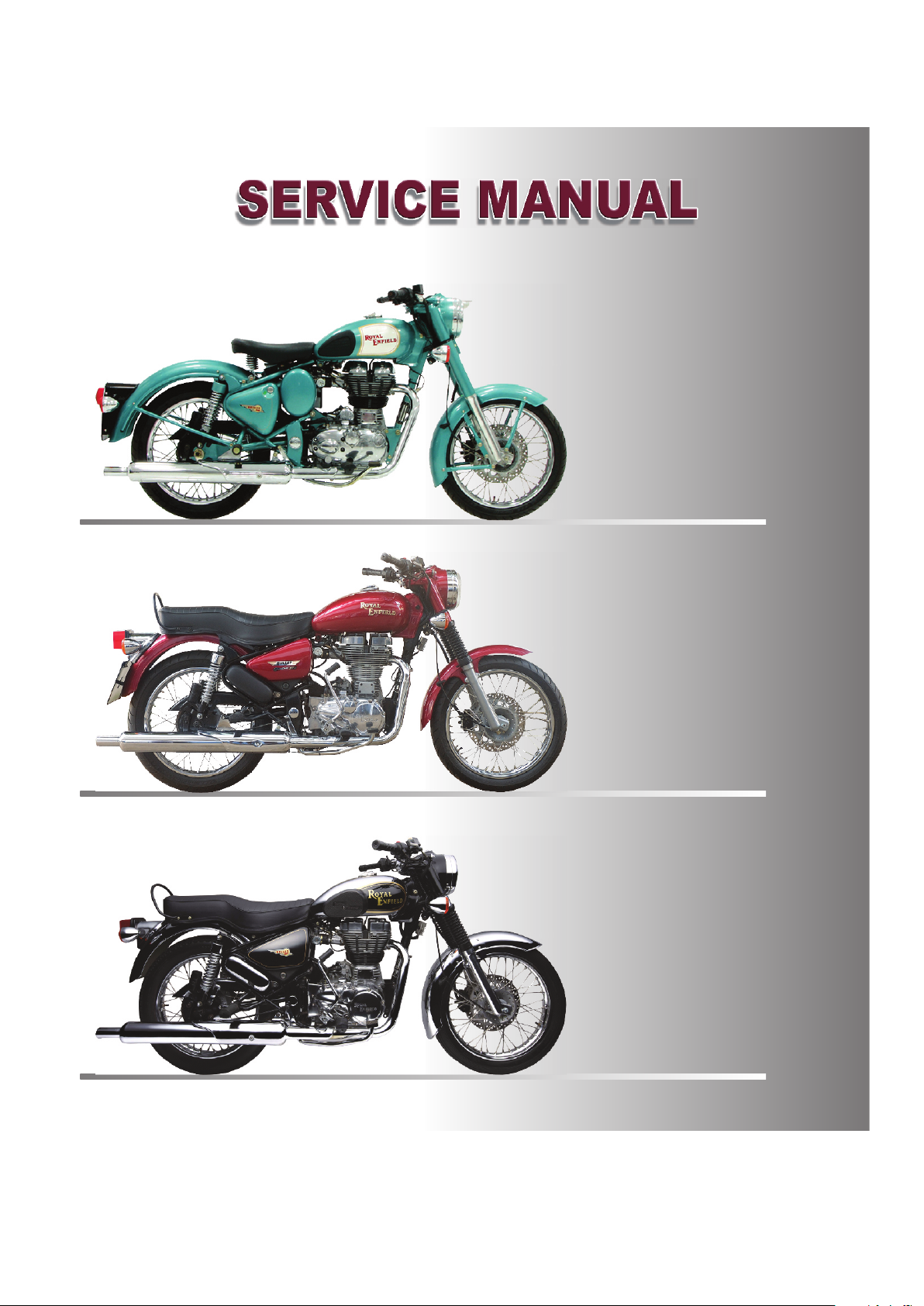

ROYAL ENFIELD Bullet 500 Classic User Manual

Bullet Classic EFI (C5)

Bullet Electra EFI (E5)

Bullet EFI (G5)

INTRODUCTIONINTRODUCTION

INTRODUCTIONINTRODUCTION

INTRODUCTION

SECTIONSECTION

SECTIONSECTION

SECTION

ONE 01ONE 01

ONE 01ONE 01

ONE 01

01-1

PREFPREF

PREFPREF

PREF

AA

AA

A

CECE

CECE

CE

Part No. 597451 / Qty. 500 / May ‘09

We are pleased to release this workshop manual for the new generation of Royal Enfield

Motorcycles fitted with unit construction engine, electronically controlled “Engine Management

System” and fuel injection technology.

We have endeavoured to make this manual user friendly. However, we welcome your valuable

suggestions for improvements which you may write to us or email us at vvikram@royalenfield.com.

Service Head Quarters,

Royal Enfield

Chennai.

“ © Copyright 2009 EICHER MOTORS LIMITED, UNIT ROYAL ENFIELD.

All Rights Reserved. No part of this Service technical manual shall be copied,

distributed or otherwise dealt, without the express permission in written from Eicher

Motors Limited, Unit Royal Enfield, who remains the sole owner of this manual .”

01-2

FOREWFOREW

FOREWFOREW

FOREW

ORDORD

ORDORD

ORD

PREPARATION FOR SERVICE

Good preparation is very important for carrying out correct service job. The motorcycle should be

cleaned well before starting a repair job. Cleaning will occasionally uncover sources of trouble.

Availability of tools, measuring instruments and parts should be ensured before commensing an

overhaul, since Interruption to locate tools or parts can cause distraction and needless delay. Use of

special tools will ensure a quality service.

USE OF GENUINE SPARE PARTS

Use only genuine Royal Enfield spares whenever replacing parts. Use of non genuine parts can

seriously affect motorcycle performance and may result in costly rework, vehicle down time and

above all customer dissatisfaction.

NOTE :

Proper service and repair is important for the safe and reliable operation of all mechanical products.

The service procedures recommended and detailed in this manual will help to carry out correct repairs.

SAFETY

Every care is taken to ensure that the information given in this manual is correct at the time of going to

print. However, Royal Enfield does not assume responsibility for any damage, loss or injury caused to

the vehicle or to the person carrying out repairs, due to errors or omissions in this manual.

IMPORTANT NOTICE

All images shown are only for reference to explain and may not be exactly the same on the motorcycle.

Technical specifications are subject to change without prior notice.

Because of changes that may occur in the manufacturing process, since this manual was printed, it

is possible some instructions or illustrations found within this manual may differ from those found on

the vehicle. However the technical information found within this manual is correct at the time, when it

was approved for printing.

Future modifications, improvements etc will be communicated to our Authorised Distributors / Importers

as and when changes are done to the motorcycle.

01-3

HOHO

HOHO

HO

W W

W W

W

TT

TT

T

O USE O USE

O USE O USE

O USE

YY

YY

Y

OUROUR

OUROUR

OUR

SERSER

SERSER

SER

VICE MANUVICE MANU

VICE MANUVICE MANU

VICE MANU

ALAL

ALAL

AL

Pictorial presentation of various activities, make

this manual easy to understand and user friendly.

This service manual is divided into 10 Sections

01 to 10. Page numbers for each section starts

with 01. Thus, page 05-10 indicates 10th page

of section 5.

The sections are subdivided into subjects and

presented in the following order.

SECTION ONE O1SECTION ONE O1

SECTION ONE O1SECTION ONE O1

SECTION ONE O1

INTRODUCTIONINTRODUCTION

INTRODUCTIONINTRODUCTION

INTRODUCTION

The manual and its arrangements

SECTION TWO 02SECTION TWO 02

SECTION TWO 02SECTION TWO 02

SECTION TWO 02

GENERALGENERAL

GENERALGENERAL

GENERAL

Salient features of the Unit construction engine

& engine management system

Four stroke cycle operation

Basic terminology of automobiles

Technical specifications

Identification of Chassis No., Engine No.,

List of special tools and its applications

Control cables and wiring harness routing.

SECTION THREE 03SECTION THREE 03

SECTION THREE 03SECTION THREE 03

SECTION THREE 03

SERSER

SERSER

SER

VICE DVICE D

VICE DVICE D

VICE D

AA

AA

A

TT

TT

T

AA

AA

A

Service limits of components

Periodical maintenance chart

SECTION FOUR 04SECTION FOUR 04

SECTION FOUR 04SECTION FOUR 04

SECTION FOUR 04

ENGINEENGINE

ENGINEENGINE

ENGINE

Lubrication system

Roller hydraulic Valve lifter (RHVL)

Auto decompressor

Electric starter system & sprag mechanism

Auto Chain Tensioner Assembly

Engine breather System

Clutch System

Inlet manifold & Throttle body

Blow up Charts.

SECTION FIVE 05SECTION FIVE 05

SECTION FIVE 05SECTION FIVE 05

SECTION FIVE 05

ENGINE DISMANTLINGENGINE DISMANTLING

ENGINE DISMANTLINGENGINE DISMANTLING

ENGINE DISMANTLING

INSPECTION & INSPECTION &

INSPECTION & INSPECTION &

INSPECTION &

ASSEMBLASSEMBL

ASSEMBLASSEMBL

ASSEMBL

YY

YY

Y

Torque Specification - Engine

Engine dismantling procedure

Vital parts - Description

Unidirectional fittings list

Engine assembling procedure

SECTION SIX 06SECTION SIX 06

SECTION SIX 06SECTION SIX 06

SECTION SIX 06

ENGINE MANENGINE MAN

ENGINE MANENGINE MAN

ENGINE MAN

AA

AA

A

GEMENTGEMENT

GEMENTGEMENT

GEMENT

SYSY

SYSY

SY

STEMSTEM

STEMSTEM

STEM

Functional Diagram

Components description

Function of components

Identification of a malfunction in EMS

Do’s & Dont’s

Trouble shooting

SECTION SEVEN 07SECTION SEVEN 07

SECTION SEVEN 07SECTION SEVEN 07

SECTION SEVEN 07

WHEELS & BRAKESWHEELS & BRAKES

WHEELS & BRAKESWHEELS & BRAKES

WHEELS & BRAKES

Torque Specification - Chassis

Front wheel removal & reassembly

Disc brake

- General instruction

- Master Cylinder & Caliper overhauling

- Bleeding procedure

- Disc inspection

Rear wheel removal & reassembly

Rear Brake removal & reassembly

01-4

SECTION EIGHT 08SECTION EIGHT 08

SECTION EIGHT 08SECTION EIGHT 08

SECTION EIGHT 08

SUSPENSION ANDSUSPENSION AND

SUSPENSION ANDSUSPENSION AND

SUSPENSION AND

STEERINGSTEERING

STEERINGSTEERING

STEERING

Front fork working principle

Front fork removal & reassembly

Steering stem removal & reassembly

Gas filled shock absorber

- Working principle

- Removal and assembly

- Adjustment of shock absorber

- Recharging of shock absorber

Swing Arm

- Removal

- Bush lubrication / replacement

- Reassembly

Centre Stand Removal & Reassembly

SECTION NINE 9SECTION NINE 9

SECTION NINE 9SECTION NINE 9

SECTION NINE 9

ELECTRICALSELECTRICALS

ELECTRICALSELECTRICALS

ELECTRICALS

Electrical symbols

Battery

- Precautions

- Charging

- Maintenance

Spark plug maintenance & Inspecton

Checking procedure of electrical

components:

- Starter coil

- Pulsar coil

- Ignition coil

- Suppressor Cap

- Battery

- Horn

- Relay starter

- Starter motor

- IC Flasher

- RR Unit

- TPS Unit

Electrical parts Inspection

- Clutch switch

- Starter switch

- Switch modules LH & RH

Do’s and Dont’s

Wiring Diagrams

- Ignition circuit

- Starter and charging

- Complete Wiring diagram

Trouble shooting

SECTION TEN 10SECTION TEN 10

SECTION TEN 10SECTION TEN 10

SECTION TEN 10

TRTR

TRTR

TR

OUBLE SHOOOUBLE SHOO

OUBLE SHOOOUBLE SHOO

OUBLE SHOO

TINGTING

TINGTING

TING

SAFETY DEFINITIONSSAFETY DEFINITIONS

SAFETY DEFINITIONSSAFETY DEFINITIONS

SAFETY DEFINITIONS

Important aspects to be noted are given as

follows in the manual.

NOTE

Provides important information that will have to

be adhered to while carrying out repairs.

CAUTION

Indicates activities that are important to be

noted. Non-adherance may result in breakage

and or functional failures of the assembly.

SPECIAL TOOLS

Contains details of the special tools and its

usage, These tools have been specially designed

for a specific purpose.

GENERALGENERAL

GENERALGENERAL

GENERAL

SECTIONSECTION

SECTIONSECTION

SECTION

TWO 02TWO 02

TWO 02TWO 02

TWO 02

02-1

SALIENT FEASALIENT FEA

SALIENT FEASALIENT FEA

SALIENT FEA

TURES OF TURES OF

TURES OF TURES OF

TURES OF

THE UNIT CONSTRTHE UNIT CONSTR

THE UNIT CONSTRTHE UNIT CONSTR

THE UNIT CONSTR

UCTIONUCTION

UCTIONUCTION

UCTION

ENGINE & ENGINE MANENGINE & ENGINE MAN

ENGINE & ENGINE MANENGINE & ENGINE MAN

ENGINE & ENGINE MAN

AA

AA

A

GEMENT SYGEMENT SY

GEMENT SYGEMENT SY

GEMENT SY

STEMSTEM

STEMSTEM

STEM

• HIGH TORQUE ENGINE

• ENHANCED POWER DELIVERY

• HYDRAULIC TAPPETS

• AUTO DECOMPRESSOR

• AUTO CHAIN TENSIONER FOR

PRIMARY CHAIN

• HIGH CAPACITY TRACHOIDAL OIL

PUMP FOR BETTER LUBRICATION

• IMPROVED ACCELERATION & HIGH

SPEED CRUISING

• EXCELLENT COLD STARTING

ABILITY

• ACCURATELY CONTROLLED, AIR

FUEL MIXTURE & IGNITION TIMING

BY THE ENGINE CONTROL UNIT

• IMPROVED PERFORMANCE AND

FUEL EFFICIENCY THRO FUEL

INJECTION SYSTEM.

FOUR STRFOUR STR

FOUR STRFOUR STR

FOUR STR

OKE CYOKE CY

OKE CYOKE CY

OKE CY

CLE OPERACLE OPERA

CLE OPERACLE OPERA

CLE OPERA

TIONTION

TIONTION

TION

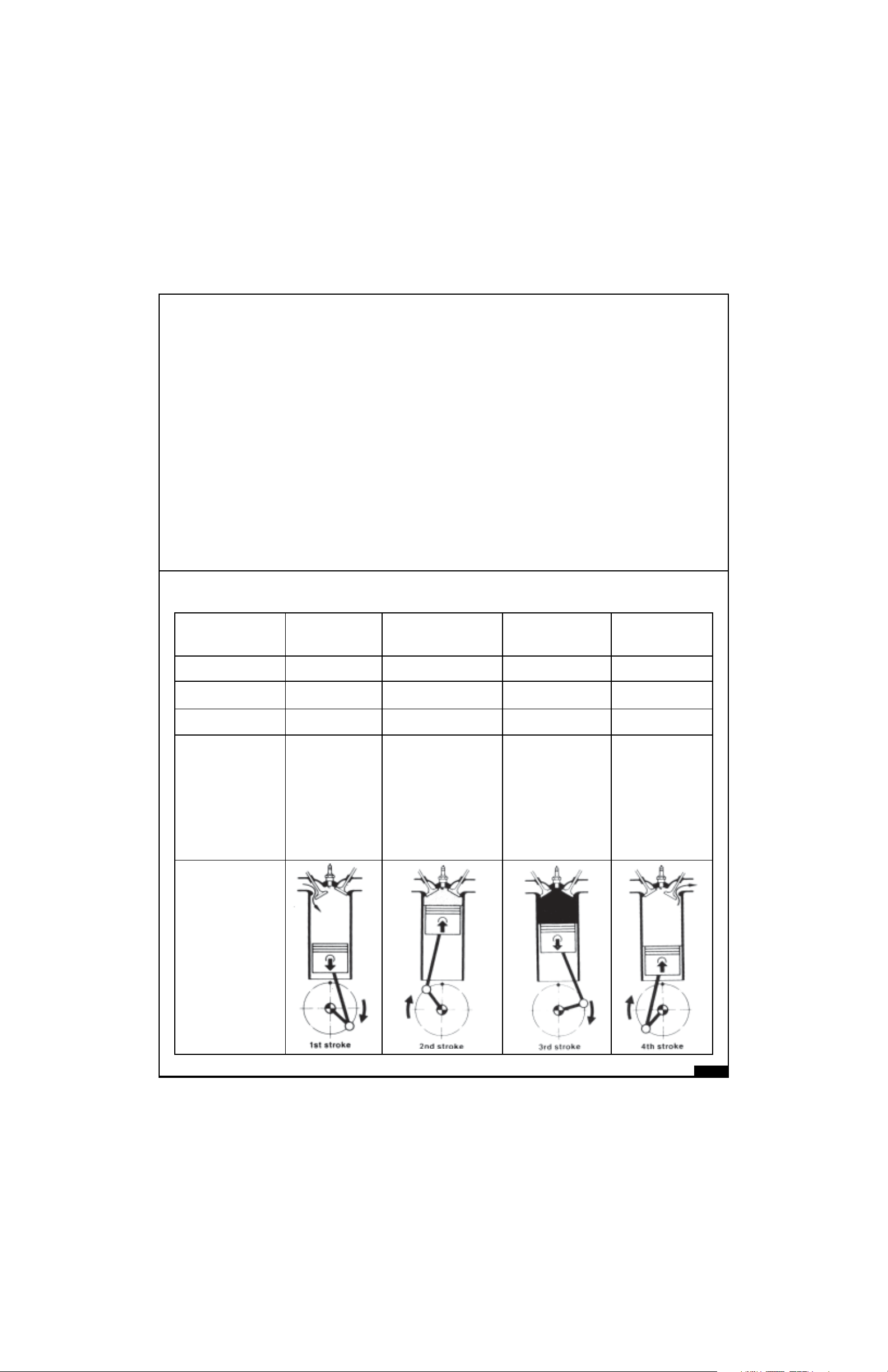

SUCTION COMPRESSION POWER EXHAUST

STROKE

STROKE STROKE STROKE

Inlet Valve Open Closed Closed Closed

Exhaust Valve Closed Closed Closed Open

Piston Movement TDC to BDC BDC to TDC TDC to BDC BDC to TDC

Gas Flow Air Petrol Air Petrol Air petrol mixture Exhaust gas

mixture is mixture gets burns, gas

expands. flows out.

drawn into compressed. Piston is

cylinder Few degrees before pushed down.

BTDC, spark plug

produces spark.

02-2

BASIC BASIC

BASIC BASIC

BASIC

TERMINOLTERMINOL

TERMINOLTERMINOL

TERMINOL

OGY OF OGY OF

OGY OF OGY OF

OGY OF

AUTAUT

AUTAUT

AUT

OMOBILESOMOBILES

OMOBILESOMOBILES

OMOBILES

Fuel

Air

Power

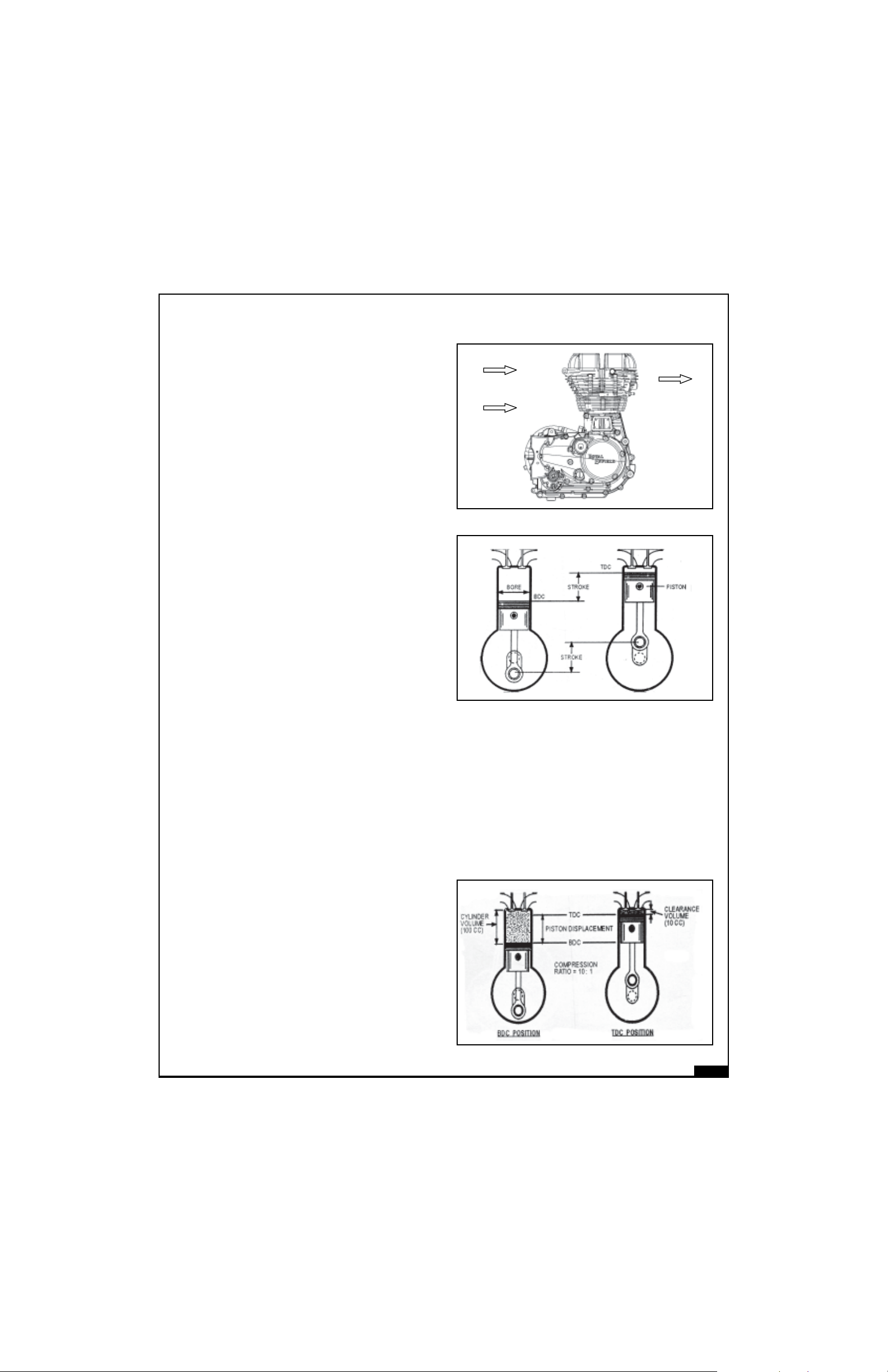

CUBIC CAPACITY / DISPLACEMENT :

It is a volume generated by piston when it travels from TDC to BDC. It is measured as Cubic Centimeter

(CC). It can be mathematically arrived at with the radious of the piston and the stroke of the engine.

(πr²× l, when ‘r’ is the radius of the piston and ‘l’ is the length of the stroke). It is also known as Swept

Volume or Displacement volume.

CLEARANCE VOLUME :

It is the nominal volume of the space above the

piston in the combustion chamber when piston

is at the topmost position (TDC).

ENGINE :

The Engine helps to convert Chemical energy

availbale in petrol into heat energy then to

mechanical energy for motion. It is the heart of

the vehicle in which power is generated for

moving the vehicle.

BORE :

Bore is the inside diameter of the cyclinder block

in which Piston moves up and down.

TDC :

TDC stands for Top Dead Center. It is the top

most position to which the piston can travel in

the cylinder barrel.

BDC :

BDC stands for Bottom Dead Center. It is the

bottom most position to which the piston can

travel in the cylinder barrel.

STROKE :

It is a distance travelled by piston from TDC to

BDC or Vice Versa.

02-3

TOTAL VOLUME :

It is the sum of the swept voume (Displacement volume) and Clearance volume.

Total Volume = Swept volume + Clerance volume.

COMPRESSION RATIO :

It is a ratio between total volume in the engine to the clearance volume available at the end of

compression stroke.

Total volume of air fuel mixture

Clearance volume

VOLUMETRIC EFFICIENCY :

Volumetric efficiency is the ratio between the volume of air fuel mixture that actually enters the cylinder

and Swept volume.

Volumetric Efficiency

= Volume of air fuel mixture inhaled during suction stroke

Swept volume

HORSE POWER (HP OR PS) :

HP : Horse Power

PS : PFERDESTARKE is German unit of power. Horse Power is the ability of the engine to do a

certain amount of work in a given time.

One Horse power is the power required for lifting a weight of 75 Kg. through vertical distance of one

meter in one second.

Conversion :

1PS = 0.986 HP = 0.735 KW

1 HP = 1.014 PS = 0.744 KW

1KW = 1.360 PS = 1.340 HP

Compression ratio =

02-4

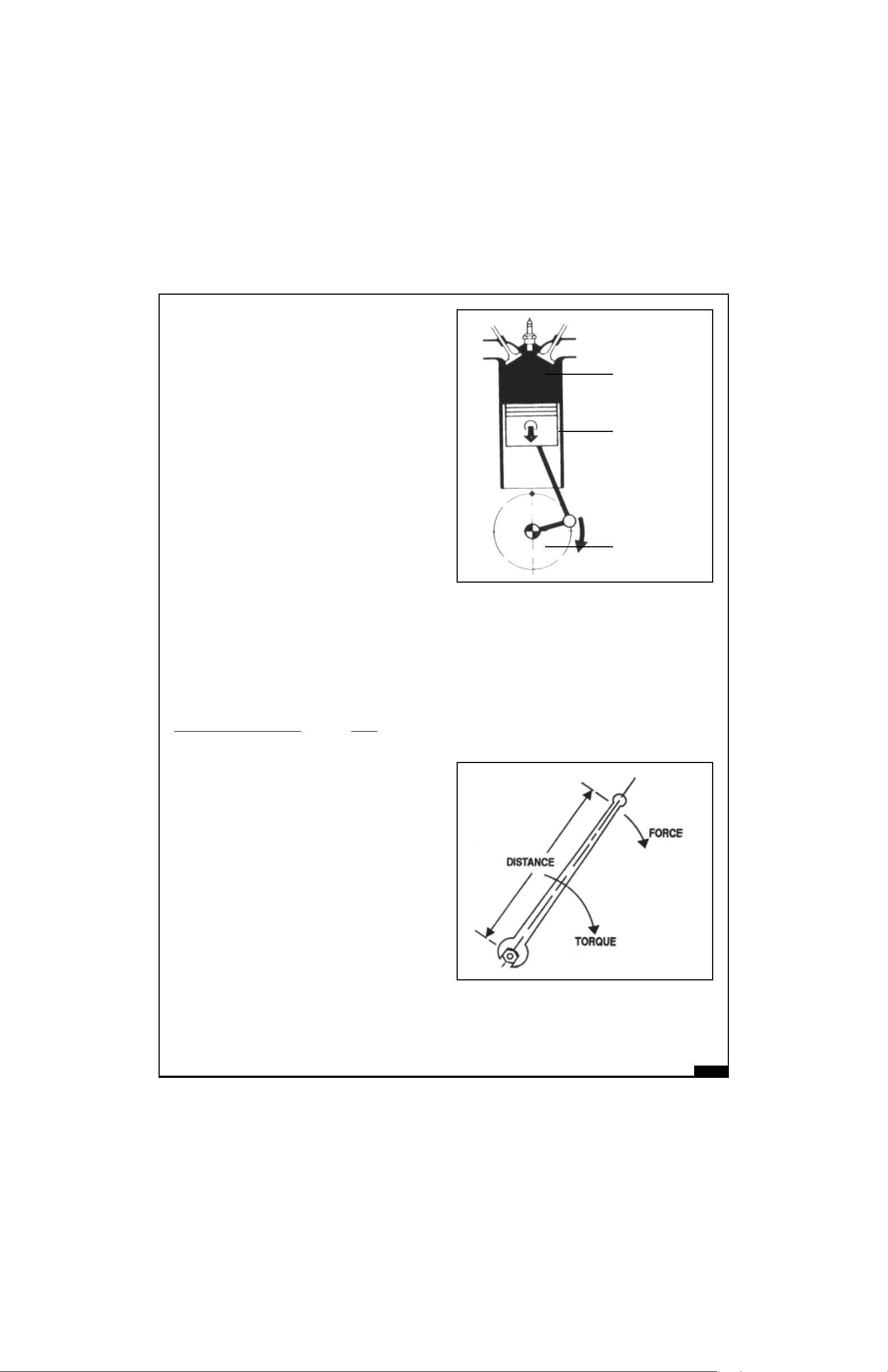

IHP :

IHP stands for Indicated Horse Power. Indicated

Horse Power is the power actually developed

inside the engine cylinder by combustion process.

It is utilised to drive the piston.

FHP :

FHP stands for Frictionl Horse Power.

It is the amount of horse power used or lost to

overcome the friction between various engine

components.

BHP :

BHP stands for Brake Horse Power

Brake Horse Power is the amount of Power actually available at the crankshaft or output shaft. It

is calculated by using dynamometer.

BHP = IHP - FHP

MECHANICAL EFFICIENCY :

Mechanical Efficiency is the ratio between Brake horsepower and Indicated horse power.

Brake horsepower = BHP

Indicated Horse power IHP

TORQUE :

Torque is a twisting or turning force or effort. It is the

product of a distance and force in circular motion.

In the picture shown the torque-applied is the product

of distance (distance between the center of the bolt

and point where force is acting) and the amount of

force applied.

With the same force, if the distance is increased,

the torque will also increase and if distance is

reduced, torque applied will also be reduced.

CONVERSION :

1kg-m = 7.23 lb.ft = 9.81 N-m.

1lb.ft = 0.138 Kg-m = 1.356 N-m.

1 N-m = 0.102 Kg-m = 0.737 lb.ft

1HP (Horse

Power Available

after explosion)

FHP (Frictional

Losses)

BHP (Horse

Power Avaiable at

Crankshaft)

02-5

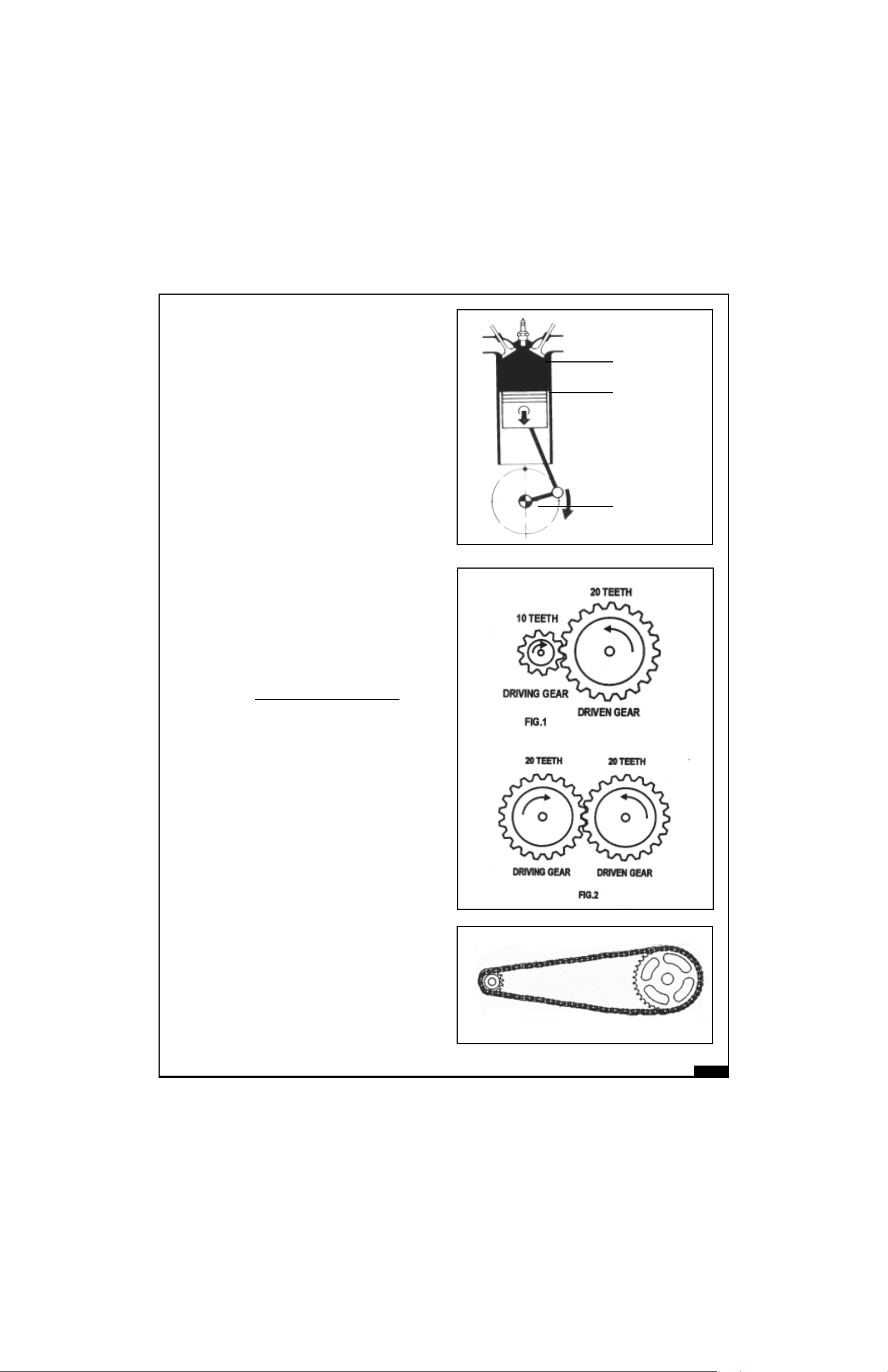

IGNITION TIMING :

Ignition timing is the timing at which spark

commences so that the spark from the spark

plug can ignite the mixture in the combusion

chamber at the end of TDC during compression

stroke.

If spark occurs earlier than specified ignition

timing, it is called “Advance” timing.

If spark occurs after the specified ignition timing,

it is called “Retard” timing.

IDLING SPEED :

It is the speed of the crankshaft (i.e. RPM) of the

engine when the throttle is in closed pisition.

GEAR RATIO :

The relative rotation between “Driven Gear” and

“Driving Gear” is known as the “Gear Ratio”. It is

determined by number of teeth on the respective

gears.

Gear Ratio =

No. of teeth of Driven Gear

No. of teeth of Driving Gear

In Fig. 1, the Gear ratio is 20 ÷ 10 = 2 : 1

In Fig. 2, the Gear ratio is 20 ÷ 20 = 1 : 1

Gear ratios multiply the engine torque to fulfil

various demands for pulling the vehicle like.

- More effort is required during initial

movement of the vehicle.

- More effort is required to climb an elevation.

- More effort is required while driving in

muddy or sandy surfaces.

FINAL DRIVE RATIO :

It is a relative rotation between the engine

sprocket and the sprocket on the rear wheel.

Both the sprockets are connected through drive

chain.

Final drive ratio further multiplies the torque

available at the output shaft.

TDC Position

Ignition Timing

Position

Ignition Timing in

Degrees

02-6

TECHNICAL SPECIFICATECHNICAL SPECIFICA

TECHNICAL SPECIFICATECHNICAL SPECIFICA

TECHNICAL SPECIFICA

TIONSTIONS

TIONSTIONS

TIONS

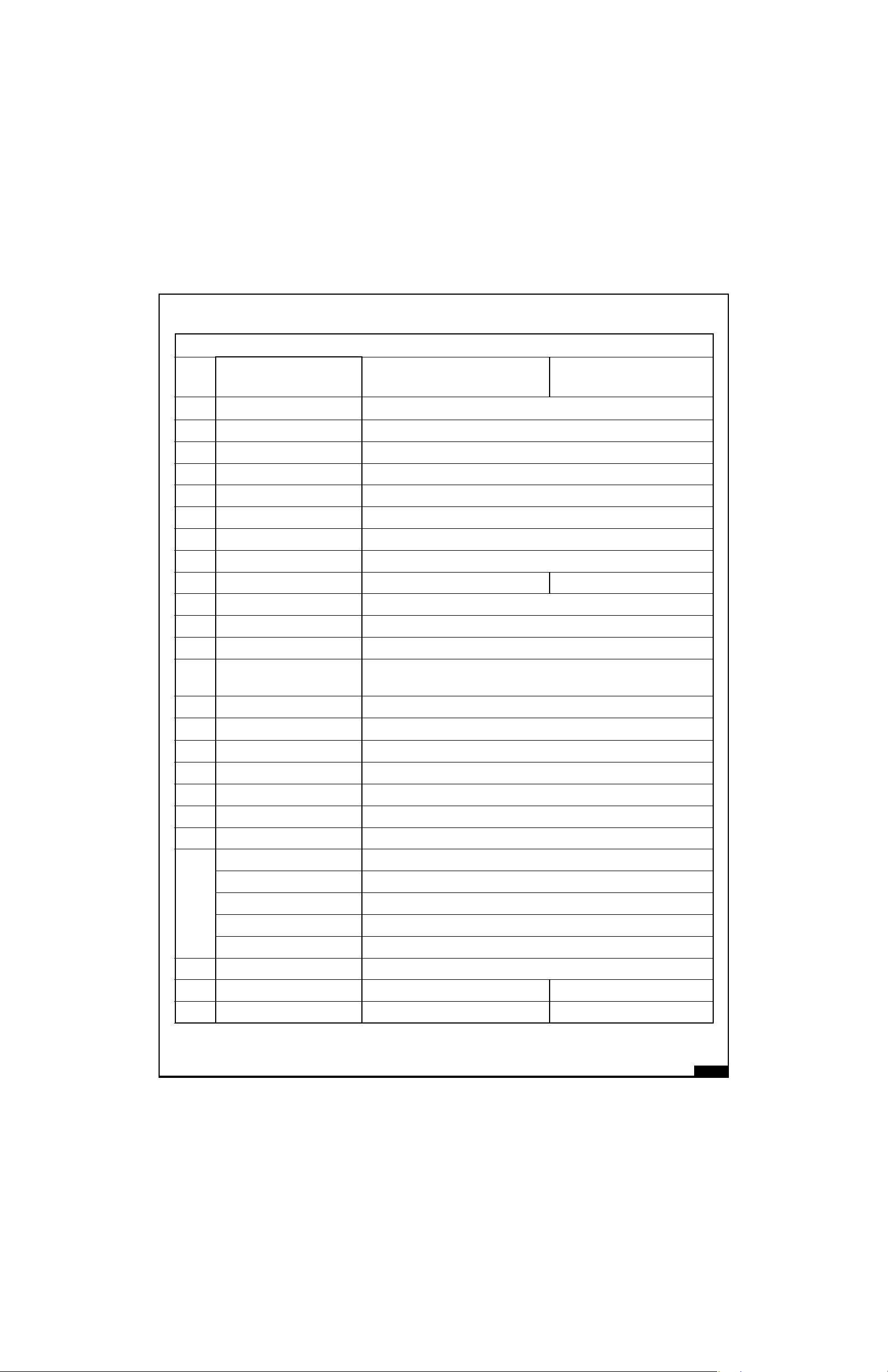

A. ENGINE AND ENGINE SYSTEMS

BULLET ELECTRA EFI (E5) BULLET CLASSIC EFI

BULLET EFI (G5) (C5)

1. Engine Type 4 Stroke Single Cylinder, Air cooled

2. Bore 84mm

3. Stroke 90mm

4. Displacement 499cc

5. Compression ratio 8.5:1

6. Max Power @ rpm 20.3 Kw @ 5250 rpm

7. Max Torque @ rpm 41.3 Nm @ 4500 rpm

8. Idle rpm 1050 ± 200 rpm

9. Starting Kick & Electric Start Electric Start

10. Air filter element Paper element

11. Lubrication Forced Lubrication, Wet Sump

12. Engine oil tank capacity 2.75 litres

13. Engine oil grade

JASO MA -15W-50, API SL Grade,

ESTER-Semi Synthetic Oil

14. Cooling Natural air flow

B. TRANSMISSION

1. Clutch Wet multiplate

2. Primary drive 3/8” Duplex chain & sprocket

3. Primary ratio 2.15 : 1

4. Gear box 5 Speed Constant Mesh

5. Overall Ratio

1

st

3.063 : 1

2

nd

2.013 : 1

3

rd

1.522 : 1

4

th

1.212 : 1

5

th

1 : 1

6. Secondary drive 5/8” Chain & Sprocket

7. Secondary ratio 2.235 : 1 2.11:1

8. Drive Chain links 101 Pitch 102 Pitch

02-7

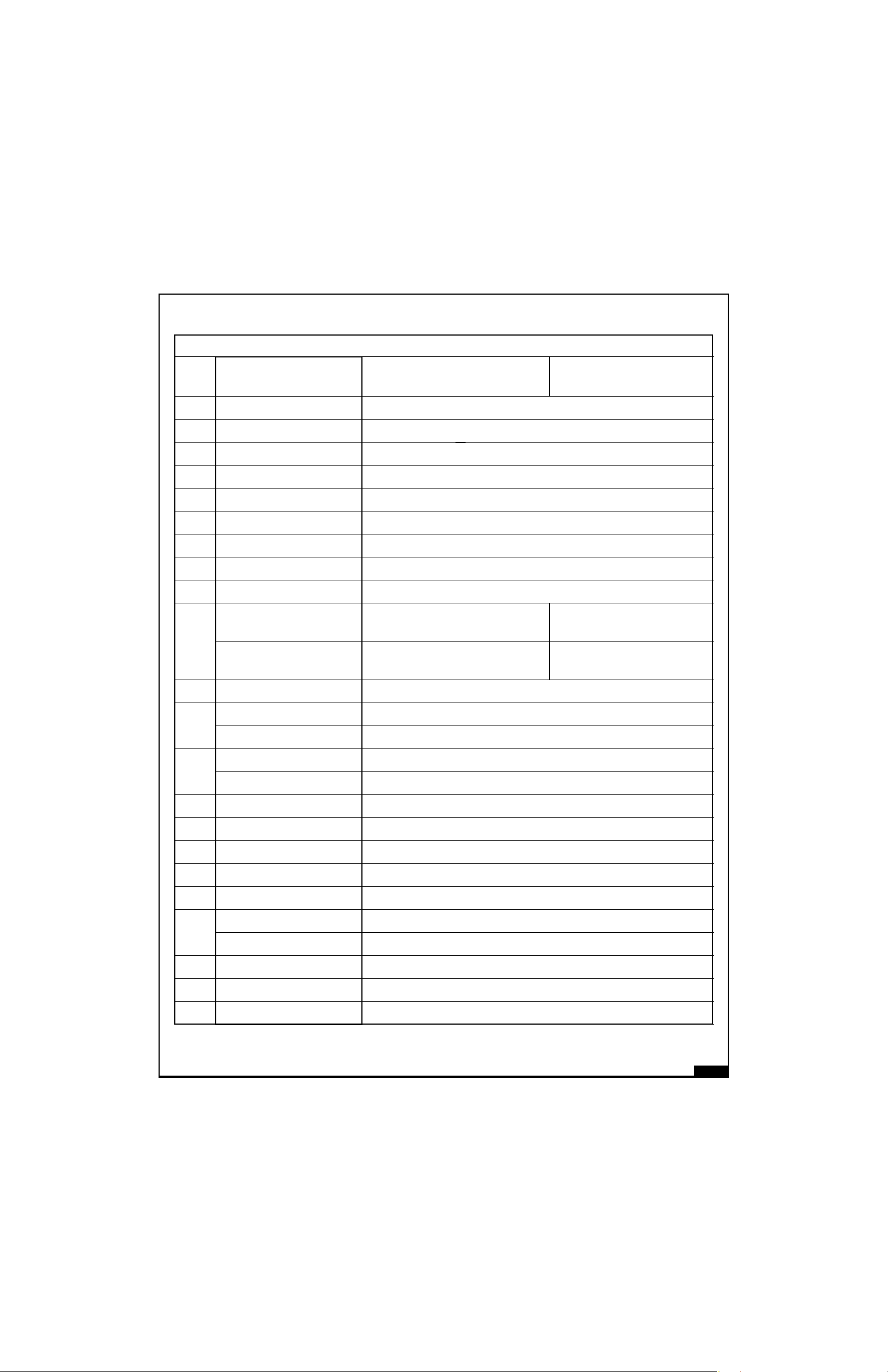

C. CHASSIS

BULLET ELECTRA EFI (E5) BULLET CLASSIC EFI

BULLET EFI (G5) (C5)

1. Frame Tubular

2. Front Suspension Telescopic, hydraulic damping, Stroke 130 mm

3. Rear Suspension Swing arm with gas shock absorbers

4. Fr. Fork oil capacity 265 cc + 2.5 cc / each leg

5. Front fork oil SAE 10W -30

6. Front Brake Hydraulic, Hand operated, 280 mm dia ventilated disc

7. Rear Brake Mechanical, Foot operated, 153 mm internal expanding

8. Brake Oil Capacity 60 ml

9. Brake Oil Grade DOT 3 or DOT 4

10. Tyre size : Front 90X90 - 19” - 51V 90X90 - 18” 51V

3.25X19

Rear 100/90 - 19” - 57V 110/80-18” - 58V

3.5X90

D. TYRE PRESSURE

1. Solo : Front 18 PSI

Rear 28 PSI

2. With Pillion : Front 20 PSI

Rear 30 PSI

3. Steering lock In built

4. Fuel tank capacity 14.5 ±1 litres

5. Reserve 2.75 litres

E. ELECTRICALS

1. Generation Alternator

2. System 12V - DC

3. Battery 12V - 14 AH

4. Spark plug Mico - WR7 DDC 4

5. Spark plug gap 0.7 to 0.8 mm

6. Head lamp 12V, 60/55w

02-8

BULLET ELECTRA EFI (E5) BULLET CLASSIC EFI

BULLET EFI (G5) (C5)

7. Tail / Brake Lamp 12V 5 / 21W

8. Speedometer lamp 12V, 3.4W

9. Hi beam indicator 12V, 2W

10. Neutral lamp Tell tale 12V, 2W

11. Turn Signal Tell Tale 12V, 2W

12. Turn signal 12V, 10W

13. Horn 12V DC

F. WEIGHTS

1. Mass of Vehicle in running order 187 Kg.

2. Max pay load 178 Kgs.

3. Max technical permissible mass 365 Kg.

G. DIMENSIONS

1. Length 2200 mm 2160 mm

2. Width 800 mm

3. Height 1100 mm 1050 mm

4. Wheel base 1370 mm

5. Ground clearance 140 mm

6. Saddle height 820 mm 800 mm

H. PERFORMANCE

1. Max. speed 132 Kmph (83 Miles)

NOTE :

1. Values given above are for your guidelines only

2. In view of continuous improvements, specifications are likely to change without

notice

02-9

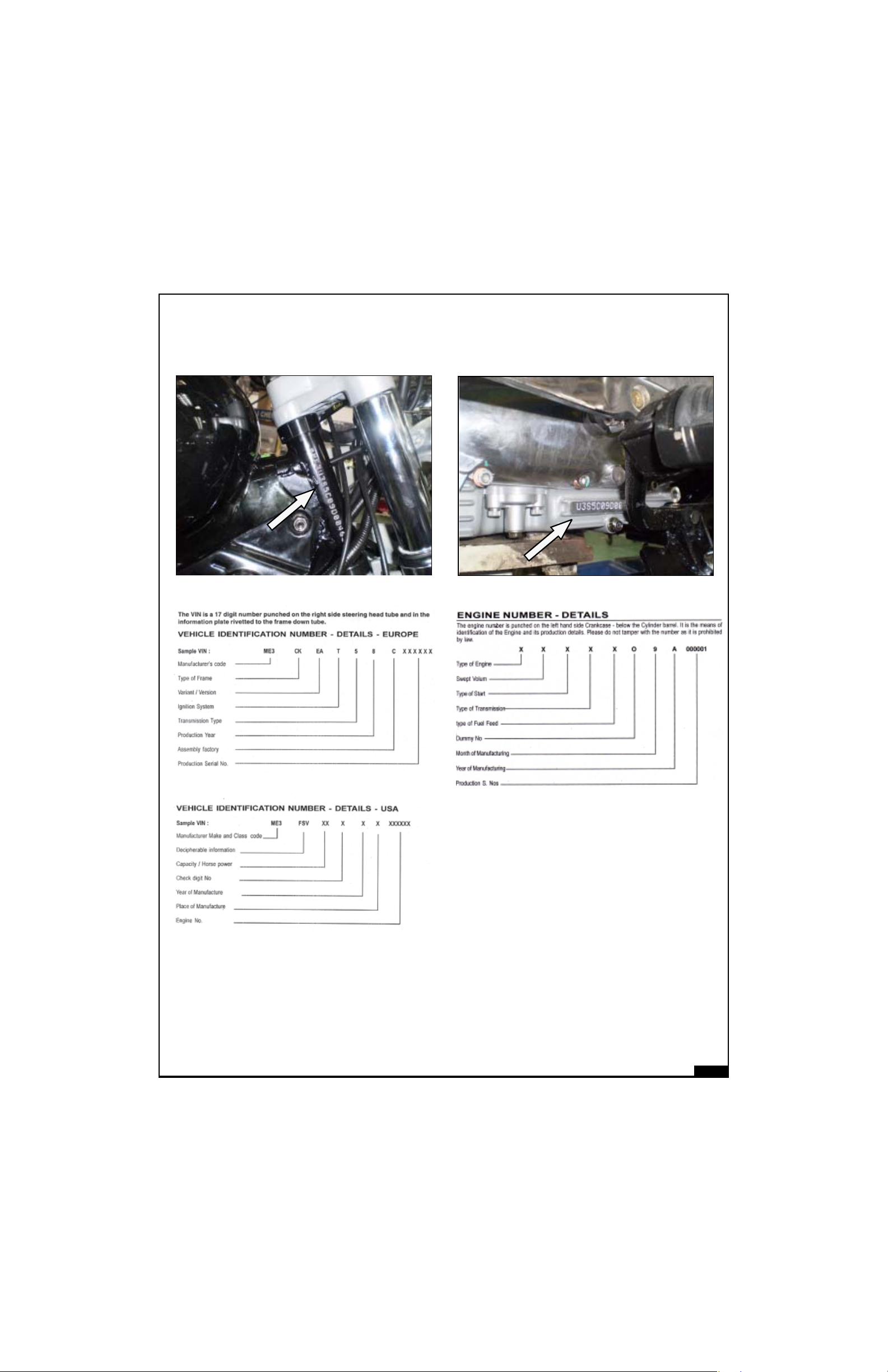

IDENTIFICAIDENTIFICA

IDENTIFICAIDENTIFICA

IDENTIFICA

TION OF CHASSIS NOTION OF CHASSIS NO

TION OF CHASSIS NOTION OF CHASSIS NO

TION OF CHASSIS NO

.,.,

.,.,

.,

ENGINE NO ENGINE NO

ENGINE NO ENGINE NO

ENGINE NO

,,

,,

,

ENGINENO.

CHASSIS NO.

02-10

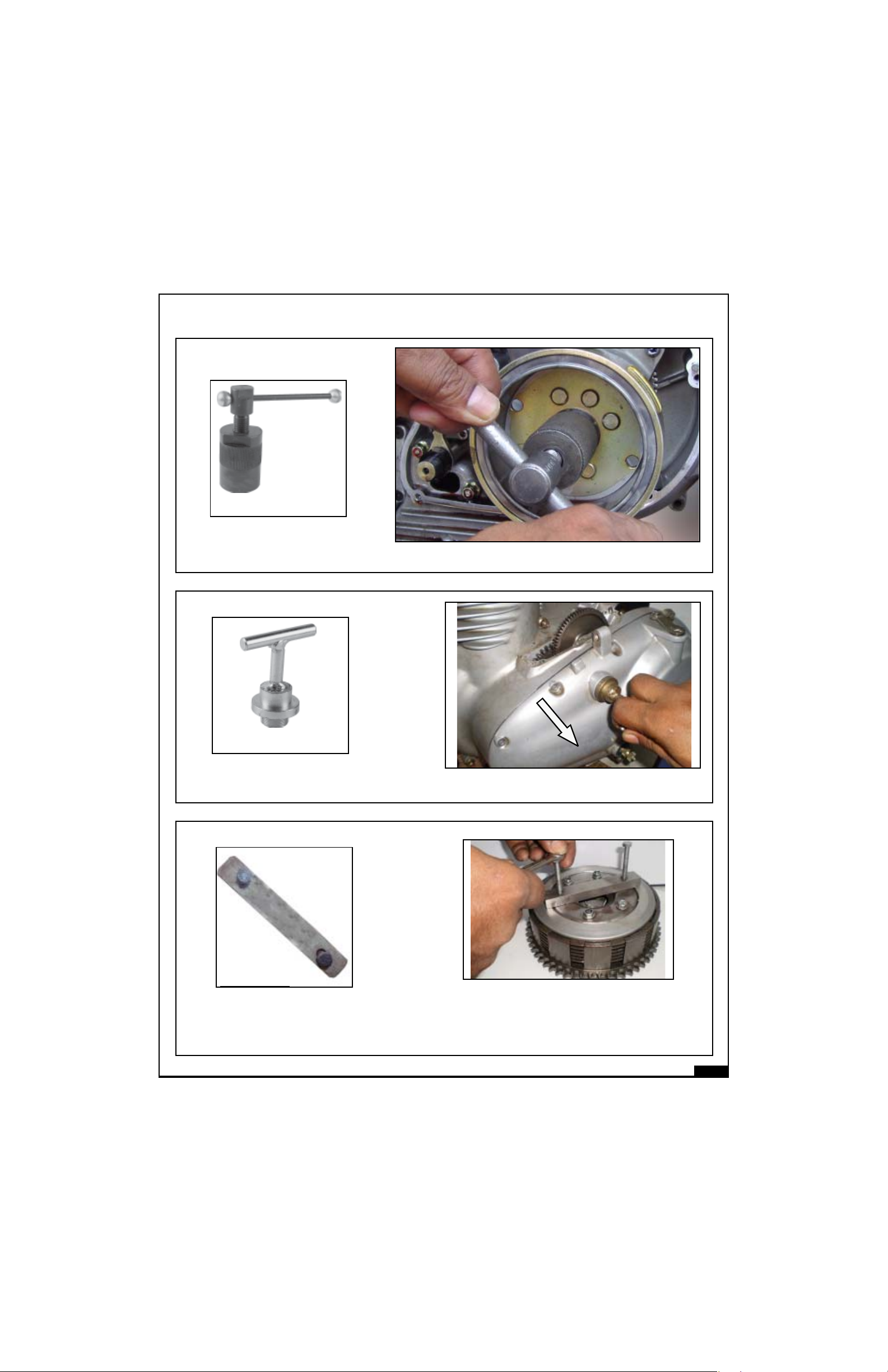

ST 25128-2

Magneto Puller for TCI

Chain case outer puller (TCI)

Application : Removal of magneto assembly

Application : To compress clutch springs while

removing & refitting Clutch plates.

ST-25594-4

Clutch spring assy.

Application :To remove Crank case LH cover

LIST OF SPECIAL LIST OF SPECIAL

LIST OF SPECIAL LIST OF SPECIAL

LIST OF SPECIAL

TT

TT

T

OOLS OOLS

OOLS OOLS

OOLS

AND ITS AND ITS

AND ITS AND ITS

AND ITS

APPLICAAPPLICA

APPLICAAPPLICA

APPLICA

TIONTION

TIONTION

TION

ST 25151-4

02-11

LIST OF SPECIAL LIST OF SPECIAL

LIST OF SPECIAL LIST OF SPECIAL

LIST OF SPECIAL

TT

TT

T

OOLS OOLS

OOLS OOLS

OOLS

AND ITS AND ITS

AND ITS AND ITS

AND ITS

APPLICAAPPLICA

APPLICAAPPLICA

APPLICA

TIONTION

TIONTION

TION

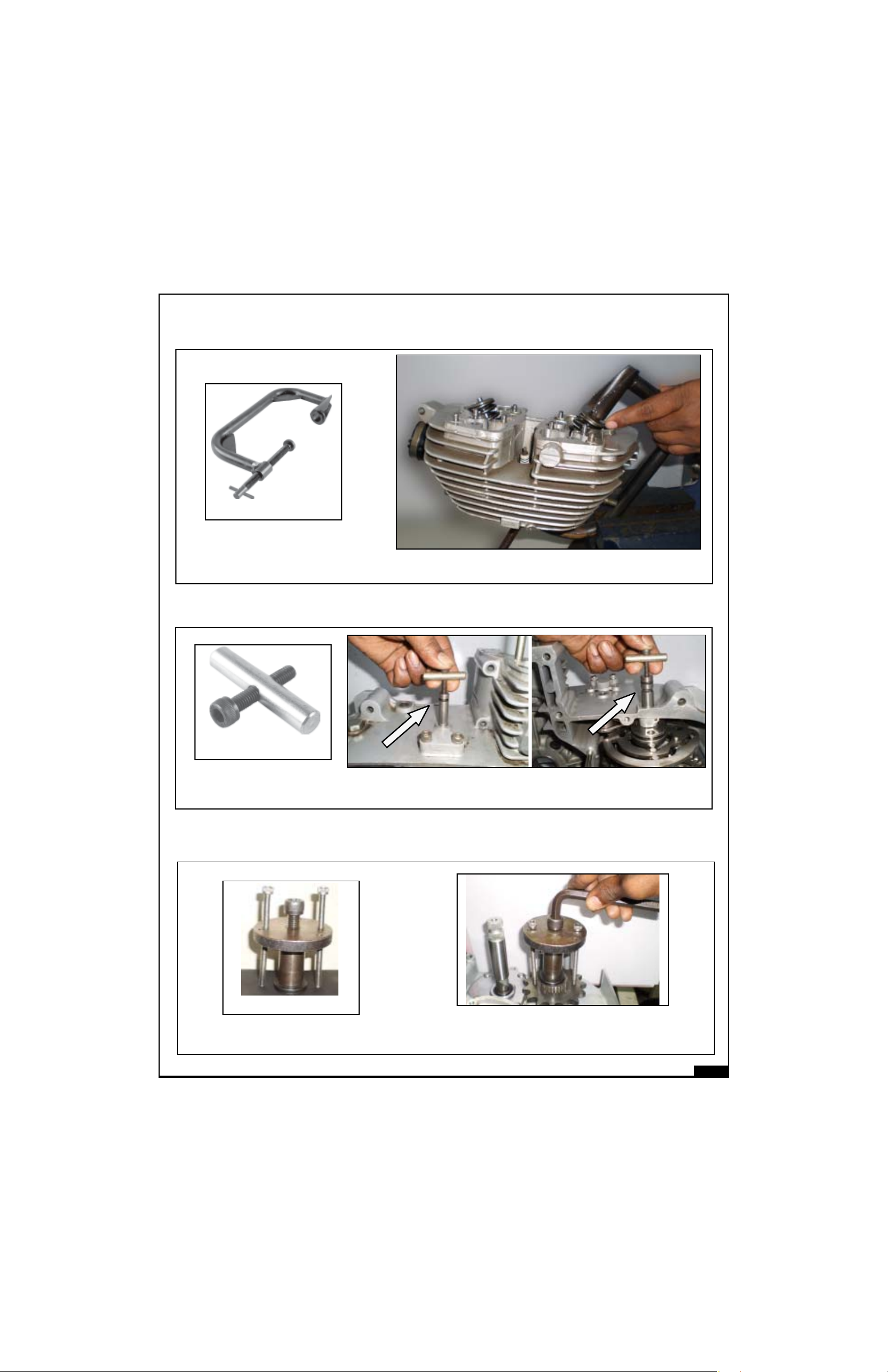

Application : Fitment of gear shaft oil seal on crank case

LH cover.

Application : To remove and tightening of cylinder

head nut.

Oil seal adopter

ST 25118-4

Cylinder head nut tightening tool

Application : To hold Clutch Sprocket while removing / tightening

the Clutch & Sprag Sprocket Nut.

Clutch centre nut

ST-25591-4

02-12

LIST OF SPECIAL LIST OF SPECIAL

LIST OF SPECIAL LIST OF SPECIAL

LIST OF SPECIAL

TT

TT

T

OOLS OOLS

OOLS OOLS

OOLS

AND ITS AND ITS

AND ITS AND ITS

AND ITS

APPLICAAPPLICA

APPLICAAPPLICA

APPLICA

TIONTION

TIONTION

TION

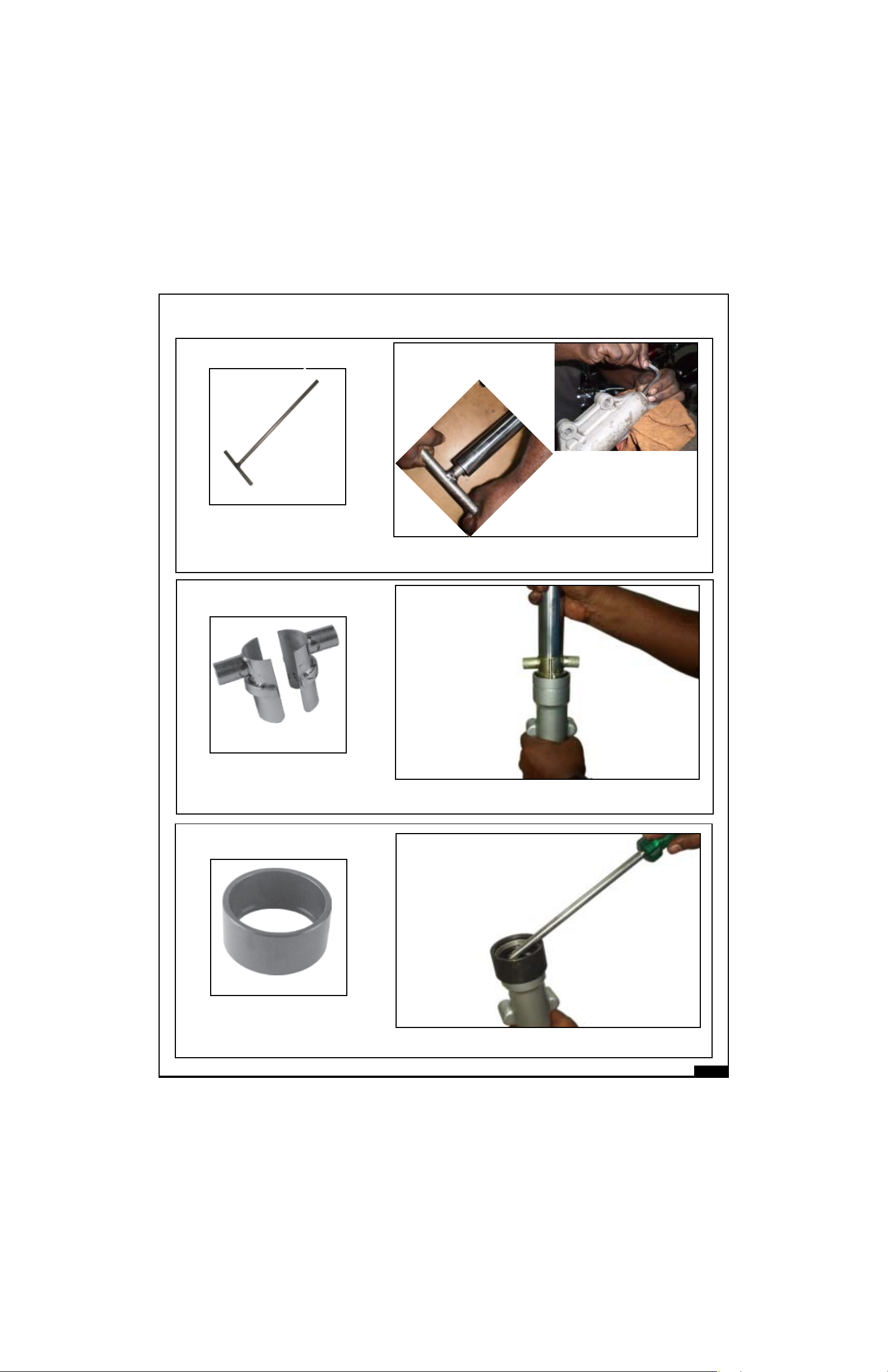

ST 25123-1

Valve Spring compressor

Application : To compress the valve spring for removal

and fitting of valve.

Application : To remove front drive sprocket

from Sleeve Gear.

FD sprocket removal tool

ST 25

ST 25153-4

Extractor for 5 Speed

Gear box Pivot Pin

Application : To remove Gear Rocker Shaft top pivot pin and Gear

Cam Plate pivot pin.

02-13

ST

Front fork main tube spanner

Application : Loosening and tightening of front fork main

tube with fork end

LIST OF SPECIAL LIST OF SPECIAL

LIST OF SPECIAL LIST OF SPECIAL

LIST OF SPECIAL

TT

TT

T

OOLS OOLS

OOLS OOLS

OOLS

AND ITS AND ITS

AND ITS AND ITS

AND ITS

APPLICAAPPLICA

APPLICAAPPLICA

APPLICA

TIONTION

TIONTION

TION

ST 25114-4

Extractor for Fork oil seal

Application : Removal of oil seal in front fork bottom tube

ST 25112-4

Expander for front fork oil seal

Application : Expander for oil seal while inserting main

tube into bottom tube of front fork

02-14

ST 25113-4

Mandrel for oil seal

Application : Fitment of oil seal in front fork bottom tube

LIST OF SPECIAL LIST OF SPECIAL

LIST OF SPECIAL LIST OF SPECIAL

LIST OF SPECIAL

TT

TT

T

OOLS OOLS

OOLS OOLS

OOLS

AND ITS AND ITS

AND ITS AND ITS

AND ITS

APPLICAAPPLICA

APPLICAAPPLICA

APPLICA

TIONTION

TIONTION

TION

ST 25244-4

Application :To adjust gas filled shock absorber

Adjuster Special Spanner

ST 25110-3

Gauge for tightening chain stay

Application : Alignment of Swing Arm while tightening

02-15

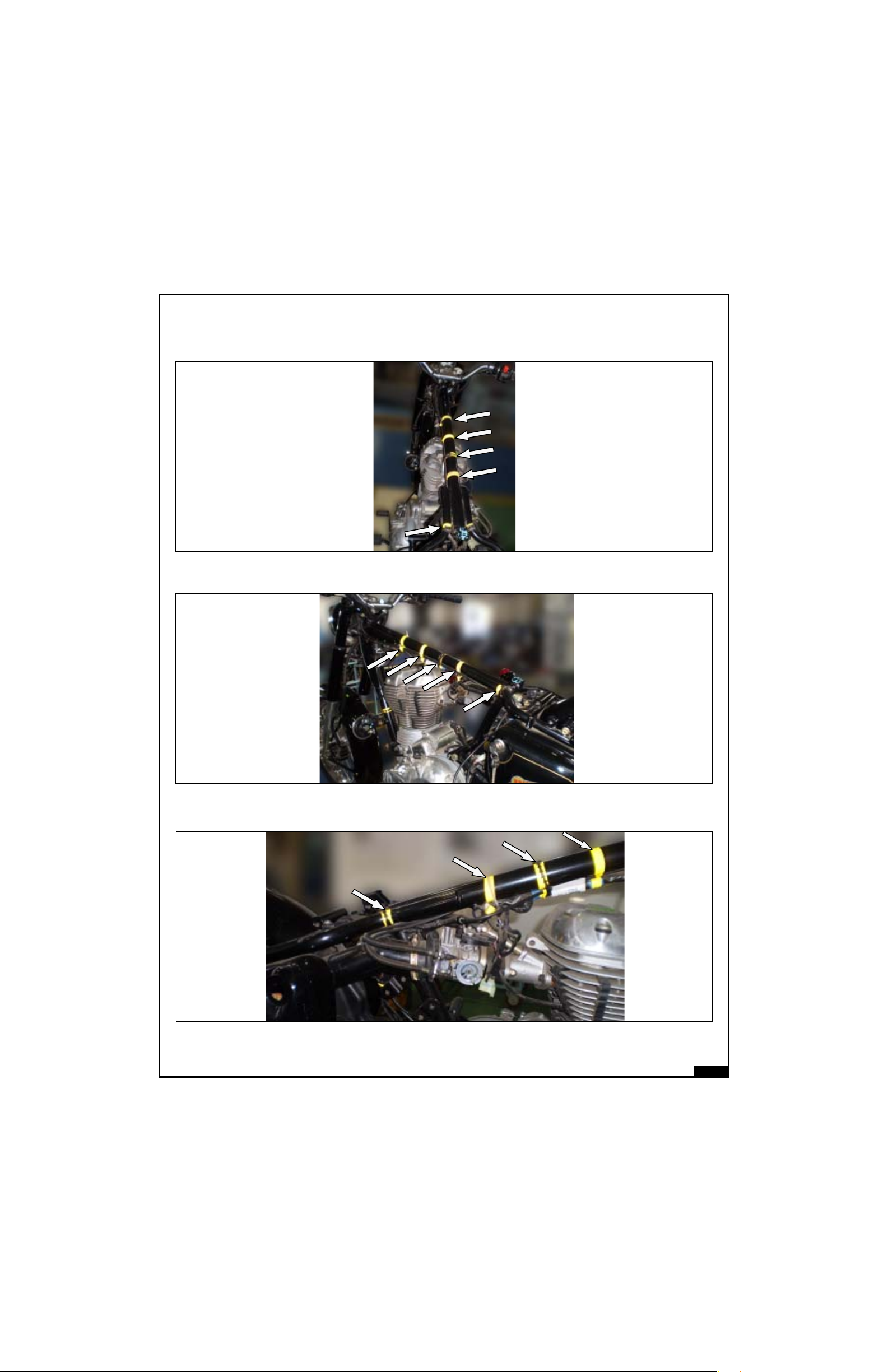

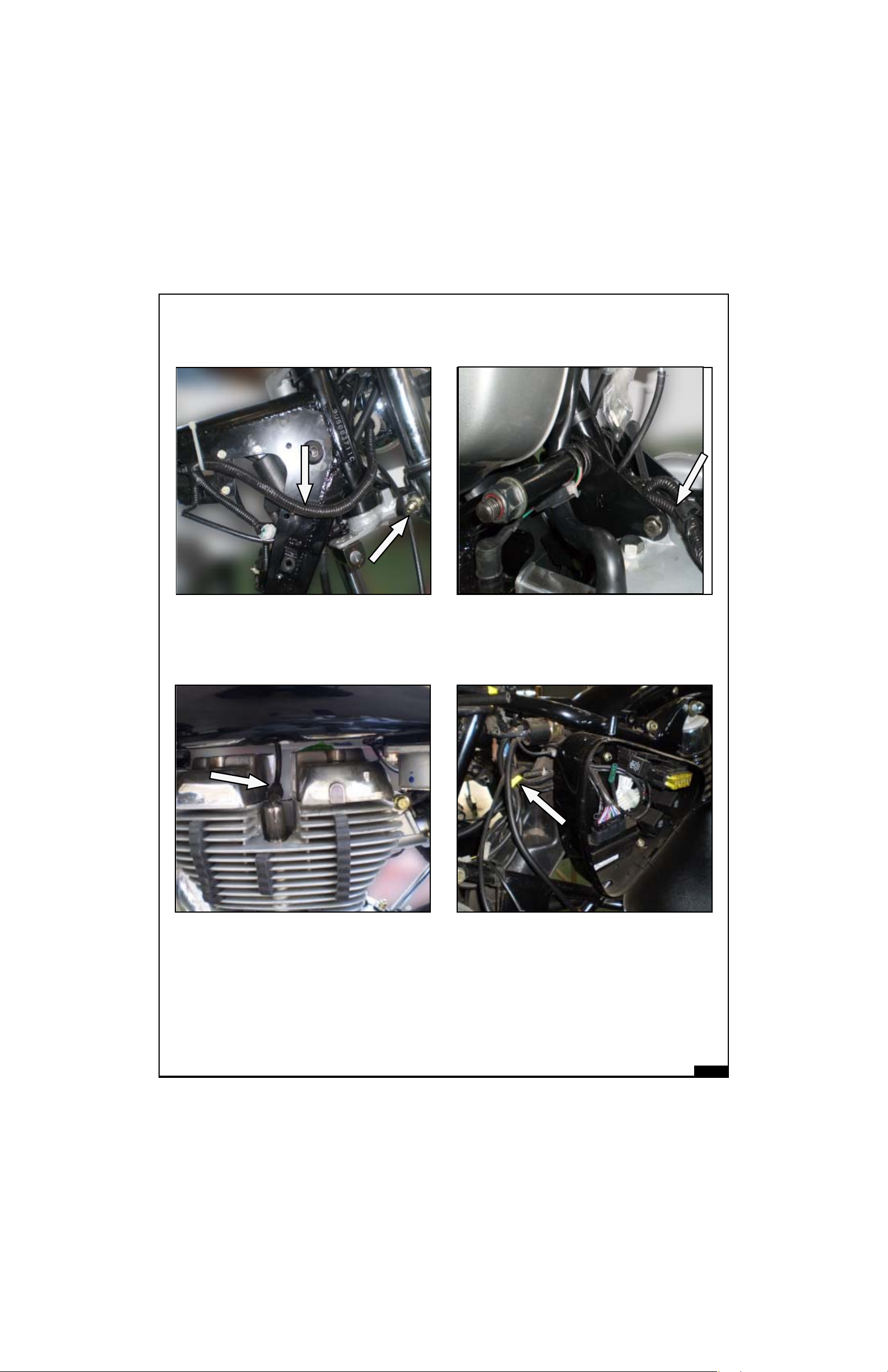

UNDER TANK AND SEAT TOP VIEW

UNDER TANK LH VIEW

UNDER TANK RH VIEW

ALL CONTROL CABLES & WIRING HARNESS ROUTING

CONTROL CABLES AND WIRING HARNESS ROUTINGCONTROL CABLES AND WIRING HARNESS ROUTING

CONTROL CABLES AND WIRING HARNESS ROUTINGCONTROL CABLES AND WIRING HARNESS ROUTING

CONTROL CABLES AND WIRING HARNESS ROUTING

02-16

GENERAL GENERAL

GENERAL GENERAL

GENERAL

VEHICLE INFORMAVEHICLE INFORMA

VEHICLE INFORMAVEHICLE INFORMA

VEHICLE INFORMA

TIONTION

TIONTION

TION

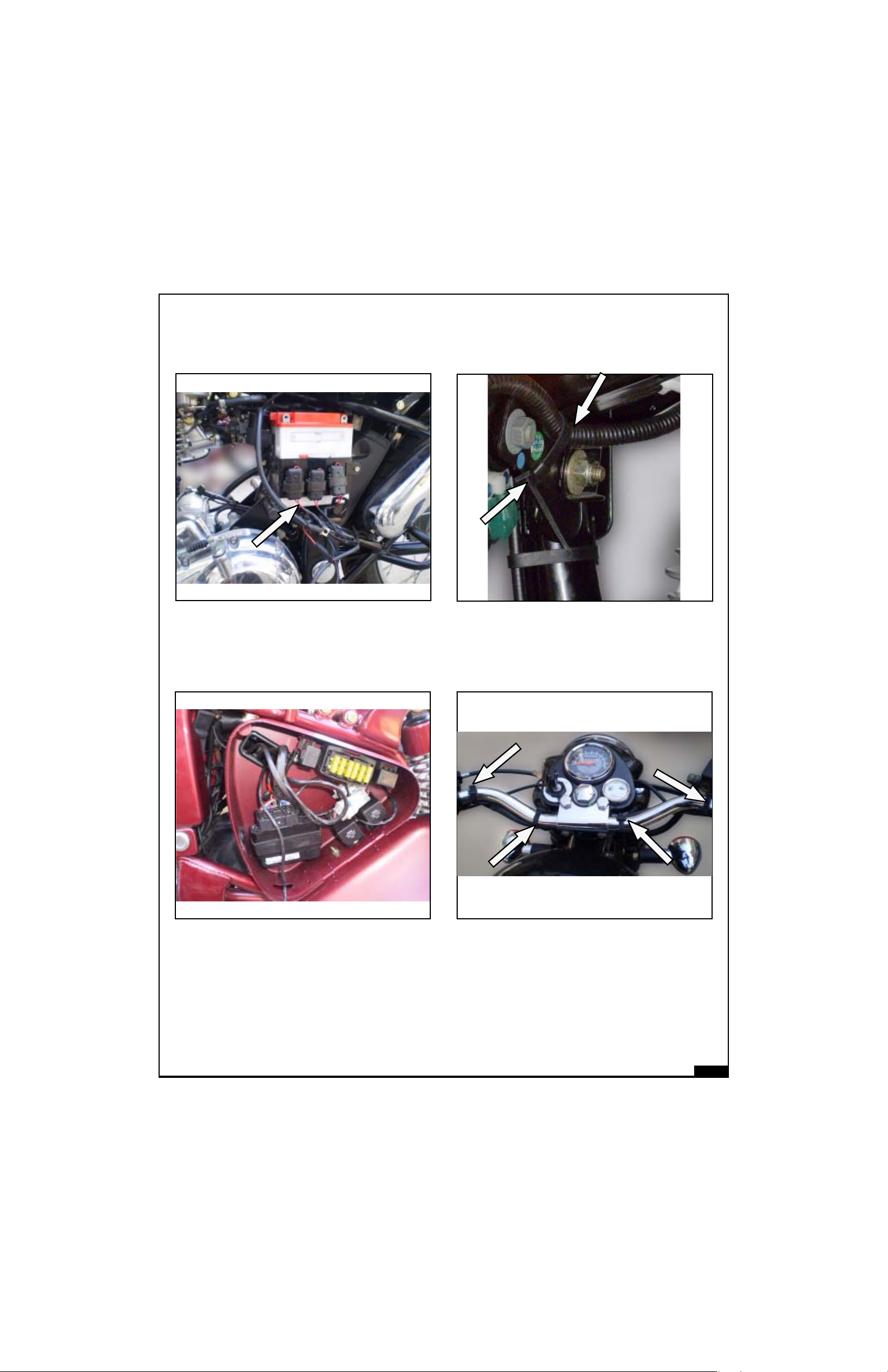

HARNESS ROUTING STEERING RH

MAGNETO WIRES ROUTING

PLUG WIRE ROUTING

STARTER RELAY CABLE

ROUTING

02-17

GENERAL GENERAL

GENERAL GENERAL

GENERAL

VEHICLE INFORMAVEHICLE INFORMA

VEHICLE INFORMAVEHICLE INFORMA

VEHICLE INFORMA

TIONTION

TIONTION

TION

FUSE CARRIERS

ARRANGEMENT (E5 & G5)

HORN WIRE ROUTING

HANDLE BAR WIRES ROUTING

FUSE CARRIERS

ARRANGEMENT (C5)

02-18

GENERAL GENERAL

GENERAL GENERAL

GENERAL

VEHICLE INFORMAVEHICLE INFORMA

VEHICLE INFORMAVEHICLE INFORMA

VEHICLE INFORMA

TIONTION

TIONTION

TION

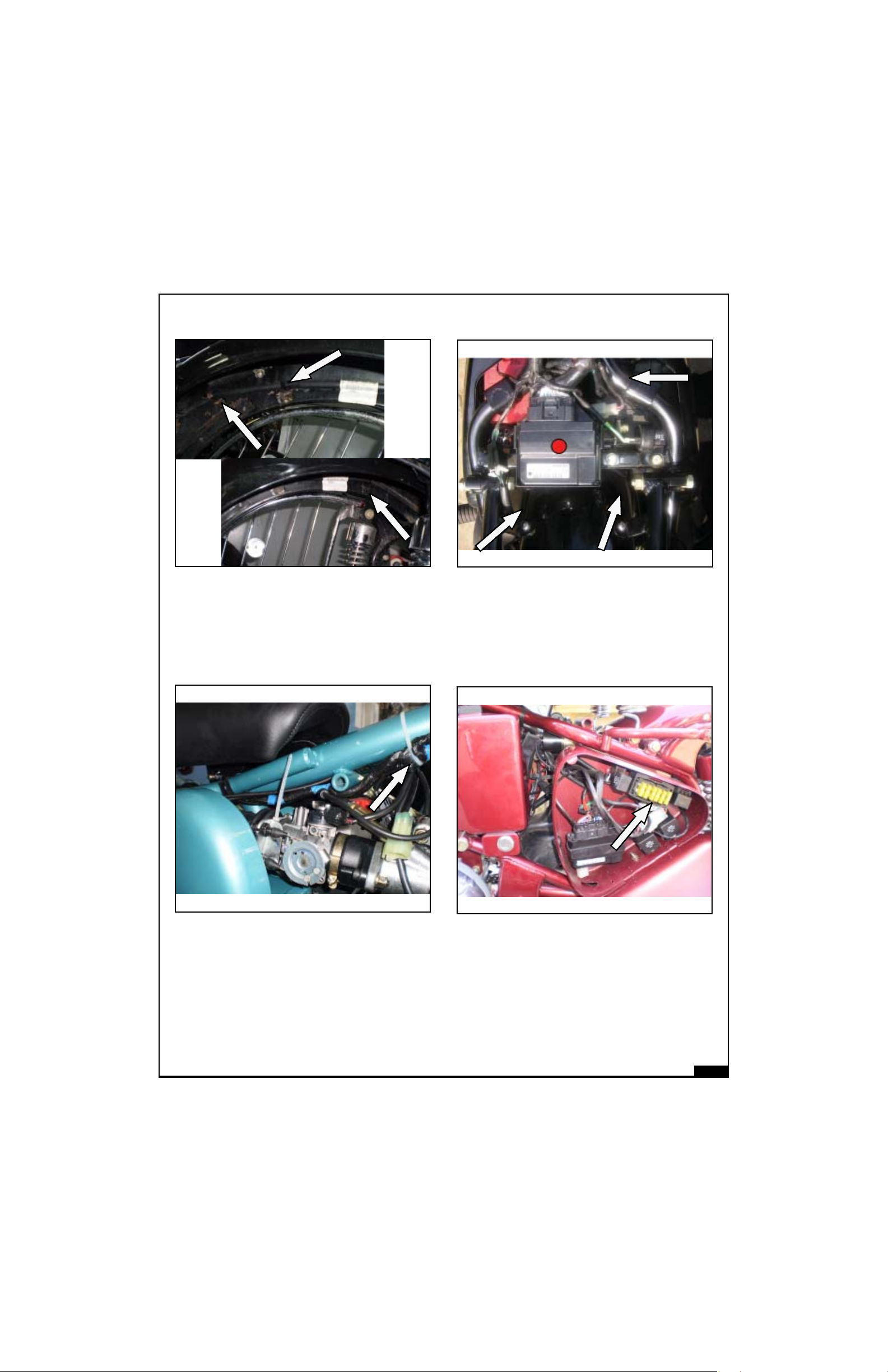

TAIL LAMP & TRAFFICATOR

WIRES ROUTING

ECU MOUNTING BULLET

ELECTRA EFI (E5 & G5)

THROTTLE BODY MOUNTING

WITH CABLES

ECU MOUNTING BULLET

CLASSIC EFI (C5)

SERVICE DSERVICE D

SERVICE DSERVICE D

SERVICE D

AA

AA

A

TT

TT

T

AA

AA

A

SECTIONSECTION

SECTIONSECTION

SECTION

THREE 03THREE 03

THREE 03THREE 03

THREE 03

03-1

SERSER

SERSER

SER

VICE LIMITS OF COMPONENTS VICE LIMITS OF COMPONENTS

VICE LIMITS OF COMPONENTS VICE LIMITS OF COMPONENTS

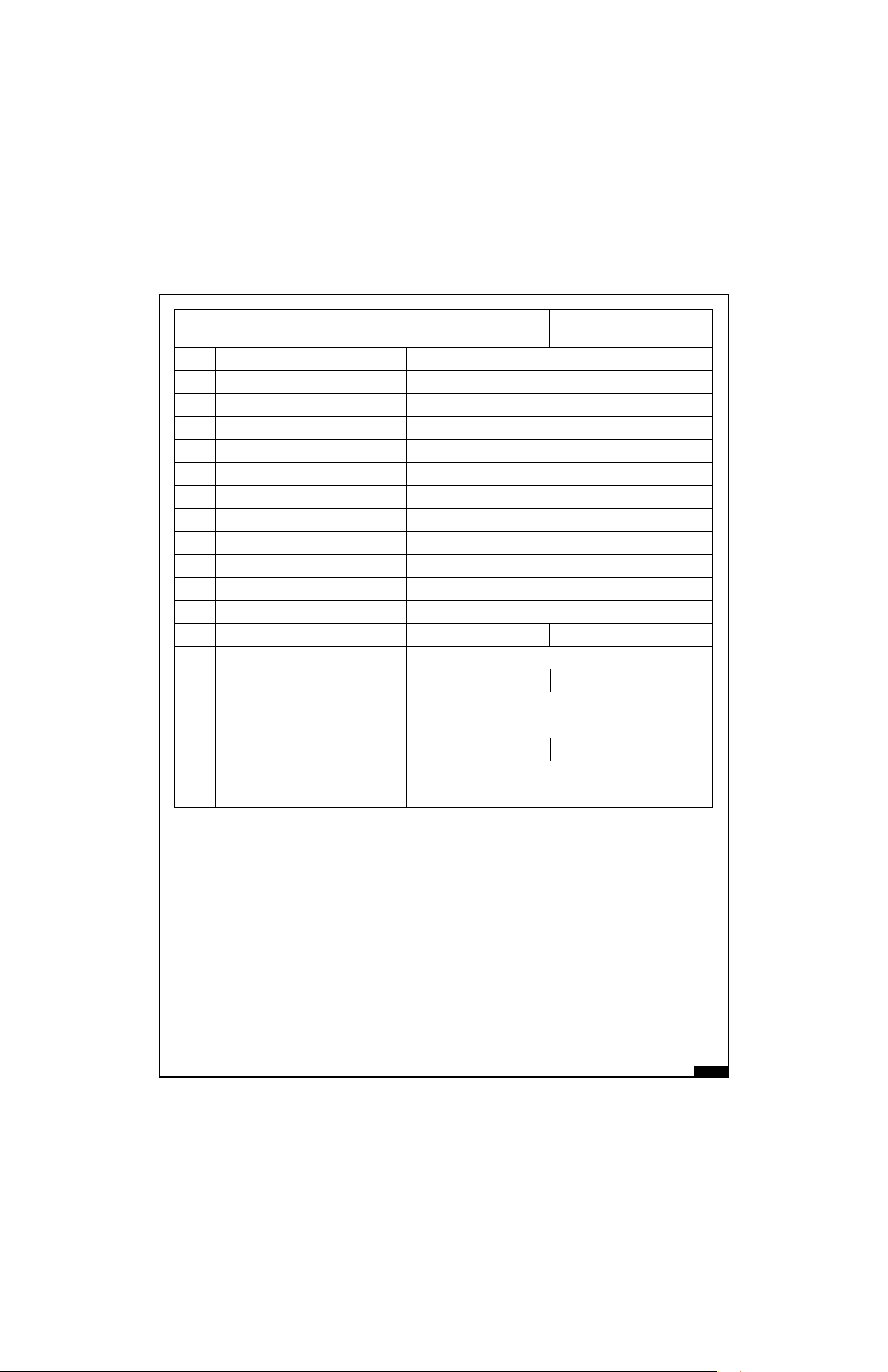

VICE LIMITS OF COMPONENTS (All units in mm unless specified)

WEAR LIMITS

Wear limits are given as new min, new max and service limits.

New components must be within the limits specified. Components within service limits may be reused

after careful inspection. Use of parts beyond service limit can reduce the operating life of the component

and may affect the motorcycle performance seriously.

New Min.

New Max.

Service Limit

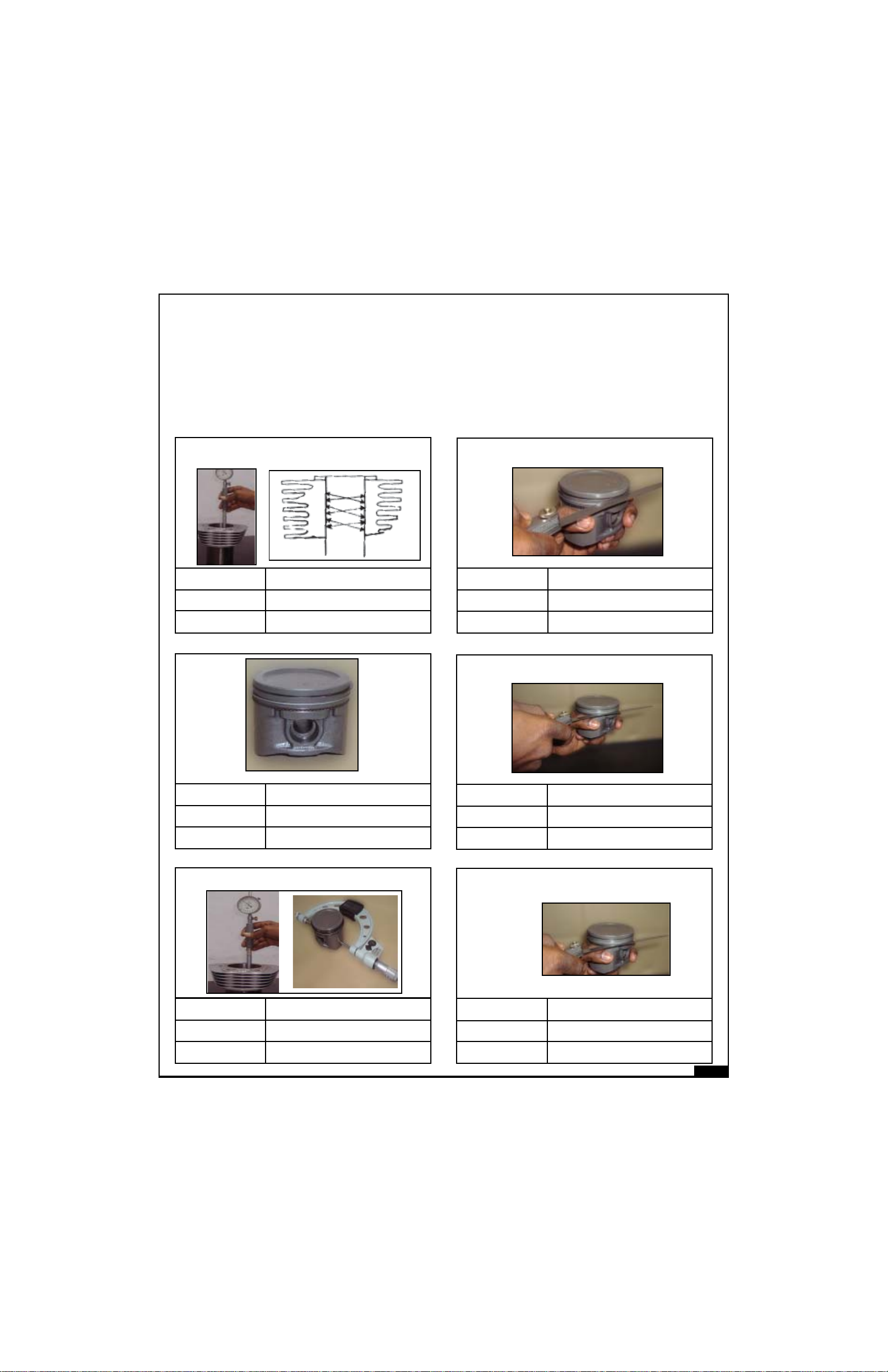

Ring to groove clearance : oil ring

0.06

0.15

0.21

New Min.

New Max.

Service Limit

0.095

0.115

0.30

Piston to bore clearance

New Min.

New Max.

Service Limit

Ring to groove clearance comp rings - Middle

0.03

0.07

0.15

New Min.

New Max.

Service Limit

Piston

83.940

83.970

83.890

New Min.

New Max.

Service Limit

0.03

0.07

0.11

New Min.

New Max.

Service Limit

84.045

84.075

84.190

Cylinder bore

Cylinder bore :

Point of measurement

Ring to groove clearance : Comp. Top rings

A

B

C

03-2

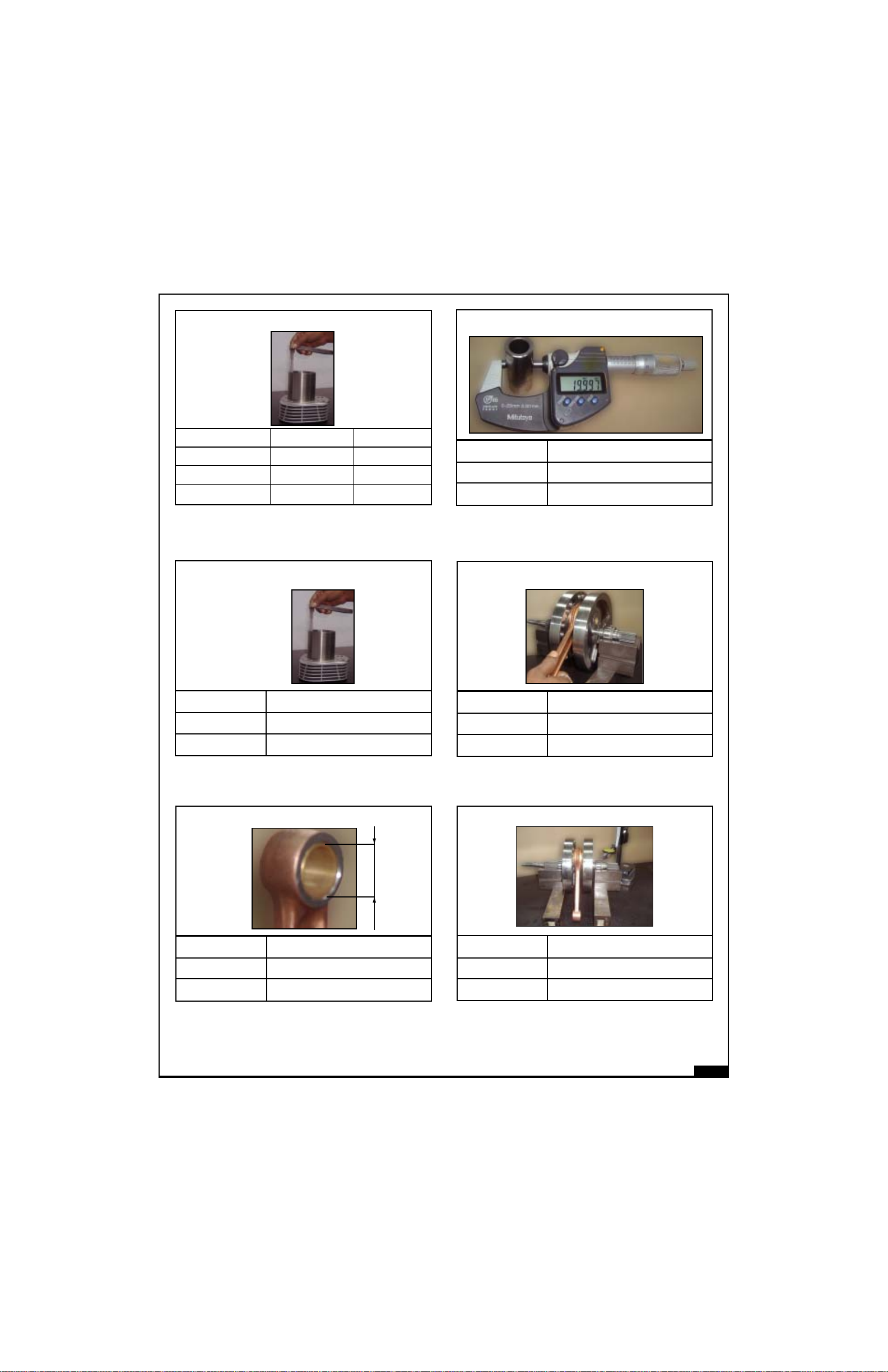

New Min.

New Max.

Service Limit

Piston ring end gap : compression

Piston Pin diameter

19.992

19.997

19.982

From top 1st 2nd

New Min. 0.20 0.35

New Max. 0.35 0.50

Service Limit 0.70 0.85

New Min.

New Max.

Service Limit

New Min.

New Max.

Service Limit

Piston ring end gap - Oil Ring

Big end axial play

0.20

0.55

0.65

0.20

0.70

0.90

New Min.

New Max.

Service Limit

Crank shaft : Run out

0.00

0.04

0.08

New Min.

New Max.

Service Limit

Small end bore inner diameter

20.007

20.016

20.046

03-3

New Min.

New Max.

Service Limit

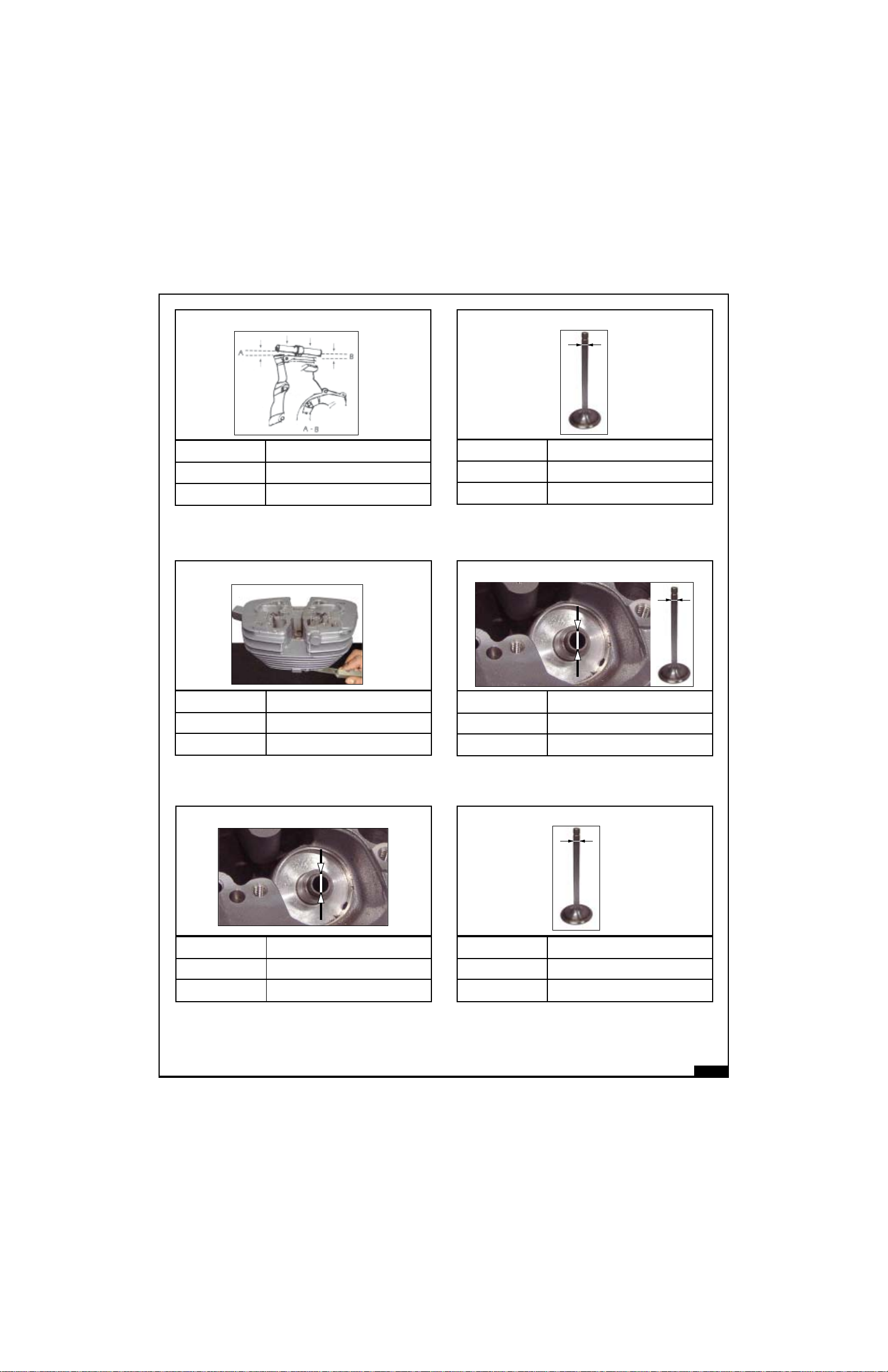

Connecting rod bend

0.00

0.05

0.08

New Min.

New Max.

Service Limit

Valve stem OD (Inlet)

6.965

6.980

6.955

New Min.

New Max.

Service Limit

Valve to guide (inlet) clearance

0.02

0.05

0.08

New Min.

New Max.

Service Limit

Cylinder Head warpage

0.00

0.05

0.07

New Min.

New Max.

Service Limit

Valve stem OD (Exhaust)

6.945

6.960

6.935

New Min.

New Max.

Service Limit

Valve guide bore

7.00

7.015

7.25

03-4

New Min.

New Max.

Service Limit

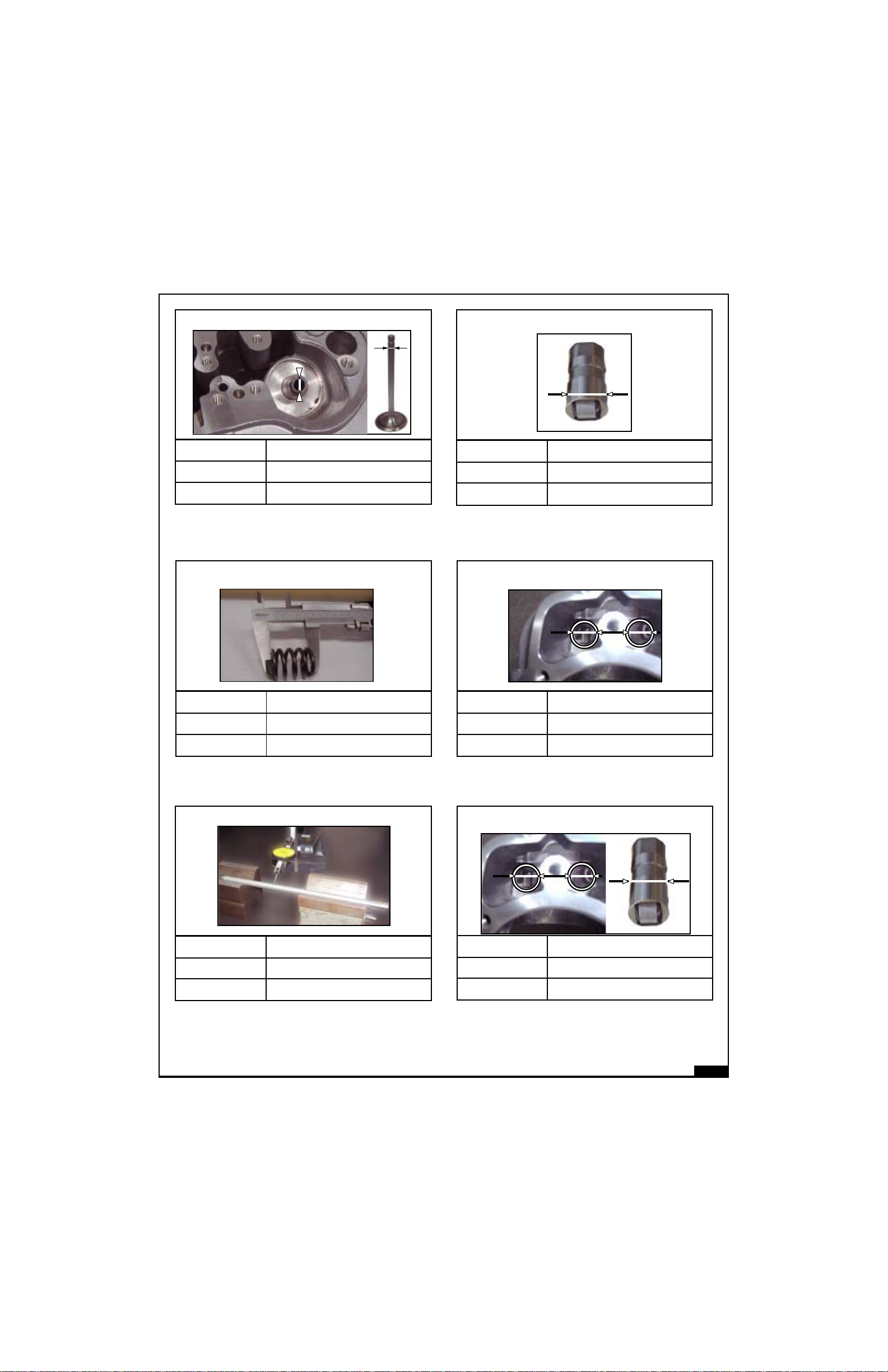

Valve to guide (Exhaust) Clearance

0.04

0.07

1.00

New Min.

New Max.

Service Limit

Hydraulic Tappet OD

21.387

21.405

21.380

New Min.

New Max.

Service Limit

Valve Spring : length

42.80

44.80

41.50

New Min.

New Max.

Service Limit

21.417

21.438

21.450

Hydraulic Tappet guide bore

New Min.

New Max.

Service Limit

Push rod run out

0.00

0.02

0.05

New Min.

New Max.

Service Limit

0.012

0.051

0.060

Hydraulic tappet to guide clearance

Loading...

Loading...