Page 1

Quick Start Guide

00825-0300-4530, Rev AC

Rosemount® Guided Wave Radar

Mounting Instructions for Segmented Probe

August 2015

Page 2

Quick Start Guide

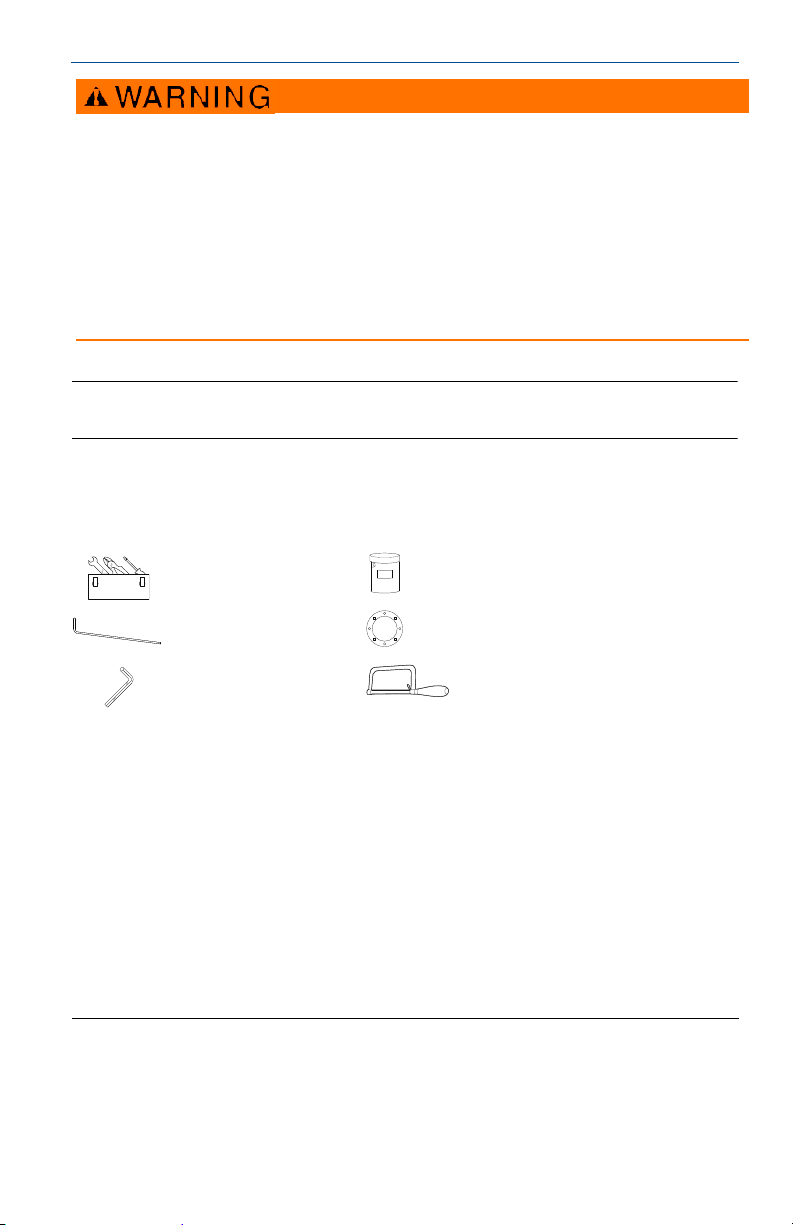

Standard tools, e.g.

screwdriver, wrench, pliers

Anti-seize paste or PTFE tape

(for NPT threaded connection)

Two support tools

(supplied)

Gasket

(for BSP/G threaded, flanged, and Tri Clamp

conne ctions)

Allen key

(supplied)

Saw

Failure to follow safe installation and service guidelines could result in serious injury.

Make sure only qualified personnel perform installation or service.

Use the equipment only as specified in t he relevant Quick Start Guide and Reference Manual:

Rosemount 3300 Series Reference Manual (document number 00809-0100-4811)

Rosemount 3308 Series Wireless Guided Wave Radar, 3308A Reference Manual (document number

00809-0100-4308)

Rosemount 5300 Series Reference Manual (document number 00809-0100-4530)

Rosemount 3300 Series Quick Start Guide (document number 00825-0100-4811)

Rosemount 3308 Series Wireless Guided Wave Radar, 3308A Quick Start Guides (document numbers

00825-0100-4308 and 00825-0300-4308)

Rosemount 5300 Series Quick Start Guide (document number 00825-0100-4530)

Failure to do so may impair the protection provided by the equipment.

August 2015

Note

The same instructions apply for the Rosemount 3300, 3308, and 5300 Series Transmitters.

Required equipment

Contents

Required equipment . . . . . . . . . . . . . . . . . . . . . . 2

Segmented probe parts . . . . . . . . . . . . . . . . . . . 3

Verify probe length . . . . . . . . . . . . . . . . . . . . . . . 4

2

Assemble the segmented probe . . . . . . . . . . . . 5

Adjust the probe length . . . . . . . . . . . . . . . . . . 17

Page 3

August 2015

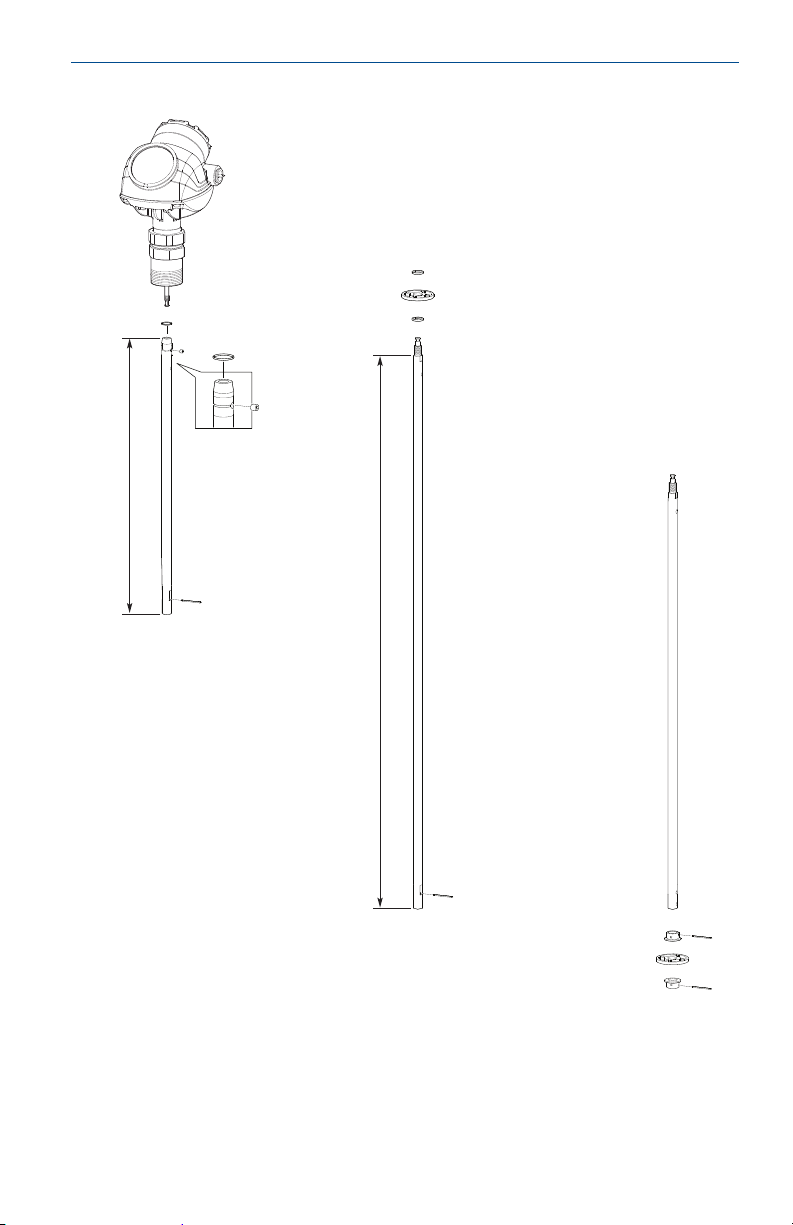

A

B

D

G

E

C

I

J

D

E

F

H

I

D

D

31.5

(800)

Dimensions are in inches (mm).

15.2

(385)

Segmented probe parts

Quick Start Guide

A. Safety ring F. Centering disc in PTFE (optional)

B. Screw G. Middle segment

C. To p se gme nt H. Bottom segment (length varies depending on total probe length)

D. Split pin I. Bushing (for the centering disc at the probe end)

E. PTFE washer (optional) J. Bottom centering disc in PTFE or Stainless Steel (optional)

3

Page 4

Quick Start Guide

L =

SN:

Probe length

Probe segments box

Verify probe length

Segmented probe ordered with model code 4S

Before installation, verify the probe length (L) on the label. If the probe length

needs to be adjusted, see “Adjust the probe length” on page 17.

Segmented probe ordered as spare part kit

Before installation, the number of segments that add up to the desired probe

length must be determined. Also, the bottom segment may need to be

shortened. See “Adjust the probe length” on page 17.

August 2015

4

Page 5

August 2015

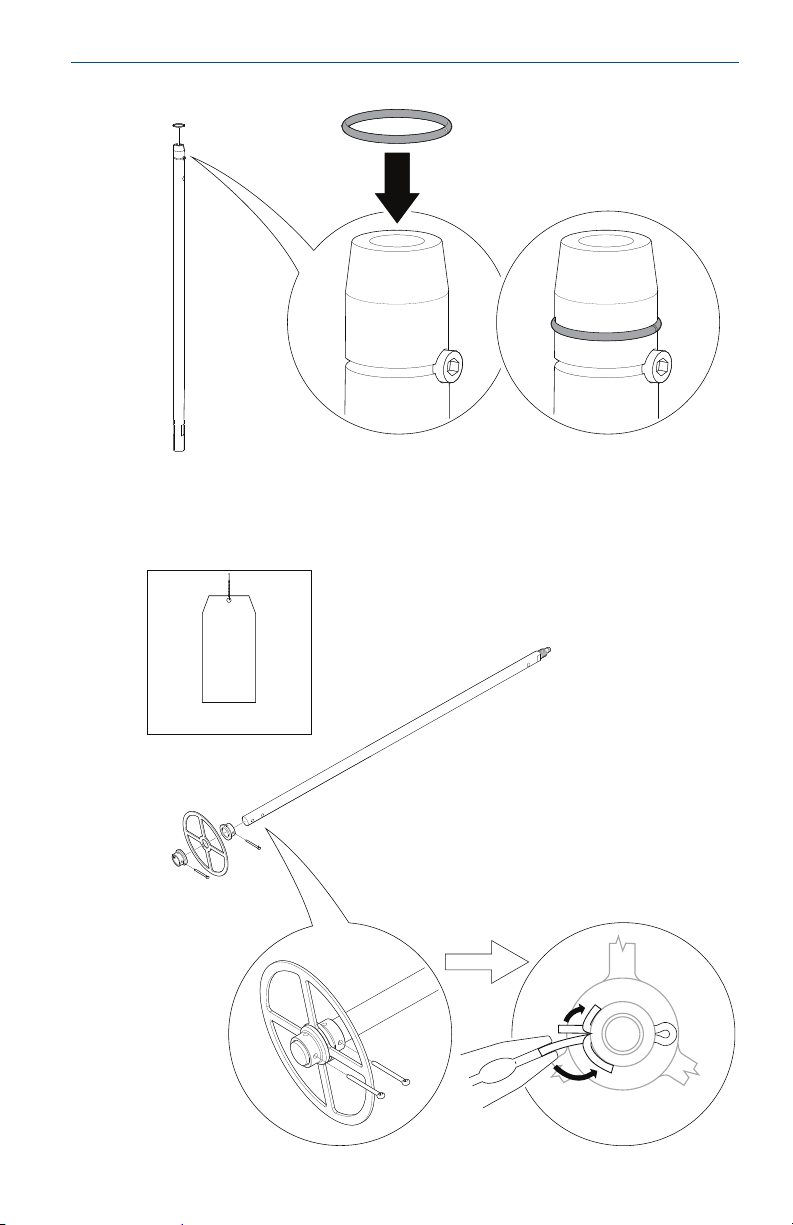

Top Segment

~

2 turns

Quick Start Guide

Assemble the segmented probe

Note

If there is enough space beside the tank, the probe can be assembled before inserting it into the

tank.

1. Insert the stop screw to the top segment. Tighten approximately 2 turns.

5

Page 6

Quick Start Guide

Bottom Segment

2. Pre-assemble the safety ring.

3. Optional: If ordered, mount the centering disc on the bottom segment of the

probe.

August 2015

6

Page 7

August 2015

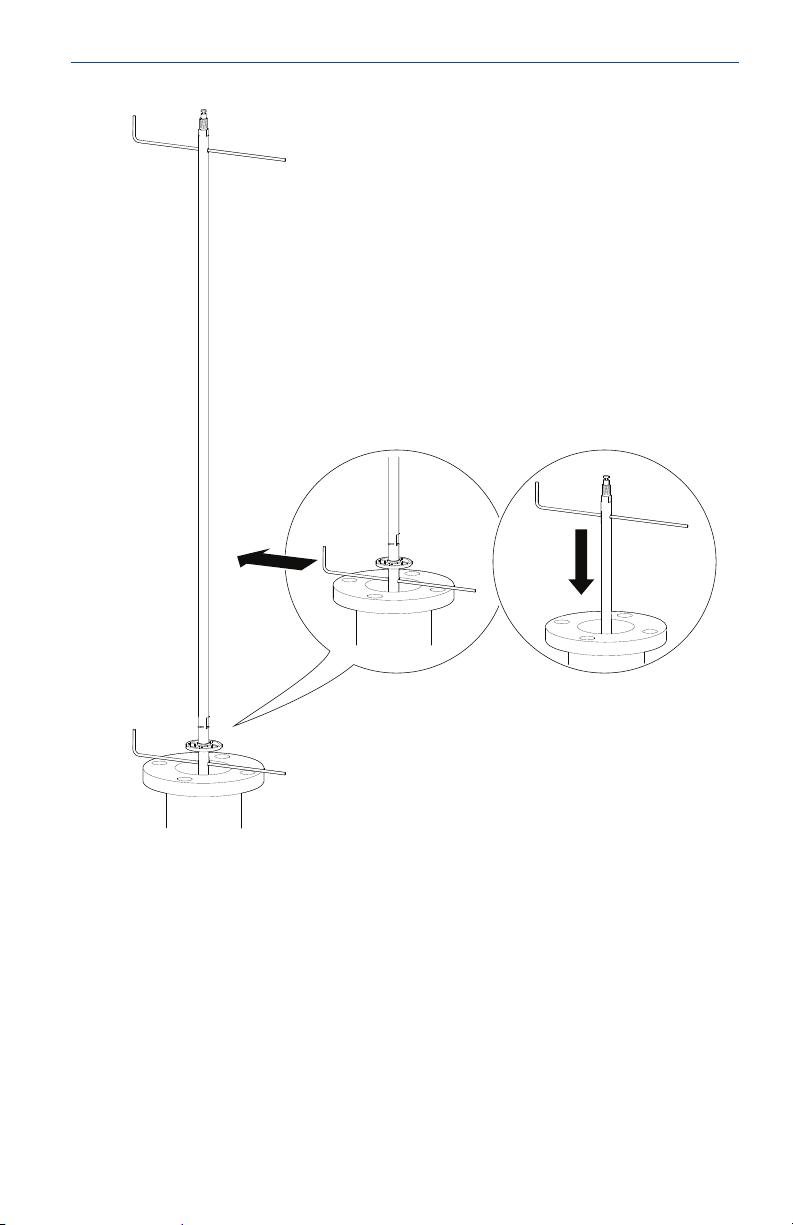

Bottom Segment

Note

Maximum five pcs/probe

Minimum two segments between each centering disc

4. Insert the support tool.

Quick Start Guide

5. Optional: If ordered, mount the centering disc.

7

Page 8

Quick Start Guide

Hand tighten

6. Mount a middle segment.

August 2015

8

Page 9

August 2015

7. Secure the split pin.

Quick Start Guide

9

Page 10

Quick Start Guide

8. Insert the second support tool.

August 2015

10

Page 11

August 2015

9. Remove the first support tool and lower the probe into the tank.

Quick Start Guide

10. Repeat steps 5 to 9 until all segments are mounted. Make sure to finish with

the top segment of the probe.

11

Page 12

Quick Start Guide

Use anti-seize paste or PTFE tape

according to your site procedures.

11. Seal and protect threads.

Only for NPT threaded tank connection.

August 2015

12

Page 13

August 2015

Flange / Tri Clamp Threaded

Gasket

Sealant on

threads (NPT)

or

Gasket (BSP/G)

Note

For safety reasons, at least two people are needed when mounting the device.

Make sure to hold the device above the tank. High loads can break the support tool.

12. Attach the probe to the device.

Quick Start Guide

13

Page 14

Quick Start Guide

13. Tighten the stop screw and slide the safety ring into the groove.

August 2015

14. Remove the support tool.

14

Page 15

August 2015

Flange ThreadedTri Clamp

15. Mount the device on the tank.

Quick Start Guide

16. Rotate the housing to the desired direction.

15

Page 16

Quick Start Guide

17. Tighten the nut. The torque must be 30 Lbft (40 Nm).

18. For the 3300 and 5300, connect the wiring.

For further instructions, see the Rosemount 3300 Series (document number

00825-0100-4811) and the Rosemount 5300 Series (document number

00825-0100-4530) Quick Start Guides.

August 2015

19. For the 3308A, insert power module and connect to device.

For further instructions, see the Rosemount 3308 Series Wireless Guided

Wave Radar, 3308A Quick Start Guides (document numbers

00825-0100-4308 and 00825-0300-4308).

16

Page 17

August 2015

L, desired probe length:

L

n, number of middle segments:

n

Y, length of bottom segment:

Y

Y < 0.4 in. (10 mm)

Y ≥ 0.4 in. (10 mm)

Y = 31.5 in. (800 mm)

Quick Start Guide

Adjust the probe length

1. Determine L, the desired probe length.

2. Determine n, the number of middle segments needed for the desired probe

length. See Tab l e 1 and Table 2 on page 19.

3. Calculate Y, the length of the bottom segment. See Tab l e 1 and Tab le 2 on

page 19.

4. Continue as follows:

Length of bottom segment (Y) Action

• Continue with step (7).

Do not use the bottom segment.

• Continue with step (5) and cut the

bottom segment.

1. Add one extra middle segment to

the calculated n.

2. Continue with step (7).

17

Page 18

Quick Start Guide

12

3

4

5

6

7

8

0

12

3

0

Y

Note

Make sure the bottom segment is fixed while cutting.

Y

Drilling fixture

5. Mark where to cut the bottom segment.

6. Cut the bottom segment at the mark.

August 2015

7. Optional: If a bottom centering disc is ordered, then drill two holes on the

bottom segment using the drilling fixture.

18

Page 19

August 2015

Quick Start Guide

Table 1. Determination of Probe Segments for Standard Seal

Desired probe length (L)

in. mm in. mm

15.8 ≤ L ≤ 47.2 400 ≤ L ≤ 1200 0 pc Y = L -15.8 Y = L - 400

47.2 < L ≤ 78.7 1200 < L ≤ 2000 1 pc Y = L - 47.2 Y = L - 1200

78.7 < L ≤ 110.2 2000 < L ≤ 2800 2 pcs Y = L - 78.7 Y = L - 2000

110.2 < L ≤ 141.7 2800 < L ≤ 3600 3 pcs Y = L - 110.2 Y = L - 2800

141.7 < L ≤ 173.2 3600 < L ≤ 4400 4 pcs Y = L - 141.7 Y = L - 3600

173.2 < L ≤ 204.7 4400 < L ≤ 5200 5 pcs Y = L - 173.2 Y = L - 4400

204.7 < L ≤ 236.2 5200 < L ≤ 6000 6 pcs Y = L - 204.7 Y = L - 5200

236.2 < L ≤ 267.7 6000 < L ≤ 6800 7 pcs Y = L - 236.2 Y = L - 6000

267.7 < L ≤ 299.2 6800 < L ≤ 7600 8 pcs Y = L - 267.7 Y = L - 6800

299.2 < L ≤ 330.7 7600 < L ≤ 8400 9 pcs Y = L - 299.2 Y = L - 7600

330.7 < L ≤ 362.2 8400 < L ≤ 9200 10 pcs Y = L - 330.7 Y = L - 8400

362.2 < L ≤ 393.7 9200 < L ≤ 10000 11 pcs Y = L - 362.2 Y = L - 9200

1. Maximum probe length is 19 ft 8 in. (6 m) for the 3300 Series and 32 ft 9 in. (10 m) for the 3308 and 5300

Series.

(1)

Number of middle

segments (n)

Length of bottom segment (Y)

Table 2. Determination of Probe Segments for HTHP/HP/C Seal

Desired probe length (L)

in. mm in. mm

17.3 ≤ L ≤ 48.8 440 ≤ L ≤ 1240 0 pc Y = L - 17.3 Y = L - 440

48.8 < L ≤ 80.3 1240 < L ≤ 2040 1 pc Y = L - 48.8 Y = L - 1240

80.3 < L ≤ 111.8 2040 < L ≤ 2840 2 pcs Y = L - 80.3 Y = L - 2040

111.8 < L ≤ 143.3 2840 < L ≤ 3640 3 pcs Y = L - 111.8 Y = L - 2840

143.3 < L ≤ 174.8 3640 < L ≤ 4440 4 pcs Y = L - 143.3 Y = L - 3640

174.8 < L ≤ 206.3 4440 < L ≤ 5240 5 pcs Y = L - 174.8 Y = L - 4440

206.3 < L ≤ 237.8 5240 < L ≤ 6040 6 pcs Y = L - 206.3 Y = L - 5240

237.8 < L ≤ 269.3 6040 < L ≤ 6840 7 pcs Y = L - 237.8 Y = L - 6040

269.3 < L ≤ 300.8 6840 < L ≤ 7640 8 pcs Y = L - 269.3 Y = L - 6840

300.8 < L ≤ 332.3 7640 < L ≤ 8440 9 pcs Y = L - 300.8 Y = L - 7640

332.3 < L ≤ 363.8 8440 < L ≤ 9240 10 pcs Y = L - 332.3 Y = L - 8440

363.8 < L ≤ 393.7 9240 < L ≤ 10000 11 pcs Y = L - 363.8 Y = L - 9240

1. Maximum probe length is 19 ft 8 in. (6 m) for the 3300 Series and 32 ft 9 in. (10 m) for the 3308 and 5300

Series.

(1)

Number of middle

segments (n)

Length of bottom segment (Y)

19

Page 20

Global Headquarters

Emerson Process Management

6021 Innovation Blvd.

Shakopee, MN 55379, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RFQ.RMD-RCC@EmersonProcess.com

North America Regional Office

Emerson Process Management

8200 Market Blvd.

Chanhassen, MN 55317, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RMT-NA.RCCRFQ@Emerson.com

Latin America Regional Office

Emerson Process Management

1300 Concord Terrace, Suite 400

Sunrise, Florida, 33323, USA

+1 954 846 5030

+1 954 846 5121

RFQ.RMD-RCC@EmersonProcess.com

Europe Regional Office

Emerson Process Management Europe GmbH

Neuhofstrasse 19a P.O. Box 1046

CH 6340 Baar

Switzerland

+41 (0) 41 768 6111

+41 (0) 41 768 6300

RFQ.RMD-RCC@EmersonProcess.com

Asia Pacific Regional Office

Emerson Process Management Asia Pacific Pte Ltd

1 Pandan Crescent

Singapore 128461

+65 6777 8211

+65 6777 0947

Enquiries@AP.EmersonProcess.com

Middle East and Africa Regional Office

Emerson Process Management

Emerson FZE P.O. Box 17033,

Jebel Ali Free Zone - South 2

Dubai, United Arab Emirates

+971 4 8118100

+971 4 8865465

RFQ.RMTMEA@Emerson.com

*00825-0300-4530*

Quick Start Guide

00825-0300-4530, Rev AC

Standard Terms and Conditions of Sale can be found at:

www.rosemount.com\terms_of_sale.

The Emerson logo is a trademark and service mark of Emerson Electric Co.

Rosemount and Rosemount logotype are registered trademarks of

Rosemount Inc.

All other marks are the property of their respective owners.

© 2015 Rosemount Inc. All rights reserved.

August 2015

Loading...

Loading...