Page 1

Dokument

UMA 148

Rev 1 Page

1 (6)

User manual

CF8-D/W-IN

General

The sensor CF8-D/W-IN is used to measure the carbon dioxide concentration inside incubators.

All functions can be modified from a PC with the communication cable.

Page 2

Dokument

UMA 148

Rev 1 Page

2 (6)

output range for OUT1. See note 1

output range for OUT2 See note 1.

Functional description

This part describes t he function of the configurati on of CF8-D/W-IN. Pleas e note that the two outputs

may completely or partly have other functions. These functions may be reprogrammed after the

installation. To be sure that every unit is correctly programmed, in accordance to the actual

application, a check by a PC and the standard UIP software (version 4.0 or higher) is necessary.

OUT1 and OUT2 are used for the measuring signal of carbon dioxide concentration.

OUT1 = measuring signal of carbon dioxide concentration

OUT2 = measuring signal of carbon dioxide concentration

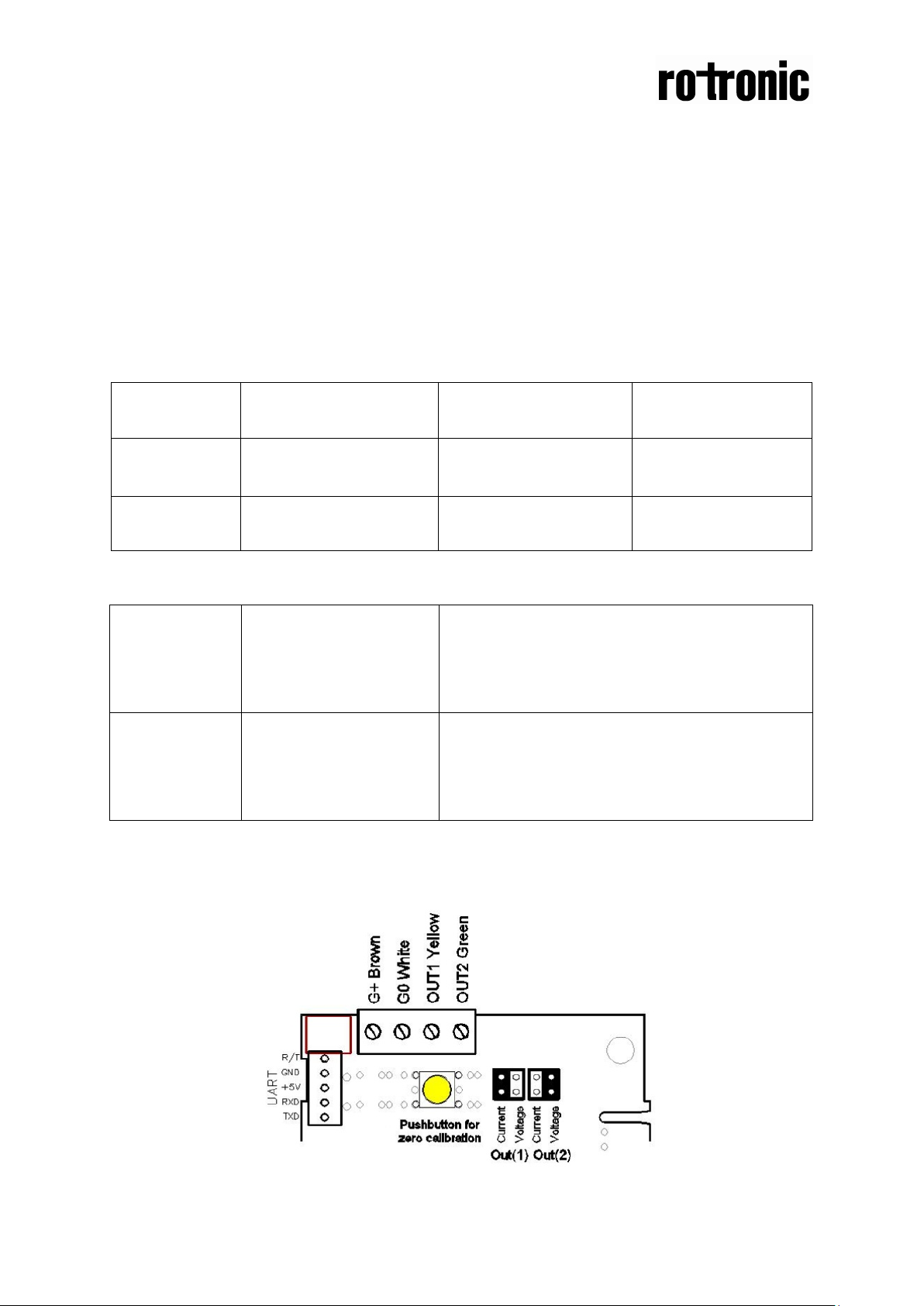

Terminal

OUT1

Standard configuration

4-20mA

Standard settings *

0-3 % CO

2

Standard function

Measuring signal

OUT2

0-5VDC

0-2 % CO2

Measuring signal

Table I. Default configuration of CF8-D/W-IN

OUT1

OUT2

Current

Voltage

Current

Voltage

Connection in position “Current” provides 4-20mA

output range for OUT1. See note 1

Connection in position “Voltage” provides 2-10VDC

Connection in position “Current” provides 0-10mA

output range for OUT2. See note 1

Connection in position “Voltage” provides 0-5VDC

Table II. Configuration jumpers for

CF8-D/W-IN

Note 1: During start up the unit may deliver up to 10 VDC or 20 mA for up to half a second.

Page 3

Dokument

UMA 148

Rev 1 Page

3 (6)

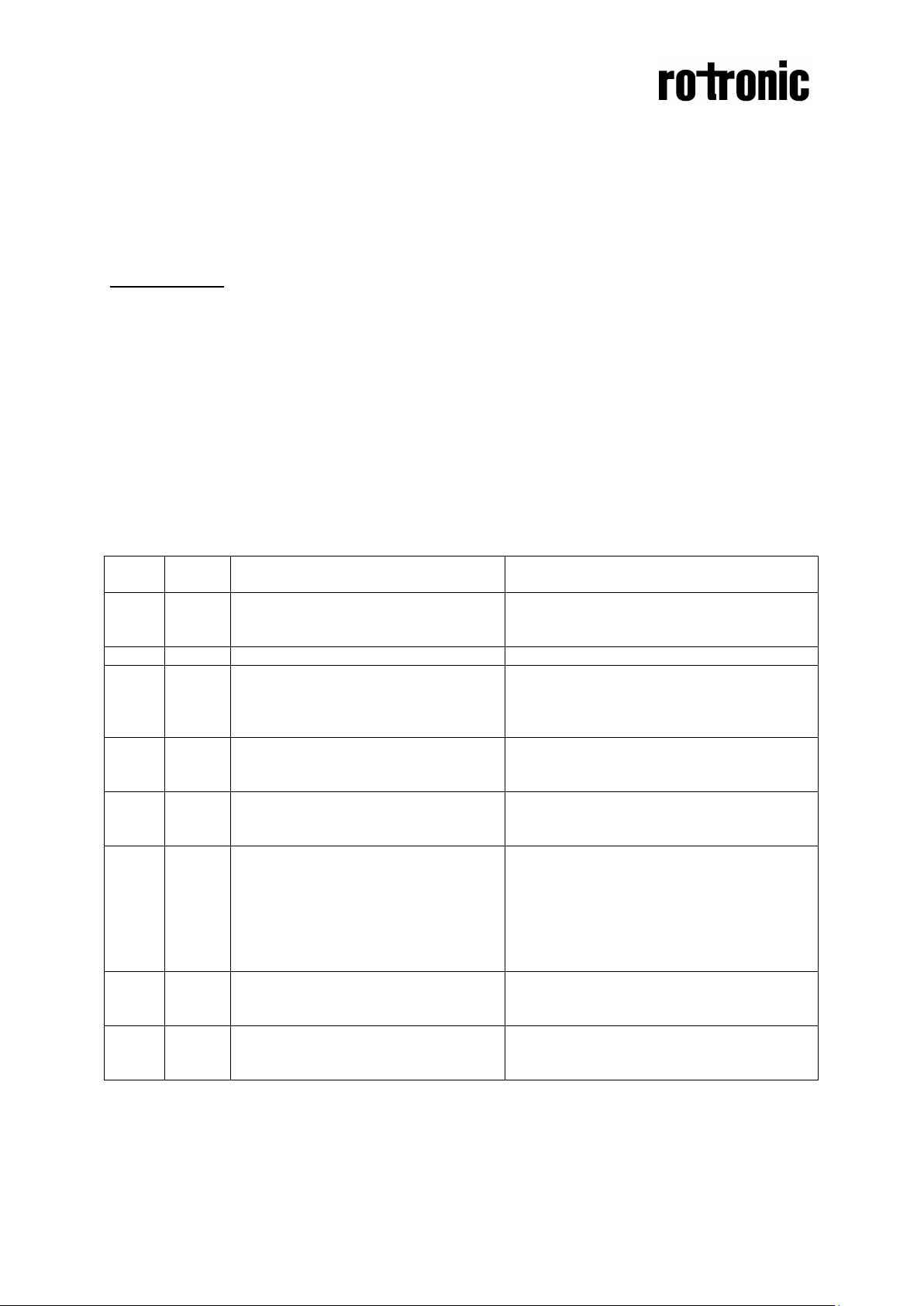

Bit #

Error

code

Error description

Suggested action

0

N/A

Fatal Error

Push buttons are not operating.

Try to restart sensor by power OFF/ON.

1

2

Reserved

2

4

Algorithm Error.

Try to restart sensor by power OFF/ON.

Contact local distributor

3

8

Output Error

calculation and generation.

Check connections and loads of outputs.

software version 4.0 and higher.

4

16

Self Diagnostic Error.

calibration or sensor replacement.

Check detailed self diagnostic status with

Contact local distributor

5

32

Out Of Range Error

error disappearance.

Try sensor in fresh air.

6

64

Memory Error

operations.

Check detailed settings and configuration

7

128

Warm Up state

failure. Resets after restart sequence.

If it doesn’t disappear in half a minute,

Functional test of CF8-D/W-IN

The unit has two LED’s -one yellow and one red. These LED’s indicate the status of the controller.

Yellow LED - ”Call for maintenance” is lit, if an error flag is set or the measurement is out of range.

The yellow LED flashes in series during Automatic Zero Point Calibration.

Red LED - ”Relay active” is lit for eight minutes when a zero point calibration has been executed.

PLEASE NOTE!

The sensor accuracy is defined at continuous operation.

Self diagnostics

The system contains complete self diagnostic procedures. A full system test is executed automatically

every time the power is turned on. For CF8-D/W-IN the internal voltage regulators and outputs are

checked. In addition, constantly during operation, the sensor probes are checked against failure by

checking the valid dynamic measurement ranges. These different system checks return error bytes to

the system RAM. If any error is detected, the yellow LED will be li t until the error has vanished and the

error flag is reset. “Warm up” and “Out of Range” are the only bits that are reset automatically after

return to normal state. All other error bits have to be reset manually after return to normal state by

power off and restart.

Descriptions of the different codes are listed below.

Yellow LED continuously flashes.

Indicate wrong EEPROM

configuration.

Detected errors during output signals

May indicate the need of zero

Accompanies most of other errors.

Can also indicate overload or failures

of sensors and inputs.

Resets automatically after source of

Non fatal error during memory

Is always set after power up or power

Contact local distributor

Check detailed settings and configuration

with UIP software version 4.0 and higher.

Check detailed status of outputs with UIP

UIP software version 4.0 and higher.

Check detailed status of measurements

with UIP software version 4.0 and higher.

See Note 1!

with UIP software version 4.0 and higher.

check power stability.

Note 1. Any probe is out of range. Occurs, for instance, during over exposure of CO2 sensor, in which

case the error code will automatically reset when the measurement values return to normal. Could

also indicate the need of zero point calibrat ion.

Remark: If several errors are detected at the same time the different error code numbers will be

added together into one single error code!

Page 4

Dokument

UMA 148

Rev 1 Page

4 (6)

Automatic Zero Point Calibration

The CF8-D/W-IN sensors have a function for easy automatic zero point calibration. The calibration

should be done after installation and at least once every year. The calibration can be done on site. It is

only necessary to connect the zero gas without any further action required from the operator, but to

check the verification signal offered from the system.

1. Unscrew one of the filters from the sensor housing and replace it with a hose nippl e.

2. Connect the zero gas to the nipple. The sensor automatically enters phase 1 of the calibration

procedure when the CO

during calibration.

3. When the calibration starts the yellow LED starts to flash. The sensor continues the procedure

until the readings of the sensor are stable enough and are below the limit of Automatic Zero Point

Calibration. If the conditions are not good enough for calibration within eight minutes the sensor

returns to normal measuring operation without calibration.

4. When the calibration is successfully executed the yellow LED flashes four times, pauses and

flashes another four times for an eight minutes acknowledgement period, phase 2. During the

acknowledgement period the relay is closed and the red LED is lit.

5. Remove the zero gas during the acknowledgement period. The sensor returns to norm al

measuring mode as soon as the calibration is ready. The yellow LED continues flashing, the red

LED is lit and the relay is closed independent of gas removal.

The zero gas can be generated by passing air through the chemical absorber in the service bag

F0005 or by using nitrogen in a gas bottle. Not more than three minutes shall pass before the yellow

LED starts to flash. If the yellow LED does not start to flash the zero gas is not good enough or the

sensor is not stable enough. Wait ten minutes before another attempt to calibrate the sensor.

If the sensor does not enter phase 1 even if the conditions are good push the push button on the PCB

until the red LED is lit to force a manual zero point calibration. Push the push button for at least ten

seconds.

concentration drops sharply. See figure 2. Do not remove the zero gas

2

Page 5

Dokument

UMA 148

Rev 1 Page

5 (6)

is reached

800

700

Normal

measurement

Phase 1 Check

calibration conditions

Phase 2 Acknowledgement period

600

Zero gas

Yellow LED

500

flashes

Automatic Zero

Point Calibration

400

ppm CO2

300

200

100

Calibration is executed The yellow

LED flashes four times The red LED

is lit The relay is closed

0

0 50 100 150 200 250 300 350

Time seconds

Figure 2. An example of Automatic Zero Point Cal ibra t ion

The Automatic Zero Point Calibration should be executed after installation and at least once a

year.

Trouble shooting

The yellow LED does not start to flash. The sensor does not enter calibration mode within three

minutes.

1. The absorber of the zero gas bag is not fresh. Remove the old absorber and refill the bottle with

fresh. The absorber is corrosive! Be careful and wear eye protection goggles.

2. The flow of the zero gas is too small or air is leaking into the sensor. The gas flow must be about

0,5 l/min.

3. Push the push button on the PCB for ten seconds (until the red LED is lit) to force manual zero

point calibration. Please check the gas before pushing the push button since the calibration is

executed even if the gas is not good enough.

Contact the dealer if the sensor still does not enter the calibration mode.

Page 6

Dokument

UMA 148

Rev 1 Page

6 (6)

This product is in accordance with the

EMC Directive 89/336/EEC and the

Low Voltage Directive 73/23/E EC inclu di ng

amendments by the CE-marking Directive

93/68/EEC

The product fulfils the following demands:

EN50081-1, EN55011(B)

EN50082-2, EN61000-4-2,-3,-4,-5, Level3

Loading...

Loading...