Page 1

Quick Start Guide

00825-0100-4327, Rev 01

Rosemount™ 326P Pressure Transmitter

January 2019

Page 2

2

Page 3

Quick Start Guide Contents

00825-0100-4327 January 2019

Contents

Chapter 1 Introduction.................................................................................................................. 5

1.1 Pressure specifications..................................................................................................................... 5

1.2 Operating modes............................................................................................................................. 7

1.3 Functions..........................................................................................................................................7

Chapter 2 Installation...................................................................................................................11

2.1 Installation orientation (3-A® standards).........................................................................................11

2.2 Hygienic process connection adapter installation...........................................................................11

2.3 Electrical connection...................................................................................................................... 11

Chapter 3 Operation.................................................................................................................... 15

3.1 Display and function buttons..........................................................................................................15

3.2 Menu..............................................................................................................................................17

3.3 Parameter settings......................................................................................................................... 21

Chapter 4 Setting ranges..............................................................................................................33

Chapter 5 Troubleshooting.......................................................................................................... 41

5.1 Error messages............................................................................................................................... 41

5.2 Warning messages......................................................................................................................... 41

Chapter 6 Product certifications...................................................................................................43

6.1 European directive information...................................................................................................... 43

6.2 Ordinary location information........................................................................................................ 43

6.3 3-A® certification............................................................................................................................43

6.4 Other industry certifications...........................................................................................................43

Chapter 7 Factory settings........................................................................................................... 45

Quick Start Guide 3

Page 4

Contents Quick Start Guide

January 2019 00825-0100-4327

4 Quick Start Guide

Page 5

Quick Start Guide Introduction

00825-0100-4327 January 2019

1 Introduction

The pressure transmitter measures and monitors pressure in a facility.

1.1 Pressure specifications

To ensure product performance and safety, adhere to the following specifications.

1.1.1 Measuring range

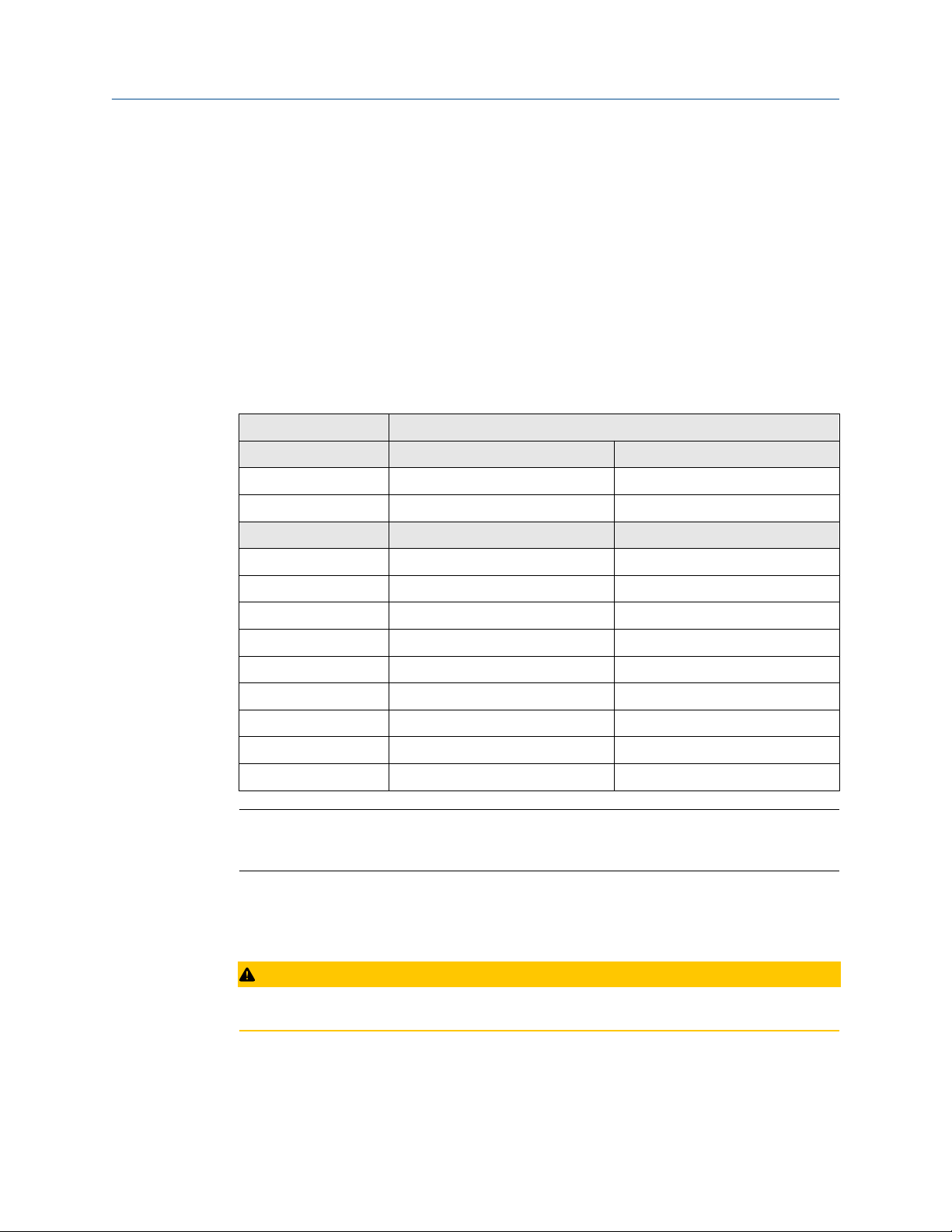

This table shows the range at which the pressure transmitter is able to measure pressure.

Pressure range Measuring range limits

inH2O mbar

1A -2.0 to 40 -5 to 99.5

2A -5.0 to 100 -12.4 to 248.8

1.1.2

psi bar

3A -14.5 to 14.5 -1 to 1

2B -0.73 to 14.5 -0.05 to 1

4A -1.45 to 20 -0.1 to 1.38

5A -1.8 to 36 -0.124 to 2.48

6A -14.5 to 55 -1 to 3.79

7A -14.5 to 85 -1 to 5.86

8A -14.5 to 145 -1 to 10

9A -14.5 to 230 -1 to 15.9

1B -14.5 to 360 -1 to 24.8

Note

The pressure transmitter is vacuum resistant. There are restrictions for nominal pressure

ranges at or below 4.35 psi (300 mbar). Adhere to the specifications in the data sheet.

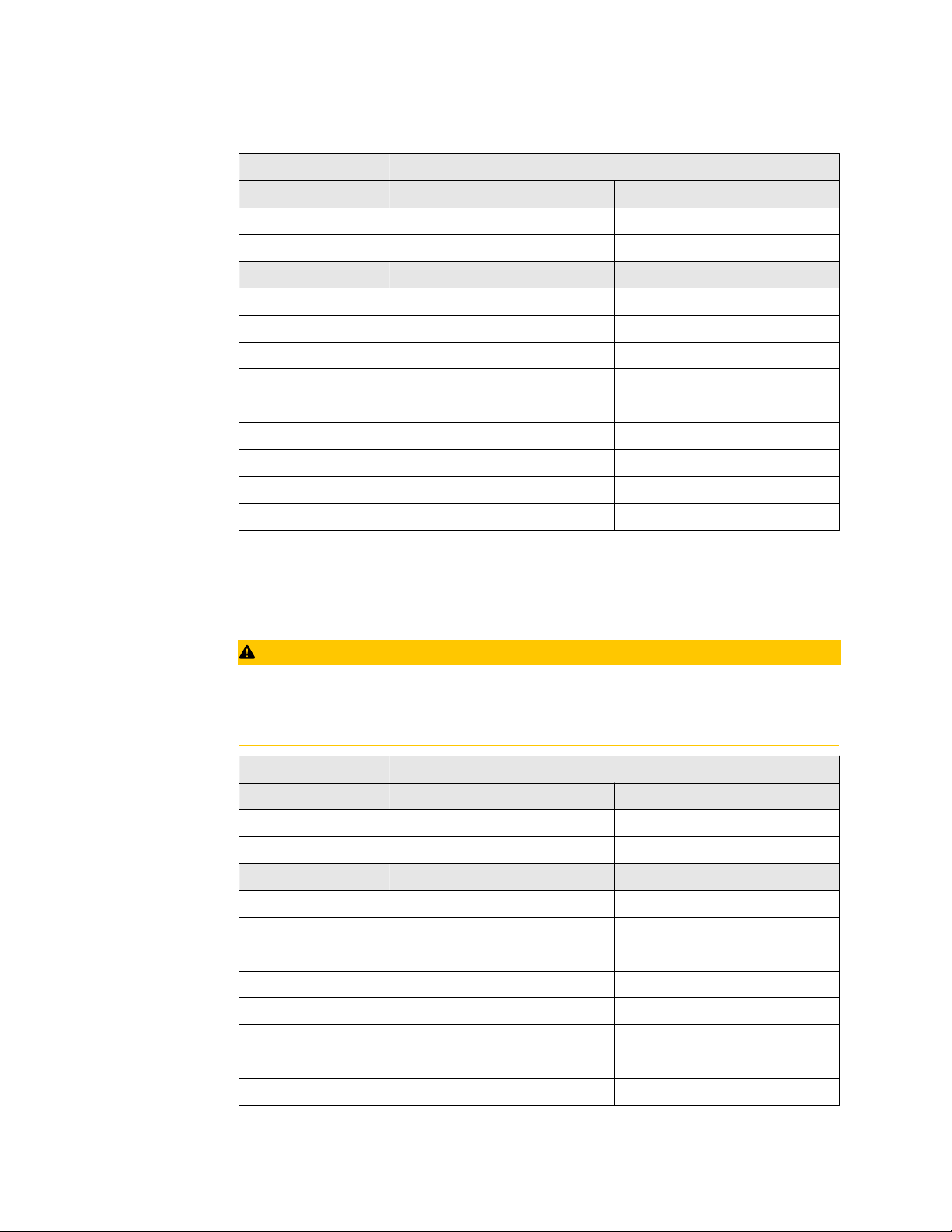

Overpressure limits

The table in this topic shows maximum allowable pressure for the pressure transmitter.

CAUTION

Take appropriate measures to avoid exceeding the specified overpressure limits.

Quick Start Guide 5

Page 6

Introduction Quick Start Guide

January 2019 00825-0100-4327

Pressure range Overpressure limits

inH2O bar

1A 1606 4

2A 2400 6

psi bar

3A 145 10

2B 145 10

4A 215 15

5A 290 20

6A 435 30

7A 435 30

8A 725 50

9A 1085 75

1B 1450 100

1.1.3 Burst pressure limits

The burst pressure limit is the pressure at which the pressure transmitter will no longer

function or be damaged.

CAUTION

Do not exceed the burst pressure limit. Exceeding the burst pressure limit can damage the

pressure transmitter. Continuing to use the pressure transmitter after exceeding the burst

pressure limit can cause damage and physical injury.

Pressure range

1A 12044 30

2A 12044 30

3A 435 30

2B 435 30

4A 580 40

5A 725 50

6A 1450 100

Burst pressure limits

inH2O bar

psi bar

7A 1450 100

8A 2175 150

9A 3625 250

6 Quick Start Guide

Page 7

Quick Start Guide Introduction

00825-0100-4327 January 2019

Pressure range Burst pressure limits

1B 5075 350

1.2 Operating modes

The wiring configuration sets the operating mode. After wiring the pressure transmitter, it

automatically recognizes the connections and changes to the respective operating mode.

For more information, see Electrical connection.

1.2.1 Two-wire operation

OUT2 (pin 2)

The analog signal proportional to pressure (4-20 mA or 20-4 mA).

1.2.2 Three-wire operation

OUT1 (pin 4)

OUT2 (pin 2)

Switching signal for system pressure limit value

• Switching signal used for system pressure limit value

• Analog signal proportional to pressure (4-20 mA or 20-4 mA)

1.3 Functions

The Rosemount 326P Pressure transmitter performs the functions described in this

section.

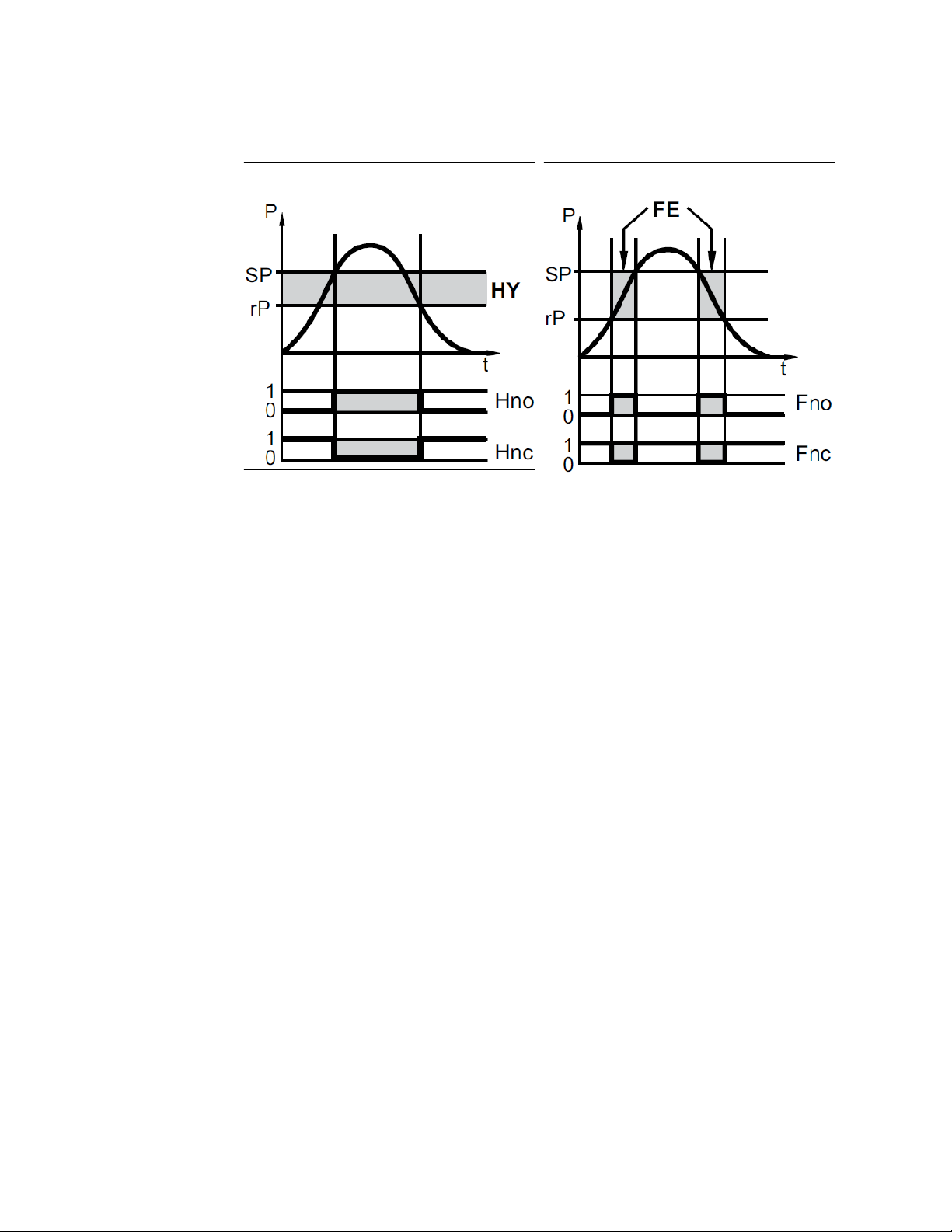

1.3.1

Switching function

The switching function is available only for three-wire operations. OUT1 or OUT2 changes

its switching status if the pressure is above or below the set switching limits (SPx, rPx).

These switching functions are available:

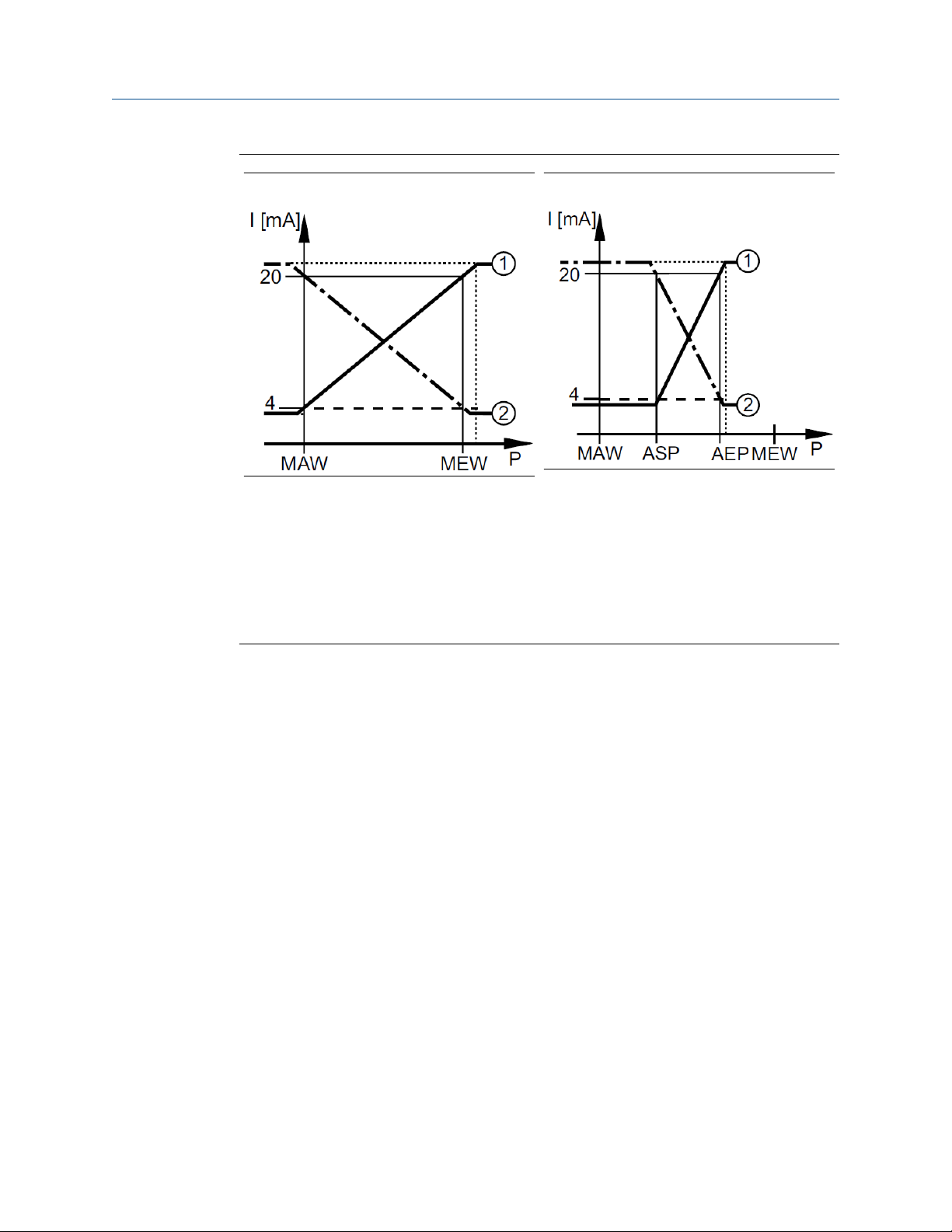

• Hysteresis function/normally open: OUx = Hno (Figure 1-1)

• Hysteresis function/normally closed: OUx = Hnc (Figure 1-1)

First set the set point (SPx), then the reset point (rPx) with the requested difference.

• Window function/normally open: OUx = Fno (Figure 1-2)

• Window function/normally closed: OUx = Fnc (Figure 1-2)

Set the width of the window using the difference between SPx and rPx. SPx is the upper

value and rPx is the lower value.

Quick Start Guide 7

Page 8

Introduction Quick Start Guide

January 2019 00825-0100-4327

Figure 1-1: Hysteresis function Figure 1-2: Window function

• SP: Set point

• rP: Reset point

• P: Pressure

• Hy: Hysteresis

• Hno: Hysteresis function/normally open

• Hnc: Hysteresis function/normally closed

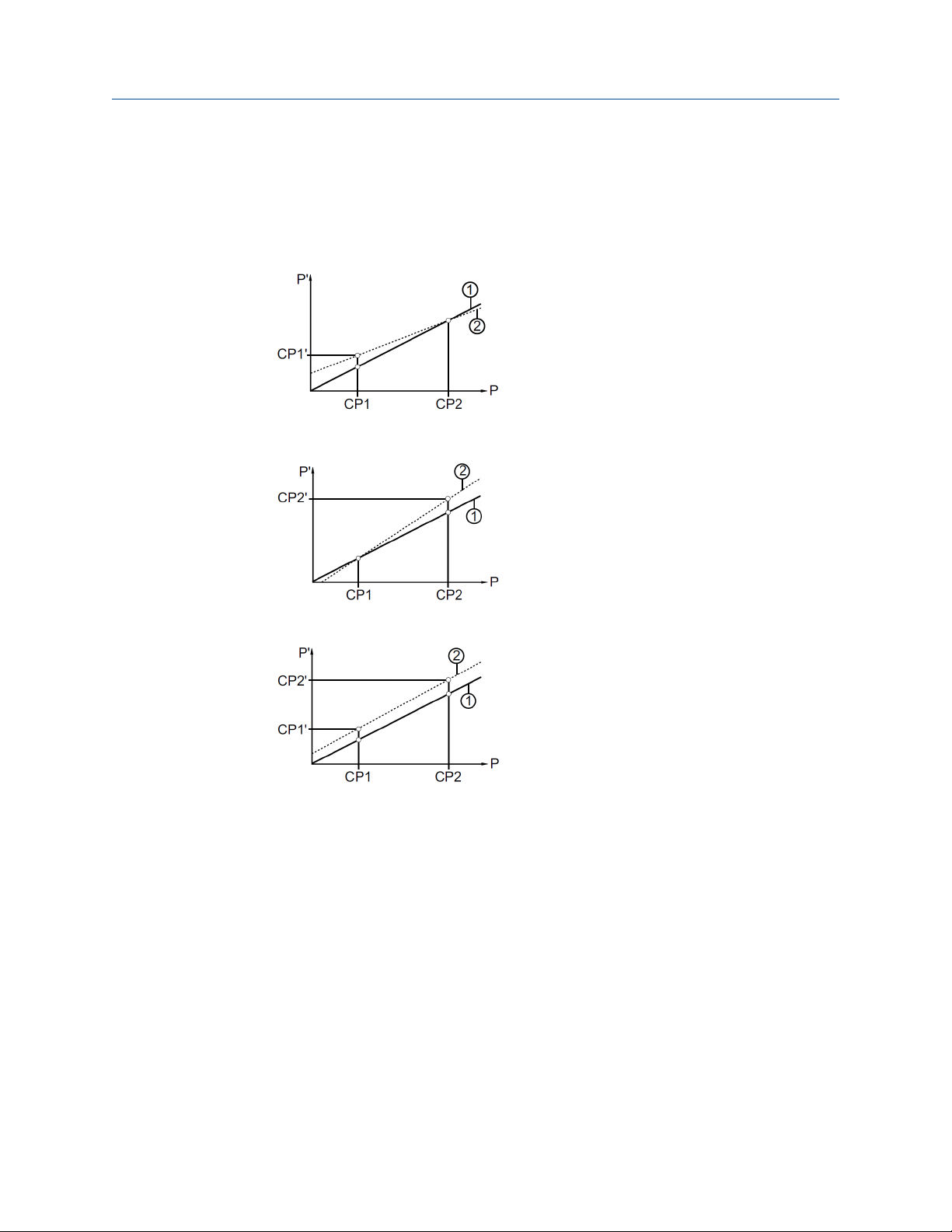

1.3.2 Analog signal

The transmitter communicates measured pressure using an analog signal.

OU2 defines whether the set measuring range is provided as 4-20 mA (OU2 = I) or as 20-4

mA (OU2 = InEG).

Rerange the transmitter (set new values for ASP and AEP) by either manually entering

range points or with an applied pressure source.

• Applying a pressure source for the analog start point (tASP) or manually setting the

parameter (ASP) defines the measured value when the analog signal is 4 mA (20 mA at

InEG).

• Applying a pressure source for the analog end point (tASP) or manually setting the

parameter (ASP) defines the measured value when the output signal is 20 mA (4 mA at

InEG).

• FE: Window

• Fno: Window function/normally open

• Fnc: Window function/normally closed

Minimum distance between ASP and AEP is 25 percent of the upper range limit (maximum

rangedown 4:1). For pressure range 3A, the minimum distance is 25 percent of the

measuring span.

8 Quick Start Guide

Page 9

Quick Start Guide

00825-0100-4327 January 2019

Figure 1-3: Factory setting Figure 1-4: Transmitter reranged

P: system pressure

Introduction

1.3.3

MAW: initial value of the measuring range (Lower range limit [LRL])

MEW: final value of the measuring range (Upper range limit [URL])

1: OU2 = I

2: OU2 = InEG

In the set measuring range the output signal is between 4 and 20 mA (OU2 = I) or between

20 and 4 mA (OU2 = InEG). When pressure is outside the set measuring range, the output

signal is as follows:

• System pressure above the measuring range:

— Output signal > 20 mA if OU2 = I.

— Output signal 4 to 3.8 mA if OU2 = InEG.

• System pressure below the measuring range:

— Output signal 4 to 3.8 mA if OU2 = I.

— Output signal > 20 mA if OU2 = InEG.

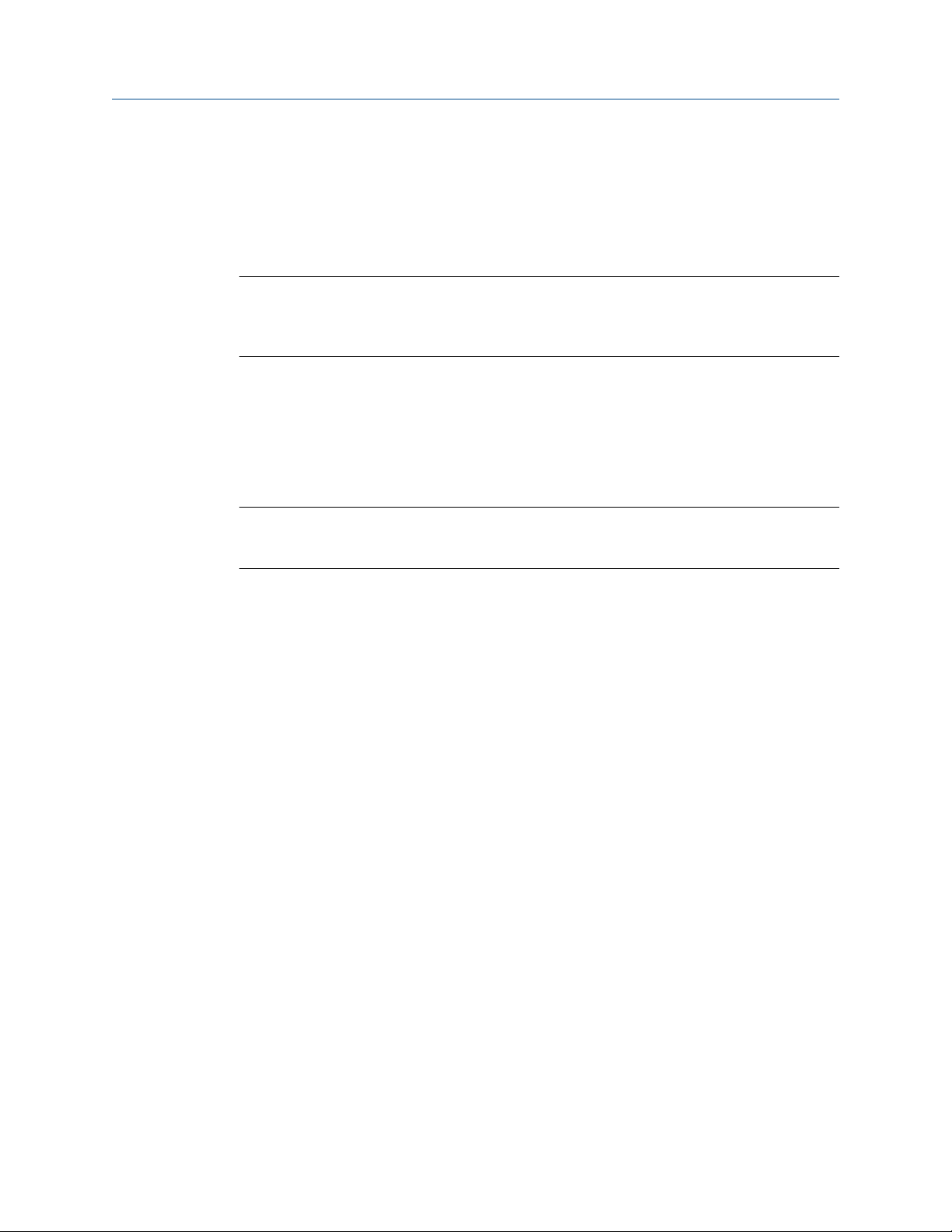

Customer-specific calibration (sensor trim)

A customer specific calibration (sensor trim) corrects the pressure offset and pressure

range to match a pressure standard. This provides a slope correction to the transmitter's

current characterization curve. An accurate pressure standard is required for a full

calibration. For more information on performing a Sensor Trim, see Perform a sensor trim.

• Sensor Trim is a two-point sensor calibration that applies two end-point pressures

(CP1, CP2) then linearizes the output between them. CP1 and CP2 must be within the

scaled measuring range. For more information, see Analog signal.

• Zero trim is a single-point offset adjustment. It compensates for mounting position

effects and is most effective when performed with the transmitter installed in its final

Quick Start Guide 9

Page 10

Introduction Quick Start Guide

January 2019 00825-0100-4327

mounting position. Since zero trim maintains the slope of the characterization curve,

do not use it in place of a Sensor Trim over the full sensor range. For more information,

see Perform manual zero trim.

Reset the calibration by resetting all parameters to the factory default settings. For more

information, see Resetting all parameters to factory default settings.

• P: measured pressure

P‘: modified measured value

• CP1: calibration point 1

CP1‘: modified measured value for CP1

• CP2: calibration point 2

• 1: curve of measured values at factory

setting

• 2: curve of measured values after calibration

• P: measured pressure

P‘: modified measured value

• CP1: calibration point 1

CP2: calibration point 2

CP2‘: modified measured value for CP2

• 1: curve of measured values at factory

setting

• 2: curve of measured values after calibration

• P: measured pressure

P‘: modified measured value

• CP1: calibration point 1

CP1‘: modified measured value for CP1

• CP2: calibration point 2

CP2‘: modified measured value for CP2

• 1: curve of measured values at factory

setting

• 2: curve of measured values after calibration

10 Quick Start Guide

Page 11

Quick Start Guide

00825-0100-4327 January 2019

Installation

2 Installation

This section contains instructions for installing and wiring the Rosemount 326P Pressure

Transmitter.

Note

Before installing or removing the unit, ensure no pressure is applied to the system. Note

that when the pressure transmitter displays 0%, pressure might still be applied to the

system.

2.1 Installation orientation (3-A® standards)

For optimized cleaning of the measuring element in hygienic areas according to the 3-A

standards, follow these guidelines when installing the pressure transmitter.

To ensure the medium can run off the measuring element, do not install the unit at the

lowest point of a pipe or container.

Note

This product is not suitable for use where the criteria for paragraph E1.2 / 63-03 of the

3-A® standard 63-03 must be met.

2.2 Hygienic process connection adapter installation

Hygienic process connection adapters allow the transmitter to be installed according to

application requirements. All connection adapters include an EPDM O-ring. More sealing

rings are available to be ordered as accessories. See the Rosemount 326P Product Data

Sheet for all available connectors and accessories. Hygienic process connection adapters

include installation instructions with the packaging.

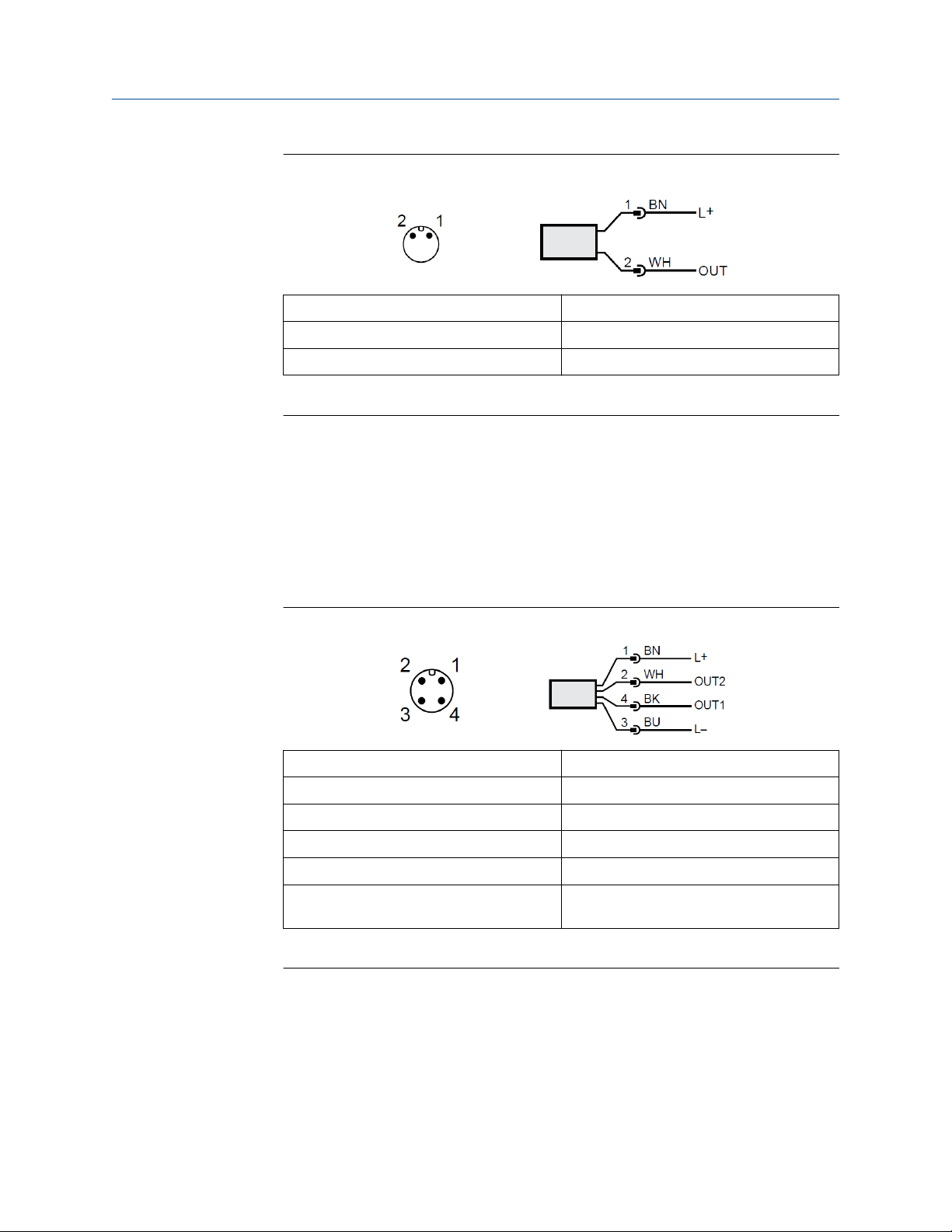

2.3 Electrical connection

This section provides instructions for wiring the pressure transmitter. A qualified

electrician must wire the pressure transmitter. The electrical installation must adhere to

national and international regulations.

Voltage supply according to EN 50178, SELV, PELV.

2.3.1

Wiring for two-wire operation

Follow these steps to wire the pressure transmitter for two-wire operation.

Procedure

1. Disconnect the power.

2. Wire the pressure transmitter according to Figure 2-1.

Quick Start Guide 11

Page 12

Installation Quick Start Guide

January 2019 00825-0100-4327

Figure 2-1: Connection for two-wire operation

BN Brown

WH White

OUT Analog output (4-20 mA)

Colors to DIN EN 60947-5-2

2.3.2

Wiring for three-wire operation

Follow these steps to wire the pressure transmitter for three-wire operation.

Procedure

1. Disconnect the power.

2. Wire the pressure transmitter according to Figure 2-2.

Figure 2-2: Connection for three-wire operation

BK

BN Brown

BU Blue

WH White

OUT1 Switching output

OUT2 Switching output or analog output (4-20

Black

mA)

Colors to DIN EN 60947-5-2

12 Quick Start Guide

Page 13

Quick Start Guide Installation

00825-0100-4327 January 2019

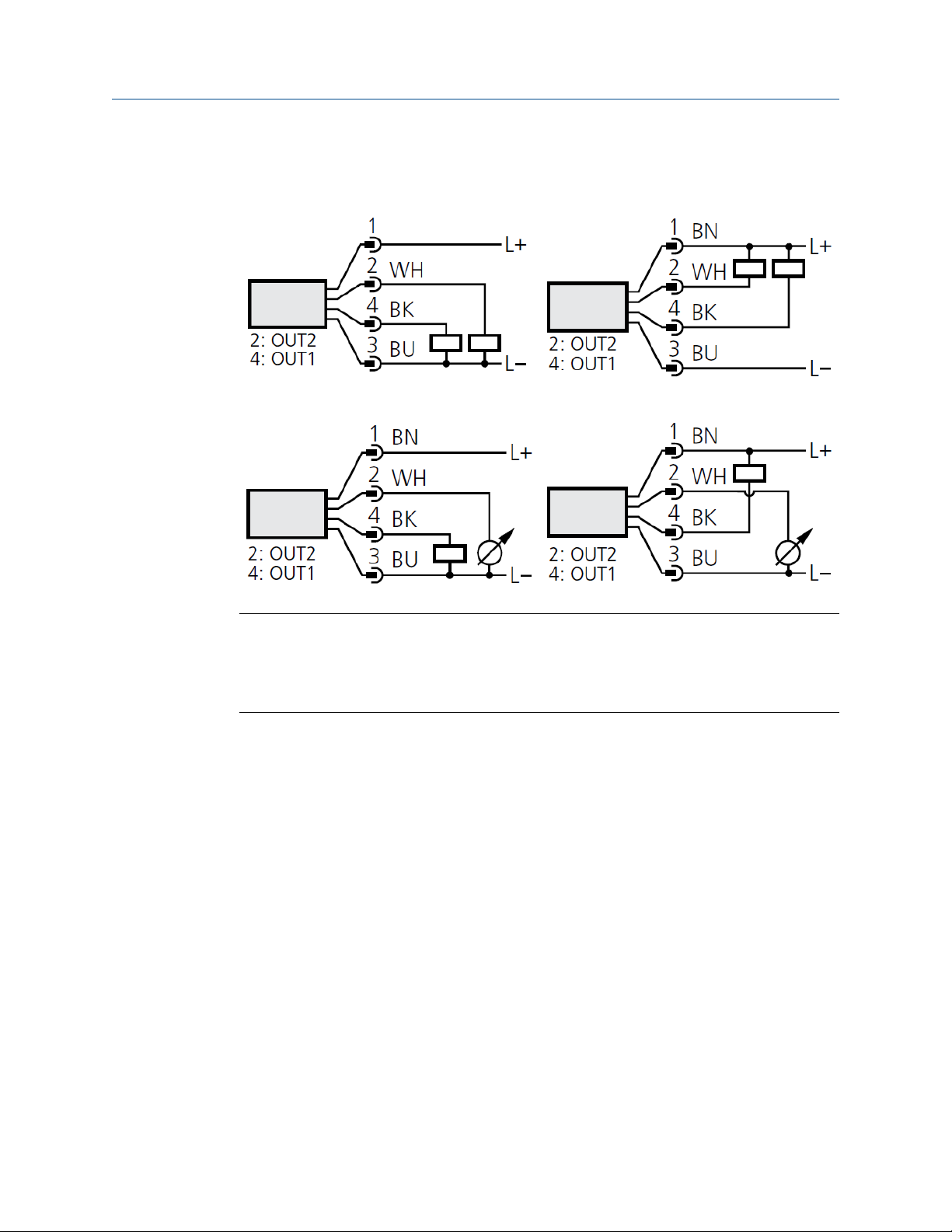

Wiring examples

2 x positive switching 2 x negative switching

1 x positive switching / 1 x analog 1 x negative switching / 1 x analog

Note

If the analog signal current (I) is selected in the menu under OU2 and the output is not

connected (resistor = infinite), the pressure transmitter displays the error message W532

in intervals. This does not affect the measuring result. As an alternative, configure OU2 to

a switching output.

Quick Start Guide 13

Page 14

Installation Quick Start Guide

January 2019 00825-0100-4327

14 Quick Start Guide

Page 15

Quick Start Guide Operation

00825-0100-4327 January 2019

3 Operation

This section provides instructions for configuring parameter settings.

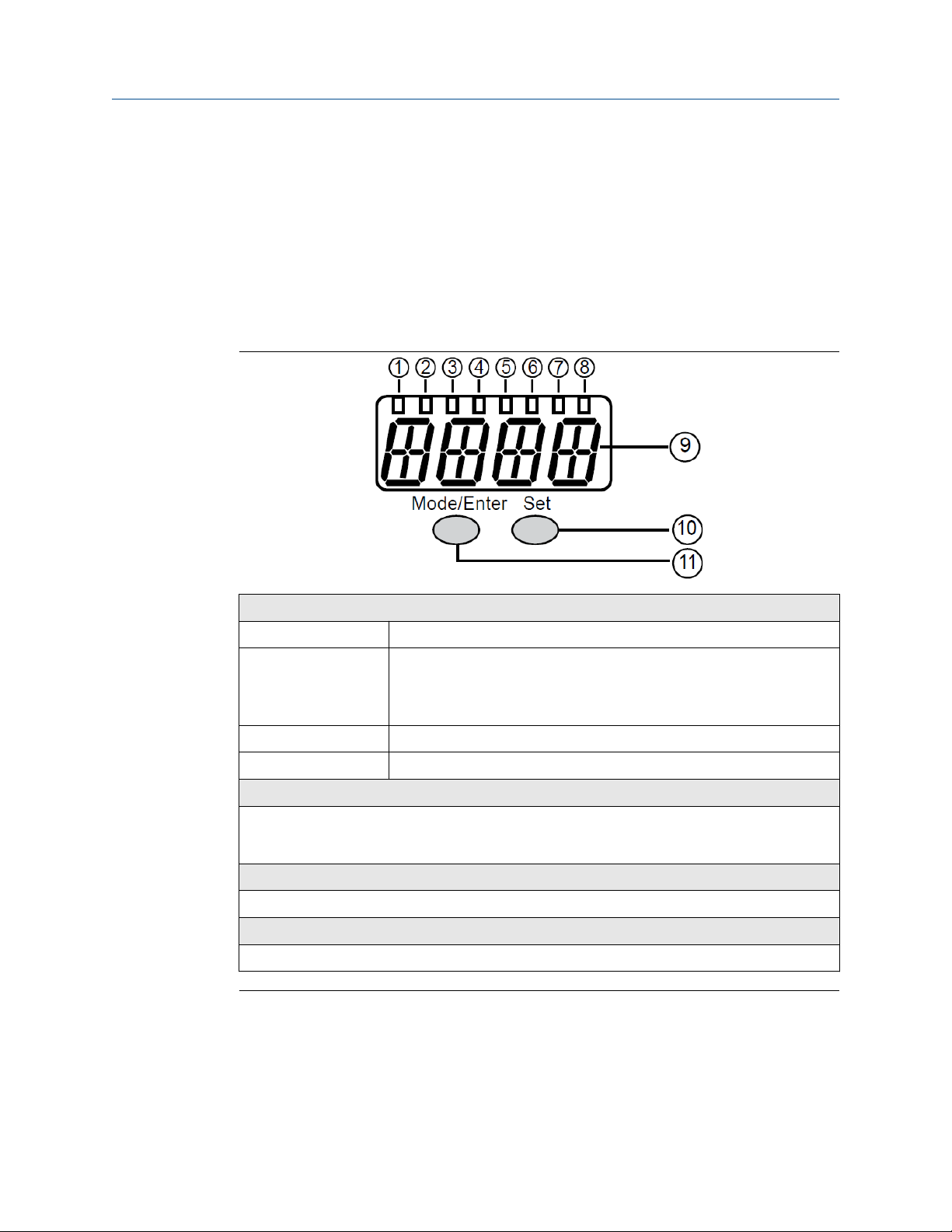

3.1 Display and function buttons

The pressure transmitter displays information using the display and can be controlled

using the function buttons.

1 to 8: Indicator LEDs

LED 1 to LED 5 System pressure in the set unit of measurement.

LED 6 If OU2 is configured as an analog output, it indicates the system pressure

in percent of the scaling of the analog output (range ASP to AEP).

If OU2 is configured as a switching output, it indicates the system

pressure in percent of the upper range limit (URL).

LED 7 Switching status of OUT2 (illuminates when output 2 is switched).

LED 8 Switching status of OUT1 (illuminates if output 1 is switched).

9: Alphanumeric display, 4 digits

• Current system pressure

• Parameters and parameter values

10: Set button

Selects a parameter from the menu and modifies the value by holding pressed for five seconds.

11: Mode/Enter button

Scrolls through the menu and acknowledges parameter values.

Quick Start Guide 15

Page 16

Operation Quick Start Guide

January 2019 00825-0100-4327

3.1.1 Read the set parameters

Follow these steps to view the set parameter values.

Procedure

1. Press Mode/Enter until the pressure transmitter displays the desired parameter.

2. Press Set.

The pressure transmitter displays the value currently set for the selected parameter

for 15 seconds then returns to run mode.

3.1.2 Change the display in run mode

Follow these steps to view the pressure measurement in different indicator types. During

normal operation, the pressure transmitter displays the pressure measurement in the

selected unit of measurement.

Procedure

• Press Set.

The pressure transmitter displays the following information for 15 seconds:

— System pressure in percent of the set scaling of the analog output if OU2 is

configured as analog output.

— System pressure in percent of the upper range limit if OU2 is configured as

switching output.

16 Quick Start Guide

Page 17

Quick Start Guide Operation

00825-0100-4327 January 2019

3.2 Menu

This section explains the pressure transmitter menu options and structure.

3.2.1 Main menu structure

The main menu includes options for accessing other menus, setting output functions, and

changing the display mode.

Figure 3-1: Main menu

• 1: Change to the extended functions menu (level 2)

• Menu items highlighted gray are not available for two-wire operation.

Option

SP1/rP1

OU1

OU2 Output function for OUT2:

tCOF Perform Zero Trim.

Quick Start Guide 17

(1)

(1)

Description

Upper and lower limit values for system pressure at which OUT1 switches.

Output function for OUT1:

Switching signal for the pressure limit values: hysteresis function (H ..) or

window function (F ..), either normally open (. no) or normally closed (. nc).

• Switching signal for the pressure limit values: hysteresis function (H ..) or

window function (F ..), either normally open (. no) or normally closed (. nc);

(only available for three-wire operation).

• analog signal for the current system pressure: 4-20 mA (I), 20-4 mA (InEG).

Page 18

Operation

January 2019 00825-0100-4327

Option Description

tASP Set analog start point (4 mA if OU2 = I, 20 mA if OU2 = InEG) using an applied

pressure source.

tAEP Set analog end point (20 mA if OU2 = I, 4 mA if OU2 = InEG) using an applied

pressure source.

SP2/rP2

EF Extended functions and opening the extended functions menu (level 2).

(1) Not active in a two-wire operation.

(1)

Upper and lower limit values for system pressure at which OUT2 switches.

Quick Start Guide

3.2.2 Extended functions menu

The extended functions menu provides options for configuring pressure transmitter

parameters.

Figure 3-2: Extended functions menu (level 2)

• 1: Change to the main menu

• 2: Change to the simulation menu

Menu items highlighted gray are not available for two-wire operation.

18 Quick Start Guide

Page 19

Quick Start Guide Operation

00825-0100-4327 January 2019

Table 3-1: Extended functions menu options

Option Description

Uni Standard unit of measurement for system pressure

SELd Display mode:

1. Pressure in the unit set in Uni

2. Pressure in percent of the set scaling of the analog output

ASP Analog start point for system pressure: measured value at which 4 mA is

provided (20 mA if OU2 = InEG)

AEP Analog end point for system pressure: measured value at which 20 mA is

provided (4 mA if OU2 = InEG)

HI Highest measured system pressure

LO Lowest measured system pressure

COF Zero trim

(1)

dS1

(1)

dr1

dS2

(1)

dr2

FOU1

(1)

(1)

Switch-on delay for OUT1

Switch-off delay for OUT1

Switch-on delay for OUT2; only active if OU2 = Hnc, Hno, Fnc or Fno

Switch-off delay for OUT2; only active if OU2 = Hnc, Hno, Fnc or Fno

Status of output 1 in case of an internal fault

FOU2 Status of output 2 in case of an internal fault

(1)

P-n

Switching logic for the outputs: pnp or npn

dAP Damping for switching outputs and display

dAA Damping for analog output (OUT2)

diS Update rate and orientation of the display

CAL Calibration function (setting the curve of measured values)

CP1 Calibration point 1

CP2 Calibration point 2

SIM Switch to the simulation menu (level 3)

rES Restore factory default settings

(1) Not active in a two-wire operation.

Quick Start Guide 19

Page 20

Operation Quick Start Guide

January 2019 00825-0100-4327

3.2.3 Simulation menu

The simulation menu provides options for configuring and executing transmitter

simulations.

Figure 3-3: Simulation menu (SEL=OU)

The options shown appear when SEL is set to OU.

Table 3-2: Simulation menu (SEL=OU)

Option Description

SEL Status to be simulated. Output functions OU.

(1)

S.OU1

S.OU2 Simulation values for OUT2; only active if SEL = OU.

S.TIM Time for the simulation process in minutes.

S.ON Starts the simulation process.

(1) Not active in two-wire operation

Simulation values for OUT1; only active for three-wire operation and if SEL =

OU.

• OPEN: Output inactive

• CLOS: Output active

• For three-wire operation and if OUT2 has been configured as switching

output: output inactive (OPEN) or active (CLOS).

• If OUT2 is set as an analog output: analog signal between 3.6 and 21.1 mA

During the simulation process the display alternately shows SIM and the

current operation indication.

If the simulation process is aborted, the pressure transmitter displays S.OFF for

two seconds, then SEL is active again.

20 Quick Start Guide

Page 21

Quick Start Guide Operation

00825-0100-4327 January 2019

Figure 3-4: Simulation menu (SEL = Proc)

The options shown appear when SEL is set to OU.

Table 3-3: Simulation menu (SEL = Proc)

Option Description

SEL Status to be simulated: Process value Proc.

S.Pr Simulation of a process value; active only if SEL = Proc. Any value between

lower and upper range limits (LRL and URL).

S.TIM Time for the simulation process in minutes.

S.ON Starts the simulation process.

During the simulation process the display alternately shows SIM and the

current operation indication.

If the simulation process is aborted, the pressure transmitter displays S.OFF for

two seconds, then SEL is active again.

3.3 Parameter settings

This section provides instructions for modifying parameter values. While modifying

parameter values, the pressure transmitter remains in operating mode. It continues to

monitor pressure levels using the existing parameter values until the new parameter

Quick Start Guide 21

Page 22

Operation

January 2019 00825-0100-4327

values are set. The pressure transmitter changes the parameter values immediately for

COF, CP1, and CP2.

Quick Start Guide

3.3.1 Modify parameter settings

Follow these steps to modify parameter values.

Procedure

1. Press Mode/Enter to select a parameter.

2. Press and hold Set.

The pressure transmitter flashes the current value for five seconds.

3. Modify the parameter value.

• Press Set to change the value incrementally.

• Press and hold Set to change the value continuously.

• To reduce the value, continue to press Set until the pressure transmitter reaches

the value limit and restarts at the value minimum.

4. Press Mode/Enter.

The pressure transmitter displays the parameter and saves the new parameter

value.

Switching menu levels

Follow these steps to change from the main menu to the extended functions menu.

Procedure

1. Press Mode/Enter until the pressure transmitter displays EF.

2. Press Set.

The pressure transmitter displays Uni.

3. If the extended menu is locked with an access code, enter the access code.

a) Press Set until the pressure transmitter displays the valid access code.

b) Press Mode/Enter.

By default the extended functions menu is unlocked.

Locking and unlocking the pressure transmitter

Follow these steps to lock or unlock the pressure transmitter. While locked, the pressure

transmitter does not allow parameter values to change and displays Loc if attempted.

Procedure

1. To lock: press and hold Mode/Enter and Set for 10 seconds.

The pressure transmitter locks and displays Loc.

2. To unlock: press and hold Mode/Enter and Set for 10 seconds while the pressure

transmitter is locked.

The pressure transmitter unlocks and displays uLoc.

22 Quick Start Guide

Page 23

Quick Start Guide

00825-0100-4327 January 2019

Operation

3.3.2 Configuring the display

This section provides instructions for changing how the pressure transmitter displays

pressure data.

Change the unit of measurement

Follow these steps to change the unit of measurement in which the pressure transmitter

displays process pressure.

Procedure

1. Select Uni from the extended functions menu.

2. Press and hold Set to modify the parameter value.

3. Select a unit of measurement.

• For bar or mbar, select bAr or mbAr

• For mPa or kPa, select MPA or kPA

• For psi, select PSI (only available with pressure ranges 3A, 5A, 6A, 8A, 1B, 2B)

• For InH2O, select IH2O (only available with pressure ranges 1A, 2A, 3A, 5A, 2B)

• For mWS, select mWS (only available with pressure ranges 3A, 5A, 2B)

• For mmWS, select mmWS (only available with pressure ranges 1A, 2A)

4. Press Mode/Enter.

Change the indication type

Follow these steps to change how the pressure transmitter displays pressure level.

Procedure

1. Select SELd from the extended functions menu.

2. Press and hold Set to modify the parameter value.

3. Select a type of indication.

• P: system pressure in the unit set in Uni.

• P%: system pressure in percent of the set scaling of the analog output; the

following applies: 0% = ASP value ; 100% = AEP value. If OU2 is configured as

switching output, ASP and AEP are not active. In this case the following applies:

0% = lower range limit (LRL) / 100% = upper range limit (URL).

4. Press Mode/Enter.

Note

Pressure may still be applied to the system if the pressure transmitter shows 0%

pressure.

Quick Start Guide 23

Page 24

Operation

January 2019 00825-0100-4327

Quick Start Guide

Change the update rate and display orientation

The update rate sets how often the pressure transmitter displays new data. The diS

parameter also sets the orientation of the display. Follow these steps to change the update

rate and orientation of the display.

Procedure

1. Select diS from the extended functions menu.

2. Press and hold Set to modify the parameter value.

3. Select an update rate or an update rate with a rotated display.

• d1: Updates the measured values every 50 ms.

• d2: Updates the measured values every 200 ms.

• d3: Updates the measured values every 600 ms.

• rd1, rd2, rd3: Rotates the display by 180° and selects the corresponding update

rate.

• OFF: Deactivates the display while in run mode. When a button is pressed, the

pressure transmitter displays the system pressure for 15 seconds. Pressing

Mode/Enter again activates the display. The LED indicators remain active when

the display is deactivated. Also, the pressure transmitter displays error messages

when the display is deactivated.

3.3.3

Set output signals

This section provides instructions for setting output functions and limits.

Setting output functions

Follow these steps to set the function of output 1 and output 2.

Procedure

1. Select OU1 from the menu.

2. Press and hold Set to modify the parameter value.

3. Set the switching function.

• Hno: hysteresis function/NO

• Hnc: hysteresis function/NC

• Fno: window function/NO

• Fnc: window function/NC

4. Press Mode/Enter.

5. Select OU2 from the menu.

6. Press and hold Set to modify the parameter value.

7. Set the function.

• Hno: hysteresis function/NO

24 Quick Start Guide

Page 25

Quick Start Guide

00825-0100-4327 January 2019

• Hnc: hysteresis function/NC

• Fno: window function/NO

• Fnc: window function/NC

• I: current signal proportional to pressure 4-20 mA

• InEG: current signal proportional to pressure 20-4 mA

8. Press Mode/Enter.

Operation

Set switching limits

Follow these steps to set the limits that cause the outputs to switch.

Procedure

1. Select SP1 or SP2 from the menu.

2. Press and hold Set to modify the parameter value.

3. Set the limit at which the output switches.

4. Press Mode/Enter.

5. Select rP1 or rP2 from the menu.

6. Press and hold Set to modify the parameter value.

7. Set the limit at which the output resets.

The rPx value is always lower than SPx. The pressure transmitter accepts only values

lower than the value for SPx.

8. Press Mode/Enter.

Automatically scale the analog output

Follow these steps to set the start and end value of the analog output to the current

system pressure reading. If the automatic setting is invalid, the pressure transmitter

displays UL or OL. After acknowledging an incorrect value, the pressure senor displays Err

and does not accept the incorrect value.

Procedure

1. Set the minimum pressure requested in the system.

a) Select tASP from the menu.

b) Press and hold Set.

The display flashes the current set value.

c) Release Set when the value stops flashing.

The pressure transmitter displays the new value.

d) Press Mode/Enter.

The current system pressure is defined as the start value for the analog

signal.

2. Set the maximum pressure requested in the system.

a) Select tAEP from the menu.

Quick Start Guide 25

Page 26

Operation

January 2019 00825-0100-4327

b) Press and hold Set.

The current value flashes on the display.

c) Release Set when the value stops flashing.

The pressure transmitter displays the new value.

d) Press Mode/Enter.

The pressure transmitter sets the current system pressure as the end value

for the analog signal.

Quick Start Guide

Manually scale the analog output

Follow these steps to manually set the start value (ASP) and end value (AEP) for the analog

output. The values for ASP and AEP must be within defined limits.

Procedure

1. Select ASP from the extended functions menu.

2. Press and hold Set to modify the parameter value.

3. Set the measured value at which the pressure transmitter provides 4 mA (20 mA if

OU2 = InEG).

4. Select AEP from the extended functions menu.

5. Press and hold Set to modify the parameter value.

6. Set the measured value at which the pressure transmitter provides 20 mA (4 mA if

OU2 = InEG).

3.3.4

Note

The minimum distance between ASP and AEP must be 25 percent of the upper

range limit (maximum rangedown is 4:1).

Optional settings

This section provides instructions for modifying optional settings. Modification of these

settings is not required for normal operation of the pressure transmitter.

Perform manual zero trim

Follow these steps to manually scale the pressure offset by +/-5 percent. Use this after

installation to trim out any measurement offsets because of mounting effects.

Procedure

1. Select COF from the extended functions menu.

2. Press and hold Set to modify the parameter value.

3. Set the value between -5% and 5%.

The pressure transmitter modifies the measured pressure by this value.

26 Quick Start Guide

Page 27

Quick Start Guide Operation

00825-0100-4327 January 2019

Perform an automatic zero trim

Follow these steps to automatically scale the pressure offset by +/-5 percent. Use this after

installation to trim out any measurement offsets because of mounting effects.

Prerequisites

Ensure no pressure is applied to the pressure transmitter.

Procedure

1. Select tCOF from the menu.

2. Press and hold Set.

The current offset value appears then the current system pressure appears.

3. Release Set.

4. Press Mode/Enter to confirm the new offset value.

Setting output reaction to fault conditions

Follow these steps to modify how the outputs react to fault conditions.

Procedure

1. Select FOU1 from the extended functions menu.

2. Press and hold Set to modify the parameter value.

3. Set the value for output 1.

• On: output 1 switches on in case of a fault.

• OFF: output 1 switches off in case of a fault.

• OU: output 1 switches irrespective of a fault as defined by parameters SP1, rP1

und OU1.

4. Select FOU2 from the extended functions menu.

5. Press and hold Set to modify the parameter value.

6. Set the value for output 2.

• On: output 2 switches on in case of a fault, the analog signal goes to the upper

final value.

• OFF: output 2 switches off in case of a fault, the analog signal goes to the lower

final value.

• OU: output 2 switches irrespective of the fault as defined by parameters SP2,

rP2, OU2. The analog signal corresponds to the measured value.

Postrequisites

For more information on error messages, see Error messages.

Quick Start Guide 27

Page 28

Operation

January 2019 00825-0100-4327

Quick Start Guide

Setting a delay for the switching outputs

Follow these steps to modify the time before an output switches after a fault. The

maximum delay time is 50 seconds.

Procedure

1. Select the switch-on delay parameter for the output from the extended functions

menu.

• Select dS1 to modify the switch-on delay for OUT1.

• Select dS2 to modify the switch-on delay for OUT2.

2. Press and hold Set to modify the parameter value.

3. Set the value between 0.1 and 50 seconds.

4. Select the switch-off delay parameter for the output from the extended functions

menu.

• Select dr1 to modify the switch-off delay for OUT1.

• Select dr2 to modify the switch-off delay for OUT2.

5. Press and hold Set to modify the parameter value.

6. Set the value between 0.1 and 50 seconds.

Setting the value to 0.0 deactivates the delay.

Setting the output logic for the switching outputs

Follow these steps to change the output logic for the switching outputs.

Procedure

1. Select P-n from the extended functions menu.

2. Press and hold Set to modify the parameter value.

3. Set the parameter to PnP or nPn.

4. Press Mode/Enter.

Setting damping for the switching signal

Damping the switching signal prevents the outputs from erroneously switching because of

erratic pressure readings. The damping value is the response time in seconds between

pressure change and change to the switching status. The damping value also influences

the value displayed on the pressure transmitter and the switching frequency (fmax = 1 ÷

2dAP).

Procedure

1. Select dAP from the extended functions menu.

2. Press and hold Set to modify the parameter value.

3. Set the value between 0.0 and 30 seconds.

A value of 0.0 seconds deactivates damping.

4. Press Mode/Enter.

28 Quick Start Guide

Page 29

Quick Start Guide

00825-0100-4327 January 2019

Operation

Setting a damping for the analog signal

Damping the analog signal prevents the 4-20 mA output from erroneously changing

because of erratic pressure readings. The analog damping value is the response time in

seconds between pressure change and the change of the analog signal.

Procedure

1. Select dAA from the extended functions menu.

2. Press and hold Set to modify the parameter value.

3. Set a value between 0.01 and 99.99 seconds.

A value of 0.0 seconds deactivates damping.

4. Press Mode/Enter.

Perform a sensor trim

Follow these steps to perform a sensor trim and calibrate the pressure transmitter

measurement.

Procedure

1. Apply a defined reference pressure to the transmitter between ASP and AEP.

2. Select CAL from the menu.

3. Press Set.

The pressure transmitter displays CP1.

4. Press and hold Set for five seconds.

The pressure transmitter displays the current pressure measurement.

5. Press Set until the pressure transmitter displays the reference pressure.

The pressure output can change by up to two percent of the upper range limit.

6. Press Mode/Enter.

The pressure transmitter displays CP1.

7. Press Mode/Enter again.

The pressure transmitter displays CP2.

8. To apply a second point on the curve or measured values, apply a second defined

reference pressure to the transmitter.

The minimum distance between the calibration points CP1 and CP2 is five percent

of the upper range limit.

9. Press and hold Set for five seconds.

The pressure transmitter displays the current pressure measurement.

10. Press Set until the pressure transmitter displays the reference pressure or the

corresponding analog signal is provided on OUT2.

The pressure output can change by up to two percent of the upper range limit.

11. Press Mode/Enter.

The pressure transmitter displays CP2.

12. Press Mode/Enter again.

The pressure transmitter displays CAL.

Quick Start Guide 29

Page 30

Operation

January 2019 00825-0100-4327

Quick Start Guide

3.3.5 Service fuctions

This section provides instructions for viewing and managing parameters.

View the highest and lowest measured pressure

The pressure transmitter saves the highest and lowest measured preasure values. Follow

these steps to view the highest and lowest pressure values previously measured by the

pressure transmitter.

Procedure

1. To view the maximum pressure value, select HI from the extended functions menu.

2. To view the minimum pressure value, select LO from the extended functions menu.

Deleting high and low pressure memory

Follow these steps to clear the highest and lowest pressure readings on the pressure

transmitter.

Procedure

3.3.6

1. Select HI or LO from the extended functions menu.

2. Press and hold Set until the pressure transmitter displays ---.

3. Press Mode/Enter.

Resetting all parameters to factory default settings

Follow these steps to reset all of the parameters to the factory default settings.

Prerequisites

Before resetting the parameters, record the current parameters using Factory settings.

Procedure

1. Select rES from the extended functions menu.

2. Press and hold Set until the pressure transmitter displays ---.

3. Press Mode/Enter.

Simulation function

During a simulation, the pressure transmitter replicates error conditions for testing

purposes. This section includes instructions for using the simulation function.

Open the simulation menu

Open the simulation menu to view simulation options and parameters.

Procedure

1. Select EF from the menu.

2. Press Set.

30 Quick Start Guide

Page 31

Quick Start Guide

00825-0100-4327 January 2019

The extended functions menu opens.

3. Select SIM from the menu.

4. Press Set.

The simulation menu opens. The first option is SEL.

Operation

Set the simulation output state

Follow these steps to set the output state for a simulation.

Procedure

1. Select SEL from the simulation menu.

2. Press and hold Set to change the simulation menu to OU.

3. For three-wire operation, select S.OU1 from the simulation menu.

For two-wire operation, skip to step Step 6.

4. Press and hold Set to set the value.

• OPEN: output 1 not active/open

• CLOS: output 1 active/closed

5. Press Mode/Enter.

6. Select S.OU2 from the simulation menu.

7. Press and hold Set to set the value.

• If OU2 = Hnc, Hno, Fnc or Fno (not in two-wire operation):

— OPEN: output 2 not active/open.

— CLOS: output 2 active/closed.

• If OU2 = I or InEG:

— 3.60-21.10 mA in steps of 0.01 mA.

8. Press Mode/Enter.

Set the simulation pressure value

The pressure transmitter will display the simulation pressure value during the simulation.

Follow these steps to set the pressure value for the simulation.

Procedure

1. Select SEL from the simulation menu.

2. Press and hold Set to change the simulation menu to Proc.

3. Press Mode/Enter.

The pressure transmitter displays S.Pr.

4. Select S.Pr from the simulation menu.

5. Press and hold Set to modify the pressure value.

6. Press Mode/Enter.

Quick Start Guide 31

Page 32

Operation Quick Start Guide

January 2019 00825-0100-4327

Set simulation duration

Follow these steps to set the duration of the simulation. Simulations can run between 1-60

minutes.

Procedure

1. Select S.TIM from the simulation menu.

2. Press and hold Set to modify the parameter value.

3. Set the duration value between 1-60 minutes.

4. Press Mode/Enter.

Start a simulation

Follow these steps to start a simulation.

Prerequisites

Set the simulation parameters.

Procedure

1. Select S.ON from the simulation menu.

2. Press and hold Set until the pressure transmitter displays SIM and the current

operating indicator.

Current operation indications include:

• Current system pressure if SEL = OU.

• Simulated measured value set in S.Pr if SEL = Proc.

The simulation runs until the set duration time elapses. Then, the pressure transmitter

displays S.OFF then SEL.

Abort a simulation

Follow these steps to stop a simulation before the duration time elapses.

Procedure

Press Mode/Enter or Set.

The pressure transmitter displays S.OFF for two seconds then displays SEL.

32 Quick Start Guide

Page 33

Quick Start Guide Setting ranges

00825-0100-4327 January 2019

4 Setting ranges

This section contains the minimum and maximum settings for the specified parameters by

pressure range.

Table 4-1: SP1 and SP2

Unit Minimum Maximum Step increment

Pressure range 1A

inH2O -1.92 40.00 0.04

mbar -4.8 99.5 0.1

kPa -0.48 9.95 0.01

mmWS -49 1016 1

Pressure range 2A

inH2O -4.8 100.0 0.1

mbar -12.0 248.8 0.2

kPa -1.20 24.88 0.02

mmWS -122 2540 2

Pressure range 3A

psi -14.45 14.50 0.05

inH20 -400 401 1

mbar -998 1000 1

kPa -99.8 100.0 0.1

mWS -10.18 10.20 0.01

Pressure range 2B

psi -0.70 14.50 0.01

inH2O -19.2 401.6 0.4

mbar -48 1000 1

kPa -4.8 100.0 0.1

mWS -0.49 10.20 0.01

Pressure range 4A

psi -1.4 20.00 0.02

inH2O -39 637.0 0.5

mbar -96 1586 2

kPa -9.6 158.6 0.2

mWS -0.98 16.1 0.02

Quick Start Guide 33

Page 34

Setting ranges Quick Start Guide

January 2019 00825-0100-4327

Table 4-1: SP1 and SP2 (continued)

Unit Minimum Maximum Step increment

Pressure range 5A

psi -1.74 36.00 0.03

inH2O -48 997 1

bar -0.120 2.482 0.002

kPa -12.0 248.2 0.2

mWS -1.22 25.31 0.01

Pressure range 6A

psi -14.35 55.00 0.05

bar -0.990 3.79 0.005

kPa -99.0 379.0 0.5

Pressure range 7A

psi -14.4 85.0 0.1

bar -0.99 5.860 0.005

kPa -99.0 586.0 0.5

Pressure range 8A

psi -14.2 145.0 0.1

bar -0.98 10.00 0.01

MPa -0.098 1.000 0.001

Pressure range 9A

psi -14.2 230.0 0.2

bar -0.98 15.86 0.02

MPa -0.098 1.586 0.002

Pressure range 1B

psi -13.8 360.0 0.3

bar -0.96 24.82 0.02

MPa -0.096 2.482 0.002

Table 4-2: rP1 and rP2

Unit Minimum Maximum Step increment

Pressure range 1A

inH2O -2.00 39.92 0.04

mbar -5.0 99.3 0.1

kPa -0.50 9.93 0.01

mmWS -51 1014 1

34 Quick Start Guide

Page 35

Quick Start Guide Setting ranges

00825-0100-4327 January 2019

Table 4-2: rP1 and rP2 (continued)

Unit Minimum Maximum Step increment

Pressure range 2A

inH2O -5.0 99.8 0.1

mbar -12.4 248.4 0.2

kPa -1.24 24.84 0.02

mmWS -126 2536 2

Pressure range 3A

psi -14.50 14.45 0.05

inH2O -401 400 1

mbar -1000 998 1

kPa -100.0 99.8 0.1

mWS -10.20 10.18 0.01

Pressure range 2B

psi -0.73 14.47 0.01

inH2O -20.0 400.8 0.4

mbar -50 998 1

kPa -5.0 99.8 0.1

mWS -0.51 10.18 0.01

Pressure range 4A

psi -1.44 19.96 0.02

inH2O -40 636 0.5

mbar -100 1582 2

kPa -10.0 158.2 0.2

mWS -1.02 16.06 0.02

Pressure range 5A

psi -1.80 35.94 0.03

inH2O -50 995 1

bar -0.124 2.478 0.002

kPa -12.4 247.8 0.2

mWS -1.26 25.29 0.01

Pressure range 6A

psi -14.50 54.9 0.05

bar -1.000 3.78 0.005

kPa -100.0 378 0.5

Quick Start Guide 35

Page 36

Setting ranges Quick Start Guide

January 2019 00825-0100-4327

Table 4-2: rP1 and rP2 (continued)

Unit Minimum Maximum Step increment

Pressure range 7A

psi -14.5 84.8 0.1

bar -1.0 5.85 0.005

kPa -100.0 585.0 0.5

Pressure range 8A

psi -14.5 144.7 0.1

bar -1.00 9.98 0.01

MPa -0.100 0.998 0.001

9A

psi -14.6 229.6 0.2

bar -1.0 15.82 0.02

MPa -0.1 1.582 0.002

Pressure range 1B

psi -14.4 359.4 0.3

bar -1.00 24.78 0.02

MPa -0.100 2.478 0.002

Table 4-3: ASP

Unit Minimum Maximum Step increment

Pressure range 1A

inH2O -2.00 30.00 0.04

mbar -5.0 74.6 0.1

kPa -0.50 7.46 0.01

mmWS -51 762 1

Pressure range 2A

inH2O -5.0 75.0 0.1

mbar -12.4 186.6 0.2

kPa -1.24 18.66 0.02

mmWS -126 1904 2

Pressure range 3A

psi -14.50 7.25 0.05

inH2O -401 201 1

mbar -1000 500 1

kPa -100.0 50.0 0.1

36 Quick Start Guide

Page 37

Quick Start Guide Setting ranges

00825-0100-4327 January 2019

Table 4-3: ASP (continued)

Unit Minimum Maximum Step increment

mWS -10.20 5.10 0.01

Pressure range 2B

psi -0.73 10.88 0.01

inH2O -20.0 301.2 0.4

mbar -50 750 1

kPa -5.0 75.0 0.1

mWS -0.51 7.65 0.01

Pressure range 4A

psi -1.46 15.00 0.02

inH2O -40 477.5 0.5

mbar -100 1188 2

kPa -10.0 118.8 0.2

mWS -1.02 12.06 0.02

Pressure range 5A

psi -1.80 27.00 0.03

inH2O -50 747 1

bar -0.124 1.860 0.002

kPa -12.4 186.0 0.2

mWS -1.26 18.98 0.01

Pressure range 6A

psi -14.50 41.25 0.05

bar -1.000 2.840 0.005

kPa -100.0 284.0 0.5

Pressure range 7A

psi -14.5 63.7 0.1

bar -1.0 4.395 0.005

kPa -100.0 439.5 0.5

Pressure range 8A

psi -14.5 108.7 0.1

bar -1.00 7.50 0.01

MPa -0.100 0.750 0.001

Pressure range 9A

psi -14.6 172.4 0.2

Quick Start Guide 37

Page 38

Setting ranges Quick Start Guide

January 2019 00825-0100-4327

Table 4-3: ASP (continued)

Unit Minimum Maximum Step increment

bar -1.0 11.88 0.02

MPa -0.1 1.19 0.002

Pressure range 1B

psi -14.4 270.0 0.3

bar -1.00 18.58 0.02

MPa -0.100 1.862 0.002

Table 4-4: AEP

Unit Minimum Maximum Step increment

Pressure range 1A

inH2O 8.00 40 0.04

mbar 19.9 95.5 0.1

kPa 1.99 9.95 0.01

mmWS 203 1016 1

Pressure range 2A

inH2O 20.0 100 0.1

mbar 49.8 248.8 0.2

kPa 4.98 24.88 0.02

mmWS 510 2540 2

Pressure range 3A

psi -7.25 14.50 0.05

inH2O -201 401 1

mbar -500 1000 1

kPa -50.0 100.0 0.1

mWS -5.10 10.20 0.01

Pressure range 2B

psi 2.90 14.50 0.01

inH2O 80.4 401.6 0.4

mbar 200 1000 1

kPa 20.0 100.0 0.1

mWS 2.04 10.20 0.01

Pressure range 4A

psi 3.54 20 0.02

inH2O 199.5 637 0.5

38 Quick Start Guide

Page 39

Quick Start Guide Setting ranges

00825-0100-4327 January 2019

Table 4-4: AEP (continued)

Unit Minimum Maximum Step increment

mbar 298 1586 2

kPa 29.8 158.6 0.2

mWS 3.02 16.1 0.02

Pressure range 5A

psi 7.20 36 0.03

inH2O 200 997 1

bar 0.498 2.482 0.002

kPa 49.8 248.2 0.2

mWS 5.07 25.31 0.01

Pressure range 6A

psi -0.75 55 0.05

bar -.050 3.79 0.005

kPa -5.0 379 0.5

Pressure range 7A

psi 6.8 85 0.1

bar 0.465 5.86 0.005

kPa 46.5 586 0.5

Pressure range 8A

psi 21.8 145.0 0.1

bar 1.50 10.00 0.01

MPa 0.150 1.000 0.001

Pressure range 9A

psi 43.0 230 0.2

bar 2.98 15.86 0.02

MPa 0.298 1.586 0.002

Pressure range 1B

psi 75.6 360.0 0.3

bar 5.20 24.82 0.02

MPa 0.522 2.482 0.002

Quick Start Guide 39

Page 40

Setting ranges Quick Start Guide

January 2019 00825-0100-4327

40 Quick Start Guide

Page 41

Quick Start Guide Troubleshooting

00825-0100-4327 January 2019

5 Troubleshooting

The pressure transmitter monitors itself for issues then reports the issues using the

display. If the pressure transmitter detects a fault, it will react according to FOU1 and

FOU2. Use the information in this section to identify and resolve common issues with the

pressure transmitter.

5.1 Error messages

Use the information in the table below to resolve errors with the pressure transmitter.

Display Description Corrective actions

Off The supply voltage is too low (fault

number W403).

PARA The parameter setting is outside the

permitted range.

E100 The pressure transmitter detected an

internal error.

5.2 Warning messages

Use the information in the table below to resolve issues indicated by warning messages

with the pressure transmitter.

Display

SC1 OUT1 Flashes Excessive current switching

SC2 OUT2 Flashes Excessive current switching

LED Status Description Corrective actions

output 1.

output 2.

• Check and/or correct the supply

voltage.

• In a two-wire operation, check

and/or correct the connected

load.

Reset the parameter.

Replace the pressure transmitter.

Check switching output 1 for a

short circuit or excessive

current then remove the fault.

Check switching output 2 for a

short circuit or excessive

current then remove the fault.

SC OUT1 and

OUT2 are

flashing

OL The measured value is more

UL The measured value is more

Quick Start Guide 41

Excessive current switching

output 1 and switching output

2.

than five percent above the

upper range limit (URL).

than five percent below the

lower range limit (LRL).

Check switching output 1 and 2

for a short circuit or excessive

current then remove the fault.

Check the system pressure and

correct it if necessary.

Check the system pressure and

correct it if necessary.

Page 42

Troubleshooting Quick Start Guide

January 2019 00825-0100-4327

Display LED Status Description Corrective actions

W531 The analog output is at the

upper limit (20.5 mA).

Loc The pressure transmitter does

not allow parameter settings to

change because the buttons

are locked.

W530 The analog output is at the

lower limit (3.8 mA).

W532 The load at the analog output is

too high

(1)

W203 The pressure transmitter

encountered an error during

the temperature compensation

of the pressure measurement

which can result in reduced

accuracy.

W703 The medium temperature is

above 302 °F (150 °C)

W704 The medium temperature is

below -22°F (-30°C).

Increase the AEP value if

possible (for OU2 = InEG,

increase ASP value) or reduce

the system pressure.

Unlock the buttons.(Locking

and unlocking the pressure

transmitter)

Reduce the ASP value (for OU2

= InEG increase AEP value) or

increase the system pressure.

Reduce the load at output 2 or

increase the supply voltage.

Replace the pressure

transmitter.

Reduce the medium

temperature.

Increase the medium

temperature.

W161 The pressure transmitter

temperature is above 194°F

Remove any insulation around

the pressure transmitter.

(90°C).

W162 The pressure transmitter

temperature is below -22°F

Insulate the pressure

transmitter.

(-30°C).

(1) The pressure transmitter displays this message only for a three-wire operation. For two-wire

operation, it detects and displays under voltage. If the pressure transmitter does not use OU2 for

the application, avoid the message by defining a switching function for OU2

42 Quick Start Guide

Page 43

Quick Start Guide Product certifications

00825-0100-4327 January 2019

6 Product certifications

6.1 European directive information

The most recent revision of the EC Declaration of Conformity can be found at

Emerson.com/Rosemount.

6.2 Ordinary location information

As standard, this product has been examined and tested to determine that the design

meets the basic electrical, mechanical, and fire protection requirements by a nationally

recognized test laboratory (NRTL) as accredited by the Federal Occupational Safety and

Health Administration (OSHA).

6.3 3-A® certification

This product is authorized to display the 3-A symbol. Ensure gaskets and process

connection accessories selected for installation meet both the application and 3-A

requirements. A certificate of compliance is available at Emerson.com/Rosemount.

6.4 Other industry certifications

All Rosemount 326P transmitter surfaces and materials which come into contact with

process medium comply with the following regulations:

• (EC) No. 1935/2004

• (EC) No. 2023/2006

• CFR Title 21 (FDA) § 186.1256

• CFR Title 21 (FDA) § 177.2600

• CFR Title 21 (FDA) § 177.1550

• CFR Title 21 (FDA) § 177. 2415

Quick Start Guide 43

Page 44

Product certifications Quick Start Guide

January 2019 00825-0100-4327

44 Quick Start Guide

Page 45

Quick Start Guide Factory settings

00825-0100-4327 January 2019

7 Factory settings

Use this worksheet to record parameter values.

Setting Factory default setting User-defined setting

SP1 ~25% URL

rP1 ~23% URL

OU1 Hno

OU2 I

SP2 ~75% URL

rP2 ~73% URL

COF / tCOF 0.0

ASP / tASP 0% URL

Pressure range 3A: -14.5 psi (-1

bar)

AEP / tAEP 100% URL

(1)(2)

(1)(2)

(1)(2)

(1)(2)

(1)

(1)

Uni psi/inH2O

SELd P

dS1 0.0

dr1 0.0

dS2 0.0

dr2 0.0

FOU1 OU

FOU2 OU

P-n pnp

dAP 0.06

dAA 0.03

dis d2

CP1 0.00

CP2 0.00

(1) The set percentage of the upper range limit (URL)(the percentage of the measuring span).

(2) For specific default factory settings, see Table 7-1.

Table 7-1: Specific factory settings for SP1, rP1, SP2, and rP2

Pressure range SP1 rP1 SP2 rP2

inH2O

1A 10.04 9.24 30.12 29.32

Quick Start Guide 45

Page 46

Factory settings Quick Start Guide

January 2019 00825-0100-4327

Table 7-1: Specific factory settings for SP1, rP1, SP2, and rP2 (continued)

Pressure range SP1 rP1 SP2 rP2

2A 25.1 23.1 75.3 73.3

psi

3A -7.25 -7.85 7.25 6.65

2B 3.63 3.34 10.88 10.59

4A 5.8 5.34 17.40 16.94

5A 9.06 5.34 17.40 16.94

6A 14.50 13.35 43.50 42.35

7A 21.8 20.0 65.3 63.5

8A 36.3 33.4 108.8 105.9

9A 58.0 53.4 174.0 169.4

1B 90.6 83.4 271.8 264.6

46 Quick Start Guide

Page 47

Quick Start Guide

00825-0100-4327 January 2019

Quick Start Guide 47

Page 48

*00825-0100-4327*

00825-0100-4327

Rev. 01

2019

Global Headquarters

Emerson Automation Solutions

6021 Innovation Blvd

Shakopee, MN 55379, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RFQ.RMD-RCC@Emerson.com

Linkedin.com/company/Emerson-Automation-Solutions

Twitter.com/Rosemount_News

Facebook.com/Rosemount

Youtube.com/user/RosemountMeasurement

North America Regional Office

Emerson Automation Solutions

8200 Market Blvd.

Chanhassen, MN 55317, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RMT-NA.RCCRF@Emerson.com

©

2019 Emerson. All rights reserved.

Emerson Terms and Conditions of Sale are available upon request. The Emerson logo is a

trademark and service mark of Emerson Electric Co. Rosemount is mark of one of the

Emerson family of companies. All other marks are the property of their respective owners.

Loading...

Loading...