Page 1

DigiTemp

Digital Thermometer

(Standard Version)

Instruction Manual

R

Page 2

DigiTemp Digital Thermometer

Instruction Manual

Page 1

The DigiTemp battery-powered digital thermometer is designed to suit a wide range of industrial applications which demand accurate measurement of temperature. The DigiTemp is housed in a robust stainless steel case, sealed to IP67 rating, which is suitable for hostile industrial environments without additional protection. Powered by two standard AA alkaline cells, the DigiTemp

gives two years of continuous maintenance-free operation.

Installation

Ambient conditions : Best measurement accuracy will be achieved if the DigiTemp is operated close to the calibration temperature of 20ºC (68ºF). Avoid siting the DigiTemp where there is extreme vibration.

Location and mounting : Thermometers fitted with a rigid stem of 6.35 or 12.7mm diameter are intended to be supported by

means of a fixed or sliding gland. Do not overtighten the gland nut. Instruments which are fitted with flexible or semi-rigid minerally-insulated stems are generally supplied with a three-hole mounting flange which allows the thermometer to be either surface or

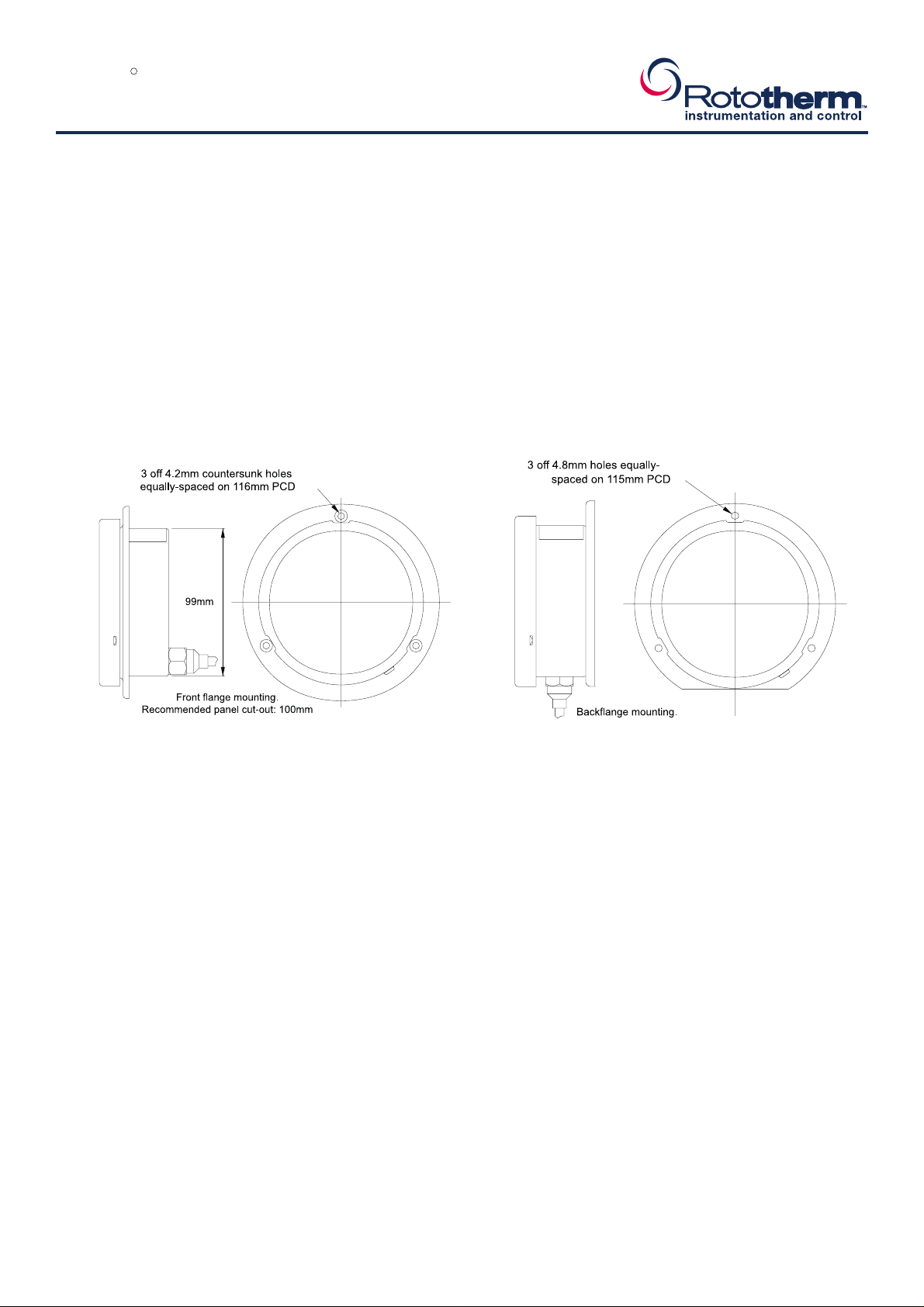

panel-mounted. The fixing centres of the flanges are as indicated in Figure 1 below.

R

Figure 1 - Mounting details for panel (front flange) and surface (back flange) versions.

Immersion length : For accurate temperature measurement it is essential that the sensitive portion of the stem (generally the

section 19mm from the tip of the stem) is fully immersed in the medium to be measured. It is recommended that the immersion

length should be at least three times the length of the sensitive portion of the stem.

Process conditions and thermowells : Ensure that the stem material of the DigiTemp (generally stainless steel, 316 grade) is

compatible with any chemically aggressive medium that it may come into contact with. If the process medium is under pressure

(3.5 bar or greater), for safety reasons the stem of the DigiTemp should be protected by a thermowell ('pocket') designed to suit

the process conditions. A wide range of thermowells are available from British Rototherm, please contact the Sales Office for

advice.

Display units

The display reading may be given in degrees Celsius or Fahrenheit according to the position of the internal jumper which is

shown in Figure 3. Dials marked with either °C or °F are available, part numbers DT0039-C (°C) and DT0040-C (°F).

Over and under-range indications

Should the measured temperature lie below or above the range of the DigiTemp the display will read either Undr or OvEr. The

temperature range of the instrument is shown on the label attached to the top of the case.

Page 3

DigiTemp Digital Thermometer

Instruction Manual

Page 2

R

Battery replacement

The instrument is powered by two alkaline manganese 1.5 volt cells, type LR6 (AA). When these are due for replacement the display will alternate between the temperature reading and message bAtt. This warning will be given when the battery voltage falls

to 2.0 volts (1.0 volt per cell), at which point the battery has approximately two months' life remaining. An internal voltage regulator circuit maintains measurement accuracy until the battery voltage falls to approximately 1.5 volts. Always replace the cells in

pairs, do not mix old and new cells.

To replace the battery unscrew the front bezel ring and remove the window and sealing gasket. Remove the two nylon-headed

screws and lift off the dial. Remove the old cells and fit two "AA" size 1.5V alkaline manganese cells into the battery holder. The

correct polarity of the cells is shown in Figure 2 below and is also marked on the battery holder. (The instrument will not be damaged if the cells are fitted incorrectly.) Refit the dial, place the sealing gasket on the front face of the case then centre the window on the gasket. Refit the bezel ring tightly with firm hand pressure.

Figure 2 - Correct battery polarity

Calibration

Each DigiTemp thermometer is fully calibrated during manufacture and certificates of calibration may be requested at time of

ordering. It is recommended that the calibration of the thermometer should be checked against a known temperature standard

every 12 months or at intervals specified by relevant quality assurance procedures. British Rototherm offers a rapid in-house

recalibration service for its temperature measurement products, traceable to national standards. Please contact the Sales Office

for details.

Procedure

Calibration of the DigiTemp thermometer is achieved by adjusting two multi-turn trimmer potentiometers which are located behind

the dial. One trimmer (P1) provides adjustment of the zero reading, a second (P2) controls the span.

An ice bath reference should be used when setting the zero trimmer to give a reading of 0°C (32°F) and the span adjustments

may be made by comparing the readings of the DigiTemp with those of an accurate reference standard thermometer at a higher

temperature. (For best accuracy the higher temperature should be close to the upper measurement limit.) If a standard thermometer and high temperature bath are not available the DigiTemp may be checked by immersing the stem in boiling water

(100°C, 212°F).

1. Fully immerse the stem in a bath containing a mixture of clean crushed ice and water. Allow time for the stem to settle at

the temperature of the ice bath, stir the bath occasionally. Adjust the zero trimmer potentiometer if necessary until a

reading of 0.0°C is obtained (32.0°F for the °F version).

2. Transfer the stem to a high temperature calibration bath (e.g. 100°C) containing a reference thermometer if available.

The tip of the stem should be placed close to that of the reference. Allow sufficient time for the stem temperature to

reach that of the bath, then adjust the span trimmer potentiometer (P2) until the display reading matches the reference.

3. Return the DigiTemp stem to the ice bath and check that the 0°C reading has not altered. It may be necessary to repeat

the above zero and span adjustments several times until both readings are satisfactory.

Page 4

Calibration (continued)

4. Refit the dial, place the sealing gasket on the front face of the case then centre the window on the gasket. Refit the

bezel ring tightly with firm hand pressure.

CAUTION! Observe correct safety procedures when working with high temperature calibration baths.

Figure 3 - Internal view of case showing calibration trimmers and °C / °F selection jumpers

Minimum and maximum reading option

The Digitemp may be fitted with an option which stores the maximum and minimum measured temperatures. These temperatures

may be displayed or cleared by means of magnetically-operated switches without opening the sealed case.

To display the minimum and maximum temperatures : Place a bar magnet on the top right-hand side of the case within the

box marked Min - Max on the instrument label. The DigiTemp display will then alternate between the maximum and minimum values as long as the magnet is held in place. The maximum temperature is shown after the display message Hi and the minimum

value follows Lo.

To reset (clear) the minimum and maximum values : Place a bar magnet on the top left-hand side of the case within the box

marked Min-Max Clear on the instrument label. After approximately 5 seconds the minimum and maximum values will be

cleared, confirmed by the display message HiLo CLrd. Note that the minimum and maximum readings will also be cleared if the

battery is removed.

Warranty

The Rototherm DigiTemp thermometer is guaranteed to be free of manufacturing defects for a period of one year from the date of

purchase. To obtain service under this warranty the instrument should be returned in its original packaging either to British

Rototherm or its distributors. This warranty excludes the battery, damage due to battery leakage or misuse. Any details given in

this instruction sheet are subject to change without notice.

DigiTemp Digital Thermometer

Instruction Manual

Page 3

R

Page 5

Specifications

Sensor: Platinum RTD or thermocouple (Type K class 1 as standard, others available to order)

Measurement ranges: T/C: -100 to +1000°C (-148 to +1832°F) 1° resolution RTD: -50 to +200°C (-58 to +392°F) 0.1°

resolution (Specific temperature range is dependent on sensor & stem construction)

Accuracy: T/C: ±1°C ± 1 digit

RTD: ±0.2°C ± 1 digit

Stability: T/C: Zero : ±0.05°C per °C ambient change

Span : ±0.01% of span per °C ambient change

RTD: Zero : ±0.005°C per °C ambient change

Span : ±0.003% of span per °C ambient change

(Figures for T/C variant include CJ compensation)

Sensor linearisation: Automatic, via software.

Cold junction Automatic (T/C only).

compensation :

Display: 4 digit LCD with 12.7mm (1/2") high characters. °C or °F selectable by internal jumper

Update interval: 0.6 seconds approximately

Temperature Limits: Storage: -20 to 85°C (-4 to 185°F)

Ambient Operating: -20 to +60°C (-4 to 140°F)

Power Source: 3V battery, 2 x 1.5V "AA" alkaline cells.

Battery Life: 2 years.

Low battery warning: Display will alternate between temperature reading and BATT

Electromagnetic BS EN 50081-1 : 1992 BS EN 50082-2 : 1995

compatibility (EMC):

Case: 100mm dia. 304 stainless steel case, 316 stainless steel stem.

Ingress Protection: IP67

Details given in this instruction sheet are subject to change without notice.

British Rototherm Co. Ltd.,

Kenfig Industrial Estate, Margam,

Port Talbot, West Glamorgan,

SA13 2PW, United Kingdom.

Telephone: +44 (0) 1656) 740551

Facsimile: +44 (0) 745915/741275

E-mail: rototherm@rototherm.co.uk

Web Site: www.rototherm.co.uk

ISO 9001

Certificate No. FM11958

DigiTemp Digital Thermometer

Instruction Manual

Page 4

R

JAG 10/2003

Loading...

Loading...