Page 1

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Instruction Manual

Document Title

Page

1 of 54

PF4

Differential Pressurep and Temperature Transmitter

Instruction Manual

Document Type

© 2014; Rotronic AG E-M-PF4-V1_00

Page 2

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

Contents

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Document Type

Page

2 of 54

Contents ............................................................................................................................................................ 2

1 Overview ........................................................ .............................................................. ........................ 4

2 Dimensions .......................................................................................................................................... 5

3 General Description ............................................................................................................................ 6

3.1 Power Supply ................................................................................................................................... 6

3.2 Differential Pressure Measurement .................................................................................................. 7

3.3 Pt100 Connection ........................................................................................................................... 11

3.4 HC2 Connection ............................................................................................................................. 11

3.5 Analog Outputs ............................................................................................................................... 12

3.6 Relay .............................................................................................................................................. 14

3.7 Service Interface ............................................................................................................................. 14

3.8 Display and Keys ............................................................................................................................ 15

3.9 HW4 Software Compatibility ........................................................................................................... 16

4 Mechanical Installation ..................................................................................................................... 17

4.1 General ........................................................................................................................................... 17

4.2 Housing .......................................................................................................................................... 17

4.3 Mounting ......................................................................................................................................... 18

4.4 Differential Pressure Connection .................................................................................................... 18

4.5 HC2 / Analog Connection ............................................................................................................... 19

4.6 Pt100 Connection ........................................................................................................................... 21

5 Electrical Installation ........................................................................................................................ 22

5.2 Wiring ............................................................................................................................................. 24

6 Operation ................................................ ........................................................... ................................ 26

6.1 Differential Pressure ....................................................................................................................... 26

6.2 Analog Outputs ............................................................................................................................... 28

6.3 Ethernet Connection ....................................................................................................................... 28

6.4 Analog Input ................................................................................................................................... 29

6.5 Display and Keys ............................................................................................................................ 33

6.6 Relay .............................................................................................................................................. 42

7 Maintenance .................................................. ................................................................. ................... 43

7.1 Service Cable ................................................................................................................................. 43

7.2 Service Port .................................................................................................................................... 43

© 2014; Rotronic AG E-M-PF4-V1_00

Page 3

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Document Type

Page

3 of 54

7.3 Device Calibration and Adjustment Procedure ............................................................................... 44

7.4 Validation of Analog Output Signals ............................................................................................... 48

8 Firmware Update ............................................................................................................................... 48

9 Technical Data ................................................................................................................................... 49

10 Accessories ....................................................................................................................................... 53

10.1 Service Cable ................................................................................................................................. 53

10.2 Pressure Tubes .............................................................................................................................. 53

10.1 Mounting Elements ......................................................................................................................... 53

11 Additional Documents ...................................................................................................................... 54

12 Document Versions ........................................................................................................................... 54

© 2014; Rotronic AG E-M-PF4-V1_00

Page 4

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Document Type

Page

4 of 54

Scope:

This manual is valid for the PF4 transmitter series with firmware version V3.x. The low-order digit of the firmware

version stands for minor changes, e.g. correction of errors that do not influence the main functionality of the

device.

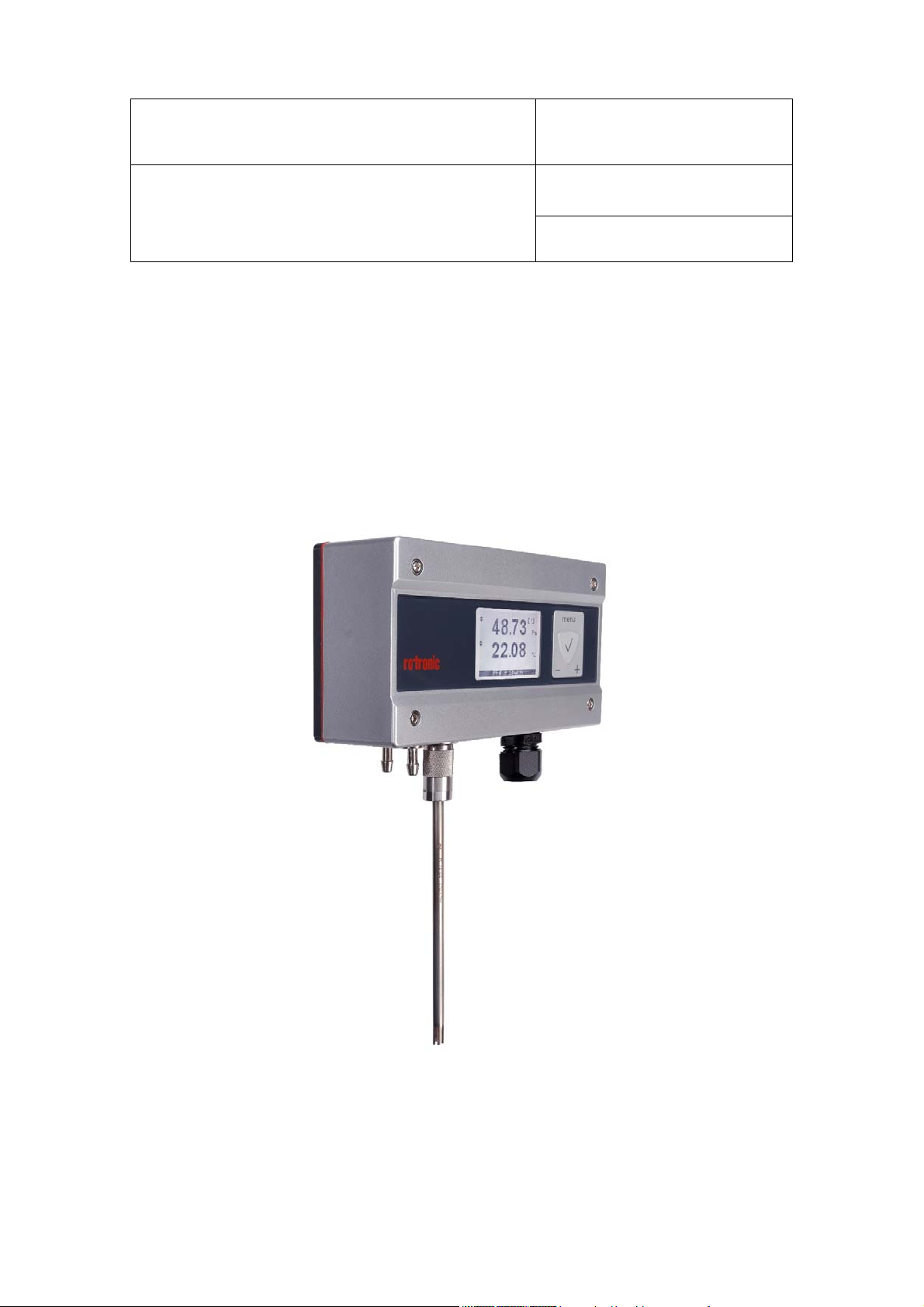

1 Overview

The PF4 is a high-precision differential pressure transmitter. The integrated measurement technology is able to

detect very small differential pressures. The measurement results can be shown on the built-in display and

exported via the analog outputs. Optional connection of a HygroClip2 probe, Pt100 sensor or analog input signal

is possible. The isolated change-over switch of a relay can be controlled with configurable alarms.

Main features of the PF4 transmitter:

High-precision measurement and long-term stability

Fast response time and low hysteresis

Freely configurable analog signals

Isolated integral relay switch contact

Large overload range

Optional HygroClip2 connection for humidity, temperature or analog signals

Selectable units

High immunity to dust and humidity in the environment

New firmware updates will fix newly discovered issues and add new features. The user is encouraged to stay

up to date with the newest firmware.

© 2014; Rotronic AG E-M-PF4-V1_00

Page 5

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Document Type

Page

5 of 54

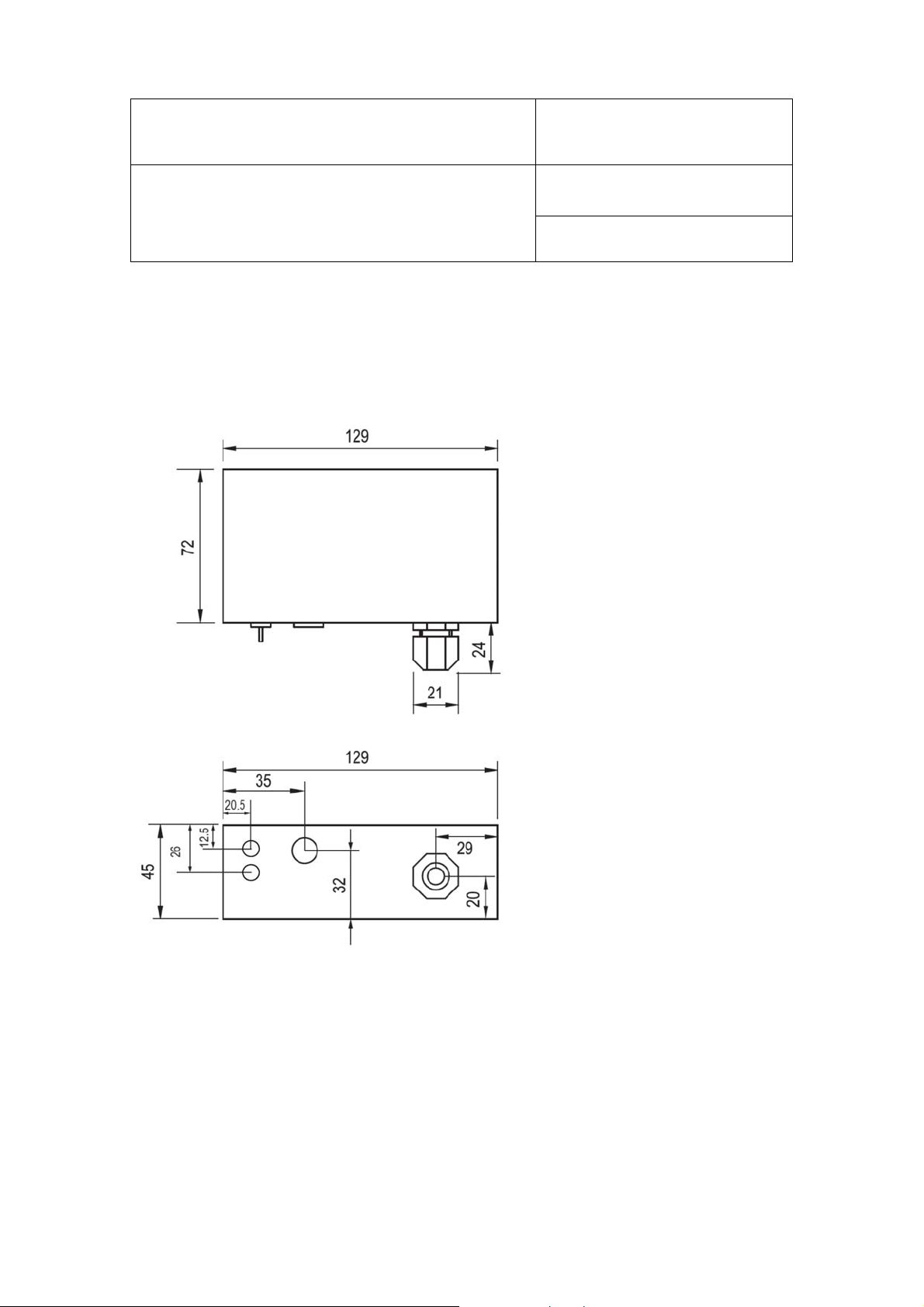

2 Dimensions

The PF4 comes as wall-mounted unit in a ROTRONIC housing. The following drawings show the relevant overall

dimensions in mm.

Figure 1: Important overall dimensions of the PF4

© 2014; Rotronic AG E-M-PF4-V1_00

Page 6

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Document Type

Page

6 of 54

3 General Description

3.1 Power Supply

The PF4 is only available as three-wire version without galvanic isolation. For configuration purposes, the device

can also be supplied with power via the service interface (Mini-USB port inside housing). During configuration

with the service interface there is insufficient power to run the differential pressure sensor to its most accurate

performance levels. The USB service connector should be used only for configuration purposes.

3.1.1 Power Supply / Current Consumption

Power supply specifications for the PF4:

Operating Voltage Current Consumption

15…40 VDC <70 mA / <150 mA (with Ethernet interface)

14…28 VAC – 50/60 Hz <70 mA / <450 mA (with Ethernet interface)

© 2014; Rotronic AG E-M-PF4-V1_00

Page 7

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Document Type

Page

7 of 54

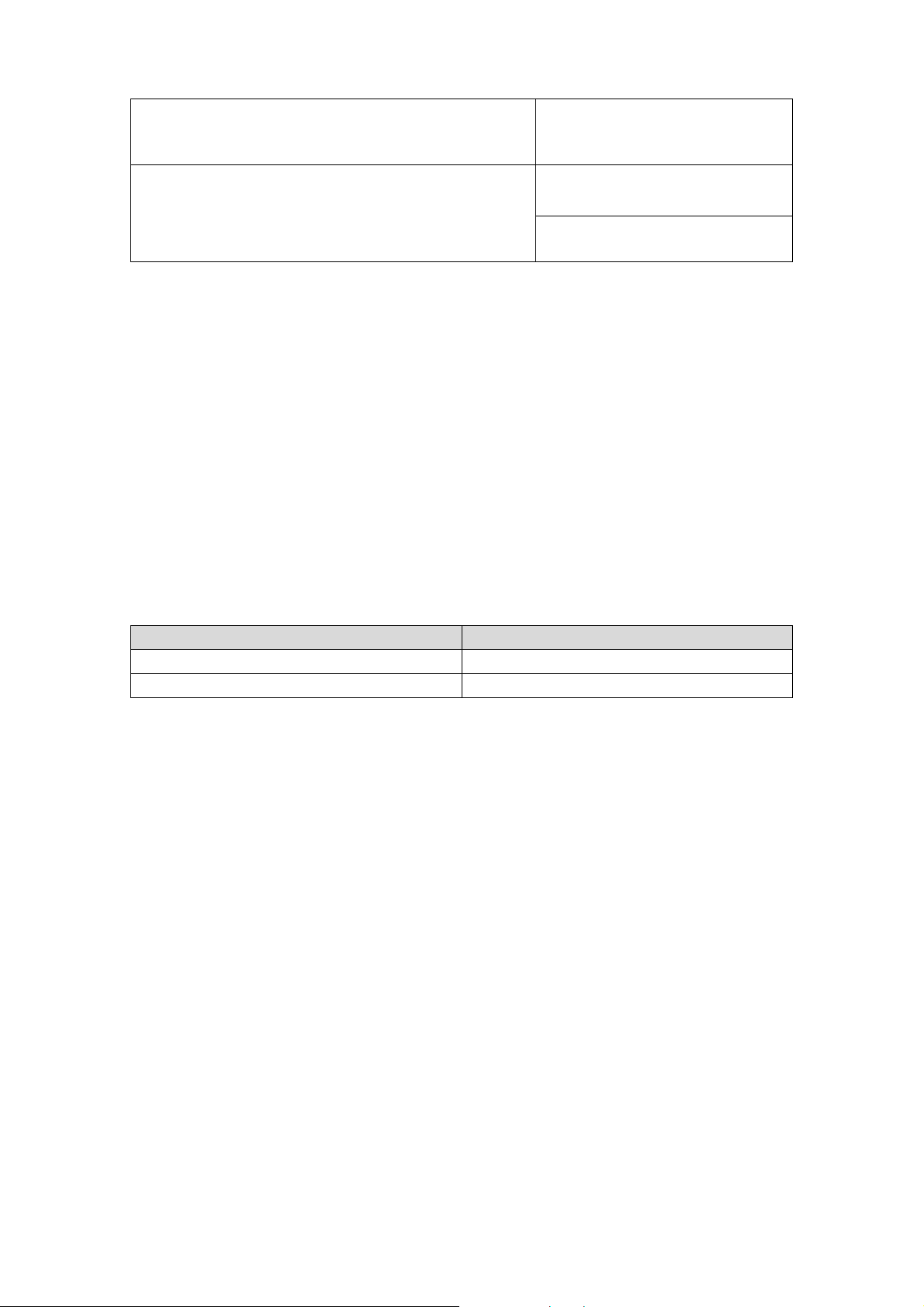

3.2 Differential Pressure Measurement

The differential pressure measurement is based on the principle of thermal mass flow. A flow limiter in a tube

generates a differential pressure. A very small quantity of gas diverted by a bypass before and after the limiter

(max. 180 µl/min) is passed over a differential pressure sensor (∆p sensor) and then returned to the main flow.

Figure 2 on the left shows the principle of this mass flow measurement.

Figure 2:

Principle of the mass flow measurement (left) and cross-section of MEMS differential pressure sensor (right)

The ∆p sensor contains a heating element and a temperature sensor each before and after the heating element.

Due to the differential-pressure dependent flow velocity in the flow passage of the ∆p sensor, the downstream

temperature sensor heats up more or less than the upstream temperature sensor. In this way it is possible to

obtain an output voltage from the ∆p sensor as potential difference between the temperature sensor output

signals that is, following careful linearization, strictly proportional to the volume flow.

The sensor used in the PF4 series is based on a 2x2 mm silicon chip (Figure 2, right). This enables production

of an extremely small and exactly reproducible flow passage with a very high pneumatic resistance, resulting in

extremely small sensor flow rates (max. 180 µl/min) and practically independent of the bypass tube lengths and

dust and moisture loads in the gas stream.

Conclusion: The high measuring sensitivity, accuracy and long-term stability of the ROTRONIC PF4 series

make it the ideal choice for monitoring volume flows and pressures in energy-efficient and economical ventilation

and air conditioning systems.

© 2014; Rotronic AG E-M-PF4-V1_00

Page 8

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Instruction Manual

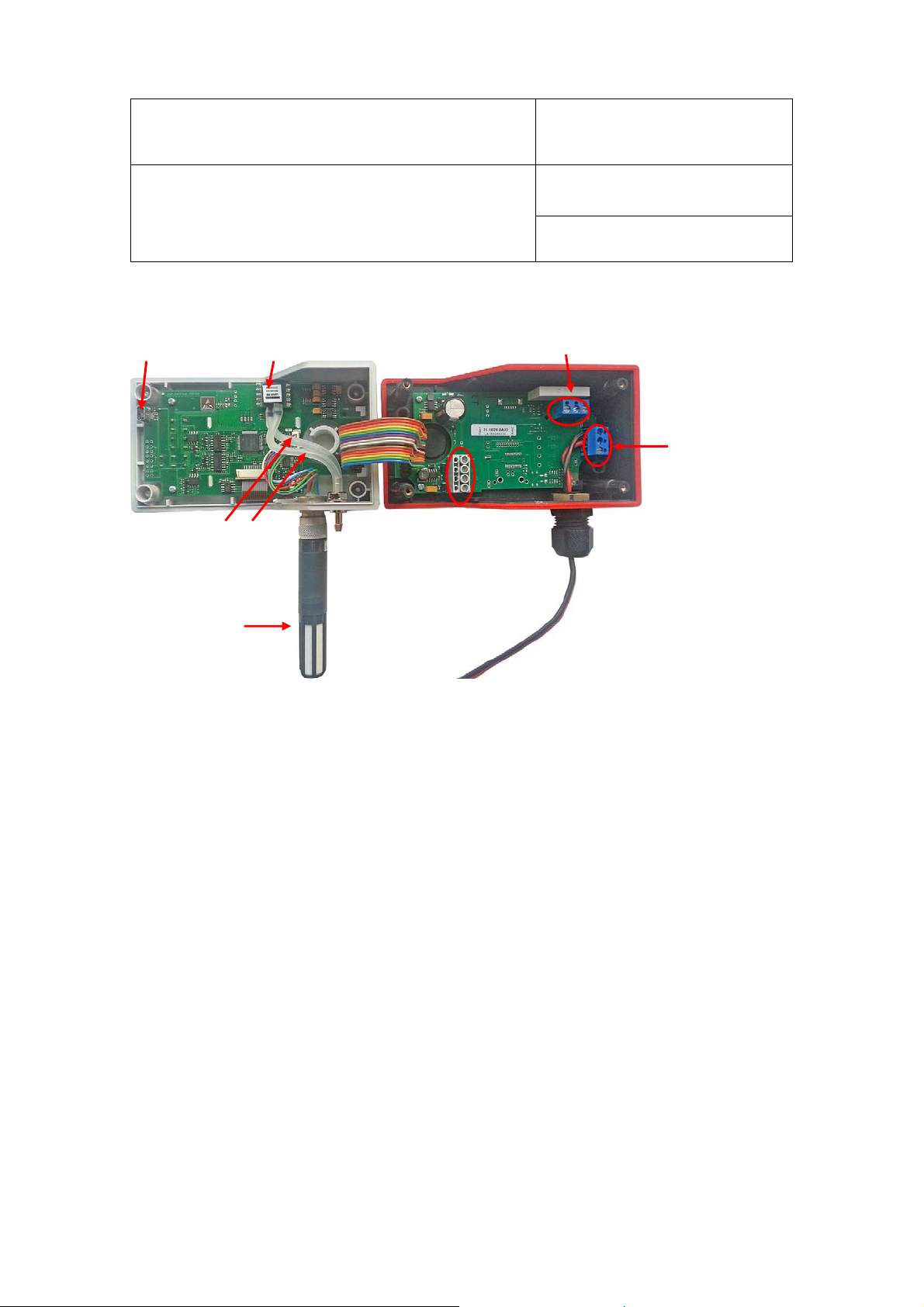

Document Title

Inside View:

Mini-USB

service connector

Differential pressure

sensor

Terminals K3 for

isolated relay contacts

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Document Type

Page

8 of 54

Terminals K2 for power

supply

Differential pressure

tubes

HC2 sensor for

temperature and

relative humidity

Terminals K4 for analog

temp. and differential

Figure 3: Inside view with description of the main components of the PF4

3.2.1 Differential Pressure Measurement Ranges

The following sensor measurement ranges are available:

-25...+25 Pa

-50…+50 Pa

-100…+100 Pa

-250…+250 Pa

-500…+500 Pa

Differential pressures outside the specified ranges are shown, but the measurement results are not reliable.

© 2014; Rotronic AG E-M-PF4-V1_00

Page 9

E-M-PF4-V1_00

Document Code Unit

Rotronic AG

Bassersdorf, Switzerland

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

Page

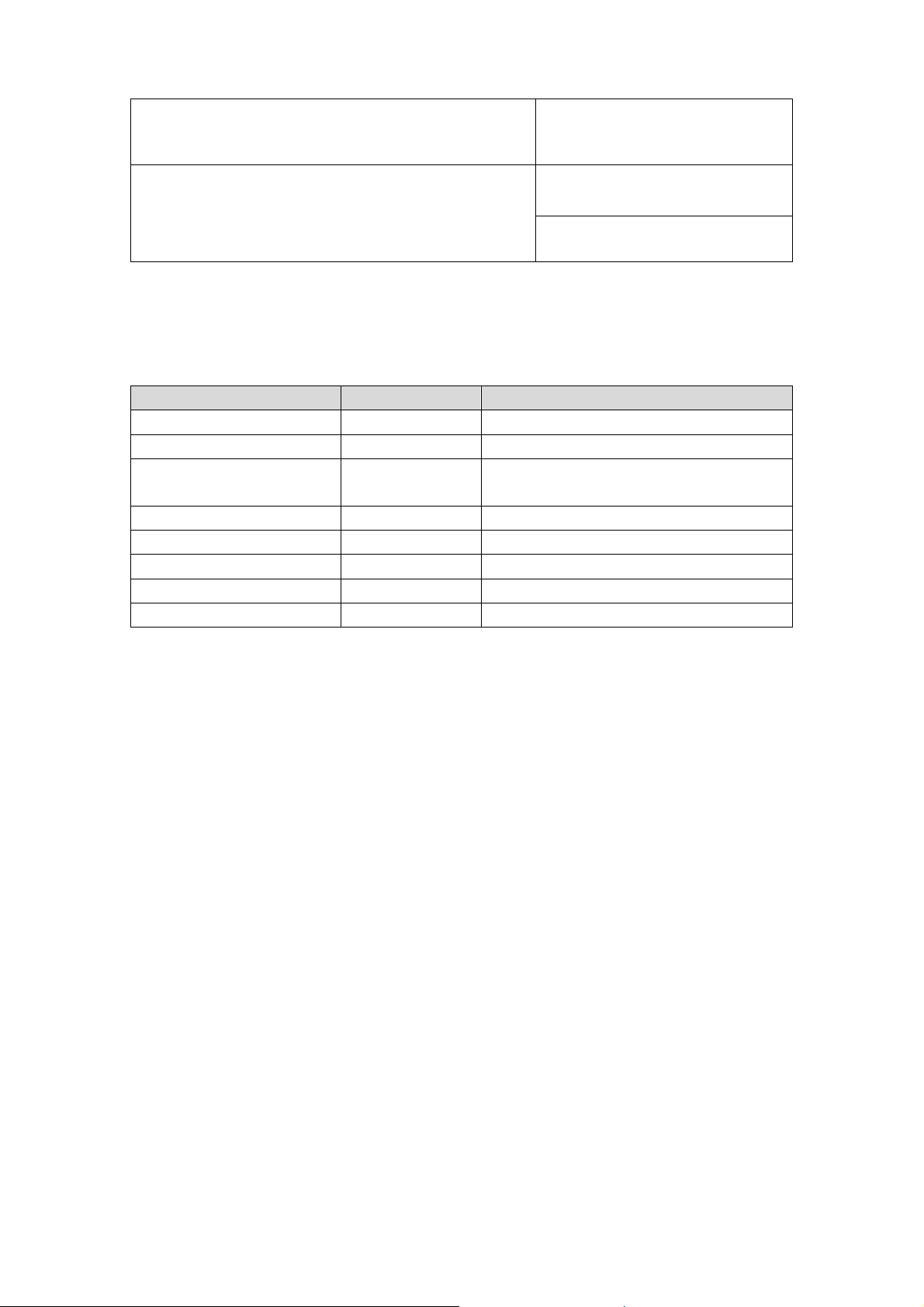

3.2.2 Unit Systems

The following unit systems are available:

Unit Unit Symbol Remarks

Pascal Pa 1 Pa = 1 N/m²

Inch water column inH2O 1 inH2O (4 °C) = 249.089 Pa

Milli-pound-force per square

inch

Millibar mbar 1 mbar = 0.001 bar = 100 Pa

mm mercury column mmHg 1 mmHg (0 °C) = 133.322 Pa

mm water column mmH2O 1 mmH2O (4 °C) = 9.80665 Pa

Torr Torr 1 Torr = 133.322 Pa

Gram per square centimeter g/cm2 1 g/cm2 = 98.0665 Pa

mpsi 1 mpsi = 0.001 psi = 6.89476 Pa

Instruction Manual

Document Type

9 of 54

© 2014; Rotronic AG E-M-PF4-V1_00

Page 10

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Document Type

Page

10 of 54

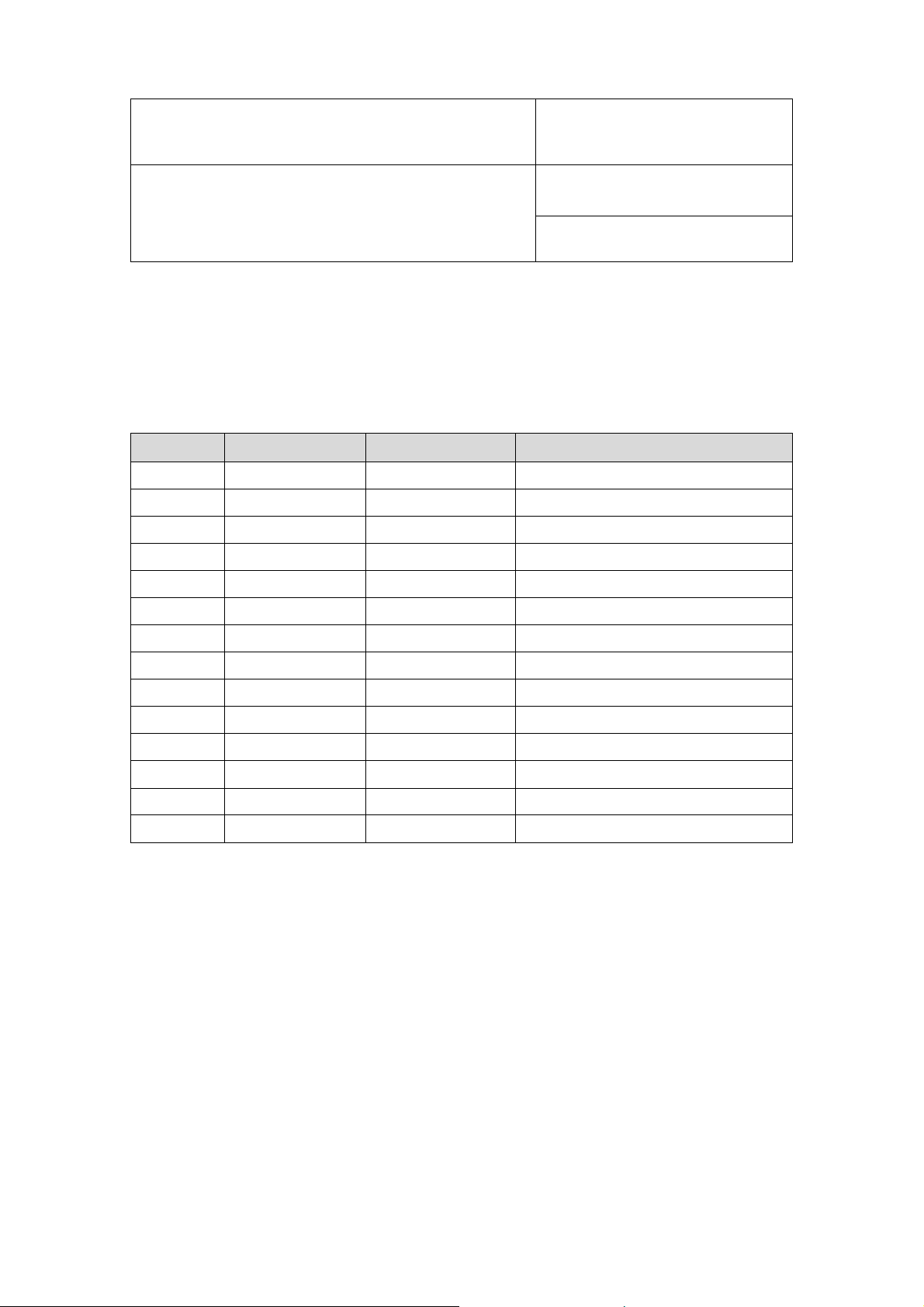

3.2.3 Filters

The curve of the differential pressure measured values can be smoothened with the help of a low-pass filter

with selectable time constant. There are 13 smoothing filter stages available. Practice has shown stages 0...7

meet most application requirements.

Filter Stage

0 0 s 0 s No filtering

1 0.4 s 1.8 s Weak filtering

2 0.9 s 4.3 s …

3 1.9 s 9.3 s …

Time Constant 63 Time Constant 99

Description

4 3.9 s 19.3 s …

5 7.8 s 39.2 s …

6 15.8 s 78.9 s …

7 32.0 s 2.7 min. …

8 1.0 min. 5.3 min. Strong filtering

9 2.1 min. 10.6 min. …

10 4.2 min. 21.2 min. …

11 8.5 min. 42.4 min. …

12 17.0 min. 1.4 h …

13 33.9 min. 2.8 h Extremely strong filtering

3.2.4 Simulator Value

When the simulator value has been activated, a defined simulator value is used instead of the current measured

value.

© 2014; Rotronic AG E-M-PF4-V1_00

Page 11

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Document Type

Page

11 of 54

3.3 Pt100 Connection

A Pt100 temperature sensor can optionally be connected to the four-pin connector (Binder series 711). The

possible measurement range depends on the Pt100 sensor and is max. -100...200 °C.

3.3.1 Unit Systems

The following unit systems are available for temperature measurement:

°C

°F

3.3.2 Simulator Value

When the simulator value has been activated, a defined simulator value is used instead of the current measured

value.

3.4 HC2 Connection

The PF4 optionally comes with a HC2 connection socket. It can be used for all HC2 probes in the ROTRONIC

portfolio. Alternatively, one pin of the socket can be used as analog current or voltage input. It must be

established on ordering the device whether the pin can evaluate current or voltage signals; it cannot be

reconfigured to do so later on (see chapter 6.4 ).

3.4.1 Unit Systems

The following unit systems are available for the HC2 connection:

%RH

°C / °F

mV / mA

© 2014; Rotronic AG E-M-PF4-V1_00

Page 12

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Document Type

Page

12 of 54

3.4.2 Simulator Value

When the simulation value has been activated, a defined simulator value is used instead of the current measured

value.

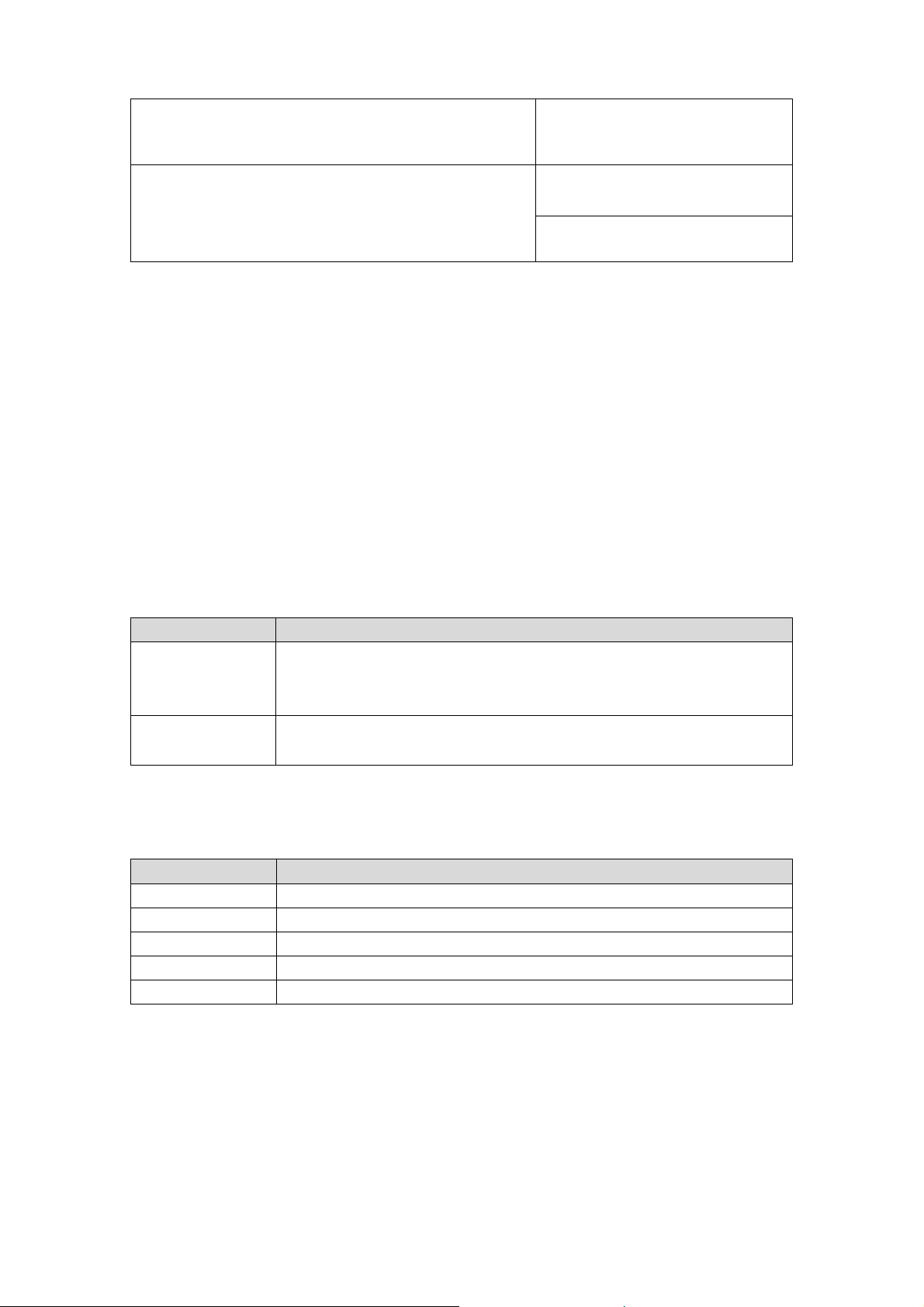

3.5 Analog Outputs

The ROTRONIC HW4 software enables free configuration and scaling of the analog outputs. The measured

values (differential pressure, humidity, temperature, calculation value) can be assigned at will to any analog

output (Out1, Out2) and the required range can also be scaled freely.

The following output ranges are available:

Type Range

Voltage

Current

The different variants of the analog output each have a minimal offset:

Signal Type Maximum Offset at Start of Range

0...1 V 3 mV

0...5 V 50 mV

0...10 V 90 mV

0...20 mA 4 µA

4...20 mA No offset

0…1 V

0…5 V

0…10 V

0…20 mA

4…20 mA

© 2014; Rotronic AG E-M-PF4-V1_00

Page 13

E-M-PF4-V1_00

A

Document Code Unit

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Document Type

Page

13 of 54

3.5.1 Scale

The scale can be changed at will with the ROTRONIC HW4 software in a range from -9,999 to +99,999. The

limits of the sensor must, however, be observed (see chapter 3.2 /3.3 / 3.4 ).

The devices have one of the following optional default settings on delivery:

Differential Pressure Humidity Temperature

0…+10 Pa

0…+25 Pa

0…+50 Pa

0…+100 Pa

0…+250 Pa

0…+500 Pa

-25…+25 Pa

-50…+50 Pa

-100…+100 Pa

-250…+250 Pa

-500…+500 Pa

0…100 %RH

0…50 °C

0…70 °C

+10…40 °C

0…+100 °F

0…+200 °F

nalog Input

0…3.2 V

0…25 mA

© 2014; Rotronic AG E-M-PF4-V1_00

Page 14

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Document Type

Page

14 of 54

3.6 Relay

The PF4 provides a freely configurable internal isolated relay contact.

Normally closed (NC)

Common (COM)

Normally open (NO)

The relay can be controlled by freely configurable alarms. The following can also be set:

Time delay

The relay is only switched on when an alarm endures for a certain minimum time.

Switch off when alarm finished

The relay automatically disengages when the alarm is no longer active; otherwise the relay remains

active until it is reset manually.

Maximum duty cycle

The relay stays on for at most the time set and is then switched off.

The relay can only be activated by a measured value. Assignment of more than one measured value is not

possible.

3.7 Service Interface

Using the HW4 software, the service interface (UART) allows device settings, loading of language data and

updating of the firmware. The service interface is located inside the housing. It is connected to the computer

with the HW4 software with an AC3006 or AC3009 connection cable.

Important:

The PF4 can be supplied with power through the service cable. The service cable provides insufficient power

for correct differential power measurement.

For sensor adjustment, the PF4 must be supplied with power from a suitable power source via the terminals

provided (K2-1: -/~, K2-2: +/~).

© 2014; Rotronic AG E-M-PF4-V1_00

Page 15

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Document Type

Page

15 of 54

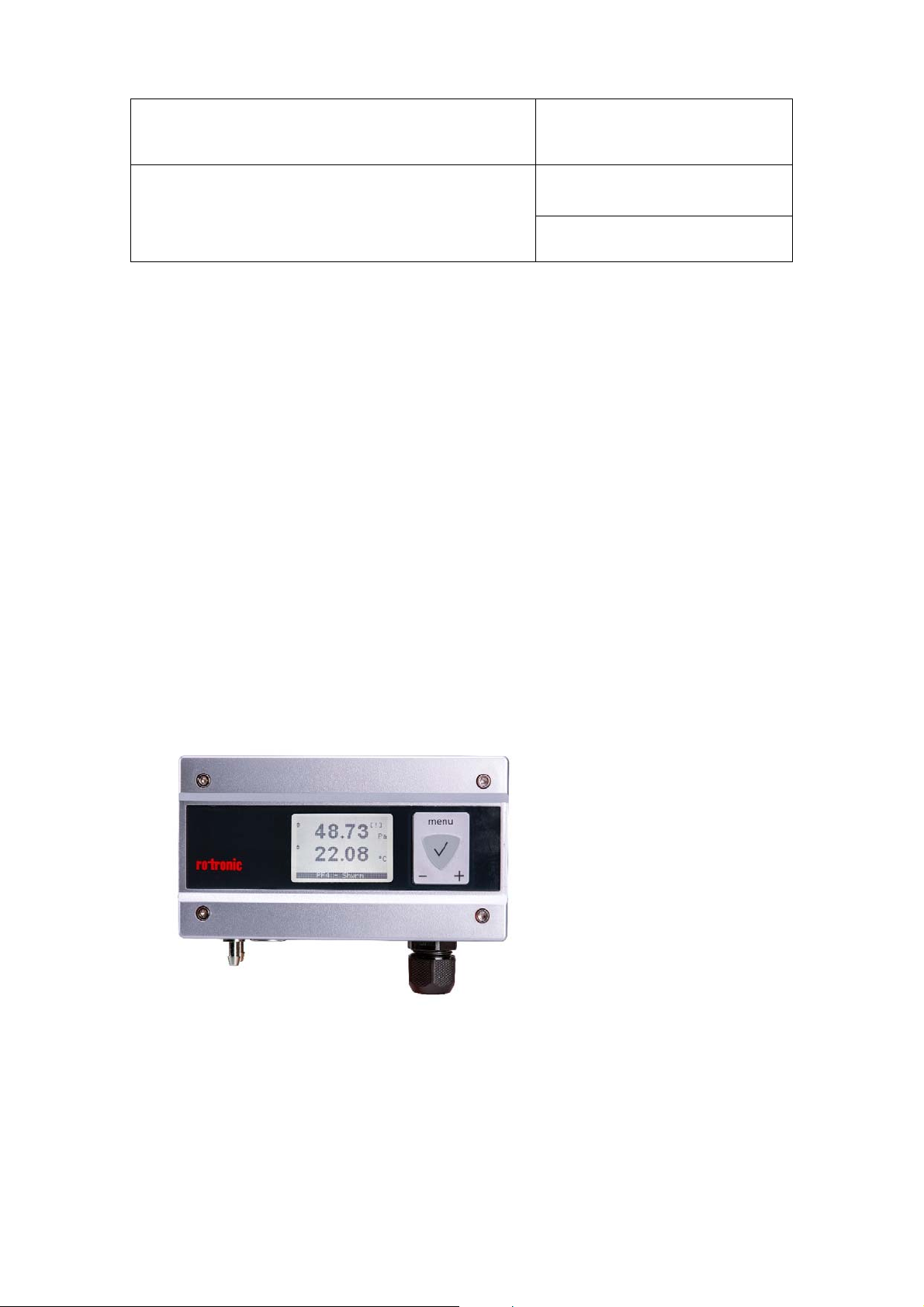

3.8 Display and Keys

The optional LCD for the PF4 has a backlight.

The display unit is configurable. Depending on the version (differential pressure / differential pressure & Pt100

/ differential pressure & HC2 connection), the different parameters can be assigned to the different display lines.

In the full version with HC2 connection, there are three display lines available. They can be assigned the

following parameters:

differential pressure

humidity

temperature

analog input (is only shown when analog input is active)

calculation

no value

The first line of the display shows the differential pressure, the second the relative humidity and the third the

temperature or calculated value such as dew point / frost point. A trend indicator can also be configured for

every line.

The optional LCD for the PF4 has a backlight. The first line of the

display shows the differential pressure, the second the relative

humidity and the third the temperature or calculated value such

as dew point / frost point. The display can be configured to show

a trend indicator in every line.

Figure 4: Display of the PF4 with connected HC2 probe

Keys:

menu: Open menu / Next-higher menu level

+: Increase value

-: Decrease value

: OK / Next-lower menu level

3.8.1 Alarms

Measured values with an alarm are shown with an exclamation mark [!]. Alarms are configured with the HW4

software.

© 2014; Rotronic AG E-M-PF4-V1_00

Page 16

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Document Type

Page

16 of 54

3.8.2 Decimals

The PF4 adjusts the number of decimal places automatically on the basis of the current measured value. The

display therefore always shows the measured value clearly with the corresponding number of significant

decimals.

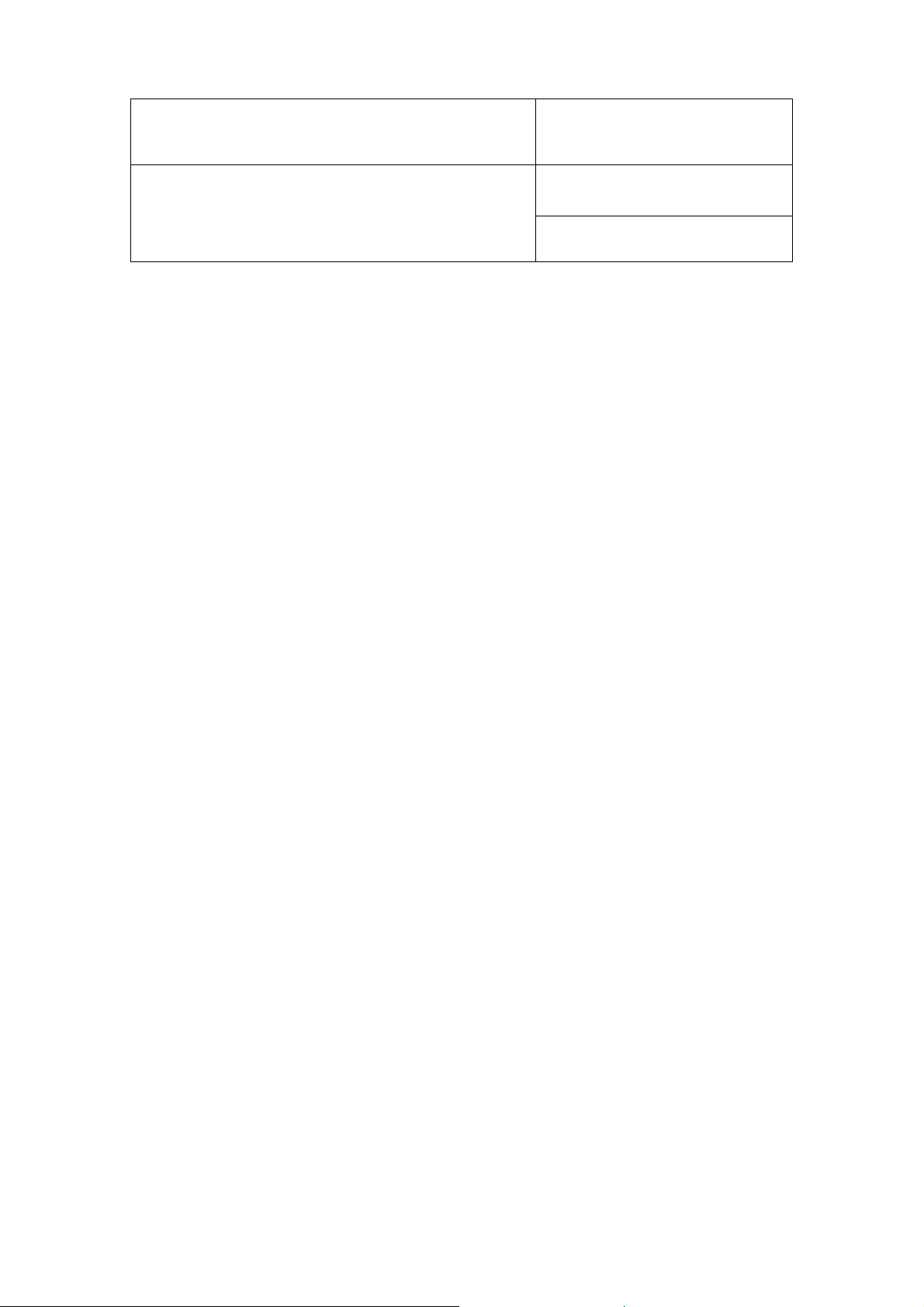

3.9 HW4 Software Compatibility

PF4 differential pressure transmitters are integrated completely in the HW4 software - devices with only

differential pressure measurement or additional Pt100 connector from V3.2 and later, and with HC2 connection

option from V3.4.

PF4 Version Supported in HW4 from Version:

PF4 without additional connector

PF4 with B4 connector

PF4 with E2 connector HW4 V3.4

HW4 V3.2

© 2014; Rotronic AG E-M-PF4-V1_00

Page 17

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Document Type

Page

17 of 54

4 Mechanical Installation

4.1 General

The PF4 can be mounted on a wall or on a DIN top-hat rail. The position of the device and thus of the differential

pressure sensor has no influence on measurement, i.e. the device is not sensitive to position. However, for

exact measurement, the device must not move and must not be exposed to vibrations.

IMPORTANT:

After complete mechanical installation, the atmospheric pressure must be programmed in the device as

described in chapter 6.1.1.

4.2 Housing

The housing can be opened by unscrewing four screws. The screw breakthroughs for wall mounting and

electrical connections for the power supply, analog outputs, service interface and the relay are to be found inside

the housing.

Figure 5: Front view PF4 housing

© 2014; Rotronic AG E-M-PF4-V1_00

Page 18

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

4.3 Mounting

Method 1: The PF4 comes with two screws, two wall plugs and two rubber

washers. There are two screw depressions in the bottom part of the housing

(closed on delivery). Use the template delivered with the PF4 to drill the holes

in the wall and put in the wall plugs. Place a rubber washer under each screw

head. Put a screw in each depression and push through the bottom of the

depression.

Method 2: The mounting kit AC5002 (not included) is needed for mounting on

a DIN top-hat rail (35 mm / 1 3/8"). The mounting kit consists of two clips, which

are fastened to the back of the housing with the screws supplied.

Figure 6: Mounting kit AC5002 and drilling points for wall mounting

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Document Type

Page

18 of 54

4.4 Differential Pressure Connection

Tubes with an internal diameter of 4 mm can be connected. The tubes must be fastened securely so that

they do not move or vibrate during operation. This would falsify the measurement.

Configuration of differential pressure connections:

+: Positive pressure connection

-: Negative pressure connection

Figure 7: Differential pressure connections and E2 socket on the bottom side of the PF4

© 2014; Rotronic AG E-M-PF4-V1_00

Page 19

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Document Type

Page

19 of 54

4.5 HC2 / Analog Connection

The PF4 can optionally be ordered with an E2 socket. This interface and its possible uses are described below.

4.5.1 Use of HC2 Probe

The PF4 can optionally be set up for a HC2 probe. After connection of

a HC2 probe, it is possible to measure and display three parameters:

Differential pressure

Humidity

Temperature / Calculation

Figure 8: E2 and differential pressure connection on the bottom side

of the PF4

All HC2 probes currently available can be connected. The measured data of the HC2 probe is evaluated digitally

and shown on the display. Two of the measured values can be assigned to the analog outputs (chapter 6.2 )

and processed further. The optional Ethernet interface (chapter 6.3 ) of the PF4 can output all measured values.

4.5.2 Use of Analog Input

The device menu is used to switch between use of a HC2 probe and an analog third-party probe. The display

of the PF4 switches automatically to the units mA / mV of the analog input.

The input is reconfigured with the device menu:

MENU > Probe Information > Sensor Type

Select between the following options:

HC2 Digital HC2 probes are read out

Analog In Analog input is used

The PF4 then asks the user to confirm the sensor change and restarts with the corresponding display

configuration.

Remark:

© 2014; Rotronic AG E-M-PF4-V1_00

Page 20

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Document Type

Page

20 of 54

The PF4 does not contain a power supply for an analog third-party probe. If adequate, the power supply for the

HC2 probe can be used via the pins V+ and GND (see Figure 9).

When using an analog probe, be sure to define both the voltage signal range and the measurement range of

the probe. The HW4 software requires definition of the measurement range for an analog probe. The HW4

software can also be used to change the probe type for the input.

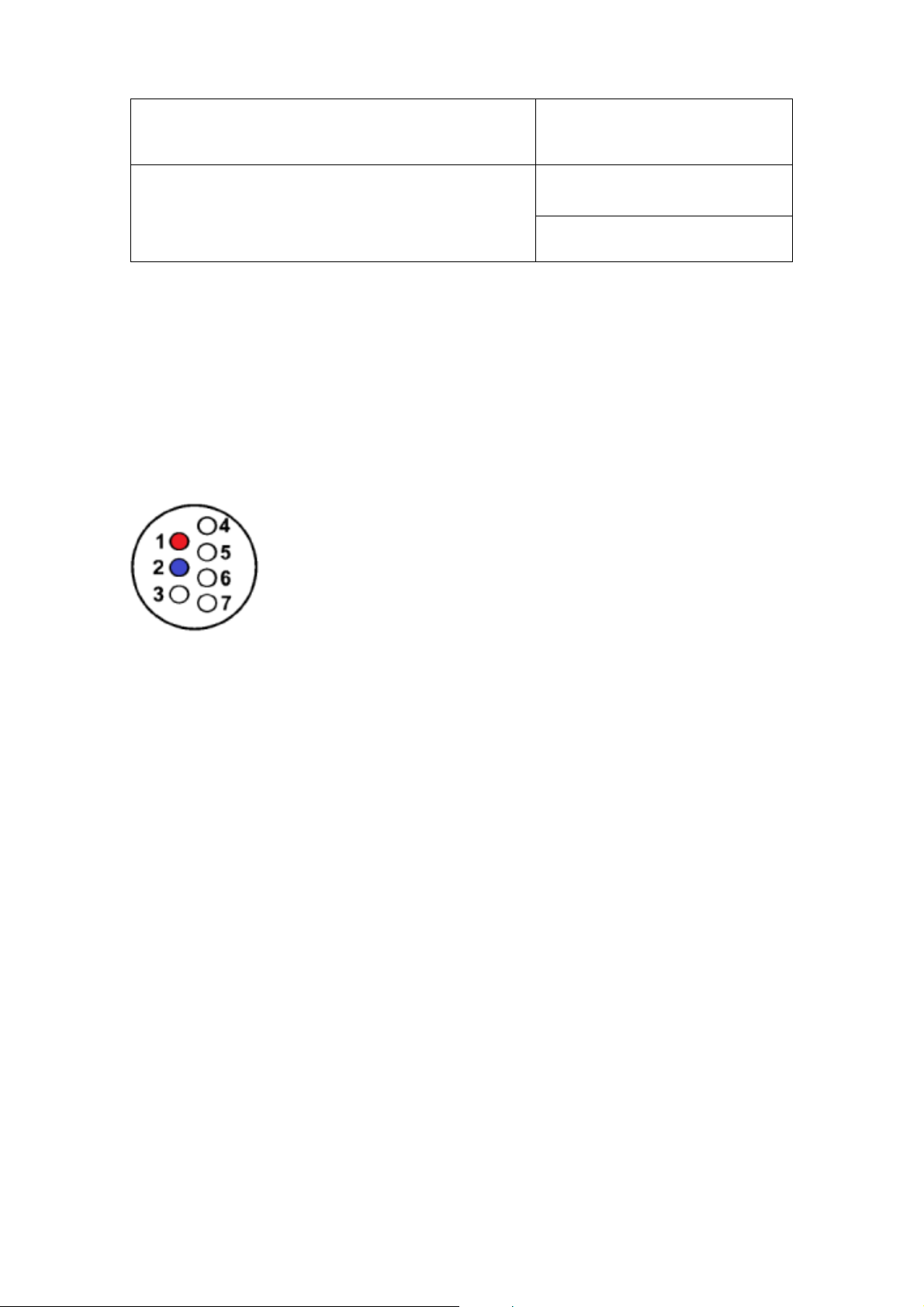

Pin Configuration E2 Connection

Figure 9: Pin configuration of the E2 socket (view from front)

1) V+: Digital probe: 3.3 VDC, 10 mA

2) GND: Digital and supply ground

3) RXD: UART digital probe

4) TXD: UART digital probe

5) ANA IN: Analog input: 0…3.2 V / 0…25 mA

6) NU: Not used

7) AGND: (Analog GND)

© 2014; Rotronic AG E-M-PF4-V1_00

Page 21

E-M-PF4-V1_00

Document Code Unit

Rotronic AG

Bassersdorf, Switzerland

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

4.6 Pt100 Connection

The PF4 comes optionally with a Pt100 connection with four-pin connector

(Binder series 711) for all Pt100 probes from ROTRONIC and all variants

of third-party Pt100 probes.

Figure 10: Pt100 and differential pressure connection on the bottom side of the PF4

Instruction Manual

Page

21 of 54

Document Type

Wiring Diagram / Pin Configuration

Figure 11 shows the pin configuration and wiring diagram for the Pt100 probe.

Figure 11: Four-wire wiring of the Pt100

© 2014; Rotronic AG E-M-PF4-V1_00

Page 22

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Document Type

Page

22 of 54

5 Electrical Installation

This section describes the general safety precautions for electric wiring.

5.1.1 Cable Grip and Cable Specifications

The PF4 comes with a M16 cable grip with screw cable gland. The M16 cable grip offers effective sealing if

cables with external diameters of 6 to 7 mm (0.236 to 0.275 inch) with connection wires per 18 AWG are used.

5.1.2 General Connection Information

Heavy machinery and measuring instruments should not share the same electric cables for power supply. If this

cannot be avoided, noise filters and surge protectors should be used, as integrated in most UPS devices.

5.1.3 Signal Cable Information

The following guidelines are derived from the European standard EN 50170 for the transmission of signals by

copper wires. Note on installation planning: when determining the position of machinery and equipment, the

rules given in EN 50170 should be followed with due regard to local circumstances.

All ROTRONIC products are tested for electromagnetic compatibility according to EMC Directive 2004/108/EC

and the following European standards:

- EN 61000-6-1: 2007, EN 61000-6-2: 2005

- EN 61000-6-3: 2007, EN 61000-6-4: 2007

Whenever the level of electromagnetic interference is expected to be high, both the devices and signal cables

should be placed as far away as possible from the source of interference.

In general, signal cables should be installed in bundles or channels / conduits, separate from other cables as

indicated in the table below:

© 2014; Rotronic AG E-M-PF4-V1_00

Page 23

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

Bus signals such as RS-485

Data signals for PCs, printers, etc.

Shielded analog inputs

Unshielded DC voltage (<= 60 V)

Shielded process signals (<= 25 V)

Unshielded AC voltage (<= 25 V)

Coaxial cables for CRT monitors

in common bundles or channels / conduits

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Document Type

Page

23 of 54

DC voltage from 60 V to 400 V (unshielded)

AC voltage from 25 V to 400 V (unshielded)

DC and AC voltage > 400 V (unshielded)

Telephone lines

Lines leading into EX-rated areas

in separated bundles or channels / conduits,

without minimum distance

in separated bundles or channels / conduits,

without minimum distance

© 2014; Rotronic AG E-M-PF4-V1_00

Page 24

E-M-PF4-V1_00

Document Code Unit

Rotronic AG

Bassersdorf, Switzerland

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

5.2 Wiring

This section describes the wiring of the device with connection possibilities.

5.2.1 Electrical Diagrams

The PF4 is wired with a four-pin connection cable

for transmission of the electrical power and

measured values. The maximum permissible

cable length depends on the voltage drop caused

by the flow of current to the devices connected to

the PF4 outputs. The effective load of a PF4 output

comprises the cable and load resistance and

should amount to at least 1000 ohm. The cable

resistance should not be more than 1/1000 of the

load resistance.

Figure 12: Voltage outputs

Instruction Manual

Page

24 of 54

Document Type

The maximum permissible length of the cable

connecting the unit to other devices is determined

by the total resistance resulting from addition of

the cable resistance and resistance of the devices

connected to the unit in series. This resistance

should not exceed 500 ohm (load).

Figure 13: Current outputs

© 2014; Rotronic AG E-M-PF4-V1_00

Page 25

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

Terminals Description

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Document Type

Page

25 of 54

K2-1: V-

K2-2: V+

K2-3: Protective ground

Ethernet

(optional)

Figure 14: Connection terminals on the board

Note:

Terminal K2-3 (protective ground) is connected with GND due to the closed solder jumper B5. To remove this

connection, open solder jumper B5.

Warning:

Before connecting the PF4 to an active Ethernet network, make sure it is configured correctly for IP

communication. Otherwise conflicts could disturb communication in the network.

K3-1: NC Normally closed – relay not energized

K3-2: COM Common – common contact

K3-3: NO Normally open – relay energized

K4-1: OUT1

K4-2: OUT2

K4-3: GND

K4-4: GND Ground (connected to other GND)

Power supply: 15…40 VDC (-) or

14…28 VAC

Power supply: 15…40 VDC (+) or

14…28 VAC

Differential pressure analog output

(+)

Temperature / Humidity

analog output (+)

Ground (connected to other GND),

see note below

© 2014; Rotronic AG E-M-PF4-V1_00

Page 26

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

6 Operation

This chapter describes handling of the device in operation.

6.1 Differential Pressure

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Document Type

Page

26 of 54

6.1.1

Ambient Pressure

The differential pressure sensor in the device is dependent on the local absolute ambient atmospheric pressure

P

. This must be communicated to the PF4 per display or HW4 software in order to attain the measuring

abs

accuracy named in the data sheet. P

can be determined with a barometer.

abs

Note:

The "atmospheric pressure at the place of use" QFE is to be used and not the "normalized atmospheric

pressure" QFF, which is communicated in weather forecasts (see also http://de.wikipedia.org/wiki/QFE#QFE).

The ambient pressure enters the measurement as follows and the differential pressure is compensated

automatically on the basis of the ambient pressure setting:

Formula Legend

∆

∆

1000

∆

∆

Real differential pressure [Pa]

Measured differential pressure [Pa]

Ambient pressure [hPa]

Relationship between altitude and pressure (on average):

Formula:

1

where 1013.25

.

ö

© 2014; Rotronic AG E-M-PF4-V1_00

Page 27

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

1050

1000

950

900

850

800

750

700

Atmosphericpressure[hPa]

650

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Document Type

Page

27 of 54

600

Altitude[m]

Figure 15: Graph showing the correlation between atmospheric pressure and altitude

© 2014; Rotronic AG E-M-PF4-V1_00

Page 28

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Document Type

Page

28 of 54

6.1.2 Dust and Humidity

Since the flow of air through the differential pressure sensor is very low (max. 180 µl/min), dust particles already

settle on the inside walls of the inlet tube and do not reach the sensor. The device is thus largely insensitive to

dust in the air being measured. The same applies to condensing air in the tube. As a result very little humidity

is transported to the sensor.

6.2 Analog Outputs

The analog outputs of the PF4 are configured at the factory according to the order specifications. If a change

is required use HW4 software to modify the instrument configuration.

6.3 Ethernet Connection

The PF4 with digital option uses the standard RO-ASCII protocol. Users who wish to evaluate the measured

data without ROTRONIC HW4 software are asked to consult ROTRONIC.

The Ethernet interface of the PF4 can be used best together with a PC with installed HW4 software (version 3.2

or later). Users may in principle access the measured data of the PF4 with any communication software. This

is described in detail in the document E-M-AC3000-CP.

Before connecting the PF4 to an active Ethernet network, it is first necessary to configure the TCP/IP settings.

You can find instructions for this in the HW4 manual E-M-HW4v3-Main (chapter 7.4) and the technical

guidelines E-M-TCPIP-Conf. The manuals can be downloaded from the website www.rotronic.com.

WARNING:

Before connecting the PF4 to an active Ethernet network, make sure it is configured correctly for IP

communication. Otherwise conflicts could disturb communication in the network.

© 2014; Rotronic AG E-M-PF4-V1_00

Page 29

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Document Type

Page

29 of 54

6.4 Analog Input

The measurement range for the input voltage lies between 0 and 3.2 V if a voltage input is configured and from

0...25 mA if a current input is configured. It must be stipulated in the order code whether the analog input is to

be configured as current or voltage measurement (see also chapter 3.4 ).

6.4.1 Display for Analog Input

The measured values of the analog input are shown in the display in mV / mA by default. For the analog input,

input signals smaller than 0 mV / mA are shown as ˅˅.˅˅. Input signals greater than 3.2 V / 25 mA are shown

in the display as

the effective input signal measured lies outside the permissible range.

The number of decimals shown in the display of the analog input is adjusted automatically in dependence on

the input or scale value.

˄˄.˄˄. This display is also shown if a display calculated via Range and Scale is wanted

and

6.4.2 Unit Systems

The default analog input unit is mV / mA. A user-specific unit can be configured in the HW4 software (e.g. %,

mbar, etc.). There are a maximum of four characters available for this.

6.4.3 Accuracy

The accuracy of the analog input is better than 0.5% of the displayed value and additionally ±1 digit of the last

place of the display.

© 2014; Rotronic AG E-M-PF4-V1_00

Page 30

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Document Type

Page

30 of 54

6.4.4 Scaling of the Analog Input

The analog input can be scaled within the range 0…3.2 V / 0…25 mA. If, for example, only 1...2.5 V are to be

shown in the display due to the application or a connected third-party probe, the analog input must be scaled

accordingly. Figure 16 illustrates scaling of the analog input.

Legend for

Input-Range: 0…3.2 V / 0…25 mA

RangeLo: 0 V / 0 mA (lowest input value)

RangeHi: 3.2 V / 25 mA (highest input value)

ScaleLo: Bottom scale limit (min. value shown in display)

ScaleHi: Top scale limit (max. value shown in display)

Figure 16: Graphic representation of scaling the analog input

Figure16:

Example:

An ambient pressure sensor with an analog output of 500…1000 mV (900…1100 hPa) is to be connected and

its signal shown in hPa. The Input-Range with the limits RangeLo = 500 mV and RangeHi = 1000 mV and the

display range Scale with ScaleLo = 900 and ScaleHi = 1100 mean that an input voltage of 500 mV shows the

value 900 in the display and an input voltage of 1000 mV the value 1100. The unit is configured with the HW4

software as "hPa".

Remark on PF4 with HC2 and analog input:

The formula for calculation of the Display-Value is:

© 2014; Rotronic AG E-M-PF4-V1_00

∗

Page 31

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

Examples:

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Document Type

Page

31 of 54

6.4.5 Output Scale

The display range (Scale = ScaleHi - ScaleLo) of the Display-Value can be selected freely within the complete

display range (Display-Scale), but may not exceed the maximum display range of

-9,999…99,999.

The output range (Output-Range = RangeHi - RangeLo) of the output signal (Output-Value) can be selected

freely within the complete output range (Voltage- / Current-Range), but may not exceed the maximum output

range, cf. chapter 3.5 (0…1 V / 0…5 V / 0…10 V / 0…24 mA / 4…24 mA). Fixed values (Fix-Value) are treated

in the same way as Display-Values.

Figure 17: Graphic representation of scaling the analog output

© 2014; Rotronic AG E-M-PF4-V1_00

Page 32

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

Remark on PF4 with HC2 and analog input:

The formula for calculation of the Output-Value is:

Examples:

∗

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Document Type

Page

32 of 54

© 2014; Rotronic AG E-M-PF4-V1_00

Page 33

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

6.5 Display and Keys

Figure 18: Display of the PF4 with connected HC2 probe

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Document Type

Page

MENU key:

open / close menu

ENTER key:

select menu point

Menu navigation keys + / -

change value: increase / decrease

33 of 54

Note:

Unauthorized use of the menu can be prevented by locking the setting "Display Menu" (using the HW4 software

> Device Manager > Display).

The display shows different measured values in dependence on the configuration of the device.

Device Variant Displays Units

© 2014; Rotronic AG E-M-PF4-V1_00

Page 34

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Document Type

Page

34 of 54

Differential pressure

Differential pressure & Pt100

connection

Differential pressure in Pascal

[Pa]

Differential pressure in Pascal

[Pa]

Temperature in degrees Celsius

[°C]

© 2014; Rotronic AG E-M-PF4-V1_00

Page 35

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Document Type

Page

35 of 54

Differential pressure [Pa]

Relative humidity [%RH]

Temperature [°C]

Differential pressure [Pa]

Relative humidity [%RH]

Differential pressure & HC2

connection

Remark:

It is possible to switch between display of the temperature and the calculations by pressing the Enter key [].

It is likewise possible to change between use of the HC2 probe and analog input in the device menu, as

described in chapter 4.5.2.

Pressing the – and + keys switches between the different calculations:

Ew [hPa], E [hPa], Ds [g/m³], R (g/kg), Q [g/kg], Dv [g/m³], H [kJkg], Tw [°C], Fp [°C], Dp [°C].

Calculation [°C]

Differential pressure [Pa]

Voltage [mV]

Differential pressure [Pa]

Current [mA]

© 2014; Rotronic AG E-M-PF4-V1_00

Page 36

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Document Type

Page

36 of 54

6.5.1 PF4 Menu

The menu structure depends on the hardware configuration of the device. The following three variants are

possible:

Only differential pressure

Differential pressure & Pt100 connection

Differential pressure & HC2 connection

Variant 1: Only differential pressure

Main Menu

Menu Navigation (valid for all menus)

Select Options

(Enter key) Selection of the menu point

Device Settings

Device Information

Settings for Differential Pressure

or menu

+ Line up; option right

- Line down; option left

Select Options

Units

Backlight

Contrast 0…99 (suitable setting 15…40)

Trend

Pressure

Value 1

The device information cannot be changed (except for "Name" and "Address").

"Name" and "Address" can be set with the HW4 software.

Select Options

Unit

Return; menu one level up

Unit for the ambient pressure (Pressure):

Metric, English

On, Off, Key Press

On, Off

Ambient pressure (suitable setting: 950 - 1050 hPa):

0…9,999 hPa (Units: Metric)

0…9,999 inHg (Units: English)

Main display: None, DiffPress

Unit for the differential pressure: Pa, inH

mbar, mmHg, mmH

O, Torr, g/cm2

2

0, mpsi,

2

© 2014; Rotronic AG E-M-PF4-V1_00

Page 37

E-M-PF4-V1_00

Document Code Unit

Rotronic AG

Bassersdorf, Switzerland

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

Filters

RefValue Current differential pressure can be changed

<Adjust> Applies change to RefValue

<Zero Adjust> Performs a zero adjustment

<Reset Adjustment> Cancels the last change (<Adjust>, <Zero Adjust>)

Filter value (0 = fast, 13 = very slow): 0…13 (suitable

setting 0…7)

Instruction Manual

Page

37 of 54

Document Type

© 2014; Rotronic AG E-M-PF4-V1_00

Page 38

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

Variant 2: Differential pressure & Pt100 connection

Main Menu

Menu Navigation (valid for all menus)

Select Options

(Enter key)

Selection of the menu point

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Document Type

Page

38 of 54

Device Settings

Device Information

Settings for Differential Pressure

Pt100 Adjust (1)

or menu

+ Line up; option right

- Line down; option left

Select Options

Units

Backlight

Contrast 0…99 (suitable setting 15…40)

Trend

Pressure

Value 1

Value 2

The device information cannot be changed (except for "Name" and "Address").

"Name" and "Address" can be set with the HW4 software.

Select Options

Unit

Filters

RefValue Current differential pressure can be changed

<Adjust> Applies change to RefValue

<Zero Adjust> Performs a zero adjustment

<Reset Adjustment> Cancels the last change (<Adjust>, <Zero Adjust>)

Return; menu one level up

Unit for the ambient pressure (Pressure):

Metric, English

On, Off, Key Press

On, Off

Ambient pressure (suitable setting: 950 - 1050 hPa):

0…9,999 hPa (Units: Metric)

0…9,999 inHg (Units: English)

Main display: None, DiffPress, TempPt100

Main display: None, DiffPress, TempPt100

Unit for the differential pressure: Pa, inH

mmHg, mmH

Filter value (0 = fast, 13 = very slow): 0…13 (suitable

setting 0…7)

O, Torr, g/cm2

2

0, mpsi, mbar,

2

© 2014; Rotronic AG E-M-PF4-V1_00

Page 39

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

Display when a Pt100 sensor is not connected

Pt100 Adjust (2)

Display when a Pt100 sensor is connected

Select Options

RefValue The current temperature shown can be changed

<Adjust> Applies change to RefValue

<Reset Adjustment> Cancels the last change made with <Adjust>

Variant 3: Differential pressure & HC2 connection

Main Menu

Menu Navigation (valid for all menus)

Select Options

(Enter key) Selection of the menu point

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Document Type

Page

39 of 54

Device Settings

Device Information

or menu

+ Line up; option right

- Line down; option left

Select Options

Units

Backlight

Contrast 0…99 (suitable setting 15…40)

Trend

Pressure

Value 1 None, DiffPress, Humi HC2, Temp HC2, Calc

Value 2

Value 3

The device information cannot be changed (except for "Name" and "Address").

"Name" and "Address" can be set with the HW4 software.

Return; menu one level up

Unit for the ambient pressure (Pressure):

Metric, English

On, Off, Key Press

On, Off

Ambient pressure (suitable setting: 950 - 1050 hPa):

0…9,999 hPa (Units: Metric)

0…9,999 inHg (Units: English)

None, DiffPress, Humi HC2, Temp HC2, Calc

None, DiffPress, Humi HC2, Temp HC2, Calc

© 2014; Rotronic AG E-M-PF4-V1_00

Page 40

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

Settings for Differential Pressure

Select Options

Unit for the differential pressure: Pa, inH

mmHg, mmH

Filter value (0 = fast, 13 = very slow): 0…13 (suitable

setting 0…7)

Select sensor: HC2, Analog In

Probe Information (1)

Unit

Filters

RefValue Current differential pressure can be changed

<Adjust> Applies change to RefValue

<Zero Adjust> Performs a zero adjustment

<Reset Adjustment> Cancels the last change (<Adjust>, <Zero Adjust>)

Display when a HC2 sensor is not connected

Select Options

Sensor Type

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Document Type

40 of 54

0, mpsi, mbar,

2

O, Torr, g/cm2

2

Page

Probe Information (2)

Humidity Adjust (1)

Humidity Adjust (2)

Display when a HC2 sensor is connected

Select Options

Version HC2 sensor: current firmware version

Serial No. HC2 sensor: serial number

Address HC2 sensor: sensor address

Name HC2 sensor: sensor name

SensorTest HC2 sensor: quality of sensor

Record

SensorType

Display when a HC2 sensor is not connected

Display when a HC2 sensor is connected

Select Options

RefValue Current relative humidity can be changed

Acquired

<Acquire>

<Delete>

HC2 sensor: Off, On

Select sensor: HC2, Analog In

© 2014; Rotronic AG E-M-PF4-V1_00

Page 41

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

<Adjust> Applies change to RefValue

Temperature Adjust (1)

Display when a HC2 sensor is not connected

Temperature Adjust (2)

Display when a HC2 sensor is connected

Select Options

RefValue The current temperature can be changed

<Adjust> Applies change to RefValue

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Document Type

Page

41 of 54

Exchange Sensor

Exchange Sensor is started after selecting Analog In in menu Probe

Information

The HC2 sensor can be substituted by an analog input (depending on order

code, for current or voltage measurement).

The action is only started after confirmation by pressing the Enter key [].

If the Enter key [] is not pressed within about 10 seconds, the device

returns to the menu Probe Information.

Exchange HC2 sensor for the analog input and press any key

If a key is not pressed within about 20 seconds, the device starts

automatically with the new settings.

The device is started with the new settings.

Summary of procedure:

MENU > Probe Information > Enter > Sensor Type HC2 > Sensor Type Analog In

> Enter > Change Sensors > Any Key

© 2014; Rotronic AG E-M-PF4-V1_00

Page 42

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Document Type

Page

42 of 54

6.6 Relay

The relay can be used in operation as an alarm switch contact. The functions have already been described in

section 3.6 . The relay is configured with the HW4 software, as described in the manual E-M-HW4v3-P-001.

6.6.1 Connections

The relay switch contacts are located at terminal block K3 (see Figure 14).

Connection Designation Description

COM Common Center tap of the change-over switch

NO Normally open Open when relay is not energized, closed when relay is energized

NC Normally closed Closed when relay is not energized, open when relay is energized

© 2014; Rotronic AG E-M-PF4-V1_00

Page 43

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Document Type

Page

43 of 54

7 Maintenance

Warning:

If only the service cable AC3009 is used to supply power to the PF4, the differential pressure shown will not be

correct because the voltage supply to the electronics is insufficient. For calibration or adjustment with the HW4

software, therefore, the power must be supplied via terminal block K2 in the bottom part of the housing.

7.1 Service Cable

Suitable service cables

AC3006: requires additional power supply to the device

AC3009: supplies the device directly with 5 VDC, differential pressure measurement will,

however, not be correct without external power supply

7.2 Service Port

The Mini-USB service port is located inside the device. The device must be opened by unscrewing the four

screws on the front of the housing in order to gain access to the Mini-USB service port.

Remark: AC3006 / AC3009 may be used as service cable.

Figure 19: Location of the service port on the top side of the circuit board

© 2014; Rotronic AG E-M-PF4-V1_00

Page 44

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Document Type

Page

44 of 54

7.3 Device Calibration and Adjustment Procedure

Both the differential pressure sensor and the corresponding electronics are very stable and require no

maintenance. They do not normally need to be changed or recalibrated after factory calibration. For maximum

accuracy, however, we recommend regular calibration of the device and adjustment when necessary.

Important:

When carrying out calibration or adjustment work on the open device, make sure you do not touch either the

sensor or the compressed air tubes.

7.3.1 Adjust Differential Pressure

The differential pressure can be adjusted at two points.

Zero

Any reference point in the sensor measurement range

Zero Adjustment

1. Connect the pressure connections with a short tube

2. Select "<Zero Adjust>" in MENU > Differential Pressure

After successful zero adjustment, "OK" is shown in the display.

Reference Value Adjustment

1. Apply a defined differential pressure or determine the current differential pressure with a reference

instrument connected in parallel.

2. Enter the reference value determined in MENU > Differential Pressure > RefValue.

3. Select "<Adjust>" in MENU > Differential Pressure.

After successful adjustment, "OK" is shown in the display.

Reset Adjustment

The following procedure is used to reset adjustment to the factory setting.

1. Select "<Reset Adjustment>" in MENU > Differential Pressure

After successful resetting of the adjustment, "OK" is shown in the display.

© 2014; Rotronic AG E-M-PF4-V1_00

Page 45

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Document Type

Page

45 of 54

7.3.2 Adjust Pt100

Reference Value Adjustment

1. Enter a defined reference value with a Pt100 simulator or record the current nominal temperature with

a reference instrument.

2. Enter the reference value determined in MENU > Pt100 > RefValue.

3. Select "<Adjust>" in MENU > Pt100.

After successful adjustment, "OK" is shown in the display.

Reset Adjustment

The following procedure is used to reset adjustment to the factory setting.

1. Select "<Reset Adjustment>" in MENU > Pt100

After successful resetting of the adjustment, "OK" is shown in the display.

© 2014; Rotronic AG E-M-PF4-V1_00

Page 46

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Document Type

Page

46 of 54

7.3.3 Adjust HC2 Probe

Both the Pt100-RTD temperature sensor used in the probe and the corresponding electronics are very stable

and do not normally need to be calibrated after initial factory calibration.

The long-term stability of the HYGROMER humidity sensor from ROTRONIC is normally better than 1 %RH per

year. For maximum accuracy, it is advisable to check the calibration of the probe every six to 12 months.

Applications in which the probe is exposed to considerable contamination could require more frequent checks.

Temperature Adjustment

The optional keypad of the PF4 enables one-point adjustment of the temperature or humidity in relation to a

reference. A one-point adjustment results in the same offset being added to all measured values.

When the temperature is stable, press the MENU key to open the internal menu in the display.

Select Temperature Adjust with the (-) key and press ENTER.

Make sure that the text line beginning with RefValue is selected and press ENTER.

Change the reference value to the temperature reference value with the (+) or (-) key.

Move to the text line Adjust with the (-) key and press ENTER.

The PF4 confirms adjustment with the message "Adjust OK".

Press the MENU key two times to leave the menu and return the PF4 to normal operation.

Note:

The following principle applies: perform temperature adjustment before humidity adjustment.

The calibration point is deleted automatically from the probe memory after adjustment.

Since the PF4 does not have a real-time clock, the date of the adjustment is not written in the probe. If it

is important to record the adjustment date, use the HW4 software to adjust the probe.

© 2014; Rotronic AG E-M-PF4-V1_00

Page 47

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Document Type

Page

47 of 54

Humidity Adjustment

The keypad of the PF4 enables multi-point adjustment of the humidity. The effect of a humidity adjustment

differs in dependence on the number of calibration points entered into the probe memory before adjustment:

One calibration point adds an offset to all measured values.

Two calibration points influence the offset and gain of the measurement curve.

Three or more calibration points influence the offset, gain and linearity of the measurement curve.

For maximum accuracy, three to four calibration points distributed over the measurement range in question

should be used. The calibration points (maximum 100) can be entered in any order, but we recommend working

from low humidity values to high humidity values.

When the humidity is stable, press the MENU key to open the internal menu in the display.

Select Humidity Adjust with the (-) key and press ENTER.

Make sure that the text line beginning with RefValue is selected and press ENTER.

Change the reference value to the reference humidity with the (+) or (-) key.

Move to the text line Acquire with the (-) key and press ENTER.

Note that the counter "Acquired" will be increased by 1 (number of calibration points in probe memory).

When all calibration points have been acquired, move to the text line Adjust with the (-) key and press

ENTER. Only adjust the probe when all calibration points have been acquired.

The PF4 confirms adjustment with the message "Adjust OK".

Press the MENU key two times to leave the menu and return the PF4 to normal operation.

© 2014; Rotronic AG E-M-PF4-V1_00

Page 48

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Document Type

Page

48 of 54

Note:

All calibration points are deleted automatically from the probe memory after adjustment.

The text line Delete can be used to delete all calibration points before probe adjustment.

Since the PF4 does not have a real-time clock, the date of the adjustment is not written in the probe. If it

is important to record the adjustment date, use the HW4 software to adjust the probe.

7.4 Validation of Analog Output Signals

Using the HW4 software, it is possible to set fixed values with which the analog output signals can be validated.

8 Firmware Update

The firmware can be updated with the HW4 software. Firmware updates are available for downloading on the

ROTRONIC website. To update the firmware, the PF4 must be connected to the HW4 with service cable

AC3006. The PF4 must remain connected to the computer throughout the update process and there must be a

stable power supply for the complete duration of the process.

Flashing of the display backlight indicates a firmware update is in progress.

© 2014; Rotronic AG E-M-PF4-V1_00

Page 49

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Document Type

Page

49 of 54

9 Technical Data

General

Device type

Circuit type 3-wire circuit

Mounting types W (Wall)

Power Supply and Connections

Supply voltage (VDD) 15...40 VDC / 14...28 VAC

Rated current consumption DC supply

Rated current consumption AC supply

Electrical connections Terminal block and M16 cable grip, optional RJ-45 Ethernet connector

Polarity protection Protective diode on V+

Humidity and Temperature Measurement

Differential pressure transmitter with analog output signals and optional

Ethernet interface

<70 mA (only analog outputs)

<150 mA (with Ethernet interface)

<70 mA (only analog outputs)

<450 mA (with Ethernet interface)

With HC2

With Pt100

See document E-M-HC2 Probes > Specifications.

Accuracy: ±0.2 °C

Meas. range: -100…200 °C (depending on probe type)

Differential Pressure Measurement

Measurement ranges -25…+25 Pa / -50…+50 Pa / -100…+100 Pa / -250…+250 Pa / -500…+500 Pa

Accuracy ±1.0 %Full Scale Span

Response time sensor 63

Ambient pressure dependence 0.1 %/hPa

Air flow 120 – 180 µl/min

Pressure resistance 2 bar (2,000 hPa)

Long-term stability <0.3 %/year

Adjustment points Zero, reference point

<10 ms (only sensor element)

© 2014; Rotronic AG E-M-PF4-V1_00

Page 50

E-M-PF4-V1_00

Document Code Unit

Rotronic AG

Bassersdorf, Switzerland

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

Analog Input

Measurement range

Accuracy 0.5% of current measured value

Temperature dependence

Calculated Parameters

Psychrometric parameters

Startup Time and Measurement Interval

Startup time <5 s (typical)

Measurement interval 1 s (typical)

Voltage: 0…3.2 V

Current: 0…25 mA

Voltage: ±30 mV

Current: ±60 µA

Dew point (Dp) above and below freezing point

Frost point (Fp) below freezing point and dew point above freezing point

Wet bulb temperature (Tw)

Enthalpy (H)

Vapor concentration (Dv)

Specific humidity (Q)

Mixing ratio by weight (R)

Vapor concentration at saturation (Dvs)

Vapor partial pressure (E)

Vapor saturation pressure (Ew)

Instruction Manual

Page

50 of 54

Document Type

© 2014; Rotronic AG E-M-PF4-V1_00

Page 51

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

Configurable Analog Outputs

Output 1 Can be assigned to every parameter

Default parameter Differential pressure

Default range Per order code

Output 2 Can be assigned to every parameter

Default parameter Relative humidity / Temperature

Default range Per order code

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Document Type

Page

51 of 54

Output 1 and output 2

Signal type

Accuracy analog output

User-configurable range limits -9,999...+99,999 units

Refresh interval 1 s

Short circuit tolerant Yes

Max. load 500 Ω (current output)

Min. load resistance 1000 Ω (voltage output)

0…20 mA

4…20 mA

0…1 V

0…5 V

0…10 V

(user-configurable)

±10 mV (voltage output)

±20 µA (current output)

Digital Interface

Interface type Ethernet, wired

Service Connector

Interface type UART (TTL Level)

Max. length of service cable 5 m (16.4 ft)

© 2014; Rotronic AG E-M-PF4-V1_00

Page 52

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Instruction Manual

Document Title

General Specifications

Relay switching capacity <50 VAC / <75 VDC / <1 A

Optional display LC, resolution 1 or 2 decimals, backlight, trend and alarm indicators

Housing material ABS

Page

Housing protection grade

Dimensions 129 x 72 x 45 mm

Weight 240 g

Conformity with S ta n da rds

CE / EMC immunity

Solder type Lead free (RoHS directive)

Fire protection class Corresponds to UL94-HB

FDA / GAMP directives CFR21 Part 11 and GAMP5

Environmental Limits

Storage and transit 0...70 °C / 0...90 %RH, non-condensing

Operation 0...70 °C / 0...90 %RH, non-condensing

IP65 (without Ethernet interface)

IP40 (with Ethernet interface)

EMC Directive 2004/108/EC: EN 61000-6-1: 2007, EN 61000-6-2: 2005

EN 61000-6-3: 2007, EN 61000-6-4: 2007

52 of 54

Document Type

© 2014; Rotronic AG E-M-PF4-V1_00

Page 53

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Instruction Manual

Document Title

10 Accessories

10.1 Service Cable

Order Code Description

AC3006

AC3009

Service cable, USB to UART

Service cable, USB to UART with integrated

power supply

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Document Type

Page

53 of 54

10.2 Pressure Tubes

AC6001 Connection tube with 4 mm diameter

10.1 Mounting Elements

Order Code Description

Mounting kit for DIN top-hat rail (consisting of

two clips, which are fastened to the back of the

AC5002

housing with the screws supplied).

DIN top-hat rail (35 mm / 1 3/8") not included.

© 2014; Rotronic AG E-M-PF4-V1_00

Page 54

E-M-PF4-V1_00

Document Code Unit

PF4 Differential Pressure Transmitter:

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual

Instruction Manual

Document Title

Page

11 Additional Documents

Document Name Contents

E-M-HC2 Probes HC2 manual

E-M-HW4v3-Main HW4 software main manual

E-M-TCPIP-Conf Manual for Ethernet configuration of ROTRONIC instruments

E-M-AC3000-CP Communication protocol for all AirChip3000 instruments

E-M-HW4v3-P-001 HW4 software manual for PF4

Document Type

54 of 54

12 Document Versions

Doc. Release Date Remark

E-M-PF4-V1_00 March 2014 Release document

© 2014; Rotronic AG E-M-PF4-V1_00

Loading...

Loading...