Page 1

Reference Manual

00809-0100-4727, Rev EA

October 2010

Rosemount 8700 Series

Magnetic Flowmeter Sensors

www.rosemount.com

Page 2

Page 3

Reference Manual

NOTICE

00809-0100-4727, Rev EA

October 2010

Rosemount 8700 Series

Magnetic Flowmeter Sensors

Read this manual before working with the product. For personal and system safety, and for

optimum product performance, make sure you thoroughly understand the contents before

installing, using, or maintaining this product.

Within the United States, Rosemount Inc. has two toll-free assistance numbers.

Customer Central: 1-800-999-9307(7:00 a.m. to 7:00 p.m. CST)

Technical support, quoting, and order-related questions.

North American1-800-654-7768 (24 hours a day – Includes Canada)

Response Center: Equipment service needs.

For equipment service or support needs outside the United States, your local Emerson

Process Management representative.

The products described in this document are NOT designed for

nuclear-qualified applications.

Using non-nuclear qualified products in applications that require

nuclear-qualified hardware or products may cause inaccurate readings.

For information on Rosemount nuclear-qualified products, contact your local Emerson

Process Management Sales Representative.

www.rosemount.com

Page 4

Page 5

Reference Manual

00809-0100-4727, Rev EA

October 2010

Rosemount 8700 Series

Table of Contents

SECTION 1

Introduction

SECTION 2

Installation

Manual Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Return of Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Safety Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Sensor Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Sensor Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Upstream/Downstream Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Sensor Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Flow Direction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Installation (Flanged Sensor). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Gaskets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Flange Bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Installation (Wafer Sensor) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Gaskets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Flange Bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Installation (Sanitary Sensor). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Gaskets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Alignment and Bolting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Process Leak Protection (Optional). . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Standard Housing Configuration . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Relief Valves. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Process Leak Containment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Conduit Ports and Connections . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Conduit Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Electrical Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Sensor Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Rosemount Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Transmitter to Sensor Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

SECTION 3

Operation and

Maintenance

www.rosemount.com

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Material Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Magnetic Flowmeter Sizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Page 6

Rosemount 8700 Series

Reference Manual

00809-0100-4727, Rev EA

October 2010

SECTION 4

Maintenance and

Troubleshooting

APPENDIX A

Reference Data

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Installation Check and Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Diagnostic Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Transmitter Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Quick Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Step 1: Wiring Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Step 2: Process Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Step 3: Installed Sensor Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Step 4: Uninstalled Sensor Tests. . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Rosemount 8700 Series Product Specifications Overview . . . . . . . . .A-1

E-Series Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . .A-5

High Signal System Performance Specifications. . . . . . . . . . . . . . . . .A-7

Rosemount Flanged Sensor Specifications. . . . . . . . . . . . . . . . . . . . .A-9

Flanged Sensor Functional Specifications. . . . . . . . . . . . . . . . . . . . . .A-9

Flanged Sensor Physical Specifications . . . . . . . . . . . . . . . . . . . . . .A-11

Rosemount 8711 Wafer Sensor Specifications. . . . . . . . . . . . . . . . .A-13

8711 Functional Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-13

8711 Physical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-14

Rosemount 8721 Sanitary Sensor Specifications . . . . . . . . . . . . . . .A-16

8721 Functional Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-16

8721 Physical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-17

Dimensional Drawings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-20

Rosemount Flanged Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . .A-36

Rosemount High-Signal Magmeter System . . . . . . . . . . . . . . . . .A-36

Options (Include with selected model number) . . . . . . . . . . . . . .A-39

Rosemount 8711 Wafer Sensors . . . . . . . . . . . . . . . . . . . . . . . . .A-43

Options (Include with selected model number) . . . . . . . . . . . . . .A-45

Rosemount 8721 Hygienic Sensors . . . . . . . . . . . . . . . . . . . . . . .A-46

Options (Include with selected model number) . . . . . . . . . . . . . .A-47

Tagging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-48

Ordering Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-48

Standard Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-48

Cable Requirements for Remote Transmitters. . . . . . . . . . . . . . .A-48

APPENDIX B

Approvals

TOC-2

Approved Manufacturing Locations. . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

European Directive Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

ATEX Directive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

European Pressure Equipment Directive (PED) (97/23/EC) . . . . .B-1

Electro Magnetic Compatibility (EMC) (2004/108/EC) . . . . . . . . . .B-2

Low Voltage Directive (2006/95/EC) . . . . . . . . . . . . . . . . . . . . . . .B-2

Other important guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-2

IECEx Certificates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-2

Hazardous Locations Product Approvals Offering. . . . . . . . . . . . . . . .B-3

Hazardous Location Certifications. . . . . . . . . . . . . . . . . . . . . . . . . . . .B-7

North American Certifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-7

Canadian Standards Association (CSA). . . . . . . . . . . . . . . . . . . . .B-7

European Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-7

International Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-8

Page 7

Reference Manual

00809-0100-4727, Rev EA

October 2010

Section 1 Introduction

Manual Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-1

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-2

Return of Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-2

Rosemount 8700 Series

MANUAL DESCRIPTION The Rosemount

separate sensor and transmitter units. This manual is design ed to assist in the

installation and operation of Rosemount 8705, 8707 High -Signal, and 8711

Magnetic Flowmeter Sensor.

Attempting to install and operate the Rosemount 8705, 8707 High-Signal, or 8711

Magnetic Flowmeter Sensor without reviewing the instructions contained in this manual

could result in personal injury or equipment damage.

Section 1: Introduction

• Manual description

• Safety information

• Return of material

Section 2: Installation

• Installation instructions

Section 3: Operation and Maintenance

• Sensor calibration number

• Sensor configuration information.

®

Series 8700 Magnetic Flowmeter System combines

www.rosemount.com

Section 4: Maintenance and Troubleshooting

• Troubleshooting procedures

• Electrical circuit diagrams

Appendix A: Reference Data

• Instructions for removing and replacing the field-removable

electrode assembly

Appendix B: ApprovalsAppendix B: Approvals

• Approved Manufacturing Locations

• European Directive Information

• Hazardous Locations Product Approvals Offering

• Hazardous Location Certifications

Page 8

Reference Manual

See “Safety Information” on page 4-1 for complete warning information.

00809-0100-4727, Rev EA

Rosemount 8700 Series

October 2010

SAFETY INFORMATION Procedures and instructions in this manual may require special preca utions to

ensure the safety of the personnel performing the operations. Refer to the

safety messages listed at the beginning of each section before performing

any operations.

RETURN OF MATERIALS To expedite the return process outside the United States, contact the nearest

Rosemount representative.

Within the United States and Canada, call the North American Response

Center using the 800-654-RSMT (7768) toll-free number. The Response

Center, available 24 hours a day, will assist you with any needed information

or materials.

The center will ask for product model and serial numbers, and will provide a

Return Material Authorization (RMA) number. The center will also ask for the

name of the process material to which the product was last exposed.

Mishandling products exposed to a hazardous subst ance may result in death

or serious injury. If the product being returned was exposed to a hazardous

substance as defined by OSHA, a copy of the required Material Safety Data

Sheet (MSDS) for each hazardous substance identified must be included with

the returned goods.

The North American Response Center will detail the additional information

and procedures necessary to return goods exposed to hazardous

substances.

1-2

Page 9

Reference Manual

00809-0100-4727, Rev EA

October 2010

Section 2 Installation

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-1

Sensor Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-3

Sensor Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-4

Installation (Flanged Sensor) . . . . . . . . . . . . . . . . . . . . . . page 2-7

Installation (Wafer Sensor) . . . . . . . . . . . . . . . . . . . . . . . . page 2-10

Installation (Sanitary Sensor) . . . . . . . . . . . . . . . . . . . . . . page 2-12

Process Leak Protection (Optional) . . . . . . . . . . . . . . . . . page 2-13

Process Leak Protection (Optional) . . . . . . . . . . . . . . . . . page 2-13

Sensor Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-18

This section covers the steps required to physically install the magnetic

sensor. Instructions and procedures in this section may require special

precautions to ensure the safety of the personnel performing the operations.

Please refer to the following safety messages before performing any

operation in this section.

Rosemount 8700 Series

SAFETY MESSAGES This symbol is used throughout this manual to indicate that special attention

to warning information is required.

Failure to follow these installation guidelines could result in death or serious injury:

Installation and servicing instructions are for use by qualified personnel only. Do not perform

any servicing other than that contained in the operating instructions, unless qualified. Verify

that the operating environment of the sensor and transmitter is consistent with the

appropriate hazardous area approval.

Do not connect a Rosemount transmitter to a non-Rosemount sensor that is located in an

explosive atmosphere.

www.rosemount.com

Page 10

Rosemount 8700 Series

Explosions could result in death or serious injury:

Installation of this transmitter in an explosive environment must be in accordance with the

appropriate local, national, and international standards, codes, and practices. Please review

the approvals section of this reference manual for any restrictions associated with a safe

installation.

Electrical shock can result in death or serious injury

Avoid contact with the leads and terminals. High voltage that may be present on leads can

cause electrical shock.

The sensor liner is vulnerable to handling damage. Never place anything through the sensor

for the purpose of lifting or gaining leverage. Liner damage can render the sensor useless.

To avoid possible damage to the sensor liner ends, do not use metallic or spiral-wound

gaskets. If frequent removal is anticipated, take precautions to protect the liner ends. Short

spool pieces attached to the sensor ends are often used for protection.

Correct flange bolt tightening is crucial for proper sensor operation and life. All bolts must be

tightened in the proper sequence to the specified torque limits. Failure to observe these

instructions could result in severe damage to the sensor lining and possible sensor

replacement.

Emerson Process Management can supply lining protectors to prevent liner damage during

removal, installation, and excessive bolt torquing.

Reference Manual

00809-0100-4727, Rev EA

October 2010

2-2

Page 11

Reference Manual

See ”Safety Messages” on pages 2-1 and 2-2 for complete warning information.

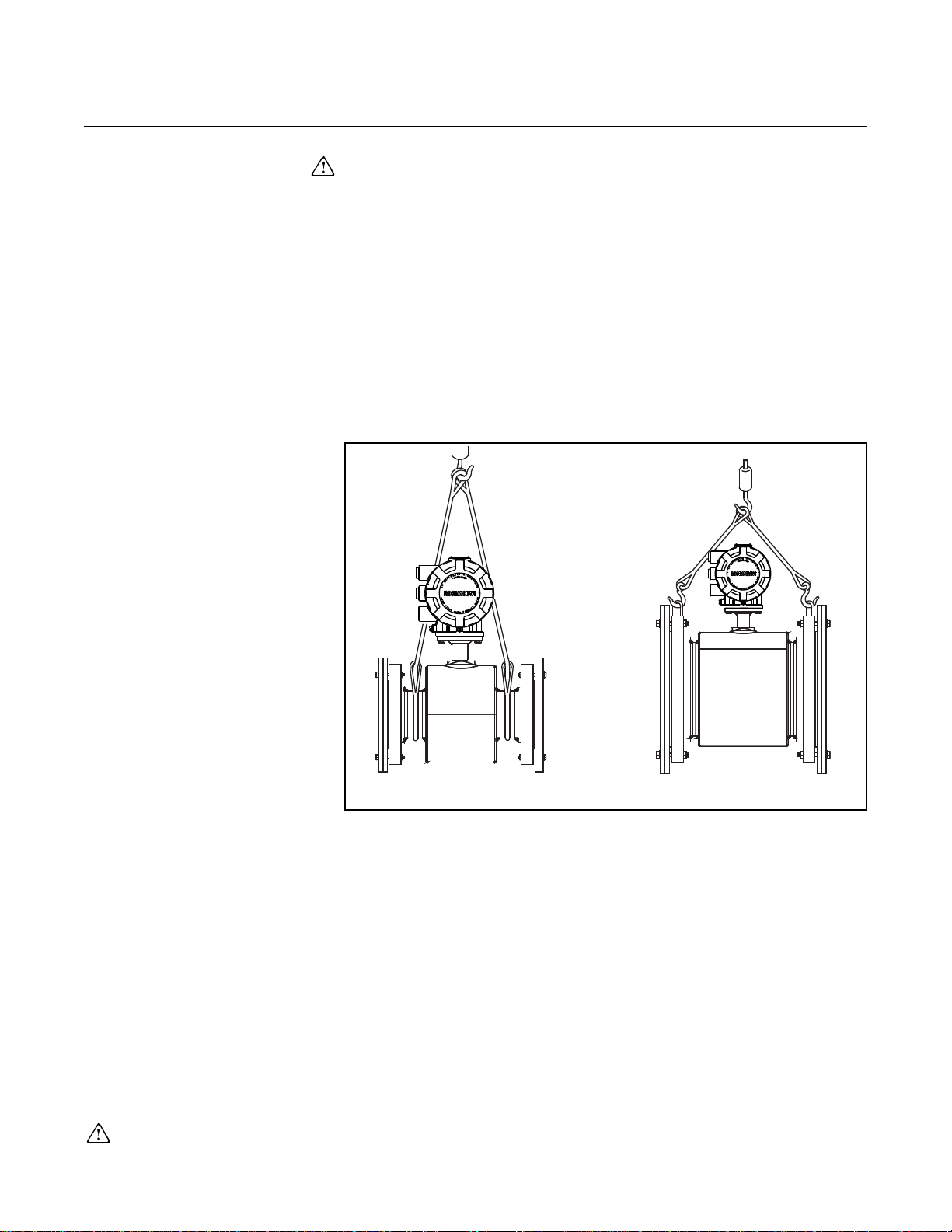

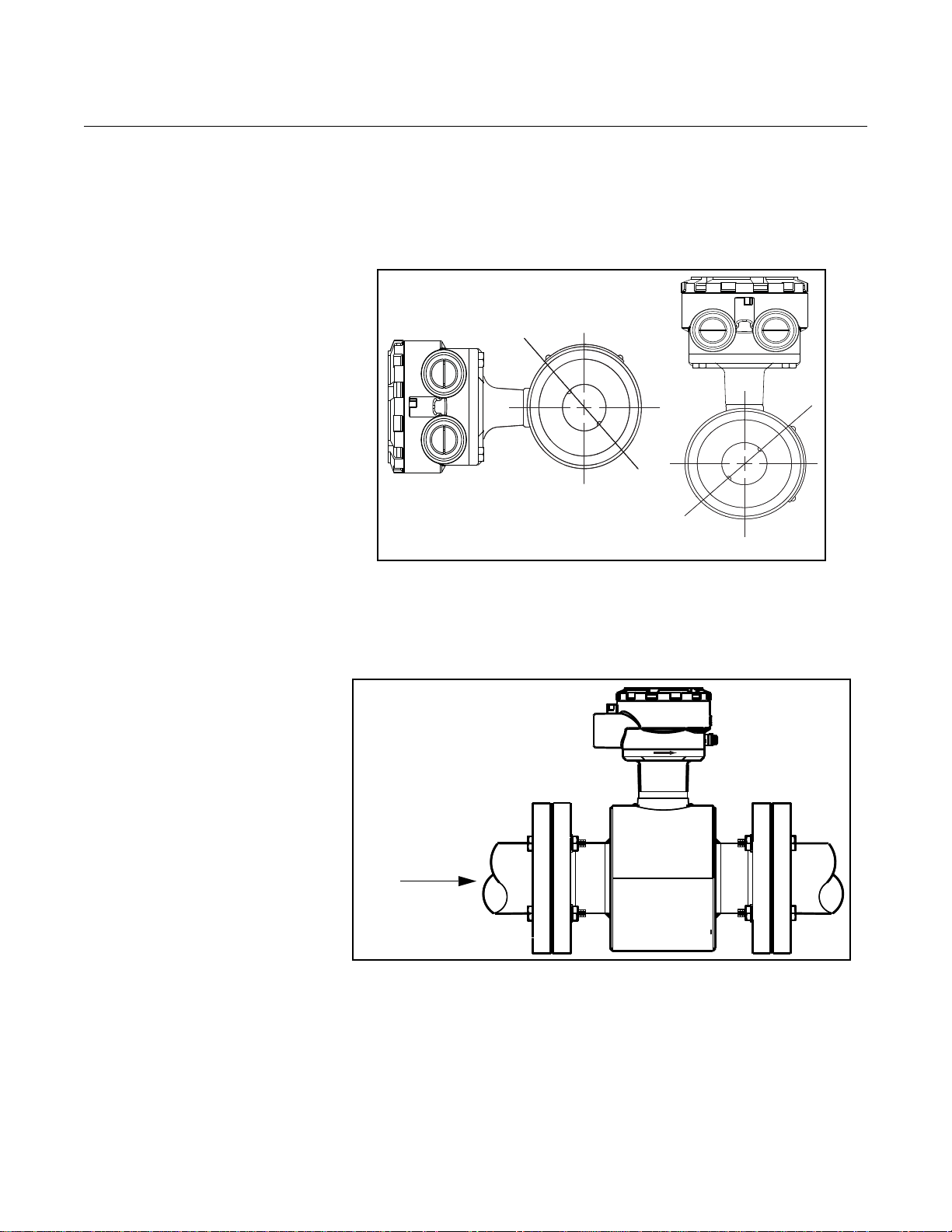

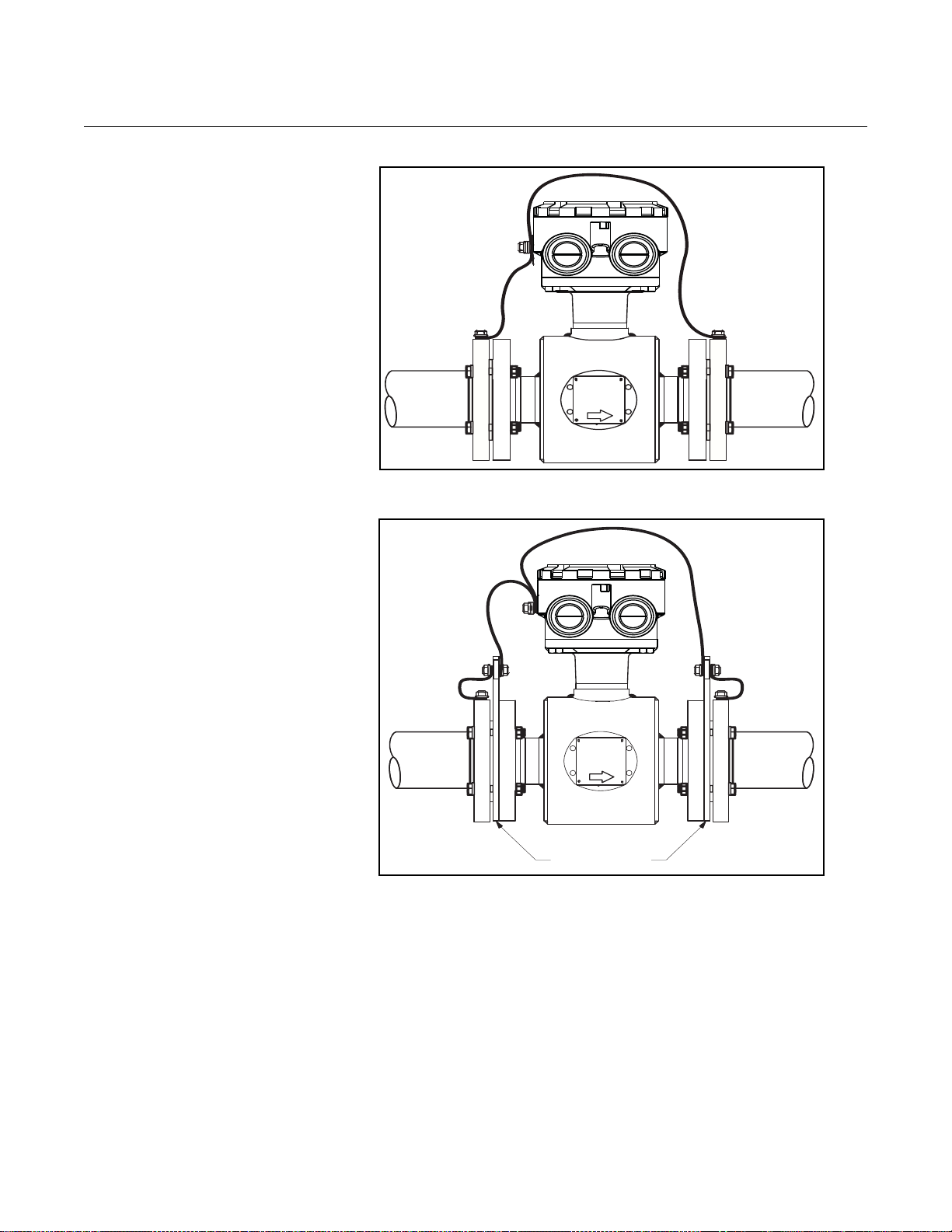

Without Lifting Lugs

With Lifting Lugs

00809-0100-4727, Rev EA

October 2010

Rosemount 8700 Series

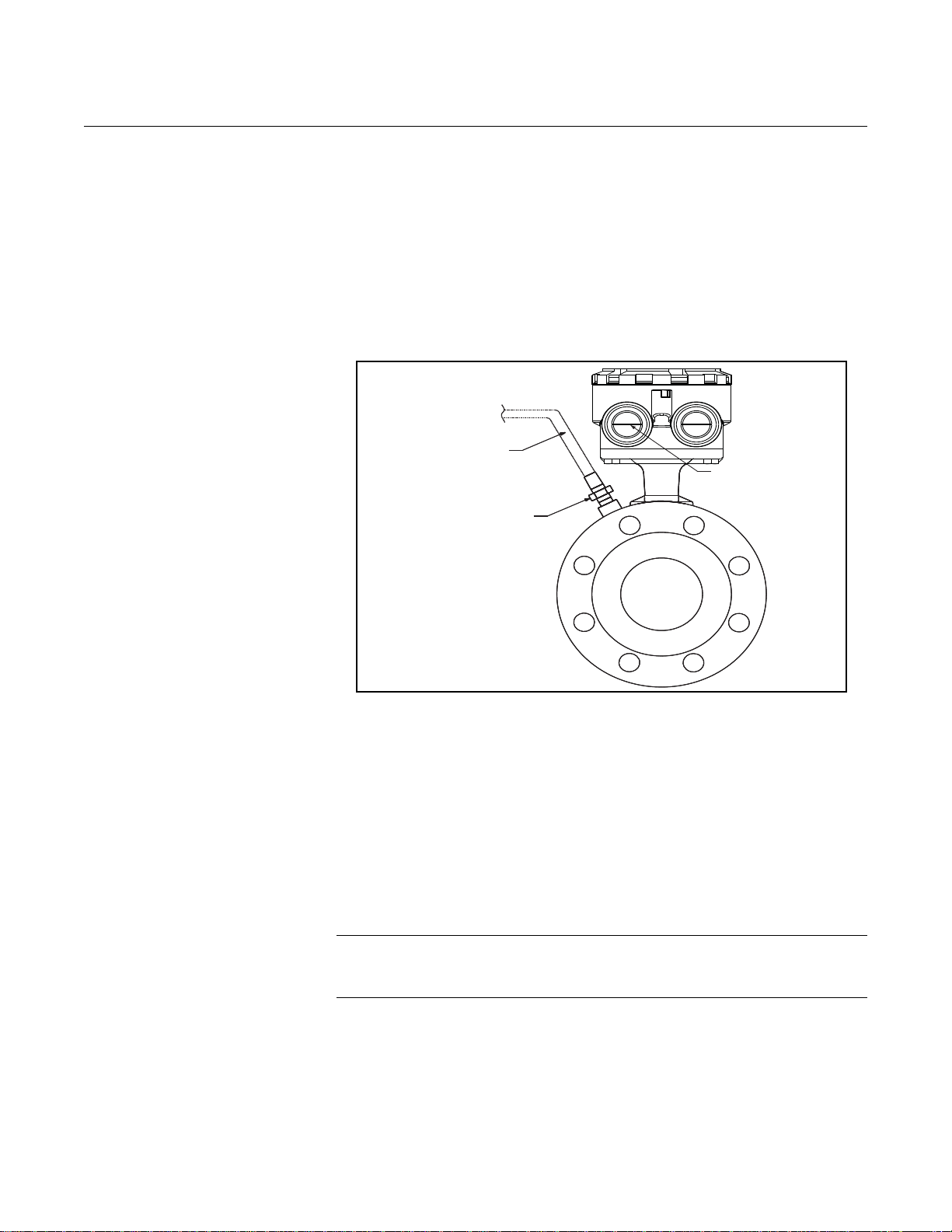

SENSOR HANDLING Handle all parts carefully to prevent damage. Whenever possible, transport

the system to the installation site in the original shipping containers.

PTFE-lined sensors are shipped with end covers that protect it from both

mechanical damage and normal unrestrained distortion. Remove the end

covers just before installation.

Flanged sensors with a lifting lug on each flange make the sensor easier to

handle when it is transported and lowered into place at the installation site.

Flanged sensors that do not have lugs must be supported with a lifting sling

on each side of the housing.

Figure 2-1 shows sensors correctly supported for handling and installation.

Notice the plywood end pieces are still in place to protect the sensor liner

during transportation.

Figure 2-1. Rosemount 8705

Sensor Support for Handling

2-3

Page 12

Reference Manual

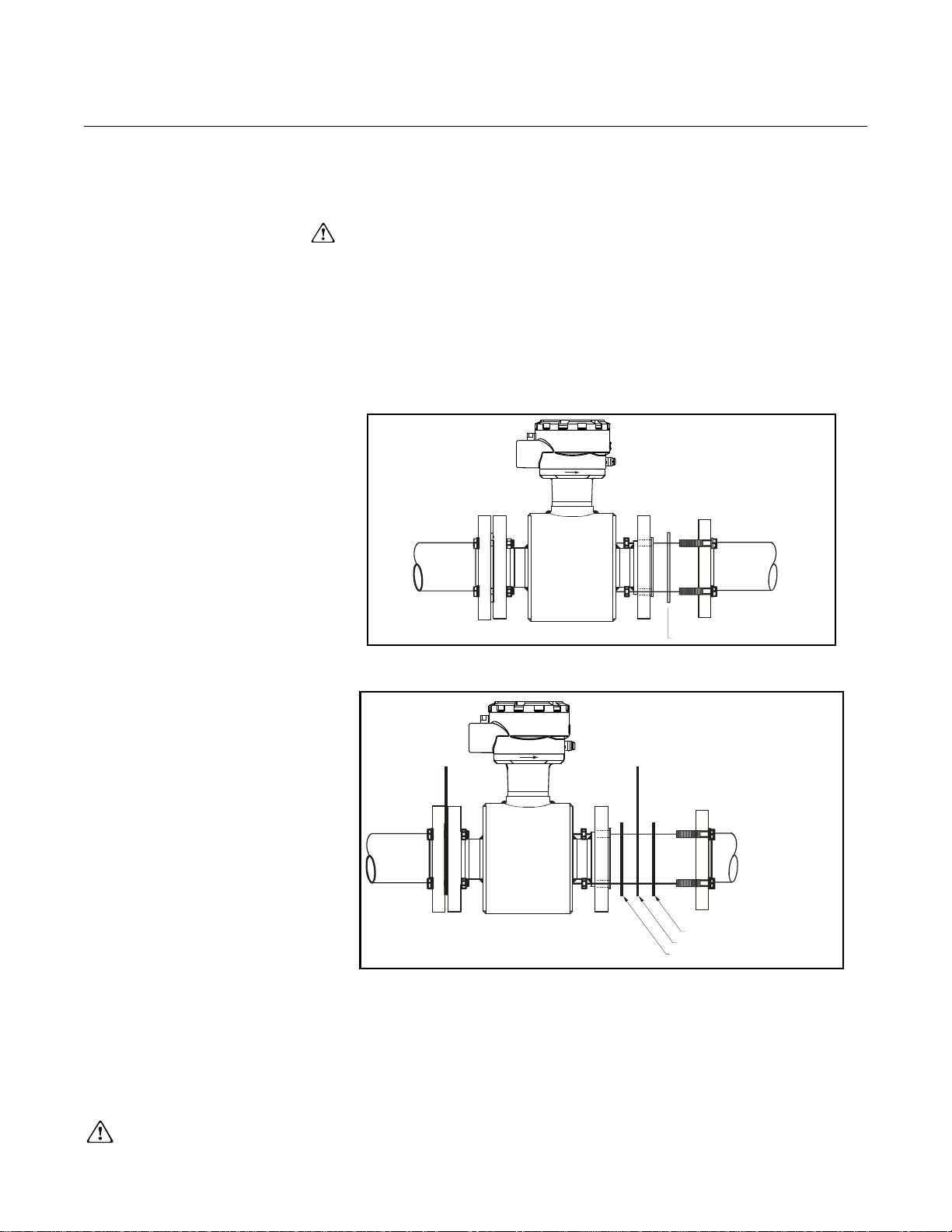

FLOW

5 Pipe Diameters

2 Pipe Diameters

FLOW

FLOW

00809-0100-4727, Rev EA

Rosemount 8700 Series

October 2010

SENSOR MOUNTING Physical mounting of a sensor is similar to installing a typical section of pipe.

Conventional tools, equipment, and accessories (bolts, gaskets, and

grounding hardware) are required.

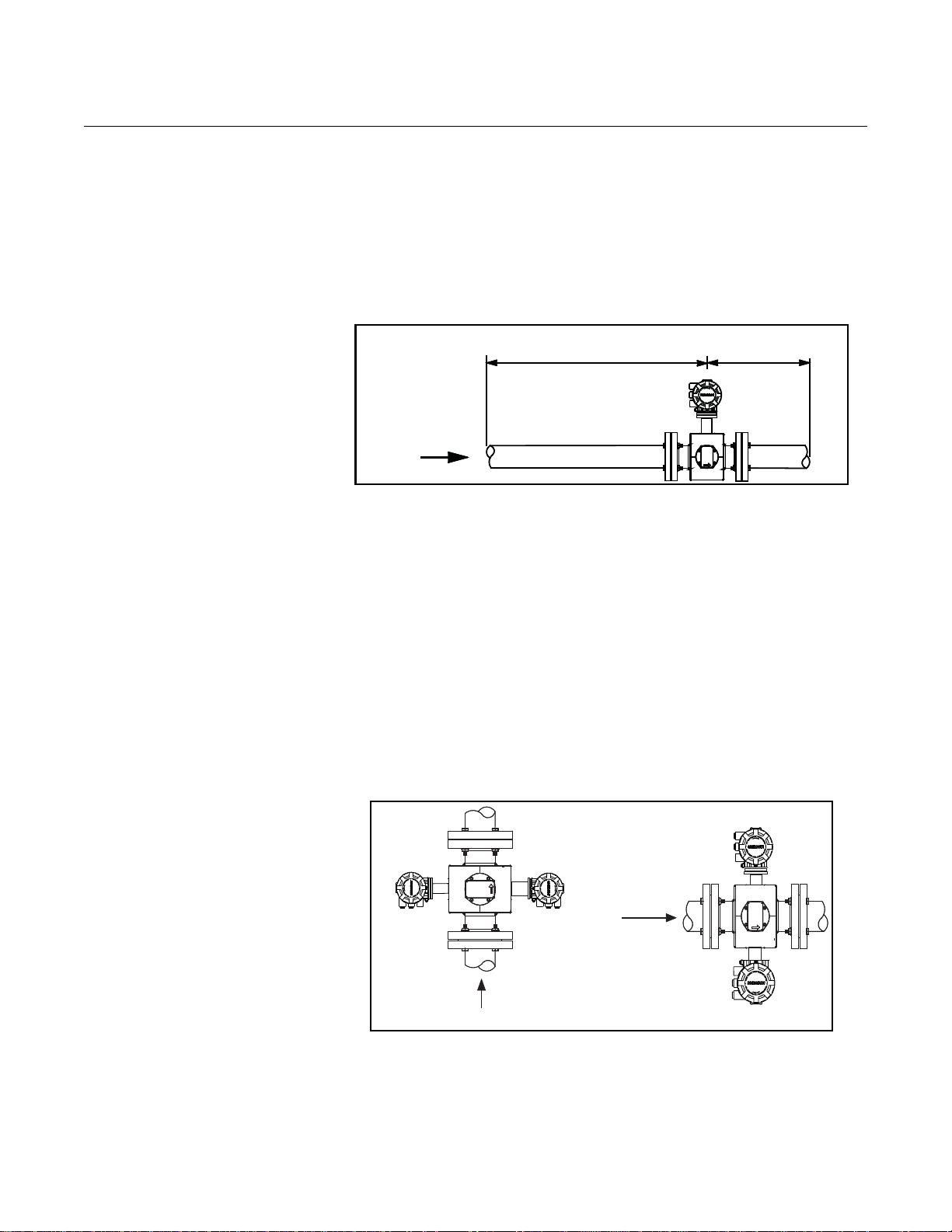

Upstream/Downstream

Piping

Figure 2-2. Upstream and

Downstream

Straight Pipe Diameters

To ensure specification accuracy over widely varying process conditions,

install the sensor a minimum of five straight pipe diameters upstream and two

pipe diameters downstream from the electrode plane (see Figure 2-2).

Sensor Orientation The sensor should be installed in a position that ensures the sensor remains

full during operation. Figures 2-3, 2-4, and 2-5 show the proper sensor

orientation for the most common installations. The following orientations

ensure that the electrodes are in the optimum plane to minimize the ef fects of

entrapped gas.

Vertical installation allows upward process fluid flow and is generally

preferred. Upward flow keeps the cross-sectional area full, regardless

of flow rate. Orientation of the electrode plane is unimportant in vertical

installations. As illustrated in Figures 2-3 and 2-4, avoid downward flows

where back pressure does not ensure that the se nsor remains full at all times.

Figure 2-3. Vertical Sensor

Orientation

Installations with reduced straight runs from 0 to five pipe diameters are

possible. In reduced straight pipe run installations, performance will shift to as

much as 0.5% of rate. Reported flow rates will still be highly repeatable.

2-4

Page 13

Reference Manual

FLOW

FLOW

FLOW

00809-0100-4727, Rev EA

October 2010

Figure 2-4. Incline or Decline

Orientation

Rosemount 8700 Series

Horizontal installation should be restricted to low piping sections that are

normally full. Orient the electrode plane to within 45 degrees of horizontal in

horizontal installations. A deviation of more than 45 degrees of horizontal

would place an electrode at or near the top of the sensor thereby making it

more susceptible to insulation by air or entrapped gas at the top of the

sensor.

Figure 2-5. Horizontal Sensor

Orientation

2-5

Page 14

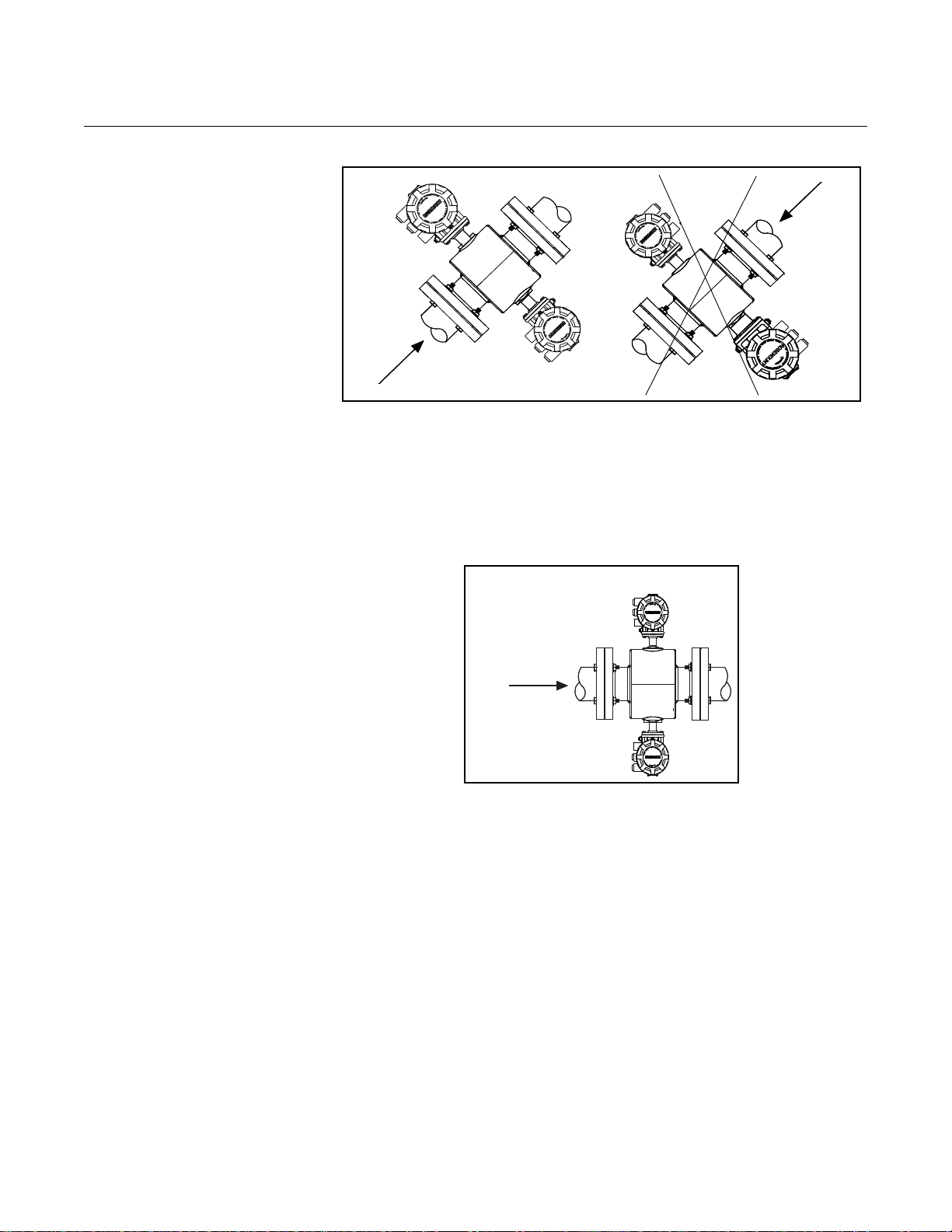

Rosemount 8700 Series

The electrodes in the Rosemount 8711 are properly oriented when the top of

the sensor is either vertical or horizontal, as shown in Figure 2-6. Avoid any

mounting orientation that positions the top of the sensor at 45 degrees from

the vertical or horizontal position.

Figure 2-6. Rosemount 8711

Mounting Position

Reference Manual

00809-0100-4727, Rev EA

October 2010

45° Electrode Plane

45° Electrode Plane

Flow Direction The sensor should be mounted so that the FORWARD end of the flow arrow,

shown on the sensor identification tag, points in the direction of flow through

the sensor (see Figure 2-7).

Figure 2-7. Flow Direction

FLOW

2-6

Page 15

Reference Manual

See ”Safety Messages” on pages 2-1 and 2-2 for complete warning information.

Gasket (Supplied by user)

Gasket (Supplied by user)

Grounding Ring

Gasket (Supplied by user)

00809-0100-4727, Rev EA

October 2010

Rosemount 8700 Series

INSTALLATION (FLANGED SENSOR)

The following section should be used as a guide in the installation of the

flange-type Rosemount 8705 and Rosemount 8707 High-Signal Sensors.

Refer to page 2-10 for installation of the wafer-type Rosemount 8711 Sensor.

Gaskets The sensor requires a gasket at each of its connections to adjacent devices or

piping. The gasket material selected must be compatible with the process fluid and

operating conditions. Metallic or spiral-wound gaskets can damage the

liner. If the gaskets will be removed frequently, protect the liner ends. All other

applications (including sensors with lining protectors or a grounding electrode)

require only one gasket on each end connection, as shown in Figure 2-8. If

grounding rings are used, gaskets are required on each side of the groundin g

ring, as shown in Figure 2-9.

Figure 2-8. Gasket Placement

Figure 2-9. Gasket Placement

with Non-attached Grounding

Rings

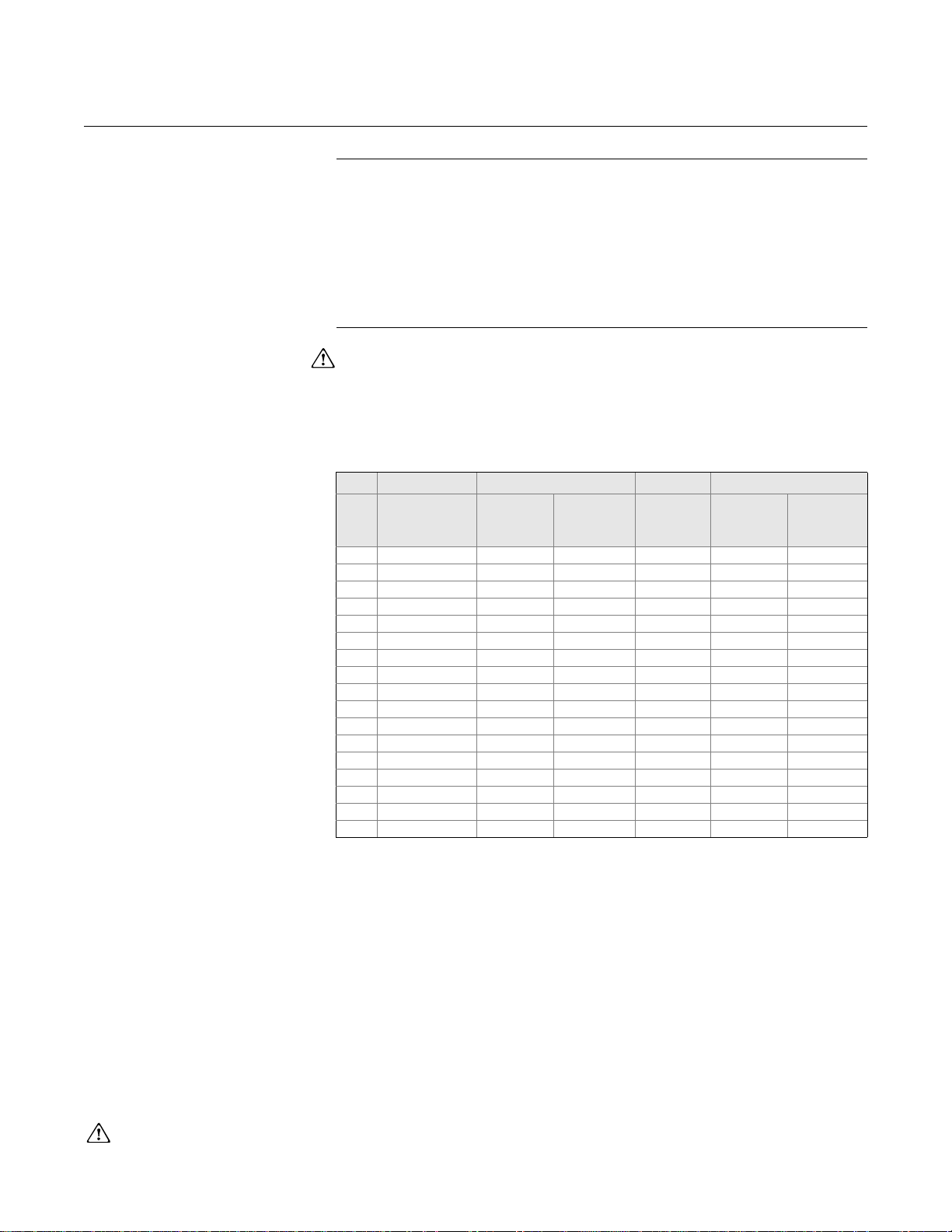

Flange Bolts Suggested torque values by sensor line size and liner type are listed in Table

2-1 on page 2-8 for ASME B16.5 (ANSI) flanges and Table 2-2 and Table 2-3

for DIN flanges. Consult the factory for other flange ratings. Tighten flange

bolts in the incremental sequence as shown in Figure 2- 10. See Table 2-1 and

Table 2-2 for bolt sizes and hole diameters.

2-7

Page 16

Rosemount 8700 Series

See ”Safety Messages” on pages 2-1 and 2-2 for complete warning information.

NOTE

Do not bolt one side at a time. Tighten each side simultaneously. Example:

1. Snug left

2. Snug right

3. Tighten left

4. Tighten right

Do not snug and tighten the upstream side and then snug and tighten the

downstream side. Failure to alternate between the upstream a nd downstream

flanges when tightening bolts may result in liner damage.

Always check for leaks at the flanges after tightening the flange bolts. Failure

to use the correct flange bolt tightening methods can result in severe dam age.

All sensors require a second torquing 24 hours after initial flange bolt

tightening.

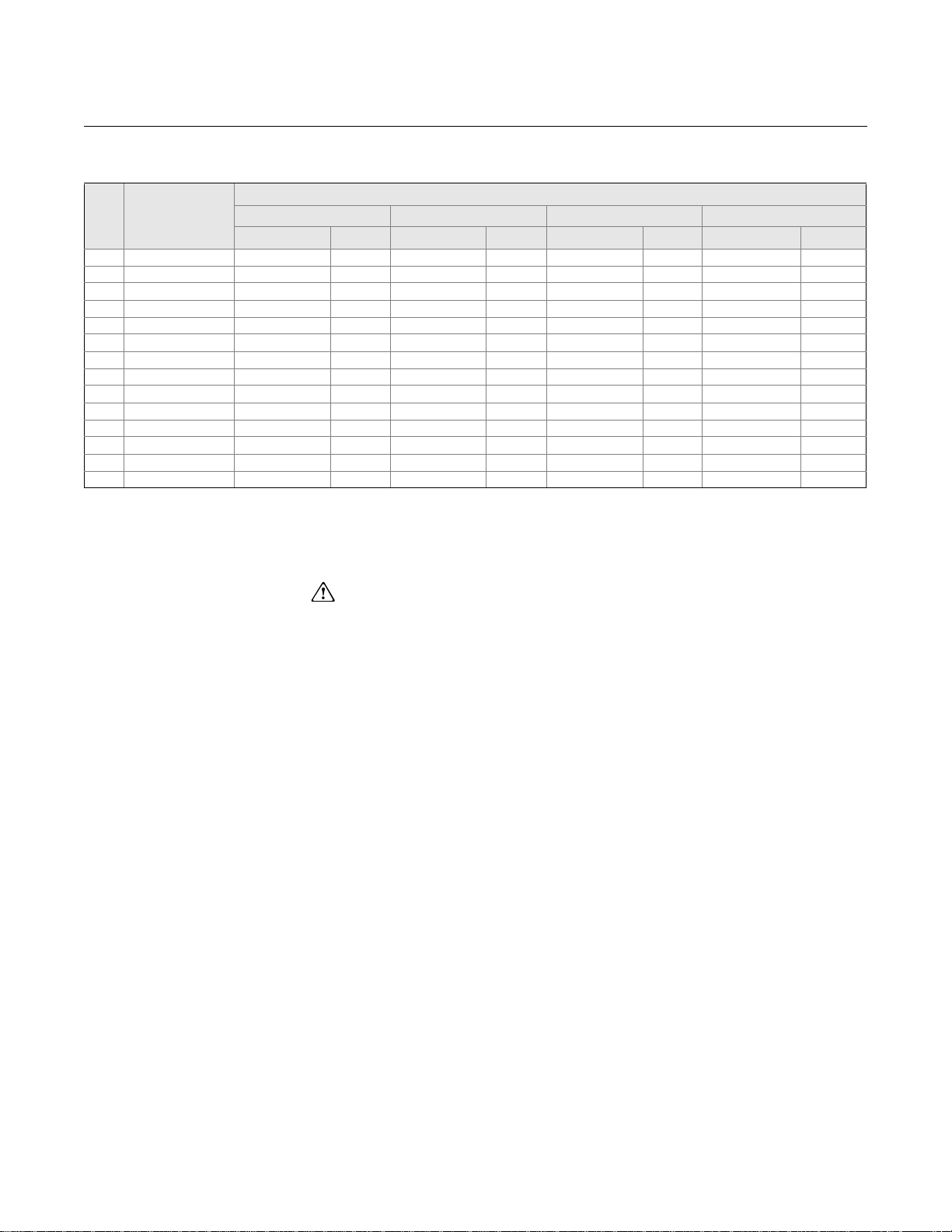

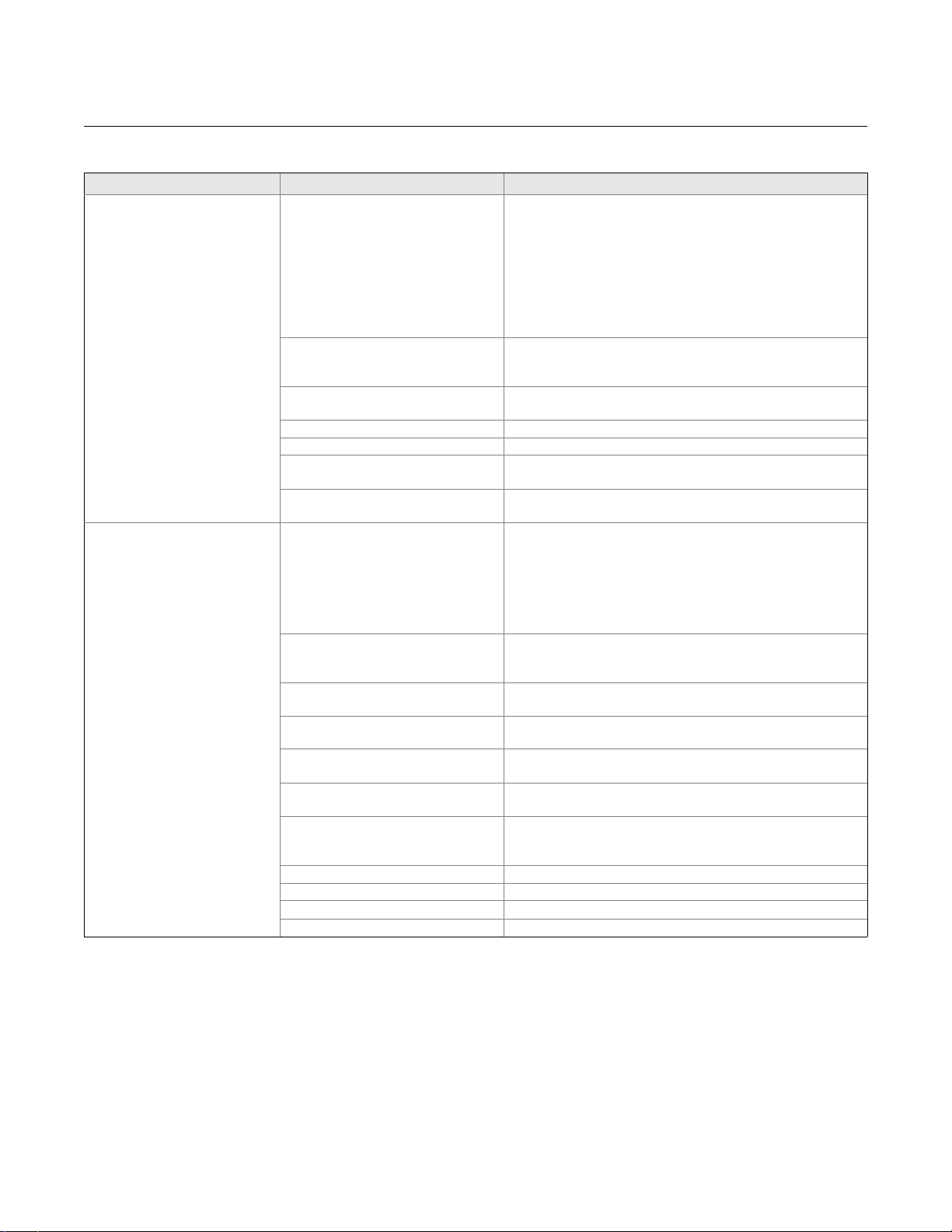

Table 2-1. Flange Bolt Torque Specifications for Rosemount 8705 and 8707

High-Signal Sensors

Size

Code

005 0.5-in. (15 mm) 8 8 8 8 010 1- in. (25 mm) 8 12 13 13 015 1.5-in. (40 mm) 13 25 29 29 7

020 2-in. (50 mm) 19 17 20 20 14

030 3-in. (80 mm) 34 35 41 41 23

040 4-in. (100 mm) 26 50 68 68 17

060 6-in. (150mm) 45 50 77 77 30

080 8-in. (200 mm) 60 82 121 121 42

100 10-in. (250 mm) 55 80 129 129 40

120 12-in. (300 mm) 65 125 146 146 55

140 14-in. (350 mm) 85 110 194 194 70

160 16-in. (400 mm) 85 160 274 274 65

180 18-in. (450 mm) 120 170 432 432 95

200 20-in. (500 mm) 110 175 444 444 90

240 24-in. (600 mm) 165 280 731 731 140

300 30-in. (750 mm) 195 375 - - 165

360 36-in. (900 mm) 280 575 - - 245

(1) Derated available with PTFE lining only.

For sensors with ANSI 600# full rated, 900#, 1500#, and 2500# flanges, the

liner is protected from over-compression by the flange design. Standard

flange torque specifications as determined by ANSI and ASME should be

followed. No special precaution is required to prevent liner damage caused by

over torquing. Bolt tightening procedures laid out in this Quick Installation

Guide must still be followed.

Line Size

Reference Manual

00809-0100-4727, Rev EA

October 2010

PTFE/ETFE liner Polyurethane liner

(1)

Class 150

(pound-feet)

Class 150

(pound-feet)

Class 300

(pound-feet)

Class 600

(Derated to

1000 psi)

Class 300

(pound-feet)

To prevent liner damage on any magnetic flowmeter, a flat gasket must be

used. For optimum results on meters with high pressure flanges (ANSI 600#

or above), it is recommended that a flat full face gasket be used.

Under NO circumstances should a spiral wound or flexitallic gasket be used

as this will damage the liner sealing surface.

2-8

Page 17

Reference Manual

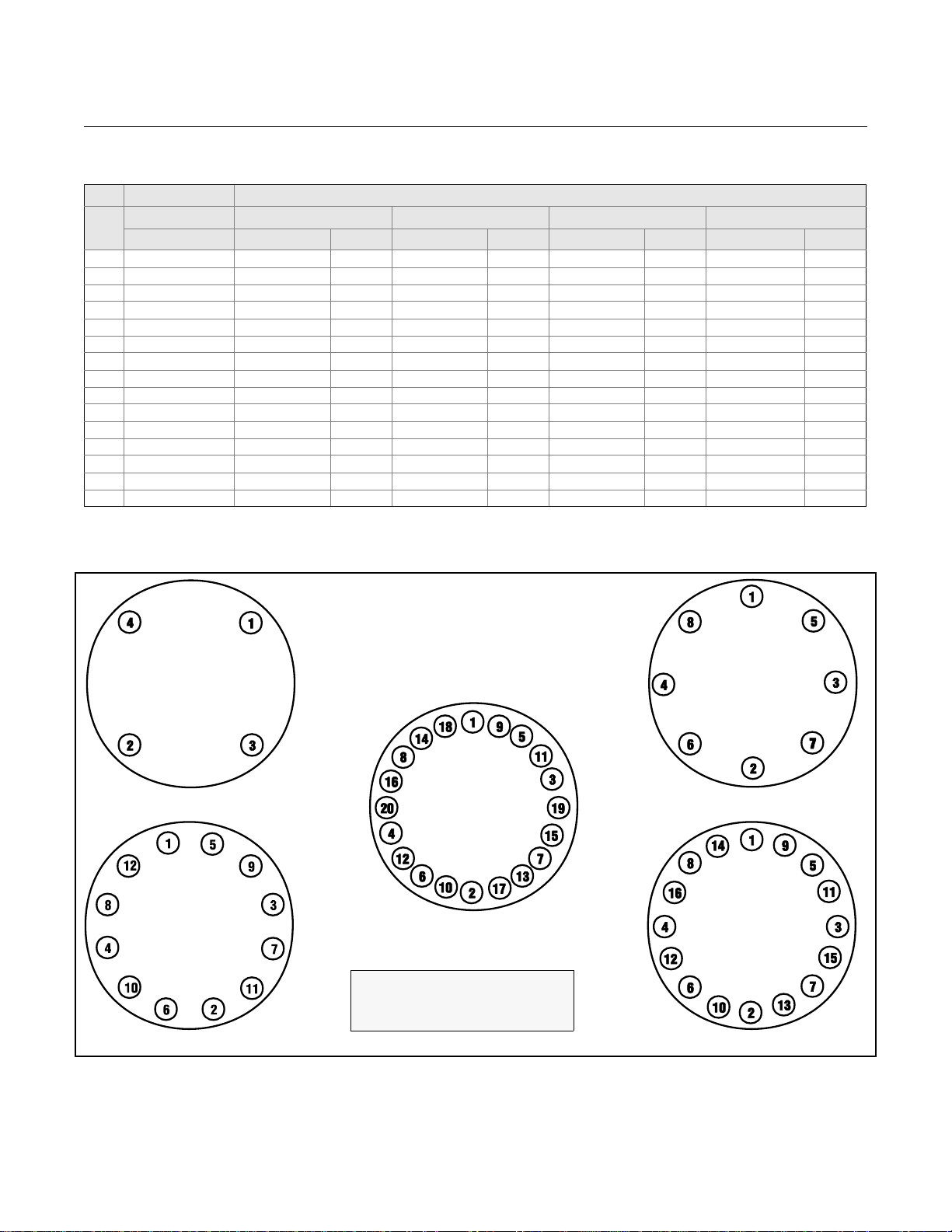

4-Bolt

8-Bolt

12-Bolt

14-Bolt

20-Bolt

Torque the flange bolts

in increments according to

the above numerical sequence.

00809-0100-4727, Rev EA

October 2010

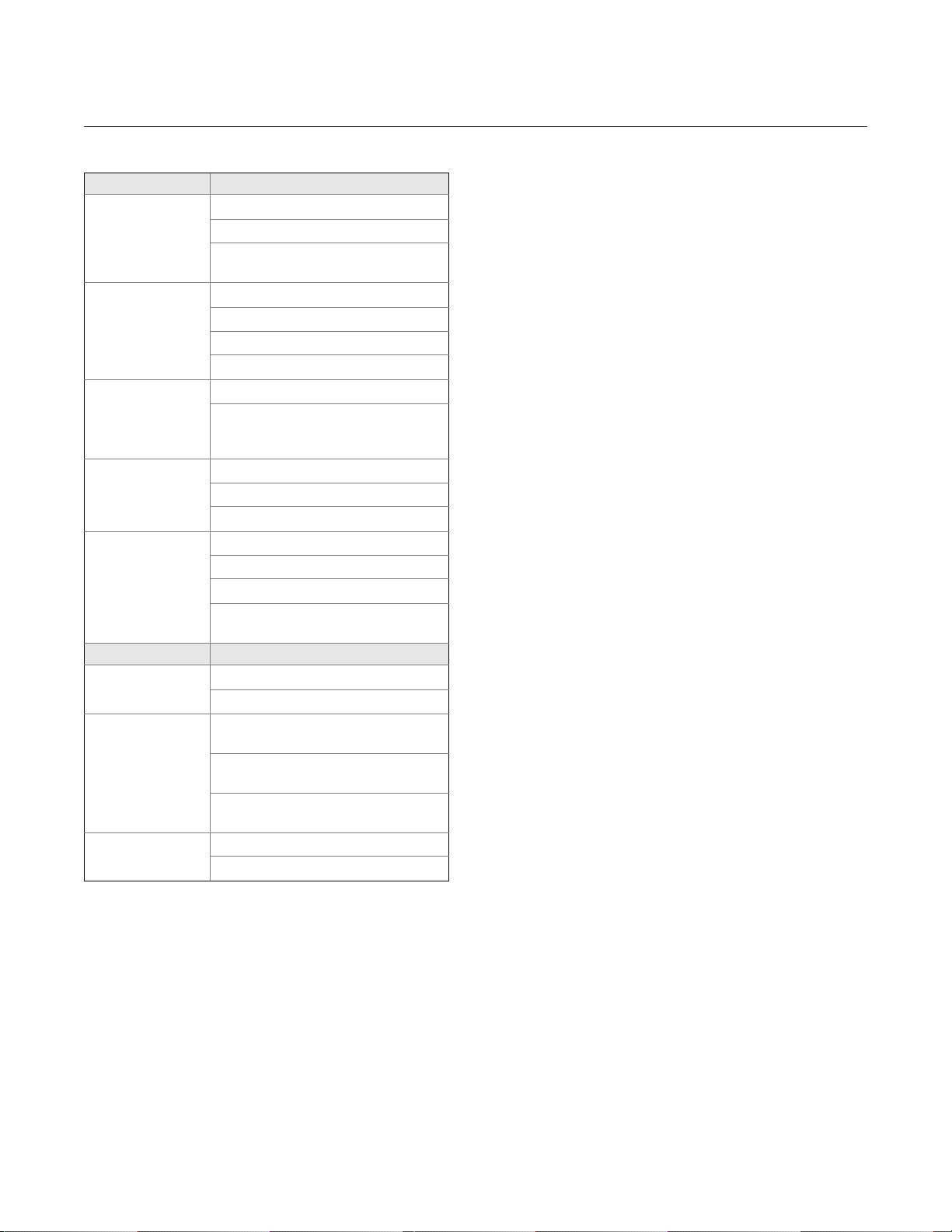

Table 2-2. Flange Bolt Torque and Bolt Load Specifications for Rosemount 8705

PTFE/ETFE liner

Size

Code

0051/2-in. (15 mm) 7 3209 7 3809 7 3809 7 4173

010 1-in. (25 mm) 13 6983 13 6983 13 6983 13 8816

015 11/2-in. (40 mm) 24 9983 24 9983 24 9983 24 13010

020 2-in. (50 mm) 25 10420 25 10420 25 10420 25 14457

030 3-in. (80 mm) 14 5935 14 5935 18 7612 18 12264

040 4-in. (100 mm) 17 7038 17 7038 30 9944 30 16021

060 6-in. (150mm) 23 7522 32 10587 60 16571 60 26698

080 8-in. (200 mm) 35 11516 35 11694 66 18304 66 36263

100 10-in. (250 mm) 31 10406 59 16506 105 25835 105 48041

120 12-in. (300 mm) 43 14439 82 22903 109 26886 109 51614

140 14-in. (350 mm) 42 13927 80 22091 156 34578 156 73825

160 16-in. (400 mm) 65 18189 117 28851 224 45158 224 99501

180 18-in. (450 mm) 56 15431 99 24477 — — — 67953

200 20-in. (500 mm) 66 18342 131 29094 225 45538 225 73367

240 24-in. (600 mm) 104 25754 202 40850 345 63940 345 103014

Line Size (Newton-meter) (Newton) (Newton-meter) (Newton) (Newton-meter) (Newton) (Newton-meter) (Newton)

PN10 PN 16 PN 25 PN 40

Rosemount 8700 Series

Figure 2-10. Flange Bolt

To rquing Sequence

2-9

Page 18

Reference Manual

00809-0100-4727, Rev EA

Rosemount 8700 Series

Table 2-3. Flange Bolt Torque and Bolt Load Specifications for Rosemount 8705

Polyurethane Liner

Size

Code

0051/2-in. (15 mm) 1 521 1 826 2 1293 6 3333

010 1-in. (25 mm) 2 1191 3 1890 5 2958 10 5555

015 11/2-in. (40 mm) 5 1960 7 3109 12 4867 20 8332

020 2-in. (50 mm) 6 2535 10 4021 15 6294 26 10831

030 3-in. (80 mm) 5 2246 9 3563 13 5577 24 19998

040 4-in. (100 mm) 7 3033 12 4812 23 7531 35 11665

060 6-in. (150mm) 16 5311 25 8425 47 13186 75 20829

080 8-in. (200 mm) 27 8971 28 9487 53 14849 100 24687

100 10-in. (250 mm) 26 8637 49 13700 87 21443 155 34547

120 12-in. (300 mm) 36 12117 69 19220 91 22563 165 36660

140 14-in. (350 mm) 35 11693 67 18547 131 29030 235 47466

160 16-in. (400 mm) 55 15393 99 24417 189 38218 335 62026

200 20-in. (500 mm) 58 15989 114 25361 197 39696 375 64091

240 24-in. (600 mm) 92 22699 178 36006 304 56357 615 91094

Line Size

(Newton-meter) (Newton) (Newton-meter) (Newton) (Newton-meter) (Newton) (Newton-meter) (Newton)

PN 10 PN 16 PN 25 PN 40

October 2010

INSTALLATION (WAFER SENSOR)

The following section should be used as a guide in the installation of the

Rosemount 8711 Sensor. Refer to page 2-7 for installation of the flange-type

Rosemount 8705 and 8707 High-Signal sensor.

Gaskets The sensor requires a gasket at each of its connections to adjacent devices or

piping. The gasket material selected must be compatible with the process

fluid and operating conditions. Metallic or spiral-wound gaskets can

damage the liner. If the gaskets will be removed frequently, protect the

liner ends. If grounding rings are used, a gasket is required on each side of

the grounding ring.

Alignment and Bolting

1. On 11/2 - through 8-in. (40 through 200 mm) line sizes, place centering

rings over each end of the sensor. The smaller line sizes, 0.15through 1-in. (4 through 25 mm), do not require centering rings.

2. Insert studs for the bottom side of the sensor between the pipe

flanges. Stud specifications are listed in Table 2-4. Using carbon

steel bolts on smaller line sizes, 0.15- through 1-in.

(4 through 25 mm), rather than the required stainless steel bolts,

will degrade performance.

2-10

Page 19

Reference Manual

00809-0100-4727, Rev EA

October 2010

Rosemount 8700 Series

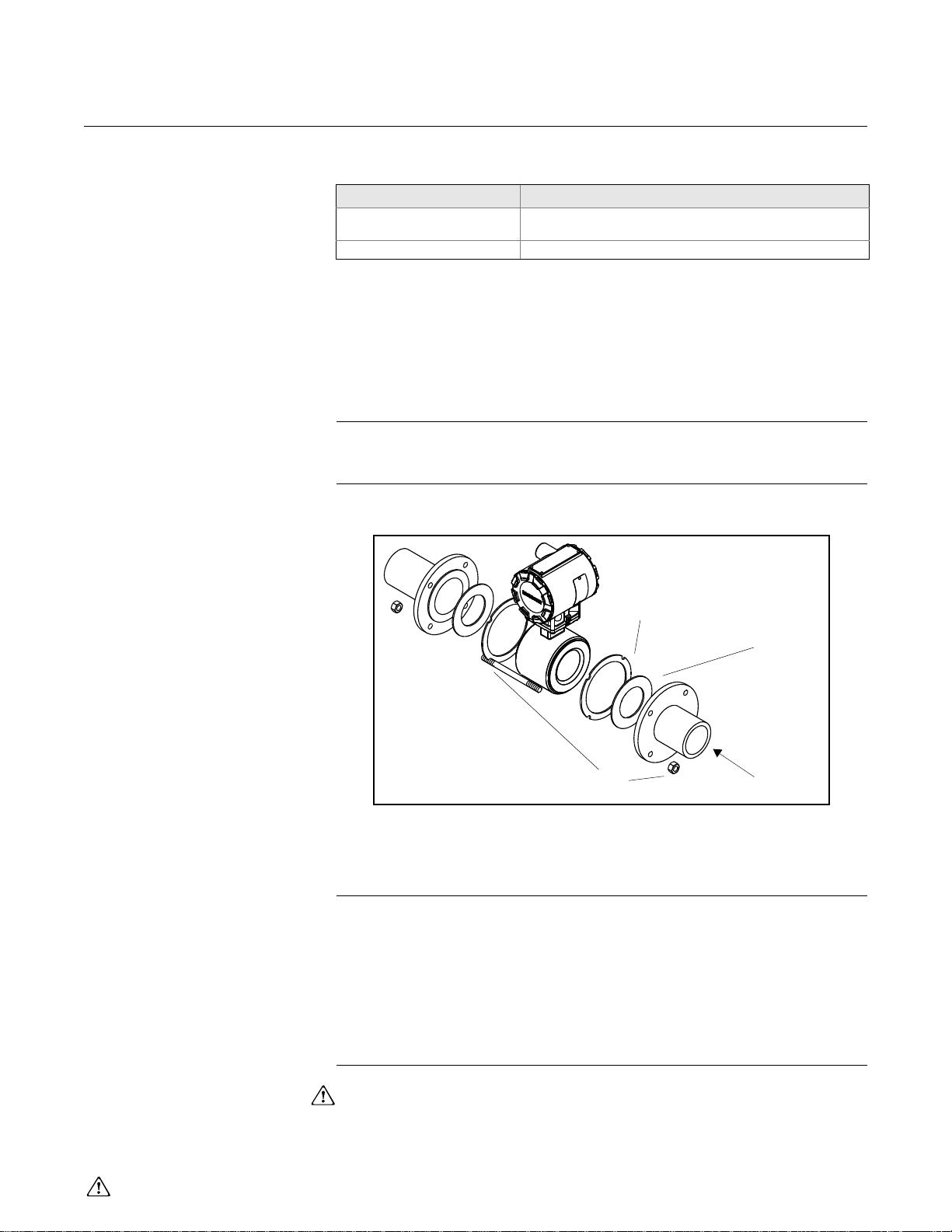

Table 2-4. Stud Specifications

Nominal Sensor Size Stud Specifications

0.15 – 1-in. (4 – 25 mm) 316 SST ASTM A193, Grade B8M

Class 1 threaded mounted studs

11/2 – 8-in. (40 – 200 mm) CS, ASTM A193, Grade B7, threaded mounting studs

3. Place the sensor between the flanges. Make sure that the centering

rings are properly placed in the studs. The studs should be aligned

with the markings on the rings that correspond to the flange you are

using.

4. Insert the remaining studs, washers, and nuts.

5. Tighten to the torque specifications shown in Table 2-5. Do not

overtighten the bolts or the liner may be damaged.

NOTE

On the 4- and 6- in. PN 10-16, insert the sensor with rings first and then insert

the studs. The slots on this ring scenario are located on the inside of the ring.

Figure 2-11. Gasket Placement

with Centering Rings

Centering Rings

Installation, Studs

Nuts and Washers

Customer-supplied

Gasket

FLOW

Flange Bolts Sensor sizes and torque values for both Class 1 50 and Class 300 flan ges are

listed in Table 2-5. Tighten flange bolts in the incremental sequence, shown in

Figure 2-10.

NOTE

Do not bolt one side at a time. Tighten each side simultaneously. Example:

1. Snug left

2. Snug right

3. Tighten left

4. Tighten right

Do not snug and tighten the upstream side and then snug and tighten the

downstream side. Failure to alternate between the upstream and downstream

flanges when tightening bolts may result in liner damage.

Always check for leaks at the flanges after tightening the flange

bolts. All sensors require a second torquing 24 hours after initial flange bolt

tightening.

See ”Safety Messages” on pages 2-1 and 2-2 for complete warning information.

2-11

Page 20

Reference Manual

User supplied clamp

User supplied gasket

00809-0100-4727, Rev EA

Rosemount 8700 Series

October 2010

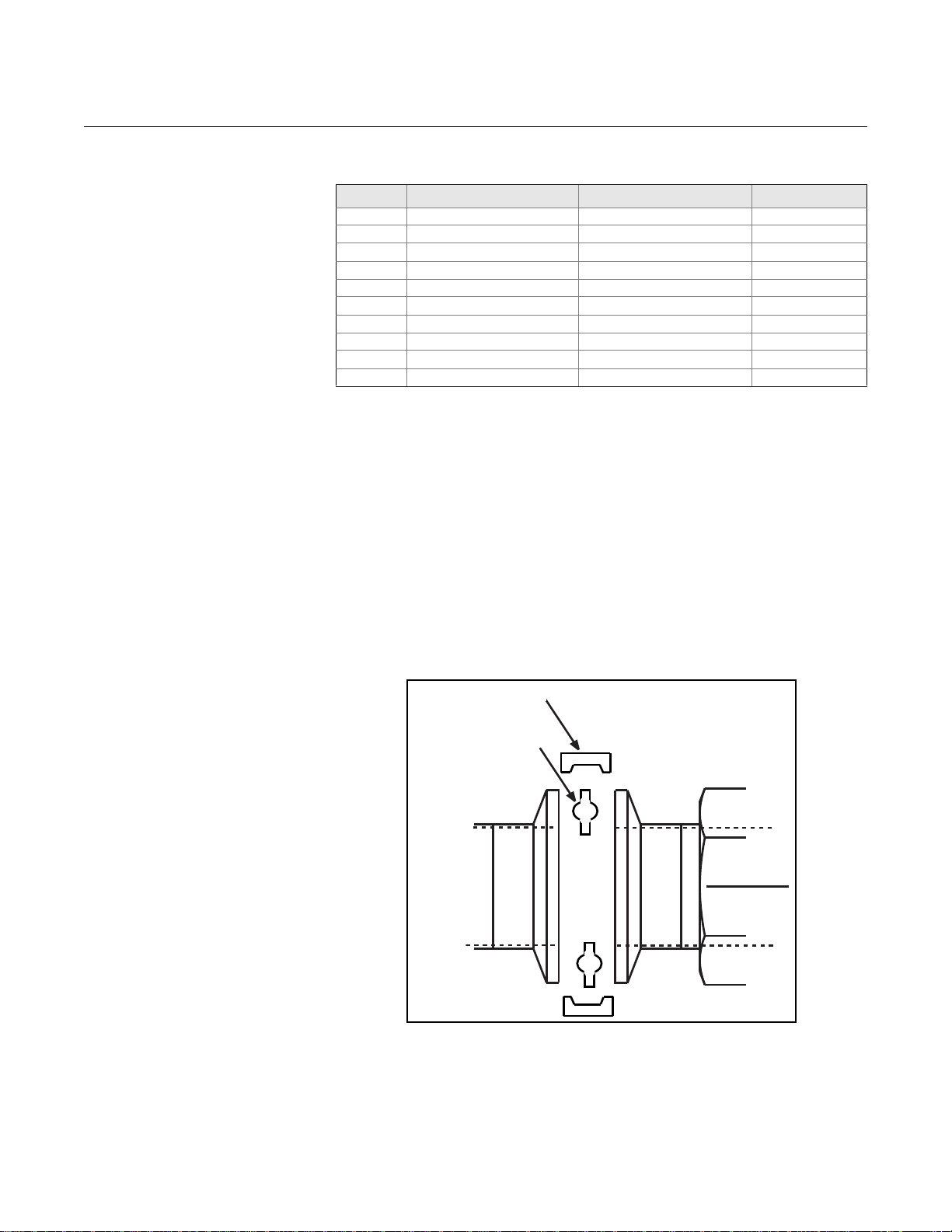

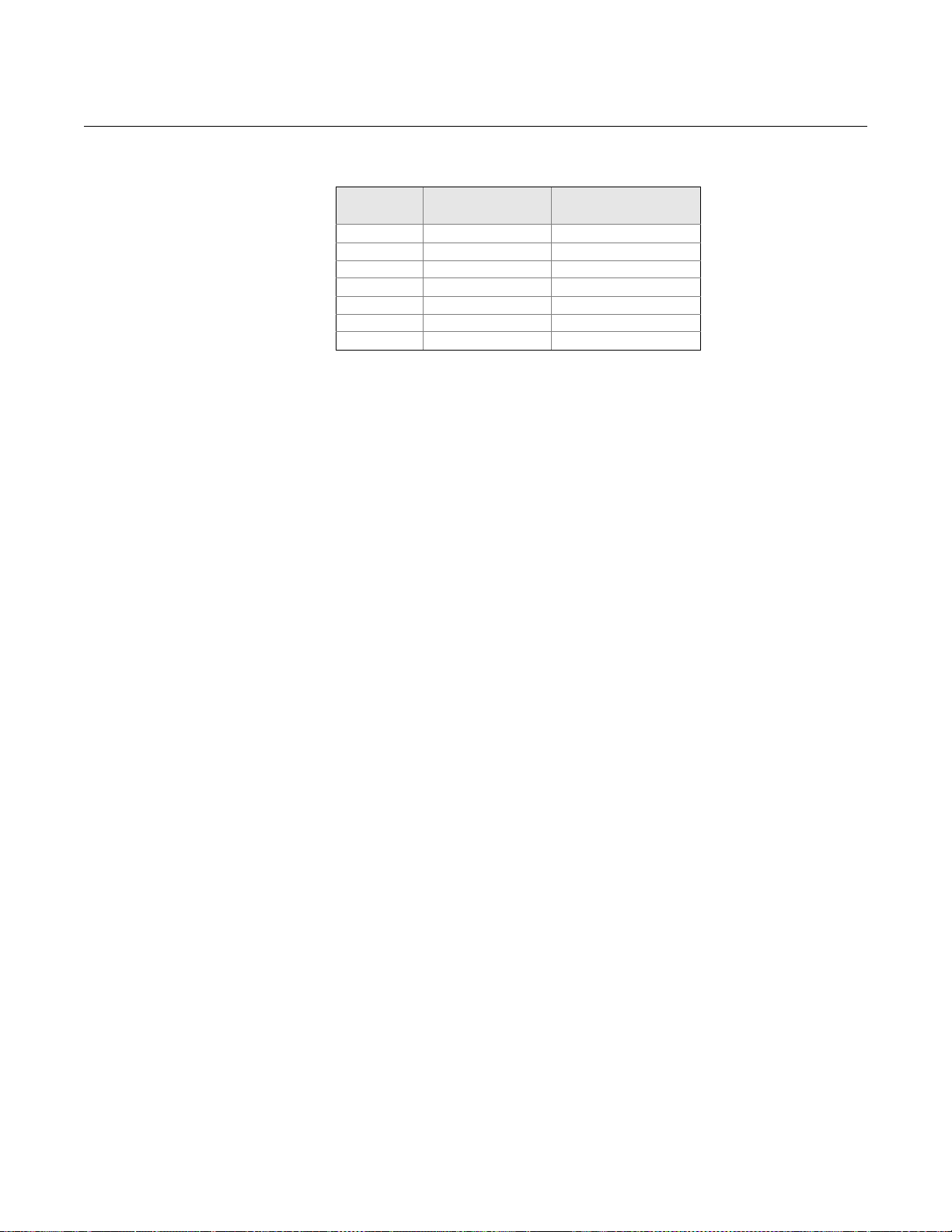

Table 2-5. Flange bolt Torque Specifications of Rosemount 8711 Sensors

Size Code Line Size Pound-feet Newton-meter

15F 0.15-in. (4 mm) 5 6.8

30F 0.30-in. (8 mm) 5 6.8

005

010 1-in. (25 mm) 10 13.6

015 11/2-in. (40 mm) 15 20.5

020 2-in. (50 mm) 25 34.1

030 3-in. (80 mm) 40 54.6

040 4-in. (100 mm) 30 40.1

060 6-in. (150 mm) 50 68.2

080 8-in. (200 mm) 70 81.9

1

/2-in. (15 mm) 5 6.8

INSTALLATION (SANITARY SENSOR)

Gaskets The sensor requires a gasket at each of its connections to adjacent devices or

piping. The gasket material selected must be compatible with the process

fluid and operating conditions. Gaskets ar e supplied with all Rosemo unt 8721

Sanitary sensors except when the process connection is an IDF sanitary

screw type.

Alignment and Bolting Standard plant practices should be followed when installing a magmeter with

Figure 2-12. Rosemount 8721

Sanitary Installation

sanitary fittings. Unique torque values and bolting techniq ue s ar e no t

required.

2-12

Page 21

Reference Manual

1

/2–14 NPT Conduit

Connection

(no relief valve)

00809-0100-4727, Rev EA

October 2010

Rosemount 8700 Series

PROCESS LEAK PROTECTION (OPTIONAL)

Standard Housing

Configuration

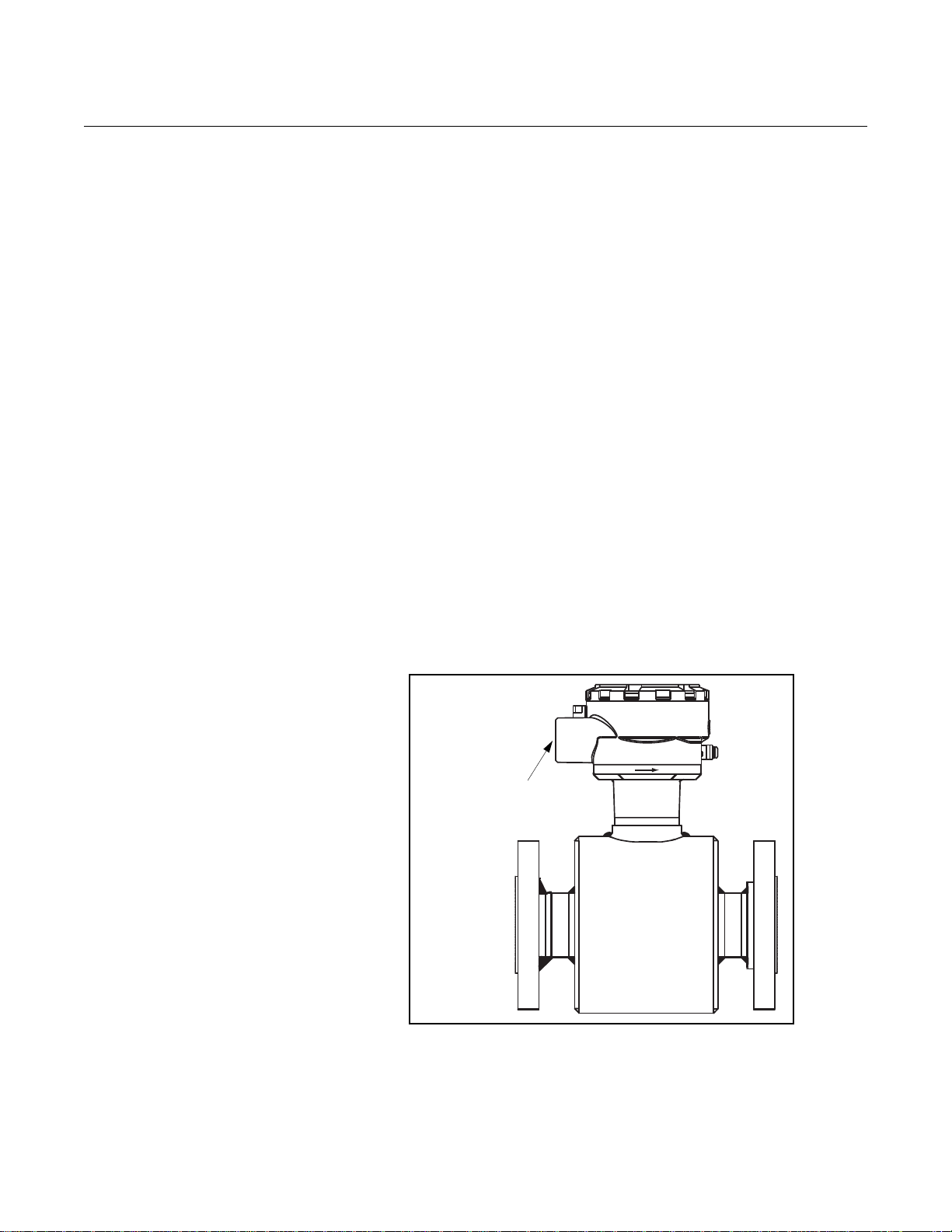

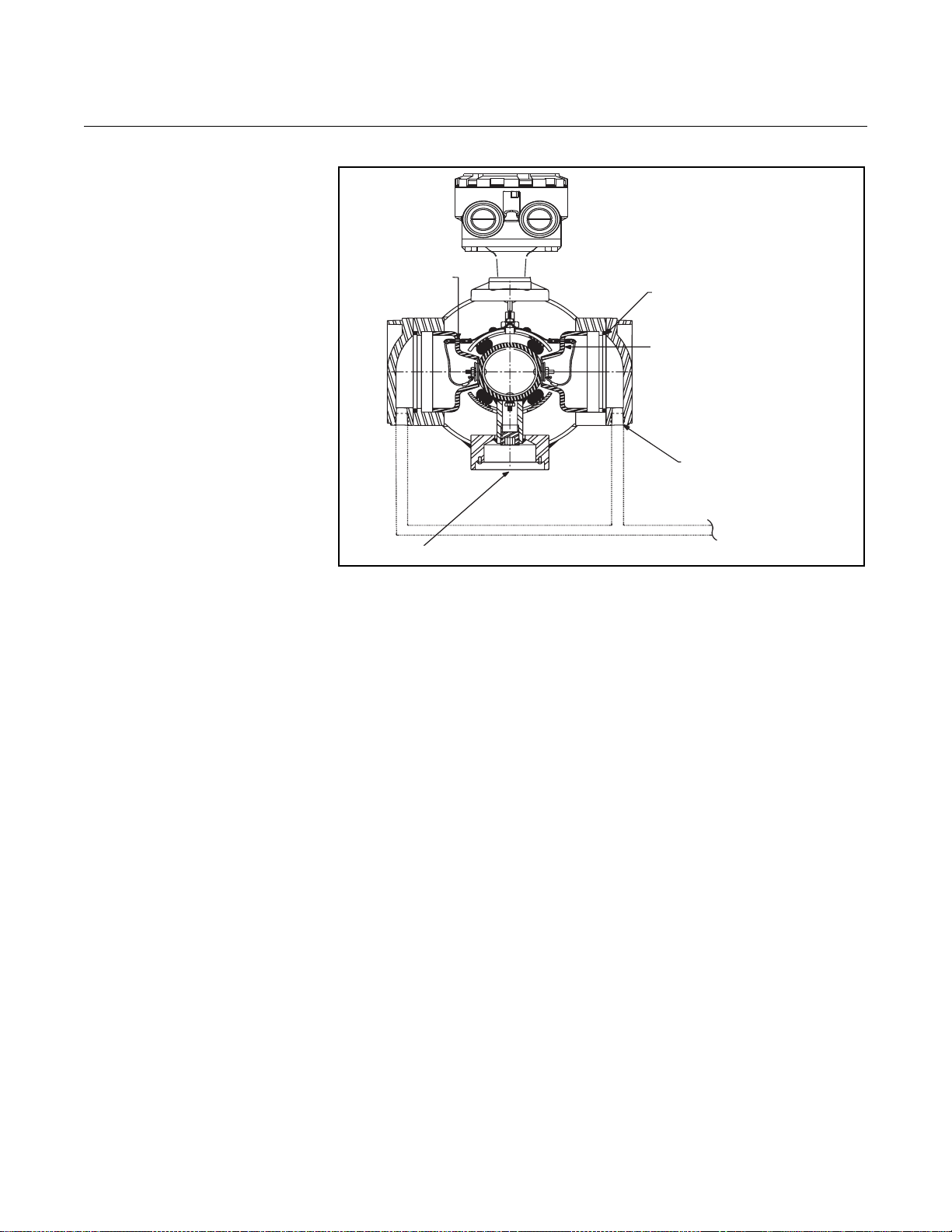

The Rosemount 8705 and 8707 High-Signal Sensor housing is fabricated

from carbon steel to perform two separate functions. First, it provides

shielding for the sensor magnetics so that external disturbances cannot

interfere with the magnetic field and thus affect the flow measu re m en t.

Second, it provides the physical protection to the coils and other internal

components from contamination and physical d amage that might occur in an

industrial environment. The housing is completely welded and gasket-free.

The three housing configurations are identified by the W0, W1, or W3 in the

model number option code when ordering. Below are brief description s of

each housing configuration, which are followed by a more detailed overview.

• Code W0 — sealed, welded coil housing (standard configuration)

• Code W1 — sealed, welded coil housing with a relief valve capable of

venting fugitive emissions to a safe location (additional plumbing from

the sensor to a safe area, installed by the user, is required to vent

properly)

• Code W3 — sealed, welded coil housing with separate electrode

compartments capable of venting fugitive emissions (additional

plumbing from the sensor to a safe area, installed by the user, is

required to vent properly)

The standard housing configuration is identified by a code W0 in the model

number. This configuration does not provide separate electrode

compartments with external electrode access. In the even t of a pr oc es s leak,

these models will not protect the coils or other sensitive areas around the

sensor from exposure to the pressure fluid (Figure 2-13).

Figure 2-13. Standard Housing

Configuration — Sealed Welded

Housing (Option Code W0)

2-13

Page 22

Reference Manual

00809-0100-4727, Rev EA

Rosemount 8700 Series

October 2010

Relief Valves The first optional configuration, identified by the W1 in the model number

option code, uses a completely welded coil housing. This configuration does

not provide separate electrode compartments with external electrode access.

This optional housing configuration provides a relief valve in the housing to

prevent possible overpressuring, caused by damage to the lining or other

situations that might allow process pressure to enter the housing. The relief

valve will vent when the pressure inside the sensor housing exceeds five psi.

Additional piping (provided by the user) may be connected to this relief valve

to drain any process leakage to safe containment (see Figure 2-14).

Figure 2-14. Coil-Housing

Configuration — Standard

Welded Housing With Relief

Valve (Option Code W1)

Optional:

Use drain port to

plumb to a safe area

(Supplied by user)

¼'' NPT – 5 psi

Pressure Relief Valve

1

/2 – 14 NPT Conduit

Connection

Process Leak

Containment

The second optional configuration, identified as option code W3 in the model

number, divides the coil housing into three compartments: one for each

electrode and one for the coils. Should a damaged liner or electrode fault

allow process fluid to migrate behind the electrode seals, the fluid is cont ained

in the electrode compartment. The sealed electrode compartment prevents

the process fluid from entering the coil compartment wh er e it woul d dam ag e

the coils and other internal components.

The electrode compartments are designed to contain the process fluid at full

line pressure. An O-ring sealed cover provides access to each of the

electrode compartments from outside the sensor; drainports are provided in

each cover for the removal of fluid.

NOTE

The electrode compartment could contain full line pressure and it must be

depressurized before the cover is removed.

2-14

Page 23

Reference Manual

00809-0100-4727, Rev EA

October 2010

Figure 2-15. Housing

Configuration — Sealed

Electrode Compartment (Option

Code W3)

Rosemount 8700 Series

Conduit Ports and

Connections

Fused Glass Seal

Grounding Electrode Port

O-ring Seal

Sealed Electrode Compartment

1

/2 - 27 NPT

Optional:

Use drain port to

plumb to a safe area

(Supplied by user)

If necessary, capture any process fluid leakage, connect the appropriate

piping to the drainports, and provide for proper disposal (see Figure 2-15).

Both the sensor and transmitter junction boxes have ports for 1/2-in. NPT

conduit connections, with optional CM20 and PG 13.5 adapter connections

available. These connections should be made in accordance with national,

local or plant electrical codes. Unused ports should be sealed with metal

plugs and PTFE tape or other thread sealant. Connections should also be

made in accordance with area approval require m ents, see exam ples below

for details. Proper electrical installation is necessary to prevent errors due to

electrical noise and interference. Separate conduits are not necessary for the

coil drive and signal cables connecting the transmitter to the sensor, but a

dedicated conduit line between each transmitter and sensor is required. A

shielded cable must be used.

Example 1: Installing flanged sensors into an IP68 area. Sensors must be

installed with IP68 cable glands and cable to maintain IP68 rating. Unused

conduit connections must be properly sealed to prevent water ingress. For

added protection, dielectric gel can be used to pot the sensor terminal block.

Consult technical document 00840-0100-4750 when installing meters into an

IP68 installation.

Example 2: Installing flowmeters into explosion-proof/flameproof areas.

Conduit connections and conduit must be rated for use in the hazardous area

to maintain flowmeter approval rating. Consult Appendix B: of this manual for

installation requirements for hazardous areas.

2-15

Page 24

Reference Manual

NOTE

Dimensions are in

inches

(millimeters).

1.00

(26)

Cable Shield

00809-0100-4727, Rev EA

Rosemount 8700 Series

October 2010

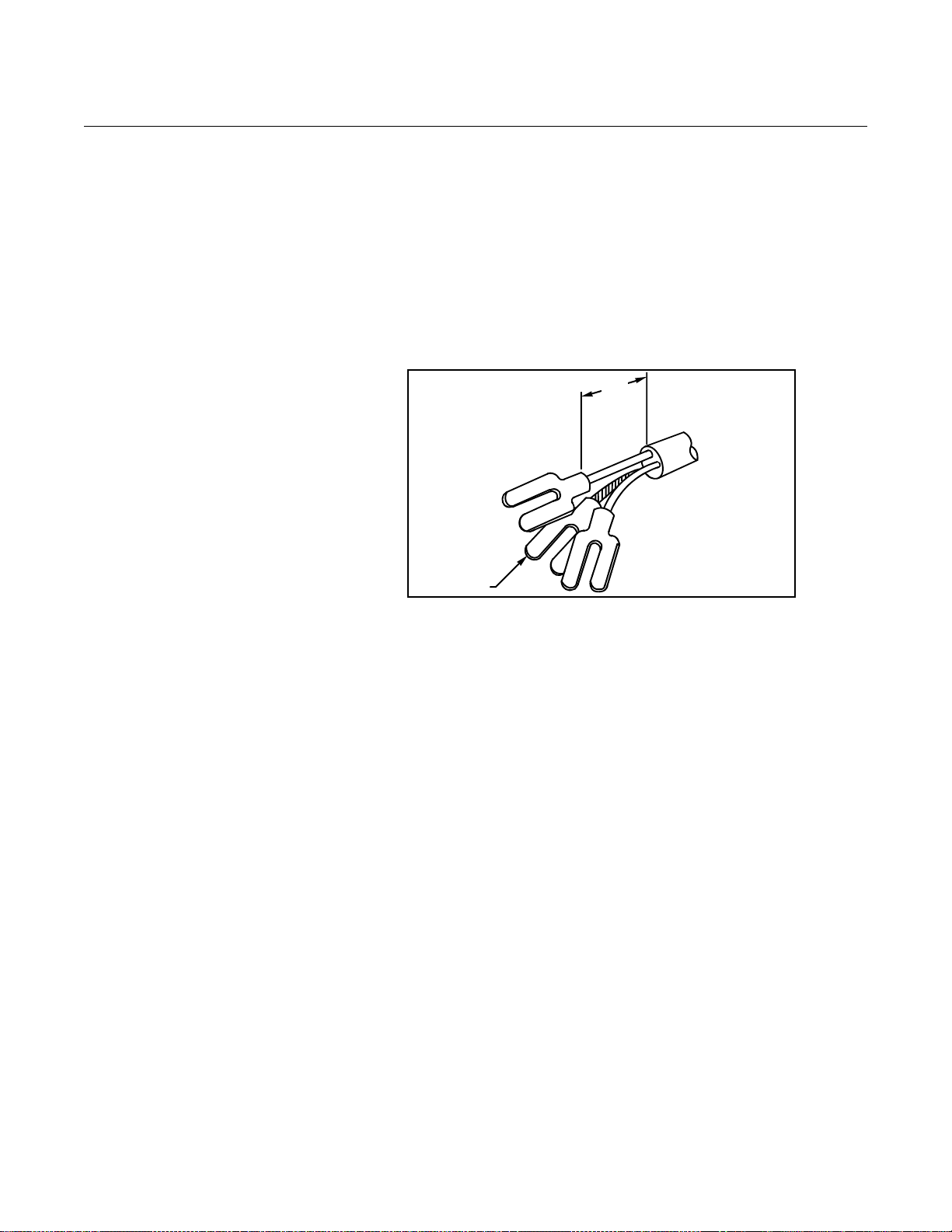

Conduit Cables Run the appropriate size cable through the conduit connections in your

magnetic flowmeter system. Run the power cable from the power source to

the transmitter . Do n ot run power cab les and outpu t signal cables in the same

conduit. For remote mount installations, run the coil drive and electrode

cables between the flowmeter and transmitter. Refer to Electrical

Considerations for wire type. Prepare the ends of the coil drive and electrode

cables as shown in Figure 2-16. Limit the unshielded wire length to 1-in. on

both the electrode and coil drive cables. Excessive lead length or failure to

connect cable shields can create electrical noise, resulting in unstable meter

readings.

Figure 2-16. Cable Preparation

Detail

2-16

Page 25

Reference Manual

00809-0100-4727, Rev EA

October 2010

Rosemount 8700 Series

Electrical Considerations Before making any electri cal connections to the Rosemount transmitter,

consider the following standards and be sure to have the proper power

supply, conduit, and other accessories. When preparing all wire connections,

remove only the insulation required to fit the wire completely under the

terminal connection. Removal of excessive insulation may result in an

unwanted electrical short to the transmitter housing or other wire connections.

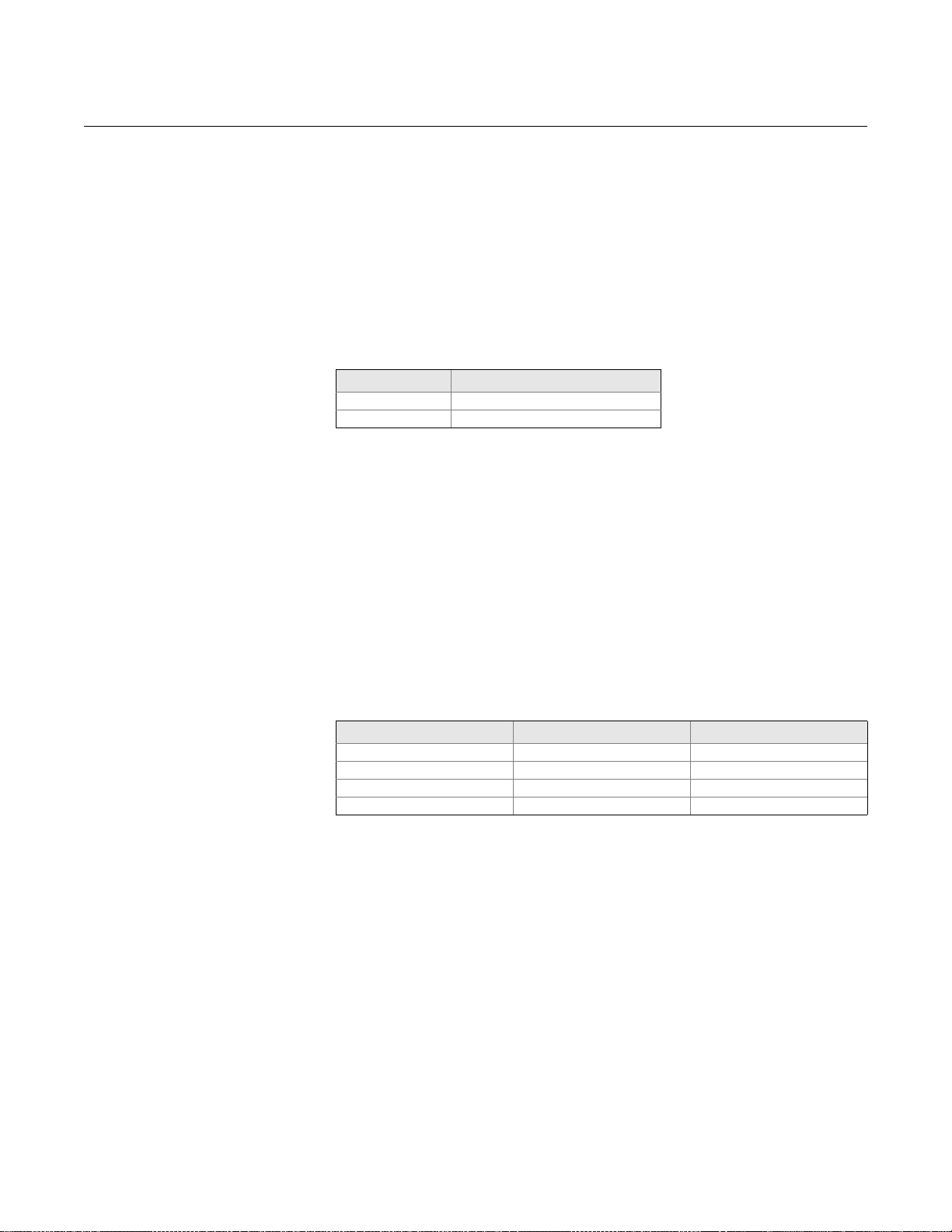

Transmitter Input Power

The Rosemount transmitter is designed to be powered b y 90 -25 0 Vac, 50–60

Hz or 12–42 Vdc. The eighth digit in the transmitter model number design ates

the appropriate power supply requirement.

Model Number Power Supply Requirement

1 90-250 Vac

2 12-42 Vdc

Supply Wire Temperature Rating

Use 14 to 18 AWG wire rated for the proper temperatu re of the application.

For connections in ambient temperatures above 140 °F (60 °C), use a wire

rated for 176 °F (80 °C). For ambients greater than 176 °F (80 °C), use a

wire rated for 230 °F (110 °C). For DC powered transmitters with extended

power cable lengths, verify that there is a minimum of 12 Vdc at the

terminals of the transmitter.

Disconnects

Connect the device through an external disconnect or circuit breaker.

Clearly label the disconnect or circuit breaker and locate it near the

transmitter.

Consult the applicable Rosemount Transmitter Documentation for detailed

transmitter installation instructions.

Transmitter Quick Installation Guide Manual

8732E HART 00825-0100-4662 00809-0100-4662

8732E FOUNDATION fieldbus 00825-0100-4663 00809-0100-4663

8732E Profibus PA 00825-0100-4665 00809-0100-4665

8712E HART 00825-0100-4664 00809-0100-4664

2-17

Page 26

Reference Manual

Coil Drive

and

Electrode

Cables

Power

Power

Outputs

Outputs

Coil Drive

and

Electrode

Cables

Power

Outputs

Power

Outputs

00809-0100-4727, Rev EA

Rosemount 8700 Series

October 2010

SENSOR CONNECTIONS This section covers the steps required to physically install the transmitter

including wiring and calibration.

Rosemount Sensors To connect the transmitter to a non-Rosemount sensor, refer to the

appropriate wiring diagram in “Universal Sensor Wiring Diagrams” on

page E-1. The calibration procedure listed is not required for use with

Rosemount sensors.

Transmitter to Sensor

Wiring

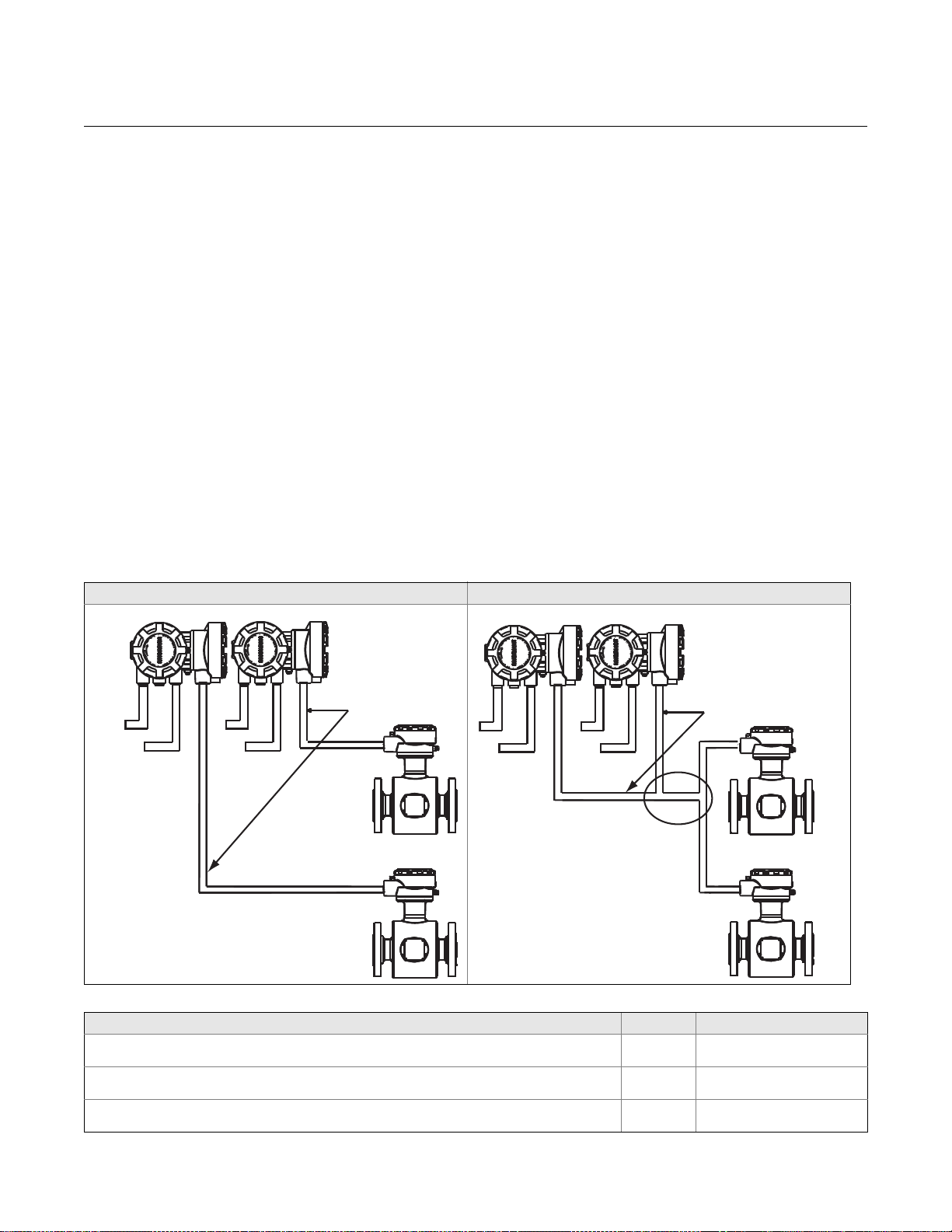

Figure 2-17. Conduit

Preparation

Correct Incorrect

Flanged and wafer sensors have two conduit ports as shown in Figur e 2-17.

Either one may be used for both the coil drive and electrode cables. Use the

stainless steel plug that is provided to seal the unused conduit port. Use

PTFE tape or thread sealant appropriate for the installation when sealing the

conduit.

A single dedicated conduit run for the coil drive and electrode cables is

needed between a sensor and a remote transmitter. Bundled cables in a

single conduit are likely to create interference and noise problems in your

system. Use one set of cables per conduit run. See Figure 2-17 for proper

conduit installation diagram and Table 2-6 for recommended cable. For

integral and remote wiring diagrams refer to Figure 2-18.

Table 2-6. Cable Requirements

Description Units Part Number

Signal Cable (20 AWG) Belden 8762, Alpha 2411 equivalent ft

Coil Drive Cable (14 AWG) Belden 8720, Alpha 2442 equivalent ft

Combination Signal and Coil Drive Cable (18 AWG)

(1) Combination signal and coil drive cable is not recommended for high-signal magme ter system. For remote mou nt installatio ns, combination signal and coil

2-18

drive cable should be limited to less than 330 ft. (100 m).

08712-0061-0001

m

(1)

m

ft

m

08712-0061-2003

08712-0060-0001

08712-0060-2003

08712-0752-0001

08712-0752-2003

Page 27

Reference Manual

00809-0100-4727, Rev EA

October 2010

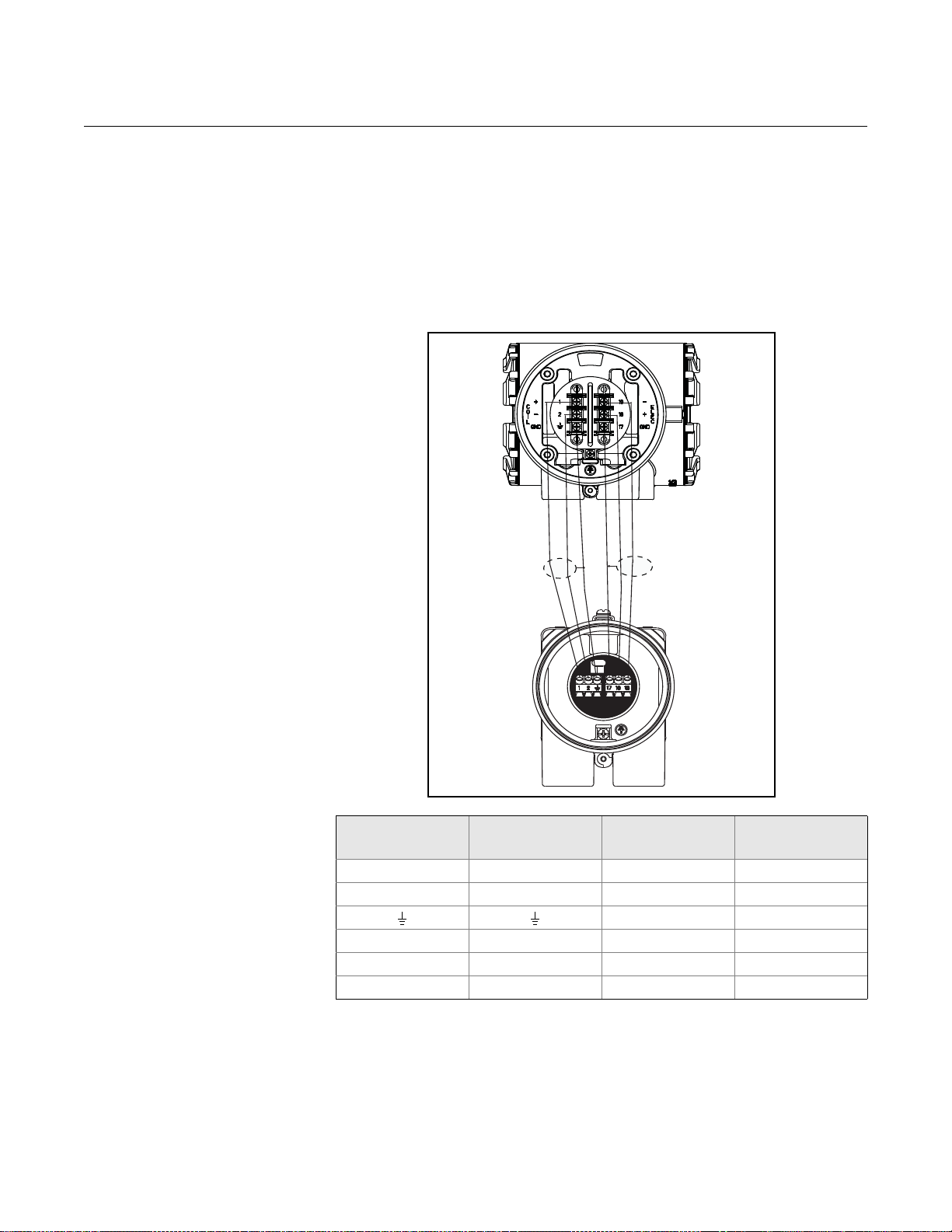

Figure 2-18. Wiring Diagram

Rosemount 8700 Series

Rosemount recommends using the combination signal and coil drive for N5,

E5 approved sensors for optimum performance.

Remote transmitter installations require equal lengths of signal and coil drive

cables. Integrally mounted transmitters are factory wired and do not require

interconnecting cables.

Lengths from 5 to 1,000 ft. (1.5 to 300 m.) may be specified, and will be

shipped with the sensor.

Transmitter

Ter minal

1 1 14 Clear or Red

2 2 14 Black

17 17 20 Shield

18 18 20 Black

19 19 20 Clear or Red

Sensor Terminal Wire Gauge Wire Color

14 Shield

2-19

Page 28

Rosemount 8700 Series

Reference Manual

00809-0100-4727, Rev EA

October 2010

2-20

Page 29

Reference Manual

00809-0100-4727, Rev EA

October 2010

Rosemount 8700 Series

Section 3 Operation and Maintenance

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-1

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-1

Material Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-3

Magnetic Flowmeter Sizing . . . . . . . . . . . . . . . . . . . . . . . . page 3-4

This section covers basic operation, software functionality, and basic

configuration procedures for the Magnetic Sensor. For more information about

the technology and the function blocks used in the sensor, refer to

Appendix A: Reference Data and Appendix C: Field-Removable Electrodes.

CALIBRATION Rosemount sensor are wet calibrated at the factory. They do not need further

calibration during installation.

GROUNDING Process grounding the sensor is one of the most important details of sensor

installation. Proper process grounding ensures that th e transmitter amplifier is

referenced to the process. This creates the lowest noise environment for the

transmitter to make a stable reading. Use Table 3-1 to determine which

grounding option to follow for proper installation.

NOTE

Consult factory for installations requiring cathodic protection or situations

where there are high currents or high potential in the process.

The sensor case should always be earth grounded in accordance with

national and local electrical codes. Failure to do so may impair the protection

provided by the equipment. The most effective grounding method is direct

connection from the sensor to earth ground with minimal impedance.

The Internal Ground Connection (Protective Ground Connection), located

inside the junction box, is the Internal Ground Connection screw. This screw

is identified by the ground symbol:

Table 3-1. Grounding Installation

Grounding Options

Type of Pipe No Grounding Options Grounding Rings Grounding Electrodes Lining Protectors

Conductive Unlined Pipe See Figure 3-1 Not Required Not Required See Figure 3-2

Conductive Lined Pipe Insufficient Grounding See Figure 3-2 See Figure 3-1 See Figure 3-2

Non-Conductive Pipe Insufficient Grounding See Figure 3-3 See Figure 3-4 See Figure 3-3

www.rosemount.com

Page 30

Rosemount 8700 Series

Grounding Rings or

Lining Protectors

Figure 3-1. No Grounding

Options or Grounding Electrode

in Lined Pipe

Figure 3-2. Grounding with

Grounding Rings or Lining

Protectors

Reference Manual

00809-0100-4727, Rev EA

October 2010

3-2

Page 31

Reference Manual

Grounding Rings or

Lining Protectors

00809-0100-4727, Rev EA

October 2010

Figure 3-3. Grounding with

Grounding Rings or Lining

Protectors

Rosemount 8700 Series

Figure 3-4. Grounding with

Grounding Electrodes

MATERIAL SELECTION Several liner types, electrode materials, and electrode types are available on

Rosemount Magnetic Sensor to ensure compatibility with virtually any

application. See Appendix A: for information on liner types, on electrode

materials, and electrode types. For further guidance on selecting materials,

refer to the Magnetic Flowmeter Material Selection Guide located on

Rosemount.com (document number 00816-0100-3033).

3-3

Page 32

Rosemount 8700 Series

Velocity =

Flow Rate

Factor

Velocity =

Velocity = 1.7 m/s

800

(L/min.)

Velocity =

Velocity = 7.56 ft/s

300 (gpm)

39.679

Reference Manual

00809-0100-4727, Rev EA

October 2010

MAGNETIC FLOWMETER SIZING

Flowmeter Sizing

Because of its effect on flow velocity, sensor size is an important

consideration. It may be necessary to select a magnetic flowmeter that is

larger or smaller than the adjacent piping to ensure the fluid velocity is in the

specified measuring range of the sensor. Suggested guidelines and examples

for sizing normal velocities in different applications are listed in Table 3-2,

Table 3-3, and Table 3-4. Operation outside these guidelines may also give

acceptable performance.

Table 3-2. Sizing Guidelines

Application Velocity Range (ft/s) Velocity Range (m/s)

Normal Service

Abrasive Slurries

Non-Abrasive Slurries

2–20 0.6–6.1

3–10 0.9–3.1

5–15 1.5–4.6

To convert flow rate to velocity, use the appropriate factor listed in Table 3-2

and the following equation:

Example: SI Units

Magmeter Size: 100 mm (factor from Table 3-3 = 492.0)

Normal Flow Rate: 800 L/min.

3-4

Example: English Units

Magmeter Size: 4-in. (factor from Table 3-3 = 39.679)

Normal Flow Rate: 300 GPM

Page 33

Reference Manual

00809-0100-4727, Rev EA

October 2010

Rosemount 8700 Series

Table 3-3. Line Size vs. Conversion Factor

Nominal Line Size

Inches (mm)

0.30 (8) 0.220 2.732

½ (15) 0.947 11.745

1 (25) 2.693 33.407

1½ (40) 6.345 78.69

2 (50) 10.459 129.7

2 ½ (65) 14.922 185.0

3 (80) 23.042 285.7

4 (100) 39.679 492.0

6 (150) 90.048 1,116

8 (200) 155.94 1,933

10 (250) 245.78 3,048

12 (300) 352.51 4,371

14 (350) 421.70 5,229

16 (400) 550.80 6,830

18 (450) 697.19 8,645

20 (500) 866.51 10,745

24 (600) 1,253.2 15,541

30 (750) 2,006.0 24,877

36 (900) 2,935.0 36,398

Gallons Per Minute Factor

Liters Per

Minute Factor

3-5

Page 34

Reference Manual

00809-0100-4727, Rev EA

Rosemount 8700 Series

Table 3-4. Line Size vs. Velocity/Rate

Minimum/Maximum Flow Rate

Nominal

Line Size in

Inches

(mm)

.15 (4) 0.002 0.055 0.16 2.14 0.01 0.21 0.68 8.16

.30 (8) 0.009 0.220 0.66 8.58 0.03 0.83 2.73 32.76

1

/2 (15) 0.038 0.947 2.84 36.93 0.14 3.58 11.74 140.88

1 (25) 0.108 2.694 8.08 105.07 0.41 10.18 33.40 424.80

1

1

/2 (40) 0.254 6.345 19.03 247.46 0.96 23.98 78.69 944.28

2 (50) 0.418 10.459 31.37 407.90 1.58 39.54 129.7 1,556

1

2

/2 (65) 0.597 14.922 44.77 582.0 2.22 55.51 185.0 2,220

3 (80) 0.922 23.042 69.12 898.64 3.49 87.10 285.7 3,428

4 (100) 1.588 39.667 119.0 1547.0 6.00 138.6 492.0 5,904

6 (150) 3.600 90.048 270.1 3511.8 13.61 340.3 1,116 13,400

8 (200) 6.240 155.94 467.7 6081.7 23.59 589.4 1,933 23,204

10 (250) 9.840 245.78 737.3 9585.4 37.20 929.0 3,048 36,576

12 (300) 14.200 352.51 1,059 13,747 53.68 1,332 4,371 52,548

14 (350) 16.800 421.70 1,265 16,446 63.50 1,594 5,230 62,755

16 (400) 22.000 550.80 1,652 21,481 83.16 2,082 6,830 81,964

18 (450) 27.800 697.19 2,091 27,190 105.0 2,635 8,646 103,750

20 (500) 34.600 866.51 2,599 33,793 130.7 3,275 10,740 128,948

24 (600) 50.200 1,253.2 3,759 48,874 189.7 4,737 15,540 186,496

30 (750) 80.200 2,006.0 6,018 78,234 303.1 7,582 24,880 298,527

36 (900) 117.40 2,935.0 8,805 114,465 443.7 11,094 36,390 436,779

at 0.04 ft/s

(Low-flow

Cutoff)

Gallons per Minute Liters per Minute

at 1 ft/s

(Min Range

Setting)

at 3 ft/s

at 39 ft/s

(Max Range

Setting)

at 0.012 m/s

(Low-flow

Cutoff)

at 0.3 m/s

(Min Range

Setting)

at 1 m/s

October 2010

at 12 m/s

(Max Range

Setting)

3-6

Page 35

Reference Manual

00809-0100-4727, Rev EA

October 2010

Rosemount 8700 Series

Section 4 Maintenance and

Troubleshooting

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4-1

Installation Check and Guide . . . . . . . . . . . . . . . . . . . . . . page 4-2

Diagnostic Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4-3

Transmitter Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . page 4-5

Quick Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4-7

This section covers basic transmitter and sensor troubleshooting. Problems in

the magnetic flowmeter system are usually indicated by incorrect output

readings from the system, error messages, or failed tests. Consider all

sources when identifying a problem in your system. If the problem persists,

consult your local Rosemount representative to determine if the material

should be returned to the factory . Emerson Process Management offers

several diagnostics that aid in the troubleshooting process.

SAFETY INFORMATION

Instructions and procedures in this section may require special precautions to

ensure the safety of the personnel performing the operations. Please read the

following safety messages before performing any operation described in this

section. Refer to these warnings when appropriate throughout this section.

Failure to follow these installation guidelines could result in death or serious injury:

Installation and servicing instructions are for use by qualified personnel only. Do not perform

any servicing other than that contained in the operating instructions, unless qualified. Verify

that the operating environment of the sensor and transmitter is consistent with the

appropriate FM or CSA approval.

Do not connect a Rosemount transmitter to a non-Rosemount sensor that is located in an

explosive atmosphere.

Mishandling products exposed to a hazardous substance may result in death or serious

injury. If the product being returned was exposed to a hazardous substance as defined by

OSHA, a copy of the required Material Safety Data Sheet (MSDS) for each hazardous

substance identified must be included with the returned goods.

The Rosemount transmitter performs self diagnostics on the entire magnetic

flowmeter system: the transmitter, the sensor, and the interconnecting wiring.

By sequentially troubleshooting each individual piece of the magmeter

system, it becomes easier to pinpoint the prob lem an d ma ke the app rop ria te

adjustments.

www.rosemount.com

If there are problems with a new magmeter installation, se e “In stallation

Check and Guide” on page 4-2 for a quick guide to solve the most common

installation problems. For existing magmeter installations, Table 4-4 lists the

most common magmeter problems and corrective actions.

Page 36

Rosemount 8700 Series

Reference Manual

00809-0100-4727, Rev EA

October 2010

INSTALLATION CHECK AND GUIDE

Use this guide to check new installations of Rosemount magnetic flowmeter

systems that appear to malfunction.

Before You Begin

Transmitter

Apply power to your system before making the following transmitter checks.

1. Verify that the correct sensor calibration number is entered in th e

transmitter. The calibration number is listed on the sensor nameplate.

2. Verify that the correct sensor line size is entered in the transmitter.

The line size value is listed on the sensor nameplate.

3. Verify that the function blocks are not in Out of Service mode.

4. Verify that the transmitter is functioning correctly by using the 8714i

Meter Verification diagnostic or the 8714D Calibration Reference

Standard.

Sensor

Be sure that power to your system is removed before beginning sensor

checks.

1. For horizontal flow installations, ensure that the ele ctrodes remain

covered by process fluid.

For vertical or inclined installations, ensure that the process fluid

is flowing up into the sensor to keep the electrodes covered by

process fluid.

2. Ensure that the grounding straps on the sensor are connected to

grounding rings, lining protectors, or the adjacent pipe flanges.

Improper grounding will cause erratic operation of the system.

Wiring for Remote Configurations

1. The signal wire and coil drive wire must be twisted shielded cable.

Emerson Process Management, Rosemount division, recommends

20 AWG twisted shielded cable for the elec trodes and 14 AWG

twisted shielded cable for the coils.

2. The cable shield must be conne cted at both ends of the electrode an d

coil drive cables. Connection of the signal wire shield at both ends is

necessary for proper operation. It is recommended that the coil drive

wire shield also be connected at both ends for maximum flowmeter

performance.

3. The signal and coil drive wires must be separate cables, unless

Emerson Process Management specified combo cable is used. See

Table 2-2 on page 2-11.

4. The single conduit that houses both the sign al and coil drive cables

should not contain any other wires.

Process Fluid

1. The process fluid conductivity should be 5 microsiemens

(5 micro mhos) per cm minimum.

2. The process fluid must be free of air and gasses.

3. The sensor should be full of process fluid.

4-2

Page 37

Reference Manual

00809-0100-4727, Rev EA

October 2010

Rosemount 8700 Series

DIAGNOSTIC MESSAGES

Problems in the magnetic flowmeter system are usually indicated by incorrect

output readings from the system, error messages, or failed te sts. Consider all

sources in identifying a problem in your system.

Table 4-1. Rosemount Basic Diagnostic Messages

Local Display Error

Message

“Empty Pipe Detected” Empty Pipe Empty Pipe None - message will clear when pipe is full

“Coil Drive Open

Circuit”

“Auto Zero Failure

(Cycle power to clear

messages, no changes

were made)”

“Universal Trim Failure” Univ Trim Fail No flow in pipe while performing

“Electronics Failure” Electronics Fail Electronics self check failure Replace Electronics

“Electronics

Temperature Out of

Range”

“Reverse Flow

Detected”

“Sensor Hi Limit

Exceeded”

“DSP Hardware not

compatible with

software”

Message (English)

Wiring Error Check that wiring matches appropriate wiring diagrams -

Electrode Error Perform sensor tests C and D (see Table 4-5 on page 4-8)

Conductivity less than 5 microsiemens

per cm

Intermittent Diagnostic Adjust tuning of Empty Pipe parameters

Coil Open Ckt Improper wiring Check coil drive wiring and sensor coils

Other manufacturer’s sensor Change coil current to 75 mA

Circuit Board Failure Replace Rosemount 8732 Electronics

Coil Circuit OPEN Fuse Return to factory for fuse replacement

Auto Zero Fail Flow is not set to zero Force flow to zero, perform autozero

Unshielded cable in use Change wire to shielded cable

Moisture problems See moisture problems in “Accuracy Section”

Empty pipe is present Fill sensor with process fluid

Universal Auto Trim

Wiring error Check that wiring matches appropriate wiring diagrams -

Flow rate is changing in pipe while

performing Universal Auto-Trim routine

Flow rate through sensor is

significantly different than value

entered during Universal Auto-Trim

routine

Incorrect calibration number entered

into transmitter for Universal Auto-Trim

routine

Wrong sensor size selected Correct sensor size setting - See “Line Size” on page 3-9

Sensor failure Perform sensor tests C and D (see Table 4-5 on page 4-8)

Temp Out of Rng Ambient temperature exceeded the

electronics temperature limits

Reverse Flow Electrode or coil wires reverse Verify wiring between sensor and transmitter

Flow is reverse Turn ON Reverse Flow Enable to read flow

Sensor installed backwards Re-install sensor correctly, or switch either the electrode

Flow >Sens limit Flow rate is greater than 43 ft/sec Lower flow velocity, increase pipe diameter

Improper wiring Check coil drive wiring and sensor coils

Incompatible SW DSP Software Revision is not equal to

Hornet’s Expectations.

Potential Cause Corrective Action

see Appendix E: Universal Sensor Wiring Diagrams

Increase Conductivity to greater than or equal to 5

microsiemens per cm

Perform sensor test A - Sensor Coil

Perform a Universal Auto Trim to select the proper coil

current

Establish a known flow in sensor, and perform Universal

Auto-Trim calibration

see “Universal Sensor Wiring Diagrams” on page E-1

Establish a constant flow in sensor , and perform Universal

Auto-Trim calibration

Verify flow in sensor and perform Universal Auto-Trim

calibration

Replace sensor calibration number with

1000005010000001

Move transmitter to a location with an ambient

temperature range of -40 to 165 °F (-40 to 74 °C)

wires (18 and 19) or the coil wires (1 and 2)

Perform sensor test A - Sensor Coil (see Table 4-5 on

page 4-8)

Install software revision equal to Hornet's Expectation

4-3

Page 38

Reference Manual

00809-0100-4727, Rev EA

Rosemount 8700 Series

Table 4-2. Rosemount Advanced Diagnostic Messages

Local Display Error

Message

Grounding/Wiring

Fault

High Process Noise Hi Process Noise Slurry flows - mining/pulp stock Decrease the flow rate below 10 ft/s (3 m/s)

Message (English)

Grnd/Wire Fault Improper installation of wiring See “Sensor Connections” on page 2-11

Coil/Electrode shield not connected See “Sensor Connections” on page 2-11

Improper process grounding See “Grounding” on page 5-12

Faulty ground connection Check wiring for corrosion, moisture in the terminal block,

Sensor not full Verify sensor is full and empty pipe diagnostic is on

Chemical additives upstream of the

sensor

Electrode not compatible with the

process fluid

Air in line Move the sensor to another location in the process line to

Electrode coating Use bulletnose electrodes

Styrofoam or other insulating particles Complete the possible solutions listed under “Step 2:

Low conductivity fluids

(below 10 microsiemens/cm)

Potential Cause Corrective Action

and refer to “Grounding” on page 5-12

Complete the possible solutions listed under “Step 2:

Process Noise” on page 4-7

Move injection point downstream of the sensor, or move

the sensor

Complete the possible solutions listed under “Step 2:

Process Noise” on page 4-7

Refer to the Rosemount Magnetic Flowmeter Material

Selection Guide (00816-0100-3033)

ensure that it is full under all conditions

Downsize sensor to increases flowrate above 3 ft/s (1 m/s)

Periodically clean sensor

Process Noise” on page 4-7

Consult factory

Trim electrode and coil wires - refer to “Installation” on

page 2-1

October 2010

Table 4-3. Rosemount SMART Meter Verification Diagnostic Messages

Message Potential Cause Corrective Action

8714i Failed

Transmitter Calibration Verification

test failed

Sensor Calibration test failed Verify pass/fail criteria

Sensor Coil Circuit test failed Verify pass/fail criteria

Sensor Electrode Circuit test failed Verify pass/fail criteria

Verify pass/fail criteria

Rerun 8714i Meter Verification under no flow conditions

Verify calibration using 8714D Calibration Standard

Perform digital trim

Replace electronics board

Perform sensor test - see Table 4-5 on page 4-8

Perform sensor test - see Table 4-5 on page 4-8

Perform sensor test - see Table 4-5 on page 4-8

4-4

Page 39

Reference Manual

00809-0100-4727, Rev EA

October 2010

TRANSMITTER TROUBLESHOOTING

Table 4-4. Advanced Troubleshooting

Symptom Potential Cause Corrective Action

Does not appear to be within

rated accuracy

Noisy Process Chemical additives upstream of

Transmitter, control system, or other

receiving device not configured

properly

Electrode Coating Use bulletnose electrodes;

Air in line Move the sensor to another location in the process line to

Moisture problem Perform the sensor Tests A, B, C, and D

Improper wiring If electrode shield and signal wires are switched, flow indication

Flow rate is below 1 ft/s

(specification issue)

Auto zero was not performed when the

coil drive frequency was changed from

5 Hz to 37 Hz

Sensor failure–Shorted electrode Perform the sensor Tests C and D

Sensor failure–Shorted or open coil Perform the sensor Tests A and B

Transmitter failure Verify transmitter operation with an 8714 Calibration Standard or

magnetic flowmeter

Sludge flows–Mining/Coal/

Sand/Slurries (other slurries with

hard particles)

Styrofoam or other insulating particles

in process

Electrode coating Use replaceable electrodes in Rosemount 8705.

Air in line Move the sensor to another location in the process line to

Low conductivity fluids (below 10

microsiemens/cm)

Advanced Troubleshooting continued on next page

Rosemount 8700 Series

Check all configuration variables for the transmitter, sensor,

communicator, and/or control system

Check these other transmitter settings:

•Sensor calibration number

•Units

•Line size

Downsize sensor to increase flow rate above 3 ft/s;

Periodically clean sensor

ensure that it is full under all conditions.

(see Table 4-5 on page 4-8)

will be about half of what is expected. Check wiring diagrams for

your application.

See accuracy specification for specific transmitter and sensor

Set the coil drive frequency to 37 Hz, verify the sensor is full,

verify there is no flow, and perform the auto zero function.

(see Table 4-5 on page 4-8)

(see Table 4-5 on page 4-8)

replace the electronic board

Complete the Noisy Process Basic procedure. Move injection

point downstream of magnetic flowmeter, or move magnetic

flowmeter.

Decrease flow rate below 10 ft/s

Complete the Noisy Process Basic procedure;

Consult factory

Use a smaller sensor to increase flow rate above 3 ft/s.

Periodically clean sensor.

ensure that it is full under all conditions.

• Trim electrode and coil wires – see “Conduit Cables” on

page 2-6

• Keep flow rate below 3 FPS

• Integral mount transmitter

• Use 8712-0752-1,3 cable

• Use N0 approval sensor

4-5

Page 40

Rosemount 8700 Series

Table 4-4. Advanced Troubleshooting

Symptom Potential Cause Corrective Action

Meter output is unstable Medium to low conductivity fluids (10–

25 microsiemens/cm) combined with

cable vibration or 60 Hz interference

Electrode incompatibility Check the Technical Data Sheet, Magnetic Flowmeter Material

Improper grounding Check ground wiring – see “Mount the Transmitter” on page 2-3

High local magnetic or electric fields Move magnetic flowmeter (20–25 ft away is usually acceptable)

Control loop improperly tuned Check control loop tuning

Sticky valve (look for periodic

oscillation of meter output)

Sensor failure Perform the sensor Tests A, B, C, and D

Reading does not appear to be

within rated accuracy

Transmitter, control system, or other

receiving device not configured

properly

Electrode coating Use bulletnose electrodes in the Rosemount 8705 Sensor.

Air in line Move the sensor to another location in the process line to

Flow rate is below 1 ft/s

(specification issue)

Insufficient upstream/downstream

pipe diameter

Cables for multiple magmeters run

through same conduit

Auto zero was not performed when the

coil drive frequency was changed from

5 Hz to 37.5 Hz

Sensor failure—shorted electrode See Table 4-5 on page4-8

Sensor failure—shorted or open coil See Table 4-5 on page 4-8

Transmitter failure Replace the electronics board

Transmitter wired to correct sensor Check wiring

Reference Manual

00809-0100-4727, Rev EA

October 2010

Eliminate cable vibration:

• Integral mount

• Move cable to lower vibration run

• Tie down cable mechanically

• Trim electrode and coil wires

• See “Conduit Cables” on page 2-6

• Route cable line away from other equipment

powered by 60 Hz

• Use 8712-0752-1,3 cable

Selection Guide (document number 00816-0100-3033), for

chemical compatibility with electrode material.

for wiring and grounding procedures

Service valve

(See Table 4-5 on page 4-8)

Check all configuration variables for the transmitter, sensor,

communicator, and/or control system

Check these other transmitter settings:

Sensor calibration number

Units

Line size

Downsize the sensor to increase the flow rate above 3 ft/s.

Periodically clean the sensor

ensure that it is full under all conditions

See the accuracy specification for specific transmitter and

sensor

Move sensor to location where 5 pipe diameters upstream and 2

pipe diameters downstream is possible

Run only one conduit cable between each sensor and

transmitter

Perform the auto zero function with full pipe and no flow

4-6

Page 41

Reference Manual

00809-0100-4727, Rev EA

October 2010

Rosemount 8700 Series

QUICK TROUBLESHOOTING

Step 1: Wiring Errors The most common magmeter problem is wiring between the sensor and the

transmitter in remote mount installations. The signal wire and coil drive wire

must be twisted shielded cable: 20 AWG twisted shielded cable for the

electrodes and 14 AWG twisted shielded cable for the coils. Ensure that the

cable shield is connected at both ends of the electrode and coil drive cables.

Signal and coil drive wires must have their own cable s. The single conduit that

houses both the signal and coil drive cables should not contain any other

wires. For more information on proper wir ing practices, refe r to “T ran smitter to

Sensor Wiring” on page 2-11.

Step 2: Process Noise In some circumstances, process conditions rather than the magmeter can

cause the meter output to be unstable. Possible solutions for addressing a

noisy process situation are given below. When the output attains the desired

stability, no further steps are required.

Use the Auto Zero function to initialize the transmitter for use with the 37 .5 Hz

coil drive mode only. Run this function only with the transmitter and sensor

installed in the process. The sensor must be filled with process fluid with zero

flow rate. Before running the auto zero function, be sure the coil drive mode is

set to 37.5 Hz.

Step 3: Installed Sensor

Tests

Set the loop to manual if necessary and begin the auto zero procedure. The

transmitter completes the procedure automatically in about 90 seconds. A

symbol appears in the lower right-hand corner of the display to indicate that

the procedure is running.

1. Change the coil drive to 37.5 Hz. Complete the Auto Zero function, if

possible (see “Coil Drive Frequency” on page 4-13).

2. Turn on Digital Signal Processing (see “Signal Processing” on

page 4-25).

3. Increase the damping (see “Damping” on page 3-17).

If the preceding steps fail to resolve the process noise symptoms, consult

your Rosemount sales representative about using a high-sig nal magnetic

flowmeter system.

If a problem with an installed sensor is identified, Table 4-5 can assist in

troubleshooting the sensor. Before performing any of the sensor tests,

disconnect or turn off power to the transmitter. To interpret the results, the

hazardous location certification for the sensor must be known. Applicable

codes for the Rosemount 8705 are N0, N5, and KD. Applicable codes for the

Rosemount 8707 are N0 and N5. Applicable codes for the Rosemount 8711

are N0, N5, E5, and KD. Always check the operation of test equipment before

each test.

If possible, take all readings from inside the sensor junction box. If the sensor

junction box is inaccessible, take measurements as close as possible.

Readings taken at the terminals of remote-mount transmitters that are more

than 100 feet away from the sensor may provide incorrect or inconclusive

information and should be avoided. A sensor circuit diagram is provided in

Figure 4-1 on page 4-9.

4-7

Page 42

Rosemount 8700 Series

2 R18

0.2

R1R–

2

300

R1R–21500

1nanosiemens

1

1gigaohm

----------------------------=

1nanosiemens

1

1109ohm

------------------------------ -=

Table 4-5. Sensor Test

Test

A. Sensor

Coil

B. Shields to

Case

C. Coil Shield

to Coil

D. Electrode

Shield to

Electrode

Sensor

Location

Installed or

Uninstalled

Installed or

Uninstalled

Installed or

Uninstalled

Installed LCR (Set to

Required

Equipment

Multimeter 1 and 2 = R

Multimeter 17 and

Multimeter 1 and

Resistance

and 120 Hz)

Measuring at

Connections

and case

ground

17 and case

ground

2 and

18 and 17 = R

19 and 17 = R

Reference Manual

00809-0100-4727, Rev EA

October 2010

Expected Value Potential Cause Corrective Action

(< 1nS)

(< 1nS)

R1 and R2 should be stable

1

NO:

2

N5, E5, CD,

ED:

• Open or

Shorted Coil

• Moisture in

terminal block

• Leaky electrode

• Process behind

liner

• Process behind

liner

• Leaky electrode

• Moisture in

terminal block

• Unstable R1 or

values

R

2

confirm coated

electrode

• Shorted

electrode

• Electrode not in

contact with

process

• Empty Pipe

• Low conductivity

• Leaky electrode

• Remove and

replace sensor

• Clean terminal

block

• Remove sensor

• Remove sensor

and dry

• Clean terminal

block

• Confirm with

sensor coil test

• Remove coating

from sensor wall

• Use bulletnose

electrodes

• Repeat

measurement

• Pull sensor,

complete test in

Table 4-6 and

Table 4-7 on

page 4-10 out of

line.

To test the sensor, a multimeter capable of measuring conductance in

nanosiemens is preferred. Nanosiemens is the reciprocal of resistance.

or

4-8

Page 43

Reference Manual

68.1k (not applicable for

sensors with N0 hazardous

certification approval option

code)

Sensor Housing

68.1k

See “Safety Information” on page 4-1 for complete warning information.

00809-0100-4727, Rev EA

October 2010

Figure 4-1. Sensor Circuit

Diagram

Rosemount 8700 Series

Step 4: Uninstalled

Sensor Tests

An uninstalled sensor can also be used for sensor troubleshooting. To

interpret the results, the hazardous location certification for the sensor must

be known. Applicable codes for the Rosemount 8705 are N0, N5, and KD.

Applicable codes for the Rosemount 8707 are N0 and N5. Applicable codes

for the Rosemount 8711 are N0, N5, E5, and KD.

A sensor circuit diagram is provided in Figure 4-1. Take measurements from

the terminal block and on the electrode head inside th e se nso r. The

measurement electrodes, 18 and 19, are on opposite sides in the inside

diameter. If applicable, the third grounding electrode is in between the other

two electrodes. On Rosemount 8711 sensors, electrode 18 is ne ar the sensor

junction box and electrode 19 is near the bottom of the sensor (Figure 4-2).

The different sensor models will have slightly different resistance readings.