Page 1

MODEL RTO FILLED SYSTEM

TEMPERATURE RECORDERS,

RPO PRESSURE RECORDERS &

RECORDERS CONTROLLERS

(ELECTRICAL CONTROL)

Instruction Manual

Introduction 1

Specification 1

Description of Operation 1

Receipt of Recorder 1

Dimensions and Fixing 2

Installation 2

Mounting 2

Access to Recorder 2

Electrical Connections 2

Process Connections 3

Operation 4

Fitting a Chart 4

Inking System 4

Set Point Adjustment 4

Zero Adjustment 5

Start-up Check 5

Start-up Procedure 5

Calibration 6

Maintenance 8

Replacing a Filled System 8

Replacing a Pressure System 8

Fault Finding 9

Spares List 10

The chart drive and control system on this system may be operated from

a mains voltage supply.

The mains must be switched off before any mechanical adjustments

(other than of the set pointer) or carrying out any maintenance or fault

finding procedures.

When making electrical adjustments observe the warning notes in the

text.

Page 2

Accuracy +/- 1 % FSD.

Ambient -20°C to +50°C

Chart Drive Synchronous electric, battery or mechanical

spring wound. 24 hour or 7 day.

(Other rotations on request).

Inking System Disposable fibre tipped pens.

Single pen: red. Two pen: red and blue.

Three pen: red, blue and green

Case Glass filled polyester resin.

Protection rated to IP55.

Window Acrylic.

Power Supply 200 to 250 volts, 50 Hz (60Hz available);

100 to 110 volts, 50 Hz (60Hz available).

Instruments without electrical control require no

power supply provided that a clockwork drive is

fitted.

Battery operated chart drives require 1.5 volt 'C'

type cell.

Electrical Alarm and Control

Contact Rating 0.1A at 250v A.C. (non inductive)

(when fitted) 0.01A at 250v D.C. (non inductive)

Relay contact 10A at 250v 50Hz.

rating: (when fitted)5A at 415v 50Hz.

Contact

Adjustment Range2% to 100%

Weight

(approx.) Single pen: 6.5kg (14.25 Ib)

Two pen: 7 kg (15.5 Ib)

Three pen: 7.5 kg (16.75 Ib)

Portable single pen: 8.6 kg (19 Ib)

The above weight includes 3 metres (10 ft)

of capillary. For each additional 3 metres add

0.25 kg (0.5 Ib).

Mounting Suitable for surface or panel mounting.

(Pipe mounting and portable options available)

For instruments fitted with Temperature Systems

Measuring Element

Rototherm thermal bourdon tube temperature

compensated.

Capillary Microbore stainless steel tube with 3mm

diameter stainless steel cover (type C1) as

standard, other capillaries are available.

Bulb and Stem Stainless Steel BS970 316 S16.

Fittings Compression gland (adjustable).

stainless steel 8S970 316 (1/2" BSP is

standard). Other BSP NPT API etc. are

available on request.

(Suitable for pressures up to 3.5 Bar).

For Instruments Fitted with Pressure Systems

Measuring Element

Stainless Steel or Phosphor Bronze Bourdon

tube or pressure capsule as applicable.

Connection

Standard 3/8" BSP male with nut and tail pipe suitable for

6.35mm (0.25") outside diameter tube or 3/8"

inside diameter tube.

Portable 3/8" BSP male with nut and tail pipe suitable for

6.35mm (0.25") outside diameter tube or 3/8"

inside diameter tube.

Receiver type 1/4" BSP female.

input 3-15 p.s.i.

(0.2 - 1 Bar)

The RTO and RPO series of instruments are designed to measure,

record and control process variables such as temperature,

pressure and humidity. A maximum of three measuring systems

can be provided in each instrument; a fluid expansion/gas

expansion system is used for temperature recording, a wet and

dry bulb system for humidity and a bourdon or diaphragm

capsule for pressure measurement. The measured values are

continuously recorded on a calibrated circular chart which is

rotated at a constant speed by a mechanical or electrical clock.

Control of the process variable is provided electrically.

Temperature Recorder

As the temperature rises, the fluid in the thermometer bulb

expands and partially uncoils the Bourdon tube fitted inside the

instrument. This movement is transferred by a mechanical linkage to

the pen arm which records the temperature on a calibrated chart.

Humidity Recorder - Wet and Dry Bulb

The relative humidity can be obtained from the temperatures

measured by the wet and dry bulb thermometer using hygrometric or

psychrometric tables.

Pressure Recorder

On medium and high pressure ranges an increase in pressure

partially uncoils a Bourdon tube fitted inside the instrument. This

movement is transferred by mechanical linkage to the pen arm

which records the pressure on a calibrated chart.

A capsule stack is fitted for low pressure ranges and the expansion

of the system resulting from an increase in pressure is transferred

by a mechanical linkage to the pen arm.

For vacuum range a contraction of the capsule stack results from

an increase in vacuum and this movement is transferred by a

mechanical linkage to the pen arm.

The temperature recorder complete with a packet of charts, case

keys and pen packs is dispatched in a protective casing which

should be preferably replaced after inspection, as protection until the

instrument is ready for installation.

The spare pen pack(s) are inside the protective case. The case

keys are attached to the bottom right hand mounting stud.

When fitted the capillary tubing between the bulb and recorder

is coiled for despatch purposes. Immediately prior to installation,

this tubing must be uncoiled carefully in order to avoid twisting or

kinking

To assist with inspection, a label attached on the inside face of

the case door states the instrument serial number, chart number,

ranges of each pen and the rotation speed of the chart drive. If

the chart drive is electrical the supply voltage is stated.

SPECIFICATIONS

1

INTRODUCTION

Description of Operation

Receipt of Recorder

Page 3

Ideally the site chosen should be free from dust, corrosive

fumes, vibration and extremes of temperature.

The instrument is suitably compensated against normal

ambient temperature variations.

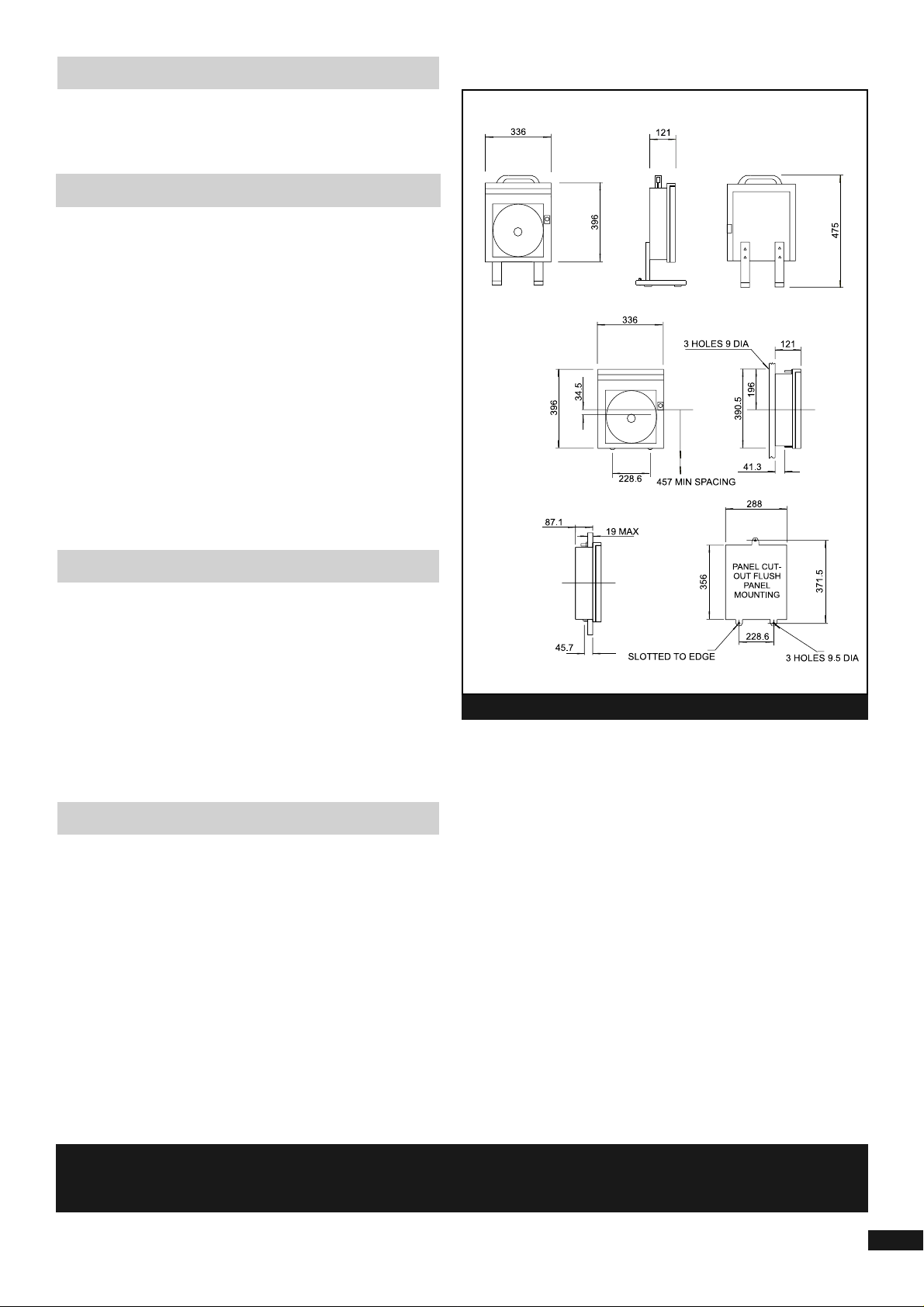

The recorder may be surface or flush panel mounted.

For surface mounting, remove the screws holding the three

brackets at the rear of the case, reverse and refit the brackets

with their ends projecting from the edges of the case.

The bracket with the keyhole slot must remain at the top of

the case.

Drill three holes in the mounting surface, of the size and at

the centres given in Fig. 1. Fit a screw (max. major diameter

6.35mm(0.25 inch)) in the top hole.

Locate the instrument on this screw and fit two smaller screws

through the remaining brackets.

For Flush Panel Mounting, make a panel cut-out to the

dimensions given in Fig 1. Drill the holes and slot to the cut-out

edge as shown. Remove the nuts and washers from the studs

projecting from behind the case flange, pass the recorder

through the cut-out and refit the washers and nuts to secure the

instrument.

To open the instrument door press the plunger of the door lock

and pull the door forward from the right. As the door is opened

the pen lifter raises the pen (or pens) away from the chart.

Remove the cotton thread that secures the pens to the pen lifter

for transit purposes.

To make electrical connections and to set contacts, remove the

chart plate by loosening the three retaining screws and carefully

lift out the chart plate via the finger hole (care is necessary to

avoid pen lifter interference with pens and control pointers).

Pull the bottom edge clear of the instrument and lower the chart

plate from behind.

Before making any electrical connections to the instrument

switch off the mains supply to be connected.

All electrical connections are made to terminal blocks in the

lower part of the case behind the chart plate.

Insert the leads through the cable glands in the underside of the

case and make connections shown on the terminal labels or the

wiring diagram supplied.

It is important to select the correct supply voltage connection.

The live line should be switched and fused with a 2 Amp fuse.

The mains supply should be earthed and connected at the

appropriate terminal within the recorder.

Alarm systems should have an independent power supply to

safeguard alarm operation in the event of mains failure.

ALARM SYSTEMS SHOULD HAVE AN INDEPENDANT POWER SUPPLY TO

SAFEGUARD ALARM OPERATION IN THE EVENT OF A MAINS FAILURE

2

Installation

Mounting

Access to Recorder

Electrical Connection

Fig. 1

all dimensions are in mm

Page 4

To avoid confusion on instruments with more than one

measuring system, capillary connections to the instruments are

- marked with the same colours as the inks used for the

corresponding pens.

Capillary Tubing

The tubing between the bulb and recorder should be routed so

that it is not subjected to large temperature changes and should be

supported in cleats. Bends must not be less than 25mm(1 inch) in

radius and under no circumstances must the tubing be cut.

Where the tubing is likely to be exposed to an extreme corrosive

atmosphere, the exterior should be treated with corrosion resistant

paint.

Immersion Types

The instrument bulb should be located where it is subject to the true

temperature of the measured medium. Temperature gradient within

the medium must be allowed for, and with bulbs allowing variable

depth of immersion (compression gland type), the bulb position

should be varied experimentally until the optimum position is found.

The full length of the sensitive portion must at all time be immersed

in the medium, but direct contact with the source of heat to the

medium must be avoided.

When securing the bulb in its location, it should be prevented from

twisting.

Where a pocket is supplied, this should be securely installed before

the bulb is inserted. It may be that the thermal response of a

pocketed bulb is improved by filling the intervening space with a

medium such as oil.

Capillary Type Bulb

This type of bulb should be installed by means of its end brackets

and to allow maximum circulation of air or gas around it, the coil

should be extended to a length of 610mm (2ft) or such that the

interval between the adjacent turns does not exceed 12.5mm (0.5

inch).

Any extension beyond this length may affect the zero reading at

the recorder. The bulb must be kept free of moisture.

Install the sensing elements (bulbs) where the humidity is to be

measured as described for temperature measuring instruments.

The wet bulb (red pen system) is kept moist by a fabric covering,

forming a wick which dips into a constant level water bath.

A distilled water supply tank should be connected to the inlet

feed pipe with a head of between 1 and 6 metres.

Use 0.25" (6.35mm) o.d. or 3/8"(9.5mm) bore solid drawn copper

tubing that has been well annealed cleaned and pressure test before

soldered into or over the tail pipe.

The solder joint and other joints in the pipeline must be secure and

leak proof. The use of PTFE tape is recommended for all thread

connections. Ensure that the sealing washer is in place when

assembling the tail pipe to the instrument connector.

A suitable seal must be inserted in the system if the medium

under pressure is liable to have a corrosive action on the

pressure element.

Gauge and Absolute Pressure Controllers.

It is recommended that a needle valve be installed in the pressure

line close to the instrument to enable pressures to be admitted

gradually. It can also be used to damp out any pressure pulsations.

A second needle valve, situated between the damping valve a

the controller, can be arranged to vent the instrument to enable

the zero to be checked.

This valve must not be fitted where steam or corrosive gases or

liquids are present.

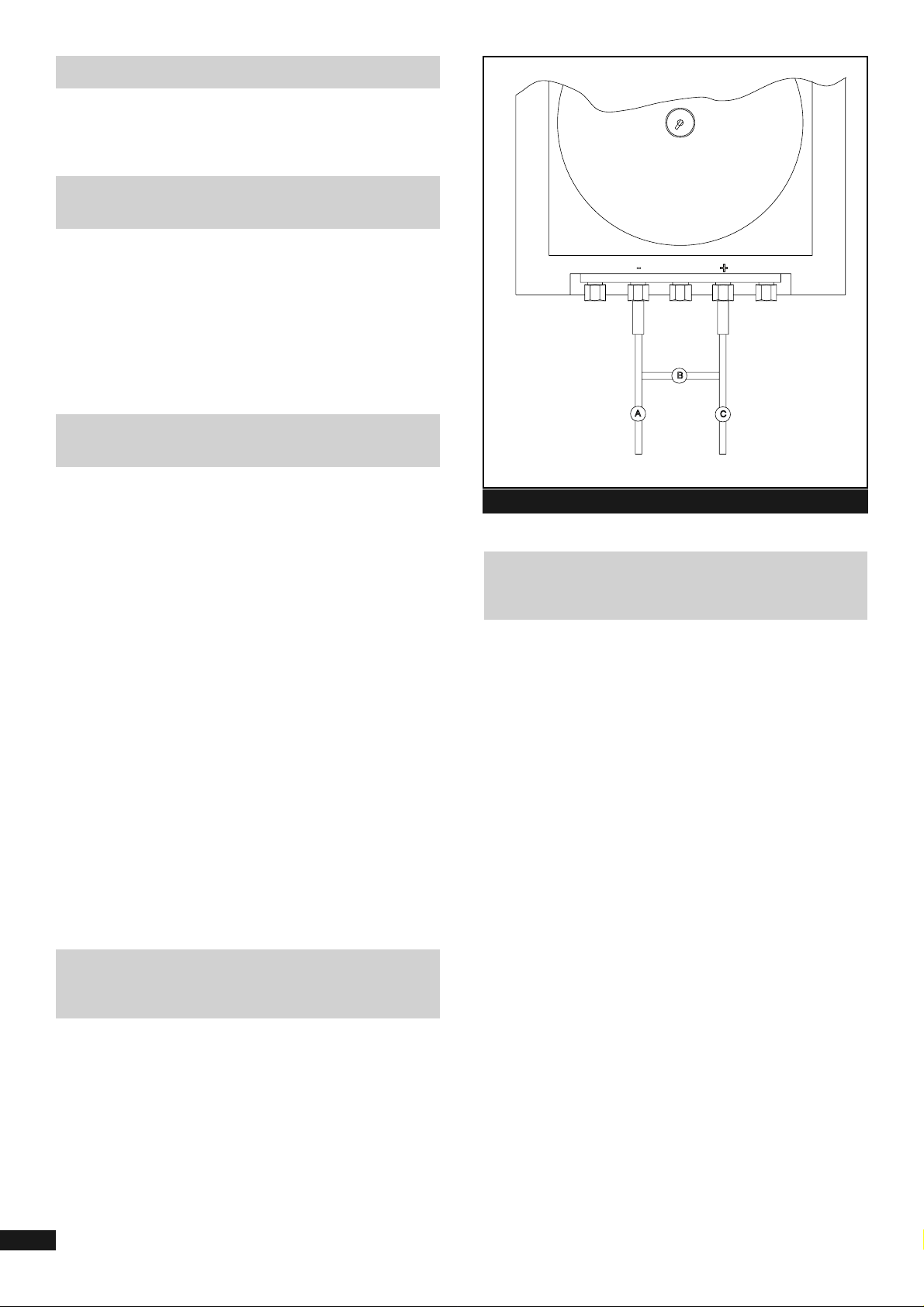

Differential Pressure Controllers

There are two pipes to each differential pressure measuring unit.

Connect the lower pressure to the (-) connector and the high

pressure to the (+) connector. Three needle valves should be

installed close to the controller, one isolating valve in each pressure

line and one balancing valve as arranged in figure 2.

3

PROCESS CONNECTIONS

FOR INSTRUMENTS FITTED WITH

TEMPERATURE SYSTEMS

LOCATION OF BULB

(DETECTING ELEMENT)

PROCESS CONNECTIONS - HUMIDITY

MEASURING ELEMENTS

(WET AND DRY BULBS)

Fig. 2

PROCESS CONNECTIONS -

FOR INSTRUMENTS FITTED WITH

PRESSURE SYSTEMS

Page 5

For Recorders Fitted with an Electrical Chart Drive

Release the chart clamp as shown in figure 3. Fit the chart onto

the spindle of the clamp and rotate the chart until the pen tip is on

the correct time line. Lower the chart clamp and press it firmly

to ensure that the locating pips pierce the chart.

Place the chart beneath the outer chart clips.

The writing system uses the fibre pen capsules.

A recess on the capsule fits onto the pen arm and the pen capsules

are easily replaced when the ink is exhausted. To fit a capsule, pull

the arm gently clear of its mountings, slide off the used capsule and

replace it with a new one of the appropriate colour.

Where there are two or more measuring systems, different colour

inks are used to distinguish the traces. The fibre tip is protected by a

plastic cap, which should be removed by pulling in line with its

length, gripping the end only and gently twisting.

Do not bend. The upper pen (red) has a long fibre Tip compared to

the lower pen (blue) which has a short fibre tip.

On instruments fitted with a third measuring system, the third pen

(green) has the longest fibre tip.

All recorders and recorder controllers are fitted with disposable

fibre tipped pens. These pens slide onto the pen arms.

The recorder pen arm is removable from the pen mechanism see

fig. 4. It is advisable to remove the pen arm from the mechanism of

recorders when fitting new pens because of the possibility of undue

forces being applied to the mechanism thus causing a possible error

shift.

Recorder controller pen arms are fixed to the mechanism and

must remain in situ when changing pens.

For instruments fitted for Temperature Systems

Disconnect Mains Power Supply

For low alarm set point slacken the lock nut securing the low contact

adjustment screw and screw the adjustment until the moving contact

just makes contact with the low contact at the point required, the set

point. Re-tighten the lock nut.

For high alarm set point, slacken the lock nut, securing the high

contact adjustment screw and screw the adjustment until the moving

contact just makes contact with the low contact at the point required,

the set point. Re-tighten the lock nut.

Note: For the low alarm, unscrewing the adjustment reduces the

set point and for the high alarm, unscrewing the

adjustment increases the set point

Note: After making any zero adjustments to instruments fitted

with control or alarm contacts the set point operating point must

be checked and adjusted as described in the section.

Zero Adjustment - temperature recorders and wet and dry bulb

humidity instruments see Fig 6.

All instruments are calibrated against reference standards before

despatch but should be checked in case of slight disturbance

during transit. Immerse a standard thermometer with a bulb and

check the readings. If adjustment is necessary open the door and

rotate the small knurled nut in Fig 6. to bring the pen

to the correct reading.

4

FITTING A CHART

INKING SYSTEM

Fig. 3

Fig. 4 Pen Arm / Ink Cartridge Fitting / Removal

Fig. 5. Alarm Contact Adjustment

SET POINT ADJUSTMENT (Fig. 5)

ZERO ADJUSTMENT (TEMPERATURE)

OPERATION

Page 6

For instruments fitted with Pressure Systems

Disconnect Mains Power Supply

For low alarm set point slacken the lock nut securing the low contact

adjustment screw and screw the adjustment until the moving contact

just makes contact with the low contact at the point required, the set

point. Re-tighten the lock nut.

For high alarm set point, slacken the lock nut, securing the high

contact adjustment screw and screw the adjustment until the moving

contact just makes contact with the low contact at the point required,

the set point. Re-tighten the lock nut.

Note: For the low alarm, unscrewing the adjustment reduces the

set point and For the high alarm, unscrewing the

adjustment increases the set point

Gauge Pressure

Vent the recorder to the atmosphere and check the reading of the

pen on the chart. If the pen does not read zero, adjust by means of

the zero nut (4 or 12).

Absolute Pressure

If the range covers atmospheric pressure, the accuracy can be

checked by venting the instrument to the atmosphere and checking

the reading against an accurate barometer.

If the range does not cover atmospheric pressure, a pressure

within this instrument range, measured against a standard pressure

gauge should be applied to the instrument.

Any adjustment is made by the zero nut (4 or 12).

Differential Pressure (Flg. 2)

To obtain a zero reading, open balance valve B and close isolating

valves A and C.

Before putting the recorder into operation make the

following checks to ascertain that it is correctly

installed and operational.

1. The pen(s) operate freely, write clearly on the chart and

pass each other without touching.

2. Measuring elements are correctly installed.

3. Measuring elements are indicating correctly.

If not, refer to zero adjustment.

4. Ensure that, in case of instruments with mechanical

clocks, the clock is running and that the correct electrical

connections have been made in instruments fitted with

electrical clocks.

5. Fit a new chart with its edge under the guide clips, set it to

the correct time line and clamp the centre fixing device

The procedure in the following paragraphs are for single pen or

dual pen instruments.

Refer to figure 7 for mechanism detail.

With the chart plate removed, cut a segment of chart and place on

the chart clarnp. Set the desired value pointer (1 or 2) to the

required value by means of the setting knob (3 or 4).

Move the actual value pen (5 or 6) until it just makes contact

with the switch arm (7).

Move the actual value pen (5 or 6) to the required deviation above

the desired value pointer (1 or 2) and adjust the high contact (9 or

10) until it just makes contact with the switch arm (7).

Low contact is set by moving the actual value pen (5 or 6) to the

required deviation below the desired value pointer (1 or 2) and

adjusting the low contact screw (8 or 11) until it just makes contact

with the switch arm (7).

Warning

Before adjusting the Contact Differential with the insulated spanner

provided, ensure that the mains supply is isolated and use a

continuity tester to establish switching points.

Be sure that all steps in the start-up check have

been completed.

1. Switch on the mains supply to the recorder.

2. Adjust set point on desired alarm/control value

(if applicable).

3. Switch on mains supply to external electric alarm/control

systems (if applicable).

5

SET POINT ADJUSTMENT

ZERO ADJUSTMENT (Fig. 6)

START-UP CHECK

Fig. 5. Alarm Contact Adjustment

CONTACT DIFFERENTIAL ADJUSTMENT FOR

TEMPERATURE AND PRESSURE RECORDERS

START-UP PROCEDURE

Page 7

Three adjustments are provided for calibration purposes:-

"Zero Adjustment" - to correct the lowest reading

"Range Adjustment" - to correct highest reading

"Scale Form Adjustment" - to correct midpoint reading

Warning

Unless the range is such that the same liquid can be used in all

baths the bulb should be wiped dry when transferring from one bath

to another.

This is particularly important when a "wide span" range; for example

0 to 450°C, where the "low point" bath would hold water and the

"high point" bath fusible salts. In such a case, it is dangerous to

insert a bulb wet with water into the salts bath.

Note

In transferring from one temperature to another there will be a

short time lag before the bulb reaches the bath temperature.

This will vary according to the range. Also, transferring a "cold"

bulb to a hot bath will affect the temperature of the bath liquid

until the thermostat has corrected for this.

Therefore, always check the bath temperature against a certified

test thermometer before taking a reading of the pen position

and making adjustments. This also applies when taking an Ice

point or that of the boiling water in baths not thermostatically

controlled.

Ice Point

The bulb should be immersed in a bath of clean crushed ice with a

large percentage of free water. The ice must not contain any salt or

other contaminant and the bulb should be cleaned before immersion. It is good practice to check the temperature with a mercury-inglass thermometer.

Boiling Point of Water

The boiling point of water varies with the barometric pressure and a

mercury-in-glass thermometer should be used to check the actual

temperature of the bath.

The bulb must not be allowed to come into contact with the heating

source.

In the following paragraphs,

the operation numbers refer to Fig 8.

1. Adjust zero nut (4 or 14) until the range adjustment screw

(5 or 6) is at right angles to the screwed link (7 or 8).

Ease the pen arm boss (12) from the pen arm spindle

taper and set the pen to the centre line of the chart.

Press the boss firmly on the taper when positioned. When

making this adjustment, do not turn the pen arm boss on

its taper except against the slightest friction, or the pen

arm retaining prongs will be bent.

2. Immerse the bulb in the low temperature bath, allow

sufficient time for the bulb to attain the bath temperature

and adjust the zero nut (4 or 14) until the pen arm

registers the temperature shown on the test thermometer.

3. Transfer the bulb to the high temperature bath, allow

sufficient time for the bulb to attain the bath temperature

and note the position of the pen.

4. If the pen rests below the correct line, halve the error by

adjusting the ranging screw (5 or 6) anticlockwise. If the

pen rests above the line, adjust the ranging screw (6)

clockwise to bring the pen to the top of the chart.

5. Return the bulb to the low temperature bath and adjust the

zero nut (4 or 14) to bring the pen to the correct line.

6. Check the top point and if still in error, repeat steps 4

and 5 until the bottom points are correct.

7. Transfer the bulb to the midpoint bath. If the pen reads

correctly, the instrument can be put into service. If there is

an error note its magnitude and proceed to step 8.

8. Ease the pen arm boss (12) from the spindle taper and set

the pen approximately 8 times the value of of the error on

the opposite side of the mid-chart line.

Press the boss firmly on the taper.

This adjustment is not possible on instruments fitted

with differential contact mechanisms as the pen boss

is factory set.

9. Return the bulb to the low temperature bath and adjust the

zero nut (4 or 14) to bring the pen to the correct value on

the scale.

10. Transfer the bulb to the midpoint bath. If not correct,

repeat step 8 (the multiple of 8 is a value, which in most

cases, will correct the midpoint error). However it may be

varied according to the results obtained.

11. Test the high temperature and if necessary, repeat steps

4, 5 and 8.

12. When all points are correct, remove the pen arm as

Fig. 4, position a centre punch in the hole in the centre

of the pen arm boss (12) and with a 4 ounce hammer

lightly applied, fix the boss on the spindle spear.

13. Replace the pen arm and return the instrument to service.

FOR INSTRUMENTS FITTED WITH

TEMPERATURE SYSTEMS

FOR INSTRUMENTS FITTED WITH

TEMPERATURE SYSTEMS

CALIBRATION

6

Page 8

In the following paragraphs,

the operation numbers refer to Fig 8.

1. Adjust zero nut (4 or 14) until the range adjustment screw

(5 or 6) is at right angles to the screwed link (7 or 8). Ease

the pen arm boss (12) from the pen arm spindle taper and

set the pen to the centre line of the chart. Press the boss

firmly on the taper when positioned. When making this

adjustment, do not turn the pen arm boss on its taper

except against the slightest friction, or the pen arm

retaining prongs will be bent.

2. With no pressure on the element, adjust the zero nut

until the pen registers zero on the chart.

3. Apply top range pressure to the element and note the

position of the pen. This may be short of the point.

4. If the pen rests below the correct line, halve the error by

adjusting the ranging screws (5 or 6) anticlockwise.

If the pen rests above the line, adjust the ranging screw

(6) clockwise to bring the pen to the top of the chart.

5. Open the connection to atmosphere and adjust the zero

nut (4 or 14) to bring the pen to zero on the chart.

6. Check the top point as step 3 and if still in error, repeat

steps 4 and 5 until the bottom points are correct.

7. Apply mid range pressure to the elements. If the pen

reads

correctly, the instrument can be put into service. If there is

an error note its magnitude and proceed to step 8.

8. Ease the pen arm boss (12) from the spindle taper and set

the pen approximately 8 times the value of the error on

the opposite side of the mid-chart line.

Press the boss firmly on the taper.

This adjustment is not possible on instruments fitted

with differential contact mechanisms as the pen boss is

factory set.

9. Open the connection to atmosphere and adjust the

zero-nut (4 or14) to bring the pen to zero on the chart.

10. Apply midpoint pressure to the element. If not correct,

repeat step 8 (the multiple of 8 is a value, which in most

cases, will correct midpoint error. However, it may be

varied according to the results obtained).

11. Test the top point as step 3, and if necessary repeat

from step 4 to step 6.

12. When all points are correct, remove the pen arm as

Fig 4, position a centre punch in the hole in the centre of

the pen arm boss (12) and with a 4 ounce hammer, lightly

applied, fix the boss on the spindle spear.

13. Replace the pen arm and return the instrument to service.

The recorder is fully compensated for changes in ambient

temperature.

The linkage between the Bourdon tube element and pen mechanism

incorporates bimetallic washers which expand or contract for

increase and decrease of ambient temperature.

To protect the pen mechanism in the event that the measured

variable goes significantly outside the span of the instrument,

the connecting link(s) incorporate "overload" springs.

The overload spring is used if the measured variable is likely to go

significantly above the maximum chart reading. Under these

conditions the movement of the Bourdon tube drives into the spring

allowing the pen mechanism to rest against the top point stop.

Under normal operation where the pen records within the instrument

range the spring is fully extended.

General

• Keep the instrument clean and treat with care.

• Where there is a risk of corrosion, the bulb should be inspected

periodically.

• If corrosion is evident, it should be removed, if possible by

non-abrasive treatment.

• Any contamination on the bulb should be removed.

Caution

Before removing the bulb or pocket, ensure that the plant is shut

down and the bulb is not under any pressure.

Zero Adjustment (For temperature Systems)

If a careful check against a known and steady temperature shows

the pen reading to be in error this can be corrected by means of the

zero nut (4 or 12) shown in Fig 6.

Other Adjustments

If the zero error found above is large, the top value of the range

should be checked after the zero error has been corrected. A

small error in the span can be corrected by adjusting the ranging

screw (6) clockwise to shorten the range or anticlockwise to

lengthen the range. If the error is large, the measuring element

is suspect and should be renewed.

7

FOR INSTRUMENTS FITTED WITH

TEMPERATURE SYSTEMS

Fig. 7

INSTRUMENT COMPENSATION

OVERLOAD PROTECTION SPRING

INSTRUMENT COMPENSATION

Page 9

Removal of a faulty system (Fig 6)

1. If an electronic clock is fitted, switch off and disconnect the

mains supply.

2. Remove the bulb from its location and remove the

instrument to a clean work bench.

3. Open the recorder door and remove the pen(s) and chart

plate.

4. If the lower system of a duplex instrument is faulty,

unscrew the zero nut (12) and remove compensation

washers (11) from the link (8), noting the number and

arrangement. (these items will be required for the new

systems). Remove the two Bourdon securing screws (9)

and slide the Bourdon, including overload spring assembly

(10) off the screwed link (8).

5. If the upper system is faulty remove the two Bourdon

securing screws (5) and slide the Bourdon, including

overload spring assembly (2) off the screwed link (1).

Leave the zero adjustment nut (4) and compensation

washers (3) on the link (these will be required for the

new system).

6. Slacken the lock nut on the system adaptor (14) and

remove the outlet plate securing screws (13), draw the

outlet plate away from the case, taking care not to

damage the second system of a duplex instrument.

7. Unscrew the lock nut (14) and remove the system from

the outlet plate, passing the capillary through the slot.

Pass the Bourdon through the case aperture and the

gasket (15).

Removal of a Faulty System.

1. If an electric clock is fitted, switch off and disconnect the

mains supply.

2. Disconnect the pressure input and remove the recorder to

a clean workbench.

3. Open the recorder door and remove the chart plate.

If the upper system is a Bourdon, unscrew adaptor lock

nut (14) and carefully remove adaptor from outlet plate. If

the system is a diaphragm assembly, unscrew 1/8" BSP

nut from adaptor on the outlet plate (16).

4. For lower systems, unscrew zero nut (12), remove the

securing screws (9) and slide the pressure element,

including overloading spring assembly (10), off the

screwed link (8).

5. For upper systems, remove the two screws (5) and slide

the pressure element including overload spring assembly

(2) off the screwed link (1).

1. Slide the overload spring assembly on the pressure

element over the screwed link and secure the element

with two screws.

If a lower system, screw the zero nut (12) on to the

screwed link.

2. If a Bourdon system, insert the adaptor into the outlet

plate and secure with the lock nut (14). If a diaphragm

unit, connect the nut and nipple (16) to the adaptor on the

outlet plate.

3. Cut a segment of the recorder chart and with suitable

rigid backing clamp in position ready for calibration.

Support the case in a vertical position.

4. Connect suitable pressure test equipment to the input

connector.

8

REPLACING A FILLED SYSTEM

REPLACING A PRESSURE SYSTEM

FITTING A NEW SYSTEM

Fig. 8

MAINTENANCE

Page 10

Recorder pen inaccurate or gives no indication

Probable Cause Measuring element broken; capillary plugged or

broken

Action Check element / capillary; replace system if

necessary

Probable Cause Damaged linkage in recorder

Action Repair and re-connect if possible; replace

linkage if necessary

Probable Cause Recorder out of calibration, measuring element

damaged

Action Set-up and recalibrate

Probable Cause Pen boss disengaged from mechanism spindle

Action Refer to calibration & Fig 8

No record or poor trace on chart

Probable Cause Pen not inking

Action Fit new capsule

Probable Cause Pen tension insufficient

Action Re-tension pen arm

Probable Cause Pen trace unsatisfactory

Action Re-tension pen arm; replace ink capsule

Chart not rotating (mechanical clock)

Probable Cause Clock unwound

Action Rewind, replace if broken (refer to spares page)

Probable Cause Clock over-wound

Action Replace clock

Chart not rotating (electric clock)

Probable Cause Mains supply disconnected

Action Connect mains supply to instrument

Probable Cause Chart not secured in chart clamp assembly

Action Fit new chart and secure

Probable Cause Chart not secured in chart clamp assembly

Action Tighten Clamp

Probable Cause Chart clamp assembly loose

Action Re-tighten chart clamp assembly; replace if

broken (refer to spares page)

FAULT FINDING

9

AFTER CARRYING OUT THE FAULT FINDING,

THE PROBLEM IS STILL EVIDENT, CONTACT

BRITISH ROTOTHERM OR YOUR LOCAL AUTHORISED

BRITISH ROTOTHERM DISTRIBUTOR FOR SPARES

INFORMATION AND TECHNICAL SUPPORT

AND ADVICE

Page 11

10

Note

For replacement of measuring systems the instrument serial number must be supplied and in the case of instruments

which have more than one measuring system, the position of the system.

Measuring system Quote instrument serial number for replacement

Chart Quote number on chart supplied or range and rotation

Pen Arm (red) 23985-11

Pen Arm (blue) 23984-11

Pen Arm (green) 23985-11

Pen Pack (red) PK2

Pen Pack (blue) PK1

Pen Pack (green) PK4

Chart Clamp Assembly 28279-04 (for instruments fitted with an electrical clock)

Link Assembly (100mm) (inc. zero nut) 19152-04

Link Assembly (150mm) (inc. zero nut) 19153-04

Overload Spring Assembly 18916-04

Recorder Case & Door Assembly 25524-04

Door Lock & Keys (2) 24834-11

Door Window 16622-51

Cable Gland (Nylon) 16381-11

Terminal Block (12 way) 16378-11

Platinum Contact Assembly 19904-04

10 Amp Relay (11 Pin)

24V 27494-11

240V 24979-11

110V 23951-11

Electric Clock Quote RTO chart speed, voltage & frequency

Battery Chart Drive 24 Hour Rotation 27190-11

Battery Chart Drive 7 Day Rotation 27173-11

Battery Chart Drive Chart Mount 29804-52

Mechanical / Battery Chart Drive Chart Knob 17404-52

Mechanical Chart Drive Chart Mount 17405-52

Mechanical Chart Drive 1 hour 28938-11

Mechanical Chart Drive 8 hour 28762-11

Mechanical Chart Drive 12 hour 24062-11

Mechanical Chart Drive 24 hour 24063-11

Mechanical Chart Drive 7 day 24065-11

Mechanical Chart Drive 28 day 28731-11

Mechanical Chart Drive 24 hour / 7 day 28937-11

Bimetal Compensation Washer Normal 24773-51

Bimetal Compensation Washer Reverse 29168-51

6" Wick wet & Dry Bulb System 100016

For instruments fitted with Pressure Systems

3/8 inch BSP Gland Nut Brass 16692-51

3/8 inch BSP Gland Nut St/Steel 17599-51

3/8 inch BSP Tail piece Brass 16992-51

3/8 inch BSP Tail piece St/Steel 17600-51

3/8 inch BSP Fibre Washer 16695-11 16695-11

SPARES LIST

THE LIST CONTAINS PARTS CONSIDERED NECESSARY UNDER

NORMAL SERVICING CONDITIONS. FOR INFORMATION CONCERNING FURTHER

SPARES PLEASE CONTACT THE MANUFACTURER

Page 12

British Rototherm Co. Ltd.,

Kenfig Industrial Estate, Margam,

Port Talbot, West Glamorgan SA13 2PW

United Kingdom

Telephone: +44 (0) 1656 740 551

Facsimile: +44 (0) 1656 745 915 / 741 275

E-mail: sales@rototherm.co.uk

Web site: www.rototherm.co.uk

© British Rototherm Co. Ltd., 2002. E&OE.

RTORPOMan 07/02

ISO 9001

Certificate No. FM11958

Loading...

Loading...