Page 1

E-M-AwTherm-V1.1

Rotronic AG

Bassersdorf, Switzerland

Document Type

Document code Unit

AwTherm: Water Activity at Controlled Temperature

Document title

Instruction Manual Version 1.1

© 2009-2010; Rotronic AG E-M-AwTherm v1.1

Instruction Manual

Page 2

E-M-AwTherm-V1.1

Rotronic AG

Bassersdorf, Switzerland

Advisory Notice

Document Type

Document code Unit

AwTherm: Important notice before first use

Document title

Contents of the Standard Supply Package:

• AwTherm stabilised temperature water activity meter with either PS-14 or PS-40 sample

cup holder

• HW4-P-Quick-V3 software code sticker

• MicroUSB cable for connection to HW4

• MicroUSB memory stick including HW4 and User Manual

• Power cables for UK or US/EU/CH

© 2009-2010; Rotronic AG E-M-AwTherm v1.1

Page 3

E-M-AwTherm-V1.1

Rotronic AG

Bassersdorf, Switzerland

Table of Contents

Document Type

Document code Unit

AwTherm: Table of Contents

Document title

1 Scope of Document ................................................................................................................ 1

1.1 Introducing the AwTherm ...................................................................................................... 1

1.2 Measuring Technology ........................................................................................................... 1

1.3 Calibration .............................................................................................................................. 1

2 Setting up the AwTherm ........................................................................................................ 2

2.1 Physical Location .................................................................................................................... 2

2.2 Electrical Supply ..................................................................................................................... 2

2.3 AwTherm Assembly ............................................................................................................... 4

2.4 Sample cup size ...................................................................................................................... 5

3 AwTherm Operation .............................................................................................................. 6

3.1 Switching On .......................................................................................................................... 6

3.2 AwTherm Interface ................................................................................................................ 7

3.2.1 Basic Navigation ........................................................................................................ 8

3.2.2 Main Menu ................................................................................................................ 9

3.2.3 AwTherm Settings ................................................................................................... 10

3.2.4 Setting the AwTherm Set Point Temperature ......................................................... 13

3.3 Making Measurements ........................................................................................................ 14

3.3.1 Starting a measurement run ................................................................................... 16

3.3.2 AwE Mode ............................................................................................................... 17

3.3.3 AwQ Mode .............................................................................................................. 18

3.4 Switching off the AwTherm ................................................................................................. 19

3.5 Preparing the Unit for Transit or Storage ............................................................................ 20

4 Sample preparation ............................................................................................................. 21

4.1 Protection from environment .............................................................................................. 21

4.2 Sample size and temperature equilibration time ................................................................ 21

4.3 Best Practices ....................................................................................................................... 21

4.3.1 Precondition samples to measurement temperature ............................................ 21

4.3.2 Avoid condensation................................................................................................. 21

4.3.3 Define procedures ................................................................................................... 22

5 PC Software ......................................................................................................................... 22

5.1 HW4 ..................................................................................................................................... 22

5.2 HW4 Support ........................................................................................................................ 22

6 Servicing and Maintenance .................................................................................................. 23

6.1 AwTherm Calibration ........................................................................................................... 23

6.1.1 Remove measuring head for calibration ................................................................. 23

6.1.2 Calibrate in Hygrogen2 ............................................................................................ 26

6.2 AwTherm Cleaning ............................................................................................................... 26

6.2.1 External surfaces ..................................................................................................... 26

6.2.2 Filter ........................................................................................................................ 26

6.2.3 Chamber .................................................................................................................. 27

6.3 Annual Servicing of AwTherm .............................................................................................. 28

6.4 Firmware Updates ................................................................................................................ 29

A1: AwTherm / Screen Messages ................................................................................................. 31

A2: AwTherm Specifications ........................................................................................................ 32

A3: AwTherm Order Codes .......................................................................................................... 33

© 2012; Rotronic AG E-M-AwTherm v1.1

Page 4

E-M-AwTherm-V1.1

Rotronic AG

Bassersdorf, Switzerland

Table of Contents

Document Type

Document code Unit

AwTherm: Table of Contents

Document title

A4: AwTherm Environmental Conditions ..................................................................................... 33

A5: Electrical Specifications ......................................................................................................... 33

A6: Battery disposal and replacement ......................................................................................... 34

B1: AwTherm Warranty Statement .............................................................................................. 35

B2: Manufacturer & Service Centre Contact Information .............................................................. 36

© 2012; Rotronic AG E-M-AwTherm v1.1

Page 5

E-M-AwTherm-V1.1

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual for Software

Version 1.1

Document Type

Document code Unit

AwTherm: Water Activity at Controlled Temperature

Document title

Page 1

1 Scope of Document

This instruction manual refers to AwTherm running software version Aw-v1.00. To determine the

software version your instrument is running please refer to the Device Info screen as shown in

Section 3.2.1. Updates are available on www.awtherm.com

. This manual refers to the operation,

care and maintenance of the instrument itself, and best practices when making measurements.

For theory, background and further information on water activity, please refer to

www.awtherm.com.

1.1 Introducing the AwTherm

AwTherm is a temperature controlled water activity station – used for determining the water

activity of a sample, maintained at a known temperature. Water activity, which is used as a

measure of product consistency, is a parameter that is strongly dependent on temperature, and so

for consistent, repeatable measurements, it is vital to maintain known and stable thermal

conditions.

AwTherm is based on the same technology as the Rotronic HygroGen2 temperature and humidity

calibration suite of instruments which manipulate forced air to create highly stable thermal

conditions with minimal gradients within the measurement environment.

1.2 Measuring Technology

AwTherm uses a Rotronic HygroClip2 series probe to control and measure conditions.

1.3 Calibration

Calibration is an essential part of any reliable measurement process. AwTherm has a removable

measuring head which can be removed entirely (see Section 6.1.1) for calibration of both Aw and

Temperature parameters against references traceable to National Standards, using for example a

HygroGen2 temperature and humidity calibration system. The removed head is attached to the

HygroGen2 or a PC running Rotronic HW4 software (see section 5) using a special cable (not

supplied). Alternatively, the Aw parameter only can be calibrated in situ using Rotronic Calibration

Salts and adjusted using HW4 running on a PC connected to the AwTherm via its micro USB port.

© 2012; Rotronic AG E-M-AwTherm v1.1

Page 6

E-M-AwTherm-V1.1

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual for Software

Version 1.1

Document Type

Document code Unit

AwTherm: Water Activity at Controlled Temperature

Document title

Page 2

2 Setting up the AwTherm

2.1 Physical Location

To ensure correct operation please ensure that:

1. The unit is level and stable;

2. There is at least 15 mm clearance underneath and at least 100 mm at the back of the unit

to enable adequate air flow;

2.2 Electrical Supply

Power Isolation

The unit is supplied with a mains cord set. The unit should be disconnected from the electrical

supply before the unit is moved, cleaned or has water added or removed.

Earthing

This unit must be earthed. Provision for the safety earth is made through the electrical mains

connection (Figure 2, item 5) to which all parts of the unit requiring earthing are internally

connected. An earthed electrical supply is required.

Earth Leakage Current

Due to RF filtering there is an earth leakage current, within the limits specified in EN 610101:2001. This may affect mains power circuits protected by Residual Current Device (RCD) or

Ground Fault Detector (GFD) type circuit breakers (particularly if used in multiples or with other

equipment with an earth leakage current on the same supply circuit).

Over Current Protection

To protect the internal circuitry against excess currents, the mains supply to the unit must be

connected with the mains cord set provided with the unit and to an appropriate mains supply.

Voltage Rating

The unit is designed to work within the limits of a 110-230 VAC 50-60 Hz mains supply with voltage

fluctuations up to ± 10% of the nominal voltage. The unit is rated impulse withstand (over voltage)

category II of IEC 60364-4-443. Where occasional voltage transients over 2.5 kV are expected or

measured, it may be necessary that the power installation to the unit includes a transient limiting

device.

© 2012; Rotronic AG E-M-AwTherm v1.1

Page 7

E-M-AwTherm-V1.1

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual for Software

Version 1.1

Document Type

Document code Unit

AwTherm: Water Activity at Controlled Temperature

Document title

Page 3

Mains Filtration

If there is risk of power spikes or breaks, it is recommended that an Uninterruptable Power Supply

(UPS) is used to provide continued power and mains filtration. This should be rated according to

the AwTherm power specifications (see Appendix A5: Electrical Specifications) and the time

required to run/shutdown during power outage.

Conductive Pollution

The unit is rated Pollution Degree 2 and must not be operated in environments where conductive

pollutants (for example carbon) may enter the unit (this includes excessive moisture ingress).

© 2012; Rotronic AG E-M-AwTherm v1.1

Page 8

E-M-AwTherm-V1.1

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual for Software

Version 1.1

Document Type

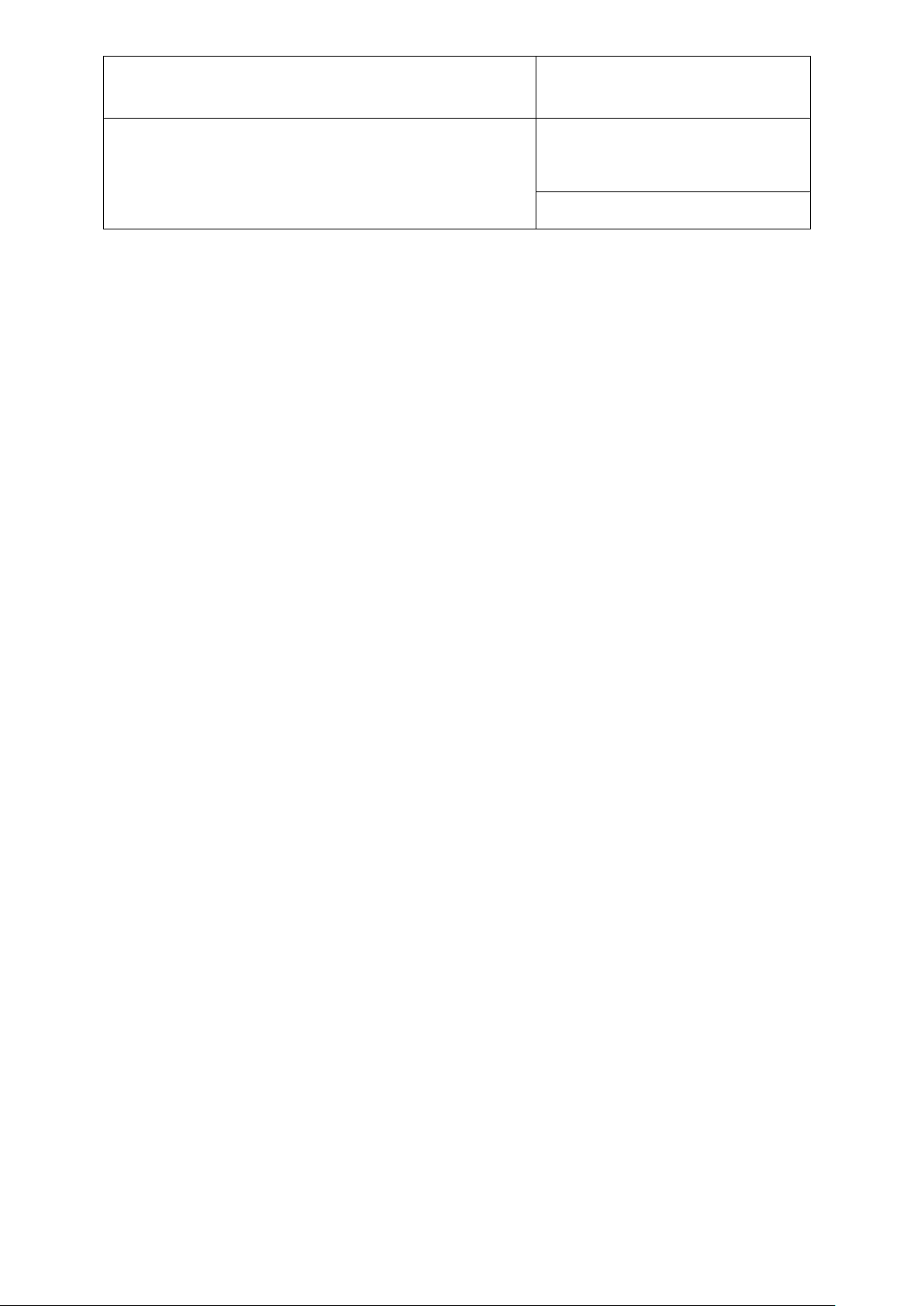

1) Lid

14) Screen

Document code Unit

AwTherm: Water Activity at Controlled Temperature

Document title

2.3 AwTherm Assembly

Page 4

Figure 2-1 - AwTherm Assembly (with lid open, front and rear view)

2) Removable measuring head

3) Sensor

4) Rubber seal

5) Electrical mains connection

6) Heat pump

7) Air flow sleeve

8) Sample cup

9) PSU fan outlet Heat pump fan outlet

Figure 2-2 Sample Chamber

10) Heat pump fan outlet

11) Micro USB port

12) Sample cup holder (PS14 or PS40)

13) Touch buttons

© 2012; Rotronic AG E-M-AwTherm v1.1

Page 9

E-M-AwTherm-V1.1

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual for Software

Version 1.1

Document Type

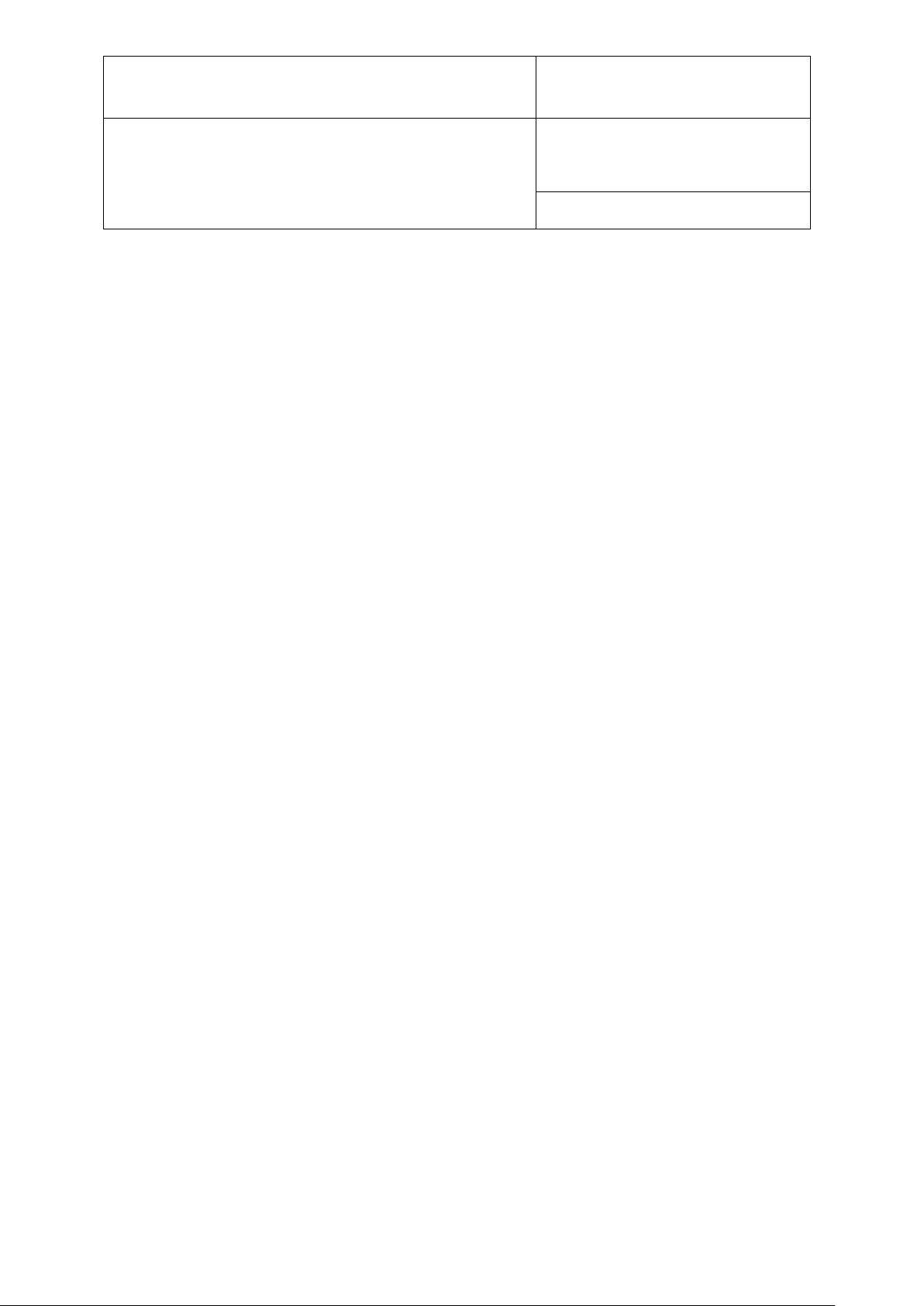

Figure 2-3 AwTherm Assembly (lid closed)

Figure 2-4 Removable filter (heat pump fan)

Figure 2-5 AwTherm Touch Interface

Document code Unit

AwTherm: Water Activity at Controlled Temperature

Document title

Page 5

15) Touch Button (up)

16) Touch button (down)

17) Touch button (ENTER)

18) Removable heat pump fan filter

2.4 Sample cup size

AwTherm is available in either PS14 (14mm depth) or PS40 (40mm depth) sample cup holder sizes.

Alternative sample cup holders are available as accessories (see Section A3: AwTherm Order

Codes).

Note that sample equilibrium time is dependent on the sample space, and so the selection of

sample cup size should be the smaller PS14 size where possible. For example powders and liquids

would merit selecting the smaller PS14 size; samples that are impractical for this size, e.g. large

seeds and pet foods, would merit the larger PS40 sample cup.

© 2012; Rotronic AG E-M-AwTherm v1.1

Page 10

E-M-AwTherm-V1.1

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual for Software

Version 1.1

Document Type

Document code Unit

AwTherm: Water Activity at Controlled Temperature

Document title

Page 6

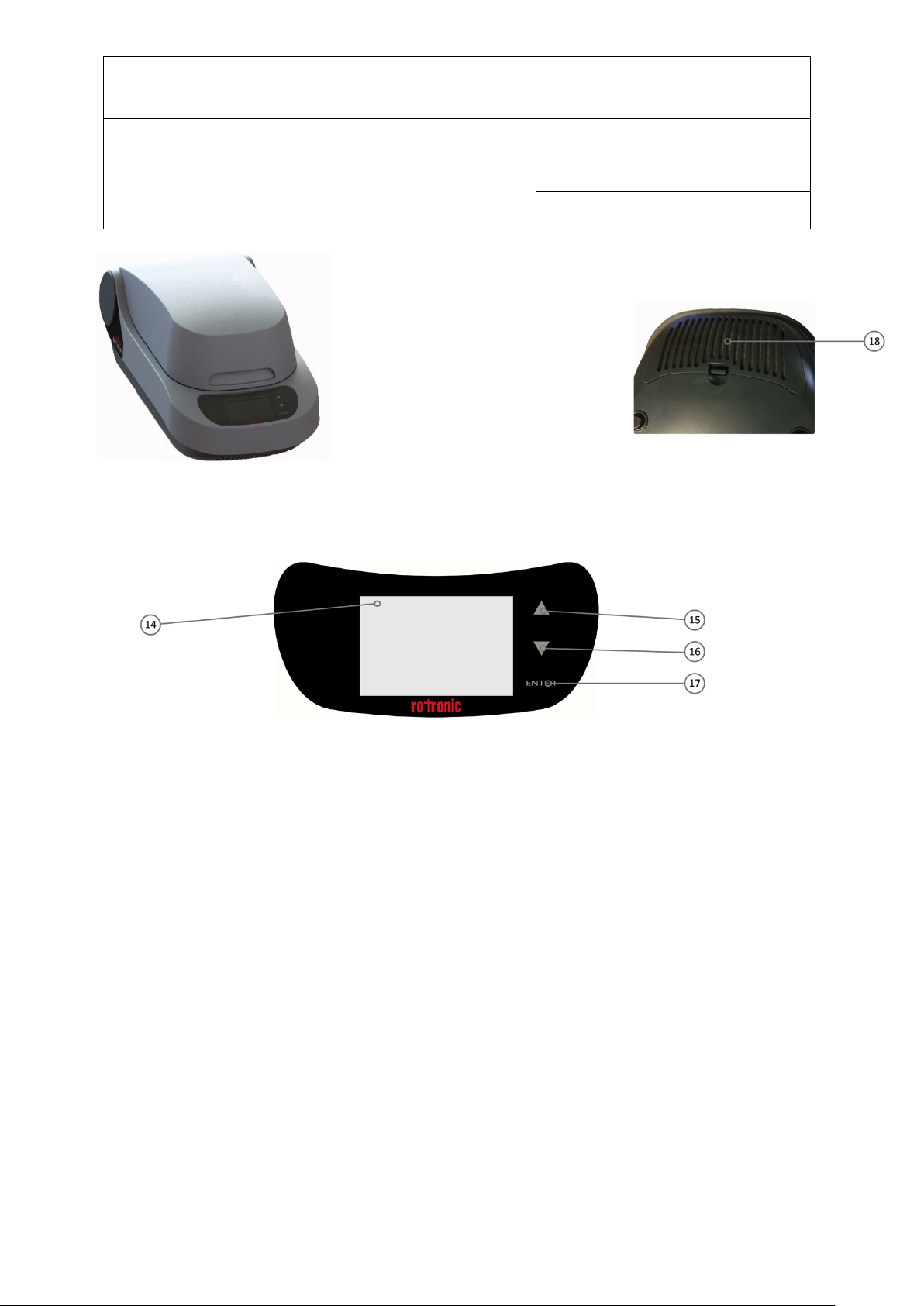

3 AwTherm Operation

3.1 Switching On

1. Ensure the electrical mains supply is correctly plugged in and switched on.

2. Switch the unit on by pressing the ENTER button once.

3. The fans within the unit will switch on giving an immediate audible indication the unit is

powered.

4. The loading screen will display (Figure 3-1)

5. The controller will power up and display the Top Level screen (as shown in Figure 3-2).

Figure 3-1 Boot screen

On power up:

• The temperature set-point defaults to the last set value.

• The temperature control defaults to automatic mode (controlling the temperature).

© 2012; Rotronic AG E-M-AwTherm v1.1

Page 11

E-M-AwTherm-V1.1

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual for Software

Version 1.1

Document Type

Document code Unit

AwTherm: Water Activity at Controlled Temperature

Document title

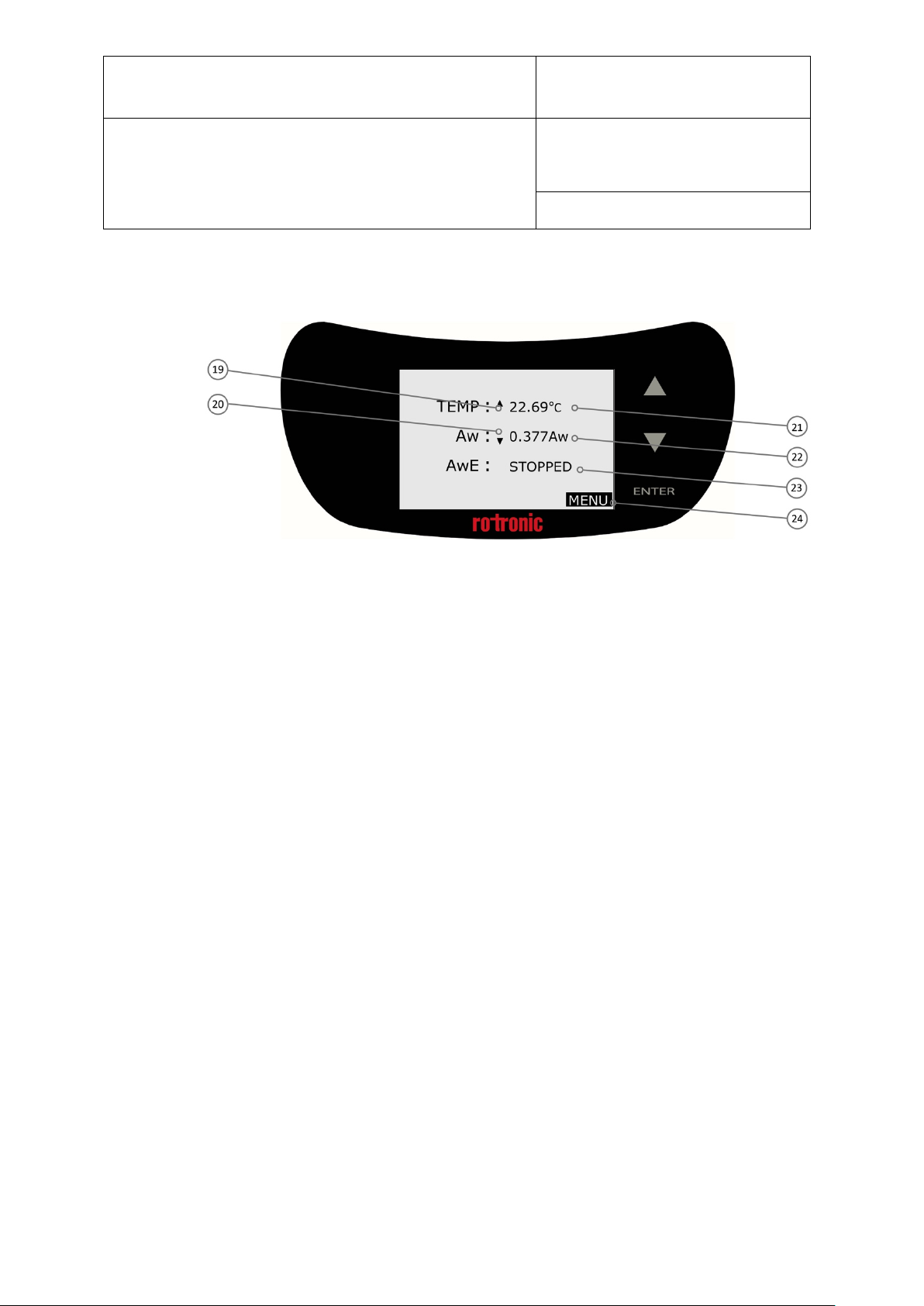

3.2 AwTherm Interface

Figure 3-2 AwTherm Top Level Screen

19) Temperature trend indication

20) Aw trend indication

21) Temperature field

22) Live Aw reading

23) Status field

24) MENU

Page 7

© 2012; Rotronic AG E-M-AwTherm v1.1

Page 12

E-M-AwTherm-V1.1

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual for Software

Version 1.1

Document Type

Document code Unit

AwTherm: Water Activity at Controlled Temperature

Document title

Page 8

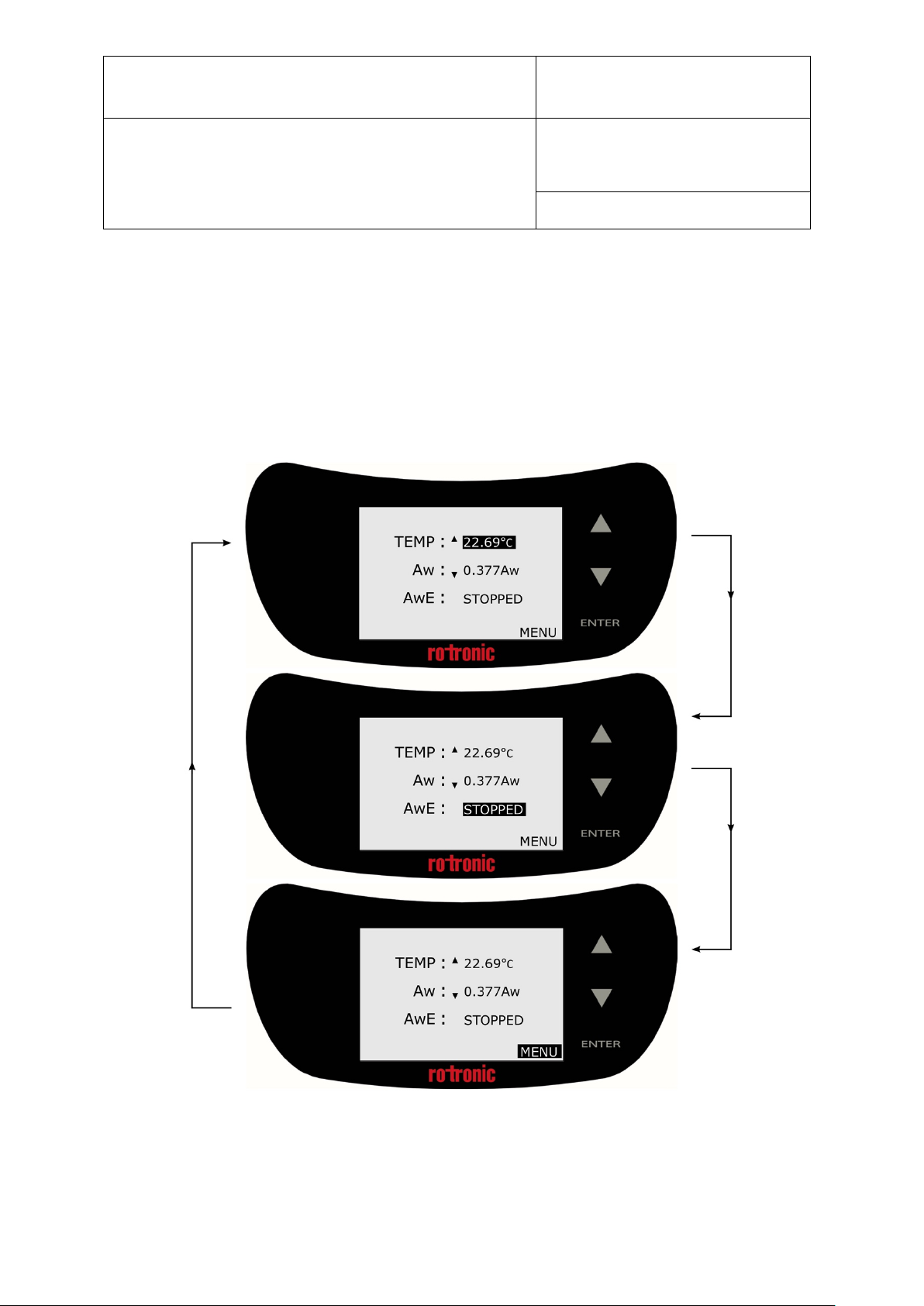

3.2.1 Basic Navigation

The AwTherm interface consists of a Top Level Screen with 3 fields which can be manipulated: (set

point) temperature, status, and device settings (Menu). Pressing the up or down arrow scrolls

through each of these, highlighting each one in turn. To select one, press the ENTER button. The

field will flash, and the functionality activated.

Figure 3-3 Basic Function Navigation

© 2012; Rotronic AG E-M-AwTherm v1.1

Page 13

E-M-AwTherm-V1.1

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual for Software

Version 1.1

Document Type

Document code Unit

AwTherm: Water Activity at Controlled Temperature

Document title

Page 9

3.2.2 Main Menu

There are a number of AwTherm system and program settings that can be configured. To access

the settings, select MENU and press the ENTER button.

Figure 3-4 Access Device Settings Menu

NB For all menus and sub-menus, to return to the previous screen, scroll down to the RETURN

field and press the ENTER button.

© 2012; Rotronic AG E-M-AwTherm v1.1

Page 14

E-M-AwTherm-V1.1

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual for Software

Version 1.1

Document Type

Document code Unit

AwTherm: Water Activity at Controlled Temperature

Document title

Page 10

Any adjustable parameter can be selected using the UP/DOWN and ENTER touch buttons in the

same manner as described for basic menu navigation. The parameter can be adjusted using the

UP/DOWN buttons and set by pressing the ENTER button.

Please note, by pressing and holding the up or down arrow keys, the speed of any numeric

incrementation will increase (autoscroll).

3.2.3 AwTherm Settings

i) Device Info displays the serial numbers of the unit itself, the AirChip Sensor and the firmware

version that the AwTherm is running.

Figure 3-5 Device Info

ii) Device Settings; Enable or disable temperature control (on by default), disable the Trend

Indication for temperature (19) and Aw (20) as shown in Figure 6, and configure the Aw measuring

mode: AwE or Aw-Quick (see section , below). Touch buttons can be set to make an audible sound

when activated, contrast adjusted (default optimal setting is 35%), and touchpad sensitivity

adjusted – from a value from 0-5. Please note, if touch pad has poor responsivity, try each

individual setting in turn until best results achieved.

Figure 3-6 Device Settings

© 2012; Rotronic AG E-M-AwTherm v1.1

Page 15

E-M-AwTherm-V1.1

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual for Software

Version 1.1

Document Type

Document code Unit

AwTherm: Water Activity at Controlled Temperature

Document title

Page 11

iii) Time/Date Settings; Date and time can be set and displayed on the AwTherm (off by default).

Time/date is only displayed for convenience and is not used a part of data logging and therefore is

not crucial to the operation of the instrument. Data logging is performed using Rotronic HW4

software running on an external PC (see Section 5.1).

Please note the date format [DD/MM/YYYY] is fixed and cannot be changed.

Figure 3-7 Time/date Settings

iv) AwE Settings; the AwE Tolerance, Temperature tolerance, and process complete audible beep

volume can be configured here. Further details regarding AwE measurement mode are found in

Section

3.3.2.

Figure 3-8 AwE Settings

© 2012; Rotronic AG E-M-AwTherm v1.1

Page 16

E-M-AwTherm-V1.1

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual for Software

Version 1.1

Document Type

Document code Unit

AwTherm: Water Activity at Controlled Temperature

Document title

Page 12

v) AwQ Settings; the Aw-Quick dwell time and temperature tolerance, and process complete

audible beep volume can be configured here. Further details regarding AwQ measurement mode

are found in Section

3.3.3.

Figure 3-9 AwQ Settings

vi) Service; the AwTherm firmware can be updated via this menu using a Micro USB drive inserted

into the Micro USB port (11) on the rear of the AwTherm.

Select the Update Firmware field and change the NO to YES using the up or down arrow keys and

press ENTER. Further details about updating the firmware are found in Section 6.4. There is also an

indication of the internal CMOS battery condition.

© 2012; Rotronic AG E-M-AwTherm v1.1

Figure 3-10 Service

Page 17

E-M-AwTherm-V1.1

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual for Software

Version 1.1

Document Type

Document code Unit

AwTherm: Water Activity at Controlled Temperature

Document title

Page 13

3.2.4 Setting the AwTherm Set Point Temperature

Figure 3-11 AwTherm Top Level Screen

With the Temperature Control parameter turned on (Section 3.2.3), and the lid (1) closed, the

AwTherm will control the temperature of the sample chamber environment (12). The heat pump

(6) controls the temperature of the air which is circulated through the airflow sleeve (7) around

the outside the walls of the sample chamber.

To set the temperature, from the Top Level screen (Figure 3-11), use the up and down arrows to

select the Temperature parameter. Press ENTER; the temperature parameter will flash (Figure 3-

12) and the label will change to SP (set point).

Use the UP/DOWN touch buttons to adjust the value to the desired temperature and press ENTER

to accept it.

© 2012; Rotronic AG E-M-AwTherm v1.1

Figure 3-12 Select Temperature parameter

Page 18

E-M-AwTherm-V1.1

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual for Software

Version 1.1

Document Type

Document code Unit

AwTherm: Water Activity at Controlled Temperature

Document title

Page 14

Figure 3-13 Define new Set Point Temperature

AwTherm will now control the temperature of the chamber to the new temperature. The time it

takes for the chamber to reach the temperature will depend on the ambient conditions, and the

initial and set point temperatures. Depending on the magnitude of the temperature change

required, the instrument will slightly overshoot, before coming back and stabilising. The Trend

Indicator (19) will show whether the unit is heating or cooling. When stable (to within the defined

AwE/AwQ temperature tolerance – see Section 3.3) the Trend Indicator will display up and down

indicators simultaneously.

Note that the chamber will reach a stable set point temperature before the sample, depending on

the initial temperature of the sample. See Sample Preparation: best practices and operational

considerations (Section 4.3) below for further details and advice.

3.3 Making Measurements

AwTherm features two modes for measuring water activity.

● AwE mode:

In this mode AwTherm monitors the stability of both temperature and humidity. The

measurement is automatically ended as soon as both humidity and temperature reach

equilibrium. The natural (or static) equilibration of most products typically requires from 15 to 60

minutes and can take as long as a couple of hours.

© 2012; Rotronic AG E-M-AwTherm v1.1

Page 19

E-M-AwTherm-V1.1

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual for Software

Version 1.1

Document Type

Document code Unit

AwTherm: Water Activity at Controlled Temperature

Document title

Page 15

● AwQuick mode:

In the AwQuick mode, AwTherm uses an algorithm to project the full equilibrium value (water

activity) of the measured product. The measurement is automatically ended and typically requires

typically about 5 minutes. AwTherm performs the following tasks:

1) The value of the humidity signal is constantly monitored

2) The stability of the temperature signal is constantly monitored

3) After an initial period of time (dwell time), AwTherm uses the humidity data to project the end

value of the equilibration process (water activity). The measurement ends automatically as soon

as the projected Aw value is stable.

With the dwell time set to 4 minutes, measurements typically require about 5 minutes. When

temperature conditions are stable (both at the product and probe), the measurement obtained

with the AwQuick mode is generally within ± 0.005 aw of the measurement that would be

obtained by waiting for full equilibration (AwE mode).

Aw mode can be selected in Device Settings as described above (Section 3.2.3). Load your sample

into the instrument, following the guidelines as outlined in Section 4.

© 2012; Rotronic AG E-M-AwTherm v1.1

Page 20

E-M-AwTherm-V1.1

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual for Software

Version 1.1

Document Type

Document code Unit

AwTherm: Water Activity at Controlled Temperature

Document title

Page 16

3.3.1 Starting a measurement run

To start a measurement run, at the Top Level screen, select the status field and press ENTER.

Figure 3-14 Select status field

Then use the UP/DOWN touch buttons to and select START, and then press ENTER.

The measurement run will now begin.

At the end of the run, the AwTherm will sound an audible beep (if so configured, see Section 3.2.3)

and hold the values on the screen, displaying FINISHED in the status field.

The following section describes the operation of each mode, AwE and AwQ as a flowchart.

© 2012; Rotronic AG E-M-AwTherm v1.1

Figure 3-15 Select START and press ENTER

Page 21

E-M-AwTherm-V1.1

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual for Software

Version 1.1

Document Type

Document code Unit

AwTherm: Water Activity at Controlled Temperature

Document title

3.3.2 AwE Mode

Page 17

Figure 3-16 AwE process flowchart

© 2012; Rotronic AG E-M-AwTherm v1.1

Page 22

E-M-AwTherm-V1.1

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual for Software

Version 1.1

Document Type

Document code Unit

AwTherm: Water Activity at Controlled Temperature

Document title

3.3.3 AwQ Mode

Page 18

Figure 3-17 AwQ process flowchart

© 2012; Rotronic AG E-M-AwTherm v1.1

Page 23

E-M-AwTherm-V1.1

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual for Software

Version 1.1

Document Type

Document code Unit

AwTherm: Water Activity at Controlled Temperature

Document title

Page 19

3.4 Switching off the AwTherm

To turn off AwTherm, press and hold the ENTER touch button until the Shutting Down screen

appears and the progress bar has completed.

To cancel the shutdown process at any time, simply stop pressing the ENTER touch button.

Figure 3-18 Shutting Down screen

DO NOT switch off at the wall before the AwTherm has shutdown.

DO NOT switch off at the back of the AwTherm before it has shutdown.

© 2012; Rotronic AG E-M-AwTherm v1.1

Page 24

E-M-AwTherm-V1.1

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual for Software

Version 1.1

Document Type

Document code Unit

AwTherm: Water Activity at Controlled Temperature

Document title

3.5 Preparing the Unit for Transit or Storage

If the AwTherm needs to be shipped, always use the original double-layer cardboard and

foam packaging.

Page 20

© 2012; Rotronic AG E-M-AwTherm v1.1

Page 25

E-M-AwTherm-V1.1

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual for Software

Version 1.1

Document Type

Document code Unit

AwTherm: Water Activity at Controlled Temperature

Document title

Page 21

4 Sample preparation

4.1 Protection from environment

Fundamentally any sample will try to come into equilibrium with its environment, so it is vitally

important to keep samples as protected from the ambient environment as possible – to avoid its

water activity changing before loading into the instrument. This is best achieved by placing the

sample in a Rotronic PS14 or PS40 sample cup with a lid in place until the sample is ready to be

placed in the instrument and its lid closed.

This is particularly important if the sample is chilled as vapour may condense on the sample, and

render any measurement invalid.

4.2 Sample size and temperature equilibration time

Adequate time should be allowed for the sample to reach temperature in order to make a valid

measurement. The time taken depends on the size, weight, and specific heat capacity of the

sample. Difficulties in knowing the sample has reached the required temperature throughout are

mitigated by consistency in procedures and practices as described in the following sections.

4.3 Best Practices

4.3.1 Precondition samples to measurement temperature

If the samples being tested are part of a process, if at all possible, make measurements at the

temperature that the sample comes out of the process, and minimize the time taken to load the

sample into the AwTherm.

4.3.2 Avoid condensation

If your sample is chilled below ambient or you need to make measurements at low temperatures,

there is a risk of condensation forming. Condensation can form on chilled samples or on the inside

of the AwTherm when the lid is open. As a guide in normal laboratory conditions, condensation

can form on surfaces that are <15°C. It may be necessary to place the AwTherm in a cooler (drier)

environment to prevent this occurring

© 2012; Rotronic AG E-M-AwTherm v1.1

Page 26

E-M-AwTherm-V1.1

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual for Software

Version 1.1

Document Type

Document code Unit

AwTherm: Water Activity at Controlled Temperature

Document title

Page 22

4.3.3 Define procedures

Water activity is a qualitative measurement of product consistency, and so to record useful data, it

is vitally important to make measurements in a consistent way. Define procedures: dwell times,

tolerances, etc, and be consistent with their implementation.

5 PC Software

5.1 HW4

AwTherm is bundled with ROTRONIC HW4 logging software which can be loaded on any PC

running a Windows OS. Once installed simply connect the AwTherm to a PC via the MicroUSB port

with the supplied cable.

HW4 features include:

• Instrument configuration

• Data acquisition

• Measurement display and graphing

• Calibration and adjustment

For further details on the AwTherm operation from within HW4, please refer to the HW4

documentation http://www.rotronic.co.uk/productattachments/index/download?id=949

5.2 HW4 Support

Support for HW4 is available via email. Please contact support@rotronic.ch including your full

contact details, the AwTherm serial number and HW4 product key, and a description of your query

or problem. You will receive a response within a maximum of two working days.

© 2012; Rotronic AG E-M-AwTherm v1.1

Page 27

E-M-AwTherm-V1.1

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual for Software

Version 1.1

Document Type

Document code Unit

AwTherm: Water Activity at Controlled Temperature

Document title

Page 23

6 Servicing and Maintenance

6.1 AwTherm Calibration

A unique feature of the AwTherm is the ability to remove the entire head to calibrate both the Aw

and temperature sensors.

Alternatively, AwTherm can be calibrated in-situ for Aw using Rotronic calibration salts.

6.1.1 Remove measuring head for calibration

© 2012; Rotronic AG E-M-AwTherm v1.1

Page 28

E-M-AwTherm-V1.1

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual for Software

Version 1.1

Document Type

Document code Unit

AwTherm: Water Activity at Controlled Temperature

Document title

Page 24

© 2012; Rotronic AG E-M-AwTherm v1.1

Page 29

E-M-AwTherm-V1.1

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual for Software

Version 1.1

Document Type

Document code Unit

AwTherm: Water Activity at Controlled Temperature

Document title

Page 25

© 2012; Rotronic AG E-M-AwTherm v1.1

Page 30

E-M-AwTherm-V1.1

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual for Software

Version 1.1

Document Type

Document code Unit

AwTherm: Water Activity at Controlled Temperature

Document title

Page 26

6.1.2 Calibrate in Hygrogen2

To minimise AwTherm downtime, alternative measuring heads can be fitted in place of the

existing head while it is being calibrated. To order spare heads, see Appendix A3: AwTherm Order

Codes.

6.2 AwTherm Cleaning

Prior to cleaning, the unit should be disconnected from the electrical mains supply.

6.2.1 External surfaces

The external surfaces of the AwTherm may be cleaned with a lint-free cloth dampened with a mild

soap solution. Care must be taken not to allow fluids into any of the apertures on the unit.

The fan inlet filter can be cleaned using a vacuum cleaner to remove any particulates.

6.2.2 Filter

© 2012; Rotronic AG E-M-AwTherm v1.1

Page 31

E-M-AwTherm-V1.1

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual for Software

Version 1.1

Document Type

Document code Unit

AwTherm: Water Activity at Controlled Temperature

Document title

Page 27

6.2.3 Chamber

Periodically it is recommended that the internal surfaces of the AwTherm chamber. The bottom

half can be removed and placed in a dishwasher.

© 2012; Rotronic AG E-M-AwTherm v1.1

Page 32

E-M-AwTherm-V1.1

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual for Software

Version 1.1

Document Type

Document code Unit

AwTherm: Water Activity at Controlled Temperature

Document title

Page 28

6.3 Annual Servicing of AwTherm

The unit does not require routine user maintenance beyond that described in this Section.

Under no circumstance should the unit be opened by personnel unauthorised by the

manufacturer. Doing so will void the manufacturer’s warranty, and expose potentially

dangerous electrical hazards.

© 2012; Rotronic AG E-M-AwTherm v1.1

Page 33

E-M-AwTherm-V1.1

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual for Software

Version 1.1

Document Type

Document code Unit

AwTherm: Water Activity at Controlled Temperature

Document title

Page 29

6.4 Firmware Updates

To update the AwTherm firmware, select the Service menu, as described in Section 3.2.3 (vi), and

change the default ‘NO’ to ‘YES’ and press ENTER to continue.

The AwTherm will ask for a pen drive. Insert a micro USB stick loaded with the desired firmware in

its root directory. The firmware will be a file called “AW_image.hex”

Select ‘YES’ and press ENTER to continue. The AwTherm will restart.

© 2012; Rotronic AG E-M-AwTherm v1.1

Page 34

E-M-AwTherm-V1.1

Rotronic AG

Bassersdorf, Switzerland

Instruction Manual for Software

Version 1.1

Document Type

Document code Unit

AwTherm: Water Activity at Controlled Temperature

Document title

The AwTherm will verify the firmware image and re-flash its memory.

Page 30

The software will start as normal. You can then check the new software version in Device Info as

detailed in Section 3.2.3(i).

© 2012; Rotronic AG E-M-AwTherm v1.1

Page 35

A1: AwTherm / Screen Messages

Should the AwTherm fail to communicate with the sensor head, a Hardware Diagnostic page will

display.

Page 36

General

Device type

Temperature-stabilized water-activity measure

ment

Operating conditions

1..40 °C (34..107 °F)

Measurement range

0.005…1.000 aw

±0.1 °C (±0.18 °F)

Power supply

110..230 V / 50..60 Hz

Display

8-line LCD with touch operation

Sample sizes

Variable (14 mm / 40 mm)

Technical Information

Current Consumption

≤

2 A Temperature-control range

0..60 °C (32..140 °F)

Temperature stability

±0.01 °C/min (±0.018 °F/min)

Chamber-temperature gra

dient

<0.1 °C (<0.18 °F)

Firmware update

Via USB port

Functions

HW4-compatible

Yes (v 3.6.0 and higher)

aw-Quick function

Yes

Interface

Micro USB

ROTRONIC humidity standards (via HW4)

Trend indicator

Yes

Probes

Sensor

HYGROMER® IN-1

Maintenance / Calibration

Annual calibration (recommended)

Long-Term Stability

<0.01 aw/year

Temperature sensor

Pt100, DIN 1/3 Class B

Approval / Conformity

Standards

ISO 21807

IEC/ EN 61010-1:2010

IP protection

IP21

Housing / Mechanical parts

Housing material

PC / ABS

Housing dimensions

400 x 180 x 180 mm

AwT-PS40: Ø46 x 40 mm

Weight

4200 g

A2: AwTherm Specifications

Accuracy

Calibration / Adjustment

±0.005 aw

Aw & Temperature:

HG2-S (probe removed with AwT-CAL)

Aw:

CE / EMC

Sample container holder dimensions

EMC 2004/108/EC

AwT-PS14: Ø46 x 14 mm

Page 37

AW-Therm

AwTherm-PS14

AwTherm Body incl. Standard AwT-MHS and AwT-PS14

AwTherm-PS40

AwTherm Body incl. Standard AwT-MHS and AwT-PS40

AW-Therm SET

AwTherm-SET

AwTherm Body incl. Standard AwT-MHS and AwT-PS14 AND AwT-PS40

AWTherm Measuring Heads

AwT-MHS

AwTherm measurement head standard

AWTherm sample container holder

AwT-PS14

AwTherm sample holder for PS14 (ordered separately), depth 14mm

AwT-PS14

AwTherm sample holder for PS40 (ordered separately), depth 40mm

Sample container

PS-14

Pack of 100 sample containers for AwT-PS14

PS-40

Pack of 100 sample containers for AwT-PS40

A3: AwTherm Order Codes

A4: AwTherm Environmental Conditions

This standard applies to equipment designed to be safe at least under the following

conditions:

• For indoor use only

• Altitude up to 2000 m

• Ambient temperature 5°C to 40°C

• Maximum relative humidity 80 % for temperatures up to 31 °C decreasing

linearly to 50 % Relative Humidity at 40 °C

• Pollution degree 2

A5: Electrical Specifications

• Input voltage is from 90VAC to 264VAC; Auto Ranging

• Input Frequency range from 47Hz to 63Hz

• Input current is 3.5A at 100VAC or 1.5A at 240VAC

• Power inlet IEC socket

Page 38

A6: Battery disposal and replacement

Batteries must not be disposed of as ordinary refuse. Please use a local battery

recycler.

Replacement batteries are available from Rotronic. These are Lithium rechargeable

batteries and must only be replaced with the same type. The replacement battery

will be supplied with plastic tweezers; do not use a metal tool to remove the

battery as this will cause a short circuit. Be sure to insert the new battery using the

correct polarity as shown.

Use of a non-rechargeable battery, or incorrectly inserting the battery could lead to

explosion.

Page 39

B1: AwTherm Warranty Statement

ROTRONIC will grant a warranty for the AwTherm for a period of 24 months from the date of

delivery in respect of any evidenced faulty workmanship and materials. The warranty period is

extended by a further 24 months when the unit is serviced at a ROTRONIC approved service centre

24 months after the date of supply. Should the instrument be proven not to meet the published

specifications or to be contrary to contract upon inspection, the customer shall grant ROTRONIC

the opportunity hereunder of repairing the fault by returning the unit carriage paid to ROTRONIC.

Should the supply or delivery of any improvement or replacement not prove possible, the

customer may choose between having the purchase price reduced or in demanding the contract of

sale to be rescinded (conversion). Damage resulting from natural wear and tear, an act of God or

non compliance with the operating instructions shall be excluded from the warranty as well as

mechanical interference by the customer or by third parties with plant and equipment of

ROTRONIC without its written permission. No liability will be accepted for defects, damage or

injury caused due to installation not carried out in accordance with the manufacturer’s installation

instructions.

The instrument maintains a record of the usage and this may only be reset by an authorised

service centre; this will determine the warranty period granted.

Page 40

Manufacturer/UK Service

Switzerland Service Centre:

USA Service Centre:

Germany Service Centre :

France Service Centre:

China Service Centre:

B2: Manufacturer & Service Centre Contact Information

Centre :

Rotronic Instruments (UK) Ltd

Crompton Fields

Crompton Way

Crawley RH10 9EE

United Kingdom

Phone : +44(0)1293 571000

Fax : +44(0)1293 571008

www.rotronic.co.uk

instruments@rotronic.co.uk

Rotronic Messgeräte GmbH

Einsteinstrasse 17-23

76275 Ettlingen

Deutschland

info@rotronic.de

www.rotronic.de

Phone +49 7243 383 250

Fax +49 7243 383 260

Rotronic AG

Grindelstrasse 6

CH-8303

Bassersdorf

Switzerland

Phone +41 1 838 1144

Fax +41 1 837 0073

www.rotronic.ch

humidity@rotronic.ch

Rotronic s.a.r.l.

56, bd de Courcerin,

F-77183 Croissy Beaubourg

France

humidite@rotronic.fr

www.rotronic.fr

Phone +33 160 95 07 10

Fax +33 160 17 12 56

Rotronic Instrument Corp.

Suite 150

135 Engineers Road

Hauppauge, NY 11788,

USA

Phone +1 631 427 38 98

Fax +1 631 427 39 02

sales@rotronic-sa.com

www.rotronic-usa.com

Rotronic Shanghai

Representative Office

2B,Zao Fong Universe Building

No.1800 Zhong Shan West

Road,

200233 Shanghai

China

info@rotronic.cn

www.rotronic.cn

Phone +86 40 08162018

Fax +86 10 82254374

Loading...

Loading...