Page 1

C105 Circular Case Recorder

Operating Instructions

instrumentation and control

The chart drive and control system on this instrument may be operated from a mains voltage supply. The mains must

be switched off before making any mechanical adjustments other than of the set pointers or carrying out any

maintenance or fault finding procedures. When making electrical adjustments observe the warning notes in the text.

INTRODUCTION 2

Identification 2

Specification 3

INSTALLATION 4

Mounting 4

Access to Recorder 5

Process Connections 5

Electrical Connections 5

OPERATION 6

Mechanical Clock 6

Fitting a Chart 6

Set Pointer Adjustment 6

Inking System 6

Zero Adjustment 7

Start-up Check 7

Start-up Procedure 7

Description of Operation 8

Electrical alarm/control system 10

Programme Control 10

MAINTENANCE 11

Cutting a programme cam 11

Pen Adjustment 11

Calibration 11

Servicing 12

Wet and Dry Bulb Water Bath 13

SPECIAL INSTRUCTIONS & DIAGRAMS 14

FAULT FINDING 15

SPARES LIST 15 & 16

Page No. Page No.

CONTENTS

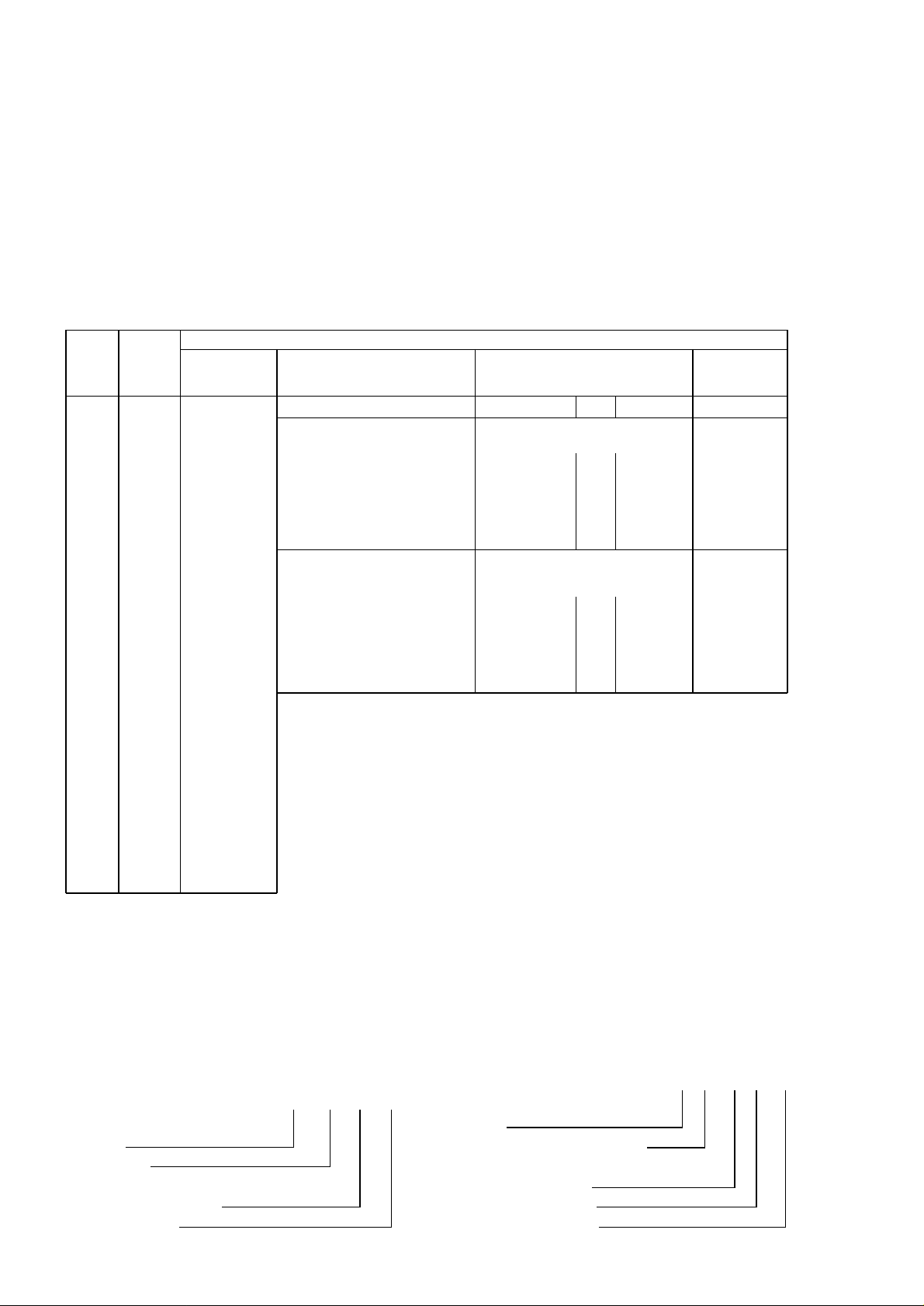

Fig. 1.

Page 2

2

INTRODUCTION

The C105 series of instruments is designed to measure, record and control process variables such as

temperature, pressure and humidity. A maximum of two measuring systems is provided in each

instrument; a fluid expansion type or bimetallic system is used for temperature recording, a hygroscopic

element or a wet and dry bulb system for humidity and a Bourdon tube or diaphragm for pressure

measurement. The measured values are continuously recorded on a calibrated circular chart which is

rotated at a constant speed by a mechanical or electric clock. Control of the process variable is provided

electrically.

Basic

Type

Number

C10

Recorder

with

105mm

pen

travel

on

circular

chart

5 One

pen

6 Two

pen

1 T emperature

(Fluid

expansion

system)

2 Pressure

(‘C’ Spring–

316 st.steel)

3 Pressure

(Spiral

Bourdon –

phosphor

bronze)

4 Pressure

(Spiral

Bourdon –

321 st.steel)

5 Pressure

Capsule

Stack –

beryllium

copper)

6 Pressure

(Diaphragm

Stack –

beryllium

copper)

7 Relative Humidity

(Goldbeater skin)

– External

9 Pressure

(Coiled Tube –

316 st.steel

No. of

Measuring

Points

Programme

Control Cam

(Single Pen

only)

Measured

Variable

Each Pen

Alarm or Control Mode Set Points

No. 1 No. 2 Nos. 3 & 4

17 Record only – – – – –

Electric Alarm/Control Position of Pen in relation to

with Relay Output Set Point when Relay is energised

00 Two Step Above – None, or any – or C

01 Two Step Below – combination – or C

05 Three Step Below Below applicable –

06 Three Step Above Above to Set Points –

09 High-low Above Below No. 1 & 2 –

03 Double 2 Step Above/Above – – or C

04 Double 2 Step Below/Below – – or C

Contact Action at Set Point

Electric Alarm/Control when Pen moves towards

Contacts only – no Relay outside of Chart

60 Two Step –Contact Mode C Make – – or C

61 Two Step –Contact Mode A Break – None, or any – or C

65 Three Step –Contact Mode AA Break Break combination –

66 Three Step –Contact Mode CC Make Make applicable –

69 High-Low –Contact Mode CA Make Break to Set Points –

63 Double 2 Step –Contact Mode D Make/Make – No. 1 & 2 – or C

64 Double 2 Step –Contact Mode B Break/Break – – or C

Notes:

Code No. is built up thus:

Single Pen C105/1 1 63 C

One Pen

Temperature

Double 2 Step –

Contacts only (no relay)

Programme Cam

Two Pen C106/3 00/1 17

Two Pens

No. 1 Pen – Pressure (Bourdon)

– 2 Step Elec. Alarm

with Relay

No. 2 Pen – Temperature

– Record only

(

(

(

Page 3

3

Specification

General:

Chart diameter 255mm

Writing width 105mm

Intrinsic error ± 1% span maximum (±2% R.H. for hygroscopic

membrane system)

Operating temperature limits –10

o

to +50oC Except for

Operating humidity limits 0 to 80% R.H. humidity recorders

Zero error due to ambient temp. variations ±0.05% span/

o

C typical

Chart speeds 1 rev every 12 hours, 24 hours or 7 days

Chart drive Synchronous electric motor or mechanical clock

Power supply voltage and frequency 200/250V or 100/120V, 50 or 60Hz

Mounting Wall or panel

Temperature measuring instruments:

Measuring systems Fluid expansion

Maximum length capillary 30m

Minimum span 40

o

C

Maximum span 500

o

C

Span limits – 30

o

C to +600oC

Pressure measuring instruments:

Measuring system Capsule stack, Bourdon tube or coiled tube

Minimum span 0 to 1 bar vacuum or pressure.

Maximum span 1200 bar

Span limits –1 bar to 1200 bar

Connection size Ranges up to 40 bar: a inch B.S.P.) with nut and tail

Ranges over 40 bar: 2 inch B.S.P.) piece for 8mm tube

Humidity measuring instruments:

Measuring systems Sensitive hygroscopic membrane and fluid filled system

for temperature measurement, or wet and dry bulb fluid

expansion systems.

Spans 20 to 100% R.H. (hygroscopic membrane);

0 to 40

o

C (fluid filled systems)

Operating temperature limits 0 to 40

o

C

Operating humidity limits 30 to 85% R.H.

Maximum length of capillary

(wet and dry bulb system) 30m (each bulb)

Electric alarm or control:

Instrument contacts 20mA inductive or 30mA non-inductive load max.

Contact action Make above or below set point as required

Relays Delayed action double pole change-over, 5A, 240V

50Hz non-inductive load, as standard

(Refer to wiring Diagram, p.14).

Relay action Energised above or below set point as required.

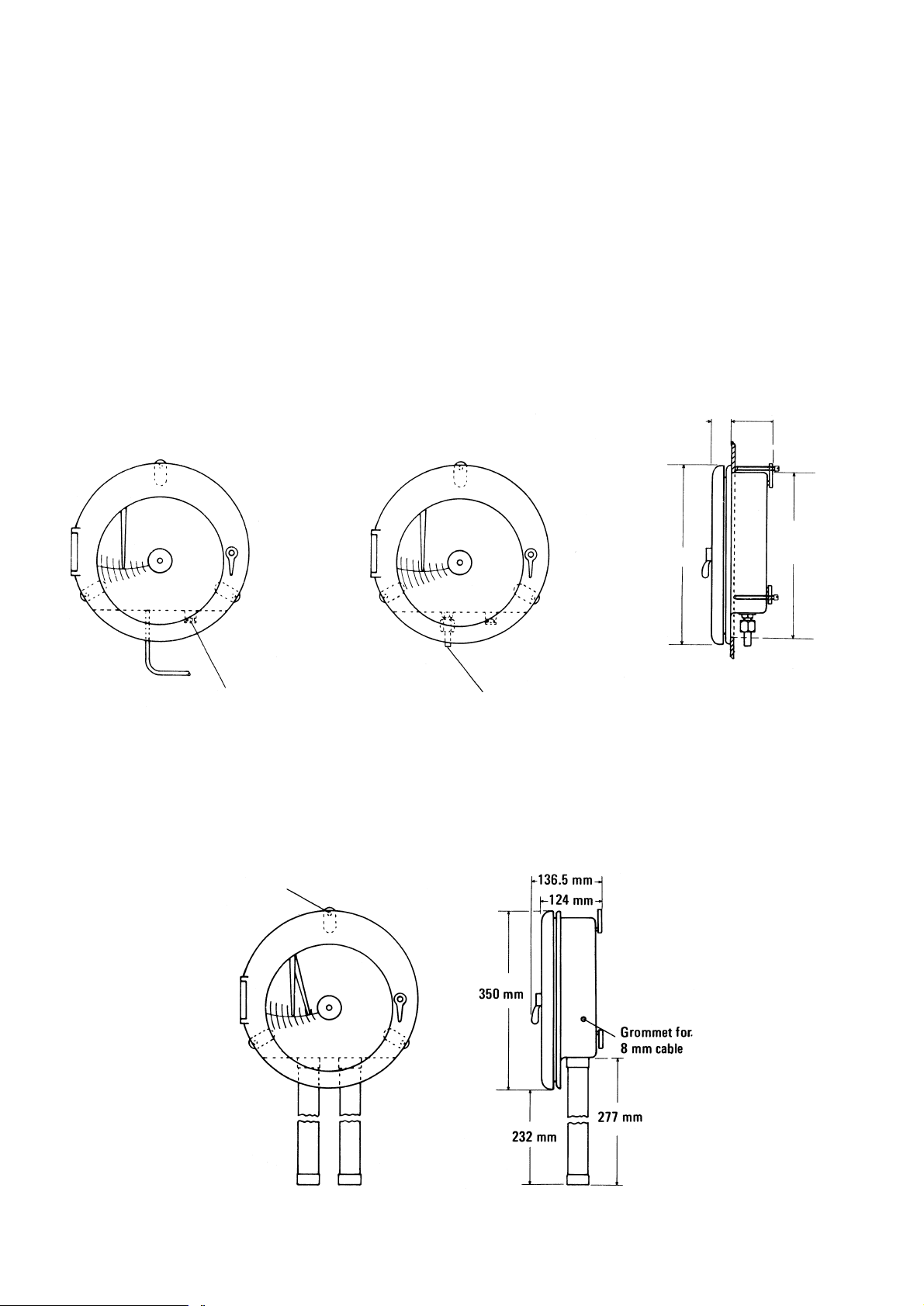

Overall dimensions 350mm wide; 137mm deep; 350mm high

(Temp & R.H. 582mm high)

Panel cut-out 318mm diameter

Maximum panel thickness 25mm

Weight 10kg

667788

Page 4

4

INSTALLATION

Mounting

The instrument can be wall or panel mounted using the same fixing brackets. Do not install near any very hot

apparatus, e.g. ovens, steam pipes or flues. Mount the recorder vertically in a position free from vibration and

excessive temperature.

For panel mounting remove the fixing screws and rotate the fixing brackets so that the instrument can be inserted

in the hole in the panel. Return the brackets to their original position and insert the fixing screws. Tighten the

screws until they bear against the back of the panel.

Hygroscopic measuring instruments have external measuring elements requiring a clearance of 240mm below the

case, and must be wall mounted.

Temperature Recorder

Temperature and Relative Humidity Recorder

Wall Mounting

Pressure Recorder

Panel Mounting

41 mm

83 mm

350 mm

Panel

cut-out

dia. 318 mm

Cable gland for

w” conduit

a” or 2” B.S.P. union with nut,

and tailpiece

Three holes at 120º on 340 mm p.c.d.

to take 6.4 mm diam. screws

for wall mounting

Fig. 2.

Page 5

5

Access to Recorder

To open the door, unlock, and turn the latch anticlockwise. As the door is opened the pen lifter raises the pen (or

pens) away from the chart. Remove the chart (see page 6).

If the instrument is connected to the mains, switch off the mains supply before dismantling further.

For access to the terminal blocks remove the lower plastic plate from behind the chart by undoing the one

retaining screw.

For access to the relays and measuring systems, first remove the chart. Unhook the pens from their mounting

(see Fig. 3.). Remove the three screws from the outside edge of the chart plate. (The pen lifter is secured by one

of these screws and must also be removed). Lower the chart plate carefully. The chart motor is mounted on the

back of the chart plate and if the motor is an electric one it remains connected to the terminal block in the lower

part of the case.

When replacing the chart plate reverse the above procedure. The coil on the pen lifter should be against the side

of the case when the retaining screw is tightened.

Process Connections

To avoid confusion on instruments with more than one measuring system, setting pointers are labelled and

Bourdon tube capillary connections to the instrument are painted with the same colours as the inks used for the

corresponding pens.

Process connections – temperature measuring instruments:

Install the sensing element (bulb) of the instrument in the apparatus where the temperature is to be measured.

The circulation around this element should be good and it should not be too close to any heating or cooling coil or

other controlling medium. Fasten the capillary tubing at frequent intervals to rigid supports avoiding sharp bends

of less than 50mm. radius anywhere along its length. The tubing must not touch or run close to any hot apparatus

and should take the path least subject to temperature variation. If the temperature source is likely to move or

vibrate allow one or two coils of 100mm. diameter of the capillary tube to eliminate stress of the tubing.

If the atmosphere around the capillary tube is likely to be corrosive, paint the tube with anti-corrosive paint and

ensure this is maintained.

Process connections – pressure measuring instruments:

Connect the Bourdon tube sensing element to the measuring point on the apparatus using pressure tubing of the

same or similar material as the Bourdon tube and of sufficient pressure rating. Slope the run of the tubing so that

any condensate is drained away from the instrument and does not affect the accuracy of measurement. For

measurement of steam pressure or other hot vapours, form a condensate trap below the instrument.

Process connections – humidity measuring instruments (wet and dry bulb):

Install the sensing elements (bulbs) where the humidity is to be measured as described for temperature

measuring instruments. The wet bulb (red pen system) is kept moist by a fabric covering, forming a wick which

dips into a constant level water bath. Adistilled water supply tank should be connected to the inlet feed pipe with

a head of between 1 and 6 metres.

It is important to install the bulbs in a position where the air speed is 3.6 metres per second or more. Below this

speed inaccuracies of bulb depression may occur. The air should pass over the bulbs in such a direction that the

water evaporating from the wet bulb does not pass over the dry bulb. The water must be kept clean and free from

impurities. The temperature of the bath and all piping must not fall below 0

o

C. See also page 13.

Electrical Connections

Before making any connections to the instrument switch off the mains supply to be connected.

All electrical connections are made to terminal blocks in the lower part of the case behind the lower section of the

chart plate.

Insert the leads through the cable gland in the underside of the case (see Fig. 2.) and make the connections as

shown on the terminal labels or Wiring Diagram (page 14). The live line should be switched and fused with a 2

amp fuse. If the instrument is mounted on an insulated panel the case should be earthed.

Page 6

6

OPERATION

Mechanical Clock

To wind the mechanical clock first remove the chart as described below.

This exposes the clock key, which is permanently fitted in the front recess of the clock moulding.

To wind the clock turn the key clockwise. Do not overwind.

Fitting a Chart (Spider Clamp)

Unscrew the milled head on the centre of the clock

spindle until the spider retracts. Remove the chart. Fit

the new chart over the spider head onto the locating

boss. Rotate the chart until the pen tip coincides with the

correct time line and clamp by screwing down the milled

head. On a two-pen instrument the outer (red) pen,

should be set on the correct time line.

Fitting a Chart (Lever Clamp) – Fig 2(a)

Release the clamp as shown. Remove the old chart. Fit

the new chart on the spindle and rotate the chart until

the pen tip is on the correct time line. Lower the chart

clamp and press on it firmly to ensure that the locating

pips pierce the chart.

Set Pointer Adjustment

To set the desired alarm/control point slacken the

clamping knob at the right-hand end of the setting

pointer (Fig. 5), position the pointer on the desired value

and re-tighten the clamp.

Inking System

The pen is tied during transit, but if dislodged it can be

simply reassembled as shown. The pen arm is forked,

one prong being pointed, the other curved. The pointed

prong fits into a conical hole in screw S and curved one

into the V shaped groove V. The pen is held in position

by a spring X and hook Y. On the rear pen the hook Y

faces towards the rear.

The writing system uses fibre pen capsules. Adovetail

on the capsule fits into a slot at the end of the pen arm

and the capsules are easily replaced when the ink is

exhausted. To fit a capsule, pull the pen arm gently clear

of its mountings S and V and unhook it from instrument.

Slide off the used capsule and replace it with a new one

of the appropriate colour. Where there are two

measuring systems, different coloured inks are used to

distinguish the traces. The fibre tip is protected by a

plastic cap, which should be removed by pulling in line

with its length, gripping the end only and gently twisting.

Do not bend. The front pen (red) has a long fibre tip and

the rear pen (green) a short tip.

Place the spring X over the hook Y and gently pull the

pen arm to locate it in its mountings S and V. Take care

not to bend the pen arm.

In some instruments, (supplied to special order only) fibre pen capsules are not used and each pen reservoir

must be filled with ink using the dropper supplied in the ink bottle. Each pen should be cleaned occasionally by

drawing the edge of a piece of stiff paper through it. If it becomes dirty or greasy remove the pen arm and wash

the pen methylated spirits.

Fig. 2(a) Chart Lever Clamp

Fig. 3

Release

Pen arm

Plastic cap

Capsule dovetail

Dovetail slot

Capsule

Pull and

twist

Clamp

Page 7

7

Zero adjustment

NOTE: After making any zero adjustment to instruments fitted with control or alarm contacts the relay operating

point must be checked and adjusted as described on page 10.

Zero adjustment – temperature recorders and wet and dry bulb humidity instruments:

All instruments are calibrated against a standard thermometer before despatch but should be checked in case of

slight disturbance during transit. Immerse a standard thermometer with the bulb and check the readings. If

adjustment is necessary open the door and rotate the small knurled screw S (in Fig. 3.) to bring the pen to the

correct reading.

Zero adjustment – pressure recorders:

Use a reliable pressure gauge to check the readings and

adjust, if necessary, as for the temperature recorder.

Zero adjustment – temperature and humidity recorders:

Check the temperature reading against a standard mercury-in-

glass thermometer and the humidity reading against a whirling

hygrometer using hygrometric tables to relate humidity to wet

and dry thermometer readings.

Hygrometric tables are compiled by the Meteorological Office

and obtainable from H.M. Stationery Office. Alternatively use

the Psychrometric tables by C.F. Marvin (issued by U.S.

Department of Commerce Weather Bureau) and obtainable

from C.F. Casella & Co. Ltd., Regent House, Brittania Walk,

London N.1.

The zero setting may be adjusted using screw S (Fig. 3). If the

humidity reading requires more correction than that provided

by S, screw J, accessible through the bottom of the guard,

may be adjusted (Fig. 4).

In a bimetallic temperature measuring system the linkages and

zero adjustments are the same as for the hygroscopic

measuring system.

Start-up Check

Before putting the controller into operation make certain it is correctly installed and operational by checking that:

1. The pens operate freely, write cleanly on the chart and can pass each other without touching.

2. Measuring elements are correctly installed.

3. Measuring systems are indicating correctly. If not refer to Zero Adjustment, above.

4. On electrical controllers:

Relays are energised above or below set point as required. If they are not, see Changing the Control Action,

page 10.

5. If a mechanical clock is fitted check that it is wound up (see Mechanical Clock, page 6).

Start-up procedure

Be sure that all steps in the start-up check have been completed.

1. Switch on mains supply to recorder.

2. Position setting pointers on desired alarm/control values.

3. Switch on mains supply to external electric alarm/control systems.

Fig. 4

Linearity adjustment

Ratio arm

Screw J

Hygroscopic

membrane

Pivots

Page 8

Description of Operation

Temperature recorder (see Fig. 5.)

As the temperature rises, the fluid in the thermometer bulb expands and partially uncoils the spiral Bourdon tube

fitted inside the instrument. This movement is transferred by a mechanical linkage to the pen arm which records

the temperature on a calibrated chart.

Pressure recorder

On medium and high pressure ranges an increase in pressure partially uncoils a Bourdon tube fitted inside the

instrument. This movement is transferred by a mechanical linkage to the pen arm which records the pressure on a

calibrated chart.

A capsule stack or diaphragm system is fitted for low pressure ranges and the expansion of the system resulting

from an increase in pressure is transferred by a mechanical linkage to the pen arm.

8

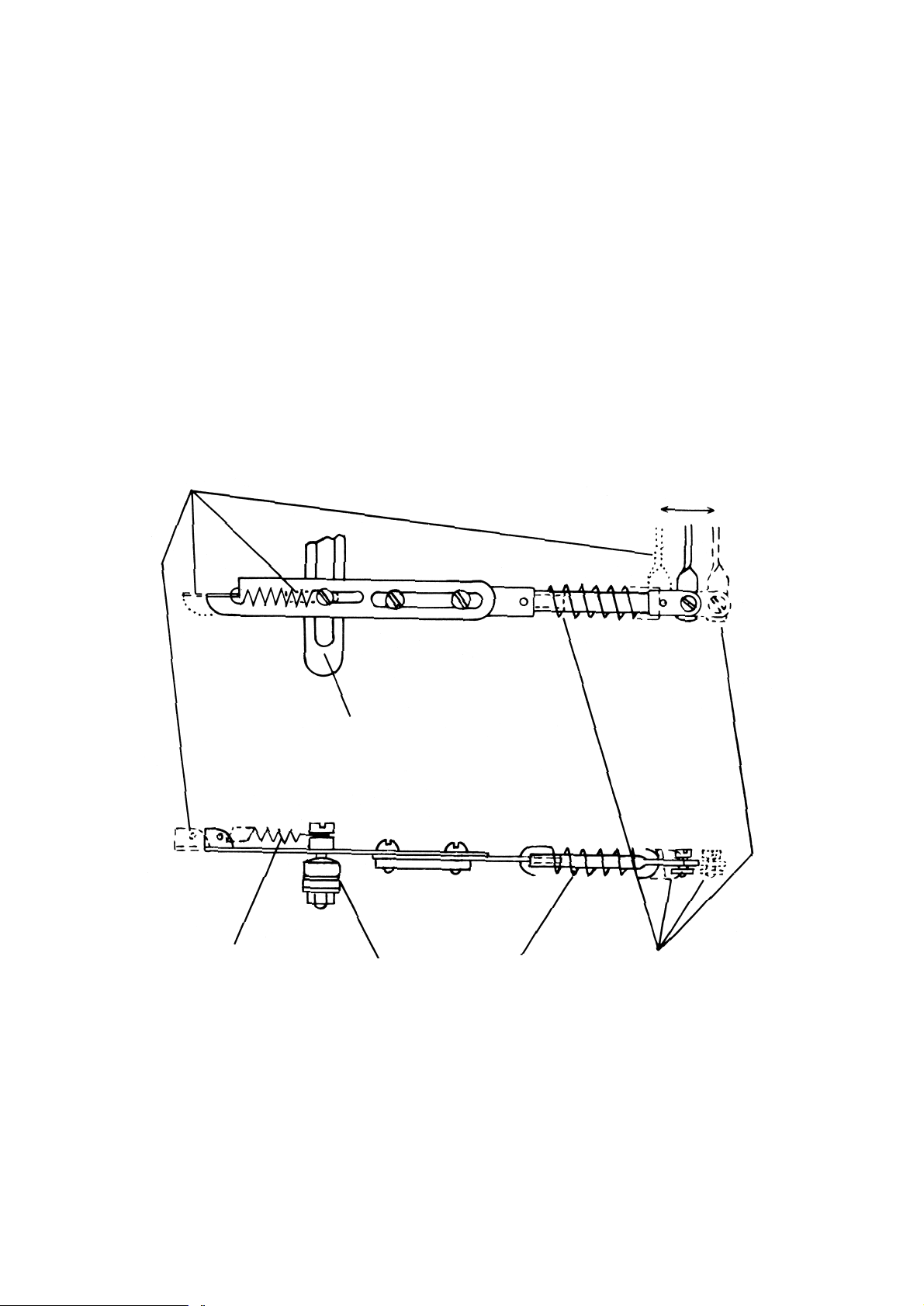

Fig. 5

Bourdon tube

Set-up spring

Linearity adjustment

Ratio arm pivot

Control unit

Drive link

striker pin

Coarse zero adjustment

Compensator

Setting pointers

Control arm

Terminal block

Relays

Control unit

fixing screws

Setting pointer

clamp

Page 9

9

Temperature and humidity recorder (see Fig. 4)

The air circulates around a strip of animal tissue (Goldbeater skin) the length of which varies with the relative

humidity. The membrane is mounted under light spring tension and is connected by means of a bell crank lever

and linkage to a pen arm which records the humidity on a calibrated chart. Temperature is measured by a fluid

filled system which is mounted to the left of the humidity element and mechanically linked to a second pen arm.

Humidity recorder – wet and dry bulb

The relative humidity can be obtained from the temperatures measured by the wet and dry bulb thermometer

using hygrometric or psychrometric tables.

Set up and Overload Protection Springs

To protect the pen mechanics if the measured variable goes significantly outside the span of the instrument the

connecting link may incorporate “set up” and/or “overload” springs (see Fig. 6.).

The set up spring (also shown in Fig. 5.) is used if the measured variable is liable to go significantly below the

chart zero reading, e.g. on a temperature recorder calibrated 100–600

o

C where the measuring element is subject

to normal ambient temperatures during transit. Under these conditions the movement of the Bourdon tube

compensator extends the spring allowing the pen mechanism to rest against the zero stop.

The overload spring is used if the measured variable is liable to go significantly above the maximum chart

reading. Under these conditions the movement of the Bourdon tube compensator extends the spring allowing the

pen mechanism to rest against the top point stop.

Fig. 6

Overload action

Movement of Bourdon Tube compensator

Overload spring

Ratio arm pivot

Set up spring

Set up action

Page 10

Electrical alarm/control system

Each relay is switched by a contact mounted on an arm linked to the setting pointer which makes or breaks with a

contact attached to the recording pen linkage when the pen reaches the set point (see Fig. 5.). The striker is fixed

relative to the pen arm and a spring loaded contact is fitted to the setting pointer linkage. One set of changeover

contacts is available for external connection for each set point. The contacts are usually labelled “normally closed”

(NC), “common” (C) and “normally open”

(NO) where normally means that no current

is flowing through the relay coil. Refer to

page 14 for any special wiring information.

On wet and dry bulb humidity controllers in

addition to standard control contacts for the

dry temperature a contact may be fitted on

the dry bulb pen linkage so that the wet

bulb depression may be controlled.

Alarm systems should have an independent

power supply to safeguard alarm operation

in the event of mains failure.

Adjusting the relay operating point

If the measured value indication is correct and the relay operates at a value other than that shown by the setting

pointer, the error may be corrected as follows. Move the setting pointer to the indicated value. Switch off the

electrical supply to the recorder and remove the chart, pens and upper chart plate. Slacken the two nylon screws

on the control unit (see Figs. 5 and 7) and slide it along the control arm until the sprung contact just touches the

fixed contact. Re-tighten the screws and replace the chart plate etc. Check the relay now operates at the desired

set point.

Changing the Control Action

Switch off the electrical supply to the recorder and remove the chart, pens and upper chart plate.

To change the relay action from energised below set point (E.B.) to energised above set point (E.A.) or vice-versa

the control unit incorporating the spring loaded contact should be unscrewed from the control arm and a unit with

the contact spring loaded in the reverse direction fitted in its place (see Fig. 7). Adjust the relay operating point as

described above. Tighten the screws and replace the chart plate etc.

Programme Control

Programming is provided by a shaped transparent cam

driven by the chart motor and linked by a cam follower

to a control unit inside the instrument case. The control

unit continually operates external regulating equipment

in accordance with the configuration of the cam. The

measuring system monitors and records the process

variable as in the basic C105 instrument.

The programming cam is mounted over the chart directly

on to the chart drive shaft. The cam follower is a pivoted

arm with a roller lightly sprung against the edge of the

cam at one end and a linkage to the internal control unit

at the other. The cam follower is deflected as the cam

rotates and actuates the electrical control unit. All cams

are interchangeable.

10

Fig. 7. Electrical Control Contacts

Fig. 8

Sprung contact

E.A.

E.B.

Striker pin

Slots for fixing screws

Part no. 15321–80

Cam follower

Programme cam

Cam clamp nut

Chart

Part no. 15321–79

Page 11

11

MAINTENANCE

Cutting a programme cam

The required programme should be drawn on to a spare recorder chart and transferred using carbon paper or a

similar method to the paper covering on the cam blank. Mark on this trace significant points of the programme

where the process state is important. Mark drilling centres on the radii of these programme points exactly 3mm

out from the points. Drill through with a 6mm drill. Join up the programme points using a saw, and smooth off the

profile between the points.

A cam cut in this way will only provide a programme which is an approximation to the requirement owing to

variations in the distance between the cam-follower and the pen at different positions on the chart. If required,

precise programme cams can be supplied to customers’ specifications.

Fitting a new pen arm

Refer to the SPARES LIST, page 15 for the part numbers of the two pen arms. Make sure the correct replacement

arm (front or rear pen) is obtained. Follow the fitting instructions outlined under Inking System, page 6.

After fitting a new arm check the pen indication on the chart near the zero end of the range. See Zero Adjustment,

page 7.

Pen Adjustment

The pen lifter must be below the arm before the clock is

started. If the pen is bent, the effective length of the pen

arm will be altered so that the pen will not record the

correct time at all temperatures. If when the chart is

stationary the time increases as the pen moves towards

the outside of the chart, the pen arm is too long, and

vice versa, see Fig. 9. The error can be corrected by

careful straightening of the pen or by bowing the pen

arm slightly. Adjust the pressure if necessary by bending

the hook Y in Fig. 3.

Instruments with more than one pen are adjusted in the

same way as those with only one. Each pen is adjusted

independently. The mounting for the pen arm closest to

the chart (the green pen) is reversed and the fibre tip nib

is shorter so that each pen can move freely across the

other’s path. Only the red pen will indicate the correct

time; the green pen being set to record 4mm in advance

of the red.

Calibration – Temperature or Pressure System; Wet and Dry Bulb Relative Humidity System

Switch off the electrical supply to the recorder.

Make sure all pivots and linkages are free moving and adjust as follows:

Allow recorder to stabilise with measuring element in a low temperature (or pressure) just above scale

minimum. Pen should record within ±1% of span of correct value. If necessary adjust zero screw S, Fig. 3.

If pen is significantly out of line with cockpiece, i.e. more than about 5 angular degrees, adjust screw S to

line up pen with cockpiece. Loosen the coarse zero adjustment screw holding the serrated compensator

carrier, Fig. 5. and adjust pen to record true value, making a fine adjustment on screw S after the coarse

zero adjustment screw has been re-tightened.

Allow the recorder to stabilise with measuring element in high temperature (or pressure) just under scale

maximum. Pen should record within ±1% of span of correct value. If not, adjust by moving the link

connecting the compensator arm to the ratio arm on the cockpiece, see Fig. 5. In order to move the link,

loosen the nut at the back of the ratio arm pivot. Raising the pivot will increase the pen movement and

lowering the pivot will reduce the movement. Re-tighten after adjustment.

Repeat steps 1 and 2 until no further adjustment is necessary.

1.

2.

3.

Fig. 9

Decrease length

Red pen arm too long

Red pen trace correct

Green pen trace correct

Red pen arm too short

Length of bow

Increase length

Page 12

12

Calibration – Relative Humidity System (hygroscopic membrane)

Switch off the electrical supply to the recorder.

During manufacture the measuring element is calibrated in atmospheres of known equivalent relative humidity.

These atmospheres are generated by specific salt solutions at constant temperature in apparatus which is unlikely

to be available to the average instrument user.

Calibration checks can be made without salt solution by using a Whirling Hygrometer and comparing the pen

record with figures obtained from psychrometric tables (see page 7) in various ambient relative humidities, taking

care to allow the recorder time to stabilise at each reading.

Make sure all pivots and linkages are free moving and adjust as follows:

Allow the recorder to stabilise with the measuring element in a low ambient R.H. Pen should record within

±2% R.H. of correct value. If not, adjust zero screw J Fig. 4, in the mounting of the humidity element.

Allow the recorder to stabilise with the measuring element in a high ambient R.H. Pen should record within

±2% R.H. of correct value. If not, adjust by moving the position of the link pivot on the cockpiece ratio arm,

Fig. 4. In order to move the link loosen the nut at the back of the pivot. Raising the pivot will increase the

pen movement and lowering the pivot will reduce the movement. Re-tighten after adjustment.

Repeat steps 1 and 2 until pen records within ±2% of true R.H. at both positions on chart.

Linearity Adjustments to the measuring systems

Linearity adjustments are only likely to be needed if a measuring element has been replaced. Switch off the

electrical supply to the recorder. Follow the appropriate calibration procedure making an additional calibration

check at approximately centre span after the instrument has been adjusted to record correctly at high and low

readings. If necessary, slightly adjust the length of the connecting link (see Figs. 4 and 5). To gain access to the

connecting link remove the chart, pens and upper chart plate as described under Access to Recorder. After

adjusting the length of the link replace the chart plate, etc. recalibrate at high and low readings and then repeat

the centre span calibration check. Continue to make adjustments in this order until the record at all three points is

within specification.

Servicing – General

Every six months lubricate metal bearings using a good quality molybdenised clock oil, such as Moebius 8040/35

clock oil. Do not use this lubricant on any nylon parts. Wipe off any excess lubricant with a clean lint free cloth.

Oiling the mechanical clock

After a long period of operation the clock should be oiled. The complete clock can be detached by unscrewing the

three fixing screws when the chart plate is removed. Use a high grade of clock oil. (This operation should only be

carried out by a suitably experienced person).

1.

2.

3.

Page 13

13

Wet and Dry Bulb Water Bath

The wick should be changed frequently, the period between changes depending on the surrounding atmosphere.

In wood drying kilns, etc., the wick should be renewed once a week but in clean atmospheres, e.g. offices, it can

be left as long as three weeks. The water must be kept clean and free from impurities.

Fig. 10. Wet and Dry Bulb Water Bath

298.5 mm

Bulb clamp

Dry bulb

Wet bulb

with wick covering

Mounting holes

13.5 mm dia.

127 mm

130 mm

A.

B.

Water bath

Inlet union

Note: Water supply maximum pressure 6 metre head.

231.5 mm

Overflow union

Optimum air flow direction

For capillary entry from the

right mount clamp Ausing

holes B

Page 14

14

SPECIAL INSTRUCTIONS & DIAGRAMS

Page 15

15

FAULT FINDING

Recorder pen is inaccurate or gives no indication

1. Measuring element broken; capillary plugged or broken on temperature recorder.

Check elements or capillary and replace as necessary.

2. Disconnected linkage in recorder.

Re-connect or repair as necessary.

3. Recorder out of calibration, measuring element not damaged.

Check and calibrate if necessary, pages 11 and 12.

No record on chart

1. Pen not inking.

Fit new pen capsule, page 6.

2. Chart drive motor stopped.

Rewind, page 6. Replace if broken.

3. Chart clamp broken.

Replace by new assembly.

Poor Control – Electrical

1. Faulty relay.

Replace relay.

2. Friction in measuring system.

Correct action of measuring system.

3. Lack of electrical power in circuit being controlled.

Increase power rating of control equipment.

4. Power in circuit being controlled too high.

Decrease power rating of control equipment.

SPARES LIST

Description Part Number Reference

Chart Quote the number on the chart

supplied or duration and range. Fig. 1

Chart clamp assembly (not programme controllers) 15321/608 Fig. 2(a)

Chart drive motor – electrical (assembled on moulding) Quote chart speed voltage and mains

frequency .

Chart drive motor – mechanical Quote chart speed and specify

“mechanical”.

Circlip – setting pointer spindle 600353

Electrical Control with spring contact on the Control Arm:

Spring contact assembly-relay energized below set point 15321 / 79 (min. type A) Fig. 7

Spring contact assembly-relay energized above set point 15321 / 80 (max. type C) Fig. 7

Striker contact pin 19 s.w.g. silver wire Figs. 5 & 7

Hinge 15 / 240 Fig. 1

Hinge – pin 15 / 243

Hinge – screw 15 / 211

Hinge – spring 15 / 220

Key for lock FA558

Lock with spring washer and catch 22656 / 142 Fig. 1

Pen arm – green (rear position) 15321 / 328 (stamped 8 on pen arm) Figs. 1 & 3

Pen arm – red (front position) 15321 / 327 (stamped 7 on pen arm) Figs. 1 & 3

Pen capsule – green P105M/0302 (pack of 5) Fig. 3

Pen capsule – red P105M/0301 (pack of 5) Fig. 3

Pen lifter 15 / 277

Page 16

16

SPARES LIST (continued)

Description Part Number Reference

Pressure Recorders:

Tailpiece St/St 2” BSP 22251 / 9

Tailpiece St/St a” BSP 17600 / 01

Tailpiece Brass 2” BSP 22251 / 22

Tailpiece Brass a” BSP 16992 / 51

Nut St/St 2” BSP 22251 / 10 Fig. 2

Nut St/St a” BSP 17599 / 01

Nut Brass 2” BSP 22251 / 20

Nut St/St a” BSP 16692 / 01

Fibre washer 2” BSP 22 / 745

Fibre washer a” BSP 22 / 746

Programme Controllers:

Chart carrier 17271 / 26

Chart clamp nut 17271 / 27

Cam clamp nut 17271 / 6 Fig. 8

Cam blank 17271 / 29

Relay (electrical) – 5 amp 87294

3 amp 600492

Setting pointer clamp nut 15321 / 245

Stud – panel mounting 100013 Fig. 2

Temperature and Humidity Recorders:

Element guard 22 / 401

Wick for Wet & Dry Bulb Water Bath 100016 Fig. 10

Window glass 15 / 204

Window perspex 15 / 204C

Zero screw ‘S’ 15 / 228 Fig. 3

Made Up kits:

Relay type 2400 (Part No. 600169) is no longer available as a spare part and is

replaced by one of the following relay kits.

Single relay replacement:

(200/250V, 50 or 60 Hz supply) 15321 / 542 / 1

(100/120V, 50 or 60 Hz supply) 15321 / 542 / 2 Refer to

Double relay replacement: Service Aid

(200/250V, 50 or 60 hz supply) 15321 / 543 / 1 No. 15321 / 545

(100/120V, 50 or 60 Hz supply) 15321 / 543 / 2

For information on other Spare Parts or Kits contact British Rototherm.

678

6644774488

6447448

We reserve the right to amend specification without notice

© The British Rototherm Company Limited 1990.

The British Rototherm Company Limited

Margam, Port Talbot, West Glamorgan U.K. SA13 2PW

Telephone: (01656) 740551

Fax: (01656) 745915

E-Mail: rototherm@rototherm.co.uk

Distributor

HP • (01656) 788038

15321-524/1

R. 0390

Loading...

Loading...