Page 1

Quality Uncompromised

®

Technical

DVD PLAYER

RDV-985

Manual

Table of Contents

Specification......................................1

Information........................................2~17

Block Diagrams.................................18~22

Schematic Diagram ..........................23~33

PCB Assembly..................................34~36

Parts List...........................................37~47

Specifications

General

Readable Discs: DVD VIDEO, Audio CD, VIDE CD, SUPER VIDEO CD

Video Fomat: PAL or NTSC selectable

Video Output

VIDEO OUT (pin jack): 1.0 Vp-p (75 ohms)

S-VIDEO OUT (S jack):

Y Output: 1.0 Vp-p (75 ohms)

C Output: 286 mVp-p (75 ohms)

Horizontal Resolution: 500 Lines

Signal to Noise Ratio: 65 dB

Audio Output

ANALOG OUT (pin jack): 2.0 Vrms (10 kohms)

DIGITAL OUT (optical): - 21 to -15 dBm (peak)

Audio Characteristics

Frequency Response:

CD: (sampling frequency 44.1 kHz): 2 Hz to 20 kHz

DVD (sampling frequency 48 kHz): 2 Hz to 22 kHz

DVD (sampling frequency 96 kHz): 2 Hz to 44 kHz

Dynamic Range:

16 bit: More than 100 dB

20 bit: More than 108 dB

24 bit: More than 108 dB

Wow and Flutter: Unmeasurable (less than

Total Harmonics Distortion: Less than 0.002%

Physical

Power Requirements:

USA Version: AC 120V, 60 Hz

European Version: AC 230V, 50 Hz

Power Consumption: 23 W (POWER ON), 2 W (STANBY mode)

Weight: 4.7 kg (10.4 lbs)

Dimensions (W x H x D): 445 x 112 x 338 mm

1/2 x 47/16 x 135/16 inch

17

±

0.002%)

THE ROTEL CO., LTD.

SHINSEN-BLD. 4F 10-10 SHINSEN-CHO, SHIBUYA-KU,

TOKYO 150-0045, JAPAN

Serial. NO.

Beginning

Y-356A-0109/W

Page 2

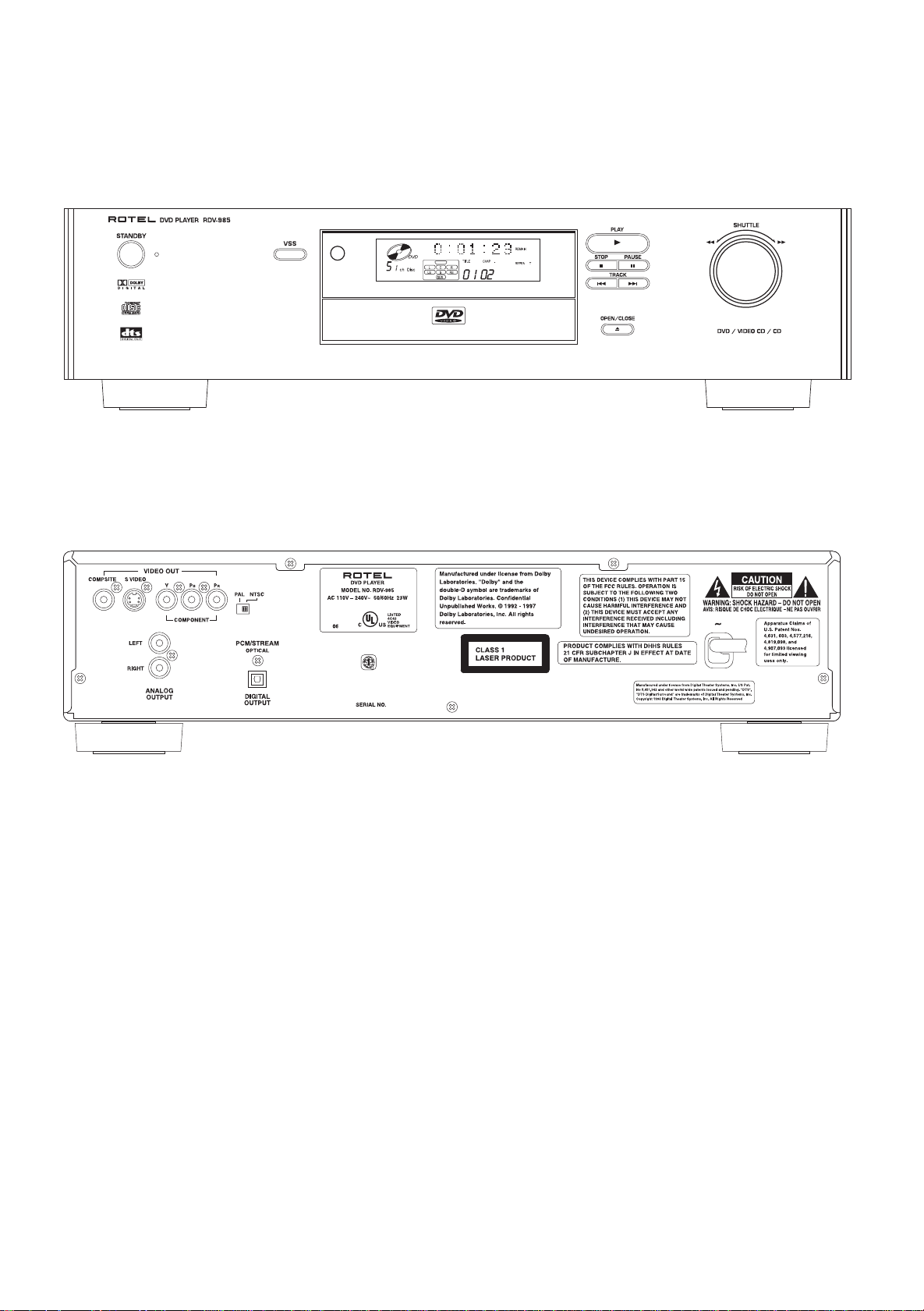

Appearance

2

Page 3

Main Adjustment

3

Adjustment and confirmation matter

(1) Auto adjustment method

If microprocessor (IC401, IC402, IC714, IC716) or servo board (LEA10047) is replaced, initialize

the D VD player in the following matter:

ref. separate sheet.

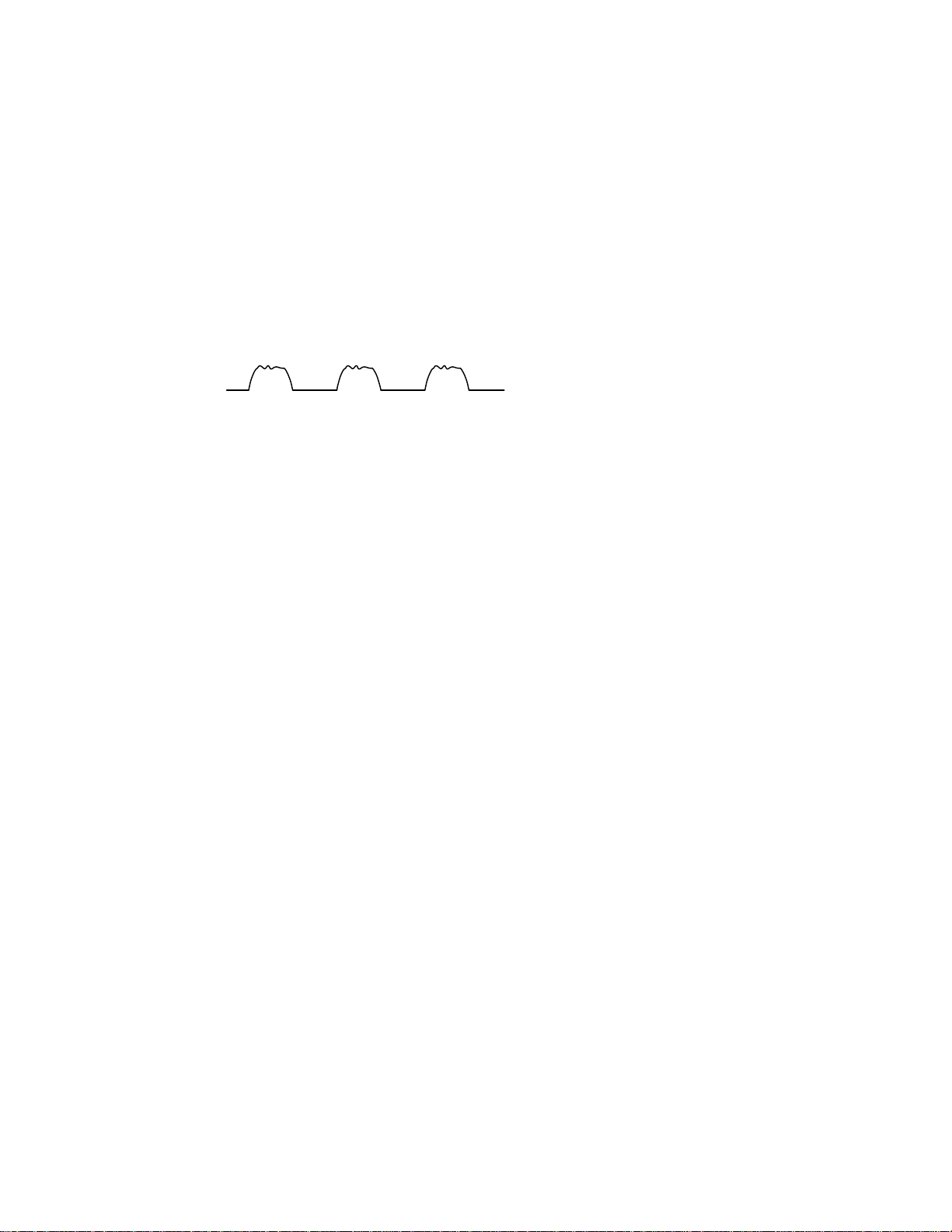

(2) Confirmation of DVD RF level

1.The oscilloscope is connected between "1"(RFOP) of

CN104 and "2"(GND).

2.Reproduction of the test disc ( VT-502)

made by JVC.

3.It is confirmed that RF LEVEL is 350mVp-p 150mVp-p.

4.When there is disorder in the waveform road cuts etc,

test disk is exchanged and measured.

+

-

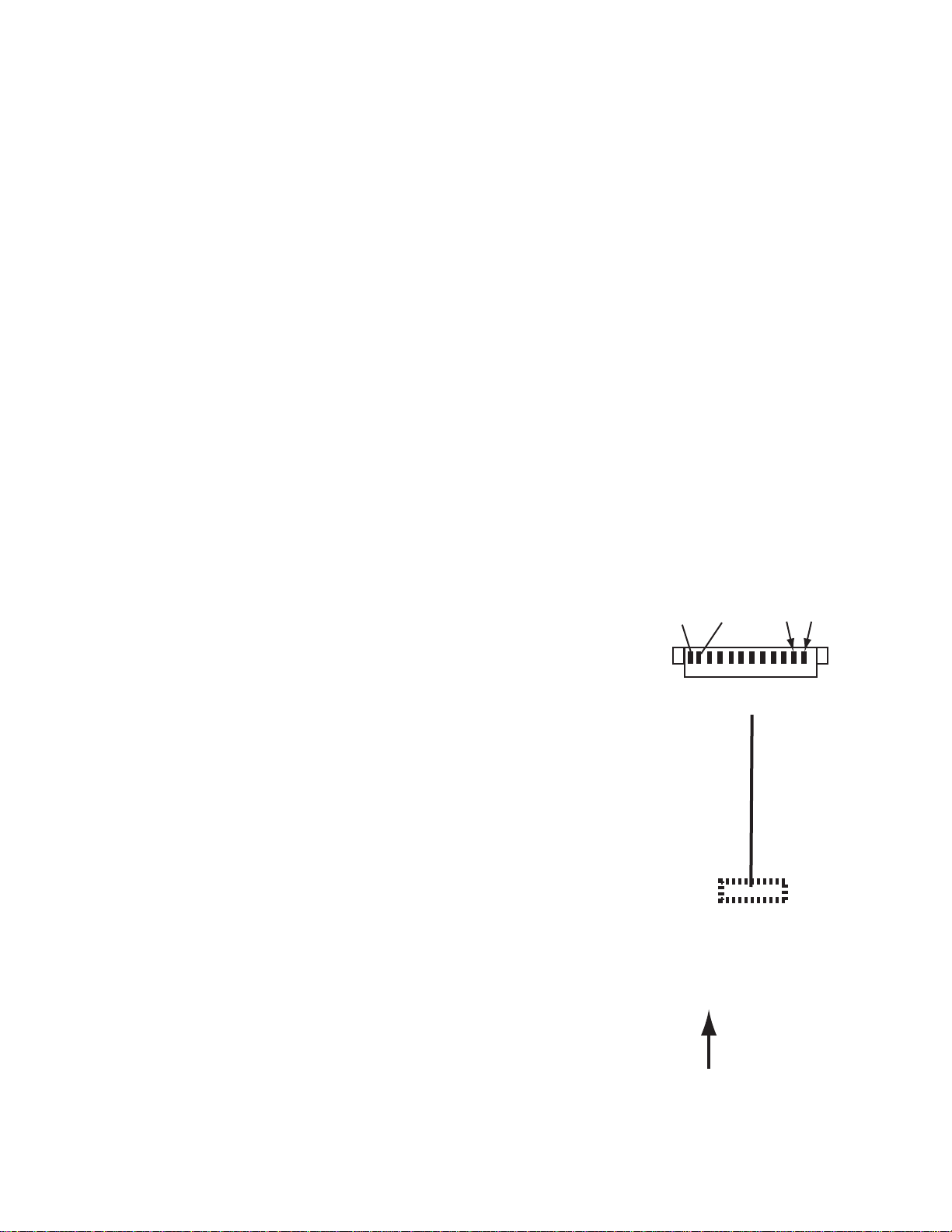

(3) Confirmation of CD jitter level and RF level

1. The CD jitter meter is connected between "11"(GND)

of CN104 and "12"(FLTOUT).

The RF level is observed at the same time.

2.The first test disk(CTS-1000) made of JVC is reproduced.

3.It is confirmed that RF LEVEL is 360 100mVp-p.

5. When there is disorder in the waveform road cuts

etc, test disk is exchanged and measured.

+

-

GNDGNDFLTOUT

12 ~ 1

CN104

Servo control P.C.B

LEA20001

DVD SERVO CONTROL PWB

"1""2""11""12"

RFOP

FRONT SIDE

Page 4

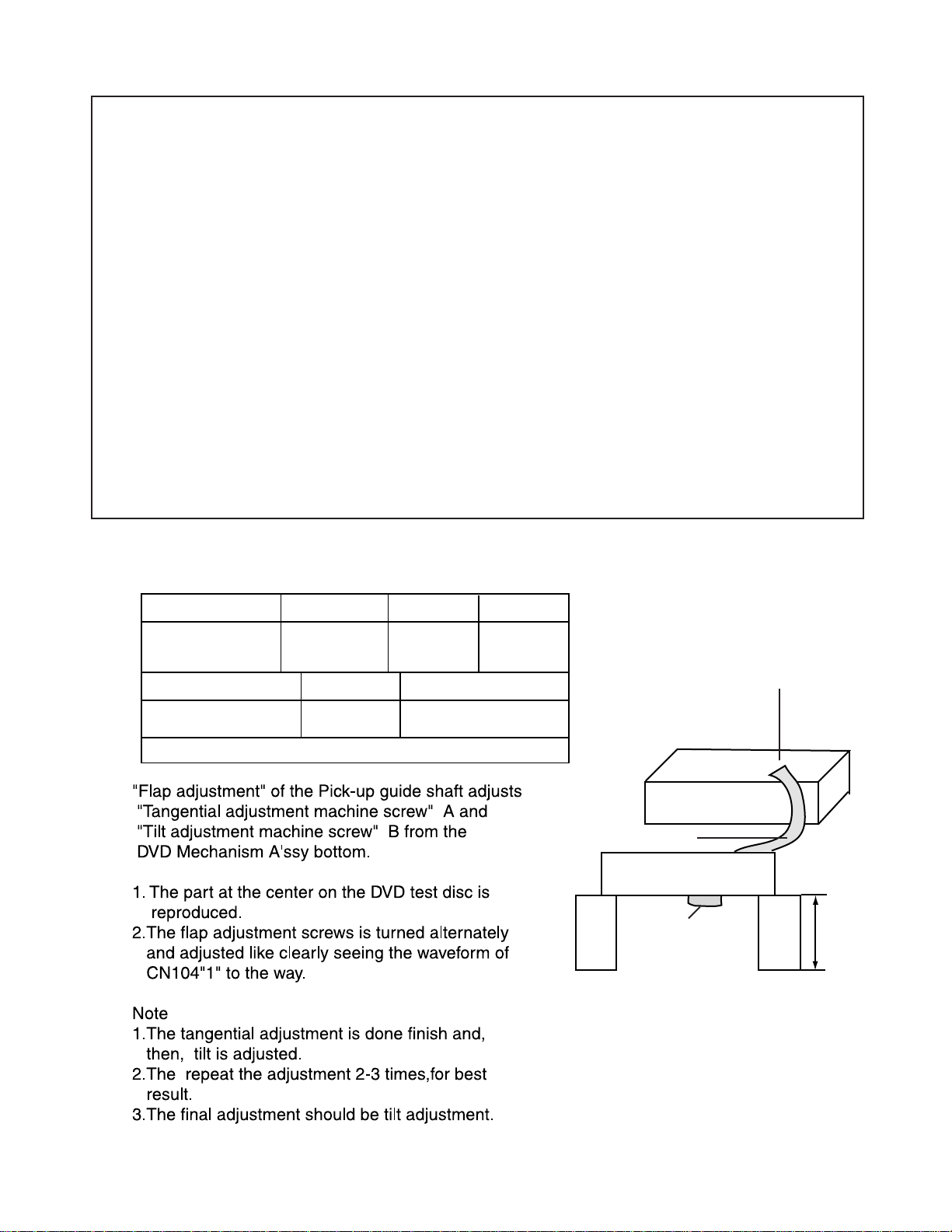

(4)Flap adjustment of the Pick-up guide shaft

4

Attention !!

RDV-985 is adjusted from issue machine because of the FL display on the way.

Please go in the adjustment method before changes according to the following procedures.

Measurement

CN104 pin"1"

GND:CN104 pin"2"

Measurement machine

Oscilloscope

General tool : Hex-head wrench(2mm)

Adjustment point

Refer to Fig.2

connections

Refer to Fig.1

Mode

Reproduction

part

Extension cord No.

QUQ110-3740AM

Disc

VT-502

Extension Cord

DVD Mechanism A'ssy

CN11 of

Stand

Connection PWB

CN101 of DVD Servo Control PWB

RDV-985

Stand

200mm

Fig.1

Page 5

Confirmation after adjustment.

5

Confirm to reproduce video CD and CD after

the DVD test disc is adjusted and to find abnormality.

B

Fig.2

A

A

(5) About keeping the disc

As for the DVD test disc, plane accuracy is demanded.Please note the keeping place on the disc.

1. Please do not put the disc directly on the work desk etc. after uses .

2.T o keep the planarity of the disc, politely handle ,and please put in a special case and keep

the disc v ertically after uses .

Please k eep keeping the disc in a cool place where direct sunshine and the air-conditioning

wind do not dr ive.

3.When the disc cur ves,an accurate adjustment cannot be done.

Please e xchange for a new test disc and adjust optics.

4Other discs might not be ab le to be reproduced when adjusting on a curved disc.

Point of adjustment

* Please execute the static electricity protection measures before starting the

adjustment.

* When the following parts are exchanged,optical adjustment "Adjust the flap of the disc motor"

is necessary.

1.The disc motor w as exchanged.

2.The laser pic k up was exchanged.

3.The tr averse motor unit was exchanged.

Note

Additionally , please adjust the flap of the disc motor when the picture quality deterioration is

seen .The basic adjustment though, is unnecessar y for part exchange in the traverse.

An optical adjustment in the laser pick up cannot be done.

Please adjust the flap of the disc motor after e xchanging the laser pick up.

* When the traverse unit is exchanged, the adjustment is basically unnecessary.

Page 6

Check points for each error

6

(1) Spindle start error

*Defective spindle motor

Are there 10ohms resistance between each pin of CN101 "29~31"?

(The power supply is turned off and measured.)

*Hall element: Is sine wave output between CN101 "23" and "24", between "25" and "26",

and between "27" and "28" during rotation?

In either case, replace the mechanical unit.

*Defective spindle driver (IC251)

Is a driving wave output from CN101 "29~31" ?

During

rotation

Is IC251 "9" at "H" level (START)?

Servo IC --- Is control signal sent to the motor driver ?

IC201 "95" : Duty is 50% during stop, but varies during rotation (greatly varies at start).

--- If not sent, pattern or servo IC (IC201) is defective.

R259 : approx 2.5V during stop, but varies during rotation (greatly varies at start).

--- of not sent, pattern or servo IC (IC201) is defective.

Is FG input to servo IC ?

Observe FG wave from IC201 "89". --- If not output, pattern, IC251 or IC201 is defective.

(2) Disc Detection, Distinction error (no disc, no REFNV)

* Laser is defective.

* Front End Processor is defective (IC101).

* APC circuit is defective. --- Q101.

* Pattern is defective. --- Lines for CN101 "15" and "17".

Lines for between IC201 "2" and IC101 "2"(LDONA),

between IC201 "3" and IC101 "1" (LDONB).

* Servo IC is defective (IC201).

* Is signal sent to IC201(servo)"71" AS2 ?

* IC101 --- For signal from IC101 to IC301, is signal output from IC101 "88" (RFAS1) and

IC101 "69" REENV ?

Page 7

(3) Traverse movement NG

7

* For automatic adjustment, traverse movement occurs only when the position is changed to retry

judging the disc type after the 1st judgment resulted in an error. Therefore, traverse movement

rarely occurs because, in most cases, disc judgment at the current position (1st time judgment)

is executed successfully. (Of course, NG rarely occurs in this step.)

Note: 1st time judgment of disc type resulted in NG. --- The re-judgment of disc type may not be

successful. Therefore, after removing the cause of traverse movement, re-execute automatic

adjustment and confirm that no problem exists.

* Check point

a)During stop

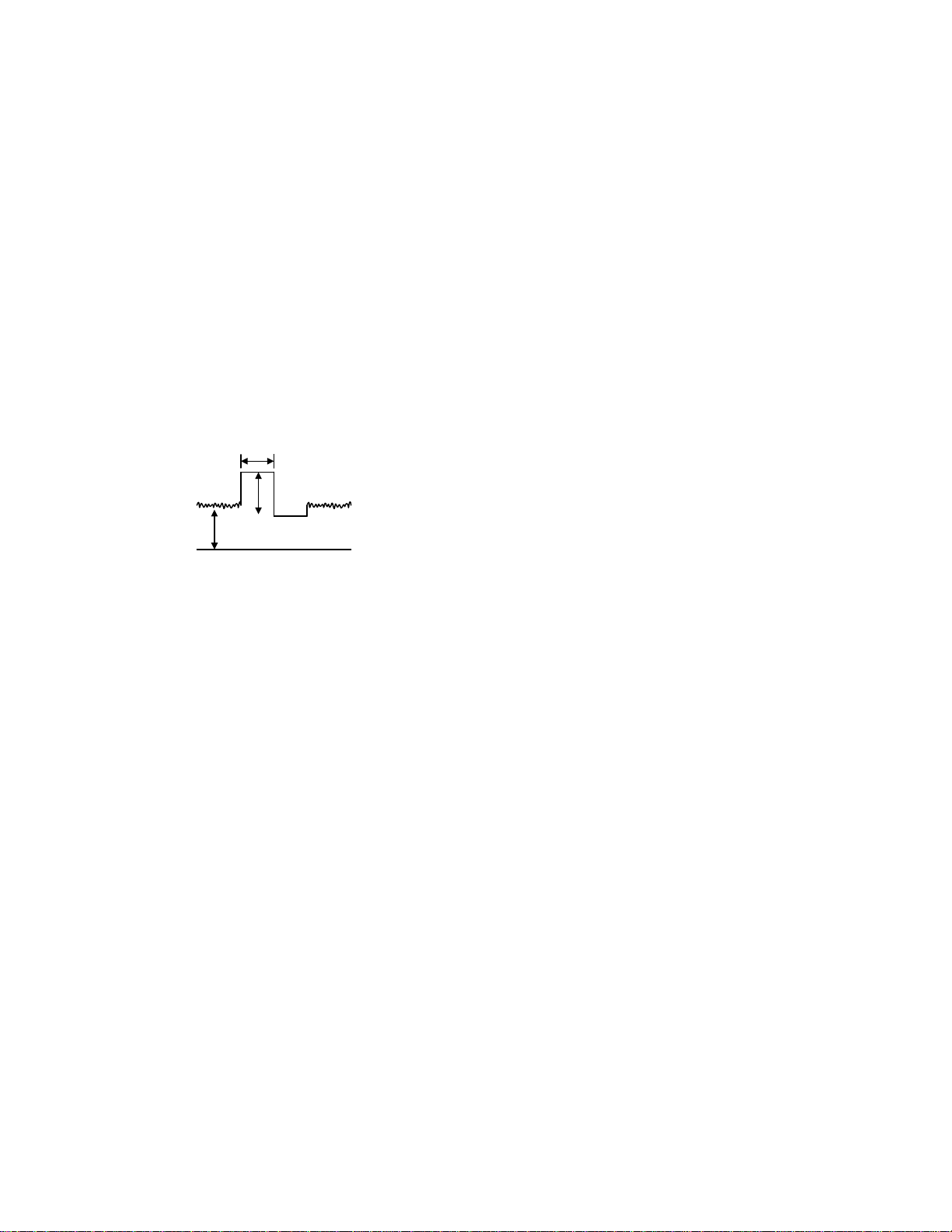

Whether 50% duty pulse is output to R273

Whether between R274 and C271 is at approx. 2.5VDC

Offset voltage between CN101 "34" and "35" (scores mV if exists)

b)When tray is opened or closed

Check by oscilloscope whether a rectangular wave signal is output from CN101 "34" or "35".

50msec

2.5V

Approx.

500mV

GND

If checking a) or b) resulted in NG, IC201 maybe defective.

(4) Focus ON NG

* Is FE output ? --- Pattern, IC101

* Is FCDRV signal sent ? (R286) --- Pattern, IC301

* Is driving voltage sent ?

CN101 "20", "21" --- If NG, pattern, driver, mechanical unit (with the power turned off, measure the

resistance between CN101 "20" and "21").

* Does CN101 "7"(SRF1) become "H" and is the focus drawing in done?

--- Mechanical unit (laser power too low), IC101(defective gain)

--- Moreover, It is thought that abnormality is found in the disk.

* Mechanical unit is defective.

(5) Tracking ON NG

* When the tracking loop cannot be drawn in, IC201 "39" (/TRON) does not become "L".

* Mechanical unit is defective.

Because the under mentioned adjustment value is abnormal, it is not possible to draw in normally.

* Periphery of driver (IC271)

Constant or IC it self is def ective.

(When passing without becoming abnor mal while adjusting the following.)

* Servo IC (IC201)

When improper ly adjusted due to defective IC.

[F ocus position rough adjustment]

[Phase diff erence cancellation rough adjustment]

[T racking balance adjustment]

Page 8

(6) Spindle CLV NG

8

* When the spindle cannot be shifted to CLV Servo, does not become "H" between IC301 "69"

and IC201"37".

* IC201 Is signal output from CN103 "1" (RFOP)?

* IC201 Is signal output from CN103 "11" (DSLIP)?

* IC201 Is signal output from CN103 "6" to "9" (binary-coded clock and data)?

* IC201 Is "39" (/TRON) at "L" level ?

* IC301 "74" to "76" --- Is signal output to IC201 "24", "25", "28" (In case of only CD).

(Serial communication of rotation information)

* Spindle motor driver is defective.

Even when one of the three phases is defective, item (1) may be passed.

--- Check the second item in (1) above.

* C260 to C263 Defective soldering

If noise eliminating capacitors are not properly soldered, noise may ride on the waveform.

* Besides, the undermentioned cause is thought though specific of the cause is difficult because various

factors are thought.

Mechanism is defective.(jitter)

IC101, IC201.

(7) Address read NG

* Besides, the undermentioned cause is thought though specific of the cause is difficult because various

factors are thought.

Mechanism is defective. (jitter)

IC201, IC301, IC401.

The disc is dirty or the wound has adhered.

(8) Between layers jump NG (double-layer disc only)

* When the focus flight is generated when jumps between layers.

Because all adjustments for L1 layer must be successful, this error may rarely be due to a

circuit defect.

* Crosstalk might occur from tracking to focus system. (See (11) ) --- Replace the mechanical unit.

* Driver surroundings.

* Defect of constant and IC.

* For double-layer discs, after checking CLV on layer L1, jumps to layer L0 after mode changes to FG.

Then tracking is turned off, and adjustments are executed from the focus position coarse adjustment

in order.

* When the jump between layers is done on the single-layer disk, the disk distinction error is thought.

--- The laser power is low (RF level is confirmed by CN102 "1" (RFOP)).

--- AS1, AS2, REFNV Is the signal sent to between IC101 and IC201 ?

Page 9

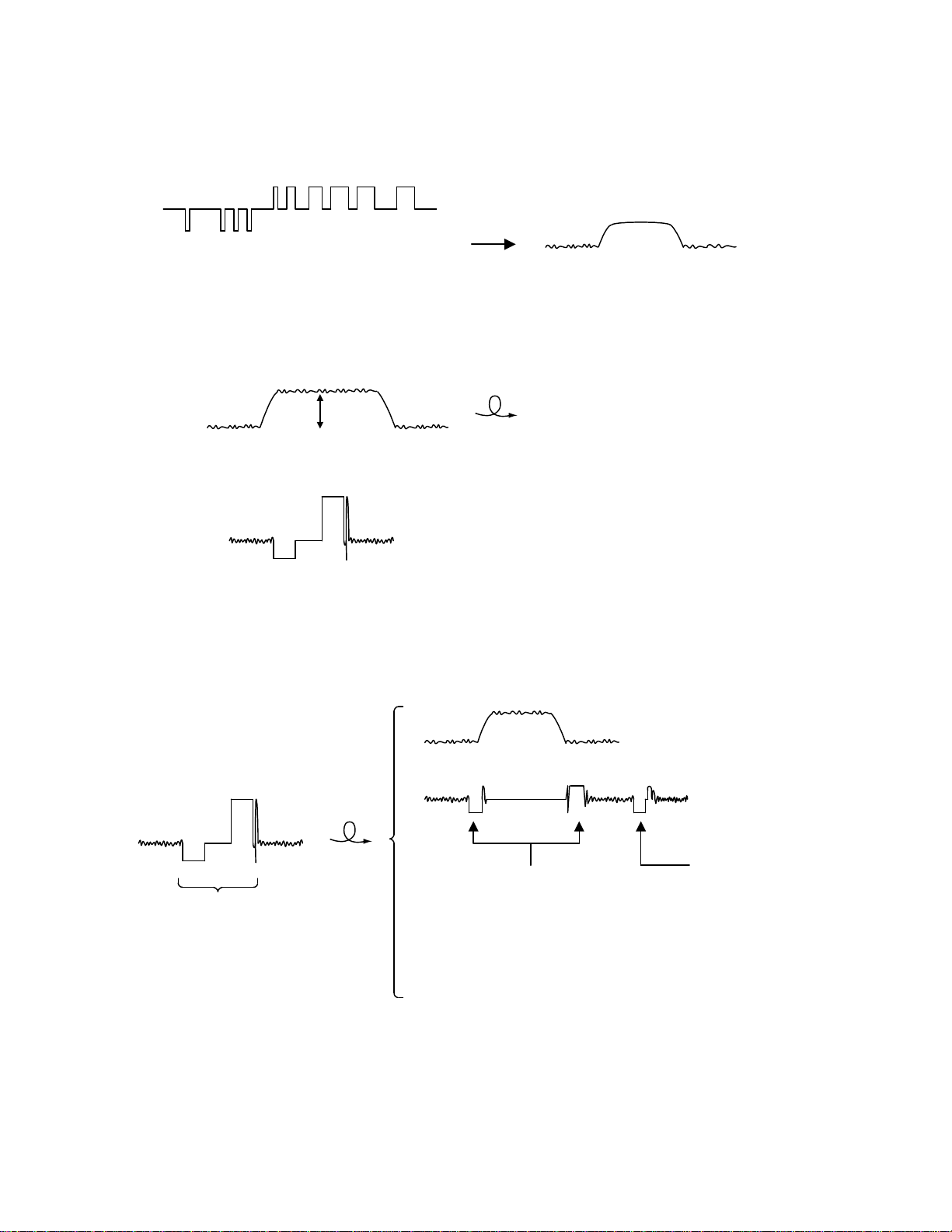

(9) Neither picture nor sound is output

9

* Cannot search

a) Can the feed system be driven?

Chec k the waveform of TRSDRV signal (R273). --- Waveform between R274 and C271.

Search results in a change of duty

(three v alues with 2.5V at the center)

(The figure is e xaggerated.)

Chec k the waveform of CN101 "1" and "2". --- After the driver (IC271)

Approx.

2.5V

For short-distance search, the waveform

becomes roundish, not trapezoidal, and

voltage is low.

b) Is kick available?

Chec k the TRDRV signal waveform from R289.

Chec k the waveform of CN101 "22" and "23" --- After the driver (IC271)

Although diff ers in amplitude and DC offset, the waveform is similar to that of R289

Long-distance seek

Feed

Tracking

Kick pulse (fine seek) is

inserted after longdistance seek.

(Not one)

Kick pulse

Acceleration pulse at start;

deceleration pulse at stop

(each one)

(In the direction of search,

opposite to this figure)

Hold (DC) during feed

Page 10

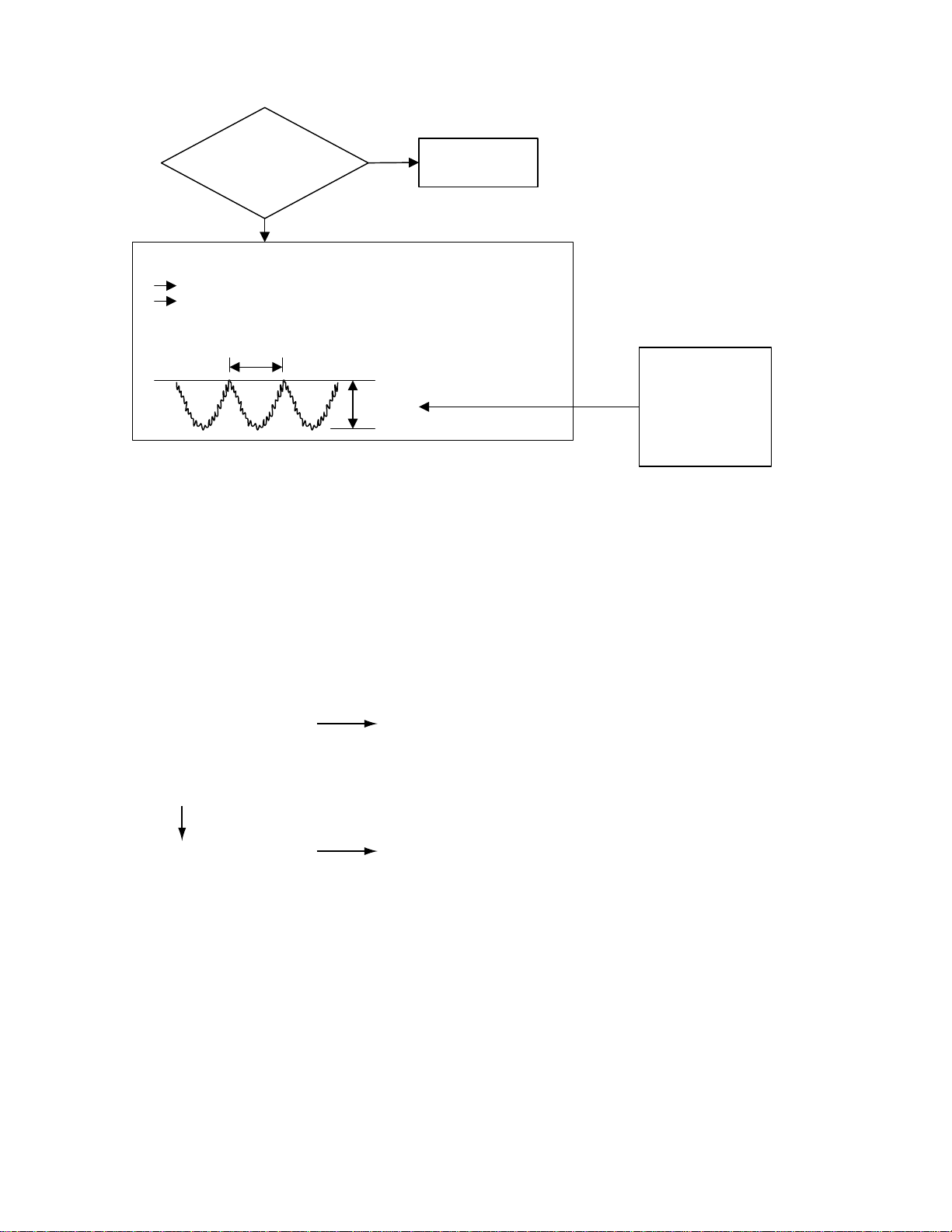

(10) Picture is distorted or abnormal sound occurs at intervals of several seconds.

10

Does JITOUT

change periodically?

(2V or more in peak

value, except

during kick)

YES

Feed system is defective (drive gain is defective: too large).

Check the waveform according to a) in (9).

Play back a simple disc with no angle change.

OK when the following waveform appears at intervals

of several seconds.

5~10Sec.

1~1.2V

Some system other

NO

than servo may be

defective.

If this voltage is too

high (2V or more, for

example), feed motor

may be defective, or

the mechanical unit

has seized.

(11) Others (unusual events experienced to date)

* Problem occurs with double-layer discs although no problem occurs with single-layer DVD.

(Error occurs, or search becomes unstable and takes longer.)

Crosstalk might occur from tracking to focus system.

--- When FE was observed during search (skip, etc.), it was found that a wave resembling TE

with an amplitude of 200mVp-p was riding on FE.

--- Mechanical unit was replaced.

* Error frequently occurred in the outer part of discs although no error occurred in the inner part.

--- Mechanical unit was replaced because tilt seemed to be defective.

(12) CD During normal playback operation

a) Is TOC reading normal?

NO

Please refer to "Servo Volume" flow.

Displays total time

for CD-DA.

Shifts to double-speed

mode for V-CD.

b)Playback possible?

YES

NO

*--:-- is displayed during FL serch.

According to [*Cannot serch ] for DVD(9), check the feed

and tracking systems.

*No sound is output although the time is displayed.(CA-DA)

*DAC, etc, other than servo.

*The passage of time is not stable, or picture is abnormal.(V-CD)

*The wound of the disc and dirt are confirmed.

(13) Others

V-CD : Frequent occurrence of error in inside and outer.

(Even the disk without the wound : when generated.)

Waveform observation

--- Is the oscillation frequency of about 700~900Hz output?

(Borrow a pertinent disk for the complaint for the combination with the disk.)

--- Exchanges mechanism for the mechanism resonance.

Page 11

Precautions for Service

11

Handling of Traverse Unit and Laser Pickup

1. Do not touch any peripheral element of the pickup or the actuator.

2. The traverse unit and the pickup are precision devices and therefore must not be subjected to

strong shoc k.

3. Do not use a tester to examine the laser diode. (The diode can easily be destroyed by the

inter nal power supply of the tester.)

4. To replace the traverse unit, pull out the metal short pin for protection from charging.

5. When replacing the pickup, after mounting a new pickup, remove the solder on the short land

which is pro vided at the center of the flexible wire to open the circuit.

6. Half-fixed resistors for laser power adjustment are adjusted in pairs at shipment to match the

char acteristics of the optical block.

Do not change the setting of these half-fix ed resistors for laser power adjustment.

Destruction of Traverse Unit and Laser Pickup by Static Electricity

Laser diodes are easily destroyed by static electricity charged on clothing

or the human body . Before repairing peripheral elements of the traverse

unit or pic kup, be sure to take the following electrostatic protection:

1. Wear an antistatic wrist wrap.

2. With a conductive sheet or a steel plate on the workbench on which

the traverse unit or the pick up is to be repaired, ground the sheet

or the plate.

3. After removing the flexible wire from the connector (CN101),

short-circuit the flexible wire by the metal clip.

4. Short-circuit the laser diode by soldering the land which is provided

at the center of the flexible wire for the pickup.

After completing the repair , remove the solder

to open the circuit.

Short-circuit

Page 12

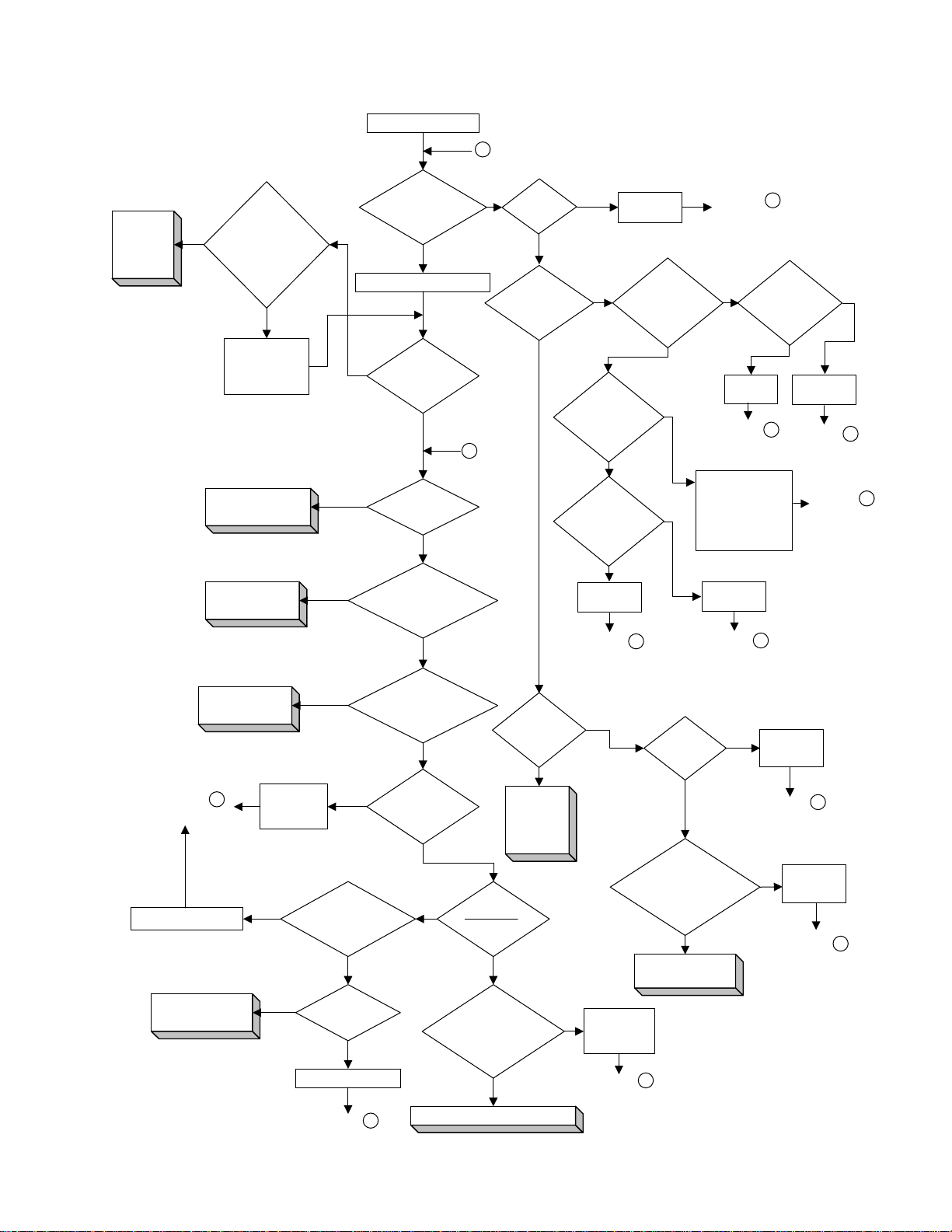

Troubleshooting

1.Power-on processing

12

Connect to outlet.

A

to

Micro-

computer

Volume.

NO

POWER switch of

processing is OK.

to Power Supply

Does

the lamp

goes out when

remote control

box is turned

ON?

YES

Check S867

(power switch)

and the line

to IC714.

Power-on

Volume.

P.STAND-BY

indicating lamp

Press POWER switch.

NO

indicating lamp

YES

NO

voltage applied at each

lights up?

YES

STANDBY

goes out?

Does FL

light up?

NO

Correct

lead

of FL?

YES

NO YES

fuse is blown

IC953"1" at

approx.5.6V?

YES

B

F901

Voltage of

YES

Replace

F901.

NO

NO

wave detected on

the anode side of

Does the

oscillation wave

come out to

IC901"3"?

NO

Does the

DC voltage(input

AC 1.4V) come out to

D901 output side

NO

Replace

D901.

Return to A

and recheck.

Is the AC

D953?

NO

YES

YES

Return to A

and recheck.

YES

Connecting wires

to the soldered

part of the pins of

T902(transformer)

and anode of T902

is examined.

Replace

Return to A

and recheck.

Is energizing

of "cathode of D953"

and "pin1 of IC953"

YES

Replace

D953.

Return to A

and recheck.

IC901.

normal?

NO

Repair the

wiring.

Return to A

and recheck.

Return to A

and recheck.

to Power Supply

Return to B

and recheck.

Repair the wiring.

To Microcomputer

Volume.

Volume.

Check

IC831,R843

and C833.

between IC831"13"

and IC714"76" OK?

NO

NO

NO

Is connection

YES

Voltage

of CN831"19"

at +5V?

YES

Replace IC831.

Return to B

and recheck

Correct voltage

applied to IC831

(FL driver)?

YES

Oscillating

wave output from

IC831"20"?

YES

NONO

of IC831"14"-"16" and

IC714"2" to "4" OK?

To Microcomputer Volume.

of IC953"3"

computer

Voltage

of IC831"13"

(P.ON RESET)

at +5V?

YES

Is connection

YES

Voltage

at 5 V?

to

Micro-

Volume.

YES

NO

NO

OK between IC953"3"

Repair the

wiring.

Return to B

and recheck.

Is IC953

hot?

YES

Continuity

and IC714"16",

"62" and "99"?

OK

To Microcomputer

Volume.

NO

NG

Replace

IC953.

Return to A

and recheck.

Repair the

wiring.

Return to A

and recheck.

Page 13

2. Power Supply Volume

13

With all the wiring removed, check unit power board.

(1) Remove all flat wires and wire assemblies which are connected to CN801, CN805, CN806.

(2) Short -circuit CN805"4" (POWER ON:B168) and "5" (B5V:B167). (Set each regulator to ON.)

(3)

The load resistance is connected between CN805"5"(B5V:B167) and "8,9"(D.GND:B164).

(4) Connect to the outlet and check the voltage at each part.

(For the voltage specification, see the wiring diagram.)

* If the load resistance is not connected, the voltage is not output to "B167".

Then restore the connection of CN801, CN805, CN806 and check voltage.

(1) Remove the wire short -circuiting CN805"4" and "5".

(2) Remove the load resistance.

(3) Restore the connection of CN801, CN805, CN806.

(4) Connect to the outlet.

(5) Turn the POWER switch on and check the voltage at each part.

If voltage abnormally drops when CN801, CN805, CN806 are connected (load is connected) though the voltage

was at the normal level when CN801, CN805, CN806 were disconnected(load is connected), or if the protective

element (fuse, etc.) is opened, the load which is supplied power may be defective or the wiring may be

short-circuited.

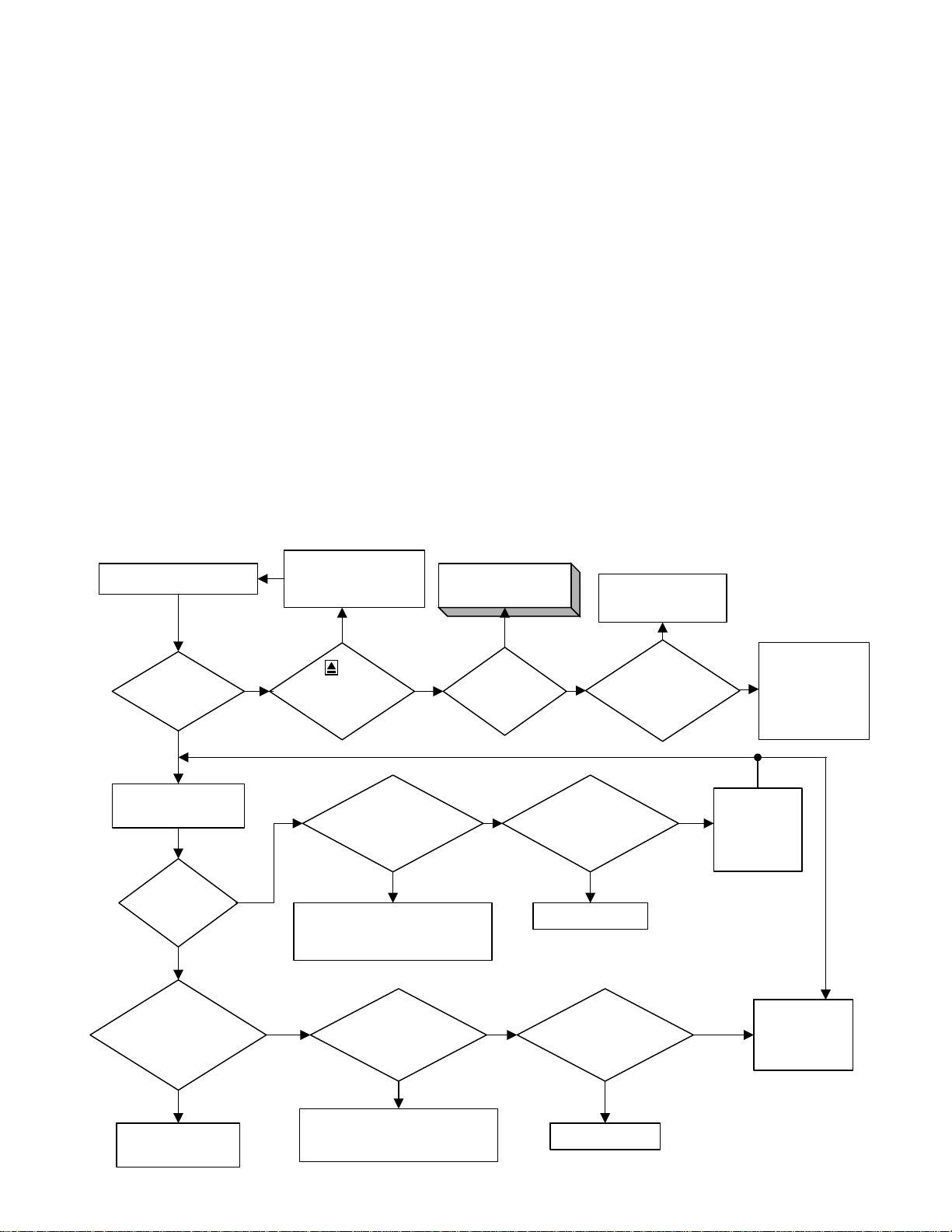

3. Open/Close Operation

Press OPEN/CLOSE key

Does the tray

smoothly open?

YES

Press in by hand

when fully opened.

Ejected

Does the tray

retreat?

YES

Voltage

between CN102"4"

and "5" at 0V when

tray ends

retreating?

OPEN/CLOSE

operation is OK.

NO

NO

Check S835 (OPEN/

CLOSE) and the

wiring to IC714.

YES

of

the remote control

box functions

normally?

CN102"1" at 0V when

tray opening operation

Check the connection between

CN102 and mechanical unit.

Check the mechanical unit.

CN102"3" at 0V when

Check the connection between

CN102 and mechanical unit.

Check the mechanical unit.

NO

Voltage of

ends?

NO

Voltage of

tray closing

ends?

NO

To Microcomputer

Volume.

NO

Voltage

of IC401"52"

at 0V?

YES

YES

IC401"52" at 0V when

tray opening operation

Check IC251 and

the periphery.

YES

Voltage of

Replace IC401.

IC401"51" at 0V when

tray closing

Replace IC401

voltage applied

between CN102"4"

and "5"?

ends?

YES

Voltage of

ends?

YESYES

Any

NO

NO

YES

Check the

connection

of CN102"1"

and

IC401"52"

NO

Check the

connection

between CN102

and mechanical

unit. Check the

mechanical unit.

Check the

connection of

CN102"3" and

IC401"51".

Page 14

4. Microcomputer Volume

14

Processing of Each Microcomputer

* IC714 System microcomputer (sub-microcomputer)

After powering on, this microcomputer is continuously activated to control keys and remote control

signals.

According to key operations or remote control signals, it controls (turns on/off) the power for

LSIs including IC401 (main microcomputer) and the audio/video output circuit.

It also controls the resetting of the main microcomputer, FL driver IC (IC831) for FL display, and

various LED displays.

* IC401 Main microcomputer

This microcomputer controls a group of LSIs of servo and signal processing sections according to

commands from the system microcomputer.

After receiving time information from the signal processing section, it transmits the information

together with the status to the system microcomputer.

It controls the resetting of the LSIs of the servo and signal processing sections.

It has IC402 (16Mbit ROM) as an external ROM.

Normal Starting Conditions

* IC714 System microcomputer

(1) +5V must be applied to "16" and "62".

(2) Oscillators of "13" and "15" must be oscillating correctly.

(3) Input to "12" (RESET) must be at +5V (reset cancel).

If above (1) to (3) are not satisfied when the P.STANDBY indicating lamp does not light at

power-on, IC714 may be defective.

* IC401 Main microcomputer

(1) +5V must be applied to "17","22","34","54","66"

(2) Clock signal (13.5MHz) must be input to "23" from IC301 (ODC LSI).

(3) Input to "82" (RST) must be at +5V (reset cancel).

(4) Communication line with IC714 ("57","58,"67"~"69") and that with IC402 (external ROM)

("13"~"16","26"~"33","35"~"42","44","93"~"100") must work normally.

If above (1) to (3) are not satisfied when the P.STANDBY indicating lamp goes out but FL does not

light when the POWER switch is turned on, IC401, IC714 or IC402 may be defective.

Page 15

5. Audio Volume

15

CN704 is

checked

IC850

Q851,Q852

is checked

YES

Is sound

output from

headphone?

YES

OK

The position of

the screw

fastening the

front panel is

confirmed.

This screw : because

there is working

of the ground.

Power

supplied correctly

to each IC?

YES

Is sound

signal output

from J702 (pin

jack)?

NO

Is sound

output from

headphone?

YES

Check Q711,

Q712 and J702

(soldered part).

NO

*

NO NONO

to Power Supply

Volume

IC702 are supplied

power from IC718.

Check I/O voltage of IC718.

Approx

. 5V

Voltage of

Q708 collector at

-12V?

YES

IC714 is

checked

Is

digital signal

output from

IC702"7"?

YES

Is

digital signal output

from IC701"20"?

YES

Is digital

signal output from

IC702"10", "13", "16"

and "19"?

YES

Check IC703, IC704

and their periphery.

NO

NO

NO

Check IC702

and PLL.

Replace

IC701.

Replace

IC702.

* PLL normal lock voltage

Between TP701 and TP702.

When fs=44.1kHz

When fs=48kHz

When fs=96kHz

0.6V

0.9V

2.6V

* Changing over the cutoff frequency of analog LPF

When fs=44.1kHz or 48kHz,

Microcomputer port FS2 is at the "L" level,

and Q703 and Q704 are turned ON.

When fs=96kHz,

Microcomputer port FS2 is at the "H" level,

and Q703 and Q704 are turned OFF.

Page 16

6. Video Volume

16

Power

supplied correctly

to each IC?

YES

Is video

signal output from

J602 S terminal?

NO

Is signal

output from CN601"4"

YES

Check L603

L604,IC611

NO

to Power Supply

Volume

* +5V power for video section is

supplied from IC654.

Check I/O voltage of IC654.

YES

NO

?

Is video

signal output from

J603 composite

terminal?

YES

OK

Check the insertion of

NO

IC621,IC622,L604

L603,CN601

Is clock

signal input to

IC551"9"?

YES

Is digital

signal output from

IC551"1" to"8", "10" and

"11"?

YES

NO

NO

Check

IC501.

Check

IC501.

Service tips

*

(1) The disc playback screen is in the normal condition but graphics in the "ON SCREEN"

mode are abnormal => Replace IC553.

(2) Only 1/4 compressed playback screen of DVD or video-CD is abnormal => Replace IC552.

Signal flow of DISC media

DISC

IC101

FEP

IC301

ODC

IC501

AV DEC.

Check

IC551.

VIDEO

CIRCUIT

IC702

DAC

VIDEO

LPF

AUDIO

Page 17

7.Servo volume

17

Press

"OPEN/CLOSE"

key

Is the opening

operation of

TRAY normal?

Y

After "FL" displays

"Close", is "Reading"

displayed?

Y

Does the DISC

rotate ?

Y

Does pick-up

lens move up

and down?

Y

Does the

displayed in FL

is "NO DISC"?

N

Is drawing in

FOCUS normal ?

to OPEN/CLOSE

N

Operation Section

N

N

(1)Spindle start error

N

Does CN101"4"

(SWTRV) become 0V ?

Y

(3) Traverse

moving NG

Y

(2) Disc detection,

Distinction error

from A

*only two layer

disc (DVD)

Is the jump between

layers OK?

N

(16) Jump between

FE

layers NG

LO LI

Y

Was information on

N

the disk obtained?

(In case of NG, disc

(15) Address

read NG

eject at tray open.)

Y

N

N

Can you reproduce ?

(9) Checkpoint

according to error

Y

OK !

FE

OFF

ON

(It is NG when

tick tack retrying.)

Y

Is drawing in

TRACKING normal ?

TE

OFF

ON

Does IC201"39"

(/TRON) become "L" ?

Y

Is the shift to

spindle CLV OK ?

Does IC201"37"

(PLLOK) become "H" ?

Y

to A

N

(4) Focus ON NG

N

(8) Tracking ON NG

N

(14)Spindle CLV NG

Page 18

Block diagrams (DVD SERVO CONTROL Section)

18

FROM

CN601

OF

LVA10054-A2

(VIDEO &

648

CN503

JACK)

10

1

~ ~

11

151921

CN502

TO

10

CN701

OF

LVA10054-A1

31

32

(CPU)

378

1

33

Y OUT

C OUT

Pb OUT

IC554

VIDEO ENCODER

12, 14

V5V

OSC

X371

33.86MHz

IC371,IC372

1

IC374

CLK169

TC7WH74FU-X

13, 28

47~50

FEP

(Front End Processor)

LVA10047

BLANK

Pr OUT

39~46

MC44724AVFU

3, 46, 7

VREF

TC7SH04FU

ODC

99

ERROR

STATES

SIGNALS

CONTROL

20, 21

68

IC101

AN8706FHQ

LD

PHOTO DETECTORS

IC552

2M FRAM

IC555

+2.5 REG.

MC33269D

CPU DATAS

27

59, 60

UPD42280GU-30

WAITODC

OR GATE

AND GATE

IC301

108

MN103005ANZG

(Optical Disc Controller)

FG

ST/SP

9

16

111

FC

IC251

25, 27

AN8485SB

SPINDLE DRIVER

2~7

22, 26,28

CN101

15,27

16~23 36

(MN4777AS-XE)

FRD 0~7

FWD 0~7

GRAPHIC CONTROLLER

WAIT

IC311,IC312

TC7SH08FU

TC7SH32FU

45

IC201

ADSC

91, 93

14, 99

Servo Controller)

(Advanced Digital

11

CONTROL

9, 104,105

9, 20

23, 26

TRVSW

15~18

4CH DRIVER

FEED +/-

M +/-

11, 12

ACTT+/-

95~100

CA 0~19

CO 0~7

1~ 8

10, 11

IC551

JCE8011

9 25

STREAM DATAS . CD DA DATAS

IC321,IC322

TC7WH74FU

TC74VHC00FT

28

MN67705EA

12,13 35, 38 35, 38

SIGNALS

19,18

IC271

BA5983FM

13, 14

ACTF+/-

43

8M ROM

WAITDEC

CLK338

TOPEN

IC553

HSYNC

TCLOSE

DA DATA1

JCE8038-X

VSYNC

VD 0~7

13

OSC.

TRAY IN / TRAY OUT

CN102

DA LRCK

DA BCK

163,172,173

AV DECODER

15

178

IC502

27MHZ

NAXO265-001X

118

71, 76

51, 52

2

70,72

CPSCK

SDOUT

159

IC501

ZIVA3-PA1

8~11

2~4,6

1

3

CLK135

LSI RST

82

23

IC401

UNIT CPU

23

9,10

X401

CRYSTAL

16M SDRAM

16M SDRAM

IC507

TC7WH74FU

5

WAIT

CPU DATAS

1

IC402

16M ROM

MN102LP25G

7

13.5MHz

IC505

D4516161AG5-A10

(MN45V17160BT-10)

(KM41651020CTG10)

IC504

D4516161AG5-A10

(MN45V17160BT-10)

(KM41651020CTG10)

CSDEC

CPU DATAS

POWER ON

M27C1602CZ

M9V

D3.3V

D5V

652

CN501

8

LASER

PICK-UP

MOTOR

SPINDLE

FEED

MOTOR

DIGITAL 5V

POWER ON

DIGITAL 3.3V

MOTOR DRIVE 9V

MOTOR

REST SW.

LOADING

OPEN/

CLOSE SW.

ELM-V002

ASSEMBLY

DVD MECHANISM

OF

LVA10053-A1

FROM CN805

(Power Supply)

Page 19

Block diagrams (DC REGURATOR Section)

19

B5V

D5V

P.ON

D3.3V

6

852

+3.3V REG.

4

IC951

PQ05RF2

M9V

FROM CN501 OF

RS/

2SC1740S/

Q964,Q965

2SB1565/EF/

CN806

-20V

Q951,Q952

FL ON/OFF

DTA144ESA-T

2SC2060/QR/,

F1F2-VDSP

B5V

1

2

345

-24V

4.9V

5.0V

-26.3V

Q962

-30V REG.

D5V

FROM FW831 OF

LVA10053-A2

D960

+5V REG.

D950

2SA933S/RS/

(DISPLAY)

3

1

IC953

LM2940CT-5.0

7

CN805

2

+5V REG.

1

LVA10047

(DVD SERVO

CONTROL 1)

V+12V

+12V

1

3

CN801

+12V REG.

Q953,Q954

2SB1565/EF/

ON/OFF

DTA114YS,

Q955,Q956

TDC144ESA

-12V

P.MUTE

5

FROM FW702 OF

6

Q964

-12V REG.

D961,D963

2SC1740S/RS/

Q957,Q958,

ON/OFF

LVA10054-A1

(CPU)

D962

DTC114YS,

DTA114ESA

2SC2394/EF/

Q959,Q960

D951

C960

AC-DC

LVA10053-A1

D952

AC-DC

C963,C964

14

15

16

1

D901

AC-DC

S1WB/A/60-4101

T901

LINE FILTER

QQR0894-001

L961

L952

D953

AC-DC

C965,C966

11

T902

QQS0028-001

TRANFORMER

5

D904

C914

AC-DC

4

IC901

SWITCHING

REGURATOR

L955

D954

AC-DC

C979,C997

9

7

10

D908

D910

AC-DC

1

STR-F6652

Q966

D972,D973

C965,C966

MUTE DETECTION

RS/

Q961

2SC1740S/

PC901

PC123F

FEED BACK

D956

AC-DC

L957

C982,C984

PC902

PC123F

MODE SW.

D957

AC-DC

L959

C987,C989

AC IN

Page 20

Bloc k dia grams (VIDEO OUT & A UDIO OUT)

20

TO CN702

LVA10047

(DVD SERVO

CONTROL 2)

VIDEO SIGNAL IN

CN601

2

10

8

4

6

Pr

Pb

C

LVA10054-A2

V5V

4MHz LPF

1

L601

QQR0712-001

4MHz LPF

1

L602

QQR0712-001

Y

L603

6MHz LPF

1

QQR0713-001

3.58MHz BPF

L604

QQR0714-001

3

3

8

5

3

1

NJM2268D

4

IC621

Y AMP

COMPOSITE AMP

NJM2268D

NJM2268D

IC622

Q672

IC601

Pr,Pb AMP

NJM2267D

8 8

1 5

Y

IC622

C AMP

(2/2)

C

58

(1/2)

41

J601

5

4

2

Pr

Pb

Y

J602

3

S-VIDEO

4

OUT

J602

COMPOSITE

VIDEO OUT

COMPONENT

VIDEO OUT

TO CN502 OF

LVA10047

(DVD SERVO

CONTROL 1)

IEC958

AUDIO DATA IN

TO CN502 OF

LVA10047

(DVD SERVO

CONTROL 1)

CN701

1

4

2

DIN

IC702

LPF

MN35503-X

OUT1D

OUT2D

13 2

16

2

1

IC703

LPF

NJM4580L

1

IC704

LPF

NJM4580L

5

7

5

7

LVA10054-A1

J706

1

J702

OPTICAL

DIGTAL OUT

GP1F32T

Lch

AUDIO OUT

Rch

Page 21

TO CN831 OF

21

LVA10053-A2

(DISPLAY)

TO FW601 OF

A10054-A2

LV

(VIDEO & JA

TO CN801 OF

LVA10053-A1

(Power Supply)

Block diagrams (SYSTEM CONTROL & FL DRIVER Section)

CK)

CN703

1

4

7

15

5

16

CN702

2

6

9

19

20

CN701

19

20

21

33

4

1

7

8

+12V

DO1

IEC958

LRCK

BCK

KEY MATRIX

83,84,86~92

KEY MATRIX

83,84,86~92

REMO

SHUTTLE

VS1

VSD

SCK

RXD

TXD

POWER ON

KEY00~KEY03

KEYI0~KEYI5

KEY00~KEY03

KEYI0~KEYI5

19

REMO

95

SHUT1

46

VS1

47

VSD

SYSTEM CPU

IC714

M30622MC-736FP

7

OSDCK

5

OSDDO

6

OSDDI

11

POWER ON

RESET

XIN

EECS,

EECK,

EEDI,

EEDO

MUTE59FS2

71

12

15

27~30

3

4

2

LRCK

BCK

DIN

FS2

MN35503

RESET

IC717

1

RST

PST574CMT-X

OSC

X701

16MHz

PLL BLOCK

D701~D703,

L703

23

28

XIN

PDO

DAC

IC702

OUT1D

OUT2D

F.RESPONCE SW.

Q704~Q708

13

16

EEPROM

IC715

TC75H08F-X

CS

SKDIDO

123

4

LPF

IC703,IC704

NJM4580L

+5V

MUTE

LVA10054-A1

+5V REG.

IC718

3

OUT

IN

NJM78M05

+12V

+12V

-12V

P.MUTE

MUTE

Q708

Q711,Q712

DTA114ESA-T

2SD1302/ST/T

D706,D707

R OUT

L OUT

1

RDV-985

1

TO CN801 OF

LV

(POWER SUPPL

FW702

3

1

POWER

SUPPLY

5

6

J702

ANALOG

AUDIO OUT

OPTICAL

DIGITAL OUT

J706

GP1F32T

OPTICAL

DIGITAL OUT

A10053-A1

Y)

FROM CN703

OF LVA10054-A1

(CPU)

TO CN806 OF

LVA10053-A1

(CPU)

-VDSP

B5V

D5V

CN703

16

5

1

4

7

15

FW831

1

F1

2

F2

3

4

5

REMOTE CONTROL

~

SDATA,FLSCK,CS,POR

KEY MATRIX

~

KEY

MATRIX

S835,

S844~S848

SHUTTLE

RECEIVER

IC832

GP1U271X

1

REMO

13~16

FL DRIVER

QLF0049-001

1~3,108~109

IC831

M66004SP

FL DISPLAY

D1831

53~58

LVA10053-A4

D5V

LVA10053-A3

32

CN833

CN832

B5V

LVA10053-A2

1

1

3

3

6

~

~

6

SHUTTLE

S831

POWER

LED

D831

KEY

VSS S833

POWER S867

Page 22

Meno

22

Page 23

DVD Servo Control 1

DIGT

DIGT

AL D

AL D

AT

A SIGNAL

A SIGNAL

BLOCK A

BLOCK C

BLOCK B

BLOCK D

23

RDV-985

K371

22

47

Page 24

I

RDV-985 RDV-985

to Block C

to Block B

Block A

k A

24

Page 25

RDV-985

to Block A

to Block D

Block B

k B

25

Page 26

RDV-985

to Block D

to Block A

Block C

26

Page 27

RDV-985

DIGTAL DATA SIGNAL

to Block C

to Block B

Block D

27

Page 28

RDV-985 RDV-985

DVD Servo Control 2

ol 2

AUDIO SIGNAL

DIGTAL DATA SIGNAL

VIDEO SIGNAL

28

R549

HY57V161610DTC8

HY57V161610DTC8

Page 29

RDV-985

Display

29

VSS

Page 30

RDV-985

y

RDV-985

y

RDV-985

y

RDV-985

y

RDV-985

y

RDV-985

y

RDV-985

y

RDV-985

y

Power Supply

30

RDV-985

750K

750K

QNZ0136-001Z

QMF51U1-1R6-S

1000PF/AC250V

0.47(2W)

120uF/400V

LE40597-001A

4700PF/AC250V

68K(2W)

PC123F

Page 31

Video & Jac

31

RDV-985

AUDIO SIGNAL

VIDEO SIGNAL

Page 32

RDV-985

RDV-985

CPU

AUDIO SIGNAL

32

Page 33

2-53

Connection

33

RDV-985

Page 34

Printed circuit board

34

RDV-985

Display board

Power supply board

Page 35

CPU & Video & Jack board

35

RDV-985

S601

NTSC/PAL SW

Page 36

Servo control board

36

(BOTOM SIDE)

(TOP SIDE)

R374

Page 37

PARTS LIST

37

[RDV-985]

* All printed circuit boards and its assemblies are not available as service parts.

Page 38

Parts List 1/8

38

SYMBOL PARTS NO. DESCRIPTION SYMBOL PARTS NO. DESCRIPTION

POWER SUPPLY, FL DISPLAY BOARD LVA10053

BK901 E409182-001SM GRAND TERMINAL D844 1SS199-02-T2 SI DIODE

C832 QER61AM-476Z ELECTROLYTIC CAPACITOR 10V47uF D845 1SS199-02-T2 SI DIODE

C833 QCBB1HK-101Y CERAMIC CAPACITOR 50V100PF D901 S1WB/A/60-4101 BRIDGE DIODE

C834 QDVB1EZ-223Y CERAMIC CAPACITOR 0.022uF D902 ERA18-04-T1 FR DIODE

C835 QCBB1HK-471Y CERAMIC CAPACITOR 50V470PF D903 ERA18-04-T1 FR DIODE

C836 QCBB1HK-471Y CERAMIC CAPACITOR 50V470PF D904 ERA18-04-T1 FR DIODE

C837 QCBB1HK-471Y CERAMIC CAPACITOR 50V470PF D908 ERA18-04-T1 FR DIODE

C838 QDVB1EZ-223Y CERAMIC CAPACITOR 0.022uF D910 ERA18-04-T1 FR DIODE

C839 QER61AM-226Z ELECTROLYTIC CAPACITOR 10V22uF D911 1SS133-T2 DIODE

C841 QCFB1HZ-104Y CERAMIC CAPACITOR 0.1uF D950 MTZJ27C-T2 ZENER DIODE

C842 QER41HM-475 ELECTROLYTIC CAPACITOR 50V4.7uF D951 ERA18-04-T1 FR DIODE

C902 QFZ9067-683 M CAPACITOR 0.068uF D952 ERA18-04-T1 FR DIODE

C905 QCZ9079-102 CERAMIC CAPACITOR 1000PF D953 FMB-24 SB DIODE

C906 QCZ9079-102 CERAMIC CAPACITOR 1000PF D954 ERA18-04-T1 FR DIODE

C907 QEZ0374-826 ELECTROLYTIC CAPACITOR 400V120uF D956 ERA18-04-T1 FR DIODE

C908 QCZ0136-332Z CERAMIC CAPACITOR 3300PF D957 ERA18-04-T1 FR DIODE

C909 QCZ0136-101Z CERAMIC CAPACITOR 100PF D960 MTZJ2.0A-T2 ZENER DIODE

C910 QCS11HJ-221 CERAMIC CAPACITOR 50V220PF D961 MTZJ12C-T2 ZENER DIODE

C913 QCZ0136-221Z CERAMIC CAPACITOR 220PF D962 MTZJ12C-T2 ZENER DIODE

C914 QEMU1EM-396Z ELECTROLYTIC CAPACITOR 25V39uF D963 1SS133-T2 DIODE

C915 QCBB1HK-471Y CERAMIC CAPACITOR 50V470PF D964 1SS133-T2 DIODE

C916 QCZ9079-332 CERAMIC CAPACITOR 3300PF D965 MTZJ5.1C-T2 ZENER DIODE

C919 QCFB1HZ-104Y CERAMIC CAPACITOR 0.1uF D970 1SS133-T2 DIODE

C931 QCZ0205-155Z MULTI-LAYER CERAMIC CAP 1.5uF D972 1SS133-T2 DIODE

C932 QCZ0205-155Z MULTI-LAYER CERAMIC CAP 1.5uF D973 1SS133-T2 DIODE

C933 QCZ0205-155Z MULTI-LAYER CERAMIC CAP 1.5uF D974 1SS133-T2 DIODE

C951 QCS11HJ-101 CERAMIC CAPACITOR 50V100PF DI831 QLF0049-001 FL TUBE

C952 QCS11HJ-101 CERAMIC CAPACITOR 50V100PF EP951 QNZ0136-001Z EARTH PLATE

C953 QCS11HJ-101 CERAMIC CAPACITOR 50V100PF EP952 QNZ0136-001Z EARTH PLATE

C954 QCS11HJ-101 CERAMIC CAPACITOR 50V100PF FC901 QNZ0136-001Z FUSE CLIP

C956 QCS11HJ-101 CERAMIC CAPACITOR 50V100PF FC902 QNZ0136-001Z FUSE CLIP

C957 QCS11HJ-101 CERAMIC CAPACITOR 50V100PF HS901 LE40597-001A HEAT SINK

C960 QEMU1AM-107Z ELECTROLYTIC CAPACITOR 10V100uF HS964 LE40595-001A HEAT SINK

C961 QCZ0205-155Z MULTI-LAYER CERAMIC CAP 1.5uF IC831 M66004SP FL DRIVER IC

C962 QET41HM-226 ELECTROLYTIC CAPACITOR 50V22uF IC832 GP1U271X OPTICAL RECIVER

C963 QEMU1VM-396Z ELECTROLYTIC CAPACITOR 35V39uF IC901 STR-F6652 IC

C964 QET41HM-226 ELECTROLYTIC CAPACITOR 50V22uF IC951 PQO5RF2 IC

C965 QEMS1AM-108 ELECTROLYTIC CAPACITOR 10V1000uF IC953 LM2940CT-5.0 IC

C966 QET41AM-477 ELECTROLYTIC CAPACITOR 10V470uF JT801 QGD2501C1-03Z SOCKET I.M OF CN801 TO AUDIO

C967 QFV41HJ-104 TF CAPACITOR 50V0.1uF JT806 QGD2501C1-03Z SOCKET I.M OF CN806 TO FRONT

C968 QFV41HJ-104 TF CAPACITOR 50V0.1uF JT811 QGD2501C1-03Z SOCKET I.M OF CN801 TO AUDIO

C969 QET41AM-277 ELECTROLYTIC CAPACITOR 10V220uF JT816 QGD2501C1-03Z SOCKET I.M OF CN806 TO FRONT

C970 QFV41HJ-104 TF CAPACITOR 50V0.1uF K902 QQR0601-001Z FERRITE BEADS

C973 QET41AM-107 ELECTROLYTIC CAPACITOR 10V100uF L951 QQL01BK-R22Z P COIL

C976 QFV41HJ-104 TF CAPACITOR 50V0.1uF L952 QQL31AK-101Z INDUCTOR

C977 QFV41HJ-104 TF CAPACITOR 50V0.1uF L955 QQL31AK-101Z INDUCTOR

C978 QET41AM-107 ELECTROLYTIC CAPACITOR 10V100uF L957 QQL31AK-101Z INDUCTOR

C979 QEMS1CM-827 ELECTROLYTIC CAPACITOR 16V820uF L959 QQL31AK-101Z INDUCTOR

C981 QCZ0205-155Z MULTI-LAYER CERAMIC CAP 1.5uF PC901 PC123FY IC (PHOTO COUPLE )

C982 QEMS1EM-567 ELECTROLYTIC CAPACITOR 25V560uF PC902 PC123FY IC (PHOTO COUPLE )

C984 QET41EM-227 ELECTROLYTIC CAPACITOR 25V220uF Q831 DTC114YSA-T DIGITAL TRANSISTOR

C985 QET41CM-476 ELECTROLYTIC CAPACITOR 16V47uF Q951 2SC2060/QR/-T TRANSISTOR

C986 QET41CM-107 ELECTROLYTIC CAPACITOR 16V100uF Q952 DTA144ESA-T DIGITAL TRANSISTOR

C987 QEMU1EM-187Z ELECTROLYTIC CAPACITOR 25V180uF Q953 2SB1565/EF/ TRANSISTOR

C989 QET41EM-107 ELECTROLYTIC CAPACITOR 25V100uF Q954 2SC1740S/RS/-T TRANSISTOR

C990 QET41CM-476 ELECTROLYTIC CAPACITOR 16V47uF Q955 DTA144YSA-T DIGITAL TRANSISTOR

C991 QET41CM-107 ELECTROLYTIC CAPACITOR 16V100uF Q956 DTC114ESA-T DIGITAL TRANSISTOR

C992 QET41HM-474 ELECTROLYTIC CAPACITOR 50V0.47uF Q957 2SD2394/EF/ TRANSISTOR

C993 QCS11HJ-101 CERAMIC CAPACITOR 50V100PF Q958 2SA933S/RS/-T TRANSISTOR

C994 QDVB1EZ-223Y CERAMIC CAPACITOR 0.022uF Q959 DTC114YSA-T DIGITAL TRANSISTOR

C995 QET41CM-227 ELECTROLYTIC CAPACITOR 16V220uF Q960 DTA114ESA-T DIGITAL TRANSISTOR

C996 QET41CM-226 ELECTROLYTIC CAPACITOR 16V22uF Q961 2SC1740S/RS/-T TRANSISTOR

C997 QET41CM-227 ELECTROLYTIC CAPACITOR 16V220uF Q962 2SA933S/RS/-T TRANSISTOR

CN805 WJK0053-002A 8PIN WIRE TO MAIN Q964 2SB1565/EF/ TRANSISTOR

CN831 QGF1016C1-19 CONNECTOR TO AUDIO Q965 2SC1740S/RS/-T TRANSISTOR

CN832 QGB2014N1-06 CONNECTOR TO POWER KEY Q966 2SA933S/RS/-T TRANSISTOR

CN833 QGB2014P1-06 CONNECTOR R1126 QRE141J-101Y CARBON RESISTOR 100 1/4W

CP951 ICP-N10-T ICP R801 QRE141J-472Y CARBON RESISTOR 4.7K 1/4W

D831 SLR-342VC-T LED STANDBY R802 QRE141J-472Y CARBON RESISTOR 4.7K 1/4W

D842 1SS199-02-T2 SI DIODE

Page 39

Parts List 2/8

39

SYMBOL PARTS NO. DESCRIPTION SYMBOL PARTS NO. DESCRIPTION

R803 QRE141J-472Y CARBON RESISTOR 4.7K 1/4W C603 QETN1AM-108Z ELECTROLYTIC CAPACITOR 10V1000uF

R804 QRE141J-472Y CARBON RESISTOR 4.7K 1/4W C604 QETN1AM-108Z ELECTROLYTIC CAPACITOR 10V1000uF

R805 QRE141J-472Y CARBON RESISTOR 4.7K 1/4W C605 QETN1AM-107Z ELECTROLYTIC CAPACITOR 10V100uF

R806 QRE141J-472Y CARBON RESISTOR 4.7K 1/4W C606 QDX31EM-473Z CERAMIC CAPACITOR 0.047uF

R831 QRE141J-331Y CARBON RESISTOR 330 1/4W C611 QETM1CM-228 ELECTROLYTIC CAPACITOR 16V2200uF

R843 QRE141J-273Y CARBON RESISTOR 27K 1/4W C612 QETN0JM-227Z ELECTROLYTIC CAPACITOR 6.3V220uF

R845 QRE141J-102Y CARBON RESISTOR 1K 1/4W C613 QCZ0205-155Z MULTI-LAYER CERAMIC CAP 1.5uF

R846 QRE141J-102Y CARBON RESISTOR 1K 1/4W C614 QCZ0205-155Z MULTI-LAYER CERAMIC CAP 1.5uF

R847 QRE141J-102Y CARBON RESISTOR 1K 1/4W C621 QCZ0205-155Z MULTI-LAYER CERAMIC CAP 1.5uF

R848 QRE141J-102Y CARBON RESISTOR 1K 1/4W C624 QCZ0205-155Z MULTI-LAYER CERAMIC CAP 1.5uF

R849 QRE141J-222Y CARBON RESISTOR 2.2K 1/4W C625 QETN1AM-108Z ELECTROLYTIC CAPACITOR 10V1000uF

R850 QRE141J-222Y CARBON RESISTOR 2.2K 1/4W C626 QET41AM-108 ELECTROLYTIC CAPACITOR 10V1000uF

R851 QRE141J-222Y CARBON RESISTOR 2.2K 1/4W C627 QET41AM-107 ELECTROLYTIC CAPACITOR 10V100uF

R900 QRE141J-221Y CARBON RESISTOR 220 1/4W C628 QDX31EM-473Z CERAMIC CAPACITOR 0.047uF

R901 QRL01DJ-683X OMF RESISTOR 68K 1W C662 QDGB1HK-102Y CERAMIC CAPACITOR 1000PF

R903 QRE141J-270Y CARBON RESISTOR 27 1/4W C671 QDX31EM-473Z CERAMIC CAPACITOR 0.047uF

R904 QRE141J-222Y CARBON RESISTOR 2.2K 1/4W C672 QDX31EM-104Z CERAMIC CAPACITOR 0.1uF

R905 QRL027J-683 METAL OXIDE FILM RESISTOR 68K 2W C673 QCZ0205-155Z MULTI-LAYER CERAMIC CAP 1.5uF

R906 QRE141J-681Y CARBON RESISTOR 680 1/4W C674 QET41AM-108 ELECTROLYTIC CAPACITOR 10V1000uF

R907 QRT022J-R47 UNF. MF. RESISTOR 0.47 2W C675 QET41AM-107 ELECTROLYTIC CAPACITOR 10V100uF

R908 QRE141J-332Y CARBON RESISTOR 3.3K 1/4W C676 QDX31EM-473Z CERAMIC CAPACITOR 0.047uF

R911 QRE141J-155Y CARBON RESISTOR 1.5M 1/4W C694 QET41AM-108 ELECTROLYTIC CAPACITOR 10V1000uF

R952 QRE141J-103Y CARBON RESISTOR 10K 1/4W C695 QDX31EM-104Z CERAMIC CAPACITOR 0.1uF

R953 QRE141J-103Y CARBON RESISTOR 10K 1/4W C704 QFV41HJ-474 CAPACITOR 50V0.47uF

R954 QRZ9006-4R7X F CAPACITOR 4.7 1/0W C705 QDYB1CM-103Y AB CAPACITOR 0.01uF

R955 QRE141J-223Y CARBON RESISTOR 22K 1/4W C706 QDGB1HK-102Y CERAMIC CAPACITOR 1000PF

R956 QRE141J-103Y CARBON RESISTOR 10K 1/4W C707 QDGB1HK-102Y CERAMIC CAPACITOR 1000PF

R957 QRE141J-103Y CARBON RESISTOR 10K 1/4W C708 QDX31EM-473Z CERAMIC CAPACITOR 0.047uF

R958 QRE141J-102Y CARBON RESISTOR 1K 1/4W C714 QCS31HJ-331Z CERAMIC CAPACITOR 330PF

R959 QRE141J-102Y CARBON RESISTOR 1K 1/4W C717 QCFB1HZ-104Y CERAMIC CAPACITOR 0.1uF

R960 QRE141J-101Y CARBON RESISTOR 100 1/4W C719 QCFB1HZ-104Y CERAMIC CAPACITOR 0.1uF

R961 QRE141J-681Y CARBON RESISTOR 680 1/4W C720 QCS11HJ-102 CERAMIC CAPACITOR 50V1000PF

R962 QRE141J-105Y CARBON RESISTOR 1M1/4W C721 QCFB1HZ-104Y CERAMIC CAPACITOR 0.1uF

R963 QRE141J-101Y CARBON RESISTOR 100 1/4W C722 QCFB1HZ-104Y CERAMIC CAPACITOR 0.1uF

R964 QRE141J-105Y CARBON RESISTOR 1M 1/4W C723 QCFB1HZ-104Y CERAMIC CAPACITOR 0.1uF

R965 QRE141J-103Y CARBON RESISTOR 10K 1/4W C724 QETN0JM-477Z ELECTROLYTIC CAPACITOR 6.3V470uF

R966 QRK126J-2R7X CARBON RESISTOR 2.7 1/4W C725 QCZ0205-155Z MULTI-LAYER CERAMIC CAP 1.5uF

R967 QRZ9005-100X FUSIBLE RESISTOR I/M 10 1W C726 QCZ0205-155Z MULTI-LAYER CERAMIC CAP 1.5uF

R968 QRK126J-2R7X CARBON RESISTOR 2.7 1/4W C727 QCZ0205-155Z MULTI-LAYER CERAMIC CAP 1.5uF

R969 QRE141J-221Y CARBON RESISTOR 220 1/4W C728 QETN0JM-477Z ELECTROLYTIC CAPACITOR 6.3V470uF

R971 QRE141J-472Y CARBON RESISTOR 4.7K 1/4W C729 QETN0JM-477Z ELECTROLYTIC CAPACITOR 6.3V470uF

R972 QRE141J-152Y CARBON RESISTOR 1.5K 1/4W C730 QCZ0205-155Z MULTI-LAYER CERAMIC CAP 1.5uF

R973 QRE141J-102Y CARBON RESISTOR 1K 1/4W C731 QCZ0205-155Z MULTI-LAYER CERAMIC CAP 1.5uF

R974 QRE141J-562Y CARBON RESISTOR 5.6K 1/4W C732 QCZ0205-155Z MULTI-LAYER CERAMIC CAP 1.5uF

R975 QRE141J-562Y CARBON RESISTOR 5.6K 1/4W C733 QETN0JM-477Z ELECTROLYTIC CAPACITOR 6.3V470uF

R976 QRE141J-221Y CARBON RESISTOR 220 1/4W C734 QCF11HZ-473 CERAMIC CAPACITOR 0.047uF

R980 QRE141J-821Y CARBON RESISTOR 820 1/4W C735 QCF11HZ-103 CERAMIC CAPACITOR 0.01uF

S831 QVQ0123-B15 SHUTTLE VARIABLE RESISTOR C736 QDYB1CM-103Y AB CAPACITOR 0.01uF

S833 QSW0499-001Z PUSH SWITCH VSS C737 QFLC1HJ-152Z M CAPACITOR 50V1500PF

S835 QSW0499-001Z PUSH SWITCH OPEN/CLOSE C738 QFLC1HJ-181Z M CAPACITOR 50V180PF

S844 QSW0499-001Z PUSH SWITCH BWD SKIP C739 QFN41HJ-333 M CAPACITOR 50V0.033uF

S845 QSW0499-001Z PUSH SWITCH FWD SKIP C740 QFN41HJ-103 M CAPACITOR 50V0.01uF

S846 QSW0499-001Z PUSH SWITCH STOP C741 QFLC1HJ-152Z M CAPACITOR 50V1500PF

S847 QSW0499-001Z PUSH SWITCH PAUSE C742 QFLC1HJ-182Z M CAPACITOR 50V1800PF

S848 QSW0499-001Z PUSH SWITCH PLAY C743 QET41CM-477 ELECTROLYTIC CAPACITOR 16V470uF

S867 QSW0499-001Z PUSH SWITCH POWER C744 QET41CM-477 ELECTROLYTIC CAPACITOR 16V470uF

T901 QQR0894-001 LINE FILTER C745 QFLC1HJ-152Z M CAPACITOR 50V1500PF

T902 QQS0028-001 SWITCH TRANSFORMER C746 QFLC1HJ-181Z M CAPACITOR 50V180PF

TB901 QNZ0079-001Z TAB C747 QFN41HJ-333 M CAPACITOR 50V0.033uF

TB902 QNZ0079-001Z TAB C748 QFN41HJ-103 M CAPACITOR 50V0.01uF

AUDIO, VIDEO, CPU BOARD LVB10054

BK693 LE30696-001A EARTH PLATE C751 QET41CM-477 ELECTROLYTIC CAPACITOR 16V470uF

C1024 QET41CM-477 ELECTROLYTIC CAPACITOR 16V470uF C752 QET41CM-477 ELECTROLYTIC CAPACITOR 16V470uF

C1025 QET41CM-477 ELECTROLYTIC CAPACITOR 16V470uF C755 QDXB1CM-152Y CERAMIC CAPACITOR 1500PF

C1026 QETN0JM-477Z ELECTROLYTIC CAPACITOR 6.3V470uF C760 QFLC1HJ-152Z M CAPACITOR 50V1500PF

C1037 QET41CM-107 ELECTROLYTIC CAPACITOR 16V100uF C761 QET41EM-476 ELECTROLYTIC CAPACITOR 25V47uF

C1038 QCFB1HZ-104Y CERAMIC CAPACITOR 0.1uF C762 QFLC1HJ-152Z M CAPACITOR 50V1500PF

C601 QETN1CM-226Z ELECTROLYTIC CAPACITOR 16V22uF C763 QET41EM-476 ELECTROLYTIC CAPACITOR 25V47uF

C602 QETN1CM-226Z ELECTROLYTIC CAPACITOR 16V22uF C764 QFLC1HJ-152Z M CAPACITOR 50V1500PF

C749 QFLC1HJ-152Z M CAPACITOR 50V1500PF

C750 QFLC1HJ-182Z M CAPACITOR 50V1800PF

Page 40

Parts List 3/8

40

SYMBOL PARTS NO. DESCRIPTION SYMBOL PARTS NO. DESCRIPTION

C765 QCF11HZ-473 CERAMIC CAPACITOR 0.047uF R1005 QRE141J-103Y CARBON RESISTOR 10K 1/4

CN601 VMC0075-010N 10P PLUG ASSY TO MAIN R1006 QRE141J-273Y CARBON RESISTOR 27K 1/4

CN701 QGF1016C1-35 FFC/FPC CONNECTOR TO MAIN R1007 QRE141J-561Y CARBON RESISTOR 560 1/4

CN703 QGF1016C1-19 CONNECTOR TO FRONT R1008 QRE141J-151Y CARBON RESISTOR 150 1/4

D601 1SS133-T2 DIODE R1009 QRE141J-103Y CARBON RESISTOR 10K 1/4

D602 1SS133-T2 DIODE R1010 QRE141J-273Y CARBON RESISTOR 27K 1/4

D603 1SS133-T2 DIODE R1119 QRE141J-391Y CARBON RESISTOR 390 1/4

D604 1SS133-T2 DIODE R1121 QRE141J-104Y CARBON RESISTOR 100K 1/4

D605 1SS133-T2 DIODE R1124 QRE141J-2R2Y CARBON RESISTOR 2.2 1/4

D701 KV15555N-T VARI CAP R1125 QRE141J-105Y CARBON RESISTOR 1M 1/4

D702 KV15555N-T VARI CAP R1130 QRE141J-471Y CARBON RESISTOR 470 1/4

D703 MTZJ5.1C-T2 ZENER DIODE R1196 QRE141J-472Y CARBON RESISTOR 4.7K 1/4

D706 1SS133-T2 DIODE R601 QRE141J-222Y CARBON RESISTOR 2.2K 1/4W

D707 1SS133-T2 DIODE R602 QRE141J-222Y CARBON RESISTOR 2.2K 1/4W

D714 1SS133-T2 DIODE R603 QRE141J-102Y CARBON RESISTOR 1K 1/4W

D799 1SS133-T2 DIODE R604 QRE141J-102Y CARBON RESISTOR 1K 1/4W

FW702 QUM106-24DGZ4 PARA RIBON WIRE TO POWER R605 QRE141J-222Y CARBON RESISTOR 2.2K 1/4W

IC601 NJM2267D IC R606 QRE141J-222Y CARBON RESISTOR 2.2K 1/4W

IC611 NJM78M05FA IC R607 QRE141J-102Y CARBON RESISTOR 1K 1/4W

IC621 NJM2267D IC R608 QRE141J-102Y CARBON RESISTOR 1K 1/4W

IC622 NJM2268D IC R609 QRE141J-221Y CARBON RESISTOR 220R 1/4W

IC702 MN35503-X IC R610 QRE141J-221Y CARBON RESISTOR 220R 1/4W

IC703 NJM4580L IC R611 QRE141J-750Y CARBON RESISTOR 75R 1/4W

IC704 NJM4580L IC R612 QRE141J-750Y CARBON RESISTOR 75R 1/4W

IC714 M30622MC-577FP IC R615 QRE141J-102Y CARBON RESISTOR 1K 1/4

IC716 AK93C45A IC R621 QRE141J-153Y CARBON RESISTOR 15K 1/4

IC717 IC-PST9140-T IC R622 QRE141J-752Y CARBON RESISTOR 7.5K 1/4

IC718 NJM78M05FA IC R623 QRE141J-102Y CARBON RESISTOR 1K 1/4

J601 QNN0312-001 PIN JACK (COMPONENT) R624 QRE141J-102Y CARBON RESISTOR 1K 1/4

J602 QND0019-001 S-CONNECTOR R625 QRE141J-102Y CARBON RESISTOR 1K 1/4

J603 QNN0106-001 PIN JACK (COMPOSITE) R626 QRE141J-221Y CARBON RESISTOR 220K 1/4

J702 QNN0216-001 PIN JACK (AUDIO) R627 QRE141J-102Y CARBON RESISTOR 1K 1/4

J706 GP1F32T OPTICAL JACK R630 QRE141J-221Y CARBON RESISTOR 220K 1/4

JT701 QGD2501C1-05Z SOCKET R631 QRE141J-222Y CARBON RESISTOR 2.2K 1/4

JT702 QGD2501C1-05Z SOCKET R632 QRE141J-750Y CARBON RESISTOR 75R 1/4W

K601 QQR0601-001Z FERRITE BEADS R633 QRE141J-750Y CARBON RESISTOR 75 1/4

K602 QQR0601-001Z FERRITE BEADS R665 QRE141J-101Y CARBON RESISTOR 100 1/4

K603 QQR0601-001Z FERRITE BEADS R666 QRE141J-101Y CARBON RESISTOR 100 1/4

K702 QQR0601-001Z FERRITE BEADS R671 QRE141J-562Y CARBON RESISTOR 5.6K 1/4W

K703 QQR0601-001Z FERRITE BEADS R672 QRE141J-562Y CARBON RESISTOR 5.6K 1/4

K704 QQR0601-001 FERRITE BEADS R673 QRE141J-102Y CARBON RESISTOR 1K 1/4

K707 QQR0601-001Z FERRITE BEADS R674 QRE141J-102Y CARBON RESISTOR 1K 1/4

K708 QQR0601-001Z FERRITE BEADS R675 QRE141J-102Y CARBON RESISTOR 1K 1/4

K709 QQR0601-001Z FERRITE BEADS R676 QRE141J-750Y CARBON RESISTOR 75 1/4

K710 QQR0601-001Z FERRITE BEADS R679 QRE141J-102Y CARBON RESISTOR 1K 1/4

L601 QQR0712-001 LPF R680 QRE141J-102Y CARBON RESISTOR 1K 1/4

L602 QQR0712-001 LPF R681 QRE141J-221Y CARBON RESISTOR 220 1/4

L603 QQR0713-001 LPF R682 QRE141J-222Y CARBON RESISTOR 2.2K 1/4

L604 QQR0714-001 BPF R683 QRE141J-750Y CARBON RESISTOR 75 1/4

L661 QQL121K-3R3Y INDUCTOR R684 QRE141J-103Y CARBON RESISTOR 10K 1/4W

L662 QQL121K-221Y INDUCTOR R694 QRE141J-750Y CARBON RESISTOR 75R 1/4W

L703 QQL121M-1R2Y INDUCTOR R695 QRE141J-750Y CARBON RESISTOR 75R 1/4W

Q601 2SA933/RS/-T TRANSISTOR R703 QRE141J-103Y CARBON RESISTOR 10K 1/4W

Q602 2SA933/RS/-T TRANSISTOR R707 QRE141J-472Y CARBON RESISTOR 4.7K 1/4

Q603 2SA933/RS/-T TRANSISTOR R708 QRE141J-472Y CARBON RESISTOR 4.7K 1/4

Q604 2SA933/RS/-T TRANSISTOR R711 QRE141J-102Y CARBON RESISTOR 1K 1/4

Q621 2SA933/RS/-T TRANSISTOR R728 QRE141J-333Y CARBON RESISTOR 33K 1/4

Q622 2SA933/RS/-T TRANSISTOR R729 QRE141J-102Y CARBON RESISTOR 1K 1/4

Q623 2SA933/RS/-T TRANSISTOR R730 QRE141J-333Y CARBON RESISTOR 33K 1/4

Q671 2SA933/RS/-T TRANSISTOR R731 QRE141J-104Y CARBON RESISTOR 100K 1/4

Q672 2SA933/RS/-T TRANSISTOR R732 QRE141J-333Y CARBON RESISTOR 33K 1/4

Q701 DTC114ESA-T DIGITAL TRANSISTOR R733 QRE141J-104Y CARBON RESISTOR 100K 1/4

Q704 DTA114ESA-T DIGITAL TRANSISTOR R734 QRE141J-181Y CARBON RESISTOR 180 1/4

Q705 2SD1302/ST/-T TRANSISTOR R735 QRE141J-104Y CARBON RESISTOR 100K 1/4

Q706 2SD1302/ST/-T TRANSISTOR R736 QRE141J-153Y CARBON RESISTOR 15K 1/4

Q708 DTA114ESA-T DIGITAL TRANSISTOR R737 QRE141J-102Y CARBON RESISTOR 1K 1/4

Q711 2SD1302/ST/-T TRANSISTOR R738 QRE141J-473Y CARBON RESISTOR 47K 1/4

Q712 2SD1302/ST/-T TRANSISTOR R739 QRE141J-560Y CARBON RESISTOR 56 1/4

R1003 QRE141J-561Y CARBON RESISTOR 560 1/4 R740 QRE141J-560Y CARBON RESISTOR 56 1/4

R1004 QRE141J-151Y CARBON RESISTOR 150 1/4 R741 QRE141J-471Y CARBON RESISTOR 470 1/4

Page 41

Parts List 4/8

41

SYMBOL PARTS NO. DESCRIPTION SYMBOL PARTS NO. DESCRIPTION

R742 QRE141J-471Y CARBON RESISTOR 470 1/4 C120 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

R743 QRE141J-471Y CARBON RESISTOR 470 1/4 C121 NCB21CK-334X CERAMIC CAPACITOR 0.33uF

R744 QRE141J-471Y CARBON RESISTOR 470 1/4 C122 NCS31HJ-121X CERAMIC CAPACITOR 1200PF

R745 QRE141J-511Y CARBON RESISTOR 510 1/4 C123 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

R746 QRE141J-152Y CARBON RESISTOR 1.5K 1/4 C124 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

R747 QRE141J-560Y CARBON RESISTOR 56 1/4 C125 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

R748 QRE141J-101Y CARBON RESISTOR 100 1/4 C126 NCB31HJ-221X CERAMIC CAPACITOR 220PF

R749 QRE141J-471Y CARBON RESISTOR 470 1/4 C127 NCB31HJ-221X CERAMIC CAPACITOR 220PF

R750 QRE141J-102Y CARBON RESISTOR 1K 1/4 C128 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

R751 QRE141J-471Y CARBON RESISTOR 470 1/4 C129 NCB21CK-224X CERAMIC CAPACITOR 0.22uF

R752 QRE141J-152Y CARBON RESISTOR 1.5K 1/4 C130 NCB31HK-102X CERAMIC CAPACITOR 1000PF

R753 QRE141J-560Y CARBON RESISTOR 56 1/4 C131 NCB31HK-681X CERAMIC CAPACITOR 680PF

R754 QRE141J-1602Y METAL FILM RESISTOR 16 1/4W C132 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

R755 QRE141J-183Y CARBON RESISTOR 18K 1/4 C133 NEX40JM-566X ELECTROLYTIC CAPACITOR 6.3V56uF

R756 QRE141J-1602Y METAL FILM RESISTOR 16 1/4W C134 NCB11CK-105X CERAMIC CAPACITOR 1uF

R757 QRE141J-821Y CARBON RESISTOR 820 1/4 C135 NCB31HJ-221X CERAMIC CAPACITOR 220PF

R758 QRE141J-243Y CARBON RESISTOR 24K 1/4 C136 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

R759 QRE141J-243Y CARBON RESISTOR 24K 1/4 C137 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

R760 QRE141J-682Y CARBON RESISTOR 6.8K 1/4 C138 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

R761 QRE141J-362Y CARBON RESISTOR 3.6K 1/4 C139 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

R762 QRE141J-103Y CARBON RESISTOR 10K 1/4 C140 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

R763 QRE141J-561Y CARBON RESISTOR 560 1/4 C141 NCB31HJ-820X CERAMIC CAPACITOR 82PF

R764 QRE141J-561Y CARBON RESISTOR 560 1/4 C142 NCB31HK-222X CERAMIC CAPACITOR 2200PF

R765 QRE141J-105Y CARBON RESISTOR 1M 1/4 C143 NCB21CK-224X CERAMIC CAPACITOR 0.22uF

R766 QRE141J-221Y CARBON RESISTOR 220 1/4 C144 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

R767 QRE141J-821Y CARBON RESISTOR 820 1/4 C145 NCB11CK-105X CERAMIC CAPACITOR 1uF

R768 QRE141J-221Y CARBON RESISTOR 220 1/4 C151 NEX40JM-156X ELECTROLYTIC CAPACITOR 6.3V15uF

R769 QRE141J-183Y CARBON RESISTOR 18K 1/4 C152 NEX40JM-156X ELECTROLYTIC CAPACITOR 6.3V15uF

R770 QRE141J-1602Y METAL FILM RESISTOR 16 1/4W C153 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

R771 QRE141J-183Y CARBON RESISTOR 18K 1/4 C154 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

R772 QRE141J-1602Y METAL FILM RESISTOR 16 1/4W C191 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

R773 QRE141J-821Y CARBON RESISTOR 820 1/4 C192 NEA70JM-107X ELECTROLYTIC CAPACITOR 6.3V100uF

R774 QRE141J-243Y CARBON RESISTOR 24K 1/4 C201 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

R775 QRE141J-243Y CARBON RESISTOR 24K 1/4 C202 NCB31CK-393X CERAMIC CAPACITOR 0.039uF

R776 QRE141J-682Y CARBON RESISTOR 6.8K 1/4 C203 NCB31CK-393X CERAMIC CAPACITOR 0.039uF

R777 QRE141J-362Y CARBON RESISTOR 3.6K 1/4 C204 NCB31CK-393X CERAMIC CAPACITOR 0.039uF

R778 QRE141J-103Y CARBON RESISTOR 10K 1/4 C205 NCB31CK-393X CERAMIC CAPACITOR 0.039uF

R779 QRE141J-561Y CARBON RESISTOR 560 1/4 C206 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

R780 QRE141J-561Y CARBON RESISTOR 560 1/4 C208 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

R781 QRE141J-105Y CARBON RESISTOR 1M 1/4 C209 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

R782 QRE141J-221Y CARBON RESISTOR 220 1/4 C210 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

R783 QRE141J-821Y CARBON RESISTOR 820 1/4 C211 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

R784 QRE141J-221Y CARBON RESISTOR 220 1/4 C212 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

R785 QRE141J-183Y CARBON RESISTOR 18K 1/4 C213 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

R796 QRE141J-473Y CARBON RESISTOR 47K 1/4 C214 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

S601 QSW0454-001 SWITCH C215 NCB31HK-392X CERAMIC CAPACITOR 3900PF

SP702 VYH7653-003 IC HOLDER C217 NCB31HK-821X CERAMIC CAPACITOR 820PF

SP714 VYH7653-011 IC HOLDER C218 NCB31HK-331X CERAMIC CAPACITOR 330PF

X701 QAX0516-0012 CERAMIC RESONATOR 16MHz C219 NCB31HK-471X CERAMIC CAPACITOR 470PF

SERVO CONTROL-1, 2 BOARD LVA10047

C101 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C223 NCB31HK-821X CERAMIC CAPACITOR 820PF

C102 NEA70JM-476X ELECTROLYTIC CAPACITOR 6.3V47uF C224 NEA70JM-226X ELECTROLYTIC CAPACITOR 6.3V22uF

C103 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C225 NCB11CK-105X CERAMIC CAPACITOR 1uF

C104 NCS31HJ-560X CERAMIC CAPACITOR 56PF C226 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C105 NCS31HJ-101X CERAMIC CAPACITOR 100PF C227 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C106 NEA71CM-106X ELECTROLYTIC CAPACITOR 16V10uF C228 NEA70JM-107X ELECTROLYTIC CAPACITOR 6.3V100uF

C107 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C229 NCB11CK-105X CERAMIC CAPACITOR 1uF

C108 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C230 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C109 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C231 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C110 NCS31HJ-101X CERAMIC CAPACITOR 100PF C232 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C111 NCB21CK-184X CERAMIC CAPACITOR 0.18PF C233 NCB31HJ-330X CERAMIC CAPACITOR 33PF

C112 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C234 NCB31HK-331X CERAMIC CAPACITOR 330PF

C113 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C235 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C114 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C236 NCB31CK-823X CERAMIC CAPACITOR 0.082uF

C115 NCB31HK-392X CERAMIC CAPACITOR 3900PF C237 NCB31CK-823X CERAMIC CAPACITOR 0.082uF

C116 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C241 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C117 NCB11CK-105X CERAMIC CAPACITOR 1uF C242 NEA70JM-107X ELECTROLYTIC CAPACITOR 6.3V100uF

C118 NEX40JM-336X ELECTROLYTIC CAPACITOR 6.3V33uF C251 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C119 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C252 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C221 NCB31HK-271X CERAMIC CAPACITOR 270PF

C222 NCB31HK-821X CERAMIC CAPACITOR 820PF

Page 42

Parts List 5/8

42

SYMBOL PARTS NO. DESCRIPTION SYMBOL PARTS NO. DESCRIPTION

C253 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C501 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C254 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C502 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C255 NEA70JM-226X ELECTROLYTIC CAPACITOR 6.3V22uF C503 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C256 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C504 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C257 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C505 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C258 NEA70JM-226X ELECTROLYTIC CAPACITOR 6.3V22uF C506 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C259 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C507 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C261 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C508 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C262 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C509 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C263 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C510 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C264 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C511 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C271 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C512 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C273 NCB31HK-102X CERAMIC CAPACITOR 1000PF C513 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C275 NCB31HK-102X CERAMIC CAPACITOR 1000PF C514 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C276 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C515 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C281 NEA70JM-226X ELECTROLYTIC CAPACITOR 6.3V22uF C516 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C282 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C517 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C284 NCB31CK-102X CERAMIC CAPACITOR 1000PF C518 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C286 NCB31CK-102X CERAMIC CAPACITOR 1000PF C519 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C287 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C520 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C288 NEA70JM-226X ELECTROLYTIC CAPACITOR 6.3V22uF C521 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C291 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C522 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C292 NEA71CM-476X ELECTROLYTIC CAPACITOR 16V47uF C523 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C301 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C524 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C302 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C525 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C303 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C526 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C304 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C527 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C305 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C528 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C306 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C529 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C307 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C530 NEA70JM-107X ELECTROLYTIC CAPACITOR 6.3V100uF

C308 NCB31CK-103X CERAMIC CAPACITOR 0.01uF C531 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C309 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C532 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C310 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C533 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C311 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C534 NEA70JM-107X ELECTROLYTIC CAPACITOR 6.3V100uF

C314 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C535 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C315 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C536 NCB31CK-103X CERAMIC CAPACITOR 0.01uF

C316 NEA70JM-107X ELECTROLYTIC CAPACITOR 6.3V100uF C537 NEA70JM-226X ELECTROLYTIC CAPACITOR 6.3V22uF

C317 NCB11CK-105X CERAMIC CAPACITOR 1uF C538 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C318 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C539 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C319 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C540 NEA70JM-226X ELECTROLYTIC CAPACITOR 6.3V22uF

C320 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C541 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C321 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C542 NEA70JM-226X ELECTROLYTIC CAPACITOR 6.3V22uF

C322 NEA70JM-107X ELECTROLYTIC CAPACITOR 6.3V100uF C543 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C323 NCB11CK-105X CERAMIC CAPACITOR 1uF C551 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C324 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C552 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C341 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C553 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C342 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C554 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C343 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C555 NEA70JM-226X ELECTROLYTIC CAPACITOR 6.3V22uF

C344 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C556 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C371 NCS31HJ-100X CERAMIC CAPACITOR 10PF C557 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C372 NCS31HJ-100X CERAMIC CAPACITOR 10PF C558 NEA70JM-226X ELECTROLYTIC CAPACITOR 6.3V22uF

C373 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C559 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C374 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C561 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C376 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C562 NEA70JM-226X ELECTROLYTIC CAPACITOR 6.3V22uF

C391 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C563 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C392 NEA70JM-226X ELECTROLYTIC CAPACITOR 6.3V22uF C564 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C401 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C565 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C402 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C566 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C405 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C567 NEA70JM-226X ELECTROLYTIC CAPACITOR 6.3V22uF

C406 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C568 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C407 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C569 NEA70JM-226X ELECTROLYTIC CAPACITOR 6.3V22uF

C408 NEA70JM-226X ELECTROLYTIC CAPACITOR 6.3V22uF C571 NCB31CK-104X CERAMIC CAPACITOR 0.1uF

C409 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C572 NEX40JM-156X ELECTROLYTIC CAPACITOR 6.3V15uF

C411 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C6 NCB21CK-104X CERAMIC CAPACITOR 0.1uF

C412 NCB31CK-104X CERAMIC CAPACITOR 0.1uF C8 NCB21CK-104X CERAMIC CAPACITOR 0.1uF

C441 NCB31CK-104X CERAMIC CAPACITOR 0.1uF CN101 QGF1016C2-37W CONNECTOR MECHA

C442 NEX40JM-156X ELECTROLYTIC CAPACITOR 6.3V15uF CN103 QGF1016C2-07W CONNECTOR LOADING

C452 NCB31CK-104X CERAMIC CAPACITOR 0.1uF CN104 QGA2001C2-12X W TO B CONNECTOR

C491 NCB31CK-104X CERAMIC CAPACITOR 0.1uF CN501 QGA2001C2-08X W TO B CONNECTOR POWER

C492 NEA70JM-226X ELECTROLYTIC CAPACITOR 6.3V22uF CN502 QGF1016C2-35W CONNECTOR SYSTEM

Page 43

Parts List 6/8

43

SYMBOL PARTS NO. DESCRIPTION SYMBOL PARTS NO. DESCRIPTION

CN503 QGA2001C2-10X W TO B CONNECTOR VIDEO K559 NQR0007-002X FERRITE BEADS C.M.

D201 1SS355-X DIODE C.M. K561 NQR0007-002X FERRITE BEADS C.M.

D202 1SS355-X DIODE C.M. K562 NQR0007-002X FERRITE BEADS C.M.

D203 1SS355-X DIODE C.M. K563 NQR0007-002X FERRITE BEADS C.M.

D272 DAP202K-X DIGITAL TRANSISTOR K564 NQR0007-002X FERRITE BEADS C.M.

D402 1SS355-X DIODE C.M. K565 NQR0007-002X FERRITE BEADS C.M.

D403 1SS355-X DIODE C.M. K566 NQR0007-002X FERRITE BEADS C.M.

D551 1SS355-X DIODE C.M. K567 NQR0007-002X FERRITE BEADS C.M.

D552 1SS355-X DIODE C.M. K568 NQR0007-002X FERRITE BEADS C.M.

IC101 AN8706FHQ IC K569 NQR0007-002X FERRITE BEADS C.M.

IC102 RN5RZ20BA-X IC K570 NQR0007-002X FERRITE BEADS C.M.

IC201 MN67705EA IC K571 NQR0007-002X FERRITE BEADS C.M.

IC251 AN8485SB-W IC K572 NQR0007-002X FERRITE BEADS C.M.

IC271 BA5983FM-X IC K573 NQR0007-002X FERRITE BEADS C.M.

IC301 MN103007BGA IC K574 NQR0007-002X FERRITE BEADS C.M.

IC311 TC7SH08FU-X IC K575 NQR0007-002X FERRITE BEADS C.M.

IC312 TC7SH32FU-X IC K576 NQR0007-002X FERRITE BEADS C.M.

IC321 TC7WH74FU-X IC K577 NQR0007-002X FERRITE BEADS C.M.

IC322

IC371 TC7SHU04FU-X IC (DIGITAL) K579 NQR0007-002X FERRITE BEADS C.M.

IC372 TC7SHU04FU-X IC (DIGITAL) K581 NQR0007-002X FERRITE BEADS C.M.

IC374 TC7WH74FU-X IC K582 NQR0007-002X FERRITE BEADS C.M.

IC401* MN102L25GCP IC (IC402 PAIR) K583 NQR0007-002X FERRITE BEADS C.M.

IC401* MN102L25GCZ IC (after S/N 0061001) K584 NQR0007-002X FERRITE BEADS C.M.

IC402*

IC402*

IC403 AK93C65AF-X IC K587 NQR0007-002X FERRITE BEADS C.M.

IC452 TC7WT125FU-X IC (DIGITAL) K589 NQR0007-002X FERRITE BEADS C.M.

IC501 ZIVA3-PA1 IC K590 NQR0007-002X FERRITE BEADS C.M.

IC502 NAX0265-001X CRYSTAL 27MHZ K591 NQR0007-002X FERRITE BEADS C.M.

IC503

IC504

IC505

IC551 JCE8011 IC (DIGITAL) Q101 2SB1424/QR/-X TRANSISTOR

IC552

IC553

IC554 MC44724AVFU IC Q104 DTC124EE-X DIGI TRANSISTOR

IC555 MC33269D-X IC Q105 DTC144EE-X TRANSISTOR

K101 NQR0007-002X FERRITE BEADS C.M. Q251 DTC144EE-X TRANSISTOR

K102 NQR0007-002X FERRITE BEADS C.M. Q252 DTC144EE-X TRANSISTOR

K103 NQR0007-002X FERRITE BEADS C.M. Q253 DTC144EE-X TRANSISTOR

K155 NQR0007-002X FERRITE BEADS C.M. Q254 DTC144EE-X TRANSISTOR

K156 NQR0007-002X FERRITE BEADS C.M. Q255 DTC144EE-X TRANSISTOR

K157 NQR0007-002X FERRITE BEADS C.M. R101 NRS125J-270X MG RESISTOR 27

K158 NQR0007-002X FERRITE BEADS C.M. R102 NRS125J-2R2X MG RESISTOR 2.2

K159 NQR0007-002X FERRITE BEADS C.M. R103 NRSA63J-123X MG RESISTOR 12K

K160 NQR0007-002X FERRITE BEADS C.M. R104 NRSA63J-103X MG RESISTOR 10K

K201 NQR0007-002X FERRITE BEADS C.M. R106 NRSA63J-223X MG RESISTOR 22K

K202 NQR0007-002X FERRITE BEADS C.M. R108 NRSA63J-103X MG RESISTOR 10K

K251 NQR0007-002X FERRITE BEADS C.M. R109 NRSA63J-823X MG RESISTOR 82K

K271 NQR0007-002X FERRITE BEADS C.M. R110 NRSA63J-393X MG RESISTOR 39K

K301 NQR0007-002X FERRITE BEADS C.M. R112 NRVA63D-123X MG RESISTOR 12K

K302 NQR0007-002X FERRITE BEADS C.M. R113 NRSA63J-393X MG RESISTOR 39K

K371 NQR0007-002X FERRITE BEADS C.M. R114 NRSA63J-272X MG RESISTOR 27K

K401 NQR0007-002X FERRITE BEADS C.M. R115 NRSA63J-223X MG RESISTOR 22K

K402 NQR0007-002X FERRITE BEADS C.M. R116 NRSA63J-103X MG RESISTOR 10K

K501 NQR0007-002X FERRITE BEADS C.M. R117 NRSA63J-223X MG RESISTOR 22K

K502 NQR0007-002X FERRITE BEADS C.M. R118 NRSA63J-153X MG RESISTOR 15K

K503 NQR0007-002X FERRITE BEADS C.M. R119 NRSA63J-155X MG RESISTOR 1.5M

K504 NQR0201-001X FERRITE BEADS C.M. R120 NRVA63D-332X METAL FILM RESISTOR 3.3K

K505 NQR0269-001X FERRITE BEADS C.M. R121 NRSA63J-474X MG RESISTOR 470K

K550 NQR0007-002X FERRITE BEADS C.M. R122 NRSA63J-474X MG RESISTOR 470K

K551 NQR0007-002X FERRITE BEADS C.M. R123 NRSA63J-822X MG RESISTOR 8.2K

K552 NQR0007-002X FERRITE BEADS C.M. R124 NRSA63J-183X MG RESISTOR 18K

K553 NQR0007-002X FERRITE BEADS C.M. R125 NRSA63J-154X MG RESISTOR 150K

K554 NQR0007-002X FERRITE BEADS C.M. R126 NRSA63J-564X MG RESISTOR 560K

K555 NQR0007-002X FERRITE BEADS C.M. R127 NRSA63J-123X MG RESISTOR 12K

K556 NQR0007-002X FERRITE BEADS C.M. R128 NRSA63J-223X MG RESISTOR 22K

K557 NQR0007-002X FERRITE BEADS C.M. R129 NRSA63J-103X MG RESISTOR 10K

K558 NQR0007-002X FERRITE BEADS C.M. R130 NRSA63J-822X MG RESISTOR 8.2K

TC74VHCOOFT-X

MSM27C1602CZ61X

MSM531622F61G-X

TC74VHCOOFT-X

HY57V161610DTC8

HY57V161610DTC8

UPD42280GU-30-X

MSM531622F56G-X

IC K578 NQR0007-002X FERRITE BEADS C.M.

IC (IC401 PAIR) K585 NQR0007-002X FERRITE BEADS C.M.

IC (after S/N 0061001) K586 NQR0007-002X FERRITE BEADS C.M.

IC K592 NQR0007-002X FERRITE BEADS C.M.

IC L191 NQL044K-100X INDUCTOR C.M

IC L241 NQL044K-100X INDUCTOR C.M

IC Q102 DTC124EE-X DIGI TRANSISTOR

IC Q103 DTC124EE-X DIGI TRANSISTOR

Page 44

Parts List 7/8

44

SYMBOL PARTS NO. DESCRIPTION SYMBOL PARTS NO. DESCRIPTION

R131 NRSA63J-0R0X MG RESISTOR 0 R271 NRSA63J-243X MG RESISTOR 24K

R151 NRSA63J-0R0X MG RESISTOR 0 R272 NRSA63J-103X MG RESISTOR 10K

R152 NRSA63J-0R0X MG RESISTOR 0 R273 NRSA63J-103X MG RESISTOR 10K

R153 NRSA63J-0R0X MG RESISTOR 0 R274 NRSA63J-0R0X MG RESISTOR 0

R154 NRSA63J-0R0X MG RESISTOR 0 R275 NRSA63J-243X MG RESISTOR 24K

R201 NRSA63J-102X MG RESISTOR 1K R276 NRSA63J-103X MG RESISTOR 10K

R202 NRSA63J-102X MG RESISTOR 1K R277 NRSA63J-103X MG RESISTOR 10K

R203 NRSA63J-102X MG RESISTOR 1K R278 NRSA63J-0R0X MG RESISTOR 0