Page 1

Reference Manual

00809-0100-4021, Rev JC

December 2019

Rosemount™ 3144P Temperature Transmitter

with Rosemount X-well™ Technology

Page 2

NOTICE

Read this manual before working with the product. For personal and system safety, and for optimum product performance,

ensure you thoroughly understand the contents before installing, using, or maintaining this product.

Within the United States, Emerson has two toll-free assistance numbers:

Customer Central (Technical support, quoting, and order-related questions): 1-800-999-9307 (7:00 am to 7:00 pm Central Time)

North American Response Center (Equipment service needs): 1-800-654-7768 (24 hours)

International: (952)-906-8888

CAUTION

The products described in this document are NOT designed for nuclear-qualified applications.

Using non-nuclear qualified products in applications that require nuclear-qualified hardware or products may cause inaccurate

readings.

For information on Rosemount nuclear-qualified products, contact your local Emerson Sales Representative.

WARNING

Failure to follow these installation guidelines could result in death or serious injury.

Ensure only qualified personnel perform installation or service.

Electrical shock could cause death or serious injury.

Use extreme caution when making contact with the leads and terminals.

Explosions could result in death or serious injury.

Do not remove the connection head cover in explosive atmospheres when the circuit is live.

Before powering a FOUNDATION™ Fieldbus segment in an explosive atmosphere, ensure the instruments in the loop are installed in

accordance with intrinsically safe or non-incendive field wiring practices.

Verify that the operating atmosphere of the transmitter is consistent with the appropriate hazardous locations certifications.

All connection head covers must be fully engaged to meet explosion-proof requirements.

Process leaks could result in death or serious injury.

Do not remove the thermowell while in operation.

Install and tighten thermowells or sensors before applying pressure.

Physical access

Unauthorized personnel may potentially cause significant damage to and/or misconfiguration of end users’ equipment. This could

be intentional or unintentional and needs to be protected against.

Physical security is an important part of any security program and fundamental to protecting your system. Restrict physical access

by unauthorized personnel to protect end users’ assets. This is true for all systems used within the facility.

2

Page 3

Reference Manual Contents

00809-0100-4021 December 2019

Contents

Chapter 1 Introduction.................................................................................................................. 5

1.1 Using this manual.............................................................................................................................5

1.2 Rosemount 3144P revisions............................................................................................................. 6

1.3 Confirm HART revision capability....................................................................................................10

Chapter 2 Installation...................................................................................................................11

2.1 Installation considerations..............................................................................................................11

2.2 Commissioning.............................................................................................................................. 13

2.3 Mounting....................................................................................................................................... 16

2.4 Installation..................................................................................................................................... 17

2.5 Wiring............................................................................................................................................ 23

2.6 Foundation Fieldbus....................................................................................................................... 27

2.7 Power supply..................................................................................................................................28

2.8 Grounding......................................................................................................................................29

2.9 Wire and apply power.....................................................................................................................32

Chapter 3 HART Commissioning...................................................................................................33

3.1 Overview........................................................................................................................................ 33

3.2 Confirm HART revision capability....................................................................................................33

3.3 Safety messages.............................................................................................................................34

3.4 Field Communicator.......................................................................................................................34

3.5 Review configuration data..............................................................................................................44

3.6 Check output..................................................................................................................................44

3.7 Configuration................................................................................................................................. 44

3.8 Rosemount X-well Technology configuration................................................................................. 99

3.9 Device output configuration.........................................................................................................102

3.10 Device information.....................................................................................................................104

3.11 Measurement filtering................................................................................................................106

3.12 Diagnostics and service.............................................................................................................. 108

3.13 Multidrop communication..........................................................................................................109

3.14 Use with the HART Tri-Loop........................................................................................................110

3.15 Configure Thermocouple Degradation in guided setup.............................................................. 113

3.16 Configure Thermocouple Degradation in manual setup............................................................. 118

3.17 Active Thermocouple Degradation Alerts...................................................................................123

3.18 Minimum/maximum tracking diagnostic....................................................................................128

3.19 Calibration..................................................................................................................................136

3.20 Trim the transmitter...................................................................................................................137

3.21 Output trim or scaled output trim.............................................................................................. 147

Reference Manual iii

Page 4

Contents Reference Manual

December 2019 00809-0100-4021

3.22 Troubleshooting.........................................................................................................................148

Chapter 4 FOUNDATION Fieldbus Configuration......................................................................... 157

4.1 Overview...................................................................................................................................... 157

4.2 Safety messages...........................................................................................................................157

4.3 Device description........................................................................................................................157

4.4 Node address............................................................................................................................... 158

4.5 Modes.......................................................................................................................................... 158

4.6 Link Active Scheduler (LAS)...........................................................................................................159

4.7 Capabilities...................................................................................................................................159

4.8 FOUNDATION Fieldbus function blocks............................................................................................ 160

4.9 Resource block............................................................................................................................. 162

4.10 Analog Input (AI)........................................................................................................................ 175

4.11 Operation...................................................................................................................................182

4.12 Troubleshooting guides..............................................................................................................188

Chapter 5 Operation and maintenance.......................................................................................193

5.1 Safety messages...........................................................................................................................193

5.2 Maintenance................................................................................................................................ 193

5.3 Return of materials.......................................................................................................................195

Chapter 6 Safety Instrumented Systems (SIS) requirements....................................................... 197

6.1 SIS certification.............................................................................................................................197

6.2 Safety certified identification........................................................................................................197

6.3 Installation................................................................................................................................... 197

6.4 Configuration...............................................................................................................................198

6.5 Operation and maintenance.........................................................................................................200

6.6 Specifications............................................................................................................................... 201

6.7 Spare parts................................................................................................................................... 202

Appendix A Reference data........................................................................................................... 203

A.1 Product Certifications...................................................................................................................203

A.2 Ordering Information, Specifications, and Drawings.................................................................... 203

iv Rosemount 3144P

Page 5

Reference Manual

00809-0100-4021 December 2019

Introduction

1 Introduction

1.1 Using this manual

The sections in this manual provide information on installing, operating, and maintaining

the Rosemount™ 3144P Temperature Transmitter. The sections are organized as follows:

• Installation contains mechanical and electrical installation instructions.

• HART Commissioning contains techniques for properly commissioning the device.

• FOUNDATION Fieldbus Configuration provides instruction on commissioning and

operating the Rosemount 3144P Transmitter. This chapter also includes information

on software functions, configuration parameters, and online variables.

• Operation and maintenance contains operation and maintenance techniques.

• Safety Instrumented Systems (SIS) Requirements provides identification, installation,

configuration, operation and maintenance, and inspection information for Safety

Instrumented Systems.

1.1.1

• Reference Data supplies reference and specification data, as well as ordering

information and contains intrinsic safety approval information, European ATEX

directive information, and approval drawings.

Transmitter

Industry-leading temperature transmitter delivers unmatched field reliability and

innovative process measurement solutions:

• Rosemount X-Well™ Technology provides a Complete Point Solution™ for accurately

measuring process temperature in monitoring applications without the requirement of

a thermowell or process penetration

• Superior accuracy and stability

• Dual and single sensor capability with universal sensor inputs (RTD, T/C, mV, ohms)

• Comprehensive sensor and process diagnostics offering

• IEC 61508 safety certification

• Dual-compartment housing

• Large LCD display

• Selectable HART® Revision (5 and 7) or FOUNDATION Fieldbus protocols

Improve efficiency with Best-in-Class product specifications and capabilities:

• Reduce maintenance and improve performance with industry leading accuracy and

stability.

• Improve measurement accuracy by 75 percent with Transmitter-Sensor Matching.

• Ensure process health with system alerts and easy-to-use Device Dashboards.

Reference Manual 5

Page 6

Introduction Reference Manual

December 2019 00809-0100-4021

• Easily check device status and values on local LCD display with large percent range

graph.

• Achieve high reliability and installation ease with the industry's most rugged dual

compartment design.

Optimize measurement reliability with diagnostics designed for any protocol on any host

system.

• Thermocouple Degradation Diagnostic monitors the health of a thermocouple loop,

enabling preventative maintenance.

• Minimum and Maximum Temperature Tracking tracks and records temperature

extremes of the process sensors and the ambient environment.

• Sensor Drift Alert detects sensor drift and alerts you.

• The Hot Backup™ feature provides temperature measurement redundancy.

Refer to the following literature for a full range of compatible connection heads, sensors,

and thermowells provided by Emerson:

• Rosemount Volume 1 Temperature Sensors and Accessories Product Data Sheet

• Rosemount DIN-Style Temperature Sensors and Thermowells (Metric) Product Data

Sheet

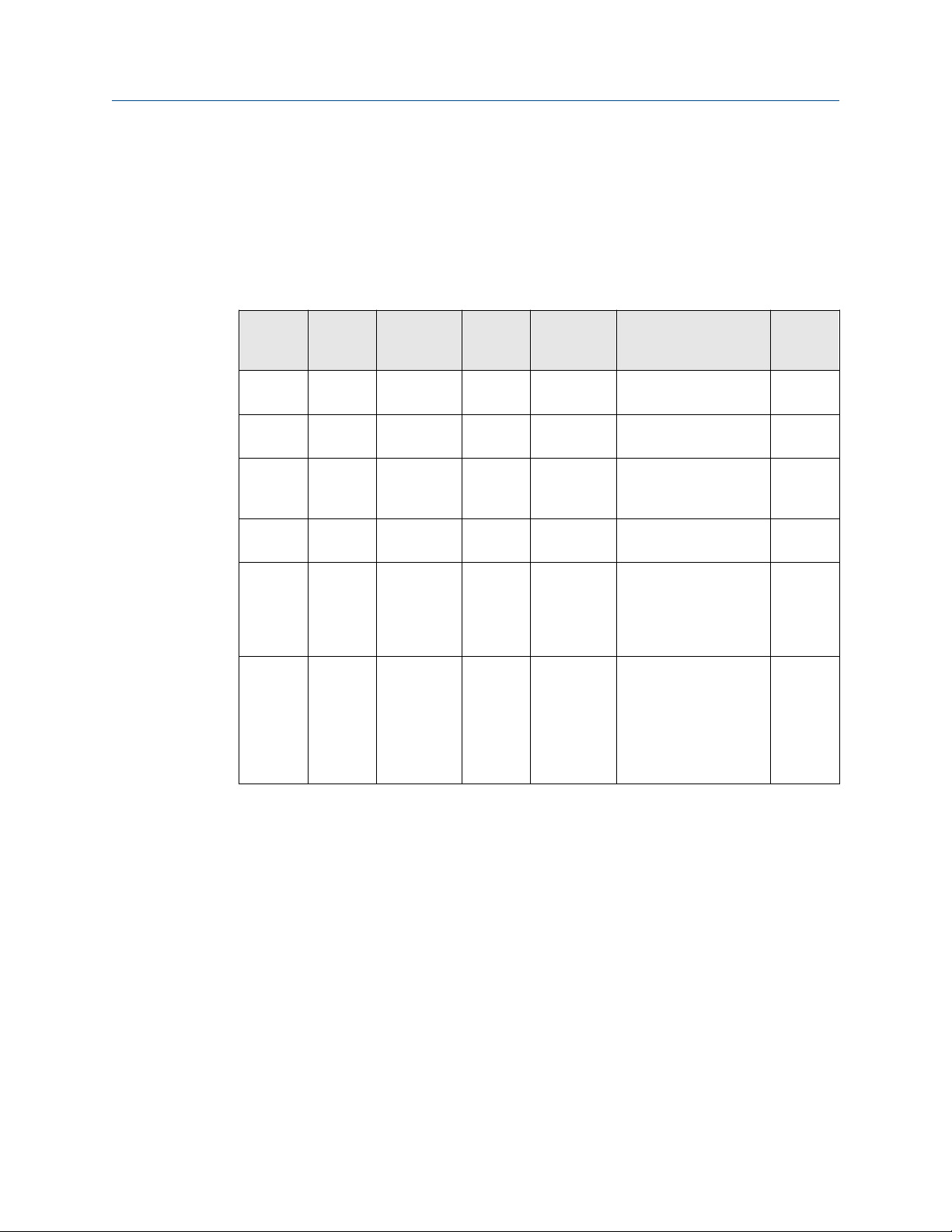

1.2 Rosemount 3144P revisions

HART protocol

The initial release of the Rosemount 3144P HART was device revision 3. Each additional

revision contains incremental improvements. summarizes these changes.

Table 1-1: HART Revisions

Software

release date

April 2017 1.2.1 1.0.0 3 7 7

April 2012 1.1.1 N/A 2 7 6

Feb 2007 N/A N/A 1 5 4

Identify device Field device driver Review

NAMUR

software

revision

NAMUR

hardware

Revision

HART

software

revision

HART

universal

(1)

revision

5 5

5 5

(2)

)

Device

revision

(3)

(4)

(4)

(4)

instructions

Manual

document

number

00809-0100-40

21

Dec 2003 N/A N/A N/A 5 3

(1) NAMUR software revision is located in the hardware tag of the device. You can read the HART

software revision with a HART capable configuration tool.

(2) Device driver file names use device and DD devision (e.g. 10_07). HART protocol is designed to

enable legacy driver revisions to continue to communicate with new HART devices. To access this

functionality, download the new device driver. Emerson recommends downloading the new

device driver to ensure new functionality.

6 Rosemount 3144P

Page 7

Reference Manual Introduction

00809-0100-4021 December 2019

(3) Rosemount X-well sensor type.

(4) HART Revision 5 and 7 selectable, Thermocouple Degradation Diagnostic, Min/Max Tracking.

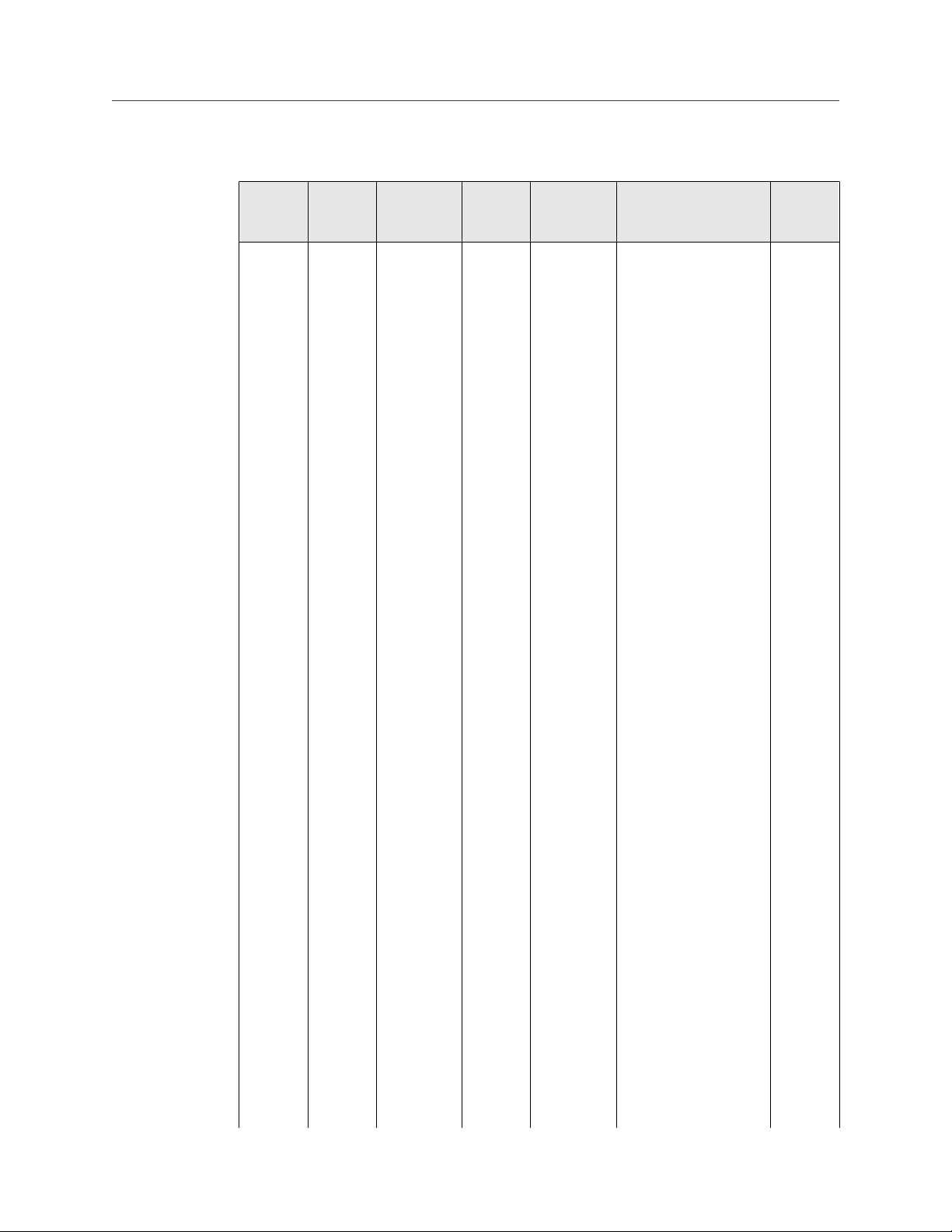

FOUNDATION Fieldbus

The following table summarizes the Rosemount 3144P FOUNDATION™ Fieldbus revision

history.

Table 1-2: FOUNDATION Fieldbus Revisions

Device

revision

Rev 1 1.00.011 5 N/A N/A Initial release. Mar.

Rev 1 1.00.024 5 N/A N/A Minor product

Rev 1 1.00.024 6 N/A N/A Minor product

Rev 1 1.01.004 6 N/A N/A Software update. Oct.

Rev 1 1.01.010 7 N/A N/A Component

Rev 2 2.02.003 7 N/A N/A FF Sensor and Process

Software

revision

Hardware

revision

NAMUR

software

revision

NAMUR

hardware

revision

Description Date

2004

Sep.

maintenance, software.

maintenance,

hardware.

obsolescence hardware

change and software to

support the hardware

change.

Diagnostic Release

(D01): Thermocouple

Degradation Diagnostic

and Minimum and

Maximum Temperature

Tracking.

2004

Dec.

2004

2005

Feb.

2007

Nov.

2008

Reference Manual 7

Page 8

Introduction Reference Manual

December 2019 00809-0100-4021

Table 1-2: FOUNDATION Fieldbus Revisions (continued)

Device

revision

Rev 3 3.10.23 7 1.3.1 1.0.0 Device Compliance to

Software

revision

Hardware

revision

NAMUR

software

revision

NAMUR

hardware

revision

Description Date

ITK 6.0.1. Addition of

NE107 device

diagnostic information.

Ease of use

improvements

including:

• Hot Backup

functionality has

been moved to the

transducer block,

allowing easier

configuration from

the DD.

• Device is shipped

with the simulate

switch ON, allowing

device alerts

simulation without

cover removal.

• Device has unique

block names using

the last four digits

(XXXX) of the

output board serial

number, e.g.

AI_1400_XXXX

• All blocks are

instantiated before

shipping, including

model option code

dependent blocks.

The product also

has all parameters

initialized so that its

primary

measurement is

available with no

user changes

required.

• All devices ship will

AI block scheduled.

• Customer will be

able to use old DD

files when replacing

a device with a

newer rev device;

this is possible for

devices with device

June

2013

8 Rosemount 3144P

Page 9

Reference Manual Introduction

00809-0100-4021 December 2019

Device

revision

Software

revision

Hardware

revision

NAMUR

software

revision

NAMUR

hardware

revision

Description Date

revision number 3

and above.

• Wherever possible,

the product ships

with parameters

initialized to

common values.

The product shall

ship with no

uninitialized

parameters that will

keep the

transmitter from

providing its

primary

measurement right

out of the box.

• The product's

default block tags

are be less than or

equal to 16

characters in

length.

• Custom function

blocks were

replaced with

enhanced function

blocks.

• Default block tags

include

underscores, “_”,

instead of white

spaces.

• The CF file has a

better description

of the device,

including

meaningful defaults

and example values.

• Device provides

means to properly

range graphs and

charts in the device

dashboards.

Reference Manual 9

Page 10

Introduction Reference Manual

December 2019 00809-0100-4021

1.3 Confirm HART revision capability

Confirm the HART capability of the system devices prior to transmitter installation.

Prerequisites

If using HART based control or asset management systems, confirm the HART capability of

those systems prior to transmitter installation. Not all systems are capable of

communicating with HART Revision 7protocol. You can configure the transmitter for

either HART Revision 5 or Revision 7.

Switch HART revision mode

If the HART configuration tool is not capable of communicating with HART Revision 7, the

transmitter will load a Generic Menu with limited capability. The following procedures will

switch the HART revision mode from the Generic Menu.

Procedure

Select Manual Setup → Device Information → Identification → Message.

a) To change to HART Revision 5, enter HART5 in the Message field.

b) To change to HART Revision 7, enter HART7 in the Message field.

10 Rosemount 3144P

Page 11

(1,500

°F)

T

emperat

u

r

e

Oven

(

1,

0

00 °F)

Tempera

ture

Oven

(

4

82 °

F)

T

em

p

er

ature

Oven

Housing Temperature

Rise Above

Ambient °C (°F)

60 (108)

50 (90)

40 (72)

0

30 (54)

20 (36)

10 (18)

3

4

5 6

7 8 9

Extension Length (in.)

815 °C

250 °

C

5

40 °C

22

3.6

Reference Manual Installation

00809-0100-4021 December 2019

2 Installation

2.1 Installation considerations

2.1.1 General

Electrical temperature sensors, such as resistance temperature detectors (RTDs) and

thermocouples (T/Cs), produce low-level signals proportional to temperature. The

Rosemount X-well™ 3144P Temperature Transmitter converts low-level signals to HART

or FOUNDATION™ Fieldbus and then transmits the signals to the control system via two

power/signal wires.

®

2.1.2

2.1.3

Electrical

Proper electrical installation is essential to prevent errors due to sensor lead resistance and

electrical noise. For HART communications, the current loop must have between 250 and

1100 ohms resistance. Refer to for sensor and current loop connections. Foundation

Fieldbus devices must have proper termination and power conditioning for reliable

operation. Shielded cables must be used for Foundation Fieldbus and may only be

grounded in one place.

Temperature effects

Temperature effects

The transmitter will operate within specifications for ambient temperatures between –40

and 185 °F (–40 and 85 °C). Since heat from the process is transferred from the thermowell

to the transmitter housing, if the expected process temperature is near or beyond

specification limits, consider using additional thermowell lagging, an extension nipple, or

a remote mounting configuration to isolate the transmitter from the process. Figure 2-1

details the relationship between housing temperature rise and extension length.

Figure 2-1: Transmitter Housing Temperature Rise versus Extension Length for a Test

Installation

Reference Manual 11

Page 12

Installation

December 2019 00809-0100-4021

Example

The maximum permissible housing temperature rise (T) can be calculated by subtracting

the maximum ambient temperature (A) from the transmitter’s ambient temperature

specification limit (S). For instance, if A = 40 °C.

T = S – A

T = 85 °C – 40 °C

T = 45 °C

For a process temperature of 540 °C (1004 °F), an extension length of 3.6-in (91.4 mm)

yields a housing temperature rise (R) of 22 °C (72 °F), providing a safety margin of 23 °C

(73 °F). A 6.0-in.(152.4 mm) extension length (R = 10 °C [50 °F]) offers a higher safety

margin (35 °C [95 °F]) and reduces temperature-effect errors but would probably require

extra transmitter support. Gauge the requirements for individual applications along this

scale. If a thermowell with lagging is used, the extension length may be reduced by the

length of the lagging.

Reference Manual

2.1.4

2.1.5

Moist or corrosive environments

The Rosemount 3144P Transmitter has a highly reliable dual compartment housing

designed to resist moisture and corrosion. The sealed electronics module is mounted in a

compartment that is isolated from the terminal side with conduit entries. O-ring seals

protect the interior when the covers are properly installed. In humid environments,

however, it is possible for moisture to accumulate in conduit lines and drain into the

housing.

Note

Each transmitter is marked with a tag indicating the approvals. Install the transmitter

according to all applicable installation codes, and approval and installation drawings (see

Rosemount 3144P Product Data Sheet). Verify that the operating atmosphere of the

transmitter is consistent with the hazardous locations certifications. Once a device labeled

with multiple approval types is installed, it should not be reinstalled using any of the other

labeled approval types. To ensure this, the approval label should be permanently marked

to distinguish the approval type(s) used.

Location and position

When choosing an installation location and position, take access to the transmitter into

account.

Terminal side of electronics housing

Mount the transmitter so the terminal side is accessible, allowing adequate clearance for

cover removal. Best practice is to mount the transmitter with the conduit entries in a

vertical position to allow for moisture drainage.

Circuit side of electronics housing

Mount the transmitter so the circuit side is accessible, providing adequate clearance for

cover removal. Additional room is required for LCD display installation. The transmitter

may be mounted directly to or remotely from the sensor. Using optional mounting

12 Rosemount 3144P

Page 13

Reference Manual Installation

00809-0100-4021 December 2019

brackets, the transmitter may be mounted to a flat surface or a 2.0-in. (50.8 mm)

diameter pipe (see Mounting).

2.1.6 Software compatibility

Replacement transmitters may contain revised software that is not fully compatible with

the existing software. The latest device descriptors (DD) are available with new Field

Communicators or they can be loaded into existing communicators at any Emerson

Service Center or via the Easy Upgrade process. For more information on upgrading a Field

Communicator, see HART Commissioning.

To download new device drivers, visit Emerson.com/Rosemount/Device-Install-Kits.

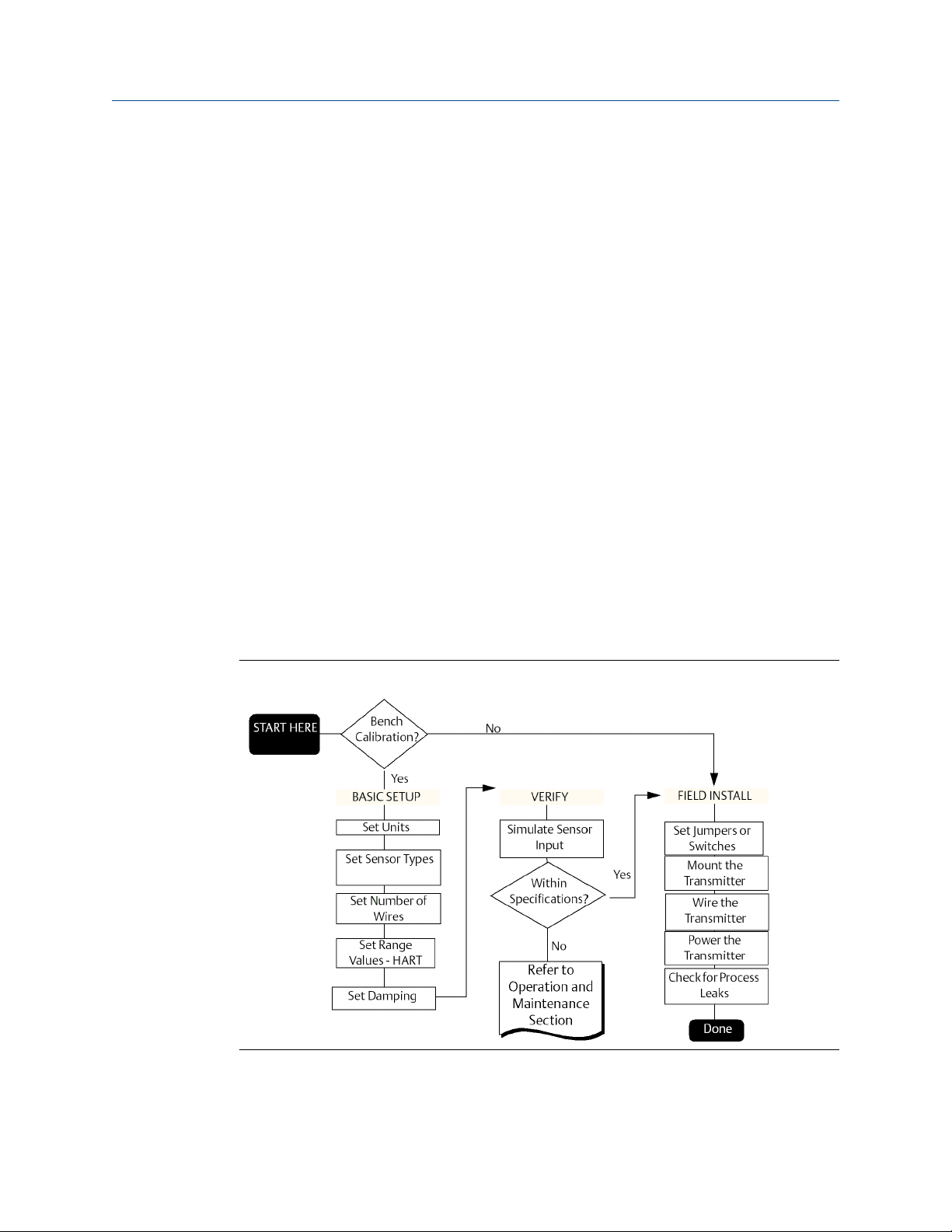

2.2 Commissioning

The transmitter must be configured for certain basic variables to operate. In many cases,

these variables are pre-configured at the factory. Configuration may be required if the

variables need to be changed.

Commissioning consists of testing the transmitter and verifying transmitter configuration

data. Transmitters can be commissioned either before or after installation. Commissioning

the transmitter on the bench before installation using a Field Communicator or AMS

Device Manager ensures that all transmitter components are in working order.

For more information on using the Field Communicator with the transmitter, see HART

Commissioning. For more information on using the Rosemount 3144 with FOUNDATION

Fieldbus, see FOUNDATION Fieldbus Configuration.

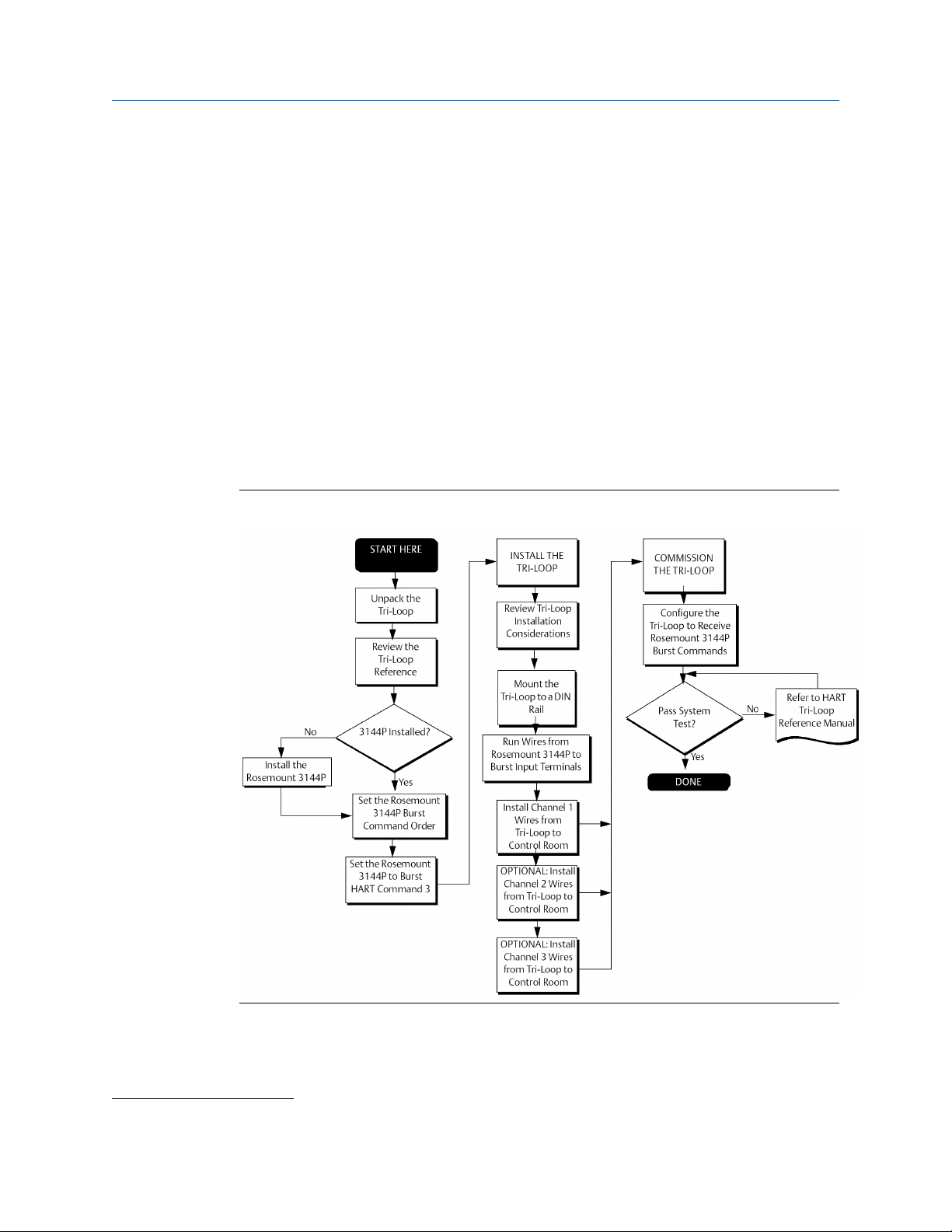

Figure 2-2: Installation Flowchart

Reference Manual 13

Page 14

Installation

December 2019 00809-0100-4021

Reference Manual

2.2.1 Setting the loop to manual

Set the process application loop to manual when sending or requesting data that would

disrupt the loop or change the output of the transmitter. The Field Communicator or AMS

Device Manager will prompt to set the loop to manual, when necessary. Acknowledging

the prompt does not set the loop to manual, it is only a reminder. Setting the loop to

manual is a separate operation.

2.2.2 Set switches

The security and simulate switches are located on the top center of the electronics

module.

Note

The factory ships the simulate switch in the "ON" position.

HART

Set the switches without an LCD display

Procedure

1. If the transmitter is installed in a loop, set the loop to manual mode and disconnect

the power.

2.

Remove the housing cover on the electronics side of the transmitter. Do not

remove the transmitter cover in explosive atmospheres with a live circuit.

3. Set the switches to the desired position (see Figure 2-3).

4. Replace the transmitter cover. Both transmitter covers must be fully engaged to

meet explosion-proof requirements.

5. Apply power and set the loop to automatic mode.

Set the switches with an LCD display

Procedure

1. If the transmitter is installed in a loop, set the loop to manual mode and disconnect

the power.

2. Remove the housing cover on the electronics side of the transmitter. Do not

remove the transmitter cover in explosive atmospheres with a live circuit.

3. Unscrew the LCD display screws and gently slide the meter straight off.

4. Set the switches to the desired position (see Figure 2-3).

5. Gently slide the LCD display back into place, taking extra precautions with the 10

pin connection.

6. Replace and tighten the LCD display screws to secure the LCD display.

7. Replace the transmitter cover. Both transmitter covers must be fully engaged to

meet explosion-proof requirements.

8. Apply power and set the loop to automatic mode.

14 Rosemount 3144P

Page 15

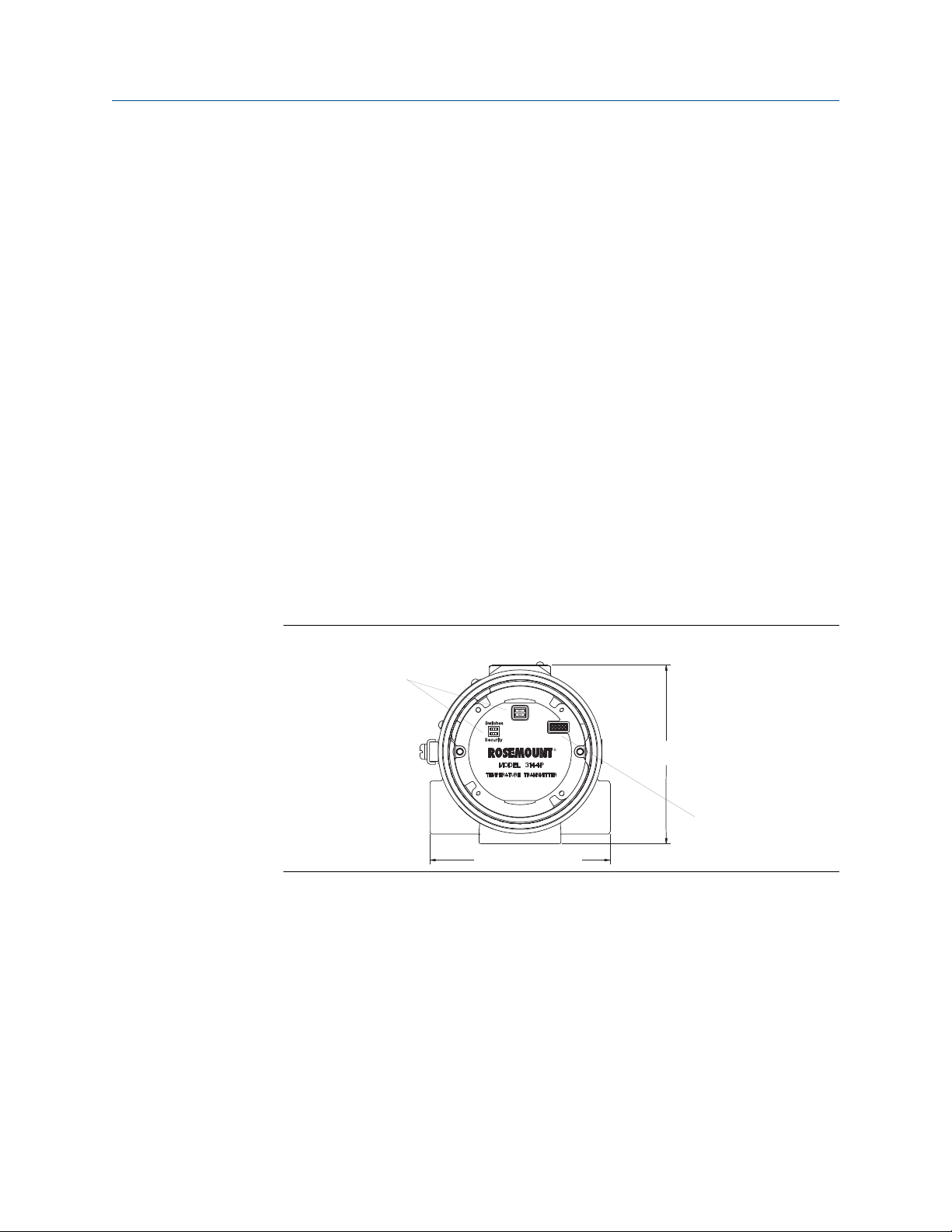

4.37-in. (110,9 mm)

4.40-in. (111,8 mm)

A

B

Reference Manual

00809-0100-4021 December 2019

Installation

FOUNDATION Fieldbus

Set switches without LCD display

Procedure

1. Set the loop to Out-of-Service (OOS) mode (if applicable) and disconnect the

power.

2. Remove the electronics housing cover.

3. Set the switches to the desired position.

4. Reattach housing cover.

5. Apply power and set the loop to in-service mode.

Set switches with LCD display

Procedure

1. Set the loop to OOS (if applicable) and disconnect the power.

2. Remove the housing cover on the electronics side of the transmitter.

3. Unscrew the LCD display screws and gently pull the meter straight off.

4. Set the switches to the desired position.

5. Replace and tighten the LCD display screws to secure the LCD display.

6. Replace the transmitter cover.

7. Apply power and set the loop to In-service mode.

Figure 2-3: Transmitter Switch Locations

Write protect switch (HART and FOUNDATION Fieldbus)

The transmitter is equipped with a write-protect switch that can be positioned to prevent

accidental or deliberate change of configuration data.

Alarm switch (HART Protocol)

An automatic diagnostic routine monitors the transmitter during normal operation. If the

diagnostic routine detects a sensor failure or an electronics failure, the transmitter goes

into alarm (high or low, depending on the position of the failure mode switch).

Reference Manual 15

Page 16

Installation Reference Manual

December 2019 00809-0100-4021

The analog alarm and saturation values used by the transmitter depend on whether it is

configured to standard or NAMUR-compliant operation. These values are also customconfigurable in both the factory and the field using the HART Communications. The limits

are:

• 21.0 ≤ I ≤ 23 for high alarm

• 20.5 ≤ I ≤ 20.9 for high saturation

• 3.70 ≤ I ≤ 3.90 for low saturation

• 3.50 ≤ I ≤ 3.75 for low alarm

Note

A 0.1 mA separation between low saturation and low alarm is required.

Table 2-1: Values for Standard and NAMUR Operation

Standard operation (factory default) NAMUR-compliant operation

Fail high 21.75 mA ≤ I Fail high 21.0 mA ≤ I

High saturation 20.5 mA High saturation 20.5 mA

Low saturation 3.9 mA Low saturation 3.8 mA

Fail low I ≤ 3.75 mA Fail low I ≤ 3.6 mA

Simulate switch (FOUNDATION Fieldbus)

Simulate switch is used to replace the channel value coming from the sensor transducer

block. For testing purposes, it manually simulates the output of the analog input block to a

desired value.

2.3 Mounting

If possible, the transmitter should be mounted at a high point in the conduit run so

moisture from the conduits will not drain into the housing. The terminal compartment

could fill with water if the transmitter is mounted at a low point in the conduit run. In some

instances, the installation of a poured conduit seal, such as the one pictured in Figure 2-5,

is advisable. Remove the terminal compartment cover periodically and inspect the

transmitter for moisture and corrosion.

Figure 2-4: Incorrect Conduit Installation

16 Rosemount 3144P

Page 17

A

D

B

E

F

C

Reference Manual Installation

00809-0100-4021 December 2019

Figure 2-5: Recommended Mounting with Drain Seal

A. Sealing compound

B. Union coupling with extension

C. Conduit for field wiring

D. Thermowell

E. Sensor hex

F. Poured conduit seal (where required)

If mounting the transmitter directly to the sensor assembly, use the process shown in

Figure 2-6. If mounting the transmitter apart from the sensor assembly, use conduit

between the sensor and transmitter. The transmitter accepts male conduit fittings with ½

–14 NPT, M20 × 1.5 (CM 20), PG 13.5 (PG 11), or JIS G ½ threads (M20 × 1.5 (CM 20),

PG 13.5 (PG 11), or JIS G ½ threads are provided by an adapter). Make sure only qualified

personnel perform the installation.

The transmitter may require supplementary support under high-vibration conditions,

particularly if used with extensive thermowell lagging or long extension fittings. Pipestand mounting, using one of the optional mounting brackets, is recommended for use in

high-vibration conditions.

2.4 Installation

Installation is to be performed by qualified personnel. No special installation is required in

addition to the standard installation practices outlined in this document. Always ensure a

proper seal by installing the electronics housing cover(s) so that metal contacts metal.

The loop should be designed so the terminal voltage does not drop below 12 Vdc when

the transmitter output is 24.5 mA.

Environmental limits are available in the Rosemount 3144P Temperature Transmitter

Product Page.

Reference Manual 17

Page 18

A

B

C

E

D

Installation Reference Manual

December 2019 00809-0100-4021

2.4.1 Typical North American installation

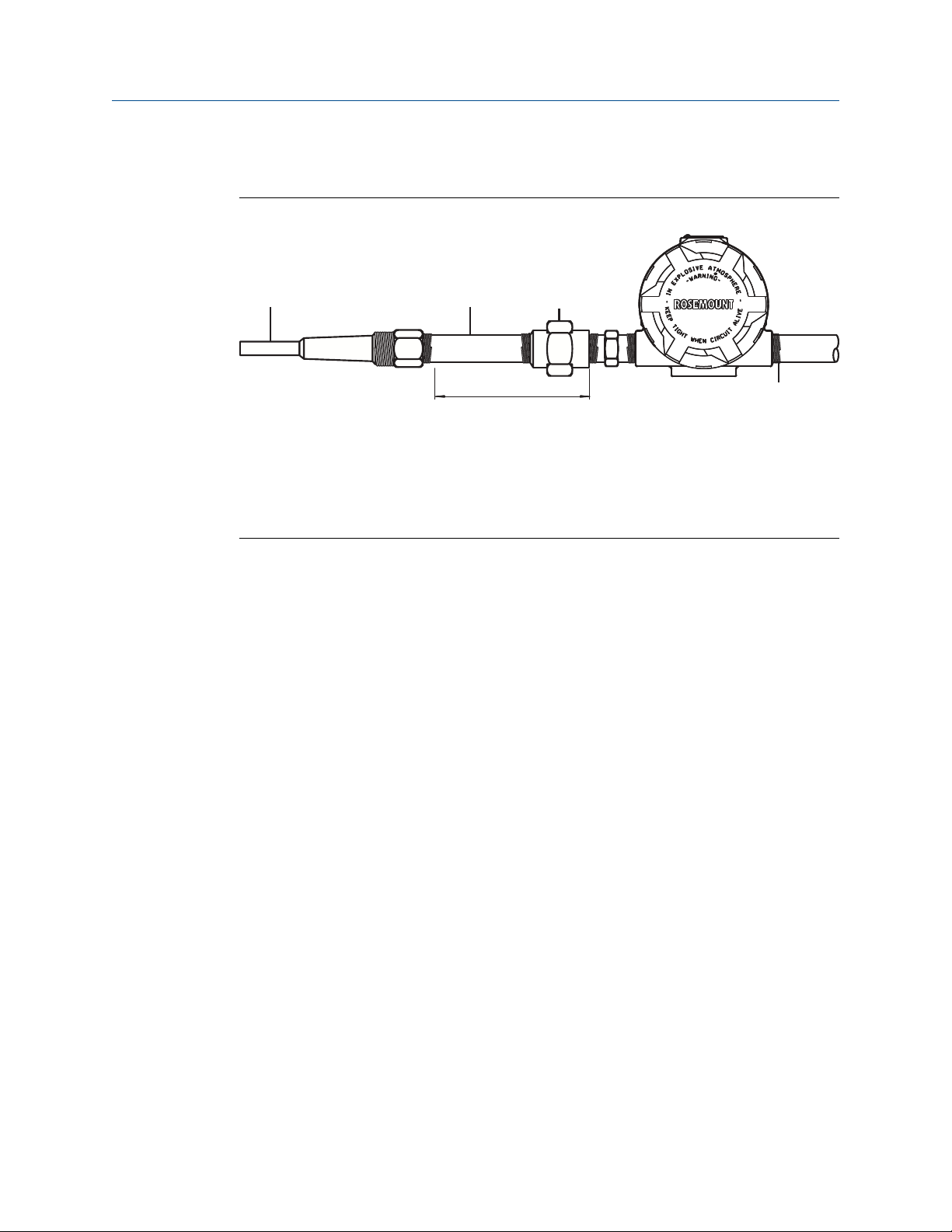

Figure 2-6: Typical Direct-Mounted Configuration

A. Thermowell

B. Extension (nipple)

C. Union or coupling

D. Conduit for field wiring (dc power)

E. Extension fitting length

Procedure

1. Mount the thermowell to the process container wall.

2. Install and tighten thermowells.

3. Perform a leak check.

4. Attach any necessary unions, couplings, and extension fittings. Seal the fitting

threads with an approved thread sealant, such as silicone or PTFE tape (if required).

5. Screw the sensor into the thermowell or directly into the process (depending on

installation requirements).

6. Verify all sealing requirements.

7. Attach the transmitter to the thermowell/sensor assembly. Seal all threads with an

approved thread sealant, such as silicone or PTFE tape (if required).

8. Install field wiring conduit into the open transmitter conduit entry (for remote

mounting) and feed wires into the transmitter housing.

9. Pull the field wiring leads into the terminal side of the housing.

10. Attach the sensor leads to the transmitter sensor terminals.

The wiring diagram is located inside the housing cover.

11. Attach and tighten both transmitter covers.

18 Rosemount 3144P

Page 19

A

B

C

D

E

Reference Manual

00809-0100-4021 December 2019

Installation

2.4.2 Typical European installation

Figure 2-7: Typical Remote-Mounted Configuration with Cable Glands

A. Cable gland

B. Shielded cable from sensor to transmitter

C. Shielded cable from transmitter to control room

D. 2-in. (50 mm) pipe

E. B4 mounting bracket

2.4.3

Procedure

1. Mount the thermowell to the process container wall.

2. Install and tighten thermowells.

3. Perform a leak check.

4. Attach a connection head to the thermowell.

5. Insert sensor into the thermowell and wire the sensor to the connection head.

The wiring diagram is located inside the connection head.

6. Mount the transmitter to a 2-in. (50 mm) pipe or a panel using one of the optional

mounting brackets.

7. Attach cable glands to the shielded cable running from the connection head to the

transmitter conduit entry.

8. Run the shielded cable from the opposite conduit entry on the transmitter back to

the control room.

9. Insert shielded cable leads through the cable entries into the connection head/

transmitter. Connect and tighten cable glands.

10. Connect the shielded cable leads to the connection head terminals (located inside

the connection head) and to the sensor wiring terminals (located inside the

transmitter housing).

Rosemount X-well installation

Rosemount X-well™ Technology is for temperature monitoring applications and is not

intended for control or safety applications. It is available in the Rosemount 3144P

Temperature Transmitter in a factory assembled direct mount configuration with a

Rosemount 0085 Pipe Clamp Sensor. It cannot be used in a remote mount configuration.

Rosemount X-well Technology will only work as specified with factory supplied and

Reference Manual 19

assembled Rosemount 0085 Pipe Clamp silver tipped single element sensor with an 80

mm extension length. It will not work as specified if used with other sensors. Installation

Page 20

Installation

December 2019 00809-0100-4021

and use of incorrect sensor will result in inaccurate process temperature calculations. It is

extremely important that the above requirements and installation steps below are

followed to ensure that Rosemount X-well Technology works as specified.

In general, pipe clamp sensor installation best practices shall be followed. See Rosemount

0085 Pipe Clamp Sensor Quick Start Guide with Rosemount X-well Technology specific

requirements noted:

1. Mount transmitter directly on pipe clamp sensor in order for Rosemount X-well

Technology to properly function.

2. Install assembly away from dynamic external temperature sources such as a boiler

or heat tracing.

3. Ensure for the pipe clamp sensor tip to make direct contact with the pipe surface for

Rosemount X-well Technology. Moisture build-up between sensor and pipe surface,

or sensor hang-up in assembly can cause inaccurate process temperature

calculations. Refer to installation best practices in Rosemount 0085 Pipe Clamp

Sensor Quick Start Guide to ensure proper sensor to pipe surface contact.

4. Insulation ½-in. thick minimum with a R-value of > 0.42 m² × K/W) is required over

the sensor clamp assembly and sensor extension up to transmitter head to prevent

heat loss. Apply a minimum of six inches of insulation on each side of the pipe

clamp sensor. Care should be taken to minimize air gaps between insulation and

pipe.

Reference Manual

2.4.4

Note

DO NOT apply insulation over transmitter head as it will result in longer response

times and may damage transmitter electronics.

5. Although it will come factory configured as such, ensure that pipe clamp RTD

sensor is assembled in 4-wire configuration.

Figure 2-8: Rosemount 3144P Transmitter with Rosemount X-well Technology

Installation

Install Rosemount X-well in conjunction with a Rosemount 333 Tri-Loop (HART/4–20 mA only)

Use the dual-sensor option Rosemount 3144P Transmitter that is operating with two

sensors in conjunction with a Rosemount 333 HART Tri-Loop™ HART-to-Analog Signal

Converter to acquire an independent 4–20 mA analog output signal for each sensor input.

20 Rosemount 3144P

Page 21

Reference Manual Installation

00809-0100-4021 December 2019

The transmitter can be configured to output four of the six following digital process

variables:

• Sensor 1

• Sensor 2

• Differential temperature

• Average temperature

• First good temperature

• Transmitter terminal temperature

• Surface temperature (Rosemount X-well only)

The HART Tri-Loop reads the digital signal and outputs any or all of these variables into as

many as three separate 4–20 mA analog channels.

Refer to Figure 2-9 for basic installation information. Refer to the Rosemount 333 HARTto-Analog Reference Manual signal converter for complete installation information.

Figure 2-9: HART Tri-Loop Installation Flowchart

(1)

(1) See Use with the HART Tri-Loop for configuration information.

Reference Manual 21

Page 22

Installation Reference Manual

December 2019 00809-0100-4021

2.4.5 LCD display

Transmitters ordered with the LCD display option (code M5) are shipped with the LCD

display installed. After-market installation of the LCD display on a conventional transmitter

requires a small instrument screwdriver and the LCD display kit, which includes:

• LCD display assembly

• Extended cover with cover O-ring in place

• Captive screws (quantity 2)

• 10-pin interconnection header

To install the LCD display:

Procedure

1. If the transmitter is installed in a loop, set the loop to manual (HART)/out-of-service

(FOUNDATION Fieldbus) mode and disconnect the power.

2. Remove the housing cover from the electronics side of the transmitter. Do not

remove the transmitter covers in explosive atmospheres with a live circuit.

3. Ensure that the transmitter write protect switch is set to the Off position. If

transmitter security is On, the transmitter cannot be configured to recognize the

LCD display. If security On is desired, configure the transmitter for the LCD display,

and then install the meter.

4. Insert the interconnection header in the 10-pin socket on the face of the electronics

module. Insert the pins into the electronics LCD display interface.

5. The meter can be rotated in 90-degree increments for easy viewing. Position one of

the four 10-pin sockets on the back of the meter to accept the interconnection

header.

6. Attach the LCD display assembly to the interconnection pins, then thread and

tighten the LCD display screws into the holes on the electronics module.

7. Attach the extended cover; tighten at least one-third turn after the O-ring contacts

the transmitter housing. Both transmitter covers must be fully engaged to meet

explosion proof requirements.

8. Apply power and set the loop to automatic (HART)/in-service (FOUNDATION Fieldbus)

mode.

Once the LCD display is installed, configure the transmitter to recognize the meter

option. Refer to LCD display options or LCD display transducer block (index number

1200) (FOUNDATION Fieldbus).

Note

Observe the following LCD display temperature limits:

Operating: –40 to 185 °F (–40 to 85 °C)

Storage: –76 to 185 °F (–60 to 85 °C)

22 Rosemount 3144P

Page 23

A

B

C

D

E

F

G

H

Reference Manual

00809-0100-4021 December 2019

Installation

2.4.6 Multichannel installation (HART/4–20 mA only)

Several transmitters can be connected to a single master power supply (see figure below).

In this case, the system may be grounded only at the negative power supply terminal. In

multichannel installations, where several transmitters depend on one power supply and

the loss of all transmitters would cause operational problems, consider an uninterrupted

power supply or a back-up battery. The diodes shown in Figure 2-10 prevent unwanted

charging or discharging of the back-up battery.

Figure 2-10: Multichannel Installations

Between 250 and 1100 Ω If no load resistor

A. Transmitter 1

B. Transmitter 2

C. R

Lead

D. Readout or controller 1

E. Readout or controller 2

F. Battery backup

G. Power supply dc

2.5 Wiring

2.5.1 HART/4–20 mA

Field wiring

The power to the transmitter is supplied over the signal wiring. Signal wiring does not

need to be shielded, but twisted pairs should be used for best results. Do not run

unshielded signal wiring in conduit or open trays with power wiring or near heavy electrical

equipment because high voltage may be present on the leads and may cause an electrical

shock.

Note

Do not apply high voltage (e.g., AC line voltage) to the power or sensor terminals, since

high voltage can damage the unit.

To wire the transmitter for power:

Reference Manual 23

Page 24

“-”

“+”

Test

A

B

B

A

“+”

“-”

Installation Reference Manual

December 2019 00809-0100-4021

Figure 2-11: Transmitter Terminal Block Wiring Connection

Wiring connection

Wiring connection

(with “T1” integral transient protection

option)

A. Sensor terminals (1–5)

B. Ground

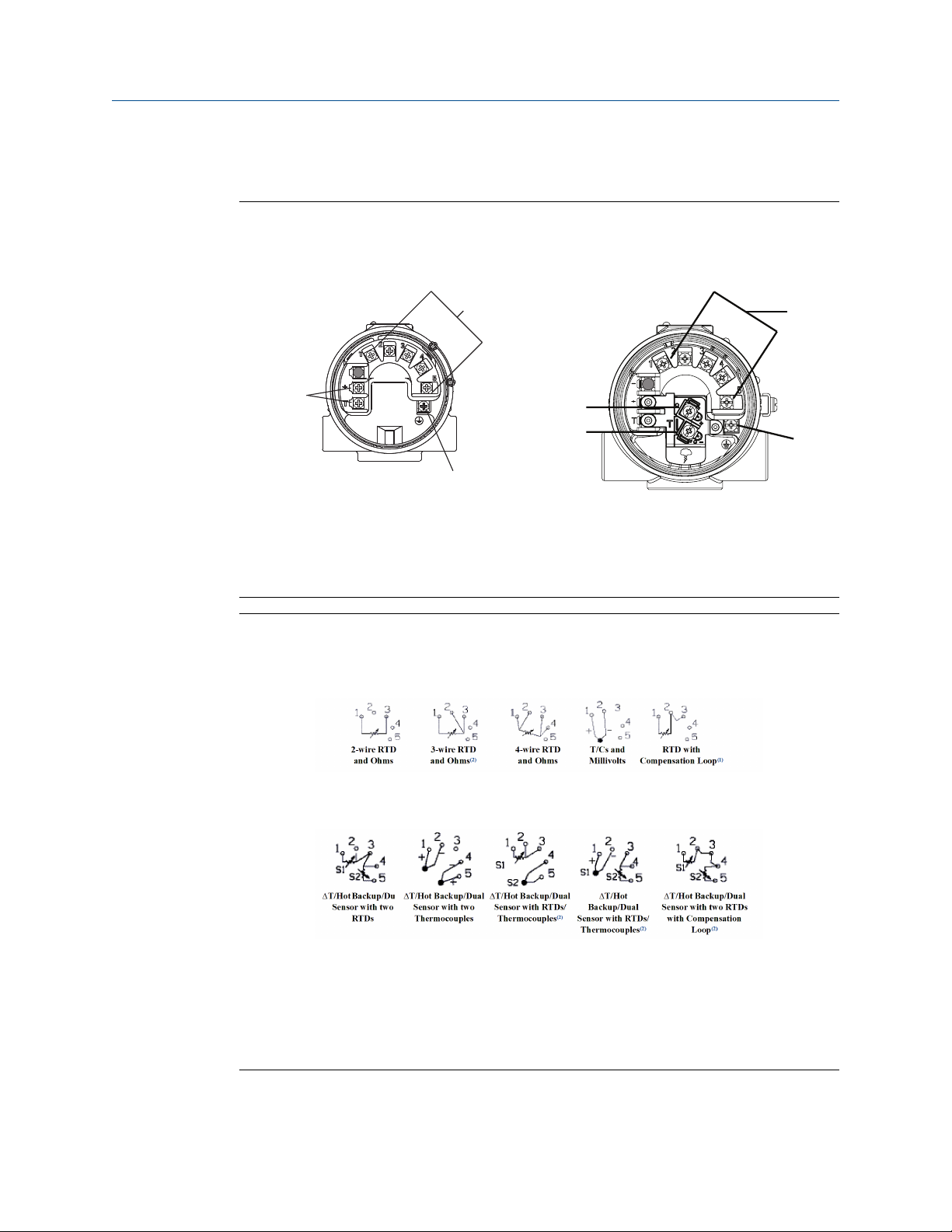

Figure 2-12: Sensor Wiring Diagram for HART/4–20 mA

Single-sensor connections

Dual-sensor connections

(1) (2)

(1) Transmitter must be configured for a 3-wire RTD in order to recognize an RTD with a

compensation loop.

(2) Emerson provides 4-wire sensors for all single-element RTDs. Use these RTDs in 2- or 3-wire

24 Rosemount 3144P

configurations by leaving the unneeded leads disconnected and insulated with electrical tape.

Page 25

Reference Manual Installation

00809-0100-4021 December 2019

Procedure

1. Remove the transmitter covers.

Do not remove the transmitter covers in an explosive atmosphere when the circuit

is live.

2. Connect the positive power lead to the terminal marked “+” and the negative

power lead to the terminal marked “–” as shown in Figure 2-11.

Crimped lugs are recommended when wiring to screw terminals.

3. Tighten the terminal screws to ensure good contact is made. No additional power

wiring is required.

4. Replace the transmitter covers making sure both transmitter covers are fully

engaged to meet explosion-proof requirements.

Power/current loop connections

Use copper wire of a sufficient size to ensure that the voltage across the transmitter power

terminals does not go below 12.0 Vdc.

1. Connect the current signal leads as shown in Figure 2-13.

2. Recheck the polarity and connections.

3. Turn the power ON.

For information about multichannel installations, refer to Multichannel installation

(HART/4–20 mA only).

Note

Do not connect the power/signal wiring to the test terminal. The voltage present on the

power/signal leads may burn out the reverse-polarity protection diode built into the test

terminal. If the test terminal’s reverse polarity protection diode is burned out by the

incorrect power/signal wiring, the transmitter can still be operated by jumping the current

from the test terminal to the “–” terminal. See Test terminal (HART/4–20 mA only) for use

of the terminal.

Reference Manual 25

Page 26

A

C

or*

B

Installation Reference Manual

December 2019 00809-0100-4021

Figure 2-13: Connecting a Field Communicator to a Transmitter Loop (HART/4–20

mA)

A. Power/signal terminals

B. 250 ≤ RL ≤ 1100

C. Power supply

Note

The signal wire may be grounded at any point or left ungrounded.

Note

AMS Device Manager software or a Field Communicator can be connected at any

termination point in the signal loop. The signal loop must have between 250 and 1100

ohms load for communications.

26 Rosemount 3144P

Page 27

A

C

B

B

C

A

Reference Manual Installation

00809-0100-4021 December 2019

2.6 Foundation Fieldbus

Figure 2-14: Transmitter Terminal Block

Wiring connection Wiring connection

(with “T1” integral transient protection option)

A. Sensor terminals (1–5)

B. Power terminals

C. Ground

Figure 2-15: Sensor Wiring Diagram for FOUNDATION Fieldbus

Single-sensor connections

Dual-sensor connections

(1) (2)

(1) Transmitter must be configured for a 3-wire RTD in order to recognize an RTD with a

compensation loop.

(2) Emerson provides 4-wire sensors for all single-element RTDs. Use these RTDs in 2- or 3-wire

Reference Manual 27

configurations by leaving the unneeded leads disconnected and insulated with electrical tape.

Page 28

Installation

December 2019 00809-0100-4021

RTD or ohm inputs

If the transmitter is mounted remotely from a 3- or 4-wire RTD, it will operate within

specifications, without recalibration, for lead wire resistances of up to 60 ohms per lead

(equivalent to 1,000 ft. of 20 AWG wire). In this case, the leads between the RTD and

transmitter should be shielded. If using only two leads (or a compensation loop lead wire

configuration), both RTD leads are in series with the sensor element, so significant errors

can occur if the lead lengths exceed one foot of 20 AWG wire. For longer runs, attach a

third or fourth lead as described above. To eliminate 2-wire lead resistance error, the 2wire offset command can be used. This allows the user to input the measured lead wire

resistance, resulting in the transmitter adjusting the temperature to correct the error.

When using Rosemount X-well Technology, the Rosemount 3144P Temperature

Transmitter is required to be assembled to a Rosemount 0085 Pipe Clamp RTD Sensor in a

direct mount 4-wire configuration. It can be changed to 3- or 2-wired configuration, if

required, in the field.

Thermocouple or millivolt inputs

For direct-mount applications, connect the thermocouple directly to the transmitter. If

mounting the transmitter remotely from the sensor, use appropriate thermocouple

extension wire. Make connections for millivolt inputs with copper wire. Use shielding for

long runs of wire.

Reference Manual

Note

For HART transmitters, the use of two grounded thermocouples with a dual option

transmitter is not recommended. For applications in which the use of two thermocouples

is desired, connect either two ungrounded thermocouples, one grounded and one

ungrounded thermocouple, or one dual element thermocouple.

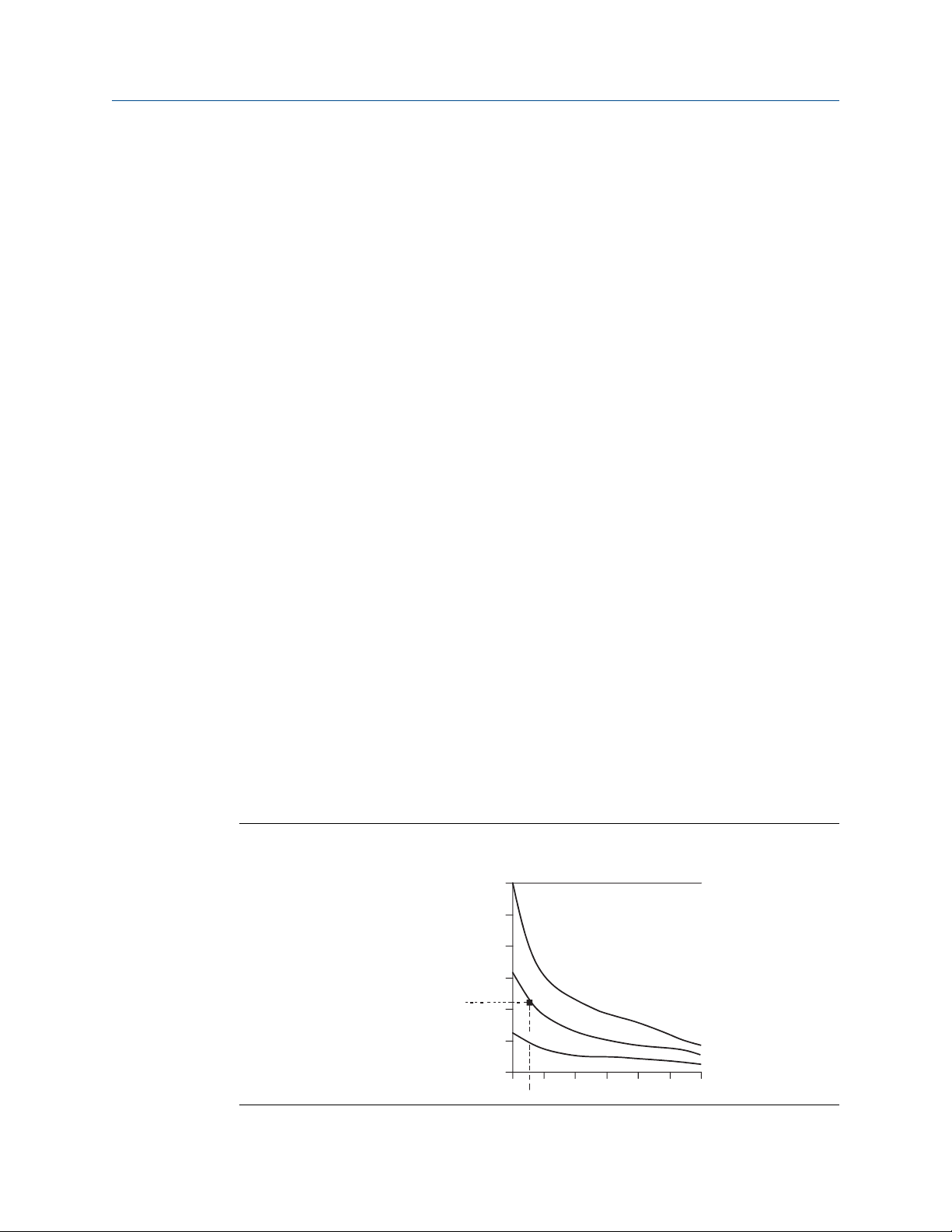

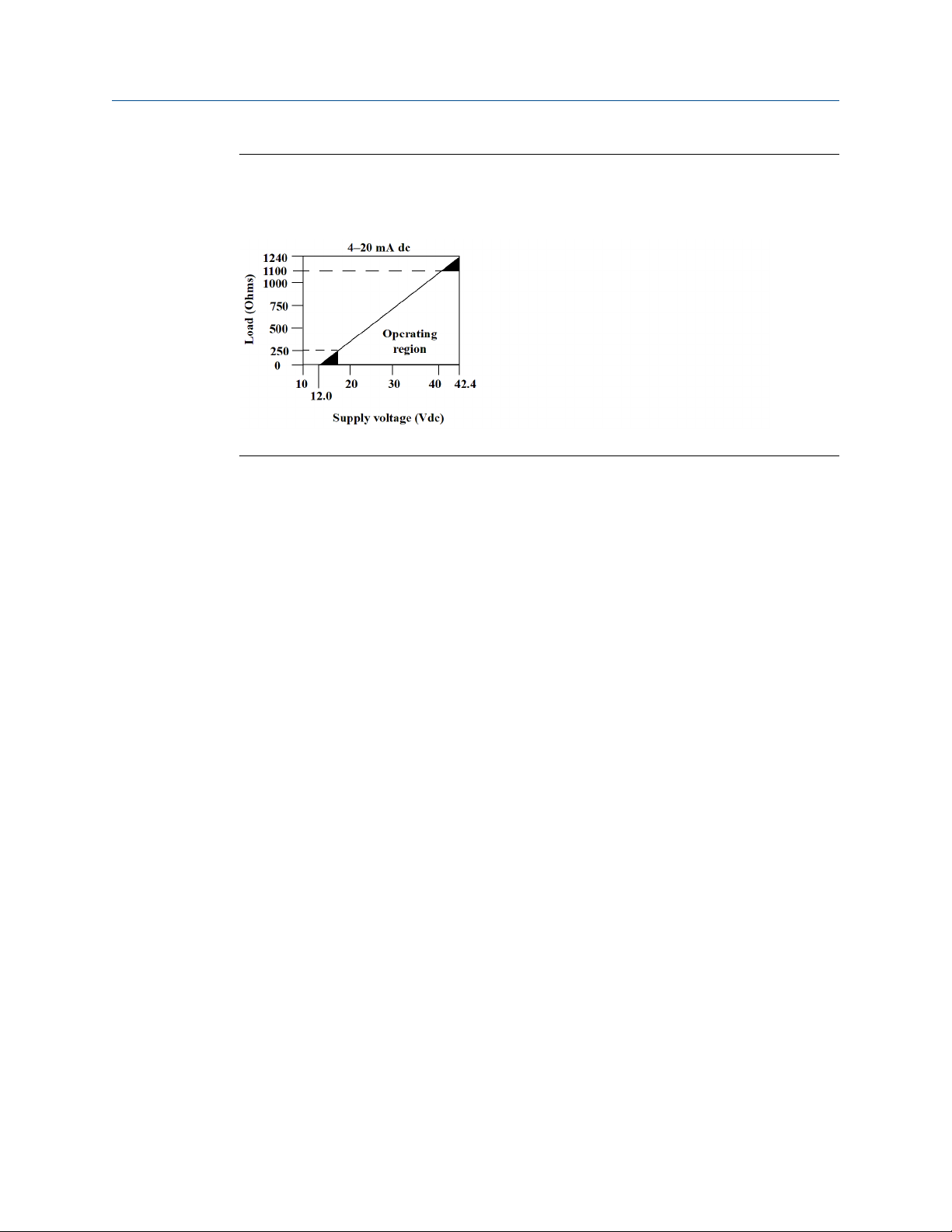

2.7 Power supply

HART

An external power supply is required to operate the transmitter (not included). The input

voltage range of the transmitter is 12 to 42.4 Vdc. This is the power required across the

transmitter power terminals. The power terminals are rated to 42.4 Vdc. With 250 ohms

of resistance in the loop, the transmitter requires a minimum of 18.1 Vdc for

communication.

The power supplied to the transmitter is determined by the total loop resistance and

should not drop below the lift-off voltage. The lift-off voltage is the minimum supply

voltage required for any given total loop resistance. See Figure 2-16 to determine the

required supply voltage. If the power drops below the lift-off voltage while the transmitter

is being configured, the transmitter may output incorrect information.

The dc power supply should provide power with less than two percent ripple. The total

resistance load is the sum of the resistance of the signal leads and the load resistance of

any controller, indicator, or related piece of equipment in the loop. Note that the

resistance of intrinsic safety barriers, if used, must be included.

Note

Permanent damage to the transmitter could result if the voltage drops below 12.0 Vdc at

the power terminals, when changing transmitter configuration parameters.

28 Rosemount 3144P

Page 29

Reference Manual

00809-0100-4021 December 2019

Figure 2-16: Load Limits

Maximum load = 40.8 × (Supply voltage–12.0)

FOUNDATION Fieldbus

Powered over FOUNDATION Fieldbus with standard Fieldbus power supplies, the transmitter

operates between 9.0 and 32.0 Vdc, 11 mA maximum. Transmitter power terminals are

rated to 42.4 Vdc.

Installation

The power terminals on the transmitter are polarity insensitive.

2.7.1

Surges/transients

The transmitter will withstand electrical transients of the energy level usually encountered

in static discharges or induced switching; however, high-voltage transients, such as those

induced in wiring from nearby lightning strikes, can damage both the transmitter and the

sensor.

The integral transient protection terminal block (option code T1) protects against highvoltage transients. The integral transient protection terminal block is available as an

ordered option, or as an accessory.

2.8 Grounding

Sensor shielding

The currents in the leads induced by electromagnetic interference can be reduced by

shielding. Shielding carries the current to ground and away from the leads and electronics.

If the ends of the shields are adequately grounded, only a small amount of current will

actually enter the transmitter.

If the ends of the shield are left ungrounded, voltage is created between the shield and the

transmitter housing and also between the shield and earth at the element end. The

transmitter may not be able to compensate for this voltage, causing it to lose

communication and/or go into alarm. Instead of the shield carrying the currents away

from the transmitter, the currents will now flow through the sensor leads into the

transmitter circuitry where it will interfere with the circuit operation.

Reference Manual 29

Page 30

Installation Reference Manual

December 2019 00809-0100-4021

2.8.1 Ungrounded thermocouple, mV, and RTD/ohm inputs

Option 1: Recommended for ungrounded transmitter housing

1. Connect the signal wiring shield to the sensor wiring shield.

2. Ensure the two shields are tied together and electrically isolated from the

transmitter housing.

3. Ground the shield at the power supply end only.

4. Ensure the shield at the sensor is electrically isolated from the surrounding fixtures

that may be grounded.

a. Connect shields together, electrically isolated from the transmitter.

A. Sensor wires

B. Transmitter

C. 4-20 mA loop

D. Shield ground point

E. DCS

Option 2: Recommended for grounded transmitter housing

1. Ground the transmitter housing then connect the sensor wiring shield to the

transmitter housing (see Transmitter housing).

2. Ensure the shield at the sensor end is electrically isolated from surrounding fixtures

that may be grounded.

3. Ground the signal wiring shield at the power supply end.

30 Rosemount 3144P

Page 31

Reference Manual

00809-0100-4021 December 2019

A. Sensor wires

B. Transmitter

C. 4-20 mA loop

D. Shield ground point

E. DCS

Option 3

Installation

1. Ground the sensor wiring shield at the sensor, if possible.

2. Ensure the sensor wiring and signal wiring shields are electrically isolated from the

transmitter housing and other fixtures that may be grounded.

3. Ground the signal wiring shield at the power supply end.

A. Sensor wires

B. Transmitter

C. 4-20 mA loop

D. Shield ground point

E. DCS

2.8.2

Reference Manual 31

Grounded thermocouple inputs

Procedure

1. Ground the sensor wiring shield at the sensor.

2. Ensure the sensor wiring and signal wiring shields are electrically isolated from the

transmitter housing and other fixtures that may be grounded.

Page 32

A

B

D

C

E

D

Installation Reference Manual

December 2019 00809-0100-4021

3. Ground the signal wiring shield at the power supply end.

A. Sensor wires

B. Transmitter

C. 4–20 mA loop

D. Shield ground point

E. DCS

2.8.3

Transmitter housing

Ground the transmitter housing according to local or site electrical requirements. An

internal ground terminal is standard. An optional external ground lug assembly (option

code G1) can also be ordered, if needed. Ordering certain hazardous approvals

automatically includes an external ground lug.

2.9 Wire and apply power

Connect the transmitter to a FOUNDATION Fieldbus network. Two terminators and a power

conditioner are required. The voltage at the transmitter terminal must be between nine

and 32 Vdc to operate properly.

32 Rosemount 3144P

Page 33

Reference Manual HART Commissioning

00809-0100-4021 December 2019

3 HART Commissioning

3.1 Overview

This section contains information on commissioning and tasks that should be performed

on the bench prior to installation. This section contains Rosemount™ 3144P HART

Configuration information only. The Field Communicator and instructions are given to

perform configuration functions.

For convenience, Field Communicator Fast Key sequences are labeled “Fast Keys” for each

software function below the appropriate headings.

HART 7 Fast Keys

AMS Device Manager help can be found in the AMS Device Manager on-line guides within

the AMS Device Manager system.

1, 2, 3, etc.

3.2 Confirm HART revision capability

If using HART based control or asset management systems, confirm the HART Protocol

capability of those systems prior to transmitter installation. Not all systems are capable of

communicating with HART Revision 7. This transmitter can be configured for either HART

Revision 5 or Revision 7.

3.2.1

Switch HART revision mode

If the HART Protocol configuration tool is not capable of communicating with HART

Revision 7, the transmitter will load a generic menu with limited capability. The following

procedures will switch the HART Revision mode from the generic menu:

®

Procedure

Select Manual Setup > Device Information > Identification > Message.

a. To change to HART Revision 5, Enter “HART5” in the Message field.

b. To change to HART Revision 5, Enter “HART7” in the Message field.

Reference Manual 33

Page 34

HART Commissioning Reference Manual

December 2019 00809-0100-4021

3.3 Safety messages

Instructions and procedures in this section may require special precautions to ensure the

safety of the personnel performing the operations. Information that potentially raises

safety issues is indicated by a warning symbol ( ). Refer to the following safety messages

before performing an operation preceded by this symbol.

WARNING

Explosions could result in death or serious injury.

• Do not remove the instrument cover in explosive atmospheres when the circuit is live.

• Before connecting a handheld communicator in an explosive atmosphere, ensure that

the instruments in the loop are installed in accordance with intrinsically safe or nonincendive field wiring practices.

• Both transmitter covers must be fully engaged to meet explosion-proof requirements.

Electrical shock could cause death or serious injury.

• If the sensor is installed in a high-voltage environment and a fault or installation error

occurs, high voltage may be present on transmitter leads and terminals.

• Use extreme caution when making contact with the leads and terminals.

Process leaks could result in death or serious injury.

• Do not remove the thermowell while in operation.

• Install and tighten thermowells and sensors before applying pressure.

3.4 Field Communicator

The menu tree and Fast Key sequences use the following device revisions:

• Device dashboard: Device revision 5 and 7, DD v1

The Field Communicator exchanges information with the transmitter from the control

room, the instrument site, or any wiring termination point in the loop. To facilitate

communication, connect the Field Communicator in parallel with the transmitter (see

Figure 2-16) using the loop connection ports on the top of the field communicator. The

connections are non-polarized. Do not make connections to the nickel–cadmium (NiCad)

recharger jack in explosive atmospheres. Before connecting the Field Communicator in an

explosive atmosphere, make sure the instruments in the loop are installed according to

intrinsically safe or non-incendive field wiring practices.

34 Rosemount 3144P

Page 35

Reference Manual HART Commissioning

00809-0100-4021 December 2019

3.4.1 Updating the HART communication software

The Field Communicator software may need to be updated to take advantage of the

additional features available in the latest Rosemount 3144P Transmitter. Perform the

following steps to determine if an upgrade is necessary.

Procedure

1. Select Rosemount from the list of manufacturers 5 and 6 and 3144 Temp from the

list of models

2. If the Field Device Rev choices include “Dev v1”, “Dev v2”, “Dev v3”, or “Dev v4”

(with any DD version), then the user will be able to connect to the device with

reduced functionality. To unlock full functionality, download and install the new

DD.

Note

The original release of the safety-certified Rosemount 3144P uses the name “3144P

SIS” from the model list and requires “Dev v2, DD v1.”

Note

If communication is initiated with an improved Rosemount 3144P using a

communicator that only has a previous version of the transmitter device descriptors

(DDs), the communicator will display the following message:

NOTICE: Upgrade to the field communicator software to access new XMTR functions.

Continue with old description?

YES: The communicator will communicate properly with the transmitter using the

existing transmitter

DDs. However, new software features of the DD in the communicator will not be

accessible.

NO: The communicator will default to a generic transmitter functionality.

If YES is selected after the transmitter is configured to utilize the new features of the

improved transmitters (such as Dual Input configuration or one of the added sensor

input types–DIN Type L or DIN Type U), the user will experience trouble

communicating with the transmitter and will be prompted to turn the

communicator off. To prevent this from happening, either upgrade the

communicator to the latest DD or answer NO to the above question and default to

the generic transmitter functionality.

Reference Manual 35

Page 36

HART Commissioning Reference Manual

December 2019 00809-0100-4021

3.4.2 Device Dashboard menu tree

Figure 3-1: HART 5- Overview

36 Rosemount 3144P

Page 37

Reference Manual HART Commissioning

00809-0100-4021 December 2019

Figure 3-2: HART 5 - Configure

Reference Manual 37

Page 38

HART Commissioning Reference Manual

December 2019 00809-0100-4021

Figure 3-3: HART 5- Service Tools

38 Rosemount 3144P

Page 39

Reference Manual HART Commissioning

00809-0100-4021 December 2019

Figure 3-4: HART 7- Overview

Reference Manual 39

Page 40

HART Commissioning Reference Manual

December 2019 00809-0100-4021

Figure 3-5: HART 7- Configure

40 Rosemount 3144P

Page 41

Reference Manual HART Commissioning

00809-0100-4021 December 2019

Figure 3-6: HART 7- Service Tools

Reference Manual 41

Page 42

HART Commissioning Reference Manual

December 2019 00809-0100-4021

3.4.3 Device dashboard Fast Key sequence

Fast Key sequences are listed below for common Rosemount 3144P Transmitter functions.

Note

The Fast Key sequences assume that “Device Revision Dev 5 (HART 5) or v7 (HART 7), DD

v1” is being used. Table 3-1 provides alphabetical function lists for all Field Communicator

tasks as well as their corresponding Fast Key sequences.

Table 3-1: Fast Key Sequences

Function HART 5 Fast Keys HART 7 Fast Keys

2-wire offset Sensor 1 2, 2, 1, 5 2, 2, 1, 6

2-wire offset Sensor 2 2, 2, 2, 5 2, 2, 2, 6

Alarm values 2, 2, 5, 6 2, 2, 5, 6

Analog calibration 3, 4, 5 3, 4, 5

Analog output 2, 2, 5 2, 2, 5

Average temperature setup 2, 2, 3, 3 2, 2, 3, 3

Burst mode N/A 2, 2, 8, 4

Comm status N/A 1, 2

Configure additional messages N/A 2, 2, 8, 4, 7

Configure Hot Backup

Date 2, 2, 7, 1, 2 2, 2, 7, 1, 3

Descriptor 2, 2, 7, 1, 3 2, 2, 7, 1, 4

Device information 2, 2, 7, 1 2, 2, 7, 1

Differential temperature setup 2, 2, 3, 1 2, 2, 3, 1

Filter 50/60 Hz 2, 2, 7, 5, 1 2, 2, 7, 5, 1

Find device N/A 3, 4, 6, 2

First good temperature setup 2, 2, 3, 2 2, 2, 3, 2

Hardware revision 1, 8, 2, 3 1, 11, 2, 3

HART Lock N/A 2, 2, 9, 2

Intermittent sensor detect 2, 2, 7, 5, 2 2, 2, 7, 5, 2

Lock status N/A 1, 11, 3, 7

Long tag N/A 2, 2, 7, 2

Loop test 3, 5, 1 3, 5, 1

™

2, 2, 4, 1, 3 2, 2, 4, 1, 3

LRV (Lower Range Value) 2, 2, 5, 5, 3 2, 2, 5, 5, 3

Message 2, 2, 7, 1, 4 2, 2, 7, 1, 5

Open sensor holdoff 2, 2, 7, 4 2, 2, 7, 4

Percent range 2, 2, 5, 4 2, 2, 5, 4

42 Rosemount 3144P

Page 43

Reference Manual HART Commissioning

00809-0100-4021 December 2019

Table 3-1: Fast Key Sequences (continued)

Function HART 5 Fast Keys HART 7 Fast Keys

Sensor 1 configuration 2, 2, 1 2, 2, 2

Sensor 1 serial number 2, 2, 1, 7 2, 2, 1, 8

Sensor 1 setup 2, 2, 1 2, 2, 1

Sensor 1 status N/A 2, 2, 1, 2

Sensor 1 type 2, 2, 1, 2 2, 2, 1, 3

Sensor 1 unit 2, 2, 1, 4 2, 2, 1, 5

Sensor 2 configuration 2, 2, 2 2, 2, 2

Sensor 2 serial number 2, 2, 2, 7 2, 2, 2, 8

Sensor 2 setup 2, 2, 2 2, 2, 2

Sensor 2 status N/A 2, 2, 2, 2

Sensor 2 type 2, 2, 2, 2 2, 2, 2, 3

Sensor 2 unit 2, 2, 2, 4 2, 2, 2, 5

Sensor drift alert 2, 2, 4, 2 2, 2, 4, 2

Simulate device variables N/A 3, 5, 2

Software revision 1, 8, 2, 4 1, 11, 2, 4

Tag 2, 2, 7, 1, 1 2, 2, 7, 1, 1

Terminal temperature units 2, 2, 7, 3 2, 2, 7, 3

URV (Upper Range Value) 2, 2, 5, 5, 2 2, 2, 5, 5, 2

Variable mapping 2, 2, 8, 5 2, 2, 8, 5

Thermocouple diagnostic 2, 1, 7, 1 2, 1, 7, 1

Min/max tracking 2, 1, 7, 2 2, 1, 7, 2

Rosemount X-well™ setup N/A 2, 2, 1, 11

Reference Manual 43

Page 44

HART Commissioning Reference Manual

December 2019 00809-0100-4021

3.5 Review configuration data

Before operating the transmitter in an actual installation, review all of the factory-set

configuration data to ensure that it reflects the current application.

3.5.1 Review

HART 5 Fast Keys 1, 4

HART 7 Fast keys 2, 2

Field Communicator

Review the transmitter configuration parameters set at the factory to ensure accuracy and

compatibility with the particular application. After activating the Review function, scroll

through the data list and check each variable. If changes to the transmitter configuration

data are necessary, refer to Configuration.

3.6 Check output

Before performing other transmitter online operations, review the configuration of the

Rosemount 3144P Transmitter digital output parameters to ensure that the transmitter is

operating properly.

3.6.1

Analog output

HART 5 Fast Keys 2, 2, 5

HART 7 Fast Keys 2, 2, 5

Field Communicator

The Rosemount 3144P process variables provide the transmitter output. The PROCESS

VARIABLE menu displays the process variables, including sensed temperature, percent

range, and analog output. These process variables are continuously updated. The primary

variable is 4–20 mA analog signal.

3.7 Configuration

The Rosemount 3144P must have certain basic variables configured to operate. In many

cases, these variables are pre-configured at the factory. Configuration may be required if

the configuration variables need revision.

3.7.1

44 Rosemount 3144P

Variable mapping

HART 5 Fast Keys 2, 2, 8, 5

HART 7 Fast Keys 2, 2, 8, 5

Page 45

Reference Manual HART Commissioning

00809-0100-4021 December 2019

Field Communicator

The Variable Mapping menu displays the sequence of the process variables. Select 5

Variable Re-Map to change this configuration. The Rosemount 3144P single sensor input

configuration screens allow selection of the primary variable (PV) and the secondary

variable (SV). When the Select PV screen appears Snsr 1 or Terminal Temperature must

be selected.

The Rosemount 3144P dual-sensor option configuration screens allow selection of the

primary variable (PV), secondary variable (SV), tertiary variable (TV), and quaternary

variable (QV). Variable choices are Sensor 1, Sensor 2, Differential Temperature, Average

Temperature, First-Good Temperature, Terminal Temperature, and Not Used. The primary

variable is the 4–20 mA analog signal.

3.7.2 Sensor configuration

HART 5 Fast Keys 2, 1, 1

HART 7 Fast Keys 2, 1, 1

3.7.3

Field Communicator

Sensor configuration contains information for updating the sensor type, connections,

units, and damping.

Change type and connections

HART 5 Fast Keys

HART 7 Fast Keys

The connections command allows the user to select the sensor type and the number of

sensor wires to be connected from the following list:

• 2-, 3-, or 4-wire Pt 100, Rosemount X-well, Pt 200, Pt 500, Pt 1000 (platinum) RTDs (α =

0.00385 Ω/Ω/°C)

• 2-, 3-, or 4-wire Pt 100, Pt 200 (platinum) RTDs (α = 0.003916 Ω/Ω/°C)

• 2-, 3-, or 4-wire Ni 120 (nickel) RTDs

• 2-, 3-, or 4-wire Cu 10 (copper) RTDs

• IEC/NIST/DIN Type B, E, J, K, R, S, T thermocouples

Sensor 1: 2, 2, 1

Sensor 2: 2, 2, 2

Sensor 1: 2, 2, 1

Sensor 2: 2, 2, 2

• DIN type L, U thermocouples

• ASTM Type W5Re/W26Re thermocouple

• GOST Type L thermocouples

• –10 to 100 millivolts

• 2-, 3-, or 4-wire 0 to 2000 ohms

Reference Manual 45

Page 46

HART Commissioning Reference Manual

December 2019 00809-0100-4021

Contact an Emerson representative for information on temperature sensors, thermowells,

and accessory mounting hardware that is available through Emerson.

3.7.4 Output units

3.7.5

HART 5 Fast Keys

HART 7 Fast Keys

The Sensor 1 unit and Sensor 2 unit commands set the desired primary variable units. The

transmitter output can be set to one of the following engineering units:

• Degrees Celsius

• Degrees Fahrenheit

• Degrees Rankine

• Kelvin

• Ohms

• Millivolts

Sensor 1: 2, 2, 1, 4

Sensor 2: 2, 2, 2, 4

Sensor 1: 2, 2, 1, 5

Sensor 2: 2, 2, 2, 5

Sensor 1 serial number

HART 5 Fast Keys 2, 2, 1, 7

HART 7 Fast Keys 2, 2, 1, 8

3.7.6

The serial number of the attached sensor can be listed in the sensor 1 S/N variable. It is

useful for identifying sensors and tracking sensor calibration information.

Sensor 2 serial number

HART 5 Fast Keys 2, 2, 2, 7

HART 7 Fast Keys 2, 2, 2, 8

The serial number of a second sensor can be listed in the sensor 2 S/N variable.

46 Rosemount 3144P

Page 47

Reference Manual HART Commissioning

00809-0100-4021 December 2019

3.7.7 2-wire RTD offset

3.7.8

3.7.9

HART 5 Fast Keys

HART 7 Fast Keys

The 2-wire offset command allows the measured lead wire resistance to be input, which

results in the transmitter adjusting its temperature measurement to correct the error

caused by this resistance. Because of a lack of lead wire compensation within the RTD,

temperature measurements made with a 2-wire RTD are often inaccurate.

Sensor 1: 2, 2, 1, 5

Sensor 2: 2, 2, 2, 5

Sensor 1: 2, 2, 1, 6

Sensor 2: 2, 2, 2, 6

Terminal (body) temperature

HART 5 Fast Keys 2, 2, 7, 3

HART 7 Fast Keys 2, 2, 7, 3

The Terminal Temp command sets the terminal temperature units to indicate the

temperature at the transmitter terminals.

Dual-sensor configuration

HART 5 Fast Keys 2, 2, 3

HART 7 Fast Keys 2, 2, 3

Dual-sensor configuration sets the functions that can be used with a dual-sensor

configured transmitter, including differential temperature, average temperature, first

good temperature.

Differential pressure

HART 5 Fast Keys

HART 7 Fast Keys 2, 2, 3, 1

Field Communicator

The transmitter configured for a dual-sensor can accept any two inputs then display the

differential temperature between them. Use the following procedure with traditional Fast

Keys to configure the transmitter to measure differential temperature:

Note

This procedure reports the differential temperature as the primary variable analog signal.

If this is not needed, assign differential temperature to the secondary, tertiary, or

quaternary variable.

Note

The transmitter determines the differential temperature by subtracting the reading of

Sensor 2 from Sensor 1 (S1– S2). Ensure this order of subtraction is consistent with the

2, 2, 3, 1

Reference Manual 47

Page 48

HART Commissioning Reference Manual

December 2019 00809-0100-4021

desired reading for the application. Refer to Figure 2-4, or inside the transmitter terminalside cover for sensor wiring diagrams.

If using an LCD display for local indication, configure the meter to read the appropriate

variables by using LCD display options.

Average temperature

HART 5 Fast Keys 2, 2, 3, 3

HART 7 Fast Keys 2, 2, 3, 3

Field Communicator

The transmitter configured for dual-sensors can output and display the average

temperature of any two inputs. Use the following procedure with Traditional Fast Keys to

configure the transmitter to measure the average temperature:

Configure sensor 1 and sensor 2 appropriately. Select 1 Device Setup, 3 Configuration, 2

Sensor Configuration, 1 Change Type and Conn. to set the sensor type and number of wires

for sensor 1. Repeat for Sensor 2.

Note

This procedure configures the average temperature as the primary variable analog signal.

If this is not needed, assign the average temperature to the secondary, tertiary, or

quaternary variable.

If using an LCD display, configure it to read the appropriate variables using LCD display

options.

Note

If Sensor 1 and/or sensor 2 should fail while PV is configured for average temperature and