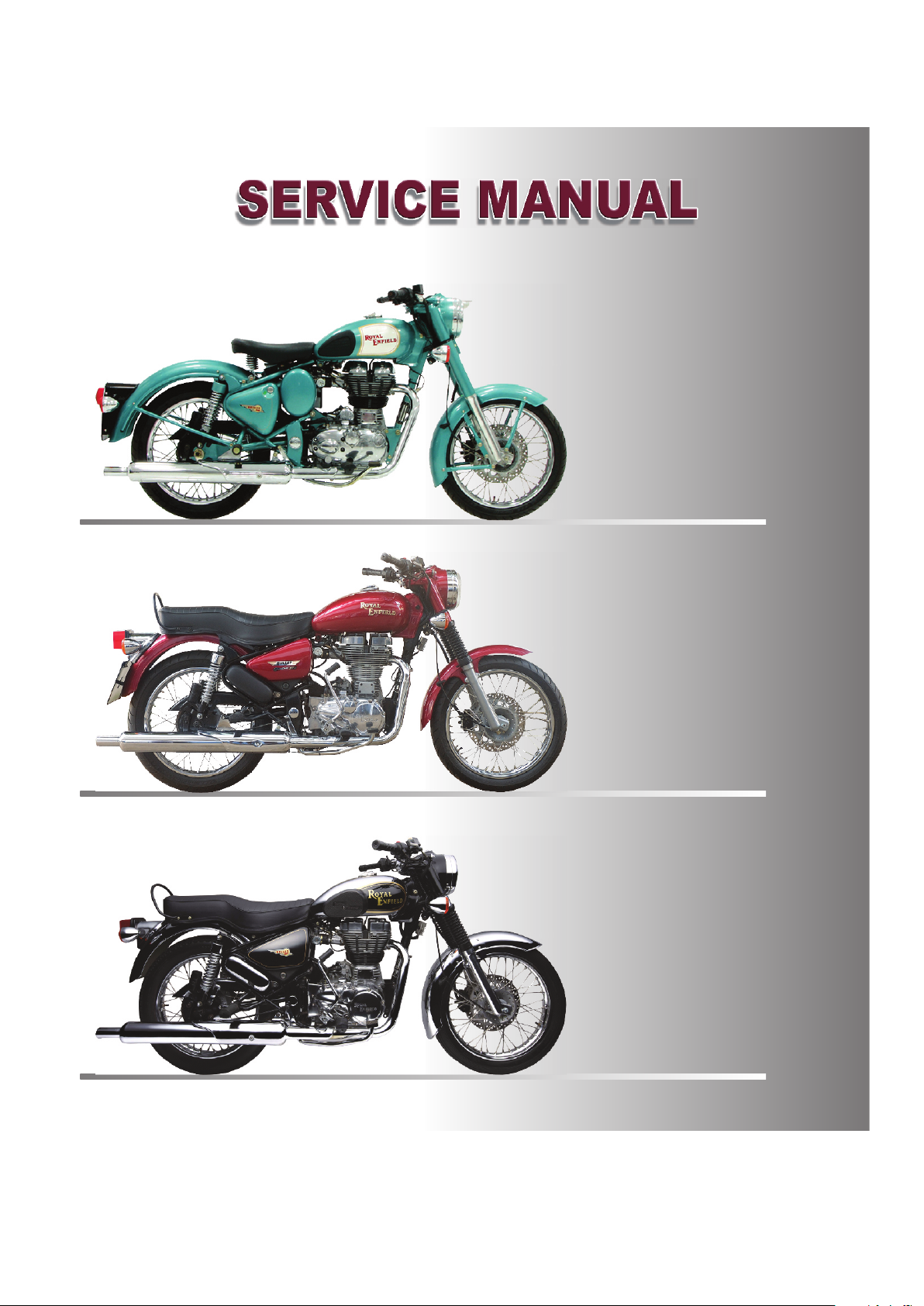

Page 1

Bullet Classic EFI (C5)

Bullet Electra EFI (E5)

Bullet EFI (G5)

Page 2

SECTIONSECTION

SECTION

SECTIONSECTION

ONE 01ONE 01

ONE 01

ONE 01ONE 01

INTRODUCTIONINTRODUCTION

INTRODUCTION

INTRODUCTIONINTRODUCTION

Page 3

PREFPREF

PREF

PREFPREF

We are pleased to release this workshop manual for the new generation of Royal Enfield

Motorcycles fitted with unit construction engine, electronically controlled “Engine Management

System” and fuel injection technology.

We have endeavoured to make this manual user friendly. However, we welcome your valuable

suggestions for improvements which you may write to us or email us at vvikram@royalenfield.com.

Service Head Quarters,

Royal Enfield

Chennai.

AA

A

AA

CECE

CE

CECE

“ © Copyright 2009 EICHER MOTORS LIMITED, UNIT ROYAL ENFIELD.

All Rights Reserved. No part of this Service technical manual shall be copied,

distributed or otherwise dealt, without the express permission in written from Eicher

Motors Limited, Unit Royal Enfield, who remains the sole owner of this manual .”

Part No. 597451 / Qty. 500 / May ‘09

01-1

Page 4

FOREWFOREW

FOREW

FOREWFOREW

ORDORD

ORD

ORDORD

PREPARATION FOR SERVICE

Good preparation is very important for carrying out correct service job. The motorcycle should be

cleaned well before starting a repair job. Cleaning will occasionally uncover sources of trouble.

Availability of tools, measuring instruments and parts should be ensured before commensing an

overhaul, since Interruption to locate tools or parts can cause distraction and needless delay. Use of

special tools will ensure a quality service.

USE OF GENUINE SPARE PARTS

Use only genuine Royal Enfield spares whenever replacing parts. Use of non genuine parts can

seriously affect motorcycle performance and may result in costly rework, vehicle down time and

above all customer dissatisfaction.

NOTE :

Proper service and repair is important for the safe and reliable operation of all mechanical products.

The service procedures recommended and detailed in this manual will help to carry out correct repairs.

SAFETY

Every care is taken to ensure that the information given in this manual is correct at the time of going to

print. However, Royal Enfield does not assume responsibility for any damage, loss or injury caused to

the vehicle or to the person carrying out repairs, due to errors or omissions in this manual.

IMPORTANT NOTICE

All images shown are only for reference to explain and may not be exactly the same on the motorcycle.

Technical specifications are subject to change without prior notice.

Because of changes that may occur in the manufacturing process, since this manual was printed, it

is possible some instructions or illustrations found within this manual may differ from those found on

the vehicle. However the technical information found within this manual is correct at the time, when it

was approved for printing.

Future modifications, improvements etc will be communicated to our Authorised Distributors / Importers

as and when changes are done to the motorcycle.

01-2

Page 5

HOHO

W W

TT

HO

W

HOHO

W W

SERSER

SER

SERSER

Pictorial presentation of various activities, make

this manual easy to understand and user friendly.

This service manual is divided into 10 Sections

01 to 10. Page numbers for each section starts

with 01. Thus, page 05-10 indicates 10th page

of section 5.

O USE O USE

T

O USE

TT

O USE O USE

VICE MANUVICE MANU

VICE MANU

VICE MANUVICE MANU

YY

OUROUR

Y

OUR

YY

OUROUR

ALAL

AL

ALAL

Engine breather System

Clutch System

Inlet manifold & Throttle body

Blow up Charts.

SECTION FIVE 05SECTION FIVE 05

SECTION FIVE 05

SECTION FIVE 05SECTION FIVE 05

ENGINE DISMANTLINGENGINE DISMANTLING

ENGINE DISMANTLING

ENGINE DISMANTLINGENGINE DISMANTLING

INSPECTION & INSPECTION &

INSPECTION &

INSPECTION & INSPECTION &

Torque Specification - Engine

ASSEMBLASSEMBL

ASSEMBL

ASSEMBLASSEMBL

YY

Y

YY

The sections are subdivided into subjects and

presented in the following order.

SECTION ONE O1SECTION ONE O1

SECTION ONE O1

SECTION ONE O1SECTION ONE O1

INTRODUCTIONINTRODUCTION

INTRODUCTION

INTRODUCTIONINTRODUCTION

The manual and its arrangements

SECTION TWO 02SECTION TWO 02

SECTION TWO 02

SECTION TWO 02SECTION TWO 02

GENERALGENERAL

GENERAL

GENERALGENERAL

Salient features of the Unit construction engine

& engine management system

Four stroke cycle operation

Basic terminology of automobiles

Technical specifications

Identification of Chassis No., Engine No.,

List of special tools and its applications

Control cables and wiring harness routing.

SECTION THREE 03SECTION THREE 03

SECTION THREE 03

SECTION THREE 03SECTION THREE 03

SERSER

SER

SERSER

VICE DVICE D

VICE D

VICE DVICE D

AA

A

AA

TT

T

TT

AA

A

AA

Engine dismantling procedure

Vital parts - Description

Unidirectional fittings list

Engine assembling procedure

SECTION SIX 06SECTION SIX 06

SECTION SIX 06

SECTION SIX 06SECTION SIX 06

ENGINE MANENGINE MAN

ENGINE MAN

ENGINE MANENGINE MAN

SYSY

STEMSTEM

SY

STEM

SYSY

STEMSTEM

Functional Diagram

Components description

Function of components

Identification of a malfunction in EMS

Do’s & Dont’s

Trouble shooting

SECTION SEVEN 07SECTION SEVEN 07

SECTION SEVEN 07

SECTION SEVEN 07SECTION SEVEN 07

WHEELS & BRAKESWHEELS & BRAKES

WHEELS & BRAKES

WHEELS & BRAKESWHEELS & BRAKES

Torque Specification - Chassis

Front wheel removal & reassembly

AA

GEMENTGEMENT

A

GEMENT

AA

GEMENTGEMENT

Service limits of components

Periodical maintenance chart

SECTION FOUR 04SECTION FOUR 04

SECTION FOUR 04

SECTION FOUR 04SECTION FOUR 04

ENGINEENGINE

ENGINE

ENGINEENGINE

Lubrication system

Roller hydraulic Valve lifter (RHVL)

Auto decompressor

Electric starter system & sprag mechanism

Auto Chain Tensioner Assembly

Disc brake

- General instruction

- Master Cylinder & Caliper overhauling

- Bleeding procedure

- Disc inspection

Rear wheel removal & reassembly

Rear Brake removal & reassembly

01-3

Page 6

SECTION EIGHT 08SECTION EIGHT 08

SECTION EIGHT 08

SECTION EIGHT 08SECTION EIGHT 08

SUSPENSION ANDSUSPENSION AND

SUSPENSION AND

SUSPENSION ANDSUSPENSION AND

STEERINGSTEERING

STEERING

STEERINGSTEERING

- Relay starter

- Starter motor

- IC Flasher

Front fork working principle

Front fork removal & reassembly

Steering stem removal & reassembly

Gas filled shock absorber

- Working principle

- Removal and assembly

- Adjustment of shock absorber

- Recharging of shock absorber

Swing Arm

- Removal

- Bush lubrication / replacement

- Reassembly

Centre Stand Removal & Reassembly

SECTION NINE 9SECTION NINE 9

SECTION NINE 9

SECTION NINE 9SECTION NINE 9

ELECTRICALSELECTRICALS

ELECTRICALS

ELECTRICALSELECTRICALS

Electrical symbols

Battery

- Precautions

- Charging

- RR Unit

- TPS Unit

Electrical parts Inspection

- Clutch switch

- Starter switch

- Switch modules LH & RH

Do’s and Dont’s

Wiring Diagrams

- Ignition circuit

- Starter and charging

- Complete Wiring diagram

Trouble shooting

SECTION TEN 10SECTION TEN 10

SECTION TEN 10

SECTION TEN 10SECTION TEN 10

TRTR

OUBLE SHOOOUBLE SHOO

TR

OUBLE SHOO

TRTR

OUBLE SHOOOUBLE SHOO

SAFETY DEFINITIONSSAFETY DEFINITIONS

SAFETY DEFINITIONS

SAFETY DEFINITIONSSAFETY DEFINITIONS

Important aspects to be noted are given as

follows in the manual.

TINGTING

TING

TINGTING

- Maintenance

Spark plug maintenance & Inspecton

Checking procedure of electrical

components:

- Starter coil

- Pulsar coil

- Ignition coil

- Suppressor Cap

- Battery

- Horn

NOTE

Provides important information that will have to

be adhered to while carrying out repairs.

CAUTION

Indicates activities that are important to be

noted. Non-adherance may result in breakage

and or functional failures of the assembly.

SPECIAL TOOLS

Contains details of the special tools and its

usage, These tools have been specially designed

for a specific purpose.

01-4

Page 7

SECTIONSECTION

SECTION

SECTIONSECTION

TWO 02TWO 02

TWO 02

TWO 02TWO 02

GENERALGENERAL

GENERAL

GENERALGENERAL

Page 8

SALIENT FEASALIENT FEA

SALIENT FEA

SALIENT FEASALIENT FEA

ENGINE & ENGINE MANENGINE & ENGINE MAN

ENGINE & ENGINE MAN

ENGINE & ENGINE MANENGINE & ENGINE MAN

TURES OF TURES OF

TURES OF

TURES OF TURES OF

THE UNIT CONSTRTHE UNIT CONSTR

THE UNIT CONSTR

THE UNIT CONSTRTHE UNIT CONSTR

AA

GEMENT SYGEMENT SY

A

GEMENT SY

AA

GEMENT SYGEMENT SY

STEMSTEM

STEM

STEMSTEM

UCTIONUCTION

UCTION

UCTIONUCTION

• HIGH TORQUE ENGINE

• ENHANCED POWER DELIVERY

• HYDRAULIC TAPPETS

• AUTO DECOMPRESSOR

• AUTO CHAIN TENSIONER FOR

PRIMARY CHAIN

• HIGH CAPACITY TRACHOIDAL OIL

PUMP FOR BETTER LUBRICATION

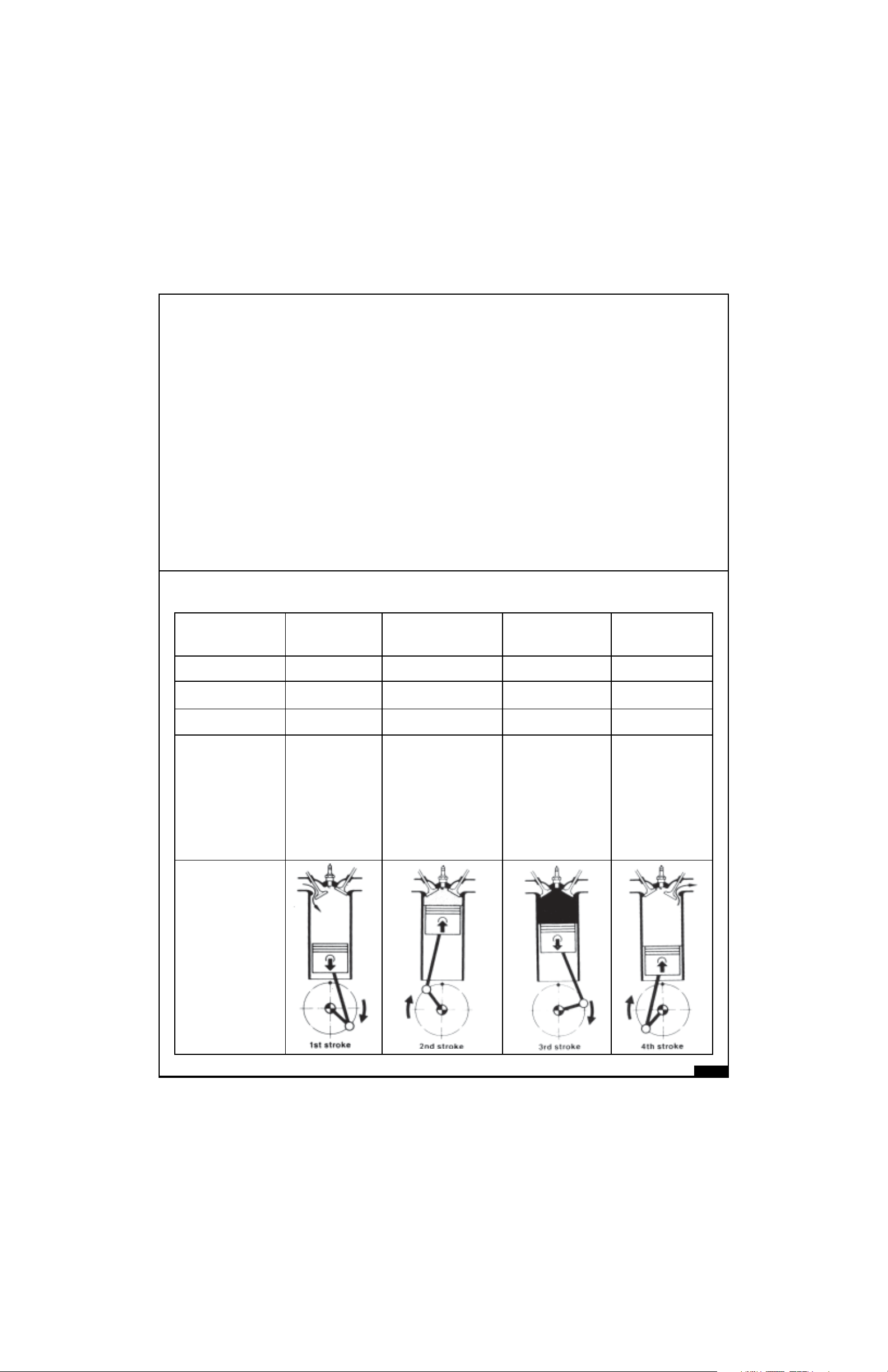

FOUR STRFOUR STR

FOUR STR

FOUR STRFOUR STR

SUCTION COMPRESSION POWER EXHAUST

STROKE

Inlet Valve Open Closed Closed Closed

OKE CYOKE CY

OKE CY

OKE CYOKE CY

STROKE STROKE STROKE

• IMPROVED ACCELERATION & HIGH

SPEED CRUISING

• EXCELLENT COLD STARTING

ABILITY

• ACCURATELY CONTROLLED, AIR

FUEL MIXTURE & IGNITION TIMING

BY THE ENGINE CONTROL UNIT

• IMPROVED PERFORMANCE AND

FUEL EFFICIENCY THRO FUEL

INJECTION SYSTEM.

CLE OPERACLE OPERA

CLE OPERA

CLE OPERACLE OPERA

TIONTION

TION

TIONTION

Exhaust Valve Closed Closed Closed Open

Piston Movement TDC to BDC BDC to TDC TDC to BDC BDC to TDC

Gas Flow Air Petrol Air Petrol Air petrol mixture Exhaust gas

mixture is mixture gets burns, gas

expands. flows out.

drawn into compressed. Piston is

cylinder Few degrees before pushed down.

BTDC, spark plug

produces spark.

02-1

Page 9

BASIC BASIC

BASIC

BASIC BASIC

TERMINOLTERMINOL

TERMINOL

TERMINOLTERMINOL

OGY OF OGY OF

OGY OF

OGY OF OGY OF

ENGINE :

The Engine helps to convert Chemical energy

availbale in petrol into heat energy then to

mechanical energy for motion. It is the heart of

the vehicle in which power is generated for

moving the vehicle.

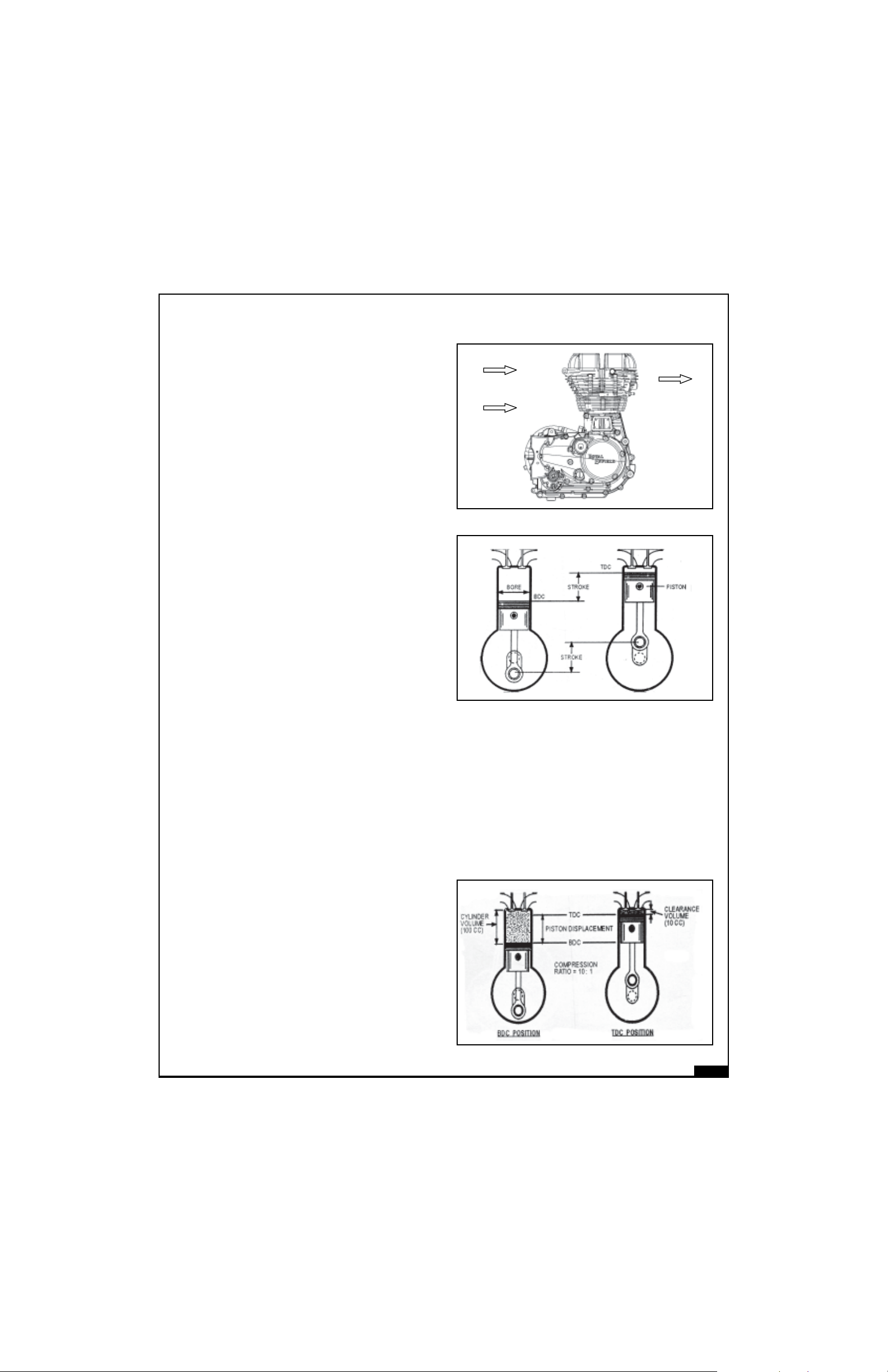

BORE :

Bore is the inside diameter of the cyclinder block

in which Piston moves up and down.

TDC :

TDC stands for Top Dead Center. It is the top

most position to which the piston can travel in

the cylinder barrel.

BDC :

AUTAUT

AUT

AUTAUT

Fuel

Air

OMOBILESOMOBILES

OMOBILES

OMOBILESOMOBILES

Power

BDC stands for Bottom Dead Center. It is the

bottom most position to which the piston can

travel in the cylinder barrel.

STROKE :

It is a distance travelled by piston from TDC to

BDC or Vice Versa.

CUBIC CAPACITY / DISPLACEMENT :

It is a volume generated by piston when it travels from TDC to BDC. It is measured as Cubic Centimeter

(CC). It can be mathematically arrived at with the radious of the piston and the stroke of the engine.

(πr²× l, when ‘r’ is the radius of the piston and ‘l’ is the length of the stroke). It is also known as Swept

Volume or Displacement volume.

CLEARANCE VOLUME :

It is the nominal volume of the space above the

piston in the combustion chamber when piston

is at the topmost position (TDC).

02-2

Page 10

TOTAL VOLUME :

It is the sum of the swept voume (Displacement volume) and Clearance volume.

Total Volume = Swept volume + Clerance volume.

COMPRESSION RATIO :

It is a ratio between total volume in the engine to the clearance volume available at the end of

compression stroke.

Compression ratio =

Total volume of air fuel mixture

Clearance volume

VOLUMETRIC EFFICIENCY :

Volumetric efficiency is the ratio between the volume of air fuel mixture that actually enters the cylinder

and Swept volume.

Volumetric Efficiency

= Volume of air fuel mixture inhaled during suction stroke

Swept volume

HORSE POWER (HP OR PS) :

HP : Horse Power

PS : PFERDESTARKE is German unit of power. Horse Power is the ability of the engine to do a

certain amount of work in a given time.

One Horse power is the power required for lifting a weight of 75 Kg. through vertical distance of one

meter in one second.

Conversion :

1PS = 0.986 HP = 0.735 KW

1 HP = 1.014 PS = 0.744 KW

1KW = 1.360 PS = 1.340 HP

02-3

Page 11

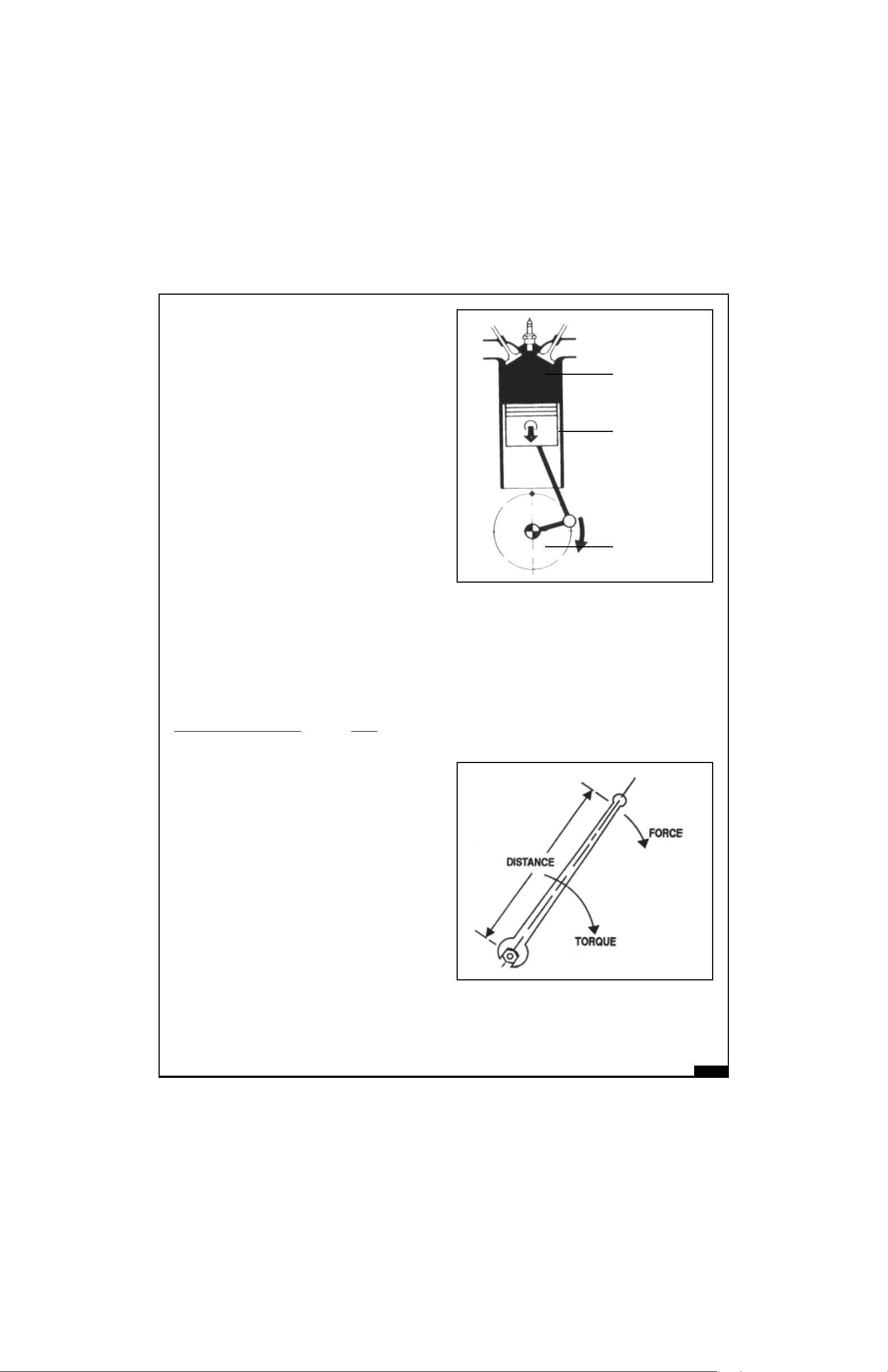

IHP :

IHP stands for Indicated Horse Power. Indicated

Horse Power is the power actually developed

inside the engine cylinder by combustion process.

It is utilised to drive the piston.

1HP (Horse

Power Available

after explosion)

FHP :

FHP (Frictional

Losses)

FHP stands for Frictionl Horse Power.

It is the amount of horse power used or lost to

overcome the friction between various engine

components.

BHP :

BHP stands for Brake Horse Power

BHP (Horse

Power Avaiable at

Crankshaft)

Brake Horse Power is the amount of Power actually available at the crankshaft or output shaft. It

is calculated by using dynamometer.

BHP = IHP - FHP

MECHANICAL EFFICIENCY :

Mechanical Efficiency is the ratio between Brake horsepower and Indicated horse power.

Brake horsepower = BHP

Indicated Horse power IHP

TORQUE :

Torque is a twisting or turning force or effort. It is the

product of a distance and force in circular motion.

In the picture shown the torque-applied is the product

of distance (distance between the center of the bolt

and point where force is acting) and the amount of

force applied.

With the same force, if the distance is increased,

the torque will also increase and if distance is

reduced, torque applied will also be reduced.

CONVERSION :

1kg-m = 7.23 lb.ft = 9.81 N-m.

1lb.ft = 0.138 Kg-m = 1.356 N-m.

1 N-m = 0.102 Kg-m = 0.737 lb.ft

02-4

Page 12

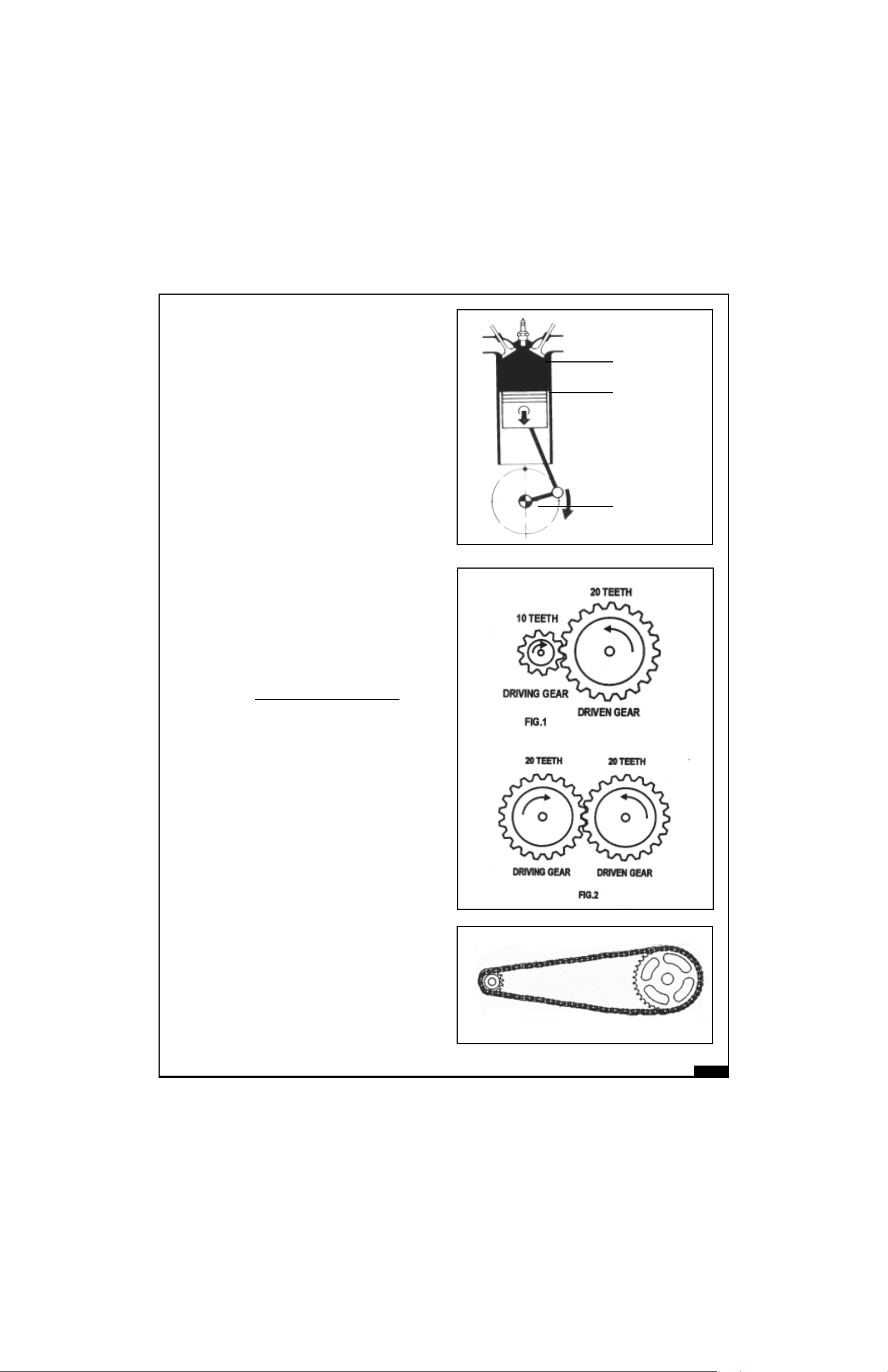

IGNITION TIMING :

Ignition timing is the timing at which spark

commences so that the spark from the spark

plug can ignite the mixture in the combusion

chamber at the end of TDC during compression

stroke.

If spark occurs earlier than specified ignition

timing, it is called “Advance” timing.

If spark occurs after the specified ignition timing,

it is called “Retard” timing.

IDLING SPEED :

It is the speed of the crankshaft (i.e. RPM) of the

engine when the throttle is in closed pisition.

GEAR RATIO :

The relative rotation between “Driven Gear” and

“Driving Gear” is known as the “Gear Ratio”. It is

determined by number of teeth on the respective

gears.

TDC Position

Ignition Timing

Position

Ignition Timing in

Degrees

Gear Ratio =

No. of teeth of Driven Gear

No. of teeth of Driving Gear

In Fig. 1, the Gear ratio is 20 ÷ 10 = 2 : 1

In Fig. 2, the Gear ratio is 20 ÷ 20 = 1 : 1

Gear ratios multiply the engine torque to fulfil

various demands for pulling the vehicle like.

- More effort is required during initial

movement of the vehicle.

- More effort is required to climb an elevation.

- More effort is required while driving in

muddy or sandy surfaces.

FINAL DRIVE RATIO :

It is a relative rotation between the engine

sprocket and the sprocket on the rear wheel.

Both the sprockets are connected through drive

chain.

Final drive ratio further multiplies the torque

available at the output shaft.

02-5

Page 13

TECHNICAL SPECIFICATECHNICAL SPECIFICA

TECHNICAL SPECIFICA

TECHNICAL SPECIFICATECHNICAL SPECIFICA

TIONSTIONS

TIONS

TIONSTIONS

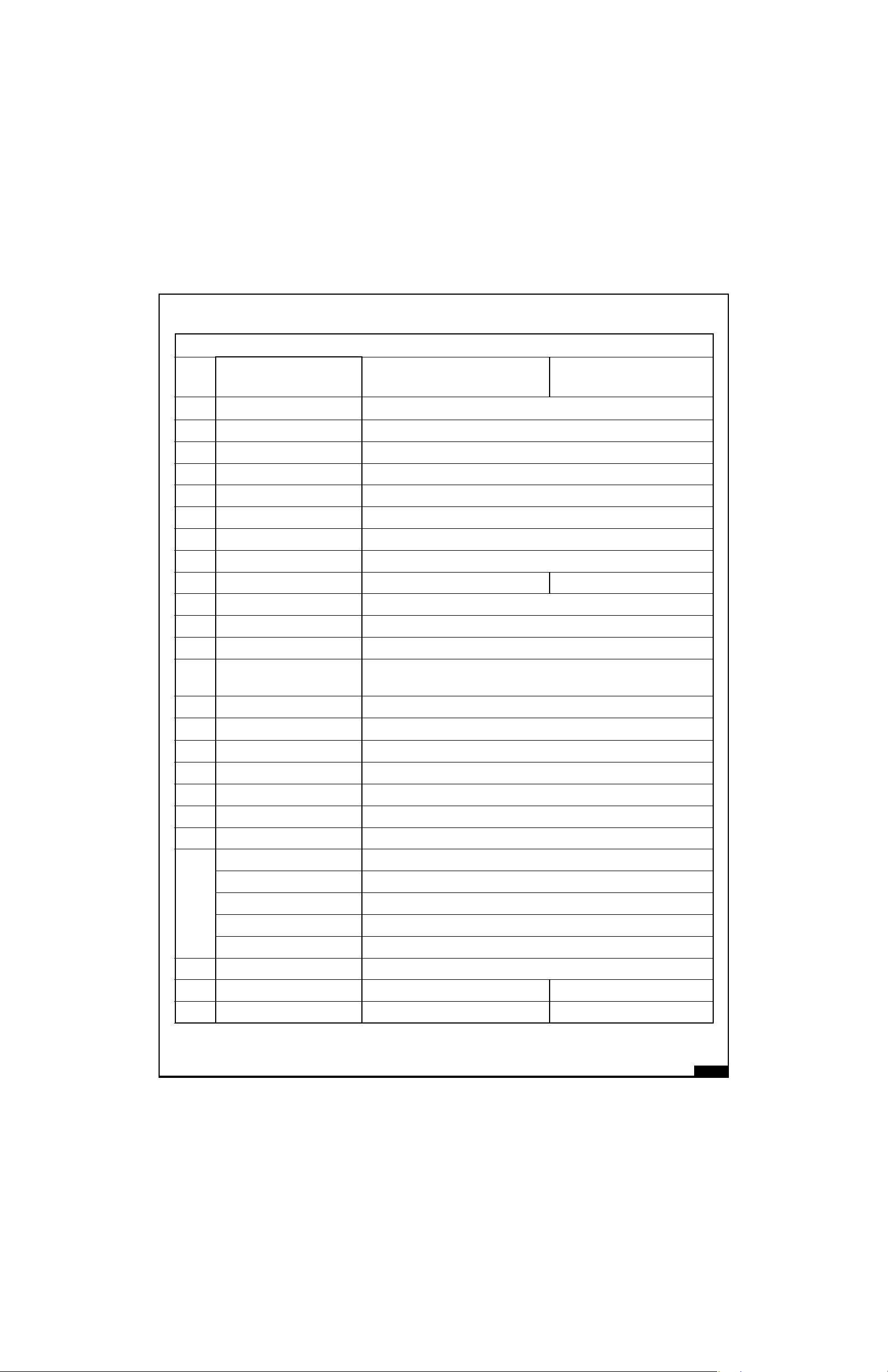

A. ENGINE AND ENGINE SYSTEMS

BULLET ELECTRA EFI (E5) BULLET CLASSIC EFI

BULLET EFI (G5) (C5)

1. Engine Type 4 Stroke Single Cylinder, Air cooled

2. Bore 84mm

3. Stroke 90mm

4. Displacement 499cc

5. Compression ratio 8.5:1

6. Max Power @ rpm 20.3 Kw @ 5250 rpm

7. Max Torque @ rpm 41.3 Nm @ 4500 rpm

8. Idle rpm 1050 ± 200 rpm

9. Starting Kick & Electric Start Electric Start

10. Air filter element Paper element

11. Lubrication Forced Lubrication, Wet Sump

12. Engine oil tank capacity 2.75 litres

13. Engine oil grade

JASO MA -15W-50, API SL Grade,

ESTER-Semi Synthetic Oil

14. Cooling Natural air flow

B. TRANSMISSION

1. Clutch Wet multiplate

2. Primary drive 3/8” Duplex chain & sprocket

3. Primary ratio 2.15 : 1

4. Gear box 5 Speed Constant Mesh

5. Overall Ratio

st

1

nd

2

rd

3

th

4

th

5

6. Secondary drive 5/8” Chain & Sprocket

3.063 : 1

2.013 : 1

1.522 : 1

1.212 : 1

1 : 1

7. Secondary ratio 2.235 : 1 2.11:1

8. Drive Chain links 101 Pitch 102 Pitch

02-6

Page 14

C. CHASSIS

BULLET ELECTRA EFI (E5) BULLET CLASSIC EFI

BULLET EFI (G5) (C5)

1. Frame Tubular

2. Front Suspension Telescopic, hydraulic damping, Stroke 130 mm

3. Rear Suspension Swing arm with gas shock absorbers

4. Fr. Fork oil capacity 265 cc + 2.5 cc / each leg

5. Front fork oil SAE 10W -30

6. Front Brake Hydraulic, Hand operated, 280 mm dia ventilated disc

7. Rear Brake Mechanical, Foot operated, 153 mm internal expanding

8. Brake Oil Capacity 60 ml

9. Brake Oil Grade DOT 3 or DOT 4

10. Tyre size : Front 90X90 - 19” - 51V 90X90 - 18” 51V

3.25X19

Rear 100/90 - 19” - 57V 110/80-18” - 58V

3.5X90

D. TYRE PRESSURE

1. Solo : Front 18 PSI

Rear 28 PSI

2. With Pillion : Front 20 PSI

Rear 30 PSI

3. Steering lock In built

4. Fuel tank capacity 14.5 ±1 litres

5. Reserve 2.75 litres

E. ELECTRICALS

1. Generation Alternator

2. System 12V - DC

3. Battery 12V - 14 AH

4. Spark plug Mico - WR7 DDC 4

5. Spark plug gap 0.7 to 0.8 mm

6. Head lamp 12V, 60/55w

02-7

Page 15

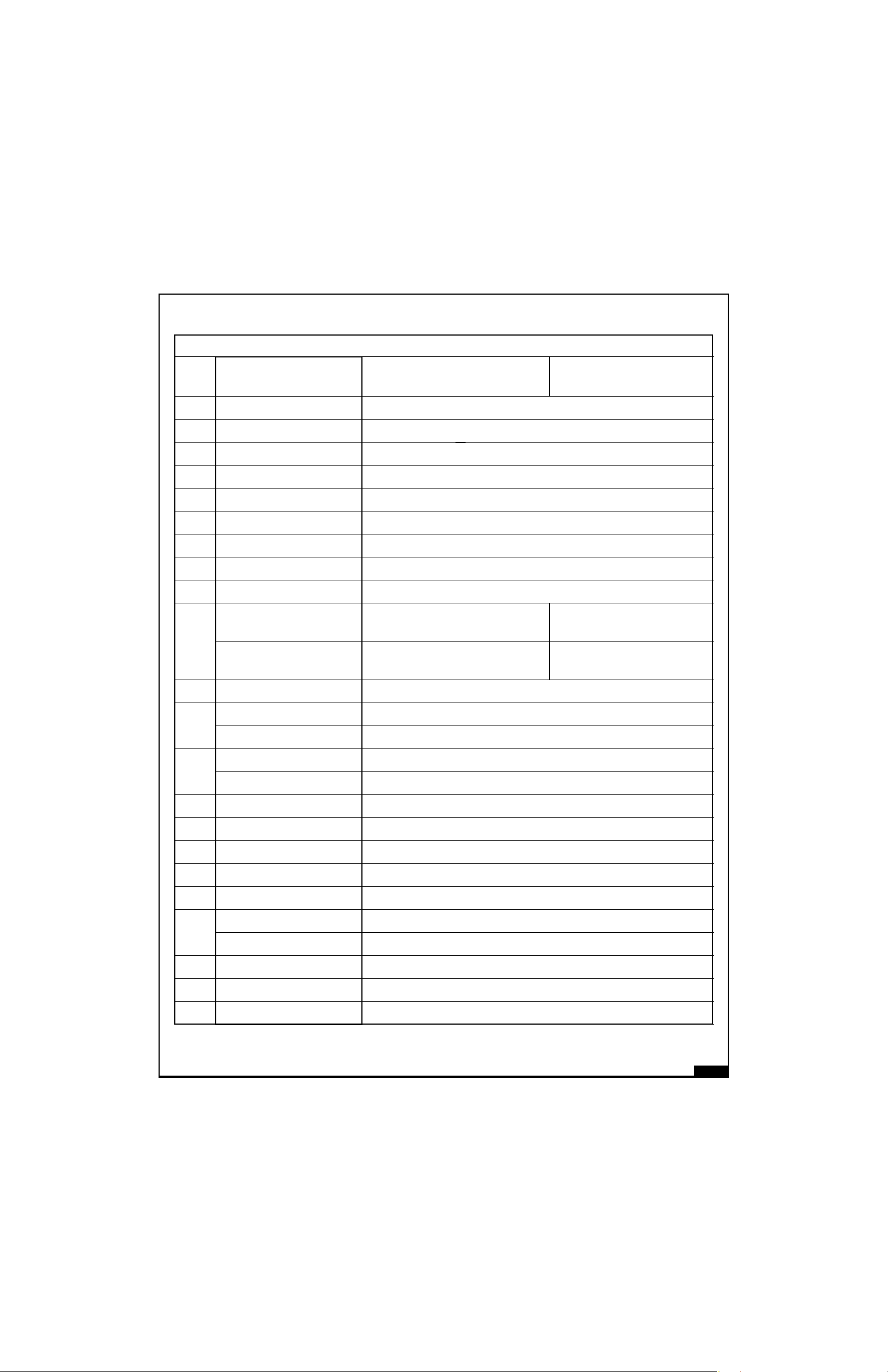

BULLET ELECTRA EFI (E5) BULLET CLASSIC EFI

BULLET EFI (G5) (C5)

7. Tail / Brake Lamp 12V 5 / 21W

8. Speedometer lamp 12V, 3.4W

9. Hi beam indicator 12V, 2W

10. Neutral lamp Tell tale 12V, 2W

11. Turn Signal Tell Tale 12V, 2W

12. Turn signal 12V, 10W

13. Horn 12V DC

F. WEIGHTS

1. Mass of Vehicle in running order 187 Kg.

2. Max pay load 178 Kgs.

3. Max technical permissible mass 365 Kg.

G. DIMENSIONS

1. Length 2200 mm 2160 mm

2. Width 800 mm

3. Height 1100 mm 1050 mm

4. Wheel base 1370 mm

5. Ground clearance 140 mm

6. Saddle height 820 mm 800 mm

H. PERFORMANCE

1. Max. speed 132 Kmph (83 Miles)

NOTE :

1. Values given above are for your guidelines only

2. In view of continuous improvements, specifications are likely to change without

notice

02-8

Page 16

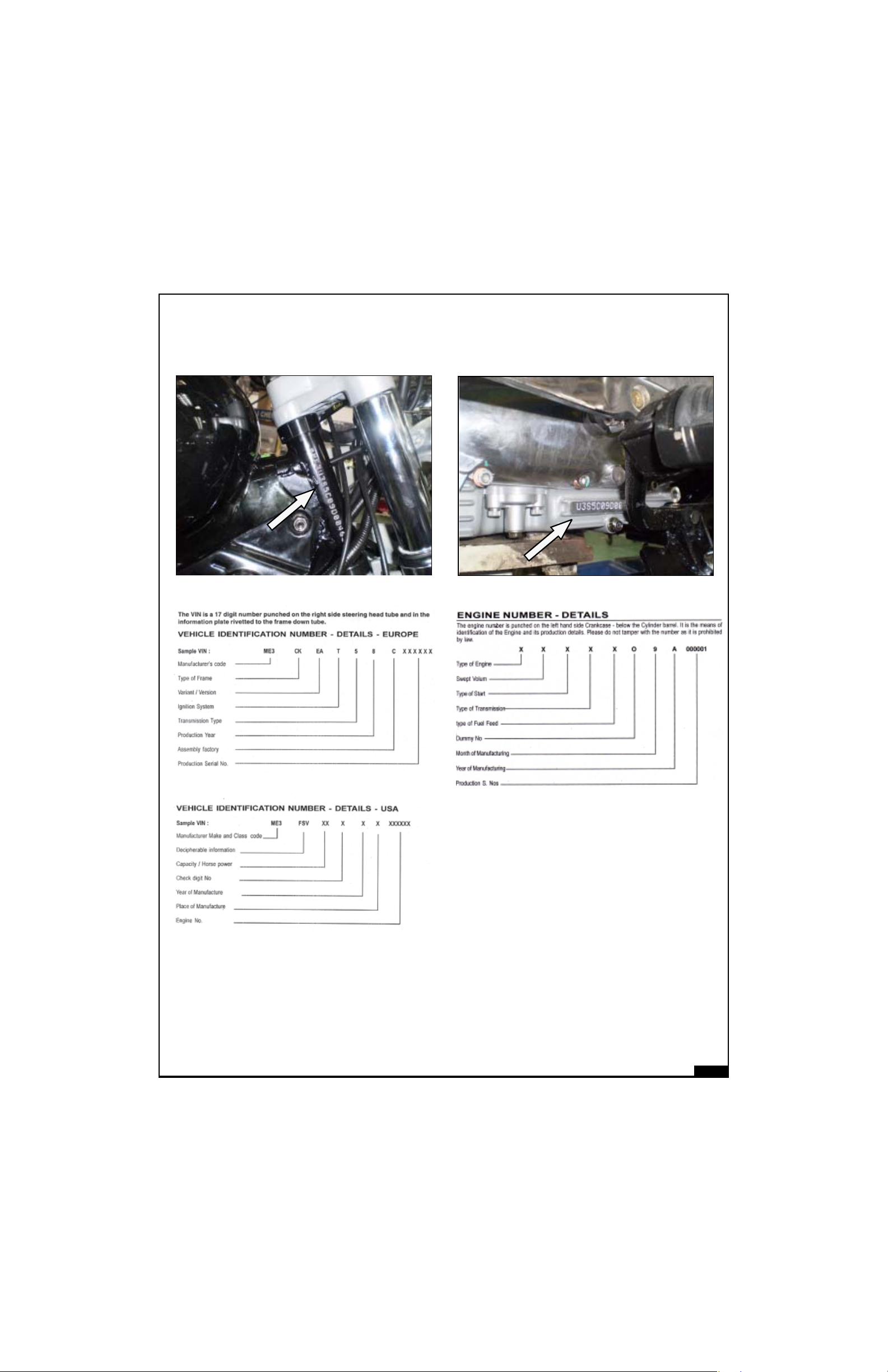

IDENTIFICAIDENTIFICA

IDENTIFICA

IDENTIFICAIDENTIFICA

TION OF CHASSIS NOTION OF CHASSIS NO

TION OF CHASSIS NO

TION OF CHASSIS NOTION OF CHASSIS NO

.,.,

ENGINE NO ENGINE NO

.,

ENGINE NO

.,.,

ENGINE NO ENGINE NO

,,

,

,,

CHASSIS NO.

ENGINENO.

02-9

Page 17

LIST OF SPECIAL LIST OF SPECIAL

LIST OF SPECIAL

LIST OF SPECIAL LIST OF SPECIAL

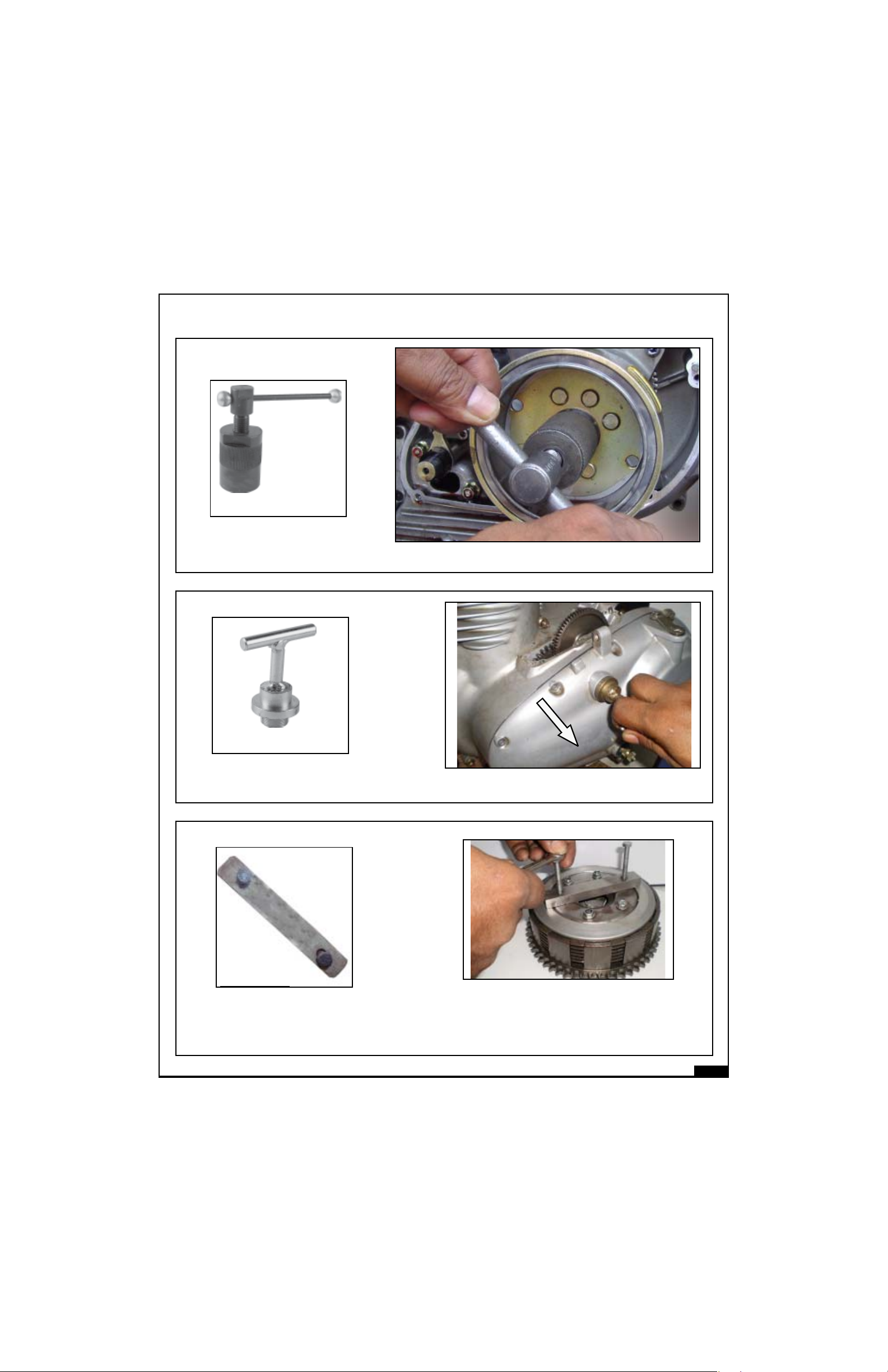

ST 25128-2

Magneto Puller for TCI

TT

OOLS OOLS

T

OOLS

TT

OOLS OOLS

Application : Removal of magneto assembly

AND ITS AND ITS

AND ITS

AND ITS AND ITS

APPLICAAPPLICA

APPLICA

APPLICAAPPLICA

TIONTION

TION

TIONTION

ST 25151-4

Chain case outer puller (TCI)

ST-25594-4

Clutch spring assy.

Application :To remove Crank case LH cover

Application : To compress clutch springs while

removing & refitting Clutch plates.

02-10

Page 18

LIST OF SPECIAL LIST OF SPECIAL

LIST OF SPECIAL

LIST OF SPECIAL LIST OF SPECIAL

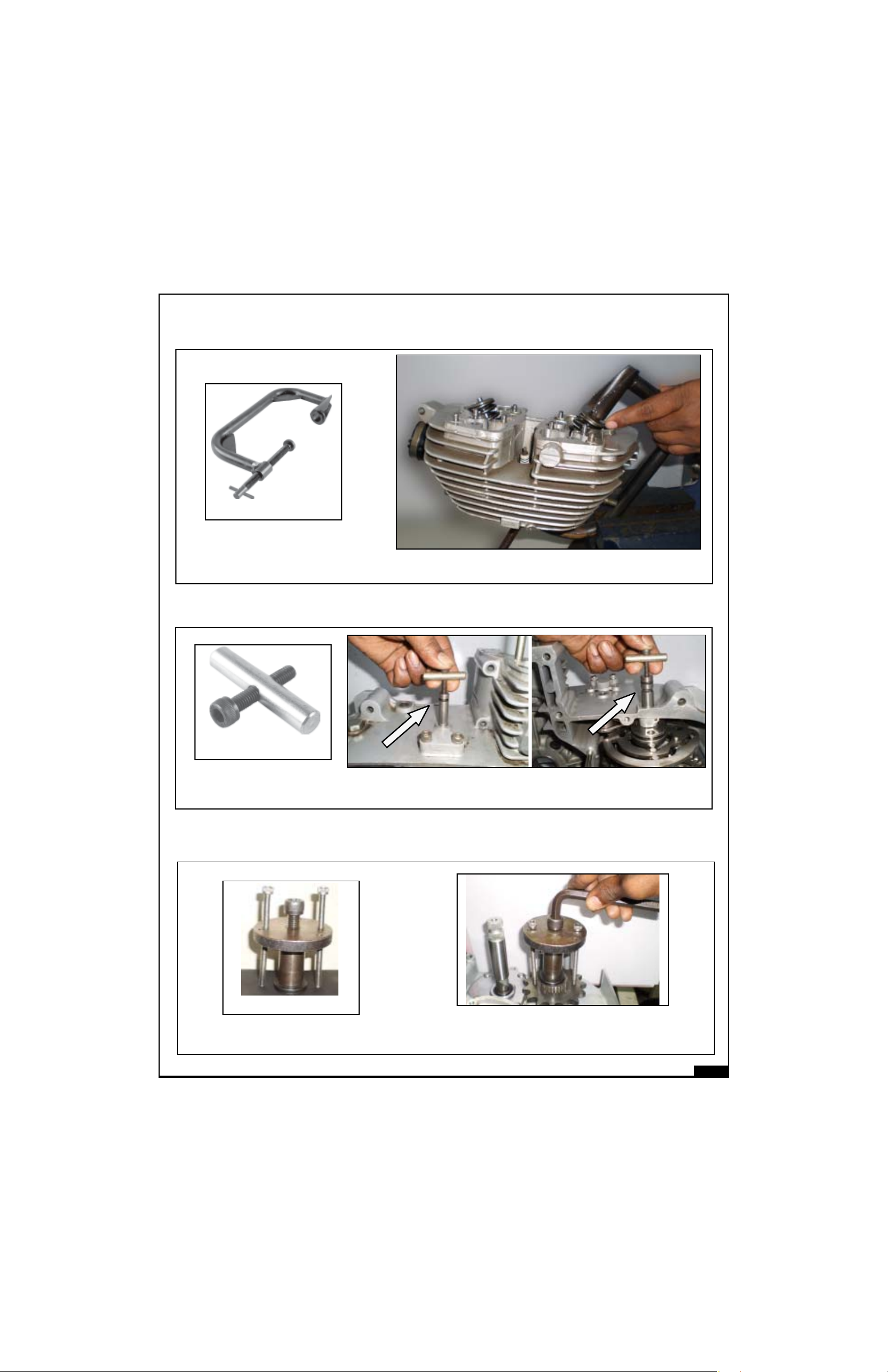

ST-25591-4

Clutch centre nut

TT

OOLS OOLS

T

OOLS

TT

OOLS OOLS

Application : To hold Clutch Sprocket while removing / tightening

the Clutch & Sprag Sprocket Nut.

AND ITS AND ITS

AND ITS

AND ITS AND ITS

APPLICAAPPLICA

APPLICA

APPLICAAPPLICA

TIONTION

TION

TIONTION

Oil seal adopter

ST 25118-4

Cylinder head nut tightening tool

Application : Fitment of gear shaft oil seal on crank case

LH cover.

Application : To remove and tightening of cylinder

head nut.

02-11

Page 19

LIST OF SPECIAL LIST OF SPECIAL

LIST OF SPECIAL

LIST OF SPECIAL LIST OF SPECIAL

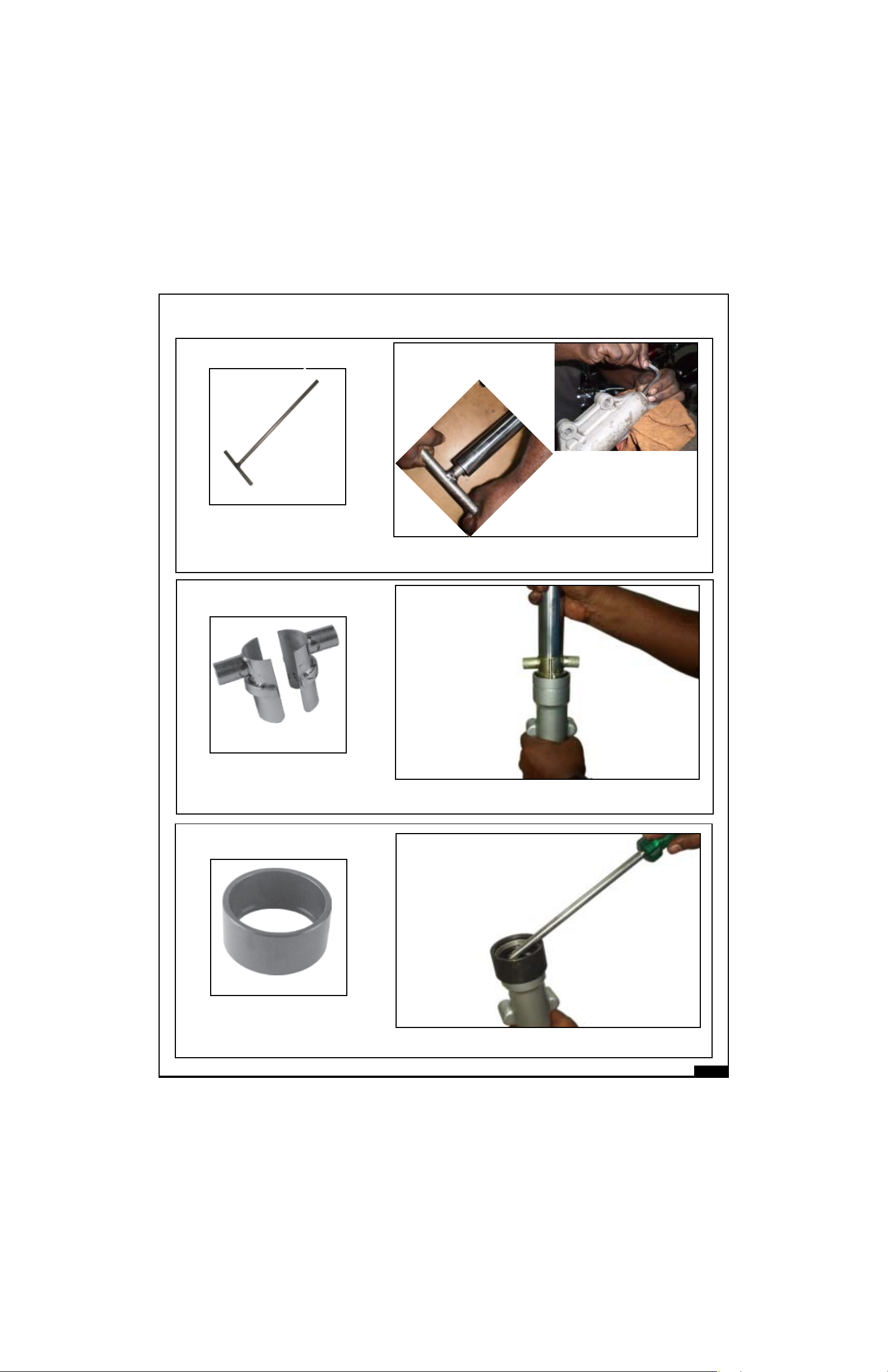

ST 25123-1

Valve Spring compressor

TT

OOLS OOLS

T

OOLS

TT

OOLS OOLS

Application : To compress the valve spring for removal

AND ITS AND ITS

AND ITS

AND ITS AND ITS

and fitting of valve.

APPLICAAPPLICA

APPLICA

APPLICAAPPLICA

TIONTION

TION

TIONTION

ST 25153-4

Extractor for 5 Speed

Gear box Pivot Pin

ST 25

FD sprocket removal tool

Application : To remove Gear Rocker Shaft top pivot pin and Gear

Cam Plate pivot pin.

Application : To remove front drive sprocket

from Sleeve Gear.

02-12

Page 20

LIST OF SPECIAL LIST OF SPECIAL

LIST OF SPECIAL

LIST OF SPECIAL LIST OF SPECIAL

ST

Front fork main tube spanner

TT

OOLS OOLS

T

OOLS

TT

OOLS OOLS

Application : Loosening and tightening of front fork main

AND ITS AND ITS

AND ITS

AND ITS AND ITS

tube with fork end

APPLICAAPPLICA

APPLICA

APPLICAAPPLICA

TIONTION

TION

TIONTION

ST 25112-4

Expander for front fork oil seal

ST 25114-4

Extractor for Fork oil seal

Application : Expander for oil seal while inserting main

tube into bottom tube of front fork

Application : Removal of oil seal in front fork bottom tube

02-13

Page 21

LIST OF SPECIAL LIST OF SPECIAL

LIST OF SPECIAL

LIST OF SPECIAL LIST OF SPECIAL

ST 25113-4

Mandrel for oil seal

TT

OOLS OOLS

T

OOLS

TT

OOLS OOLS

Application : Fitment of oil seal in front fork bottom tube

AND ITS AND ITS

AND ITS

AND ITS AND ITS

APPLICAAPPLICA

APPLICA

APPLICAAPPLICA

TIONTION

TION

TIONTION

ST 25110-3

Gauge for tightening chain stay

ST 25244-4

Adjuster Special Spanner

Application : Alignment of Swing Arm while tightening

Application :To adjust gas filled shock absorber

02-14

Page 22

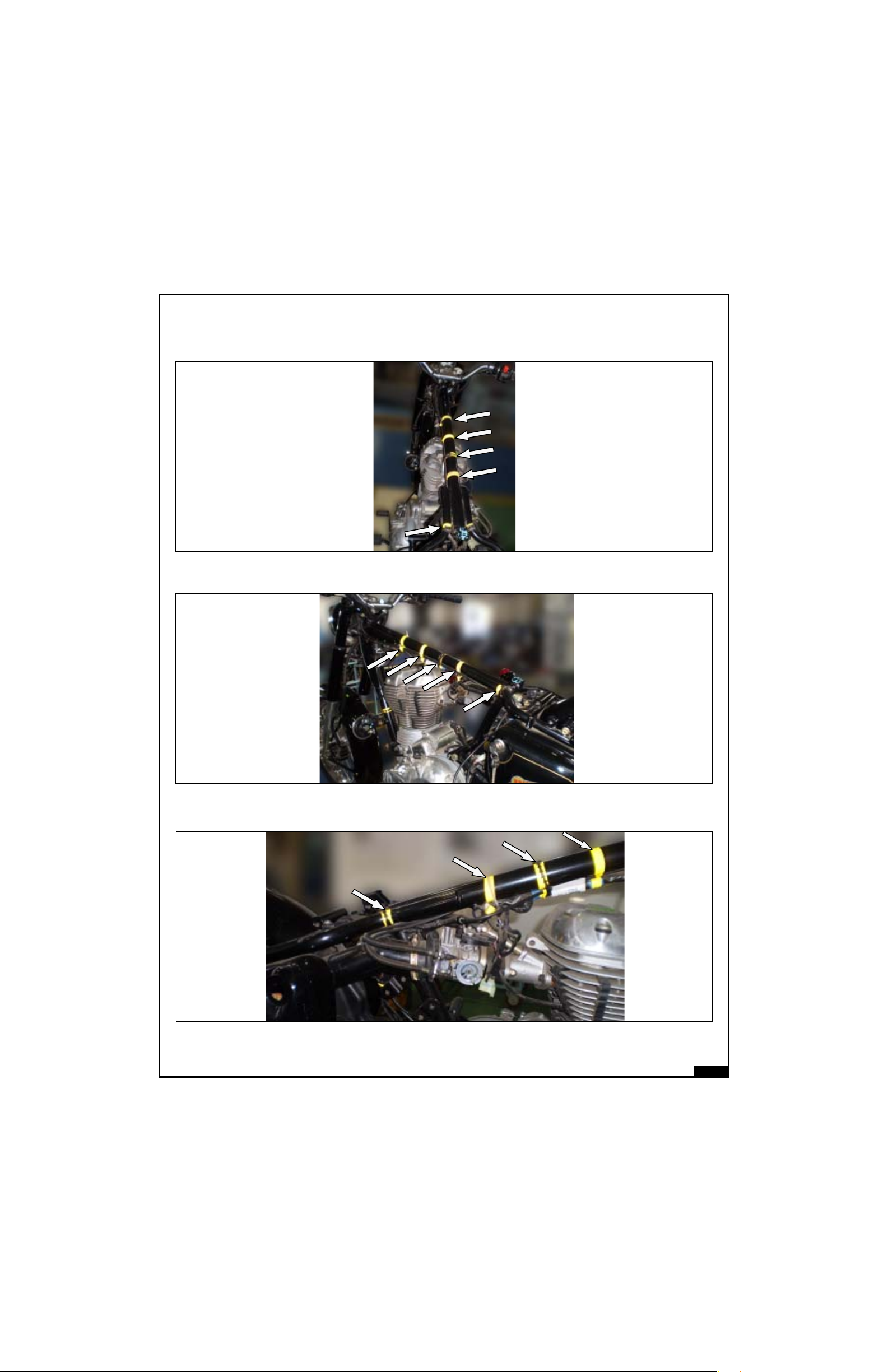

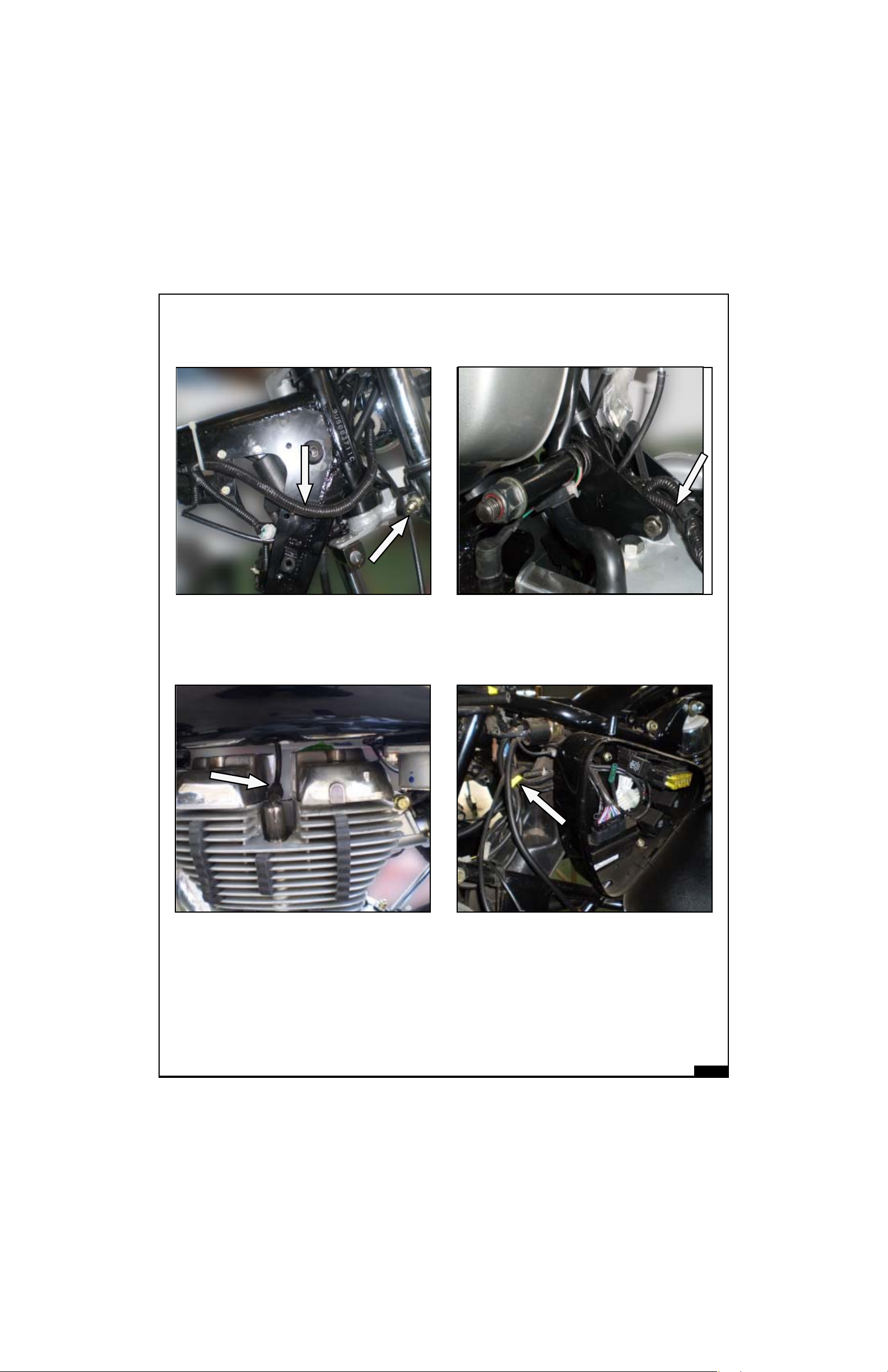

CONTROL CABLES AND WIRING HARNESS ROUTINGCONTROL CABLES AND WIRING HARNESS ROUTING

CONTROL CABLES AND WIRING HARNESS ROUTING

CONTROL CABLES AND WIRING HARNESS ROUTINGCONTROL CABLES AND WIRING HARNESS ROUTING

ALL CONTROL CABLES & WIRING HARNESS ROUTING

UNDER TANK AND SEAT TOP VIEW

UNDER TANK LH VIEW

UNDER TANK RH VIEW

02-15

Page 23

GENERAL GENERAL

GENERAL

GENERAL GENERAL

VEHICLE INFORMAVEHICLE INFORMA

VEHICLE INFORMA

VEHICLE INFORMAVEHICLE INFORMA

TIONTION

TION

TIONTION

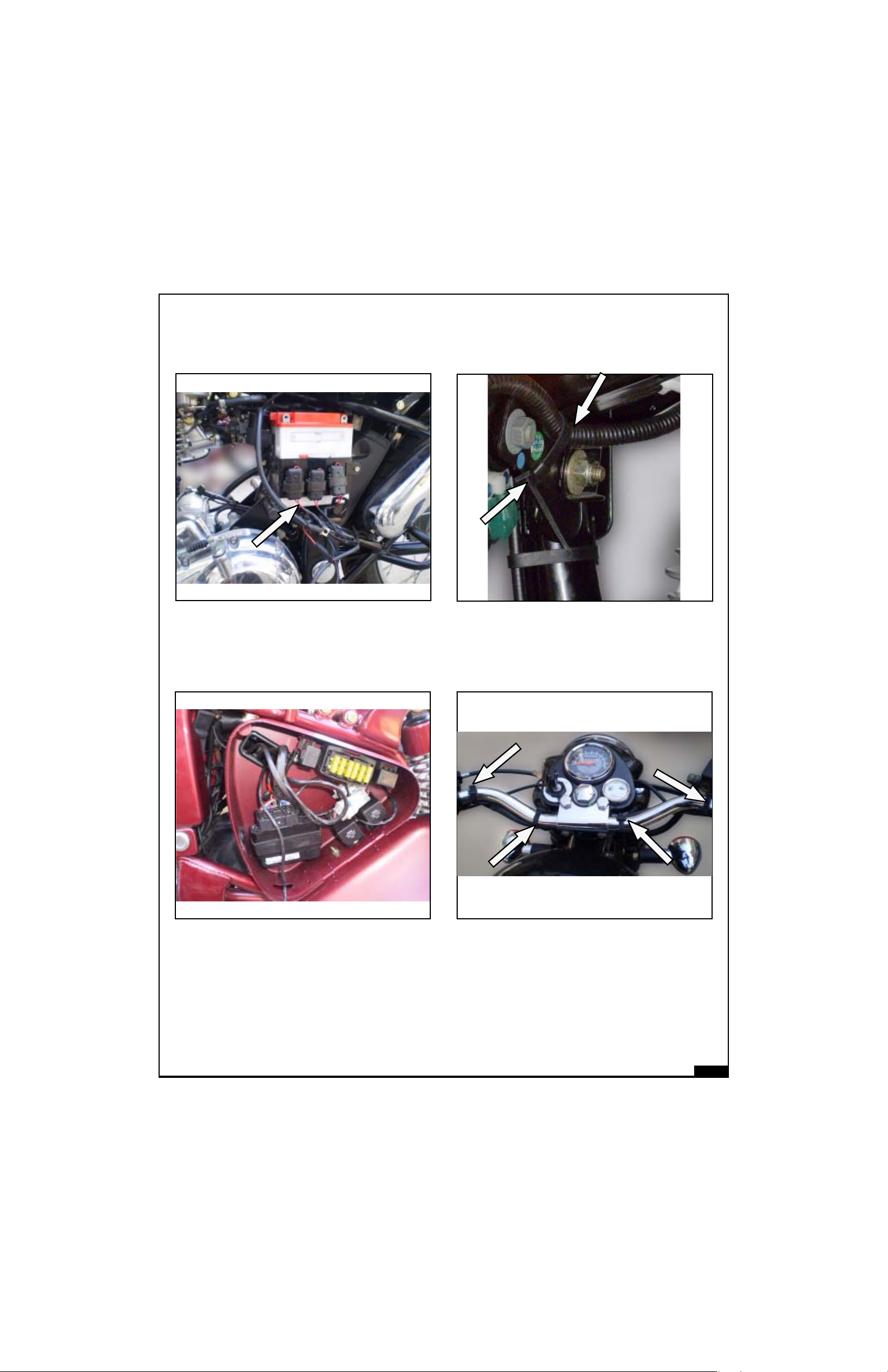

HARNESS ROUTING STEERING RH

PLUG WIRE ROUTING

MAGNETO WIRES ROUTING

STARTER RELAY CABLE

ROUTING

02-16

Page 24

GENERAL GENERAL

GENERAL

GENERAL GENERAL

VEHICLE INFORMAVEHICLE INFORMA

VEHICLE INFORMA

VEHICLE INFORMAVEHICLE INFORMA

TIONTION

TION

TIONTION

FUSE CARRIERS

ARRANGEMENT (E5 & G5)

FUSE CARRIERS

ARRANGEMENT (C5)

HORN WIRE ROUTING

HANDLE BAR WIRES ROUTING

02-17

Page 25

GENERAL GENERAL

GENERAL

GENERAL GENERAL

VEHICLE INFORMAVEHICLE INFORMA

VEHICLE INFORMA

VEHICLE INFORMAVEHICLE INFORMA

TIONTION

TION

TIONTION

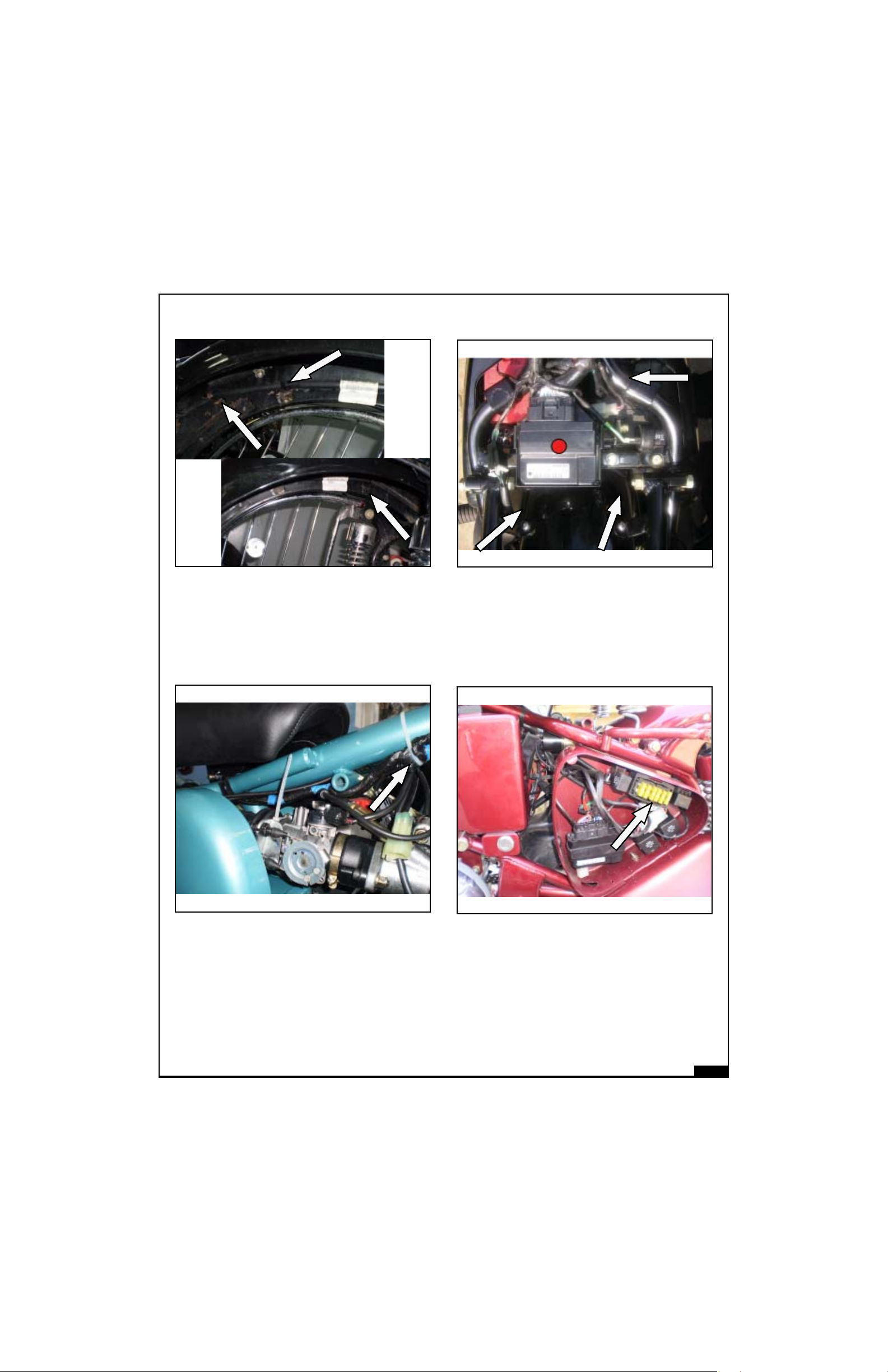

TAIL LAMP & TRAFFICATOR

WIRES ROUTING

ECU MOUNTING BULLET

ELECTRA EFI (E5 & G5)

THROTTLE BODY MOUNTING

WITH CABLES

ECU MOUNTING BULLET

CLASSIC EFI (C5)

02-18

Page 26

SECTIONSECTION

SECTION

SECTIONSECTION

THREE 03THREE 03

THREE 03

THREE 03THREE 03

SERVICE DSERVICE D

SERVICE D

SERVICE DSERVICE D

AA

A

AA

TT

T

TT

AA

A

AA

Page 27

SERSER

SER

SERSER

VICE LIMITS OF COMPONENTS VICE LIMITS OF COMPONENTS

VICE LIMITS OF COMPONENTS (All units in mm unless specified)

VICE LIMITS OF COMPONENTS VICE LIMITS OF COMPONENTS

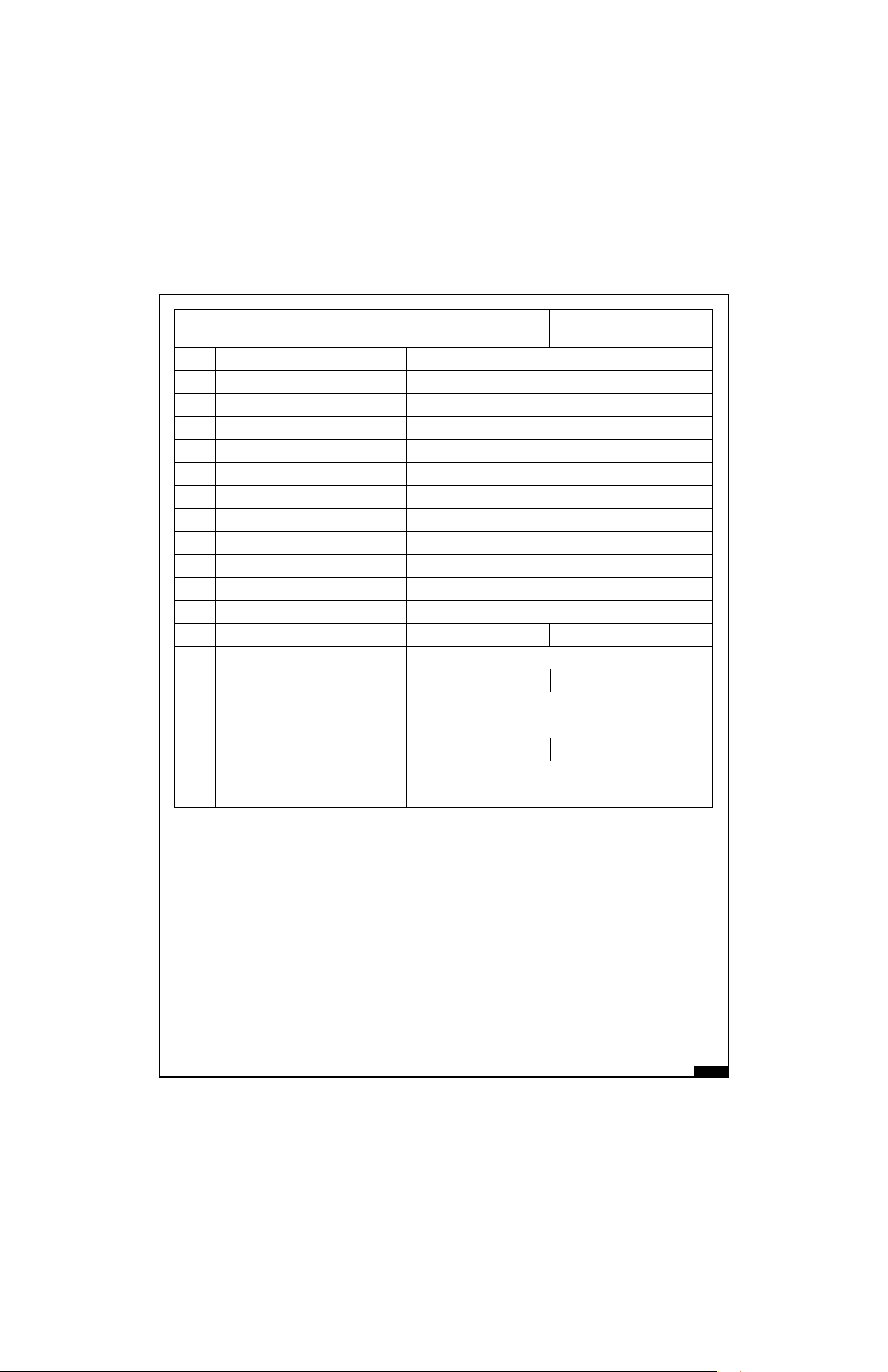

WEAR LIMITS

Wear limits are given as new min, new max and service limits.

New components must be within the limits specified. Components within service limits may be reused

after careful inspection. Use of parts beyond service limit can reduce the operating life of the component

and may affect the motorcycle performance seriously.

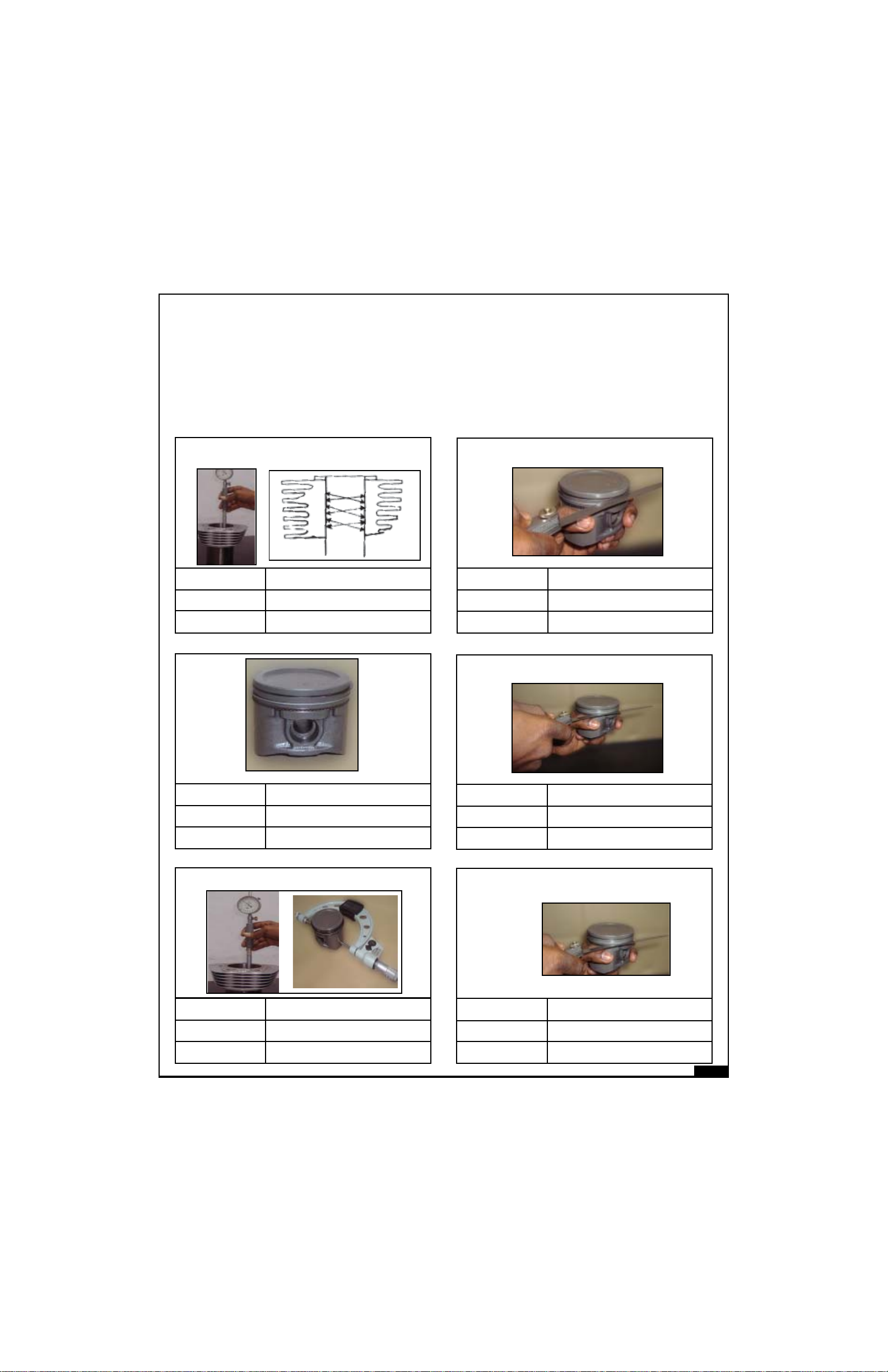

Cylinder bore

New Min.

New Max.

Service Limit

Cylinder bore :

Point of measurement

A

B

C

84.045

84.075

84.190

Piston

Ring to groove clearance : Comp. Top rings

New Min.

New Max.

Service Limit

Ring to groove clearance comp rings - Middle

0.03

0.07

0.11

New Min.

New Max.

Service Limit

New Min.

New Max.

Service Limit

83.940

83.970

83.890

Piston to bore clearance

0.095

0.115

0.30

New Min.

New Max.

Service Limit

Ring to groove clearance : oil ring

New Min.

New Max.

Service Limit

0.03

0.07

0.15

0.06

0.15

0.21

03-1

Page 28

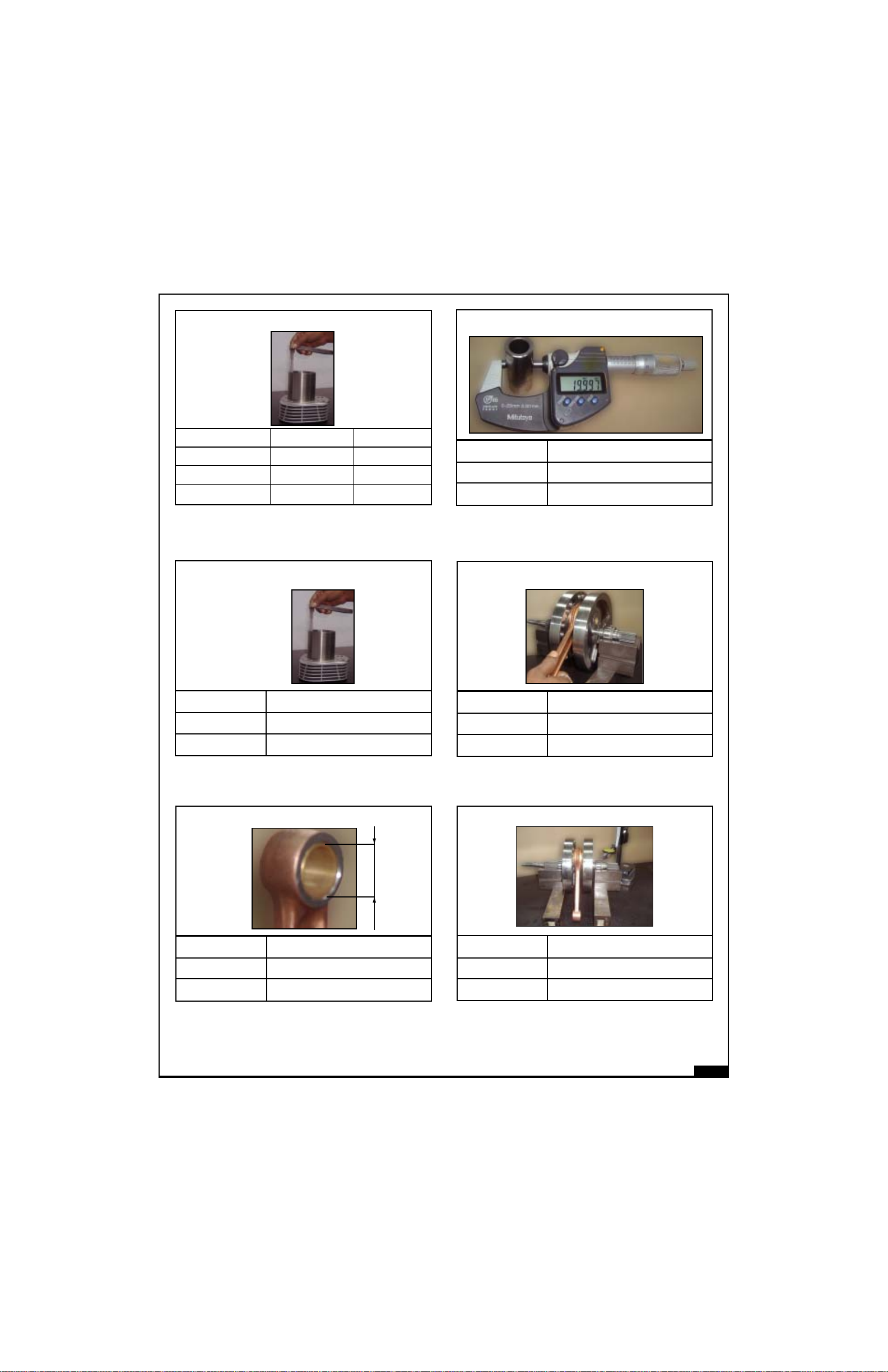

Piston ring end gap : compression

From top 1st 2nd

New Min. 0.20 0.35

New Max. 0.35 0.50

Service Limit 0.70 0.85

New Min.

New Max.

Service Limit

Piston Pin diameter

19.992

19.997

19.982

New Min.

New Max.

Service Limit

Piston ring end gap - Oil Ring

0.20

0.70

0.90

Small end bore inner diameter

New Min.

New Max.

Service Limit

Big end axial play

0.20

0.55

0.65

Crank shaft : Run out

New Min.

New Max.

Service Limit

20.007

20.016

20.046

New Min.

New Max.

Service Limit

0.00

0.04

0.08

03-2

Page 29

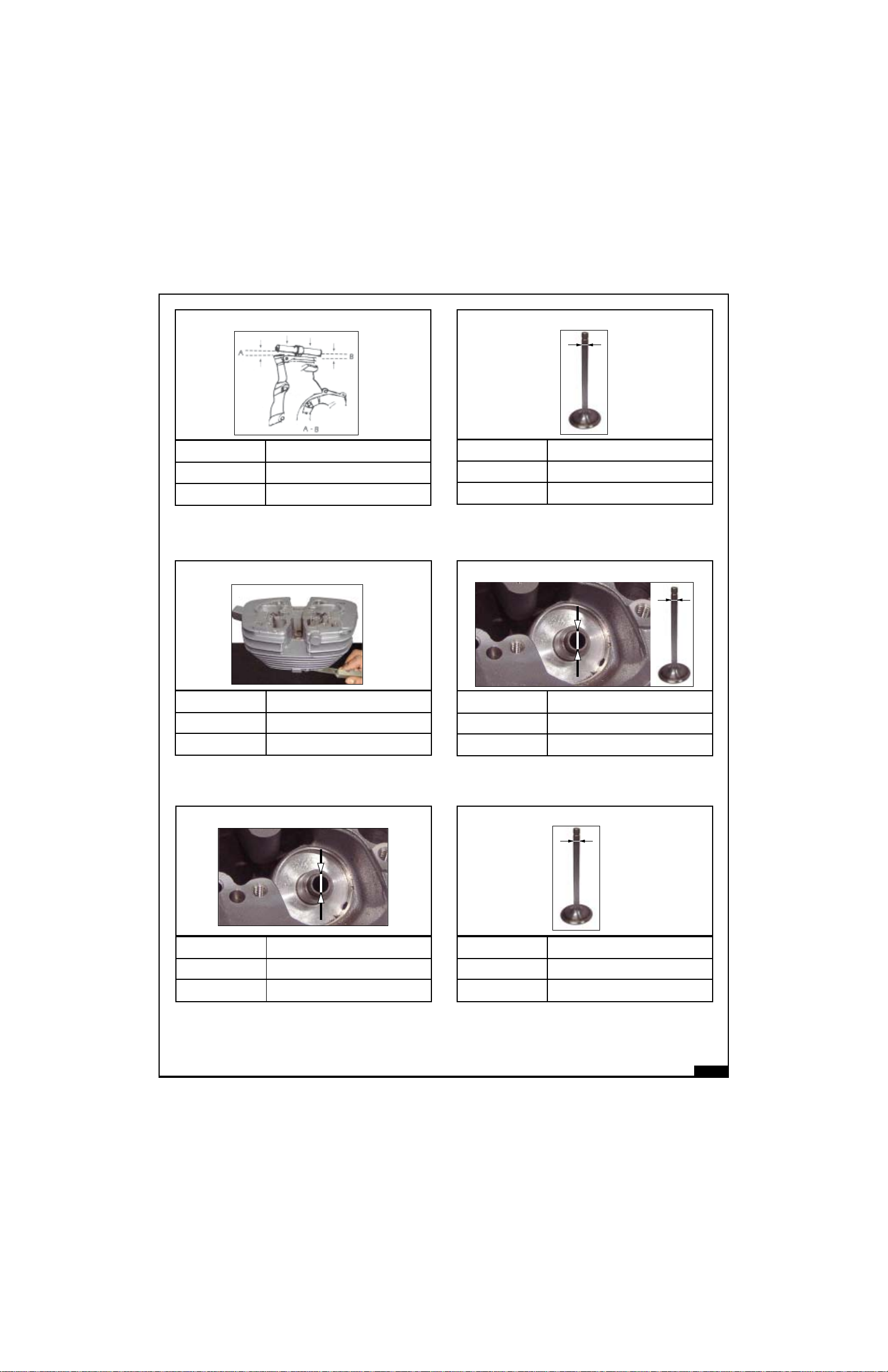

Connecting rod bend

Valve stem OD (Inlet)

New Min.

New Max.

Service Limit

New Min.

New Max.

Service Limit

0.00

0.05

0.08

Cylinder Head warpage

0.00

0.05

0.07

New Min.

New Max.

Service Limit

New Min.

New Max.

Service Limit

6.965

6.980

6.955

Valve to guide (inlet) clearance

0.02

0.05

0.08

New Min.

New Max.

Service Limit

Valve guide bore

7.00

7.015

7.25

New Min.

New Max.

Service Limit

Valve stem OD (Exhaust)

6.945

6.960

6.935

03-3

Page 30

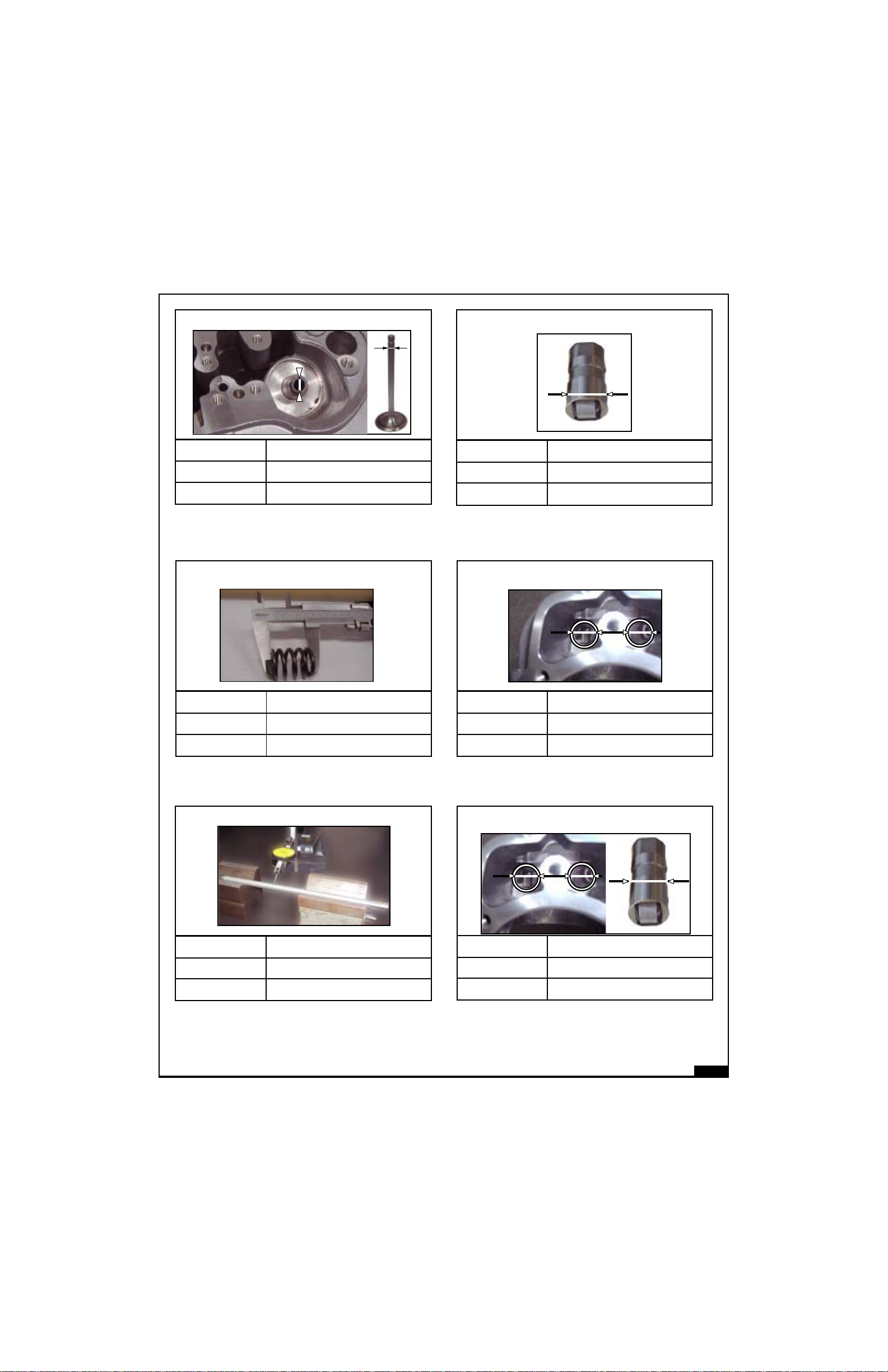

Valve to guide (Exhaust) Clearance

Hydraulic Tappet OD

New Min.

New Max.

Service Limit

New Min.

New Max.

Service Limit

0.04

0.07

1.00

Valve Spring : length

42.80

44.80

41.50

New Min.

New Max.

Service Limit

New Min.

New Max.

Service Limit

21.387

21.405

21.380

Hydraulic Tappet guide bore

21.417

21.438

21.450

New Min.

New Max.

Service Limit

Push rod run out

0.00

0.02

0.05

Hydraulic tappet to guide clearance

New Min.

New Max.

Service Limit

0.012

0.051

0.060

03-4

Page 31

Main shaft Outer diameter

Selector fork shaft outer diameter

A

B

Location A B

New Min. 19.99 23.93

New Max. 20.00 23.95

Service Limit 19.97 23.90

Lay shaft Outer diameter

X

Y

Location X Y

New Min. 17.99 23.95

New Max. 18.00 23.97

Service Limit 17.97 23.93

New Min.

New Max.

Service Limit

New Min.

New Max.

Service Limit

9.96

9.98

9.94

Selector fork inner diameter

10.00

10.03

9.98

New Min.

New Max.

Service Limit

Cam plate inner diameter

13.01

13.03

13.00

New Min.

New Max.

Service Limit

Selector fork lug thikness

3.90

3.95

3.88

03-5

Page 32

Lay shaft 1st gear inner diameter

Pivot cam plate outside diameter

New Min.

New Max.

Service Limit

Lay shaft 2nd gear inner diameter

New Min.

New Max.

Service Limit

18.03

18.06

18.09

24.00

24.03

24.06

New Min.

New Max.

Service Limit

New Min.

New Max.

Service Limit

12.98

13.00

12.96

Clutch spring Length

64.5

65.5

60.0

Main shaft 3rd & 4th gear inner diameter

MS 4

New Min.

New Max.

Service Limit

24.00

24.03

24.06

MS 3

Friction plate with insert : thickness

New Min.

New Max.

Service Limit

2.95

3.05

2.60

03-6

Page 33

Clutch steel plate : Distortion

Throttle cable free play

New Min.

New Max.

Service Limit

Duplex Chain - Length across 21 pins

New Min.

New Max.

Service Limit

0.00

0.05

0.10

190.00

191.00

195.00

New Min.

New Max.

Service Limit

New Min.

New Max.

Service Limit

-

1 mm

2 mm

Drive chain : slackness

20.00

30.00

-

New Min.

New Max.

Service Limit

Clutch cable -Free play

2 mm

4 mm

-

New Min.

New Max.

Service Limit

Rear Sprocket chain pull off

-

-

5.00

03-7

Page 34

Sprocket

Brake drum rear : Internal dia.

GOOD

New Min.

New Max.

Service Limit

Drive chain length across 21 pins

REPLACE

Sharp, bend broken teeth

New Min.

New Max.

Service Limit

152.40

152.50

153.50

Wheel rim: Face out / Run out

New Min.

New Max.

Service Limit

New Min.

New Max.

Service Limit

320

322

328

Brake lining thickness

3.80

4.06

2.00

New Min.

New Max.

Service Limit

New Min.

New Max.

Service Limit

0

1.0 mm

2.00 mm

Axle shaft : run out

0.00

0.01

0.02

03-8

Page 35

Main tube - run out

Caliper Piston Outer Diameter

OD

New Min.

New Max.

Service Limit

Front fork assembly spring : length

New Min.

New Max.

Service Limit

0.00

-

0.04

538

544

527

New Min.

New Max.

Service Limit

New Min.

New Max.

Service Limit

-

-

25.31mm

Master Cylinder piston OD

-

-

12.64 mm

New Min.

New Max.

Service Limit

Caliper Bore Inner Diameter

ID

-

-

25.46 mm

New Min.

New Max.

Service Limit

Master Cylinder Bore

-

-

12.76 mm

03-9

Page 36

Tyre tread : Depth

New Min.

New Max.

Service Limit

New Min.

New Max.

Service Limit

-

-

1.00 mm

Spark Plug Gap

0.7

0.8

-

03-10

Page 37

PERIODICAL MAINTENANCEPERIODICAL MAINTENANCE

PERIODICAL MAINTENANCE

PERIODICAL MAINTENANCEPERIODICAL MAINTENANCE

The schedule provided herein is based upon average riding conditions and indicates the mileage at which regular

inspections, adjustments, replacements and lubrications must be carried out. The frequency of the maintenance

must be shortened depending upon the severity of the driving condition OR if the motorcycle is used in a very dusty

environment, severe climatic cold and hot conditions, bad roads, stagnant water etc.,

S.

No.

DESCRIPTION

SCHEDULE

Kms (x 1000) 0.5 3 6 9 12 15 18 21 24 27 30

Miles (x 1000) 0.3 2 3.75 6 7.5 9.5 11.25 13 15 17 18.75

1 Engine Oil R R R R R R

2 Engine oil filter R R R R R R

3 Engine sump oil strainer C C C C C C

4

Magnetic drain plug under gear box on crankcase RH

CCCCCC

5 Spark plug A A A A A R AAAA R

6 HT lead I I I I I I I I I I I

7 Fuel hose I I I I R I I I R I I

8 Fuel Pump Check for screw tightness in all services

9 Accelerator cable play A A A A A A AAAA A

10 Rubber hose, Air filter to Throttle body I I I I R I I I R I I

11 Rubber hose, Inlet manifold I I I I R I I I R I I

12 Air filter element C C C C R C C C R C C

13 Inlet / Exhaust valve seating I I

14 Cylinder head D

15 Exhaust system D

16 Rear brake pedal pivot L L L L L L LLLL L

17 Battery terminals (apply petroleum jelly) C C C C C C C C C C C

18 Battery Electrolyte level I I I I I I I I I I I

19 Earth wire eyelet (behind battery carrier) I I

20 Fork oil R R

21 Rear brake cams L L L L L

22 Steering ball races L L

23 Spokes tightness I I I I I I

24 Wheel rim run out I I I I I

25 Tyre wear I I I I I I I I I I

A : Adjust C : Clean D : De-carboniseI : Inspect L : Lubricate R : Replace

NOTE :

For maintenance after 30,000 Kms, (18,750 miles) please repeat the same frequency levels specified above.

03-11

Page 38

PERIODICAL MAINTENANCPERIODICAL MAINTENANC

PERIODICAL MAINTENANC

PERIODICAL MAINTENANCPERIODICAL MAINTENANC

EE

E

EE

AIR FILTER CLEANING

BULLET ELECTRA EFI (E5/G5)

Remove the 2 air filter lid mounting screws

and take out air filter lid

Remove the 3 cover mounting screws &

take out cover

BULLET ELECTRA CLASSIC EFI (CS)

Blow compressed air from outside to

inside.

Check for cracks, holes, clogging etc.

Replace, if defective

Assemble in the reverse order of

dismantling.

SPARK PLUG CLEANING

Disconnect suppressor cap and remove

spark plug using spark plug spanner.

Clean insulator tip and electrodes using a

pointed scrapper or plug cleaner.

Open filter box cover RH

Remove centre mounting nut

Take out the air filter element

Tap off the dirt

Check and set electrode gap to 0.7 to 0.8

mm.

Refit the spark plug and connect the H.T.

lead

NOTE :

A serviceable spark plug produces thick

light blue spark across the electrode. If

spark plug produces yellow / red, side

sparks, replace it with new.

03-12

Page 39

PERIODICAL MAINTENANCPERIODICAL MAINTENANC

PERIODICAL MAINTENANC

PERIODICAL MAINTENANCPERIODICAL MAINTENANC

EE

E

EE

ENGINE OIL

OIL LEVEL CHECK

Place the motorcycle on the centre stand

Before checking the oil level start and warm

the engine for few minutes. Switch “OFF”

the ignition, wait for two minutes and then

check oil level at the inspection window on

the RH Crankcase cover

DRAINING PROCEDURE :

Keep a clean tray under the engine

Remove the two Hex Flange Bolts M5 X 16,

Sump drain Cap, “O” ring and Suction filter

Assy.

Remove the Magnetic Plug assy along with

its washer.

TILT VEHICLE RH & LH

Two level marks are provided on the

Oil level window in Cover RH Max. & Min.

If oil level is below the Min mark top up, till

the level in between Max and Min mark. Do

not overfill.

NOTE :

Oil capacity Min to Max mark is approx

350 ml.

Max

Min

OIL CHANGE :

Refer Periodical Maintenance chart

(page No. 03-10) for frequency.

Keep vehicle on level ground.

Start the engine and warm up sufficiently

so that the oil drains faster.

After the oil drains out, remove vehicle from

centre stand and tilt the vehicle to both LH

and RH sides 3 to 4 times to drain out

maximum oil.

Quantity of oil that can be drained in 2.35

Litres approximately.

Tighten the oil drain bolt with washer.

Assemble the cleaned suction filter element

in to Crank case and fix drain cap with

“O”ring.

Fill up with 15W50 API SL grade.

Refil oil quantity 2.40 Litres approximately.

03-13

Page 40

REMOVAL OF OIL FILTER ELEMENT:

The oil filter element is located on the

Crankcase Cover RH

Remove the oil filter cap mounting screws.

Remove the oil filter cap along with gasket

(Bullet Electra EFI (E5/G5) “O” ring (Bullet

Classic EFI (C5)

Remove the washer, spring, spring cap,

“O” ring and filter element.

NOTE :

Replace oil filter element whenever engine

oil is changed.

RE ASSEMBLY

Soak the new oil filter in oil for 15 minutes.

Refil the oil filter and other parts in the reverse

order of disassembly.

Start Engine, warm up for a few minutes,

switch off engine and check the oil level.

Oil level should be just below ‘Max’ level.

REAR BRAKE SWITCH ADJUSTMENT

NOTE :

Always re-check brake lamp after

adjustment of brake pedal level and

free play.

REAR WHEEL CHAIN

SLACKNESS ADJUSTMENT :

Check slackness, It should be in between

25 to 30 mm

Ensure to hold the eccentric sleeve by

spanner while tightening the lock nut which

prevent the rotation of the sleeve during

tightening the lock nut.

The backlash is first adjusted between

pinion to exhaust gear and then exhaust to

inlet gear to get effective backlash

adjustment.

Check brake light switch operation.

Loosen bottom nut and tighten top nut till the

brake light comes on when brake pedal is

pressed.

Tighten the bottom nut duly ensuring that the

brake lamp is not glowing continously.

In case brake light is continously glowing

then readjust till correct position in achieved.

03-14

Page 41

The tightening torque for M10 lock nut is

2 KG-M. This must be ensured.

Over size Cam Spindle (For Spares)

570040 : 0.1 mm Over size Spindle

570041 : 0.2 mm Over Size Spindle

CAUTION :

- After the first 800 kms (500 miles) the

backlash between the cam gears must be

checked. If a slight cam noise is observed,

then adjustment of the eccentric sleeve

has to be carried out as mentioned above.

- After adjustment to the required backlash,

both the Inlet & Exhaust lock nut in the

spindle must be tightened to the specified

torque.

If more or less adjust as follows -

Initially clean then lubricate chain > EP90

oil and rotate rear wheel.

Remove split pin and Hex castle nut on the

RH side.

Loosen anchor nut.

Loosen the brake rod nut

Loosen Hex lock nut.

Turn the adjuster cams on both sides till

25 to 30 mm chain slackness is achieved

Check and ensure that the number of

notches from the punch mark on the cam

to the notch resting on the pin are equal on

both sides.

03-15

Page 42

Rotate the wheel and apply brake and

tighten all the nuts and lock the split pin.

BRAKE CAM GREASING

(EVERY 6,000 KMS)

Remove the brake cover plate.

Clean the brake cam and apply grease.

Refit the cover plate.

REAR SHOCK ABSORBERS

ADJUSTMENT

The rear shock absorber spring preload can

be increased or reduced according to road

and load conditions.

Increase the spring preload for high load

operation.

BRAKE PEDAL PLAY ADJUSTMENT

PEDAL FREE PLAY 20 TO 30 MM

Turn in/out the adjuster nut for correct pedal

play

Reduce the spring preload for low load

operation.

The adjuster provided on the bottom of the

spring has five notches.

To carry out the adjustment proceed as

follows :

-Using special tool, place it on the slot

provided on the adjuster.

-Turn the adjuster such that the adjuster

moves up to increase the spring preload

and vice versa to reduce the spring preload.

03-16

Page 43

CAUTION

-Adjust both left and right shock absorbers

to the same notch.

FRONT FORK

A. OIL LEVEL CHECK

(EVERY 6000 KMS)

Take out front fork from the vehicle.

Remove bolt cap.

Fill 265 ml of API SG 10W-30 oil in each

leg .

Bump the fork several times and then

assemble bolt cap with “O” ring (to release

air lock if any).

Assemble back all removed parts.

DISC BRAKE FLUID LEVEL CHECK

Check brake fluid is above the ‘Min’ level in

master cylinder.

MAX

MIN

Check oil level with a 5 mm dia rod.

The level height must be 370 to 380 mm.

Top up, with API SG 10 W-30 oil, if required

B. OIL CHANGE

(EVERY 12,000 KMS)

Remove the fork ends from the vehicle.

Check as detailed in the Section 8

Top up if level is below ‘Min’ mark.

To Top up the fluid, remove the master

cylinder top cover 2 screws and take out

cover, plate & diaphragm.

Top up brake Fluid DOT 3 or DOT 4 upto

“MAX” level.

CAUTION :

As the brake fluid is highly corrosive, take

care that it does not spill over other parts.

It is suggested to wipe brake fluid

immediately, if there is any spill over in other

parts,using a soft cloth (preferably a wet

cloth).

(For further details Ref. page No. 07-12)

STEERING PLAY ADJUSTMENT

(EVERY 6,000 KMS)

Keep a wooden plank under the stand.

Rock the front end and feel the play at stem

top end as shown in fig.

03-17

Page 44

If felt, adjust as follows :

Loosen crown plate bolts as shown

picture ‘A’

B

A

Tighten stem lock nut as shown picture ‘B’

Check play.

Steering to be free with out any play.

Tighten all the screws in reverse order.

Pack grease in the top ball race.

Assemble the steering stem.

WHEEL ALIGNMENT CHECK

Hold the vehicle upright off the stand on

level ground.

Stretch a string about 100 mm above the

ground along the wheels.

If the string touches two points on the rear

wheel and two points on the front wheel (Four

point contact) then the wheels are aligned.

If string touches only three points on the

two wheels, the alignment is incorrect

STEERING BALL RACE LUBRICATION

(EVERY 12,000 KMS)

Remove steering stem assembly.

Clean and check the balls and races

thoroughly for damages / pittings /

discolouration.

Change them if found defective.

Pack grease and balls on the bottom ball

race as shown in Fig.

Adjust the rear wheel, chain adjuster till the

string touches four points.

CLUTCH CABLE FREE PLAY : (2-3mm)

LEVER END

Check clutch cable button seating position

inside lever and condition of the cable.

03-18

Page 45

Screw in or out the cable adjuster for

setting the required play at lever end (2 to

3 mm).

(B ) ADJUSTMENT AT THROTTLE BODY END

Loosen the lock nuts on both the cables.

Adjust both cables unitform and tighten the

lock nuts.

After adjustment refix cable boot.

PRIMARY CHAIN TENSION ADJUSTMENT

This vehicle is fitted with Auto chain

tensioner. Hence there is no need for

periodic manual adjustment.

THROTTLE CABLE PLAY

ADJUSTMENT

Throttle rotor free play 2-3 mm.

There are two adjuster provided - one at the top

near the throttle grip and the other on the throttle

body. Minor adjustments can be carried out at

the top.

(A ) ADJUSTMENT AT HANDLE BAR END

Slide the rubber boot, use 10 mm spanner

to adjust cable outer and lock the nut. Move

the rubber boot over the lock nuts.

THROTTLE CABLE ASSY REPLACEMENT

While replacing throttle cable following

procedure is recommended

- (A) Connect throttle cable to Rotor /

throttle grip assembly

- (B) Connect cable to throttle body and

ensure the recommended free play.

- (C) Route and strap the cable properly.

BATTERY ELECTROLYTE LEVEL :

Electrolyte level can be seen through the

casing

Level to be between max and min marks

NOTE :

Incase of maintenanace free

battery following procedure not applicable.

03-19

Page 46

If required, top up with distilled water

SPECIFIC GRAVITY CHECKING :

Check specific gravity (SG) with a

hydrometer

VALVE TIMING CUM ECCENTRIC CAM

SPINDLE

Bring piston to TDC so that the key way in the

Rotor assembly is at 12o Clock position

Check position of the exhaust cam teeth

between two punch marks with punch mark on

the Fly wheel RH shaft timing gear.

Similarly check position of the inlet cam single

punch mark align with the single punch mark on

the exhaust cam.

Specific Gravity - Min 1.22 & Max 1.24

If less, recharge the battery.

TERMINAL CLEANING :

Clean terminal with warm water and

apply petroleum jelly.

In case of sulphation clean by zero base

emary paper.

ECCENTRIC CAM SPINDLE ADJUSTMENT

The center distance adjustment of gears

is achieved by rotating the eccentric sleeve

and locking it on the spindle by using M 10

lock nut once the desired backlash is

arrived.

DECARBONISING

(EVERY 30,000 KMS)

CYLINDER HEAD

( For further details please Ref. page No.09-3)

Remove carbon from the valves, ports and

combustion chamber by scrapping. Take

care not to cause any damage to the valve

faces or valve seat inserts. Scrape gently

to avoid scoring the cylinder head.

03-20

Page 47

Remove the piston rings carefully. For

cleaning the groove in the piston, a piece

of broken piston ring thrust into a wooden

handle and filed to a chisel point can be

used.

Standard : 0.9 - 1.1 mm

Service Limit : 1.5 mm

Valve seat width is not within specification,

reface the valve seat.

CYLINDER HEAD AND VALVES

VALVE SEAT INSPECTION

Clean both Inlet & Exhaust valves and

thoroughly remove the carbon deposits

Apply light coating of Prussian blue to the

valve seats.

NOTE :

Ensure proper valve seat contact by

taping the valve in the valve seat

without rotating.

CAUTION :

If a valve face is burnt or badly worn or if it

contacts the seat unevenly, replace the valve.

Inspect the valve seat face for :

Damage face :

Replace the valve and reface the valve

seat.

Uneven seat width :

Bent or collapsed valve stem.

Replace the valve and reface the valve

seat.

Remove the valve and inspect the width of

each seat.

The seat contact should be within the

specified width and even all around the

circumference

Contact area is too high or too low. Reface

the valve seat.

03-21

Page 48

VALVE SEAT REFACING

Valve Seat cutters, a grinder or equivalent

valve seat refacing equipment are

recommended to correct worn valve seat.

If the contact area is too high on the valve,

the seat must be lowered using a 32 degree

flat cutter.

Use a 45 degree cutter to remove the

roughness or irregularities from the seat.

Using 32 degree cutter, remove top 1/4 of

the existing valve seat material.

Using 60 degree cutter, remove the bottom

1/4 of the old seat.

If the contact area is too low on the valve,

the seat must be raised using a 60 degree

inner cutter.

NOTE :

Reface the valve seat with a 45 degree cutter

when a valve guide is replaced.

Remove the cutter and inspect the area.

Install a 45 degree finish cutter and cut the

seat to proper width.

Make sure that all printing and irregularities

are removed. Refinish if necessary.

Standard seat width : 0.9 - 1.1 mm

03-22

Page 49

After cutting the seat, apply lapping

compound to the valve face and lap the

valve using light pressure.

NOTE :

Excessive lapping pressure may deform

or damage the seat.

Change the angle of lapping tool frequently

to prevent uneven seat wear.

Lapping compound can cause damage if

it enters between the valve stem and

guide.

After lapping, wash any residual compound

off the cylinder head and valve.

Recheck the seat contact after lapping.

Clean the cylinder head assembly with

solvent and blow through all oil passages

with compressed air.

Install the valve spring seats and new valve

stem seals.

Lubricate each valve stem with clean

engine oil.

Insert the intake and exhaust valve into the

valve guides.

The Parts detail of Cylinder Head assembly

NOTE :

To avoid damage to the seating face, turn

the valve slowly while inserting.

(For further details Ref. page No.05-55)

1. CYLINDER HEAD

2. SPLIT COLLAR

3. RETAINER, SPRING

4. VALVE SPRING

5. VALVE STEM SEAL

6. SEAT, SPRING

7. VALVE GUIDE

8. PLUG

9. VALVE SEAT INSERT, EXHAUST

10. VALVE EXHAUST

11. VALVE INLET

12. VALVE SEAT INSERT, INLET

03-23

Page 50

ENGINE COMPRESSION TEST

STEP-A

Start and warmup the engine to normal

running temperature.

Remove the spark plug & connect

compression gauge.

c) Switch “OFF” Ignition and engine

stop switch condition.

a) Remove spark plug & put few drops of

engine oil into the combustion chamber.

b) Connect compression gauge & repeat

the procedure as explained in the

step-A.

If compression pressure does not

increase, then check for

- blown out cylinder head gasket

- improper torque of Rocker bearing

bolts or cylinder head nuts.

- valve seat - damage / leakage

- valvestem bend

- cylinder head warpage

Hold the throttle open fully and kick several

times (5 to 6 times).

Note down the reading and repeat the

above process 3 times. Take to average

mean reading in 100 ± 10 PSI which is the

correct compression pressure. Specified

engine compression pressure.

STEP-B

In case compression pressure is less than

80 PSI, then refit spark plug & start again

to warmup the engine.

- improper valve timing

If compression pressure reading

increases, then check for

- Improper alignment of piston ring

(end gap position)

- piston ring jamed in groove.

- scoring / seizure of cylinder barrel /

piston

- worn out piston/rings

- worn out cylinder barrel

NOTE :

In case compression pressure is more

than 110 PSI then engine requires

Decarbonisation of cylinder head /

piston (combustion chamber).

03-24

Page 51

SECTIONSECTION

SECTION

SECTIONSECTION

FOUR 04FOUR 04

FOUR 04

FOUR 04FOUR 04

ENGINEENGINE

ENGINE

ENGINEENGINE

Page 52

LUBRICALUBRICA

LUBRICA

LUBRICALUBRICA

TION SYTION SY

TION SY

TION SYTION SY

STEMSTEM

STEM

STEMSTEM

04-1

Page 53

FLY

LUBRICALUBRICA

LUBRICA

LUBRICALUBRICA

TION SYTION SY

TION SY

TION SYTION SY

ROCKER

PUSH ROD

OIL PUMP

STEMSTEM

STEM

STEMSTEM

HYDRAULIC

CAM

STRAINER

CRANK

OIL SUMP

LUBRICATION SYSTEM :

Oil from the oil tank is circulated to various parts through a powerful oil pump, the capacity of which

is 4.5 litres per minute @ 2750 rpm. The oil in the sump gets filtered through an oill strainer located

in the crankcase and then pumped into the oil filter element located in the RH Cover. From here oil

is circulated to 3 main areas. The first branch goes to flywheel to lubricate crank shaft as well as

barrel piston assembly. The second branch goes to hydraulic tappet to maintain the oil pressure

constantly. The third branch goes to rocker assembly and drains down to RH cover chamber through

the push rod tunnel.

LUBRICATION OIL :

3 Specification: MOTUL 3000 4T PLUS 15W50 API, JASO MA SL - GRADE ESTER-Semi Synthetic

3 Oil capacity: 2.75 l - Initial oil filling: through Oil filler Cap = 2.5 l, through Crankcse LH Cover: 0.25 l

Oil pump : TROCHOID TYPE

Trichoidal high flow oil pump delivers oil with a pressure of 4.5 Bar. This provides

good lubrication to all the moving parts and enhances the life of the moving

parts in the engine.

04-2

Page 54

HYDRAHYDRA

HYDRA

HYDRAHYDRA

ULIC ULIC

ULIC

ULIC ULIC

TT

APPETS (ROLLER HYDRAAPPETS (ROLLER HYDRA

T

APPETS (ROLLER HYDRA

TT

APPETS (ROLLER HYDRAAPPETS (ROLLER HYDRA

LIFTER (RHVL)LIFTER (RHVL)

LIFTER (RHVL)

LIFTER (RHVL)LIFTER (RHVL)

HYDRAULIC TAPPET :

The Hydraulic tappet, (also known as RHVL Roller Hydraulic Valve Lifter) is located between

the cam and pushrod in the valve train

mechanism. It not only serves as a valve lifter

most importantly, it automatically and constantly

adjusts itself to compensate for any extra

clearance in the valve train mechanism when

the engine is running at various RPM. The

automatic adjustment is achieved with the aid

of hydraulic pressure inside the hydraulic tappet.

BENEFITS OF HYDRAULIC TAPPET :

3 Eliminates the need for manual and

periodic push rod height adjustments.

3 Compensates for clearances in the valve

train mechanism due to wear of moving

parts OR due to variations in engine

temperature.

ULIC ULIC

ULIC

ULIC ULIC

VV

V

VV

ALAL

AL

ALAL

VEVE

VE

VEVE

ROLLER HYDRAULIC VALVE LIFTER

PUSH ROD OIL

ESCAPING OIL

(D) PUSHROD

SEAT

(C)DISC VALVE

(B) OVER

HEAD OIL

FLOW PATH

OIL INLET

OIL HEAD, OIL DELIVERY CON-

TROL VALVE, LOCKING ACTION

CHECK BALL

(A) HIGH PRESSURE CHAMBER

OIL FLOW PATH

(E) LOW

PRESSURE

CHAMBER

OUTER BODY

OIL TRANSFER ANULUS

PLUNGER

CHECK BALL

SEAT

AIR ESCAPE PATH

THROUGH PLUNGER

CLEARANCE

(F) TRAPPED AIR VOLUME

(H) HIGH PRESURE

CHAMBER

ROLLER

04-3

Page 55

WORKING PRINCIPLE :

Oil enters the hydraulic tappets through a feed

hole in the body and flows into the plunger through

the plunger feed hole, filling the “low pressure

chamber” (E, in Figure)

The oil also flows around the check ball and

through the slots of the ball retainer to fill the cavity

below the plunger, called the “high pressure

chamber” (A, in Figure). Oil is forced down into

this area by momentary low pressure which

occurs once during each cam rotation.

As the hydrauilic tappet rises due to the cam

rotation, the full load of the valve train is applied

on the tappet. A predetermined and closely held

clearance of .0002/.0003 inch (.0051/.0076 mm)

between the outer diameter of the plunger and the

inner diameter of the tappet body allows a

controlled amount of oil to escape up from the high

pressure chamber.

This oil compresses the plunger spring and allows

a small relative movement of the plunger with

respect to the body.

The metering valve moves sufficiently to keep the

push rod seat hole free and unclogged. When the

engine is switched off, the valve seats on the

shoulder of the plunger to minimize drain back of

oil.

If the engine structure or valve train expands or

contracts with changes in engine temperature or

other differentials, the hydraulic tappets will

automatically adjust its own internal length to

compensate for these changes.

PRECAUTIONARY MEASURES :

The hydraulic tappets have minute holes for the

oil to circulate and to also act at the hydraulic

media, hence oil contamination must be at the

minumum. The oil and the filters in the engine,

must be changed periodically as specified.

Whenever the tappets are removed for service

OR stored in spares, they must be kept upright

(the push rod seating surface pointing upwards

and the rollers at the bottom pointing downwards)

to prevent the oil from draining off.

As cam further rotates, the tappets returns to its

original position. At this time, the plunger spring

provides the force to maintain zero back lash in

the valve train mechanism and forces the plunger

back to its original position. This allows engine oil

to once again fill the high pressure chamber so

that the cycle can be repeated during the next cam

rotation.

The overhead oil supply is accurately metered from

the “low pressure chamber”, which is at engine oil

pressure, by using a flat metal disk (metering valve

C, in Figure), which wobbles against a cylindrical

radius curved surface on the bottom of the push rod

seat (D, in Figure). Oil flows up through the hole in

the push rod seat to lubricate the overhead valve

train components (oil flow path B, in Figure).

04-4

Page 56

AUTAUT

AUT

AUTAUT

O DECOMPRESSORO DECOMPRESSOR

O DECOMPRESSOR

O DECOMPRESSORO DECOMPRESSOR

WORKING PRINCIPLE

The auto decompressor is assembled in the

exhaust cam and consists of a flyweight, spring

and pin. These are assembled in the cam

assembly with a screw

During inital cranking of the engine, the cam

rotation will be under 350 RPM. At this speed,

the flyweight will be at its resting position which

causes the pin to protrude above the base circle

of the cam lobe. This will cause the hydraulic

tappet to raise and will cause the exhaust valve

to be open thus letting out the compression form

the cylinder head.

As the engine starts, the cam rotation increases

beyond 350 RPM which inturn will cause the

flyweight to open and force the pin to rotate and

its projection will go below the cam lobe. This

will cause the tappet to return to its resting

poisition and will close the exhaust valve thus

holding the compression required to start the

engine

BENEFITS OF AUTO DECOMPRESSOR :

3 Eliminates the need to fix a manual system

which will need to be adjusted and serivced

periodically.

3 Helps in easy starting of the engine

3 Helps to reduce high initial load on the

electric start motor

04-5

Page 57

ELECTRIC STELECTRIC ST

ELECTRIC ST

ELECTRIC STELECTRIC ST

ARAR

TER SYTER SY

AR

TER SY

ARAR

TER SYTER SY

STEM & SPRASTEM & SPRA

STEM & SPRA

STEM & SPRASTEM & SPRA

G MECHANISMG MECHANISM

G MECHANISM

G MECHANISMG MECHANISM

WORKING PRINCIPLE

The sprag is located in the primary sprocket on the crankcase drive side. This provides better rigidity

of the sprag mechanism during initial crankin.

The auto decompressor mechanism further helps in reducing the load on the sprag during intitial

cranking and also prevents reversal phenomenon of the crank shaft.

04-6

Page 58

AA

A

AA

UTUT

O CHAIN O CHAIN

UT

O CHAIN

UTUT

O CHAIN O CHAIN

TENSIONER TENSIONER

TENSIONER

TENSIONER TENSIONER

ASSEMBLASSEMBL

ASSEMBL

ASSEMBLASSEMBL

YY

Y

YY

WORKING PRINCIPLE

The auto chain tensioner has a spring loaded plunger mechanism with a ratchet arrangement. It

eliminates need for manual adjustment of the primary chain tension.

It is assembled on the crankcase LH below the chain tensioner pad. The spring loaded plunger

applies force on the chain tensioner pad thereby lifting it and holding aginst the primary chain to the

required tension.

The oneway rachet mechanism in the auto chain tensioner ensures that the plunger does not drop

down due to the downward force of the chain tensioner pad.

It does not require any maintenance or service.

04-7

Page 59

ENGINE BREAENGINE BREA

ENGINE BREA

ENGINE BREAENGINE BREA

Breather

arrangement

inside the

RH cover

THER SYTHER SY

THER SY

THER SYTHER SY

STEMSTEM

STEM

STEMSTEM

WORKING PRINCIPLE

The engine breather system is located on the RH cover of the crankcase. A connecting hole directs

the engine breathing into a chamber in the RH cover which has an inbuilt deflector to deflect the oil

that may come along with the fumes from the crankcase. This oil gets drained through a small hole

provided at the bottom of the breather chamber.

The emission passes through the deflector chamber and goes to the air filter housing and passes

through the inlet manifold back into the cylinder head.

04-8

Page 60

CLCL

CL

CLCL

UTUT

UT

UTUT

CH SYCH SY

CH SY

CH SYCH SY

STEMSTEM

STEM

STEMSTEM

The clutch system has a seven plate construction to achieve increase effective diameter and improved

torque carrying capacity.

The clutch is operated through a lever on the cover LH.

04-9

Page 61

INLET MANIFOLD & INLET MANIFOLD &

INLET MANIFOLD &

INLET MANIFOLD & INLET MANIFOLD &

THRTHR

THR

THRTHR

OO

TTLE BODTTLE BOD

O

TTLE BOD

OO

TTLE BODTTLE BOD

YY

Y

YY

The inlet manifold has the fuel injector located on top portion and the throttle body attach to it.

The throttle body has a butterfly valve attached which is operated buy the throttle cables attached to

a drum on the right side.

A manual Bi starter is located on the left side and is the spring and plunger type arrangement.

An idle air bypass screw is provided on the throttle body. It is the large brass coloured screw that is

accessed from the top of the throttle body. The clamps on the throttle body may be loosened and the

throttle body rotated outwards from the top to access the screw without removing the fuel tank and

to adjust the idle speed with the bike running. Turn the screw CLOCKWISE (in) to DECREASE the

idle speed. Turn the screw ANTICLOCKWISE (out) to increase the idle speed. Remember that this

is an AIR BYPASS screw – not a throttle stop screw. Turning the screw about ¼ turn will result in an

approximate 200 RPM change in the idle speed. DO NOT adjust the throttle stop screw on the side

of the throttle body unless you are using the factory software to recalibrate the base throttle opening.

04-10

Page 62

Blow Up Charts

04-11

Page 63

43

CRANK CASE RH - COVER SIDE

45

44

10

19

1

18

10

A1

2

41

A2

34

42

35

36

33

37

32

38

39

31

30

40

24

25

23

29

26

27

22

28

20

17

12

21

16

11

15

14

10

12 13

9

11

7

A1

3

10

Key Nos.

13,14,15,16,17

4

5

6

8

7

A2

Key Nos.

30,31,32,33,34

04-12

Page 64

CRANK CASE RH - COVER SIDE

KEY No. DESCRIPTION

A1 CAM GEAR ASSEMBLY-EXHAUST WITH

DECOMPRESSOR ASSY

A2 OIL PUMP ASSEMBLY

1 TAPPET DOOR BUFFED

2 CSK SOCKET HEAD SCREW M5 X 12

3 ROTOR AND RELUCTOR ASSEMBLY

4 KEY - MAGNETO

5 PLAIN WASHER,

6 HEX. NUT M12 X 1.25

7 HEX. SOCKET HEAD CAP SCREW, M6 X 30

8 HEX. SOCKET HEAD CAP SCREW, M6 X 25

9 CAM STEADY PLATE

10 DOWEL 6 MM

11 NUT - CAM SPINDLE

12 SHIM, CAM GEAR

13 PIVOT

14 PIN ASSEMBLY

15 FLY WEIGHT

16 TORSION SPRING

17 CAM GEAR SUB ASSEMBLY- EXHAUST

18 CAM SLEEVE

KEY No. DESCRIPTION

26 FD SPROCKET 17 TEETH

27 TAB WASHER

28 NUT

29 CSK SOCKET HEAD SCREW M6 X 30

30 CIRCLIP

31 PUMP DRIVE PINION (GEAR)

32 HEX. SOCKET HEAD CAP SCREW M6 X 25

33 ‘O’ RING, OIL PUMP OUTLET

34 GASKET, OIL PUMP

35 HEX FLANGE BOLT M5 X 12

36 COPPER WASHER

37 CAP, PIVOT PIN

38 ‘O’- RING

39 ‘O’ RING

40 PIVOT, CAMPLATE

41 HEX SOCKET HEAD CAP SCREW, M6 X 60

42 STARTER MOTOR ASSEMBLY

43 HYDRAULIC VALVE LIFTER ROLLER

44 COVER STARTER MOTOR

45 HEX SOCKET, BUTTON HEAD SCREW, M5 X 12

19 CAM SPINDLE ADJUSTABLE

CAM SPINDLE ADJUSTABLE ( 0.1 OVERSIZE )

CAM SPINDLE ADJUSTABLE ( 0.2 OVERSIZE )

20 CAM, GEAR - INLET

21 HEX SOCKET PAN HEAD SCREW M5 X12

22 OIL SEAL KICK STARTER

23 COVER, KICK START SHAFT

24 OIL SEAL

25 DISTANCE PIECE

04-13

Page 65

CRANK CASE LH INSIDE VIEW

04-14

Page 66

CRANK CASE LH

KEY No. DESCRIPTION

1 CRANK CASE-LH

2 CIRCLIP

3 BALL BEARING 6305 (25 X 62 X 17)

4 BEARING SPACER

5 ROLLER BEARING NU305 (25 X 62 X 17)

6 BALL BEARING 6006

7 RETAINER PLATE, MAINSHAFT BEARING

8 HEX SOCKET HD CAP SCREW , M5 X 16

9 JACK SHAFT

10 STUD, M8 X 128

11 FLANGE NUT-M8

12 NEEDLE BEARING

13 WASHER, THRUST

14 STUD M6 X 133

04-15

Page 67

CRANK CASE RH - INSIDE VIEW

18

19

12

13

11

10

16

14

15

23

24

25

28

29

30

9

17

20

22

21

26

27

5

8

4

7

6

3

2

1

04-16

Page 68

CRANK CASE RH - INSIDE VIEW

KEY No. DESCRIPTION

1 CIRCLIP

2 DEEP GROOVE BALL BEARING – SLEEVE

GEAR

3 NEEDLE BEARING

4 SLEEVE GEAR

5 NEEDLE BEARING

6 HEX. SOCKET HEAD CAP SCREW, M6 X 12

7 BRACKET - PIN - HYDRAULIC - TAPPET

8 NEEDLE ROLLER

9 BEARING

10 DOWEL - HOLLOW

11 STUD, M8 X 128

12 FLANGE NUT-M8

13 BOLT, PAWL

14 WASHER, INSPECTION SCREW

KEY No. DESCRIPTION

18 MACHINED WASHER 6.4

19 HEX. NYLOCK NUT M6 X 1

20 HEX FLANGE BOLT M5 X 16

21 DRAIN CAP - SUMP

22 O RING- DRAIN CAP

23 SUCTION FILTER ASSY

24 STOP PLATE

25 HEX. SCREW M8 X 25,

26 OIL THROWER

27 HEX. SOCKET HEAD CAP SCREW, M5 X 35

28 LOCATING PIN (PIVOT)

29 NEEDLE BEARING

30 WASHER, THRUST

15 MAGNETIC PLUG ASSEMBLY

16 SPRING

17 PAWL, CAMPLATE

04-17

Page 69

27

ENGINE COVER - RH

49

48

7

04-18

Page 70

ENGINE COVER - RH

KEY No. DESCRIPTION

1 UCE, RH COVER SUB ASSEMPLY

2 COVER, RH

3PLUG

4 RESTRICTOR (LEE PLUG)

5 SEALING WASHER 12X15.5

6 OIL LEVEL WINDOW

7 BOLT BREATHER

8 JET,CRANKSHAFT RH

9 OIL SEAL , CRANK FEED 24X10X7

10 CIRCLIP 24N

11 WASHER, INSPECTION SCREW

12 INSPECTION SCREW, IGNITION TIMING

13 O-RING

14 OIL FILLER CAP, NYLON

15 ELEMENT - OIL FILTER

16 SPRING CAP

17 WASHER

18 SPRING

19 O-RING

20 O-RING, FILTER CAP

21 GASKET, CAP OIL FILTER

22 CAP, OIL FILTER

23 HEX FLANGE BOLT M5x16

24 GASKET, COVER PLATE

25 COVER PLATE, BREATHER CHAMBER

KEY No. DESCRIPTION

26 HEX.SCREW, M5X12

27 STATOR & PULSOR COIL ASSY -

THREE PHASE

28 PULSOR COIL FIXING SCREW

29 ALLEN SCREW M6X30

30 HEX.SOCKET HEAD CAP SCREW, M6X85

31 HEX.SOCKET HEAD CAP SCREW, M6X100

32 HEX.SOCKET HEAD CAP SCREW, M6X80

33 HEX.SOCKET HEAD CAP SCREW, M6X60

34 HEX. SOCKET HEAD CAP SCREW, M6X40

35 GASKET - COVER RH

36 OIL SEAL, KICK SHAFT

37 KICK START CRANK ASSY.

38 BOSS, KICK START CRANK

39 SPRING

40 BALL DIA 6.35

41 LEVER, KICK START CRANK

42 SLEEVE, KICK START LEVER

43 WASHER

44 CIRCLIP 10

45 HEX. BOLT M8X40

46 HEX. NUT, M8

47 SEALING WASHER 6 × 10 IS : 3175 CU

48 BREATHER PIPE

49 FLYWHEEL MAGNETO 3 PHASE

04-19

Page 71

CRANK CASE LH - COVER SIDE

04-20

Page 72

CRANK CASE LH - COVER SIDE

KEY No. DESCRIPTION

1 CRANK CASE-LH

2 DOWEL (6MM)

3 COLLAR, MAINSHAFT

4 GEAR, - JACK SHAFT

5 KEY - JACK SHAFT

6 CIRCLIP 12 × IN IS 3075 (PART I)

(FOR SHAFT)

7 DOWEL

8 NEUTRAL SWITCH WITH PACKING

9 HEX.SOCKET HD.CAP SCREW,M6 X 50

10 STUD M6 X 168

11 STUD M6 X 106

12 STUD M6 X 196

13 STUD M6 X 226

14 STUD M6 X 80

15 NUT M6X1, FLANGE NYLOC TYPE

16 SHAFT, DOUBLE GEAR

17 DOUBLE GEAR - STARTER DRIVE

18 HOUSING STARTER DRIVE

19 HEX.SOCKET HD.CAP SCREW,M5 X 45

20 HEX.SOCKET HD.CAP SCREW,M5 X 25

21 DISTANCE WASHER , SPRAG CLUTCH

KEY No. DESCRIPTION

23 BUSH, C T PAD

24 CHAIN TENSIONER PAD

25 PLAIN WASHER

26 HEX.NUT,M8

27 AUTO CHAIN TENSIONER ASSEMBLY

28 O RING,CHAIN TENSIONER ASSEMBLY.

29 HEX. SOCKET HEAD CAP SCREW, M6X20

30 SPRAG CLUTCH ASSEMBLY

31 ENGINE SPROCKET

32 SPRAG CLUTCH

33 SPRAG CLUTCH GEAR

34 NEEDLE BEARING

35 WASHER

36 HEX.HEAD SCREW M12

37 CLUTCH ASSEMBLY COMPLETE

38 NYLOCK NUT

39 CLUTCH PUSH PAD

40 BALL BEARING 6001

41 PRIMARY CHAIN

42 HEX.SOCKET HEAD CAP SCREW, M6X85

43 PLAIN WASHER

22 STUD, CHAIN TENSIONER PAD

04-21

Page 73

ENGINE COVER - LH

10

8

12

17

16

15

14

18

19

20

7

9

4

11

6

3

5

2

1

13

04-22

Page 74

ENGINE COVER - LH

KEY No. DESCRIPTION

1 LH COVER SUB ASSEMBLY

2 COVER, LH

3 BUSH

4 OIL SEAL 14 X 20 X 3

5 GASKET, COVER LH

6 OIL SEAL INA G 12 X 18 X 5

7 ASSEMBLY, CLUTCH OP

8 CABLE CLEVIS, CLUTCH OPERATING LEVER

9 CLUTCH CABLE ASSEMBLY

10 PIN, CLUTCH OPERATING LEVER

11 LOCK PIN SPRING, CLUTCH OPERATING MECH.

12 SPRING, CLUTCH OP LEVER

13 HEX. SOCKET HEAD CAP SCREW, M6 X 201

14 O-RING (PLUG)

15 OIL FILLER PLUG

16 GEAR LEVER

17 SLEEVE, GEAR LEVER

18 HEX SCREW M6 X 25

19 SEALING WASHER 6 × 10 IS : 3175 CU

20 HEX NUT M6 - IS 1364 (PART 3) - 8 - ZN.PL

04-23

Page 75

GEAR TRAIN ASSEMBLY

04-24

Page 76

GEAR TRAIN ASSEMBLY

KEY No. DESCRIPTION

A1 LAY SHAFT SUB ASSEMBLY

A2 MAIN SHAFT SUB ASSEMBLY

1 MAIN SHAFT

2 MAIN SHAFT 2ND GEAR

3 WASHER, THRUST

4 MAIN SHAFT 4TH GEAR

5 CIRCLIP

6 MAIN SHAFT 3RD GEAR / 4TH GEAR

7 MAIN SHAFT 1ST GEAR7

8 LAY SHAFT

9 WASHER, THRUST

10 LAY SHAFT 2ND GEAR

11 LAY SHAFT HIGH GEAR

12 LAY SHAFT 3RD & 4TH GEAR ASSY.

KEY No. DESCRIPTION

16 BUSH

17 SELECTOR FORK LH

18 SELECTOR FORK CENTRE

19 SELECTOR FORK RH

20 SELECTOR FORK SHAFT

21 CIRCLIP 10N

22 CAM PLATE ASSEMBLY

23 RATCHET PLATE

24 RIVET, CAM PLATE/RATCHET PLATE

25 ROLLER

26 PIN

13 WASHER, THRUST

14 ASSEMBLY, LAYSHAFT 1ST GEAR

15 LAYSHAFT 1st GEAR

04-25

Page 77

GEAR SHIFTING

KICK STARTER(E5 & G5)

5

04-26

Page 78

GEAR SHIFTING

KEY No. DESCRIPTION

1 SS ROCKER SHAFT ASSEMBLY,

2 PIN PIVOT

3 STRIKER, GEAR CHANGE

4 SPRING

5 SPRING, GEAR CHANGE STRIKER

6 SPACER

7 PIVOT BEARING, ROCKER SHAFT UPPER

8 HEX. SOCKET HEAD CAP SCREW, M6 X 12

9 PIVOT BEARING, ROCKER SHAFT BOTTOM

10 ASSEMBLY, GEAR LEVER SHAFT

11 STOP PIN

12 O-RING

13 HEX. SOCKET HEAD CAP SCREW, M5 X 40

KICK STARTER(E5 & G5)

KEY No. DESCRIPTION

A1 KICKSTARTER SHAFT SUB ASSEMBLY

1 KICKSTART SHAFT

2 SPRING

3 PLUNGER

4PAWL

5 WASHER, THRUST

6 KICKSTART GEAR ASSEMBLY

7 KICKSTARTER GEAR 35T

8 BUSH

9 CIRCLIP

10 SPRING

11 HEX SCREW M6

04-27

Page 79

CYLINDER HEAD, BARREL, PISTON & CRANKSHAFT

23

15

14

25

24

27

22

18

20

11

10

9

6

3

8

2

12

26

7

5

39

19

17

21

36

38

16

4

13

30

32

38

37

34

37

38

35

37

39

38

33

29

28

31

CRANK SHAFT ASSY.

PISTON ASSY.

04-28

Page 80

CYLINDER HEAD, BARREL, PISTON & CRANKSHAFT

KEY No. DESCRIPTION

1 CYLINDER HEAD SUB ASSY

(CYLINDER HEAD, VALVE GUIDE, VALVE SEATS)

2 CYLINDER HEAD - ONLY MACHINED

HEAD

3 VALVE GUIDE

4 VALVE SEAT INSERT, EXHAUST

5 VALVE SEAT INSERT,INLET

6 DOWEL (6mm)

7 SPARK PLUG - M 10 - (UR5DC)

8 SPARK PLUG - M 14 - (W5DC)

9 SEAT, SPRING

10 VALVE STEM SEAL

11 VALVE SPRING

12 VALVE INLET

13 VALVE EXHAUST

14 RETAINER,SPRING

15 SPLIT COLLAR

16 PLUG

17 ROCKER BEARING SET-EXHAUST

18 ROCKER ARM - INLET

KEY No. DESCRIPTION

21 ROCKER ARM, EXHAUST

22 GASKET, ROCKER COVER INLET

23 ROCKER COVER - INLET

24 WASHER-SEAL