Page 1

Models 396/396VP/397/398/398VP

pH/ORP Sensors

Instruction Manual

PN 5100396

February 2001

MODEL 396 and

MODEL 398

MODEL 396VP and

MODEL 398VP

MODEL 397

Page 2

CAUTION

SENSOR/PROCESS

APPLICATION COMPATIBILITY

The wetted sensor materials may not be

compatible with process composition and

operating conditions. Application compatibility is entirely the responsibility of the

user.

DANGER

HAZARDOUS AREA INSTALLATION

This sensor is not Intrinsically Safe. or Explosion

Proof. Installations near flammable liquids or in

hazardous area locations must be carefully

evaluated by qualified on site safety personnel.

To secure and maintain an intrinsically safe

installation, an appropriate transmitter/ safety

barrier/sensor combination must be used.

The installation system must be in accordance with the governing approval agency

(FM, CSA or BASEEFA/CENELEC) hazar dous

area classification requirements. Consult your

analyzer/transmitter instruction manual for

details.

Proper installation, operation and servicing of

this sensor in a Hazardous Area Installation is

entirely the responsibility of the user.

SS-SE

March 1995

ESSENTIAL INSTRUCTIONS

READ THIS PAGE BEFORE PROCEEDING!

Rosemount Analytical designs, manufactures, and tests

its products to meet many national and international standards. Because these instruments are sophisticated

technical products, you must properly install, use, and

maintain them to ensure they continue to operate within

their normal specifications. The following instructions

must be adhered to and integrated into your safety program when installing, using, and maintaining Rosemount

Analytical products. Failure to follow the proper instructions may cause any one of the following situations to

occur: Loss of life; personal injury; property damage;

damage to this instrument; and warranty invalidation.

• Read all instructions prior to installing, operating, and

servicing the product. If this Instruction Manual is not

the correct manual, telephone 1-800-654-7768 and the

requested manual will be provided. Save this

Instruction Manual for future reference.

• If you do not understand any of the instructions, contact your Rosemount representative for clarification.

• Follow all warnings, cautions, and instructions marked

on and supplied with the product.

• Inform and educate your personnel in the proper

installation, operation, and maintenance of the product.

• Install your equipment as specified in the Installation

Instructions of the appropriate Instruction Manual and

per applicable local and national codes. Connect all

products to the proper electrical and pressure

sources.

• To ensure proper performance, use qualified personnel to install, operate, update, program, and maintain

the product.

• When replacement parts are required, ensure that

qualified people use replacement parts specified by

Rosemount. Unauthorized parts and procedures can

affect the product’s performance and place the safe

operation of your process at risk. Look alike substitutions may result in fire, electrical hazards, or improper

operation.

Rosemount Analytical Inc.

Uniloc Division

2400 Barranca Parkway

Irvine, CA 92606 USA

Tel: (949) 863-1181

http://www.RAuniloc.com

Page 3

i

MODEL 396/396VP/397/398/398VP TABLE OF CONTENTS

TUpH MODELS 396/396VP/397/398/398VP

pH/ORP SENSORS

TABLE OF CONTENTS

Section Title Page

1.0 DESCRIPTION AND SPECIFICATIONS............................................................ 1

1.1 TUpH™ Features and Applications................................................................. 1

1.2 Performance and Physical Specifications ....................................................... 2

1.3 Ordering Information........................................................................................ 3

2.0 INSTALLATION................................................................................................. 8

2.1 Unpacking and Inspection............................................................................... 8

2.2 Mounting.......................................................................................................... 8

2.3 Electrical Installation ....................................................................................... 14

3.0 START UP AND CALIBRATION........................................................................ 28

3.1 Sensor Preparation .......................................................................................... 28

3.2 Calibration Using Buffer Solutions or Grab Samples....................................... 28

4.0 MAINTENANCE................................................................................................ 29

4.1 Electrode Cleaning .......................................................................................... 29

4.2 Automatic Temperature Compensator............................................................. 29

5.0 TROUBLESHOOTING...................................................................................... 30

6.0 RETURN OF MATERIAL................................................................................... 31

6.1 General ............................................................................................................ 31

6.2 Warranty Repair............................................................................................... 31

6.3 Non Warranty Repair........................................................................................ 31

LIST OF TABLES

Number Title Page

4-1 R0 and R1 Values for Temperature Compensation Elements.......................... 29

4-2 Temperature vs Resistance of Auto T.C. Elements .......................................... 29

5-1 Troubleshooting................................................................................................ 30

Page 4

MODEL 396/396VP/397/398/398VP TABLE OF CONTENTS

ii

LIST OF FIGURES

Number Title Page

2-1 Recommended Flow Through/Insertion Installation for Models 396, 396VP, .....

398, & 398VP.................................................................................................... 9

2-2 Dimensional Drawing For Models 396 & 398................................................... 10

2-3 Dimensional Drawing For Models 396VP & 398VP........................................... 11

2-4 Submersion Installations For Models 396, 396VP, 398, & 398VP ..................... 12

2-5 Dimensional Drawings For Model 397 in the Quik-Loc Unit............................ 13

2-6 Recommended Flow Through and Insertion Installation For Model 397......... 14

2-7 Models 396/397/398 Standard Wiring option used with Models 1054A, ........

1054B, 2054, and Preamps PN 22698-02 & 22698-03.................................... 14

2-8 Models 396/397/398 Option -62 for wiring to Models 1054, 1181, 2081, 54, .

81, 3081, 4081, SoluComp, and 2700 Preamp (PN 23054-03) and ...............

remote J-box PN 23555-00.............................................................................. 14

2-9 Wiring Models 396-54 (50), 397-54 (50), & 398-54 (50) to J-Box ...................

(PN 23309-04 (03)) & Remote Preamplifier ..................................................... 15

2-10 Wiring Models 396-54, 397-54, & 398-54 (PT-100-RTD) to J-Box ..................

(PN 23555-00) & Remote Preamplifier............................................................. 16

2-11 Wiring Models 396/397/398 to Model 1181pH ................................................ 17

2-12 Wiring Models 396-54, 397-54, & 398-54 to Models 1054A pH, 1054B pH, ..

& 2054pH-54.................................................................................................... 18

2-13 Wiring Models 396-54, 397-54, & 398-54 to Models 2081pH-05 & 1054pH-54. 19

2-14 Wiring Models 396-54, 397-54, & 398-54 to Models 54, 81, 3081, & 4081..... 20

2-15 Wiring Models 396-54, 397-54, & 398-54 to SoluComp Model SCL-P-014..... 21

2-16 Wiring Models 396-54, 397-54, & 398-54 to Model 2700 Preamp................... 22

2-17 Wiring Models 396-( )-54-62-(71), 397-02-10-54-62, & 398-( )-54-62 to ........

Model 1055-01-10-22-32 ................................................................................. 22

2-18 Wiring Models 396-54-62, 397-02-54-62, & 398-54-62 to Model 1055-22-32. 22

2-19 Wire Functions and Pin Connections for Variopol Connector Cable ............... 23

2-20 Wiring Models 396VP/398VP to Model 81 thru a remote J-box....................... 23

2-21 Wiring Models 396VP/398VP to Model 81 ....................................................... 23

2-22 Wiring Models 396VP/398VP to Model 1181 ................................................... 23

2-23 Wiring Models 396VP/398VP to Model 1181, 1050/1060, 1003/1023 thru a ..

remote J-box.................................................................................................... 24

2-24 Wiring Models 396VP/398VP to Model 2081 ................................................... 24

2-25 Wiring Models 396VP/398VP to Model 3081 & 4081....................................... 24

2-26 Wiring Models 396VP/398VP to Model 2081 thru a remote J-box................... 24

2-27 Wiring Models 396VP/398VP to Model 3081 & 4081 thru a remote J-box....... 24

2-28

Wiring Models 396VP/398VP to Model 1054 ................................................... 25

2-29 Wiring Models 396VP/398VP to Model 1054A/B & 2054 ................................ 25

2-30 Wiring Models 396VP/398VP to Model 1054 thru a remote J-box................... 25

2-31

Wiring Models 396VP/398VP to Model 1054A/B & 2054 thru a remote J-box. 25

2-32 Wiring Models 396VP/398VP to Model 54/54e thru a remote J-box................ 26

2-33 Wiring Models 396VP/398VP to Model 54/54e ................................................ 26

2-34 Wiring Models 396VP/398VP to Model SCL-(P/Q)........................................... 26

2-35 Wiring Models 396VP/398VP to Model 2700 ................................................... 26

2-36 Wiring Models 396VP/398VP to Model 1055-22-32......................................... 27

Page 5

MODEL 396/396VP/397/398/398VP SECTION 1.0

DESCRIPTIONS AND SPECIFICATIONS

1

SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

1.1 TUpH™ FEATURES AND APPLICATIONS.

Rosemount Analytical has achieved a new industry

standard for the life expectancy of pH sensors with

the TUpH Sensors. The low maintenance, disposable

Models 396, 396VP, 397, 398, and 398VP TUpH

Sensors offer long life and high performance in the

measurement of pH in aqueous solutions in

pipelines, open tanks, or ponds. These TUpH sensors feature a patented, large area reference junction1for maximum resistance to process coatings,

generally found in dirty, high solid applications. In

addition, the secondary helical reference pathway

2

serves as added protection from poisoning ions. The

simplified construction, designed with user convenience in mind, does not require electrolyte replenishment or any component replacement. All models feature a large glass bulb for increased resistance to the

effects of aging for longer life. All models are available only without an integral preamplifier. The preamplifier must be in a remote location or integral to the

analyzer/transmitter. Models with a “VP” after the

model number indicate the variopol connector is

used on the sensor in place of the cable. In this case,

a separate cable with a mating VP connector must be

used. All models are compatible with all Rosemount

Analytical and most manufacturers instruments.

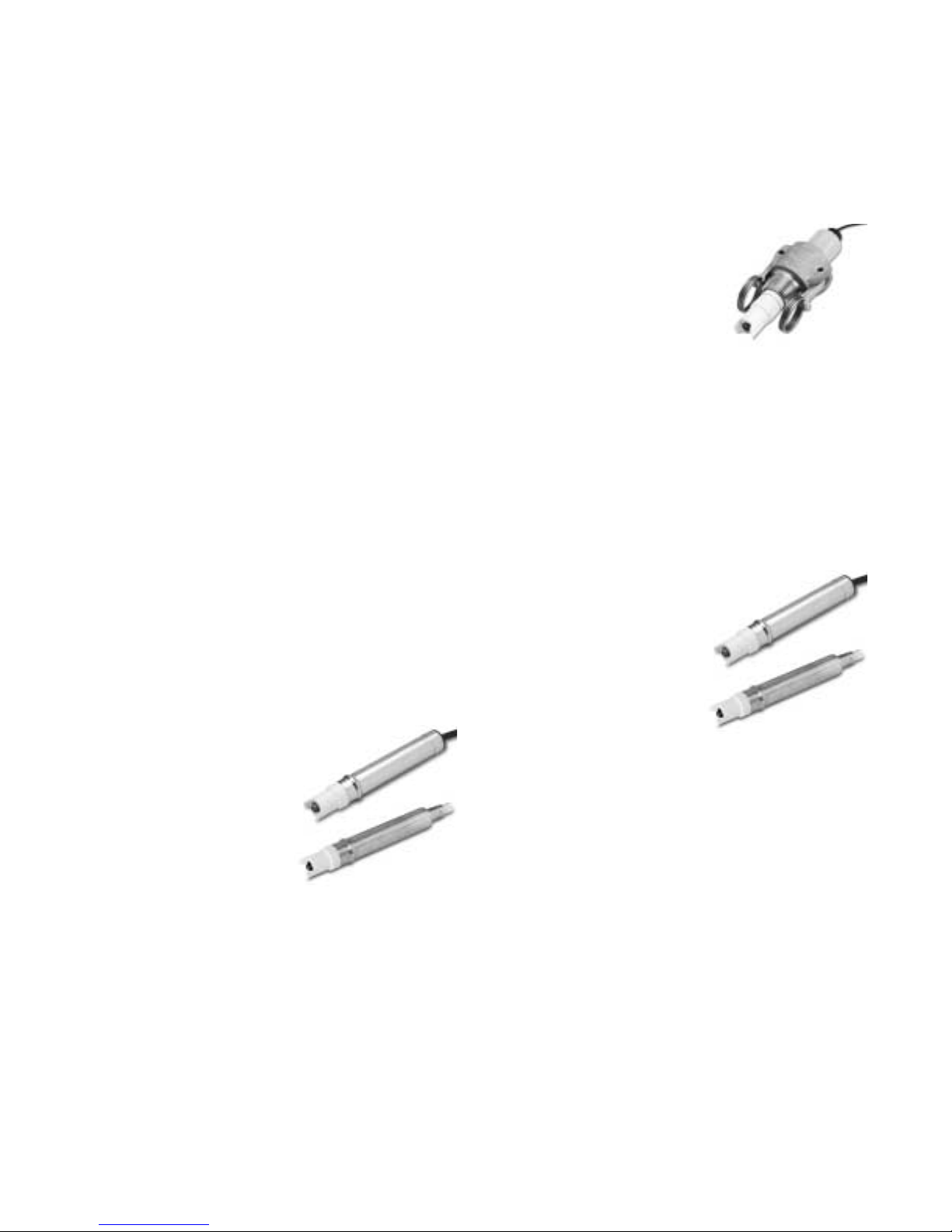

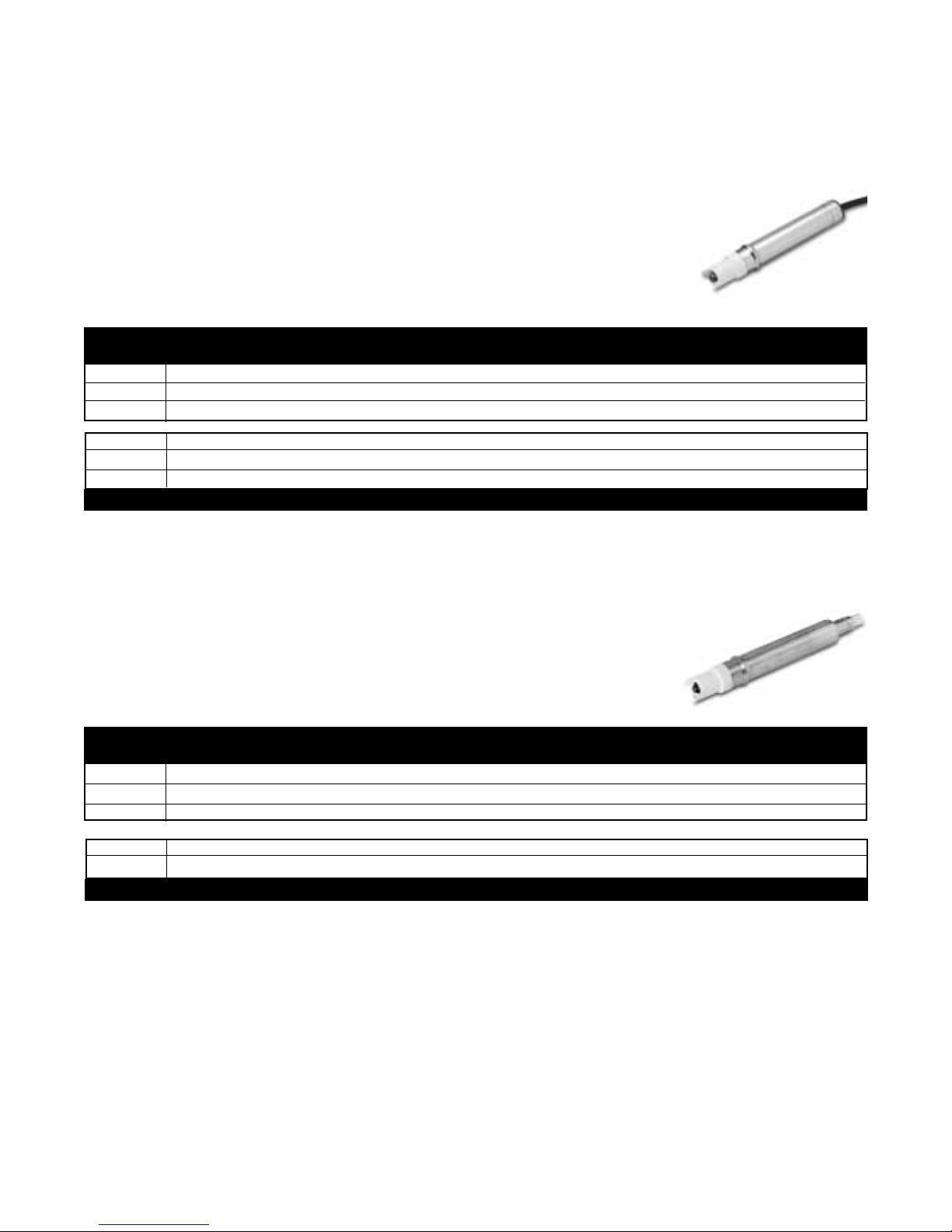

1.1.1 Model 396 and 396VP TUpH

Features and Applications.

The Models 396 and 396VP

TUpH sensors are constructed of polypropylene and

stainless steel and is completely sealed by EP (ethylene propylene) to eliminate

process intrusion. It is specifically designed for improved life in harsh, dirty applications such as lime slurry waste treatment and paper

machine headbox and pigment/dye applications

where large quantities of suspended solids are present. Installation is easily achieved through a wide variety of mounting configurations. The Model 396 features an optional front or rear 1 in. MNPT pr ocess connection for insertion, submersion, or flow through

applications.

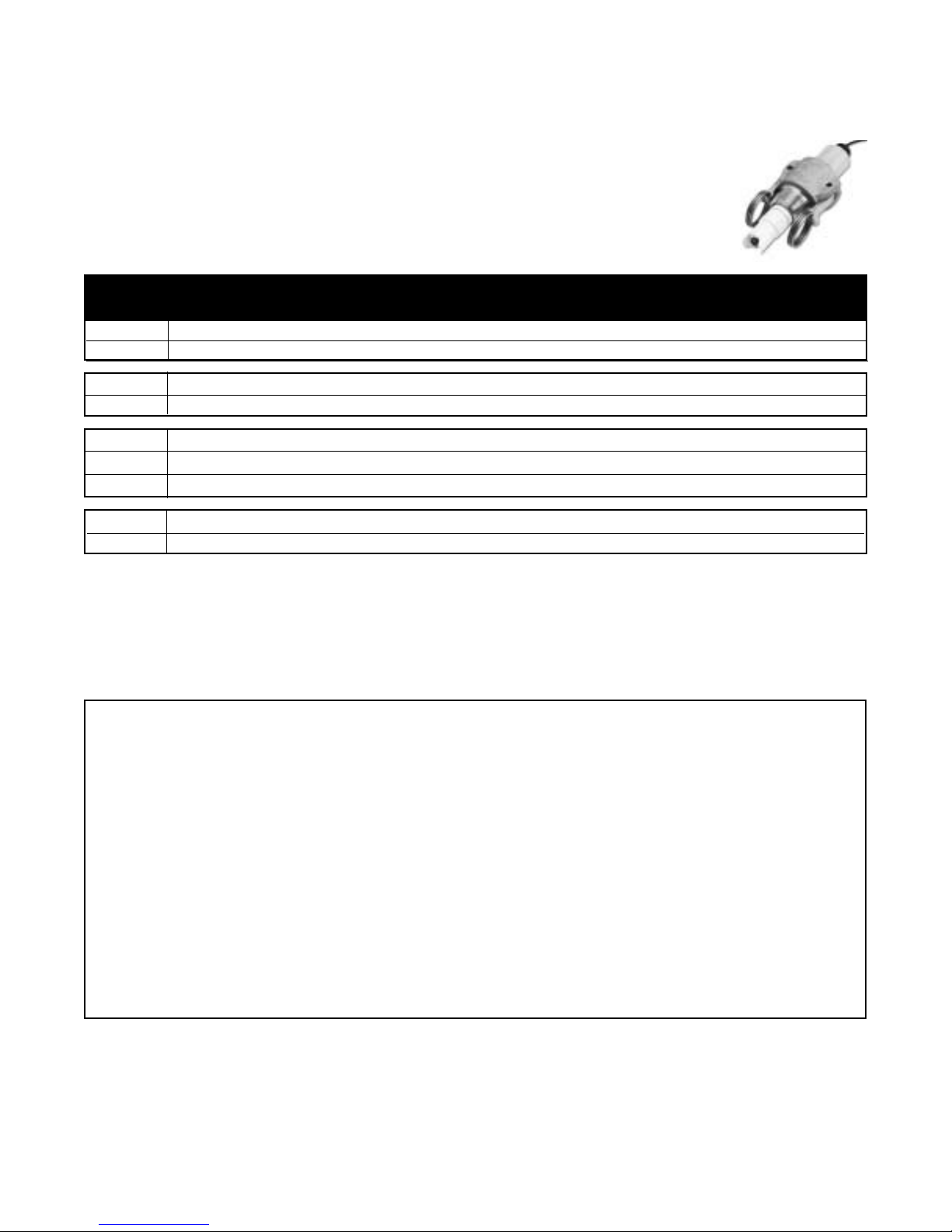

1.1.2 Model 397 TUpH and

Quik-Loc Features and

Applications. The Model 397 is

housed in a highly chemical

resistant polypropylene body

and completely sealed with EP

to eliminate process intrusion.

The Model 397 body is specifically designed for use

with the Quik-Loc Kit which consists of an adapter and

coupler. The PEEK (polyetheretherketone) adapter

enables the Model 397 sensor to fit into a 1 in. MNPT

Twin-Kam®4Kamloc®4coupler for quick and easy

removal without sensor cable twisting. The 316 stainless steel Twin-Kam®Kamloc®coupler is sealed with

EP and features “vibration resistant”5arms. The QuikLoc Kit is not recommended for use in processes with

hazardous, corrosive, or strong oxidizing chemicals

due to a risk of spray and bodily hazards.

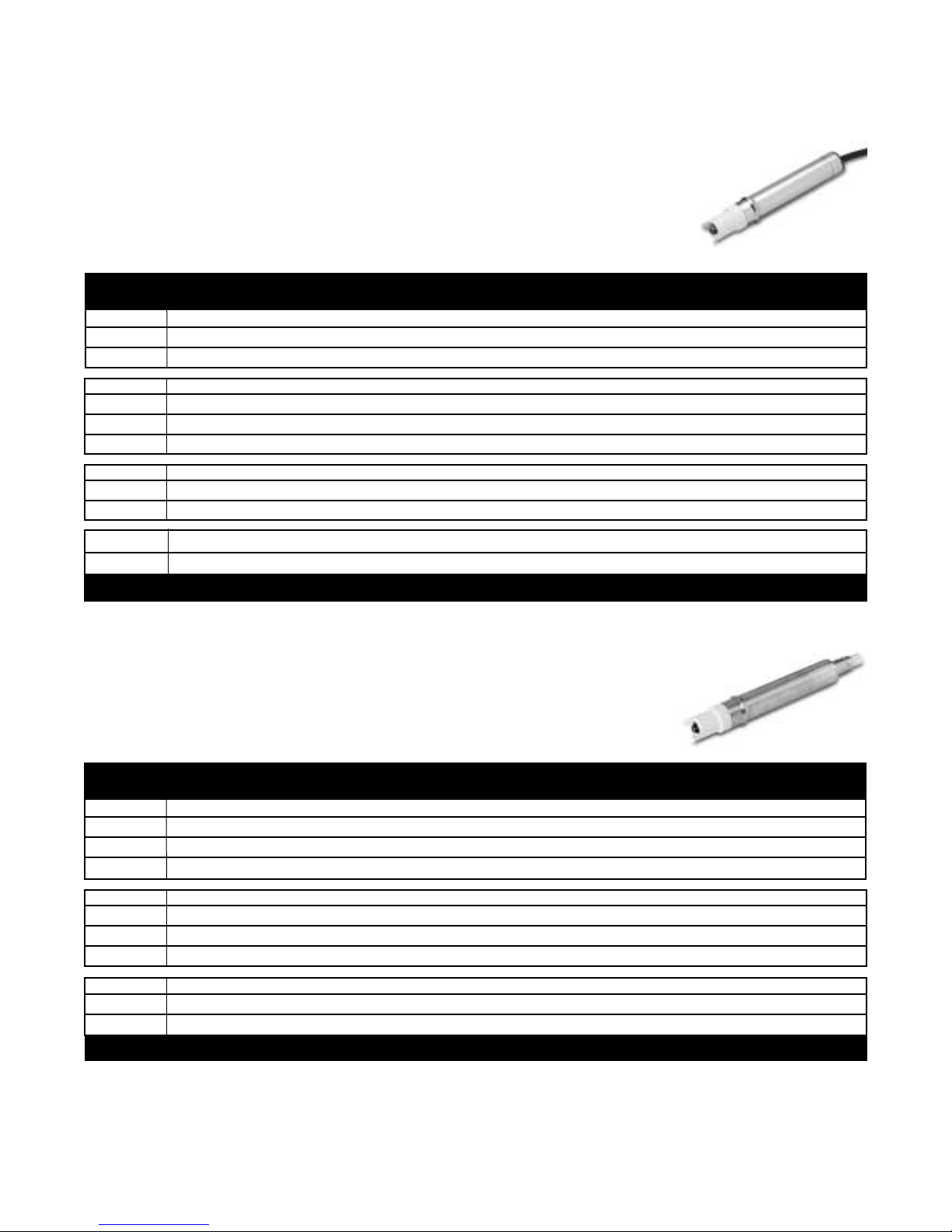

1.1.3 Model 398 and 398VP TUpH

Features and Applications.

The chemical-resistant construction of Tefzel, titanium,

and the patented TUpH reference junction make the

Models 398 and 398VP the

ideal sensors for measuring

pH in harsh process liquids.

Use Model 398 or 398VP to measure pH in sour water

strippers, in pulp bleaching towers that use chlorine

dioxide, and in process streams containing a variety

of organic solvents.

Models 398 and 398VP use the highest quality materials to provide superior chemical resistance. The sensors are housed in a titanium tube and features an

optional 1 inch MNPT process connector for insertion,

submersion, or flow-through applications. The molded

Tefzel TUpH construction is offered with a choice of

seals (Viton, EPDM, or Kalrez). Combining high quality materials with the TUpH reference technology and

A

CCUGLASS pH bulb allows for ultimate chemical

resistance and makes Models 398 and 398VP the perfect choice for measuring pH in harsh, demanding

processes.

1

May be Protected by U.S. Patent No. 5, 152, 882, Foreign Patent Pending

2

Protected by U.S. Patent No. 6, 054, 031, Foreign Patent Pending

3

A

CCUGLASS is a registered trademark of Rosemount Analytical

4

Kamlok® and Twin-Kam® are registered trademarks of CIVACON

5

CIVACON catalog, Kam-92 (REV. May, 1992)

Page 6

MODEL 396/396VP/397/398/398VP SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

2

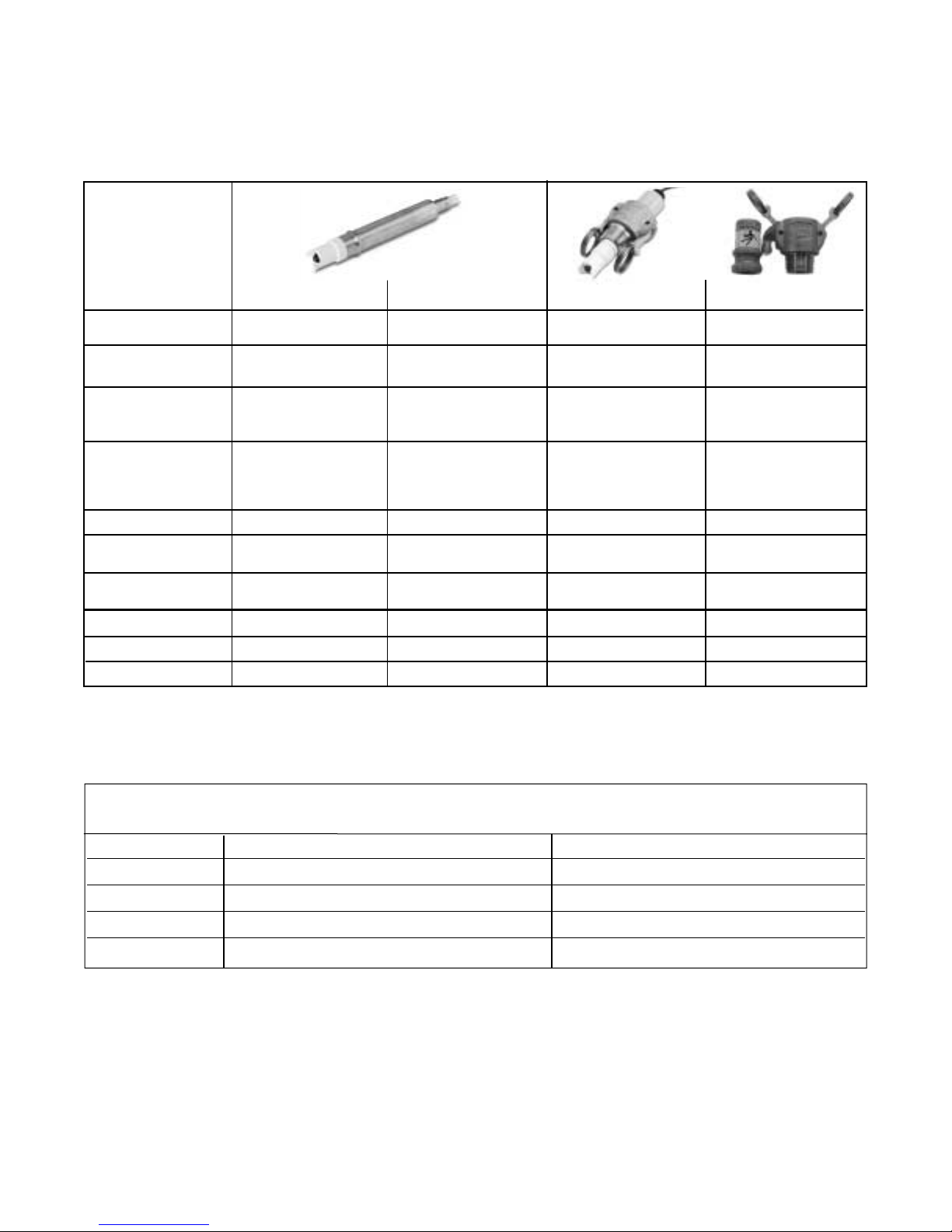

1.2 PERFORMANCE & PHYSICAL SPECIFICATIONS

SPECIFICATIONS

MODELS 396 &396VP MODELS 398 & 398VP MODEL 397 QUIK-LOC KIT

Measurements pH: 0-14 pH: 0-14 pH: 0-14 —

and Ranges ORP: -1500 to 1500 mv

Available pH GPHT hemi bulb or GPHT hemi bulb or GPHT hemi bulb —

ACCUGLASSTypes GPLR flat bulb GPLR flat bulb

Wetted Materials 316 SST, Polypropylene, Titanium, Tefzel, glass, Polypropylene, EP, glass 316 SST, EP, PEEK

EPDM, glass choice of Kalrez, Viton, or

EPDM (platinum: ORP only)

Process Connection None, use 1 in. NPT None, use 1 in. NPT None, must use Quik-Loc 1-in. MNPT

process connector, process connector, kit which includes 1 in.

PN 23166-00 or 23166-01 PN 23166-00 or 23166-01 MNPT process connection

(sold separately) (sold separately)

Temperature Range 0-100°C (32-212°F) 0-100°C (32-212°F) 0-80°C (32-176°F) —

Pressure Range- 100-1136 kPa (0-150 psig) 100-1825 kPa (0-250 psig) 100-790 kPa (0-100 psig) —

Hemi bulb

Pressure Range- 100-790 kPa (0-100 psig) 100-790 kPa (0-100 psig) — —

Flat bulb

Minimum Conductivity 75 µS/cm, nominal 75 µS/cm, nominal 75 µS/cm, nominal —

Preamplifier Options Remote Remote Remote

—

Weight/Shipping Weight 0.45 kg/0.9 kg (1 lb/2 lb) 0.45 kg/0.9 kg (1 lb/2 lb) 0.45 kg/0.9 kg (1 lb/2 lb) 0.45 kg/0.9 kg (1 lb/2 lb)

PERCENT LINEARITY

396, 396VP, 397, 398, 398VP 396, 396VP, 397, 398, 398VP

pH Range GPHT Hemi GPLR Hemi

0-2 pH 94% 93%

2-12 pH 99% 98%

12-13 pH 97% 95%

13-14 pH 92% —

Page 7

MODEL 396/396VP/397/398/398VP SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

3

1.3 ORDERING INFORMATION.

MODEL

396 TUpH INSERTION/SUBMERSION STAINLESS STEEL pH SENSOR

CODE ANALYZER/TC COMPATIBILITY (Required Selection)

50 For use with Models 1181, 1050, 1003 (3 K TC)

54 For use with Models 54, 1054, 1054A, 1054B, 2054, 2081, 2700, 81, SCL-P, 3081, and 4081 (PT-100 RTD)

CODE OPTIONAL ITEMS

62 Cable without BNC for wiring to 4081/3081/81/54 analyzers

71 Flat bulb, GPLR

396 - 54 EXAMPLE

The Model 396 pH Sensor features your selection of glass electrode type, either the

standard hemi bulb or the optional flat glass electrode combined with the coating

resistant, polypropylene reference with gel filled electrolyte. The sensor is housed

in a stainless steel body and is used with a 1 in. MNPT threaded process connector

suitable for insertion, submersion, or flow through installations. The Model 396 is

available without an integral preamplifier only and 15 ft of cable. Automatic

temperature compensation is standard 3 K Balco or PT-100 RTD.

MODEL

396VP TUpH INSERTION/SUBMERSION STAINLESS STEEL AND POLYPROPYLENE pH SENSOR (GPHT hemi bulb)

CODE ANALYZER/TC COMPATIBILITY (Required Selection)

50 For use with Models 1181, 1050, 1003 (3 K TC)

54 For use with Models 54, 1054, 1054A, 1054B, 2054, 2081, 2700, 81, 3081, 4081 and SCL-P (Pt 100 RTD)

CODE OPTIONAL OPTIONS

71 GPLR Flat bulb

396VP - 54 EXAMPLE

The Model 396VP insertion/submersion sensor is the same as Model 396 except,

instead of a cable on the back end of the sensor, it features a Variopol connector.

The watertight Variopol sensor-to-cable connector uses a mating connector cable

(ordered separately).

Page 8

MODEL 396/396VP/397/398/398VP SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

The Model 398 Sensor, housed in a titanium tube and made with a patented Tefzel reference junction, can be used with a 1 inch MNPT process connector (purchased separately). The sensor is available with a hemi bulb glass pH electrode or a platinum and

glass ORP electrode and with Pt100 or 3K temperature compensation.The 398 is provided with a standard 15 ft cable.A preamplifier must be used if the sensor is more than

15 ft from the analyzer/transmitter. Junction box kits with preamplifiers must be ordered

separately. Process connector must also be ordered separately.

CODE MEASURING ELECTRODE TYPE (Required Selection)

10 GPHT hemi glass, General Purpose High Temperature (0-14 pH)

12 ORP

CODE ANALYZER/TC COMPATIBILITY (Required Selection)

50 For Models 1181 (3K TC) [no T.C. if ordered with option -12 (ORP)]

54 For Models 1054, 1054A/B, 2054, 2081,54, 4081, 3081, 81, SCL-(P/Q), Solu Cube (PT 100 RTD)

CODE O-RING MATERIAL (Required Selection)

30 EPDM

31 Viton

32 Kalrez (recommended for applications with Chlorine Dioxide)

CODE OPTIONAL SELECTIONS (see drawings on page 4)

62 15 ft Cable, no BNC (Not Valid w/Option 50) for wiring directly to 54, 81, 3081, and 4081 Transmitter/Analyzers

MODEL

398 TUpH INSERTION/SUBMERSION TITANIUM pH SENSOR

398 - 10 - 32 - 54 EXAMPLE

The Model 398VP insertion/submersion sensor is the same as Model 398, except

the cable is replaced with a Variopol connector. The watertight Variopol sensor-tocable connector uses the mating connector cable (ordered separately).

CODE ANALYZER/TC COMPATIBILITY (Required Selection)

50 For Models 1181 (3K TC) [no T.C. if ordered with option -12 (ORP)]

54 For Models 1054, 1054A/B, 2054, 2081,54, 4081, 3081, 81, SCL-(P/Q), Solu Cube (PT 100 RTD)

CODE MEASURING ELECTRODE TYPE (Required Selection)

10 GPHT hemi glass, General Purpose High Temperature (0-14 pH)

12 ORP

13 Flat

CODE O-RING MATERIAL (Required Selection)

30 EPDM

31 Viton

32 Kalrez (recommended for applications with Chlorine Dioxide)

MODEL

398VP TUpH INSERTION/SUBMERSION TITANIUM AND TEFZEL pH/ORP SENSOR

398VP - 10 - 32 - 54 EXAMPLE

4

Page 9

5

MODEL 396/396VP/397/398/398VP SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

The TUpH Model 397 pH Sensor is housed in a polypropylene body and is designed to be

used with the Quik-Loc Kit.The sensor includes a large general purpose (GPHT) glass pH

electrode and a large area polypropylene reference junction with gel filled reference electrolyte.The Model 397 is available without an integral preamplifier only and 15 ft (4.6 m) of

cable.

MODEL

397 TUpH pH SENSOR

CODE PREAMPLIFIER/CABLE (Required Selection)

02 Without integral preamplifier, 15 ft (4.6 m) cable

CODE MEASURING ELECTRODE TYPE (Required Selection)

10 GPHT, General Purpose glass (0-14 pH)

CODE ANALYZER/TC COMPATIBILITY (Required Selection)

50 For Models 1181, 1050, 1003 (3 K Balco TC)

54 For Models 1054, 54, 81, 3081, 4081, 2054, 2081;2700-Code 02 only (PT-100 RTD)

CODE OPTIONAL OPTIONS

62 Cable without BNC for wiring to 3081/4081/81/54 analyzers

1. Quik-Loc Mounting (required for all first time installations)

Choose one: PN

23757-00, Quik-Loc Kit: for use in 1 in. tees; insertion depth 1.4 in. (35 mm)

PN

23757-01, Quik-Loc Kit: for use in 1-1/2 in. and 2 in. tees; insertion depth 2 in. (50 mm)

2. Remote Junction Boxes (optional, recommended for sensor to analyzer distances of more than 15 ft)

Choose one: PN 23555-00 includes preamplifier for Models 54, 81, 3081, 4081

PN 23309-03 and PN 22698-02 plug-in preamplifier for Model 1181Analyzer

PN 23309-04 and PN 22698-03 plug-in preamplifier for Models 1054 series, 2054, and 2081 Analyzers

PN 23054-03 includes preamplifier for Solu Cube Model 2700

3. Extension cables (used with remote junction boxes)

Choose one: PN 23646-01, 11 conductor, shielded, prepped

PN 9200273, 11 conductor, shielded, unprepped

4. Wiring Aids

Choose one: PN 9120531 BNC splitter, used in place of option -62 or BNC coax prepping for connections to

junction box (PN 23555-00); Models 1181, 1054, 2081, 54, 81, 3081, 4081; Solu Comp (SCL-P-014);

and Model 2700 Preamplifier (PN 23054-03)

NONE: No wiring aids required for connections to Models 1054A, 1054B, 2054, or preamplifiers

PN 22698-02 or 22698-03

FOR FIRST TIME 397/QUIK-LOC INSTALLATIONS, USING THE FOLLOWING GUIDE IS RECOMMENDED:

Page 10

6

MODEL 396/396VP/397/398/398VP SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

1. Process Connector Accessories (required for all first time installations with 1-inch process connection threads)

Choose one: PN 23166-00, 316 SST, 1 in. x 1 in. NPT process connector, with EPDM o-ring

PN 23166-01, Titanium, 1 in.x 1 in.NPT process connector, with EPDM o-ring

PN 9510066, Nylon, 1 in. x 1 in. NPT process connector (submersion only)

Choose one (optional process connector o-rings)

PN 9550220, Kalrez o-ring, 2-214

PN 9550099, Viton o-ring, 2-214

2. Variopol Cable (required for all first time installations) of Models 396VP and 398VP

Choose one: PN 23645-06, 15 ft cable with mating VP connector, prepped with BNC on analyzer end

PN 23645-07, 15 ft cable with mating VP connector, prepped without BNC on analyzer end*

3. Mounting Accessories (optional)

Choose one: PN 915240-03 PVC flow through tee, 3/4 in.NPT process connection

PN 915240-04 PVC flow through tee, 1 in. NPT process connection

PN 915240-05 PVC flow through tee, 1 1/2 in. NPT process connection

PN 11275-01 Sensor handrail mounting assembly

PN 2002011 1-1/2 in. CPVC Tee with 1 in. FNPT connection

PN 23728-00 Low Flow Cell, acrylic

4. Remote Junction Boxes (optional, recommended for sensor to analyzer distances of more than 15 ft)

Choose one: PN 23555-00 includes preamplifier for Models 54, 81, 3081, 4081

PN 23309-03 and PN 22698-02 plug-in preamplifier for Model 1181Analyzer

PN 23309-04 and PN 22698-03 plug-in preamplifier for Models 1054 series, 2054, 2081 Analyzers

PN 23054-03 includes preamplifier for Solu Cube Model 2700

5. Extension cables (used with remote junction boxes)

Choose one: PN 23646-01, 11 conductor, shielded, prepped

PN 9200273, 11 conductor, shielded, unprepped

6. Wiring Aids

Choose one: PN 9120531 BNC splitter, used in place of option -62 or BNC coax prepping for connections to junction box

(PN 23555-00); Models 1181, 1054, 2081, 54, 81, 3081, 4081; SoluComp (SCL-P-014);

and Model 2700 Preamplifier (PN 23054-03)

NONE: No wiring aids required for connections to preamplifier PN 22698-02, preamplifier PN 22698-03,

or Models 1054A, 1054B, and 2054

FOR FIRST TIME 396, 396VP, 398, AND 398VP INSTALLATIONS,

ROSEMOUNT ANALYTICAL RECOMMENDS USING THE FOLLOWING GUIDE:

*Used for connections to Models 1181, 1054, 2081, 54, 81, 3081, 4081, and remote junction box PN 23555-00.

Page 11

7

MODEL 396/396VP/397/398/398VP SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

ADDITIONAL ACCESSORIES FOR MODEL 396, 396VP, 398 AND 398VP TUpH SENSORS

PART NUMBER DESCRIPTION

33046-00 Ferrule 1 in., split 316 SS

33211-00 Adapter retrofit for PN 915240-04

9550167 EPDM O-ring for process connector (PN 23166-00)

9310100 Ferrule, 1 in. Teflon

1

9310096 Nut, Swage, 1 in. stainless steel

9550167 O-ring, 2-214 EPDM

1

Teflon is a registered trademark of E.I. du Pont de Nemours & Co.

ADDITIONAL ACCESSORIES FOR MODEL 397 TUpH SENSOR AND THE QUIK-LOC KIT

PART NUMBER DESCRIPTION

23753-00 PEEK replacement adapter for Quik-Loc kit (PN 23757-01)

23753-01 PEEK replacement adapter for Quik-Loc kit (PN 23757-00)

9160441 1 in. MNPT 316 stainless steel coupler

9160442 1 in. Plug, stainless steel

9160447 1 in. EP Gasket for coupler

2002011 1-1/2 in. CPVC Tee with 1 in. FNPT Connection

ADDITIONAL ACCESSORIES USED FOR MODELS 396, 396VP, 397, 398, AND 398VP TUpH SENSORS

PART NUMBER DESCRIPTION

22698-00 Preamplifier plug-in for J-box, 1003 compatible

22698-02 Preamplifier plug-in for J-box, 1181/1050 compatible

22698-03 Preamplifier plug-in for J-box, 1054A/B, 2054,2081 compatible

22743-01 Pt 100 preamplifier, 1181 compatible

22744-01 3K Preamplifier, 1181 compatible

23054-03 Remote J-box with preamplifier for Solu Cube Model 2700

23309-03 Remote Junction box, for preamplifier Model 1181

23309-04 Remote Junction box, for preamplifier Model 1054 Series, 2054, 2081

23555-00 Remote Junction box, with preamplifier, 54/3081/4081/81 compatible

23557-00 Preamplifier for Junction box for Models 54/3081/4081/81

23646-01 Extension cable 11 conductor, shielded, prepped

9200273 Extension cable11 conductor, shielded, unprepped

9210012 Buffer solution, 4.01 pH, 16 oz.

9210013 Buffer solution, 6.86 pH, 16 oz.

9210014 Buffer solution, 9.18 pH, 16 oz.

2001492 Stainless Steel Tag, Specify Marking

9200254 Cable, 4 cond., 22 AWG, 2 shielded pair

Page 12

8

2.2.1 Flow Thr ough and Insertion Mounting for Models

396, 396VP, 398, and 398VP. The Models 396, 396VP,

398, and 398VP Sensors can be used with a 1 inch

MNPT process connector at the front of the sensor for

mounting into a 1-1/2 inch tee or the process. See

Figure 2-1 for installation configurations.

2.2.2 Submersion Mounting for Models 396, 396VP,

398, and 398VP. The Models 396, 396VP, 398, and

398VP Sensors also have a 1 inch MNPT process connector available for use on the back of the sensor.

Tapered pipe threads in plastic fittings tend to loosen

after installation. It is therefore recommended that Teflon

tape be used on the threads and that the tightness of

the connection be checked frequently to assure that no

loosening has occurred. To prevent rain water or condensation from running into the sensor, a weatherproof

junction box is recommended (see Figure 2-4). The

sensor cable must be run through a protective conduit

for isolation from electrical interference or physical

abuse from the process. The sensor should be installed

within 80° of vertical, with the electrode facing down.

The sensor’ s cable should not be run with power or control wiring.

2.2.3 Quik-Loc Mounting for Model 397. The QuikLoc mounting is used with the Model 397 TUpH sensor only.

SAFETY WARNING

It is recommended that a thermometer, drain valve to relieve pressure

and pres-sure gauge be inserted

near the Quik-Loc assembly (see

Figure 2-5).

WARNING

Once the Quik-Loc unit is installed the operator should wait for the process to cool to a

safe temperature, use the pressure drain

valve to relieve all process pressure and

observe the pressure on the pressure

gauge for proper removal of the sensor

without spray or bodily injury. The Quik-Loc

kit used with the 397 TUpH sensor is not

recommended for use with hazardous, corrosive, or strong oxidizing chemicals due to

a risk of spray or bodily injury.

MODEL 396/396VP/397/398/398VP SECTION 2.0

INSTALLATION

2.1 UNPACKING AND INSPECTION. Inspect the out-

side of the carton for any damage. If damage is detected, contact the carrier immediately. Inspect the instrument and hardware. Make sure all the items in the packing list are present and in good condition. Notify the factory if any part is missing. If the sensor appears to be in

satisfactory condition, proceed to Section 2.2,

Mounting.

NOTE

Save the original packing cartons and

materials as most carriers require proof of

damage due to mishandling, etc. Also, if it

is necessary to return the instrument to the

factory , you must pack the instrument in the

same manner as it was received. Refer to

Section 6 for return instructions. If the sensor is to be stored, the vinyl boot should be

filled with pH buffer solution and replaced

on sensor tip until ready to use.

WARNING

Glass electrode must be wetted at all times

(in storage and in line) to maximize sensor

life.

2.2 MOUNTING. Each sensor has been designed to

be located in industrial process environments.

Temperature and pressure limitations must not

be exceeded at any time. A caution or warning label

regarding this matter is attached to each sensor. For

insertion, transfer the label as shown on label instructions. See Figure 2-2. For submersion applications, first

note limits then remove and discard label.

NOTE

Before mounting the sensor, shake down

the sensor to remove any air bubbles that

may be present at the tip of the pH glass

bulb. In most cases, the pH sensor can simply be installed as shipped and readings

with an accuracy of ±0.6 pH may be

obtained. To obtain greater accuracy or to

verify proper operation, the sensor must be

calibrated as a loop with its compatible analyzer or transmitter.

SECTION 2.0

INSTALLATION

Page 13

9

MODEL 396/396VP/397/398/398VP SECTION 2.0

INSTALLATION

Wrap the pipe threads of the Twin-Kam Kamloc coupler

with Teflon tape before placing it into the process pipe.

The coupler can be connected to any 1 in. process connection and must be mounted within 80° of vertical, with

the electrode facing down. Once the coupler is in place,

the adapter should be positioned onto the back end of the

sensor. (See Figure 2-5) Remove the parafilm wrapping

from the two 0-rings on the sensor, grease the o-rings with

the lube provided, and feed the sensor cable through the

adapter. Once the adapter is slipped over the sensor’s

back end, the retaining ring (which is included with every

397 sensor) should be installed on the black, grooved,

back end of the sensor body. The retaining ring secures

the sensor into the adapter. The adapter/sensor assembly

is now ready to be inserted into the coupler. With both

arms of the coupler in the released position, insert the

adapter/sensor assembly into the coupler.

NOTE

The adapter can not be inserted completely or

properly unless both arms are in the fully

released position (see Figure 2-5).

Once the adapter has been properly placed in the coupler,

both arms should be positioned in the locked position. A SurLoc

™ 1

spring arm has been provided on one arm so that the

“arm cannot be opened until the spring is released.”

2

NOTE

The sensor may obstruct flow through smaller pipes.

Once the arms of the coupler have been locked in position,

use tamper-evident safety wire on the metal rings of the

Twin-Kam arms to prevent unauthorized and/or untrained

personnel from using the Quik-Loc unit.

SAFETY WARNING

It is the responsibility of each company using the Quik-Loc Kit/ 397

TUpH Sensor to train personnel of

the injury risks associated with

using a quick-release coupler that

is placed in a hot or pressurized

process.

The Quik-Loc unit should be used only within the pressure

and temperature limits stated for the Model 397 sensor in

Section 1.2.2.

FIGURE 2-1. Recommended Flow Through and Insertion Installation

For Models 396, 396VP, 398 and 398VP

1-1/2 inch Pipe Tee (PN 2002011) with 1 inch threaded connections.

DWG. NO. REV.

40039609 B

Page 14

10

MODEL 396/396VP/397/398/398VP SECTION 2.0

INSTALLATION

FIGURE 2-2. Dimensional Drawing For Models 396 and 398

DWG. NO. REV.

40039601 D

MILLIMETER

INCH

NOTE: PRESSURE RATING SHOWN IS FOR

MODEL 396 FLAT BULB.

SEE PAGE 2 FOR

MODEL 396 AND 398

PRESSURE RATINGS.

Page 15

MODEL 396/396VP/397/398/398VP SECTION 2.0

INSTALLATION

INCH

MILLIMETER

Metal Process Connector PN 23166-xx

(xx = 00 for 316 SST and xx = 01 for titanium) can be used for insertion or submersion mounting of Models 396VP or

398VP sensors in 1-inch fittings.

The metal process connector gives the sensor various insertions depths, depending on where the

user locates the compression fitting. Also the

threads can be switched to face the cable end of

the sensor for connection to submersion pipes.

FIGURE 2-3. Dimensional Drawings: Model 396VP and 398VP Shown with Process Connector

11

Page 16

12

FIGURE 2-4. Submersion Installations For Models 396, 396VP, 398, and 398VP

DWG. NO. REV.

40039602 B

MILLIMETER

INCH

DWG. NO. REV.

40039603 B

DWG. NO. REV.

40039604 B

MODEL 396/396VP/397/398/398VP SECTION 2.0

INSTALLATION

Page 17

13

MODEL 396/396VP/397/398/398VP SECTION 2.0

INSTALLATION

FIGURE 2-5. Dimensional Drawings For Model 397 in the Quik-Loc Unit

DWG. NO. REV.

40039701 A

MILLIMETER

INCH

DWG. NO. REV.

40039702 A

DWG. NO. REV.

40039704 A

NOTE: The EP gasket (see drawing #40039702)

provided with the coupler should be periodically

inspected. If gasket shows signs of corrosion,

replacement will be necessary to ensure a proper

and secure seal between the coupler and adapter.

QUIK-LOC A B

KIT SENSOR LENGTH INSERTION DEPTH

23757-00 6.15 IN / 156 MM 1.4 IN / 35 MM

23757-01 6.15 IN / 156 MM 2.0 IN / 50 MM

Page 18

14

MODEL 396/396VP/397/398/398VP SECTION 2.0

INSTALLATION

2.3 ELECTRICAL INSTALLATION.

The Models 396, 396VP, 397, 398, and 398VP are for use

with a remote preamplifier. Each sensor comes with either a

special 15 ft low noise coax cable or a Variopol (VP) connector, which is used with a mating Variopol cable. The

cable should be handled carefully, and kept dr y and free of

corrosive chemicals at all times. Extreme care should be

used to prevent the cable from being twisted, damaged or

scraped by rough, sharp edges or surfaces. Please refer to

Figures 2-7 thru 2-18 for wiring Models 396, 397, and 398.

Please refer to Figures 2-19 thru 2-36 for wiring Models

396VP and 398VP.

DANGER

DO NOT CONNECT SENSOR CABLE TO POWER

LINES. SERIOUS INJURY MAY RESULT

.

FIGURE 2-6. Recommended Flow Through and Insertion Installation For Model 397

DWG. NO. REV.

40039703 A

FIGURE 2-7. Models 396, 397, and 398 Standard Wiring

Option used with Models 1054A, 1054B, 2054, and

Preamplifiers PN 22698-02 and 22698-03.

FIGURE 2-8.Models 396,397,and 398 Option -62 for Wiring

to Models 1054, 1181, 2081, 54, 81, 3081, 4081, SoluComp,

and 2700 Preamplifier (PN 23054-03). Also for use with

remote Junction Box PN 23555-00.

Page 19

MODEL 396/397 TABLE OF CONTENTS

15

MODEL 396/396VP/397/398/398VP SECTION 2.0

INSTALLATION

DWG. NO. REV.

40039706 C

DWG. NO. REV.

40039610 C

FIGURE 2-9. Wiring Details For Model 396-54 (50), 397-54 (50), and 398-54 (50).

For Use With Junction Box (PN 23309-04 (03)) and Remote Preamplifier

Page 20

16

DWG. NO. REV.

40038920 E

MILLIMETER

INCH

MODEL 396/396VP/397/398/398VP SECTION 2.0

INSTALLATION

SENSOR

MODELS

54, 3081,

81, 4081

pH/ORP

FIGURE 2-10. Wiring Details for Model 396-54, 397-54, and 398-54 (Pt-100 RTD). For Use With

Junction Box (PN 23555-00) and Remote Preamplifier.

Page 21

17

MODEL 396/396VP/397/398/398VP SECTION 2.0

INSTALLATION

FIGURE 2-11. Wiring Details For Models 396, 397, and 398. For Use With Model 1181 pH.

DWG. NO. REV.

40039607 C

SENSOR

Page 22

18

FIGURE 2-12. Wiring Details For Models 396-54, 397-54, and 398-54.

For Use With Models 1054ApH-54, 1054BpH-54, and 2054pH-54

DWG. NO. REV.

40039606 C

MILLIMETER

INCH

MODEL 396/396VP/397/398/398VP SECTION 2.0

INSTALLATION

SENSOR

Page 23

19

MODEL 396/396VP/397/398/398VP SECTION 2.0

INSTALLATION

FIGURE 2-13. Wiring Details For Models 396-54, 397-54, and 398-54.

For Use With Models 2081 pH-05 and 1054 pH-54

DWG. NO. REV.

40039608 C

MILLIMETER

INCH

SENSOR

Page 24

20

FIGURE 2-14. Wiring Details For Models 396-54 , 397-54, and 398-54.

For Use With Models 54, 81, 3081, and 4081.

DWG. NO. REV.

40039605 C

MILLIMETER

INCH

MODEL 396/396VP/397/398/398VP SECTION 2.0

INSTALLATION

SENSOR

Page 25

21

MODEL 396/396VP/397/398/398VP SECTION 2.0

INSTALLATION

FIGURE 2-15. Wiring Details For Models 396-54 , 397-54, and 398-54.

For Use With SoluComp Model SCL-P-014.

MILLIMETER

INCH

DWG. NO. REV.

40039611 C

SENSOR

Page 26

MODEL 396/397 TABLE OF CONTENTS

FIGURE 2-16. Wiring Models 396-54, 397-54, and 398-54 to Model 2700 Preamplifier (PN 23054-03).

MODEL 396/396VP/397/398/398VP SECTION 2.0

INSTALLATION

FIGURE 2-17. Wiring Models 396-( )-54-62-(71), 397-02-10-54-62, and 398-( )-54-62

to Model 1055-01-10-22-32

FIGURE 2-18. Wiring Models 396-54-62, 397-02-54-62, and 398-54-62 to Model 1055-22-32

22

Page 27

See below for wire functions for Models 396VP and 398VP.The Var iopol connector cable par t numbers are PN 23645-06

(with BNC) and PN 23645-07.

FIGURE 2-19. Wire Functions and Pin Connections for Variopol

connector cable

PN 23645-06 (with BNC) PN 23645-07

FIGURE 2-21. Wiring Model 396VP and 398VP to

Model 81

FIGURE 2-20. Wiring Model 396VP

and 398VP to Model 81 through a

Remote Junction Box

FIGURE 2-22. Wiring Model 396VP and 398VP to

Model 1181

MODEL 396/396VP/397/398/398VP SECTION 2.0

INSTALLATION

23

Page 28

FIGURE 2-24. Wiring Model

396VP and 398VP to Model 2081

FIGURE 2-25. Wiring Model

396VP and 398VP to Model 3081

and 4081

FIGURE 2-27. Wiring Model

396VP and 398VP to Model 3081

and 4081 through a Remote

Junction Box

FIGURE 2-26. Wiring Model

396VP and 398VP to Model 2081

through a Remote Junction Box

FIGURE 2-23. Wiring Model 396VP

and 398VP to Model 1181,

1050/1060, and 1003/1023 through

a Remote Junction Box

MODEL 396/396VP/397/398/398VP SECTION 2.0

INSTALLATION

24

Page 29

FIGURE 2-28. Wiring Model 396VP and 398VP to

Model 1054

FIGURE 2-30. Wiring Model 396VP and 398VP to

Model 1054 through a Remote Junction Box

FIGURE 2-29. Wiring Model 396VP and 398VP to

Models 1054A, 1054B, and 2054

FIGURE 2-31. Wiring Model 396VP and 398VP

to Models 1054A, 1054B, and 2054 through a

Remote Junction Box

MODEL 396/396VP/397/398/398VP SECTION 2.0

INSTALLATION

25

Page 30

FIGURE 2-33. Wiring Model 396VP/398VP to Models 54/54e

FIGURE 2-32. Wiring Model 396VP and 398VP to Models 54 and 54e through a Remote Junction Box

FIGURE 2-35. Wiring Model

396VP and 398VP to Model 2700

FIGURE 2-34. Wiring Model 396VP and

398VP to Model SCL-(P/Q)

26

MODEL 396/396VP/397/398/398VP SECTION 2.0

INSTALLATION

Page 31

MODEL 396/396VP/397/398/398VP SECTION 2.0

INSTALLATION

FIGURE 2-36. Wiring Model 396VP-54 to Model 1055-22-32

27

Page 32

MODEL 396/396VP/397/398/398VP SECTION 3.0

START UP AND CALIBRATION

SECTION 3.0

START UP AND CALIBRATION

3.1 SENSOR PREPARATION.

Shake down the sensor to remove any air bubbles

that may be present at the tip of the pH glass bulb.

In most cases, the pH sensor can simply be

installed as shipped and readings with an accuracy

of ±0.6 pH may be obtained. To obtain greater accuracy or to verify proper operation, the sensor must

be calibrated as a loop with its compatible analyzer

or transmitter.

3.2 CALIBRATION USING BUFFER

SOLUTIONS OR GRAB SAMPLES.

The pH sensor-analyzer/ transmitter loop may be

calibrated by submersing the sensor in a buffer

solution (standard solutions of known pH values) or

in a process grab sample whose pH value maybe

checked by a calibrated laboratory or portable pH

meter.

Please refer to the analyzer's or the transmitters

respective instruction manuals for proper calibration procedures.

28

Page 33

MODEL 396/397 TABLE OF CONTENTS

MODEL 396/397 TABLE OF CONTENTS

MODEL 396/396VP/397/398/398VP SECTION 4.0

MAINTENANCE

4.0 MAINTENANCE. The Model 396, 396VP, 397, 398,

and 398VP Sensors are disposable type sensors and

therefore require minimum maintenance. Every sensor

should be kept clean and free of debris and sediment

at all times. The frequency of cleaning by wiping or

brushing with a soft cloth or brush is determined by the

nature of the solution being measured. The sensor

should be removed from the process periodically and

checked in buffer solutions.

SAFETY WARNING

SENSOR IS IN PRESSURIZED SYSTEM!

May cause spray and bodily injury. Before

removing sensor , be absolutely certain that the

process pressure is reduced to 0 psig and the

process temperature is lowered to a safe level.

If the sensor will not calibrate, refer to your analyzer/

transmitter instruction manual for proper test procedures. If it is determined that the sensor has failed, it

should be discarded and replaced.

4.1 ELECTRODE CLEANING. If the electrode is coated or dirty, clean as follows:

1. Remove the sensor from process.

SAFETY WARNING

SENSOR IS IN PRESSURIZED SYSTEM

may cause spray and bodily injury. Before

removing sensor, be absolutely certain that

the process pressure is reduced to 0 psig

and the process temperature is lowered to a

safe level.

2. Wipe the glass bulb with a soft, clean, lint free cloth

or tissue. If this does not remove the dirt or coating,

go to Step 3. (Detergents clean oil and grease;

acids remove scale.)

3. Wash the glass bulb in a strong detergent solution

and rinse it in clean water. If this does not clean the

glass bulb, go to Step 4.

CAUTION

The solution used during the following check is an acid

and should be handled with care. Follow the directions of

the acid manufacturer. Wear the proper protective equipment. Do not let the solution come in contact with skin or

clothing. If contact with skin is made, immediately rinse

with clean water.

SECTION 4.0

MAINTENANCE

4. Wash the glass bulb in a dilute 5% hydrochloric acid

solution and rinse with clean water. Soaking the sensor overnight in the acid solution can improve cleaning action.

NOTE

Erroneous pH results may occur immediately after acid soak, due to reference junction potential build-up.

Replace the sensor if cleaning does not

restore sensor operation.

4.2 AUTOMATIC TEMPERATURE COMPENSATOR.

The temperature compensator element is temperature

sensitive and can be checked with an ohmmeter.

Resistance increases with temperature.

The 3K element will read 3000 ohms ±1% at 25°C (77°F)

and a Pt-100 will read 110 ohms. Resistance varies with

temperature for a 3K and Pt-100 element and can be

determined according to Table 4-2 or the following formula:

RT=Ro[l+R1(T-20)]

Where RT= Resistance

T = Temperature in °C

Refer to Table 4-1 for Roand R1values

TABLE 4-1. Roand R1Values for

Temperature Compensation Elements

Temperature °C Resistance (Ohms) ±1%

3K PT-100

0 2670 100.0

10 2802 103.8

20 2934 107.7

25 3000 109.6

30 3066 111.5

40 3198 115.4

50 3330 119.2

60 3462 123.1

70 3594 126.9

80 3726 130.8

90 3858 134.6

100 3990 138.5

Temperature

Compensation Element

R

o

R

1

3K 2934 .0045

PT-100 107.7 .00385

TABLE 4-2.Temperature vs Resistance

of Auto T.C. Elements

29

Page 34

30

MODEL 396/396VP/397/398/398VP SECTION 5.0

TROUBLESHOOTING

Trouble Probable Cause Remedy

Meter reads off scale. (Display T.C. element shorted. Check T.C. element as instructed

reads overrange.) in Section 4.2 and

replace sensor if defective.

Sensor not in process or sample Make sure sensor is in process with

stream is low. sufficient sample stream (refer to

Section 2.0 for installation details).

Open glass electrode. Replace sensor.

Reference element open - no contact.

Replace sensor.

Display reads between 3 and 6 pH Electrode cracked. Replace sensor.

regardless of actual pH of solution

or sample.

Meter or display indication swings T.C. element shorted. Check T.C. element as instructed

or jumps widely in AUTO T.C. Mode. in Section 4.2 and replace

sensor if defective.

Span between buffers extremely T.C. element open. Check T.C. element as instructed

short in AUTO T.C. Mode. in Section 4.2 and replace sensor

if defective.

Sluggish or slow meter indication Electrode coated. Clean sensor as instructed in

for real changes in pH level. Sections 4.1 Replace sensor

if cracked.

Electrode at end of life. Replace sensor.

Transmitter cannot be standardized. Electrode coated or cracked. Clean sensor as instructed in

Sections 4.1. Replace sensor

if cracked.

Transmitter short spans between Electrode at end of life, due to Replace sensor.

two different buffer values. old glass or high temperature

exposure.

Coated glass. Clean sensor as instructed in

Section 4.1. Replace sensor

if cracked.

TABLE 5-1.Troubleshooting

SECTION 5.0

TROUBLESHOOTING

Page 35

31

MODEL 396/396VP/397/398/398VP SECTION 6.0

RETURN OF MATERIAL

SECTION 6.0

RETURN OF MATERIAL

6.1 GENERAL.

To expedite the repair and return of instruments, proper communication between the customer and the factory is important. The “Return of Materials Request”

form is provided for you (in this manual) to copy and

use in case the situation arises. The accuracy and

completeness of this form will affect the processing

time of your materials. Call 1-949-863-1181 for a

Return Materials Authorization (RMA) number.

6.2 WARRANTY REP AIR.

The following is the procedure for returning instruments still under warranty:

1. Call Rosemount Analytical for authorization.

2. To verify warranty, supply the factory sales order

number or the original purchase order number. In

the case of individual parts or sub-assemblies,

the serial number on the unit must be supplied.

3. Carefully package the materials and enclose your

“Letter of Transmittal” (see Warranty). If possible,

pack the materials in the same manner as they

were received.

4. Send the package prepaid to:

Rosemount Analytical Inc., Uniloc Division

Uniloc Division

2400 Barranca Parkway

Irvine, CA 92606

Attn: Factory Repair

RMA No. ____________

Mark the package: Returned for Repair

Model No. ____

6.3 NON-WARRANTY REPAIR.

The following is the procedure for returning for repair

instruments that are no longer under warranty:

1. Call Rosemount Analytical for authorization.

2. Supply the purchase order number, and make

sure to provide the name and telephone number

of the individual to be contacted should additional information be needed.

3. Do Steps 3 and 4 of Section 6.2.

NOTE

Consult the factory for additional information regarding service or repair.

Page 36

Page 37

U.S. Field Service

Field Watch Response Center

1-800-654-7768

International

ARGENTINA

Emerson Argentina

Buenos Aires

54 1 780311,

795-9338

AUSTRALIA

Fisher-Rosemount

Pty. Ltd.

Baysw ater, Victoria

(61)(39)721-0200

AUSTRIA

Fisher-Rosemount - AG

Neudorf

(43)(2236)607

BELGIUM

Fisher-Rosemount

N.V./S.A.

Diegem

(32)(2)716-77-11

BRAZIL

Fisher-Rosemount do

Brasil Industria e

Comercio Ltda.

Sorocada

(55)(11)228 3788

CANADA

Rosemount Instruments

Ltd.

Calgary

(800) 268-1151

CHINA

Fisher-Rosemount

Pudong, Shanghai

(86)(215)899-4415

CROATIA

Fisher-Rosemount

Croatia

Zagreb

(385)(1)305 071

CZECH REPUBLIC

Fisher-Rosemount

Praha

(420)(2)81002666-7

DENMARK

Fisher-Rosemount A/S

Alleroed

(45)48-17-03-33

ENGLAND

Fisher-Rosemount

Limited

Bognor Regis

(44)(1243)863-121

FINLAND

Oy Valment-Rosemount

AG

ESPOO

(358)(9)549-541

FRANCE

Fisher-Rosemount S.A.

Lyon

(33)(7)215-98-00

GERMANY

Fisher-Rosemount

GmbH & Co.

D-63549 Hasselroth

(49)(6055)884-0

HUNGARY

Fisher-Rosemount

Budapest

(36)(1)4624001

INDIA

Fisher-Rosemount

(India) Ltd.

New Bombay

(91)(22)762-9191/9200

ITALY

Fisher-Rosemount

Italia s.r.l.

Milan

(11)(39)(39)27021

JAPAN

Fisher-Rosemount Japan

Co., Ltd.

Tokyo

(81)(3)5403-8529

KOREA

Fisher-Rosemount

Korea Ltd.

Seoul

(82)(2)515-2321

MIDDLE EAST

Fisher-Rosemount

Middle-East Dubai,

United Arab Emirates

(971)(4)835235

MALAYSIA

Rosemount Instruments

SDN BHD

Kuala Lumpur

(60)(3)244-5688

MEXICO

Fisher-Rosemount S.A.

de C.V.

Tlalnepantla

(011)(525)728-0885

NEW ZEALAND

Fisher-Rosemount

Auckland

(64)(9)444-1646

NORWAY

Fisher-Rosemount A/S

Porsgrunn

(47)35-55-5600

POLAND

Fisher-Rosemount

Warszawa

(48)(22)857 3856/

647 3865

PORTUGAL

Fisher-Rosemount

Portugal Instrumentos

Limitada

Alfragide

(351)(1)472 88 50

PUERTO RICO

Fisher-Rosemount Inc.

Guaynabo

(787)782-9955, 9956,

or 9957

ROMANIA

Fisher-Rosemount

Bucharest

40 1230 4149/50/59

RUSSIA

Fisher-Rosemount

Moscow

7095 245 86 86

SINGAPORE

Fisher-Rosemount

Singapore

Pte, Ltd

(65)777-8211

SLOVAK REPUBLIC

Fisher-Rosemount scr

Bratislava

42 17 761 973

SPAIN

Fisher-Rosemount S.A.

Madrid

(34)(1)358-91-41

SWEDEN

Fisher-Rosemount AB

Karlstad

(46)(54)19-0090

SWITZERLAND

Fisher-Rosemount AG

Baar

(41)(41)768 62 60

THE NETHERLANDS

Fisher-Rosemount BV

Rijswijk

(31)(70)413-6542

TURKEY

Fisher-Rosemount

Proses Kontrol Ltd.Sri

Istanbul

(90)(216)49 240 42-46

A Worldwide Network of Sales and Service

The Rosemount customer sales and service organization comprises a network of fully equipped support centers strategically located throughout the world. From many of these locations, the Rosemount Group provides support, distribution of finished products, repair facilities, and training for our customers.

Immediate, Reliable Analytical Support

Now there’s a way to quickly get the right answers for your liquid analytical instrumentation

questions: the Analytical Customer Support Center.

Our staff of trained professionals are ready to provide the information you need. If you are

placing an order, verifying delivery, requesting application information, or just want to contact a Rosemount Analytical representative, a toll-free call to 1-800-854-8257 will provide

you with the right people, the right answers, right now.

The right people, the right answers, right now.

Page 38

FROM: RETURN BILL T O:

_____________________________ _____________________________ _____________________________

_____________________________ _____________________________ _____________________________

_____________________________ _____________________________ _____________________________

CUSTOMER/USER MUST SUBMIT MATERIAL SAFETY SHEET (MSDS) OR COMPLETE STREAM COMPOSITION, AND/OR

LETTER CERTIFYING THE MATERIALS HAVE BEEN DISINFECTED AND/OR DETOXIFIED WHEN RETURNING ANY PRODUCT,

SAMPLE OR MATERIAL THAT HAVE BEEN EXPOSED TO OR USED IN AN ENVIRONMENT OR PROCESS THAT CONTAINS A

HAZARDOUS MATERIAL ANY OF THE ABOVE THAT IS SUBMITTED TO ROSEMOUNT ANALYTICAL WITHOUT THE MSDS

WILL BE RETURNED TO SENDER C.O.D. FOR THE SAFETY AND HEALTH OF OUR EMPLOYEES. WE THANK YOU IN

ADVANCE FOR COMPLIANCE TO THIS SUBJECT.

SENSOR OR CIRCUIT BOARD ONLY:

(Please reference where from in MODEL / SER. NO. Column)

1. PART NO._____________________________1. MODEL ____________________________________1. SER. NO. __________________

2. PART NO._____________________________2. MODEL ____________________________________2. SER. NO. __________________

3. PART NO._____________________________3. MODEL ____________________________________3. SER. NO. __________________

4. PART NO._____________________________4. MODEL ____________________________________4. SER. NO. __________________

PLEASE CHECK ONE:

■■ REPAIR AND CALIBRATE ■■ DEMO EQUIPMENT NO. ______________________________

■■ EVALUATION ■■ OTHER (EXPLAIN) ___________________________________

■■ REPLACEMENT REQUIRED? ■■ YES ■■ NO _______________________________________________________

DESCRIPTION OF MALFUNCTION:

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

WARRANTY REPAIR REQUESTED:

■■ YES-REFERENCE ORIGINAL ROSEMOUNT ANALYTICAL ORDER NO. _______________________________________________

CUSTOMER PURCHASE ORDER NO. ________________________________________________________

■■ NO-PROCEED WITH REPAIRS-INVOICE AGAINST P.O. NO._________________________________________________________

■■ NO-CONTACT WITH ESTIMATE OF REPAIR CHARGES: LETTER ■■ _________________________________________________

PHONE ■■ ________________________________________________

NAME___________________________________________________________ PHONE______________________________________________

ADDRESS_______________________________________________________________________________________________________________

_____________________________________________________________________ ZIP______________________________________________

RETURN AUTHORITY FOR CREDIT ADJUSTMENT [Please check appropriate box(s)]

■■ WRONG PART RECEIVED ■■ REPLACEMENT RECEIVED

■■ DUPLICATE SHIPMENT REFERENCE ROSEMOUNT ANALYTICAL SALES ORDER NO._____________

■■ RETURN FOR CREDIT RETURN AUTHORIZED BY: __________________________________________

WARRANTY DEFECT______________________________________________________________________________________________

_________________________________________________________________________________________________________________

24-6047

RETURN OF MATERIALS REQUEST

R

E

P

A

I

R

S

T

A

T

U

S

R

E

A

S

O

N

F

O

R

R

E

T

U

R

N

C

U

S

T

O

M

E

R

N

O

T

I

C

E

T

O

S

E

N

D

E

R

Rosemount Analytical Inc.

Uniloc Division

2400 Barranca Parkway

Irvine, CA 92606 USA

Tel: 1-800-854-8257

Fax: (949)-474-7250

Page 39

WARRANTY

Goods and part(s) (excluding consumables) manufactured by Seller are warranted to be free from defects in workmanship and material under normal use and service for a period of twelve (12) months from the date of shipment by

Seller. Consumables, pH electrodes, membranes, liquid junctions, electrolyte, O-rings, etc. are warranted to be free from

defects in workmanship and material under normal use and service for a period of ninety (90) days from date of shipment by Seller. Goods, part(s) and consumables proven by Seller to be defective in workmanship and / or material shall

be replaced or repaired, free of charge, F.O.B. Seller's factor y provided that the goods, parts(s), or consumables are

returned to Seller's designated factory, transportation charges prepaid, within the twelve (12) month period of warranty

in the case of goods and part(s), and in the case of consumables, within the ninety (90) day period of warranty . This warranty shall be in effect for replacement or repaired goods, part(s) and consumables for the remaining portion of the period of the twelve (12) month warranty in the case of goods and part(s) and the remaining portion of the ninety (90) day

warranty in the case of consumables. A defect in goods, part(s) and consumables of the commercial unit shall not operate to condemn such commercial unit when such goods, parts(s) or consumables are capable of being renewed,

repaired or replaced.

The Seller shall not be liable to the Buyer, or to any other person, for the loss or damage, directly or indirectly, arising

from the use of the equipment or goods, from breach of any warranty or from any other cause. All other warranties,

expressed or implied are hereby excluded.

IN CONSIDERATION OF THE STATED PURCHASE PRICE OF THE GOODS, SELLER GRANTS ONLY THE ABOVE STATED EXPRESS WARRANTY. NO OTHER WARRANTIES ARE GRANTED INCLUDING, BUT NOT LIMITED TO, EXPRESS

AND IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

RETURN OF MATERIAL

Material returned for repair, whether in or out of warranty, should be shipped prepaid to:

Rosemount Analytical Inc.

Uniloc Division

2400 Barranca Parkway

Irvine, CA 92606

The shipping container should be marked:

Return for Repair

Model

_______________________________

The returned material should be accompanied by a letter of transmittal which should include the following information

(make a copy of the "Return of Materials Request" found on the last page of the Manual and provide the following thereon):

1. Location type of service, and length of time of service of the device.

2. Description of the faulty operation of the device and the circumstances of the failure.

3. Name and telephone number of the person to contact if there are questions about the returned material.

4. Statement as to whether warranty or non-warranty service is requested.

5. Complete shipping instructions for return of the material.

Adherence to these procedures will expedite handling of the returned material and will prevent unnecessary additional

charges for inspection and testing to determine the problem with the device.

If the material is returned for out-of-warranty repairs, a purchase order for repairs should be enclosed.

Page 40

Rosemount Analytical Inc.

Uniloc Division

2400 Barranca Parkway

Irvine, CA 92606 USA

Tel: (949) 863-1181

http://www.RAuniloc.com

© Rosemount Analytical Inc. 2000

Credit Cards for U.S. Purchases Only.

The right people, the right answers, right now.

ON-LINE ORDERING NOW

AVAILABLE ON OUR WEB SITE

http://www.RAuniloc.com

UNILOC DIVISION

CUSTOMER SUPPORT CENTER

1-800-854-8257

Loading...

Loading...