Ross video SYNERGY 100 EDITION User Manual

Maintenance Guide

Synergy 1 / Synergy 100 Edition

Ross Video Limited

Synergy 1 / Synergy 100 • Maintenance Guide

• Ross Part Number: 4216D-001

• Document Issue: 1

• Printing Date: March 17, 2003. Printed in Canada.

The information contained in this Maintenance Guide is subject to change without

notice or obligation.

Copyright

© 2003 Ross Video Limited. All rights reserved.

Contents of this publication may not be reproduced in any form without the written

permission of Ross Video Limited. Reproduction or reverse engineering of

copyrighted software is prohibited.

Notice

The material in this manual is furnished for informational use only. It is subject to

change without notice and should not be construed as commitment by Ross Video

Limited. Ross Video Limited assumes no responsibility or liability for errors or

inaccuracies that may appear in this manual.

Trademarks

• is a registered trademark of Ross Video Limited.

• Ross, ROSS, ROSS

Video Limited.

• All other product names and any registered and unregistered

trademarks mentioned in this guide are used for identification purposes

only and remain the exclusive property of their respective owners.

, and MLE are registered trademarks of Ross

Warranty and Repair Policy

Ross Video Limited (Ross) warrants its Switchers and related options, to be free

from defects under normal use and service for a period of THREE YEARS from the

date of shipment. Fader handle assemblies are warranted for the life of the product.

If an item becomes defective within the warranty period Ross will repair or replace

the defective item, as determined solely by Ross.

Warranty repairs will be conducted at Ross, with all shipping FOB Ross dock. If

repairs are conducted at Customer Site, reasonable out-of-pocket charges will apply.

At the discretion of Ross, and on a temporary loan basis, plug in circuit boards or

other replacement parts may be supplied free of charge while defective items

undergo repair. Return packing, shipping, and special handling costs are the

responsibility of the customer.

Software upgrades for switchers, as defined by Ross, may occur from time to time.

Ross will notify Customers of such upgrades and subject to a Customer initiated

request, such upgrades will be provided free of charge within three years of the

original ship date, with shipping FOB Ross dock.

This warranty is void if products are subjected to misuse, neglect, accident, improper

installation or application, or unauthorized modification.

In no event shall Ross Video Limited be liable for direct, indirect, special, incidental,

or consequential damages (including loss of profit). Implied warranties, including

that of merchantability and fitness for a particular purpose, are expressly limited to

the duration of this warranty.

This warranty is TRANSFERABLE to subsequent owners, subject to Ross’

notification of change of ownership.

Important Regulatory and Safety Notices to Service Personnel

Please review the following material to avoid personnel injury and to prevent

product damage.

• All product servicing should be carried out by qualified service

personnel.

• This product may require specific equipment, and/or installation

procedures to be carried out to satisfy certain regulatory compliance

requirements. Notices have been included in the Operator and Service

manuals, to call attention to these specific requirements.

Symbol Meanings

• Protective Earth

• Caution. Refer to the manual for important safety or

compliance related information.

• Warning Hazardous Voltages

Cautions to Service Personnel

Please review the following important cautions:

• Use Proper Power Cords

Use only power cords specified for this product and certified for the

country of use.

• Multiple Power Cords

This equipment can be configured with more than one power cord. To

reduce the risk of shock, disconnect all power cords before servicing.

• Redundant Power Supply Connection

This equipment can be configured with dual power supply modules to

provide for power supply redundancy. To reduce the risk of shock and

to provide for maximum power supply redundancy, plug each of the

supply cords into separate branch circuits employing separate service

grounds.

• Product Power Disconnect

Certain parts of this equipment still presents a safety hazard with the

power switch(es) in the OFF position. To avoid electrical shock,

disconnect all A/C power cords before servicing.

• Grounding of the Product

The safe operation of this product requires that a protective earth

connection be provided. This protective earth is provided by a

grounding conductor in the equipment’s supply cords. To reduce the

risk of electrical shock to operator and service personnel, this ground

conductor must be connected to an earthed ground.

• Battery Replacement

This equipment contains a Lithium battery which if replaced

incorrectly, or with an incorrect type, may cause an explosion. Replace

only with the same type.

• Safety Barrier Replacement

Service barriers within this product are intended to protect operator and

service personnel from hazardous voltages. For continued safety,

replace all barriers after servicing.

Power Cord Wiring Notices

• North American

This product is supplied with certified 10A/125V SVT type supply

cords. Conductors are color coded white (neutral), black (line) and

green or green/yellow (ground).

Operation of this equipment at line voltages exceeding 130V, will

require that supply cords with appropriate voltage and current ratings

be used.

• International Power Supply Cord

This equipment is supplied with CEE 7/7 European type, 10A/250V

certified supply cords.

In some countries, it may be necessary to supply the correct mains

supply cord. Use only an approved IEC 320 C-13 type A/C line cord

rated for a minimum 10A at 250V and that meets all safety

requirements necessary for the country in which they are to be used.

Further, the safe operation of this product requires that a protective

earth connection be provided. This protective earth is provided by the

grounding conductor in the equipment’s supply cord. To reduce the

risk of electrical shock to operator and service personnel, this ground

conductor must be connected to an earthed ground.

Company Address

Ross Video Limited Ross Video Incorporated

8 John Street P.O. Box 880

Iroquois, Ontario, K0E 1K0 Ogdensburg, New York

Canada USA 13669-0880

General Business Office: (+1) 613

Fax: (+1) 613

Technical Support: (+1) 613

E-mail (Technical Support): techsupport@rossvideo.com

E-mail (General Information): solutions@rossvideo.com

Website: http://www.rossvideo.com

After hours emergency: (+1) 613

• 652 • 4886

• 652 • 4425

• 652 • 4886

• 652 • 4886, ext. 333

Contents

Introduction 1-1

About This Guide ...................................................................................................................1-1

Documentation Conventions ..................................................................................................1-3

Documentation Terms ............................................................................................................1-4

Abbreviations..........................................................................................................................1-5

Related Publications ...............................................................................................................1-6

A Word About Static Discharge .............................................................................................1-7

System Architecture 2-1

In This Chapter .......................................................................................................................2-1

Block Diagram........................................................................................................................2-2

Front Chassis Layout................................................................................................2-4

Rear Chassis Layout.................................................................................................2-4

Primary System Boards ..........................................................................................................2-5

Buses and Video Routing .......................................................................................................2-6

MLE Outputs............................................................................................................2-6

Serializer Modules....................................................................................................2-7

Aux Buses ................................................................................................................2-7

PLL and SPG............................................................................................................2-9

System Timing and Non-Sync Detectors ...............................................................2-10

CPU Structure.......................................................................................................................2-12

A Note About CPU Architecture............................................................................2-13

Power-Up Sequence .............................................................................................................2-14

A Note About Memory Registers...........................................................................2-15

A Note About the Software Upgrade Process ........................................................2-15

Board Labeling .....................................................................................................................2-17

Option Boards 3-1

In This Chapter .......................................................................................................................3-1

Optional Boards......................................................................................................................3-2

Timed Aux Bus (Synergy 1 only)...........................................................................................3-3

Installing a Timed Aux Bus......................................................................................3-3

Removing a Timed Aux Bus ....................................................................................3-4

Squeeze and Tease Board .......................................................................................................3-6

Removing or Installing the Squeeze and Tease Board...............................3-7

Squeeze and Tease Board Jumpers ............................................................3-7

Squeeze and Tease 3D Board .................................................................................................3-8

Removing or Installing the Squeeze and Tease 3D Board.........................3-9

Dual Border Generator .........................................................................................................3-10

Removing or Installing the Dual Border Generator.................................3-11

Ultimatte Insider™ Board .....................................................................................................3-12

Synergy 1 Maintenance Guide • Synergy 1/Synergy 100 Edition (Iss. 1) Contents • i

Ultimatte Insider Board Installation ...................................................................... 3-13

Ultimatte Insider Board Jumpers........................................................................... 3-14

Ultimatte Insider Board LEDs............................................................................... 3-14

Dual Aspectizer Board Installation (Synergy 1 only).......................................................... 3-15

Frame Tally Board Installation ............................................................................................ 3-17

Frame Processor (CPU) Board 4-1

In This Chapter ...................................................................................................................... 4-1

Frame Processor (CPU) Board .............................................................................................. 4-2

Frame Jumpers and Switches .................................................................................. 4-5

Deserializer Module............................................................................................................... 4-8

Serializer Module................................................................................................................... 4-9

Serializer/Deserializer Module Installation ........................................................... 4-10

Working with Installed Options 5-1

In This Chapter ...................................................................................................................... 5-1

Installed Options Menus – Synergy 1.................................................................................... 5-2

Menu Access ........................................................................................................... 5-2

Software Options Menu........................................................................................... 5-2

Panel Boards Menu.................................................................................................. 5-3

Frame Boards Menu ................................................................................................ 5-4

Option Boards Menu ............................................................................................... 5-4

Installing Serial Numbers ...................................................................................................... 5-5

Installing Software Options ................................................................................................... 5-6

Storing and Recalling Option Codes ..................................................................................... 5-7

Options Menu – Synergy 100 ................................................................................................ 5-8

Menu Access ........................................................................................................... 5-8

Options Menu .......................................................................................................... 5-8

DVE Send Option 6-1

In This Chapter ...................................................................................................................... 6-1

Installing the DVE Send Option ............................................................................................ 6-2

DVE Send Option Kit.............................................................................................. 6-2

DVE Send Installation............................................................................................. 6-2

Testing the DVE Send Option................................................................................. 6-3

Power Supplies 7-1

In This Chapter ...................................................................................................................... 7-1

A Note About Redundant Power............................................................................. 7-1

Replacing a Synergy 1 Control Panel Power Supply............................................................. 7-2

Calibrating the Control Panel Power Supply........................................................... 7-4

Replacing a Synergy 100 Control Panel Power Supply......................................................... 7-7

Replacing a Chassis Power Supply........................................................................................ 7-8

Changing a Chassis Power Supply Fan ............................................................................... 7-11

Calibration and Diagnostics 8-1

In This Chapter ...................................................................................................................... 8-1

Switcher Calibration – Synergy 1.......................................................................................... 8-2

Switcher Calibration – Synergy 100...................................................................................... 8-4

Synergy 1 Panel Diagnostic Tools......................................................................................... 8-6

Displaying Panel Information.................................................................................. 8-7

ii • Contents Synergy 1 Maintenance Guide • Synergy 1/Synergy 100 Edition (Iss. 1)

Potentiometer Test....................................................................................................8-8

Fader Test.................................................................................................................8-8

Joystick Test.............................................................................................................8-9

Button Test ...............................................................................................................8-9

Lamp Test...............................................................................................................8-10

Memory Test ..........................................................................................................8-10

Display Test............................................................................................................8-11

Disk Test ................................................................................................................8-11

TX/RX Test ............................................................................................................8-12

Tally Test................................................................................................................8-13

DIP/Jump Test........................................................................................................8-14

Synergy 1 Frame Diagnostic Tools ......................................................................................8-15

TX/RX Test ............................................................................................................8-15

DIP/Jump Test........................................................................................................8-16

GPI Test..................................................................................................................8-16

Tally Test................................................................................................................8-17

Internal Video Test.................................................................................................8-18

Synergy 100 Diagnostic Tools..............................................................................................8-20

Potentiometer Test..................................................................................................8-20

Fader Test...............................................................................................................8-21

Positioner Test........................................................................................................8-21

Button Test .............................................................................................................8-22

Lamp Test...............................................................................................................8-22

Control Panel Boards 9-1

In This Chapter .......................................................................................................................9-1

Synergy 1 Control Panel Boards.............................................................................................9-2

Synergy 1 Panel CPU Board Layout ......................................................................................9-3

Synergy 1 Rear Panel Connectors ............................................................................9-4

Synergy 100 Control Panel Boards.........................................................................................9-5

Synergy 100 Panel CPU Board Layout ..................................................................................9-6

Synergy 100 Rear Panel Connectors ........................................................................9-7

Basic Interconnections — Synergy 1 .....................................................................................9-8

Basic Interconnections — Synergy 100 .................................................................................9-9

Synergy 1 Panel Maintenance 10-1

In This Chapter .....................................................................................................................10-1

Replacing a Bulb ..................................................................................................................10-2

Replacing a Button ...............................................................................................................10-4

Replacing a Fader .................................................................................................................10-7

Replacing a Knob (Potentiometer) .......................................................................................10-9

Replacing the Display.........................................................................................................10-12

Synergy 100 Panel Maintenance 11-1

In This Chapter .....................................................................................................................11-1

Replacing a Button ...............................................................................................................11-2

Replacing the Fader ..............................................................................................................11-5

Replacing a Knob (Potentiometer) .......................................................................................11-7

Replacing a Display............................................................................................................11-10

Replacing a Rear Panel Connector .....................................................................................11-13

Replacing the Floppy Disk Drive .......................................................................................11-16

Replacing Transition Progress Bar LEDs...........................................................................11-18

Synergy 1 Maintenance Guide • Synergy 1/Synergy 100 Edition (Iss. 1) Contents • iii

Synergy 1 Control Panel Options 12-1

In This Chapter .................................................................................................................... 12-1

Installing the VTR Remote Control Option......................................................................... 12-2

Installing the Video Server Control Option......................................................................... 12-3

Installing the Audio Server Control Option......................................................................... 12-4

Miscellaneous Options 13-1

In This Chapter .................................................................................................................... 13-1

Installing the Editor Interface Option .................................................................................. 13-2

Glossary of Terms 14-1

Index 15-1

iv • Contents Synergy 1 Maintenance Guide • Synergy 1/Synergy 100 Edition (Iss. 1)

Introduction

About This Guide

This guide provides information regarding the technical theory and maintenance of

the following Synergy switchers:

• Synergy 1

• Synergy 100

As a useful tool for the field engineer, the guide takes you through the switcher’s

block diagram, the main boards and components, and the steps required to install

various options in the chassis and control panel.

The following chapters are included:

• Chapter 1, “Introduction” summarizes the guide and lists important

terms, conventions and abbreviations.

• Chapter 2, “System Architecture” describes the switcher’s block

diagram, and explains how video flows through the unit.

• Chapter 3, “Option Boards” provides basic information about the

optional boards: Serializers and Deserializers for timing Aux Buses, the

Border Generator, the Squeeze and Tease and Squeeze and Tease 3D

Board, the Ultimatte Insider Board, the Dual Aspectizer Board, and the

Frame Tally Board.

• Chapter 4, “Frame Processor (CPU) Board” provides details on the

Frame CPU board. The Serializer and Deserializer boards and their

installation are also discussed.

• Chapter 5, “Working with Installed Options” discusses the system

menus that allow you to verify the switcher’s installed options, install

serial numbers and install software options.

• Chapter 6, “DVE Send Option” outlines the procedures required to

install and test the DVE Send Option on the Synergy 1 switcher.

• Chapter 7, “Power Supplies” provides information about redundant

power, and procedures for changing control panel and frame power

supplies in the field.

Synergy 1 Maintenance Guide • Synergy 1/Synergy 100 Edition (Iss. 1) Introduction • 1-1

• Chapter 8, “Calibration and Diagnostics” provides information about

calibrating the Synergy 1 and 100 switchers, and running a variety of

diagnostic tests.

• Chapter 9, “Control Panel Boards” provides details about each

“switch” board in the control panel for the Synergy 1 and 100

switchers, plus each control panel’s CPU Board layout.

• Chapter 10, “Synergy 1 Panel Maintenance” provides detailed

instructions for basic Synergy 1 control panel maintenance procedures,

such as changing lamps and buttons.

• Chapter 11, “Synergy 100 Panel Maintenance” provides detailed

instructions for basic Synergy 100 control panel maintenance

procedures, such as replacing knobs and buttons.

• Chapter 12, “Synergy 1 Control Panel Options” provides instructions

for installing a variety of control panel options, including VTR

Remote Control, Video Server Control and Audio Server Control.

• Chapter 13, “Miscellaneous Options” provides instructions for

installing the Editor Interface Option.

• The Glossary provides a reference list of important switching and

video terms used throughout this guide.

An Index is also provided for your reference.

If, at any time, you have a question pertaining to your Ross Synergy 1 or Synergy

100 switcher, please contact us at the numbers listed in the front of this guide. Our

technical staff are always available for consultation, training, or service.

1-2 • Introduction Synergy 1 Maintenance Guide • Synergy 1/Synergy 100 Edition (Iss. 1)

Documentation Conventions

The following conventions are used throughout this guide:

• Rear panel connectors are indicated in bold-faced upper case letters.

For example:

The AUX 1 connector is ...

• Control Panel buttons are indicated in bold-faced upper case letters,

using a sans-serif font. For example:

Press WIPE to ...

• Menu names on the integral display panel are indicated in bold-faced

upper and lower case text. For example:

The Aux Bus Setup Menu allows you to ...

• Softkey labels on the integral display are indicated in bold-faced upper

and lower case letters, using a sans-serif font. They are not indicated by

the function key below the display that you press. For example:

Press Accept New Name to register ...

Synergy 1 Maintenance Guide • Synergy 1/Synergy 100 Edition (Iss. 1) Introduction • 1-3

Documentation Terms

The following terms are used throughout this guide:

• “Frame” and “Electronics Frame” both refer to the Synergy 1 or 100

• “Operator” and “User” refer to the person who uses the Synergy

• “Panel” and “Control Panel” both refer to Synergy 1 or 100

• “SDI” refers to Serial Digital Interface, a digital video signal that is

• “System” refers to the entire Synergy system, consisting of its

• “Video system” refers to the mix of interconnected digital equipment

• A “1+0 DVE” has a video connection only going from the Synergy 1

switcher’s 2 RU electronics chassis.

production switcher.

switcher’s multi-button control panel.

distributed via a single coaxial cable with BNC connectors.

electronics frame and control panel.

(including the edit controller, VTRs, DVEs, etc.) in which the Synergy

system is included.

to the DVE. Both key and fill signals are connected from the DVE to

the Synergy 1.

• A “1+1 DVE” has both a video (fill) and an key (alpha) connection

going from the Synergy 1 to the DVE. Both key and fill signals are

connected from the DVE to the Synergy 1.

• “Primary DVE” refers to the one DVE (either single or multi-channel)

that is connected to a Synergy 1 switcher via RS-422 serial control.

This type of connection allows you to run the DVE using custom

control buttons. You can also load DVE effects from the panel using

the Recall DVE button in the Global Memory System group.

• “Secondary DVE” refers to any number of DVEs that are connected to

the Synergy 1 switcher using video and key connections only — with

no RS-422 control. A secondary DVE must be controlled from its own

local control panel, or via GPI output pulses from the Synergy 1

switcher.

1-4 • Introduction Synergy 1 Maintenance Guide • Synergy 1/Synergy 100 Edition (Iss. 1)

Abbreviations

The following abbreviations are used throughout the text:

Abbreviation Definition

A-D Analog-to-Digital

AUX Auxiliary

CG Character Generator

D-A Digital-to-Analog

DA Distribution Amplifier

DDR Digital Disk Recorder

DSK Downstream Keyer

DVE Digital Video Effects

DVR Digital Video Recorder

ID Identification

MLE Multi-level Effects

PGM Program Bus

PST Preset Bus

PST PATT Preset Pattern

PV Preview

RU Rack Unit

TD Technical Director

VCR Video Cassette Recorder

VTR Video Tape Recorder

Synergy 1 Maintenance Guide • Synergy 1/Synergy 100 Edition (Iss. 1) Introduction • 1-5

Related Publications

For a complete installation and operational overview of the Synergy 1/Synergy 100

product line, refer to the following four publications:

• Synergy 1 Installation Guide, Synergy 1 Edition, (P/N: 4216D-002)

• Synergy 1 Operation Guide, Synergy 1 Edition, (P/N: 4216D-003)

• Synergy 1 Installation Guide, Synergy 100 Edition, (P/N: 4100D-

002)

• Synergy 1 Operation Guide, Synergy 100 Edition, (P/N: 4100D-003)

1-6 • Introduction Synergy 1 Maintenance Guide • Synergy 1/Synergy 100 Edition (Iss. 1)

A Word About Static Discharge

Throughout the many procedures in this Maintenance Guide, please observe all

static discharge precautions.

Caution

Avoid handling the switcher circuit boards in high static

environments such as carpeted areas, and when synthetic fiber

clothing is worn. Touch the frame to dissipate static charge

before removing boards from the frame, and exercise proper

grounding precautions when working on circuit boards.

Synergy 1 Maintenance Guide • Synergy 1/Synergy 100 Edition (Iss. 1) Introduction • 1-7

1-8 • Introduction Synergy 1 Maintenance Guide • Synergy 1/Synergy 100 Edition (Iss. 1)

System Architecture

In This Chapter

This chapter describes the boards in the Synergy 1 chassis, the overall system block

diagram, and provides an explanation of how video flows through the unit. The

following major topics are discussed:

• Block Diagram

• Front Chassis Layout

• Rear Chassis Layout

• Primary System Boards

• Buses and Video Routing

• CPU Structure

• Power-Up Sequence

• Board Labeling

In Chapter 2 of the Synergy 1 Installation Guide, Synergy 1 Edition and Synergy 1

Installation Guide, Synergy 100 Edition, refer to the “Equipment Overview”

section for a detailed discussion of the chassis front panel, back panel connectors,

internal board layout, and control panel connectors.

Synergy 1 Maintenance Guide • Synergy 1/Synergy 100 Edition (Iss. 1) System Architecture • 2-1

Block Diagram

Equalizers

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Reference

16x8

Crosspoint

Matrix

24x8

Crosspoint

Matrix

System Reference

and Clocking

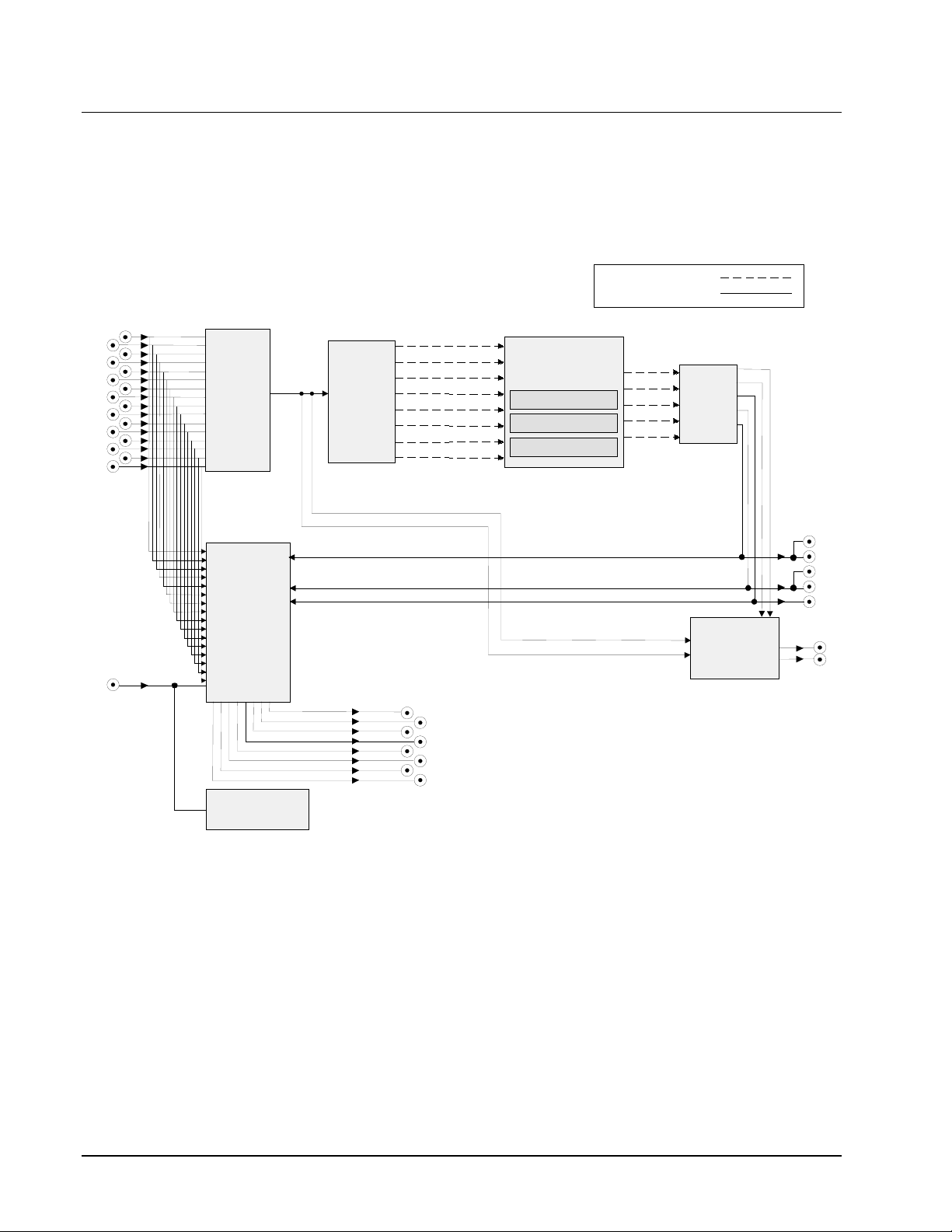

Use the block diagram below for reference throughout this chapter.

Legend:

10-Bit Parallel Digital

Serial Digital

BKGD

8 x

Outputs

8 x

4000A-061

Deserializer

Modules

Aux 1

Aux 2

Cable

Driver

PST

Key 1 Video

Key 1 Alpha

Key 2 Video

Key 2 Alpha

Key 3 Video/AUX1

Key 3 Alpha/AUX2

Aux 3 Out

Aux 4 Out

Aux 5 Out

Aux 6 Out

Aux 7 Out

Aux 8 Out

Aux 9 Out

Aux 10 Out

MLE Video

Processing Core

Squeeze & Tease

Border Generator

Ultimatte or Aspecti zer

PGM

PV

CLEAN

PGM

PV

CLEAN

AUX1

AUX2

5 x

4000A-062

Serializer

Modules

Video Switch

(Synergy 1 Only)

PGM1

PGM2

PV1

PV2

CLEAN

AUX1 OUT

AUX2 OUT

Synergy 1 Block Diagram

2-2 • System Architecture Synergy 1 Maintenance Guide • Synergy 1/Synergy 100 Edition (Iss. 1)

Note the following important points regarding the previous diagram:

• 16 external inputs are routed into the 16x8 crosspoint matrix.

• PGM, PV, and Clean Feed are fed into the 24x8 crosspoint matrix ,

which then routes the signal to Aux Buses 3 to 10.

• The crosspoint matrices provide 16 outputs:

~ Background

~ Preset

~ Key 1 Video

~ Key 2 Video

~ Key 3 Video/Aux 1

~ Key 1 Alpha

~ Key 2 Alpha

~ Key 3 Alpha/Aux 2

~ 8 x Aux (Aux Buses 3-10)

• Each output, with the exception of the 8 untimed Aux Buses, is routed

through a Deserializer Module (4000A-061) from which the signals

feed the MLE.

• Aux Buses 1 and 2 may be routed through Deserializer Modules,

through blanking circuitry (not shown), re-serialized in Serializer

Modules (4000A-062), and out through BNC connectors.

• The MLE is self-contained, with provisions for several optional

modules: Border Generator (4000A-049), Squeeze & Tease (4000A-

048), Squeeze and Tease 3D (4000A-148), Aspectizer (4000A-050),

and the Ultimatte Insider™. The MLE outputs five signals:

Note

~ Program

~ Preview

~ Aux 1 (optionally timed)

~ Aux 2 (optionally timed)

~ Clean Feed (optional)

The following two sections provide diagrams of the front and

rear chassis of the Synergy 1 and 100 switchers. For more

detailed descriptions of the components listed in the diagrams,

please refer to the “Equipment Overview” section in Chapter

2 of the Synergy 1 Installation Guide, Synergy 1 Edition or

the Synergy 1 Installation Guide, Synergy 100 Edition..

Synergy 1 Maintenance Guide • Synergy 1/Synergy 100 Edition (Iss. 1) System Architecture • 2-3

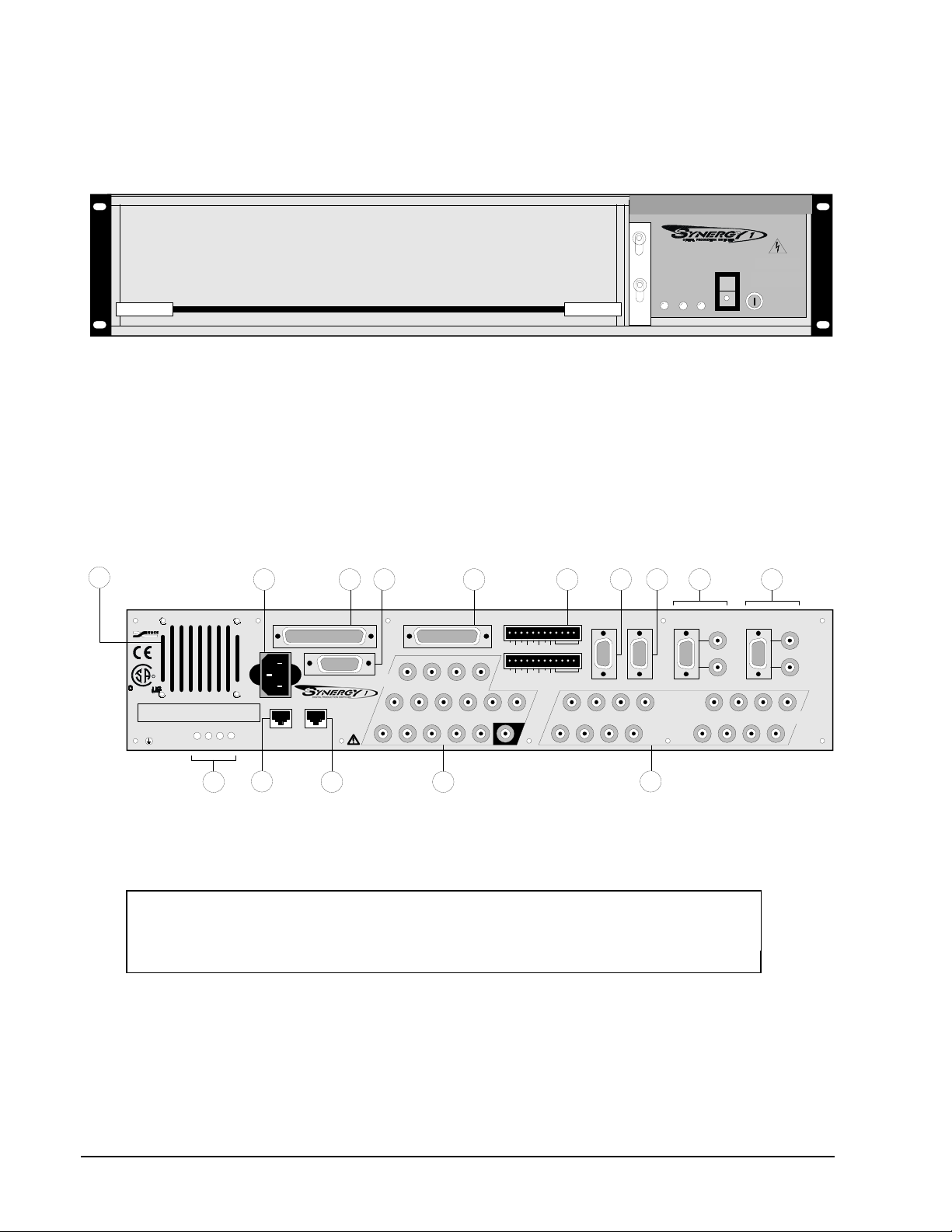

Front Chassis Layout

The figure below illustrates the front of the chassis, with the door removed.

Frame Processor (CPU) Board (4216A-001)

Synergy 1 Frame, Front View

Rear Chassis Layout

The figure below illustrates the rear connector panel of the electronics chassis. The

connector layout is identical for the Synergy 1 and Synergy 100 switchers.

CAUTION:

POWER

TO REDUCE THE RISK OF

FIRE REPLACE W ITH SAME

FAN

FAIL

PWR

FAIL

PWR

ON

FUSE AND RATING

FUSE

T4A/250V

1

R

This class A device complies with Canadian ICES-003 and part 15 of the FCC rules.

Operation is subject to the following conditions: (1) This device may not cause

harmful interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

POWER

OK

-12 +5 +10 +15

3

2

SYNERG Y

PANEL

4

210/216 PA NEL

100/110 PA NEL

MOUNT IN RACK ONLY

100-120 / 200-240V ~

AUX

PANEL

5

6

50/60 Hz

2.7A 180W

OUT

Aux 9

7

Aux 10

Aux 8

Aux 7

8

GPI I/O

Clean

Aux 1 PV1

Aux 4

Aux 2 PV2

Aux 3

Aux 5

PGM1

14

9111315

10 12 14 16 COMMON

1357

2468COMMON

PGM2Aux 6

601 REF I N

9

TALLY

EDITOR DVE

2

1

2 4 6 8 10 12 14 16

1357

Synergy 1 Frame, Rear View

1) Fan Exhaust Vent 6) Ross 210/216 Panel Connector 11) DVE Connector

2) Power Connector 7) GVG 100/110 Panel Connector 12) Peripheral 1 Connectors

3) Power Supply LEDs 8) GPI I/O Connector 13) Peripheral 2 Connectors

4) Synergy Panel Connector 9) Tally Connectors 14) Output Section

5) Aux Panel Connector 10) Editor Connector 15) Input Section

10 11 12 13

PERIPHERAL 1 PERIPHERAL 2

11 13 15

9

Rx

Tx

15

Rx

Tx

IN

2-4 • System Architecture Synergy 1 Maintenance Guide • Synergy 1/Synergy 100 Edition (Iss. 1)

Primary System Boards

The following primary system boards are referred to throughout this chapter:

• Frame Motherboard (4216A-002)

Also called the backplane, this non-removable board provides the

interconnects between the Frame Processor board, power supply and

external connections. The board has no active components.

• Frame Processor (CPU) (4216A-001)

The Frame Processor resides in the slot of the chassis. It contains the

main system microprocessor which handles high-level control

functions and all of the remote serial communication for the Synergy 1

frame. It also provides connectors for mounting of all of the optional

daughter boards.

Synergy 1 Maintenance Guide • Synergy 1/Synergy 100 Edition (Iss. 1) System Architecture • 2-5

Buses and Video Routing

The switcher’s full crosspoint matrix is 24 x 16:

• 16 external inputs

• 4 internal inputs

• 4 spare inputs

The spare inputs are currently not used.

The 16 buses (crosspoint outputs) are listed below:

• Background

• Preset

• Key 1 Video

• Key 1 Alpha

• Key 2 Video

• Key 2 Alpha

• Key 3 Video/Aux 1/DVE Video

• Key 3 Alpha/Aux 2/DVE Alpha

• 8 x Untimed Aux (Aux Buses 3-10)

MLE Outputs

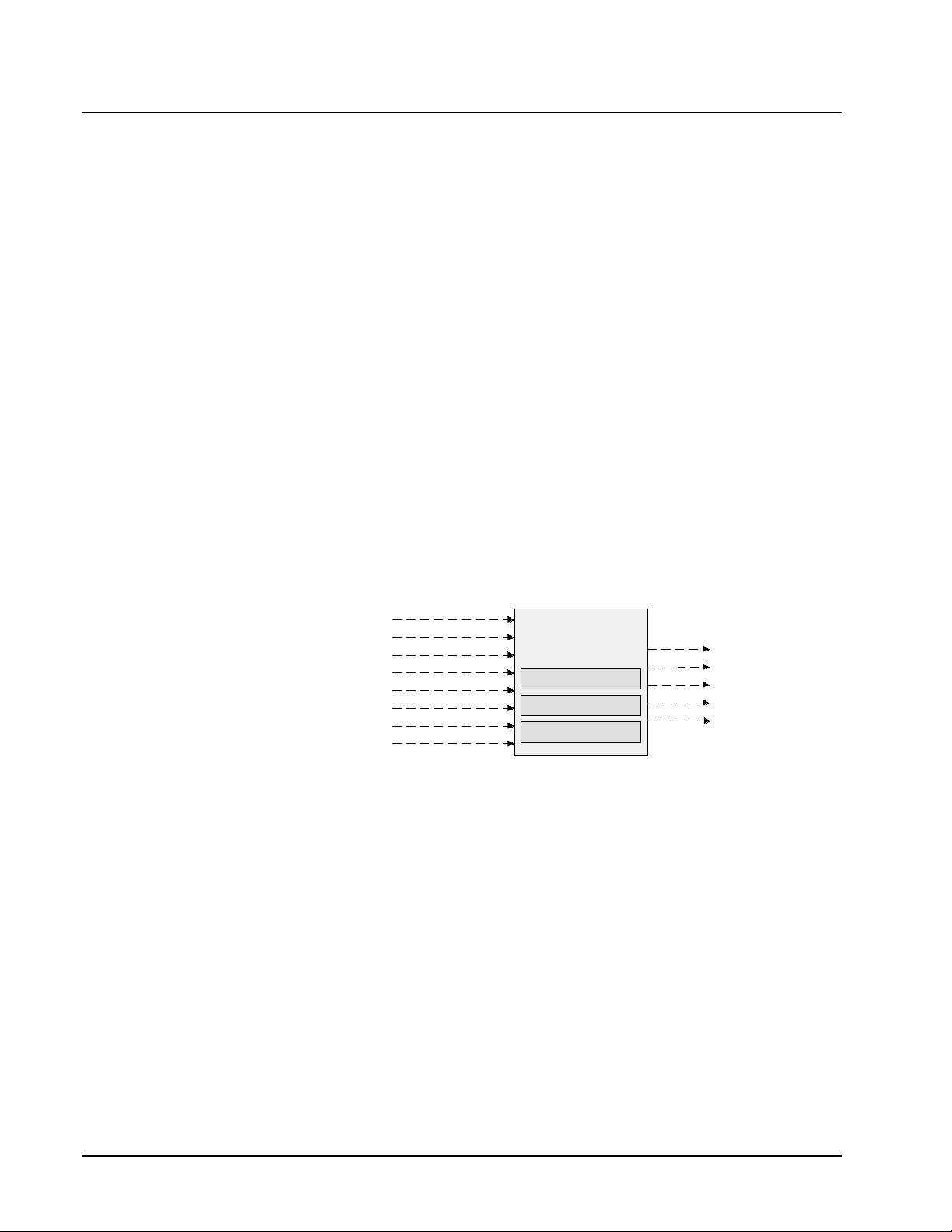

Looking closer at the MLE, it receives eight dedicated buses:

From

Crosspoint

Matrix

BKGD

PST

Key 1 Video

Key 1 Alpha

Key 2 Video

Key 2 Alpha

Key 3 Video/AUX1

Key 3 Alpha/AUX2

MLE Video

Processing Core

Squeeze & Tease

Border Generator

Ultimatte or Aspectizer

• 1 x Background

• 1 x Preset

• 1 x Key 1 Video

• 1 x Key 1 Alpha

• 1 x Key 2 Video

• 1 x Key 2 Alpha

• 1 x Key 3 Video/Aux 1/DVE Video

• 1 x Key 3 Alpha/Aux 2/DVE Alpha

PGM

PV

CLEAN

AUX1

AUX2

2-6 • System Architecture Synergy 1 Maintenance Guide • Synergy 1/Synergy 100 Edition (Iss. 1)

Coming out of the MLE are five outputs:

• Program — routed to a rear-chassis BNC output connector, to the

Preview Matrix, and also back into the crosspoint matrix.

• Preview — routed to a rear-chassis BNC output connector and to the

Preview Matrix.

• Clean Feed — routed to a rear-chassis BNC output connector and also

back into the crosspoint matrix.

• Aux 1 — routed to a rear-chassis BNC output connector through the

video switch. (Synergy 1 only)

• Aux 2 — routed to a rear-chassis BNC output connector through the

video switch. (Synergy 1 only)

Serializer Modules

Program, Preview, Clean Feed, Aux 1, and Aux 2 video each come out of the

MLE as parallel 10-bit data. These signals are then routed through small Serializer

Modules (4000A-062) as shown below.

Serializer Module

Serializer Modules convert the parallel digital video data into the serial format,

which can then be routed via coax cables through your facility, or used internally in

the Synergy’s crosspoint matrix. The crosspoint matrix requires that everything must

be in the serial format. Thus any signal that is routed to the crosspoint matrix must

go through a Serializer Module, from any given output.

Note that Clean Feed has a dedicated BNC output, just like Program and Preview,

but DVE Send is only available to the outside world by routing it into the video

switch, and then out via an Aux Bus. There is no DVE Send BNC output.

Aux Buses

The routing for Synergy 1’s Aux Buses is described in this section. Refer to the

illustrations on the following page.

Aux Buses 1 and 2 can be configured for either “timed” or “untimed” operation.

• For untimed Aux Bus operation, the lower circuit is used — going

directly from the crosspoint matrix to the video switch, and then to the

output BNC connector. No other processing is required.

Synergy 1 Maintenance Guide • Synergy 1/Synergy 100 Edition (Iss. 1) System Architecture • 2-7

MLE Video

16x8

Crosspoint

Matrix

Outputs

4000A-061

Deserializer

Modules

Aux 1 (untimed)

Aux 2 (untimed)

Key 3 Video/AUX1

Key 3 Alpha/AUX2

Processing Core

Squee ze & Tease

Border Generator

Ultimatte or Aspectizer

To Video Switch

and BNC Connectors

AUX1

AUX2

AUX1

(timed)

To Video Switch

and BNC Connectors

Aux Buses 1 and 2 Routing

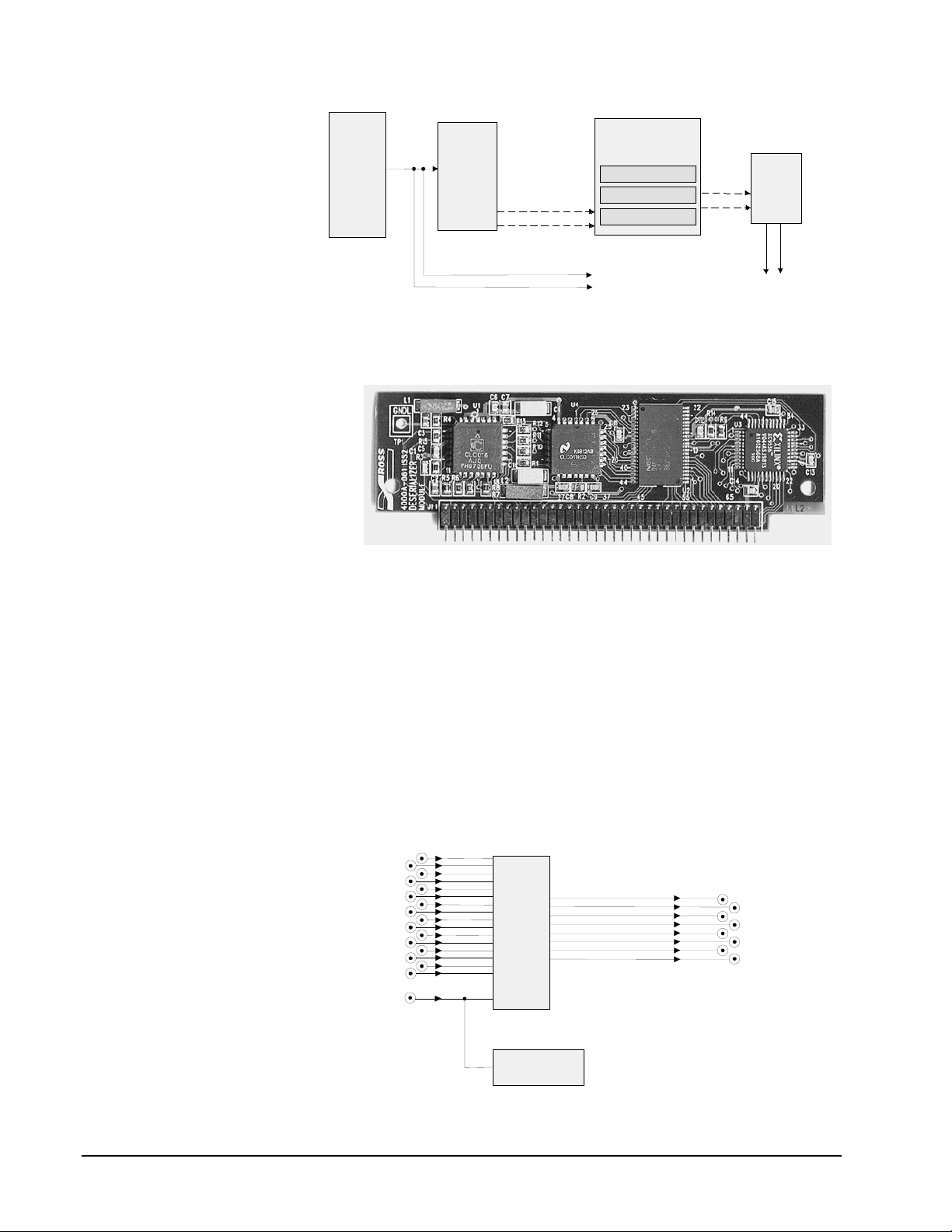

• For timed Aux Bus operation, the upper circuit is used — going first

through a Deserializer Module (4000A-061).

Deserializer Module

4000A-062

Serializer

Modules

AUX2

(timed)

The Deserializer Module converts the signal from serial data to 10-bit

parallel data, but it also handles the timing of the inputs by auto-timing

the signal to reference.

The signal is then routed into the MLE video processing core, through

circuitry that performs blanking insertion, signal clean-up, and

synchronization to system reference. Note that the blanking does not

affect the imbedded ancillary data in the vertical interval.

As the last step, the signal is routed through a Serializer module,

converted from parallel to serial, then through a driver (video switch)

to the output BNC connector.

Aux Buses 3 to 8 inclusive are untimed, and are switched directly on the crosspoint

matrix. Refer to the illustration below:

Equalizers

1

2

Reference

3

4

5

6

7

8

9

10

11

12

13

14

15

16

24x8

Crosspoint

Matrix

Cable

Driver

Aux 3 Out

Aux 4 Out

Aux 5 Out

Aux 6 Out

Aux 7 Out

Aux 8 Out

Aux 9 Out

Aux 10 Out

System Reference

and Clocking

Aux Buses 3 to 10 Routing

2-8 • System Architecture Synergy 1 Maintenance Guide • Synergy 1/Synergy 100 Edition (Iss. 1)

Regarding timing, there is very little delay on the untimed Aux Bus outputs. The

timed Aux Bus outputs, however, are delayed such that they are timed to match the

PGM output of the switcher.

PLL and SPG

The PLL (Phase Lock Loop) and SPG (Sync Pulse Generator) circuitry takes the

reference video signal from the REF IN BNC (in serial form) and creates a clean

clock — plus various other sync pulses for the system.

Dedicated

REF IN BNC

Within the PLL and SPG circuitry, there are two modes in which the Deserializer

Module (4000A-061) can work:

• The simplest mode is when the Deserializer is used for the reference.

The microprocessor tells the module to add a delay of [n] clocks. The

signal comes in — it is then delayed and fed out.

• On all other buses (e.g., MLE, Aux Buses) system software requests a

delay of [n] clocks from the reference. The reference sends a sync

pulse, then the module looks at incoming video and adjusts the delay

dynamically — delaying video by [n] from the reference signal.

Reference

Input

PLL

PLL and SPG Circuitry

10-bit

27MHz Clock

27MHz Clock

SPG

H-Sync

V-Sync

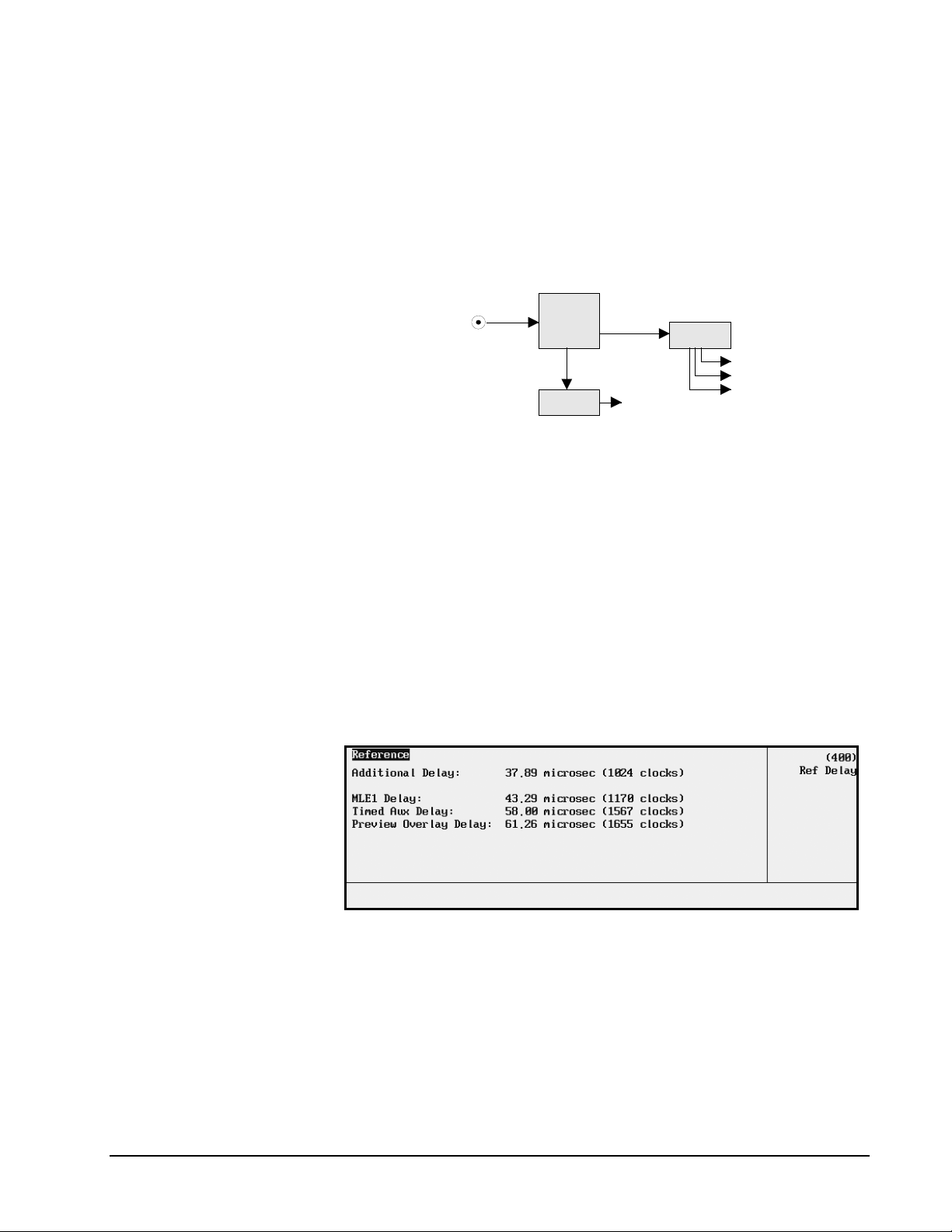

Field Pulse

System delay on the Synergy 1 is adjusted using the Reference Menu. In Chapter 7

of the Synergy 1 Installation Guide, Synergy 1 Edition, see the “Reference Delay

Adjustment” section.

Synergy 1 Reference Menu

Synergy 1 Maintenance Guide • Synergy 1/Synergy 100 Edition (Iss. 1) System Architecture • 2-9

System delay on the Synergy 100 is adjusted using the Outputs Menu. In Chapter 7

of the Synergy 1 Installation Guide, Synergy 100 Edition, see the “Outputs Menu”

section.

Outputs

Note

0. Aspect

1. Ref Dly

2. Clean BeforeKeys

3. Ancill ary data

4. Rem Aux Off

MENU

Exit

4:3

300

100

Previous

10

Down1Up

SEL

Accept

Synergy 100 Reference Menu

The output of the Deserializer module is routed to the SPG, that in turn generates

Horizontal Sync, Vertical Sync and Field Pulse.

Another output from the Deserializer module is a 27 MHz clock, which is routed to

the PLL (Phase Lock Loop). Within the PLL is a stable oscillator that regenerates

the 27 MHz clock, filtering out all jitter and generating the stable (clean) 27 MHz

signal that clocks the entire system. The net result is that if you have a jittery

reference signal, the switcher’s output will not be adversely affected on its outputs.

The PLL loop bandwidth is 300 Hz. Therefore, low frequency

jitter below 300 Hz will not be filtered out by the PLL.

If the reference is not present (or is lost), the PLL and SPG still continue to run. In

this condition however, the switcher can default to 625-line mode and the clock rate

is not guaranteed. Furthermore, the switcher may lose lock with the video.

System Timing and Non-Sync Detectors

Non-sync detection is based in the Deserializer Module (4000A-061). As discussed

above, a simple delay can be used, or the module can look at the reference signal and

then determine an offset.

The only information that the Deserializer Module has about the reference is

Horizontal Sync. The module itself guarantees that the video will be locked

horizontally — after video passes through it.

Additionally, the module’s vertical sync output is examined, and compared to that of

the reference. If the two signals do not match vertically, the system considers the

video to be non-synchronous — and the N/S (Non-Sync) LED lights on the panel

(on the bus on which the source was chosen). In this non-sync situation, the selected

video may be stable, but it will be shifted vertically.

If you have an input signal that is out of the timing window (too far out of time

horizontally), the signal may lock to the next (or to the previous) Horizontal Sync

pulse. This situation, however, can introduce a one-line offset, either up or down —

and the N/S light will again come on.

2-10 • System Architecture Synergy 1 Maintenance Guide • Synergy 1/Synergy 100 Edition (Iss. 1)

The Synergy 1 switcher “auto-times” around the reference — on the inputs. Synergy

1 specifications allow a ¼ line tolerance with regard to timing. If your input is ¼ line

early or ¼ line late, relative to the reference, the system can time it properly and

make it lock exactly. If the signal is greater than the allowed tolerance, the system

can not guarantee that it will lock to the correct “H.” It may possibly lock to the

previous H, or to the next H.

Please note:

• In order for Synergy 1 to properly auto-time late signals (with respect to the

reference), the switcher’s reference delay must be set to at least the amount of time

that the incoming signal is late. For example, if a video source arrives 1 microsecond

later than the reference, the reference delay must be set to at least 1 microsecond for

Synergy 1 to properly auto-time the source. In Chapter 7 of the Synergy 1

Installation Guide, Synergy 1 Edition, refer to the “Reference Delay Adjustment”

section for details on setting the reference delay. In the Synergy 1 Installation

Guide, Synergy 100 Edition, see the “Outputs Menu” section in Chapter 7.

• Synergy 1 has one non-sync detector per bus (including the Aux

Buses).

• The non-sync detection circuitry itself resides on the Frame Processor

board. However, the detection circuitry uses the V Sync pulse from the

Deserializer Module to determine sync status.

• The N/S LED lights only when a non-synchronous input is selected on

a given bus. Thus if three non-sync sources are chosen on PGM, KEY

and PST, each N/S LED will light on the respective buses.

• There are no non-sync detectors on untimed Aux Buses.

Synergy 1 Maintenance Guide • Synergy 1/Synergy 100 Edition (Iss. 1) System Architecture • 2-11

CPU Structure

This section describes the Synergy 1’s CPU structure, in terms of which areas are

controlled by which specific microprocessors. Effectively, Synergy 1’s CPU

structure functions as a master/slave duo-processor system, where the master

processor controls high level functionality, and delegates other tasks to slave

processors.

In a Synergy 1 system, you have two microprocessors in the frame, plus one in the

control panel. Each microprocessor is a 50 MHz floating point DSP (TMS-320-

C32, manufactured by Texas Instruments), and each is identical — running at the

same clock rate.

Processor distribution and functionality is as follows:

• One “Frame Processor” on the Frame Processor Board is responsible

for performing high level functions, and issuing commands to the MLE

processor. This processor manages all serial channels to and from the

chassis, and manages communications with all other peripheral devices

connected to the frame. In addition, it manages communications with

the control panel, and in the case of the Synergy 100 Control Panel,

communicates to the Control Panel Processor which LEDs to turn on

and off and which text to write in the various displays on the panel.

™

The Frame Processor also controls the Ultimatte

Dual Aspectizer

®

board and non-MLE functions, including all Aux

Insider board, the

Bus functions, and all crosspoint switching.

• One “MLE Processor” on the Frame Processor Board processes high-

level information that pertains to the current state and specific

commands issued on the MLE.

This high level information includes which functions are enabled or

disabled, and what configurations have been set up by the user on the

control panel. The MLE Processor translates that information, and sets

the required bits in the hardware to complete the command request.

Following are several examples:

~ If you press WIPE in the MLE and select the circle wipe in the

Pattern Control Group, that information goes to the Frame

Processor — which in turn tells the MLE Processor that a circle

wipe has been requested. The MLE Processor then draws the

proper tables required to make the image.

~ If you pull the Fader from Program to Preset, the Frame Processor

receives that information and analyses how it affects the high level

structures within the switcher — e.g., which buses are moving,

what type of effect has been requested (Dissolve, Wipe, DVE,

etc.). The Frame Processor then passes the current state of a

particular field to the MLE Processor, which then writes the

effect’s specific values to the video processing circuitry.

~ If you press the AUTO TRANS button, that command goes from

the control panel to the Frame Processor, which in turn keeps track

of which state the transition is in. Commands are then issued to the

MLE Processor to perform the transition at (for example) 4% in

one field, 8% in the next field — until complete. The MLE

Processor in turn does not process the video itself, but rather issues

2-12 • System Architecture Synergy 1 Maintenance Guide • Synergy 1/Synergy 100 Edition (Iss. 1)

Loading...

Loading...