Rosemount World Class 3000 O2 Analyzer with CRE 3000 Control Room Electronics-Rev 4.4 Manuals & Guides

Instruction Manual

IB-106-300NC Rev. 4.4

February 1998

World Class 3000

Oxygen Analyzer with CRE 3000

Control Room Electronics

http://www.processanalytic.com

ESSENTIAL INSTRUCTIONS

READ THIS PAGE BEFORE PROCEEDING!

Rosemount Analytical designs, manufactures and tests its products to meet many national and

international standards. Because these instruments are sophisticated technical products, you

MUST properly install, use, and maintain them to ensure they continue to operate within their

normal specifications. The following instructions MUST be adhered to and integrated into your

safety program when installing, using, and maintaining Rosemount Analytical products. Failure to

follow the proper instructions may cause any one of the following situations to occur: Loss of life;

personal injury; property damage; damage to this instrument; and warranty invalidation.

• Read all instructions prior to installing, operating, and servicing the product.

• If you do not understand any of the instructions, contact your Rosemount Analytical repre-

sentative for clarification.

• Follow all warnings, cautions, and instructions marked on and supplied with the product.

• Inform and educate your personnel in the proper installation, operation, and mainte-

nance of the product.

• Install your equipment as specified in the Installation Instructions of the appropriate In-

struction Manual and per applicable local and national codes. Connect all products to the

proper electrical and pressure sources.

• To ensure proper performance, use qualified personnel to install, operate, update, program,

and maintain the product.

• When replacement parts are required, ensure that qualified people use replacement parts

specified by Rosemount. Unauthorized parts and procedures can affect the product’s performance, place the safe operation of your process at risk, and VOID YOUR WARRANTY.

Look-alike substitutions may result in fire, electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers are in place, except

when maintenance is being performed by qualified persons, to prevent electrical shock

and personal injury.

The information contained in this document is subject to change without notice.

Emerson Process Management

Rosemount Analytical Inc.

Process Analytic Division

1201 N. Main St.

Orrville, OH 44667-0901

T (330) 682-9010

F (330) 684-4434

e-mail: gas.csc@EmersonProcess.com

http://www.processanalytic.com

HIGHLIGHTS OF CHANGES

Effective October, 1995 Rev. 4

Page Summary

--- General. Updated art to reflect new probe configuration.

Page 2-1 Changed installation procedure to include optional ceramic diffusor

and vee deflector.

Page 3-16 Added manual block valve requirement to required equipment

Effective June, 1996 Rev. 4.1

Page Summary

Page 2-2, 2-3 Updated figure to reflect probe modification.

Page 3-13, 3-15,

3-17

Page Summary

P-2 Added "Safety instructions for the wiring and installation of this

Page 1-6 Added NOTE 8 regarding fuse specifications and changed probe

Page 2-1 Added one WARNING to read new safety instructions and another

Page 2-8 Deleted obsolete paragraphs 2-2b.1 and 2-2b.2.

Page 2-10 Added NOTE regarding reference to Figure 2-6 for CRE unit fuse lo-

Page 2-13 Added NOTE regarding reference to Figure 2-16 for HPS fuse loca-

Page 2-14 Changed probe ground lead color code to GN/YE in Figure 2-13.

Page 2-17 Added NOTE regarding HPS fuse specifications to Figure 2-16.

Page 2-20 Added NOTE regarding reference to Figure 2-19 for MPS fuse loca-

Added note regarding ambient air not recommended for use as high

test gas.

Effective January, 1997 Rev. 4.2

apparatus".

ground lead color code to GN/YE in Figure 1-3.

WARNING regarding protective covers and grounds.

cations and specifications and added NOTE regarding CRE fuse

specifications to Figure 2-6.

tions and specifications.

tions and specifications.

Page 2-20 Added NOTE regarding MPS fuse specifications to Figure 2-19.

Page 4-1 Added WARNING regarding protective covers and grounds.

Page 7-1 Added fuses to index listing.

HIGHLIGHTS OF CHANGES (CONTINUED)

Effective May, 1997 Rev. 4.3

Page Summary

Page P-2 Added safety sheet.

Effective February, 1998 Rev. 4.4

Page Summary

Page 2-2 Figure 2-1. Change calibration gas tube dimensions.

Page 3-15 Add note on test gas flowmeter.

HIGHLIGHTS OF CHANGES

APPENDIX A

Effective May, 1996 Rev. 3

Page Summary

-- General. Updated appendix to reflect probe design changes.

Page A-13 Added “Extended temperature by-pass arrangements” to Figure A-13

(Sheet 3 of 3)

Effective June, 1996 Rev. 3.1

Page Summary

Page A-13 Updated part ordering information.

Effective August, 1996 Rev. 3.2

Page Summary

Page A-25 Updated cell replacement kit part numbers for the probe.

Effective October, 1996 Rev. 3.3

Page Summary

Page A-6 Added NOTE to Figure A-7.

Effective January, 1997 Rev. 3.4

Page Summary

Page A-1 Added warning to read new safety instructions.

Page A-12 Added protective covers and grounds warning.

Page A-16 Added protective covers and grounds warning.

Effective February, 1998 Rev. 3.5

Page Summary

Page A-18 Changed screw torque in paragraph A-11h.

Effective July, 1998 Rev. 3.6

Page Summary

-- Changed test gas to calibration gas and reference gas to reference

air throughout the appendix.

HIGHLIGHTS OF CHANGES

APPENDIX B

Effective February, 1992 Rev. 2

Page Summary

Page B-1 Figure B-1. New HPS 3000 Optional Class 1, Division 1, Group B

(IP56) Explosion-Proof Enclosure added.

Page B-11 Figure and Index No. column added to Table B-2. Replacement Parts

for Heater Power Supply.

Effective January, 1995 Rev. 2.1

Page Summary

Page B-3 Updated Figure B-3, Heater Power Supply Block Diagram for IB

consistency.

Effective January, 1997 Rev. 2.2

Page Summary

Page B-1 Added warning to read new safety instructions.

Page B-3 Corrected Table B-1 specifications list.

Page B-4 Added protective covers and grounds warning.

Page B-8 Added protective covers and grounds warning.

Page B-11 Added expanded fuse description.

HIGHLIGHTS OF CHANGES

APPENDIX C

Effective February, 1992 Rev. 2

Page Summary

Page C-4 Figure C-3. Optional Panel Mounting Kit description added.

Page C-14 Figure and Index No. column added to Table C-2. Replacement Parts

for the Master/Slave CRE 3000 Module.

Effective February, 1995 Rev. 2.1

Page Summary

Page C-5 Updated Figure C-4 for IB consistency.

Effective October, 1995 Rev. 2.2

Page Summary

Page C-5 Updated art to reflect new probe configuration.

Effective January, 1997 Rev. 2.3

Page Summary

Page C-1 Added warning to read new safety instructions.

Page C-6 Added protective covers and grounds warning.

Page C-6 Added reference to Table C-1 for replacement fuse specifications.

Page C-6 Amended Legend for Figure C-5.

Page C-7 Removed obsolete jumper, Item 14 from Figure C-5.

Page C-9 Deleted obsolete paragraph C-6c.

Page C-14 Revised Table C-2 to introduce new power supply and added ex-

panded fuse description.

HIGHLIGHTS OF CHANGES

Effective June, 1994 Rev. 2

Page Summary

APPENDIX D

Page D-1

Page D-2

Page D-3

Page D-4

Page D-7

Page D-8

Page D-10

Page D-11

Page Summary

Page D-1 Updated Figure D-1, MPS 3000 to include hinge.

Page Summary

Page D-11 Updated replacement parts list to reflect new part numbers.

MPS outline drawing changed to show new MPS.

MPS interior view replaced with new MPS in Figure D-2.

"Optional" for check valve deleted in Figure D-3.

Drawing showing location of optional Z-Purge added as Figure D-4.

Power supply replacement procedures in paragraph D-7 changed to

reflect new design in the MPS. Solenoid valve replacement procedures in paragraph D-8 changed to reflect new design in the MPS.

Old exploded view of MPS replaced with new MPS.

Paragraph D-11, Adding Probes to the new MPS, added.

Change part numbers for the power supply, solenoid valve, and test

gas flowmeter assembly. Add part numbers for reference gas flowmeter assembly and all the parts in the probe adder kit.

Effective January, 1995 Rev. 2.1

Effective May, 1996 Rev. 2.2

Effective January, 1997 Rev. 2.3

Page Summary

Page D-1

Page D-2

Page D-5

Page D-7

Page D-11

Page Summary

--- Changed test gas to calibration gas and reference gas to reference

Added warning to read new safety instructions.

Corrected Table D-1 Specifications listing, 1

Added protective covers and grounds warning.

Added protective covers and grounds warning, corrected item number errors in paragraph D-6.

Added expanded fuse descriptions.

Effective July, 1998 Rev. 2.4

air throughout the appendix.

st

entry.

HIGHLIGHTS OF CHANGES

APPENDIX G

Effective February, 1992 Rev. 1

Page Summary

Page G-8 Figure G-5. Optional Panel Mounting Kit description added.

Page G-16 Figure and Index No. column added to Table G-3. Replacement Parts

for the Master/Slave CRE 3000 Module.

Effective February, 1995 Rev. 1.1

Page Summary

Page G-6 Updated Figure G-4 for IB consistency.

Effective October, 1995 Rev. 1.2

Page Summary

Page G-2 Updated art to reflect new probe configuration.

Page G-6 Updated art to reflect new probe configuration.

Page G-11 Updated art to reflect new probe configuration.

Effective September, 1996 Rev. 1.3

Page Summary

Page G-2 Updated part numbers for processor board and DPI card.

Effective January, 1997 Rev. 1.4

Page Summary

Page G-1 Added warning to read new safety instructions.

Page G-9 Added warning to read new safety instructions and protective covers

and ground warning.

Page G-13 Removed obsolete jumper, Item 14 from Figure G-8.

Page G-14 Amended Legend for Figures G-8 and G-9, Item 14.

Page G-15 Removed obsolete jumper, Item 14 from Figure G-9.

Page G-16 Added protective covers and grounds warning.

Page G-16 Revised Table G-3 to introduce new power supply and added ex-

panded fuse description.

World Class 3000

PREFACE........................................................................................................................ P-1

Definitions ........................................................................................................................P-1

Safety Instructions .......................................................................................................... P-2

1-0 DESCRIPTION ................................................................................................................ 1-1

1-1 Component Checklist Of Typical System (Package Contents) .................................. 1-1

1-2 System Overview............................................................................................................ 1-2

2-0 INSTALLATION .............................................................................................................. 2-1

2-1 Oxygen Analyzer (Probe) Installation ........................................................................... 2-1

2-2 Control Room Electronics Module Installation............................................................. 2-8

2-3 Heater Power Supply Installation ............................................................................... 2-13

2-4 Multiprobe Test Gas Sequencer Installation ............................................................. 2-17

2-5 Installation With Two Multiprobe Test Gas Sequencers .......................................... 2-21

3-0 OPERATION ...................................................................................................................3-1

3-1 Overview.......................................................................................................................... 3-1

3-2 Front Panel Controls And Indicators .......................................................................... 3-1

3-3 Status Line...................................................................................................................... 3-2

3-4 Help Key ......................................................................................................................... 3-3

3-5 Quick Reference Chart .................................................................................................. 3-3

3-6 Main Menu ...................................................................................................................... 3-3

3-7 Data Sub-Menu...............................................................................................................3-3

3-8 Calibrate Sub-Menu........................................................................................................ 3-8

3-9 Using The Setup Sub-Menu ......................................................................................... 3-8

3-10 Calibration...................................................................................................................... 3-12

Instruction Manual

IB-106-300NC Rev. 4.4

February 1998

TABLE OF CONTENTS

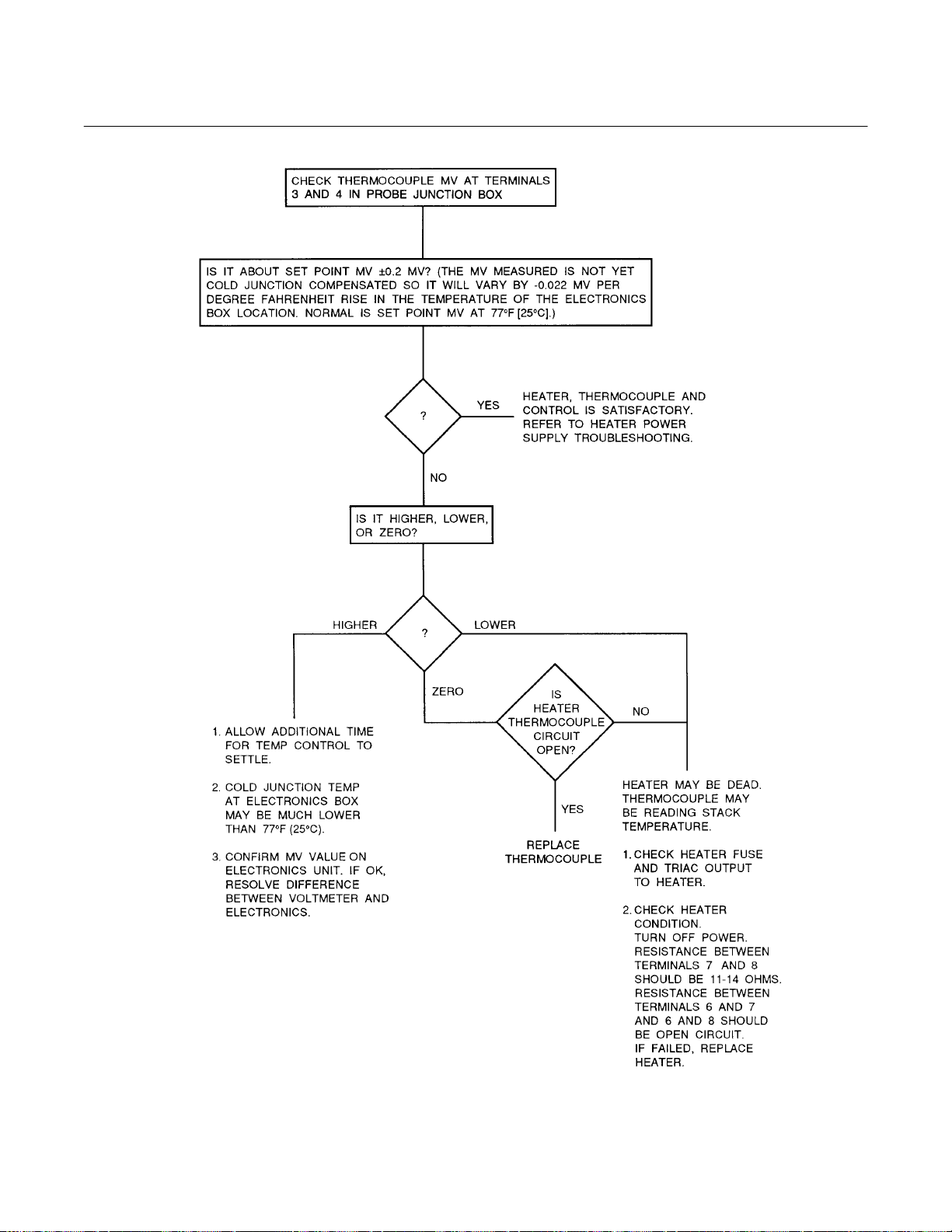

4-0 TROUBLESHOOTING .................................................................................................... 4-1

4-1 Overview.......................................................................................................................... 4-1

4-2 Special Troubleshooting Notes...................................................................................... 4-1

4-3 Probe Troubleshooting ................................................................................................... 4-1

4-4 CRE Alarm Messages ................................................................................................... 4-3

5-0 RETURN OF MATERIAL ................................................................................................ 5-1

6-0 APPENDICES ................................................................................................................. 6-1

Appendix A ......................................................................................................................A-1

Appendix B ......................................................................................................................B-1

Appendix C ......................................................................................................................C-1

Appendix D ......................................................................................................................D-1

Appendix G ......................................................................................................................G-1

7-0 INDEX.............................................................................................................................. 7-1

Rosemount Analytical Inc. A Division of Emerson Process Management i

Instruction Manual

IB-106-300 NC Rev. 4.4

February 1998

Figure 1-1. Typical System Package ....................................................................................... 1-1

Figure 1-2. Typical System Installation .................................................................................... 1-5

Figure 1-3. Typical System Wiring (Sheet 1 of 3) .................................................................... 1-6

Figure 1-4. Control Room Electronics with 6 World Class 3000 Probes ................................. 1-9

Figure 1-5. Control Room Electronics with 8 World Class 3000 Probes ............................... 1-10

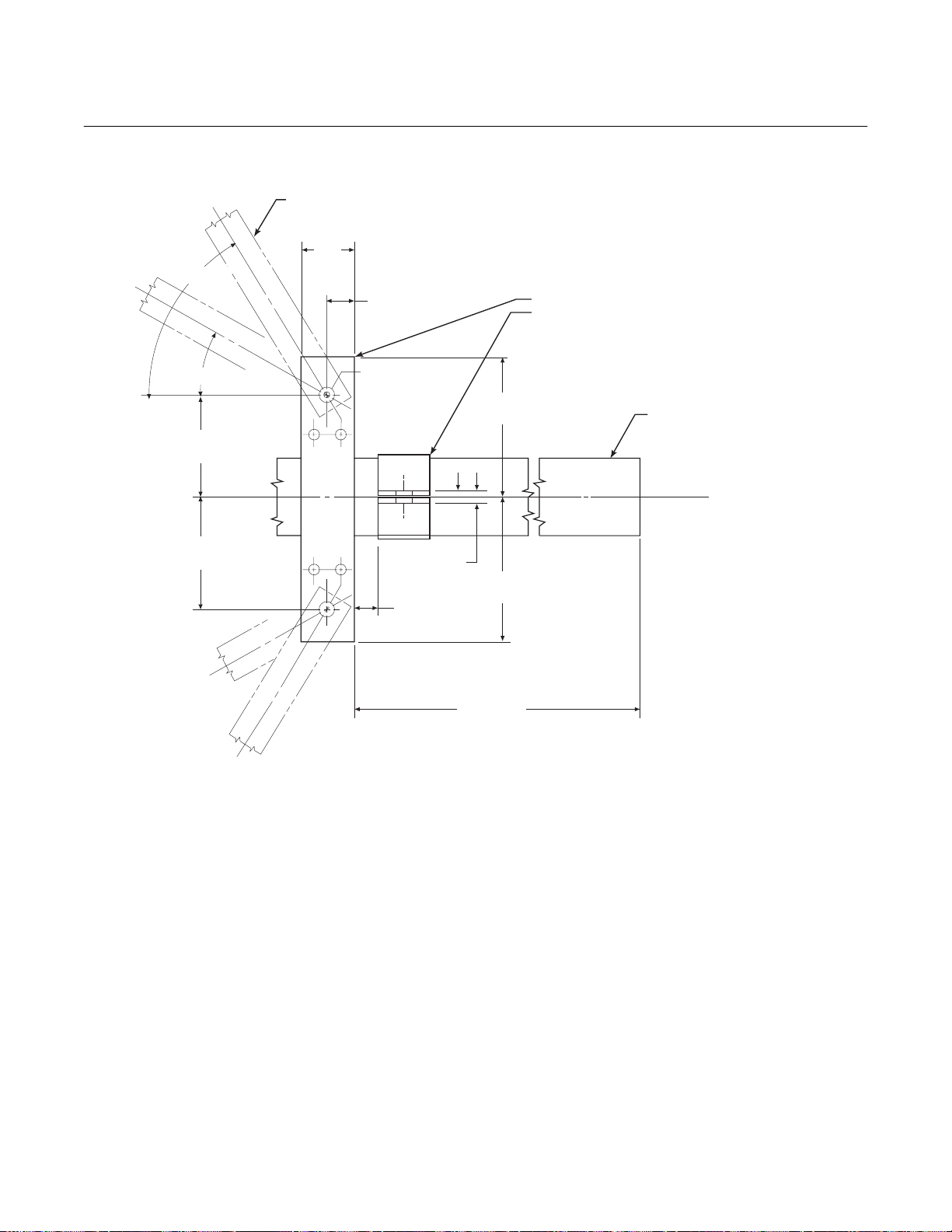

Figure 2-1. Probe Installation (Sheet 1 of 5) ............................................................................ 2-2

Figure 2-2. Orienting the Optional Vee Deflector..................................................................... 2-7

Figure 2-3. Air Set, Plant Air Connection ................................................................................. 2-8

Figure 2-4. Control Room Electronic Dimensions .................................................................... 2-9

Figure 2-5. Panel Cutout for Control Room Electronic Module................................................ 2-9

Figure 2-6. CRE Power, Analog Output, and Relay Output Connections.............................. 2-10

Figure 2-7. Analog Output Card Jumpers .............................................................................. 2-11

Figure 2-8. Relay Output Panel Jumper Configuration .......................................................... 2-11

Figure 2-9. Relay Output Card Jumper Configuration ........................................................... 2-12

Figure 2-10. DPI Card Jumpers ............................................................................................... 2-12

Figure 2-11. Optional Trim Frame and Rear Cover ................................................................. 2-12

Figure 2-12. Outline of Heater Power Supply .......................................................................... 2-13

Figure 2-13. Electrical Installation of Heater Power Supply..................................................... 2-14

Figure 2-14. Heater Power Supply Wiring Connections .......................................................... 2-15

Figure 2-15. Jumper Selection Label ....................................................................................... 2-16

Figure 2-16. Jumpers on HPS Mother Board ........................................................................... 2-17

Figure 2-17. MPS Module ........................................................................................................2-18

Figure 2-18. MPS Gas Connections ........................................................................................ 2-19

Figure 2-19. Typical CRE to MPS Connections ....................................................................... 2-20

Figure 2-20. Typical CRE to MPS Connections, 5 or 6 Probes ............................................... 2-22

Figure 2-21. Typical CRE to MPS Connections, 7 or 8 Probes ............................................... 2-24

Figure 3-1. CRE Front Panel....................................................................................................3-1

Figure 3-2. Quick Reference Chart (Sheet 1 of 2) ................................................................... 3-4

Figure 3-3. Typical Calibration Setup ..................................................................................... 3-14

Figure 3-4. Portable Rosemount Oxygen Test Gas Kit......................................................... 3-15

Figure 3-5. Typical Portable Test Calibration Setup ............................................................. 3-16

Figure 3-6. Typical Automatic Calibration System ................................................................. 3-18

World Class 3000

LIST OF ILLUSTRATIONS

LIST OF TABLES

Table 2-1. Analog Output Card Jumper Configuration ......................................................... 2-11

Table 2-2. DPI Card Jumper Configuration........................................................................... 2-11

Table 2-3. Typical CRE SETUP Data for 5 or 6 Probe Configuration................................... 2-21

Table 2-4. Typical CRE SETUP Data for 7 or 8 Probe Configuration................................... 2-23

Table 3-1. Sample HELP Messages ....................................................................................... 3-3

Table 3-2. MAIN Menu ............................................................................................................ 3-3

Table 3-3. DATA Sub-Menu.................................................................................................... 3-6

Table 3-4. Perform Calibration Error Messages ..................................................................... 3-8

Table 3-5. CALIBRATE Sub-Menu ......................................................................................... 3-9

Table 3-6. SETUP Sub-Menu ............................................................................................... 3-10

Table 3-7. Efficiency Constants. ........................................................................................... 3-12

Table 4-1. Fault Finding .......................................................................................................... 4-2

ii Rosemount Analytical Inc. A Division of Emerson Process Management

World Class 3000

The purpose of this manual is to provide information concerning the components, functions, installation and maintenance of this particular World Class 3000 module.

Some sections may describe equipment not used in your configuration. The user should

become thoroughly familiar with the operation of this module before operating it. Read

this instruction manual completely.

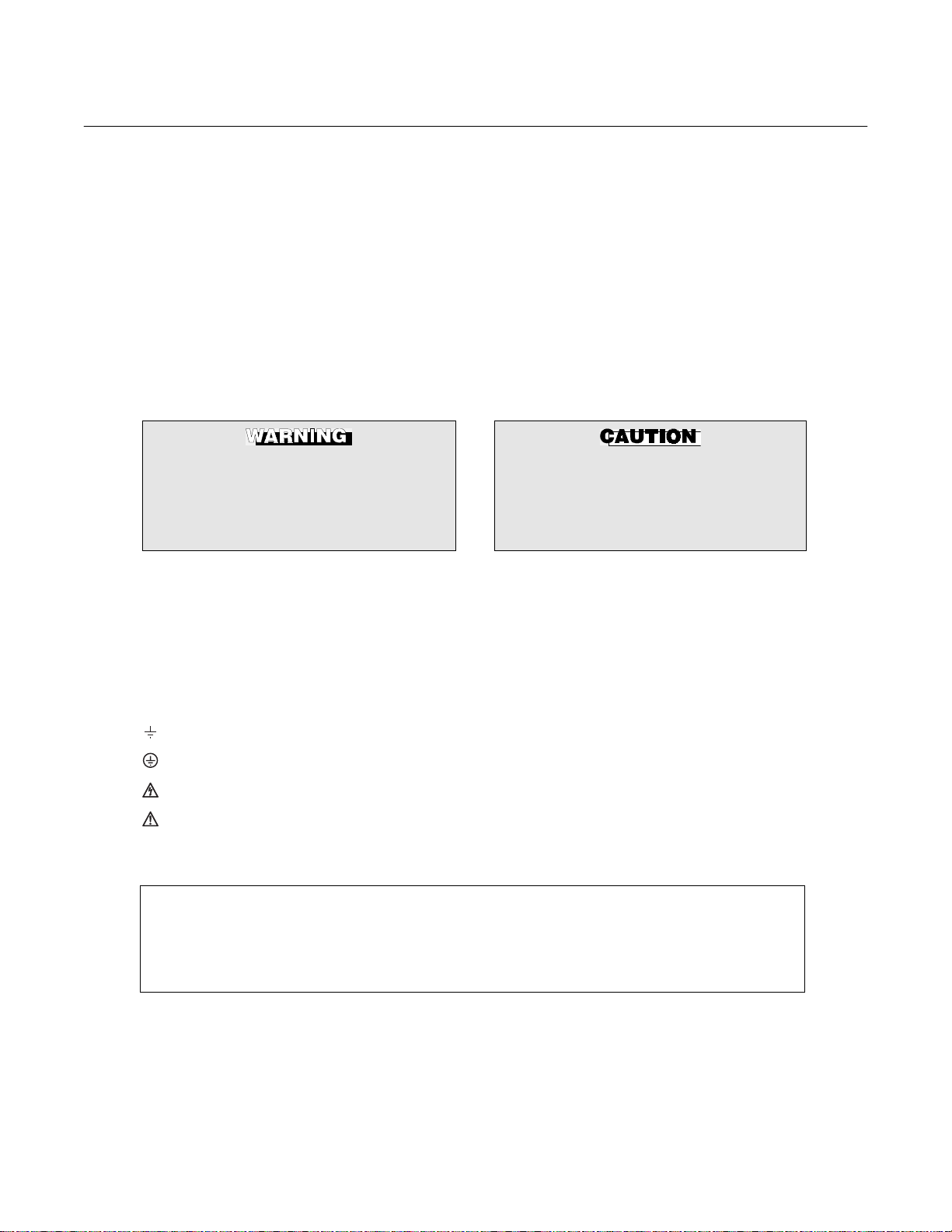

The following definitions apply to WARNINGS, CAUTIONS, and NOTES found throughout this

publication.

Instruction Manual

IB-106-300NC Rev. 4.4

February 1998

PREFACE

DEFINITIONS

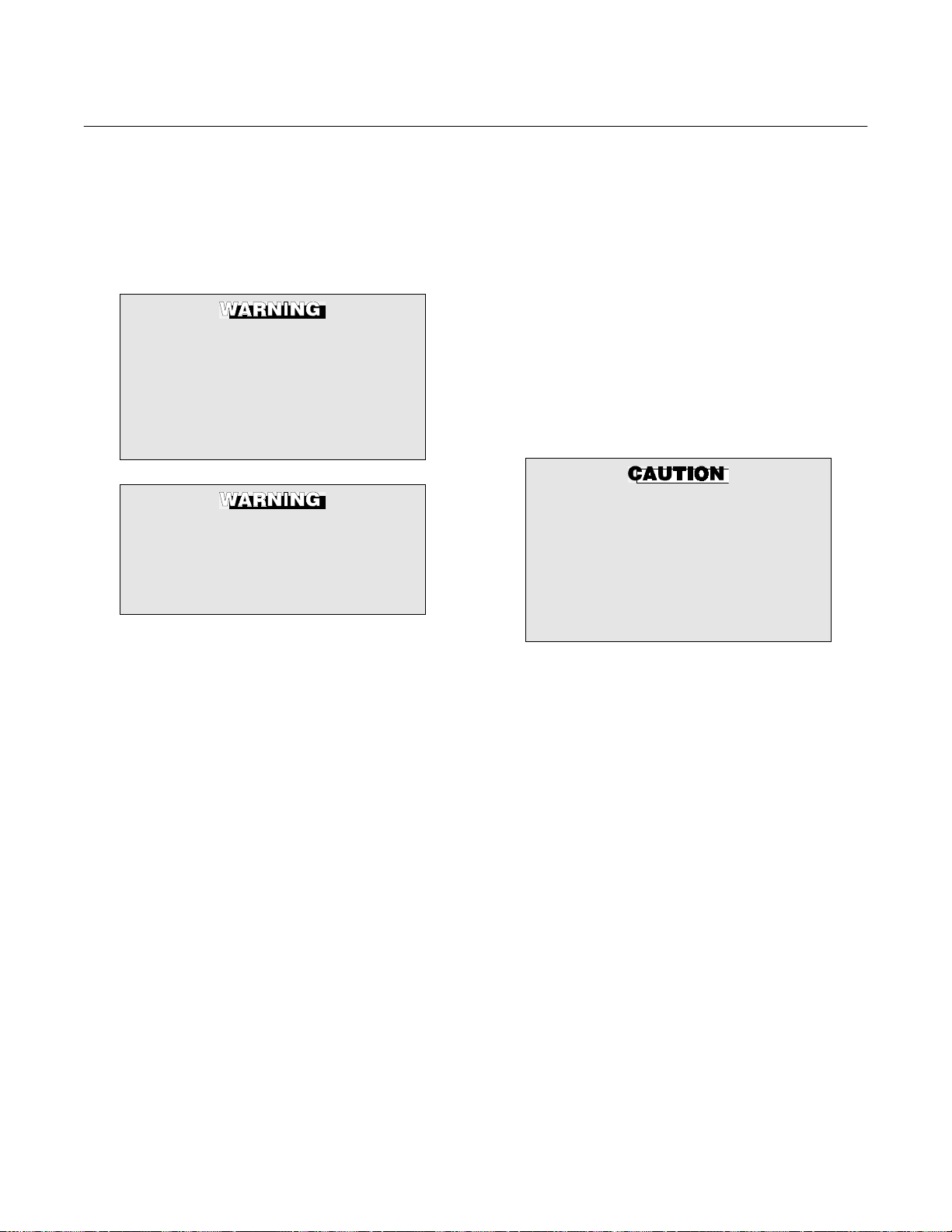

Highlights an operation or maintenance

procedure, practice, condition, statement, etc. If not strictly observed, could

result in injury, death, or long-term

health hazards of personnel.

Highlights an essential operating procedure,

condition, or statement.

: EARTH (GROUND) TERMINAL

: PROTECTIVE CONDUCTOR TERMINAL

: RISK OF ELECTRICAL SHOCK

: WARNING: REFER TO INSTRUCTION BULLETIN

NOTE TO USERS

Highlights an operation or maintenance

procedure, practice, condition, statement, etc. If not strictly observed, could

result in damage to or destruction of

equipment, or loss of effectiveness.

NOTE

The number in the lower right corner of each illustration in this publication is a manual illustration number. It is not a part number, and is not related to the illustration in any technical

manner.

Rosemount Analytical Inc. A Division of Emerson Process Management P-1

Instruction Manual

IB-106-300 NC Rev. 4.4

February 1998

FOR THE WIRING AND INSTALLATION

The following safety instructions apply specifically to all EU member states. They should

be strictly adhered to in order to assure compliance with the Low Voltage Directive. NonEU states should also comply with the following unless superseded by local or National

Standards.

1. Adequate earth connections should be made to all earthing points, internal and external,

where provided.

2. After installation or troubleshooting, all safety covers and safety grounds must be replaced.

The integrity of all earth terminals must be maintained at all times.

3. Mains supply cords should comply with the requirements of IEC227 or IEC245.

World Class 3000

IMPORTANT

SAFETY INSTRUCTIONS

OF THIS APPARATUS

4. All wiring shall be suitable for use in an ambient temperature of greater than 75°C.

5. All cable glands used should be of such internal dimensions as to provide adequate cable

anchorage.

6. To ensure safe operation of this equipment, connection to the mains supply should only be

made through a circuit breaker which will disconnect all circuits carrying conductors during a

fault situation. The circuit breaker may also include a mechanically operated isolating switch.

If not, then another means of disconnecting the equipment from the supply must be provided

and clearly marked as such. Circuit breakers or switches must comply with a recognized

standard such as IEC947. All wiring must conform with any local standards.

7. Where equipment or covers are marked with the symbol to the right, hazardous voltages are likely to be present beneath. These covers should only be

removed when power is removed from the equipment — and then only by

trained service personnel.

8. Where equipment or covers are marked with the symbol to the right, there is a

danger from hot surfaces beneath. These covers should only be removed by

trained service personnel when power is removed from the equipment. Certain surfaces may remain hot to the touch.

9. Where equipment or covers are marked with the symbol to the right, refer to

the Operator Manual for instructions.

10. All graphical symbols used in this product are from one or more of the following standards: EN61010-1, IEC417, and ISO3864.

P-2 Rosemount Analytical Inc. A Division of Emerson Process Management

World Class 3000

1

Instruction Manual

IB-106-300NC Rev. 4.4

February 1998

SECTION 1

DESCRIPTION

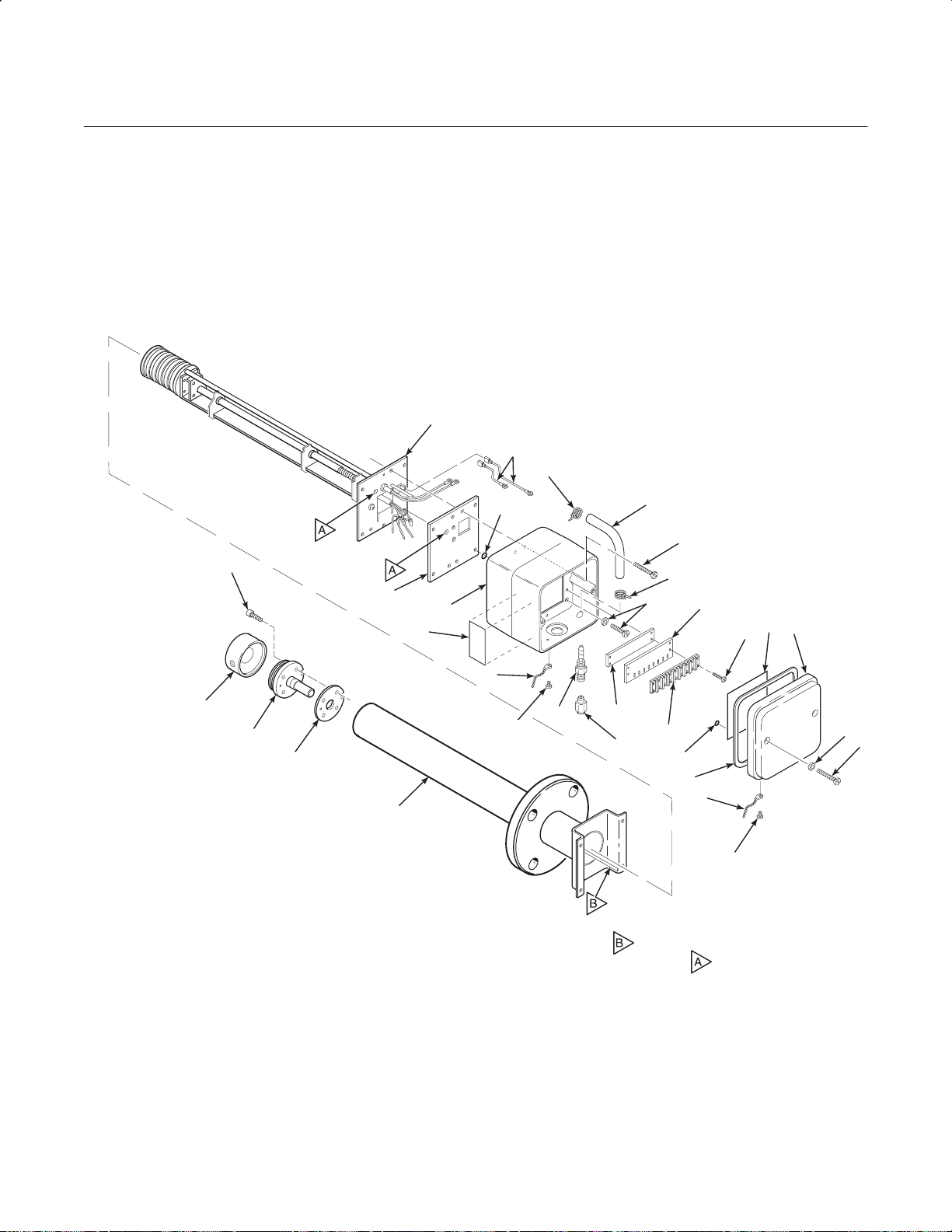

1-1 COMPONENT CHECKLIST OF TYPICAL

SYSTEM (PACKAGE CONTENTS)

A typical Rosemount World Class 3000 Oxygen

Analyzer with CRE 3000 Control Room Elec-

1. Control Room Electronics

2. Instruction Bulletin

3. Multiprobe Test Gas Sequencer (Optional)

4. Heater Power Supply

5. Oxygen Analyzer (Probe)

6. System Cable

7. Adapter Plate with mounting hardware and gasket

8. Reference Air Set (If MPS not supplied)

1

tronics should contain the items shown in Figure

1-1. Record the part number, serial number, and

order number for each component of your system in the table located on the first page of the

manual.

3

2

4

8

5

7

6

19270001

Figure 1-1. Typical System Package

Rosemount Analytical Inc. A Division of Emerson Process Management Description 1-1

Instruction Manual

IB-106-300 NC Rev. 4.4

February 1998

World Class 3000

1-2 SYSTEM OVERVIEW

a. Scope

This Instruction Bulletin has been designed

to supply details needed to install, start up,

operate, and maintain the Rosemount World

Class 3000 Oxygen Analyzer with CRE

3000 Control Room Electronics. The Control

Room Electronic Module (CRE) can be interfaced with up to eight World Class 3000

probes. The CRE provides all necessary

intelligence for controlling the probe and optional MPS 3000 Multiprobe Test Gas

Sequencer.

Appendices, at the back of this manual,

detail each component and option from the

standpoint of troubleshooting, repair, and

spare parts.

b. System Description

The Rosemount Oxygen Analyzer (Probe) is

designed to measure the net concentration

of oxygen in an industrial process, i.e., the

oxygen remaining after all fuels have been

oxidized. The probe is permanently positioned within an exhaust duct or stack and

performs its task without the use of a sampling system.

The equipment measures oxygen percentage by reading the voltage developed

across a heated electrochemical cell, which

consists of a small yttria-stabilized, zirconia

disc. Both sides of the disc are coated with

porous metal electrodes. When operated at

the proper temperature, the millivolt output

voltage of the cell is given by the following

Nernst equation:

EMF = KT log10(P1/P2) + C0

Where:

1 P2 is the partial pressure of the oxygen

in the measured gas on one side of the

cell,

2 P1 is the partial pressure of the oxygen

in the reference gas on the other side,

3 T is the absolute temperature,

4 C is the cell constant,

5 K is an arithmetic constant.

NOTE

For best results, use clean, dry, instrument air (20.95% oxygen) as a reference gas.

When the cell is at operating temperature

and there are unequal oxygen concentrations across the cell, oxygen ions will travel

from the high partial pressure of oxygen

side to the low partial pressure side of the

cell. The resulting logarithmic output voltage

is approximately 50 mV per decade.

Because the magnitude of the output is proportional to the logarithm of the inverse of

the sample of the oxygen partial pressure,

the output signal increases as the oxygen

concentration of the sample gas decreases.

This characteristic enables the oxygen

analyzer to provide exceptional sensitivity at

low oxygen concentrations.

Oxygen analyzer equipment measures net

oxygen concentration in the presence of all

the products of combustion, including water

vapor. Therefore, it may be considered an

analysis on a "wet" basis. In comparison

with older methods, such as the Orsat apparatus, which provides an analysis on a "dry"

gas basis, the "wet" analysis will, in general,

indicate a lower percentage of oxygen. The

difference will be proportional to the water

content of the sampled gas stream.

c. System Configuration

The equipment discussed in this manual

consists of three major components: the

oxygen analyzer (probe), the control room

electronics (CRE), and the heater power

supply (HPS). The HPS is required when

the cable run between the probe and the

electronics is greater than 150 feet (46 m).

There is also an optional multiprobe test gas

sequencer (MPS) to facilitate automatic

calibration of the probes.

Probes are available in five length options,

giving the user the flexibility to use an in situ

penetration appropriate to the size of the

stack or duct. The options on length are 18

inches (457 mm), 3 feet (0.91 m), 6 feet

(1.83 m), 9 feet (2.74 m), or 12 feet

(3.66 m).

1-2 Description Rosemount Analytical Inc. A Division of Emerson Process Management

World Class 3000

1

Instruction Manual

IB-106-300NC Rev. 4.4

February 1998

The CRE contains electronics that control

probe temperature (in conjunction with the

HPS), supply power, and provide isolated

outputs that are proportional to the measured oxygen concentration. The oxygen

sensing cell is maintained at a constant

temperature by modulating the duty cycle of

the probe heater. The CRE accepts millivolt

signals generated by the sensing cell and

produces outputs to be used by remotely

connected devices. The CRE output is isolated and selectable to provide voltage or

current. For a detailed description of the

CRE, refer to Appendix C.

The heater power supply (HPS) provides an

interface between the CRE and the probe.

The HPS contains a transformer for supplying proper voltage to the probe heater.

The enclosure has been designed to meet

NEMA 4X (IP65) specifications for water

tightness; an optional enclosure to meet

Class 1, Division 1, Group B (IP65) explosion proof is also available. For a detailed

description of the HPS, refer to Appendix B.

6. The heater power supply can be located up to 150 feet (46 m) from the

probe and up to 1200 (366 m) feet from

the control room electronics.

7. All electronic modules are adaptable to

100, 120, 220, and 240 line voltages.

8. RS-232 serial link for serial printer,

baud range selectable; optional RS232 serial link with computer interface

suitable for an IBM Personal Computer

or modem (available in the future).

e. Handling the Oxygen Analyzer

NOTE

Retain packaging in which the oxygen

analyzer arrived from the factory in

case any components are to be

shipped to another site. This packaging has been designed to protect the

product.

Systems with multiprobe applications may

employ an optional Multiprobe Test Gas

Sequencer (MPS). The MPS provides

automatic test gas sequencing for up to four

probes to accommodate automatic calibration. For a detailed description of the MPS,

refer to Appendix D.

d. System Features

1. Unique and patented electronic cell

protection action that automatically

protects sensor cell when the analyzer

detects reducing atmospheres.

2. Output voltage and sensitivity increase

as the oxygen concentration decreases.

3. User friendly, menu driven operator

interface with contact-sensitive on-line

help.

4. Field replaceable cell.

5. Analyzer constructed of rugged 316

LSS for all wetted parts.

It is important that printed circuit

boards and integrated circuits are

handled only when adequate antistatic

precautions have been taken to prevent possible equipment damage.

The oxygen analyzer is designed for

industrial application. Treat each

component of the system with care to

avoid physical damage. The probe

contains components made from ceramics, which are susceptible to shock

when mishandled.

f. System Considerations

Prior to installation of your Rosemount

World Class 3000 Oxygen Analyzer with

Control Room Electronics make sure that

you have all of the components necessary

to make the system installation. Ensure that

all the components are properly integrated

to make the system functional.

Once you have verified that you have all the

components, select mounting locations and

Rosemount Analytical Inc. A Division of Emerson Process Management Description 1-3

Instruction Manual

IB-106-300 NC Rev. 4.4

February 1998

World Class 3000

determine how each component will be

placed in terms of available power supply,

ambient temperatures, environmental considerations, convenience, and serviceability.

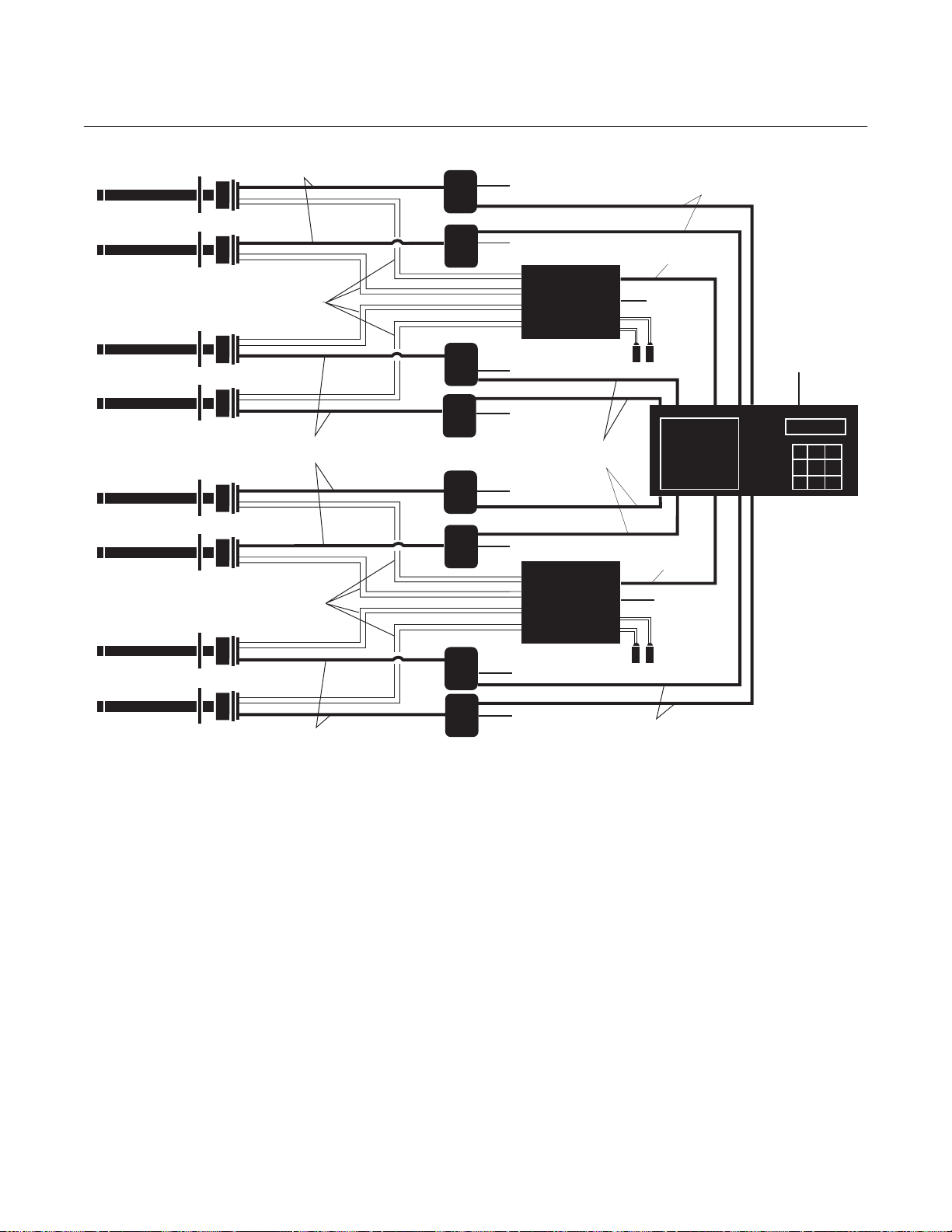

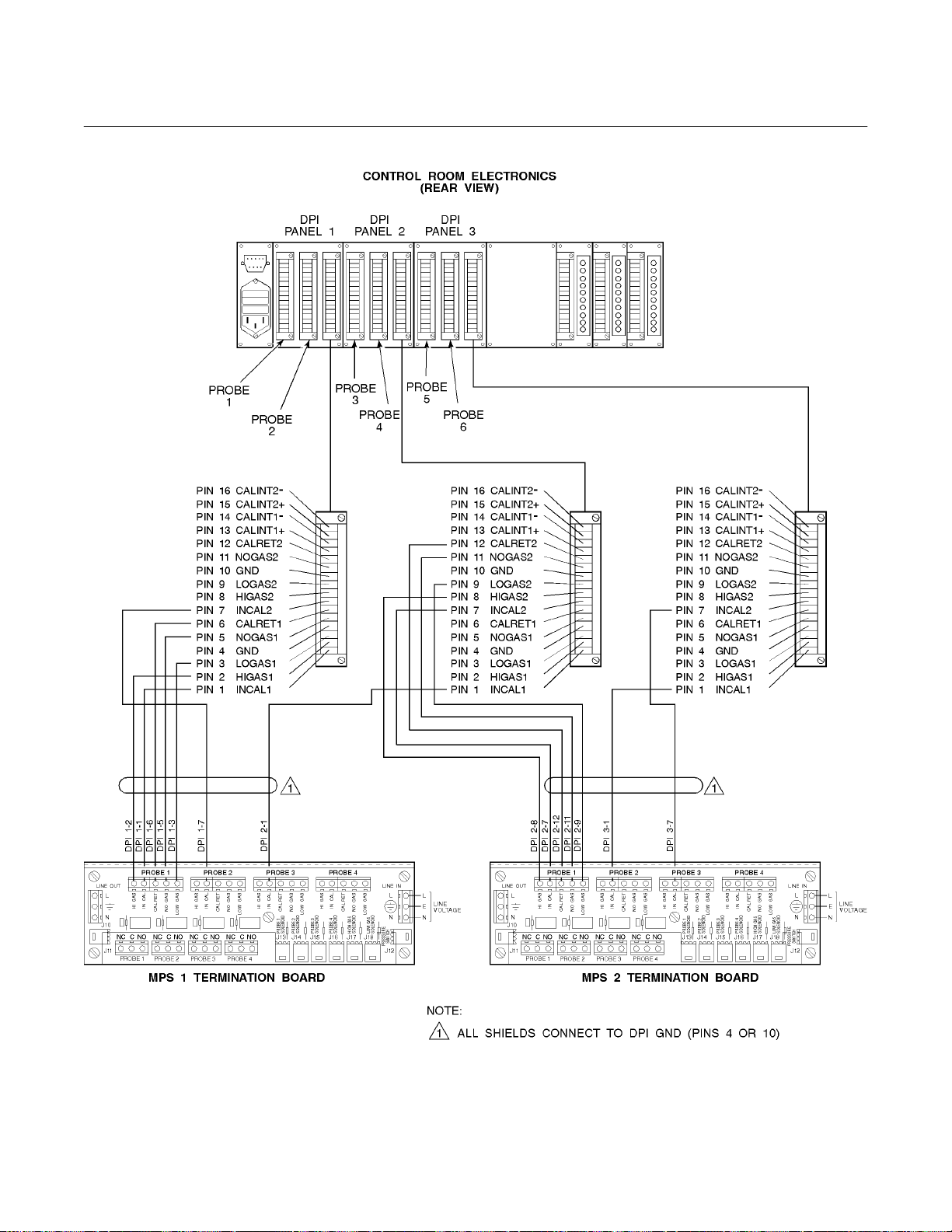

A typical system installation is illustrated in

Figure 1-2. Figure 1-3 shows a typical system wiring. For details on installing the individual components of the system, refer to

Section 2, Installation. Figure 1-4 is a block

diagram illustrating six World Class 3000

Probes applied to the Control Room Electronics. Figure 1-5 shows the same information but for an eight probe configuration.

After selecting the probe mounting location,

provision should be made for a platform

where the probe can be easily serviced. The

heater power supply can be located up to

150 feet (46 m) cabling distance from the

probe, and up to 1200 feet (366 m) cabling

distance from the control room electronics.

A source of instrument air is required at the

probe for reference gas use. Since the

probe is equipped with an in-place calibration feature, provision should be made for

connecting test gas tanks to the oxygen

analyzer when the probe is to be calibrated.

If test gas bottles will be hooked up permanently, a check valve must be installed next

to the calibration fittings on the probe junction box. This is to prevent breathing of calibration gas line and subsequent flue gas

condensation and corrosion. The check

valve is in addition to the stop valve in the

test gas kit or the solenoid valve in the multiprobe test gas sequencer units.

An optional Z-purge arrangement is available for applications where hazardous area

classification may be required. (See Application Data Bulletin AD 106-300B.)

1-4 Description Rosemount Analytical Inc. A Division of Emerson Process Management

World Class 3000

1

Instruction Manual

IB-106-300NC Rev. 4.4

February 1998

CALIBRATION

INSTRUMENT

AIR SUPPLY

(REF. GAS)

GAS

PRESSURE

REGULATOR

FLOWMETER

CONTROL ROOM

ELECTRONICS

GASES

STACK

STANDARD

DUCT

OXYGEN

ANALYZER

(PROBE)

HEATER POWER SUPPLY

MULTIPROBE

TEST GAS

SEQUENCER

ADAPTER

PLATE

LINE

VOLTAGE

1

2

AS

AS

.AIR

ST

IN

TEST G

TEST G

GASES

STACK

ADAPTER

PLATE

CALIBRATION

GAS

SUPPLY

REFERENCE AIR

OPTIONS

DUCT

OXYGEN

ANALYZER

(PROBE)

HEATER

POWER

SUPPLY

LINE

VOLTAGE

CONTROL ROOM

ELECTRONICS

19270002

Figure 1-2. Typical System Installation

Rosemount Analytical Inc. A Division of Emerson Process Management Description 1-5

Instruction Manual

IB-106-300 NC Rev. 4.4

February 1998

World Class 3000

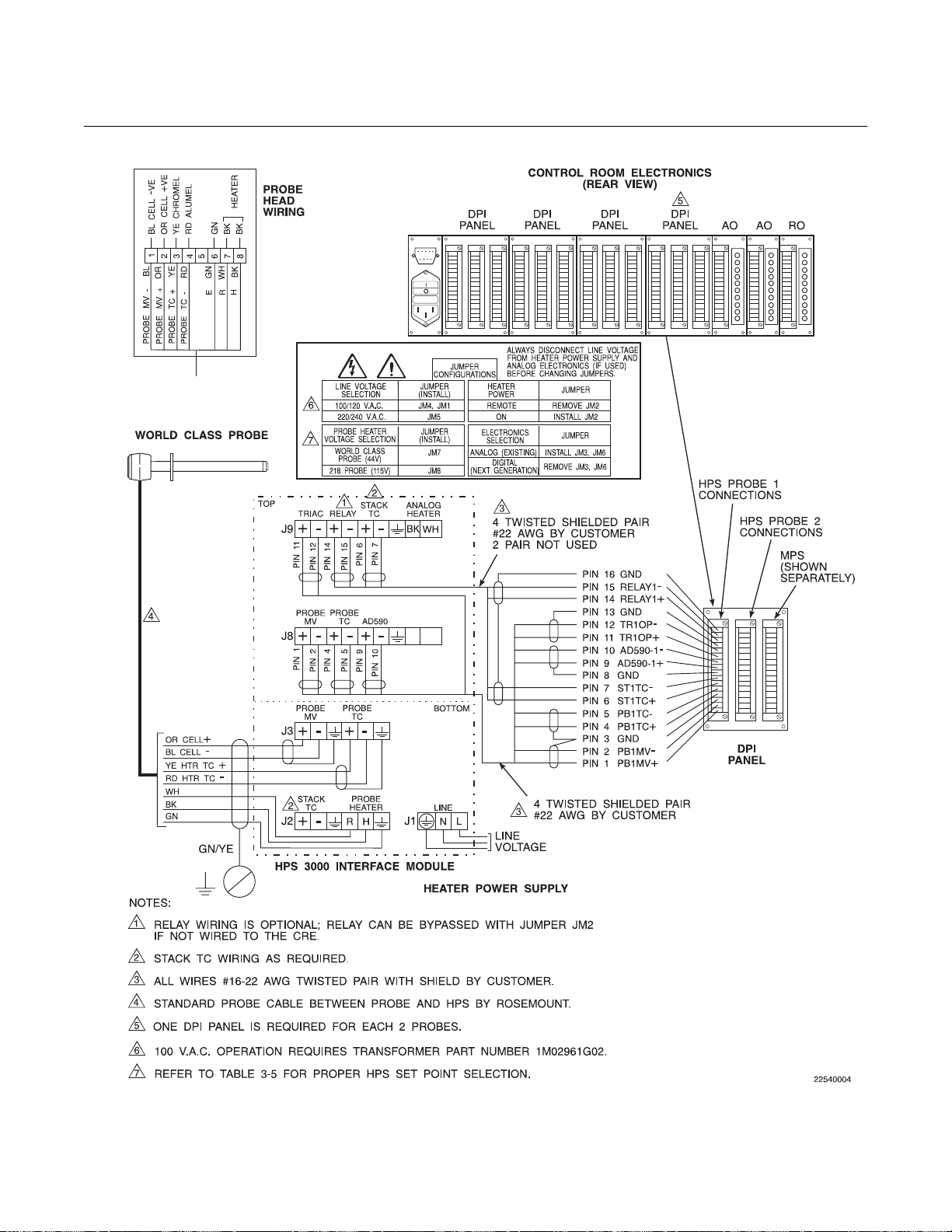

Figure 1-3. Typical System Wiring (Sheet 1 of 3)

1-6 Description Rosemount Analytical Inc. A Division of Emerson Process Management

World Class 3000

1

REMOTE MOMENTARY

CALIBRATION START

SWITCH BY CUSTOMER

PROBE 2

PROBE 1

PIN 16 CALINT2

PIN 15 CALINT2+

PIN 14 CALINT1

PIN 13 CALINT1+

PIN 12 CALRET2

PIN 11 NOGAS2

PIN 10 GND

PIN 9 LOGAS2

PIN 8 HIGAS2

PIN 7 INCAL2

PIN 6 CALRET1

PIN 5 NOGAS1

PIN 4 GND

PIN 3 LOGAS1

PIN 2 HIGAS1

PIN 1 INCAL1

Instruction Manual

IB-106-300NC Rev. 4.4

February 1998

-

-

DETAIL B

TO DPI FOR

PIN 1

PROBES 3 AND 4

PIN 7

IF REQUIRED

PIN 3

PIN 6

PIN 5

PIN 1

PIN 2

PIN 7

8 CONDUCTOR

SHIELDED CABLE

#16 AWG BY CUSTOMER

PIN 1

PIN 7

DUPLICATE CONNECTIONS

NOT REQUIRED

PROBE 1 PROBE 2 PROBE 3 PROBE 4

LINE OUT LINE IN

L

IN CAL

HI GAS

N

CAL RET

NO GAS

LOW GAS

IN CAL

HI GAS

CAL RET

NO GAS

LOW GAS

IN CAL

HI GAS

CAL RET

NO GAS

LOW GAS

HI GAS

J10

NC C NO NC C NO NC C NO NC C NO

J13 J14 J15 J16 J17 J18

J11

PROBE 1

MULTIPROBE GAS SEQUENCER (OPTIONAL) MPS 3000 TYPICAL CONFIGURATION

PROBE 2 PROBE 3 PROBE 4

REFER TO MPS MODEL NUMBER FOR SPECIFIC CONFIGURATION

IN CAL

CAL RET

NO GAS

LOW GAS

L

N

J12

L

E

N

LINE

VOLTAGE

CRE AND MPS CONNECTIONS

Figure 1-3. Typical System Wiring (Sheet 2 of 3)

Rosemount Analytical Inc. A Division of Emerson Process Management Description 1-7

Instruction Manual

IB-106-300 NC Rev. 4.4

February 1998

World Class 3000

Figure 1-3. Typical System Wiring (Sheet 3 of 3)

1-8 Description Rosemount Analytical Inc. A Division of Emerson Process Management

World Class 3000

1

7 Conductor Cable

(150 Feet Max)

World Class 3000

Probe

HPS

3000

HPS

3000

Line Voltage

Line Voltage

Instruction Manual

IB-106-300NC Rev. 4.4

February 1998

4 Twisted Pair Plus 2 Twisted Pair

for Options (1200 Feet Max)

8 Conductor Wire

(1000 Feet Max)

World Class 3000

Probe

2 Pneumatic Lines

by Customer

(300 Feet Max)

7 Conductor Cable

(150 Feet Max)

7 Conductor Cable

(150 Feet Max)

2 Pneumatic Lines

by Customer

(300 Feet Max)

7 Conductor Cable

(150 Feet Max)

Test Gas

Sequencer

MPS 3000

Modular Design

HPS

3000

4 Twisted Pair Plus 2 Twisted Pair

4 Twisted Pair Plus 2 Twisted Pair

HPS

3000

HPS

3000

HPS

3000

Up to 4 Probes

Line Voltage

for Options (1200 Feet Max)

for Options (1200 Feet Max)

Line Voltage

Line Voltage

Test Gas

Sequencer

MPS 3000

Modular Design

Up to 4 Probes

Line Voltage

4 Twisted Pair Plus 2 Twisted Pair

for Options (1200 Feet Max)

Line Voltage

Test Gas

by Customer

8 Conductor Wire

(1000 Feet Max)

Line Voltage

Test Gas

by Customer

Line Voltage

CRE 3000

Control Room

Electronics

Line Voltage

100 to 120 Volt

220 to 240 Volt

19270004

Figure 1-4. Control Room Electronics with 6 World Class 3000 Probes

Rosemount Analytical Inc. A Division of Emerson Process Management Description 1-9

Instruction Manual

IB-106-300 NC Rev. 4.4

February 1998

World Class 3000

Probe

7 Conductor Cable

(150 Feet Max)

HPS

3000

HPS

3000

Line Voltage

Line Voltage

World Class 3000

4 Twisted Pair Plus 2 Twisted Pair

for Options (1200 Feet Max)

8 Conductor Wire

(1000 Feet Max)

World Class 3000

Probe

2 Pneumatic Lines

by Customer

(300 Feet Max)

7 Conductor Cable

(150 Feet Max)

2 Pneumatic Lines

by Customer

(300 Feet Max)

7 Conductor Cable

(150 Feet Max)

Test Gas

Sequencer

MPS 3000

Modular Design

HPS

3000

HPS

3000

4 Twisted Pair Plus 2 Twisted Pair

HPS

3000

HPS

3000

HPS

3000

HPS

3000

Up to 4 Probes

Line Voltage

Line Voltage

for Options (1200 Feet Max)

Line Voltage

Line Voltage

Test Gas

Sequencer

MPS 3000

Modular Design

Up to 4 Probes

Line Voltage

Line Voltage

Line Voltage

Test Gas

by Customer

8 Conductor Wire

(1000 Feet Max)

Line Voltage

Test Gas

by Customer

4 Twisted Pair Plus 2 Twisted Pair

for Options (1200 Feet Max)

Line Voltage

CRE 3000

Control Room

Electronics

Line Voltage

100 to 120 Volt

220 to 240 Volt

19270005

Figure 1-5. Control Room Electronics with 8 World Class 3000 Probes

1-10 Description Rosemount Analytical Inc. A Division of Emerson Process Management

World Class 3000

2

Instruction Manual

IB-106-300NC Rev. 4.4

February 1998

SECTION 2

INSTALLATION

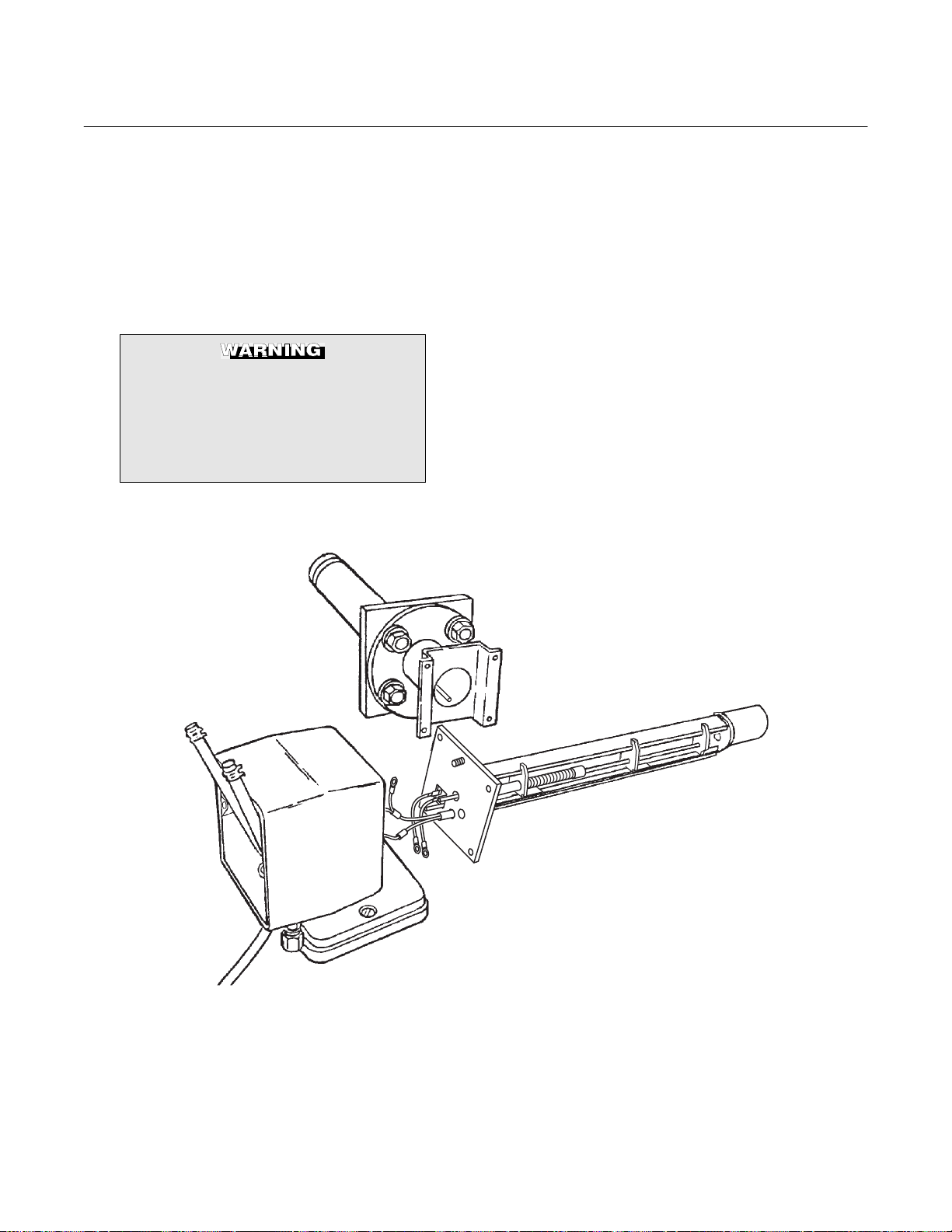

2-1 OXYGEN ANALYZER (PROBE)

INSTALLATION

Before starting to install this equipment, read the "Safety instructions for

the wiring and installation of this apparatus" at the front of this Instruction

Bulletin. Failure to follow the safety

instructions could result in serious

injury or death.

Install all protective equipment covers

and safety ground leads after installation. Failure to install covers and

ground leads could result in serious

injury or death.

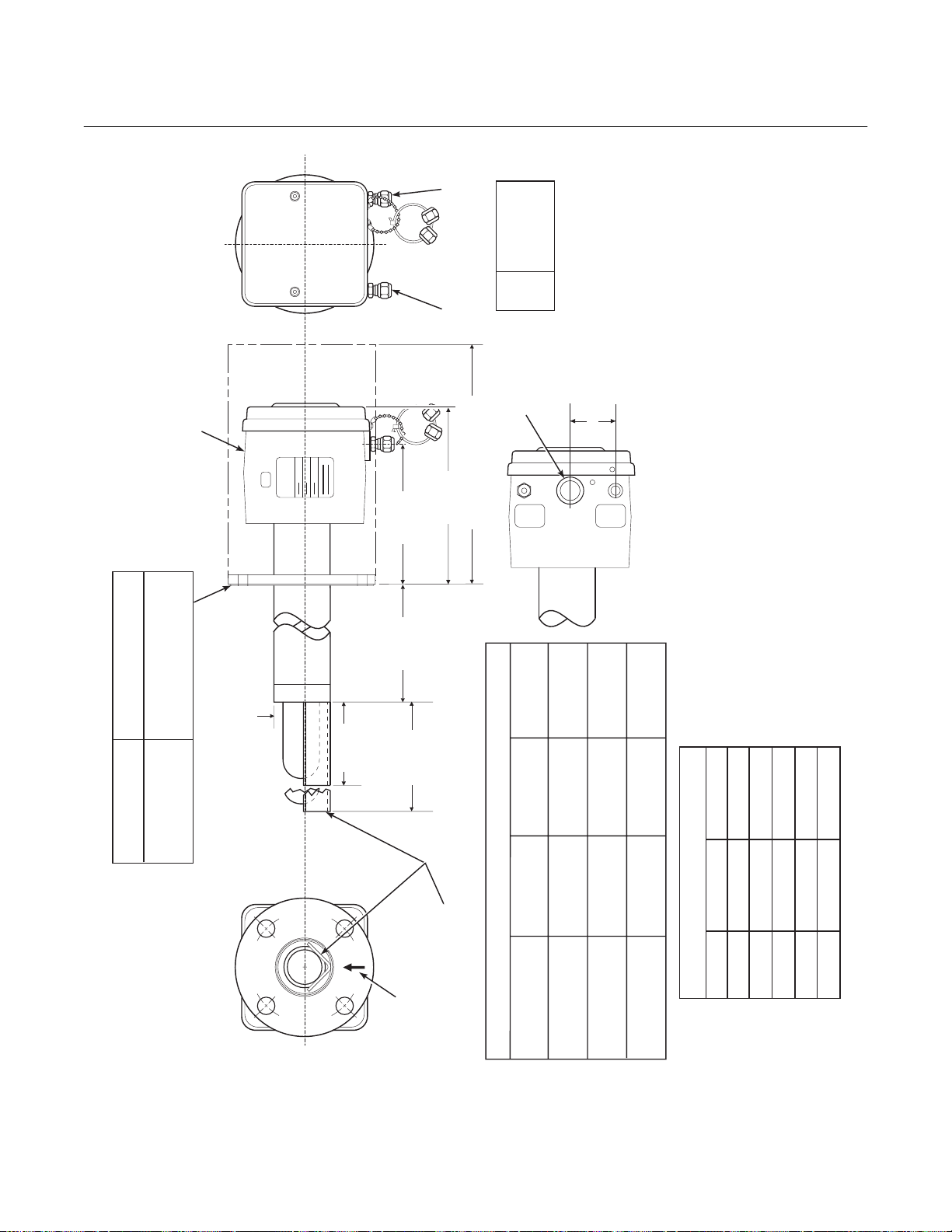

a. Selecting Location.

1. The location of the probe in the stack

or flue is most important for maximum

accuracy in the oxygen analyzing process. The probe must be positioned, so

that the gas it measures is representative of the process. Best results are

normally obtained if the probe is positioned near the center of the duct (40

to 60% insertion). A point too near the

edge or wall of the duct may not provide a representative sample because

of the possibility of gas stratification. In

addition, the sensing point should be

selected, so that the process gas temperature falls within a range of 50° to

1300°F (10° to 704°C). Figure 2-1 provides mechanical installation

references.

2. Check the flue or stack for holes and

air leakage. The presence of this condition will substantially affect the accuracy of the oxygen reading. Therefore,

either make necessary repairs or install

the probe upstream of any leakage.

3. Ensure that the area is clear of obstructions, internal and external, that

will interfere with installation. Allow

adequate clearance for removal of

probe (Figure 2-1).

4. If the probe is to be mounted outside

and subject to rain and snow conditions, make sure the back of the probe

(outside of the duct) is insulated to prevent the formation of flue gas condensate in the calibration gas lines.

Do not allow the temperature of the

probe junction box to exceed 300°F

(149°C) or damage to the unit may result. If the probe junction box temperature exceeds 300°F (149°C), the

user must fabricate a heat shield or

provide adequate cooling air to the

probe junction box.

b. Mechanical Installation.

1. Ensure that all components are available for installation of the probe. Ensure that the system cable is the

required length. If applicable, check the

optional ceramic diffusor to ensure that

it is not damaged.

2. The probe may be installed intact as it

is received. It is recommended that you

disassemble the adapter plate for each

installation.

NOTE

An abrasive shield is recommended

for high velocity particulate in the flue

stream (such as those in pulverized

coal kilns and recovery boilers). Vertical and horizontal brace clamps are

provided for 9 ft and 12 ft (2.75 m and

3.66 m) probes to provide mechanical

support of the probe. Refer to Figure

2-1, sheet 5.

3. Weld or bolt adapter plate (Figure 2-1)

onto the duct.

Rosemount Analytical Inc. A Division of Emerson Process Management Installation 2-1

Instruction Manual

IB-106-300 NC Rev. 4.4

February 1998

World Class 3000

FURNISHED IN - XIT

4512C34

ADAPTER & ACCESSORY

TO AMBIENT

INSULATE IF EXPOSED

WEATHER CONDITIONS

4512C35

4512C36

2.27 (58)

DIA MAX

ROSEMOUNT

5.85 (148.6)

DIM "A"

WITH STANDARD

REF GAS

CAL GAS

7.58 (192)

SNUBBER

DIFFUSER

ELEC

DIM "B" REMOVAL ENVELOPE

1/4 IN. TUBE

6 MM TUBE

6 MM TUBE

ANSI

DIN

JIS

1/2"

CONN

CONDUIT

GAS

CAL

JIS

4512C18H01

6.10

(155)

1.88 (48)

0.59

GAS

REF

(15)

AT THE BOTTOM

BOTTOM VIEW

INSTALL WITH CONNECTIONS

5.12

(130)

THESE FLAT FACED FLANGES ARE MANUFACTURED

TO ANSI, DIN, AND JIS BOLT PATTERNS AND ARE NOT

DIMENSIONS ARE IN INCHES WITH MILLIMETERS IN

PARENTHESES.

PRESSURE RATED.

2.

NOTES: 1.

24610001

3.80 (96.5)

DIFFUSER

FOR PROBE

WITH CERAMIC

4.90 (124.5)

ADD TO DIM "A" FOR

ARRESTOR

DIFFUSER AND FLAME

PROBE WITH CERAMIC

DIN

7.28

4512C19H01

ANSI

6.00

4512C17H01

(185)

(153)

0.71

0.75

(18)

(20)

5.71

(145)

4.75

(121)

DIM "B"

DIM "A"

27.3 (694)

16 (406)

45.3 (1151)

34 (864)

81.3 (2065)

117.3 (2980)

70 (1778)

106 (2692)

153.3 (3894)

142 (3607)

3535B18H02

3635B48H01

ANSI

JIS

0.062 THK GASKET

ADD TO DIM "A"

3535B45H01

DIN

TABLE I MOUNTING FLANGE

3FT

6FT

9FT

12 FT

PROCESS FLOW MUST

BE IN THIS DIRECTION

WITH RESPECT TO

DEFLECTOR 3534848G01

FLANGE

DIA.

HOLE

DIA.

(4) HOLES

EQ SP ON BC

TABLE II INSTALLATION/REMOVAL

18 IN.

PROBE

Figure 2-1. Probe Installation (Sheet 1 of 5)

2-2 Installation Rosemount Analytical Inc. A Division of Emerson Process Management

World Class 3000

2

7.50

7.48

BOLT

CIRCLE

0.75

(8) HOLES

DIAMETER

FLANGE

9.00 (153)

DIAMETER

TABLE IV. FLANGE SIZE

*

ANSI

7.48

0.75

0.945

9.25 (235)

9.25 (235)

*

*

JIS

DIN

5.7

(145)

14.5

(369)

DIM "D" REMOVAL ENVELOPE

PRESSURE RATED.

FLATFACED. THESE FLANGES ARE NOT

DIN, AND JIS BOLTPATTERNS AND ARE

FLANGES ARE MANUFACTURED TO ANSI,

*

7.00

(178)

SEE TABLE IV

FOR FLANGE

SIZES

Instruction Manual

IB-106-300NC Rev. 4.4

February 1998

21190008

REF AND

CAL GAS

CONNECTOR

ELECTRICAL

CONNECTOR

CAL GAS LINES

CHECK VALVE FOR

INSULATE IF

CONDITIONS

EXPOSED TO

AMBIENT WEATHER

31.1

(790)

DIM "E"

45.3

(1151)

DIM "D"

27

(686)

DIM "C"

NOMINAL MEASUREMENTS

TABLE III. REMOVAL/ INSTALLATION

3 FT

67.1

81.3

63

6 FT

(1704)

(2065)

(1600)

103.1

139.1

(2619)

(3533)

117.3

153.3

(3894)

(2980)

(P/N 3535B58G04 - JIS)

99

9 FT

(2515)

135

(3429)

12 FT

DIM "C"

0.06 THK GASKET FURNISHED

DIM "E" (WITH FLAME ARRESTOR)

(P/N 3535B58G06 - DIN)

(P/N 3535B58G02 - ANSI)

IN HARDWARE PACKAGE

Figure 2-1. Probe Installation (Sheet 2 of 5)

3.6

NOMINAL

(P/N 4843B38G02)

SNUBBER DIFFUSION/

DUST SEAL ASSEMBLY

DIMENSIONS ARE IN INCHES WITH

MILLIMETERS IN PARENTHESES.

NOTE:

Rosemount Analytical Inc. A Division of Emerson Process Management Installation 2-3

Instruction Manual

IB-106-300 NC Rev. 4.4

February 1998

World Class 3000

JIS

(P/N 3535B58G04)

DIN

(P/N 3535B58G06)

ANSI

(P/N 3535B58G02)

IN.

TABLE VI. ADAPTOR PLATE DIMENSIONS FOR ABRASIVE SHIELD

(mm)

DIMENSIONS

JIS

(P/N 4512C35G01)

9.25

9.25

9.00

"A"

6.50

(235)

(235)

(229)

(165)

4.92

(125)

(M-20 x 2.5)

3.94

(100)

(M-16 x 2)

4.75

(121)

0.625-11

"C"

"B"

DIA

THREAD

(130)

5.118

(M-12 x 1.75)

7.894

7.48

7.50

"D"

(200)

(190)

(191)

DIA

NOTE: PART NUMBERS FOR ADAPTOR PLATES INCLUDE

ATTACHING HARDWARE.

o

22.5

OUTSIDE WALL SURFACE.

CROSSHATCHED AREA IN 4

CORNERS MAY BE USED TO

FIELD BOLTING OF PLATE TO

PROVIDE ADDITIONAL HOLES FOR

AND 12 FT ABRASIVE SHIELD

ADAPTOR PLATE FOR 3, 6, 9,

INSTALLATIONS. SEE SHEET 2.

8 THREADED HOLES

EQUALLY SPACED ON

D DIA B.C.

A

ABRASIVE SHIELD

FLANGE O.D.

C

A

B

4 STUDS,

LOCKWASHERS AND

NUTS EQUALLY

SPACED ON

DIN

ANSI

TABLE V. ADAPTOR PLATE DIMENSIONS FOR PROBE

IN.

DIMENSIONS

7.5

(191)

(M-16 x 2)

(P/N 4512C36G01)

6.00

(153)

0.625-11

(P/N 4512C34G01)

"B"

"A"

(mm)

THREAD

(145)

5.708

4.75

(121)

"C"

DIA

A

o

45

A

C

ATTACHING HARDWARE.

2.500 DIA

NOTE: PART NUMBERS FOR ADAPTOR PLATES INCLUDE

C DIA B.C.

B

ORLD CLASS 3000

ADAPTOR PLATE FOR

STD W

PROBE INSTALLATION.

SEE SHEET 1.

Figure 2-1. Probe Installation (Sheet 3 of 5)

2-4 Installation Rosemount Analytical Inc. A Division of Emerson Process Management

World Class 3000

2

Instruction Manual

IB-106-300NC Rev. 4.4

February 1998

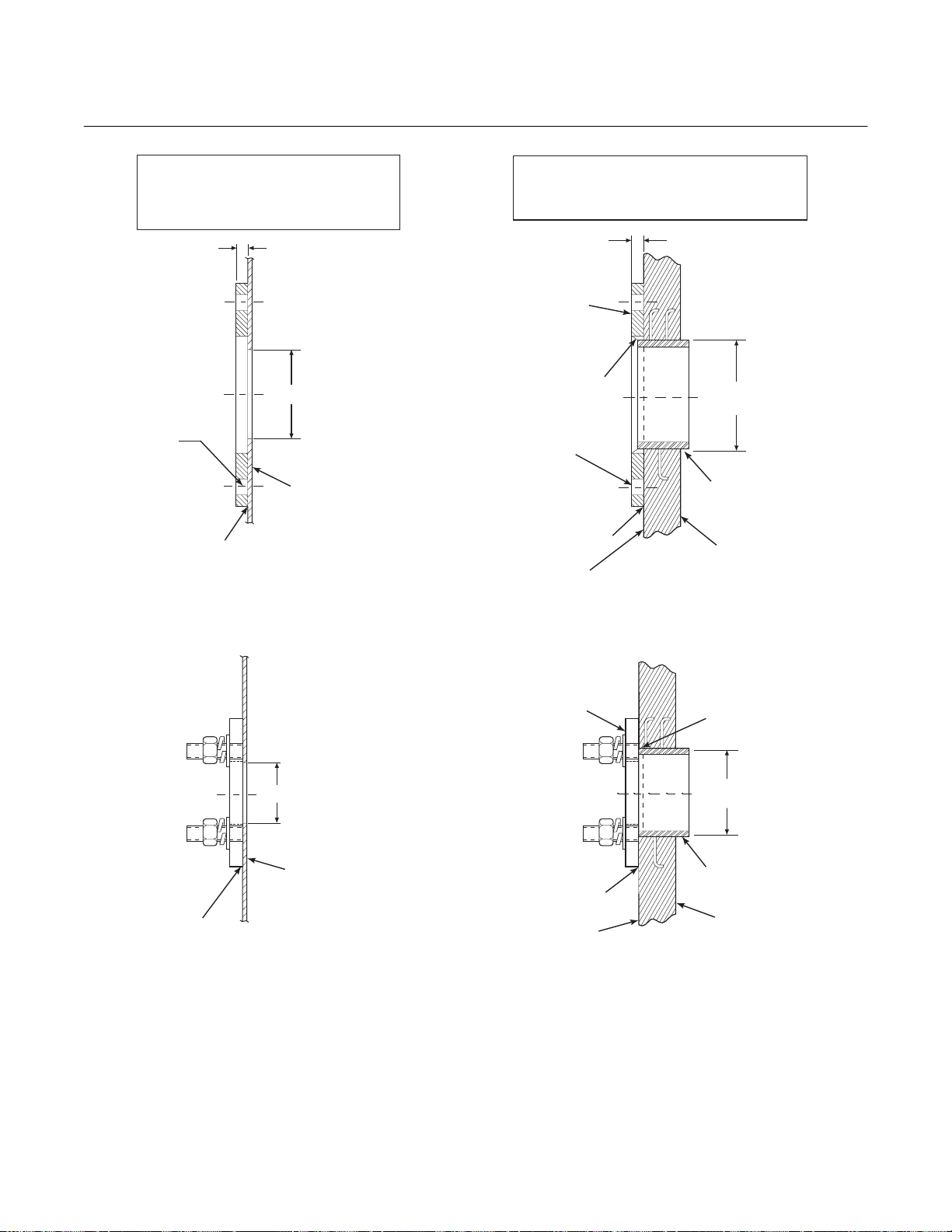

INSTALLATION FOR METAL

WALL STACK OR DUCT

CONSTRUCTION

MTG HOLES

SHOWN ROTATED

o

45 OUT OF

TRUE POSITION

WELD OR BOLT ADAPTOR

PLATE TO METAL WALL

OF STACK OR DUCT.

JOINT MUST BE AIR TIGHT.

0.50 [13]

3.75 [95]

MIN DIA HOLE

IN WALL

STACK OR DUCT

METAL WALL

INSTALLATION FOR MASONRY

WALL STACK CONSTRUCTION

0.50 [13]

BOLT ADAPTOR

PLATE TO OUTSIDE

WALL SURFACE

FIELD WELD

PIPE TO

ADAPTOR PLATE

MTG HOLES

SHOWN ROTATED

o

45 OUT OF

TRUE POSITION

JOINT MUST

BE AIRTIGHT

OUTSIDE WALL

SURFACE

NOTE: ALL MASONRY STACK WORK AND JOINTS EXCEPT

ADAPTOR PLATE NOT FURNISHED BY ROSEMOUNT.

4.50 [114]

O.D. REF

PIPE 4.00 SCHED 40

PIPE SLEEVE (NOT

BY ROSEMOUNT)

LENGTH BY CUSTOMER

MASONRY

STACK WALL

WELD OR BOLT ADAPTOR

PLATE TO METAL WALL

OF STACK OR DUCT.

JOINT MUST BE AIR TIGHT.

2.50 [63.5]

MIN DIA HOLE

IN WALL

STACK OR DUCT

METAL WALL

Figure 2-1. Probe Installation (Sheet 4 of 5)

BOLT ADAPTOR

PLATE TO OUTSIDE

WALL SURFACE

JOINT MUST

BE AIRTIGHT

OUTSIDE WALL

SURFACE

NOTE: DIMENSIONS IN INCHES WITH

MILLIMETERS IN PARENTHESES.

FIELD WELD

PIPE TO

ADAPTOR PLATE

3.50 [89]

O.D. REF

PIPE 3.00 SCHED 40

PIPE SLEEVE (NOT

BY ROSEMOUNT)

LENGTH BY CUSTOMER

MASONRY

STACK WALL

624038

Rosemount Analytical Inc. A Division of Emerson Process Management Installation 2-5

Instruction Manual

IB-106-300 NC Rev. 4.4

February 1998

World Class 3000

60oMAX.

o

30

MIN.

4.12

(105)

4.12

(105)

BRACE BARS

(NOT BY ROSEMOUNT)

2.00

(51)

1.00

(25)

2 HOLES - 0.625

(16) DIA. FOR

0.50 (12) DIA.

BOLT

1.00

(25) MAX.

0.375

(10)

NOTE: DIMENSIONS IN INCHES WITH

MILLIMETERS IN PARETHESES.

VERTICAL BRACE CLAMP ASSY.

HORIZONTAL BRACE CLAMP ASSY.

(BOTH BRACE CLAMP ASSEMBLIES ARE THE SAME.

INSTALLATION AND LOCATION OF CLAMP ASSEMBLIES

AND BRACE BARS TO BE DONE IN FIELD.)

5.62

(143)

5.62

(143)

ABRASIVE SHIELD

BY ROSEMOUNT

}

36.00 (914)

NOTE: BRACING IS FOR VERTICAL AND HORIZONTAL PROBE INSTALLATION.

EXTERNAL BRACING REQUIRED FOR 9 FT AND 12 FT

(2.75 M AND 3.66 M) PROBES AS SHOWN ABOVE.

Figure 2-1. Probe Installation (Sheet 5 of 5)

2-6 Installation Rosemount Analytical Inc. A Division of Emerson Process Management

World Class 3000

2

Instruction Manual

IB-106-300NC Rev. 4.4

February 1998

APEX

FILTER

4. If using the optional ceramic diffusor

5. In horizontal installations, the probe

6. If the system has an abrasive shield,

GAS FLOW

DIRECTION

VEE

DEFLECTOR

element, the vee deflector must be correctly oriented. Before inserting the

probe, check the direction of flow of the

gas in the duct. Orient the vee deflector

on the probe, so that the apex points

upstream toward the flow (Figure 2-2).

This may be done by loosening the

setscrews, and rotating the vee deflector to the desired position.

Retighten the setscrews.

junction box should be oriented, so that

the system cable drops vertically from

the probe junction box. In a vertical installation, the system cable can be oriented in any direction.

check the diffusion element dust seal

packings. The joints in the two packings must be staggered 180°. Also,

DIFFUSION

ELEMENT

SETSCREW

make sure that the packings are in the

hub grooves as the probe slides into

the 15° forcing cone in the abrasive

shield.

7. Insert the probe through the opening in

the mounting flange and bolt the unit to

the flange. When probe lengths selected are 9 or 12 feet (2.74 or 3.66 m),

special brackets are supplied to provide additional support for the probe

inside the flue or stack. See Figure 2-1,

sheet 5.

c. Reference Air Package

After the oxygen analyzing (probe) unit is

installed, connect the reference gas air set

to the probe junction box. The reference gas

air set should be installed in accordance

with Figure 2-3.

d. Service Required

1. Power input: 100, 115 or 220 Vac

single phase, 50 to 60 Hz, 6 amp

minimum. (See label.)

2. Compressed air: 10 psig (68.95

kPag) minimum, 225 psig (1551.38

kPag) maximum at 2 scfh (56.6 L/hr)

maximum; supplied by one of the following (less than 40 parts-per-million

total hydrocarbons). Regulator outlet

pressure should be set at 5 psi (35

kPa).

VEE

DEFLECTOR

(a) Instrument air - clean, dry.

(b) Bottled standard air with step-down

regulator.

(c) Bottled compressed gas mixture

(20.95% oxygen in nitrogen).

Figure 2-2. Orienting the Optional Vee Deflector

(d) Other equivalent clean, dry, oil-free

air supply.

Rosemount Analytical Inc. A Division of Emerson Process Management Installation 2-7

Instruction Manual

IB-106-300 NC Rev. 4.4

February 1998

World Class 3000

0.125-27 NPT FEMALE

OUTLET CONNECTION

1

4.81 (122.17)

FLOW SET

POINT KNOB

0.250 OR 6 MM OD

TUBE COMPRESSION

FITTING (SUPPLIED BY WECO)

0.250 OR 6 MM OD TUBING

(SUPPLIED BY CUSTOMER)

SCHEMATIC HOOKUP FOR REFERENCE AIR SUPPLY ON OXYGEN ANALYZER PROBE HEAD.

2

OUTLET

1.19

(30.22)

DRAIN VALVE

10.0 REF

(254)

TO PROBE

JUNCTION BOX

3

REF GAS SET

263C152G01

3.12 (79.25) MAX

2.250 (57.15)

0.25-18 NPT FEMALE

INLET CONNECTION

2.0

(50.80)

1.50

(38.10)

1 FLOWMETER 0.2-2.0 SCFH 771B635H02

2 2" PRESSURE GAGE 0-15 PSIG 275431-006

3 COMBINATION FILTER-REG. 0-30 PSIG 4505C21G01

NOTE: DIMENSIONS ARE IN INCHES WITH

2 MOUNTING HOLES

3.19 (81.03) LG

THROUGH BODY FOR

0.312 (7.92) DIA BOLTS

COMPRESSED AIR SUPPLY

10-225 PSIG MAX PRESSURE

MILLIMETERS IN PARENTHESES.

8.50 MAX

(215.90)

703020

Figure 2-3. Air Set, Plant Air Connection

2-2 CONTROL ROOM ELECTRONICS MODULE

INSTALLATION

a. Mechanical Installation

Install CRE in 19 inch (483 mm) rack using

rack mount brackets. Refer to Figure 2-4

for CRE dimensions. If installing CRE in a

panel, see Figure 2-5 for panel cutout dimensions. If installing CRE in a wall with the

optional trim frame, refer to paragraph 2-2g,

Optional Trim Frame and Rear Cover, and

Figure 2-11.

b. Electrical Connections

1. The power cable used should comply

with safety regulations in the user's

country.

2-8 Installation Rosemount Analytical Inc. A Division of Emerson Process Management

World Class 3000

2

TOP VIEW

17.62

(447,55)

19.00

(482,60)

13.25

(336,55)

16.25

(412,75)

WITH CABLE

CLEARANCE

DIMENSIONS IN INCHES WITH

NOTE:

MILLIMETERS IN PARENTHESES.

Instruction Manual

IB-106-300NC Rev. 4.4

February 1998

FRONT VIEW

0.30 DIA (4 PLS)

2.25

(57,15)

Figure 2-5. Panel Cutout for Control Room Electronic Module

5.22

(132,59)

SIDE VIEW

Figure 2-4. Control Room Electronic Dimensions

CUTOUT

17.75

(450,85)

18.31

(465,07)

5.36

(136,14)

5.22

(132,59)

Rosemount Analytical Inc. A Division of Emerson Process Management Installation 2-9

Instruction Manual

IB-106-300 NC Rev. 4.4

February 1998

World Class 3000

2. Plug the female end of the power cable

into the AC IN plug on the back of the

CRE, Figure 2-6.

3. Plug the male end of the power cable

into any acceptable power outlet for

the voltage configured.

NOTE

Refer to Figure 2-6 for CRE unit fuse

locations and specifications.

c. Analog Output and Relay Output

Connections

1. The analog outputs and relay outputs

are programmed by the user as

needed. Analog outputs are typically

sent to recording equipment such as

chart recorders. Relay outputs are typically sent to annunciators.

2. All wiring must conform to local and

national codes.

3. Connect the analog outputs and relay

outputs as shown in Figure 2-6.

Figure 2-6. CRE Power, Analog Output, and Relay Output Connections

2-10 Installation Rosemount Analytical Inc. A Division of Emerson Process Management

World Class 3000

2

Instruction Manual

IB-106-300NC Rev. 4.4

February 1998

Table 2-1. Analog Output Card Jumper

Configuration

OUTPUT

NUMBER JM1 JM2

1-4

5-8

9-12

IN

OUT

IN

IN

IN

OUT

d. Analog Output Card Jumper

Configuration

The CRE can have up to three analog output circuit boards. The jumpers on these

boards are set at the factory. Should a system ever be expanded, or in the event of

board replacement, the jumper configurations for each card are given in Table 2-1.

Refer to Figure 2-7 for the location of the

jumpers on the analog output card.

e. Relay Output Panel Jumper

Configuration

The relay output contacts can be configured

to be normally open or normally closed. This

is done by moving jumpers on the relay output card.

ANALOG OUTPUT CARD

JM1 JM2

Refer to moving jumpers on the relay output

card. Refer to Figure 2-8. The jumpers are

placed on the first two pins for normally

closed contacts and on the last two pins for

normally open contacts. Jumpers JM1 and

JM2 on the relay output card, Figure 2-9,

are installed at the factory.

f. Dual Probe Interface (DPI) Card

Configuration

A CRE may be configured with up to four

DPI cards. Refer to Table 2-2 and Figure

2-10 for DPI card jumper configurations.

Table 2-2. DPI Card Jumper Configuration

CARD

JM1 JM2

NUMBER

1

2

3

4

FOR NORMALLY

CLOSED CONTACTS

PLACE THE

JUMPER ON THE

FIRST TWO PINS.

FOR NORMALLY

OPEN CONTACTS

PLACE THE

JUMPER ON THE

LAST TWO PINS.

IN

OUT

IN

OUT

NO NC

16

15

14

13

NO NC

12

11

10

9

NO NC

8

7

6

5

NO NC

4

3

2

1

OUT

OUT

JM

18

JM

17

JM

16

JM

15

JM

14

JM

13

JM

12

JM

1

1

JM

10

JM

9

JM

8

JM

7

JM

6

JM

5

JM

4

JM

3

IN

IN

21200001

Figure 2-7. Analog Output Card Jumpers

Figure 2-8. Relay Output Panel Jumper

Configuration

Rosemount Analytical Inc. A Division of Emerson Process Management Installation 2-11

Instruction Manual

IB-106-300 NC Rev. 4.4

February 1998

JM1

JM1 JM2

JM2

Figure 2-9. Relay Output Card Jumper

Configuration

g. Optional Trim Frame and Rear Cover

The trim frame slides over the unit as shown

in Figure 2-11. The trim frame covers wall

World Class 3000

Figure 2-10. DPI Card Jumpers

cuts. The rear cover mounts to the back of

the unit with the same screws holding the

trim strips, Figure 2-11. The rear cover protects wires and terminals. The panel

mounting kit contains a trim frame and back

cover. The part number for the panel

mounting kit is 1L03636G01.

Figure 2-11. Optional Trim Frame and Rear Cover

2-12 Installation Rosemount Analytical Inc. A Division of Emerson Process Management

World Class 3000

2

Instruction Manual

IB-106-300NC Rev. 4.4

February 1998

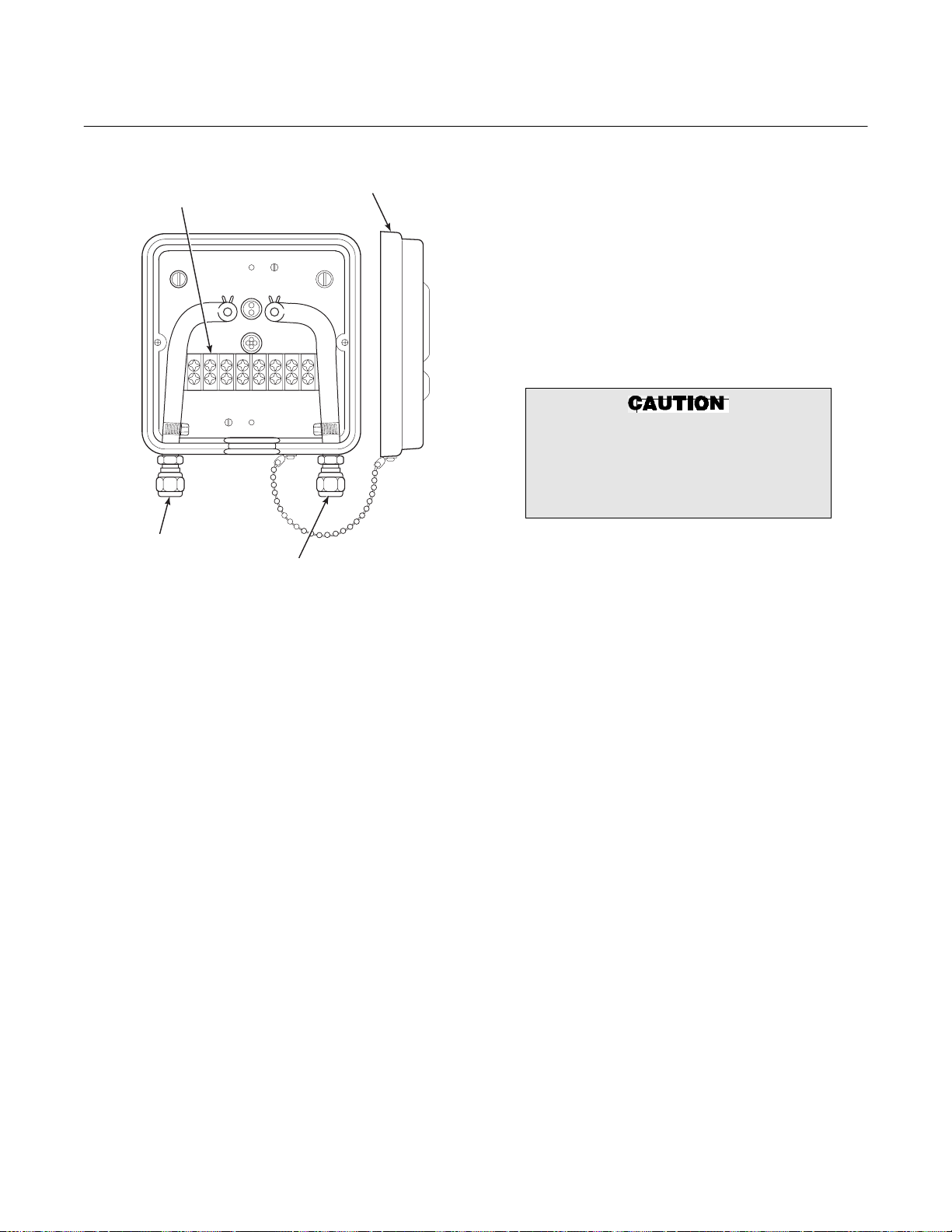

2-3 HEATER POWER SUPPLY INSTALLATION

a. Mechanical Installation

The outline drawing of the heater power

supply enclosure in Figure 2-12, shows

mounting centers and clearances. The

NEMA 4X enclosure is designed to be

mounted on a wall or bulkhead. The heater

power supply should be installed no further than 150 feet (45 m) from the probe.

The heater power supply must be located in

a location free from significant ambient temperature changes and electrical noise. Ambient temperature must be between -20° to

140°F (-30° to 60°C).

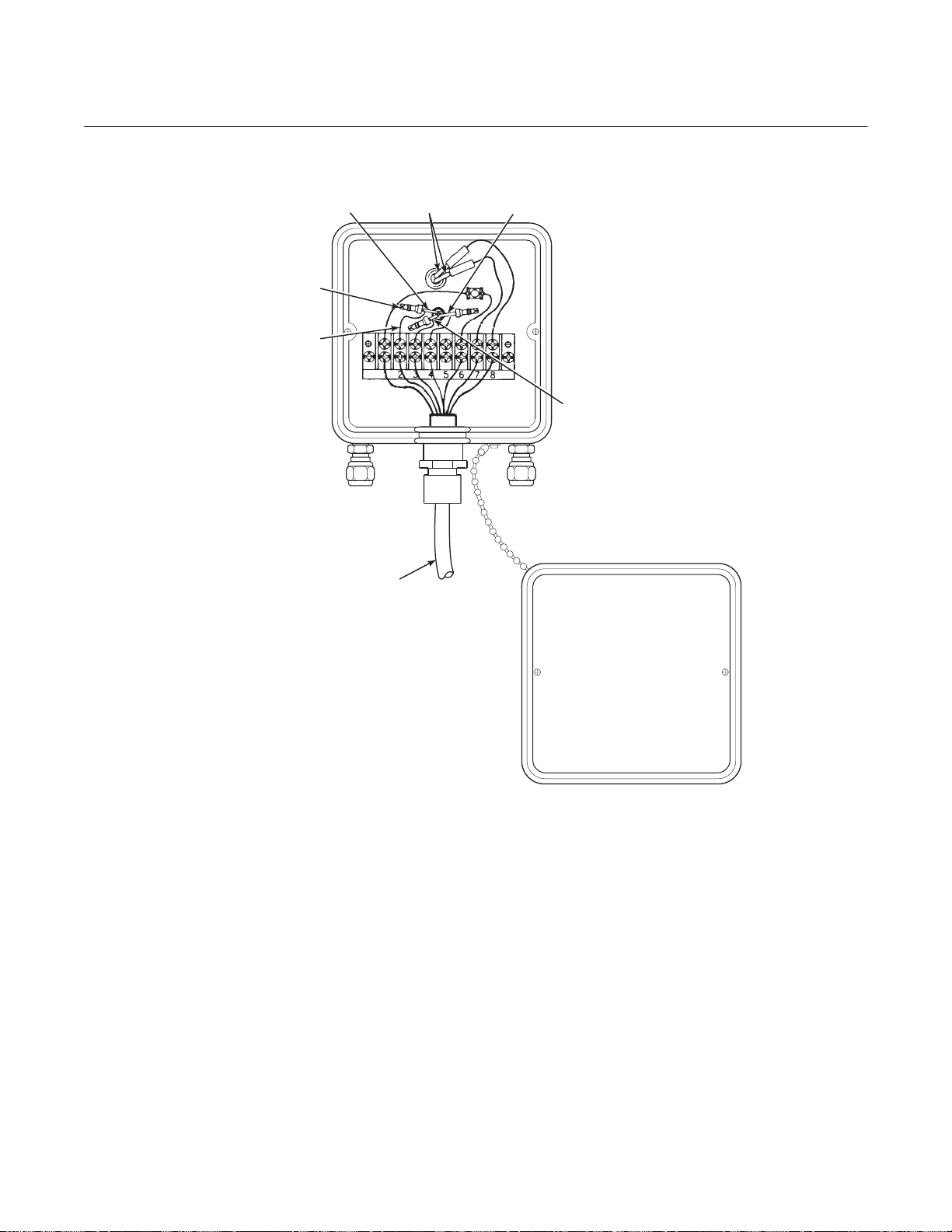

b. Electrical Connections

1. Electrical connections should be made

as described in the electrical installation diagram, Figure 2-13. The wiring

terminals are divided into two layers:

the bottom (FROM PROBE) terminals

3.25

(82.6)

NOTE: DIMENSIONS IN INCHES

7.00

(177.8)

WITH MILLIMETERS IN PARENTHESES.

3.63

(92.2)

NEMA 4X

(NON-HAZARDOUS)

should be connected first, the top

(FROM ELECTRONICS) terminals

should be connected last (Figure 2-14).

Each terminal strip has a protective

cover which must be removed when

making connections. To remove the

terminal covers, remove two slotted

screws holding cover in place. Always

reinstall terminal covers after making

connections. All wiring must conform to

local and national codes.

NOTE

Before supplying power to the heater

power supply, verify that jumpers JM3

and JM6 are removed, and JM7 is installed. JM2 is installed, if relay is not

wired.

NOTE

Refer to Figure 2-16 for HPS unit fuse

locations and specifications.

10.39

(264)

8.50

(215.9)

6.18

(156.9)

0.56 (14)

DIA (2)

MOUNTING

HOLES

686029

4.00

(101.6)

(215.9)

8.50

0.31

(7.9)

#0.31

6.00

(152.4)

(124)

6.75

(171.5)

0.13" (3.3) THK U. L. APPROVED

GASKET

1.81

(46)

4.88

(203.2)

#10-32 UNF 2A

THREADED INSERT

(0.31 x 0.31 FROM CORNER OF PLATE)

8.00

11.00

(279.4)

4.38

(111.3)

9.96

(253)

0.38

(9.7)

1.00 (25.4) MINIMUM CLEARANCE

4.72

(120)

CLASS 1, DIVISION 1, GROUP B ENCLOSURE

FOR REMOVING COVER

9.17

(233)

Figure 2-12. Outline of Heater Power Supply

Rosemount Analytical Inc. A Division of Emerson Process Management Installation 2-13

Instruction Manual

IB-106-300 NC Rev. 4.4

February 1998

World Class 3000

Figure 2-13. Electrical Installation of Heater Power Supply

2-14 Installation Rosemount Analytical Inc. A Division of Emerson Process Management

World Class 3000

2

TRANSFORMER

Instruction Manual

IB-106-300NC Rev. 4.4

February 1998

TERMINAL

COVERS

FRONT

TERMINAL STRIP

(FROM ELECTRONICS)

TRANSFORMER

TERMINAL STRIP

(FROM PROBE)

SIDE

Figure 2-14. Heater Power Supply Wiring Connections

29850005

Rosemount Analytical Inc. A Division of Emerson Process Management Installation 2-15

Instruction Manual

IB-106-300 NC Rev. 4.4

February 1998

World Class 3000

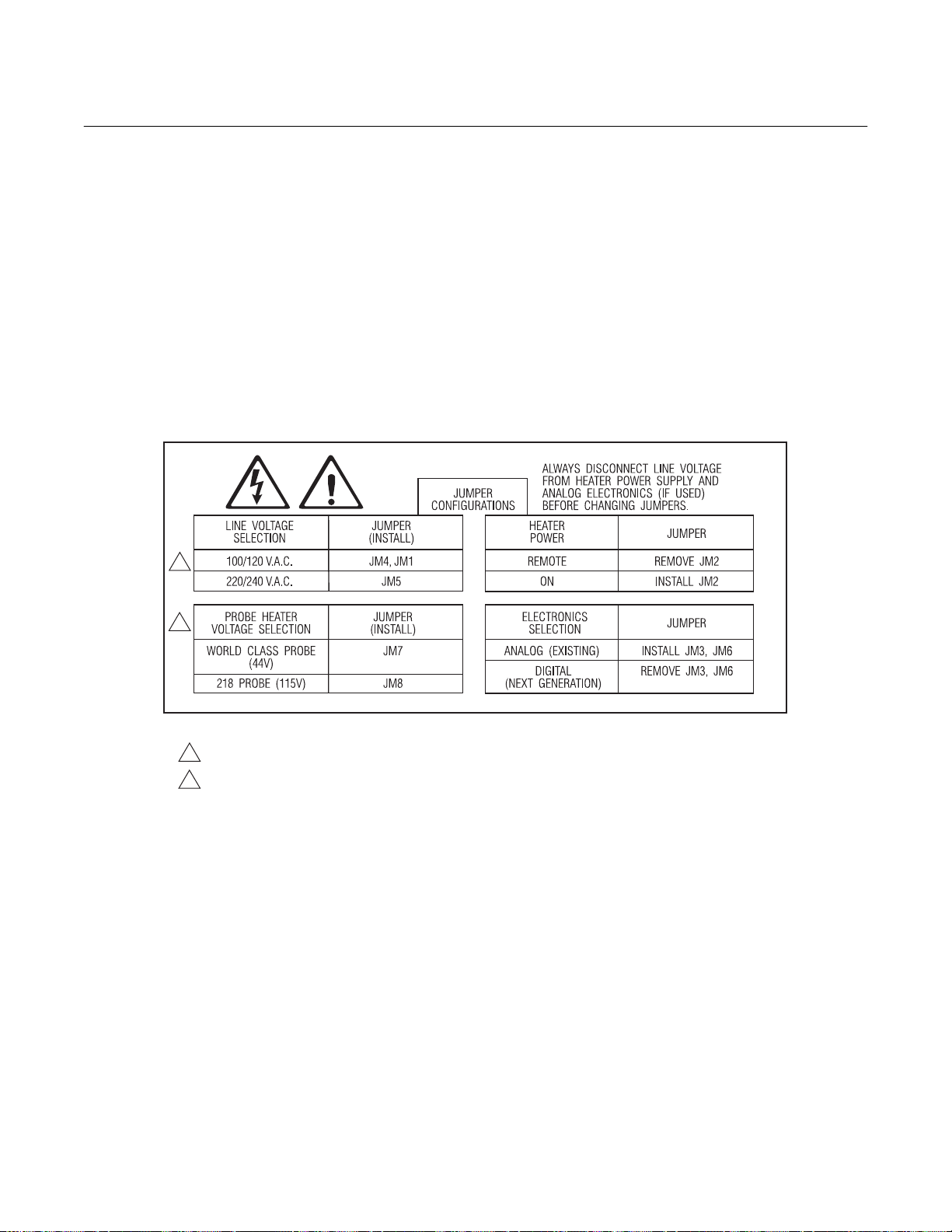

2. Power Input: 120, 220 or 240 Vac. For

120 Vac usage, install jumpers JM4

and JM1. For 220 or 240 Vac usage,

install jumper JM5 (see label, Figure 2-

15).

NOTE

For 100 Vac usage, the heater power

supply is factory-supplied with a different transformer. When using the

HPS with 100 Vac transformer, install

jumpers JM1 and JM4.

1

3. The power cable should comply with

safety regulations in the user's country

and should not be smaller than 16

gauge, 3 amp.

4. Before supplying power to the heater

power supply, verify that the jumpers

on the mother board, Figure 2-16, are

properly configured. Jumpers JM3 and

JM6 should be removed, and JM7

should be installed. Additionally, make

sure that the proper jumper for your

line voltage is installed, Figure 2-15.

JM2 is installed if relay is not wired.

2

NOTES:

100 V.A.C. OPERATION REQUIRES TRANSFORMER PART NUMBER 1M02961G02.

1

REFER TO TABLE 3-6 FOR PROPER SET POINT SELECTION.

2

Figure 2-15. Jumper Selection Label

2-16 Installation Rosemount Analytical Inc. A Division of Emerson Process Management

World Class 3000

2

JM1

Instruction Manual

IB-106-300NC Rev. 4.4

February 1998

JM2

JM4

JM7

Figure 2-16. Jumpers on HPS Mother Board

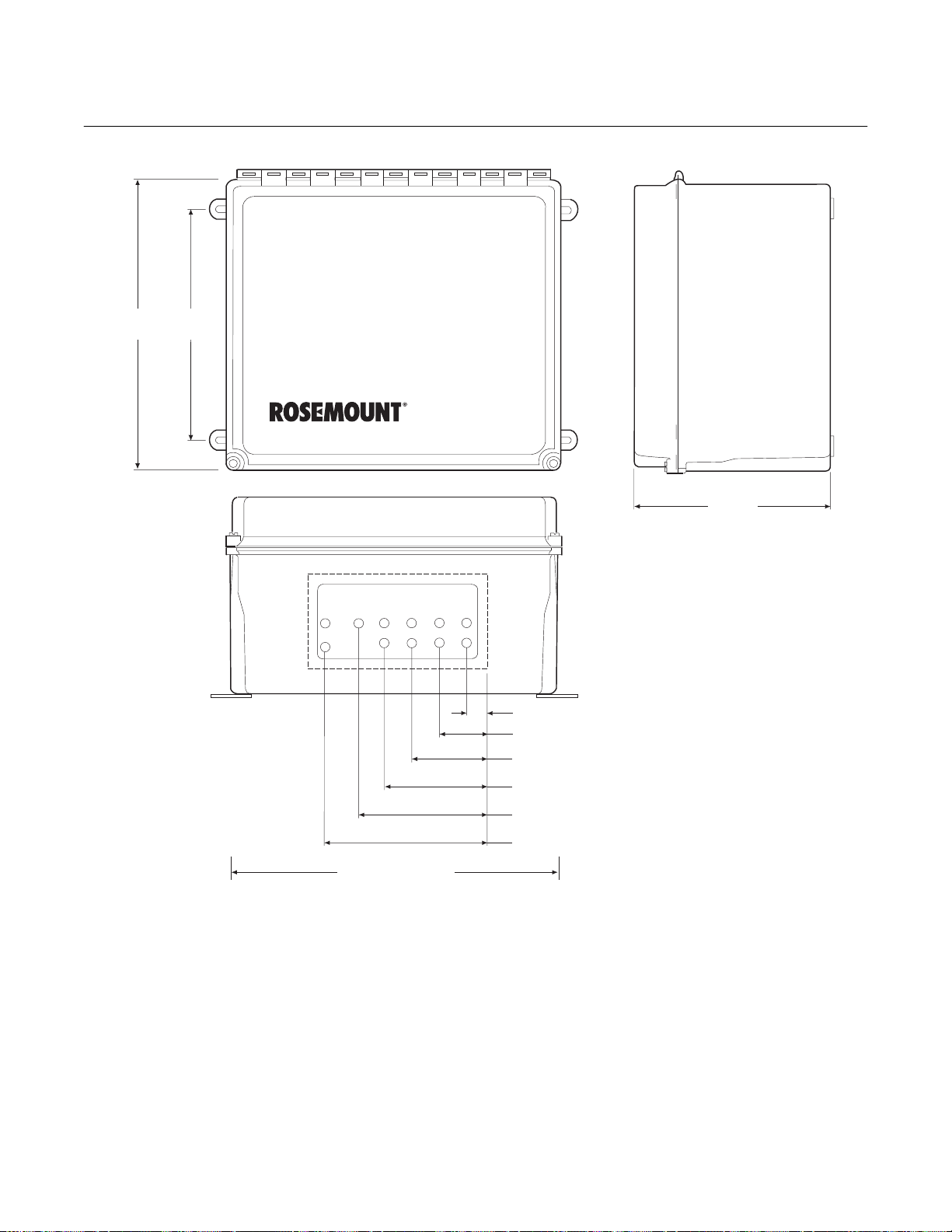

2-4 MULTIPROBE TEST GAS SEQUENCER

INSTALLATION

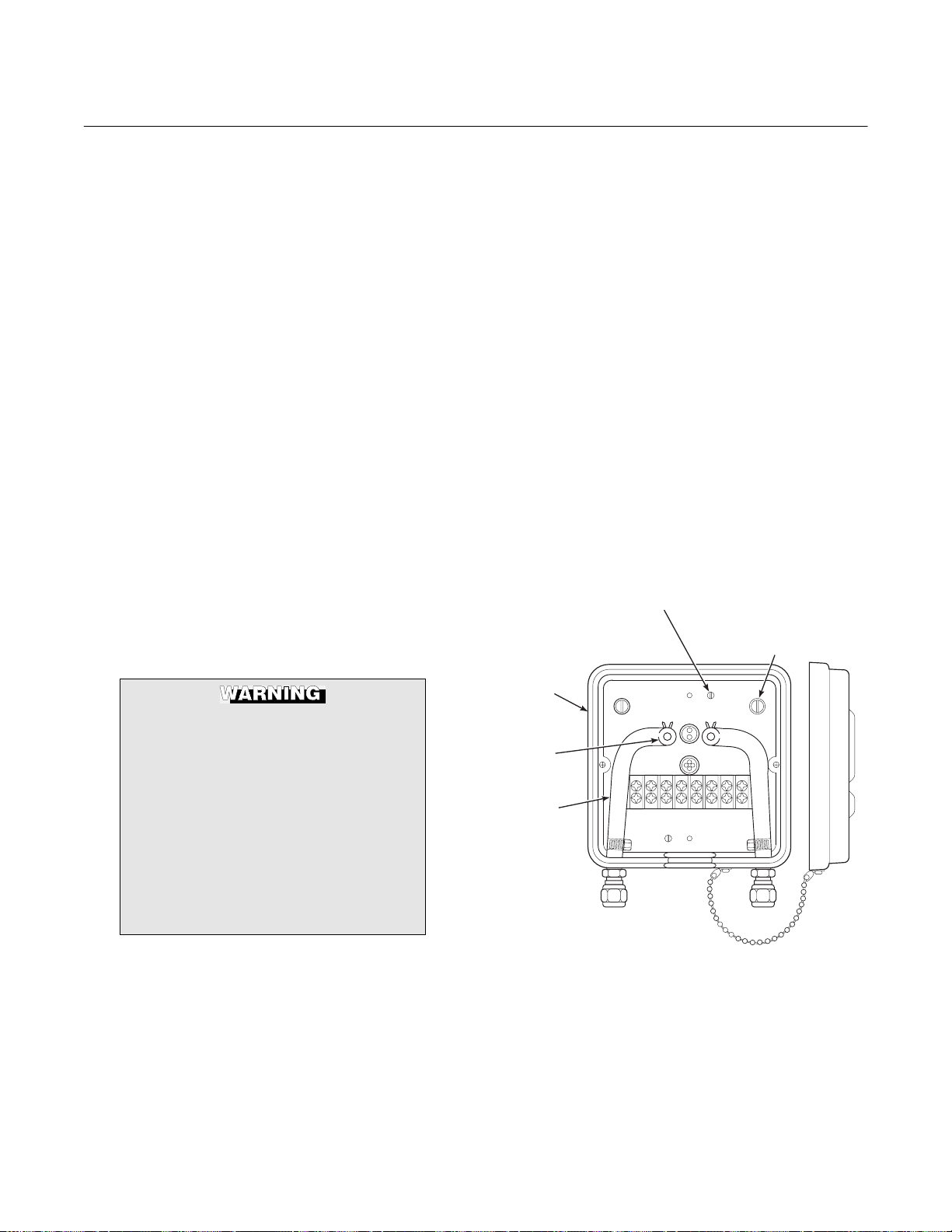

a. Mechanical Installation

The outline drawing of the MPS module in

Figure 2-17 shows mounting centers and

clearances. The box is designed to be

mounted on a wall or bulkhead. The MPS

module should be installed no further than

300 feet (91 m) piping distance from the

probe, and no more than 1000 feet (303 m)

cabling distance from the CRE. Install the

MPS module in a location where the ambient temperature is between -20° to 160°F

(-30° to 71°C).

b. Gas Connections

3D3 080G REV

JM5

JM8

JM3

JM6

2. Connect the high O

test gas to HIGH

2

GAS. The test gas pressure should be

set at 20 psi (138 kPa).

3. Connect the low O

test gas to LOW

2

GAS. The test gas pressure should be

set at 20 psi (138 kPa).

4. Connect the REF AIR OUT to the reference gas fitting on the probe junction

box.

5. Connect the TEST GAS OUT to the

calibration gas fitting on the probe

junction box. Use optional check valve

if required.

Figure 2-18 shows the bottom of the MPS

where the gas connections are made. 1/4

inch threaded fittings are used.

1. Connect the reference air supply to

INSTR. AIR IN. The air pressure regulator valve is set at the factory to 20 psi

A check valve is required for each

probe connected to an MPS to prevent

condensation of flue gas in the calibration gas lines. The check valve must

be located between the calibration fitting and the gas line.

(138 kPa). If the reference air pressure

should need readjustment, turn the

knob on the top of the valve until the

desired pressure is obtained.

Rosemount Analytical Inc. A Division of Emerson Process Management Installation 2-17

6. If the MPS is configured for multiple

probes (up to four), repeat steps 4 and

5 for each additional probe.

Instruction Manual

IB-106-300 NC Rev. 4.4

February 1998

World Class 3000

12.00

(304,80)

10.00

(254,00)

HIGH CAL

GAS IN

PROBE 1 PROBE 2 PROBE 3 PROBE4

LOW CAL

TEST GAS

GAS IN

REF AIR

INSTR

AIR

12.00

(304,80)

NOTE: DIMENSIONS ARE IN INCHES

WITH MILLIMETERS IN

TEST GAS

TEST GAS

REF AIR

TEST GAS

OUT

OUT

REF AIR

OUT

OUT

OUT

OUT

REF AIR

OUT

OUT

PARENTHESES.

0.84 (21,34)

1.96 (49,78)

3.09 (78,49)

4.21 (106,93)

5.25 (133,35)

5.54 (140,72)

14.00 (355,60) REF

Figure 2-17. MPS Module

2-18 Installation Rosemount Analytical Inc. A Division of Emerson Process Management

World Class 3000

2

DRAIN

PROBE 1 PROBE 2 PROBE 3 PROBE4

HIGH CAL

LOW CAL

TEST GAS

TEST GAS

TEST GAS

GAS IN

INSTR

GAS IN

OUT

OUT

REF AIR

REF AIR

OUT

OUT

AIR

OUT

REF AIR

OUT

TEST GAS

OUT

REF AIR

OUT

Figure 2-18. MPS Gas Connections

Instruction Manual

IB-106-300NC Rev. 4.4

February 1998

LINE IN

SIGNAL IN

c. Electrical Connections

1. Electrical connections should be made

as described in the electrical installation diagram, Figure 2-19. All wiring

must conform to local and national

codes.

NOTE

Refer to Figure 2-19 for MPS unit fuse

locations and specifications.

2. Run the line voltage through the bulkhead fitting on the bottom of the MPS

where marked LINE IN, Figure 2-18.

Connect the line voltage as shown in

Figure 2-19 to J10 LINE IN terminal on

the MPS terminal board located inside

the unit. Tighten the cord grips to provide strain relief.

3. The MPS can accommodate up to four

probes. The terminal strips on the MPS

termination board are marked PROBE

1, PROBE 2, PROBE 3, and PROBE 4.

Connect wires from these terminal

strips to the third terminal strip on a

Dual Probe Interface (DPI) on the back

of the CRE. One DPI can accommodate two probe connections.

NOTE

Only one HIGAS, LOGAS, CALRET,

and NOGAS connection are needed

per MPS unit. The HIGAS, LOGAS,

CALRET, and NOGAS connection for

probe 1 will be sufficient to work for all

the probes connected to the MPS.

4. Make the connections from the MPS to

the CRE as shown in Figure 2-19. Run

wires from the MPS Termination Board

inside the unit through the bulkhead fitting on the bottom of the unit where

marked SIGNAL IN, Figure 2-18. After

the connections are made, tighten the

cord grips to provide strain relief.

5. If more than four probes are being

used, a second MPS would be required. For installations of five to eight

probes, refer to paragraph 2-5.

6. A maximum of eight MPS units may be

connected to one CRE unit, one MPS

per probe. This may be necessary if

the system has probes spread out over

a great area. In this case, all wire connections must be made for each MPSprobe system.

Rosemount Analytical Inc. A Division of Emerson Process Management Installation 2-19

Instruction Manual

IB-106-300 NC Rev. 4.4

February 1998

World Class 3000

Figure 2-19. Typical CRE to MPS Connections

2-20 Installation Rosemount Analytical Inc. A Division of Emerson Process Management

World Class 3000

2

Instruction Manual

IB-106-300NC Rev. 4.4

February 1998

2-5 INSTALLATION WITH TWO MULTIPROBE

TEST GAS SEQUENCERS

When installing more than four probes, a second MPS unit is required. An installation of five

or six probes requires that the first three probes

are connected to the first MPS, the remainder

are connected to the second MPS. On an installation of seven or eight probes, the first four

are connected to the first MPS, the remainder

are connected to the second MPS. Refer to

paragraph 2-5a for five or six probe hookup, and

paragraph 2-5b for seven or eight probe

hookup.

a. Five or Six Probe Installation.

(Figure 2-20)

1. Connect probes 1 and 2 to CRE DPI

panel 1, probes 3 and 4 to DPI panel 2,

and probes 5 and 6 to DPI panel 3.

Table 2-3. Typical CRE SETUP Data for 5 or 6 Probe Configuration

SETUP - PROBE Sub-menu

refer to Table 3-4

Probe 1 Probe 2 Probe 3 Probe 4 Probe 5 Probe 6

2. Connect DPI panel 1 to MPS number

1, probes 1 and 2, terminal blocks.

3. Connect DPI panel 2, probe 3 connection, to MPS number 1, probe 3 terminal block.

4. Connect DPI panel 2, probe 4 connection, to MPS number 2, probe 1 terminal block.

5. Connect DPI panel 3 to MPS number

2, probes 2 and 3, terminal blocks.

6. When entering the operator set variables, as listed in Table 3-6, SETUP

Sub-menu, enter the parameters for

DPI number, UNIT number, MPS number, and CONTROLLED BY PRB

number as indicated in Table 2-3.

Parameter Selection for

CONFIGURE PROBES

PROBE____

INTERFACE

Interface Type

DPI Number

Unit Number

CALIBRATION

MPS Number

CONFIGURE MPS

MPS____

Control by PRB

DPI

1

1

1

1

DPI

1

2

1

1

DPI

2

1

1

1

DPI

2

2

2

4

DPI

3

1

2

4

DPI

3

2

2

4

Rosemount Analytical Inc. A Division of Emerson Process Management Installation 2-21

Instruction Manual

IB-106-300 NC Rev. 4.4

February 1998

World Class 3000