Page 1

Rosemount™ 5408 and 5408:SIS Level

Transmitters

Non-Contacting Radar

Reference Manual

00809-0100-4408, Rev BB

April 2018

Page 2

Rosemount 5408 and 5408:SIS Level Transmitters – Non-Contacting Radar

NOTICE

Read this manual before working with the product. For personal and system safety, and for optimum product performance, make

sure you thoroughly understand the contents before installing, using, or maintaining this product.

For technical assistance, contacts are listed below:

Customer Central

Technical support, quoting, and order-related questions.

• United States - 1-800-999-9307 (7:00 am to 7:00 pm CST)

• Asia Pacific- 65 777 8211

North American Response Center

Equipment service needs.

• 1-800-654-7768 (24 hours a day — includes Canada)

• Outside of these areas, contact your local Emerson representative.

WARNING!

Failure to follow safe installation and servicing guidelines could result in death or serious injury.

• Make sure the transmitter is installed by qualified personnel and in accordance with applicable code of practice.

• Use the equipment only as specified in this manual. Failure to do so may impair the protection provided by the equipment.

• For installations in hazardous locations, the transmitter must be installed according to the Rosemount 5408 and 5408:SIS

Product Certifications document and System Control Drawing (D7000002-885).

Explosions could result in death or serious injury.

• Verify that the operating atmosphere of the transmitter is consistent with the appropriate hazardous locations

certifications.

• Before connecting a Field Communicator in an explosive atmosphere, ensure the instruments are installed in accordance

with intrinsically safe or non-incendive field wiring practices.

• In Explosion-proof/Flameproof and Non-Incendive/Type n installations, do not remove the transmitter covers when power is

applied to the unit.

• Both transmitter covers must be fully engaged to meet Explosion-proof/Flameproof requirements.

Electrical shock could cause death or serious injury.

• Avoid contact with the leads and terminals. High voltage that may be present on leads can cause electrical shock.

• Make sure the mains power to the transmitter is off and the lines to any other external power source are disconnected or not

powered while wiring the transmitter.

Process leaks could result in death or serious injury.

• Make sure that the transmitter is handled carefully. If the process seal is damaged, gas might escape from the tank.

Any substitution of non-recognized parts may jeopardize safety. Repair, e.g. substitution of components etc., may also jeopardize

safety and is under no circumstances allowed.

• Unauthorized changes to the product are strictly prohibited as they may unintentionally and unpredictably alter

performance and jeopardize safety. Unauthorized changes that interfere with the integrity of the welds or flanges, such as

making additional perforations, compromise product integrity and safety. Equipment ratings and certifications are no

longer valid on any products that have been damaged or modified without the prior written permission of Emerson. Any

continued use of product that has been damaged or modified without the written authorization is at the customer’s sole risk

and expense.

Page 3

CAUTION!

Hot surfaces

The flange and process seal may be hot at high process temperatures. Allow to cool before servicing.

CAUTION!

The products described in this document are NOT designed for nuclear-qualified applications. Using non-nuclear qualified products

in applications that require nuclear-qualified hardware or products may cause inaccurate readings.

For information on Rosemount nuclear-qualified products, contact your local Emerson Sales Representative.

Page 4

Page 5

Contents

Contents

Chapter 1 Introduction .....................................................................................................................1

1.1 Using this manual ...........................................................................................................................1

1.2 Product recycling/disposal ............................................................................................................. 1

Chapter 2 Transmitter Overview ...................................................................................................... 3

2.1 Measurement principle .................................................................................................................. 3

2.2 Process characteristics ................................................................................................................... 4

2.2.1 Dielectric constant ...........................................................................................................4

2.2.2 Foam and turbulence .......................................................................................................4

2.2.3 Dust .................................................................................................................................5

2.2.4 Solid surface .................................................................................................................... 5

2.3 Vessel characteristics ..................................................................................................................... 6

2.3.1 In-tank obstructions ........................................................................................................ 6

2.3.2 Tank shape ...................................................................................................................... 6

2.4 Application examples ..................................................................................................................... 6

2.5 Components of the transmitter ......................................................................................................8

2.6 System integration .......................................................................................................................10

Chapter 3 Mechanical Installation .................................................................................................. 13

3.1 Safety messages ...........................................................................................................................13

3.2 Confirm approval type ..................................................................................................................13

3.3 Installation considerations ........................................................................................................... 14

3.3.1 Mounting position .........................................................................................................14

3.3.2 Free space requirements ............................................................................................... 15

3.3.3 Antenna size ..................................................................................................................16

3.3.4 Antenna inclination ....................................................................................................... 16

3.3.5 Non-metallic tanks ........................................................................................................ 17

3.3.6 Beam width and beam angle ..........................................................................................17

3.3.7 Nozzle requirements ..................................................................................................... 19

3.3.8 Still pipe/chamber installations ......................................................................................21

3.3.9 Ball valve installation ..................................................................................................... 24

3.4 Mounting preparations ................................................................................................................ 25

3.4.1 Assemble the segmented cone antenna ........................................................................ 25

3.4.2 Shorten the extended cone antenna ..............................................................................26

3.5 Mount the cone antenna .............................................................................................................. 28

3.5.1 Protective cap ................................................................................................................28

3.5.2 Flanged version ............................................................................................................. 29

3.5.3 Flanged version with air purge ring (option code PC1) ................................................... 30

3.5.4 Threaded version, antenna diameter (D) < Thread diameter (d) .....................................31

3.5.5 Threaded version, antenna diameter (D) > Thread diameter (d) .....................................34

3.5.6 Bracket mounting ..........................................................................................................36

3.5.7 Align transmitter head ...................................................................................................38

3.6 Mount the process seal antenna ...................................................................................................40

3.6.1 Flanged version ............................................................................................................. 40

3.6.2 Tri-Clamp version .......................................................................................................... 42

3.7 Mount the parabolic antenna ....................................................................................................... 43

3.7.1 Flanged version ............................................................................................................. 43

Rosemount 5408 and 5408:SIS Level Transmitters i

Page 6

Contents

3.7.2 Threaded version ...........................................................................................................45

3.7.3 Welded version ..............................................................................................................49

3.7.4 Adjust the inclination of the antenna ............................................................................. 53

3.7.5 Connect the air purging .................................................................................................56

3.8 Adjust display orientation (optional) ............................................................................................ 57

Chapter 4 Electrical Installation ......................................................................................................59

4.1 Safety messages ...........................................................................................................................59

4.2 Cable selection .............................................................................................................................59

4.3 Cable gland/conduit .....................................................................................................................60

4.4 Power supply ................................................................................................................................60

4.5 Load limitations ............................................................................................................................60

4.6 Hazardous areas ...........................................................................................................................60

4.7 Wiring diagram ............................................................................................................................ 61

4.8 Grounding ....................................................................................................................................62

4.9 Connect wiring and power up .......................................................................................................63

4.10 Optional devices .......................................................................................................................... 66

4.10.1 Rosemount™ 333 HART Tri-Loop™

................................................................................. 66

Chapter 5

Configuration .................................................................................................................69

5.1 Safety messages ...........................................................................................................................69

5.2 Overview ......................................................................................................................................69

5.3 System readiness ......................................................................................................................... 69

5.3.1 Confirm correct device driver ........................................................................................ 69

5.4 Get started with your preferred configuration tool ....................................................................... 70

5.4.1 Configuration tools ........................................................................................................70

5.4.2 Rosemount Radar Master Plus ....................................................................................... 71

5.4.3 AMS Device Manager .....................................................................................................71

5.4.4 Field Communicator ......................................................................................................72

5.5 Confirm HART revision capability ................................................................................................. 72

5.5.1 Switch HART revision mode ...........................................................................................72

5.6 Configure device using Guided Setup ...........................................................................................73

5.6.1 Configure using Rosemount Radar Master Plus ..............................................................73

5.6.2 Configure using AMS Device Manager ........................................................................... 73

5.6.3 Configure using Field Communicator .............................................................................73

5.7 Verify level ................................................................................................................................... 73

5.7.1 Use Rosemount Radar Master Plus .................................................................................74

5.7.2 Use AMS Device Manager and Field Communicator .......................................................74

5.8 Establish multidrop communication .............................................................................................75

5.8.1 Use Rosemount Radar Master Plus .................................................................................75

5.8.2 Use AMS Device Manager .............................................................................................. 75

5.8.3 Use Field Communicator ............................................................................................... 75

5.9 Use with the Rosemount 333 HART Tri-Loop ................................................................................ 75

Chapter 6 Operation ...................................................................................................................... 77

6.1 LCD display screen messages ....................................................................................................... 77

6.1.1 Startup screen sequence ............................................................................................... 77

6.1.2 Variable screens .............................................................................................................78

6.2 Set up the LCD display ..................................................................................................................79

6.2.1 Use Rosemount Radar Master Plus ................................................................................. 79

6.2.2 Use AMS Device Manager and Field Communicator ....................................................... 79

6.3 View measurement data .............................................................................................................. 79

6.3.1 Use Rosemount Radar Master Plus ................................................................................. 79

ii Reference Manual

Page 7

Contents

6.3.2 Use AMS Device Manager and Field Communicator ....................................................... 80

6.3.3 Interpret measurement status ....................................................................................... 80

6.4 Device status ................................................................................................................................81

6.4.1 Check device status ....................................................................................................... 81

Chapter 7 Service and Troubleshooting .......................................................................................... 85

7.1 Safety messages ...........................................................................................................................85

7.2 Diagnostic messages ....................................................................................................................85

7.3 Troubleshooting guide .................................................................................................................91

7.4 Service and troubleshooting tools ................................................................................................ 97

7.4.1 Using the echo curve ..................................................................................................... 97

7.4.2 Managing disturbance echoes ..................................................................................... 101

7.4.3 Perform an analog loop test .........................................................................................107

7.4.4 Use the TEST terminal .................................................................................................. 108

7.4.5 Calibrate analog out .................................................................................................... 110

7.4.6 Save a backup file of the device configuration ..............................................................110

7.4.7 Download configuration from file to device ................................................................. 111

7.4.8 Restore to default settings ...........................................................................................111

7.4.9 Use the simulation mode ............................................................................................. 111

7.4.10 View input registers ..................................................................................................... 112

7.4.11 View/edit holding registers ..........................................................................................112

7.4.12 Write protect a transmitter ..........................................................................................113

7.5 Application challenges ............................................................................................................... 114

7.5.1 Handling disturbances at top of tank ........................................................................... 114

7.5.2 Tracking of weak surface echoes close to tank bottom ................................................ 116

7.5.3 Handling ghost echoes in still pipes ............................................................................. 119

7.5.4 Handling strong double bounce echoes .......................................................................120

7.6 Replace the transmitter head ..................................................................................................... 122

7.7 Cleaning or replacing the PTFE sealing ....................................................................................... 124

7.7.1 Flanged version ........................................................................................................... 125

7.7.2 Tri Clamp version ......................................................................................................... 126

7.8 Service support .......................................................................................................................... 128

Chapter 8 Safety Instrumented Systems (4-20 mA only) ............................................................... 131

8.1 Safety messages .........................................................................................................................131

8.2 Terms and definitions .................................................................................................................131

8.3 Safety Instrumented System (SIS) certification ...........................................................................133

8.4 Safety certified identification ..................................................................................................... 134

8.5 Installation ................................................................................................................................. 135

8.5.1 Measuring range ..........................................................................................................136

8.6 Configuration .............................................................................................................................136

8.6.1 Prerequisites ................................................................................................................136

8.6.2 Configure device using Guided Setup .......................................................................... 136

8.6.3 Set operational mode .................................................................................................. 136

8.6.4 Enable safety mode ..................................................................................................... 137

8.6.5 Alarm and saturation levels ..........................................................................................137

8.7 Site acceptance ..........................................................................................................................138

8.8 Proof-testing ..............................................................................................................................138

8.8.1 Overview ..................................................................................................................... 138

8.8.2 Perform 1-point level and analog output verification ................................................... 139

8.8.3 Perfom 2-point level and analog output verification .................................................... 142

8.8.4 Perform analog output verification .............................................................................. 144

Rosemount 5408 and 5408:SIS Level Transmitters iii

Page 8

Contents

8.8.5 Perform level deviation monitoring ............................................................................. 144

8.8.6 Product repair ..............................................................................................................145

8.9 Specifications .............................................................................................................................145

8.9.1 Failure rate data ...........................................................................................................145

8.9.2 Safety deviation ...........................................................................................................145

8.9.3 Transmitter response time .......................................................................................... 145

8.9.4 Diagnostic test interval ................................................................................................ 145

8.9.5 Turn-on time ............................................................................................................... 145

Appendices and reference

Appendix A Specifications and Reference Data ................................................................................ 147

A.1 Performance specifications ........................................................................................................ 147

A.1.1 General ........................................................................................................................147

A.1.2 Measuring range ..........................................................................................................148

A.1.3 Environment ................................................................................................................150

A.2 Functional specifications ............................................................................................................ 151

A.2.1 General ........................................................................................................................151

A.2.2 Display and configuration ............................................................................................151

A.2.3 4-20 mA HART .............................................................................................................153

A.2.4 Diagnostics ..................................................................................................................155

A.2.5 Process temperature and pressure rating .................................................................... 156

A.2.6 Temperature limits ......................................................................................................157

A.2.7 Flange rating ............................................................................................................... 158

A.2.8 Conditions used for flange strength calculations ......................................................... 159

A.2.9 Air purging .................................................................................................................. 161

A.2.10 System integration ...................................................................................................... 162

A.3 Physical specifications ................................................................................................................ 163

A.3.1 Material selection ........................................................................................................ 163

A.3.2 Engineered solutions ................................................................................................... 163

A.3.3 Housing and enclosure ................................................................................................ 163

A.3.4 Tank connection ..........................................................................................................164

A.3.5 Flange dimensions .......................................................................................................164

A.3.6 Antenna versions .........................................................................................................164

A.3.7 Material exposed to tank atmosphere ..........................................................................164

A.4 Ordering Information ................................................................................................................. 165

A.4.1 Rosemount 5408 Level Transmitter .............................................................................165

A.4.2 Rosemount 5408:SIS Level Transmitter ....................................................................... 170

A.5 Availability of process connections .............................................................................................176

A.6 Spare parts and accessories ........................................................................................................178

A.6.1 Accessories ..................................................................................................................185

A.7 Dimensional drawings ................................................................................................................186

A.7.1 Standard flanges ..........................................................................................................190

Appendix B Product Certifications ...................................................................................................193

B.1 European directive information ..................................................................................................193

B.2 Safety Instrumented Systems (SIS) .............................................................................................193

B.3 Telecommunication compliance ................................................................................................ 193

B.4 FCC ............................................................................................................................................ 194

B.5 IC ............................................................................................................................................... 194

B.6 Radio Equipment Directive (RED) 2014/53/EU ........................................................................... 195

B.7 Installing equipment in North America .......................................................................................196

iv Reference Manual

Page 9

Contents

B.8 U.S.A. ......................................................................................................................................... 196

B.8.1 E5 Explosionproof (XP), Dust-Ignitionproof (DIP) ......................................................... 196

B.8.2 I5 Intrinsic Safety (IS), Non-Incendive (NI) .................................................................... 198

B.9 Canada .......................................................................................................................................199

B.9.1 E6 Explosionproof, Dust-Ignitionproof ......................................................................... 199

B.9.2 I6 Intrinsically Safe and Non-Incendive Systems ........................................................... 201

B.10 Europe ....................................................................................................................................... 203

B.10.1 E1 ATEX Flameproof .................................................................................................... 203

B.10.2 I1 ATEX Intrinsic Safety ................................................................................................ 204

B.10.3 N1 ATEX Type N: Non-Sparking ....................................................................................206

B.11 International .............................................................................................................................. 206

B.11.1 E7 IECEx Flameproof .................................................................................................... 206

B.11.2 I7 IECEx Intrinsic Safety ................................................................................................ 207

B.11.3 N7 IECEx Type N: Non-Sparking ................................................................................... 209

B.12 Brazil .......................................................................................................................................... 209

B.12.1 E2 INMETRO Flameproof ..............................................................................................209

B.12.2 I2 INMETRO Intrinsic Safety ......................................................................................... 210

B.12.3 N2 INMETRO Type N: Non-Sparking ............................................................................. 210

B.13 China ..........................................................................................................................................211

B.13.1 E3 Flameproof ............................................................................................................. 211

B.13.2 I3 Intrinsic Safety ......................................................................................................... 211

B.13.3 N3 Type N: Non-Sparking .............................................................................................211

B.14 India ...........................................................................................................................................212

B.14.1 Intrinsic Safety ............................................................................................................. 212

B.14.2 Flameproof Safety ....................................................................................................... 212

B.14.3 Intrinsic Safety and Flameproof ................................................................................... 212

B.15 Republic of Korea ....................................................................................................................... 212

B.15.1 IP Intrinsic Safety ......................................................................................................... 212

B.16 Additional certifications ............................................................................................................. 213

B.16.1 QT Safety-certified to IEC 61508:2010 with certificate of FMEDA data ......................... 213

B.16.2 Suitable for intended use ............................................................................................. 213

B.16.3 U1 Overfill prevention ..................................................................................................213

B.16.4 QA 3-A ......................................................................................................................... 213

B.17 Installation drawings .................................................................................................................. 214

Appendix C Configuration Parameters ............................................................................................ 221

C.1 Menu tree .................................................................................................................................. 221

C.2 Device setup .............................................................................................................................. 223

C.2.1 HART protocol ............................................................................................................. 223

C.2.2 Units ............................................................................................................................224

C.2.3 Analog output ............................................................................................................. 224

C.2.4 Display .........................................................................................................................225

C.2.5 Security ....................................................................................................................... 225

C.2.6 Device Information ......................................................................................................226

C.3 Level setup ................................................................................................................................. 227

C.3.1 Geometry .................................................................................................................... 227

C.3.2 Environment ................................................................................................................235

C.3.3 Volume ........................................................................................................................236

C.3.4 Scaled variable .............................................................................................................236

C.3.5 Antenna .......................................................................................................................237

C.3.6 Advanced .................................................................................................................... 239

C.4 Alert setup ................................................................................................................................. 245

Rosemount 5408 and 5408:SIS Level Transmitters v

Page 10

Contents

C.4.1 Measurement recovery ................................................................................................245

C.4.2 Signal quality alert ....................................................................................................... 245

C.4.3 High/low user defined alert ..........................................................................................246

vi Reference Manual

Page 11

1 Introduction

1.1 Using this manual

The sections in this manual provide information on installing, operating, and maintaining

the Rosemount™ 5408 and 5408:SIS Level Transmitters – Non-Contacting Radar.

The sections are organized as follows:

Chapter 2 provides an introduction to theory of operation, a description of the transmitter,

information on typical applications, and process characteristics.

Chapter 3 contains mechanical installation instructions.

Chapter 4 contains electrical installation instructions.

Chapter 5 provides instructions on configuration of the transmitter.

Introduction

Chapter 6 contains operation and maintenance techniques.

Chapter 7 provides troubleshooting techniques for the most common operating problems.

Chapter 8 contains identification, commissioning, maintenance, and operations

information for safety-certified transmitter used in Safety Instrumented Systems (SIS)

applications.

Appendix A supplies reference and specification data, as well as ordering information.

Appendix B contains safety approval information and approval drawings.

Appendix C provides extended information about the configuration parameters.

1.2 Product recycling/disposal

Recycling of equipment and packaging should be taken into consideration and disposed of

in accordance with local and national legislation/regulations.

Rosemount 5408 and 5408:SIS Level Transmitters 1

Page 12

Introduction

2 Reference Manual

Page 13

2 Transmitter Overview

G

I

LQ

I

PD[

I

PLQ

I

RXW

I

LQ

I

RXW

W

I

$

&

'

%

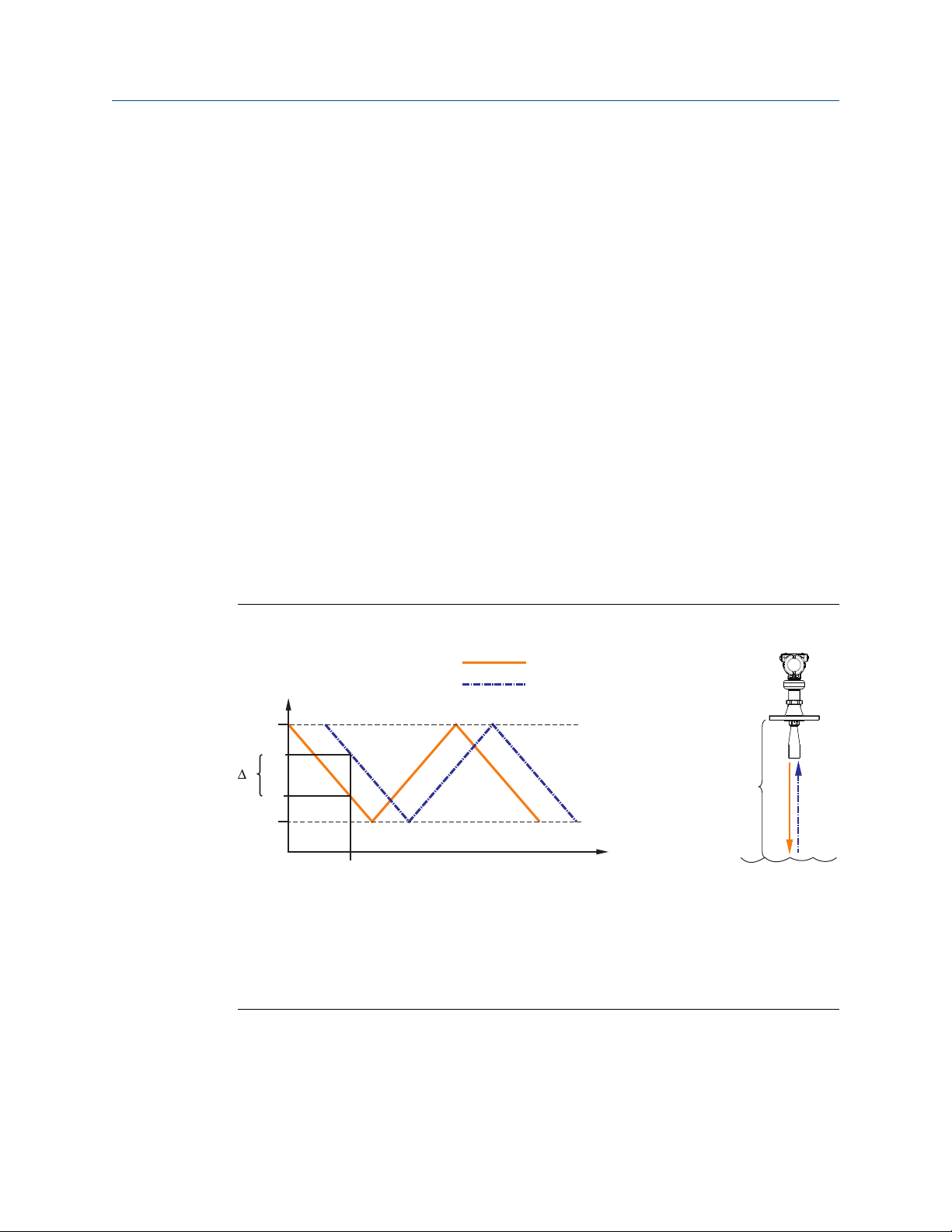

2.1 Measurement principle

The Rosemount™ 5408 and 5408:SIS are two-wire transmitters for continuous level

measurements over a broad range of liquids, slurries, and solids. The measurement

principle is fast-sweep Frequency Modulated Continuous Wave (FMCW).

The transmitter continuously emits signal sweeps with a constantly varying frequency

towards the product surface. Since the transmitter continuously changes the frequency of

the transmitted signal, there will be a difference in frequency between the transmitted and

the reflected signals (see Figure 2-1).

The frequency of the reflected signal is subtracted from the frequency of the signal

transmitted at that moment, resulting in a low frequency signal which is proportional to

the distance to the product surface. This signal is further processed to obtain fast, reliable,

and highly accurate level measurements. See Figure 2-2 for a schematic overview of the

signal processing.

Transmitter Overview

FMCW-methodFigure 2-1:

Δf≈d=distance

A. Frequency (GHz)

Time (s)

B.

C. Transmitted signal

D. Reflected signal

Rosemount 5408 and 5408:SIS Level Transmitters 3

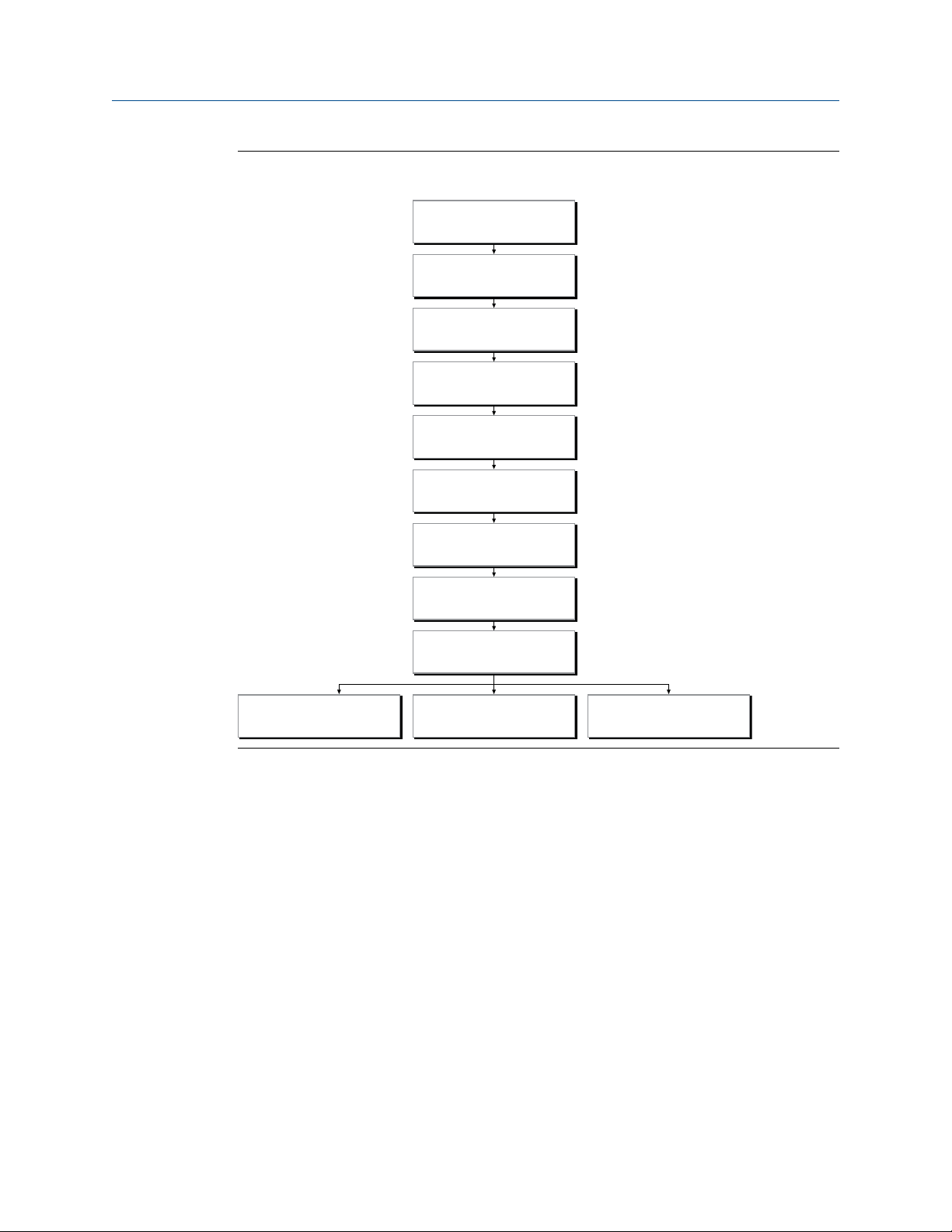

Page 14

Peak search

Fast Fourier transform

(FFT)

Peak interpolation

Echo tracker

Echo identifier

Distance filtering

Variable calculation

Aout handler LCD handler HART

Microwave module

A/D coverter

Transmitter Overview

Flowchart of the Signal ProcessingFigure 2-2:

2.2 Process characteristics

2.2.1 Dielectric constant

A key parameter for measurement performance is reflectivity. A high dielectric constant of

the media provides better reflection and enables a longer measuring range.

2.2.2 Foam and turbulence

Foaming liquids or turbulence may cause weak and varying surface echo amplitudes. The

effects of turbulence are usually minor, but in the most challenging conditions, the

transmitter may be mounted in a still pipe. In addition, measurement performance can be

optimized by configuring the appropriate process conditions settings, see

Process conditions.

4 Reference Manual

Page 15

Measurement in foamy applications depends largely on the foam properties. When the

foam is light and airy, the actual product level is measured. For heavy and dense foam, the

transmitter may measure the level of the foam’s upper surface. The Double Surface

Handling function allows the user to select if the foam layer or product surface should be

used as output (see Double surface handling).

2.2.3 Dust

Dust is often present in solids applications, and even if the non-contacting radar is not

affected by the dust in the vapor space, dust can be sticky and create a layer on the

antenna. If this layer becomes too thick, it may affect the measurement. This is best

managed by using air purging.

2.2.4 Solid surface

Solids have some common characteristics which may cause weak and varying surface

reflections. The surface is rarely flat or horizontal, the angle of the sloping surface differs

during filling and emptying, and the dielectric constant of many solids is fairly

low.Table 2-1 presents common characteristics of some solids applications.

Transmitter Overview

The parabolic antenna is ideal for applications with weak surface reflections. A larger

diameter concentrates the radar beam and ensures maximum antenna gain. The parabolic

antenna comes with a swivel connection that adjusts for angled tank roofs.

Common Characteristics of Solids ApplicationsTable 2-1:

Common characteristics

Particle size Vapor space

Applications

Wood chip bins Yes Yes Yes Yes Possible

Grain silo - small kernel grains Yes Yes No Yes No

Grain silo - large kernel grains No Yes No No No

Lime stone silo No Yes Yes Possible No

Cement - raw mill silo Yes Yes No Yes No

Cement - finished product silo Yes Yes No Yes No

Coal bin Yes Yes Yes Yes Yes

Saw dust Yes Yes No Yes No

High consistency - pulp stock No No No No Yes

Alumina Yes Yes No Yes No

Salt No Yes Yes No No

Dust or powder Small (<1 in.) Larger (>1 in.) Dust Steam or condensation

Rosemount 5408 and 5408:SIS Level Transmitters 5

Page 16

Transmitter Overview

2.3 Vessel characteristics

2.3.1 In-tank obstructions

The transmitter should be mounted so that objects such as heating coils, ladders, and

agitators are not in the radar signal path. These objects may cause false echoes resulting in

reduced measurement performance. However, the transmitter has built-in functions

designed to reduce the influence from disturbing objects where such objects cannot be

totally avoided.

Vertical and inclined structures cause minimal effect since the radar signal is scattered

rather than directed back to the antenna.

2.3.2 Tank shape

The shape of the tank bottom affects the measurement signal when the product surface is

close to the tank bottom. The transmitter has built-in functions which optimize

measurement performance for various bottom shapes.

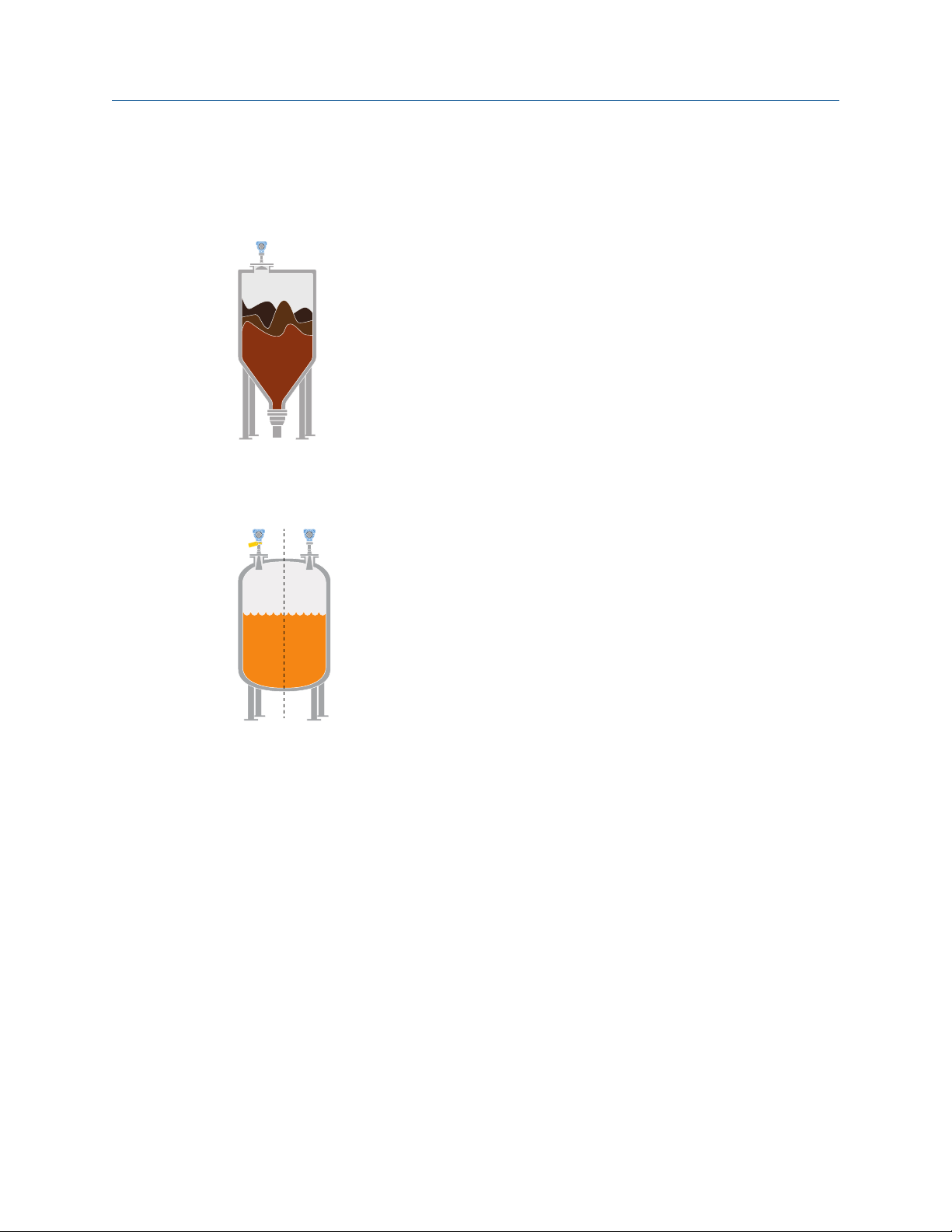

2.4 Application examples

The Rosemount 5408 and 5408:SIS are ideal for level measurements over a broad range of

liquid and solids applications. The transmitters are virtually unaffected by changing

density, temperature, pressure, media dielectric, pH, and viscosity. Non-contacting radar

level is ideal for harsh conditions such as corrosive and sticky media, or when internal tank

obstructions are a limiting factor.

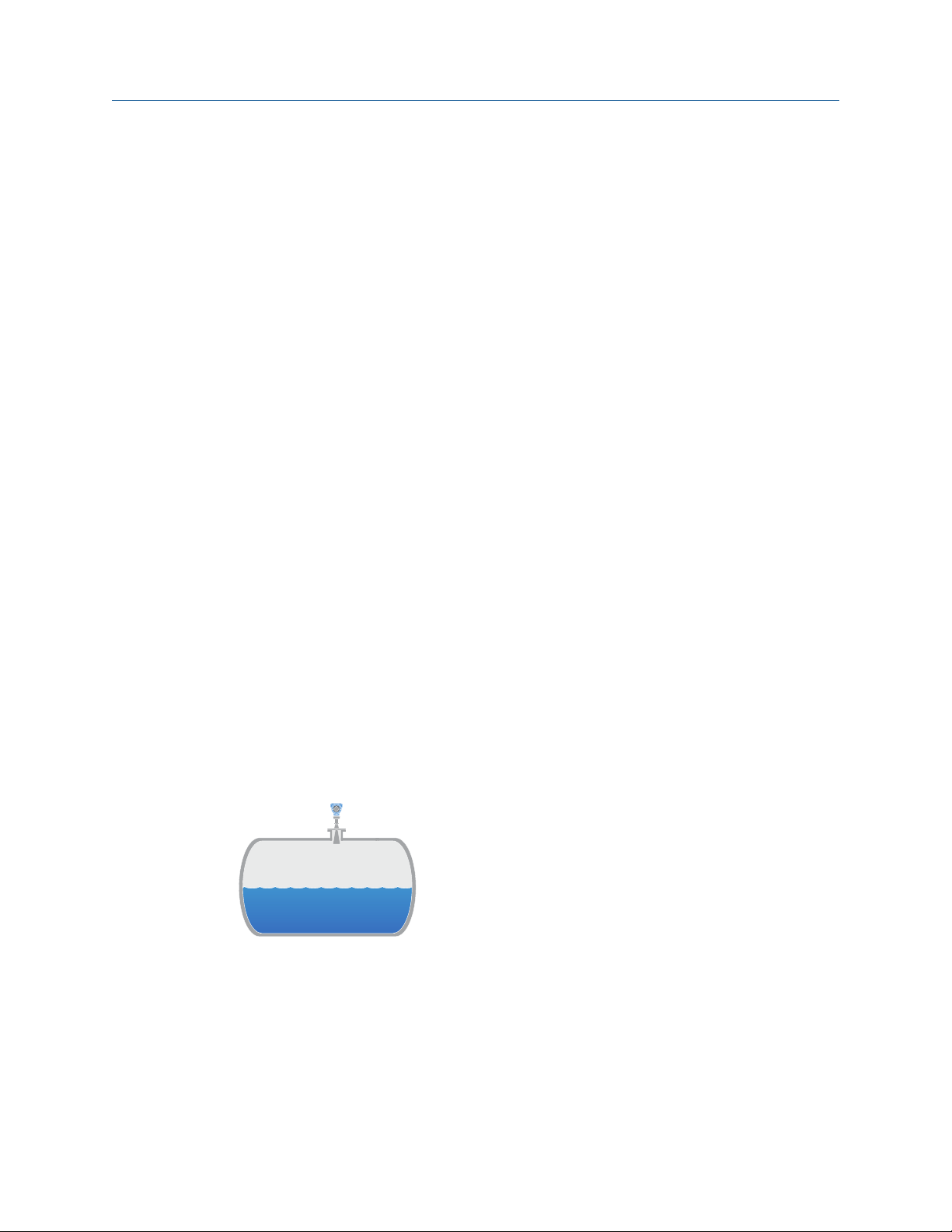

Storage and buffer tanks

The Rosemount 5408 provides accurate and reliable level measurement for both metallic

or non-metallic vessels containing almost any liquid (e.g. oil, gas condensate, water,

chemicals).

Reactors

The Rosemount 5408 is ideal for the most challenging applications, including reactors

where there can be agitation, foaming, condensation as well as high temperatures and

pressures.

6 Reference Manual

Page 17

Transmitter Overview

Blenders and mixers

The Rosemount 5408 can help you withstand the rigors of blenders and mixing tanks. Easy

to install and commission, it is also unaffected by virtually any fluid property change.

Open atmospheric applications

The Rosemount 5408 measures reliably in open applications, from short range sumps or

ponds to long range dams.

Still pipe and chamber installations

The Rosemount 5408 is an excellent choice for level measurement in tanks with still pipes.

It may also be used in chambers, but guided wave radar is generally the best fit for these

applications. See Section 3.3.8 for installation guidelines.

Rosemount 5408 and 5408:SIS Level Transmitters 7

Page 18

SI

L 2

Transmitter Overview

Bulk solids

The Rosemount 5408 is the ideal solution for small to medium sized silos with rapid level

changes. The narrow beam avoids internal obstructions while still keeping good level

measurement.

Safety applications

The Rosemount 5408:SIS is the ideal choice for safety functions such as overfill prevention,

level deviation monitoring or dry-run prevention.

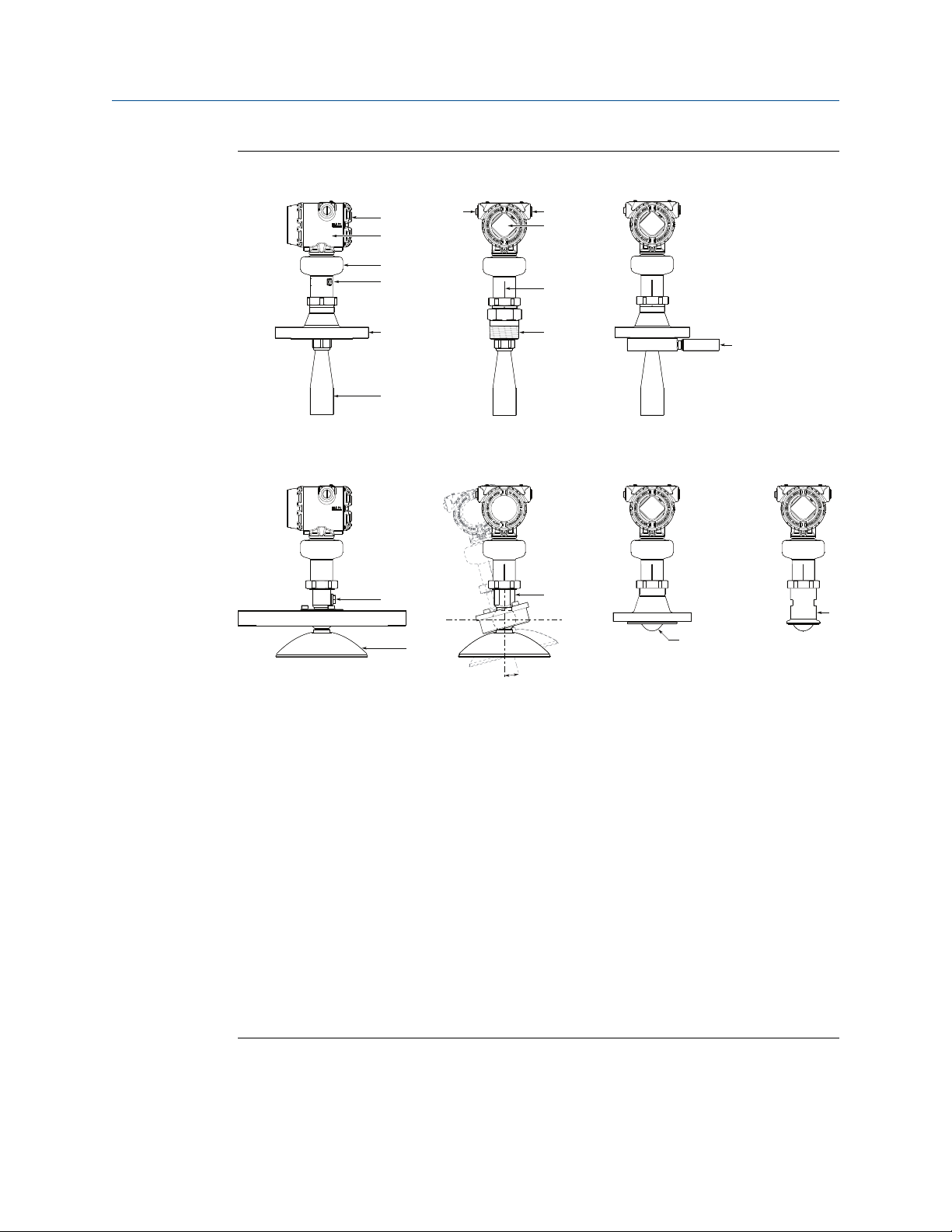

2.5 Components of the transmitter

Figure 2-3 shows the different components of the transmitter. There are different antenna

types and sizes available for various applications.

8 Reference Manual

Page 19

$

%

&

'

(

*

.

*

-

,

)

/

0

+

1

sr

2

3

Transmitter Overview

ComponentsFigure 2-3:

A. Terminal compartment I. Alignment marker (one per side)

B. Transmitter housing (aluminum or stainless steel) J. Threaded process connection (NPT or BSPP

C. Sensor module with signal processing electronics K. Air purge ring (option code PC1 for cone an-

(G))

tenna)

D. External ground screw L. Integrated air purge connection

E. Flanged process connection M. Parabolic antenna

F. Cone antenna N. Parabolic antenna with swivel mount

G. Two cable/conduit entries (½-14 NPT, M20 x 1.5,

or G½)

Optional adapters: eurofast™ and minifast

™

O. Process seal antenna

H. LCD display (optional) P. Tri-Clamp process connection

Rosemount 5408 and 5408:SIS Level Transmitters 9

Page 20

Transmitter Overview

2.6 System integration

The transmitter is loop-powered, and uses the same two wires for power supply and

output signal. The output is a 4-20 mA analog signal superimposed with a digital HART

signal. The transmitter can be configured for either HART Revision 6 (default) or 7 (option

code HR7). The HART Revision can be switched in field.

By using the optional Rosemount 333 HART Tri-Loop™, the digital HART signal can be

converted into three additional 4-20 mA analog signals. With the HART protocol,

multidrop configuration is possible. In this case, communication is restricted to digital,

since current is fixed to the 4 mA minimum value.

The transmitter can be combined with the Emerson™ Wireless 775 THUM™ Adapter to

wirelessly communicate HART data with IEC 62591 (WirelessHART®) technology. In

addition, the transmitter can be connected to a Rosemount 751 Field Signal Indicator, or it

can be equipped with an LCD display.

The transmitter can easily be configured by using a PC with the Rosemount Radar Master

Plus software (running in the Instrument Inspector™ Application), a Field Communicator,

the AMS Device Manager, or any other Device Descriptor (DD) or Field Device Integration

(FDI) compatible host system.

The Rosemount 5408 and 5408:SIS are compliant with NAMUR NE 107 Field Diagnostics

for standardized device diagnostic information.

10 Reference Manual

Page 21

$%&

(

)

*

+

'

,

Transmitter Overview

System ArchitectureFigure 2-4:

A. Emerson Wireless 775 THUM Adapter

B. Rosemount 5408

C.

Rosemount 751

D. Field Communicator

E. Approved IS barrier (for Intrinsically Safe installations only)

F. Rosemount 333

G. Host/DCS system

H. HART modem

I. Rosemount Radar Master Plus or AMS Device Manager

Rosemount 5408 and 5408:SIS Level Transmitters 11

Page 22

Transmitter Overview

12 Reference Manual

Page 23

3 Mechanical Installation

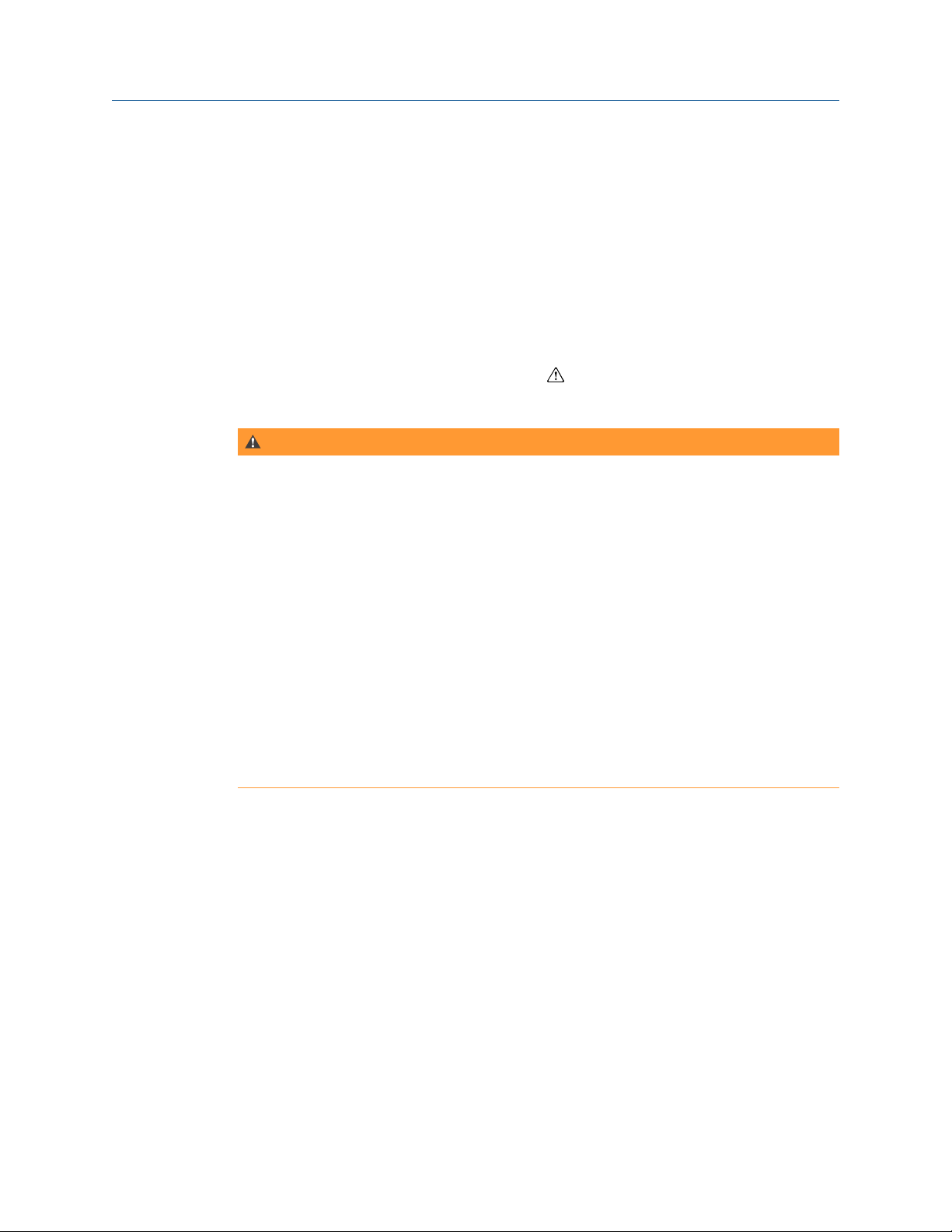

3.1 Safety messages

Instructions and procedures in this section may require special precautions to ensure the

safety of the personnel performing the operations. Information that potentially raises

safety issues is indicated by a warning symbol ( ). Refer to the following safety messages

before performing an operation preceded by this symbol.

WARNING!

Failure to follow safe installation and servicing guidelines could result in death or serious

injury.

• Make sure the transmitter is installed by qualified personnel and in accordance with

applicable code of practice.

• Use the equipment only as specified in this manual. Failure to do so may impair the

protection provided by the equipment.

• For installations in hazardous locations, the transmitter must be installed according to

the Rosemount 5408 and 5408:SIS Product Certifications document and System Control

Drawing (D7000002-885).

Mechanical Installation

Process leaks could result in death or serious injury.

• Make sure that the transmitter is handled carefully. If the process seal is damaged, gas

might escape from the tank.

Explosions could result in death or serious injury.

• Verify that the operating atmosphere of the transmitter is consistent with the

appropriate hazardous locations certifications.

3.2 Confirm approval type

For hazardous locations transmitters labeled with multiple approval types:

Permanently mark the checkbox of the selected approval type(s).

Rosemount 5408 and 5408:SIS Level Transmitters 13

Page 24

Mechanical Installation

Label with Multiple Approval TypesFigure 3-1:

3.3 Installation considerations

Before installing the transmitter, follow recommendations for mounting position,

sufficient free space, nozzle requirements, etc.

3.3.1 Mounting position

When finding an appropriate location on the tank for the transmitter, the conditions of the

tank must be carefully considered.

Consider the following guidelines when mounting the transmitter:

• For optimal performance, the transmitter should be installed in locations with a

clear and unobstructed view of the product surface.

• The transmitter should be mounted with as few internal structures as possible

within the signal beam, see Section 3.3.6.

• Do not install the transmitter in the center of the tank.

• Do not mount close to or above the inlet stream.

• Multiple Rosemount 5408 and 5408:SIS Level Transmitters can be used in the same

tank without interfering with each other.

14 Reference Manual

Page 25

/

$

/

%

Mechanical Installation

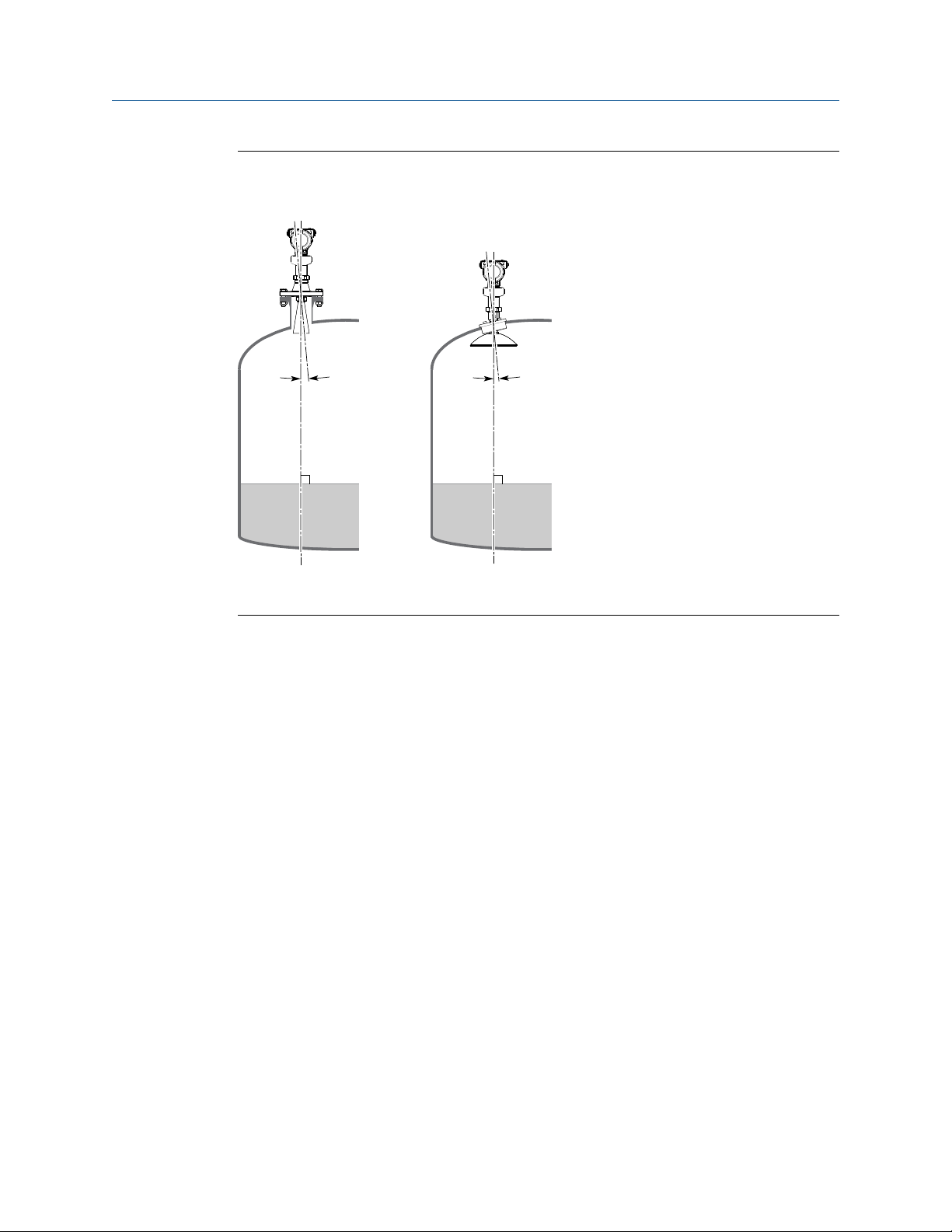

Recommended Mounting PositionFigure 3-2:

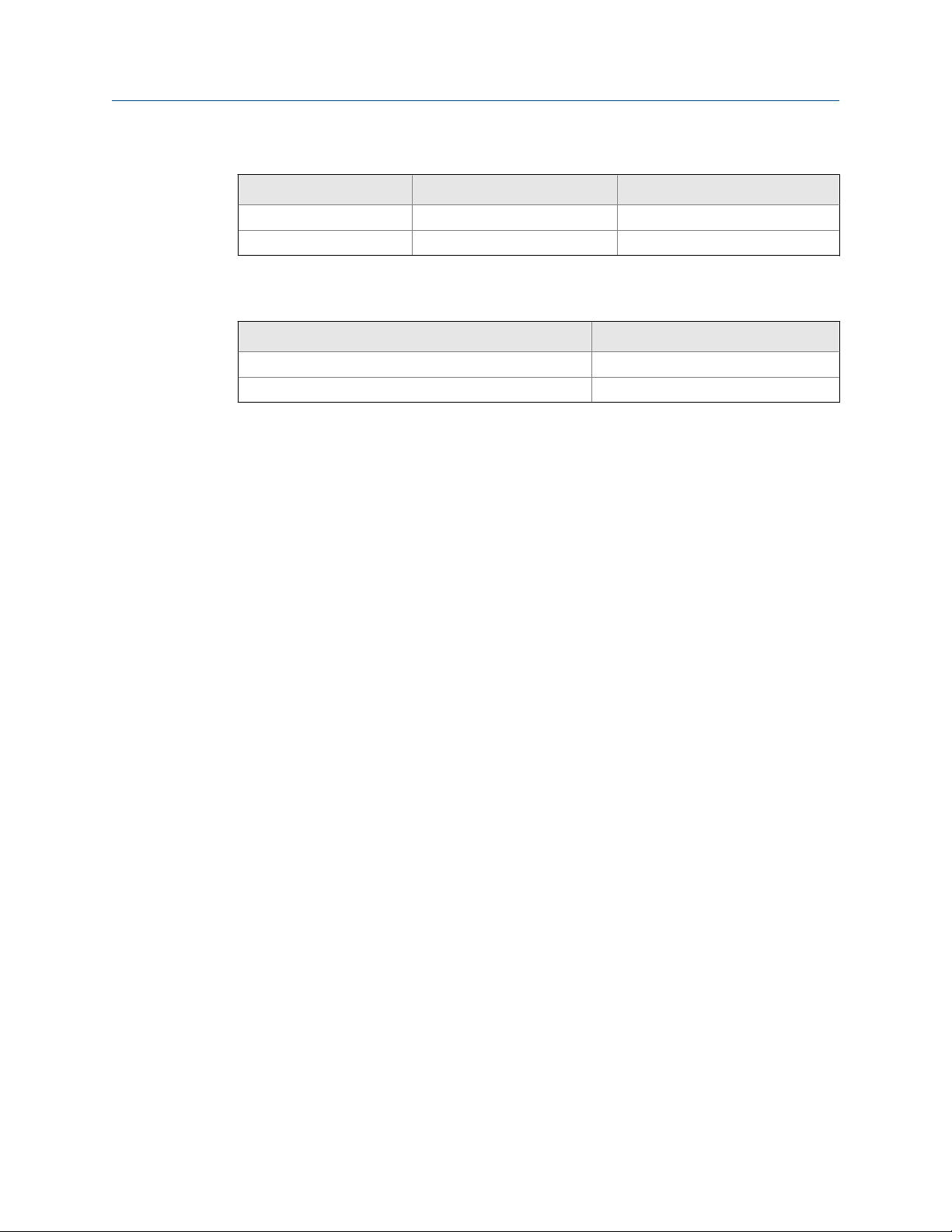

3.3.2 Free space requirements

If the transmitter is mounted close to a wall or other tank obstructions such as heating

coils and ladders, noise might appear in the measurement signal. Therefore the following

minimum clearance, according to Table 3-1, must be maintained.

For easy access to the transmitter, mount it with sufficient service space (see Table 3-2).

Free Space RequirementsFigure 3-3:

Rosemount 5408 and 5408:SIS Level Transmitters 15

Page 26

Mechanical Installation

Distance to Tank Wall (L)Table 3-1:

Application Minimum Recommended

Liquids 8 in. (200 mm) ½ of tank radius

Solids 8 in. (200 mm) ⅔ of tank radius

Free Space RequirementsTable 3-2:

Description Distance

Service space width (A) 20 in. (500 mm)

Service space height (B) 24 in. (600 mm)

3.3.3 Antenna size

Choose as large antenna diameter as possible. A larger antenna diameter concentrates the

radar beam and ensures maximum antenna gain. Increased antenna gain permits greater

margin for weak surface echoes.

In addition, a larger antenna diameter results in a smaller beam angle and thereby, less

interference from any internal structures in the tank.

3.3.4 Antenna inclination

Ensure the antenna is aligned perpendicular to the product surface (see Figure 3-4). The

parabolic antenna comes with a swivel connection that adjusts for angled tank roofs.

Note that if the surface echo is weak in solids applications, then a small inclination of the

parabolic antenna toward the surface slope may improve the performance.

16 Reference Manual

Page 27

Max. 1.5°

90°

A

B

90°

Max. 3°

Mechanical Installation

InclinationFigure 3-4:

A. Cone antenna/process seal antenna

Parabolic antenna

B.

3.3.5 Non-metallic tanks

The walls in non-metallic tanks can be invisible to the radar signal, so nearby objects

outside the tank may cause disturbing radar echoes. Wherever possible, the transmitter

should be positioned so that objects close to the tank are kept outside the signal beam.

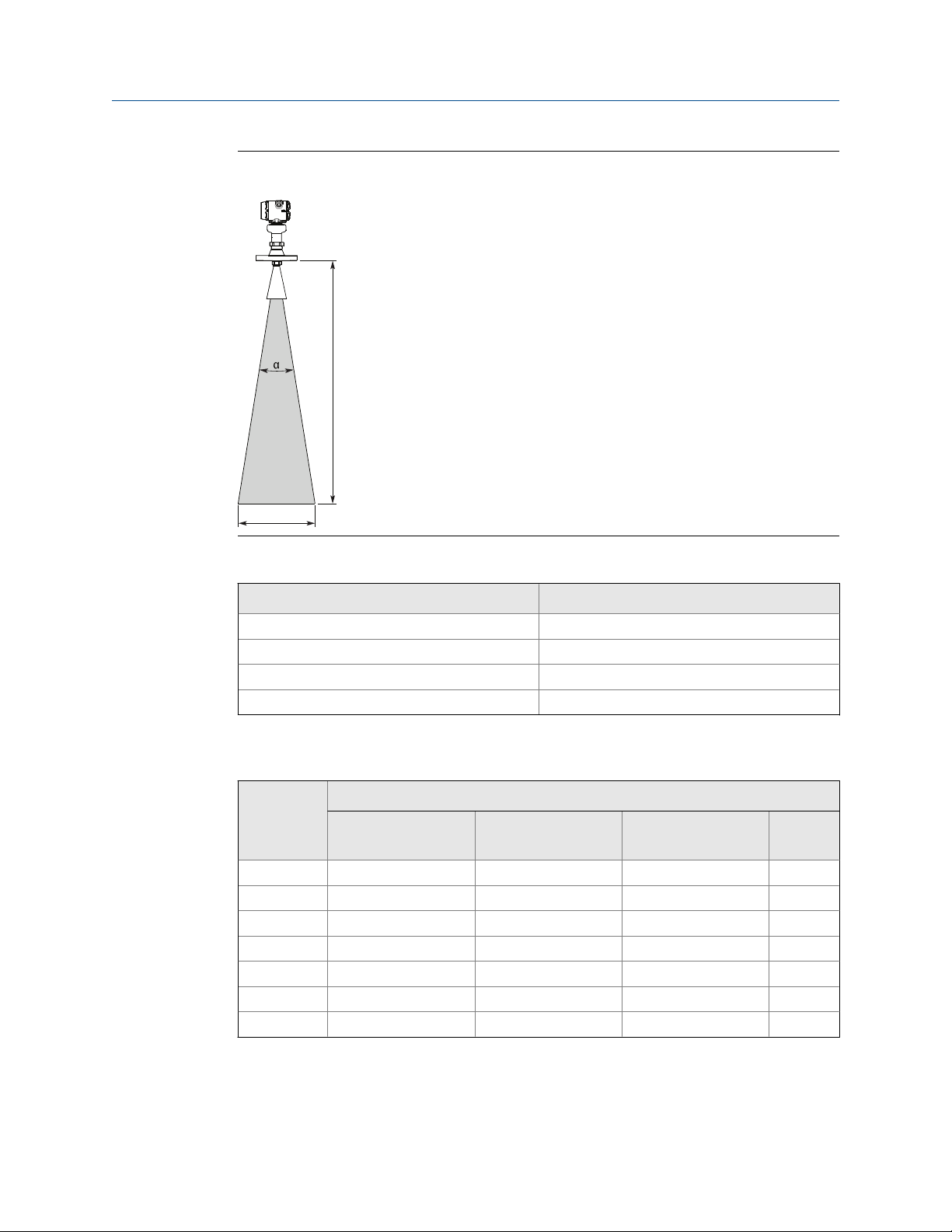

3.3.6 Beam width and beam angle

The transmitter should be mounted with as few internal structures as possible within the

signal beam. Refer to Table 3-3 for beam angle and Table 3-4 for beam width at different

distances.

Rosemount 5408 and 5408:SIS Level Transmitters 17

Page 28

'

:

Mechanical Installation

Beam Angle and Beam WidthFigure 3-5:

Beam AngleTable 3-3:

Antenna size Beam angle (α)

2-in. (DN50) cone/process seal 18°

3-in. (DN80) cone/process seal 14°

4-in. (DN100) cone/process seal 10°

8-in. (DN200) parabolic 4.5°

Beam Width, ft. (m)Table 3-4:

Beam width (W)

2-in. cone/ process

Distance (D)

16 (5) 5.2 (1.6) 4.0 (1.2) 2.9 (0.9) 1.3 (0.4)

33 (10) 10.4 (3.2) 8.1 (2.5) 5.7 (1.8) 2.6 (0.8)

49 (15) 15.6 (4.8) 12.1 (3.7) 8.6 (2.6) 3.9 (1.2)

66 (20) 20.8 (6.3) 16.1 (4.9) 11.5 (3.5) 5.2 (1.6)

82 (25) 26.0 (7.9) 20.1 (6.1) 14.3 (4.4) 6.4 (2.0)

98 (30) 31.2 (9.5) 24.2 (7.4) 17.2 (5.3) 7.7 (2.4)

131 (40) 41.6 (12.7) 32.2 (9.8) 23.0 (7.0) 10.3 (3.1)

seal

3-in. cone/ process

seal

4-in. cone/ process

seal Parabolic

18 Reference Manual

Page 29

3.3.7 Nozzle requirements

H

> 0.4 in. (10 mm)

D

In order to allow the microwaves to propagate undisturbed, the nozzle dimensions should

be kept within the specified limits as given in Table 3-5, Table 3-6, and Table 3-7.

Nozzle requirements for cone antenna

For best performance, the cone antenna should extend at least 0.4 in. (10 mm) below the

nozzle. If required, use the extended cone antenna versions (option code S1 or S2).

However, the antenna can be recessed in smooth nozzles up to 4 ft. (1.2 m). Note that if

the inside of the nozzle has irregularities (e.g. due to bad welding, rust, or deposit), then

use the extend cone antenna.

Mounting of the Cone AntennaFigure 3-6:

Mechanical Installation

Nozzle Requirements for Cone Antenna, in Inches (Millimeters)Table 3-5:

Recommended maximum nozzle height (H)

Antenna size Minimum nozzle diameter (D)

2-in. (DN50) 1.94 (49.3) 5.71 (145) 4.69 (119)

3-in. (DN80) 2.80 (71.0) 5.63 (143) 4.61 (117)

4-in. (DN100) 3.78 (96.0) 6.54 (166) 5.51 (140)

(1) The antennas are sized to fit within schedule 80 or lower schedules.

(2) The values are valid for cone antennas without antenna extension.

(3)

For liquid applications, the cone antenna can be recessed in smooth nozzles up to 4 ft. (1.2 m), but note that the accuracy may be

reduced in the region close to the nozzle.

(1)

Antenna Antenna with air purge ring (code PC1)

(2)(3)

Nozzle requirements for process seal antenna

The antenna can be used on nozzles up to 4 ft. (1.2 m). Disturbing objects inside the nozzle

may impact the measurement, and should therefore be avoided.

Rosemount 5408 and 5408:SIS Level Transmitters 19

Page 30

+

'

+

'

Mechanical Installation

Mounting of the Process Seal AntennaFigure 3-7:

Nozzle Requirements for Process Seal AntennaTable 3-6:

Recommended maximum nozzle height

(1)

Antenna size Minimum nozzle diameter (D)

(H)

(2)

2-in. (DN50) 1.77 in. (45 mm) 4 ft. (1.2 m)

3-in. (DN80) 2.76 in. (70 mm) 4 ft. (1.2 m)

4-in. (DN100) 2.76 in. (70 mm) 4 ft. (1.2 m)

(1) The antennas are sized to fit within schedule 120 or lower schedules.

For hygienic applications, the nozzle height (H) must not exceed 2

(2)

cleanability. Maximum nozzle height is 5 in. (127 mm).

× nozzle diameter (D) to ensure

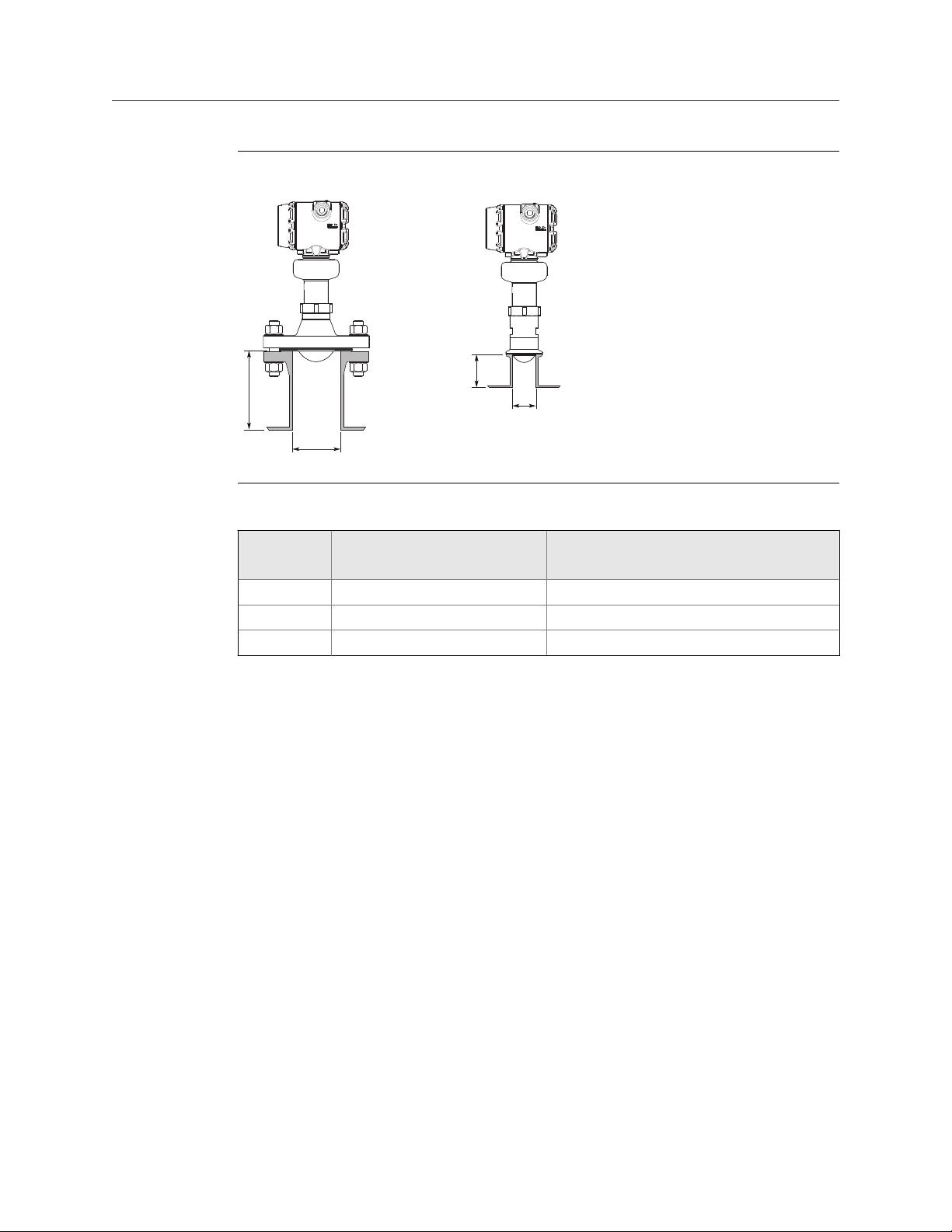

Nozzle requirements for parabolic antenna

See Table 3-7 for nozzle height recommendations at different inclination angle.

20 Reference Manual

Page 31

Mounting of the Parabolic AntennaFigure 3-8:

H

Ø 8 in. (200 mm)

A B

H

D

A. Nozzle mounting

Flange mounting in manhole cover

B.

Nozzle Requirements for Parabolic Antenna, in Inches (Millimeters)Table 3-7:

Mechanical Installation

Nozzle size (D) Inclination angle (α) Maximum nozzle height (H)

Pipe schedule std, Ø 8 in. (200 mm) 0° 5.9 (150)

3° 5.5 (140)

6° 1.6 (40)

9° 1.2 (30)

12° 1.0 (25)

15° 0.6 (15)

Pipe schedule std, Ø10 in. (250 mm) 0° 8.0 (200)

3° 8.0 (200)

6° 8.0 (200)

9° 8.0 (200)

12° 5.9 (150)

15° 4.3 (110)

(1) Note that the inside of the nozzle must be smooth (i.e. avoid bad welding, rust, or deposit).

3.3.8 Still pipe/chamber installations

Installation in still pipe/chamber is recommended for tanks where there are excessive

foaming or turbulence. Still pipe/chamber may also be used to avoid disturbing objects in

the tank.

(1)

Still pipe

Consider the following still pipe requirements:

Rosemount 5408 and 5408:SIS Level Transmitters 21

Page 32

Mechanical Installation

Pipe

Holes

Antenna

• Pipes should be an all-metal material.

• Pipe should have a constant inside diameter.

• The inner surface must be smooth and clear of any rough edges.

(Smooth pipe joints are acceptable, but may reduce accuracy.)

• The end of the pipe must extend beyond the zero level.

• Maximum hole diameter is 1 in. (25 mm).

• Minimum distance between holes is 6 in. (150 mm).

• Holes should be drilled on one side only and deburred.

• Drill one hole above maximum product surface.

• All cone/process seal antenna sizes can be used for still pipe/chamber

installations.

• The gap between the cone antenna and the still pipe should be

maximum 0.2 in. (5 mm). If required, order a larger antenna and cut on

location. See Table A-19 for antenna dimensions.

22 Reference Manual

Page 33

$

'

(

)

%

&

Mechanical Installation

Still Pipe RequirementsFigure 3-9:

A. Max. 0.2 in. (5 mm)

B. Max. 1 in. (25 mm)

Min. 6 in. (150 mm)

C.

D. Max. 1°

E. Level = 100%

F. Level = 0%

Chamber

Consider the following chamber requirements:

• Pipes should be an all-metal material.

• Pipe should have a constant inside diameter.

• Inlet pipes should not protrude into the inside of the stand pipe.

• The inner surface must be smooth and clear of any rough edges. (Smooth pipe joints

are acceptable, but may reduce accuracy.)

• The gap between the cone antenna and the stand pipe should be maximum 0.2 in.

(5 mm). If required, order a larger antenna and cut on location. See Table A-19 for

antenna dimensions.

Rosemount 5408 and 5408:SIS Level Transmitters 23

Page 34

$

%

&

'

Mechanical Installation

Chamber RequirementsFigure 3-10:

A. Min. 0.4 in. (10 mm)

B. Min. 6 in. (150 mm)

C.

Max. 1°

D. Max. 0.2 in. (5 mm)

For more information and installation requirements, refer to the Guidelines for Choosing

and Installing Radar in Stilling Wells and Bypass Chambers Technical Note.

3.3.9 Ball valve installation

The transmitter can be isolated from the process by using a valve:

• Use a full-port ball valve.

• Ensure there is no edge between the ball valve and the nozzle or still pipe, the inside

should be smooth.

• Valves can be combined with still pipes.

24 Reference Manual

Page 35

3.4 Mounting preparations

1 2

3

4

5

6

7

8

0

9

3.4.1 Assemble the segmented cone antenna

This section applies to the segmented cone antenna (option code S2). Use only one

segment; the total antenna length should not exceed 47.2 in. (1200 mm).

To determine the antenna length, follow the guidelines in section Section 3.3.7.

Procedure

1. Insert the segment into the cone antenna until it bottoms.

2. Mark where to cut the segment.

Mechanical Installation

3. Remove and cut the segment at the marking.

4. Remove any burrs.

5. Insert the segment into the cone antenna until it bottoms.

6. Secure the segment to the antenna.

Rosemount 5408 and 5408:SIS Level Transmitters 25

Page 36

1

2

3 4

/

1 2

3

4

5

6

7

8

0

9

1 2

3

4

5

6

0

Mechanical Installation

7. Measure the Antenna Extension Length (L).

8. Update the transmitter configuration to the new Antenna Extension Length (L).

• Rosemount Radar Master Plus:

- Under Configure, select Level Setup > Antenna.

• AMS Device Manager and Field Communicator:

- Select Configure > Manual Setup > Level Setup > Antenna.

3.4.2 Shorten the extended cone antenna

This section only applies to the extended cone antenna (option code S1).

To determine the antenna length, follow the guidelines in section Section 3.3.7.

Procedure

1. Mark where to cut the antenna.

2. Cut the antenna at the marking.

26 Reference Manual

Page 37

/

1 2

3

4

5

6

0

Mechanical Installation

3. Remove any burrs.

4. Measure the Antenna Extension Length (L).

5. Update the transmitter configuration to the new Antenna Extension Length (L).

• Rosemount Radar Master Plus:

- Under Configure, select Level Setup > Antenna.

• AMS Device Manager and Field Communicator:

- Select Configure > Manual Setup > Level Setup > Antenna.

Rosemount 5408 and 5408:SIS Level Transmitters 27

Page 38

G

'

G

'

$

&'

(

%

Mechanical Installation

3.5 Mount the cone antenna

OverviewFigure 3-11:

A. Flanged version (see page 29)

B.

C. Threaded version, D < d (see page 31)

D. Threaded version, D > d (see page 34)

E. Bracket mounting (see page 36)

3.5.1 Protective cap

For spare antennas, keep the protective cap in place until installing the transmitter head.

The cap protects the process seal from dust and water.

28 Reference Manual

Flanged version with air purge ring (see

page 30)

Page 39

Protective CapFigure 3-12:

Gasket

3.5.2 Flanged version

1. If applicable, assemble the segmented cone antenna (see Section 3.4.1).

2. Lower transmitter with antenna and flange into the nozzle.

Mechanical Installation

3. Tighten bolts and nuts with sufficient torque for the flange and gasket choice.

4. Align the transmitter head (see Section 3.5.7).

Rosemount 5408 and 5408:SIS Level Transmitters 29

Page 40

Antenna with air purge holes

Mechanical Installation

3.5.3 Flanged version with air purge ring (option code PC1)

1. If applicable, assemble the segmented cone antenna (see Section 3.4.1).

2. Place a suitable gasket on the tank flange.

3. Place the purge ring over the gasket.

4. Place a suitable gasket over the purge ring.

Note

A minimum gasket thickness of 0.125 in. (3.2 mm) is required for flanges with protective

plate design.

5. Lower transmitter with antenna and flange into the nozzle.

6. Tighten bolts and nuts with sufficient torque for the flange and gasket choice.

30 Reference Manual

Page 41

1.0 in. (25.5 mm)

0.4 in. (10 mm)

or

G3/8-in.

Mechanical Installation

7. Connect the air purging system. Use thread sealant or suitable gasket according to

your site procedures.

Incoming Air Supply SpecificationTable 3-8:

Maximum pressure Recommended pressure

190 psi (13 bar) 100 to 115 psi (7 to 8 bar)

8. Align the transmitter head (see Section 3.5.7).

3.5.4 Threaded version, antenna diameter (D) < Thread diameter (d)

Flanged tank connection

1. If applicable, assemble the segmented cone antenna (see

Rosemount 5408 and 5408:SIS Level Transmitters 31

Section 3.4.1).

Page 42

Mechanical Installation

2. Place a suitable gasket on the tank flange.

3. Place the customer supplied flange over the gasket.

4. Tighten the bolts and nuts with sufficient torque for the flange and gasket choice.

5. Apply anti-seize paste or PTFE tape on threads according to your site procedures.

Gasket may be used as a sealant for adapters with 1½- or 2-in. BSPP (G) threads.

6. Lower transmitter with antenna and flange into the nozzle.

32 Reference Manual

Page 43

Gasket

(for 1½-in. and 2-in.

BSPP (G) threads only)

7. Align the transmitter head (see Section 3.5.7).

Threaded tank connection

Mechanical Installation

1.

If applicable, assemble the segmented cone antenna (see

Section 3.4.1).

2. Apply anti-seize paste or PTFE tape on threads according to your site procedures.

Gasket may be used as a sealant for adapters with 1½- or 2-in. BSPP (G) threads.

3. Mount the transmitter on the tank.

Rosemount 5408 and 5408:SIS Level Transmitters 33

Page 44

Gasket

(for 1½-in. and 2-in.

BSPP (G) threads only)

H2 mm

Microwave launcher

Mechanical Installation

4. Align the transmitter head (see Section 3.5.7).

3.5.5 Threaded version, antenna diameter (D) > Thread diameter (d)

1. If applicable, assemble the segmented cone antenna (see Section 3.4.1).

2.

Unscrew and remove the antenna.

Note

Be careful not to scratch the microwave launcher. The microwave launcher is sensitive to

mechanical impacts.

34 Reference Manual

Page 45

Gasket

(for 1½-in. and 2-in.

BSPP (G) threads only)

H2 mm

38 mm

Torque 250 in-lb (28 N-m)

Torque 5 in-lb (0.5 N-m)

Mechanical Installation

3. Apply anti-seize paste or PTFE tape on threads according to your site procedures.

Gasket may be used as a sealant for adapters with 1½- or 2-in. BSPP (G) threads.

4. Mount the adapter on the customer supplied flange.

5. Mount the antenna.

Note

Visually inspect the microwave launcher for damage and dirt.

6. Lower transmitter with antenna and flange into the nozzle.

Rosemount 5408 and 5408:SIS Level Transmitters 35

Page 46

Gasket

Mechanical Installation

7. Tighten the bolts and nuts with sufficient torque for the flange and gasket choice.

8. Screw the adapter until it is properly tightened.

9. Align the transmitter head (see Section 3.5.7).

3.5.6 Bracket mounting

1. Mount the bracket to the pipe/wall.

On pipe:

36 Reference Manual

Page 47

4X

Horizontal pipe

Vertical pipe

On wall:

4X

H2 mm

2. Mount the holder to the bracket.

Mechanical Installation

3. Unscrew and remove the antenna.

Note

Be careful not to scratch the microwave launcher. The microwave launcher is sensitive to

mechanical impacts.

Rosemount 5408 and 5408:SIS Level Transmitters 37

Page 48

Microwave launcher

H2 mm

38 mm

Torque 5 in-lb (0.5 N-m)

Mechanical Installation

4. Screw the transmitter into the holder.

5. Mount the antenna.

6. Align the transmitter head (see Section 3.5.7).

3.5.7 Align transmitter head

1. Loosen the nut slightly and turn the transmitter.

38 Reference Manual

Page 49

60 mm

2. Verify the transmitter head is properly aligned.

60 mm

Torque 355 in-lb (40 N-m)

Option Description

Open tank Align the marking on the sensor module toward the tank wall (see Figure 3-13).

Still pipe Align the external ground screw toward the holes of the still pipe (see

Figure 3-14).

Chamber Align the external ground screw toward the process connections (see

Figure 3-15).

Mechanical Installation

3. Tighten the nut.

Open TankFigure 3-13:

Rosemount 5408 and 5408:SIS Level Transmitters 39

Page 50

$%

Mechanical Installation

Still pipeFigure 3-14:

ChamberFigure 3-15:

3.6 Mount the process seal antenna

A. Flanged version (see page 40)

B. Tri-Clamp version (see

3.6.1 Flanged version

1. Lower the transmitter into the nozzle.

40 Reference Manual

OverviewFigure 3-16:

page 42)

Page 51

Note

PTFE sealing

Be careful not to scratch or otherwise damage the PTFE sealing.

Mechanical Installation

2. Tighten the bolts and nuts (see Table 3-9).

Note

• Re-tighten after 24 hours and again after the first temperature cycle.

• Check at regular intervals and re-tighten if necessary.

Rosemount 5408 and 5408:SIS Level Transmitters 41

Page 52

PTFE sealing

Mechanical Installation

Torque Value, lb-ft (N-m)Table 3-9:

Process connection rating

ASME B16.5 EN1092-1 JIS B2220

Process connection size

2-in./DN50/50A 29 (40) 52 (70) 15 (20) 26 (35) 29 (40) 18 (25)

3-in./DN80/80A 33 (45) 48 (65) 37 (50) 37 (50) 41 (55) 22 (30)

4-in./DN100/100A 59 (80) 52 (70) 37 (50) 37 (50) 74 (100) 26 (35)

(1) The conditions used for the calculation are: Standard mating metal flange, A193 B8M Cl.2 / A4-70 bolt material, and a friction

coefficient of μ=0.16.

(2) Low strength bolt and non-metallic mating flange may require lower tightening torque.

(1) (2)

Class 150 Class 300 PN6 PN10/PN16 PN25/PN40 10K

(1)(2)

3. Align the transmitter head (see Section 3.5.7).

3.6.2 Tri-Clamp version

1. Lower the transmitter into the nozzle.

Note

Be careful not to scratch or otherwise damage the PTFE sealing.

2. Tighten the clamp to the recommended torque (see the manufacturer’s instruction

manual).

42 Reference Manual

Page 53

3. Align the transmitter head (see Section 3.5.7).

$%&

Gasket

3.7 Mount the parabolic antenna

OverviewFigure 3-17:

Mechanical Installation

A. Flanged version (see page 43)

B. Threaded version (see

C. Welded version (see page 49)

page 45)

3.7.1 Flanged version

1. Lower the flange and antenna assembly into the nozzle.

Rosemount 5408 and 5408:SIS Level Transmitters 43

Page 54

Mechanical Installation

2. Tighten the bolts and nuts with sufficient torque for the flange and gasket choice.

3. Adjust the inclination of the antenna (see Section 3.7.4).

4. Connect the air purging system (see Section 3.7.5).

44 Reference Manual

Page 55

3.7.2 Threaded version

2x

[

(

[

)

[

*

[

'

[

&

[

%

[

$

ComponentsFigure 3-18:

Mechanical Installation

A. Antenna E. Lock nut BSPP (G) 3½"

B. Purge plug kit F. Antenna adapter with ball joint

C. Threaded sleeve G. O-ring

D. M20 adapter

Procedure

1. Remove the lock nut.

Rosemount 5408 and 5408:SIS Level Transmitters 45

Page 56

(

)

*

Ø 3.98 ± 0.02 in.

(Ø 101 ± 0.6 mm)

OR

G 3½"

Max. 1.18 in. (30 mm)

> 0.59 in. (15 mm)

D

A

O-rings

Mechanical Installation

2. Mount the O-ring.

3. Mount the antenna adapter on flange/manhole cover. Ensure the antenna adapter

fits tightly to the flange/manhole cover.

4. Remove the M20 adapter and visually inspect the O-rings for damage and dirt.

5. Carefully insert the antenna.

46 Reference Manual

Page 57

6. Secure the antenna.

27 mm

C

D

Torque 180 in-lb (20 N-m)

H2 mm

Torque 5 in-lb (0.5 N-m)

Mechanical Installation

7. Tighten the set screw.

8. Lower the antenna assembly into the tank.

Rosemount 5408 and 5408:SIS Level Transmitters 47

Page 58

Gasket

Mechanical Installation

9. Tighten the bolts and nuts with sufficient torque for the flange and gasket choice.

10. Adjust the inclination of the antenna (see Section 3.7.4).

11. Connect the air purging system (see

Section 3.7.5).

48 Reference Manual

Page 59

3.7.3 Welded version

[

(

[

*

[

)

[

+

[

-

[

,

[

'

[

&

[

.

[

/

[

$

[

%

ComponentsFigure 3-19:

Mechanical Installation

A. Antenna G. Weld protection bar

B. Purge plug kit H. O-ring

C. Threaded sleeve I. Ball joint

D. M20 adapter J. Clamp flange

E Weld protection plate K. Washer

F Flange ball L. M8 screw

Rosemount 5408 and 5408:SIS Level Transmitters 49

Page 60

Ø 3.94 ± 0.02 in.

(Ø 100 ± 0.5 mm)

Max. 1.18 in. (30 mm)

G

E

E

F

Mechanical Installation

Procedure

1. Mount the protection plates to flange/manhole cover. These plates protect the

internal surfaces of the flange ball from dust and sparks during welding.

2. Weld the flange ball.

3. Remove the protection plates and visually inspect the internal surfaces of the flange

ball for damage and dirt.

50 Reference Manual

Page 61

4. Mount the O-ring.

+

H6 mm

Torque 65 in-lb (7 N-m)

J

L

K

I

Mechanical Installation

5. Mount the ball joint.

a.

Insert the ball joint and place the clamp flange with the “7 Nm” marking side up.

Gradually tighten the M8 screws.

b.

6. Remove the M20 adapter and visually inspect the O-rings for damage and dirt.

Rosemount 5408 and 5408:SIS Level Transmitters 51

Page 62

D

A

O-rings

27 mm

C

D

Torque 180 in-lb (20 N-m)

H2 mm

Torque 5 in-lb (0.5 N-m)

Mechanical Installation

7. Carefully insert the antenna.

8. Secure the antenna.

9. Tighten the set screw.

10. Lower the antenna assembly into the tank.

52 Reference Manual

Page 63

Gasket

Mechanical Installation