Ross video RVS 210A User Manual

RVS 210A

Installation Manual

RVS 210A • Installation Manual

The information contained in this guide is subject to change without notice or

obligation.

Copyright

© 2003 Ross Video Limited. All rights reserved.

Contents of this publication may not be reproduced in any form without the written

permission of Ross Video Limited. Reproduction or reverse engineering of

copyrighted software is prohibited.

Notice

The material in this guide is furnished for informational use only. It is subject to

change without notice and should not be construed as commitment by Ross Video

Limited. Ross Video Limited assumes no responsibility or liability for errors or

inaccuracies that may appear in this manual.

Trademarks

• Ross Part Number: A2210-293

• Document Issue: 2C

• Printing Date: April 1, 2004. Printed in Canada.

Company Address

• is a registered trademark of Ross Video Limited.

• Ross, ROSS, ROSS

and RossGear are registered trademarks of Ross

Video Limited.

• All other product names and any registered and unregistered

trademarks mentioned in this guide are used for identification purposes

only and remain the exclusive property of their respective owners.

Ross Video Limited Ross Video Incorporated

8 John Street P.O. Box 880

Iroquois, Ontario, K0E 1K0 Ogdensburg, New York

Canada USA 13669-0880

General Business Office: (+1) 613

Fax: (+1) 613

Technical Support: (+1) 613

E-mail (Technical Support): techsupport@rossvideo.com

E-mail (General Information): solutions@rossvideo.com

Website: http://www.rossvideo.com

After hours emergency: (+1) 613

• 652 • 4886

• 652 • 4425

• 652 • 4886

• 652 • 4886, ext. 333

TABLE OF CONTENTS

Supplement to RVS 210A Installation Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Add 1....

Alternate Editor Mode ....................................................... Add 1....

Supplement to RVS 210A Installation Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Add 2...

Editor Parity Setting ......................................................... Add 2....

SECTION 1: INTRODUCTION

GENERAL ..................................................................... 1-1.......

UNPACKING .................................................................. 1-2.......

SECTION 2: CONTROL PANEL INSTALLATION

CONTROL PANEL ............................................................. 2-1.......

PUSH-BUTTON LENS CAP DESIGNATIONS .................................... 2-2.......

TALLY CONNECTIONS ........................................................ 2-3.......

SECTION 3: ELECTRONICS FRAME and PCB INSTALLATION

ELECTRONICS FRAME ........................................................ 3-1.......

PRINTED CIRCUIT BOARD INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2.......

INSTALLING the POWER SUPPLY ............................................. 3-3.......

SECTION 4: SYSTEM INTERCONNECT

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1.......

CONTROL CABLE CONNECTION .............................................. 4-2.......

REFERENCE INPUTS .......................................................... 4-3.......

Standard Pulse Regenerator ................................................ 4-3.......

INPUT PULSE PCB ............................................................ 4-4.......

POWERING UP THE SWITCHER ............................................... 4-5.......

MANUAL RESET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6.......

PRELIMINARY FUNCTIONAL CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7.......

PRIMARY INPUTS ............................................................. 4-9.......

ADDITIONAL INPUTS .......................................................... 4-10......

GENERAL PURPOSE INTERFACE (GPI) ........................................ 4-11......

OUTPUTS ..................................................................... 4-12......

1-1

2-1

3-1

4-1

RVS 210A Installation Manual iii

Contents

SECTION 5: SYSTEM SET UP and TIMING

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1.......

DIAGNOSTIC and SET UP MODES ............................................. 5-2.......

The MODIFY Button

Diagnostic Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3......

DIAG1: Switch Echo Test

DIAG2: Lamp Test

Optional Set Up Modes ........................................................ 5-4.......

Default States ................................................................. 5-5......

Mode Selection Sequence ..................................................... 5-6.......

Alternate Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7......

INIT - Default All Parameters

TIME

...............................................................

PROC

SYSTEM TIMING ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9......

Horizontal Sync Timing — Systems with Pulse Input PCB (2216-46) . . . . . . . . . . . . 5-10.....

Horizontal Sync Timing — Systems with Pulse Regenerator PCB (2216-047) . . . . 5-11.....

Horizontal Timing of Video Input Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12.....

Burst (Subcarrier) Timing ..................................................... 5-13.....

Timing of Video and Key Inputs to DSK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14.....

.............................................................

........................................................

..........................................

.................................................

.......................................

.......

.......

.......

.......

.......

.......

5-1

5-2

5-3

5-3

5-7

5-8

5-9

SECTION 6: INSTALLING and ADJUSTING OPTIONS

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1.......

CONTROL PANEL MOUNTING OPTIONS ....................................... 6-2.......

Rack Mount Adaptor ........................................................ 6-2.......

Installation Procedure . .. ........................................... 6-2.......

In-desk Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4.......

Installation Procedure . .. ........................................... 6-4.......

SERIAL INTERFACE (EDITOR PORT) .......................................... 6-5.......

General ....................................................................... 6-5.......

Serial Interface Connection .................................................. 6-5.......

To Set Up the Serial Interface .................................................. 6-6.......

To Set the Baud Rate . . . ........................................... 6-6.......

To Set the Editor Select Address ................................... 6-6.......

To Set the Serial Transmission Standard . .......................... 6-6.......

To Set the Editor Parity ...................................................... 6-8.......

To Verify Editor Parity Setting ............................................... 6-8.......

RGB CHROMA KEYER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9.......

To Set Up the RGB Chroma Keyer (2210-44) ................................ 6-9.......

PULSE REGENERATOR ....................................................... 6-10......

6-1

RVS 210A Installation Manual iv

Contents

SECTION 7: SPECIFICATIONS

A: VIDEO CHARACTERISTICS ................................................. 7-1.......

B: PULSE CHARACTERISTICS ................................................. 7-1.......

C: KEY INPUTS ............................................................... 7-2.......

D: SUBCARRIER INPUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2.......

E: PERFORMANCE ............................................................ 7-3.......

F: SYSTEM TIMING (nominal) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4.......

G: ENVIRONMENT ............................................................ 7-5.......

H: MECHANICAL and POWER ................................................. 7-5.......

SECTION 8: DRAWINGS

Appendix A

Warranty & Repair Policy ...................................................... A-1 ......

7-1

8-1

A-1

RVS 210A Installation Manual v

Contents

RVS 210A Installation Manual vi

Supplement to RVS 210A Installation Manual

Alternate Editor Mode

With issue 2.6 and later software, an alternate editor mode is provided for interfacing a

Grass Valley Group Editor with a Ross switcher. In this editor mode, the memory size is

reduced; the maximum byte count is 115 or 73 (H). This mode is selected by setting

switch 7 on S1 (on the 2216-42A/B circuit board) to "on", as shown below. When

operating the switcher in this editor mode, two of the alternate memory modes, modes 3

and 4 discussed in the Operator's Manual, will not function.

Switch 7

Figure 1 Selection of Alternate Editor Mode

42

RVS 210A Installation Manual Addendum Add 1

Supplement to RVS 210A Installation Manual

Editor Parity Setting

RVS 210A switchers with issues 3.1 and earlier software communicated with the "ODD"

parity serial transmission format only. Recently, a few editor manufactures have

(arbitrarily) chosen to communicate using either "EVEN" parity of "NO" parity. Different

parity settings between different devices are incompatible and make editor control of the

switcher impossible.

To resolve this problem, RVS 210A's using issues 3.2 software and later will now

support all possible parity standards. The switcher is still shipped factory set to ODD

parity which is, by far, the most common standard.

To change the editor protocol parity standard:

1. Find the 8 position dip switch labeled S1 located on the 2216-42A/B circuit board in

the electronics rack frame. It is located at the far end of the PCB near the connector.

2. Switches 5 & 6 on S1 are used to choose between ODD, EVEN, and NO parity. Set

them as required by the editor manufacturer.

The settings are as follows:

Switch 5 Switch 6 Parity Setting

OFF OFF ODD

OFF ON EVEN

ON OFF NO

ON ON ODD

You may note that ODD parity will be selected in the cases where the switches are both

ON or both OFF.

It is also possible to verify the settings of these switches using a MODIFY mode at the

switcher control panel:

1. Press MODIFY, then EDIT (button 6 on the key bus)

2. Press button 4 on the PST bus.

The Auto Transition display will show one of the following:

P - O for ODD parity

P - E for EVEN parity

P - - for NO parity.

Again, changing these settings requires adjusting the dip switches in the electronics rack

frame.

Press the MODIFY button a second time to return the switcher to normal operation.

RVS 210A Installation Manual Addendum Add 2

GENERAL

SECTION 1: INTRODUCTION

This manual explains how to install the RVS 210A video switcher and make all necessary

system connections. A vectorscope and oscilloscope or waveform monitor will be

required to do an accurate installation.

Final configuration of the switcher is done using the RVS 210A Operator's Manual which

provides information on the switcher's alternate operating modes.

Procedures for retrofitting electronic options are not included in this manual; this

information is given in specific "Installation Instructions" which are shipped with each

option.

The order of the overall installation procedure is:

Unpacking

Control panel installation

Electronics frame and circuit board installation

System interconnect

System timing

Adjustments and set-up of options (if applicable).

Figure 1-1 The RVS 210A Control Panel

RVS 210A Installation Manual 1-1

Unpacking INTRODUCTION

UNPACKING

The complete RVS 210A switcher is shipped in three or more boxes:

One box contains the control panel

A second box contains the electronics frame

Additional boxes contain the three main circuit boards for the electronics frame,

the power supply module, manuals, and all other options and accessories.

Once the boxes are unpacked, check the contents against the packing list to ensure that all

items are included. If any items are missing or damaged, contact your sales representative

or Ross Video Limited, immediately.

CAUTION:

STATIC DISCHARGE can cause serious damage to sensitive semiconductor

devices. Avoid handling the switcher circuit boards in high static

environments such as carpeted areas and when synthetic fiber clothing is

worn. Touch the frame to dissipate static charge before removing boards

from the frame and exercise grounding precautions when working on circuit

boards.

SWITCH SYSTEM POWER OFF before installing or removing printed

circuit boards or control cable J6, which supplies power to the control panel.

The circuitry used throughout the switcher is largely CMOS, accounting for

the system's low current drain.

RVS 210A Installation Manual 1-2

SECTION 2: CONTROL PANEL INSTALLATION

CONTROL PANEL

There are no special requirements for installation of the control panel. It is fitted with

four non-skid rubber feet for ease of desktop or table top mounting. If the switcher was

purchased with the optional in-desk endblocks or rack mount adaptor, refer to the

"Installing and Adjusting Options" section for desk cutout size and assembly instructions.

RVS 210A Installation Manual 2-1

Push-button Lens Cap Designations CONTROL PANEL INSTALLATION

PUSH-BUTTON LENS CAP DESIGNATIONS

Cut out the designation film inserts and install them in the crosspoint push-button lens

caps. These inserts are used to identify the video inputs connected to each crosspoint. A

standard film with common input designations is included in the switcher shipment. If a

designation that you require has not been included on the film and it is a type likely to be

needed by other switcher users, Ross Video would be pleased to consider adding it to the

standard film.

Remove the lens assembly from the crosspoint switch by pulling straight upward on the

lens cap. Remove the lens cap from the lens and place the desired input designation under

the lens cap.

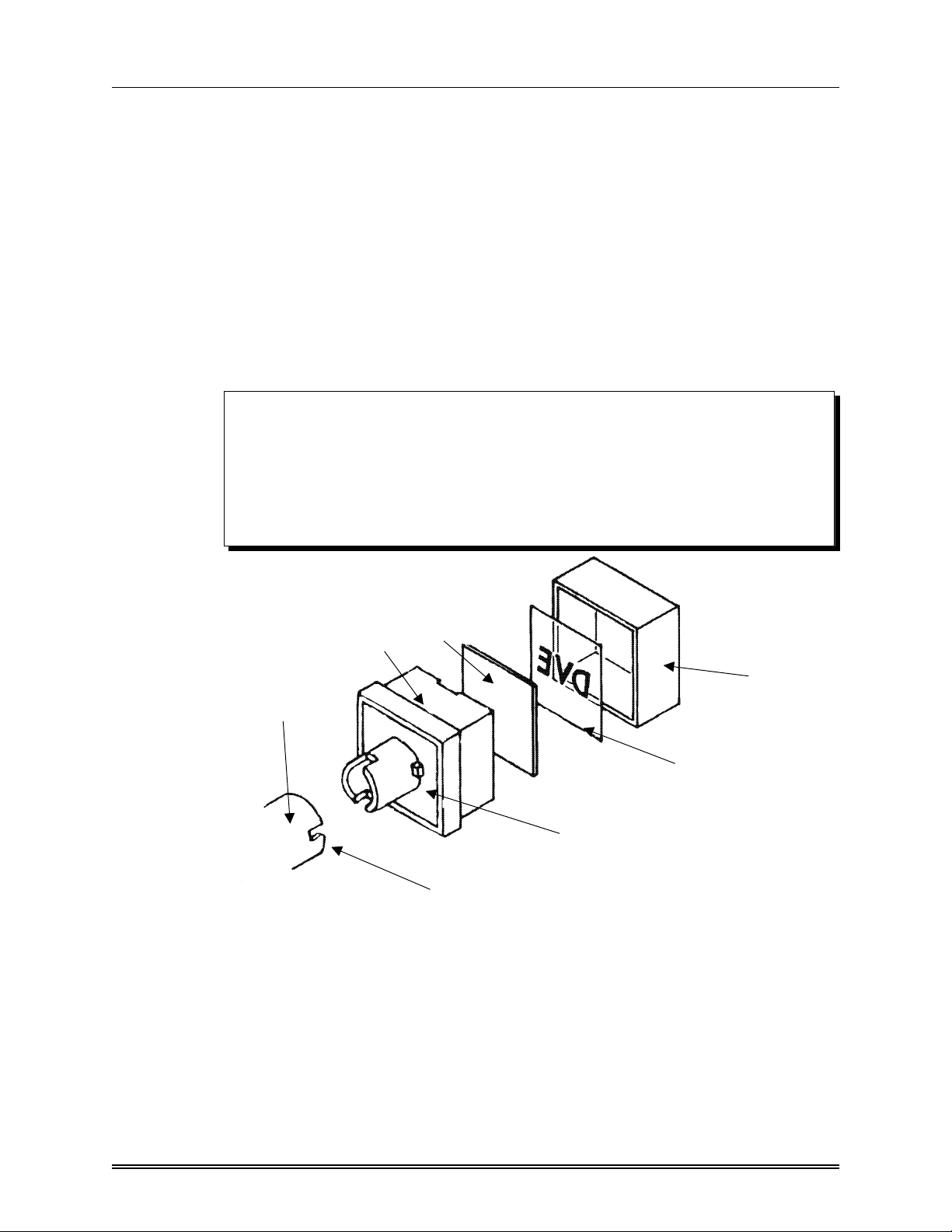

shows the lens assembly.

NOTE:

Be sure to line up the locating lug on the lens with the locating slot in the

crosspoint switch when re-installing the lens assembly.

will pop off when the crosspoint is pressed and released.

The designation film must read correctly with the lens locating lugs at the sides, not

at the top and bottom.

Figure 2-1

, "Push-button Designation Film Installation" on the next page,

Otherwise, the lens cap

Switch

Lens (2 pieces)

Figure 2-1

Push-button Designation Film Installation

Lens Cap

Designation Film

Locating Lug (1 each side)

Locating Slot (1 each side)

RVS 210A Installation Manual 2-2

Tally Connections CONTROL PANEL INSTALLATION

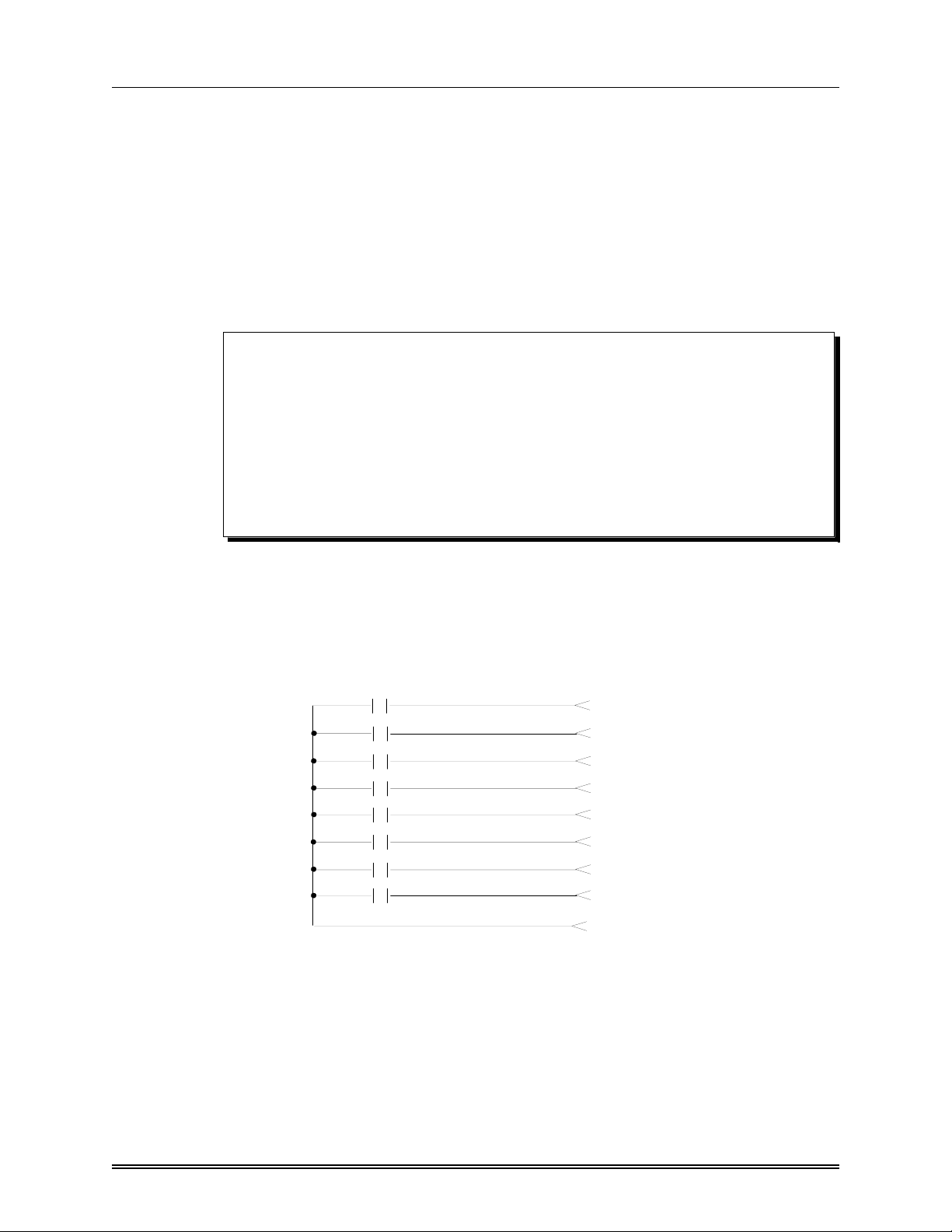

TALLY CONNECTIONS

The tally connector, "J7 - TALLY", is located on the rear of the control panel.

Figure 2-2

shows the tally connection relay circuit. Using this drawing, wire the mating 50-pin tally

connector which is provided with the switcher.

Connect the completed tally cable to connector J7, making the connection straight on and

allowing at least 4 inches of cable clearance at the rear of the control panel. Fasten the

clips to hold the connector in place. Run the cable in accordance with good engineering

practice and ensure that the cable will not be subjected to physical abuse.

NOTE:

1. All relay contacts are normally open.

2. Maximum switch ratings for tally relay contacts are 10 VA resistive.

DO NOT

exceed 100 Volts between common and any tally. Maximum closed contact current

carrying capacity for a single tally is 0.5 Amp. Maximum current on common lead

should not exceed 1 Amp where possible.

For inductive loads derate both VA rating and maximum voltage by a factor of 10

(i.e. 1 VA and 10 V) where possible.

TALLY CONNECTIONS

RELAY CIRCUIT

Input#*

Relay#

2 K1

3 K2

4 K3

5 K4

6 K5

7 K6

8 K7

9 K8

*Black (not supplied)

relay contacts

Figure 2-2

J7 Pin

Tally Connections

Function

1 Tally 1

2 Tally 2

3 Tally 3

4 Tally 4

5 Tally 5

6 Tally 6

7

Tally 7

8 Tally 8

50 Common

RVS 210A Installation Manual 2-3

NOTES

CONTROL PANEL INSTALLATION

RVS 210A Installation Manual 2-4

SECTION 3: ELECTRONICS FRAME and PCB

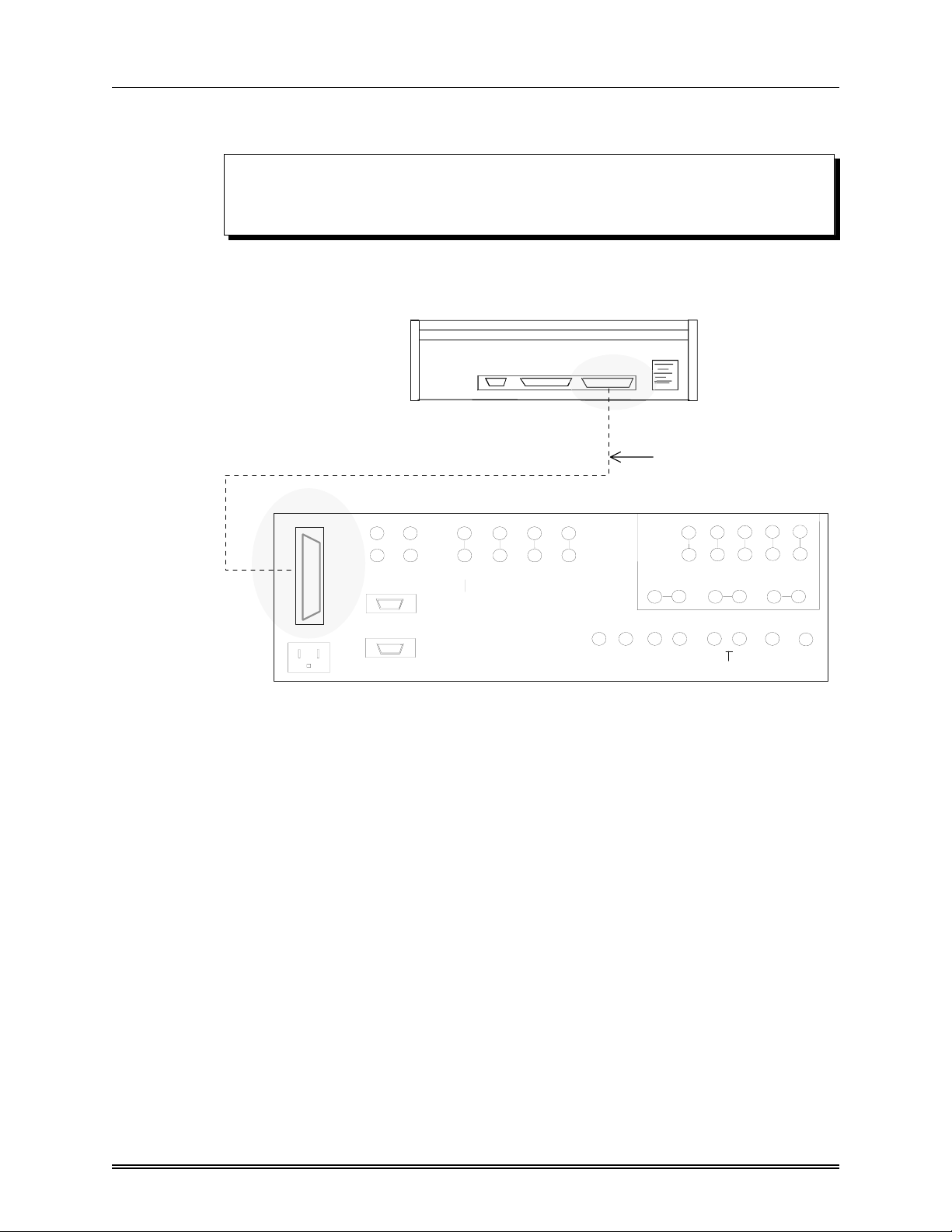

ELECTRONICS FRAME

The rack-mountable electronics frame requires 3 rack units of height (5.25 inches) and

extends a depth of 18.25 inches (46.4 centimeters) into a standard 19-inch wide

equipment rack.

For maximum stability during operation, the frame should be mounted in such a way as

to allow adequate ventilation of the unit. Ensure that the right-hand side of the frame is

clear so that the inlet to the power supply circulating fan is not restricted in any way. The

frame location should be accessible, reasonably dust-free, and dry.

INSTALLATION

RVS 210A Installation Manual 3-1

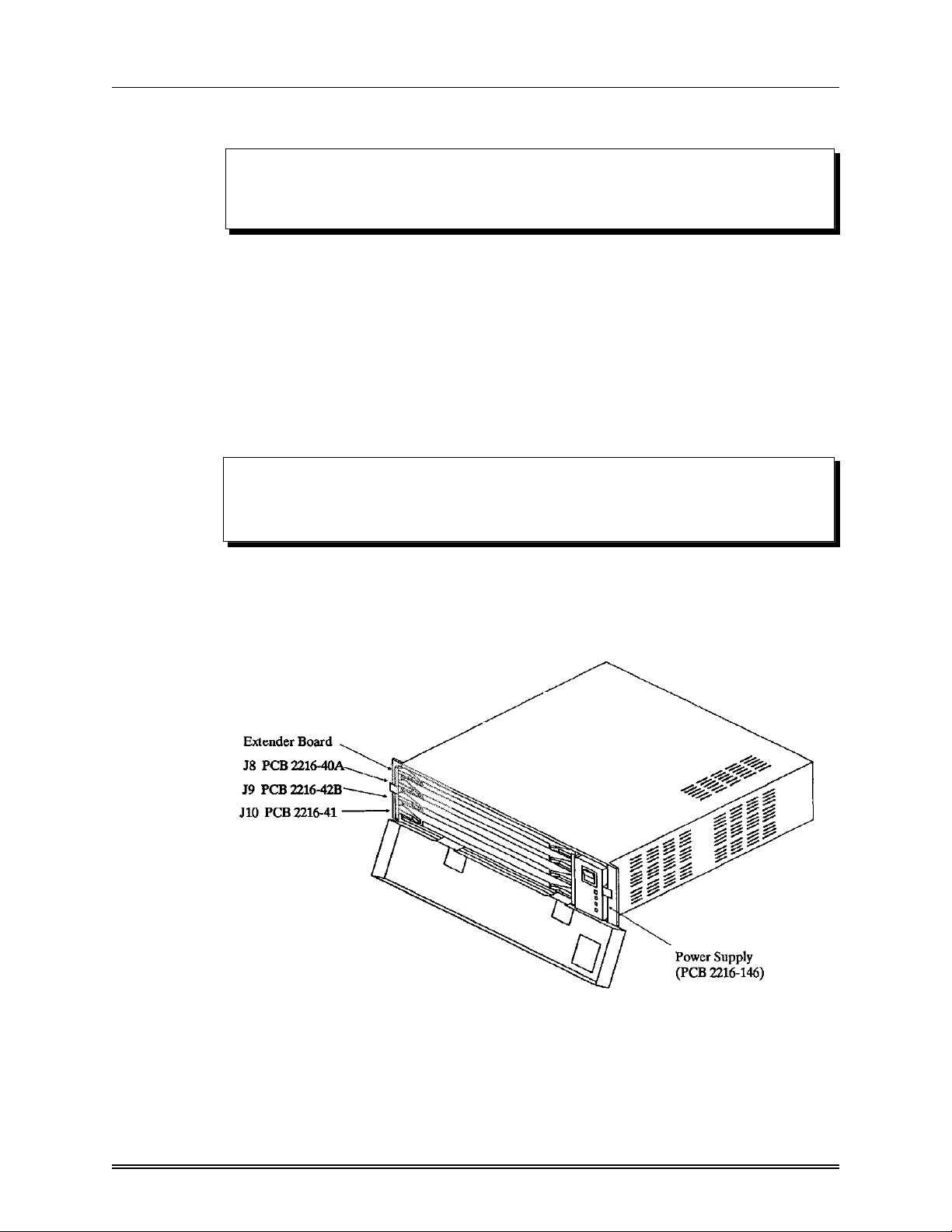

Printed Circuit Board Installation ELECTRONICS FRAME AND PCB INSTALLATION

PRINTED CIRCUIT BOARD INSTALLATION

CAUTION:

SWITCH SYSTEM POWER OFF before installing or removing any printed

circuit boards or control cable J6.

To avoid damage during shipping, the circuit boards are

frame. All boards plug into the frame from the front.

Open the door of the electronics frame by unscrewing the lock pins and pulling outward

and down on the door. The door swings down on its hinges and can be pulled out on

support rails, allowing it to hang down in front of the rack. This provides clear access to

the circuit boards.

An identification label indicating board locations is located on the inside of the frame

door. Board locations are shown in

NOTE:

Boards may be individually keyed. Therefore, trying to force a board into the

wrong slot in the rear of the electronics frame may cause physical damage.

Ensure that all of the circuit boards are tightly pushed into their connectors at the rear of

the frame. Circuit board extractors are provided on the sides of the PCBs to allow easy

installation and removal.

Figure 3-1

below.

shipped installed in the

not

Figure 3-1 PCB Locations in Electronics Frame

RVS 210A Installation Manual 3-2

Installing the Power Supply ELECTRONICS FRAME AND PCB INSTALLATION

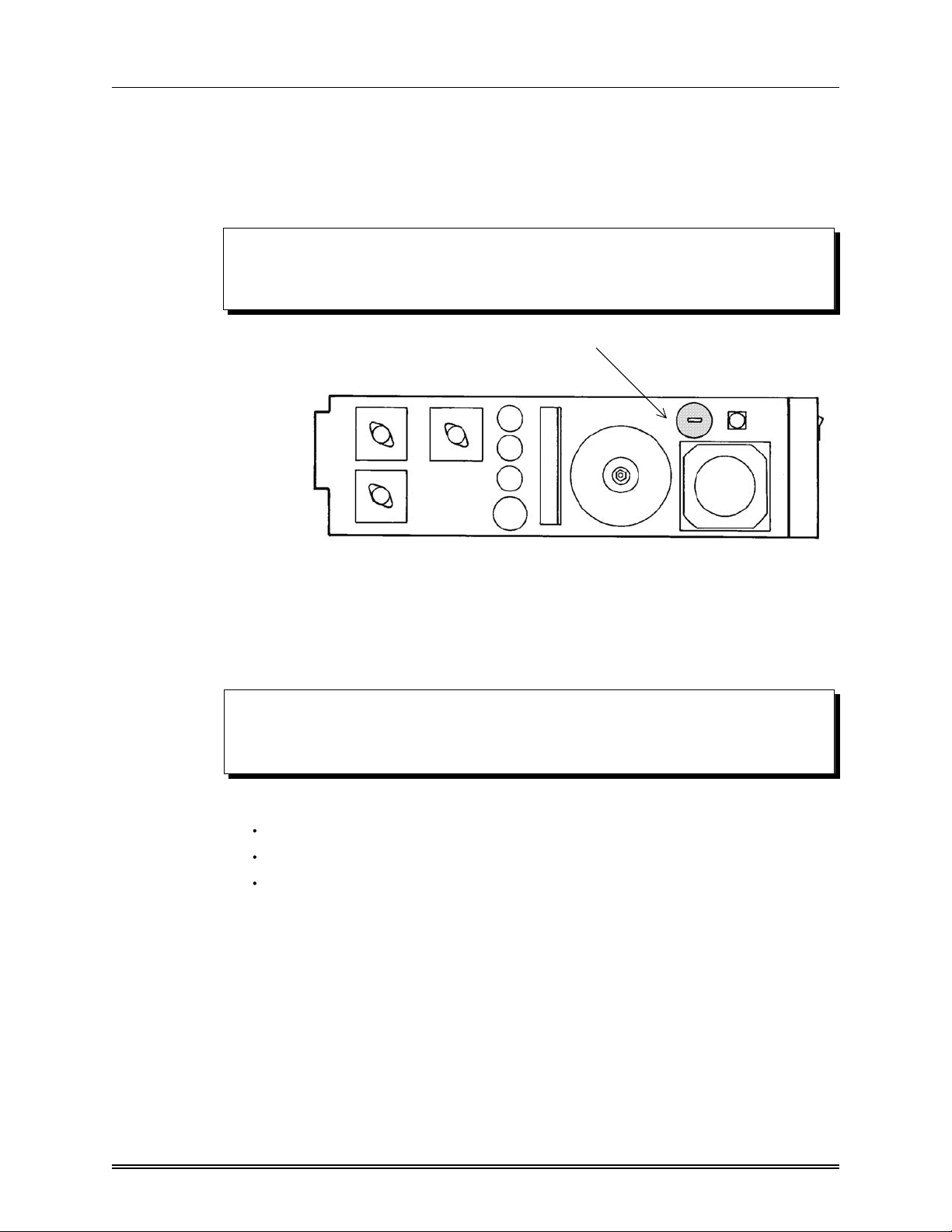

INSTALLING the POWER SUPPLY

All Ross switchers are shipped from the factory with AC power standards correctly set

for the destination country. Power supply input voltage is factory-selected using the dial

on the power supply circuit board, as shown in Figure 3-2.

NOTE:

CHECK that the voltage indicated on the selector corresponds to the mains

voltage, call your dealer or Ross Video Limited.

Voltage Selector

Figure 3-2 Power Supply Input Voltage Selection

After confirming that the proper power supply voltage has been set, install the power

supply in its slot in the right hand section of the electronics frame. Push the power supply

in firmly to ensure a tight connection at the rear of the frame. Connect the power cord at

the rear of the electronics frame to an AC outlet.

NOTE:

In some countries, it may be necessary to remove the 3-conductor plug supplied

and replace it with the standard electrical plug for local power supply.

The wiring designations by color are:

BLACK - power (or "line" side)

WHITE - neutral (or "return" side)

GREEN - ground (or "earth").

RVS 210A Installation Manual 3-3

ELECTRONICS FRAME AND PCB INSTALLATION

NOTES

RVS 210A Installation Manual 3-4

SECTION 4: SYSTEM INTERCONNECT

INTRODUCTION

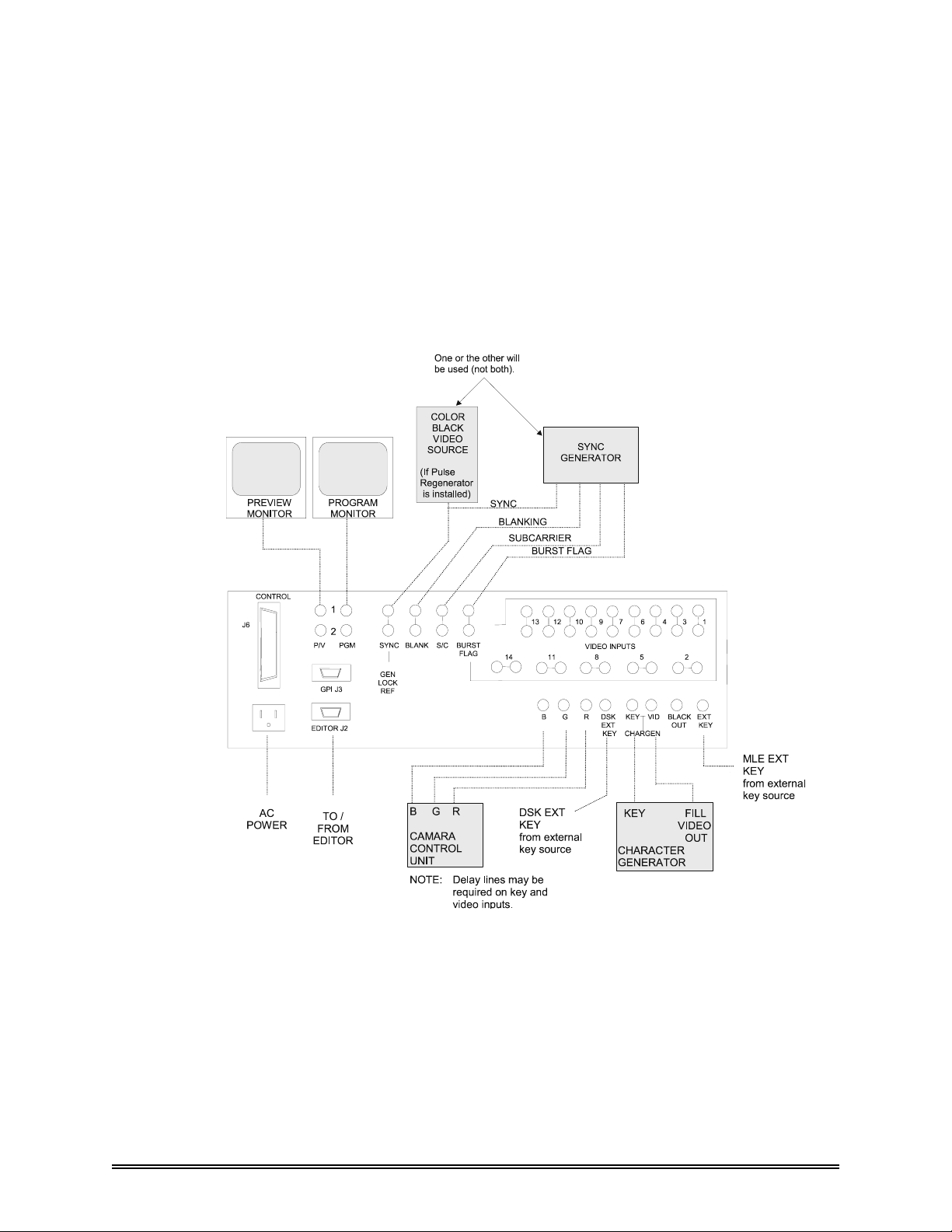

The figure below shows typical interconnections for the switcher. The connection points

on the rear of the electronics frame are clear labeled.

Figure 4-1 Typical System Interconnect

Once the control cable, J6, and system reference signals are connected, a preliminary

functional check can be performed to ensure that the switcher is passing video. All Ross

Video products undergo thorough quality control and testing procedures before shipment.

The preliminary check will simply indicate that no damage has occurred during transit

and that all boards are correctly installed before completing the installation.

RVS 210A Installation Manual 4-1

Control Cable Connection SYSTEM INTERCONNECT

CONTROL CABLE CONNECTION

CAUTION:

SWITCH SYSTEM POWER OFF before installing or removing control

cable J6.

Install the supplied 50-conductor control cable between the "J6 — CONTROL"

connectors on the rear of the control panel and the rear of the electronics frame. (See

Figure 4-2 below).

J11 ACC PORT

J7 TALLY

J6 CONTROL

J6 CONTROL

50-conductor control cable

J6

CONTROL

P/V

GPI J3

EDITOR J2

1

2

PGM

SYNC

GEN

LOCK

REF

BLANK

S/C BURST

FLAG

VIDEO

INPUTS

G

B

7

8

DSK

R

EXT

KEY

6

5

KEY

CHAR GEN

43

VID

BLACK

OUT

1

2

EXT

KEY

Figure 4-2 Connection — Control Panel to Frame

Make the connections straight on, allowing at least 4 inches of cable clearance at the rear

of the panel and also at the rear of the frame. Fasten the clips to hold the connectors in

place.

Cable must be run in accordance with good engineering practice. Ensure that there is

sufficient room for the cable and that enough slack is left in the cable run to permit long,

gentle bends. Always be careful to install cables so that they will not be subjected to

physical abuse.

RVS 210A Installation Manual 4-2

Loading...

Loading...