Page 1

Important measurement data

OverviewOverview

SoftwareSoftware

DatacenterDatacenter

Contract ModulesContract Modules

ServicesServices

DatasheetsDatasheets

AlarmingAlarming

HardwareHardware

Data securityData security

just a click away!

With the most

flexible continuous

Monitoring System

SaaS

50008E/2 018-12

1

Page 2

Rotronic Monitoring System

Watch the short Explain-it MovieWatch the short Explain-it Movie

RMS – ROTRONIC MONITORING SYSTEM

The Rotronic continuous Monitoring System allows users to monitor anything from anywhere using an on-premise or

cloud (SaaS) solution.

Strongly regulated applications

• Fridges

• Cold rooms

• Freezers

• Transport with dry ice

• Cryogenics with nitrogen tanks

• Blood banks

• Clean rooms

• Warehouses

Less regulated applications such as:

• Museums

• Archives

• Storage areas

• And much more...

Customize your own RMS Architecture

2

Page 3

Rotronic Monitoring System

Multiple parameter monitoring

RMS monitors various parameters to ensure that the environment meets the required specifications for any application.

1. Digital probes give acces to a complete audit trail and easy digital calibration thanks to the probe hot swap possibility:

• Relative humidity

• Temperature

• CO

2

• Differential pressure

2. Other inputs and outputs for third party devices (particle counters, air flow and other such parameters):

• 0/4…20mA for the integration of existing devices or other parameters

• 0…10V for the integration of existing devices or other parameters

• Digital inputs for door contacts, leak detectors, etc.

• Digital outputs to switch alarm beacons

– Webcams to enable a snap shot to add to automatically generated reports and see the application

in real time (mouse-over)

mA

V

Real time camera view (mouse over)

– Any 3rd party devices with a documented protocol

– LoRa devices via the API function

3

Page 4

Rotronic Monitoring System

Find out more at www.rotronic.com/rmsFind out more at www.rotronic.com/rms

Wireless or wired secure data communication

1. Wireless:

• Data stored on the logger with a battery backup and 24V power supply

• Redundant or parallel operation with various gateways

• Decrease wiring costs

• No more looking for errors in cabling

• Projects accomplished faster due to no cable requirements

• Easy to relocated physical measuring points

• Fast and easy implementation of new measuring points

• Monitor mobile equipment

• 868 or 915 MHz

2. Wired:

• Data stored on the logger with a backup battery, PoE and 24V power supply

• No loss of communication for high risk applications

• Link up to the existing Ethernet network

Compliance

1. Validatable software (new releases on a 6 months basis)

2. FDA CFR 21 Part 11 compliant

3. EU Annex 11 compliant

4. Developed based upon the GAMP©5 recommendations

5. Complete GxP documentation and an IQ testing script (from the URS to the IQ/OQ/PQ)

Real time monitoring and alarming

The RMS software will inform you in real time via E-Mail, SMS and telephone call should a measurement point be out of

limits! Automatic reporting allow for a hassle free solution and a quick login via mobile phone, tablet, PC or laptop will

give you either a chart, table or a layout overview of the current situation, with short cuts to all events listed within the

audit trail.

4

Page 5

Rotronic Monitoring System

MONITORING SOFTWARE

Main Software Features

• Alarm overview – see directly how many alarms are active and where they are coming from

• Receive alerts via interactive phone, SMS’s and E-Mails

• Audit trail to see exactly what happened and when

• Monitor multiple locations – one system for all your monitoring locations

• Input floor plans – get a real overview of the setup

• Scalable – prefect for single points in small installations to thousands of points in worldwide installations

• Automatic report generation

• Integration of Rotronic and any third party hardware – analog and digital

• Automatic validation scripts – for fast and effective OQ validation

• Continuously developing based around customer feedback

• Create custom dashboards per user

• FDA 21 CFR Part 11 & EU Annex 11 complaint

• GAMP©5 conform for GxP applications

Additional Features

• Calibrate all of your measuring points, possibility to adjust all of the Rotronic devices

• Archive all measuring points that are no longer needed, keeping access to the data for as long as necessary

• Save all your documents in the system: user manuals, data sheets, calibration certificates, SOP’s...

5

Page 6

Rotronic Monitoring System

SaaS

SaaS

Main software benefits

• Compliance, audit and risk management

• Time saving with automatic data collection and report generation

• 24/7 real-time centralised monitoring of all operations

• All critical measurements in one system

• Real time alarming for critical measuring points

Software solutions

1. Fast & Easy with the Rotronic SaaS Cloud solution

Forget the hassle of having to maintain your IT infrastructure and focus only on what is crucial to your

application. You can setup multiple measurement points in various locations and access the data from

any device with a browser and internet connection. Setup alarms and notifications to be sure that you

are always informed of what is happening!

2. Remain compliant to GxP regulations with the Rotronic Exclusive SaaS Cloud solution

Hosted on a high security and redundant datacentre with your own virtual server, you can run the Rotronic category 4 software in the cloud throughout each and every GxP compliant facility. Equip your

worldwide facilities with the RMS hardware and access all of the data, including the audit trail, alarming and data analysis functions from a completely validated system.

3. Take advantage of your own IT infrastructure with the RMS on-premise solution

Hosted on a high security and redundant datacentre with your own virtual server, you can run the

Rotronic category 4 software in the cloud throughout each and every GxP compliant facility. Equip your

worldwide facilities with the RMS hardware and access all of the data, including the audit trail, alarming and data analysis functions from a completely validated system.

6

Page 7

Rotronic Monitoring System

11

22

33

445566

66

112233

44

55

66

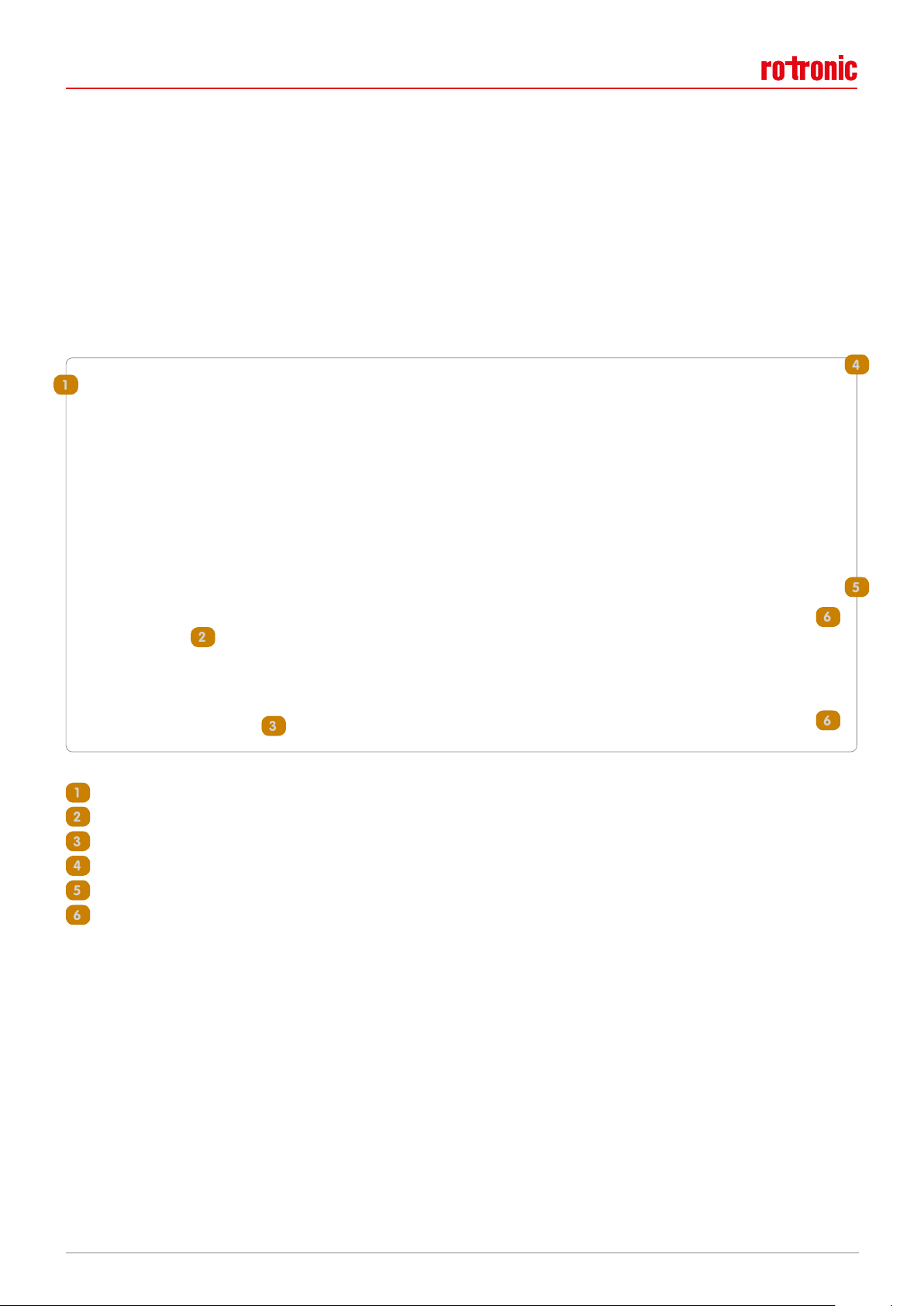

System Overview

RMS offers different views/tabs to present your system data, customised to your needs.

• Chart – measured values graphically and numerically and direct notification status

• Table – measured values numerically and various other data

• Layout – measured values numerically with placement in a room layout

• Dashboard – individual dashboard for each and every user

• Events – audit logs, alarms, warnings and system messages

Chart view

Upload your company logo

Group information by location, room…

Real-time measurement value and live status

Current logged on user, and notification overview

Historical overview

Alarms bands for a visual depicture of warnings and alarms

7

Page 8

Rotronic Monitoring System

11

22

33

11

11

112222

22

33

33

33

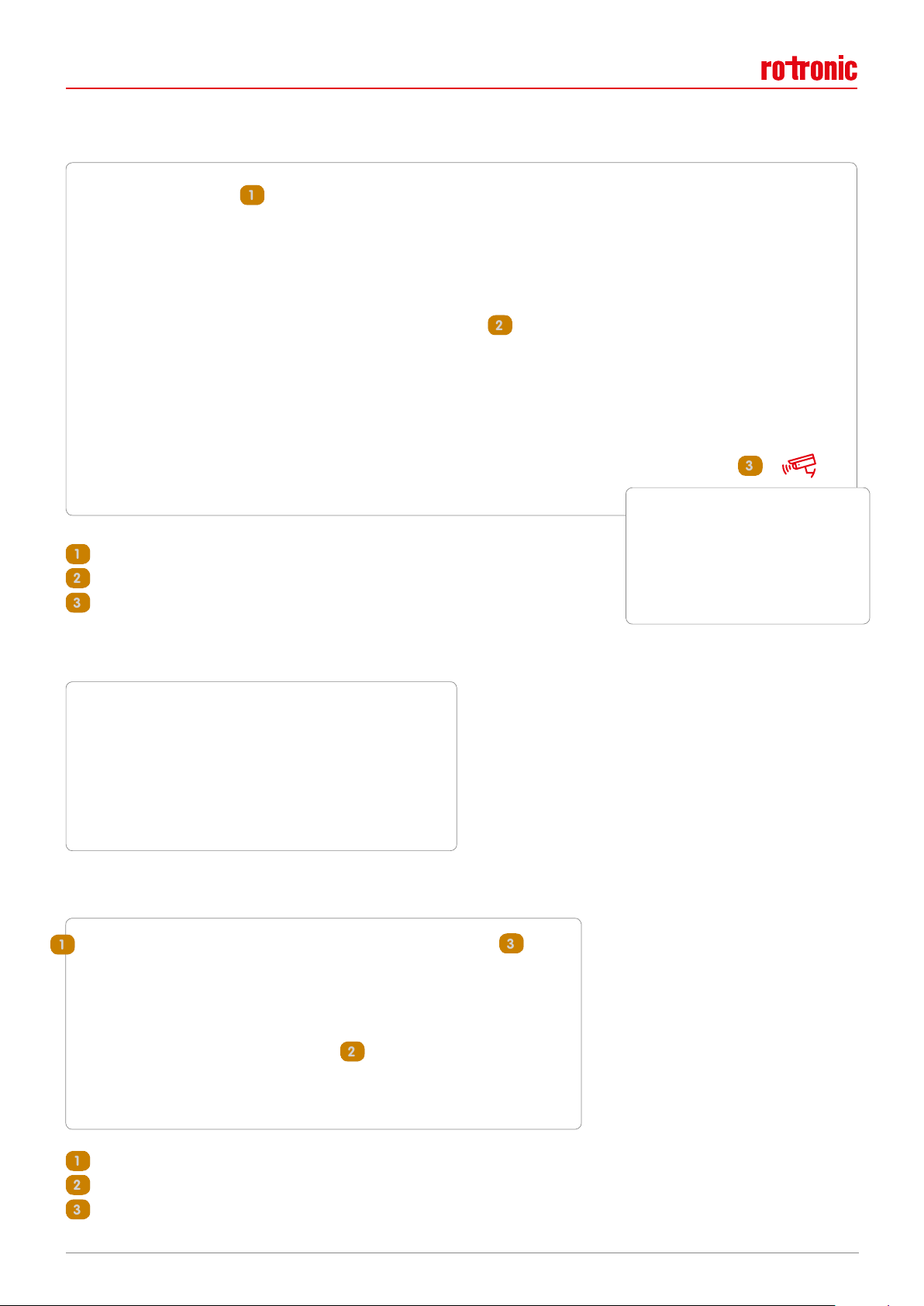

Layout view

Real time camera view (mouse over)

Mouse over detailed measurement point

Standard measurement point overview

Mouse over IP camera for a snap shot of the current situation

Dashboard view: user defined

Events view (audit trail)

Define the notifications shown in the audit trail

See the actual status and user inputs of each individual event

Filter the audit trail based upon your requirements

8

Page 9

Rotronic Monitoring System

IT risk

certified

DATACENTER

RMS Database Security

When purchasing the RMS SaaS solution, Rotronic works together with the company 4Net. They provide a virtual data

centre for the Rotronic Monitoring System server and database. 4Net uses the Interxion data centre. Interxion’s Zurich

data centre provides an ultra-secure, known location for storing and processing data in line with Swiss data protection

regulations. Like all Interxion data centres, Zurich operates in full accordance with the ITILv3 framework and has ISO

27001 and ISO 22301 certification. Their compliance with the FINMA circular 07/8 is externally audited.

Operational excellence:

• 99.999% availability SLA

• 2N or N+1 configurations for all critical systems

• 24x7 operation and monitoring

Sustainability:

• 100% renewable energy

• Carbon neutral, certified by myclimate

®

Security:

• Monitored 24x7 by CCTV and security patrols

Resilience and business continuity:

• 24x7 monitoring and alarms for ever y critical system

• Connectivity: quadruple-entr y fibre from separate carrier main routes and rapidly installed cross connects

• Power: secured grid supply from two sub-stations from two different power providers, two power feeds for all

equipment, each independently equipped with a power supply and generator backup with full load capacity for

indefinite running

• Environment: SLAs on temperature and humidity in line with ASHRAE recommendations, N+1 cooling, sophisticated

water and very early smoke detection systems, Inergen® gas fire suppression in line with local regulations and

designed for maximum safety and minimum damage

• Backups saved in a second data centre also located in Switzerland but 80 km away from the main one

9

Page 10

Rotronic Monitoring System

ALARMING

Rotronic Monitoring System alarm protocols were set up to ensure that critical alarms cannot be missed. Notifications can

be triggered based upon the risk level.

Four levels of alarming are available, activation is based on the defined risk:

• Reminder for events that are non-urgent:

– Low battery (device)

– Simulator connected (measuring point)

– Reminder that a calibration is due

– Data gap after downloading missing measured values

• Warning for measured values that are out of limit (measuring point)

• Alarming for measured values that are out of limit (measuring point)

• Error for urgent hardware errors:

– Device timeout (device)

– Sensor error (measuring point)

An overview of the alarms can be seen once the user has logged into the system. The user only sees the alarms relevant

to his granted access rights. Each measuring point, if not conforming, will be attributed a different colour based upon the

alarm status:

Critical alarms can also be set up with a warning before alarms are activated. Hysteresis and a delay can be set up for the

warning, with upper and lower limits defined, as well as for the alarming.

All alarms are clearly shown in the audit trail indicating the unique ID for the event, the time and date of the alarm, information about what the alarm is, the target (the measuring point or device) as well as additional details.

Viewing the audit trail, it is easily possible to see if an alarm has been either acknowledged, or if it has ended. If an alarm

is acknowledged, the time, date, name of the user who acknowledged the alarm as well as the alarm details are also

saved and visible within the audit trail. Within the audit trail, it is also possible to close or inhibit an alarm.

10

Page 11

Rotronic Monitoring System

Alarms can be set up based upon either the measuring point, or via an alarm scheme. For alarms based upon the measuring point the choice of options is limited. Within an alarm scheme the user has the possibility to set a condition such

as an active time as well as a warning. An action can be configured in both situations.

The various alarms can be notified in different ways and can be sent to just one or multiple users.

• E-Mail

• SMS *

• Telephone call *

• Switch relay

• Send data via TCP

* The user’s telephone number must be added to the system.

E-Mail alarm: When setting the system up with a TCP/IP based camera, a snap-shot can be added to the E-Mail with a

chart (either as a PDF or included in the body of the E-Mail).

SMS alarm: The alarm will be sent out in the language in which the software is configured.

Telephone call: Within the system settings, the user can decide the information stated during the telephone call, from the

device/measuring point ID to a measuring point comment. For the telephone call, if various users are selected, the system

will call the first user on the list and continue through the list. Only when one user inhibits the alarm via the telephone will

calling stop. The inhibition time from the telephone call is also set up within the system settings.

Switch relay: If a device with a relay is included in the system, then with the alarm scheme, it is possible to trigger that

alarm to action either a visual or audible alarm, or another type.

Send data via TCP: Data can be transmitted to a TCP/IP device to switch a device to either On or Off.

It is also possible to set up IF-THEN scripts to trigger actions on the basis of one or more defined pre-conditions.

11

Page 12

Rotronic Monitoring System

HARDWARE

Lan and Wireless System

All RMS components are connected via a LAN or a wireless interface. All data is transmitted to the SQL database and

visualised via a web browser.

RMS Wall module

The RMS wall module is designed for applications where the module is visible to users:

simple and practicle. The module can be fixed

to the wall and easily wiped clean. The RMS

Wall module is available with either a LAN or

a wireless (868 or 915MHz) interface. The

module can be powered either via PoE (LAN

version only), 24V or battery and can store

44’000 data points.

Wall module devices:

• RMS-LOG-L / 868 / 915

• RMS-GW-868 / 915

The RMS Wall module also exists with display.

Wall module with display devices:

• RMS-D-L

The RMS Mini module

The RMS Mini module is only available with a

wireless interface (868 or 915MHz) and battery powered, with a storage of up to 12’000*

data points.

RMS Din Rail module

The RMS Din Rail module is for installation

where esthetiques are not crucial to the application. The RMS Din Rail module is available

with either a LAN or a wireless (868 or

915MHz) interface. The module can be powered either via PoE (LAN version only), 24V or

battery and can store 44’000 data points.

Din Rail module devices:

• RMS-DI-L-R

• RMS-DO-L-R

RMS Converter

The RMS Converter allows for integration of

digital third party devices with an Ethernet

connection. The converter will translate the

digital protocol and send it to the database,

the values are then visble via the web browser. The converter also has an onboard 7 day

memory** should the network go down. The

device is limited to 100 devices.

RMS converter:

• RMS-CONVERTER-100

Mini module devices:

• RMS-MLOG-T-868 / 915

• RMS-MLOG-T10-868 / 915

• RMS-MDI-868

• RMS-MLOG-B-868 / 915

• RMS-MADC-868-A / 915-A

• RMS-MADC-868-V

• RMS-MLOG-LGT-868

* Please check each device individually for the data storage possibilities.

** The converter should be on the same network as the third party device.

12

Page 13

Rotronic Monitoring System

DATA SECURITY / -INTEGRITY / FDA CONFORMITY

Data security, data integrity, data availability: these three terms play a central role in monitoring systems. The RMS

reassuringly scores in all these fields.

Data Security

Data security means the data cannot be accessed by unauthorized persons. This is achieved through encryption during

data transfer and storage.

Data Security in RMS

The monitoring system provides encryption of the data during transfer. This means the data can neither be tapped or

manipulated by so-called retry attacks. The security of the stored database in RMS is ensured by the IT structure. The

Rotronic Cloud is protected by certified IT data centers. If the database is located in the customer’s server center, the

customer defines the security infrastructure. Rotronic then offers IT support.

FDA/GMP Requirements

Regulators in the pharmaceutical and food industries demand that all relevant events are recorded so they are traceable.

This is achieved through the electronic marking of all calibration measurements and verification processes. The so-called

“electronic recording” requires unique identification of certificates. This means that every calibration certificate with a

date and inspection stamp must be traceable such that the calibration chain can be verified.

Audit Trail

When a monitoring system is commissioned, it is calibrated and validated. In this way the operator assures his Quality

department that the system works correctly. During subsequent operation, all relevant changes must be recorded in full.

The audit trail guarantees recording of all changes in the system such as, for example, change in measurement probes,

user activities, battery change. This in turn ensures that all events can be tracked at a later date.

Data Availability

For some manufacturar’s systems, data availability can contradict data security because secure data are difficult to access. The user must authenticate themselves and use secure connections or verified platforms. Nevertheless, the trend

is clearly moving towards worldwide data accessibility allowing platform-independent viewing and evaluation.

Data Integrity

Ensuring data integrity means guaranteeing secure transmission and storage. A measured value must not change during

transmission because of disruptions. Data transmission and storage must therefore be safe from manipulation. This is

achieved with CRC checksums and intermediate storage during data transmission. In this way, faulty data communication

is recognized and the data stored in the buffer memory are sent again until the transmission has been finished.

All data in RMS are sent with CRC checksums and confirmed by the recipient after receipt. Faulty data transmission is thus

ruled out. Should the data not arrive with the recipient, they are stored intermediately by the logger and can then be

transmitted at a later point in time when the connection has been restored.

13

Page 14

Rotronic Monitoring System

RMS Communications

14

Page 15

Rotronic Monitoring System

RMS SERVICES

Project Procedure

The Rotronic Monitoring System (RMS) is a hardware and software solution adjustable to your requirements for a continuous monitoring system. The complete system conforms to GAMP5, Rotronic is well aware that our support is crucial to

your project, so we offer a complete solution. From the user requirement specifications to the IQ/OP/PQ with our detailed

documentation finishing off with tailor made training for your employees.

Furthermore the RMS software is delivered as a GAMP software category 4 system.Our main goal is to fully understand

your requirements and deliver the best continuous monitoring system for you and your company.

Review of the URS

Rotronic has designed a functional description document explaining each and every function

of the RMS software. This description will help you create your own URS, but it might also

help you adapt the one you already have striving to provide the best risk based approach to

compliant GxP computerised systems. Don’t know exactly how to build up your URS? No need

to worry, Rotronic have the knowledge and documentation required to help support you in

any case.

The continuous monitoring system RMS is a very flexible solution both on the hardware and

the software side (R&D and production in the Headquarters in Switzerland). You have a problem, let us work together to give you the perfect solution. A personal discussion is of the

upmost importance though, only when speaking to you can we really understand your requirements for a continuous monitoring system!

Design Concept

After fully understanding your requirements, a project is setup at Rotronic. Each and every

step is listed, costs evaluated and an initial time line defined. A crucial point is software adaptations, any adaptions are follow a stringent testing process within Rotronic, so project

timing is a key to a successful roll out of your continuous monitoring project.

Rotronic has the possibility to carry out the complete monitoring system project, from the

heat mapping of the various areas to the physical installation of the devices. Internally, the

project team needs to understand your requirements in order to deliver your solution based

upon your time line. Our main aim is an optimised communication based upon information

transfer to the entire team: sales, product management, inside sales, after sales, production

and R&D are all involved already in this initial process.

Conceptual Offer

Rotronic will give you an initial quotation based upon your URS and the project planning. This

initial quotation is rarely the final quotation, but a ball park figure that will help you to get a

feeling for the costs of a project. Products will be added and removed, services will be adapted… The initial quotation will help you get a feel for the market and already an understanding

of what working with Rotronic is like. We are more than happy to invest time in a project, so

that you get the best continuous monitoring solution possible!

15

Page 16

Rotronic Monitoring System

On site Demo Installation

Pricing and promises in hand, we consider it important that customers actually tr y out the

RMS. Be it via our cloud solution or our server software, our engineering team will offer you a

solution based upon your requirements. When you start to play with the software, very quickly, thanks to its simple and effective design, you can work your way through the different

functions and get a real understanding for what the system can offer.

With just a few measurement points, you can already get a feeling for what is going on in the

various locations that you monitor. Increase of CO2, people are in the room, a temperature

decrease might mean that the heating has been cut off, the lux increase, the sun is coming

up… Everything of course can be verified by adding an IP camera next to the measurement

point to confirm what you are seeing.

You can get a feel for the alarming functions, an overview of how the audit trail actually works

and what data you can extract from the system! We will support for the optimal installation of

your demonstration, you need to test it to understand the flexibility of what Rotronic can offer

you. After seeing the demo, new ideas will appear and will help

Final Offer

You now understand that the sky is not the limit with our universal RMS. You’ve had new

ideas, seen new potential and have accordingly updated your URS. Rotronic has been with

you throughout this process and can now give you a tailor made quotation responding to your

exact detailed requirements for a continuous monitoring system.

Verification from the Customer

Of course, a market comparison is necessary! The flexibility and quality of RMS, the professionalism of our team and the complete package that we can offer will be sure to make Rotronic a very competitive partner for your project. Need more details from our side, don’t

hesitate to give us a call. Remember, we are FDA 21 CFR Part 11 and GAMP 5 conform for the

most demanding applications, but we can also help you with smaller projects where these

regulations are not required. With the Rotronic Monitoring System, we have a shoe that fits

every foot.

Installation /Commissioning

Congratulations on choosing to partner with Rotronic on your project! After a review of the

project planning and time lines, we can start with the physical installation of the devices, the

setup of the software and SQL database on your server, the configuration of the software and

the hardware (this is as well something that you can choose to do on your own, we are always

happy to offer a helping hand). The heat mapping or the wireless signal mapping can both be

carried out with the helping hand of Rotronic should this be a necessity.

16

Page 17

Rotronic Monitoring System

Validation

The software is validatable, so time to validate your continuous monitoring system. If you did

the URS with the Rotronic documentation, then we can also offer the rest of the validation

documentation, the validation master plan, the risk assessment, the functional requirement

specifications, the configuration specification, the requirement traceability matrix, the validation script specification, the installation qualification, the operation qualification and the

performance qualification of course followed by your tailor made training.

This validation model is based upon the GAMP5 standard and is recognised throughout the

pharmaceutical world. The entire validation will prove that your system replies to your URS.

Even if you didn’t use the Rotronic URS, you can still use the Rotronic documentation as

guidelines. With our team of trained professionals, Rotronic can carr y out the validation of

your system partially or fully if required.

Maintenance and Support

Who better to receive support from but from the manufacturer?

Maintaining your system is crucial for the running of your processes. Rotronic offers packages from ISO-17025 and ISO-9001 calibrations only (temperature, relative humidity, dew

point, differential pressure) to hardware and software maintenance contracts, build around

your requirements. The software is also setup in a way that it makes hardware changes ever

so simple and effective. Like the system our support is already very flexible!

17

Page 18

Rotronic Monitoring System

RMS CONTRACT MODULES

Create your tailored version based on the various modules

Software Hardware General Support Installation

Services

PURCHASE PURCHASE INCLUSIVE OPTIONAL OPTIONAL COMPULSARY

RENT PURCHASE INCLUSIVE OPTIONAL OPTIONAL INCLUSIVE

PURCHASE RENT INCLUSIVE OPTIONAL OPTIONAL COMPULSARY

RENT RENT INCLUSIVE OPTIONAL OPTIONAL INCLUSIVE

Onsite

Maintenance

Premium Support

What we can offer

SaaS

SaaS

Fast & Easy Software only Solution

Take advantage of our SaaS solution, freeing you from complex software and IT

hardware management and benefit from our outstanding IT infrastructure with

a state of the art security and data redundancy setup. You are guaranteed to

have a 99.01% availability of your data with no hidden costs! You will also benefit from free software improvements and upgrades throughout the lifetime of

your monitoring system.

Carefree Hardware Solution

You also have the possibility to also rent the hardware from us! Rotronic will keep an

inventory of relevant measurement product for you so that you do not have to manage anything other than returning the defective units to us. Should a product fail or

break, it will be replaced within 24 working hours1. No more issues with making

room in your warehouse, finding the devices when you need them and no more cash

tied up in possibly never used stock.

SaaS Software &

Contract

SaaS Software

Contract

Hardware

only

Carefree Installation Service

You and your team are too busy or you do not have access to qualified personnel. Your configurable environmental monitoring system can be setup to run,

exactly how you want it to as soon as the devices are delivered. Let us install

and configure your hardware and software; you will not have to lift a finger!

Carefree Maintenance SLA

Once your system is up and running, who better than Rotronic to service your

system. We can calibrate (ISO-17025 or traceable) your devices on a yearly basis, calibrations on site are also possible. At the same time change filters,

O-rings and make sure that hardware is running the latest firmware. To guarantee data redundancy, we can also change batteries and ensure that your system

is running smoothly.

1

For customers in Switzerland.

Overview

Service

SLA

Onsite

Maintenance

18

Page 19

Rotronic Monitoring System

Questions? Do not hesitate to contact us: rms@rotronic.chQuestions? Do not hesitate to contact us: rms@rotronic.ch

V

Fully Compliant Exclusive Contract

For GxP compliant systems that require validation, Rotronic offers a turnkey

solution from A to Z. Let us know what your user requirement specifications are

and let us provide you with the solution!

On-Premise Support

If you already have solid IT infrastructure in place, responding to your security

policies and up to date with the latest norms, we also offer all of the above with

an on-premise software solution.

Stay up to date premium Support

Stay up to date and improve your monitoring with the latest software updates

and features sent out to you on a regular basis.

Contract

Exclusive SaaS

Overview

Support

SLA

Premium Support

19

Page 20

Rotronic Monitoring System

RMS Data LoggerRMS Data Logger

RMS GatewayRMS Gateway

RMS Mini LoggerRMS Mini Logger

RMS ConverterRMS Converter

RMS-8ADC-L-R-ARMS-8ADC-L-R-A

RMS-PCD-S-XXXRMS-PCD-S-XXX

RMS-CCD-S-XXRMS-CCD-S-XX

RMS DisplayRMS Display

RMS-DI-L-RRMS-DI-L-R

RMS-DO-L-RRMS-DO-L-R

RMS-8ADC-L-R-VRMS-8ADC-L-R-V

RMS-4RTD-L-RRMS-4RTD-L-R

CF632-W-INC-20CF632-W-INC-20

AD-0001AD-0001

WB-0001WB-0001

RMS AccessoriesRMS Accessories

RMS-HCD-SRMS-HCD-S

DATA SHEETS

20

Page 21

www.rotronic.com

1

The Hygroclip Digital RMS-HCD was specif ically designed for use as part of the Rotronic Monitoring System (RMS). Building upon our experience we

improved the power consumption so that it is usable by battery powered system like the RMS wireless data loggers. Having less cabling reduces

installation cost and increases the flexibility of the installation.

Standard

Compatible with the following with RMS data loggers such as the RMS-LOG-L (LAN data logger), RMS-LOG-868 (Wireless and RMS-LOG-915.

• Application Range 0…100 %RH, -40…85 °C

• Accuracy ±0.8 %RH, ±0.1 K @ 23°C

• Factory-adjustment @ 23°C and 10, 35, 80 %RH

• Humidity Sensor HYGROMER HT-1

• Long-term stability < 1% RH /year

Industrie

Industry probes have a sensor head separated from the measurement electronic by a cable. This allows a higher application range for the sensor

head.

• Application Range sensor head 0…100 %RH, -100…190 °C

• Application Range electronic 0…100 %RH, -40…85 °C

• Accuracy ±0.8 %RH, ±0.1 K @ 23°C

• Factory-adjustment @ 23°C and 10, 35, 80 %RH

• Materials PPS, stainless steel 1.4301

• Humidity Sensor HYGROMER HT-1

• Long-term stability < 1% RH /year

Order Code Type

RMS-HCD-S Black Probe

RMS-HCD-S3 White Probe

Order Code Cable length

RMS-HCD-IC102 2 m

RMS-HCD-IC105 5 m

RMS- HCD-S RMS-HCD-IC102

RMS-HCD-IC105

59083E/2018-08

RMS-HCD

Advantages

• Measures relative humidity and temperature

• Outstanding accuracy, repeatability and long-term stability

• Advanced probe housing and construction

• Compatible with RMS data loggers and RMS Soft ware

• Low power

Applications

• Pharmaceutical Monitoring

• Food Monitoring

• Museum Monitoring

• Monitoring conform to GxP and FDA CFR PART 11

Page 22

Possible Filters

Order Code Filter carrier Filter Element Pore size Application Range

SPA-PCB-PE

SPA-PCB-PTFE PTFE, white

SPA-PCB-WM Wire mesh 1.4401

SPA-PCW-PE

SPA-PCW-PTFE PTFE, white

SPA-PCW-WM Wire mesh 1.4401

SPA-PE

SPA-PTFE PTFE, white 10 μm -100...200 °C

Polycarbonate, black

Polycarbonate, white

No filter carrier, only f ilter

Polyethylene, white 40-50 μm

10 μm

Polyethylene, white 40-50 μm

10 μm

Polyethylene 40-50 μm

-50 …100 °C

Possible Extension Cables

It is possible to extend the distance between the probe and its reading device with extension cable.

• Passive connection are possible up to 5m (see table below for possible options).

RMS-HCD probe

Ex-x xA Extension cable

Max imum 5 m

Reading Device

RMS-LOG-868

RMS-LOG-915

TECHNICAL INFORMATION

RMS-HCD-S, RMS-HCD-S3

108 mm Ø 15 mm

RMS-HCD-IC102, RMS-HCD-IC105

15O mm

111 mm

144 mm

RMS-LOG-L

Order Code Cable Leng th Color

E2-01A 1 m

BlackE2-02A 2 m

E2-05A 5 m

E3-01A 1 m

WhiteE3- 02A 2 m

E3-05A 5 m

Technical Data

Humidity sensor

Temperature sensor

Operating humidity

Operating temperature

Accuracy @ 23 °C

Supply voltage

Current consumption

Protection rating

Digital communication

Compatible devices

Compliance

HYGROMER HT-1

PT1000, Class 1/3 B (RMS-HCD-S)

PT100, Class 1/3 B (RMS-HCD-IC)

0…10 0 %RH

-40…+85 °C RMS-HCD-S

-40…+85 °C RMS-HCD-IC electronic

-100 …190 ° C RMS-HCD-IC sensor head

±0.8 %RH

±0.1 K

2.5…5.5 VDC

5 mA (RMS-HCD-S)

12 mA (RMS-HCD-IC)

IP65

UART

RMS-LOG-L

RMS-LOG-868

RMS-LOG-915

GAMP5

FDA 21 CFR Part 11

Subject to technical change without notice. Printing and other errors reserved.

2

www.rotronic.com

59083E/2018-08

Page 23

www.rotronic.com

1

The Rotronic dif ferential pressure probes are ideal for clean rooms, operating theaters and applications where even minor differences in pressure can

have a big effect. Thanks to our two different measurement methods (thermal mass flow measurement and diaphragm measurement), we offer the

perfect solution for every requirement. Together with other measurement parameters, these probes can be integrated in RMS per fectly.

Compatible with

• RMS-LOG: Wireless ≥V1.5/LAN data loggers ≥V1.4

Dimensions

59067E/2018-09

RMS-PCD-S-XXX

TECHNICAL INFORMATION

Advantages

• High-precision measurement and long-term stability

• With ambient pressure compensation

• Large overload range

• With flow or diaphragm sensor technology

• Compatible with RMS logger, RMS On-premises software

and SaaS solutions

Applications

• HVAC

• Cleanroom

Ø 32 mm

113 mm

197 mm

105 mm

87 mm

76 mm

Page 24

TECHNICAL INFORMATION

General specifications FDA & GAMP compatibility

Sensor type

Parameter

1

Accuracy

at 23 °C ±3 K

Long-term stability

3

Flow Membrane

Differential pressure

±1% F S ±1% FS

2

±0.1% FSS/year ±2% FSS/year for ±25Pa

probe

±1% FSS/year for ±50Pa

probe

±0.5% FSS/year for

±100 Pa probe

±0.25% FSS/year for

±250Pa und ±500Pa

probes

Zero point compensation

4

Automatic, 1x

per measure-

Manual, with external

tube; via R MS software

5

ment interval

Medium

Air Air & non-aggressive

gases

Ambient pressure

Automatic Not necessary

compensation

Adjustment and calibration

Factory adjustment/calibration:

5 points

Customer adjustment: max. 9 points

Measurement range

-25...+25 Pa / -50…+50 Pa / -100...+100 Pa /

-250...+250 Pa / -500…+500 Pa

Pressure resistance

5 bar 0.7 bar

(burst pressure)

Leak rate

Startup time

Measurement interval

<180 µl/min. 0 µl/min.

<0.5 s

1 s probe

≥10s RMS / 1s Modbus

Response time ττ 63

Range of application

<1 s

-20…+80°C (0…+70°C temp.-comp.)

0…95% RH non-condensing

Voltage

Current consumption

Battery life

RMS wireless logger

3.3 – 5.5 V

30 mA (avg.) 12 mA (avg.)

60d @ 10s

130d @ 10s interval

interval

350d @ 60s

650d @ 60s interval

interval

Battery life

LAN logger

70d @ 10s

interval

395d @ 60s

180d @ 10s interval

840d @ 60s inter val

interval

Protocols

1

Ple ase see the device ma nual for detaile d considerations .

2

For ma ximum accuracy, Rotronic recommends strongly to perform a zero point compensation

af ter the installat ion and initial op eration and to repe at it annually. For a ggressive enviro n ment s / gas media, a more f requent zero poi nt compensation i s advised. Plea se see the device

manual for detailed considerations.

3

Hi ghly reducible by a zer o point compensat ion of the RMS- PCD-S-Mx x (membrane sen sor).

4

A zero point adjustment is recommended for every installation or position change.

5

Ple ase see the device ma nual for detaile d considerations .

Modbus RTU

FDA / GAMP directives

Housing / Mechanical parts

Housing material

Fire protection class

Dimensions

Pressure connections

Weight

IP protection class

FDA CFR21 Par t 11 / GAMP5

Polycarbonate (housing)

Stainless steel DIN 1.4305

(nuts, connectors)

Corresponds to UL94-HB

Ø 32 mm x 87 mm

Tubing connector internal

Ø 4 mm x 10 mm

60 g

IP65

2

www.rotronic.com

59067E/2018-09 Subject to technical change without notice. Printing and other errors reserved.

Page 25

www.rotronic.com

The Rotronic CO2 probes are ideal for of fice rooms and applications whe-

re the quality of room air has a big effect. Together with other measure-

ment parameters, these probes can be integrated in RMS perfectly.

Compatible with

• RMS-LOG: Wireless ≥V1.5/LAN data loggers ≥V1.4

Dimensions

1

Acc uracy relates to the uncertainty of c alibration mix tures +- 1 %

59069E/20 18-09

RMS-CCD-S-XX

TECHNICAL INFORMATION

Subjec t to technical change wit hout notice. P rinting and ot her errors r eserved .

Advantages

• High-precision measurement and long-term stability

• With ambient pressure compensation

• Large measurement range

• With automatic CO2 calibration

• Compatible with RMS-Logger, RMS On-premises software

and SaaS solutions

Applications

• Open-Plan Offices

• Classrooms

• Shopping Centers

113 mm

186 mm

105 mm

76 mm

Ø 32 mm

Measurement principle

Infrared (NDIR)

Parameter

CO

2

concentration (ppm / %)

Accuracy @ 25 °C ±10 K,

20 – 60 %RH

(after min. 3 weeks ABC)

1

±50 ppm ±3 % of read value

@ 0 – 2000 ppm

±10 % of read value

@ 2000–10,000 ppm

Medium

Air & non-aggressive gases

Ambient pressure &

temperature compensation

Automatic (300 – 110 0hP a)

Adjustment and calibration

Factor y adjustment/calibration: 1 point

Customer adjustment: max. 9 points

Measurement range

0…2000ppm / 5000ppm / 10'000ppm

Resolution

1 ppm

Startup time

≤300s

Measurement interval

16s pro be

Response time ττ 63

130s @ level descending

87s @ level ascending

Range of application

0…50°C, 0…95%RH non-condensing

Voltage

3.3 – 5.5V

Current consumption

(16 s interval)

20 mA (avg.) / peak 260 mA

Battery life

(RMS wireless/LAN logger)

2.7d @ 10s/60s inter val

Interface

UART

Protocols

Modbus RTU

FDA / GAMP directives

FDA CFR21 Par t 11 / GAMP5

Housing material

Polycarbonate (housing)

Stainless steel DIN 1.4305 (nuts)

Fire protection class

Corresponds to UL94-V2

Dimensions

Ø 32mm x 87mm

Weight

55g

IP protection class

IP40

Page 26

www.rotronic.com

TECHNICAL INFORMATION

The data logger is the flexible component between the probe and the da-

tabase in the Rotronic Monitoring System. It stores 44,000 pairs of mea-

sured values from the interchangeable CO2, differential pressure, humid-

ity or low dew point probe, and transmits them to the RMS database via

LAN or wireless link. It guarantees absolute data protection, even if power

supply and communications should break down temporarily.

Compatible with:

• CCD-S CO2 probe

• PCD-S Differential pressure probe

• HCD-S Humidity and temperature probe

• RMS-GW Gateway

• RMS-WEB On-premises software

• RMS-CLD SaaS solutions

Dimensions

59057E/2018-04

RMS DATA LOGGER

General specifications

Measured parameters Humidity & temperature, CO

2

, differential

pressure, LDP

Range of application -40..70 °C / 0..100 %RH

Storage conditions -40..30 °C / 0..95 %RH

Maximum altitude 2000 m ASL

Power supply 24 VDC ±10 % / <100 mA / Bat tery: RMS-BAT

(2xAA , LiSocl2) / PoE: 802.3af-2003, Class 1

AC adapter requirements 24 VDC ±10 % / 4 W nominal /

<15 W power-limited

Battery life 3 years (at 23 °C, measurement inter val 1 min.,

HCD-S probe)

Device data

Measurement interval 10 s to 15 min.

Startup time < 10 s

Order code RMS-LOG-L RMS-LOG-868 RMS-LOG-915

Interfaces Ethernet ISM 868 MHz ISM 915 MHz

Indoor wireless

range

- 20..50 meters 15..25 meters

Protocols HTTP / MODBUS TCP

Ethernet cable

requirement

Min. Cat. 5, SFTP, max. 30 m

Conformity with standards

FDA / GA MP directives FDA CFR21 Par t 11 / GAMP 5

Housing / Mechanics

Housing material ABS

Fire protection class UL94 –V2

Dimensions 105 x 113 x 38 mm

IP protection class IP65

Weight 200 g

Subject to technical change without notice. Printing and other errors reserved.

Advantages

• 44,000 data point memor y

• Fail-safe, thanks to internal battery

• Wireless or LAN inter face

• Compatible with RMS Gateway, RMS Server Software and RMS Cloud

• Conforms to FDA CFR 21 Part 11 / GAMP 5

Applications

• Pharma monitoring

• Food monitoring

• Museum monitoring

105 mm

113 mm

38 mm

Page 27

www.rotronic.com

1

59059E/2018-12

mA

V

RMS MINI WIRELESS LOGGER

TECHNICAL INFORMATION

Advantages

• Saves up to 10,000 measured values

• Fail-safe thanks to internal battery and battery monitoring

• Battery life up to 3 years

• Conforms to FDA 21 CFR Part 11 / GAMP5

• ISM band 868 MHz / 915 MHz

Applications

• Environmental chambers

• Pharmaceutical industr y

• Analog third-part y devices

• Incubators

Compatible with

• RMS-GW-868: Firmware V1.0

• RMS-GW-915: Firmware V1.5

• Software V1.2: RMS-MLOG-T10-868

• Software V1.2.1: 915 MHz devices

Dimensions / Connections

Top view

Rubber cap (front view)

* with wall bracket

Wall bracket

General specifications

Device t ype RMS Mini Wireless Logger

Memor y size 10,000 measured values

13,000 data points (RMS-MLOG-B)

Range of application (elec-

tronics)

-30...85 °C / 0...100 %RH

-40…85 °C/0…100 %RH (RMS-MLOG -B)

Storage conditions -30...30 °C / 0...95 %RH

Battery RMS- BAT

Battery life 3 years (at 23 °C and 1 minute inter val)

2.7 years (RMS-MLOG-B)

Measurement interval 10 s to 15 min (software dependant)

Wireless interface ISM 868 MHz ISM 915 MHz

Indoor wireless range 20...50 meters 15...25 meters

Conformity with standards

FDA / GAMP directives FDA 21 CFR Par t 11 / GAMP5

Housing / Mechanics

Housing material ABS

Dimensions 83 x 29 x 29 mm

IP protection class IP65, IP30 (RMS-LOG-B)

Fire protection class UL94-V2

83 (87*) mm

29 (32*) mm

87.4 mm

65 mm

3.7 mm

7.5 m m

14 mm

Rubber cap

Grommet

Button

Status LED

26 mm

Page 28

www.rotronic.com

2

TECHNICAL INFORMATION

59059D/2018-12

Type Range / Accuracy

Temperature

& humidity

RMS-MLOG-B-868

RMS-MLOG-B-915

-40...85 °C (±0.5 °C @ 25 °C / ±1 °C @ 0...70 °C / ±3.5 °C @ rest of temperature range) /

0…100 %RH (±3 %RH @ 25 °C)

Temperature RMS-MLOG-T-868

RMS-MLOG-T-915

-30...85 °C (±0.4 °C @ 25 °C)

Details: see page 3

Temperature with

external probe (NTC)

Further NTC probes

available in various

lengths. Please con-

tact Rotronic.

RMS-MLOG-T10-868

RMS-MLOG-T10-915

Accessories

Item no.

T10-0001 T10-0002 T10-0003 T10-0004

Application

Cryotechnolog y Freezers,

dry ice...

Standard Cable duct

monitoring

Probe operating range

-196...-90 °C -80...200 °C -50...200 °C -50...200 °C

NTC accuracy

range

-196...-90 °C -80...150 °C -50...120 °C -50...120 °C

Dimensions /

Housing

Ø 6 x 50 mm / stainless steel

Cable length

2 m

Power input RMS-MADC-868-V (0...10 V)

RMS-MADC-868-A

RMS-MADC-915-A

(0...20 mA)

0...10 VDC ( ±0.1 V @ 25 °C)

0...20 mA or 4...20 mA (shunt 110 Ohm) ±0.2 mA @ 25 °C

Digital input RMS-MDI-868

Accessories

Item no.

DC-0001

Application

Door contact / magnetic trigger

Switch

Normally open

Cable length

30 cm

Mounting

M3 screws

IP

IP65

Illumination RMS-MLOG-LGT-868 T he RMS-MLOG-LGT detect s light, meaning that it is possible to monitor the difference bet ween dark

and light. The LUX measurement values are not precise and are only used for scaling. T he device is not

designed for an accurate LUX measurement.

mA

V

Page 29

TEMPERATURE ACCURACY

RMS-MLOG-T & T10 accuracy overview

The RMS-MLOG-T10-X XX allows users to implement their own NTC sensor. It is possible to add the NTC nominal value and B constant within the RMS

software. For NTC’s from Rotronic, simply choose the NTC from the dropdown list (as of Software V1.2).

The RMS-MLOG-T10-X XX can be calibrated and adjusted (2 points) via the RMS soft ware. When using external NTC’s, please account for the accuracy

of the RMS-MLOG electronics.

Accuracy overview

T10-0001*

Accuracy between -196...-90 °C ±2.5 °C

T10-0002*

Accurac y at 25 °C ±0.2 °C

Accurac y at -80...-30 °C ±1 °C

Accurac y at -30...40 °C ±0.5 °C

Accurac y at 40...70 °C ±1 °C

Accurac y at 70...200 °C ±3 °C

T10-0003* and T10-0004*

Accurac y at 25 °C ±0.4 °C

Accurac y at -50...0 °C ±1 °C

Accurac y at 0...30 °C ±0.5 °C

Accurac y at 30...60 °C ±1 °C

Accurac y at 60...90 °C ±1.5 °C

Accurac y at 90...200 °C ±3.2 °C

RMS-MLOG-T-XXX

Accurac y at 25 °C ±0.4 °C

Accurac y at -30...0 °C ±1.3 °C

Accurac y at 0...40 °C ±1 °C

Accurac y at 40...85 °C ±1.5 °C

RMS-MLOG-T10-XX X electronic measurement accuracy

Accurac y at 25 °C ±0.1 °C

Accurac y at -200...-40 °C ±0.4 °C

Accurac y at -40...150 °C ±0.3 °C

Accurac y at 150...200 °C ±0.6 °C

RMS-MLOG-T10-XXX electronic temperature accuracy

Accurac y at 25 °C ±0.0 °C

Accurac y at -30...85 °C ±0.3 °C

To calculate the total accuracy of the RMS-MLOG-T10-XX X, it is necessary to add all variables together.

* NTC accuracy

Examples at various temperatures

Use of the T10- 0002 at 25 °C and the RMS -MLOG-T10-XXX at 25 °C

T10-0002 accuracy at 25 °C ±0.2 °C

RMS-MLOG-T10-XXX electronic measurement accuracy

at 25 °C

RMS-MLOG-T10-XXX electronic temperature

accuracy at 25 °C

Total accuracy at 25 °C ±0.3 °C

Use of the T10- 0001 at -196 °C and the RMS-MLOG-T10-XX X at 25 °C

T10-0001 accuracy at -196 °C ±2.5 °C

RMS-MLOG-T10-XXX electronic measurement accuracy

at -196 °C

RMS-MLOG-T10-XXX electronic temperature

accuracy at 25 °C

Total accuracy with the sensor at -196 °C

and the logger at 25 °C

Use of the T10- 0003 at 35 °C and the RMS-MLOG-T10-XX X at 35 °C

T10-0003 accuracy at 35 °C ±1 °C

RMS-MLOG-T10-XXX electronic measurement accuracy

at 35 °C

RMS-MLOG-T10-XXX electronic temperature

accuracy at 35 °C

Total accuracy at 35 °C ±1.6 °C

Improvement in accuracy:

When using the data logger with the inter nal NTC or any of the NTC’s

provided by Rotronic, it is possible to carry out a 1 or 2 point adjustment

in order to improve the measurement accuracy.

1 point adjustment:

• Adjustment range: -25...125 °C

• Accuracy: ±0.3 °C

• Accuracy range: adjustment point ±10 °C

2 point adjustment:

• Adjustment range: -25...125 °C

• Accuracy: ±0.3 °C

• Maximum span of the 2 adjustment points: 80 °C

±0.1 °C

±0.0 °C

±0.4 °C

±0.0 °C

±2.9 °C

±0.3 °C

±0.3 °C

3

www.rotronic.com

59059D/2018-12

Page 30

www.rotronic.com

TECHNICAL INFORMATION

The gateway is the interface bet ween the wireless data logger and the

server sof tware. It can manage up to 60 data loggers simultaneously,

collecting all wireless-logger measurement data, and passing them on

to the ser ver software. When several gateways are used in the same net-

work, they are configured redundantly. If one gateway should fail, the

measurement values are automatically sent to the ser ver soft ware via

another gateway.

Compatible with:

• RMS LOG RMS data logger

• RMS MLOG RMS mini-logger

• RMS-WEB On-premises software

• RMS-CLD SaaS solutions

Dimensions

59058E/2018-03

RMS GATEWAY

General specifications

Range of application -40..70 °C, 0..100 %RH

Storage conditions -40..30 °C, 0..95 %RH

Maximum altitude 2000 m ASL

Power supply 24 VDC ±10 % / <100 mA / PoE: 802.3

af-2003, Class 1

AC adapter requirements 24 VDC ±10 % / 4 W nominal / <15 W

power-limited

Device data

Measurement interval 10 s to 15 min.

Startup time < 10 s

Order code RMS-GW-868 RMS-GW-915

Interfaces Ethernet &

ISM868 MHz

Ethernet &

ISM 915 MHz

Indoor wireless range 20..50 meters 15..25 meters

Protocols HTTP

Ethernet cable requirement Min. Cat. 5, SFT P, max. 30 m

Conformity with standards

FDA / GA MP directives FDA CFR21 Part 11 / GAMP 5

Housing / Mechanics

Housing material ABS

Fire protection class UL94 –V2

Dimensions 105 x 113 x 38 mm

IP protection class IP65

Weight 200 g

Subject to technical change without notice. Printing and other errors reserved.

Advantages

• Connects 60 wireless data loggers simultaneously

• 5 wireless channels for parallel and redundant operation

• Compatible with RMS Wireless Data Loggers, RMS Server Sof tware

and RMS Cloud

• Conforms to FDA CFR 21 Part 11 / GAMP 5

Applications

• Monitoring of mobile equipment

• Extensible applications

• For redundant requirements

105 mm

113 mm

38 mm

Page 31

www.rotronic.com

TECHNICAL INFORMATION

The LAN display is a freely configurable display. As a remote display, it

can be placed optimally where it suits the viewer best. It is able to show

the measured values, states and alarms of RMS products. The display

shows up to four measured values. Two measured values are shown at

a time. If more than 2 measured values have been selected, the display

alternates between the values that are to be displayed ever y 5 seconds.

Compatible with:

• All measuring points

• RMS-GW RMS Gateway

• RMS-WEB RMS On-premise

• RMS-CLD RMS SaaS

Dimensions

59070E/2018-01

RMS DISPLAY

105 mm

113 mm

38 mm

General specifications

Device t ype RMS Display

Display of measuring points Up to 4 measuring points

Range of application -20...70 °C / 0...100 %RH

Storage conditions -20...30 °C / 0...95 %RH

Power supply 24 VDC ±10 % / <100 mA / PoE: 802.3

af-2003, Class 1

AC adapter requirements 24 VDC ±10 % / >4 W / power-limited

Measurement interval 10 s

Interface Ethernet

Protocols HTTP

Conformity with standards

FDA / GA MP directives FDA CFR21 Part 11 / GAMP 5

Housing / Mechanical par ts

Housing material PC, ABS

Fire protection class UL94-V2

Dimensions 105 x 113 x 38 mm

Display diagonal 2.26 inch

IP protection class IP65

Weight 206 g

Subject to technical change without notice. Printing and other errors reserved.

Advantages

• Shows up to 4 measured values

• Automatic adjustment of backlight on alarm

• Compatible with RMS data loggers, RMS On-premise

and RMS SaaS

• Conforms to FDA CFR 21 Part 11 / GAMP 5

Applications

• Critical places

• Cleanrooms

Page 32

www.rotronic.com

TECHNICAL INFORMATION

The digital input module stores all measured data on an event basis and

sends it to the database via Ethernet. The minimum pulse time is 100

ms. Should the connection be lost, the module stores the data inter-

mediately to protect data integrit y and fills up the data gaps when the

connection has been restored. The device has a batter y so that logging

of measured data is also ensured in the event of a failure in the external

power supply.

Compatible with:

• RMS-Config

• RMS-WEB On-Premise

• RMS-CLD SaaS solutions

Dimensions

59071E/2018-01

RMS-DI-L-R

General specifications

Device t ype RMS-DI-L-R

Number of inputs 2 independent digital inputs

Range of application -40..70 °C / 0..100 %RH non-condensing

Storage conditions -40..30 °C / 0..95 %RH

Maximum altitude 2000 m ASL

Power supply 24 VDC ±10 % / <100 mA / PoE: 802.3

af-2003, Class 1

AC adapter requirements 24 VDC ±10 % / 4 W nominal /<15 W

power-limited

Battery type RMS-BAT

Battery life 3 years at 23 °C

Device data

Input frequency Max. 0.833 Hz or 1.2 s

Pulse recognition >100 ms (periodically > 1.2 s)

Input circuit Logic level: 0 V / 5-24 V

Trigger threshold: ~3.77 V

Current consumption: <1 mA

Reed circuit Max. load at input 100 k Ω

Max. cable leng th at input <3 m

Measurement interval Event-based & inter val (10 s to 15 min.)

Storage capacit y 75,000 data points

Interface Ethernet

Protocols HTTP

Conformity with standards

FDA / GA MP directives FDA CFR21 Part 11 / GAMP 5

Housing / Mechanical par ts

Housing material Polycarbonate (PC)

Fire protection class UL94-V0

Dimensions 89.7 x 62.2 x 108 mm

IP protection class IP20

Weight 206 g

Subject to technical change without notice. Printing and other errors reserved.

Advantages

• Two input channels

• Data logging of up to 75,000 measured values

• Compatible with RMS-Config, RMS On-Premise and RMS SaaS

• Conforms to FDA CFR 21 Part 11 / GAMP 5

Applications

• Monitoring / Process control

• Safety and automation

• Direct condition control

Page 33

www.rotronic.com

TECHNICAL INFORMATION

The digital output module serves to display information, issue alarms

and control events. The relays can be interrogated or set via Modbus TCP

or the RMS software. It is possible to define the conditions in the RMS

software and to actuate the outputs on the basis of them.

Compatible with:

• RMS-Config

• RMS-WEB On-Premise

• RMS-CLD SaaS solutions

Dimensions

59072E/2018-01

RMS-DO-L-R

General specifications

Device t ype RMS-DO-L-R

Number of outputs 2, polarity-independent

Range of application -40..70 °C / 0..100 %RH non-condensing

Storage conditions -40..30 °C / 0..95 %RH

Maximum altitude 2000 m ASL

Power supply 24 VDC ±10 % / <100 mA / PoE: 802.3

af-2003, Class 1

AC adapter requirements 24 VDC ±10 % / 4 W nominal /<15 W

power-limited

Device data

Interface Digital signal / galvanically isolated

Relay switching capacit y 50 VAC ( peak) 1 A / 50 VDC/1 A, polarit y-

independent

Voltage output (VEX) 24 VDC (Note: The maximum current avail-

able depends on the external power supply

connected.)

Max. cable leng th at input <3 m

Measurement interval >=10 s

Interface Ethernet

Protocols HTTP

Conformity with standards

FDA / GA MP directives FDA CFR21 Part 11 / GAMP 5

Housing / Mechanical par ts

Housing material Polycarbonate (PC)

Fire protection class UL94-V0

Dimensions 89.7 x 62.2 x 108 mm

IP protection class IP20

Weight 155 g

Subject to technical change without notice. Printing and other errors reserved.

Advantages

• Two output channels

• Compatible with RMS-Config, RMS On-Premise and RMS SaaS

• Conforms to FDA CFR 21 Part 11 / GAMP 5

Applications

• Monitoring / Process control

• Building automation

• Industrial automation

Page 34

www.rotronic.com

1

59060E/2018-11

RMS-CONVERTER

TECHNICAL INFORMATION

The RMS Converter allows you to easily integrate existing devices and

networks into RMS. The RMS Converter acts as an interface, gathering

the data from digital devices and sending them to the RMS server

software/MS SQL database. With a USB dongle, the Converter can

be enhanced to a Gateway, and can connect to wireless data loggers.

In addition, third party digital devices can be integrated if the com

-

munication protocol is available. However, this function requires

support from the Rotronic R&D. Where ever possible Rotronic would

recommend replacing previous networks with RMS devices in the

long term.

Dimensions

General specifications

Device t ype RMS Converter

Number of measuring points Integration of up to 100

Range of application -0 .. 50 °C / 0 .. 95 %RH

Storage conditions -0 .. 50 °C / 0 .. 95 %RH

Electrical Supply 5 VDC

(universal mains adapter included)

Measurement interval 10 s to 15 min

Interface Ethernet

Protocols Modbus TCP

RoASCII

HTTP

SNMP

Customer-specif ic enhancements

Supported webcams D-Link DCS-2121

Conformity with Standards

FDA / GA MP directives FDA 21 CFR Par t 11 / GAMP 5

Housing / Mechanical par ts

Dimensions 94 x 78 x 30 mm

IP protection class IP20

Subject to technical change without notice. Printing and other errors reserved.

Advantages

• Integrates digital devices seamlessly into RMS

• Integrates Rotronic digital devices into RMS

• No loss of accuracy due to A/D converters, show up to

5 decimal values

• Conforms to FDA 21 CFR Part 11 / GAMP 5

Page 35

www.rotronic.com

2

59060E/2018-11

TECHNICAL INFORMATION

Compatible with (LAN connection)

• HL-NT with Ethernet docking station Data logger

• HygroLog NT with Ethernet docking station Data logger

• HF4 .. HF8 with Ethernet connection Transmitter

• PF4 with Ethernet connection Transmitter

• RMS-WEB RMS On-Premise

• RMS-CLD RMS SaaS solutions

• CRP5 Clean room panel

• RMS-8ADC-L-R-A/V Analogue to digital converter

• RMS-4RTD-L-R RTD to digital converter

• Lighthouse APEX R5 with Ethernet connection Particle counter

Network architecture with the RMS Converter

HL- NT

RMS Converter

for Rotronic devices

CRP5

Page 36

www.rotronic.com

1

RMS-8ADC-L-R-A

Advantages

• 8 isolated input channels

• Passive input up to ±20mA

• Programmable via the RMS software

• Signal LED

Applications

• Monitoring / Process control

• Building automation

• Industrial automation

RMS 8 input, analogue to digital converter

The 8 input, analogue to digital conver ter was designed to implement all analogue outputs into the digital world of RMS. The 8 inputs of fer the flexi-

bilty of using a current system with one of the newest and most flexible monitoring systems on the market today.

Attention

Function only with RMS-Converter-XXX.

Dimensions

Power supply

Analog inputs

Notes:

Terminals “2” and “4” connected internally between them (neg. reference “GNA0”).

Terminals “6” and “8” connected internally between them (neg. reference “GNA1”).

Terminals “10” and “12” connected internally between them (neg. reference “GNA2”).

Terminals “14” and “16” connected internally between them (neg. reference “GNA3”).

The refe rences “GNA0 ”, “GNA1”, “GNA2” and “GNA3” are isola ted from each other.

TECHNICAL INFORMATION

59064E/2018-03

mA

V

Page 37

TECHNICAL INFORMATION

Light signalling

LED Colour State Description

PWR Green On Device powered

Off Device not powered

Blink Watchdog alarm

STS Yellow Off Device in RUN modality

Blink Device in INIT modality

General specifications

Device t ype RMS-8ADC-L-R-A

Measured parameters Current

Memor y size 7 days memory with the RMS-Extension

Range of application -10…60°C, 0…90%rh

Storage conditions -40…85°C, 0…90%rh

Maximum altitude 2000 m ASL

Electrical supply voltage 14…30VDC

Device Data

Analog inputs 8 isolated inputs, 0/4...20 mA

Input accuracy mA ±0.05%fs

Linearit y mA ±0.1% fs

Thermal drif t FS ±0.01%/° C

Measurement interval 10 s to 15 min

(dependant on software account)

Interface output Ethernet RJ-45

Protocol Modbus TCP

Ethernet cable requirement Min. Cat 5, SFTP,max. 100m

Interface input Removable screw-terminals

Housing / Mechanical par ts

Mounting Din-rail

Dimensions 100 x 120 x 22.5mm

Weight 160 g

IP protection class IP20

Installation recommendation Seperated by at least 5mm

Defaut IP configuration 192.168.1.100

Subject to technical change without notice. Printing and other errors reserved.

2

www.rotronic.com

Page 38

www.rotronic.com

1

RMS-8ADC-L-R-V

59074E/2018-03

Advantages

• 8 isolated input channels

• Passive input up to ±10 V

• Programmable via the RMS software

• Signal LED

Applications

• Monitoring / Process control

• Building automation

• Industrial automation

RMS 8 input, analogue to digital converter

The 8 input, analogue to digital conver ter was designed to implement all analogue outputs into the digital world of RMS. The 8 inputs offer the f lexibilty

of using a current system with one of the newest and most flexible monitoring systems on the market today.

Attention

Function only with RMS-Converter-XXX.

Dimensions

Power supply

Analog inputs

Notes:

Terminals “2” and “4” connected internally between them (neg. reference “GNA0”).

Terminals “6” and “8” connected internally between them (neg. reference “GNA1”).

Terminals “10” and “12” connected internally between them (neg. reference “GNA2”).

Terminals “14” and “16” connected internally between them (neg. reference “GNA3”).

The refe rences “GNA0 ”, “GNA1”, “GNA2” and “GNA3” are isola ted from each other.

TECHNICAL INFORMATION

mA

V

Page 39

TECHNICAL INFORMATION

Light signalling

LED Colour State Description

PWR Green On Device powered

Off Device not powered

Blink Watchdog alarm

STS Yellow Off Device in RUN modality

Blink Device in INIT modality

General specifications

Device t ype RMS-8ADC-L-R-V

Measured parameters Voltage

Memor y size 7 days memory with the RMS-Extension

Range of application -10…60°C, 0…90%rh

Storage conditions -40…85°C, 0…90%rh

Maximum altitude 2000 m ASL

Electrical supply voltage 14…30VDC

Device Data

Analog inputs 8 isolated inputs, 0/4...20 mA

Input accuracy Voltage ±0.05%fs

Linearit y Voltage ±0.1%fs

Thermal drif t FS ±0.01%/° C

Measurement interval 10 s to 15 min

(dependant on software account)

Interface output Ethernet RJ-45

Protocol Modbus TCP

Ethernet cable requirement Min. Cat 5, SFTP,max. 100m

Interface input Removable screw-terminals

Housing / Mechanical par ts

Mounting Din-rail

Dimensions 100 x 120 x 22.5mm

Weight 160 g

IP protection class IP20

Installation recommendation Seperated by at least 5mm

Defaut IP configuration 192.168.1.100

Subject to technical change without notice. Printing and other errors reserved.

2

www.rotronic.com

Page 40

www.rotronic.com

1

RMS-4RTD-L-R

Advantages

• 4 isolated input channels

• Input for PT100 & PT1000

• Programmable via the RMS software

• Signal LED

Applications

• Monitoring / Process control

• Building automation

• Industrial automation

RMS analogue to digital converter with 4 inputs

The 4-input analog ue to digital conver ter was developed to implement all temperature sensors in the digital world of RMS. The 4 inputs offer the flexibility

of using a modern system with one of the newest and most flexible monitoring systems on the market today.

Attention

Function only with RMS-Converter-XXX.

Dimensions

Power supply

Analog inputs

TECHNICAL INFORMATION

59075E/2018-03

mA

V

Page 41

www.rotronic.com

2

TECHNICAL INFORMATION

General specifications

Device t ype RMS-4RTD-L-R

Measured parameters PT100, PT1000, potentiometer

Memor y size 7-day memor y with RMS-Extension

Application range -10..60 °C , 0..90 %RH

Storage conditions -40..85 °C, 0..90 %RH

Maximum altitude 2000 m ASL

Power supply 14..30 VDC

Device data

Analog inputs 4 isolated inputs

Input accuracy RT D,

resistance, potentiometer

±0.05 %FS

Linearit y RTD ±0.1 %FS

Influence line resistance

RTD/resistance 3-wire

±0.05 %FS/Ω

RTD field current 0.370 mA

Thermal drif t FS ±0.01 %/°C

Start-up time 3 min.

Measurement interval 10 s to 15 min.

(dependant on software account)

Interface output Ethernet RJ-45

Protocol Modbus TCP

Ethernet cable requirement Min. Cat. 5, SFTP, max. 100 m

Interface input Removable screw terminals

Housing / Mechanical par ts

Mounting DIN rail

Dimensions 100 x 120 x 22.5 mm

Weight 160 g

IP protection IP20

Installation recommendation Separated by at least 5 mm

Defaut IP configuration 192.168.1.100

LED Color State Description

PWR Green On Device powered

Off Device not powered

Flashing Watchdog alarm

STS Yellow Off Device in RUN mode

Flashing Device in INIT mode

RTD 2/3-wire Min. Max.

PT100 -20 0 °C 850 °C

PT1000 -200 ° C 200 °C

NI10 0 -60 °C 18 0 °C

NI1000 -60 °C 150 °C

RES 2/3-wire

Low 0 Ω 500 Ω

High 0 Ω 2000 Ω

Potentiometer 20 Ω 50 kΩ

Technical specifications (typical @ 25 °C and normal environment).

Light signals

Input type

Subject to technical change without notice. Printing and other errors reserved.

Page 42

RMS ACCESSORIES

OVERVIEW TEMPERATURE PROBES

The T10 temperature sensors are NTC (Negative Temperature Coef ficient) thermistors, meaning that the resistance of the NTC decreases with increasing temperature. T he T10 temperature sensors are compatible with the RMS-MLOG-T10-868/915 data loggers. T he data logger temperature range is

limited from -35…80°C.

The RMS temperature portfolio will cover a various array of applications, from the coldest such as liquid nitrogen tanks and cryogenic freezers to

freezers, refrigerators and cold rooms to hotter ones such as water baths, incubators, ovens and autoclaves. Certain probes are also designed for

specific applications for monitoring legionella within water pipes and monitoring room temperature.

It is crucial when set ting up your RMS-MLOG-T10-868/915 with the T10 temperature probe to configure the logger accordingly with the software as

the characteristic cur ve of each NTC is stored within the firmware. Please see for each probe below.

This list is not extensive and other probes, diameters and cable lengths are available on demand.

For accuracy information please see the RMS-MLOG data sheet.

T10-0001 T10-0002 T10-0003

• Applications: liquid nitrogen, cyrogenics…

• Application range: -196…-90°C

• Cable length: 2m

• Probe diameter: 6mm

• Probe length: 50mm

• IP65

• Select NTC T10- 0001 within RMS

T10-0004 T10-0005 T10-0006

• Applications: pipe monitoring (legionella)

• Application range: -50…120°C

• Cable length: 2m

• Probe: duct wrap

• Probe length: 50mm

• IP65

• Select NTC T10- 0003/4/6 within RMS

• Applications: Dry ice, freezers…

• Application range: -80…150°C

• Cable length: 2m

• Probe diameter: 6mm

• Probe length: 50mm

• IP65

• Select NTC T10- 0002 within RMS

• Applications: Dry ice, freezers…

• Application range: -90…0°C

• Cable length: 4m

• Probe diameter: 6mm

• Probe length: 50mm

• IP65

• Select NTC T10- 0005 within RMS

• Applications: freezers, fridges, cold rooms,

water baths, incubators, ovens…

• Application range: -50…120°C

• Cable length: 2m

• Probe diameter: 6mm

• Probe length: 50mm

• IP65

• Select NTC T10- 0003/4/6 within RMS

• Applications: freezers, fridges, cold rooms,

water baths, incubators, ovens…

• Application range: -50…120°C

• Cable length: 4m

• Probe diameter: 6mm

• Probe length: 50mm

• IP65

• Select NTC T10- 0003/4/6 within RMS

59081E/2018-08

1

www.rotronic.com

Page 43

OVERVIEW ACCESSORIES

E2-xxA extension cable

• Applications: Improved probe access for calibration purposes

• Available in 01, 02 and 05m (replace x x with the desired length)

• Compatibility: RMS-LOG-L/868/915 and HCD, PCD and CCD

E2-xx XX extension cable with open ends

• Applications: Various

• Available in 01, 02 and 05m (replace x x with the desired length)

• Compatibility: RMS-LOG-L/868/915

AC0001 Ethernet patch cable

• Applications: Ethernet wiring

• 3m

• White

• Compatibility: RMS-LOG-L, RMS-GW-868, RMS-DI/DO-L-R

AC0005 Ethernet patch cable

• Applications: Ethernet wiring

• 3m

• Red

• Compatibility: RMS-LOG-L, RMS-GW-868, RMS-DI/DO-L-R

AC1319 holder

• Applications: RMS probe wall mounting module

• Compatibility: HCD probes

AC1321 mounting kit

• Applications: RMS wall module mounting

• Mounting cone (to bring the Ethernet cable through the joint)

• Allen key

• Compatibility: RMS-LOG-L & RMS-GW-868

AC1322 holder

• Applications: RMS probe wall mounting module

• Compatibility: PCD and CCD probes

RMS-AC-0001 holder for RMS-Monitor-7

• Holder to attach the RMS-Monitor-7 to a wall

• Compatibility: RMS-Monitor-7

AC6001/XX tubing

• Applications: Tubing for differential pressure monitoring

• Diameter: 4mm

• Compatibility: PCD-S, PF4 & CRP5

WC-0001 Webcam

• Applications: Monitoring applications together with a snap shot,

PDF repor t together with a snap shot

• Application range: 0…40°C

• Resolution: 640 x 480

• Connectivity: RJ45

• Power supply: 5V

RMS-DONGLE-868

• Applications: configures 868 wireless devices with RMS-Config

• Compatibility: All 868 wireless devices

2

RMS-BAT batteries

• Applications: Fail safe power supply

• Model: ER14505M

• Application range: -55°C…80°C

• Compatibility: RMS-LOG-L/868/915, RMS-GW-868/915,

RMS-MLOG range & RMS-DI-L-R

RMS-NPK network planning kit

• Applications: Planning of a wireless net work

• RMS-MLOG and wireless USB dongle to check the wireless

communication

• Compatibility: RMS-Conf ig

21.99.1196 5 port power over Ethernet Switch

• Applications: Setting up a PoE net work

• Add up to 4 RMS LAN devices

21.99.1197 8 port power over Ethernet Switch

• Applications: Setting up a PoE net work

• Add up to 7 RMS LAN devices

RMS-PS & RMS-PS-R power supplies

• RMS-PS: 24VDC, 0.5A, 15W with connector

• RMS-PS -R: 24VDC, 60mA, 15W, Din rail

• Compatibility: RMS-LOG-L/868/915, RMS-GW-868/915,

RMS-DO/DI-L-R

DC-0001 Magnetic door contact

• Applications: Door open/close monitoring for rooms, fridges,

freezers…

• Application range: -20…70°C

• Compatibility: RMS-MDI-868/915 & RMS-DI-L-R

WB-0001 Leak detector module

• Applications: Leak monitoring for archives, storage areas…

• Application range: 0…50°C

• Battery powered

• Visual alarm

• Audible alarm

• Compatibility: RMS-MDI-868/915 & RMS-DI-L-R

AD-0001 Signal beacon

• Applications: Signal alarms to users via light and sound

• Application range: -20…50°C

• Visual alarm

• Audible alarm

• Compatibility: RMS-DO-L-R

RMS-PS-CONV

• Applications: power supply for the RMS-Converter

• Compatibility: RMS-CONVERTER-100

AC1000 naturally ventilated weather shield

• Applications: protect your outdoor temperature and relative

humidity measurement

• Application range: protection against wind speeds of up to

70m/s and horizontal precipitation

• Compatibility: HCD-S

59081E/2018-08

www.rotronic.com

Page 44

www.rotronic.com

3

59081E/2018-08

OVERVIEW FILTERS

Description

Filter carriers protect the humidity and temperature sensors against mechanical damage. Filters act as a protective barrier against contaminants/

pollutants that can influence the sensor. When choosing the correct combination of filter carrier and filter there are many factors to consider. Specif ic

conditions such as high air velocities, pollutants in the air, disinfection and cleaning routines, mechanical impacts, high bioactivity, condensation,

airborne chemical contaminants and required response time are some of the many considerations.

Plastic filter carrier Metal filter carrier

• Maximum temperature 100 °C

• Mechanical protection

• Maximum temperature 200 °C

• Mechanical protection

Overview filters

Tef lon filter s

Polyethylene filters

Sintered steel filters

(stainless steel)

Wire mesh filters (metal)

Maximum temperature (consider range of application of filter carrier)

200 °C 10 0 °C 200 °C 200 °C

Protection against par ticulates

Protection against abrasives in the air

Pore size

10 µm 40 µm 25 µm 10 µm

Max. air velocit y [m/s] (continuous load)

50 50 70 50

= low / = medium / ✔= high

Order code Filter carrier Filter element Pore size Range of application