Page 1

Dew Point Mirror 973

Operation and

Maintenance Manual

MBW Calibration Ltd.

Seminarstrasse 57

CH-5430 Wettingen / Switzerland

+41 56 426 21 33 phone

+41 56 427 14 00 fax

0Hwww.mbw.ch

info@mbw.ch

Page 2

Warranty

MBW Calibration Ltd. (MBW) warrants the products it manufactures or distributes to be free of

defects in material and workmanship under normal use and service when operated within the

specified design limitations for a period of 12 months from date of initial shipment. Under this

Warranty, MBW will, at its discretion, repair or replace any component that upon examination

by MBW or its duly authorized representatives proves to be defective during the warranty

period provided the system is returned to the factory for inspection and repair shipping

prepaid. Improper or unauthorized maintenance, storage, repair, or alteration of any kind by

personnel other than MBW or its duly authorized representatives may void all warranties.

Warranty may also be voided for misuse, neglect, accident, corrosion, and improper

installation. This Warranty is exclusive and in lieu of any and all other warranties of

merchantability, fitness for a particular purpose, or any other warranty, expressed or implied,

and all other liabilities and obligations on the part of MBW. MBW will not be liable for any

other claims or damages, either direct, indirect, or consequential arising out of the use of its

products.

Page 3

Table of Contents

Table of Contents ..................................................................................................................... i

Welcome................................................................................................................................... 1

How to Use This Manual ......................................................................................................... 1

For More Information ............................................................................................................. 1

OPERATION.........................................................................................................3

Getting Started......................................................................................................................... 3

Turning the 973 On and Off................................................................................................... 3

What You See........................................................................................................................ 3

The Touch Screen.................................................................................................................. 5

The Measuring Head Assembly.............................................................................................9

Dew Point Measurement........................................................................................................ 9

System Configuration ........................................................................................................... 12

Menu Options....................................................................................................................... 12

Display Parameters.............................................................................................................. 13

Graphing Data...................................................................................................................... 13

Control Setup....................................................................................................................... 15

Changing Units..................................................................................................................... 18

Changing Color.................................................................................................................... 19

Analog Outputs .................................................................................................................... 20

Back Panel Connections....................................................................................................... 22

Power Plug........................................................................................................................... 22

Power Switch ....................................................................................................................... 22

RS-232................................................................................................................................. 22

External Temperature.......................................................................................................... 22

Analog Outputs .................................................................................................................... 23

Gas Input and Output........................................................................................................... 23

Barometric Pressure Input................................................................................................... 23

Measurement Tips................................................................................................................. 24

Understand the Measuring Range....................................................................................... 24

Connecting Hoses................................................................................................................ 24

Cooling Requirements ......................................................................................................... 26

INSTALLATION..................................................................................................27

Facility Requirements ........................................................................................................... 27

Environmental...................................................................................................................... 27

Power................................................................................................................................... 27

Preparation for Use ............................................................................................................... 27

Benchtop Use....................................................................................................................... 27

Preparation for Shipping or Transportation ....................................................................... 27

i

Page 4

REMOTE COMMUNICATION ............................................................................29

Introduction............................................................................................................................ 29

Hardware Connection & Cabling.......................................................................................... 29

Communications Settings .................................................................................................... 30

Command Syntax .................................................................................................................. 30

General Usage..................................................................................................................... 30

Termination Characters ....................................................................................................... 30

Leading and Trailing Spaces ............................................................................................... 31

Case Sensitivity.................................................................................................................... 31

Numeric Values.................................................................................................................... 31

Command Reference............................................................................................................. 32

Commands Listed By Functional Group.............................................................................. 33

MAINTENANCE .................................................................................................

Mirror Cleaning...................................................................................................................... 37

Exterior Cleaning................................................................................................................... 38

Front Panel........................................................................................................................... 38

Rear Fan Grills..................................................................................................................... 38

37

ii

Page 5

Welcome

Congratulations! With the 973 Dew Point Mirror you will be able to perform precision dew

point and frost point measurements as well as measurements of other parameters such as

relative humidity. The 973 utilizes a full color active matrix liquid crystal display with an

integral touch panel. It has a high contrast ratio and a wide viewing angle for easy readability.

Data is displayed in large easy to read fonts. Using the on screen buttons and menus, you

can easily configure each line of the display for a variety of humidity, temperature, and

pressure parameters that may be viewed in either SI or non-SI units.

How to Use This Manual

If you have the time and inclination, you can read this manual from front to back. Since we

realize your time is valuable and that you may not wish to do that yet, we recommend the

following approach to familiarize yourself with the 973 and start using it right away.

1. With the 973 at hand, go straight to the

you can quickly learn to use the 973 to make a dew point measurement.

2. Next, read the

configure the system to meet your preferences.

3. Finally, read the

identifies all the electrical and gas connections available on the back panel and explains

how and when to use them.

System Configuration section beginning on page 12 to learn how to

Back Panel Connections section beginning on page 22. That section

Getting Started section on page 3. From there,

For More Information

For a more thorough understanding of the 973 and other humidity measurement information,

please read the remaining sections of this manual.

Installation section covers bench space, environmental, and power requirements.

The

Remote Communication section discusses the RS-232 interface both from a hardwa re

The

and software perspective. It gives details relating to cabling to connect the 973 to a

computer, and gives the syntax and examples of each of the commands that the 973

recognizes.

Maintenance section covers topics such as Mirror Cleaning and general maintenance

The

required to keep your 973 performance at its best.

If the information you seek is not in one of the manual’s included sections, never hesitate to

contact us with your questions. Relevant phone, fax, and email contact information is on the

front page of this manual.

Welcome 1

Page 6

Page 7

Operation

Getting Started

This section allows you to set up and start using the 973 right away. You’ll turn the system on

and quickly familiarize yourself with the layout and features of the display and touch screen.

Next, you’ll learn about the optical mirror assembly for later care and cleaning that may be

required. Finally, you’ll use the 973 to measure the dew point temperature. Set your 973 on the

bench and let’s get started!

Turning the 973 On and Off

The 973 needs a source of normal AC power. Have a look at the label on the back panel of the

instrument for the voltage required. Ensure that the required voltage matches that of your

standard laboratory power receptacles.

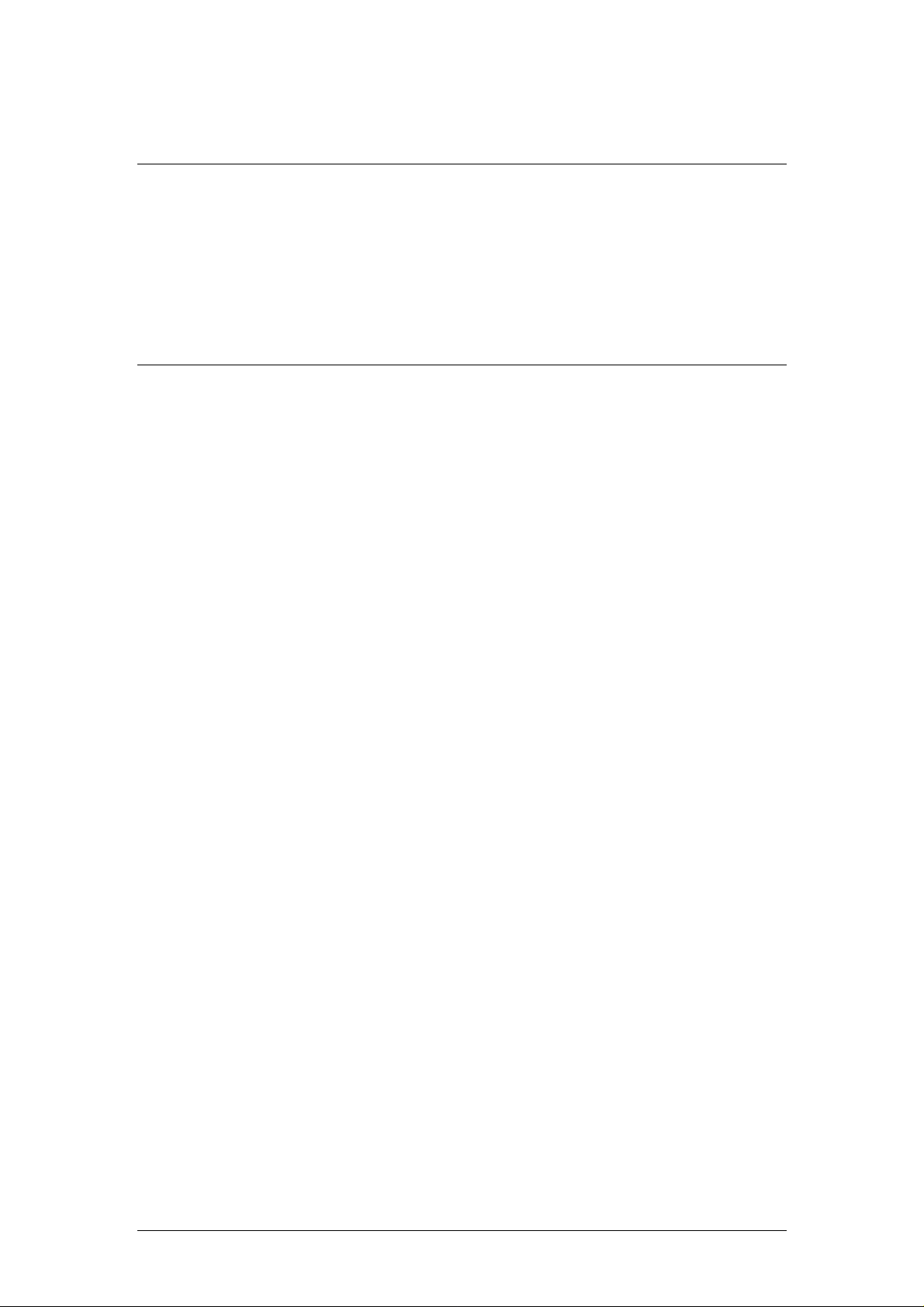

1. Using the supplied AC power cord, supply the

proper voltage to the instrument by plugging the

cord into the back of the instrument, then into an

AC receptacle of the proper voltage.

2. The power switch is located on the back panel

next to the power cord input. Turn it ON.

The display should become visible within a few

seconds. If nothing seems to happen, check the

power source. There may also be some fuses

located next to the power switch. You can remove

and replace them with known good ones. Suspect

fuses can be tested for continuity with an ohmmeter.

What You See

When power is applied to the 973, the display will activate within a few seconds. A typical

display configuration is depicted below. If you or someone else previously configured your

system, it may look slightly different. But don’t worry, we’ll show you how to set it up the way

you like.

Relative Humidity

10.00

25.41

Data

Lines

-8.41

14.695

Fixed

Function

Keys

Getting Started 3

Pump

Mirror

Check

%

External Temp

°C

Frost Point

°C

At m Pr e ss u r e

psia

M irror

Cleaning

Dew/Frost

Control

Menu

Keys

Page 8

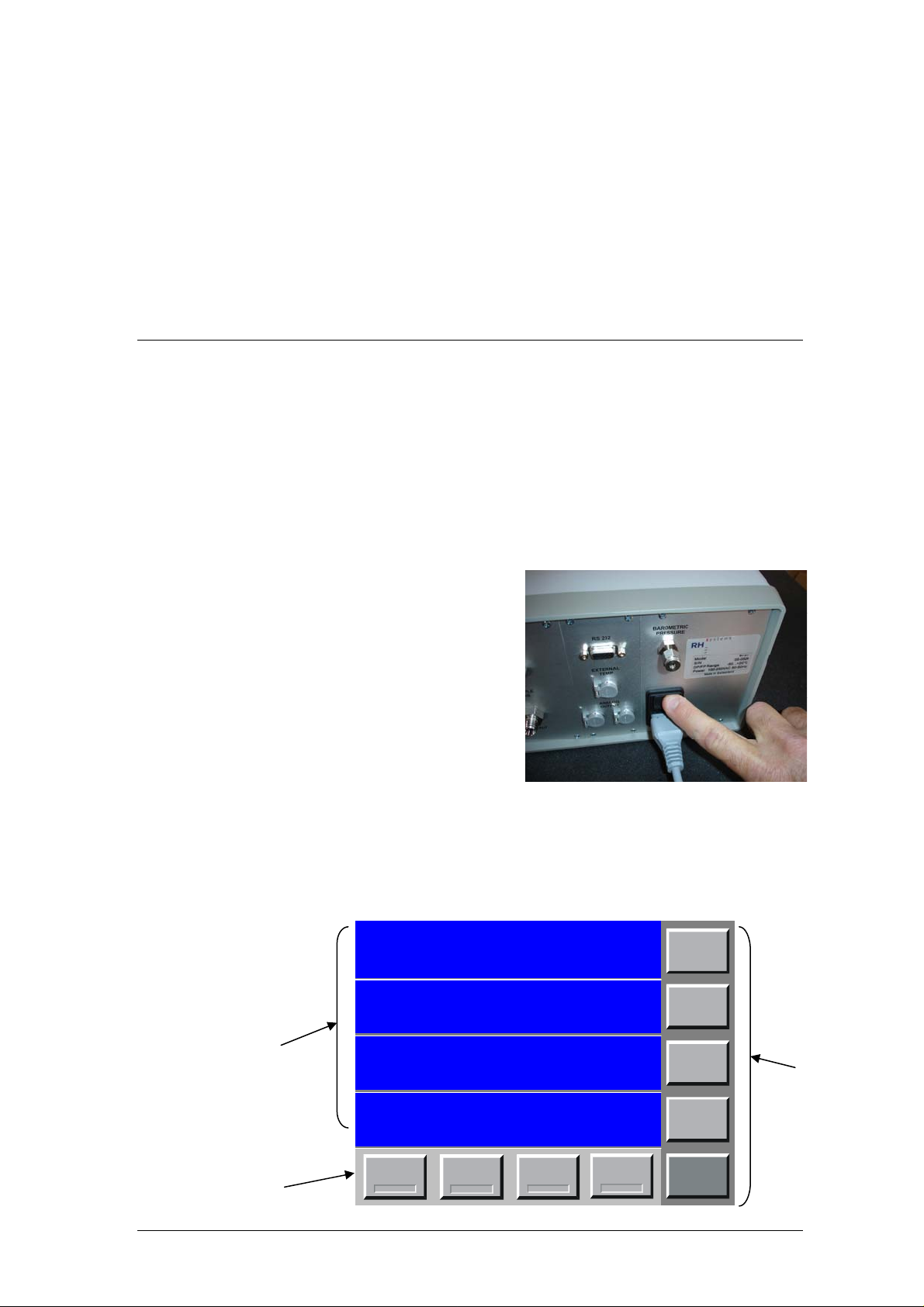

Data Lines

The first four lines of the display are for numeric or graphic representation of the measured data.

We refer to those first four lines as data lines.

If numeric, a data line contains the value to the

10.00

Relative Humidity

%

left, with the parameter description and units to

the right.

-9.8

If graphic, a data line shows a simple graph of

the data over time.

Time Span 20.16.30

-10.2

-9.65

Time Span 00:30:00

The choice of which parameter is shown on which data line, as well as whether a data line is

viewed as numeric or graphic, is easily selectable. You’ll see how to make these selections

shortly.

Status Bar

Balance

Indicator

+

STABLE

-

Frost

Density

Hi

0

Mirror

Residue

Hi

Flow Rate

0

60

30

0

The status bar contains balance, density,

contamination, and flow rate indicators. The

configuration of the status line is fixed and

never changes.

Fixed Function Keys

Pump

Mirror

Check

Mirror

Cleaning

Dew/Frost

Control

The bottom line of the display contains a row of

fixed function keys. You’ll use these keys to

start and stop the pump, enable and disable

measurement of dew point, and other things.

The function of each of these keys never

changes, and they are always available for

use.

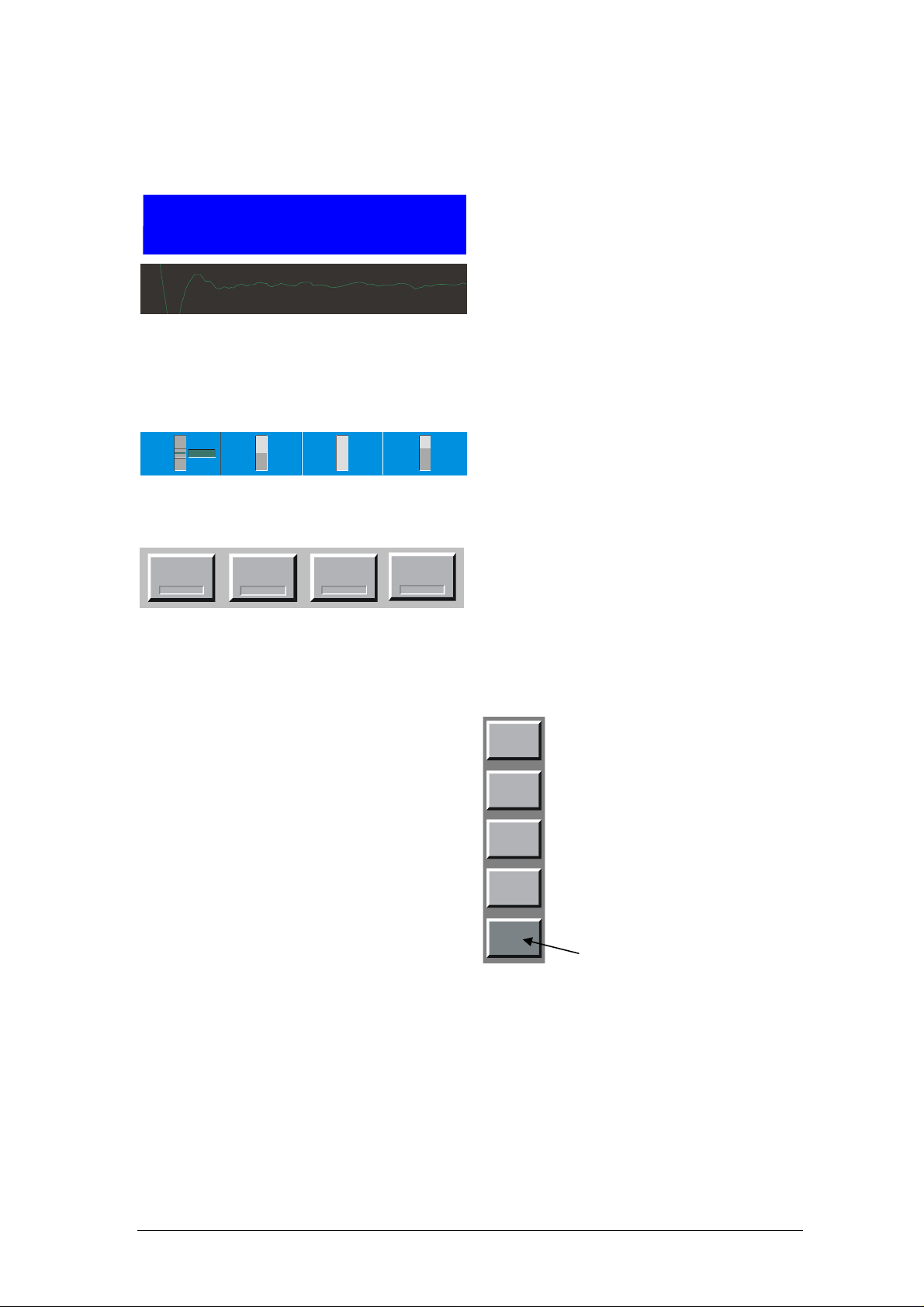

Menu Keys

To the right side of the display is a column of

menu keys. Each of these keys changes

function as needed.

Notice that the bottom key in this column is

different from the rest. The bottom key is used

to cycle the upper keys through the various

menu options. The text on the bottom key

changes to indicate the currently selected

menu option. The text of the upper keys

change based on the functions available in the

menu.

Use this key to change menus

4 Getting Started

Page 9

The Touch Screen

The 973 utilizes a touch screen for user interaction. To activate a menu option or toggle a

function on or off, simply touch the screen directly over the key or object desired.

Calibrate the Touch Screen

Before using the 973 for the first time, you may need to calibrate the touch screen to your finger

positioning preference. Here’s how –

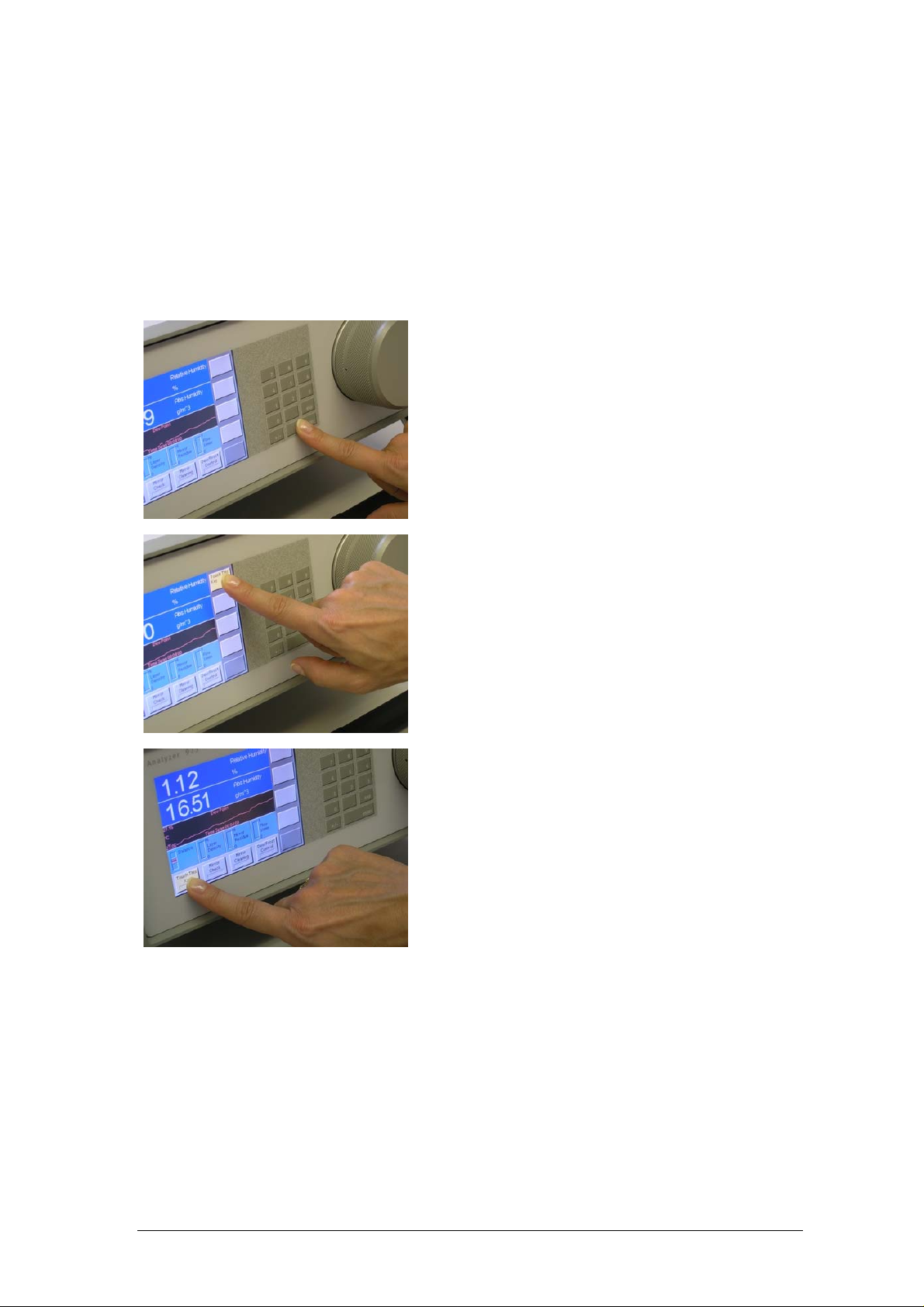

1. Press and hold the enter key on the numeric

keypad for 3 or 4 seconds. If you’ve done it

correctly, you’ll hear two loud short beeps.

If not, release the key and try again.

2. With the tip of your finger, press the center

of the yellow key in the upper right corner of

the touch screen. It is labeled ‘Touch This

Key’. Once you touch it, the yellow color

goes away and another key turns yellow.

3. Now, touch the yellow key that’s in the lower

left corner of the touch screen. Once you

touch it, the yellow color goes away and you

have successfully calibrated the touch

screen.

4. Test your new touch screen calibration by pressing each of the six blank menu keys on the

right side of the touch screen several times. If they seem not to work well, just repeat the

calibration steps again from the beginning.

You may recalibrate the touch screen as often as needed, however, it is rarely required.

Getting Started 5

Page 10

Navigating the Menus

The various menus of the right column of keys are navigated by using the key in the lower right

corner of the touch screen. Each time you press the lower right key, a new menu appears on

the keys directly above it. The menu is circular, meaning that once you go past the last menu,

the first one appears again and the process starts over. You can use the +/- key on the keypad

to move backward through the menus. Use the enter key to clear the menu.

Selecting Parameters to Display

Selecting which parameters to display on the data lines is easy. It is done with the Parameter

menu.

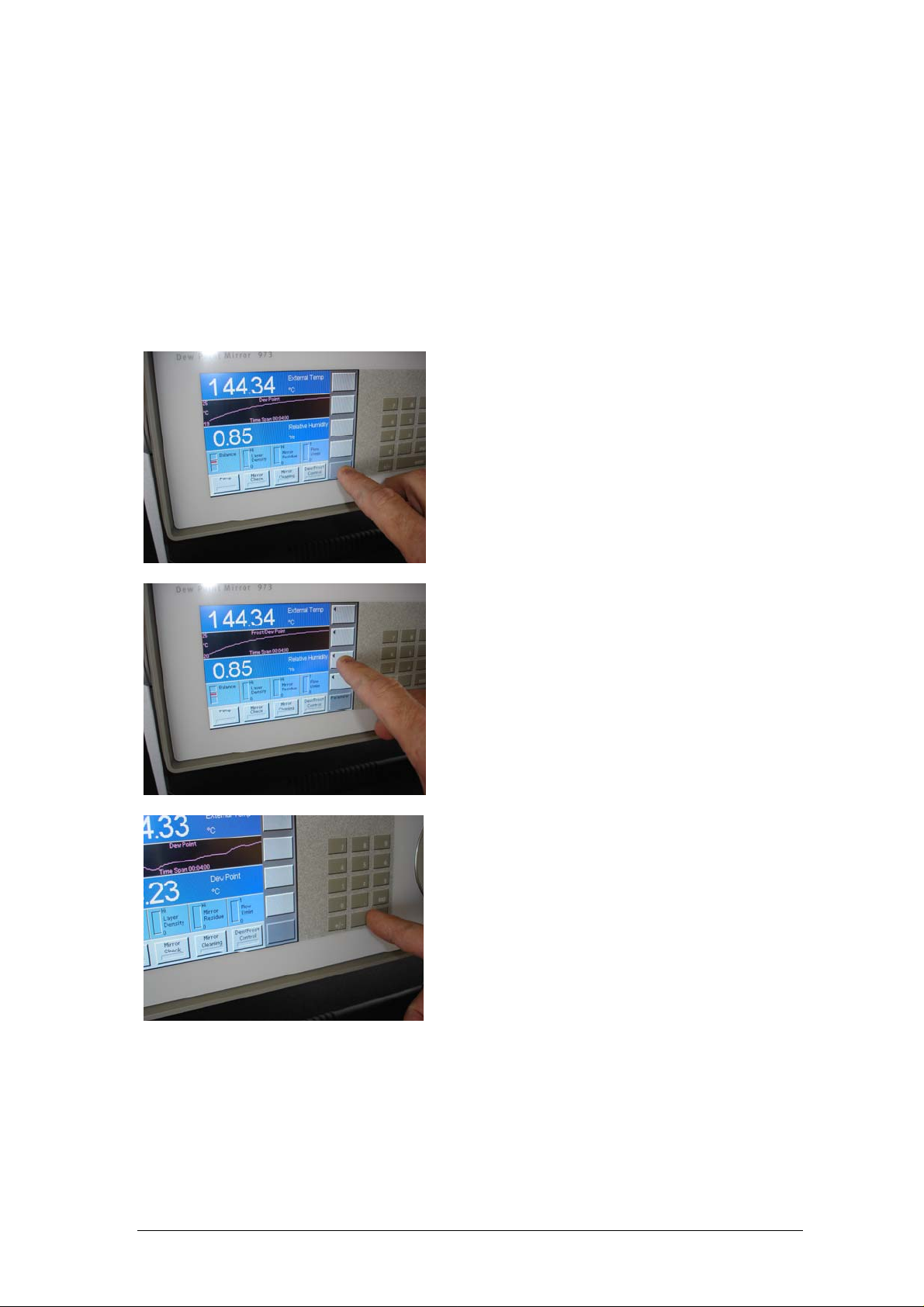

1. Use the lower right menu key to select the

Parameter menu. ‘Parameter’ appears on

the key, and the keys above get left pointing

arrows. Notice that each key corresponds

to the data line it points toward.

2. Press the arrow key corresponding to the

data line you wish to change. Notice that

each time you press the arrow key, the

parameter of the data line changes. The

parameter selection is circular, meaning that

once you reach beyond the last available

parameter the first one is again displayed

and the cycle starts over.

3. Change the parameters on any of the other

data lines with the same method.

4. If you like, you may clear the menu keys

when finished by cycling through all the

menus using the lower right key on the

touch screen, or by pressing the enter key

once. Note that this is not required and

nothing is wrong with leaving the Parameter

menu (or any other menu) on the screen.

6 Getting Started

Page 11

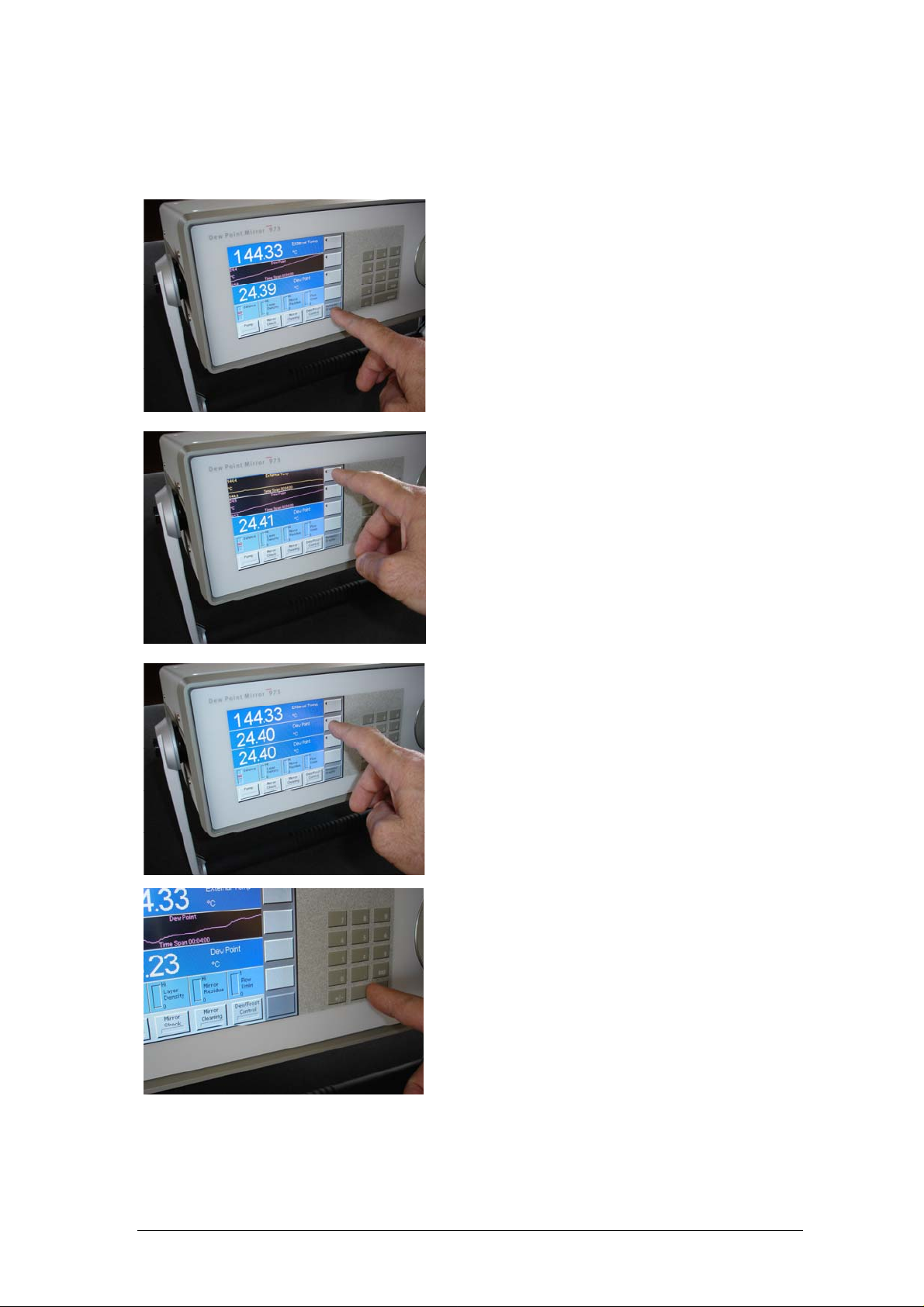

Selecting Graph vs. Numeric Data

Any data line may be viewed either as numeric or as a graph. The Numeric/Graphic menu is

used to toggle any data line between numeric and graph mode.

1. Use the lower right menu key to select the

Numeric/Graphic menu. ‘Numeric/Graphic’

appears on the key, and the keys above

contain left pointing arrows. Notice that

each key corresponds to the data line it

points toward.

2. Press the arrow key corresponding to the

data line you wish to change. Notice that

the data line toggles between numeric or

graph mode each time you press the key.

3. Select numeric or graph mode on any of the

other data lines with the same method.

Notice that if a line is currently displaying the Status

[

Bar, no arrow appears on the adjacent menu key. The

Status Bar is not changeable in the Numeric/Graphic

menu.

]

4. If you like, you may clear the menu keys

when finished by cycling through all the

menus using the lower right key on the

touch screen, or by pressing the enter key

once. Note that this is not required and

nothing is wrong with leaving the

Numeric/Graphic menu (or any other menu)

on the screen.

Getting Started 7

Page 12

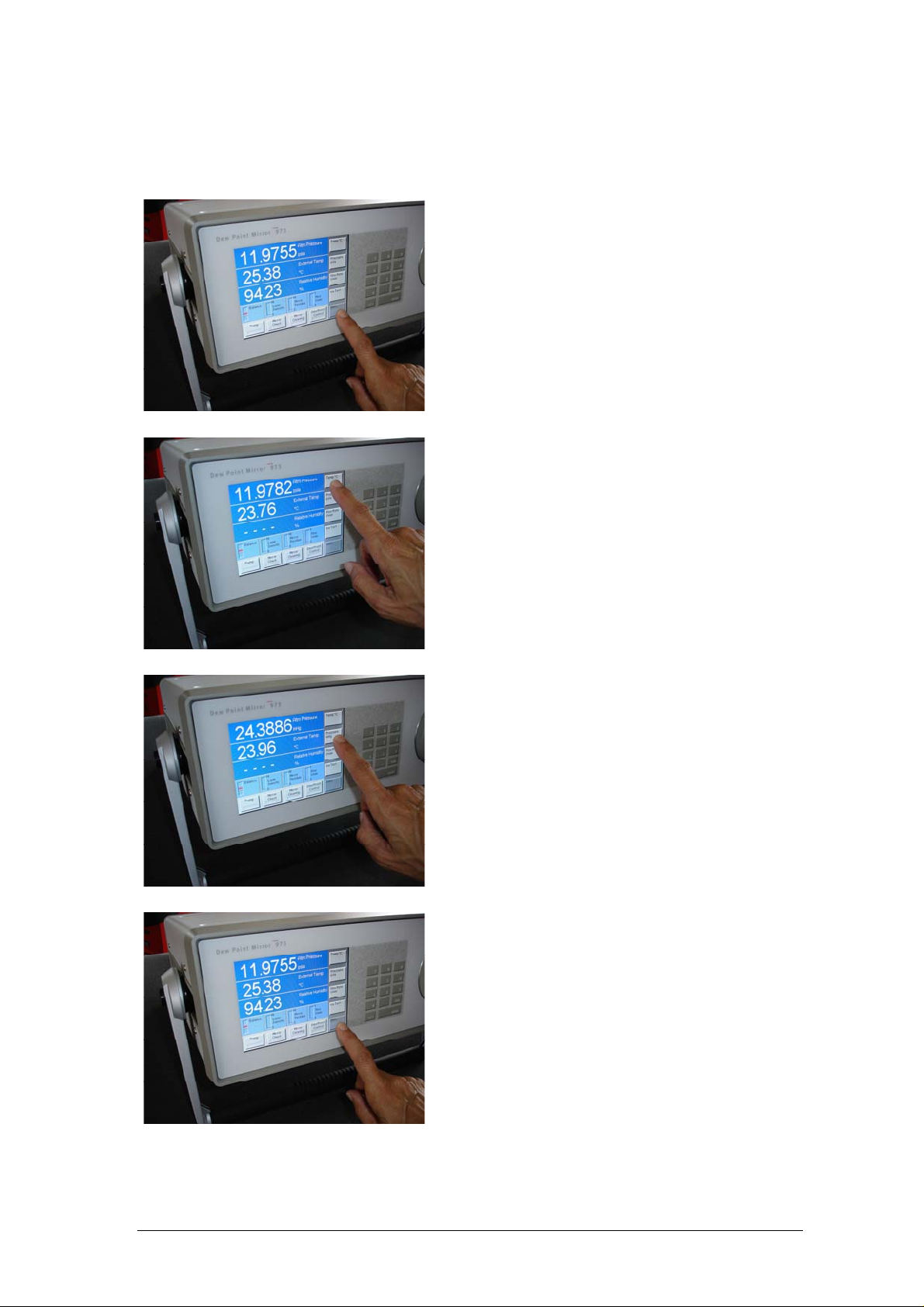

Selecting Units

The data may be viewed in any of the many available units. There are two Units menus used to

change the units of displayed data.

1. Use the lower right menu key to select the

Units menu. ‘Units’ appears on the key, and

the keys above contain current units

indications such as ‘Temp °C’. Notice that

each of the keys contain different types of

units. In this case, the keys do not correspond

to the adjacent data lines, but rather to

different units types.

2. To change temperature units, press the key

labeled ‘Temp’. Notice that the corresponding

units change each time the key is pressed.

Also notice that any data line that is currently

indicating temperature data also changes to

reflect the newly selected units.

3. Change other units (such as pressure, flow

rate, etc.) with the same method.

4. Note that there are two Units menus since

there are so many types of units that may be

changed. The second Units menu is obtained

by pressing the lower right menu key again.

5. If you like, you may clear the Units keys when

finished by cycling through all the menus using

the lower right key on the touch screen, or by

pressing the enter key once. Note that this is

not required and nothing is wrong with leaving

the Units menu (or any other menu) on the

screen.

8 Getting Started

Page 13

The Measuring Head Assembly

The heart of the 973 Dew Point Mirror instrument is

the measuring head assembly. It is designed to be

highly sensitive and accurate, yet rugged and easily

accessible for periodic mirror cleaning. Although not

required prior to initial operation, you may wish to

familiarize yourself with the location and accessibility

of the mirror and the other optical components within

this assembly.

For further discussion of the measuring head, and

the mirror cleaning procedure, refer to

Cleaning on page

37.

Mirror

Dew Point Measurement

When you power the 973 on, it begins in an idle state. In this state, it measures and displays

temperature, pressure, and flow transducers, but does not yet provide any meaningful humidity

related data. In order to provide humidity data (dew point, frost point, %RH, etc.), the Dew/Frost

Control mode must be enabled and gas must be flowing across the mirror. If %RH is desired,

note also that an external temperature probe must be connected. For external temperature

probe use, see

External Temperature on page 22.

Flow Rate

60

30

0

Pump

Dew/Frost

Control

Starting / Stopping the Pump

Some gas flow is required over the mirror when measuring the dew or frost point temperature.

The nominal gas flow desired is approximately 20 to 60 liters/hour (0.2 to 1.0 liters/minute). If

your 973 is equipped with an internal gas pump, you can use it to provide the necessary gas

flow. If not, then you may need to provide for gas flow in some manner.

Use the Pump key on the bottom row of the touch screen to toggle the pump on/off. The Flow

Rate indicator on the status line should indicate that gas is flowing. The actual rate of flow is not

critical, but is best when within the limits previously mentioned. The gas flow may be adjusted

with an external valve, or by changing the pump control parameters. See

17.

page

Pump Control on

Measuring the Room Ambient Dew Point Temperature

Enable Control

Lets use the 973 to measure the dew point temperature of the room by enabling the portion of

the system responsible for cooling and maintaining the mirror at the dew or frost point

temperature. Do so by pressing the Dew/Frost Control key. When enabled, a green bar on

the key illuminates and any dew or frost point temperature indication begins to drop as the

mirror cools toward the dew or frost point temperature. See

6 to select one of those parameters for display.

page

What You’ll See

When the Dew/Frost Control is enabled, have a look at the Status Bar (if you have your screen

set up to show it). The Status Bar has visual bar graphs that represent Balance, Density, Mirror

Residue, and Flow Rate.

Selecting Parameters to Display on

Getting Started 9

Page 14

Balance

Indicator

Frost

Density

+

STABLE

-

Hi

0

Dew/Frost

Control

The Balance Indicator

Although it is directly obtained from the intensity of the mirror’s reflected light signal, the Balance

Indicator is effectively the first derivative of the dew thickness. In other words, it indicates the

rate of growth or decay of the condensed layer on the mirror. While the dew or frost layer is

growing in thickness due to an increase in condensation on the mirror surface, the indicator is

above center. The faster the layer grows the higher the indication. Conversely, if the layer is

evaporating from the mirror surface thereby becoming thinner, the indicator is below center.

The faster it decays the lower the indication. When the indicator is in the center, it indicates that

the thickness of the dew or frost layer is neither growing nor decaying and that the layer on the

mirror surface is in equilibrium with the gas. In this center-balanced indication, there is no net

exchange of water vapor between the gas and the mirror surface. If the humidity of the gas

sample is homogeneous and of low enough variability for the control system to sense a steady

value, the Balance Indicator will illuminate a green ‘Stable’ message, and the system will emit a

few short audible beeps.

The Density Indicator

The Density Indicator graphically depicts the approximate relative thickness of the dew or frost

layer currently on the mirror surface. Since the 973 has the ability to differentiate between dew

and frost layers, it will also indicate which state the mirror’s layer is in. The label within the

density indicator will change from Layer Density (when it the state of the layer is uncertain) to

either Dew Density or Frost Density (when either dew or frost is assumed). For more

information regarding Dew/Frost point determination see

Dew / Frost Control on page 15.

Disable Control

To disable the control system, press the Dew/Frost Control key again. The green bar on the key

disappears indicating that the control is no longer enabled. Any dew or frost point temperature

indications will begin to rise toward the temperature of the measuring head, often within several

degrees of the ambient room temperature. Also, the density indication drops off and the

balance indication moves downward but eventually returns toward center.

External Temperature Connection

The 973 is equipped with an external

temperature sensor. This sensor, along with the

dew point and pressure measurement, allows

the 973 to accurately determine and display

relative humidity. The external temperature

probe connection is made at the back panel.

Gas Inlet Connection

While the previous example did not rely on any external gas connections, the 973 is equipped

with fittings for connection of gas inlet and outlet tubing. This allows the 973 to measure the

dew or frost point of chambers and other devices that can be connected to it via tubing. If you

have a gas source you wish to measure, such as a humidity generator or chamber, connect a

tube between it and the 973 gas inlet on the back of the unit.

10 Getting Started

Page 15

The input and output connectors are clearly

labeled on the Sample Gas section of the back

panel. Depending on the specific model and

ordered options, the stainless steel gas input

and output connections may be 6 mm

Swagelok, ¼ inch Swagelok, or ¼ inch Cajon

VCR.

Note that you should never attempt to measure

any gas with a dew point temperature that is at

or above the temperature of the room. If you

high dew point measurements, a Model 373H or 373HX with

heated internal components and heated hoses is required.]

do, condensation will form inside the tubing.

[For

Swagelok® Tube Fittings

Swagelok® brand tube fittings are generally used to connect the gas inlet and outlet tubes to the

973 system. Depending on the configuration of your specific 973, the back panel fittings are

either ¼” or 6 mm. When ordering tube fittings from your local Swagelok® supplier, be sure to

specify the correct size for your instrument. Swagelok® tube fittings come to you completely

assembled, finger-tight and ready for immediate use. Disassembly before use is unnecessary and

can result in dirt or foreign material getting into the fitting and causing leaks.

SWAGELOK® Tube Fittings are installed in three (3) easy steps:

Simply insert the tubing into the SWAGELOK

Make sure that the tubing rests firmly on the shoulder of

the fitting and that the nut is finger-tight.

®

Tube Fitting.

®

Before tightening the SWAGELOK

nut, scribe the nut at the 6

o’clock position.

Hold the fitting body steady with a backup wrench and tighten

the nut 1-1/4 turns.c Watch the scribe mark, make one

complete revolution and continue to the 9 o’clock position.

By scribing the nut at the 6 o’clock position as it appears to you,

there will be no doubt as to the starting position. When the nut is

tightened 1-1/4 turns to the 9 o’clock position, you can easily

see that the fitting has been properly tightened.

Use of a Swagelok

®

Gap Inspection Gage (1-1/4 turns from

finger-tight) ensures sufficient pull-up.

c

For 1/16“, 1/8“, 2 mm, 3 mm and 4 mm size tube fittings, only ¾ turn from finger-tight is necessary.

Getting Started 11

Page 16

System Configuration

You may configure many aspects of the 973 based on your preferences at the time. For

instance, you may easily select which humidity, temperature, and pressure values to indicate on

the screen, the order in which they should appear, their units, and whether each will be shown

as a number or as a graph. In addition to display configuration, you can also change how the

973 performs its control functions such as Dew/Frost determination, ORIS control, tube heating,

mirror pre-cooling, etc. Most configuration settings that you change remain valid until the next

time you change them, even if you shut the 973 off.

Menu Options

The 973 has several menus available which are used to configure the system to your

requirements. To activate each of the menus, press the lower right menu key. Notice that it is a

slightly different color than all the other keys on the touch screen.

Each time you press this menu key, the 973 advances to the next menu and the key’s label

changes to indicate which menu is currently active. Once you’ve reached the last menu item,

and press the menu key again, the menu options just start over again at the beginning.

Pressing +/- on the keypad steps backward through the menus. Pressing enter on the keypad

clears all menus from the screen. Note however, that there is no requirement to clear the

menus from the screen for any reason other than cosmetic, or for fear of accidentally changing a

configured option.

Simplified descriptions of each menu follows.

Parameter

Numeric /

Graphic

Control Setup

Units

Fore Color

Back Color

Analog

Outputs

The Parameter menu is used to select which parameter to display on each of the four

data lines. Each menu item key contains an arrow and directly corresponds with its

adjacent data line.

The Numeric/Graphic menu is used to toggle a data line between displaying the data

as numbers or as a graph. Each menu item key contains an arrow and directly

corresponds with its adjacent data line.

The Control Setup menu is used to configure such things as dew/frost control, pump

control, internal and external heater control, cooling water control, etc.

The Units menu is used to change units used for displaying data. Unit changes are

system global, meaning that if the temperature units are changed, then all temperature

values displayed (including dew and frost point temperatures) will appear in the new

units. Since there are so many units that may be configured, there are two units

menus.

The Fore Color menu is used to temporarily change the color of the lines drawn on

graphs and the color of text (number and letters). Each data line may be changed

individually. Unlike other selections, changing colors is only temporary and cycling the

power causes the 973 to return to standard color settings.

The Back Color menu is used to temporarily change the color of the background dra wn

on graphs and numeric data lines. Each data line may be changed individually. Unlike

other selections, changing colors is only temporary and cycling the power causes the

973 to return to standard color settings.

The Analog Outputs menu is used to configure the calibration, scaling, and parameter

selection for output of data to the Analog Output connectors on the back panel if your

unit is so equipped. Both analog output ports are separately configurable.

12 System Configuration

Page 17

Display Parameters

Use the Parameters menu to select which parameters to display on the data lines. When you

select parameters for display on any of the four data lines, those selections remain valid until

you change them again, even if you turn the 973 off. See

6 to select which values to display. A list of the available parameters follows. Note that

page

Selecting Parameters to Display on

not all parameters are available on all systems since some systems may not contain the

associated hardware components.

Dew Point

Frost Point

%RH

%RH WMO

Volume Ratio

Weight Ratio

Absolute Humidity

Specific Humidity

Vapor Pressure

Head Pressure

Atmospheric Pressure

Flow Rate

External Temperature

Head Temperature

Graphing Data

Any value that you can view numerically can also be viewed as a graph at any time. The 973

automatically maintains a short history of each and every selectable parameter so that a graph

may be seen instantly whenever a data line is toggled from a numeric mode to a graph mode.

Selecting Between Numeric Data and Graph

Selecting between numeric and graph modes is done with the Numeric / Grap hic menu. See

Selecting Graph vs. Numeric Data on page 7.

Changing Graph Attributes

To change the graph attributes, you need to

bring up the graph dialog. Do this by pressing

the touch screen directly on the graph whose

attributes you’d like to change.

System Configuration 13

Page 18

Scaling

Each graph can have its own scaling (or y-axis)

values. There are three distinctly different

scaling modes to choose from:

Autoscale

Fixed Range

Maximum / Minimum

You may also change the Time Span of the

graph from this dialog.

• Autoscale

Autoscale mode determines the scaling automatically so that all of the stored data will be visible

on the graph at the best possible resolution. As the range of the data changes, so does the

range of the graph. In autoscale mode, you can select a minimum that you want the graph to

scale to. This is very useful for data that is very stable with little variation. This prevents the

973 from setting the scaling to such a small range that even the highly stable data appears

visibly as wildly variable. For viewing dew or frost point graphs, setting this Autoscale Minimum

to a value of at least 0.2 or more is generally preferable. This allows the graph range to close in

on the data as it stabilizes at a point without becoming too narrow. You can experiment with this

value to determine your personal preferences with different parameters. Autoscale mode is the

power up default.

• Fixed Range

Fixed Range scaling allows you to select a fixed graph range, but automatically centered on the

current data point. In other words, as the current data varies so does the graph center point, but

the overall range remains fixed. This fixed range auto centering is mostly used to monitor data

for stability.

• Maximum / Minimum

You can specify the maximum and minimum values used for the graph. This is completely fixed

scaling. If the data falls outside the maximum and minimum values you specify, you will not see

them on the graph. If you wish to see the data that is outside the values you specified, you’ll

need to specify maximum and minimum values with a larger spread.

You can change the graph scaling at any time, and freely switch between the three scaling

modes as well. Try it.

1. Using the touch screen, press directly on the graph you which to change. A graph scaling

dialog box will appear. One of the buttons in the Description column will have a green

indicator. That shows you the currently selected mode. Note that there are three buttons –

one for each mode.

2. Press the button of the mode you’d like to change to. Note that for the MinMax option, only

the Maximum button need be pressed (as Minimum is then automatically assumed).

3. Press the corresponding button in the Change To column for the range you selected.

4. Using the numeric keypad, enter the value needed. If the number shown in the Value

column is already correct, no entry is needed here. If you make a mistake while entering

the value, use the touch screen and press on the number in error. Each time you press the

touch screen there, the number will backspace one, erasing the flawed digits.

14 System Configuration

Page 19

5. Once the value is shown is what you want press the Ok button (or the enter key) to accept

the new value, or press the Cancel button to abort all changes made to the mode and to any

values.

The only values that get accepted by the system are those that correspond with the selected

mode. In other words, if you change the value of the Autoscale Minimum, but Fixed Range is

the selected mode, the Autoscale Minimum value remains unchanged.

Time Span

Changing the time span allows you to see a longer or shorter history period for the data. The

973 stores a fixed number of data points independent of the selected time span. Changing the

time span changes the interval used for data storage. With a 15 minute time span, the graph

data is sampled and stored every few seconds. However, with a 2 hour time span, the graph

data is only sampled, stored, and updated about once a minute.

When you change the time span, the old data previously sampled and stored at the old interval

will be incrementally replaced by new data sampled at the new interval. The Time Span as

indicated on the graph will always reflect the actual time span of the currently stored data, and

will eventually agree with the time span you select. Regardless of the graph selected, the

selected time span is common to all graphs so that they all have the same time relationship to

one another.

The result of a time span change might not be seen instantaneously. It will take some time for

the old data at the old time interval to be replaced by data at the new time interval as

determined by your selected time span.

Viewing Data both as Numeric and as a Graph

Since all displayable data may be viewed either numerically or as a graph, it does not matter

which parameters are selected on which lines of the display. Often times you may even want to

select the same parameter on two different data lines. That way you can have one of them set

for numeric mode and the other one showing you a graph of that same data.

Control Setup

With the Control Setup, you can control the manner in which the 973 operates. The control

setup capabilities are accessible through the Control Setup menu. See

on page

6.

Dew / Frost Control

The 973 can control on either dew point or frost point, and has the ability to distinguish the

difference through a function known as Force Frost. The Dew / Frost Control setup menu is

used to control the Force Frost function and also allows for setup of the ORIS (Optimal

Response Injection System) operation.

Force Frost Below

For mirror temperatures above 0°C, water vapor condenses on the mirror as liq uid water (dew).

A condensation layer resulting from a mirror temperature above 0°C is considered a dew point.

For mirror temperatures far below 0°C (generally mirror temperatures below –40°C), water

vapor condenses on the mirror as solid ice (frost). A condensation layer resulting from a mirror

far below 0°C is considered a frost point.

Navigating the Menus

System Configuration 15

Page 20

However, for mirror temperatures between 0 and approximately –30°C, the state of the

condensed layer is generally indeterminate since dew can, and does, exist on the mirror in a

meta-stable state at temperatures well below 0°C. In reality, the condensed layer on the mirror

could be dew, frost, or some combination of the two. Significant errors can result if wrongful

assumptions are made and can be in excess of 2°C.

To eliminate this problem, the 973 can automatically force all sub-zero condensation to a known

state of frost using the Force Frost function. Force Frost works by rapidly cooling the mirror

below –40°C forcing the condensate to solidify to a layer of ice or frost. The mirror will then restabilize at the frost point temperature. Once the condensed layer is in a state of frost, it will

remain frost for all sub-zero mirror temperatures.

You can enable or disable the Force Frost function, and also decide at which temperature it

begins to work. From the Control Setup menu, press Dew/Frost Control (the top menu key).

Change the value of the Force Frost Below field. Mirror temperatures below this value will be

forced to frost.

Now enable or disable the Force Frost function by pressing the Force Frost Below button. A

green indicator light on the button means that the function is enabled. If the light is not

illuminated, then the Force Function is disabled, and no Force Frost will be performed.

Complete your preference by pressing Ok or the keypad’s enter key.

Enable ORIS Below

If the option is installed, the Optimal Response Injection System is used to speed system

response for very low frost point measurements typically when the gas is drier than

approximately –60°C. ORIS works by momentarily injecting a small amount of water vapor into

the dry gas stream to rapidly seed the initial formation of frost on the mirror. This process allows

the required layer to build within a matter of minutes rather than hours. ORIS is typically used

for frost point measurements below about –60°C, but allows you to set it to any reasonable

value.

You can enable or disable the ORIS function, and also decide at which temperature it begins to

work. From the Control Setup menu, press Dew/Frost Control (the top menu key). Change the

value of the Enable ORIS Below field. Mirror temperatures below this value, when there is not

yet any frost formation on the mirror, will use ORIS to more rapidly form the initial frost layer.

Now enable or disable the ORIS function by pressing the Enable ORIS Below button. A green

indicator light on the button means that the function is enabled. If the light is not illuminated,

then ORIS is disabled, and no rapid layer formation will be performed. Complete your

preference by pressing Ok or the keypad’s enter key.

Mirror Cleaning Control

When the fixed Mirror Cleaning key at the bottom of the screen is pressed, the mirror

immediately warms to a pre-specified temperature, readying the measuring head for removal of

the cover and optical assembly. If the mirror and other internal measuring head components

become exposed to normal atmospheric air while cold, the possibility of undesired condensation

exists. By warming the mirror and other internal components to a safe head removal

temperature prior to accessing the mirror, this adverse condensation is avoided.

The safe temperature to which the mirror and internal components will be warmed during a

Mirror Cleaning procedure is selectable from the Mirror Cleaning key of the Control Setup menu.

Enter a value between 20 and 50°C for the Min Head Removal Temp.

16 System Configuration

Page 21

Mirror Check Control

Mirror Check is the process of warming the mirror to evaporate all condensatio n, look for the

presence of contamination and account for it if necessary, then re-initiating a new dew or frost

point measurement. Mirror Check may be initiated manually with the fixed Mirror Check key, or

if enabled to do so, it may trigger automatically at pre-specified time intervals. During a mirror

check function, whether triggered automatically or manually, the fixed mirror check key indicates

red while heating, brown while holding at the high temperature, then yellow while allowing the

mirror to cool to reform the dew or frost layer again. Once the system has again established a

dew or frost layer, and become stable at that value, the mirror check function is complete and

the color indications are removed. To view or edit the Mirror Check parameters, press the

Mirror Check key of the Control Setup menu.

Cycle Time

If Automatic Mirror Check is desired, enable it by pressing the Cycle Time button. A green light

on the Cycle Time button indicates that automatic mirror check is enabled. Even if automatic

mirror check is not enabled, manual mirror check may be initiated at any time simply by pressing

the fixed Mirror Check key at the bottom of the screen. When automatic mirror check is

enabled, the fixed Mirror Check key also displays a countdown timer indicating the time until the

next automatic mirror check function.

Changing the Cycle Time changes the time interval between automatic mirror check operations.

Heating Time

The Heating Time determines how long to hold at the mirror check temperature before allowing

another dew or frost point measurement. A heating time of 0 results in no hold, meaning that

once the mirror check temperature has been reached, the function ends and dew/fro st contro l

resumes immediately. If a heating time greater than 0 is entered, then the mirror will heat and

remain at that temperature for the duration of the heating time value. Heating time is effective

regardless of whether mirror check was triggered automatically or manually.

Heat To

Edit the Heat To field to change the temperature that the mirror will be heated to, and optionally

held at, during Mirror Check.

Pump Control

The pump, if your system is so equipped, is a diaphragm type driven by a brushless DC motor.

Pump speed, and thus flow rate, is controlled by changing the amount of power applied to the

motor. Pump power can be set from 0 to 100%, accessed through the Pump key of the Control

Setup parameters menu. When connections to the system are made with short tubing of ¼”

diameter resulting in very little flow restriction, settings for pump power of 10 to 25% are often

acceptable. However for long tubing runs, small tubing diameters, or when restrictions are

induced (by externally installed flow meters for instance) higher pump power settings may be

required. Experiment to determine the lowest pump power setting needed to obtain the de sired

flow rate. Turn the pump on and off with the fixed Pump key.

Depending on your system configuration, a pump may not be needed. Or if a pump is installed,

it may not necessarily need to be enabled if you are sampling from a positive pressure system.

The pump, if installed, is configured with forward flowing check valves that open easily. This

allows even a slight positive pressure to be used flow gas through the head, even if the pump is

installed but not enabled.

System Configuration 17

Page 22

Changing Units

You can display system data in any of a wide variety of units. When you make a new units

selection, that selection remains until you change it again. To change units, follow the

instructions given in the Selecting Units section on page 8. Units selections are global acro ss

the system, meaning that all values of that parameter type change to reflect the chosen units.

For instance, changing the temperature units to °C forces all temperature data to appear in °C.

Note:

Data retrieved via RS-232 will always be in SI units regardless of the units chosen for display.

Also note that settings within dialog boxes used for changing system parameters are also

entered and displayed in SI units. Units only affects the four data lines of the normal display

window.

Temperature Units

Temperature values may be displayed in units of °C, °F, or K. When changing temperature

units, all temperature values, whether displayed as numeric or in a graph, change to reflect the

new units selection. Notice that the chosen units will appear on the screen both on the units

selection key and next to any temperature related values currently displayed.

Pressure Units

Pressure values may be displayed in units of Pa, hPa, kPa, MPa, atm, bar, mb, inHg, mmHg,

cmHg, inH

values (not including vapor pressure), whether displayed as numeric or in a graph, change to

reflect the new units selection. Notice that the chosen units will appear on the screen both on

the units selection key and next to any pressure related values currently displayed.

O, mmH2O, cmH2O, Torr, and psia. . When changing pressure units, pressure

2

Flow Rate Units

The gas flow rate may be displayed in units of l/min, ml/min, l/h, cfm, and cfh. When changing

flow units, an indicated flow rate will change to reflect the new units selection, whether displayed

numerically or as a graph. Notice that the chosen units will appear on the screen both on the

units selection key and next to the flow rate when displayed.

Volume Ratio Units

Humidity expressed as a volume ratio may be displayed in units of PPMV (Parts Per Million by

Volume) or PPB

change to reflect the new units selection, whether displayed numerically or as a graph. Notice

that the chosen units will appear on the screen both on the units selection key and next to the

volume ratio when displayed.

(Parts Per Billion by Volume). When changing these units, volume ratio will

V

Weight Ratio Units

Humidity expressed as a weight ratio may be displayed in units of PPMW (Parts Per Million by

Weight) or PPB

change to reflect the new units selection, whether displayed numerically or as a graph. Notice

that the chosen units will appear on the screen both on the units selection key and next to the

weight ratio when displayed.

(Parts Per Billion by Weight). When changing these units, weight ratio will

W

Absolute Humidity Units

Absolute humidity may be displayed in units of g/l, g/m3, and lb/ft3. When changing these units,

absolute humidity will change to reflect the new units selection, whether displayed numerically

or as a graph. Notice that the chosen units will appear on the screen both on the units selection

key and next to absolute humidity when displayed.

18 System Configuration

Page 23

Specific Humidity Units

Specific humidity may be displayed in units of g/g, g/kg, and lb/lb. When changing these units,

specific humidity will change to reflect the new units selection, whether displayed numerically or

as a graph. Notice that the chosen units will appear on the screen both on the units selection

key and next to specific humidity when displayed.

Vapor Pressure Units

Vapor pressure may be displayed in units of Pa, hPa, kPa, MPa, atm, bar, mb, inHg, mmHg,

cmHg, inH

pressure will change to reflect the new units selection, whether displayed numerically or as a

graph. Notice that the chosen units will appear on the screen both on the units selection key

and next to vapor pressure when displayed.

O, mmH2O, cmH2O, Torr, and psia. . When changing vapor pressure units, vapor

2

Changing Color

You are free to change the foreground and/or background color of any data line with the Fore

Color and Back Color menus. Access the Fore Color and Back Color menus with the menu

selection key discussed in the

color changes are retained. To revert to the standard system default color scheme, press and

hold the 9 key for a few seconds while in the Fore Color or Back Color menu.

Fore Color

Fore color affects the color of number and letters, and the plotting color of graphs. If you

change the fore color of a data line that is displayed numerically, the graph attributes of that line

are not affected. Likewise, if you change the fore color of a line displayed as a graph, the

numeric display attributes of that line are unaffected. Which aspect of the data line that is

affected is determined by whether that line is currently displayed as a number or as a graph

when changing the fore color.

To change a data line’s fore color:

1. Access the Fore Color menu as described in the

appears on the key, and the keys above contain left pointing arrows. Notice that each key

corresponds to the data line it points toward.

2. Press the arrow key corresponding to the data line you wish to change. Notice that the fore

color of the data line changes with each press of the key.

3. Change the fore color on any of the other data lines with the same method.

Menu Keys section on page 4. Like other system settings, these

Menu Keys section on page 4. ‘Fore Color’

Back Color

Back color affects the background color of number and letters, and the background col or of

graphs. If you change the back color of a data line that is displayed numerically, the graph

attributes of that line are not affected. Likewise, if you change the back color of a line displayed

as a graph, the numeric display attributes of that line are unaffected. Which aspect of the data

line that is affected is determined by whether that line is currently displayed as a number or as a

graph when changing the back color.

To change a data line’s back color:

1. Access the Back Color menu as described in the

Color’ appears on the key, and the keys above contain left pointing arrows. Notice that

each key corresponds to the data line it points toward.

2. Press the arrow key corresponding to the data line you wish to change. Notice that the back

color of the data line changes with each press of the key.

3. Change the back color on any of the other data lines with the same method.

System Configuration 19

Menu Keys section on page 4. ‘Back

Page 24

Analog Outputs

If this option is installed, the 973 is equipped with at least two analog outputs that are

independently configurable. For each of the analog outputs, you may easily select which

parameter to track and how to scale the selected parameter to the analog output range. These

selections are made for each of the analog outputs via the Analog Outputs menu.

1. Access the Analog Outputs menu with the menu selection key discussed in the

section on page

2. To access the selections for the first analog output, press the ‘Analog Output 1’ key. This

brings up the appropriate analog output configuration window.

3. Make necessary changes as identified in

the Output to the Data below.

4. Follow the same procedures for the second or any subsequent analog outputs as needed.

4.

Selecting Which Parameter to Track and Scaling

Selecting Which Parameter to Track

With the appropriate analog configuration window displayed, you may select which parameter to

attach to that analog output. The parameter is identified as a number in the Parameter field of

the window. Using the following list as a guide, change the parameter field to the number

indicated.

For this parameter

Dew Point [°C] 0

Frost Point [°C] 1

Units

Enter this

number

Menu Keys

RH [%] 2

RH WMO [%] 3

Volume Ratio [PPMv] 4

Weight Ratio [PPMw] 5

SF6 Volume (available on SF6 only) [%] 6

Absolute Humidity [g/m3] 7

Specific Humidity [g/kg] 8

Vapor Pressure [Pa] 9

Atmospheric Pressure (available only

when equipped with high accuracy

barometer option)

Head Pressure [Pa abs] 11

Relative Head Pressure (not available

on 973)

Flow Rate [l/min] 13

External Temperature [°C] 14

Head Temperature [°C] 15

As an example, suppose that you wish to have %RH output as an analog voltage. Since %RH

is identified as parameter 2 in the list, enter the number 2 into the parameter field of the analog

configuration window.

[Pa abs] 10

[Pa] 12

20 System Configuration

Page 25

Scaling the Output to the Data

With the appropriate configuration window displayed, you may change the data scaling of the

analog output vs. the parameter. Continuing with the example in the previous paragraph,

assume that you wish to have 0 to +1 VDC on the analog output represent 0 to +100 %RH.

Based on the example,

For this field Enter this value

Min Value 0

Max Value 100

Min Voltage 0

Max Voltage 1

Depending on the factory configuration and calibration of your specific 973, it may be equipped

with one of several different output options. Options have included ±1, ±5, or ±10 VDC.

Additionally, some units have been equipped with 4-20 mA outputs. While the most common

option is ±10 VDC (with 16-bit resolution), many older units where equipped with ±5 VDC (with

12-bit resolution). You may wish to experiment with your 973 output to determine which

configuration you have.

Voltmeter Connections

Analog output connectors are clearly identified on the instrument back panel. With the anal og

output parameters selected and properly scaled, connect a cable between the analog output

and a voltmeter. Pre-wired cables are available. If you wish to make your own cables, see

Analog Outputs on page 23 for pin-out information.

System Configuration 21

Page 26

Back Panel Connections

Power Plug

The power requirements are identified on the serial number label on the back of the instrument.

Depending on the model, fuse access may also be available on or near the power plug.

Power Switch

The main power switch is mounted on the back panel near the power plug. Use the power

switch to turn the system ON and OFF.

RS-232

The RS-232 connector is used when connecting the 973 to an external com puter. Use a

standard 9 pin cable to connect between the 973 and a desktop or laptop computer. The cable

is wired straight through with pins 1 through 9 of the male end wired to pins 1 through 9

respectively of the female end. The RS-232 extender cable is a common accessory item easily

obtained at most any computer accessory dealer.

Remote Communication on page 29 for complete discussion of the RS-232 command

See

reference and hardware connections.

External Temperature

The External Temperature plug on the back panel is used for connection of an external

temperature probe. External temperature measurements are required if certain humidity

parameters are to be computed, such as %RH. External temperature measurements are not

required for dew or frost point measurements.

If you wish to connect your own thermometers, the 973 requires

a 5 pin connector, LEMO (www.lemo.ch) part number FGG 1B

305 CLAD 42.

Red Dot aligns with Pin 1

When wiring the cable, note that pin numbering of the socket in

the back panel starts at the top and goes counter-clockwise (as

viewed from the rear of the unit). ). When viewing the solder

tubs of a disassembled 5-pin LEMO connector, pin 1 is usually

identified with a full or partial circle drawn around it, followed by

a line to the other pins in order.

After identifying pin 1, follow the line counter-clockwise from pin 1 to all other pins in succession.

Wire the cable according to the following:

Pin Position Signal

1 Top Shield

2 10 o’clock +I

3 7 o’clock +V

4 5 o’clock -V

5 2 o’clock -I

When the 5-pin LEMO connector is properly assembled, you will notice that the red dot of the

connector housing will be aligned at the top directly above pin 1.

22 Back Panel Connections

Page 27

Analog Outputs

Analog outputs, if this option is installed, are used for connection of external voltmeters or chart

recorders. The analog outputs are independently configurable.

If you wish to make your own cables, the 973 requires a 2 pin

connector, LEMO (www.lemo.ch) part number FGG 1B 302

CLAD 42.

Red Dot

aligns with

Pin 1

Wire the cable according to the following:

When the 2-pin LEMO connector is properly assembled, you will notice that the red dot of the

connector housing will be aligned at the top directly above pin 1.

When viewing the solder tubs of a disassembled 2-pin LEMO

connector, pin 1 is usually identified with a full or partial circle

drawn around it. Pin 2 should have no identifier.

Pin Position Signal

1 Top +V

2 Bottom -V

Gas Input and Output

The gas input and output fittings are used for connection of the 973 to the sample gas. Based

on the original configuration of your system, it will generally contain ¼” or 6 mm Swagelok

fittings.

While a connection to the gas input is most likely required, the gas output connection is often left

unconnected. If the fittings are capped, you’ll need to remove those caps for operation or

connection of sample lines.

®

tube

Barometric Pressure Input

Some systems are equipped with a high accuracy barometric pressure sensor for measurement

of the atmospheric pressure. Systems with a barometric pressure sensor have the pneumatic

fitting of that sensor brought to the back panel. This fitting must remain open for operation.

Back Panel Connections 23

Page 28

Measurement Tips

Since each particular 973 model is best suited for a specific dew/frost point range, it is important

to have some minimal knowledge of the expected value of the measurement in order to ensure

that the proper system is being used. In addition to proper system selection, your success will

depend on other factors as well, such as selection and connection of hoses, cooling and/or

heating requirements, flow rate, mirror cleanliness, and dew vs. frost determination. These and

other topics are discussed here in order to ensure that you achieve success with your

measurements.

Understand the Measuring Range

The 973 has a specific dew / frost point measuring range. It also has a specific range of

temperature that it can measure. These values are also converted into the appropriate relative

humidity measurement range. The typical 973 measurement range is listed below.

973 (-50°C Frost Point … +20 °C Dew Point)

The standard 973 is generally useful over a measuring range of -50°C frost point to +20°C dew

point. The mirror cooling capability and the materials used within the measuring head limit the

low end. The room ambient temperature limits the upper end. You should never attempt to

measure a dew point temperature that is at or above the temperature of the room. If you do,

condensation will form inside the tubing.

The measuring range of the dew / frost point, coupled with the measurement of temperature

allow the 973 to be useful for measurement of relative humidity from approximately 1% to 100%

RH when measured at approximately 25°C. Since relative humidity is relative to the prevailing

temperature, the RH range will change with changes in temperature.

Connecting Hoses

Your success with dew or frost point measurement may likely depend on proper selection and

connection of the hoses you use in configuration of your gas sampling system.

Types of Hoses

There are various types of hoses available for use in your gas sampling system. You should

consider the suitability for your application.

Teflon

Teflon tubing is flexible, easy to use, and is well suited for frost/dew point measurements in the

range of approximately –60 to +20 °C, and is therefore well suited for use with the 973.

Stainless Steel

Stainless steel tubing, while less convenient to use, is a good choice for all measurement

ranges.

Tygon, Nylon, Poly

Tygon, nylon, and poly tubing are not recommended for use with the 973. They are often

affected by permeation of water vapor through their shells which can adversely affect the

measurements.

24 Measurement Tips

Page 29

Hose Input and Output

Preferred Connections

When comparing two or more instruments, make the conne ction s in parallel.

Pr

Flow

Flow

Pump

Pr

Pump

Troublesome Connections

Never connect instruments in series, because of the interference between the two instruments.

Pr

Flow

Flow

Pump

Pr

Pump

Measurement Tips 25

Page 30

Cooling Requirements

Air Cooling

All 973 systems are equipped with air cooling. When air cooled, the fan speed is controlled

automatically by the computer. Air cooling is generally sufficient for measurements of frost/dew

points from approximately –50 to +20°C. Air cooling operates automatically and requires no

user input.

Water Cooling

The 973 is not equipped with any provisions for water cooling.

26 Measurement Tips

Page 31

Installation

Facility Requirements

Environmental

Your 973 is a precise laboratory quality instrument. While it does not require any special

environmental control, it works best when the temperature is stable and free of rapid transitions.

For operation, it is best when used under the following conditions:

Operating Temperature 15 to 35°C

Operating Humidity 5 to 95%RH non-condensing

Power

The 973 is equipped with a universal power supply capable of operation from 100 to 250 VAC at

50 to 60 Hz. If different, the specific power requirements will be identified on the back panel.

Preparation for Use

Prior to first measurement the instrument should be switched on for 30 minutes to warm up.

Benchtop Use

All 973 models are ready for benchtop use. Bench space of at least 24” x 24” (0.6 x 0.6 m) is

recommended.

Preparation for Shipping or Transportation

All shipping and transportation should be done in suitable padded containers. A heavy duty

container with at least 2 to 4 inches of clearance for foam padding is recommended.

Due to the design of the 973 systems, any shipping carton used should be constructed to

provide support only on the top and bottom of the side panels and on the front and rear frame of

the unit. Try not to have any load bearing directly on the face, nor on the top or bottom center of

the front or rear frame. Reusable shipping containers are available. Please contact the factory

for pricing and availability.

Prior to shipping, always cap the gas inlet and outlet fittings to prevent excess moisture and/or

contamination from entering the gas path, and to prevent damage to the fittings.

Ensure the optical head assembly and cover screw are firmly attached.

Facility Requirements 27

Page 32

Page 33

Remote Communication

Introduction

The 973 is equipped with a bidirectional RS-232 communications interface that allows it to be

connected to a remote computer. This section is intended to provide necessary information

for programming personnel regarding the use of the interface, including the hardware

connections, communications settings, and the command syntax.

Hardware Connection & Cabling

Connect a computer to the 973 using a standard RS-232 9-pin extender cable. The extender

cable has a male connector on one end and a female connector o n the other end. It is wired

straight through with pins 1 through 9 on one end wired to pins 1 through 9 on the other end.

If your computer has a 25-pin serial port connector rather than a 9-pin connector, you’ll also

need a 25-pin to 9-pin port adapter. Both the 9-pin RS-232 extender cable and the 25-pin to

9-pin port adapter are commonly available from most computer hardware dealers.

The 973 ignores the DSR and CTS handshaking signals. While th ere is no harm in

connecting all 9 pins, the 973 only requires connection of three of the pins (pins 2=TxD,

3=RxD and 5=GND). For your reference, the complete connector pin-out is listed in the

following table. Note that those signals identified by * are required, while the others are

completely optional.

Signal 973

(9 pin)

1 1 8

*TxD 2

*RxD 3

DSR 4

*GND 5 5 7

DTR 6

CTS 7

RTS 8

9 9 22

* Denotes a required connection. All others are optional.

Direction Computer

(9 pin)

Æ

Å

Å

Æ

Å

Æ

2 3

3 2

4 20

6 6

7 4

8 5

Computer

(25 pin)

Introduction 29

Page 34

Communications Settings

To communicate with the 973, set your computer to the following settings.

Baud Rate: 9600

Data Bits: 8

Stop Bits: 1

Handshaking: None

Command Syntax

This section details the general syntax guidelines regarding termination, leadin g and trailing

spaces, case sensitivity, and numeric values. Throughout this section, characters originating

from the computer will be shown for illustrative purposes in this font. Characters

originating from the 973 will be shown in this font.

General Usage

All commands require either a question mark or an equal sign to indicate whether you are

requesting data or setting new setpoints or parameters. When requesting data from the 973,

follow the command with ?, the question mark character. For example, the following requests

the current Automatic Mirror Check timing interval..

AMC.cycleTime?

The 973 replies with the current AMC cycle time. This value may have been entered from the

touch screen or as you will now see, via RS-232.

When setting new values or parameters, use =, the equal sign. For example, the following

command changes the Automatic Mirror Check timing interval to 20 minutes.

AMC.cycleTime=20

Most commands that can be set with an equal sign, such as the one in the above example,

may also be read with the question mark. That makes sense. However, there are several

commands that are considered read only, and have no corresponding ability to be set.

Examples of read only capability are measured parameters, such as dew point, frost point,

RH, etc.. While it is perfectly valid to read dew point with a command such as dp?, it

obviously makes no sense to be able to set the dew point value. Therefore, a command such

as dp=1.23 is considered invalid, and will be ignored by the 973.

Termination Characters

All commands must be terminated with either a carriage return

combination

CRL

.

F

Regardless of the command sent, the 973 will reply with a carriage return linefeed

end of the response, provided the command is recognized as valid. Here is an example:

C

(sent by the computer to the 973)

DP?

R

-10.015

CRL

(sent by the 973 back to the computer)

F

30 Communications Settings

C

or a carriage return linefeed

R

CRL

at the

F

Page 35

Even if the command is not a request for data, but rather is a command to change a setpoint

or parameter, the 973 still responds with a carriage return line feed combi nation. The

following turns on the pump (if your unit is so equipped). Notice that no data is returned, but

the 973 sends a

Pump.on = 1

CRL

CRL

acknowledgement that the command was valid.

F

C

(sent by the computer to the 973)

R

(the acknowledgement from the 973)

F

However, if the command is unrecognized, the 973 does not respond. See the example.

Abcdef?

C

(invalid command sent from the computer)

R

(no response from the 973)

Leading and Trailing Spaces

The 973 ignores leading and trailing spaces. It also ignores spaces before and after equal

signs and question marks. For example, each of the following command s is perfectly valid.

However, the following commands are invalid since spaces are embedded within the

keywords.

C

Dp?

R

C

Dp ?

Pump.on=1

R

C

R

Pump.on = 1

C

D p?

Pu mp.on=1

R

C

R

C

R

Case Sensitivity

All commands are insensitive to case. In other words, it does not matter if the command is

sent in upper case letters, lower case letters, or as some combination of the two. For

example, the commands DP?, Dp?, dP?, and dp? are identical to the 973 and will return the

measured dew point value.

Numeric Values

All numeric data sent to or received from the 973 is done so in either standard or scientific

notation. Sending a number as 12.34 is the same as sending it as 1234e-2 or as 1.234e1.

Depending on the value of numeric responses the 973 sends out, it may send the numbers in

either standard or scientific notation.

Numeric data is never appended with text of any kind. In other words, if requesting a

temperature related value, only the numeric portion of the value is sent. The units are

assumed but never sent.

The following table lists the units that numeric data adheres to, regardless of the units

selection on the touch screen display or set via the RS-232. In other words, when you

change units (even if you changed them via RS-232), you affect only what is seen on the

display. All numeric values retrieved from the RS-232 will always be in the following units.

Also, when sending data of any kind, do so in these same units.

Command Syntax 31

Page 36

Parameter Units via RS-232

Temperature °C

Pressure Pa

Flow l/m

RH %

Absolute Humidity g/m

Specific Humidity g/kg

Volume Ratio PPMv

Weight Ratio PPMw

PRT Resistance Ohms

Some values simply require integer numbers such as 1 and 0 for On and Off, while others

might need real numbers with a decimal point. The 973 recognizes both types of numbers

and will attempt to convert the values you send to the correct format. For example, the

number 0 means Off, while 1 or any other real or integer value means On.

3

Command Reference

The available commands listed here are grouped by function. If a command is considered as

a read only value, then it is shown with a question mark only. For instance, the following is

considered as read only and does not have the ability to be set.

Dp?

A command that has both read and set capability is shown in a slightly different manner. The

question mark and equal signs are shown for illustrative purposes within brackets. Those

brackets indicate that either one or the other is required. Furthermore, [=i] indicates that

the value is an integer, while [=n] indicates that the value is a real number and may

therefore include a decimal point.

Consider a command with syntax listed in the manner

ForceFrost.on[=i][?]

This indicates the following valid possibilities.

ForceFrost.on = 0

ForceFrost.on = 1

ForceFrost.on?

Now consider a command with syntax listed as

UseOris.below[=n][?]

Any of the following are valid possibilities.

UseOris.below?

UseOris.below = -5

UseOris.below = -10.25

Note that a value entered as –5.00 would be equally as valid as –5. While it makes no

sense to use a value above 0 for this UseOris example, in general the syntax listing [=n]