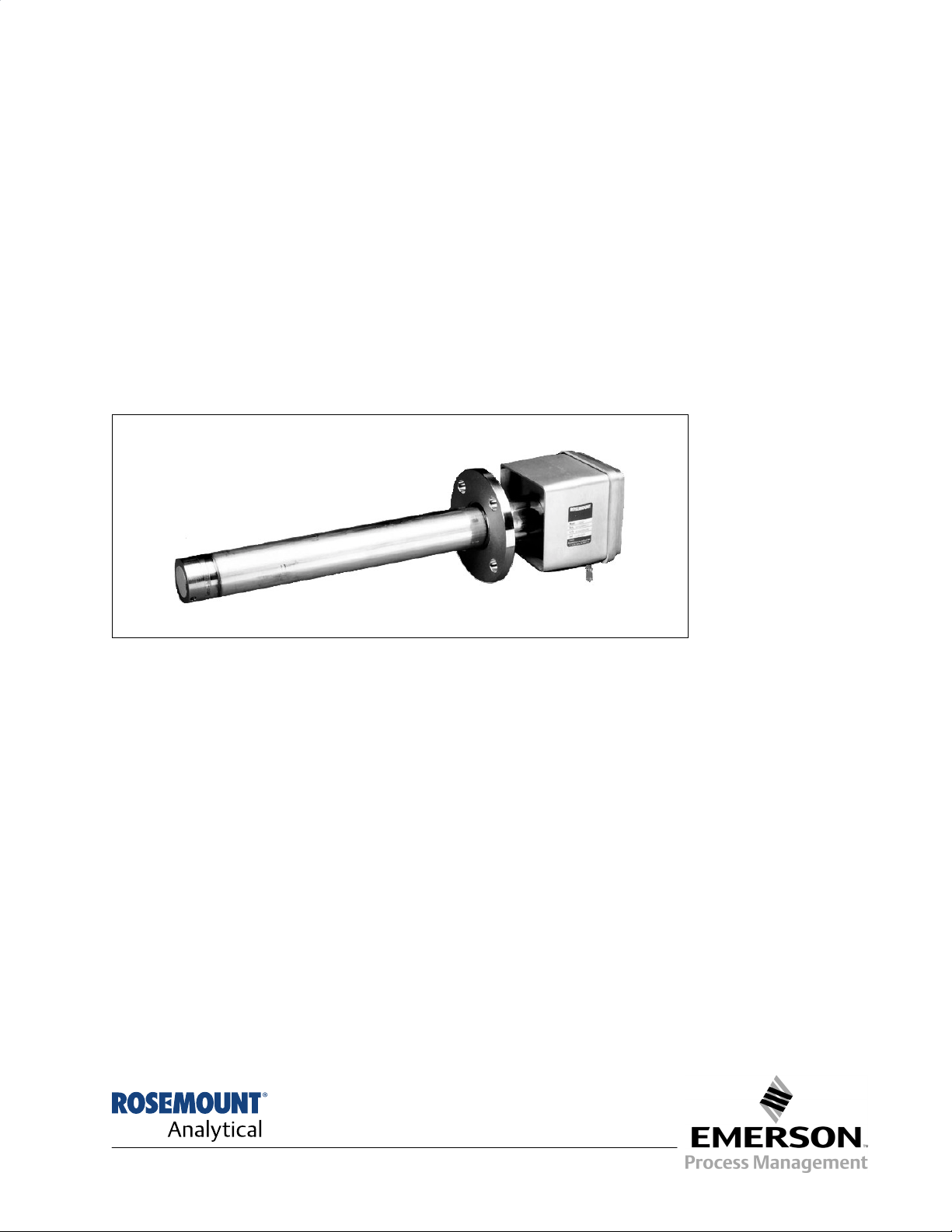

Rosemount World Class 3000 O2 Analyzer DR Direct Replacement Probe-Rev 3.3 Manuals & Guides

Instruction Manual

IB-106-300DR Rev. 3.3

February 2000

World Class 3000

Oxygen Analyzer Direct

Replacement Probe for

use with Existing Signal

Conditioning Electronics

http://www.processanalytic.com

ESSENTIAL INSTRUCTIONS

READ THIS PAGE BEFORE PROCEEDING!

Rosemount Analytical designs, manufactures and tests its products to meet many national and

international standards. Because these instruments are sophisticated technical products, you

MUST properly install, use, and maintain them to ensure they continue to operate within their

normal specifications. The following instructions MUST be adhered to and integrated into your

safety program when installing, using, and maintaining Rosemount Analytical products. Failure to

follow the proper instructions may cause any one of the following situations to occur: Loss of life;

personal injury; property damage; damage to this instrument; and warranty invalidation.

• Read all instructions prior to installing, operating, and servicing the product.

• If you do not understand any of the instructions, contact your Rosemount Analytical repre-

sentative for clarification.

• Follow all warnings, cautions, and instructions marked on and supplied with the product.

• Inform and educate your personnel in the proper installation, operation, and mainte-

nance of the product.

• Install your equipment as specified in the Installation Instructions of the appropriate In-

struction Manual and per applicable local and national codes. Connect all products to the

proper electrical and pressure sources.

• To ensure proper performance, use qualified personnel to install, operate, update, program,

and maintain the product.

• When replacement parts are required, ensure that qualified people use replacement parts

specified by Rosemount. Unauthorized parts and procedures can affect the product’s performance, place the safe operation of your process at risk, and VOID YOUR WARRANTY.

Look-alike substitutions may result in fire, electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers are in place, except

when maintenance is being performed by qualified persons, to prevent electrical shock

and personal injury.

The information contained in this document is subject to change without notice.

Emerson Process Management

Rosemount Analytical Inc.

Process Analytic Division

1201 N. Main St.

Orrville, OH 44667-0901

T (330) 682-9010

F (330) 684-4434

e-mail: gas.csc@EmersonProcess.com

http://www.processanalytic.com

HIGHLIGHTS OF CHANGES

Effective June, 1996 Rev. 3

Page Summary

--- General. Updated text and illustrations to reflect probe design

changes.

Page 1-15 Added “Extended temperature by-pass arrangements” to Figure 1-15,

sheet 3 of 3.

Effective December, 1996 Rev. 3.1

Page Summary

Page P-2 Added "Safety instructions for the wiring and installation of this

apparatus".

Page 1-4 Corrected Figure 1-3 item listing.

Page 2-1 Added one WARNING to read new safety instructions and another

WARNING regarding protective covers and grounds.

Page 3-1 Added WARNING regarding protective covers and grounds.

Page 4-1 Added WARNING regarding protective covers and grounds.

Page 4-6 Added title block to Figure 4-6.

Page 5-1 Added WARNING regarding protective covers and grounds.

Page 7-1 Corrected cell replacement kit part numbers in Table 7-1.

Page 7-2 Corrected cell replacement kit part number in Table 7-1.

Effective May, 1997 Rev. 3.2

Page Summary

Page P-2 Added safety sheet.

Effective February, 1998 Rev. 3.3

Page Summary

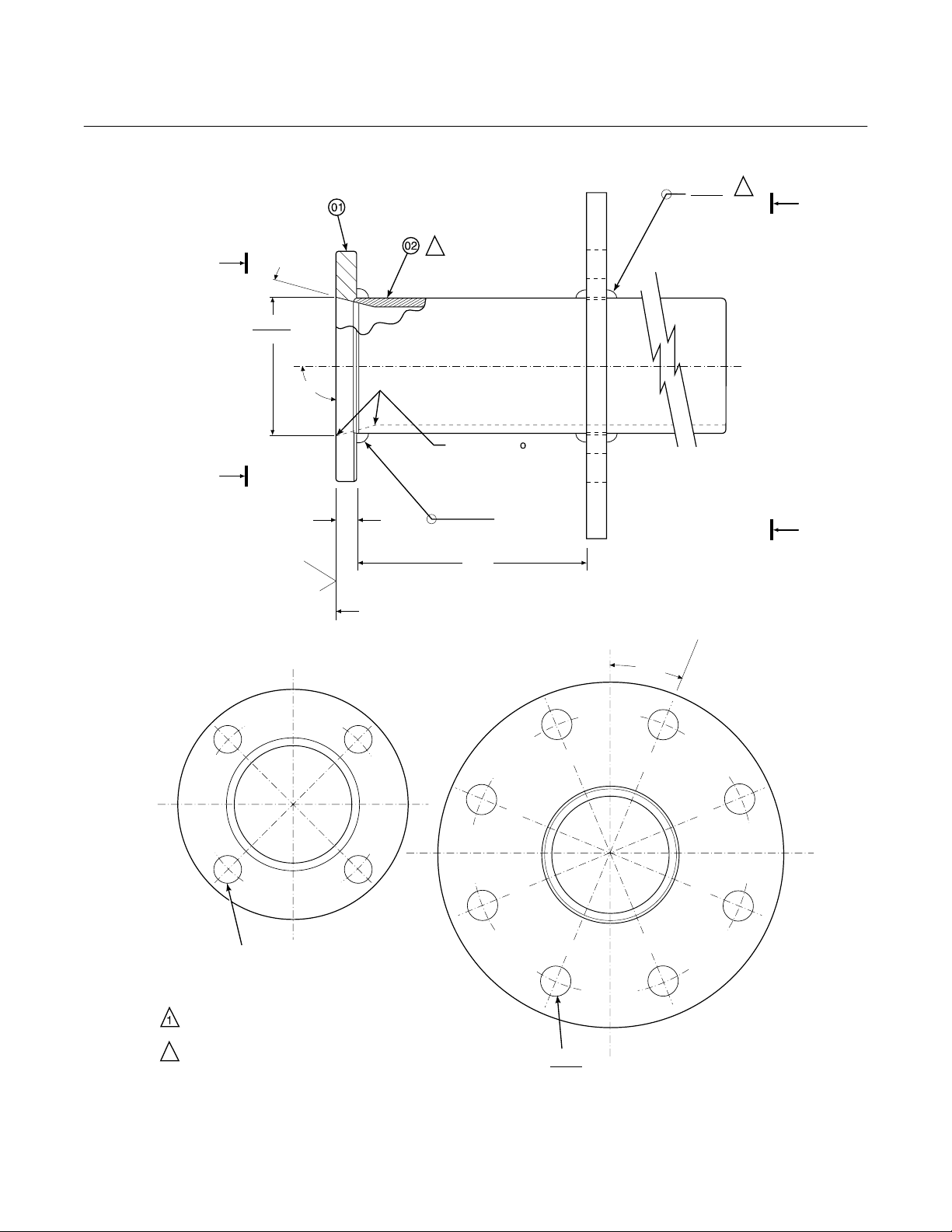

Page 2-2 Figure 2-1. Changed calibration gas tube dimensions.

World Class 3000

PREFACE.........................................................................................................................P1

Definitions ......................................................................................................................... P1

Safety Instructions ........................................................................................................... P2

1-0 DESCRIPTION AND SPECIFICATIONS........................................................................ 1-1

1-1 Component Checklist ..................................................................................................... 1-1

1-2 System Overview............................................................................................................ 1-1

1-3 Physical Description ....................................................................................................... 1-3

1-4 Probe Exterior................................................................................................................. 1-5

1-5 Probe Interior .................................................................................................................. 1-7

1-6 Junction Box .................................................................................................................... 1-8

1-7 Cable Assembly...............................................................................................................1-9

1-8 Probe Options................................................................................................................. 1-9

2-0 INSTALLATION .............................................................................................................. 2-1

2-1 Locating The Oxygen Analyzer Probe.......................................................................... 2-1

2-2 Service Required .............................................................................................................2-1

2-3 Mechanical Installation ................................................................................................... 2-6

2-4 Electrical Installation ........................................................................................................ 2-7

Instruction Manual

IB-106-300DR Rev. 3.3

February 2000

TABLE OF CONTENTS

3-0 STARTUP........................................................................................................................ 3-1

3-1 Overview.......................................................................................................................... 3-1

3-2 Models 218, 225, And 132 (Analog) Electronics Setup............................................. 3-1

3-3 Model 218A Electronics Setup ..................................................................................... 3-2

3-4 Model TC200 Veritrim Electronics Setup ..................................................................... 3-3

3-5 Model 132 Digital Electronics Setup............................................................................ 3-4

3-6 The Yokogawa ZA8C And AV8C Converter Electronics Setup ................................ 3-4

4-0 MAINTENANCE AND SERVICE .................................................................................. 4-1

4-1 Overview.......................................................................................................................... 4-1

4-2 Probe Calibration ............................................................................................................. 4-1

4-3 Cell Replacement ........................................................................................................... 4-1

4-4 Optional Ceramic Diffusion Element Replacement ..................................................... 4-3

4-5 Replacement Of Contact And Thermocouple Assembly ............................................. 4-5

4-6 Replacement Of Heater, V-Strut And Backplate Assembly ..................................... 4-7

4-7 Calibration And Reference Gas Lines For High Temperature -

Corrosive Environment Operation ................................................................................... 4-9

5-0 TROUBLESHOOTING .................................................................................................... 5-1

5-1 Overview.......................................................................................................................... 5-1

5-2 Probe Troubleshooting ................................................................................................... 5-1

6-0 RETURN OF MATERIAL .............................................................................................. 6-1

7-0 REPLACEMENT PARTS ................................................................................................ 7-1

8-0 INDEX.............................................................................................................................. 8-1

Rosemount Analytical Inc. A Division of Emerson Process Management i

Instruction Manual

IB-106-300DR Rev. 3.3

February 2000

Figure 1-1. Typical System Package ....................................................................................... 1-1

Figure 1-2. Typical System Installation .................................................................................... 1-3

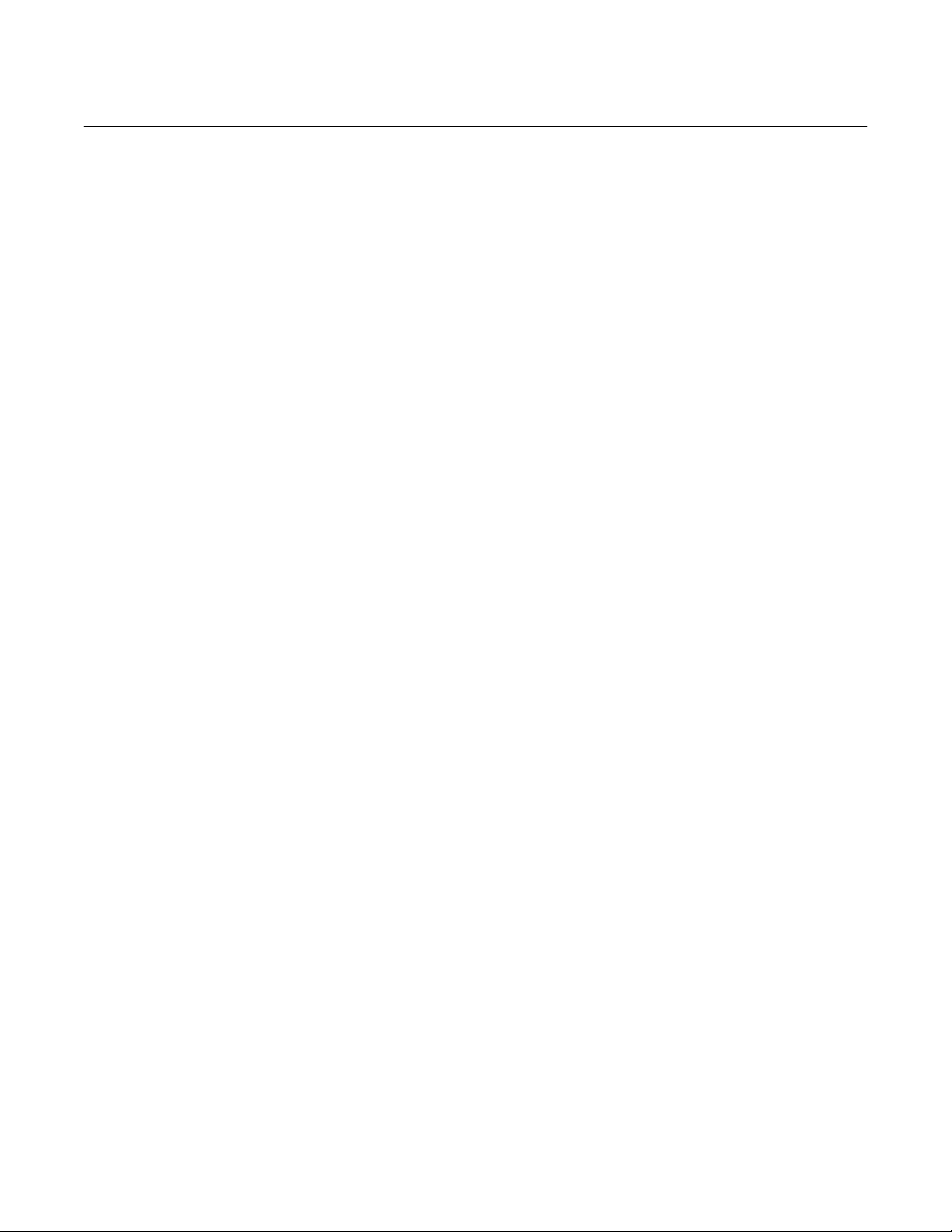

Figure 1-3. Oxygen Analyzer Probe - Exploded View.............................................................. 1-4

Figure 1-4. Main Probe Components ....................................................................................... 1-5

Figure 1-5. Cell and Tube Assemblies ..................................................................................... 1-5

Figure 1-6. Optional Ceramic Diffusor and Vee Deflector Assembly....................................... 1-7

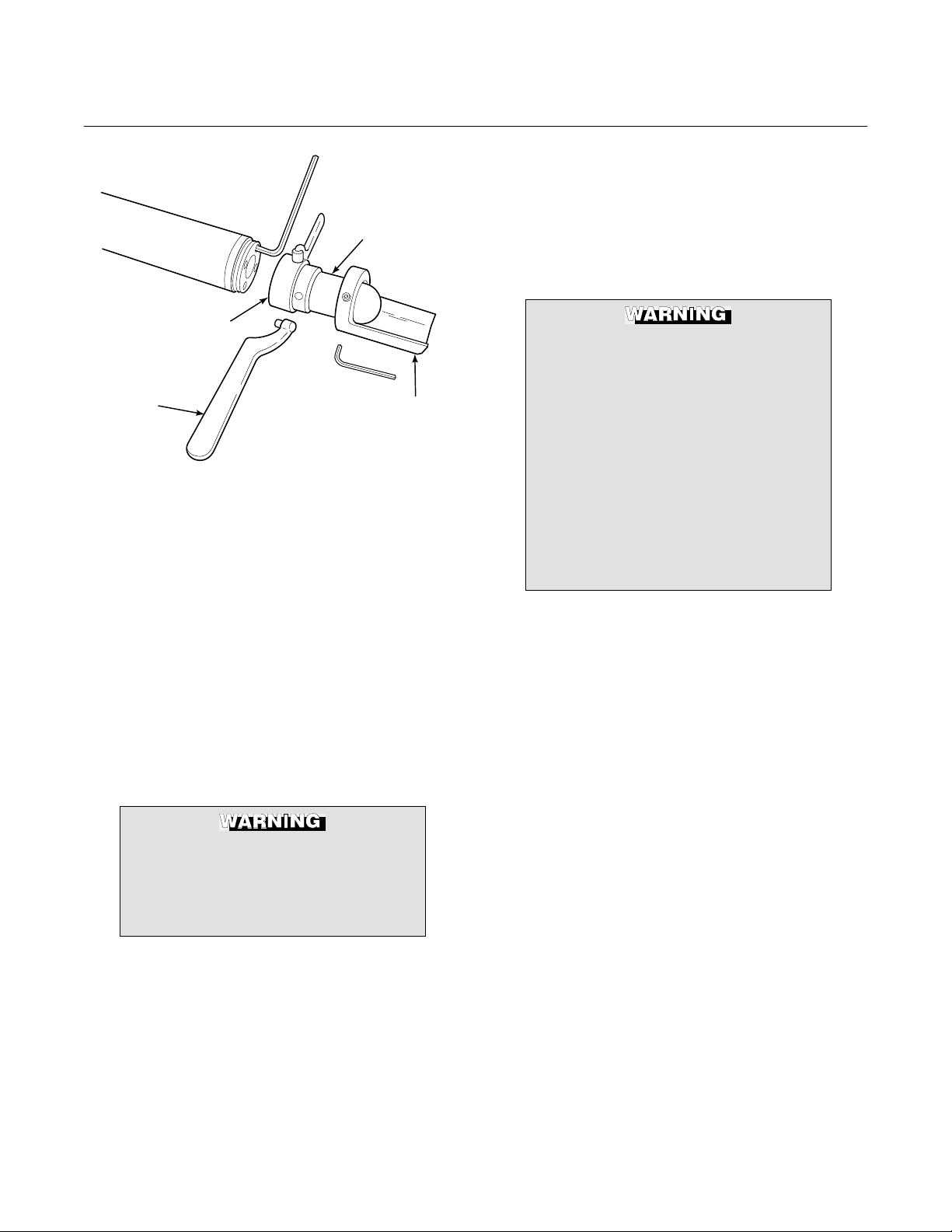

Figure 1-7. Inner Probe Assembly............................................................................................ 1-8

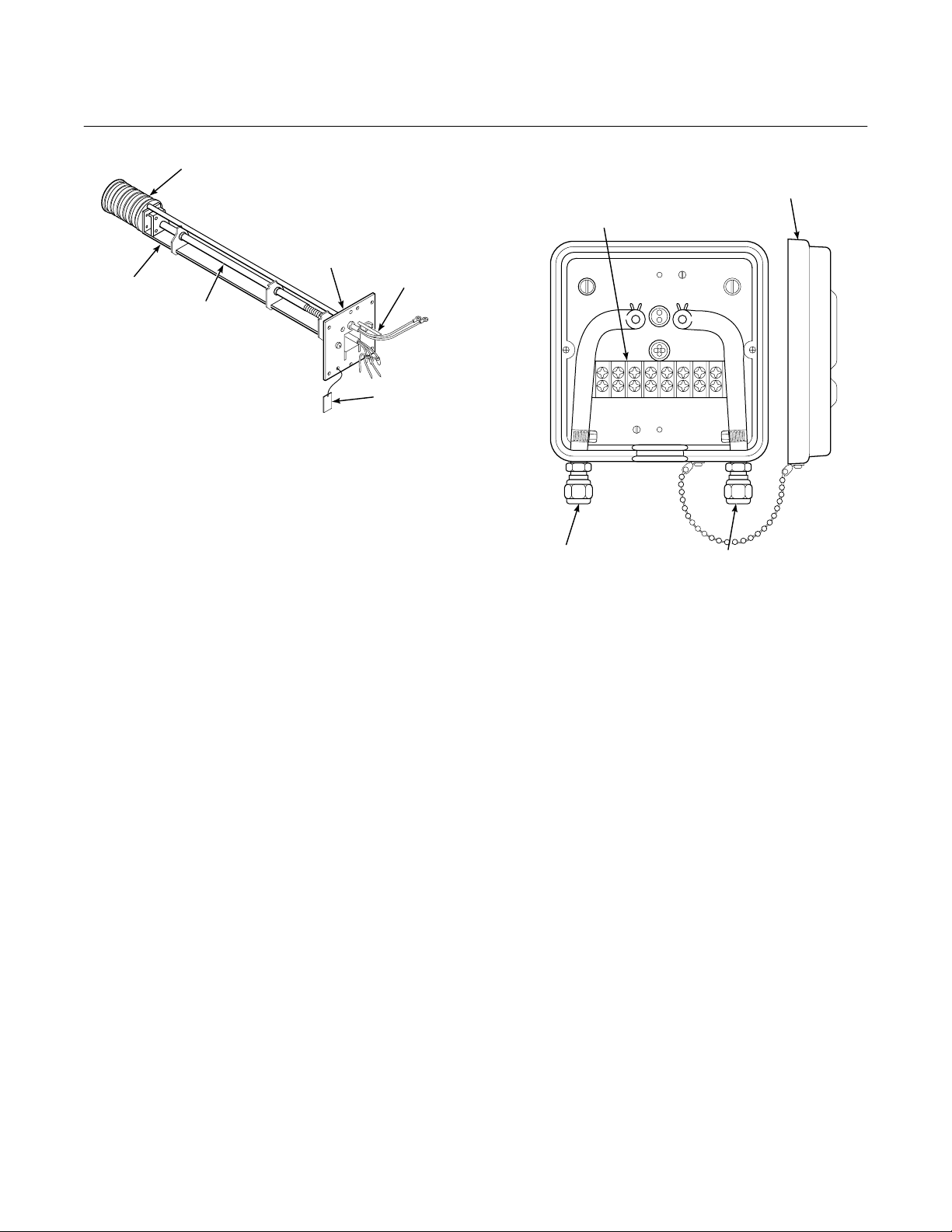

Figure 1-8. Junction Box .......................................................................................................... 1-8

Figure 1-9. Abrasive Shield Assembly ................................................................................... 1-10

Figure 1-10. Ceramic Diffusion/Dust Seal Assembly ............................................................... 1-11

Figure 1-11. Flame Arrestor Diffusion/Dust Seal Assembly..................................................... 1-11

Figure 1-12. Ceramic Diffusion Assembly................................................................................ 1-11

Figure 1-13. Flame Arrestor Diffusion Assembly ..................................................................... 1-11

Figure 1-14. Snubber Diffusion/Dust Seal Assembly............................................................... 1-12

Figure 1-15. Bypass Probe Option (Sheet 1 of 3) .................................................................... 1-13

Figure 2-1. Probe Installation (Sheet 1 of 5) ............................................................................ 2-2

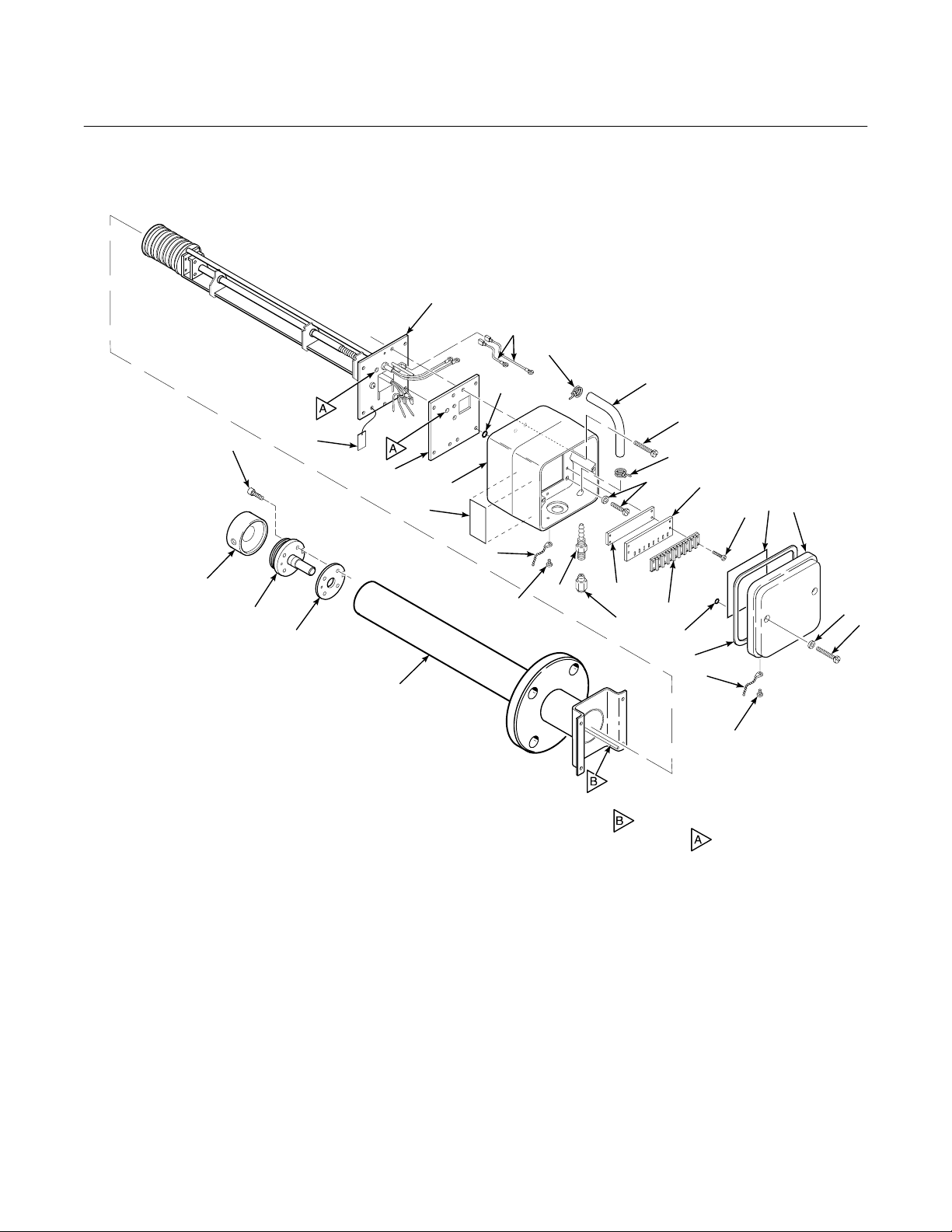

Figure 2-2. Orienting the Optional Vee Deflector ..................................................................... 2-7

Figure 2-3. Wiring the Direct Replacement Probe ................................................................... 2-8

Figure 3-1. Temperature Controller Card Calibration Points ................................................... 3-1

Figure 3-2. Main PCB (Model 218A) EPROM Replacement ................................................... 3-2

Figure 3-3. Main PCB (Model TC200) EPROM Replacement ................................................. 3-3

Figure 3-4. Main PCB (Model 132) EPROM Replacement...................................................... 3-4

Figure 3-5. DR Probe Wired to the ZA8C or A V8C Converter ................................................ 3-5

Figure 4-1. Cell Wiring Connection .......................................................................................... 4-2

Figure 4-2. Removal of Optional Ceramic Diffusor and Vee Deflector .................................... 4-3

Figure 4-3. Cell Replacement Kit ............................................................................................. 4-3

Figure 4-4. Junction Box Mechanical Connections.................................................................. 4-5

Figure 4-5. Inner Probe Replacement (Heater, V-Strut, and Backplate Assembly)................ 4-6

Figure 4-6. Heater, Strut, and Backplate Assembly (Inner Probe Assembly).......................... 4-6

Figure 4-7. Oxygen Analyzer Probe, Cross-Sectional View .................................................... 4-8

Figure 4-8. High Temperature – Corrosive Environment Kit .................................................... 4-9

World Class 3000

LIST OF ILLUSTRATIONS

LIST OF TABLES

Table 1-1. Specifications for Oxygen Analyzing Equipment

Table 5-1. Fault Finding .......................................................................................................... 5-2

Table 7-1. Replacement Parts for Probe ................................................................................ 7-1

ii Rosemount Analytical Inc. A Division of Emerson Process Management

1 2

............................................... 1-6

World Class 3000

The World Class 3000 Direct Replacement Probe can be used with any of the following

model electronics: 218, 225, 218A, ZA8C, and TC200. Read the appropriate setpoint adjustment in this manual to prevent damage to the probe.

The purpose of this manual is to provide information concerning the components, functions, installation and maintenance of this particular probe.

Some sections may describe equipment not used in your configuration. The user should

become thoroughly familiar with the operation of this module before operating it. Read

this instruction manual completely.

The following definitions apply to WARNINGS, CAUTIONS, and NOTES found throughout this

publication.

Instruction Manual

IB-106-300DR Rev. 3.3

February 2000

CAUTION

!

PREFACE

DEFINITIONS

Highlights an operation or maintenance

procedure, practice, condition, statement, etc. If not strictly observed, could

result in injury, death, or long-term

health hazards of personnel.

NOTE

Highlights an essential operating procedure,

condition, or statement.

: EARTH (GROUND) TERMINAL

: PROTECTIVE CONDUCTOR TERMINAL

: RISK OF ELECTRICAL SHOCK

: WARNING: REFER TO INSTRUCTION BULLETIN

Highlights an operation or maintenance

procedure, practice, condition, statement, etc. If not strictly observed, could

result in damage to or destruction of

equipment, or loss of effectiveness.

NOTE TO USERS

The number in the lower right corner of each illustration in this publication is a manual illustration number. It is not a part number, and is not related to the illustration in any technical

manner.

Rosemount Analytical Inc. A Division of Emerson Process Management P-1

Instruction Manual

IB-106-300DR Rev. 3.3

February 2000

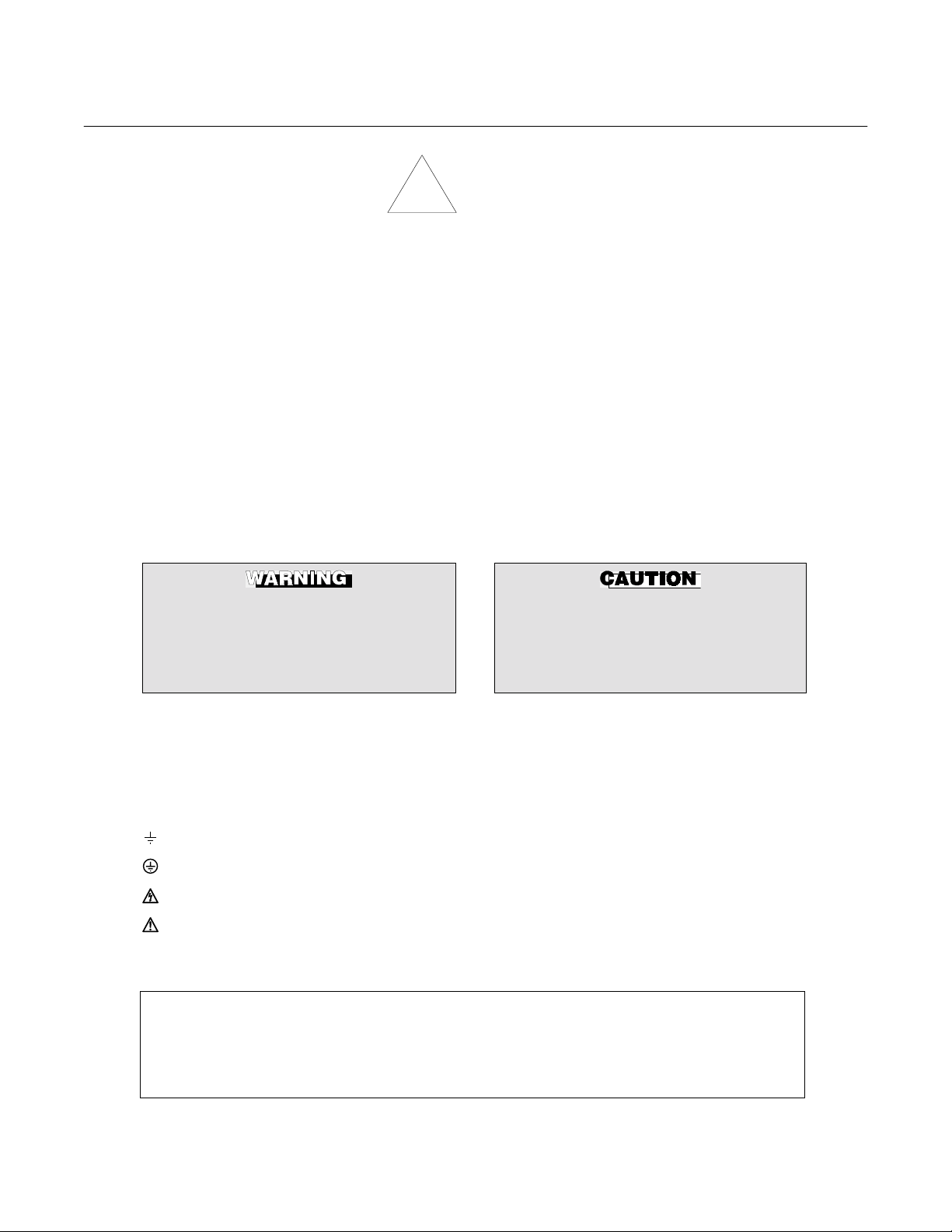

FOR THE WIRING AND INSTALLATION

The following safety instructions apply specifically to all EU member states. They should

be strictly adhered to in order to assure compliance with the Low Voltage Directive. NonEU states should also comply with the following unless superseded by local or National

Standards.

1. Adequate earth connections should be made to all earthing points, internal and external,

where provided.

2. After installation or troubleshooting, all safety covers and safety grounds must be replaced.

The integrity of all earth terminals must be maintained at all times.

3. Mains supply cords should comply with the requirements of IEC227 or IEC245.

World Class 3000

IMPORTANT

SAFETY INSTRUCTIONS

OF THIS APPARATUS

4. All wiring shall be suitable for use in an ambient temperature of greater than 75°C.

5. All cable glands used should be of such internal dimensions as to provide adequate cable

anchorage.

6. To ensure safe operation of this equipment, connection to the mains supply should only be

made through a circuit breaker which will disconnect all circuits carrying conductors during a

fault situation. The circuit breaker may also include a mechanically operated isolating switch.

If not, then another means of disconnecting the equipment from the supply must be provided

and clearly marked as such. Circuit breakers or switches must comply with a recognized

standard such as IEC947. All wiring must conform with any local standards.

7. Where equipment or covers are marked with the symbol to the right, hazardous voltages are likely to be present beneath. These covers should only be

removed when power is removed from the equipment — and then only by

trained service personnel.

8. Where equipment or covers are marked with the symbol to the right, there is a

danger from hot surfaces beneath. These covers should only be removed by

trained service personnel when power is removed from the equipment. Certain surfaces may remain hot to the touch.

9. Where equipment or covers are marked with the symbol to the right, refer to

the Operator Manual for instructions.

10. All graphical symbols used in this product are from one or more of the following standards: EN61010-1, IEC417, and ISO3864.

P-2 Rosemount Analytical Inc. A Division of Emerson Process Management

World Class 3000

1

DESCRIPTION AND SPECIFICATIONS

Instruction Manual

IB-106-300DR Rev. 3.3

February 2000

SECTION 1

1-1 COMPONENT CHECKLIST

The Direct Replacement (DR) Probe package of

the World Class 3000 Oxygen Analyzer typically

includes the probe, the instruction bulletin, and

the mounting hardware. These three items are

shown in Figure 1-1. Record the Part Number,

Serial Number, and Order Number of your

system on the first page of this manual.

1-2 SYSTEM OVERVIEW

a. Scope

This Instruction Bulletin has been designed

to supply details needed to install, start up,

and troubleshoot the Rosemount World

Class 3000 Oxygen Analyzer. The Direct

Replacement Probe can be interfaced to a

number of different and earlier model

electronics packages. These electronic

packages are not covered in this manual.

For specific information concerning calibration and operation of the system, refer to

the Instruction Bulletin applicable to your

electronics package.

b. System Function

The Rosemount Oxygen Analyzer (Probe) is

designed to measure the net concentration

of oxygen in an industrial process; i.e., the

oxygen remaining after all fuels have been

oxidized. The probe is permanently positioned within an exhaust duct or stack. The

sampling system is in situ rather than

extractive.

2

1. Oxygen Analyzer Probe

2. Mounting Adapter Plate with

Mounting Hardware and

Gasket

3. Instruction Bulletin

3

1

19290001

Figure 1-1. Typical System Package

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-1

Instruction Manual

IB-106-300DR Rev. 3.3

February 2000

World Class 3000

The equipment measures oxygen percentage by reading the voltage developed

across a heated electrochemical cell, which

consists of a small yttria-stabilized, zirconia

disc. Both sides of the disc are coated with

porous metal electrodes. When operated at

the proper temperature, the millivolt output

voltage of the sensor cell is given by the

following Nernst equation:

EMF = KT log

10(P1/P2

) + C

Where:

1. P

is the partial pressure of the oxygen

2

in the measured gas on one side of the

cell,

2. P

is the partial pressure of the oxygen

1

in the reference gas on the other side,

3. T is the absolute temperature,

4. C is the cell constant,

5. K is an arithmetic constant.

NOTE

For best results, use clean, dry,

instrument air (20.95% oxygen) as a

reference gas.

vapor. Therefore, it may be considered an

analysis on a "wet" basis. In comparison

with older methods, such as the Orsat

apparatus, which provides an analysis on a

"dry" gas basis, the "wet" analysis will, in

general, indicate a lower percentage of

oxygen. The difference will be proportional

to the water content of the sampled gas

stream.

c. System Configuration

The DR probe is similar to the Exchange

Probe (NE model) except that the DR uses

a 115 V heater like most older systems. The

DR does not require a separate power supply as does the NE. The DR probe (like the

NE) is available in five lengths. The length

of stack penetration depends on the size of

the stack or duct. The length options are

18 in., 3 ft, 6 ft, 9 ft, and 12 ft (457 mm, 0.9

m, 1.8 m, 2.7 m, and 3.7 m).

d. Features

1. Output voltage and sensitivity increase

as the oxygen concentration

decreases.

When the cell is at operating temperature,

oxygen ions will travel through the cell from

high to low oxygen partial pressures. The

resulting output voltage is about 50 mV per

decade. The voltage varies with the ratio of

oxygen partial pressures of the reference

gas over the sample gas. Thus, the output

signal increases as the sample oxygen level

decreases. This property gives the analyzer

high sensitivity at low oxygen levels.

Oxygen analyzer equipment measures net

oxygen concentration in the presence of all

the products of combustion, including water

2. In situ, non-sampling analyzer.

3. Field replaceable cell.

4. Analyzer constructed of rugged

316 LSS for all wetted parts.

5. Suitable for use in temperatures up to

1300°F (700°C).

6. The DR probe uses a 115 V heater

and does not require a separate heater

power supply.

1-2 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management

World Class 3000

1

e. Handling the Oxygen Analyzer

Instruction Manual

IB-106-300DR Rev. 3.3

February 2000

GASES

It is important that printed circuit

boards and integrated circuits are

handled only when adequate antistatic

precautions have been taken to prevent possible equipment damage.

The oxygen analyzer is designed for

industrial application. Treat each

component of the system with care to

avoid physical damage. The probe

contains components made from ceramics, which are susceptible to

shock when mishandled.

NOTE

Retain packaging in which the oxygen

analyzer arrived from the factory in

case any components are to be

shipped to another site. This packaging has been designed to protect the

product.

f. System Considerations

Prior to installation of your Rosemount

World Class 3000 Oxygen Analyzer, make

sure you have all of the components

necessary to make the system installation.

Ensure all components are properly

integrated to make the system functional.

STACK

CALIBRATION

INSTRUMENT

AIR SUPPLY

(REF. GAS)

GAS

PRESSURE

REGULATOR

FLOWMETER

EXISTING

ELECTRONICS

Figure 1-2. Typical System Installation

connecting test gas tanks to the oxygen

analyzer when the probe is to be calibrated.

NOTE

Ambient air is not recommended for

use as high test gas. An 8% O

balance in nitrogen is recommended

for high test gas.

DUCT

ADAPTER

OXYGEN

ANALYZER

(PROBE)

2

PLATE

VOLTAGE

19290002

LINE

Once you have verified you have all the

components, select mounting locations and

determine how each component will be

placed in terms of available power supply,

ambient temperatures, environmental considerations, convenience, and serviceability.

A typical installation is illustrated in Figure

1-2.

If test gas bottles will be hooked up permanently, an optional check valve is recommended next to the calibration fittings on

the probe head. This is to prevent breathing

of calibration gas line and subsequent flue

gas condensation and corrosion. The check

valve is in addition to the stop valve in the

test gas kit or the solenoid valve in the

multiprobe test gas sequencer units.

After selecting the probe mounting location,

provision should be made for a platform

1-3 PHYSICAL DESCRIPTION

where the probe can be easily serviced.

The Oxygen Analyzer Probe, Figure 1-3 conA source of instrument air is required at the

probe for reference gas use. Since the

sists of three component groups: probe exterior,

inner probe, and junction box, Figure 1-4.

probe is equipped with an in place calibration feature, provision should be made for

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-3

Instruction Manual

IB-106-300DR Rev. 3.3

February 2000

NOTE: NOT ALL PARTS SHOWN ARE AVAILABLE FOR

PURCHASE SEPARATELY. FOR LIST OF

AVAILABLE PARTS, SEE TABLE 7-1.

World Class 3000

1

26

20

18

23

21

19

16

14

20

12

29

10

17

11

13

15

9

28

3

2

4

30

27

25

24

11

22

10

5

6

NOTE: ITEM , CALIBRATION GAS TUBE,

FITS INTO HOLES WHEN PROBE IS

ASSEMBLED.

1. Heater, Strut, and Backplate 11. Probe Junction Box Cover 22. Gas Connection

Assembly 12. Cover Gasket 23. Seal Cap

2. Diffusion Assembly 13. Insulating Sheet 24. Label

3. Retainer Screw 14. O-Ring 25. Probe Junction Box

4. Cell and Flange 15. Terminal Block Screw 26. Ground Wires

5. Corrugated Seal 16. Terminal Block 27. Insulating Gasket

6. Probe Tube Assembly 17. Terminal Block Marker 28. Washer

7. Cover Screw 18. Terminal Block Mounting Plate 29. Screw

8. Washer 19. Probe Junction Box Screws 30. Tag

9. Cover Chain Screw 20. Hose Clamp

10. Cover Chain 21. Hose

35900002

8

7

Figure 1-3. Oxygen Analyzer Probe - Exploded View

1-4 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management

World Class 3000

1

PROBE

EXTERIOR

(SENSING CELL INSTALLED)

PROBE

INTERIOR

Instruction Manual

IB-106-300DR Rev. 3.3

February 2000

PROBE

JUNCTION

BOX

Figure 1-4. Main Probe Components

1-4 PROBE EXTERIOR

Primary probe exterior components include a

flange-mounted zirconium oxide cell, mounted

on a tube assembly and protected by a snubber

diffusion assembly.

a. Cell and Flange Assembly

The primary component in the cell and

flange assembly, Figure 1-5, is a

yttria-stabilized zirconium oxide cell. The

cell creates an electrical signal when the

oxygen level on one side is out of balance

with the oxygen level on the other side. This

signal is proportional to the difference in

oxygen levels.

b. Probe Tube Assembly

21240006

The tube assembly includes a flange which

mates with a stack-mounted flange (shown

attached to the probe flange in Figure 1-4).

Studs on the stack flange make installation

easy. There is also a tube to carry calibration gas from the junction box to the

process side of the cell during calibration.

PROBE TUBE

CORRUGATED

SEAL

CELL AND

FLANGE

ASSEMBLY

Four screws secure the cell and flange assembly, Figure 1-5, to the probe tube assembly. When in place, the cell is inside the

tube.

21240007

Figure 1-5. Cell and Tube Assemblies

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-5

Instruction Manual

IB-106-300DR Rev. 3.3

February 2000

World Class 3000

Table 1-1. Specifications for Oxygen Analyzing Equipment

1 2

Probe lengths, nominal ...................................................................... 18 in. (457 mm), 3 ft (0.91 m),

6 ft (1.83 m), 9 ft (2.74 m), or 12 ft (3.66 m),

depending on duct dimensions

Temperature limits in process

measurement area ....................................................................... 50° to 1300°F (10° to 704°C)

Standard/current output ................................................................ 4-20 mA dc signal (factory set)

O

indication (Digital display

2

and analog output)........................................................................ 0.1% O

or ±3% of reading, whichever is greater

2

using Rosemount test gases

System speed of response ................................................................ less than 3 seconds (amplifier output)

Resolution sensitivity ......................................................................... 0.01% O

transmitted signal

2

Probe reference air flow .................................................................... 2 scfh (56.6 L/hr) clean, dry, instrument

quality air (20.95% O

), regulated to

2

5 psi (34 kPa)

Calibration gas mixtures .................................................................... Rosemount Hagan Test Gas Kit Part No.

6296A27G01 contains 0.4% O

and 8% O

Nominal

2N2

Nominal

2N2

Calibration gas flow ........................................................................... 5 scfh (141.6 L/hr)

Power supply ..................................................................................... 115 ±10% Vac at 50/60 Hz

Power requirement ............................................................................ 200 VA

Ambient operating temperature (Junction Box)................................. 300°F (149°C) [160°F (71°C) max for YEW

replacement]

Approximate shipping weights:

18 in. (457 mm) package ....................................................... 55 lbs (24.97 kg)

3 ft (0.91 m) package ............................................................. 60 lbs (27.24 kg)

6 ft (1.83 m) package ............................................................. 65 lbs (29.51 kg)

9 ft (2.74 m) package ............................................................. 72 lbs (32.66 kg)

12 ft (3.66 m) package ........................................................... 78 lbs (35.38 kg)

1

All static performance characteristics are with operating variables constant.

2

Equipment ordered utilizing this document as reference will be supplied to the USA standard design.

Customers requiring the EEC standard design should request the EEC documentation and utilize its ordering

data. Temperatures over 1000°F (537°C) may affect the ease of field cell replaceability.

c. Snubber Diffusion Assembly

The snubber diffusion assembly protects

the cell from heavy particles and isolates

the cell from changes in temperature. The

snubber assembly threads onto the cell and

flange assembly. Pin spanner wrenches

An optional ceramic diffusor element and

vee deflector shown in Figure 1-6, is available. The ceramic diffusor assembly is also

available in a flame arresting version to

keep heat from the cell from igniting flue

gases.

(probe disassembly kit 3535B42G01) are

applied to holes in the diffusion element hub

to remove or install the snubber assembly.

1-6 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management

World Class 3000

1

Instruction Manual

IB-106-300DR Rev. 3.3

February 2000

is noted in the calibration data sheet supplied with each probe.

DIFFUSION

ELEMENT

HUB

PIN

WRENCH

VEE

DEFLECTOR

21240024

Figure 1-6. Optional Ceramic Diffusor and Vee

Deflector Assembly

Systems that use an abrasive shield require

a special diffusor assembly with a hub that

is grooved to accept two dust seal gaskets.

This special diffusor is available in both

snubber and ceramic versions. See Probe

Options, paragraph 1-8.

d. Cell – General

The components which make up the cell are

machined to close tolerances and assembled with care to provide accurate oxygen

measurements. Any replacement requires

attention to detail and care in assembly to

provide good results.

Every probe should be calibrated and

checked after repair or replacement of cell,

pad and wire, heater, and thermocouple, or

after disassembly of the probe.

There are two styles of the heater/strut

inner probe assembly. P/Ns

3D39441G06 through G10 identify the

44 V heater design. P/Ns 3D39441G01

through G05 and G11 through G15

identify the 115 V heater design. Both

styles look the same. When replacing

a strut, be sure the replacement has

the same part number as the original.

A stainless steel tag is attached to the

inner probe assembly to identify the

115V design. Operating a probe on the

wrong heater voltage can cause injury

or severe damage to equipment.

1-5 PROBE INTERIOR

The inner probe assembly, Figure 1-7, consists

of six main parts:

a. Ceramic support rod with four holes running

through the length. The holes serve as insulated paths for the cell signal wire and

thermocouple wires.

b. A heater that is helically wrapped on a

quartz support cylinder and insulated.

Failure to follow the instructions in

this manual could cause danger to

personnel and equipment. Read and

follow instructions in this manual

c. A chromel-alumel thermocouple which acts

as the sensing element for the temperature

controller. (Not visible in Figure 1-7; located

within ceramic support rod.)

carefully.

d. A platinum screen pad which forms electri-

The oxygen probe includes an inner electrode for the cell assembly. It consists of a

platinum pad and a platinum/inconel composite wire which produces the cell constant

offset voltage described in the Nernst equation.

With this pad and wire, the constant will be

between -10 and +15 mV. The cell constant

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-7

cal contact with the inner electrode of the

electrochemical cell. (Not visible in Figure

1-7; located at end of ceramic support rod.)

The pad is attached to an inconel/stainless

steel wire which carries the signal to the

terminal strip.

e. A V-strut assembly to give support to the

inner probe assembly.

Instruction Manual

IB-106-300DR Rev. 3.3

February 2000

World Class 3000

HEATER

INSULATING

GASKET

V-STRUT

CERAMIC

SUPPORT

ROD

Figure 1-7. Inner Probe Assembly

f. A tube to carry reference gas to the cell.

Refer to Section 4, Maintenance and Service,

for repair procedures for probe components.

1-6 JUNCTION BOX

The junction box, Figure 1-8, is positioned at the

external end of the probe and contains a terminal strip for electrical connections and fittings for

reference and calibration gases. Fittings are for

0.250 inch stainless steel tubing on American

units, and 6 mm tubing on European units. The

calibration fitting has a seal cap which must remain in place except during calibration. A tubing

fitting is also supplied to be used with the

calibration gas supply during calibration.

If the calibration gas bottles will be permanently

hooked up to the probe, a manual block valve is

required at the probe (between the calibration

fitting and the gas line) to prevent condensation

of flue gas down the calibration gas line.

During operation and calibration, reference gas

is supplied through the reference gas fitting to

the reference side of the cell. This gives the

REFERENCE

GAS TUBE

TAG

21220004

PROBE

JUNCTION BOX

COVER

TERMINAL

STRIP

CALIBRATION

GAS FITTING

REFERENCE

GAS FITTING

21240029

Figure 1-8. Junction Box

system a known quantity of oxygen with which

to compare the oxygen level in the process gas.

Though ambient air can be used for this purpose, accuracy can only be assured if a

reference gas air set is used.

During calibration, two gases of different known

oxygen concentrations are injected one at a

time through the calibration gas fitting. Stainless steel tubing delivers this gas to the process

side of the cell. In a healthy cell, the difference

in oxygen pressure from the process side to the

reference side of the cell will cause a millivolt

output proportional to the difference in oxygen

levels. The electronics unit can use the two millivolt outputs caused by the two calibration

gases for either automatic or semi-automatic

calibration.

1-8 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management

World Class 3000

1

Do not attempt to remove a process

gas sample through either gas fitting.

Hot gases from the process would

damage gas hoses in the junction box.

1-7 CABLE ASSEMBLY

The Westinghouse and Rosemount systems

use a 7-conductor cable to connect the probe to

the electronics package. Standard length for this

cable is 20 ft (6 m), but lengths up to 150 ft

(45 m) are available. The seven conductors

include one shielded pair of wires for the cell

millivolt signal, one shielded pair of type K wires

for the thermocouple, and three individual

16-gauge wires for the heater and for ground.

The assembled conductors are wrapped by a

TM

Teflon

jacket and braided stainless steel

Instruction Manual

IB-106-300DR Rev. 3.3

TM

shield. The Teflon

ing is suitable for high temperature use. All

metal shields are isolated at the probe end and

connect by drain wires to ground at the

electronics.

1-8 PROBE OPTIONS

a. Abrasive Shield Assembly

The abrasive shield assembly, Figure 1-9, is

a stainless-steel tube that surrounds the

probe assembly. The shield protects the

probe against particle abrasion and corrosive condensations, provides a guide for

ease of insertion, and acts as a probe position support, especially for longer length

probes. The abrasive shield assembly uses

a modified diffusion and vee deflector assembly fitted with dual dust seal packing.

and stainless steel jacket-

February 2000

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-9

Instruction Manual

IB-106-300DR Rev. 3.3

February 2000

World Class 3000

0.187

0.187

2

1

B

A

o

15

03.584

03.554

o

90

ON INSIDE BREAK

FOR SMOOTH

A

0.45 MIN

125

SKIN CUT FACE FOR 90

ROUNDED EDGE ON

BOTH ENDS OF

CHAMFER.

6.00

0.187

o

/

B

NOTES:

VIEW A

o

/

0.75 THRU 4 PLS.

EQ SP ON 4.75 B.C.

WELD ON BOTH SIDES WITH EXPANDING

CHILL BLOCK.

2

BEFORE WELDING, BUTT ITEM 2 WITH

ITEM 1 AS SHOWN.

o

/

Figure 1-9. Abrasive Shield Assembly

VIEW B

o

22.5

0.745

DIA ON A 7.50 DIA B.C. (REF)

0.755

P0009

1-10 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management

World Class 3000

1

Instruction Manual

IB-106-300DR Rev. 3.3

February 2000

P0010

Figure 1-10. Ceramic Diffusion/Dust Seal

Assembly

These modified diffusion and vee deflector

assemblies are available in standard, Figure

1-10, and flame arrestor version, Figure

1-11.

b. Ceramic Diffusion Assembly

The ceramic diffusion assembly, Figure

1-12, is the traditional design for the probe.

Used for over 25 years, the ceramic diffusion assembly provides a greater filter

surface area for the probe.

19280010

Figure 1-12. Ceramic Diffusion Assembly

c. Flame Arrestor Diffusion Assembly

Where a high concentration of unburned

fuel is present in the exhaust gases, a flame

arrestor diffusion assembly, Figure 1-11 and

Figure 1-13 is recommended.

The flame diffusion assembly includes a set

of baffles between the cell and the stack

gases. This keeps 1500°F (816°C) cell

temperatures from igniting unburned fuel in

the stack.

P0011

P0012

Figure 1-13. Flame Arrestor Diffusion Assembly

Figure 1-11. Flame Arrestor Diffusion/Dust Seal

Assembly

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-11

Instruction Manual

IB-106-300DR Rev. 3.3

February 2000

P0014

Figure 1-14. Snubber Diffusion/Dust Seal

Assembly

d. Snubber Diffusion/Dust Seal Assembly

The snubber diffusion/dust seal assembly,

Figure 1-14, is used in applications where

an abrasive shield is to be used with a

snubber type diffusion element. The dust

seal consists of two rings of packing to prevent abrasive dust from collecting inside the

abrasive shield.

World Class 3000

can be employed. The bypass system uses

an 18 inch (457 mm) or 3 foot (0.92 m)

probe mounted externally on the stack or

duct. The process or exhaust gases are directed out to the probe through a passive

sampling system using inconel tubes. Flue

gas flow induces the movement of gases

into, through, and out of the bypass unit.

The bypass arrangement does not require

the use of aspiration air and the gas which

flows past the probe is returned to the stack

or duct.

The bypass probe package is normally used

for process temperatures of 1300°F (704°C)

to 2000°F (1094°C). A higher temperature

version of the bypass provides for operation

at temperatures up to 2500°F (1372°C). In

this version the pick up tubes are made of a

special high-temperature alloy.

Overall dimensions and mounting details of

the American and European bypass systems are shown in Figure 1-15.

f. Probe Mounting Jacket Options

e. Bypass Probe Options

For processes where the flue gas exceeds

the maximum allowable temperature of

1300°F (704°C) a bypass sensor package

A probe mounting jacket option is available

to allow the probe to operate at temperatures of up to 2000°F (1095°C). A separate

instruction bulletin is available for this

option.

1-12 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management

World Class 3000

1

C).

o

A - A

Instruction Manual

IB-106-300DR Rev. 3.3

February 2000

19290005

OF FLOW

DIRECTION

TO 980

o

POINT OR

F (650

DEW

o

Y AIR REQUIRED. FITTING

TO 1800

ARDS DIRECTION ONLY.

o

NW

AX. CLEAN DR

TION GAS REQUIRED.

AX. CALIBRA

CALIBRATION AND PURGE GAS CONNECTION. BITE TYPE FITTING (PARKER CPI)

REFERENCE AIR SUPPLY CONNECTION BITE TYPE FITTING (PARKER CPI) FOR

1.

NOTES:

10 SCFH AT 32 PSIG M

0.250 O.D. TUBING. 2 SCFH AT 3 PSIG M

IS LOCATED ON FAR SIDE.

2.

TURE RANGE 1200

TURE DOES NOT GO BELOW

PERA

PERA

YZER IN A VERTICALLY DOW

C.

o

ITH ANAL

FLUE GAS OPERATING TEM

LAG TO ENSURE GAS TEM

EXCEED 500

INSTALL W

4.

5.

3.

A

GROUP NOTE

ARENTHESES.

AL CONDUCTIVITY K

ETERS IN P

TION. THERM

ILLIM

ITH M

O INCH THK INSULA

ENDED TW

M

ENSIONS ARE IN INCHES W

RECOM

EQUALS 0.5 FOR INSULATION.

DIM

7.

6.

01

A 3 FT (914.4) GAS TUBE PICK-UP

B 6 FT (1828.8) GAS TUBE PICK-UP

GASKET AND HARDWARE

06

FLANGE

CAL

GAS

VIEW

2

REF

GAS

1

4.026

(102.26)

04

03

02

I.D.

ELECT CABLE

C 9 FT (2743.2) GAS TUBE PICK-UP

BY CUSTOMER

OPTIONAL MOUNTING

ARRANGEMENT, 4 IN.

150# FLANGE SUPPLIED

05

HARDWARE

GASKET AND

06

30.62 (777.75) REF (4507C26G01)

62.50 (1587.5) REF (4507C26G03)

26.50 (673.1) REF (4507C26G01 AND G02)

37.00 (939.8) REF (4507C26G01)

73.00 (1854.2) REF (4507C26G02)

109.00 (2768.6) REF (4507C26G03)

6.0

(152.4) REF

6.50

(165.1) REF

DRAIN

STD 20 FT

(6.1 M) CABLE

A

4

6

3

FOR

INSERTION

FOR PROBE

27.31 (693.67)

AND REMOVAL

CLEARANCE REQ

3D3947G01

19.80 (502.92)

SQUARE TO GAS FLOW.

BE ORIENTED SO THAT VEE SHIELD IS

IF EQUIPPED WITH THE OPTIONAL CERAMIC

DIFFUSOR ASSEMBLY, PROBE ASSEMBLY MUST

Figure 1-15. Bypass Probe Option (Sheet 1 of 3)

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-13

Instruction Manual

IB-106-300DR Rev. 3.3

February 2000

World Class 3000

o

o

POINT OR

DEW

o

ARDS DIRECTION ONLY.

o

NW

YZER IN A VERTICALLY DOW

o

o

ITH ANAL

ARENTHESES.

ITH MILLIMETERS IN P

GROUP NOTE

A 3 FT (914.4) GAS TUBE PICK-UP

ELECT

B 6 FT (1828.8) GAS TUBE PICK-UP

C 9 FT (2743.2) GAS TUBE PICK-UP

CAL

GAS

2

CABLE

OMER

16

15

14

REF

1

13

12

11

GAS

A - A

VIEW

04

03

02

OF FLOW

DIRECTION

I.D.

4.026

(102.26)

19290006

PICKUP (3D390004G07 OR G08)

26.5 (673.1) ON 3 FT (914.4) OR 6 FT (1828.8)

62.5 (1587.5) ON 9 FT (2743.2) PICKUP (3D390004G09)

37.0 (939.8) ON 3 FT (914.4) PICKUP (3D390004G07)

73.0 (1854.2) ON 6 FT (1828.8) PICKUP (3D390004G08)

109.0 (2768.6) ON 9 FT (2743.2) PICKUP (3D390004G09)

CALIBRATION AND PURGE GAS CONNECTION. BITE TYPE FITTING (PARKER CPI)

10 SCFH AT 32 PSIG (220.64 kPa GAUGE) MAX. CALIBRATION GAS REQUIRED.

LAG TO ENSURE GAS TEMPERATURE DOES NOT GO BELOW

REFERENCE AIR SUPPLY CONNECTION BITE TYPE FITTING (PARKER CPI) FOR

0.250 O.D. TUBING. 2 SCFH AT 3 PSIG (20.69 kPa GAUGE) MAX. CLEAN DRY AIR

REQUIRED. FITTING IS LOCATED ON FAR SIDE.

1.

NOTES:

EXCEED 932 F (500 C).

3.

2.

A

A

STD CABLE

20 FT (6.1 M)

RECOMMENDED 2.0 INCH (50.8) THK INSULATION. THERMAL CONDUCTIVITY K EQUAL

0.5 FOR INSULATION.

DIMENSIONS ARE IN INCHES W

FLUE GAS OPERATING TEMPERATURE RANGE 1200 TO 1800 F (650 TO 980 C).

INSTALL W

6.

5.

4.

7.

01

INSERTION

FOR PROBE

27.31 (693.67)

CLEARANCE REQ

FLANGE

AND REMOVAL

08

07

06

AND

GASKET

HARDWARE

4

Figure 1-15. Bypass Probe Option (Sheet 2 of 3)

ELD BY CUST

W

10

09

05

FOR

19.80

(502.92)

3D3947G01

PLATE

ELDED

W

TO STACK

6.50 (165.1) REF

DRAIN

3

6

ITH THE OPTIONAL CERAMIC

SQUARE TO GAS FLOW.

BE ORIENTED SO THAT VEE SHIELD IS

IF EQUIPPED W

DIFFUSOR ASSEMBLY, PROBE ASSEMBLY MUST

1-14 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management

World Class 3000

1

PARTS LIST

NOTE DEFINER

ITEM

01 WORLD CLASS

02 GAS PICK-UP DWG

03 GAS PICK-UP DWG

04 GAS PICK-UP DWG

05 ANALYZER

06 MTG HARDWARE DWG

07 MTG HARDWARE DWG

08 MTG HARDWARE DWG

09 ANALYZER

10 ANALYZER

11 GAS PICK-UP DWG

12 GAS PICK-UP DWG

13 GAS PICK-UP DWG

14 GAS PICK-UP DWG

15 GAS PICK-UP DWG

16 GAS PICK-UP DWG

PART NAME

3000

HOUSING

HOUSING

HOUSING

PARTS LIST UNITS: INCHES GROUP NOTE A B C A B C A B C

SIZEREFERENCE

INFORMATION

DWG

DWG

DWG

DWG

PROBE 18 IN.

3 FT

6 FT

9 FT

FOR WORLD CLASS

3000 ANSI

FOR ANSI FLANGE

FOR JIS

FOR DIN

FOR JIS

FOR DIN

FOR JIS 3 FT

FOR JIS 6 FT

FOR JIS 9 FT

FOR DIN 3 FT

FOR DIN 6 FT

FOR DIN 9 FT

Instruction Manual

IB-106-300DR Rev. 3.3

FLANGE

STYLE ANSI JIS DIN

MAIL CODE

PART NUMBER

OR REF DWG

ORDER FROM

MATRIX

4507C26G01

4507C26G02

4507C26G03

3D39005G01

3535B58G01

3535B58G03

3535B58G05

3D39005G02

3D39005G03

4507C26G04

4507C26G05

4507C26G06

4507C26G07

4507C26G08

4507C26G09

G01 G02 G03 G04 G05 G06 G07 G08 G09

1

111

111

3D39004 GROUP

1

1

111

111

1

1

1

February 2000

111

111

1

1

1

Extended Temperature By-Pass Arrangements (2400°°°°F; 1300°°°°C)

GROUP

PART NO.

CODE DESCRIPTION

1U0571 G01 3’ By-pass Package with ANSI bolt pattern.

1U0571 G02 6’ By-pass Package with ANSI bolt pattern.

1U0571 G03 9’ By-pass Package with ANSI bolt pattern.

1U0571 G04 3’ By-pass Package with JIS bolt pattern.

1U0571 G05 6’ By-pass Package with JIS bolt pattern.

1U0571 G06 9’ By-pass Package with JIS bolt pattern.

1U0571 G07 3’ By-pass Package with DIN bolt pattern.

1U0571 G08 6’ By-pass Package with DIN bolt pattern.

1U0571 G09 9’ By-pass Package with DIN bolt pattern.

Figure 1-15. Bypass Probe Option (Sheet 3 of 3)

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-15

Instruction Manual

IB-106-300DR Rev. 3.3

February 2000

World Class 3000

1-16 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management

World Class 3000

2

Before starting to install this equipment, read the "Safety instructions for

the wiring and installation of this apparatus" at the front of this Instruction

Bulletin. Failure to follow the safety

instructions could result in serious

injury or death.

Install all protective equipment covers

and safety ground leads after installation. Failure to install covers and

ground leads could result in serious

injury or death.

Instruction Manual

IB-106-300DR Rev. 3.3

February 2000

SECTION 2

INSTALLATION

b. Ensure that the area is clear of obstructions,

internal and external, that will interfere with

installation. Allow adequate clearance for

removal of probe (Figure 2-1).

The junction box temperature must

not exceed 300°°°°F (149°°°°C). If used with

the Yokogawa ZA8C electronics, junction box temperature is limited to

160°°°°F (71°°°°C). To meet these limits, the

user may need to make a heat shield

or provide cooling air to the junction

box. The temperature limit is due to

the thermocouple "cold reference"

device.

2-1 LOCATING THE OXYGEN ANALYZER

PROBE

The location of the probe in the stack or flue is

most important for maximum accuracy in the

oxygen analyzing process. The probe must be

positioned so that the gas it measures is representative of the process. Best results are normally obtained if the probe is positioned near

the center of the duct (40 to 60% insertion). A

point too near the edge or wall of the duct may

not provide a representative sample because of

the possibility of gas stratification. In addition,

the sensing point should be selected so that the

process gas temperature falls within a range of

50° to 1300°F (10° to 704°C). Figure 2-1 provides mechanical installation references.

a. Check the flue or stack for holes and air

leakage. The presence of this condition will

substantially affect the accuracy of the oxygen reading. Therefore, either make necessary repairs or install the probe upstream of

any leakage.

2-2 SERVICE REQUIRED

a. Power input: 115 ±10% Vac single phase,

50 to 60 Hz, 3 amp minimum. (See label.)

b. Compressed air: 10 psig (69 kPa gauge)

minimum, 225 psig (1551 kPa gauge)

maximum at 2 scfh (56.6 L/hr) maximum;

supplied by one of the following (less than

40 parts-per-million total hydrocarbons).

Regulator outlet pressure should be set at 5

psi (35 kPa).

1. Instrument air - clean, dry.

2. Bottled standard air with step-down

regulator.

3. Bottled compressed gas mixture

(20.95% oxygen in nitrogen).

4. Other equivalent clean, dry, oil-free air

supply.

Rosemount Analytical Inc. A Division of Emerson Process Management Installation 2-1

Instruction Manual

IB-106-300DR Rev. 3.3

February 2000

World Class 3000

FURNISHED IN - XIT

4512C34

ADAPTER & ACCESSORY

TO AMBIENT

INSULATE IF EXPOSED

WEATHER CONDITIONS

4512C35

4512C36

2.27 (58)

DIA MAX

ROSEMOUNT

5.85 (148.6)

DIM "A"

WITH STANDARD

REF GAS

CAL GAS

7.58 (192)

SNUBBER

DIFFUSER

ELEC

DIM "B" REMOVAL ENVELOPE

1/4 IN. TUBE

6 MM TUBE

6 MM TUBE

ANSI

DIN

JIS

1/2"

CONN

CONDUIT

GAS

CAL

JIS

4512C18H01

6.10

(155)

1.88 (48)

0.59

GAS

REF

(15)

AT THE BOTTOM

BOTTOM VIEW

INSTALL WITH CONNECTIONS

5.12

(130)

THESE FLAT FACED FLANGES ARE MANUFACTURED

TO ANSI, DIN, AND JIS BOLT PATTERNS AND ARE NOT

DIMENSIONS ARE IN INCHES WITH MILLIMETERS IN

PARENTHESES.

PRESSURE RATED.

2.

NOTES: 1.

24610001

3.80 (96.5)

DIFFUSER

FOR PROBE

WITH CERAMIC

4.90 (124.5)

ADD TO DIM "A" FOR

ARRESTOR

DIFFUSER AND FLAME

PROBE WITH CERAMIC

DIN

7.28

4512C19H01

ANSI

6.00

4512C17H01

(185)

(153)

0.71

0.75

(18)

(20)

5.71

4.75

(145)

(121)

DIM "B"

DIM "A"

27.3 (694)

16 (406)

45.3 (1151)

34 (864)

81.3 (2065)

117.3 (2980)

70 (1778)

106 (2692)

153.3 (3894)

142 (3607)

3535B18H02

ANSI

0.062 THK GASKET

3635B48H01

3535B45H01

JIS

DIN

ADD TO DIM "A"

TABLE I MOUNTING FLANGE

3FT

6FT

9FT

12 FT

PROCESS FLOW MUST

BE IN THIS DIRECTION

WITH RESPECT TO

DEFLECTOR 3534848G01

FLANGE

DIA.

HOLE

DIA.

(4) HOLES

EQ SP ON BC

TABLE II INSTALLATION/REMOVAL

18 IN.

PROBE

Figure 2-1. Probe Installation (Sheet 1 of 5)

2-2 Installation Rosemount Analytical Inc. A Division of Emerson Process Management

World Class 3000

2

7.50

7.48

BOLT

CIRCLE

0.75

(8) HOLES

DIAMETER

FLANGE

9.00 (153)

DIAMETER

TABLE IV. FLANGE SIZE

*

ANSI

7.48

0.75

0.945

9.25 (235)

9.25 (235)

*

*

JIS

DIN

FLANGES ARE MANUFACTURED TO ANSI,

*

5.7

(145)

14.5

(369)

DIM "D" REMOVAL ENVELOPE

PRESSURE RATED.

FLAT FACED. THESE FLANGES ARE NOT

DIN, AND JIS BOLT PATTERNS AND ARE

7.00

(178)

SEE TABLE IV

FOR FLANGE

SIZES

Instruction Manual

IB-106-300DR Rev. 3.3

February 2000

21190008

REF AND

CAL GAS

CONNECTOR

ELECTRICAL

CONNECTOR

CAL GAS LINES

CHECK VALVE FOR

INSULATE IF

CONDITIONS

EXPOSED TO

AMBIENT WEATHER

31.1

(790)

DIM "E"

45.3

(1151)

DIM "D"

27

(686)

DIM "C"

NOMINAL MEASUREMENTS

TABLE III. REMOVAL / INSTALLATION

3 FT

67.1

81.3

63

6 FT

(1704)

(2065)

(1600)

103.1

(2619)

117.3

(2980)

99

(2515)

9 FT

139.1

(3533)

153.3

(3894)

(P/N 3535B58G04 - JIS)

135

12 FT

(3429)

DIM "C"

0.06 THK GASKET FURNISHED

DIM "E" (WITH FLAME ARRESTOR)

(P/N 3535B58G06 - DIN)

(P/N 3535B58G02 - ANSI)

IN HARDWARE PACKAGE

Figure 2-1. Probe Installation (Sheet 2 of 5)

3.6

NOMINAL

(P/N 4843B38G02)

SNUBBER DIFFUSION/

DUST SEAL ASSEMBLY

DIMENSIONS ARE IN INCHES WITH

MILLIMETERS IN PARENTHESES.

NOTE:

Rosemount Analytical Inc. A Division of Emerson Process Management Installation 2-3

Instruction Manual

IB-106-300DR Rev. 3.3

February 2000

JIS

(P/N 3535B58G04)

9.25

(235)

4.92

(125)

(200)

7.894

(M-20 x 2.5)

World Class 3000

16860021

8 THREADED HOLES

EQUALLY SPACED ON

D DIA B.C.

ABRASIVE SHIELD

FLANGE O.D.

DIN

(P/N 3535B58G06)

ANSI

(P/N 3535B58G02)

IN.

TABLE VI. ADAPTOR PLATE DIMENSIONS FOR ABRASIVE SHIELD

(mm)

DIMENSIONS

JIS

(P/N 4512C35G01)

9.25

9.00

"A"

6.50

(235)

(229)

(165)

3.94

(100)

4.75

(121)

"B"

DIA

(M-12 x 1.75)

7.48

(M-16 x 2)

7.50

0.625-11

"C"

"D"

THREAD

(130)

5.118

(190)

(191)

DIA

NOTE: PART NUMBERS FOR ADAPTOR PLATES INCLUDE

ATTACHING HARDWARE.

o

22.5

OUTSIDE WALL SURFACE.

CROSSHATCHED AREA IN 4

CORNERS MAY BE USED TO

FIELD BOLTING OF PLATE TO

PROVIDE ADDITIONAL HOLES FOR

AND 12 FT ABRASIVE SHIELD

ADAPTOR PLATE FOR 3, 6, 9,

INSTALLATIONS. SEE SHEET 2.

C

A

B

A

4 STUDS,

LOCKWASHERS AND

NUTS EQUALLY

SPACED ON

DIN

ANSI

TABLE V. ADAPTOR PLATE DIMENSIONS FOR PROBE

IN.

DIMENSIONS

7.5

(191)

(M-16 x 2)

(P/N 4512C36G01)

6.00

(153)

0.625-11

(P/N 4512C34G01)

"B"

"A"

(mm)

THREAD

(145)

5.708

4.75

(121)

"C"

DIA

A

o

45

A

C

ATTACHING HARDWARE.

2.500 DIA

NOTE: PART NUMBERS FOR ADAPTOR PLATES INCLUDE

C DIA B.C.

B

ADAPTOR PLATE FOR

STD WORLD CLASS 3000

PROBE INSTALLATION.

SEE SHEET 1.

Figure 2-1. Probe Installation (Sheet 3 of 5)

2-4 Installation Rosemount Analytical Inc. A Division of Emerson Process Management

World Class 3000

2

INSTALLATION FOR METAL

WALL STACK OR DUCT

CONSTRUCTION

Instruction Manual

IB-106-300DR Rev. 3.3

February 2000

INSTALLATION FOR MASONRY

WALL STACK CONSTRUCTION

MTG HOLES

SHOWN ROTATED

o

OUT OF

22.5

TRUE POSITION

WELD OR BOLT MOUNTING

PLATE TO METAL WALL

OF STACK OR DUCT.

JOINT MUST BE AIRTIGHT.

0.50 (13)

3.75 (95)

MIN DIA HOLE

IN WALL

STACK OR DUCT

METAL WALL

BOLT ADAPTOR

PLATE TO OUTSIDE

WALL SURFACE

FIELD WELD

PIPE TO

ADAPTOR PLATE

MTG HOLES

SHOWN ROTATED

o

OUT OF

22.5

TRUE POSITION

JOINT MUST

BE AIRTIGHT

OUTSIDE WALL

SURFACE

NOTE: ALL MASONRY STACK WORK AND JOINTS EXCEPT

ADAPTOR PLATE NOT FURNISHED BY ROSEMOUNT.

ABRASIVE SHIELD MOUNTING

0.50 (13)

4.50 (114)

O.D. REF

PIPE 4.00 SCHED 40

PIPE SLEEVE (NOT

BY ROSEMOUNT)

LENGTH BY CUSTOMER

MASONRY

STACK WALL

WELD OR BOLT MOUNTING

PLATE TO METAL WALL

OF STACK OR DUCT.

JOINT MUST BE AIRTIGHT.

3.25 (82.5)

MIN DIA HOLE

IN WALL

STACK OR DUCT

METAL WALL

BOLT MOUNTING

PLATE TO OUTSIDE

WALL SURFACE

OUTSIDE WALL

PROBE MOUNTING

JOINT MUST

BE AIRTIGHT

SURFACE

NOTE: DIMENSIONS IN INCHES WITH

MILLIMETERS IN PARENTHESES.

FIELD WELD

PIPE TO

ADAPTOR PLATE

4.0 (102)

O.D. REF

PIPE 3.5 SCHED 40

PIPE SLEEVE (NOT

BY ROSEMOUNT)

LENGTH BY CUSTOMER

MASONRY

STACK WALL

P0038

Figure 2-1. Probe Installation (Sheet 4 of 5)

Rosemount Analytical Inc. A Division of Emerson Process Management Installation 2-5

Instruction Manual

IB-106-300DR Rev. 3.3

February 2000

World Class 3000

o

60 MAX.

o

30 MIN.

4.12

(105)

4.12

(105)

BRACE BARS

(NOT BY ROSEMOUNT)

2.00

(51)

1.00

(25)

2 HOLES - 0.625

(16) DIA. FOR

0.50 (12) DIA.

BOLT

1.00

(25) MAX.

0.375

(10)

NOTE: DIMENSIONS IN INCHES WITH

5.62

(143)

5.62

(143)

MILLIMETERS IN PARETHESES.

VERTICAL BRACE CLAMP ASSY.

HORIZONTAL BRACE CLAMP ASSY.

(BOTH BRACE CLAMP ASSEMBLIES ARE THE SAME.

INSTALLATION AND LOCATION OF CLAMP ASSEMBLIES

AND BRACE BARS TO BE DONE IN FIELD.)

ABRASIVE SHIELD

BY ROSEMOUNT

}

NOTE: BRACING IS FOR VERTICAL AND HORIZONTAL PROBE INSTALLATION.

EXTERNAL BRACING REQUIRED FOR 9 FT AND 12 FT

(2.75 M AND 3.66 M) PROBES AS SHOWN ABOVE.

Figure 2-1. Probe Installation (Sheet 5 of 5)

2-3 MECHANICAL INSTALLATION

a. Ensure that all components are available for

installation of the probe. If equipped with the

optional ceramic diffusor, check to ensure

that it is not damaged. Ensure that the system cable is the required length.

b. The probe may be installed intact as it is re-

ceived. It is recommended that you disassemble the adapter plate for each

installation.

36.00 (914)

P0039

NOTE

An abrasive shield is recommended

for high velocity particulate in the flue

stream (such as those in coal fired

boilers, kilns, and recovery boilers).

Vertical and horizontal brace clamps

are provided for 9 ft and 12 ft (2.75 m

and 3.66 m) probes to provide mechanical support of the probe. Refer to

Figure 2-1, sheet 5.

c. Weld or bolt adapter plate (Figure 2-1) onto

the duct. Existing stack penetration and

mounting hardware may be revised, or new

mounting flanges may be installed (see

Figure 2-1, sheets 3 and 4).

2-6 Installation Rosemount Analytical Inc. A Division of Emerson Process Management

World Class 3000

2

Instruction Manual

IB-106-300DR Rev. 3.3

February 2000

d. If using the optional ceramic diffusor ele-

ment, the vee deflector must be correctly

oriented. Before inserting the probe, check

the direction of gas flow in the duct. Orient

the vee deflector on the probe so that the

apex points upstream toward the flow (Figure 2-2). This may be done by loosening the

setscrews, and rotating the vee deflector to

the desired position. Retighten the

setscrews.

GAS FLOW

DIRECTION

VEE

APEX

FILTER

DEFLECTOR

DIFFUSION

ELEMENT

SETSCREW

VEE

DEFLECTOR

e. In horizontal installations, the probe cover

should be oriented so the system cable

drops vertically from the probe cover. In a

vertical installation, the system cable can be

oriented in any direction.

f. If the system has an abrasive shield, check

the diffusion element dust seal packings.

The joints in the two packings must be

staggered 180°. Also, make sure that the

packings are in the hub grooves as the

probe slides into the 15° forcing cone in the

abrasive shield.

g. Insert the probe through the opening in the

mounting flange and bolt the unit to the

flange When probe lengths selected are 9

or 12 ft (2.74 or 3.66 m), special brackets

are supplied to provide additional support

for the probe inside the flue or stack. See

Figure 2-1, sheet 5.

2-4 ELECTRICAL INSTALLATION

Figure 2-3 shows the junction box wiring for the

direct replacement probe including the 115 V

hookup. Consult the electronics manual for the

connections to power and the existing signal

conditioning electronics.

P0017

Figure 2-2. Orienting the Optional Vee Deflector

Rosemount Analytical Inc. A Division of Emerson Process Management Installation 2-7

Instruction Manual

IB-106-300DR Rev. 3.3

February 2000

World Class 3000

NOTE: FOR YOKOGAWA (YEW) ZA8C,

115V

HEATER

}

YE CHROMEL

RD ALUMEL

OR CELL +VE

BL CELL -VE

1234567

BL

OR

JUNCTION BOX

WIRING

Upon completing installation, make sure that the probe is turned on and operating prior to

firing up the combustion process. Damage can result from having a cold probe exposed to

the process gases.

YE

RD

BK

BK

GN

WHT

8

GN

WHT

Figure 2-3. Wiring the Direct Replacement Probe

NOTE

!

PROBE

REFER TO SECTION 3-6.

TEST GAS INPUT

AT 2-3 L/MIN

(4-7 SCFH)

CHECK

VALV E

REF. GAS SUPPLY

INPUT AIR AT

1 L/MIN (2 SCFH)

19290007

During outages, and if possible, leave all probes running to prevent condensation and premature aging from thermal cycling.

If the ducts will be washed down during outage, MAKE SURE to power down the probes and

remove them from the wash area.

2-8 Installation Rosemount Analytical Inc. A Division of Emerson Process Management

World Class 3000

3

Instruction Manual

IB-106-300DR Rev. 3.3

February 2000

SECTION 3

STARTUP

3-1 OVERVIEW

This section covers the setup procedures for the

World Class 3000 Oxygen Analyzer. The DR

probe can be used with several electronics

packages including: Models 218, 218A, 225,

132 (analog and digital), TC200, and ZA8C.

Install all protective equipment covers

and safety ground leads after setup.

Failure to replace covers and ground

leads could result in serious injury or

death.

For Models 218, 225, and 132 (analog), refer to

paragraph 3-2. Additional information can be

found in IB-106-101.

For Model 218A, refer to paragraph 3-3. Additional information can be found in IB-106-101A.

For Model TC200, refer to paragraph 3-4. Additional information can be found in IB-107-020.

d. Attach voltmeter with positive (+) lead on

TP1 and negative (-) on either Pin 2 or 7.

NOTE

The voltage given above is for an ambient (machinery space) temperature

of 77°F (25°C). For each degree of ambient temperature above or below 77°F

(25°C), add or subtract 0.242 mV from

the nominal. Example: at 87°F (31°C),

the nominal voltage of -322.3 Mv

should be increased (made less negative) by 10 x 0.242 or 2.42 mV, making

the adjusted nominal -319.9 Mv.

e. Adjust potentiometer M110-1 to read -322.3

millivolts nominal.

f. Remove voltmeter leads.

g. Remove jumper wire.

TP1

M110-1

For Model 132 (digital), refer to paragraph 3-5.

Additional information can be found in IB-106106A.

For Yokogawa Model ZA8C, refer to paragraph

3-6.

3-2 MODELS 218, 225, AND 132 (ANALOG)

ELECTRONICS SETUP

Before beginning operation, it is important that

the probe heater setpoint of the existing electronics be changed to support the World Class

3000 probe. The setpoint adjustment procedure

required for Models 218, 225, and 132 analog

electronics is as follows:

a. Open electronics enclosure.

b. On temperature controller card, Figure 3-1,

connect jumper wire from TP3 to either Pin

2 or Pin 7.

c. Set voltmeter to read DC millivolts (MV).

TP3

PIN 2

(PSC)

Figure 3-1. Temperature Controller Card

23 567 1012

PIN 7 (PSC)

Calibration Points

P0019

Rosemount Analytical Inc. A Division of Emerson Process Management Startup 3-1

Instruction Manual

IB-106-300DR Rev. 3.3

February 2000

World Class 3000

3-3 MODEL 218A ELECTRONICS SETUP

Before beginning operation, it is important that

the probe heater setpoint of the existing electronics be changed to support the World Class

3000 probe. To convert the Model 218A Digital

Electronics Package for use with the DR probe,

an EPROM change is necessary. Remove Main

PCB and check back of board to identify unit as

G02 or G04. The replacement EPROM needed

is as identified below:

G02 G04

United States 1M03192G01 1M02982G01

United Kingdom 1M03192G02 1M02982G02

Germany 1M03192G03 1M02982G03

France 1M03192G04 1M02982G04

Italy 1M03192G05 1M02982G05

NOTE

The replacement EPROM when using a

multiprobe averager unit is

1M02982G10.

To replace the EPROM, proceed as follows:

a. Shut off and lock out power to the electron-

ics package.

b. Open electronics enclosure.

c. On the Main PCB, Figure 3-2, locate and

remove old EPROM.

d. Replace with new EPROM.

e. Close electronics enclosure and power up

system.

EPROM

MAIN PCB

Figure 3-2. Main PCB (Model 218A) EPROM Replacement

3-2 Startup Rosemount Analytical Inc. A Division of Emerson Process Management

P0020

World Class 3000

3

Instruction Manual

IB-106-300DR Rev. 3.3

February 2000

3-4 MODEL TC200 VERITRIM ELECTRONICS

SETUP

Before beginning operation, it is important that

the probe heater setpoint of the existing electronics be changed to support the World Class

3000 Probe. To convert the Model TC200 Electronics Package for use with the DR probe, an

EPROM change is necessary. The replacement

EPROM needed is part number 1M03154G02.

a. EPROM Replacement

To replace the EPROM, proceed as follows:

1. Shut off and lock out power to the

electronics package.

2. Open electronics enclosure.

3. On the main PCB, Figure 3-3, locate

and remove old EPROMs U11 and

U12.

b. Heater SetPoint Adjustment

EPROMS

U11 AND U12

4. Replace with new EPROMs (part number 1M03154G02) being careful to install U11 and U12 in their proper

locations.

5. Close electronics enclosure and power

up system.

The adjustment procedure required for the

Model TC200 Electronics Package is as

follows:

1. Open keylocked enclosure to access

membrane keyboard.

2. Put controller in PAR (parameter)

mode by depressing "LOCK" "▲"

"%O

" "INC" "ACK" in sequence.

2

3. Depress "ACK" pushbutton to clear

display.

DIS A/M

U12

U11

Figure 3-3. Main PCB (Model TC200) EPROM Replacement

P0021

Rosemount Analytical Inc. A Division of Emerson Process Management Startup 3-3

Instruction Manual

IB-106-300DR Rev. 3.3

February 2000

World Class 3000

4. Press "NUM" pushbutton.

5. Using "INC", "DEC" buttons, display

parameter 125.

6. Press "VAL" button.

7. Using "INC", "DEC" buttons, change

parameter 125 value to 15.4.

8. Press "ENT" to save new value.

3-5 MODEL 132 DIGITAL

ELECTRONICS SETUP

Before beginning operation, it is important that

the probe heater setpoint of the existing electronics be changed to support the World Class

3000 Probe. To convert the Model 132 Digital

Electronics Package for use with the DR probe,

an EPROM change is necessary. The replacement EPROM needed is as identified below:

United States IM03222G01

United Kingdom

Germany

France

Italy

EPROM

MAIN PCB

To replace the EPROM, proceed as follows:

a. Shut off and lock out power to the

electronics package.

b. Open electronics enclosure.

c. On the Main PCB, Figure 3-4, locate and

remove old EPROM.

d. Replace with new EPROM.

e. Close electronics enclosure and power up

system.

3-6 THE YOKOGAWA ZA8C AND AV8C CON-

VERTER ELECTRONICS SETUP

The DR probe can be wired to work with the

Yokogawa® ZA8C and AV8C Converters.

Connect the cabling from the ZA8C or AV8C

terminal to the probe terminal in the junction box

as shown in Figure 3-5.

TX2

C34

M55

CR18

R8

P61

U7

C44

U2

C48

U1

C37

LM8

R38

03

TP1

R27

XT1

C26

C27

R12

C38

U6

R38

C29

C28

U4

C30

04

C29

R26

P25

P36

CR25

C13

D12

J1

P28

O18

LED1

08

R63

R62

R54

U9

1

R41

R48

RP1

C46

TP2

C24

D14

C21

C23

D13

C12

C14

D1

C16

D2

CR17

R48

C39

20

C31

U10

C43

U3

C42

R53

U13

C22

C13

C10

C41

R42

CR15

CR16

CR24

R36

CR13

CR14

CR12

CR11

R37

BR1

C30

R44

R49

R47

U14

R43

R38

R86

CR18

R68

09

P29

P22

R64

C86

C10

U12

R61

C16

U2

C32

TR1

TX1

C38

R56

CR19

C36

C11

R46

R48

P62

C7

C9

C8

U11

R6

C48

C4

C3 C8

C47

C1

C2

C3

R9

2001A

F2

2001A

CK1

F1

C7

I

R58

R57

R59

P68

U19

U17

R18

R16

R17

U16

R11

R18

CR3

CR4

U18

R4

R5

CR1

CR2

08

A

28

28

R16

28

C46

CR7

CR6

R19

CR8

CR5

28

28

LK2

28

R7

R6

R14

R23

R28

LK1

CR21

CR20

28

28

C17

R2

R1

R21

R13

R24

CR23

CR22

5A

F3

5A

F4

FIL1

R1

CR9

R81

ALARM

MTR-T/C CELL SKG STK-T/C ML-O/P

T83

C11

T82

OFF

N

L

HEATER

E

E

N

MAIN INPUT

L

T81

SW1

MOV1

MOV2

ON

P0022

Figure 3-4. Main PCB (Model 132) EPROM Replacement

3-4 Startup Rosemount Analytical Inc. A Division of Emerson Process Management

World Class 3000

3

ZA8C

AV8C

CONVERTER

OR

WORLD CLASS 3000

REPLACEMENT PROBE

WITH ADAPTER FLANGE

Instruction Manual

IB-106-300DR Rev. 3.3

February 2000