Page 1

Flexibility with Compliance

The Amebis Stability Testing System

The Amebis Stability and

Testing System offers

Pharmaceutical and Biotech

companies the ability to quickly

and easily test product quality

for humidity and temperature

stability. Smaller product

samples and speedy results

allow for inexpensive testing

saving time and money.

Flexible and compliant Small Scale Stability Testing System

21 CFR Part 11 and GAMP compliant

Wireless technology used for data transmission

No humidity chambers required

Each test monitored in its own micro-humidity chamber

Full range of humidity conditions available (0-95%RH)

Continuous data collection throughout with automatic data backup

Improved sample integrity and less risk of cross contamination

Incorporates latest sensor technology (ROTRONIC HygroMer®

humidity sensor with Airchip 3000 )

Sensors can be easily calibrated

ROTRONIC Instrument Corp, 135 Engineers Rd, Suite 150, Hauppauge, NY 11788

Email: sales@rotronic-usa.com. Web: www.rotronic-usa.com Phone: (631) 427-3898

Page 2

The Amebis Stability Testing System is a flexible and compliant means of performing small scale stability testing.

The system can be set up in minutes with a full range of environmental conditions available. The humidity capsule

which generates the required humidity and the test material are placed in separate compartments within the test

chamber and the chamber is then sealed with a sensor cap. The humidity capsule controls the humidity within the

test chamber and the sensor on the inside of the sensor cap measures the temperature and humidity within the

chamber. Humidity capsules providing relative humidity in the range 0-95% are available in 5% increments. The

color coded humidity capsules are labeled with a product code and batch number.

The sensor cap contains the latest in sensor technology, the ROTRONIC HygroMer® humidity sensor with Airchip

3000. Each sensor cap contains a unique serial number and is supplied with a calibration certificate. A logger cap

is docked to the base station which is connected to the laptop via a USB cable. Test settings are sent to the logger

cap which is then attached to the sensor cap. The logger cap is powered by a 9V battery and contains a memory

chip and a short range transceiver. The logger cap collects and stores the temperature and humidity readings and

transmits the data wirelessly to the control software. If the initiated tests are outside wireless range for

communication with the base station then cabling and aerials can be provided to ensure wireless communication.

1. Pierce humidity capsule

seal and place in test

chamber

5. Connection of the logger cap to the sensor cap initiates the

test. Temperature and relative humidity readings are collected

and stored on the logger cap. The data is transferred wirelessly

to the control software as required by the user.

2. Place test material in either or both

3. Seal the chamber with a sensor cap

of the two smaller compartments

4. Dock logger cap on base station for programming

Page 3

Through the control software tests are initiated and data is collected. Reports can be generated on

the click of a button. The software is 21 CFR Part 11 compliant and a full range of qualification

documentation (IQ/OQ/PQ) is available.

By replacing the sample chamber with a stand the

same software and hardware can be used for

monitoring and mapping applications.

The sensor caps are easily calibrated and adjusted by the use of ROTRONIC humidity standards, a

calibration chamber and ROTRONIC HW4 Professional software.

Calibration chamber

Calibration chamber

connected to sensor cap

Sensor cap connected to laptop via

calibration cable.

Page 4

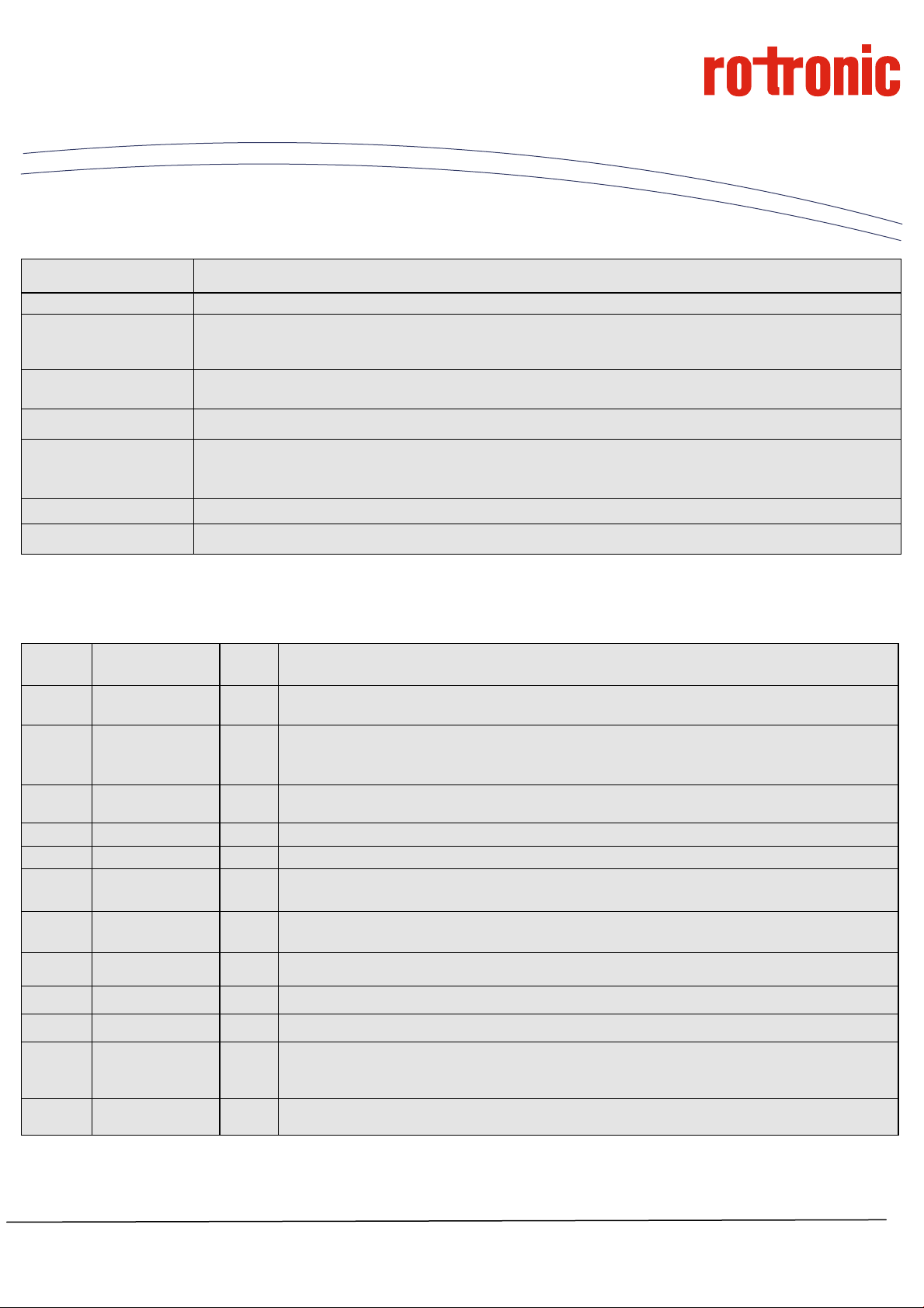

Technical Specifications

Operating Range

Sample Chamber Plastic Construction Volume 170 cm3 ; Dimensions 4.5cm (h); 7.0cm (d)

Sensor Cap Incorporates the ROTRONIC HygroMer® humidity sensor with Airchip 3000 housed within a plastic casing and containing a

Logger Cap Plastic housing containing a short range transceiver and a memory chip for storage of 8,000 temperature and humidity

Humidity Capsule Color coded plastic capsule with aluminium seal. Dimensions 3.2cm (d); 2.0cm (h)

0-60 ºC; 0-100% Relative Humidity

D-sub connector for connectivity to the logger cap and calibration cable. Supplied with a calibration certificate (SCS – Swiss

& UKAS – UK traceable ). Dimensions 7.5cm (d); 2.5cm (h)

readings. Also contains recess for holding 9V battery. Dimensions 7.5cm (d); 5.5cm (h)

Base Station Plastic housing containing a short range transceiver for wireless communication with logger caps. Also contains a D-sub

Amebis Control Software 21 CFR Part 11 compliant software for the initiation of tests, data capture and the presentation of data

Laptop ASUS EEE PC Laptop. 1gb RAM, 160 GB Hard disk, Microsoft Windows XP, Microsoft Sql Server Desktop 2000,

connector for connectivity with a docked logger cap during test set-up. Connectivity between the base station and computer is

via a USB cable which also powers the base station. Dimensions 15.5cm (d); 4.5cm (h)

Clockwatch V 4.

Ordering Information

Product

Code

F035 Amebis Stability

F00X Sensor Cap 1,10,20 Contains the temperature / humidity sensor and seals the test chamber. Logger cap connects to the sensor cap

F00S Logger Cap 1,10,20 Connects to the sensor cap and stores the temperature and humidity readings. Transmits the data wirelessly to

F014 Test Chambers 50 Hold the test material and humidity capsule during testing and are sealed by sensor caps.

F018 Humidity Capsules 50 Provide the humidity control during testing. Contact ROTRONIC for the range of humidity capsules available.

F0XX Stands 5 Fit to sensor cap to allow monitoring of environmental conditions in rooms or cabinets. Plastic construction.

Product Qty Details

Testing System

1 Contains base station, laptop with Control Software, 5 sensor caps, 5 logger caps, 5 batteries (9V) and 5 test

chambers.

to power the sensor and capture the readings. Supplied with calibration certificate. F001 =1, F002= 10, F003=20

Sensor Caps

the Control Software. F004 =1, F005=10, F006 =20 Logger Caps

Dimensions 8.3cm (d); 5.7cm (h) F056 = 5, F020 = 10, F021 = 20 Stands.

HW4-E Calibration Software 1 ROTRONIC HW4-E Software license. Single User Edition. Enables calibration of single sensor cap at a time.

HW4-P Calibration Software 1 Rotronic HW4-P Software license. Professional Edition. Enables calibration of multiple sensor caps at a time.

F028 Calibration Chamber 1 Stainless steel chamber which fits to sensor cap. Dimensions 7.0cm (d); 3.9cm (h)

F038 Calibration Cable 1 USB connectivity to computer and D-sub connectivity to sensor cap.

EAXX Calibration Standards Box of 5 ROTRONIC humidity standards for calibrating sensor caps. Supplied with Calibration Certificate. XX = %RH

PS40 Calibration Chamber

Liners

Example: EA10 = 10%RH. Standards available 0.5%RH, 5.0%RH, 10.0%RH, 11.3%RH, 20.0%RH, 35.0%RH,

50.0% RH, 65.0%RH, 75.0%RH, 80.0%RH, 95.0%RH.

100 Placed in calibration chamber and hold calibration standard during calibration of sensor cap.

Please contact us for a quotation or if you require further information.

More detailed information on our products can be found on our website.

ROTRONIC Instrument Corp, 135 Engineers Rd, Suite 150, Hauppauge, NY 11788

Email: sales@rotronic-usa.com. Web: www.rotronic-usa.com Phone: (631) 427-3898

June 10 2010 Rev.1

Loading...

Loading...