Page 1

Dokument

IMA 204

Rev 2 Page

1 (7)

Installation manual

CF3-D, CF3-D-Disp

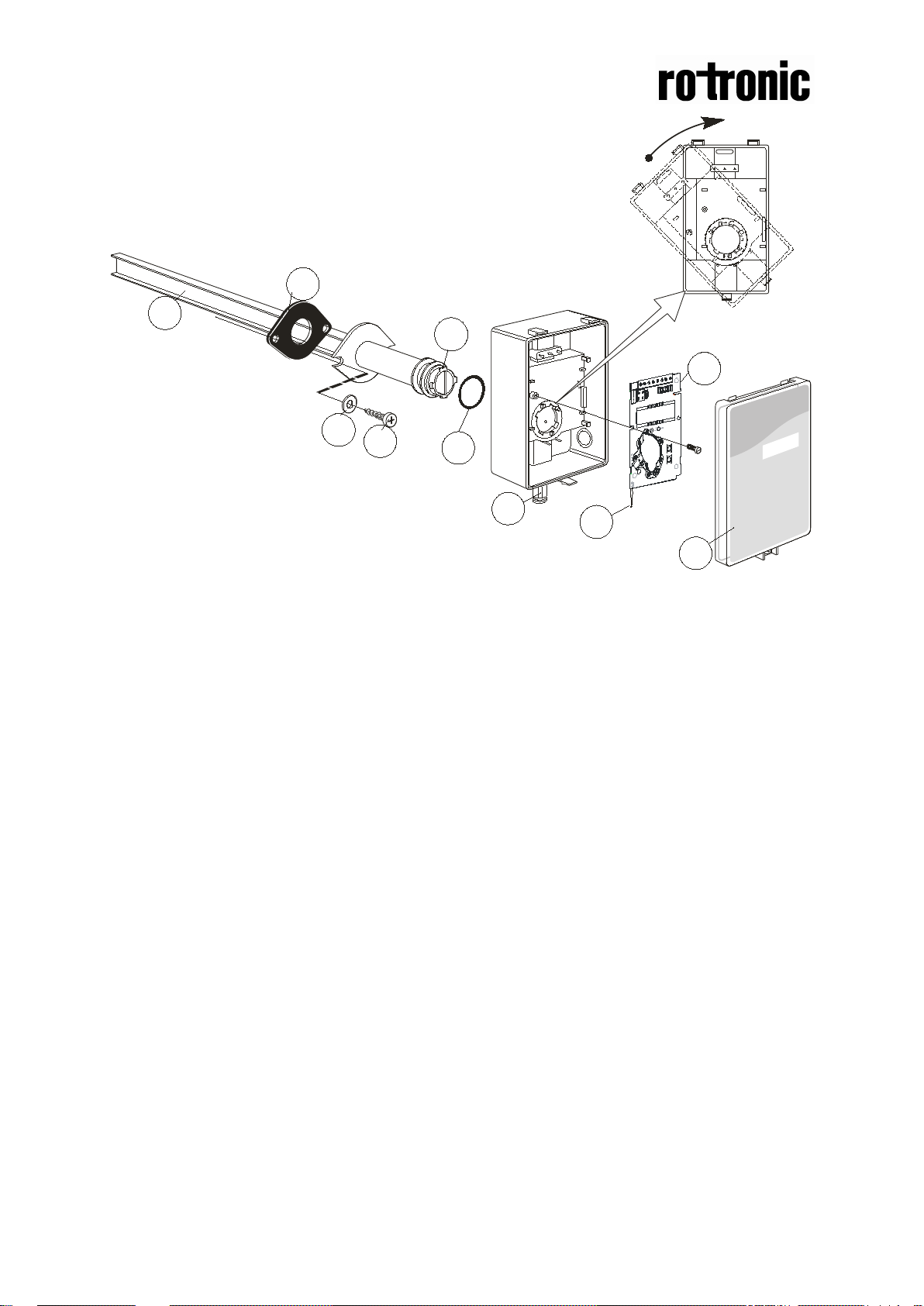

Figure 1 The sensor

General

The IAQ-sensor product CF3-D (for mounting in ventilation duc ts) is designed to

measure carbon dioxide (CO2). Option - TR is prepared for temperature

measurements by the resistive temperature probe mounted by the user. Option -Disp

displays the measured CO2 value in ppm (parts-per-million) on the LCD.

The units are designed for connecting to Direct Digital Control (DDC) with 0-10V or

2-10V signal inputs. The two parallel signal outputs Out(1) (0-10V) and Out(2) (2-10V

or 4-20 mA) give linear signal voltages or currents corresponding to the measuring

range.

The output OUT(2) also indicates the status by setting the output voltage to 1V or the

output current to 2 mA when the sensor self-diagnostics detects any error.

Page 2

Dokument

IMA 204

Rev 2 Page

2 (7)

1

2

1

2

3

4

5

6

7

9

8

10

Figure 2 Parts of the CF3-D for duct mounting

1 Sampling probe 6 O-ring 29,2x3,53 (Factor y mount ed in box )

2 Sealing gasket 7 PCB (Factory supplied mounted in box)

3 Largest locking nob 8 Snap-in lid

4 2 washers 9 PG9 cable entry bushing

5 2 screws

Page 3

Dokument

IMA 204

Rev 2 Page

3 (7)

10

Mounting of CF3-D on to the duc t.

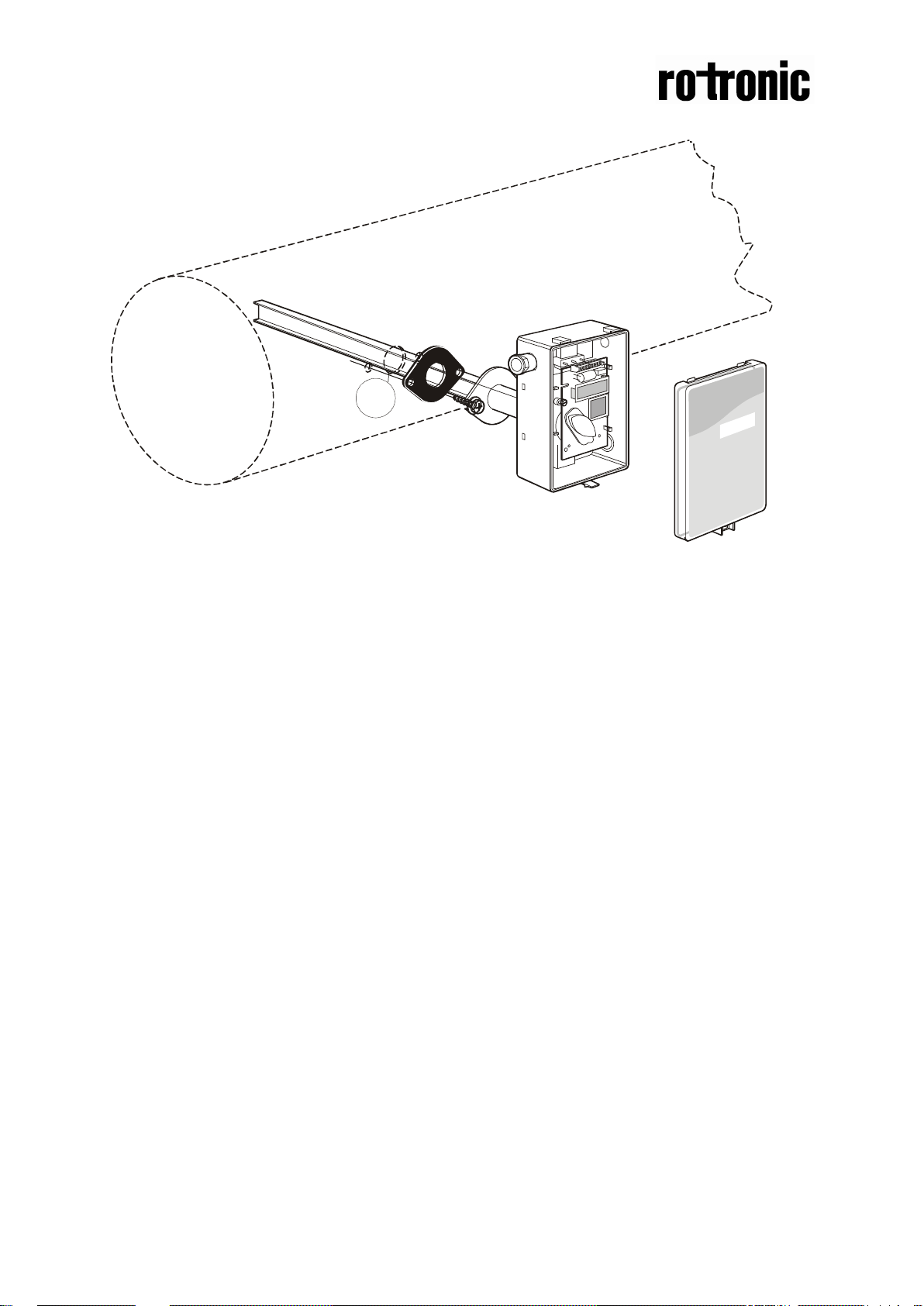

Figure 3 Mounting of the sensor to the ventilation duct

10 Hole with 25 mm diameter

11 Temperature sensor with 110 mm cable mounted in the sampling probe

Mounting Instruction

Since there might be a substantial pressure difference in duct mounting applications,

it is essential to avoid ambient air from suction into the duct mounting box. For

correct function it is indispensable that the sealing of the box cover, the cable entry

bushings, the cable feed through and the duct entrance are absolutely tight. The duct

entrance may need extra sealing paste in order to prevent leakage. The PCB must

be handed carefully and protected from electrostatic discharge.

1) Electrical cable ent ry: The box has a factory mounted cable entry bushing in

dimension PG9. Never feed more than one cable through each cable entry

bushing, or else gas might leak through!

2) Mounting the tube: Drill a hole (10) with 25 mm diameter (or 1 inch) for the

sampling probe and two holes with 4 mm diameter for the screws (5) into the air

duct and mount the tube (1) with the gasket (2). The sampling probe should be

mounted with the largest locking knob on top. The unit can be mounted with the

air coming from the left or right.

3) Attaching the sensor box is made to the sampling probe by a snap-in bayonet

fitting. Orient the box onto the sampling probe so that the box upside is on the

same side as the largest locking knob (3). When the probe is fitted into the

notches of the box, then turn the box clockwise until stop (see Figure 1). Position

1 indicates open where the box can be removed from the sampling probe. In

position 2 the box is locked to the probe.

Page 4

Dokument

IMA 204

Rev 2 Page

4 (7)

Terminal

Function

Electrical data

Remarks

Remarks

Power (+)

(-)

24 VAC/DC+ (+-

reference

Out(1)

Analogue

0-10 VDC

0-2000 ppm CO2

READY

~

~

Electrical connections

The power supply has to be connected to and . is considered as system

ground. The same ground reference has to be used for the CF3-D unit and for the

DDC/signal receiver.

PLEASE NOTE!

The same ground reference ha s to be used f or t he

unit and for the control system!

CF3-D

Out(2)

Power ground

output 1 (+)

Analogue

output 2 (+)

Table I. Connections of the main terminal of CF3-D

20%), 2W

24 VAC/DC-

2,0…10,0 VDC or

4,0 … 20,0 mA

0,9…1,6 VDC or

1.5 to 2,5 mA

0 VDC or 0mA

Standard

settings

System voltage

0-2000 ppm CO

2

Status = ERROR

Status = NOT

Settings of

this sensor

Page 5

Dokument

IMA 204

Rev 2 Page

5 (7)

Option display

+

~

+

~

+

~

Figure 4 PCB with jumper to configure OUT2 for current output 4-20mA or voltage output 2-10VDC

Figure 5 Enlarged picture of the PCB with the jumper set to current output (left position)

Figure 6 Enlarged picture of the PCB with the jumper set to voltage output (right position)

Self-diagnostics

The system contains a complete self-diagnostic procedure that is executed

automatically when the sensor is in operation. Sensors with display show a wrench if

an error is found. The wrench is shown during the first seconds after power up and if

the measuring range is exceeded. The output Out(2) indicates the same information

by setting the output voltage to 1V or 2 mA.

Page 6

Dokument

IMA 204

Rev 2 Page

6 (7)

Maintenance

The CF3-D is basically maintenance free in normal environments thanks to the built-

in self-correcting ABC algorithm.

PLEASE NOTE!

The sensor accuracy is defined at continuous operation (at least 3 weeks after

installation)

PLEASE NOTE! Electronic products should be disposed of via a suitable

recycling centre.

Page 7

Dokument

IMA 204

Rev 2 Page

7 (7)

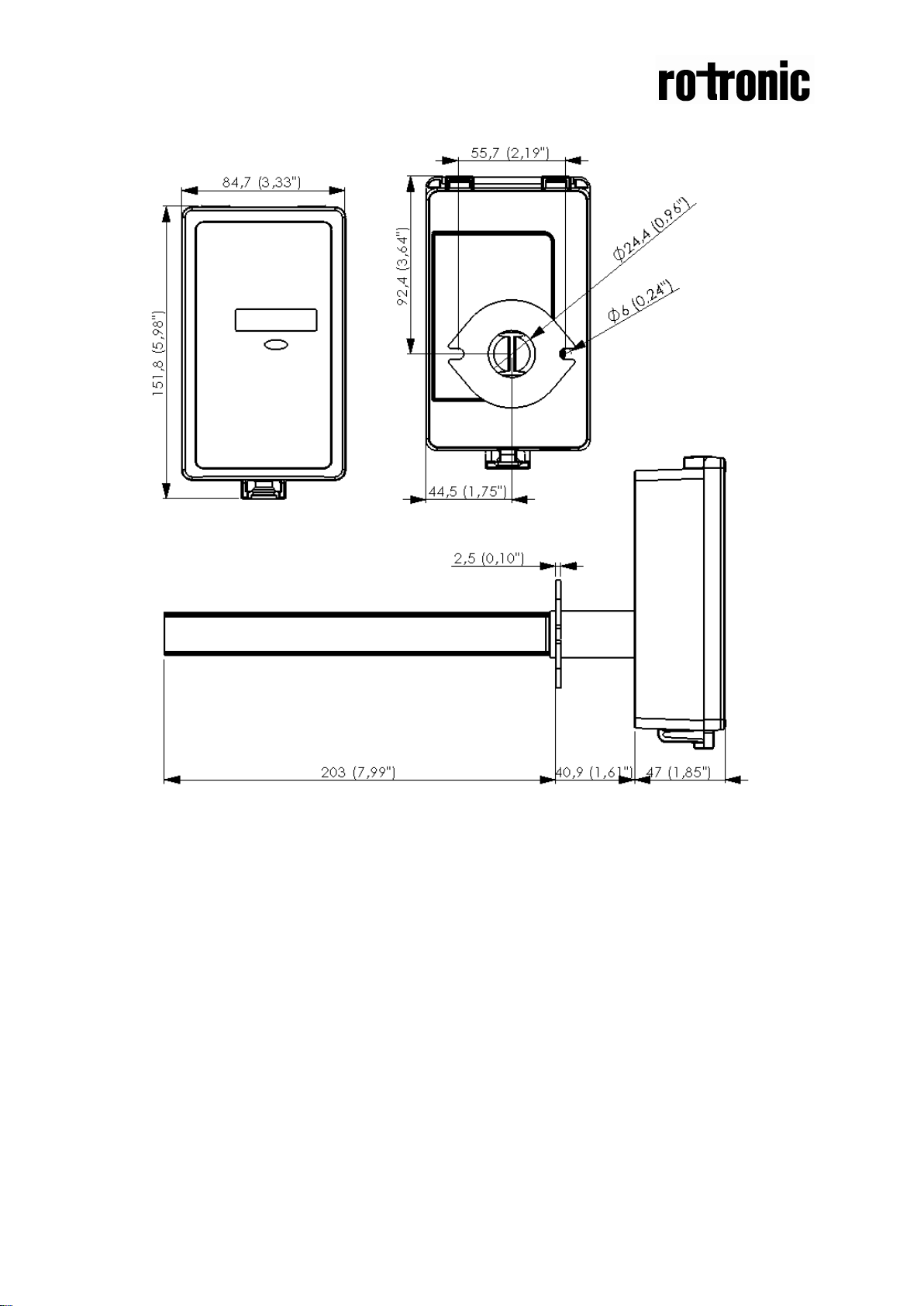

Dimensions

Figure 7 The dimensions of the sensor in mm and (inches)

Loading...

Loading...