Page 1

Quick Start Guide

00825-0100-4811, Rev JF

Rosemount™ 3300 Level Transmitter

Guided Wave Radar

April 2022

Page 2

Quick Start Guide April 2022

Contents

About this guide...........................................................................................................................3

Mount the transmitter head/probe.............................................................................................. 7

Set jumpers and switches........................................................................................................... 17

Connect wiring and power up.....................................................................................................19

Configure................................................................................................................................... 25

Environmental conditions.......................................................................................................... 31

Product certifications................................................................................................................. 32

2 Rosemount 3300 Level Transmitter

Page 3

April 2022 Quick Start Guide

1 About this guide

This start guide provides basic guidelines for the Rosemount 3300 Level

Transmitter. Refer to Rosemount 3300 Level Transmitter Reference Manual

for more instructions. The manual and this Quick Start Guide (QSG) are also

available electronically on Emerson.com/Rosemount.

WARNING

Failure to follow safe installation and servicing guidelines could result in

death or serious injury.

• Ensure only qualified personnel perform installation or service.

• Use the equipment only as specified in this Quick Start Guide and the

Reference Manual. Failure to do so may impair the protection provided

by the equipment.

• Do not perform any service other than those contained in this manual

unless you are qualified.

• Flamepath joints are not for repair. Contact the manufacturer.

Explosions could result in death or serious injury.

• Verify that the operating environment of the transmitter is consistent

with the appropriate hazardous locations specifications. See Product

certifications in this Quick Start Guide.

• In an explosion-proof/flameproof installation, do not remove the

transmitter covers when power is applied to the unit.

• Before connecting a handheld communicator in an explosive

atmosphere, ensure the instruments are installed in accordance with

intrinsically safe or non-incendive field wiring practices.

• To avoid process leaks, only use the O-ring designed to seal with the

corresponding flange adapter.

Electrical shock could cause death or serious injury.

• Avoid contact with the leads and terminals. High voltage that may be

present on leads can cause electrical shock.

• Ensure the mains power to the transmitter is off and the lines to any

other external power source are disconnected or not powered while

wiring the transmitter.

Temperature restrictions apply for Explosion-proof versions. For limits, see

certificate-specific information in the Product certifications chapter in this

document.

Quick Start Guide 3

Page 4

Quick Start Guide April 2022

WARNING

The electronics enclosures are category 2G or 2D equipment. The probes

not covered with plastic and not made of titanium, are category 1G or 1D.

The plastic covered probes or probes made of titanium, are only category 1G

equipment.

Probes with non-conducting surfaces and light metals:

• Probes covered with plastic and/or with plastic discs may generate an

ignition- capable level of electrostatic charge under certain extreme

conditions. Therefore, when the probe is used in a potentially explosive

atmosphere, appropriate measures must be taken to prevent

electrostatic discharge. These probes are not allowed in dust classified

areas.

The following probes do not contain plastic or PTFE material, and are

allowed to be placed in a Dust classified area:

Table 1-1: Probes Containing no Plastic or PTFE Material

Code Material of construction: Process connection/Probe

1 316L SST (EN 1.4404)

2 Alloy C-276 (UNS N10276) plate design if flanged version

3 Alloy 400 (UNS N04400) plate design if flanged version

5 Titanium Gr-1 and Gr-2

9 Duplex 2205 (EN 1.4462/UNS S31803) (plate design if flanged

L Alloy 625 (UNS N06625)

M Alloy 400 (UNS N04400)

H Alloy C-276 (UNS N10276)

D Duplex 2205 (EN 1.4462/UNS S31803)

version)

The Material of Construction Code can be found in the ninth character

position of the transmitter model code (for example

330xxxxx1xxxxxxxx).

4 Rosemount 3300 Level Transmitter

Page 5

Category 2D

Category 1D

Applicable marking:

Probes according to Table 1-1

Ex tb [ia Da] IIIC T85 °C…T450 °C Db

II 1/2 D Ex ia IIIC T20085 °C…T200450 °C Da /

Category 2G

Category 1G

All probes possible

II 1/2 G Ex ia IIC T6…T1 Ga /

Ex db [ia Ga] IIC T6…T1 Gb

Applicable marking:

Category 2D

Category 2D

Probes according to Table 1-1

Applicable marking:

II 2 D Ex tb IIIC T85 °C…T135 °C Db

April 2022 Quick Start Guide

• Probes and flanges containing >7.5 percent magnesium or zirconium are

not allowed in explosive dust atmosphere. Contact your Emerson sales

representative for more information.

Probes and flanges containing light metals:

• When used in category 1/2G installations, probes and flanges containing

titanium or zirconium must be mounted in such a way that sparks from

impact or friction between these parts and steel cannot occur.

Separation element (EPL Ga/Gb, Da/Db):

• The materials of the separation element are > 3 mm stainless steel and a

22 mm bushing filled with 2-part epoxy. The epoxy has a continuous

operating temperature of -55 °C ≤ COT ≤ 130 °C. Under normal operation

Quick Start Guide 5

Page 6

Quick Start Guide April 2022

the separation element is not pressurized or in contact with the process

media.

WARNING

Any substitution of non-authorized parts or repair, other than exchanging

the complete transmitter head or probe assembly, may jeopardize safety

and is prohibited.

• Unauthorized changes to the product are strictly prohibited as they may

unintentionally and unpredictably alter performance and jeopardize

safety. Unauthorized changes that interfere with the integrity of the

welds or flanges, such as making additional perforations, compromise

product integrity and safety. Equipment ratings and certifications are no

longer valid on any products that have been damaged or modified

without the prior written permission of Emerson. Any continued use of

product that has been damaged or modified without the written

authorization is at the customer’s sole risk and expense.

WARNING

Physical access

Unauthorized personnel may potentially cause significant damage to and/or

misconfiguration of end users’ equipment. This could be intentional or

unintentional and needs to be protected against.

Physical security is an important part of any security program and

fundamental to protecting your system. Restrict physical access by

unauthorized personnel to protect end users’ assets. This is true for all

systems used within the facility.

6 Rosemount 3300 Level Transmitter

Page 7

$

April 2022 Quick Start Guide

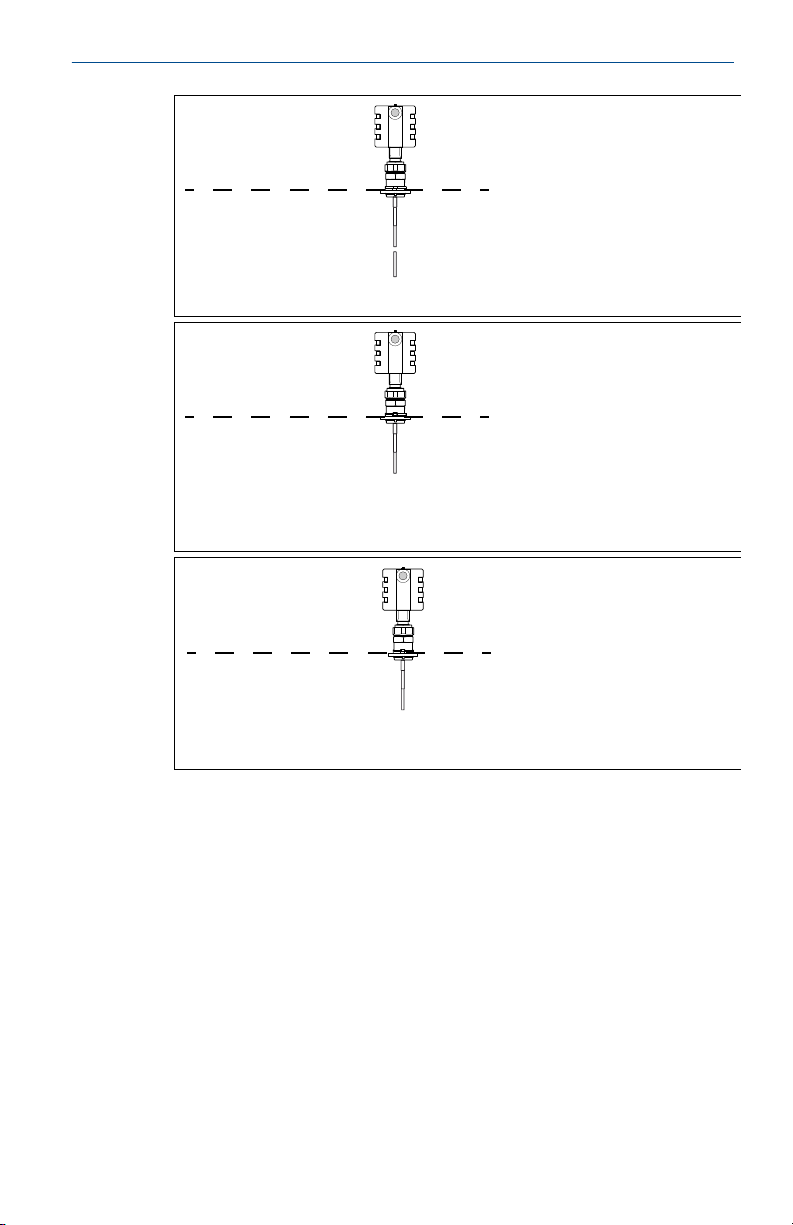

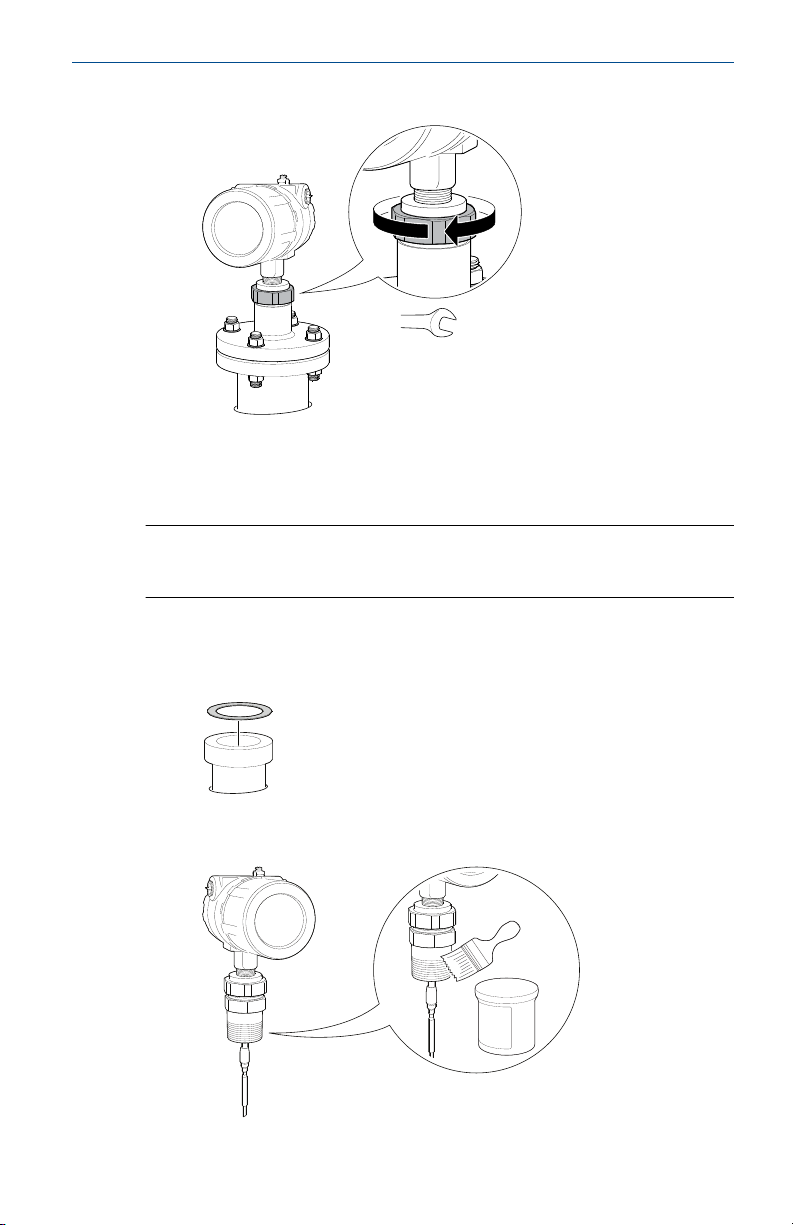

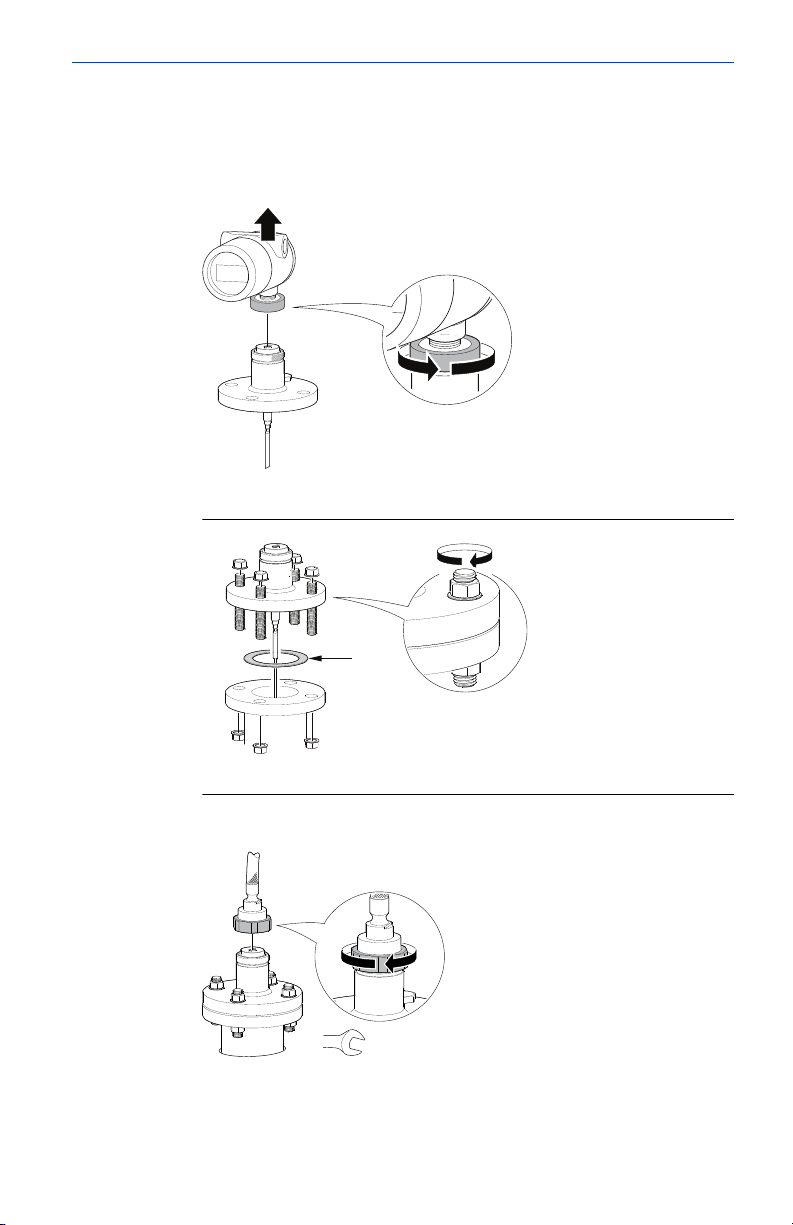

2 Mount the transmitter head/probe

2.1 Tank connection with flange

Prerequisites

Note

PTFE covered probes must be handled carefully to prevent damage to the

coating.

Procedure

1. Place a suitable gasket on top of the tank flange.

Note

Gasket should not be used for PTFE covered probe with protective

plate.

A. PTFE covered probe with protective plate

2. Lower the transmitter and probe with flange into the tank.

Quick Start Guide 7

Page 8

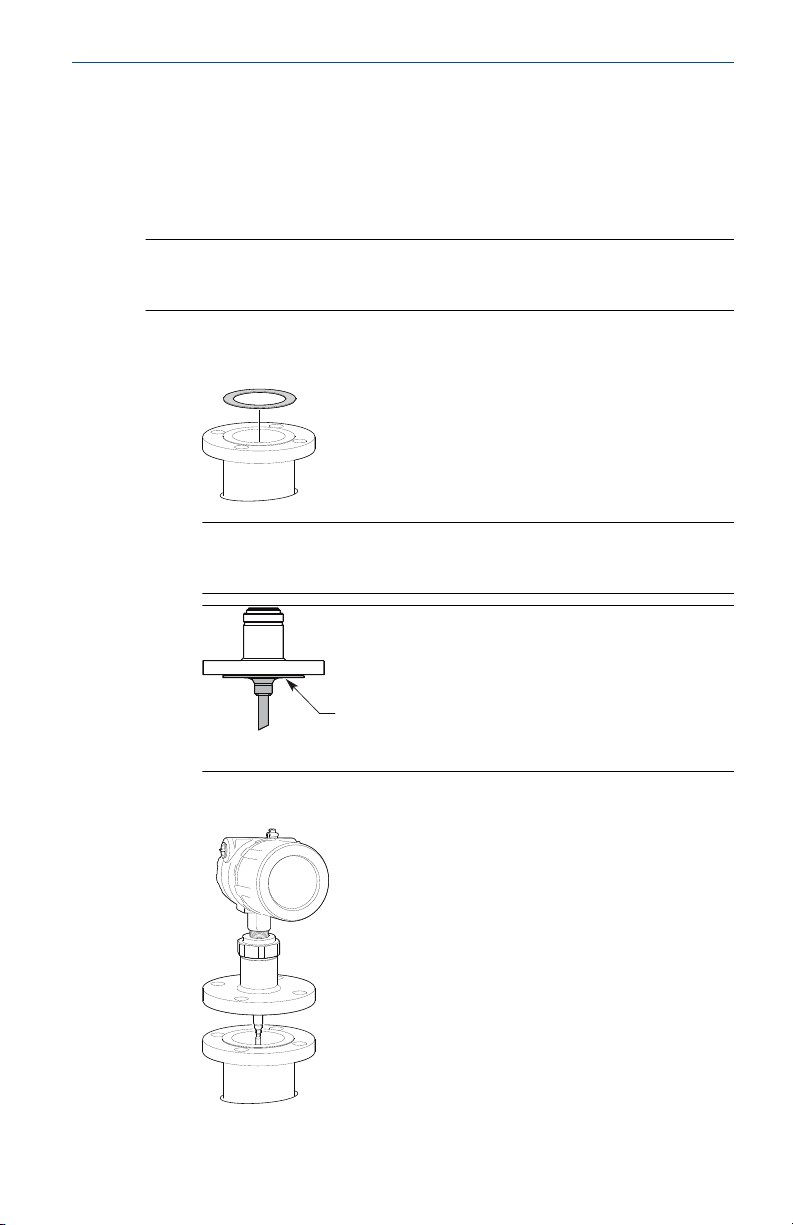

60 mm

Quick Start Guide April 2022

3. Tighten bolts and nuts with sufficient torque for the flange and

gasket choice.

4. Loosen the nut that connects the transmitter head to the probe

slightly.

5. Rotate the transmitter housing so the cable entries/display face the

desired direction.

8 Rosemount 3300 Level Transmitter

Page 9

60 mm

Torque 30 ft-lb (40 Nm)

April 2022 Quick Start Guide

6. Tighten the nut.

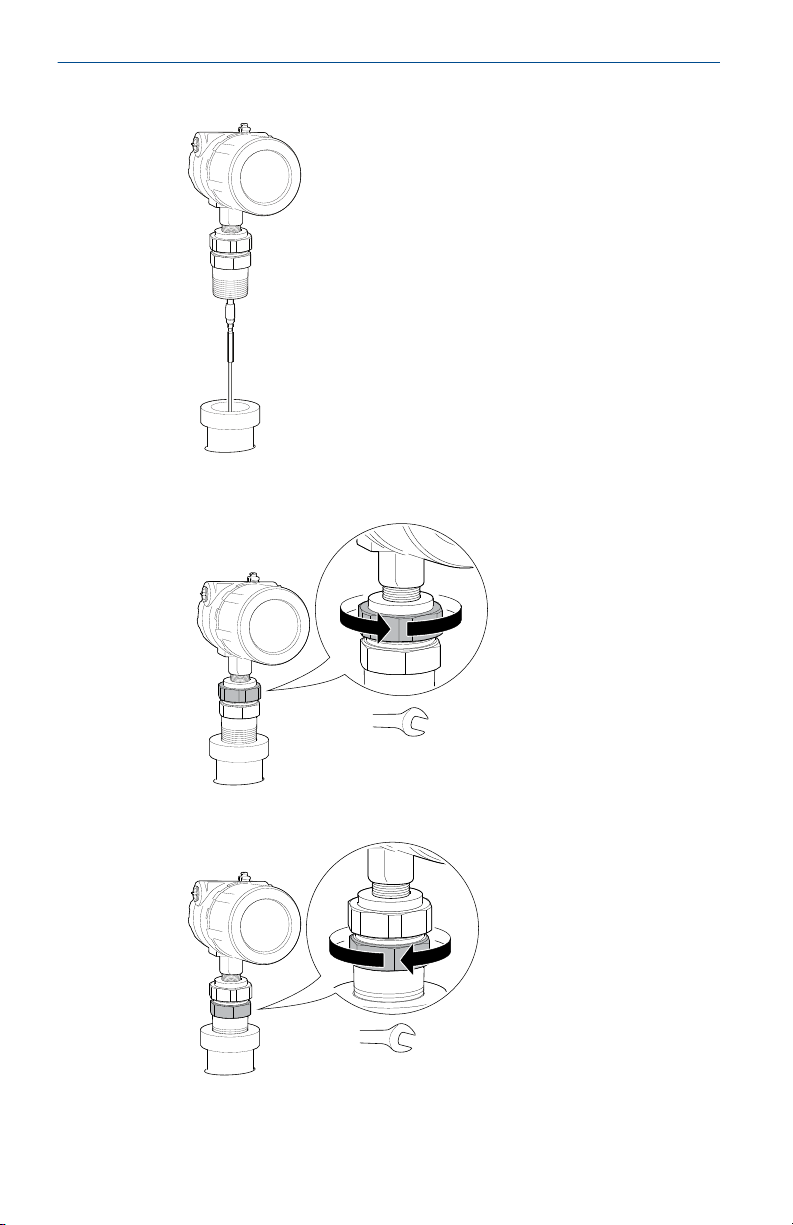

2.2 Threaded tank connection

Prerequisites

Note

PTFE covered probes must be handled carefully to prevent damage to the

coating.

Procedure

1. For adapters with BSPP (G) threads, place a suitable gasket on top of

the tank flange.

2. For adapters with NPT threads, use anti-seize paste or PTFE tape

according to your site procedures.

Quick Start Guide 9

Page 10

60 mm

52 mm / 60 mm

Quick Start Guide April 2022

3. Lower the transmitter and probe into the tank.

4. Loosen the nut that connects the transmitter head to the probe

slightly.

5. Screw the adapter into the process connection.

10 Rosemount 3300 Level Transmitter

Page 11

60 mm

Torque 30 ft-lb (40 Nm)

April 2022 Quick Start Guide

6. Rotate the transmitter housing so the cable entries/display face the

desired direction.

7. Tighten the nut.

Quick Start Guide 11

Page 12

Quick Start Guide April 2022

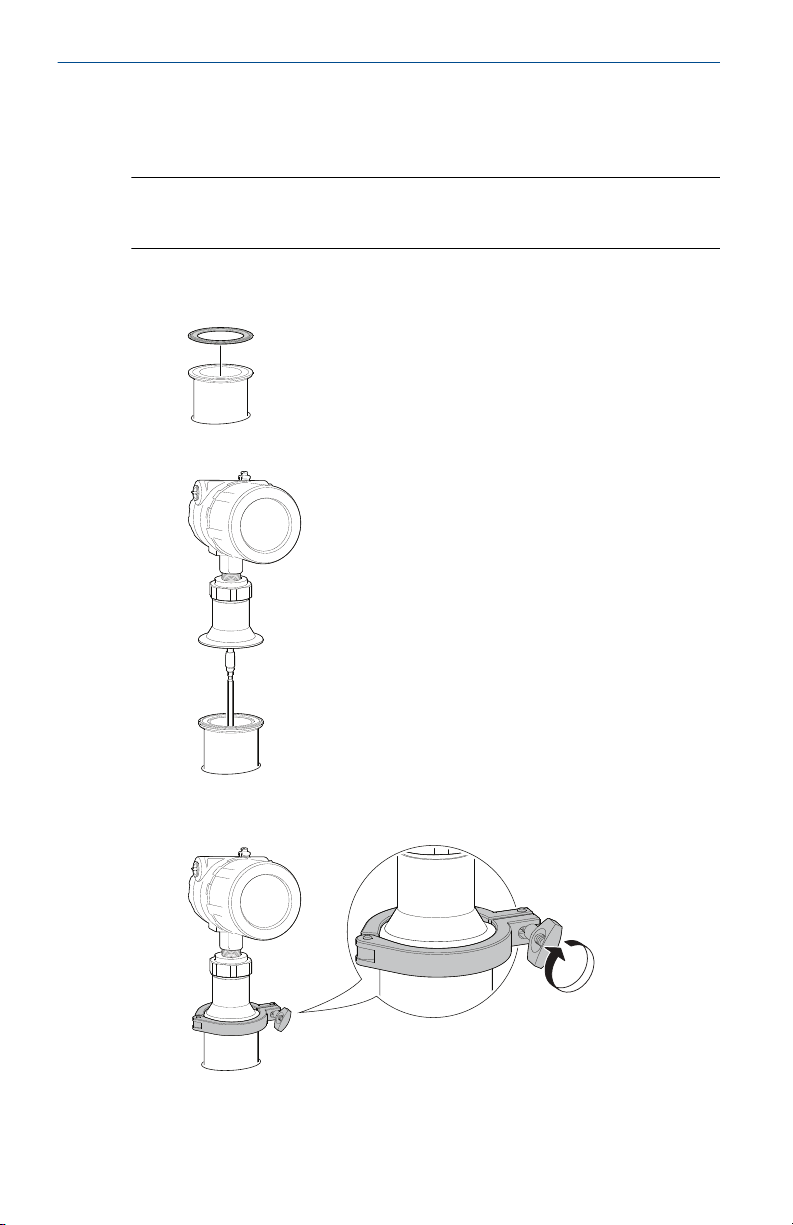

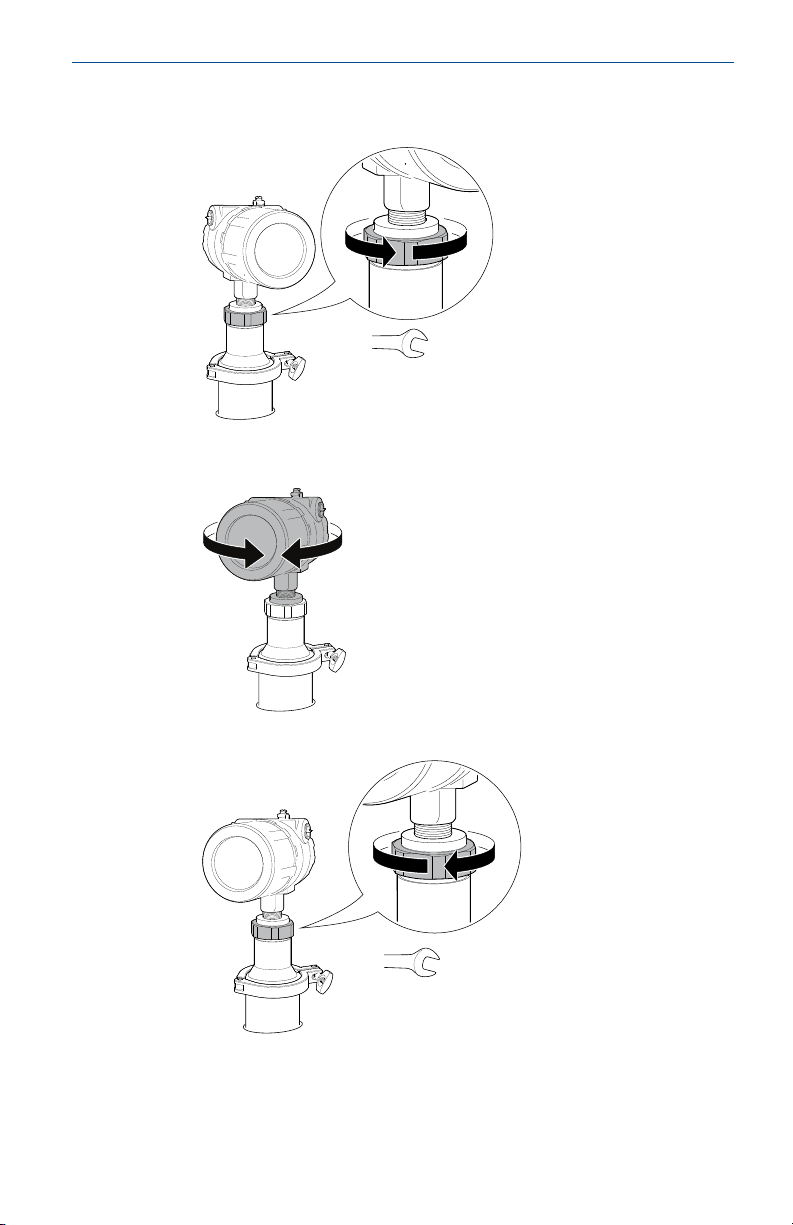

2.3 Tank connection with Tri-Clamp

Prerequisites

Note

PTFE covered probes must be handled carefully to prevent damage to the

coating.

Procedure

1. Place a suitable gasket on top of the tank flange.

2. Lower the transmitter and probe into the tank.

®

3. Tighten the clamp to the recommended torque (see the

manufacturer’s instruction manual).

12 Rosemount 3300 Level Transmitter

Page 13

60 mm

60 mm

Torque 30 ft-lb (40 Nm)

April 2022 Quick Start Guide

4. Loosen the nut that connects the transmitter head to the probe

slightly.

5. Rotate the transmitter housing so the cable entries/display face the

desired direction.

6. Tighten the nut.

Quick Start Guide 13

Page 14

4X

A

B

4X

Quick Start Guide April 2022

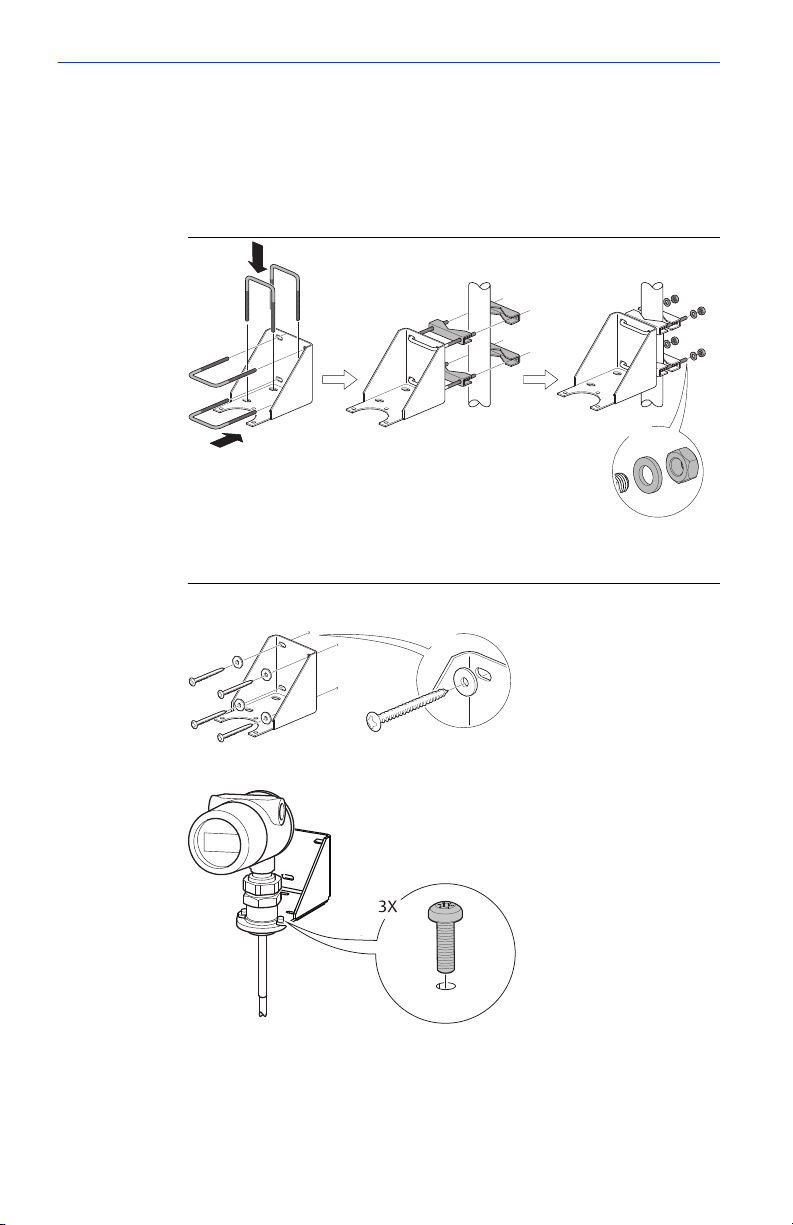

2.4 Bracket mounting

Procedure

1. Mount the bracket to the pipe/wall.

On pipe:

A. Horizontal pipe

B. Vertical pipe

On wall:

2. Mount the transmitter with probe to the bracket.

14 Rosemount 3300 Level Transmitter

Page 15

$

Torque 30 ft-lb (40 Nm)

55 mm

April 2022 Quick Start Guide

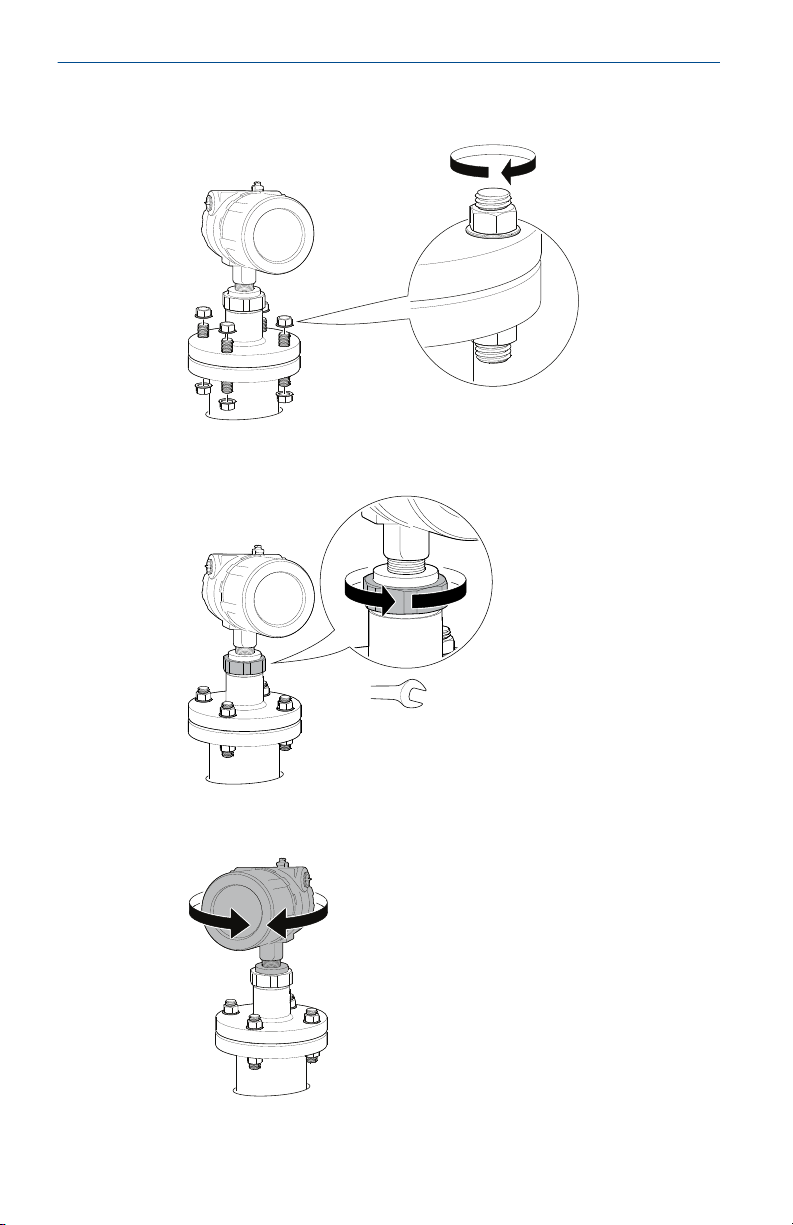

2.5 Install remote housing

Procedure

1. Carefully remove the transmitter.

2. Mount the probe on tank.

A. Gasket

3. Mount the remote connection on the probe.

Quick Start Guide 15

Page 16

4X

A

B

3X

Torque 30 ft-lb (40 Nm)

Quick Start Guide April 2022

4. Mount the bracket to the pipe.

A. Horizontal pipe

B. Vertical pipe

5. Fasten the housing support.

6. Mount the transmitter head.

16 Rosemount 3300 Level Transmitter

Page 17

April 2022 Quick Start Guide

3 Set jumpers and switches

Write Protection must be set after configuration (see Configure).

3.1 Set alarm and write protection on the circuit board

If alarm and security jumpers are not set, the transmitter operates with the

default alarm condition HIGH and Security OFF.

Procedure

1. Remove the cover on the circuit side (see label marked circuit side).

2. To set the 4-20 mA alarm output to LOW, move the alarm switch to

the LOW position.

3. To enable the security write protection feature, move the write

protect switch to the ON position.

4. Replace the cover and tighten securely.

Figure 3-1: Circuit Board

3.2 Set alarm and write protection on the LCD display

Prerequisites

To have the LCD display override the circuit board settings, the write

protection switch on the circuit board needs to be in the OFF position and

the alarm switch on the circuit board needs to be in the HIGH position.

Procedure

1. To set the 4-20 mA alarm output to LOW, place jumper between the

right and center hole position.

2. To enable the security write protection feature, place jumper

between the left and center hole position - ON.

Quick Start Guide 17

Page 18

Quick Start Guide April 2022

Figure 3-2: LCD Display

18 Rosemount 3300 Level Transmitter

Page 19

A

B

D

C

E

April 2022 Quick Start Guide

4 Connect wiring and power up

4.1 Power supply

For HART®, the input voltage is 11-42 V (11-30 V in IS applications, 16-42 V

in Explosion-proof / Flameproof applications). For Modbus®, the input

voltage is 8-30 V.

4.2 Cable selection

The transmitter requires shielded twisted pair wiring (18-12 AWG) suitable

for the supply voltage and, if applicable, approved for use in hazardous

areas.

4.3 Cable/conduit entries

The electronics housing has two entries for ½-14 NPT. Optional M20×1.5

and PG 13.5 adapters are also available. The connections are made in

accordance with local or plant electrical codes.

Make sure that unused ports are properly sealed to prevent moisture or

other contamination from entering the terminal block compartment of the

electronics housing.

Note

Remove any orange caps that may be attached. Use the enclosed metal plug

to seal the unused port.

Figure 4-1: Electronics Housing

A. Cable Entry: ½-14 NPT

Optional adapters: M20, PG13.5

B. Radar electronics

C. Dual compartment housing

D. Flanged process connections

E. Threaded process connections

Quick Start Guide 19

Page 20

A

B

C

D

G

H

E

F

Quick Start Guide April 2022

4.4 Wiring diagram

Figure 4-2: Non-Intrinsically Safe HART® Output

A. Rosemount 3300 Level Transmitter

B. Handheld communicator

C. Load resistance = 250 Ω

D. Power supply

E. HART modem

F. PC

G. Maximum voltage: Um = 250 V

H. HART: Un = 42.4 V

Note

Rosemount 3300 Level Transmitters with Flameproof/Explosion-proof HART

Output have a built-in barrier; no external barrier needed.

20 Rosemount 3300 Level Transmitter

Page 21

A

B

H

G

C

D

E

F

April 2022 Quick Start Guide

Figure 4-3: Intrinsically Safe HART Output

A. Rosemount 3300 Level Transmitter

B. Handheld communicator

C. RL= 250 Ω

D. Power supply

E. HART modem

F. PC

G. DCS

H. Approved IS barrier

IS Parameters: Ui = 30 V, Ii = 130 mA, Pi = 1 W, Li = Ci = 0

Quick Start Guide 21

Page 22

C

F G

B

A

D

E C

H

Quick Start Guide April 2022

Figure 4-4: Non-intrinsically Safe Modbus® Output

A. “A” line

B. “B” line

C. 120 Ω

D. Power supply

E. RS485 Bus

F. HART +

G. HART H. If the unit is the last transmitter on the bus, a 120 Ω termination resistor

is required.

Note

Rosemount 3300 Level Transmitters with Flameproof/Explosion-proof

Modbus Output have a built-in barrier; no external barrier needed.

22 Rosemount 3300 Level Transmitter

Page 23

C

B

A

C

B

A

April 2022 Quick Start Guide

4.5 Load limitations

For HART® communication, a minimum loop resistance of 250 Ω is required.

Maximum loop resistance is determined by the voltage level of the external

power supply, as given by the following diagrams:

Figure 4-5: Non-Hazardous Installations

A. Loop Resistance (Ohms)

B. External Power Supply Voltage (Vdc)

C. Operating region

Figure 4-6: Intrinsically Safe Installations

A. Loop Resistance (Ohms)

B. External Power Supply Voltage (Vdc)

C. Operating region

Quick Start Guide 23

Page 24

C

B

A

Quick Start Guide April 2022

Figure 4-7: Explosion-proof/Flameproof Installations

A. Loop Resistance (Ohms)

B. External Power Supply Voltage (Vdc)

C. Operating region

Note

For the Explosion-proof/Flameproof installations the diagram is only valid if

the HART load resistance is at the + side, otherwise the load resistance value

is limited to 300 Ω.

4.6 Connect the transmitter

Procedure

1. Make sure the housing is grounded according to Hazardous

Locations Certifications, national and local electrical codes.

Grounding is essential for Hazardous Location safety (even for

Flameproof/Explosion Proof versions). A ground cable with a crosssectional area of ≥ 4 mm² must be used.

2. Verify that the power supply is disconnected.

3. Remove the cover on the terminal side (see label marked field

terminals).

4. Pull the cable(s) through the cable gland/conduit.

For Explosion-proof / Flameproof installations, only use cable glands

or conduit entry devices certified Explosion-proof or Flameproof (Ex d

llC (gas) or Ex t lllC (dust)).

5. Connect the cable wires (see Wiring diagram).

6. If applicable, use the enclosed metal plug to seal any unused port.

7. Replace the cover and tighten.

24 Rosemount 3300 Level Transmitter

8. Tighten the cable gland.

9. Connect the power supply.

Page 25

April 2022 Quick Start Guide

5 Configure

If the transmitter is pre-configured at the factory, this section is only

necessary to change or verify the settings.

Configuration of the Rosemount 3300 Level Transmitter can be done either

with a handheld communicator, the AMS Device Manager, or Radar

Configuration Tools (RCT). If using the Radar Configuration Tools, a HART

modem is required.

5.1 Installing the Radar Configuration Tools (RCT) software

To install the RCT software:

Procedure

1. Insert the installation CD into your CD-ROM drive.

2. Follow the instructions.

Need help?

If the installation program does not automatically start, run

Setup.exe from the CD.

5.2 Starting RCT

®

Prerequisites

For optimum performance set COM Port Buffers to 1. Refer to the

Rosemount 3300 Level Transmitter Reference Manual for more instructions.

Procedure

Select Programs → Rosemount → RCT.

Need help?

The Help function of the RCT can be reached from the menu or by pressing

the F1 key.

Quick Start Guide 25

Page 26

Quick Start Guide April 2022

5.3 Configuration using the Wizard

Configuration of a Rosemount 3300 Level Transmitter can be done using the

installation Wizard for detailed guidance.

Procedure

1. Make sure that the Tools Bar is open (Project Bar is ticked within

View). Then select the Wizard icon or select the View → Wizard

menu option.

2. Select the Start button and follow the instructions.

5.4 Configuration using the Setup Function

If you are already familiar with the configuration procedure, or if you want to

change settings, you may use the setup function.

Procedure

1. Make sure that the Tools Bar is open (Project Bar is ticked within

View). Then select the Setup icon or select the View → Setup menu

option.

2. Select the appropriate tab:

• Info (information about the device)

• Basics

• Output

• Tank Config

• Volume (specification of tank geometry for volume calculations)

• LCD (display panel settings)

• Signal Quality Metrics (for activating/de-activating and display of

signal quality metrics, available with the DA1 option)

3. To load the parameters configured in the transmitter into the dialog

window, click the Receive Page button.

4. To load any parameter changes back to the transmitter, click the

Send Page button.

5.4.1 Setup - Basics

Units

Length, volume, and temperature units can be set. Units are used wherever

measurement and configuration data occur.

26 Rosemount 3300 Level Transmitter

Page 27

April 2022 Quick Start Guide

5.4.2 Setup - Output

Range values

The Lower Range value = 4 mA value

The Upper Range value = 20 mA value

The 4-20 mA range must not include the upper or lower Transition Zone.

(1)

Variable assignment

Rosemount 3301 available measuring parameters: Level, Distance to Level,

Total Volume. For fully immersed probe: Interface Level and Interface

Distance.

Rosemount 3302 available measuring parameters: Level, Distance to level,

Total Volume, Interface Level, Interface Distance, and Upper Product Layer

Thickness.

In the Primary Variable field, the measuring parameter is entered for the

analog signal.

More variables can be assigned if the superimposed digital HART® signal or a

HART Tri-loop™ is used.

(1)

See the Rosemount 3300 Level Transmitter Reference Manual.

Quick Start Guide 27

Page 28

Quick Start Guide April 2022

Modbus® setup

If the transmitter has the Modbus option, configuration of the

communication parameters can be set.

28 Rosemount 3300 Level Transmitter

Page 29

April 2022 Quick Start Guide

5.4.3 Setup - Tank Config

Geometry

See tank picture in window.

• Set Reference Gauge Height

• Set Upper Null Zone (if needed)

• Set Mounting Type

• Set Diameter (if Mounting Type is Nozzle or Pipe/Chamber)

• Set Nozzle Height (if Mounting Type is Nozzle)

Probe

• Set Probe Type (This parameter is pre-configured at factory.)

• Set Probe Length (This parameter is pre-configured at factory. The probe

length needs to be changed if the probe is cut in field.)

• Set Probe Angle

• If Remote Housing is mounted, set the Remote Housing length (setting

not available in DD/DTM™)

Miscellaneous settings

• Set Vapor Dielectric value (if needed)

• Set Upper Product Dielectric value (interface measurements only)

Quick Start Guide 29

Page 30

Quick Start Guide April 2022

5.5 Additional configuration to fine-tune performance

To fine-tune the transmitter’s performance, it is recommended the Trim

Near Zone function be executed after configuration is finished.

For detailed information on how to trim the near zone, see the Rosemount

3300 Level Transmitter Reference Manual.

30 Rosemount 3300 Level Transmitter

Page 31

A

B

April 2022 Quick Start Guide

6 Environmental conditions

6.1 Ambient temperature limits (for use in explosive atmospheres)

Explosion-proof/Flame-proof version: -58 °F (-50 °C) ≤ Ta ≤ +167 °F (+75 °C)

Intrinsically safe version: -58 °F (-50 °C) ≤ Ta ≤ +158 °F (+70 °C)

National deviations may apply, see Product certifications.

6.2 Process temperature restrictions

When the Rosemount 3300 is installed in high temperature applications,

consider the maximum ambient temperature. Tank insulation should not

exceed 4 in. (10 cm).

Figure 6-1 shows the maximum ambient temperature vs. process

temperature.

Figure 6-1: Ambient Temperature vs. Process Temperature

A. Ambient temperature °F (°C)

B. Process temperature °F (°C)

6.3

Quick Start Guide 31

Pressure limits

For pressure limits, see the Rosemount 3300 Level Transmitter Reference

Manual.

Page 32

Quick Start Guide April 2022

7 Product certifications

Rev 4.22

7.1 European directive information

A copy of the EU Declaration of Conformity can be found in the section EU

Declaration of Conformity. The most recent revision of the EU Declaration of

Conformity can be found at Emerson.com/Rosemount.

7.2 Ordinary location certification

As standard, the transmitter has been examined and tested to determine

that the design meets the basic electrical, mechanical, and fire protection

requirements by a nationally recognized test laboratory (NRTL) as accredited

by the Federal Occupational Safety and Health Administration (OSHA).

Pollution Degree: 2

Overvoltage Category: II

In Canada: The power to this equipment must be supplied by a source that is

categorized as “CLASS 2” and “SELV” as specified in the Canadian Electrical

Code, C22.1 and the National Electrical Code NFPA 70.

7.3 Installing equipment in North America

The US National Electrical Code® (NEC) and the Canadian Electrical Code

(CEC) permit the use of Division marked equipment in Zones and Zone

marked equipment in Divisions. The markings must be suitable for the area

classification, gas, and temperature class. This information is clearly defined

in the respective codes.

7.4

USA

7.4.1 E5 Explosionproof (XP), Dust-Ignitionproof (DIP)

Certificate

Standards

Markings

32 Rosemount 3300 Level Transmitter

FM 3013394

FM Class 3600 – 2011; FM Class 3610 – 2010; FM Class

3611 – 2004; FM Class 3615 – 2006; FM Class 3810 –

2005; ANSI/ISA 60079-0 – 2009; ANSI/ISA 60079-11 –

2009; ANSI/NEMA 250 – 1991; ANSI/IEC 60529 – 2004

XP CL I, DIV 1, GP B, C, D; DIP CLII/III, DIV 1, GP E, F, G; T5

Ta=85°C; Type 4X/IP66

Page 33

April 2022 Quick Start Guide

Specific Conditions for Safe Use (X):

1. Potential Electrostatic Charging Hazard – The enclosure contains

non-metallic material. To prevent the risk for electrostatic sparking

the plastic surface should only be cleaned with a damp cloth.

2. WARNING – The apparatus enclosure contains aluminum and is

considered to constitute a potential risk of ignition by impact or

friction. Care must be taken into account during installation and use

to prevent impact or friction.

7.4.2 I5 Intrinsic Safety (IS), Nonincendive (NI)

Certificate

Standards

FM 3013394

FM Class 3600 – 2011; FM Class 3610 – 2010; FM Class

3611 – 2004; FM Class 3615 – 2006; FM Class 3810 –

2005; ANSI/ISA 60079-0 – 2009; ANSI/ISA 60079-11 –

2009; ANSI/NEMA 250 – 1991; ANSI/IEC 60529 – 2004

Markings

IS CL I, DIV 1, GP A, B, C, D, E, F, G in accordance with

control drawing 9150077-944; IS (Entity) CL I, Zone 0,

AEx IA IIC T4 in accordance with control drawing

9150077-944, NI CL I, DIV 2, GP A, B, C, D, T4a Ta=70 °C;

Suitable for use in CL II/III DIV 2, GP A, B, C, D, T4a Ta=70

°C; Type 4X/IP66

Specific Conditions for Safe Use (X):

1. Potential Electrostatic Charging Hazard – The enclosure contains

non-metallic material. To prevent the risk for electrostatic sparking

the plastic surface should only be cleaned with a damp cloth.

2. WARNING – The apparatus enclosure contains aluminum and is

considered to constitute a potential risk of ignition by impact or

friction. Care must be taken into account during installation and use

to prevent impact or friction.

Entity parameters HART 30 V 130 mA 1 W 0 nF 0 mH

U

i

I

i

P

i

C

i

L

i

7.5 Canada

7.5.1 E6 Explosionproof, Dust-Ignitionproof

Certificate

Standards

Quick Start Guide 33

CSA02CA1250250X

CSA C22.2 No.0-M91, CSA C22.2 No.25-1966 (R2009),

CSA C22.2 No.30-M1986 (R2012), CSA C22.2 No.94M91, CSA C22.2 No.142-M1987, CAN/CSA-C22.2 No.

Page 34

Quick Start Guide April 2022

60079-0:15, CAN/CSA-C22.2 No. 60079-11:14, CSA

C22.2 No. 213-M1987 (R2013), CAN/CSA C22.2 No.

60529:05

Markings

CL I, Div.1, GP C, D;

CL II, Div.1 & 2, GP G & COAL DUST;

CL III, Div.1 T4, MAX. AMB. TEMP. +85°C

HAZ. LOC. CL I, Div.2, GP A, B, C, D

T4, MAX. AMB. TEMP. +70°C

In ambient temperatures above 60 °C, use wire or cable

rated for 90 °C minimum.

À des températures ambiantes supérieures à 60 °C,

utilisez un fil ou un câble conçu pour 90 °C minimum.

Specific Conditions for Safe Use (X):

1. The enclosure may be made of aluminum alloy and given a protective

polyurethane paint finish; however, care should be taken to protect it

from impact or abrasion if located in zone 0.

2. The probes may contain plastic materials greater than 4cm² or be

coated with plastic and these can present an electrostatic risk if

rubbed or placed in a fast moving air flow.

3. The probes may contain light alloys which can present a risk from

frictional ignitions. Care should be taken to protect them from

mechanical impact or friction during use or installation.

7.5.2 I6 Intrinsically Safe and Non-Incendive Systems

Certificate

Standards

Markings

34 Rosemount 3300 Level Transmitter

CSA02CA1250250X

CSA C22.2 No.0-M91, CSA C22.2 No.25-1966 (R2009),

CSA C22.2 No.30-M1986 (R2012), CSA C22.2 No.94M91, CSA C22.2 No.142-M1987, CAN/CSA-C22.2 No.

60079-0:15, CAN/CSA-C22.2 No. 60079-11:14, CSA

C22.2 No. 213-M1987 (R2013), CAN/CSA C22.2 No.

60529:05

CL I, DIV 1, GP A, B, C, D, T4 see installation drawing

9150077-945; Non-Incendive Class III, DIV 1, Haz-loc CL

I DIV 2, GP A, B, C, D, Maximum Ambient Temperature

+70 °C, T4, Type 4X/IP66

Page 35

April 2022 Quick Start Guide

Specific Conditions for Safe Use (X):

1. The equipment is not capable of withstanding the 500V test as

defined in EN 60079-11. This must be considered in any installation.

2. The enclosure may be made of aluminum alloy and given a protective

polyurethane paint finish; however, care should be taken to protect it

from impact or abrasion if located in zone 0.

3. The probes may contain plastic materials greater than 4cm² or be

coated with plastic and these can present an electrostatic risk if

rubbed or placed in a fast moving air flow.

4. The probes may contain light alloys which can present a risk from

frictional ignitions. Care should be taken to protect them from

mechanical impact or friction during use or installation.

7.6 Europe

7.6.1 E1 ATEX Flameproof

Certificate

Standards

KEMA 01ATEX2220X

EN IEC 60079-0:2018, EN 60079-1:2014, EN

60079-11:2012, EN 60079-26:2015, IEC

60079-26:2021, EN 60079-31:2014

Markings

II 1/2 G Ex ia IIC T6...T1 Ga / Ex db [ia Ga] IIC T6...T1

Gb

II 1/2 D Ex ia IIIC T

85 °C...T

200

450 °C Da / Ex tb [ia Da]

200

IIIC T85 °C...T450 °C Db

II 2 D Ex tb IIIC T85 °C...T135 °C Db

Ambient

temperature

range

-50 °C to +75 °C

-40 °C to +75 °C with a minimum process temperature

of -196 °C

Specific Conditions for Safe Use (X):

1. On application of the transmitter with plastic covered probes, in an

explosive gas atmosphere, precaution shall be taken to avoid danger

of ignition due to electrostatic charges on the probe.

2. On application of the transmitter in an explosive dust atmosphere,

the transmitter shall be installed in such a way that the risk from the

electrostatic discharges and propagating brush discharges caused by

rapid flow of dust at the label is avoided.

3. For probes and flanges containing light metals, an ignition hazard

due to impact or friction needs to be avoided according to EN

60079-0 clause 8.3, when used as EPL Ga/Gb equipment.

Quick Start Guide 35

Page 36

Quick Start Guide April 2022

4. Conditions which may adversely affect the material of the partition

wall shall be avoided, see instructions for details.

Temperature class /

Maximum surface

temperature

T6 / T 85 °C +75 °C +75 °C

T5 / T 100 °C + 90 °C +75 °C

T4 / T 135 °C +125 °C +75 °C

T3 / T 200 °C + 190 °C +75 °C

T2 / T 300 °C +285 °C +65 °C

T1 / T 450 °C + 400 °C +55 °C

7.6.2 I1 ATEX Intrinsic Safety

Certificate

Standards

Markings

Specific Conditions for Safe Use (X):

1. The equipment is not capable of withstanding the 500V test as

defined in EN60079-11. This must be considered in any installation.

2. The enclosure is made of aluminium alloy and given a protective

polyurethane paint finish; however, care should be taken to protect it

from impact or abrasion if located in zone 0.

BAS02ATEX1163X

EN IEC 60079-0:2018, EN 60079-11:2012

II 1G Ex ia IIC T4 Ga (-50°C ≤ Ta ≤ +70°C)

Maximum process

temperature

Maximum ambient

temperature

3. The probes may contain plastic materials greater than 4cm² or be

coated with plastic and these can present an electrostatic risk if

rubbed or placed in a fast moving air flow.

4. The probes may contain light alloys which can present a risk from

frictional ignitions. Care should be taken to protect them from

mechanical impact during use or installation.

Entity parameters HART 30 V 130 mA 1 W 0 nF 0 mH

36 Rosemount 3300 Level Transmitter

U

i

I

i

P

i

C

i

L

i

Page 37

April 2022 Quick Start Guide

7.7 International

7.7.1 E7 IECEx Flameproof

Certificate

Standards

IECEx DEK 12.0015X

IEC 60079-0:2017, IEC 60079-1:2014, IEC

60079-11:2011; IEC 60079-26:2021, IEC

60079-31:2013

Markings

Ex ia IIC T6…T1 Ga / Ex db [ia Ga] IIC T6…T1 Gb

Ex ia IIIC T

85 °C…T

200

450 °C Da / Ex tb [ia Da] IIIC

200

T85 °C…T450 °C Db

Ex tb IIIC T85 °C…T135 °C Db

Ambient

temperature

range

-50 °C to +75 °C

-40 ºC to +75 ºC with a minimum process temperature

of -196 °C

Specific Conditions for Safe Use (X):

1. On application of the transmitter with plastic covered probes, in an

explosive gas atmosphere, precaution shall be taken to avoid danger

of ignition due to electrostatic charges on the probe.

2. On application of the transmitter in an explosive dust atmosphere,

the transmitter shall be installed in such a way that the risk from

electrostatic discharges and propagating brush discharges caused by

rapid flow of dust at the label is avoided.

3. For probes and flanges containing light metals, an ignition hazard

due to impact or friction needs to be avoided according to IEC

60079-0 clause 8.3, when used as EPL Ga/Gb equipment.

4. Conditions which may adversely affect the material of the partition

wall shall be avoided, see instructions for details.

Temperature class /

Maximum surface

temperature

T6 / T 85 °C +75 °C +75 °C

T5 / T 100 °C + 90 °C +75 °C

T4 / T 135 °C +125 °C +75 °C

T3 / T 200 °C + 190 °C +75 °C

T2 / T 300 °C +285 °C +65 °C

T1 / T 450 °C + 400 °C +55 °C

Quick Start Guide 37

Maximum process

temperature

Maximum ambient

temperature

Page 38

Quick Start Guide April 2022

7.7.2 I7 IECEx Intrinsic Safety

Certificate

Standards

Markings

IECEx BAS 12.0062X

IEC 60079-0:2017, IEC 60079-11:2011

Ex ia IIC T4 Ga (-50°C ≤ Ta ≤ +70°C)

Specific Conditions for Safe Use (X):

1. The equipment is not capable of withstanding the 500V test as

defined in EN60079-11. This must be considered in any installation.

2. The enclosure is made of aluminium alloy and given a protective

polyurethane paint finish; however, care should be taken to protect it

from impact or abrasion if located in zone 0.

3. The probes may contain plastic materials greater than 4cm² or be

coated with plastic and these can present an electrostatic risk if

rubbed or placed in a fast moving air flow.

4. The probes may contain light alloys which can present a risk from

frictional ignitions. Care should be taken to protect them from

mechanical impact during use or installation.

U

Entity parameters 30 V 130 mA 1 W 0 nF 0 mH

7.8 Brazil

7.8.1 E2 INMETRO Flameproof

i

I

i

P

i

C

i

L

i

Certificate

Standards

UL-BR-17.0192X

ABNT NBR IEC 60079-0:2013, ABNT NBR IEC

60079-1:2016, ABNT NBR IEC 60079-11:2013, ABNT

NBR IEC 60079-26:2016, ABNT NBR IEC 60079-31:2014

Markings

Ex db [ia Ga] IIC T6...T1 Ga/Gb

Ex tb [ia Da] IIIC T85 °C...T450 °C Da/Db

Ex tb IIIC T85 °C...T135 °C -/Db

Specific Conditions for Safe Use (X):

1. See certificate for Specific Conditions.

38 Rosemount 3300 Level Transmitter

Page 39

April 2022 Quick Start Guide

7.8.2 I2 INMETRO Intrinsic Safety

Certificate

Standards

UL-BR-17.0198X

ABNT NBR IEC 60079-0:2008 + Errata 1:2011, ABNT NBR

IEC 60079-11:2009

Markings

Ex ia IIC T4 Ga (- 50°C ≤ Tamb ≤ + 70°C)

Specific Conditions for Safe Use (X):

1. See certificate for Specific Conditions.

U

Entity parameters 30 V 130 mA 1 W 0 nF 0 mH

7.9 China

7.9.1 E3 China Flameproof

Certificate

Standards

Markings

GYJ21.1303X

GB 3836.1-2010, GB 3836.2-2010, GB 3836.4-2010, GB

3836-20-2010, GB 12476.1-2013, GB 12476.4-2010,

GB 12476.5-2013

Ex ia IIC T6~T1 Ga/Ex d [ia Ga] IIC T6~T1 Gb

Ex iaD 20 T

Ex tD [iaD 20] A21 IP6X T85°C~450°C

Ex tD A21 IP6X T85°C~T135°C

i

85°C~T

200

I

i

200

P

i

450°C/

C

i

L

i

Specific Conditions for Safe Use (X):

1. See certificate for Specific Conditions.

7.9.2 I3 China Intrinsic Safety

Certificate

Standards

Markings

Specific Conditions for Safe Use (X):

1. See certificate for Specific Conditions.

Entity parameters 30 V 130 mA 1 W 0 nF 0 mH

Quick Start Guide 39

GYJ21.1302X

GB 3836.1-2010, GB 3836.4-2010, GB 3836.20-2010

Ex ia IIC T4 (-50°C ≤ Ta ≤ +70°C),

U

i

I

i

P

i

C

i

L

i

Page 40

Quick Start Guide April 2022

7.10 Technical Regulations Customs Union (EAC)

TR CU 020/2011 “Electromagnetic Compatibility of Technical Products”

TR CU 032/2013 “On safety of equipment and vessels under pressure”

Certificate

ЕАЭC RU С-US.АД07.В.00770/19

TR CU 012/2011 “On safety of equipment intended for use in explosive

atmospheres”

7.10.1 EM Technical Regulations Customs Union (EAC) Flameproof

Certificate

Markings

Specific Conditions for Safe Use (X):

1. See certificate for Specific Conditions.

ЕАЭС RU C-SE.AA87.B.00620-21

Ga/Gb Ex d [ia Ga] IIC T6...T1 X

Ex tb [ia Da] IIIC T85 °C…T450 °C Db X

Ex tb IIIC T85 °C…T135 °C Db X

7.10.2 IM Technical Regulations Customs Union (EAC) Intrinsic Safety

Certificate

Markings

Specific Conditions for Safe Use (X):

1. See certificate for Specific Conditions.

Entity parameters 30 V 130 mA 1 W 0 nF 0 mH

ЕАЭС RU C-SE.AA87.B.00620-21

0Ex ia IIC T4 Ga X -50°C ≤ Ta ≤ +70°C

U

i

I

i

P

i

C

i

L

i

7.11 Japan

7.11.1 E4 Japan Flameproof

Certificate

Markings

Specific Conditions for Safe Use (X):

1. See certificate for Specific Conditions.

40 Rosemount 3300 Level Transmitter

CML 20JPN1218X

Ex db [ia Ga] IIC T6…T1 Ga/Gb

Page 41

April 2022 Quick Start Guide

7.12 India

7.12.1 Flameproof

Certificate

Markings

Specific Conditions for Safe Use (X):

1. See certificate for Specific Conditions.

7.12.2 Intrinsically safe

Certificate

Markings

Specific Conditions for Safe Use (X):

1. See certificate for Specific Conditions.

7.12.3 Intrinsically safe

Certificate

Markings

Specific Conditions for Safe Use (X):

1. See certificate for Specific Conditions.

7.13

United Arab Emirates

7.13.1 Flame-proof

P119297/1

Ex d {ia Ga} IIC T6…T1 Ga/Gb

P428257/1

Ex ia IIC T4 Ga

P428258/1

II 1G Ex ia IIC T4 Ga

Certificate

Markings

20-11-28736/Q20-11-001012

Same as IECEx (E7)

7.13.2 Intrinsic Safety

Certificate

Markings

20-11-28736/Q20-11-001012

Same as IECEx (I7)

7.14 Combinations

KB

Quick Start Guide 41

Combination of E5 and E6

Page 42

Quick Start Guide April 2022

7.15 Additional certifications

7.15.1 U1 Overfill prevention

Certificate

Application

Z-65.16-416

TÜV tested and approved by DIBt for overfill prevention

according to the German WHG regulations.

7.16 Pattern approval

GOST Belarus

Certificate

GOST Kazakhstan

Certificate

GOST Russia

Certificate

GOST Uzbekistan

Certificate

China Pattern Approval

Certificate

RB-03 07 2765 10

KZ.02.02.03473-2013

SE.C.29.010.A

02.2977-14

2009-L256

7.17 Conduit plugs and adapters

IECEx Flameproof and Increased Safety

Certificate

Standards

Markings

ATEX Flameproof and Increased Safety

Certificate

Standards

Markings

42 Rosemount 3300 Level Transmitter

IECEX UL 18.0016X

IEC60079-0:2011, IEC60079-1:2014, IEC60079-7:2015,

IEC60079-31:2013

Ex de eb IIC Gb;

Ex ta IIIC Da

DEMKO 18 ATEX 1986X

EN60079-0:2012+A11:2013, EN60079-1:2014,

EN60079-7:2015, EN60079-31:2014

II 2 G Ex de IIC Gb,

Page 43

April 2022 Quick Start Guide

II 1 D Ex ta IIIC Da

Table 7-1: Conduit Plug Thread Sizes

Thread Identification mark

M20 x 1.5 M20

½ - 14 NPT ½ NPT

Table 7-2: Thread Adapter Thread Sizes

Male thread Identification mark

M20 x 1.5 – 6g M20

½- 14 NPT ½ - 14 NPT

¾ - 14 NPT ¾- 14 NPT

Female thread Identification mark

M20 x 1.5 – 6H M20

½ - 14 NPT ½ - 14 NPT

G1/2 G1/2

Specific Conditions for Safe Use (X):

1. The Blanking Elements shall not be used with an adapter.

2. Only one adapter shall be used with any single cable entry on the

associated equipment.

3. It is the end user’s responsibility to ensure that the ingress protection

rating is maintained at the interface of the equipment and the

blanking element/adapter.

4. Suitability of the temperature of the devices is to be determined

during end-use with suitably rated equipment.

Quick Start Guide 43

Page 44

Quick Start Guide April 2022

7.18 Installation drawings

Figure 7-1: 9150077-944 - System Control Drawing

44 Rosemount 3300 Level Transmitter

Page 45

April 2022 Quick Start Guide

Figure 7-2: 9150077-945 Installation Drawing

Quick Start Guide 45

Page 46

Quick Start Guide April 2022

7.19 EU Declaration of Conformity

Figure 7-3: EU Declaration of Conformity

46 Rosemount 3300 Level Transmitter

Page 47

April 2022 Quick Start Guide

Quick Start Guide 47

Page 48

Quick Start Guide April 2022

48 Rosemount 3300 Level Transmitter

Page 49

List of Model Parts with China RoHS Concentration above MCVs

含有

China RoHS

管控物峐超彯㚨⣏㳻⹎旸ῤ的部件型号列表

Part Name

部件名称

Hazardous Substances / 有害物峐

Lead

摭

(Pb)

Mercury

汞

(Hg)

Cadmium

擱

(Cd)

Hexavalent

Chromium

භ௴撔

(Cr +6)

Polybrominated

biphenyls

ከ⁏俼劗

(PBB)

Polybrominated

diphenyl ethers

ከ⁏俼劗慂(PBDE)

Electronics

Assembly

䓝⫸乬ẞ

X O O O O O

Housing

Assembly

壳体乬ẞ

O O O O O O

This table is proposed in accordance with the provision of SJ/T11364

本表格系依据

SJ/T11364

的奬⭂侴⇞ἄį

O: Indicate that said hazardous substance in all of the homogeneous materials for this part is below the limit requirement

of GB/T 26572.

O:

意宍悐ẞ䘬㚱⛯峐㛸㕁宍㚱⭛䈑峐䘬⏓慷⛯ỶḶ

GB/T 26572

所奬⭂䘬旸慷天㯪į

X: Indicate that said hazardous substance contained in at least one of the homogeneous materials used for this part is

above the limit requirement of GB/T 26572.

X:

意⛐宍悐ẞἧ䓐䘬㚱⛯峐㛸㕁慴炻军⮹㚱ᶨ䰣⛯峐㛸㕁宍㚱⭛䈑峐䘬⏓慷檀Ḷ

GB/T 26572

所奬⭂䘬旸慷天㯪į

April 2022 Quick Start Guide

7.20 China RoHS

Quick Start Guide 49

Page 50

Quick Start Guide April 2022

50 Rosemount 3300 Level Transmitter

Page 51

April 2022 Quick Start Guide

Quick Start Guide 51

Page 52

*00825-0100-4811*

Quick Start Guide

00825-0100-4811, Rev. JF

April 2022

For more information:

©

2022 Emerson. All rights reserved.

Emerson Terms and Conditions of Sale are

available upon request. The Emerson logo

is a trademark and service mark of

Emerson Electric Co. Rosemount is a mark

of one of the Emerson family of

companies. All other marks are the

property of their respective owners.

Emerson.com

Loading...

Loading...