DigiTemp

Digital Thermometer

(Intrinsically Safe Version)

Instruction Manual

R

DigiTemp Digital Thermometer - Intrinsically Safe Version

Instruction Manual

Page 1

The Rototherm DigiTemp (Intrinsically Safe Version) is a battery-powered digital thermometer designed to suit a wide range of

industrial applications in hazardous process areas where potentially explosive atmospheres may be present. The DigiTemp is

housed in a robust stainless steel case, sealed to IP67 rating, which is suitable for hostile environments without additional

protection.

Before installation

Before installing this thermometer, please read these instructions completely. Failure to do so could result in permanent damage

to the unit. Particular attention should be given to the following points:-

Hazardous area compatibility :

By reference to the intrinsic safety marking code of the DigiTemp (Eex ia IIC T4, marked on the dial and also stated on the certifi-

cate) ensure that the gauge is suitable for use in the environment of the hazardous zone.

Installation

Installation should be undertaken only by qualified personnel familiar with safety practices and standards relating to intrinsically

safe electrical apparatus.

Location and mounting :

Thermometers fitted with a rigid stem of 6.35 or 12.7mm diameter are intended to be supported by means of a fixed or sliding

gland. Do not overtighten the gland nut. Instruments which are fitted with flexible or semi-rigid minerally-insulated stems are generally supplied with a three-hole mounting flange which allows the thermometer to be either surface or panel-mounted. The fixing

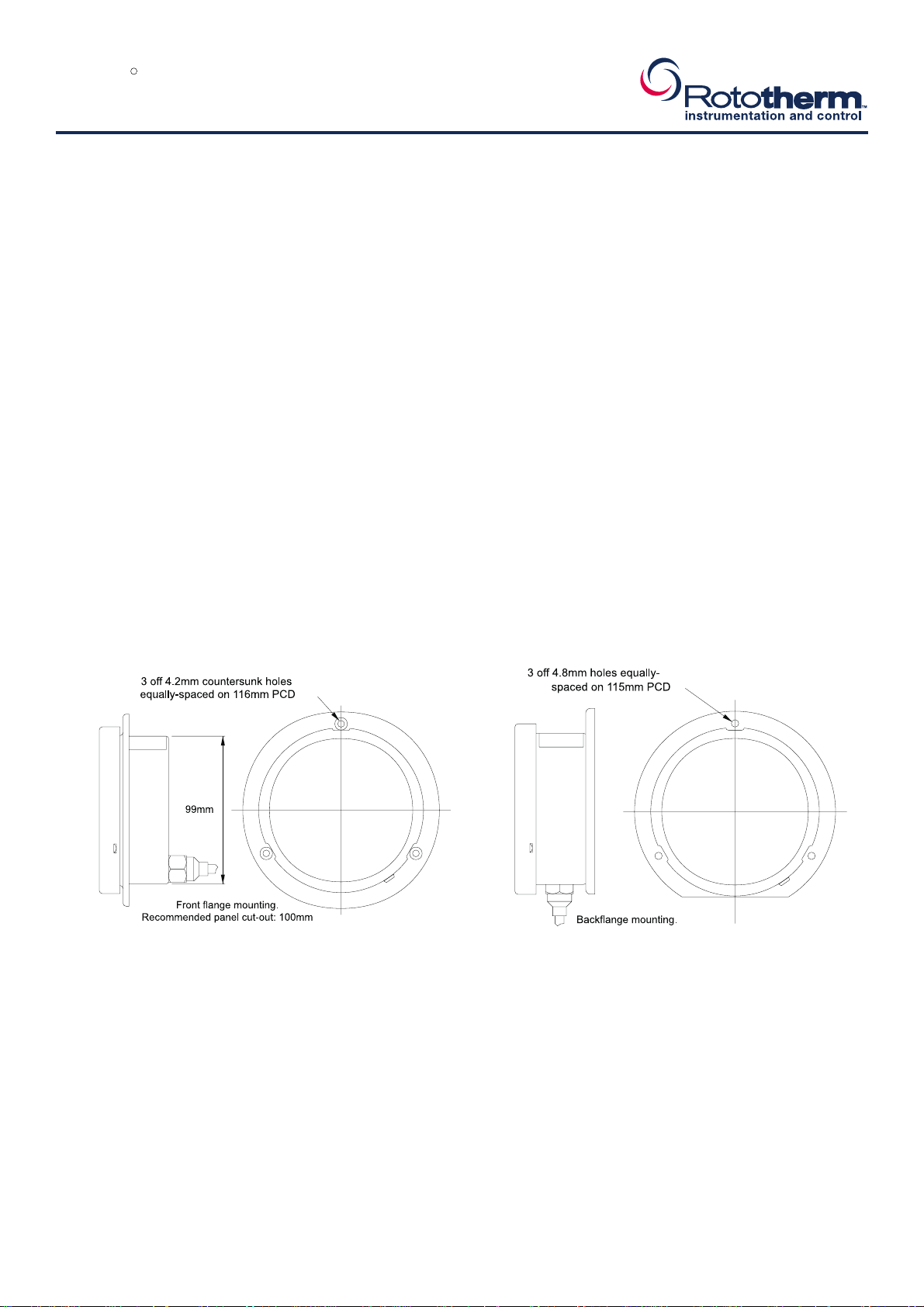

centres of the flanges are indicated in Figure 1 below.

R

Figure 1 - Mounting details for panel (front flange) and surface (back flange) versions.

Immersion length :

For accurate temperature measurement it is essential that the sensitive portion of the stem (generally the section 19mm from the

tip of the stem) is fully immersed in the medium to be measured. It is recommended that the immersion length should be at least

three times the length of the sensitive portion of the stem.

Process conditions and thermowells :

Ensure that the stem material of the DigiTemp (generally stainless steel, 316 grade) is compatible with any chemically aggressive

medium that it may come into contact with. If the process medium is under pressure (3.5bar or greater), for safety reasons the

stem of the DigiTemp should be protected by a thermowell ('pocket') designed to suit the process conditions. A wide range of

thermowells are available from British Rototherm; please contact the Sales Office for advice.

DigiTemp Digital Thermometer - Intrinsically Safe Version

Instruction Manual

Page 2

R

Variants

The DigiTemp is available in several variants using either a thermocouple or a platinum RTD probe, and offering several temperature ranges. In addition, the instrument is available with display units of degrees Celsius or degrees Fahrenheit.

Cleaning

To remove the risk of discharges due to static electricity, cleaning should only be undertaken using a damp cloth. Strong solvents

should not be used to clean the window.

Battery replacement

When the battery is nearing the end of its life the 'LOW BATTERY' warning light above the display will begin to flash. At this point

the battery has less than six months' life remaining and is due for replacement.

WARNING: For continued protection it is essential that only a battery pack of the same type is fitted. Battery replacement

must only be undertaken with the DigiTemp removed from the hazardous area.

Tools : The following tools will be required to change the battery -

Flat-bladed screwdriver approx. 6mm wide,

Cross-head screwdriver Pozidrive No. 1,

Nut-spinner or spanner 10mm A/F,

Soldering iron and solder,

Link wire approx. 50mm.

Procedure : (See Figure 2.)

1. Remove the bezel by unscrewing it from the case, anticlockwise. The window and its sealing ring may come off with the

bezel but must in any case be removed.

2. Unscrew the two screws securing the dial (at the 9 o'clock and 3 o'clock positions) and remove the dial.

3. Bypass the fuse, which is to be found immediately to the left of the display, by soldering the link wire across its two

leads. The circuit board pads which the fuse is soldered to are marked 'FUSE' and are enclosed in a small rectangle.

This is an important precaution whilst changing the battery. The fuse is very sensitive and an accidental touch of the cir

cuitry against something metallic can result in the fuse rupturing; it must then be renewed.

4. Unscrew the two screws securing the circuit board assembly (at the 11 o'clock and 5 o'clock positions). Notice a short

bonding strap between the 5 o'clock circuit fixing screw and the dial fixing pillar at the 3 o'clock position; this must be refitted as found during re-assembly. Lift the circuit assembly out of the case.

5. Remove the two nuts holding the retaining plate across the battery pack. Remove the plate and the battery pack from

the case.

6. The red lead from the battery is soldered to a pad on the circuit board (marked '+'). The black lead is either soldered to a

switch, or if this is not fitted, then to a pad on the circuit board (marked '-'). Unsolder the battery leads at the appropriate

points.

7. Replace the battery by soldering the leads of the new pack to the appropriate points. Take care to make a neat joint with

a minimum of bare wire. Trim any surplus wire projecting from the soldered-side of the circuit board.

8. Complete the operation by reversing the actions taken in 1 to 5 above.

Take care not to overtighten any of the fasteners involved.

For safety reasons the temporary link across the fuse must be removed.

When refitting the bezel make sure that the sealing gasket is between the window and the case. Tighten the bezel with

firm hand pressure.

OW

Made in U.K.

s

y

y

s

e

nuts

R

e

p

use

pack

y

Senso

eads

Figure 2 - Battery replacement (showing various stages

)

DigiTemp Digital Thermometer - Intrinsically Safe Version

Instruction Manual

Page 3

R

Calibration

Each DigiTemp thermometer is fully calibrated during manufacture and certificates of calibration may be requested at time of

ordering. It is recommended that the calibration of the thermometer should be checked against a known temperature standard

every 12 months or at intervals specified by relevant quality assurance procedures. British Rototherm offers a rapid in-house

recalibration service for its temperature measurement products, traceable to national standards. Please contact the Sales Office

for details.

WARNING: Calibration must only be undertaken with the DigiTemp removed from the hazardous area.

Tools : The following tools will be required for calibration -

Flat-bladed screwdriver approx. 6mm wide,

Flat-bladed screwdriver approx. 3mm wide.

Procedure : (See Figures 2 & 3.)

1. Remove the bezel by unscrewing it from the case, anticlockwise. The window and its sealing ring may come off with the

bezel but must in any case be removed.

2. Unscrew the two screws securing the dial (at the 9 o'clock and 3 o'clock positions) and remove the dial.

In the case of a DigiTemp variant fitted with a platinum RTD probe the calibration trimmers will be found in the 4 o'clock

position. For the thermocouple variant the trimmers will be found in the 8 o'clock position. See Figure 3. For all

instruments there are two trimmers marked 'ZERO' and 'SPAN' on the circuit board.

In the case of a DigiTemp variant fitted with a platinum RTD probe the calibration trimmers will be found in the 4 o'clock position.

For the thermocouple variant the trimmers will be found in the 8 o'clock position. See Figure 3. For all instruments there are two

trimmers marked 'ZERO' and 'SPAN' on the circuit board.

Dial securing screw

L

F

Batter

Circuit board assembl

securing screws

Bonding stra

Retaining plat

lead

r l

etaining plat

Batter

DigiTemp Digital Thermometer - Intrinsically Safe Version

Instruction Manual

Page 4

R

3. Fully immerse the stem in a bath containing a mixture of clean crushed ice and water. Allow time for the stem to settle at

the ice bath temperature, stirring occasionally. Adjust the zero trimmer if necessary until a reading of 0.0°C (or 32.0°F) is

obtained. (Remember that soluble salt impurities can result in a bath temperature below 0.0°C.)

4. Transfer the stem to a high temperature calibration bath (e.g. 100.0°C) containing a reference thermometer if available.

The tip of the DigiTemp's stem should be placed close to that of the reference thermometer. Allow time for the stem to

reach bath temperature, then adjust the span trimmer until the display reading matches the reference.

5. Return the DigiTemp stem to the ice bath and check the 0°C reading. It may be necessary to repeat the above zero and

span adjustments several times until both readings are satisfactory.

6. Refit the dial using its two screws taking care to re-position the bonding strap eyelet on top of the 3 o'clock dial pillar.

The dial screw goes through the dial, then through the eyelet, then into the pillar. Refit the gasket, window and bezel and

tighten with firm hand pressure.

CAUTION!

Observe correct safety procedures when working with high temperature calibration baths.

Fuse replacement

The 100mA encapsulated fuse is a safety-critical approved component and should only be replaced with one of the same type.

Suitable replacements, part number 28467/04, are available from British Rototherm. Should the fuse fail during normal operation

the reason for failure must be identified and any faults corrected before the fuse is replaced.

Warranty

The Rototherm DT1/2X Digital Thermometer is guaranteed to be free of manufacturing defects for a period of one year from the

date of purchase. To obtain service under this warranty the instrument should be returned in its original packaging either to British

Rototherm or its distributors.

SPAN

O

O

SPAN

Figure 3 - Calibration trimmer positions

Thermocouple Varients

Platinum RTD Varients

ZER

ZER

Specifications

BASEEFA Certificate Ex. 91C2161

Number:

Intrinsic safety class: EEx ia IIC T4

Case: 100mm diameter 304 stainless steel case and bezel.

Stems: Various, as requested to order (including 6.35mm, 12.7mm and flexible MI).

Resolution: 0.1 or 1 degree, according to variant.

Instrument accuracy: T/C: ±1°C ±1 digit typically, RTD: ±0.2°C ±1 digit.

Sensor linearisation: T/C: none, RTD: hardware.

Stability: T/C: Zero: ±0.05°C/°C ambient change

Span: ±0.01%FS/°C ambient change

RTD: Zero: ±0.005°C/°C ambient change

Span: ±0.003%FS/°C ambient change

(Figures for T/C version include CJ compensation).

Display: 4 digit liquid crystal with 12.7mm high characters.

Display units: °C or °F according to variant.

Temperature limits: Storage: -20 to 85°C

Ambient operating: -20 to +60°C.

Power source: 6V DC 4.0Ah custom battery pack.

Battery life: Approximately 2 years.

Low power warning: Flashing 'LOW BATTERY' light with less than 6 months remaining.

Ingress protection: IP67.

Weight: 625g approx.

Details given in this instruction sheet are subject to change without notice.

British Rototherm Co. Ltd.,

Kenfig Industrial Estate, Margam,

Port Talbot, West Glamorgan,

SA13 2PW, United Kingdom.

Telephone: +44 (0) 1656) 740551

Facsimile: +44 (0) 745915/741275

E-mail: rototherm@rototherm.co.uk

Web Site: www.rototherm.co.uk

ISO 9001

Certificate No. FM11958

DigiTemp Digital Thermometer - Intrinsically Safe Version

Instruction Manual

Page 5

R

DT0063-C Issue 1, October 2003

JAG 11/2003

Loading...

Loading...