Page 1

Reference manual

00809-0100-4445, Rev AA

December 2017

Rosemount® 8712EM Transmitter with HART

Protocol Reference Manual

Page 2

Page 3

Contents

Contents

Chapter 1 Safety messages ............................................................................................................ 1

Chapter 2 Introduction .................................................................................................................. 5

2.1 System description ...................................................................................................................... 5

2.2 Product recycling/disposal ...........................................................................................................7

Chapter 3 Sensor Installation ......................................................................................................... 9

3.1 Handling and Lifting Safety ..........................................................................................................9

3.2 Location and Position ................................................................................................................ 10

3.3 Sensor Installation ..................................................................................................................... 12

3.4 Process reference connection ....................................................................................................20

Chapter 4 Remote Transmitter Installation .................................................................................. 25

4.1 Pre-installation .......................................................................................................................... 25

4.2 Transmitter symbols ..................................................................................................................28

4.3 Mounting .................................................................................................................................. 29

4.4 Wiring ....................................................................................................................................... 30

Chapter 5 Basic Configuration ......................................................................................................47

5.1 Basic Setup ................................................................................................................................ 47

5.2 Local operator interface (LOI) .................................................................................................... 48

5.3 Field Communicator interface ................................................................................................... 48

5.4 Measurement units ................................................................................................................... 49

Chapter 6 Advanced installation details ....................................................................................... 51

6.1 Hardware switches .................................................................................................................... 51

6.2 Additional loops ........................................................................................................................ 53

6.3 Coil housing configuration .........................................................................................................64

Chapter 7 Operation .................................................................................................................... 71

7.1 Introduction .............................................................................................................................. 71

7.2 Local operator interface (LOI) .................................................................................................... 71

7.3 Field Communicator interface ................................................................................................... 80

Chapter 8 Advanced Configuration Functionality ......................................................................... 85

8.1 Introduction .............................................................................................................................. 85

8.2 Configure outputs ..................................................................................................................... 85

8.3 Configure HART .......................................................................................................................100

8.4 Configure LOI .......................................................................................................................... 104

8.5 Additional parameters .............................................................................................................105

8.6 Configure special units ............................................................................................................ 106

Chapter 9 Advanced Diagnostics Configuration ..........................................................................109

9.1 Introduction ............................................................................................................................ 109

9.2 Licensing and enabling ............................................................................................................ 110

9.3 Tunable empty pipe detection .................................................................................................111

9.4 Electronics temperature .......................................................................................................... 113

9.5 Ground/wiring fault detection ................................................................................................. 113

9.6 High process noise detection ...................................................................................................114

9.7 Coated electrode detection .....................................................................................................115

9.8 4-20 mA loop verification ........................................................................................................ 117

Reference manual i

Page 4

Contents

9.9 SMART™ Meter Verification ......................................................................................................118

9.10 Run manual SMART Meter Verification .................................................................................... 121

9.11 Continuous SMART Meter Verification .....................................................................................122

9.12 SMART Meter Verification test results ......................................................................................123

9.13 SMART Meter Verification measurements ............................................................................... 125

9.14 Optimizing the SMART Meter Verification ............................................................................... 127

Chapter 10 Digital Signal Processing ............................................................................................ 131

10.1 Introduction ............................................................................................................................ 131

10.2 Safety messages ......................................................................................................................131

10.3 Process noise profiles .............................................................................................................. 132

10.4 High process noise diagnostic ..................................................................................................133

10.5 Optimizing flow reading in noisy applications ..........................................................................133

10.6 Explanation of signal processing algorithm ..............................................................................136

Chapter 11 Maintenance ..............................................................................................................139

11.1 Introduction ............................................................................................................................ 139

11.2 Safety information ...................................................................................................................139

11.3 Installing a local operator interface (LOI) ................................................................................. 140

11.4 Replacing electronics stack ......................................................................................................141

11.5 Replacing a terminal block socket module ...............................................................................142

11.6 Replacing a terminal block with amp clips ............................................................................... 143

11.7 Trims ....................................................................................................................................... 144

Chapter 12 Troubleshooting ........................................................................................................ 149

12.1 Introduction ............................................................................................................................ 149

12.2 Safety information ...................................................................................................................150

12.3 Installation check and guide .................................................................................................... 150

12.4 Diagnostic messages ...............................................................................................................152

12.5 Basic troubleshooting ..............................................................................................................162

12.6 Sensor troubleshooting ........................................................................................................... 166

12.7 Installed sensor tests ............................................................................................................... 170

12.8 Uninstalled sensor tests ...........................................................................................................172

12.9 Technical support ....................................................................................................................174

12.10 Service .....................................................................................................................................175

Appendices and reference

Appendix A Product Specifications ................................................................................................177

A.1 Rosemount 8700M Flowmeter Platform specifications ........................................................... 177

A.2 Transmitter specifications ....................................................................................................... 182

A.3 8705-M Flanged Sensor Specifications .....................................................................................191

A.4 8711-M/L Wafer Sensor Specifications .....................................................................................196

A.5 8721 Hygienic (Sanitary) Sensor Specifications ........................................................................199

Appendix B Product Certifications ................................................................................................ 205

Appendix C Wiring Diagrams ........................................................................................................207

C.1 Wiring diagrams ...................................................................................................................... 208

C.2 775 Smart Wireless THUM™ Adapter wiring diagrams ..............................................................210

C.3 Field Communicator wiring diagrams ...................................................................................... 212

Appendix D Implementing a Universal Transmitter ....................................................................... 215

D.1 Safety messages ......................................................................................................................215

ii Rosemount® 8712EM Transmitter with HART Protocol Reference Manual

Page 5

Contents

D.2 Universal capability ..................................................................................................................216

D.3 Three step process ...................................................................................................................216

D.4 Wiring the universal transmitter .............................................................................................. 217

D.5 Rosemount sensors ................................................................................................................. 217

D.6 Brooks sensors .........................................................................................................................221

D.7 Endress and Hauser sensors .....................................................................................................223

D.8 Fischer and Porter sensors ....................................................................................................... 224

D.9 Foxboro sensors ...................................................................................................................... 231

D.10 Kent Veriflux VTC sensor ..........................................................................................................235

D.11 Kent sensors ............................................................................................................................237

D.12 Krohne sensors ........................................................................................................................238

D.13 Taylor sensors ..........................................................................................................................239

D.14 Yamatake Honeywell sensors .................................................................................................. 241

D.15 Yokogawa sensors ...................................................................................................................242

D.16 Generic manufacturer sensor to 8712 Transmitter .................................................................. 244

Reference manual iii

Page 6

Contents

iv Rosemount® 8712EM Transmitter with HART Protocol Reference Manual

Page 7

1 Safety messages

WARNING!

General hazards. Failure to follow these instructions could result in death or serious injury.

• Read this manual before working with the product. For personal and system safety, and

for optimum product performance, make sure you thoroughly understand the contents

before installing, using, or maintaining this product.

• Installation and servicing instructions are for use by qualified personnel only. Do not

perform any servicing other than that contained in the operating instructions, unless

qualified.

• Verify the installation is completed safely and is consistent with the operating

environment.

• Do not substitute factory components with non-factory compenents. Substitution of

components may impair Intrinsic Safety.

• Do not perform any services other than those contained in this manual.

• Process leaks may result in death or serious injury.

• Mishandling products exposed to a hazardous substance may result in death or serious

injury.

• The electrode compartment may contain line pressure; it must be depressurized before

the cover is removed.

• If the product being returned was exposed to a hazardous substance as defined by

OSHA, a copy of the required Material Safety Data Sheet (MSDS) for each hazardous

substance identified must be included with the returned goods.

• The products described in this document are NOT designed for nuclear-qualified

applications. Using non-nuclear qualified products in applications that require nuclearqualified hardware or products may cause inaccurate readings. For information on

Rosemount nuclear-qualified products, contact your local Emerson Process

Management Sales Representative.

Safety messages

Reference manual 1

Page 8

Safety messages

WARNING!

Explosion hazards. Failure to follow these instructions could cause an explosion, resulting in

death or serious injury.

• If installed in explosive atmospheres [hazardous areas, classified areas, or an “Ex”

environment], it must be assured that the device certification and installation

techniques are suitable for that particular environment.

• Do not remove transmitter covers in explosive atmospheres when the circuit is live.

Both transmitter covers must be fully engaged to meet explosion-proof requirements.

• Do not disconnect equipment when a flammable or combustible atmosphere is present.

• Before connecting a HART-based communicator in an explosive atmosphere, make sure

the instruments in the loop are installed in accordance with intrinsically safe or nonincendive field wiring practices.

• Do not connect a Rosemount transmitter to a non-Rosemount sensor that is located in

an explosive atmosphere. The transmitter has not been evaluated for use with other

manufacturers' magnetic flowmeter sensors in hazardous (Ex or Classified) areas.

Special care should be taken by the end-user and installer to ensure the transmitter

meets the safety and performance requirements of the other manufacturer’s

equipment.

• Follow national, local, and plant standards to properly earth ground the transmitter and

sensor. The earth ground must be separate from the process reference ground.

• Rosemount Magnetic Flowmeters ordered with non-standard paint options or non-

metallic labels may be subject to electrostatic discharge. To avoid electrostatic charge

build-up, do not rub the flowmeter with a dry cloth or clean with solvents.

WARNING!

Electrical hazards. Failure to follow these instructions could cause damaging and unsafe

discharge of electricity, resulting in death or serious injury.

• Follow national, local, and plant standards to properly earth ground the transmitter and

sensor. The earth ground must be separate from the process reference ground.

• Disconnect power before servicing circuits.

• Allow ten minutes for charge to dissipate prior to removing electronics compartment

cover. The electronics may store energy in this period immediately after power is

removed.

• Avoid contact with leads and terminals. High voltage that may be present on leads could

cause electrical shock.

• Rosemount Magnetic Flowmeters ordered with non-standard paint options or non-

metallic labels may be subject to electrostatic discharge. To avoid electrostatic charge

build-up, do not rub the flowmeter with a dry cloth or clean with solvents.

2 Rosemount® 8712EM Transmitter with HART Protocol Reference Manual

Page 9

Safety messages

NOTICE

Damage hazards. Failure to follow these instructions could resulting damage or destruction of

equipment.

• The sensor liner is vulnerable to handling damage. Never place anything through the

sensor for the purpose of lifting or gaining leverage. Liner damage may render the

sensor inoperable.

• Metallic or spiral-wound gaskets should not be used as they will damage the liner face of

the sensor. If spiral wound or metallic gaskets are required for the application, lining

protectors must be used. If frequent removal is anticipated, take precautions to protect

the liner ends. Short spool pieces attached to the sensor ends are often used for

protection.

• Correct flange bolt tightening is crucial for proper sensor operation and life. All bolts

must be tightened in the proper sequence to the specified torque specifications. Failure

to observe these instructions could result in severe damage to the sensor lining and

possible sensor replacement.

• In cases where high voltage/high current are present near the meter installation, ensure

proper protection methods are followed to prevent stray electricity from passing

through the meter. Failure to adequately protect the meter could result in damage to

the transmitter and lead to meter failure.

• Completely remove all electrical connections from both sensor and transmitter prior to

welding on the pipe. For maximum protection of the sensor, consider removing it from

the pipeline.

• Do not connect mains or line power to the magnetic flowtube sensor or to the

transmitter coil excitation circuit.

Reference manual 3

Page 10

Safety messages

4 Rosemount® 8712EM Transmitter with HART Protocol Reference Manual

Page 11

2 Introduction

Topics covered in this chapter:

System description

•

Product recycling/disposal

•

2.1 System description

The 8700M Magnetic Flowmeter Platform consists of a sensor and a transmitter. The

sensor is installed in-line with the process piping; the transmitter is remotely mounted to

the sensor.

Wall mount transmitterFigure 2-1:

Introduction

There are three Rosemount® flow sensors available.

8705 flanged sensorFigure 2-2:

(1) Also available for use with 8707 High Signal sensor with dual calibration (option code D2).

(1)

Reference manual 5

Page 12

Introduction

8711 wafer sensorFigure 2-3:

8721 hygienic sensorFigure 2-4:

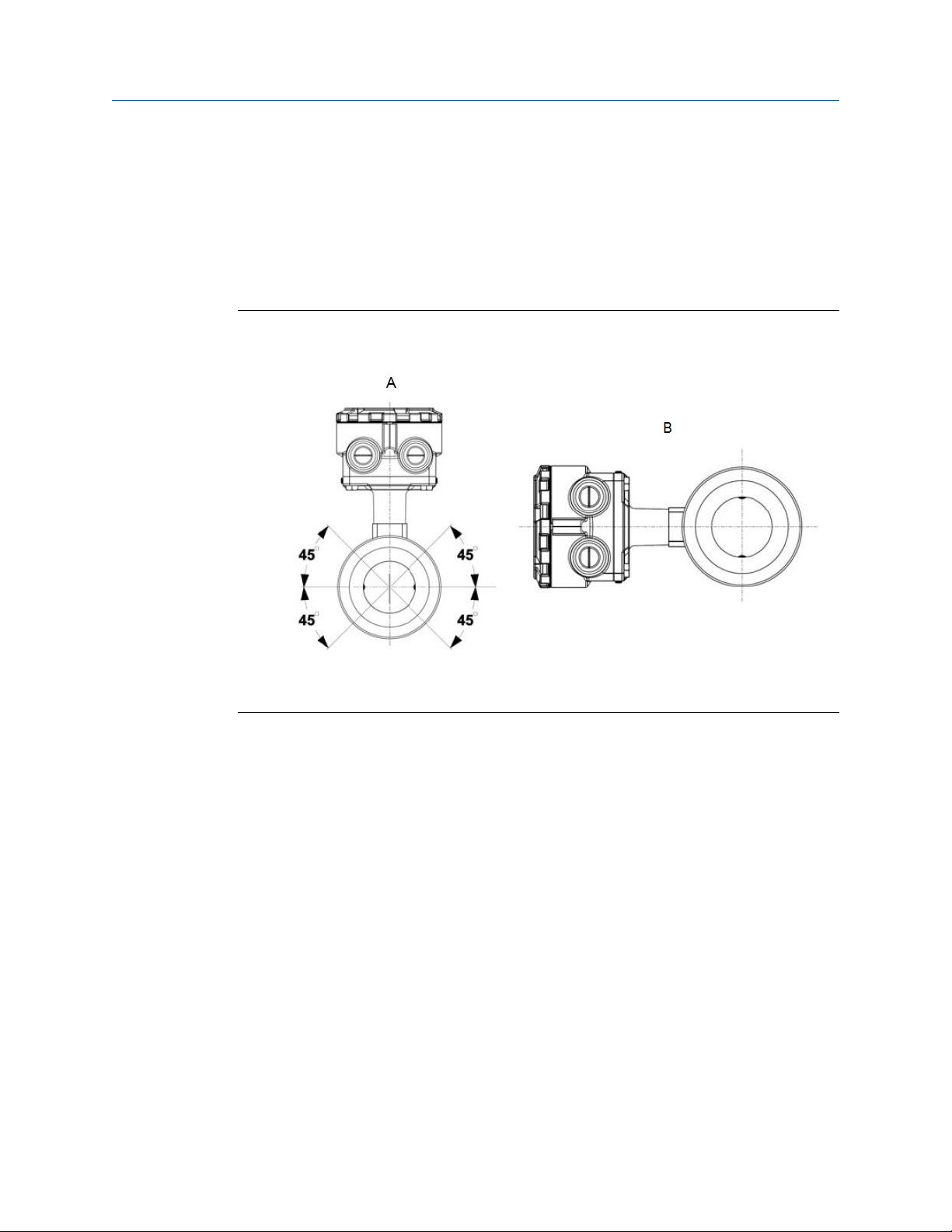

The flow sensor contains two magnetic coils located on opposite sides of the sensor. Two

electrodes, located perpendicular to the coils and opposite each other, make contact with

the liquid. The transmitter energizes the coils and creates a magnetic field. A conductive

liquid moving through the magnetic field generates an induced voltage at the electrodes.

This voltage is proportional to the flow velocity. The transmitter converts the voltage

detected by the electrodes into a flow reading. A cross-sectional view is show in Figure 2-5.

8705 Cross SectionFigure 2-5:

6 Rosemount® 8712EM Transmitter with HART Protocol Reference Manual

Page 13

2.2 Product recycling/disposal

Recycling of equipment and packaging should be taken into consideration and disposed of

in accordance with local and national legislation/regulations.

Introduction

Reference manual 7

Page 14

Introduction

8 Rosemount® 8712EM Transmitter with HART Protocol Reference Manual

Page 15

3 Sensor Installation

Topics covered in this chapter:

Handling and Lifting Safety

•

Location and Position

•

Sensor Installation

•

Process reference connection

•

This chapter provides instructions for handling and installing the flow sensor with a

remotely mounted transmitter.

Related information

Remote Transmitter Installation

Sensor Installation

3.1 Handling and Lifting Safety

CAUTION!

To reduce the risk of personal injury or damage to equipment, follow all lifting and handling

instructions.

• Handle all parts carefully to prevent damage. Whenever possible, transport the system

to the installation site in the original shipping container.

• PTFE-lined sensors are shipped with end covers that protect it from both mechanical

damage and normal unrestrained distortion. Remove the end covers just before

installation.

• Keep the shipping plugs in the conduit ports until you are ready to connect and seal

them. Appropriate care should be taken to prevent water ingress.

• The sensor should be supported by the pipeline. Pipe supports are recommended on

both the inlet and outlet sides of the sensor pipeline. There should be no additional

support attached to the sensor.

• Use proper PPE (Personal Protection Equipment) including safety glasses and steel toed

shoes.

• Do not lift the meter by holding the electronics housing or junction box.

• The sensor liner is vulnerable to handling damage. Never place anything through the

sensor for the purpose of lifting or gaining leverage. Liner damage can render the sensor

useless.

• Do not drop the device from any height.

Reference manual 9

Page 16

Sensor Installation

3.2 Location and Position

3.2.1 Environmental considerations

To ensure maximum transmitter life, avoid extreme temperatures and excessive vibration.

Typical problem areas include the following:

• Tropical/desert installations in direct sunlight

• Outdoor installations in arctic climates

Remote mounted transmitters may be installed in the control room to protect the

electronics from the harsh environment and to provide easy access for configuration or

service.

3.2.2 Upstream and downstream piping

To ensure specified accuracy over widely varying process conditions, install the sensor with

a minimum of five straight pipe diameters upstream and two pipe diameters downstream

from the electrode plane.

3.2.3

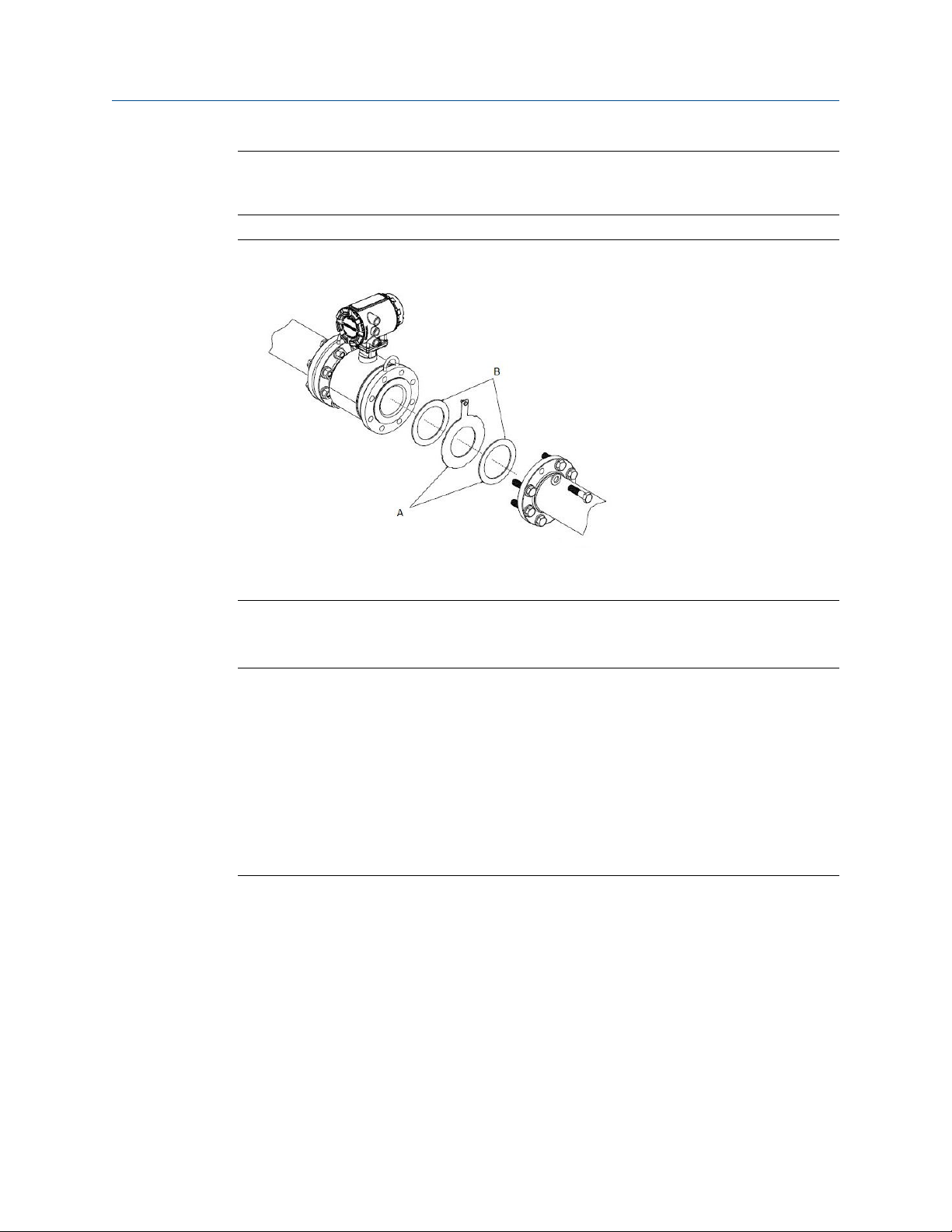

Upstream and downstream straight pipe diametersFigure 3-1:

A. Five pipe diameters (upstream)

B. Two pipe diameters (downstream)

C. Flow direction

Installations with reduced upstream and downstream straight runs are possible. In

reduced straight run installations, the meter may not meet absolute accuracy

specifications. Reported flow rates will still be highly repeatable.

Flow direction

The sensor should be mounted so that the arrow points in the direction of flow.

10 Rosemount® 8712EM Transmitter with HART Protocol Reference Manual

Page 17

Flow direction arrowFigure 3-2:

3.2.4 Sensor piping location and orientation

The sensor should be installed in a location that ensures it remains full during operation.

Depending on where it is installed, orientation must also be considered.

• Vertical installation with upward process fluid flow keeps the cross-sectional area

full, regardless of flow rate.

• Horizontal installation should be restricted to low piping sections that are normally

full.

Sensor Installation

Sensor orientationFigure 3-3:

A. Flow direction

Reference manual 11

Page 18

Sensor Installation

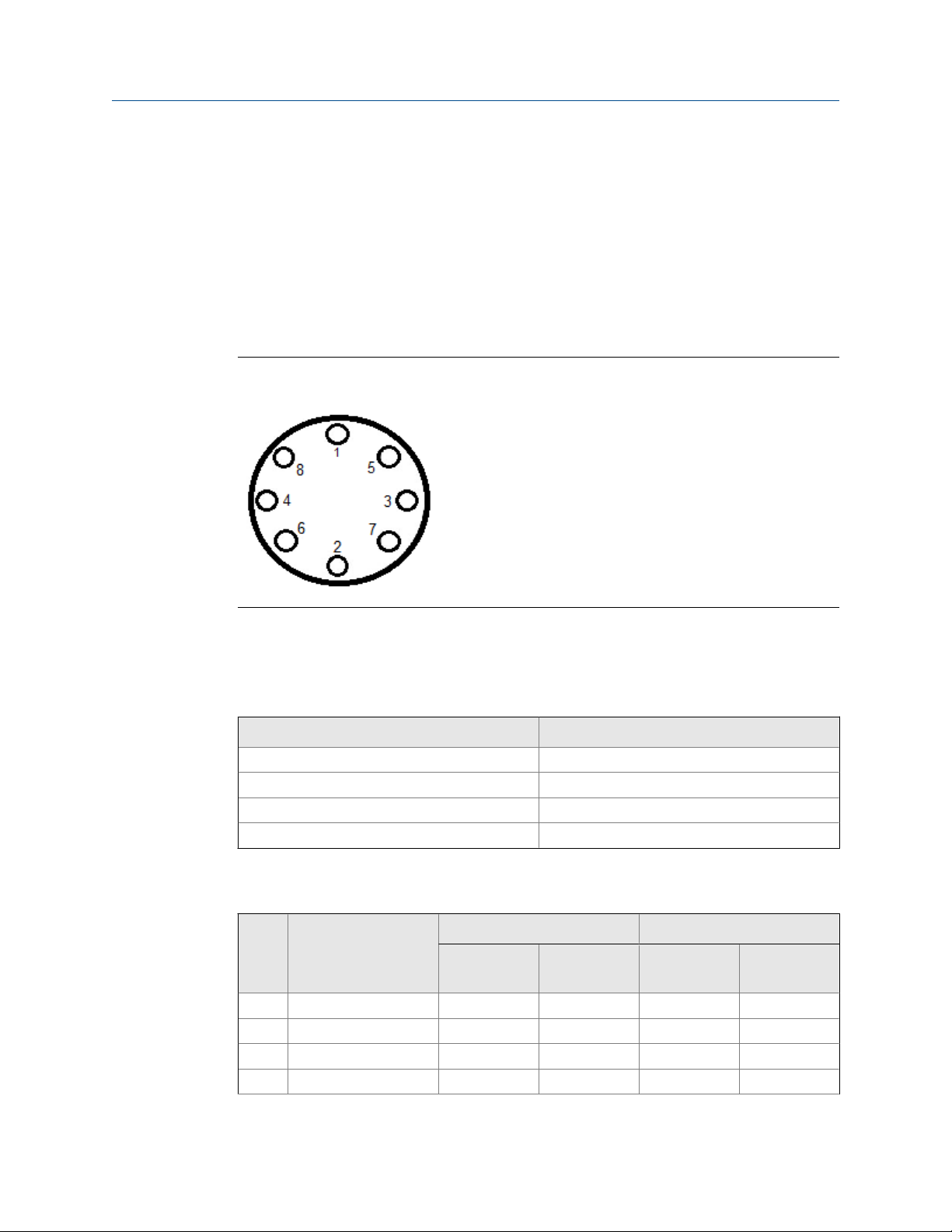

3.2.5 Electrode orientation

The electrodes in the sensor are properly oriented when the two measurement electrodes

are in the 3 and 9 o’clock positions or within 45 degrees from the horizontal, as shown on

the left side of Figure 3-4. Avoid any mounting orientation that positions the top of the

sensor at 90 degrees from the vertical position as shown on the right of the Electrode

Orientation figure.

Electrode orientationFigure 3-4:

A. Correct orientation

B. Incorrect orientation

The sensor may require a specific orientation to comply with Hazardous Area T-code

rating. Refer to the approrpirate reference manual for any potential restrictions.

3.3

Sensor Installation

3.3.1 Flanged sensors

Gaskets

The sensor requires a gasket at each process connection. The gasket material must be

compatible with the process fluid and operating conditions. Gaskets are required on each

side of a grounding ring (see Figure 3-5). All other applications (including sensors with

lining protectors or a grounding electrode) require only one gasket on each process

connection.

12 Rosemount® 8712EM Transmitter with HART Protocol Reference Manual

Page 19

Sensor Installation

Note

Metallic or spiral-wound gaskets should not be used as they will damage the liner face of the sensor.

If spiral wound or metallic gaskets are required for the application, lining protectors must be used.

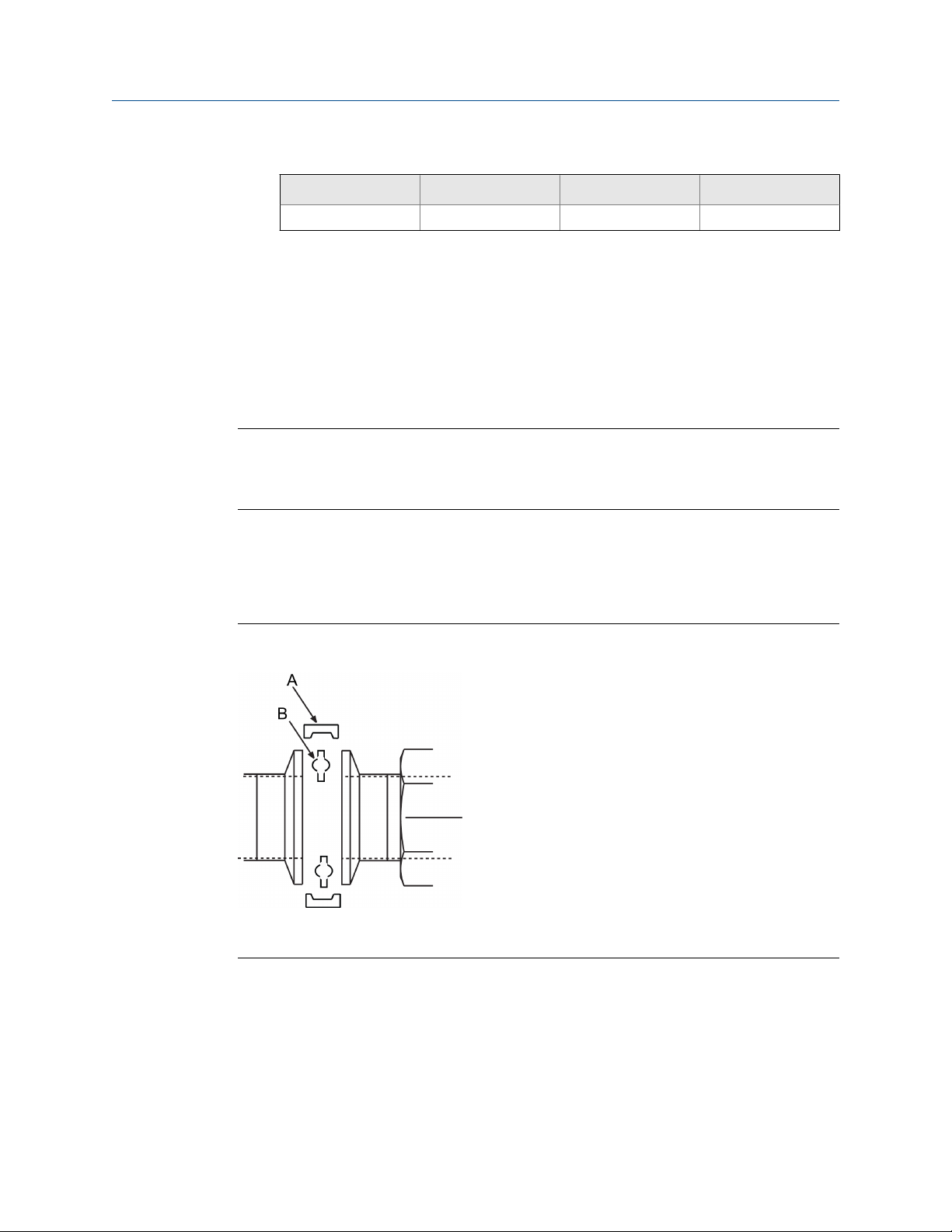

Gasket placement for flanged sensorsFigure 3-5:

A. Grounding ring and gasket (optional)

B. Customer-supplied gasket

Bolts

Note

Do not bolt one side at a time. Tighten both sides simultaneously. Example:

1. Snug upstream

2. Snug downstream

3. Tighten upstream

4. Tighten downstream

Do not snug and tighten the upstream side and then snug and tighten the downstream side. Failure

to alternate between the upstream and downstream flanges when tightening bolts may result in

liner damage.

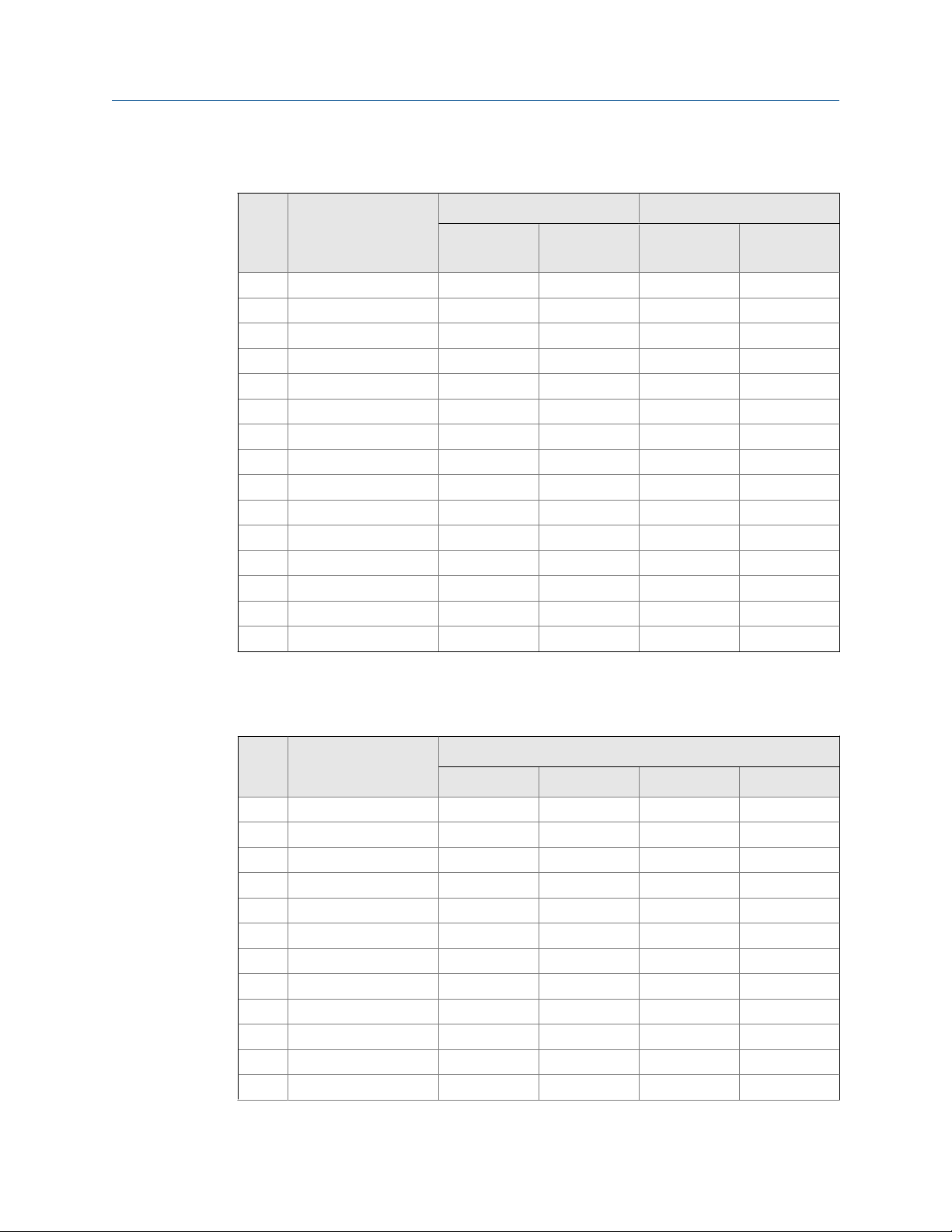

Suggested torque values by sensor line size and liner type are listed in Table 3-2 for ASME

B16.5 flanges and Table 3-3 or Table 3-4 for EN flanges. Consult the factory if the flange

rating of the sensor is not listed. Tighten flange bolts on the upstream side of the sensor in

the incremental sequence shown in Figure 3-6 to 20% of the suggested torque values.

Repeat the process on the downstream side of the sensor. For sensors with greater or

fewer flange bolts, tighten the bolts in a similar crosswise sequence. Repeat this entire

tightening sequence at 40%, 60%, 80%, and 100% of the suggested torque values.

Reference manual 13

Page 20

Sensor Installation

If leakage occurs at the suggested torque values, the bolts can be tightened in additional

10% increments until the joint stops leaking, or until the measured torque value reaches

the maximum torque value of the bolts. Practical consideration for the integrity of the liner

often leads to distinct torque values to stop leakage due to the unique combinations of

flanges, bolts, gaskets, and sensor liner material.

Check for leaks at the flanges after tightening the bolts. Failure to use the correct

tightening methods can result in severe damage. While under pressure, sensor materials

may deform over time and require a second tightening 24 hours after the initial

installation.

Flange bolt torquing sequenceFigure 3-6:

Prior to installation, identify the lining material of the flow sensor to ensure the suggested

torque values are applied.

Lining materialTable 3-1:

Fluoropolymer liners Other liners

T - PTFE P - Polyurethane

F - ETFE N - Neoprene

A - PFA L - Linatex (Natural Rubber)

K - PFA+ D - Adiprene

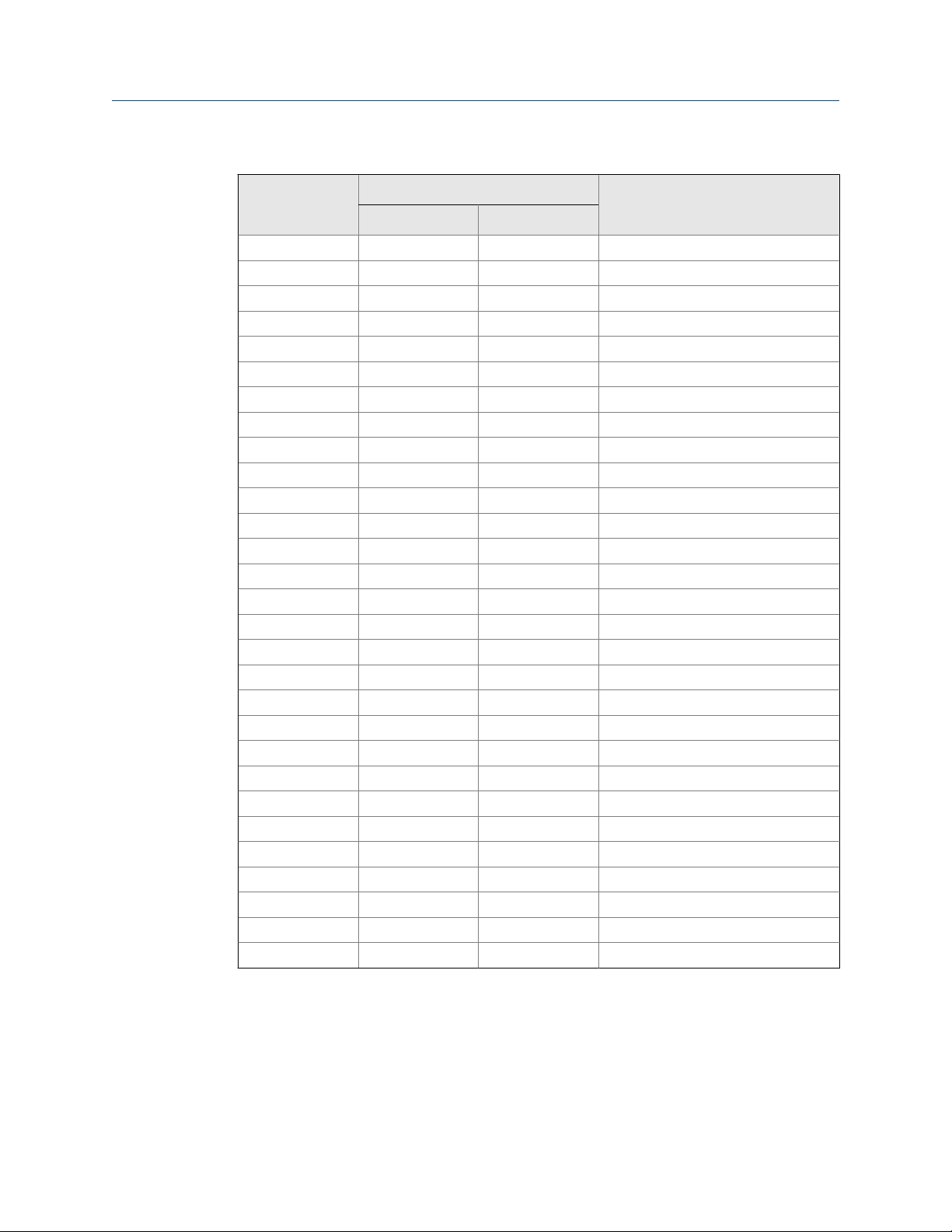

Suggested flange bolt torque values for Rosemount 8705 (ASME)Table 3-2:

Fluoropolymer liners Other liners

Size

Code Line Size

005 0.5-in. (15 mm) 8 8 N/A N /A

010 1-in. (25 mm) 8 12 6 10

015 1.5-in. (40 mm) 13 25 7 18

020 2-in. (50 mm) 19 17 14 11

Class 150

(pound-feet)

Class 300

(pound-feet)

Class 150

(pound-feet)

Class 300

(pound feet)

14 Rosemount® 8712EM Transmitter with HART Protocol Reference Manual

Page 21

Sensor Installation

Table 3-2:

(continued)

Size

Code Line Size

025 2.5-in. (65 mm) 22 24 17 16

030 3-in. (80 mm) 34 35 23 23

040 4-in. (100 mm) 26 50 17 32

050 5-in. (125 mm) 36 60 25 35

060 6-in. (150 mm) 45 50 30 37

080 8-in. (200 mm) 60 82 42 55

100 10-in. (250 mm) 55 80 40 70

120 12-in. (300 mm) 65 125 55 105

140 14-in. (350 mm) 85 110 70 95

160 16-in. (400 mm) 85 160 65 140

180 18-in. (450 mm) 120 170 95 150

200 20-in. (500 mm) 110 175 90 150

240 24-in. (600 mm) 165 280 140 250

300 30-in. (750 mm) 195 415 165 375

360 36-in. (900 mm) 280 575 245 525

Suggested flange bolt torque values for Rosemount 8705 (ASME)

Fluoropolymer liners Other liners

Class 150

(pound-feet)

Class 300

(pound-feet)

Class 150

(pound-feet)

Class 300

(pound feet)

Table 3-3:

Suggested flange bolt torque values for Rosemount 8705 sensors with

fluoropolymer liners (EN 1092-1)

Size

code Line size

005 0.5-in. (15 mm) N/A N/A N/A 10

010 1-in. (25 mm) N/A N/A N/A 20

015 1.5-in. (40 mm) N/A N/A N/A 50

020 2-in. (50 mm) N/A N/A N/A 60

025 2.5-in. (65 mm) N/A N/A N/A 50

030 3-in. (80 mm) N/A N/A N/A 50

040 4-in. (100 mm) N/A 50 N/A 70

050 5.0-in. (125 mm) N/A 70 N/A 100

060 6-in. (150mm) N/A 90 N/A 130

080 8-in. (200 mm) 130 90 130 170

100 10-in. (250 mm) 100 130 190 250

120 12-in. (300 mm) 120 170 190 270

Fluoropolymer liners (in Newton-meters)

PN 10 PN 16 PN 25 PN 40

Reference manual 15

Page 22

Sensor Installation

Table 3-3:

Suggested flange bolt torque values for Rosemount 8705 sensors with

fluoropolymer liners (EN 1092-1) (continued)

Size

code Line size

140 14-in. (350 mm) 160 220 320 410

160 16-in. (400 mm) 220 280 410 610

180 18-in. (450 mm) 190 340 330 420

200 20-in. (500 mm) 230 380 440 520

240 24-in. (600 mm) 290 570 590 850

Table 3-4:

Suggested flange bolt torque values for Rosemount 8705 sensors with

Fluoropolymer liners (in Newton-meters)

PN 10 PN 16 PN 25 PN 40

non-fluoropolymer liners (EN 1092-1)

Size

Code Line Size

005 0.5-in. (15 mm) N/A N/A N/A 20

010 1-in. (25 mm) N/A N/A N/A 30

015 1.5-in. (40 mm) N/A N/A N/A 40

020 2-in. (50 mm) N/A N/A N/A 30

025 2.5-in. (65 mm) N/A N/A N/A 35

030 3-in. (80 mm) N/A N/A N/A 30

040 4-in. (100 mm) N/A 40 N/A 50

050 5.0-in. (125 mm) N/A 50 N/A 70

060 6-in. (150mm) N/A 60 N/A 90

080 8-in. (200 mm) 90 60 90 110

100 10-in. (250 mm) 70 80 130 170

120 12-in. (300 mm) 80 110 130 180

140 14-in. (350 mm) 110 150 210 288

160 16-in. (400 mm) 150 190 280 410

180 18-in. (450 mm) 130 230 220 280

200 20-in. (500 mm) 150 260 300 350

240 24-in. (600 mm) 200 380 390 560

Non-fluoropolymer liners (in Newton-meters)

PN 10 PN 16 PN 25 PN 40

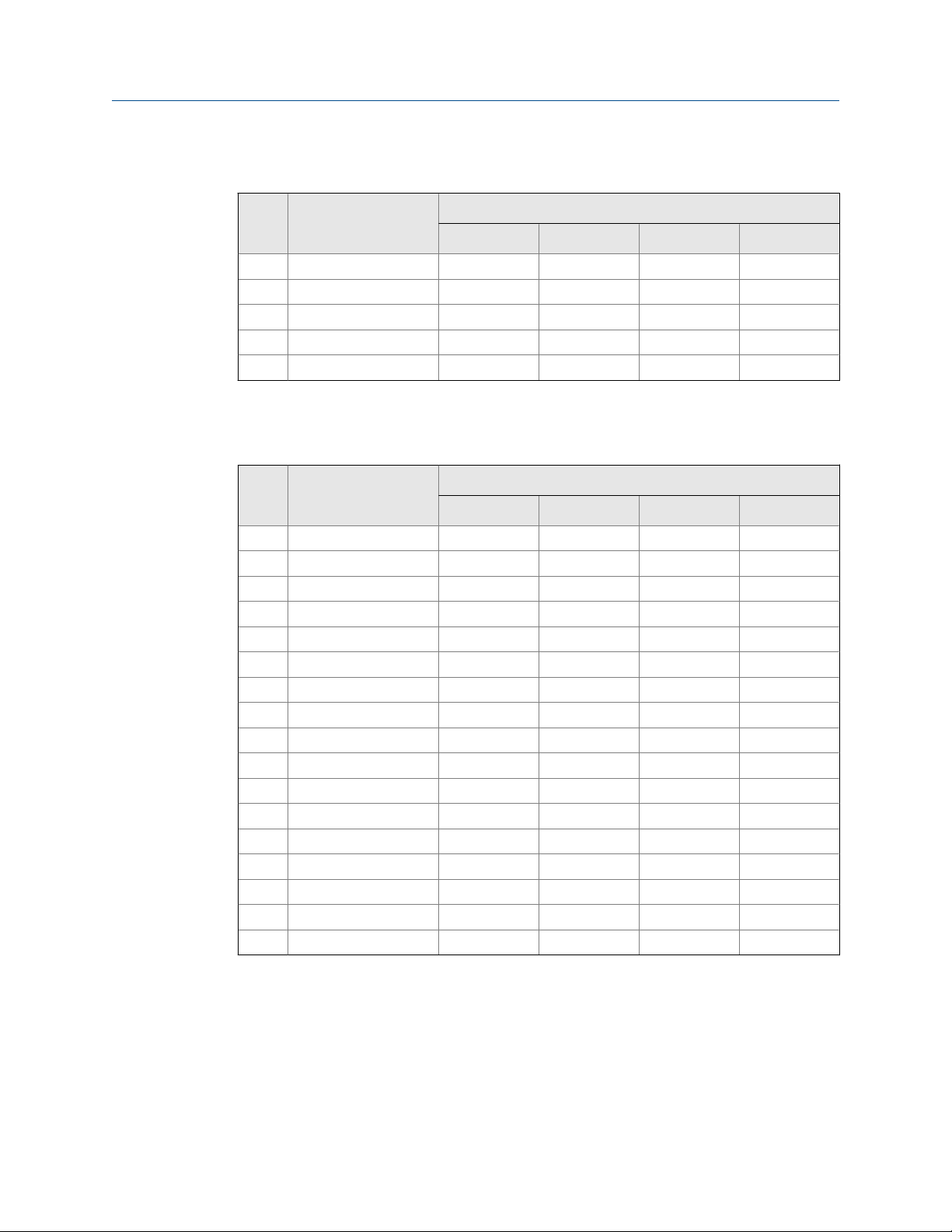

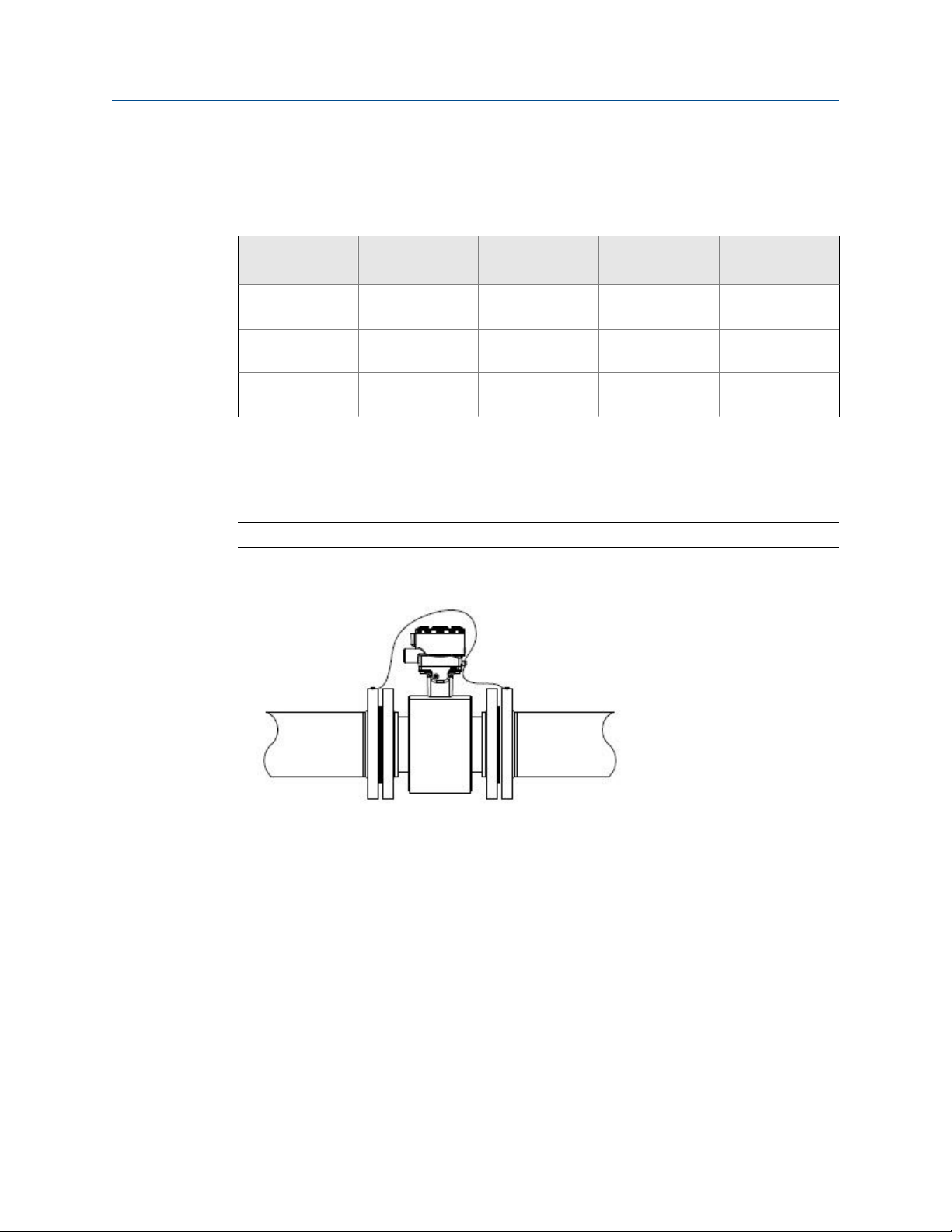

3.3.2 Wafer sensors

When installing wafer sensors, there are several components that must be included and

requirements that must be met.

16 Rosemount® 8712EM Transmitter with HART Protocol Reference Manual

Page 23

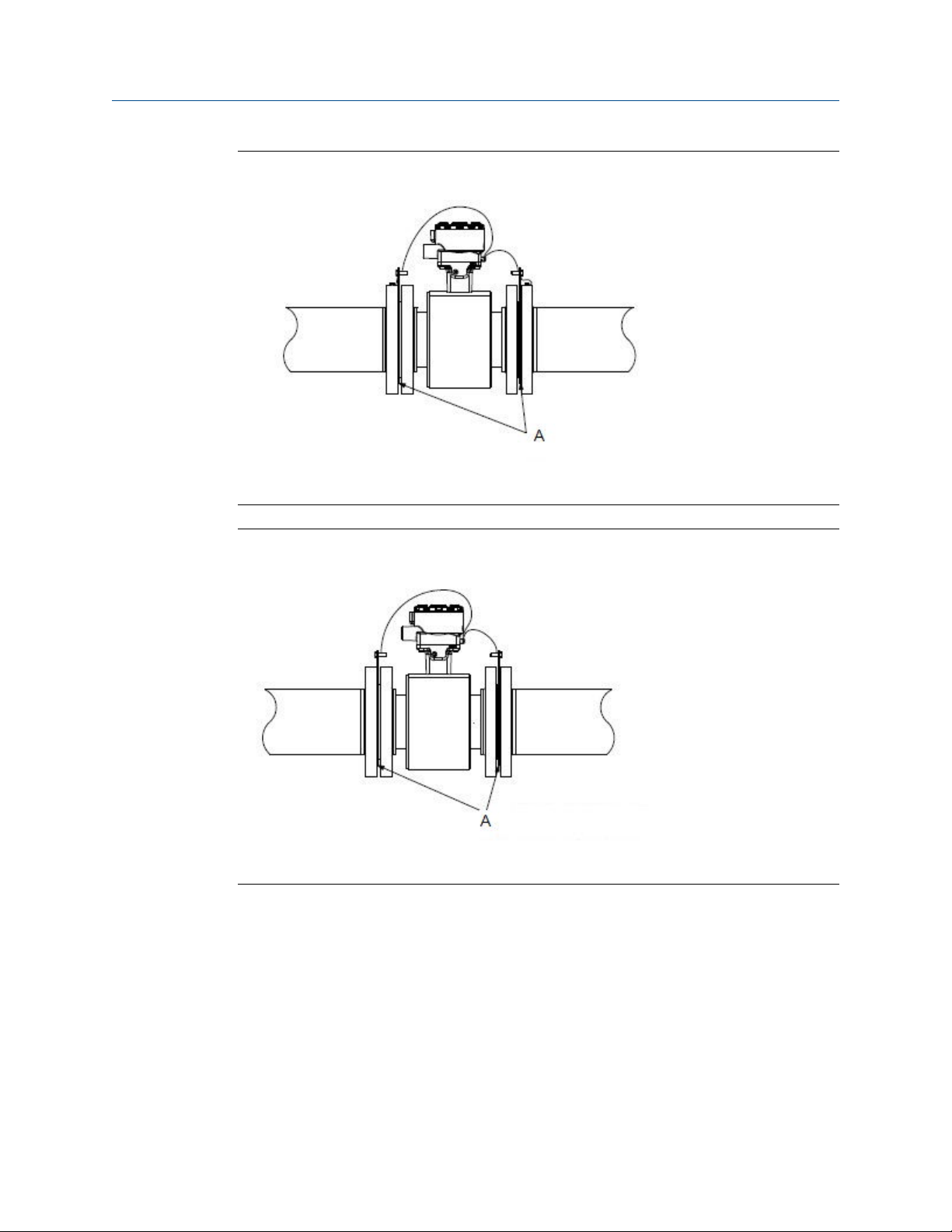

Wafer sensors installation components and assembly requirementsFigure 3-7:

A. Ground ring (optional)

B. Customer supplied gaskets

C. Spacer installation (horizontal meters)

D. Spacer installation (vertical meters)

E. O-ring

F. Installation studs, nuts, and washers (optional)

G. Wafer alignment spacer

H. Flow

Sensor Installation

Gaskets

The sensor requires a gasket at each process connection. The gasket material selected

must be compatible with the process fluid and operating conditions. Gaskets are required

on each side of a grounding ring. See Figure 3-7.

Note

Metallic or spiral-wound gaskets should not be used as they will damage the liner face of the sensor.

Alignment spacers

On 1.5 inch through 8 inch (40 through 200 mm) line sizes, Rosemount requires installing

the alignment spacers to ensure proper centering of the wafer sensor between the process

flanges. To order an Alignment Spacer Kit (quantity 3 spacers) use p/n 08711-3211-xxxx

where xxxx equals the dash number shown in Table 3-5.

Rosemount alignment spacersTable 3-5:

Line size

Dash-no. (-xxxx)

0A15 1.5 40 JIS 10K-20K

0A20 2 50 JIS 10K-20K

0A30 3 80 JIS 10K

Flange rating(in) (mm)

Reference manual 17

Page 24

Sensor Installation

Rosemount alignment spacers (continued)Table 3-5:

Line size

Dash-no. (-xxxx)

0B15 1.5 40 JIS 40K

AA15 1.5 40 ASME- 150#

AA20 2 50 ASME - 150#

AA30 3 80 ASME - 150#

AA40 4 100 ASME - 150#

AA60 6 150 ASME - 150#

AA80 8 200 ASME - 150#

AB15 1.5 40 ASME - 300#

AB20 2 50 ASME - 300#

AB30 3 80 ASME - 300#

AB40 4 100 ASME - 300#

AB60 6 150 ASME - 300#

AB80 8 200 ASME - 300#

DB40 4 100 EN 1092-1 - PN10/16

DB60 6 150 EN 1092-1 - PN10/16

DB80 8 200 EN 1092-1 - PN10/16

DC80 8 200 EN 1092-1 - PN25

DD15 1.5 40 EN 1092-1 - PN10/16/25/40

DD20 2 50 EN 1092-1 - PN10/16/25/40

DD30 3 80 EN 1092-1 - PN10/16/25/40

DD40 4 100 EN 1092-1 - PN25/40

DD60 6 150 EN 1092-1 - PN25/40

DD80 8 200 EN 1092-1 - PN40

RA80 8 200 AS40871-PN16

RC20 2 50 AS40871-PN21/35

RC30 3 80 AS40871-PN21/35

RC40 4 100 AS40871-PN21/35

RC60 6 150 AS40871-PN21/35

RC80 8 200 AS40871-PN21/35

Flange rating(in) (mm)

Studs

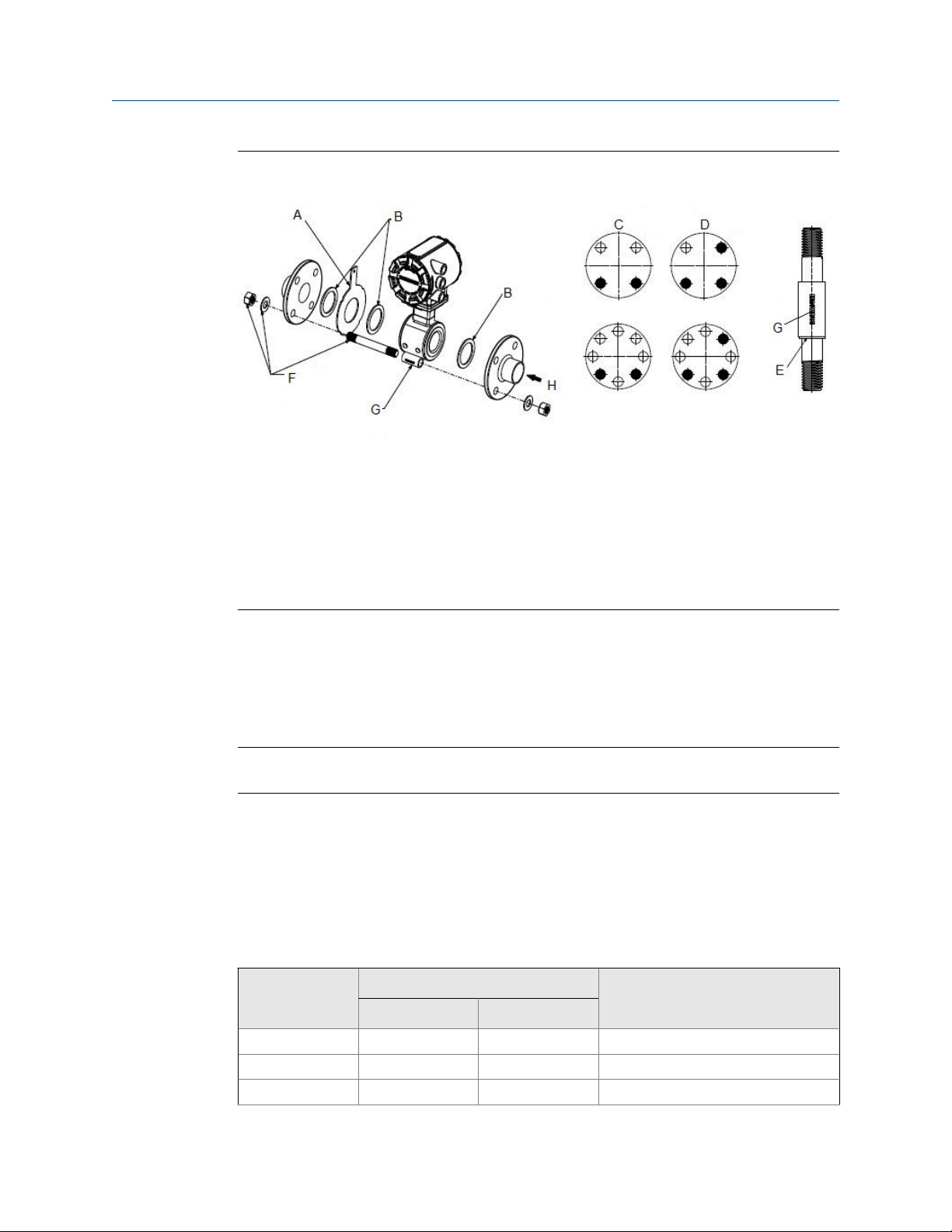

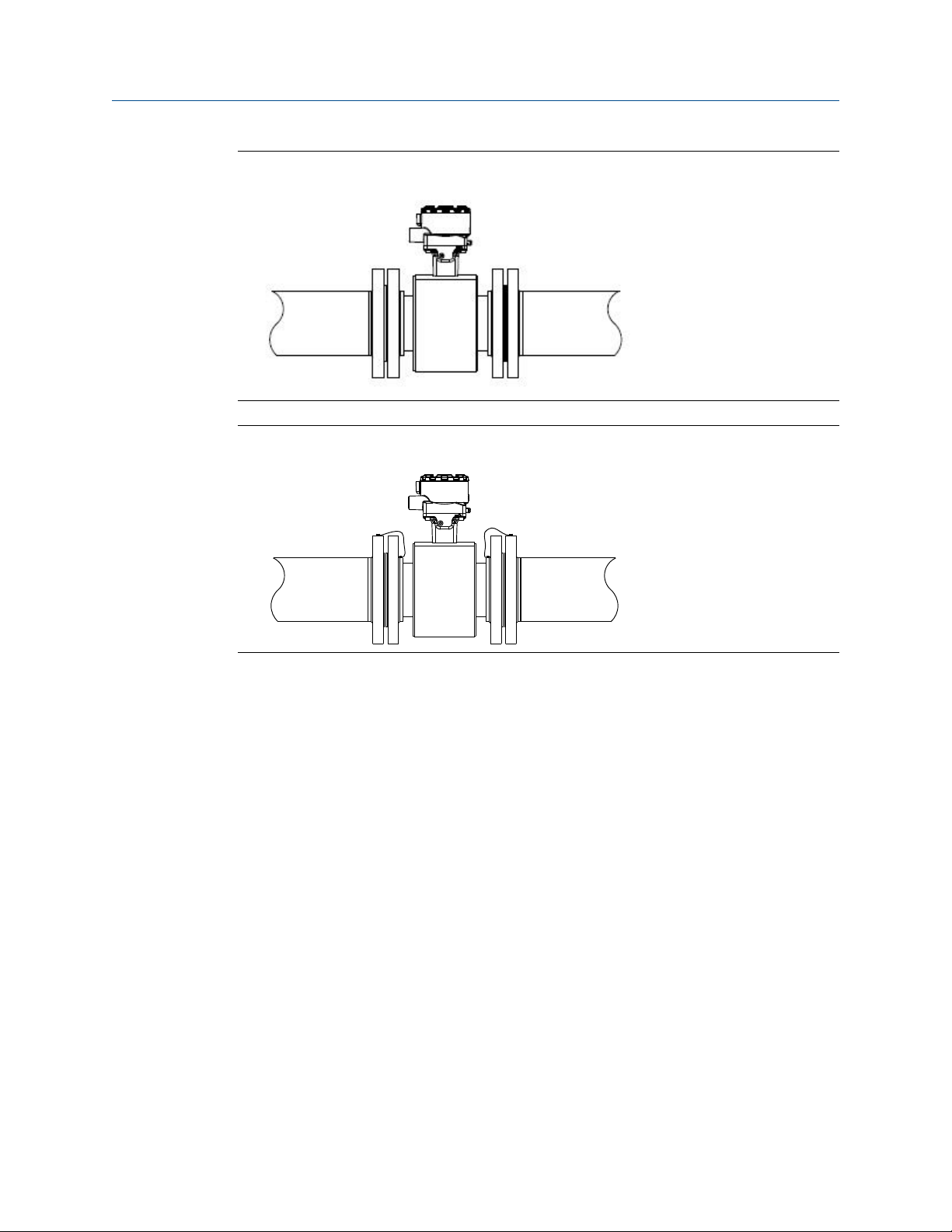

Wafer sensors require threaded studs. See Figure 3-8 for torque sequence. Always check for

leaks at the flanges after tightening the flange bolts. All sensors require a second

tightening 24 hours after initial flange bolt tightening.

18 Rosemount® 8712EM Transmitter with HART Protocol Reference Manual

Page 25

Sensor Installation

Stud specificationsTable 3-6:

Nominal sensor size Stud specifications

0.15–1-in. (4–25 mm) 316 SST ASTM A193, Grade B8M, Class 1 threaded mounted studs

1½–8-in. (40–200 mm) CS, ASTM A193, Grade B7, threaded mounting

studs

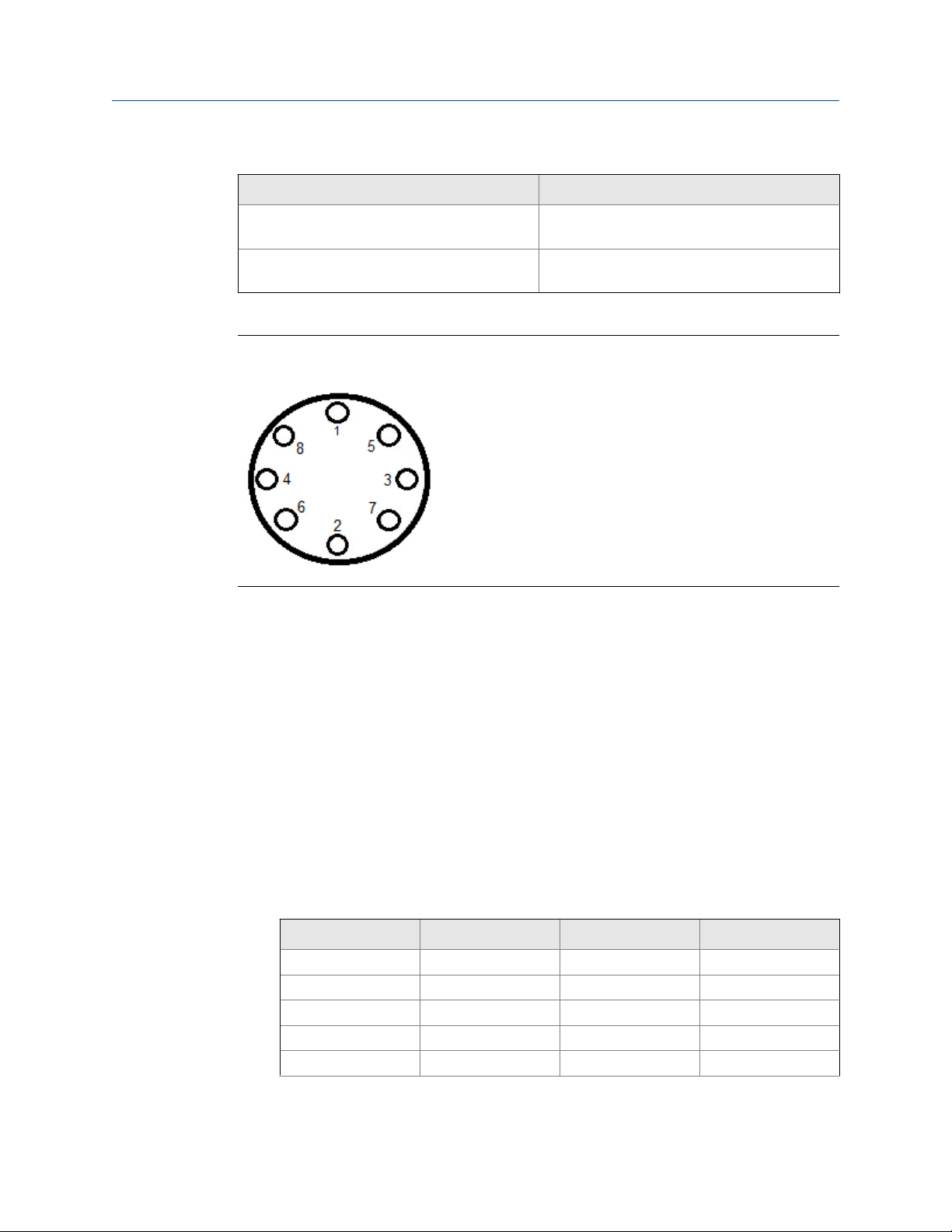

Flange bolt torquing sequenceFigure 3-8:

Installation

1. Insert studs for the the bottom side of the sensor between the pipe flanges and

center the alignment spacer in the middle of the stud. See Figure 3-7 for the bolt

hole locations recommended for the spacers provided. Stud specifications are listed

in Table 3-6.

2. Place the sensor between the flanges. Make sure the alignment spacers are properly

centered on the studs. For vertical flow installations slide the o-ring over the stud to

keep the spacer in place. See Figure 3-7. Ensure the spacers match the flange size

and class rating for the process flanges. See Table 3-5.

3. Insert the remaining studs, washers, and nuts.

4. Tighten to the torque specifications shown in Table 3-7. Do not over-tighten the

bolts or the liner may be damaged.

Rosemount 8711 torque specificationsTable 3-7:

Size code Line size Pound-feet Newton-meter

015 1.5-in. (40 mm) 15 20

020 2-in. (50 mm) 25 34

030 3-in. (80 mm) 40 54

040 4-in. (100 mm) 30 41

060 6-in. (150 mm) 50 68

Reference manual 19

Page 26

Sensor Installation

Rosemount 8711 torque specifications (continued)Table 3-7:

Size code Line size Pound-feet Newton-meter

080 8-in. (200 mm) 70 95

3.3.3 Sanitary senors

Gaskets

The sensor requires a gasket at each of its connections to adjacent devices or piping. The

gasket material selected must be compatible with the process fluid and operating

conditions.

Note

Gaskets are supplied between the IDF fitting and the process connection fitting, such as a Tri-Clamp

fitting, on all Rosemount 8721 Sanitary sensors except when the process connection fittings are not

supplied and the only connection type is an IDF fitting.

Alignment and bolting

Standard plant practices should be followed when installing a magmeter with sanitary

fittings. Unique torque values and bolting techniques are not required.

Sanitary sensor gasket and clamp alignmentFigure 3-9:

A. User supplied clamp

B. User supplied gasket

3.4

20 Rosemount® 8712EM Transmitter with HART Protocol Reference Manual

Process reference connection

The figures shown in this chapter illustrate process reference connections only. Earth

safety ground is also required as part of this installation, but is not shown in the figures.

Follow national, local, and plant electrical codes for safety ground.

Page 27

Sensor Installation

Use the Process reference options table to determine which process reference option to

follow for proper installation.

Process reference optionsTable 3-8:

Grounding

Type of pipe

Conductive unlined pipe

Conductive lined

pipe

Non-conductive

pipe

Note

For line sizes 10-inch and larger the ground strap may come attached to the sensor body near the

flange. See Figure 3-14.

Figure 3-10:

straps Grounding rings

See Figure 3-10 See Figure 3-11 See Figure 3-13 See Figure 3-11

Insufficient

grounding

Insufficient

grounding

See Figure 3-11 See Figure 3-10 See Figure 3-11

See Figure 3-12 Not recommen-

Grounding straps in conductive unlined pipe or reference electrode in

Reference electrode

ded

Lining protectors

See Figure 3-12

lined pipe

Reference manual 21

Page 28

Sensor Installation

Grounding with grounding rings or lining protectors in conductive pipeFigure 3-11:

A. Grounding rings or lining protectors

Figure 3-12:

Grounding with grounding rings or lining protectors in non-conductive

pipe

A. Grounding rings or lining protectors

22 Rosemount® 8712EM Transmitter with HART Protocol Reference Manual

Page 29

Sensor Installation

Grounding with reference electrode in conductive unlined pipeFigure 3-13:

Grounding for line sizes 10-in. and largerFigure 3-14:

Reference manual 23

Page 30

Sensor Installation

24 Rosemount® 8712EM Transmitter with HART Protocol Reference Manual

Page 31

Remote Transmitter Installation

4 Remote Transmitter Installation

Topics covered in this chapter:

Pre-installation

•

Transmitter symbols

•

Mounting

•

Wiring

•

This chapter provides instructions for installing and wiring a remotely mounted

transmitter.

Related information

Sensor Installation

4.1 Pre-installation

Before installing the transmitter, there are several pre-installation steps that should be

completed to make the installation process easier:

• Identify options and configurations that apply to your application

• Set the hardware switches if necessary

• Consider mechanical, electrical, and environmental requirements

Note

Refer to Appendix A for more detailed requirements.

Identify options and configurations

The typical transmitter installation includes a device power connection, a 4-20mA output

connection, and sensor coil and electrode connections. Other applications may require

one or more of the following configurations or options:

• Pulse output

• Discrete input/discrete output

• HART multidrop configuration

Hardware switches

The transmitter may have up to four user-selectable hardware switches. These switches

set the alarm mode, internal/external analog power, internal/external pulse power, and

transmitter security. The standard configuration for these switches when shipped from the

factory is as follows:

Reference manual 25

Page 32

Remote Transmitter Installation

Setting Factory configuration

Alarm mode High

Internal/external analog power Internal

Internal/external pulse power External

Transmitter security Off

The analog power switch and pulse power switches are not available when ordered with

intrinsically safe output, ordering code B.

In most cases, it is not necessary to change the setting of the hardware switches. If the

switch settings need to be changed, refer to Section 6.1.

Be sure to identify any additional options and configurations that apply to the installation.

Keep a list of these options for consideration during the installation and configuration

procedures.

Mechanical considerations

Hardware switch default settingsTable 4-1:

The mounting site for the transmitter should provide enough room for secure mounting,

easy access to conduit entries, full opening of the transmitter covers, and easy readability

of the Local Operator Interface (LOI) screen (if equipped).

26 Rosemount® 8712EM Transmitter with HART Protocol Reference Manual

Page 33

Remote Transmitter Installation

Rosemount 8712EM Dimensional DrawingFigure 4-1:

2.81

[71]

C

D

9.0

[229]

3.12

11.15

[283]

A

B

3.90

[99]

[79]

12.03

[306]

17.68

[449]

1.94

[49]

3.51

[89]

1.70

[43]

1.94

[49]

11.36

[289]

1.59

[40]

7.80

[198]

A. Conduit entry, 1/2-14 NPT (4 places)

B. Ground lug

C. LOI keypad cover

D. Lower cover opens for electrical connections

Note

Dimensions are in inches [Millimeters]

Electrical considerations

Before making any electrical connections to the transmitter, consider national, local, and

plant electrical installation requirements. Be sure to have the proper power supply,

conduit, and other accessories necessary to comply with these standards.

The transmitter requires external power. Ensure access to a suitable power source.

Reference manual 27

Page 34

Remote Transmitter Installation

Rosemount 8712EM Flow Transmitter

Power input AC power:

Pulsed circuit Internally powered (Active): Outputs up to

4-20mA output circuit Internally Powered (Active): Outputs up to

Um 250V

Coil excitation output 500mA, 40V max, 9W max

Electrical DataTable 4-2:

90–250VAC, 0.45A, 40VA

Standard DC power:

12–42VDC, 1.2A, 15W

Low power DC:

12–30VDC, 0.25A, 3W

12VDC, 12.1mA, 73mW

Externally powered (Passive): Input up to

28VDC, 100mA, 1W

25mA, 24VDC, 600mW

Externally Powered (Passive): Input up to 25mA,

30VDC, 750mW

4.2

Environmental considerations

To ensure maximum transmitter life, avoid extreme temperatures and excessive vibration.

Typical problem areas include the following:

• Tropical or desert installations in direct sunlight

• Outdoor installations in arctic climates

Remote mounted transmitters may be installed in the control room to protect the

electronics from the harsh environment and to provide easy access for configuration or

service.

Transmitter symbols

Caution symbol — check product documentation for details

Protective conductor (grounding) terminal

28 Rosemount® 8712EM Transmitter with HART Protocol Reference Manual

Page 35

4.3 Mounting

Wall mount transmitters are shipped with mounting hardware for use on a 2-in. pipe or flat

surface.

Mounting bracketFigure 4-2:

Remote Transmitter Installation

A

B

4.3.1

4.3.2

C

A. U-bolt

B. Saddle clamp

C. Fasteners

Pipe mounting

1. Attach the saddle clamp to the pipe using the U-bolt mounting hardware.

2. Attach the transmitter to the saddle clamp assembly with appropriate fasteners.

Surface mounting

Attach the transmitter to the mounting location using customer supplied mounting

screws. The installation of the transmitter shall be rated for four (4) times the weight of the

transmitter or 44lbs ( 20kgs).

Reference manual 29

Page 36

Remote Transmitter Installation

4.4 Wiring

4.4.1 Conduit entries and connections

Transmitter conduit entries ports are ½"-14NPT as standard, M20 conduit connections will

use an adapter. Conduit connections should be made in accordance with national, local,

and plant electrical codes. Unused conduit entries should be sealed with the appropriate

certified plugs. The plastic shipping plugs do not provide ingress protection.

4.4.2 Conduit requirements

• For installations with an intrinsically safe electrode circuit, a separate conduit for the

coil cable and the electrode cable may be required. Refer to Appendix B.

• For installations with non-intrinsically safe electrode circuit, or when using the

combination cable, a single dedicated conduit run for the coil drive and electrode

cable between the sensor and the remote transmitter may be acceptable. Removal

of the barriers for intrinsic safety isolation is permitted for non-intrinsically safe

electrode installations.

• Bundled cables from other equipment in a single conduit are likely to create

interference and noise in the system. See Figure 4-3.

• Electrode cables should not be run together in the same cable tray with power

cables.

• Output cables should not be run together with power cables.

• Select conduit size appropriate to feed cables through to the flowmeter.

30 Rosemount® 8712EM Transmitter with HART Protocol Reference Manual

Page 37

Remote Transmitter Installation

Best practice conduit preparationFigure 4-3:

4.4.3

A

A. Safety ground

B. Power

C. Coil

D. Output

E. Electrode

C D E

B

A

A

Sensor to transmitter wiring

Wiring details

Cables kits are available as individual component cables or as a combination coil/electrode

cable. Remote cables can be ordered directly using the kit numbers shown in Table 4-3,

Table 4-4, and Table 4-5. Equivalent Alpha cable part numbers are also provided as an

alternative. To order cable, specify length as quantity desired. Equal length of component

cables is required.

Examples:

• 25 feet = Qty (25) 08732-0065-0001

• 25 meters = Qty (25) 08732-0065-0002

Component cable kits - standard temperature (-20°C to 75°C)Table 4-3:

Cable kit # Description Individual cable Alpha p/n

08732-0065-0001

(feet)

Kit, component cables,

Std temp (includes Coil

and Electrode)

Coil

Electrode

2442C

2413C

Reference manual 31

Page 38

Remote Transmitter Installation

Cable kit # Description Individual cable Alpha p/n

08732-0065-0002

(meters)

08732-0065-0003

(feet)

08732-0065-0004

(meters)

Cable kit # Description Individual cable Alpha p/n

08732-0065-1001

(feet)

08732-0065-1002

(meters)

08732-0065-1003

(feet)

08732-0065-1004

(meters)

Component cable kits - standard temperature (-20°C to 75°C) (continued)Table 4-3:

Kit, component cables,

Std temp (includes Coil

and Electrode)

Kit, component cables,

Std temp (includes Coil

and I.S. Electrode)

Kit, component cables,

Std temp (includes Coil

and I.S. Electrode)

Coil

Electrode

Coil

Instrinsically Safe Blue

Electrode

Coil

Instrinsically Safe Blue

Electrode

2442C

2413C

2442C

Not available

2442C

Not available

Component cable kits - extended temperature (-50°C to 125°C)Table 4-4:

Kit, Component Cables, Ext Temp. (includes Coil and Electrode)

Kit, Component Cables, Ext Temp. (includes Coil and Electrode)

Kit, Component Cables, Ext Temp. (includes Coil and I.S.

Electrode)

Kit, Component Cables, Ext Temp. (includes Coil and I.S.

Electrode)

Coil

Electrode

Coil

Electrode

Coil

Intrinsically Safe Blue

Electrode

Coil

Intrinsically Safe Blue

Electrode

Not available

Not available

Not available

Not available

Not available

Not available

Not available

Not available

Combination cable kits - coil and electrode cable (-20°C to 80°C)Table 4-5:

Cable kit # Description

08732-0065-2001 (feet) Kit, Combination Cable, Standard

08732-0065-2002 (meters)

08732-0065-3001 (feet) Kit, Combination Cable, Submersible

08732-0065-3002 (meters)

(80°C dry/60°C Wet)

(33ft Continuous)

32 Rosemount® 8712EM Transmitter with HART Protocol Reference Manual

Page 39

Remote Transmitter Installation

Cable requirements

Shielded twisted pairs or triads must be used. For installations using the individual coil

drive and electrode cable, see Figure 4-4. Cable lengths should be limited to less than 500

feet (152 m). Consult factory for length between 500–1000 feet (152–304 m). Equal

length cable is required for each. For installations using the combination coil drive/

electrode cable, see Figure 4-5. Combination cable lengths should be limited to less than

330 feet (100 m).

Individual component cablesFigure 4-4:

A B

1 2

3

3

D

C

E

F

A. Coil drive

B. Electrode

C. Twisted, stranded, insulated 14 AWG conductors

D. Drain

E. Overlapping foil shield

F. Outer jacket

G. Twisted, stranded, insulated 20 AWG conductors

• 1 = Red

• 2 = Blue

• 3 = Drain

• 17 = Black

• 18 = Yellow

• 19 = White

17 18 19

G

Reference manual 33

Page 40

Remote Transmitter Installation

Combination coil and electrode cableFigure 4-5:

17

1

2

3

19

18

17

A

B

C

A. Electrode shield drain

B. Overlapping foil shield

C. Outer jacket

• 1 = Red

• 2 = Blue

• 3 = Drain

• 17 = Reference

• 18 = Yellow

• 19 = White

Cable preparation

Prepare the ends of the coil drive and electrode cables as shown in Figure 4-6. Remove only

enough insulation so that the exposed conductor fits completely under the terminal

connection. Best practice is to limit the unshielded length (D) of each conductor to less

than one inch. Excessive removal of insulation may result in an unwanted electrical short to

the transmitter housing or other terminal connections. Excessive unshielded length, or

failure to connect cable shields properly, may also expose the unit to electrical noise,

resulting in an unstable meter reading.

34 Rosemount® 8712EM Transmitter with HART Protocol Reference Manual

Page 41

Remote Transmitter Installation

Cable endsFigure 4-6:

D

A

B

C

A. Coil

B. Electrode

C. Combination

D. Unshielded length

WARNING!

Shock hazard! Potential shock hazard across remote junction box terminals 1 and 2 (40V).

WARNING!

Explosion hazard! Electrodes exposed to process. Use only compatible transmitter and approved

installation practices. For process temperatures greater than 284°F (140°C), use a wire rated for

257°F (125°C).

Reference manual 35

Page 42

Remote Transmitter Installation

Remote junction box terminal blocks

Remote junction box viewsFigure 4-7:

B

A

A. Sensor

B. Transmitter

Sensor/transmitter wiringTable 4-6:

Wire color Sensor terminal Transmitter terminal

Red 1 1

Blue 2 2

Shield 3 or Float 3

Black 17 17

Yellow 18 18

White 19 19

Note

For hazardous locations, refer to Appendix B.

36 Rosemount® 8712EM Transmitter with HART Protocol Reference Manual

Page 43

4.4.4 Wiring diagrams

Wiring 8712EM using component cableFigure 4-8:

Remote Transmitter Installation

Reference manual 37

Page 44

Remote Transmitter Installation

Wiring 8712EM using combination cableFigure 4-9:

38 Rosemount® 8712EM Transmitter with HART Protocol Reference Manual

Page 45

4.4.5 Power and I/O terminal blocks

Open the bottom cover of the transmitter to access the terminal block.

Note

To connect pulse output and/or discrete input/output, refer to Chapter 6, and for installations with

intrinsically safe outputs, refer to Appendix B.

8712EM Terminal blocksFigure 4-10:

N 1 2 9 10 5 6 19 18

L1 3 11 12 7 8 17

Remote Transmitter Installation

8712EM Power and I/O terminalsTable 4-7:

Terminal number AC version DC version

1 Coil Positive Coil Positive

2 Coil Negative Coil Negative

3 Coil Shield Coil Shield

5 + Pulse + Pulse

6 – Pulse – Pulse

(1)

7

(1)

8

(2)

9

(2)

10

(2)

11

(2)

12

17 Electrode Reference Electrode Reference

18 Electrode Negative Electrode Negative

19 Electrode Positive Electrode Positive

N AC (Neutral)/L2 DC (–)

L1 AC L1 DC (+)

(1) Note Polarity: Internally Powered, Terminal 7 (–) Analog HART, Terminal 8 (+) Analog HART. Externally

Powered, Terminal 7 (+) Analog HART, Terminal 8 (–) Analog HART

(2) Only available with ordering code AX.

Analog HART Analog HART

Analog HART Analog HART

+ Discrete In/Out 2 + Discrete In/Out 2

– Discrete In/Out 2 – Discrete In/Out 2

+ Discrete In/Out 1 + Discrete In/Out 1

– Discrete In/Out 1 – Discrete In/Out 1

Reference manual 39

Page 46

Remote Transmitter Installation

4.4.6 Powering the transmitter

The transmitter is available in three models. The AC powered transmitter is designed to be

powered by 90–250VAC (50/60Hz). The DC powered transmitter is designed to be

powered by 12–42VDC. The low power transmitter is designed to be powered by

12–30VDC. Before connecting power to the transmitter, be sure to have the proper power

supply, conduit, and other accessories. Wire the transmitter according to national, local,

and plant electrical requirements for the supply voltage.

If installing in a hazardous location, verify that the meter has the appropriate hazardous

area approval. Each meter has a hazardous area approval tag attached to the side of the

transmitter housing.

AC power supply requirements

Units powered by 90 - 250VAC have the following power requirements. Peak inrush is

35.7A at 250VAC supply, lasting approximately 1ms. Inrush for other supply voltages can

be estimated with: Inrush (Amps) = Supply (Volts) / 7.0

AC current requirementsFigure 4-11:

0.24

0.22

0.20

A

0.18

0.16

0.14

0.12

90

110 130 150 170B190 210 230 250

A. Supply current (amps)

B. Power supply (VAC)

40 Rosemount® 8712EM Transmitter with HART Protocol Reference Manual

Page 47

Remote Transmitter Installation

Apparent powerFigure 4-12:

34

32

30

28

A

26

24

22

20

90

110 130 150 170B190 210 230 250

A. Apparent power (VA)

B. Power supply (VAC)

DC power supply requirements

Standard DC units powered by 12VDC power supply may draw up to 1.2A of current steady

state. Low power DC units may draw up to 0.25A of current steady state. Peak inrush is

42A at 42VDC supply, lasting approximately 1ms. Inrush for other supply voltages can be

estimated with: Inrush (Amps) = Supply (Volts) / 1.0

DC current requirementsFigure 4-13:

1.2

1.1

1.0

0.9

0.8

A

0.7

0.6

0.5

0.4

0.3

0.2

12

A. Supply current (amps)

B. Power supply (VDC)

17 22 27

B

32 37 42

Reference manual 41

Page 48

Remote Transmitter Installation

0.25

0.2

0.15

A

0.1

0.05

0

A. Supply current (amps)

B. Power supply (VDC)

Supply wire requirements

Use 10–18 AWG wire rated for the proper temperature of the application. For wire 10–14

AWG use lugs or other appropriate connectors. For connections in ambient temperatures

above 122 °F (50 °C), use a wire rated for 194 °F (90 °C). For DC powered transmitters with

extended cable lengths, verify that there is a minimum of 12VDC at the terminals of the

transmitter with the device under load.

10

Low power DC current requirementsFigure 4-14:

15 20 25

B

30

Electrical disconnect requirements

Connect the device through an external disconnect or circuit breaker per national and local

electrical code.

Installation category

The installation category for the transmitter is OVERVOLTAGE CAT II.

Overcurrent protection

The transmitter requires overcurrent protection of the supply lines. Fuse rating and

compatible fuses are shown in Table 4-8.

Fuse requirementsTable 4-8:

Power system Power supply Fuse rating Manufacturer

AC power 90–250VAC 2 Amp quick acting Bussman AGC2 or

equivalent

DC power 12–42VDC 3 Amp quick acting Bussman AGC3 or

equivalent

DC low power 12–30VDC 3 Amp quick acting Bussman AGC3 or

equivalent

42 Rosemount® 8712EM Transmitter with HART Protocol Reference Manual

Page 49

Remote Transmitter Installation

Power terminals

For AC powered transmitter (90–250VAC, 50/60 Hz):

• Connect AC Neutral to Terminal N and AC Line to Terminal L1.

For DC powered transmitter:

• Connect negative to Terminal N and positive to Terminal L1.

• DC powered units may draw up to 1.2A.

Covers

Use the transmitter lower door screw to secure the terminal compartment after the

instrument has been wired and powered up. Follow these steps to ensure the housing is

properly sealed to meet ingress protection requirements:

1. Ensure all wiring is complete and close the lower door.

2. Tighten the lower door screw until the lower door is tight against the housing. Metal

to metal contact of the screw bosses is required to ensure a proper seal.

Note

Application of excessive torque may strip the threads or break the screw.

4.4.7

3. Verify the lower door is secure.

Analog output

The analog output signal is a 4-20mA current loop. Depending on the IS output option, the

loop can be powered internally or externally via a hardware switch located on the front of

the electronics stack. The switch is set to internal power when shipped from the factory.

Intrinsically safe analog output requires a shielded twisted pair cable. For HART

communication, a minimum resistance of 250 ohms is required. It is recommended to use

individually shielded twisted pair cable. The minimum conductor size is 24 AWG (0.51mm)

diameter for cable runs less than 5,000 feet (1,500m) and 20 AWG (0.81mm) diameter for

longer distances.

Note

For more information about the analog output characteristics, see Section A.2.3.

Reference manual 43

Page 50

Remote Transmitter Installation

Internal Power

Analog output wiring, internal powerFigure 4-15:

A B

A. 4–20 mA (–) to Terminal #7

B. 4–20 mA (+) to Terminal #8

Note

Terminal polarity for the analog output is reversed between internally and externally powered.

44 Rosemount® 8712EM Transmitter with HART Protocol Reference Manual

Page 51

External power

Analog output wiring, external powerFigure 4-16:

Remote Transmitter Installation

A. Power supply

• (+) to Terminal #7

• (–) to Terminal #8

Note

Terminal polarity for the analog output is reversed between internally and externally powered.

Reference manual 45

Page 52

Remote Transmitter Installation

A. Load (ohms)

B. Power supply (volts)

C. Operating region

• R

• Vps = power supply voltage (volts)

• Rmax = maximum loop resistance (ohms)

Analog loop load limitationsFigure 4-17:

600

A

0

= 31.25 (Vps–10.8)

max

C

10.8 30

B

46 Rosemount® 8712EM Transmitter with HART Protocol Reference Manual

Page 53

5 Basic Configuration

Topics covered in this chapter:

Basic Setup

•

Local operator interface (LOI)

•

Field Communicator interface

•

Measurement units

•

Once the magnetic flowmeter is installed and power has been supplied, the transmitter

must be configured through the basic setup. These parameters can be configured through

either an LOI or a HART communication device. Configuration settings are saved in

nonvolatile memory within the transmitter. Descriptions of more advanced functions are

included in Chapter 8.

Basic Configuration

5.1 Basic Setup

Tag

Tag is the quickest and shortest way of identifying and distinguishing between

transmitters. Transmitters can be tagged according to the requirements of your

application. The tag may be up to eight characters long as standard, or 32 characters long

when ordered with HART 7.

Flow units (PV)

The flow units variable specifies the format in which the flow rate will be displayed. Units

should be selected to meet your particular metering needs. .

Line size

The line size (sensor size) must be set to match the actual sensor connected to the

transmitter. The size must be specified in inches.

Upper range value (URV)

The URV sets the 20 mA point for the analog output. This value is typically set to full-scale

flow. The units that appear will be the same as those selected under the flow units

parameter. The URV may be set between –39.3 ft/s to 39.3 ft/s (–12 m/s to 12m/s). There

must be at least 1 ft/s (0.3 m/s) span between the URV and LRV.

Lower range value (LRV)

The LRV sets the 4 mA point for the analog output. This value is typically set to zero flow.

The units that appear will be the same as those selected under the flow units parameter.

The LRV may be set between –39.3 ft/s to 39.3 ft/s (–12 m/s to 12m/s). There must be at

least 1 ft/s (0.3 m/s) span between the URV and LRV.

Reference manual 47

Page 54

Basic Configuration

Calibration number

The sensor calibration number is a 16-digit number generated at the factory during flow

calibration, is unique to each sensor, and is located on the sensor tag.

5.2 Local operator interface (LOI)

To access the transmitter menu, press the XMTR MENU key. Use the UP, DOWN, LEFT(E),

and RIGHT arrows to navigate the menu structure.

The display can be locked to prevent unintentional configuration changes. The display lock

can be activated through a HART communication device, or by holding the UP arrow for

three seconds and then following the on-screen instructions.

When the display lock is activated, a lock symbol will appear in the lower right hand corner

of the display. To deactivate the display lock, hold the UP arrow for three seconds and

follow the on-screen instructions. Once deactivated, the lock symbol will no longer appear

in the lower right hand corner of the display.

5.3 Field Communicator interface

Use the menu paths to configure basic setup of the transmitter using a field

communicator.

Basic setup menu pathsTable 5-1:

Function Menu path

Basic Setup Configure > Manual Setup > Basic Setup

Flow Units Configure > Manual Setup > Basic Setup > Flow Units

PV Upper Range Value (URV) Configure > Manual Setup > Basic Setup > AO > URV

PV Lower Range Value (LRV) Configure > Manual Setup > Basic Setup > AO > LRV

Calibration Number Configure > Manual Setup > Basic Setup > Setup > Calibration

number

Line Size Configure > Manual Setup > Basic Setup > Setup > Line Size

Tag Configure > Manual Setup > Device Info > Identification > Tag

Long Tag Configure > Manual Setup > Device Info > Identification > Long

Tag

Overview Overview

48 Rosemount® 8712EM Transmitter with HART Protocol Reference Manual

Page 55

5.4 Measurement units

Volumetric flow unitsTable 5-2:

gal/sec gal/min gal/hr gal/day

L/sec L/min L/hr L/day

ft3/sec ft3/min ft3/hr ft3/day

cm3/min

m3/sec m3/min m3/hr m3/day

Impgal/sec Impgal/min Impgal/hr Impgal/day

B31/sec (1 barrel = 31

gallons)

B42/sec (1 barrel = 42

gallons)

Mass flow unitsTable 5-3:

B31/min (1 barrel = 31

gallons)

B42/min (1 barrel = 42

gallons)

B31/hr (1 barrel = 31

gallons)

B42/hr (1 barrel = 42

gallons)

Basic Configuration

B31/day (1 barrel = 31

gallons)

B42/day (1 barrel = 42

gallons)

lbs/sec lbs/min lbs/hr lbs/day

kg/sec kg/min kg/hr kg/day

(s) tons/min (s) tons/hr (s) tons/day

(m) tons/min (m) tons/hr (m) tons/day

Velocity unitsTable 5-4:

ft/sec m/sec

Reference manual 49

Page 56

Basic Configuration

50 Rosemount® 8712EM Transmitter with HART Protocol Reference Manual

Page 57

6 Advanced installation details

Topics covered in this chapter:

Hardware switches

•

Additional loops

•

Coil housing configuration

•

6.1 Hardware switches

The electronics are equipped with four user-selectable hardware switches. These switches

set the Alarm Mode, Internal/External Analog Power, Transmitter Security, and Internal/

External Pulse Power.

Definitions of these switches and their functions are provided below. To change the

settings, see below.

Advanced installation details

6.1.1 Alarm mode

If an event occurs that would trigger an alarm in the electronics, the analog output will be

driven high or low, depending on the switch position. The switch is set in the HIGH position

when shipped from the factory. Refer to Table 8-1 and Table 8-2 for analog output values of

the alarm.

6.1.2

6.1.3

Transmitter security

The SECURITY switch allows the user to lock out any configuration changes attempted on

the transmitter.

• When the security switch is in the ON position, the configuration can be viewed but

no changes can be made.

• When the security switch is in the OFF position, the configuration can be viewed and

changes can be made.

The switch is in the OFF position when the transmitter is shipped from the factory.

Note

The flow rate indication and totalizer functions remain active when the SECURITY switch is in either

position.

Internal/external analog power

The 4–20 mA loop can be powered internally by the transmitter or externally by an

external power supply. The ANALOG switch determines the source of the 4–20 mA loop

power.

Reference manual 51

Page 58

Advanced installation details

• When the switch is in the INTERNAL position, the 4–20 mA loop is powered

internally by the transmitter.

• When the switch is in the EXTERNAL position, a 10-30 VDC external power supply is

required. For more information about 4–20 mA external power, see Section 4.4.7.

The switch is in the INTERNAL position when the transmitter is shipped from the factory.

Note

External power is required for multidrop configurations.

6.1.4 Internal/external pulse power

The pulse loop can be powered internally by the transmitter or externally or by an external

power supply. The PULSE switch determines the source of the pulse loop power.

• When the switch is in the INTERNAL position, the pulse loop is powered internally by

the transmitter.

• When the switch is in the EXTERNAL position, a 5–28 VDC external supply is

required. For more information about pulse external power, see Section 6.2.1.

The switch is in the EXTERNAL position when the transmitter is shipped from the factory.

6.1.5 Changing hardware switch settings

Note

The hardware switches are located on the top side of the electronics board and changing their

settings requires opening the electronics housing. If possible, carry out these procedures away from

the plant environment in order to protect the electronics.

52 Rosemount® 8712EM Transmitter with HART Protocol Reference Manual

Page 59

Advanced installation details

Rosemount 8712EM Electronics Stack and Hardware SwitchesFigure 6-1:

6.2

Procedure

1. Place the control loop into manual control.

2. Disconnect power to the transmitter

3. Open the electronics compartment cover.

4. Identify the location of each switch (see Figure 6-1 ).

5. Change the setting of the desired switches with a small, non-metallic tool.

6. Close the electronics compartment cover. See Section 4.4.6 for details on the covers.

7. Return power to the transmitter and verify the flow measurement is correct.

8. Return the control loop to automatic control.

Additional loops

There are three additional loop connections available on the Transmitter:

• Pulse output - used for external or remote totalization.

• Channel 1 can be configured as discrete input or discrete output.

• Channel 2 can be configured as discrete output only.

Reference manual 53

Page 60

Advanced installation details

6.2.1 Connect pulse output

The pulse output function provides a galvanically isolated frequency signal that is

proportional to the flow through the sensor. The signal is typically used in conjunction with

an external totalizer or control system. The default position of the internal/external pulse

power switch is in the EXTERNAL position. The user-selectable power switch is located on

the electronics board.

External

For transmitters with the internal/external pulse power switch (output option code A) set

in the EXTERNAL position or transmitters with intrinsically safe outputs (output option

code B) the following requirements apply:

• Supply voltage: 5 to 28 VDC

• Maximum current: 100 mA

• Maximum power: 1.0 W

• Load resistance: 200 to 10k Ohms (typical value 1k Ohms). Refer to the figure

indicated:

Output option code

A 5-28 VDC See Figure 6-2

B 5 VDC See Figure 6-3

B 12 VDC See Figure 6-4

B 24 VDC See Figure 6-5

• Pulse mode: Fixed pulse width or 50% duty cycle

• Pulse duration: 0.1 to 650 ms (adjustable)

• Maximum pulse frequency:

- Output option code A is 10,000 Hz

- Output option code B is 5000 Hz

• FET switch closure: solid state switch

Supply voltage Resistance vs cable length

54 Rosemount® 8712EM Transmitter with HART Protocol Reference Manual

Page 61

Advanced installation details

Output Option Code A—Maximum Frequency vs. Cable LengthFigure 6-2:

A. Frequency (Hz)

B. Cable length (feet)

Reference manual 55

Page 62

Advanced installation details

A. Resistance (Ω)

B. Cable length (feet)

Output Option Code B—VDC SupplyFigure 6-3:

At 5000 Hz operation with a 5 VDC supply, pull-up resistances of 200 to 1000 Ohms allow cable lengths up

to 660 ft (200 m).

56 Rosemount® 8712EM Transmitter with HART Protocol Reference Manual

Page 63

Output Option Code B—2 VDC SupplyFigure 6-4:

A. Resistance (Ω)

B. Cable length (feet)

Advanced installation details

At 5000 Hz operation with a 12 VDC supply, pull-up resistances of 500 to 2500 Ohms allow cable lengths

up to 660 ft (200 m). Resistances from 500 to 1000 Ohms allow a cable length of 1000 ft (330 m).

Reference manual 57

Page 64

Advanced installation details

A. Resistance (Ω)

B. Cable length (feet)

Output Option Code B—24 VDC SupplyFigure 6-5:

At 5000 Hz operation with a 24 VDC supply, pull-up resistances of 1000 to 10,000 Ohms allow cable

lengths up to 660 ft (200 m). Resistances from 1000 to 2500 Ohms allow a cable length of 1000 ft (330

m).

58 Rosemount® 8712EM Transmitter with HART Protocol Reference Manual

Page 65

Connecting an external power supply

Advanced installation details

Figure 6-6:

Connecting an Electromechanical Totalizer/Counter with External Power

Supply

A

5

6

65

B

-

-

C

+ +

A. Schematic showing FET between terminal 5 and 6

B. Electro-mechanical counter

C. 5–24 VDC power supply

Note

Total loop impedance must be sufficient to keep loop current below maximum rating. A resistor can

be added in the loop to raise impedance.

Reference manual 59

Page 66

Advanced installation details

Figure 6-7:

Connecting to an Electronic Totalizer/Counter with External Power

Supply

A

5

6

5

B

-

6

+

+

-

C

A. Schematic showing FET between terminal 5 and 6

B. Electronic counter

C. 5–24 VDC power supply

Note

Total loop impedance must be sufficient to keep loop current below maximum rating.

Procedure

1. Ensure the power source and connecting cable meet the requirements outlined

previously.

2. Turn off the transmitter and pulse output power sources.

3. Run the power cable to the transmitter.

4. Connect - DC to terminal 6.

5. Connect + DC to terminal 5.

Internal