Page 1

00809-0100-4724

English

Rev. CA

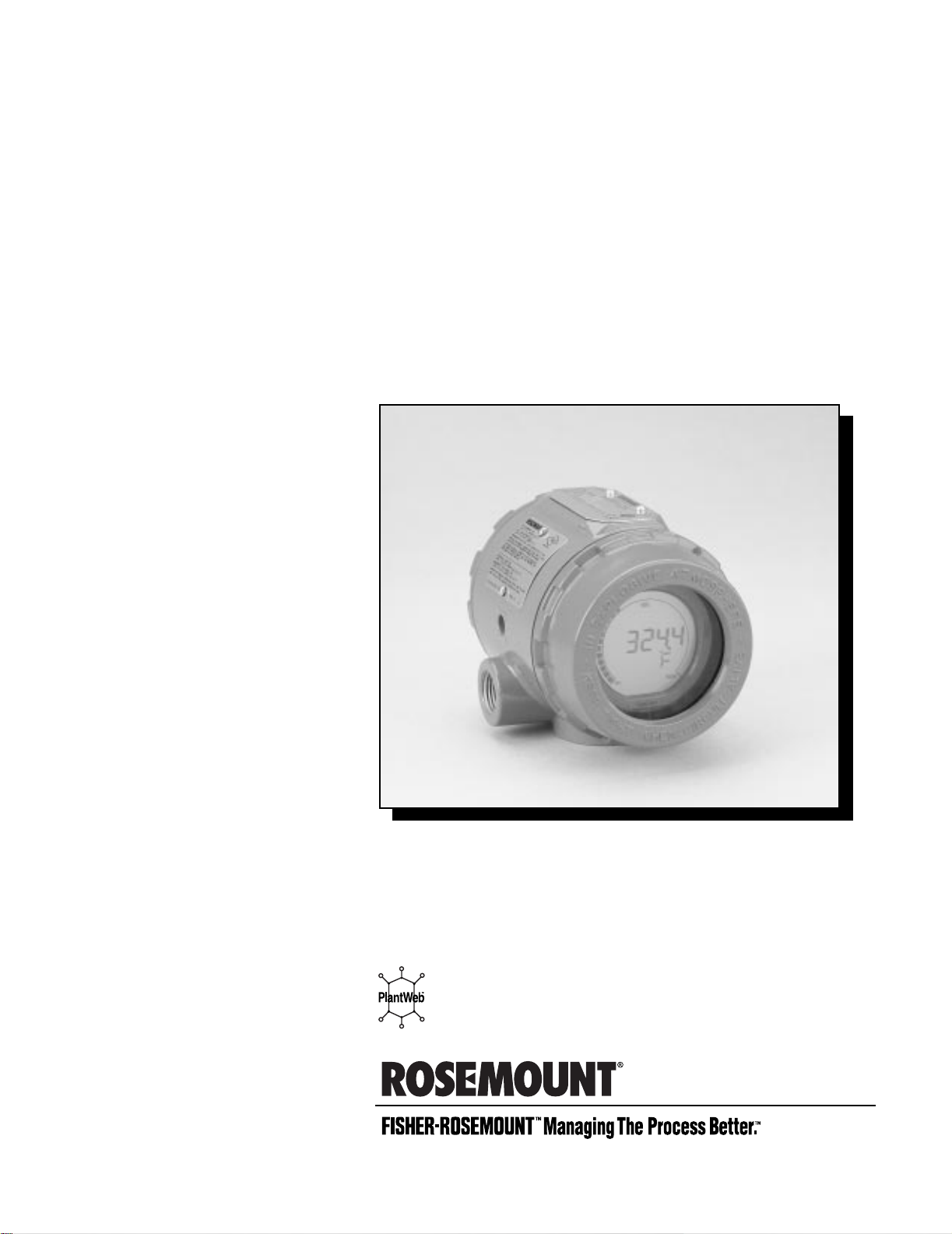

Model 3144 and 3244MV

Smart Temperature

Transmitters

Page 2

Product

Manual

Model 3144 and 3244MV Smart

Temperature Transmitters

Model 3144 and 3244MV Revision: 5.2.1

HART Communicator Field Device Revision: Dev. v2, DD v1

NOTICE

Read this manual before working with the product. For personal and system safety,and

for optimum product performance, makesure you thoroughly understandthecontents

before installing, using, or maintaining this product.

Withinthe United States, RosemountInc. has two toll-free assistance numbers:

Customer Central

Technical support, quoting, and order-related questions.

1-800-999-9307 (7:00 am to 7:00 pm CST)

North American Respon se Center

Equipment service needs.

1-800-654-7768 (24hours—includes Canada)

Outside of the United States, contact yourlocal Rosemount representative.

Rosemount Inc.

8200 Market Boulevard

Chanhassen, MN 55317 USA

Tel 1-800-999-9307

Telex 4310012

Fax (612) 949-7001

00809-0100-4724

© Rosemount Inc. 1999

http://www.rosemount.com

The products describedin thisdocument are NOTdesigned for nuclear-qualified

applications. Using non-nuclear qualified products in applications that require nuclearqualified hardware or products may cause inaccurate readings.

For information on Rosemount nuclear-qualified products, contactyourlocal Rosemount

SalesRepresentative.

Rosemount Models 3144 and 3244MV Smart Temperature Transmitters may be protected by one or more

U.S. Patents Pending. Other foreign patents pending.

Rosemount, the Rosemount logotype, SMART FAMILY, Hot Backup, and Tri-Loop are registered

trademarks of Rosemount Inc.

Teflon is a registered trademark of E.I. du Pont de Nemours & Co.

HART is a registered trademark of the HART Communication Foundation.

Minigrabber is a trademark of Pomona Electronics.

Inconel is a registered trademark of International Nickel Co.

COVER PHOTO: 3144-010AC

Fisher-Rosemount satisfies all obligations coming from legislation

to harmonise product requirements in the European Union.

Page 3

Table of Contents

SECTION 1

Introduction

SECTION 2

Installation

UsingthisManual..................................1-1

Getting Acquainted with the Transmitter ................1-2

Software Compatibility..............................1-2

Overview.........................................2-1

SafetyMessages...................................2-1

Warnings......................................2-1

Commissioning: On the Bench or in t he Loop............2-2

GeneralConsiderations..............................2-3

ElectricalConsiderations............................2-3

Power Supply...................................2-3

FieldWiring....................................2-4

Power/CurrentLoopConnections...................2-4

Grounding .....................................2-5

Surges/Transients................................2-6

Multichannel Installations .........................2-6

FailureModeandSecurityJumpers....................2-7

FailureModeJumper.............................2-7

TransmitterSecurityJumper.......................2-7

Changing the Position of the Failure Mode or

SecurityJumper.................................2-7

SensorConnections.................................2-8

RTD or Ohm Inputs ..............................2-8

Thermocouple or Millivolt Inputs ...................2-8

MechanicalConsiderations...........................2-9

Mounting......................................2-9

AccessRequirements.............................2-9

EnvironmentalConsiderations........................2-11

TemperatureEffects..............................2-11

MoistorCorrosiveEnvironments...................2-12

Hazardous Locations Installations...................2-13

InstallationProcedure...............................2-13

TypicalNorthAmericanConfiguration...............2-13

TypicalEuropeanConfiguration....................2-15

Installation in Conjunction with a Model 333

HART Tri-Loop HART-to-Analog Signal Converter ......2-16

Commissioning the Transmitter for Use with the

HARTTri-Loop...................................2-17

v

Page 4

Rosemount Model 3144 and 3244MV Smart Temperature Transmitters

SECTION 3

On-line Operations

Overview.........................................3-1

SafetyMessages...................................3-1

Warnings......................................3-1

Setting the Loop to Manual ........................3-2

ReviewConfigurationData ..........................3-2

Review........................................3-2

CheckOutput.....................................3-2

ProcessVariables................................3-2

BasicSetup.......................................3-5

SelectSensorType...............................3-5

SetOutputUnits.................................3-5

Rerange .......................................3-6

DetailedSetup.....................................3-6

50/60HzFilter..................................3-6

TerminalTemperatureSettings.....................3-6

Signal Condition ................................3-6

AnalogOutput..................................3-6

DisableSpecialSensor............................3-6

HARTOutput...................................3-6

MeterSettings ..................................3-6

AlarmValues...................................3-7

ProcessVariableDamping.........................3-7

DifferentialTemperature..........................3-8

AverageTemperature.............................3-9

HotBackup ....................................3-10

DriftAlert......................................3-11

InformationVariables...............................3-13

Tag...........................................3-13

Descriptor......................................3-13

Message.......................................3-13

Date..........................................3-13

Sensor1SerialNumber...........................3-13

Sensor2SerialNumber...........................3-13

Diagnostics and Service .............................3-14

TestDevice ....................................3-14

LoopTest......................................3-14

SensorCurrent..................................3-15

Calibration .......................................3-15

DecidingWhichTrimProceduretoUse..............3-15

SensorTrim....................................3-16

Transmitter-SensorMatching ......................3-19

OutputTrim....................................3-20

ScaledOutputTrim..............................3-21

ApplyValues...................................3-21

Multidrop Communication.........................3-21

vi

Page 5

Table of Contents

SECTION 4

Maintenance

SECTION 5

Specifications and

Reference Data

Overview.........................................4-1

SafetyMessages...................................4-1

Warning.......................................4-1

Hardware Diagnostics...............................4-2

HardwareMaintenance..............................4-3

TestTerminals..................................4-3

Sensor Checkout ................................4-3

DisassemblingtheElectronicsHousing...............4-4

AssemblingtheElectronicsHousing.................4-6

ReturnofMaterials.................................4-6

Specifications.....................................5-1

FunctionalSpecifications..........................5-1

PerformanceSpecifications........................5-6

PhysicalSpecifications ...........................5-7

TransmitterDimensionalDrawings....................5-8

ReferenceData....................................5-10

OrderingInformation...............................5-12

PartsList.........................................5-14

Intermittent Sensor Algorithm ........................5-14

Intermittent Sensor Detect (Advanced Function) .......5-18

SECTION 6

Options

Overview.........................................6-1

SafetyMessages...................................6-1

Warnings......................................6-1

Custom Transmitter Configuration (Option Code C1) . . . 6-1

Trim to Specific Ros emount RTD Calibration Schedule

(Transmitter-Sensor Matching) (Option Code C2) ......6-1

Five-PointCalibration(OptionCodeC4).............6-1

CalibrationCertificate(OptionCodeQ4).............6-2

TrimtoSpecialSensor(OptionCodeC7).............6-2

MountingBrackets(OptionCodesB4andB5).........6-2

AssemblyOptions(OptionCodeX1,X2,andX3)......6-3

External Ground Lug Assembly (Option Code G1) .....6-3

50HzLineVoltageFilter(OptionCodeF5)...........6-3

NAMUR Compliant Operation

(OptionCodesA1andCN)........................6-3

TransientProtection(OptionCodeT1)...............6-4

HotBackup(OptionCodeU1) .....................6-4

Average Temperature with Hot Backup and Drift Alert

(OptionCodeU2)................................6-5

TwoIndependentSensors(OptionCodeU4)..........6-5

DifferentialTemperature(OptionCodeU5)...........6-5

AverageTemperature(OptionCodeU6)..............6-5

LCDMeter(OptionCodeM5)........................6-6

Installing the Meter ..............................6-7

Diagnostic Messages .............................6-8

vii

Page 6

Rosemount Model 3144 and 3244MV Smart Temperature Transmitters

APPENDIX A

Transmitter Improvements

APPENDIX B

Model 275

HART Communicator

APPENDIX C

Model 268

SMART FAMILY Interface

Overview.........................................A-1

RevisionDifferencesSummary.......................A-1

Overview.........................................B-1

SafetyMessages...................................B-2

Warnings......................................B-2

Model 3144 and 3244MV Menu Trees..................B-2

Connections and Hardware...........................B-4

CommunicatorKeys................................B-6

Fast-KeySequences..............................B-8

MenusandFunctions...............................B-8

MainMenu.....................................B-8

OnlineMenu ...................................B-9

Diagnostic Messages .............................B-9

Overview.........................................C-1

SafetyMessages...................................C-1

Warnings......................................C-1

3144/3244MV ..................................C-2

Connections and Hardware...........................C-3

BasicFeatures.....................................C-3

DedicatedKeys .................................C-3

AlphanumericandShiftKeys......................C-4

FunctionKeys ..................................C-5

FunctionKeySequences..........................C-5

Diagnostics Messages ............................C-6

APPENDIX D

Overview.........................................D-1

Hazardous Area Approval

Installation Drawings

GLOSSARY Glossary.........................................G-1

INDEX Index............................................I-1

viii

Page 7

Section

1 Introduction

USING THIS MANUAL This manual is intended to assist in installing, operating, and

maintaining Rosemount Model 3144 and 3244MV Smart Temperature

Transmitters.

Section 2: In stallation

Section 2 explains how to commission transmitters; provides an

installation flowchart; and describes electrical, mechanical, and

environmental installation considerations.

Section 3: On-line Operations

Section 3 describes how to configure transmitter software, select a

sensor type, adjust the input and output electronics; and how to change

output characteristics (range settings, output type, damping, and units)

and non-output-related transmitter characteristics (including the

transmitter tag number, date, and message).

Section 4: Maintenanc e

Section 4 describes hardware diagnostics, maintenance tasks, and

hardware troubleshooting.

Section 5: Specifications and Reference Data

Section 5 lists functional, performance, and physical specification data

for the transmitter. This section also includes transmitter drawings,

ordering information, and a list of spare parts.

Section 6: Options

Section 6 presents options including the LCD meter, mounting

brackets, custom configuration and calibration, trim to special sensor,

and external ground-lug assembly.

Appendix A: Transmitter Improvements

Appendix A describes the enhancements that have been made to the

Model 3144 and 3244MV Smart Temperature Transmitters, and

includes a chart that compares previous transmitter versions to the

current improved transmitter version.

®

Appendix B: Model 275 HART

Appendix B provides a complete menu tree, a table of fast key

sequences, and other information regarding use of the Model 275

®

HART

Appendix C: Model 268 SMART FAMILY

Appendix C provides a complete menu tree and other information

regarding use of the Model 268 SMART FAMILY® Interface.

Communicator.

Communicator

®

Interface

Appendix D: Hazardous Area Approval Installation Drawings

Appendix D provides hazardous location installation drawings.

1-1

Page 8

Rosemount Model 3144 and 3244MV Smart Temperature Transmitters

GETTING ACQUAINTED WITH THE TRANSMITTER

SOFTWARE COMPATIBILITY

The Rosemount Model 3144 and 3244MV Smart Temperature

Transmitters are microprocessor-based instruments that accept input

from a wide variety of sensors, and transmit temperature data to a

control system or transmitter interface. The transmitters combine

Rosemount reliability with the flexibility of digital electronics. The

transmitters are ideal for applications that require high performance or

remote communication.

Each transmitter is designed to communicate with a HART

communicator. Communicators are used to interrogate, configure, test,

or format the transmitter, as well as other products in the Rosemount

family of microprocessor-based instruments. Moreover, HART

communicators can communicate with a transmitter from the control

room, from the transmitter site, or from any other wiring termination

point in the loop where there is between 250 and 1100 ohms resistance

between the transmitter power connection and the power supply.

Special dual-sensor features of the Model 3244MV include Hot

Backup

measurements, and four simultaneous measurement variable outputs

in addition to the analog output signal.

Software for Rosemount SMART FAMILY products is revised

periodically. Replacement transmitters may contain revised software

that is incompatible with the existing software in your HART

communicator.

®

, drift alert, differential and average temperature

Software loaded into the Model 275 HART Communicator that contains

device descriptors (DDs) compatible with the Model 3144 and 3244MV

transmitters can be included in the communicator initially, or entered

at any Rosemount Service Center upon request. Rerange and read-only

capabilities can be attained with revision 5.0 or later Model 268

communicator software. The HART Communicator Field Device

Revision Dev v2, DD v1 should be loaded into the Model 257 HART

Communicator in order to utilize all of the features available in the

Model 3144 and 3244MV. See Appendix B: Model 275 HART

Communicator for more information concerning device revisions.

Upgrading the Model 268 software to revision 7.0 will allow limited

functionality such as changing the sensor type and number of wires,

and performing trim functions. The Model 275 HART Communicator is

the necessary interface for complete functionality, and is recommended.

Contact the Rosemount Service Center nearest you to obtain the

appropriate HART communicator software.

1-2

Page 9

Section

2 Installation

OVERVIEW The information in this section includes transmitter installation

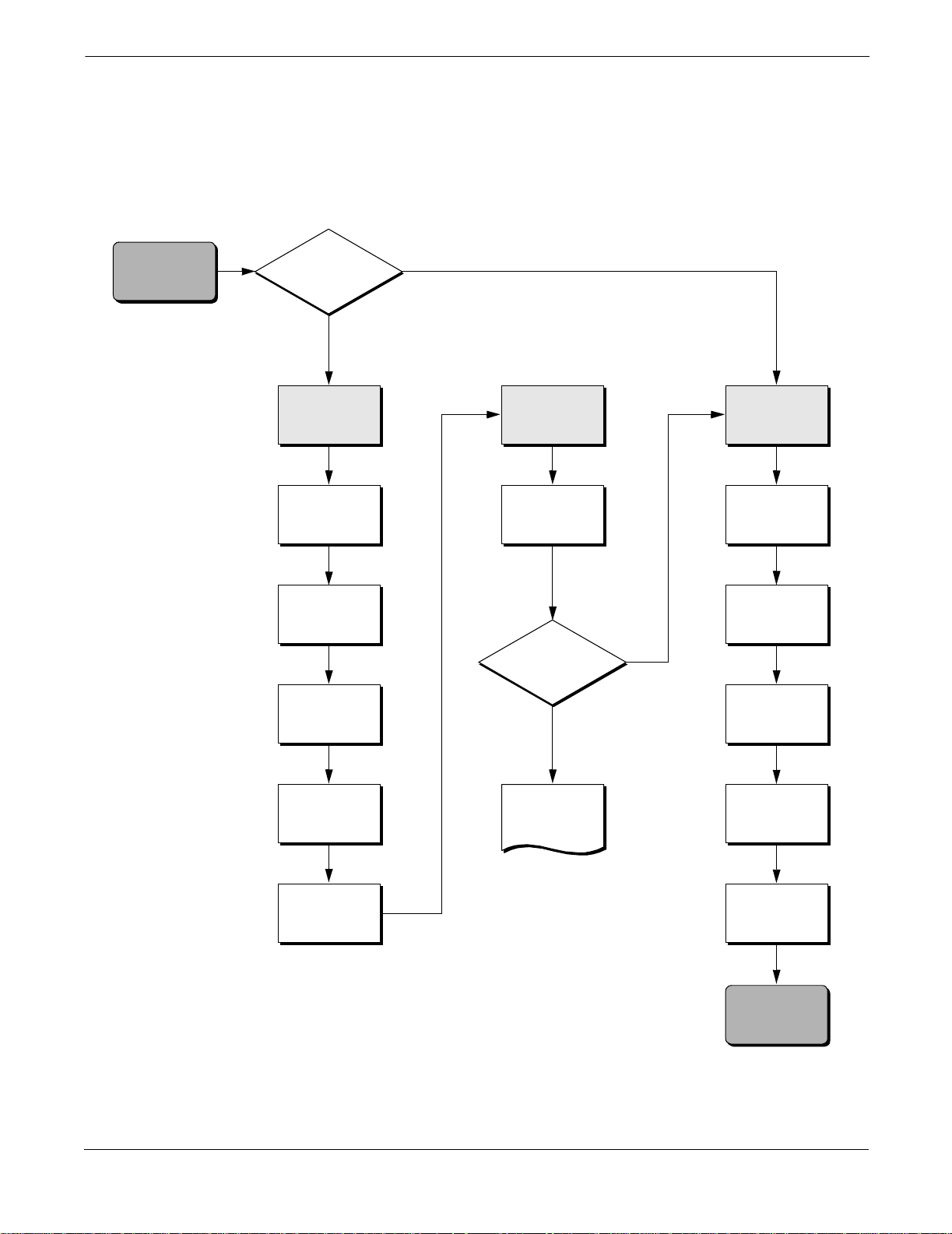

instructions, an installation flowchart (Figure 2-1 on page 2-2),

installation drawings, and special installation considerations.

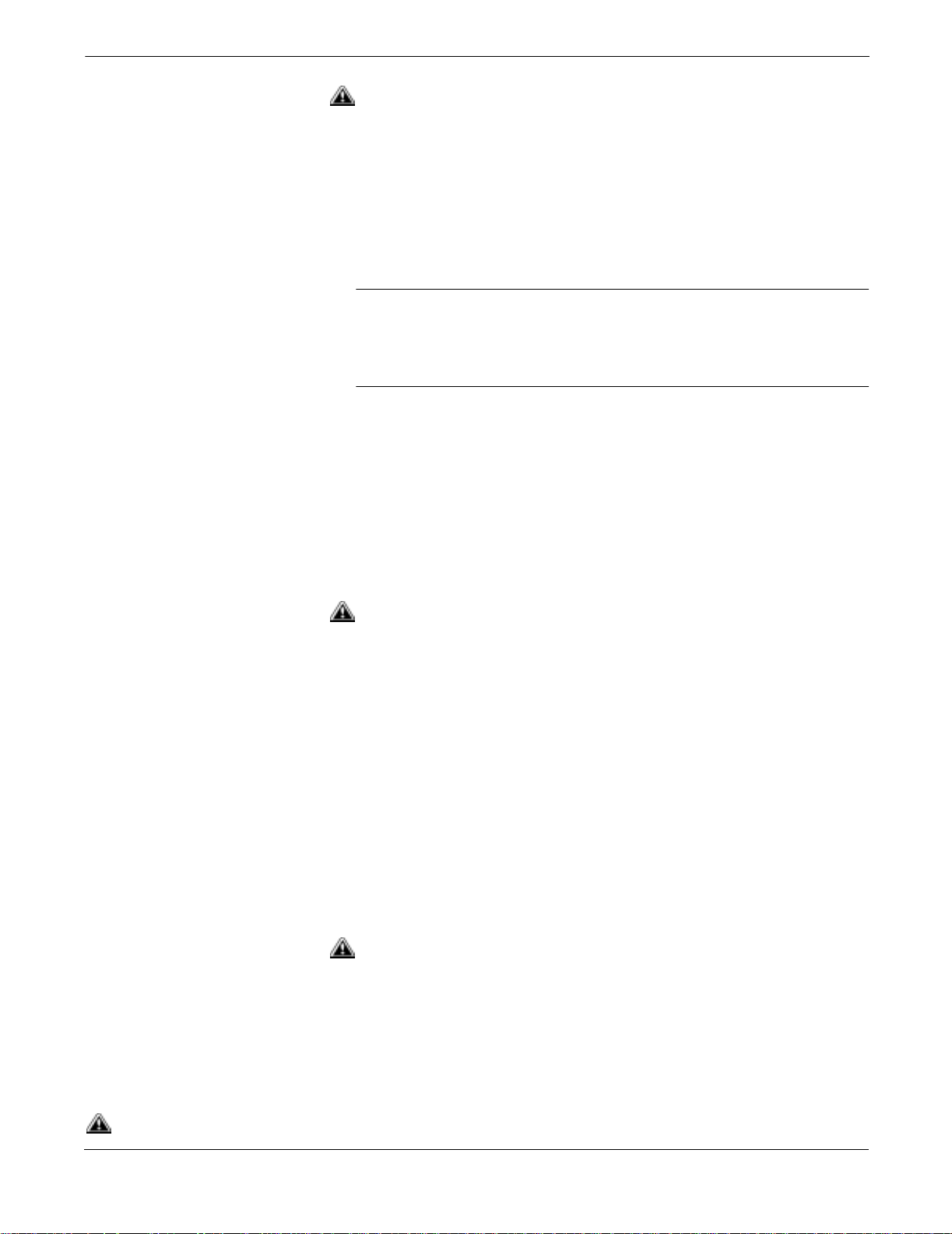

SAFETY MESSAGES Instructions and procedures in this section may require special

precautions to ensure the safety of the personnel performing the

operations. Information that potentially raises safety issues is indicated

by a warning symbol ( ). Please refer to the following safety messages

before performing an operation preceded by this symbol.

Warnings

Explosions could result in death or serious injury:

• Do not remove the transmitter cover in explosive atmospheres when the circuit

is alive.

• Before connecting a HART communicator in an explosive atmosphere, make

sure the instruments in the loop are installed in accordance with intrinsically

safe or non-incendive field wiring practices.

• Verify that the operating atmosphere of the transmitter is consistentwith the

appropriate hazardous locationscertifications.

• Bothtransmitter covers must be fully engaged to meet explosion-proof

requirements.

Failure to follow these installation guidelines could result in death or serious

injury:

• Make sure only qualified personnel perform the installation.

Process leaks could result in death or serious injury:

• Install and tighten thermowells orsensors before applyingpressure,or process

leakage may result.

• Do not remove the thermowell while in operation. Removing while in operation

may cause process fluid leaks.

Electrical shock could cause death or serious injury. If the sensor is installed in a

high-voltage environment and a fault or installation error occurs, high voltage may

be present on the transmitter leads and terminals:

• Use extreme caution when making contact with the leads and terminals.

2-1

Page 10

Rosemount Model 3144 and 3244MV Smart Temperature Transmitters

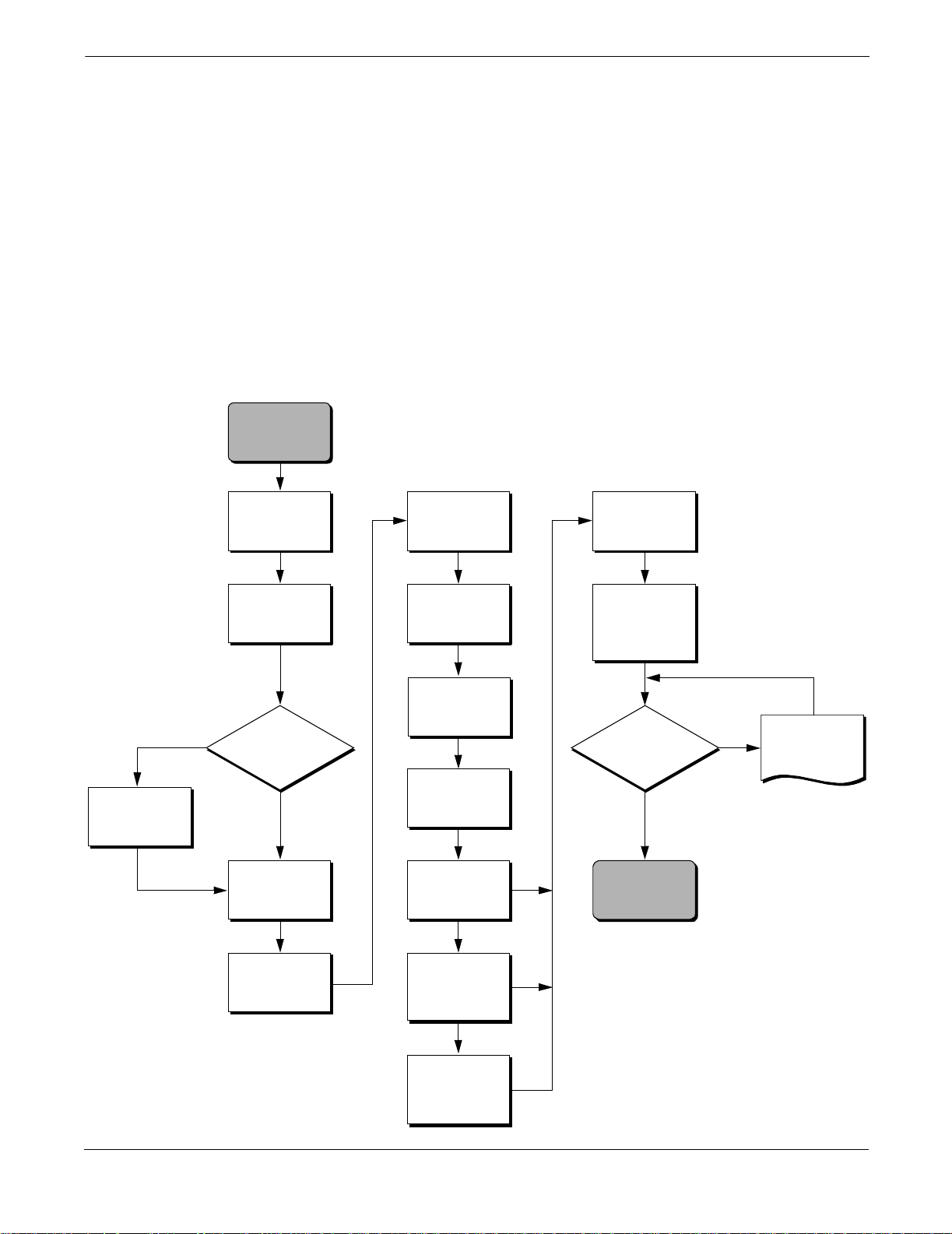

COMMISSIONING: ON THE BENCH OR IN THE LOOP

Figure 2-1. Installation Flowchart.

STA RT

HERE

Bench

Calibration?

Yes

BASIC SETUP VERIFY FIELD INSTALL

Set Units

The transmitter may be commissioned before or after installation.

However, it may be useful to commission the transmitter on the bench

before installation to ensure proper operation and to familiarize

yourself with its functionality.

No

Simulate

Sensor Input

Set Jumpers

or Switches

Set Range

Values

Set Sensor

Type

Set Num ber

of Wires

Set Damping

Within

Specifications?

No

Refer to

Section 4 :

Maintenance

Mount the

Transmitter

Yes

Wire the

Transmitter

Power the

Transmitter

Check for

Process Leaks

DONE

2-2

Page 11

Installation

GENERAL CONSIDERATIONS

Electrical temperature sensors such as resistance temperature

detectors (RTDs) and thermocouples (T/Cs) produce low-level signals

proportional to temperature. The Model 3144 and 3244MV transmitters

convert low-level sensor signals to a standard 4–20 mA dc signal that is

relatively insensitive to lead length and electrical noise. This current

signal is then transmitted to the control room via two wires.

Figures 2-9 and 2-12 show recommended mounting configurations for

transmitters and sensor assemblies. Refer to Section 6: Options for

additional transmitter mounting accessories.

ELECTRICAL CONSIDERATIONS

Proper electrical installation is necessary to prevent errors due to

sensor lead resistance and electrical noise. Shielded cable should be

used for best results in electrically noisy environments. The current

loop must have between 250 and 1100 ohms in order to communicate

with a HART communicator. Refer to Figure 2-4 on page 2-5 for sensor

and current loop connections.

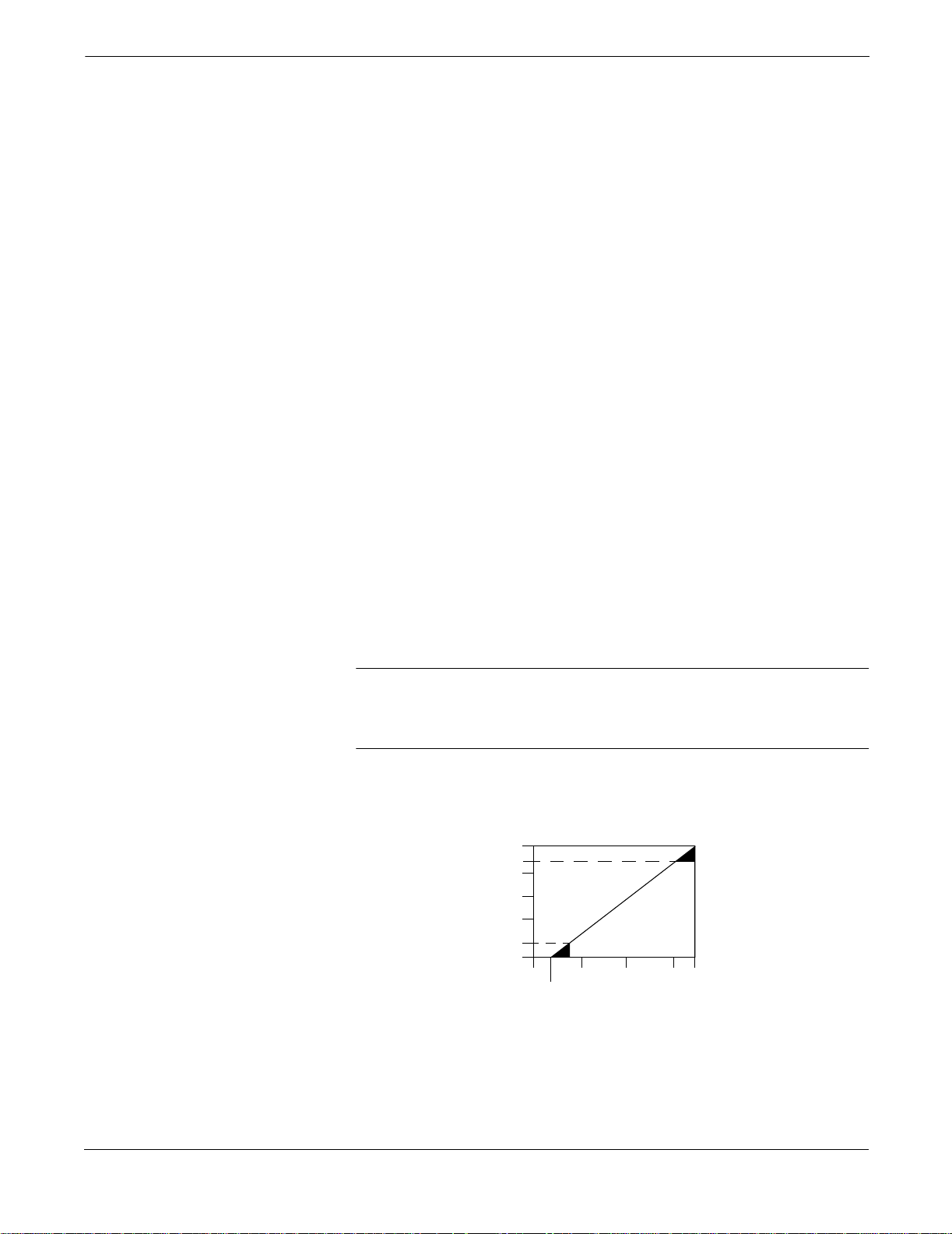

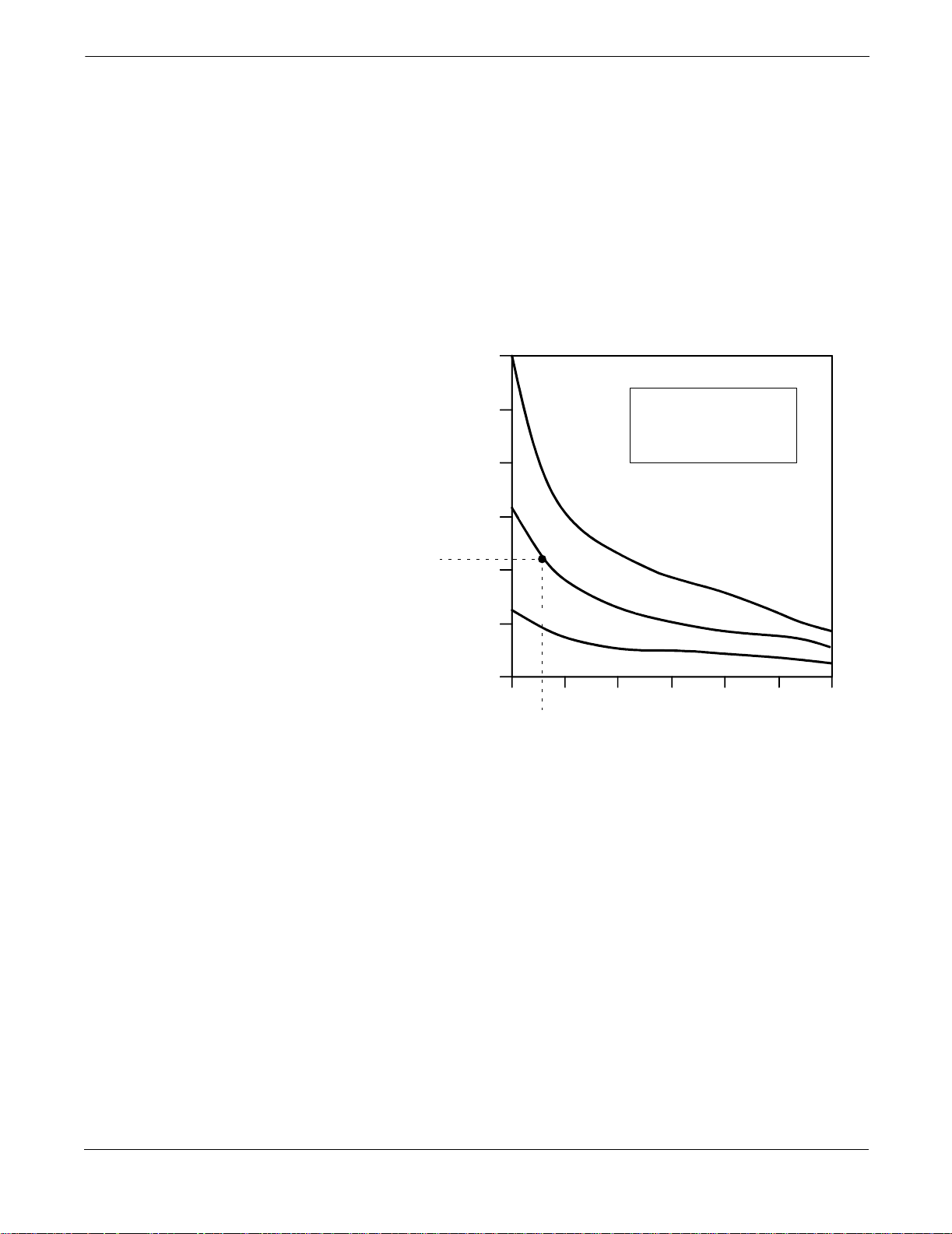

Power Supply To communicate with a transmitter, you will need a 17.75 V dc

minimum power supply. The power supplied to the transmitter should

not drop below the transmitter lift-off voltage (see Figure 2-2). If the

power drops below the lift-off voltage while the transmitter is being

configured, the transmitter may interpret the configuration

information incorrectly.

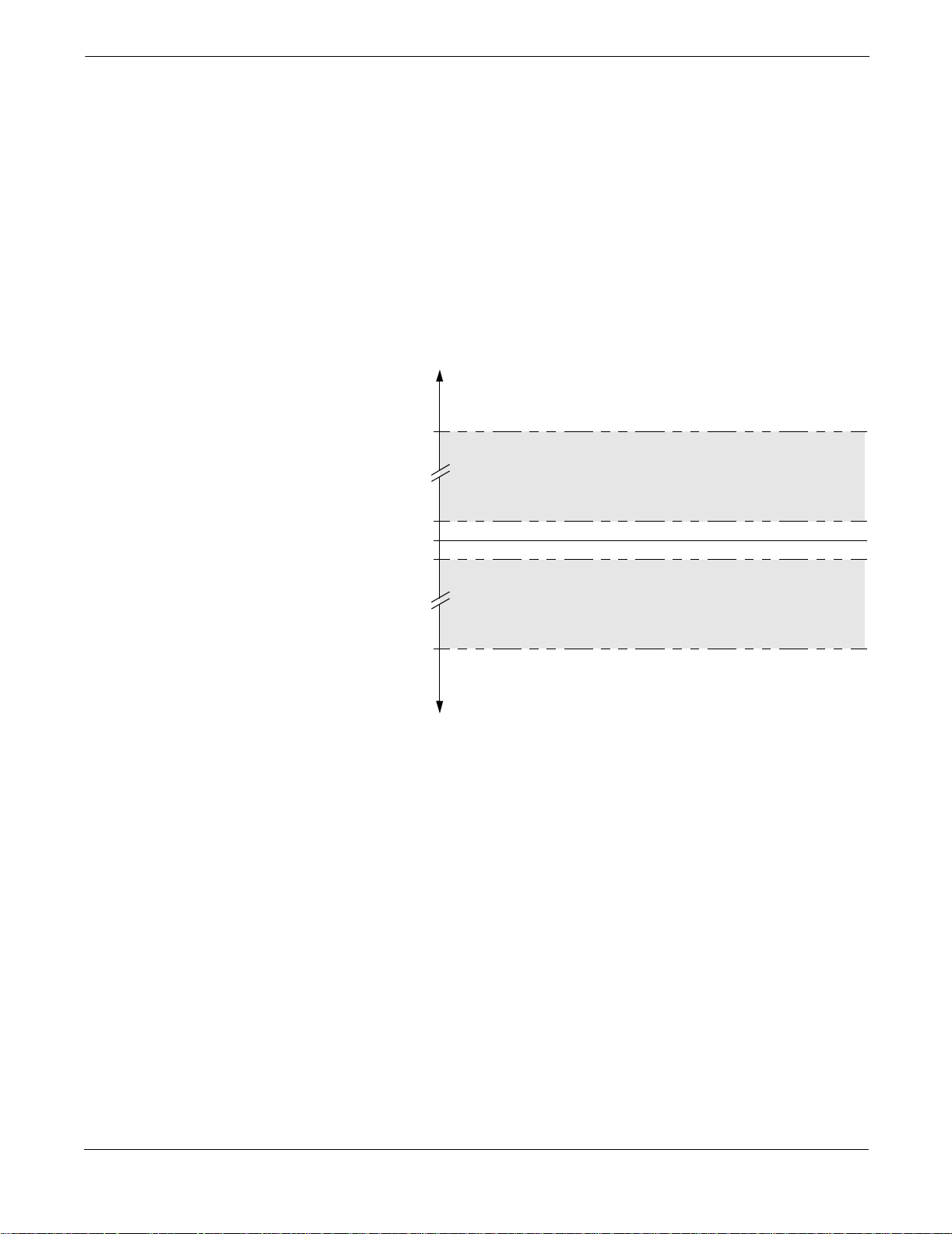

Figure 2-2. Load Limits.

The dc power supply should provide power with less than 2% ripple.

The total resistance load is the sum of the resistance of the signal leads

and the load resistance of any controller, indicator, or related piece of

equipment in the loop. Note that the resistance of intrinsic safety

barriers, if used, must be included.

NOTE

Do not allow the voltage to drop below 12.0 V dc at the transmitter

terminals when changing transmitter configuration parameters, or

permanent damage to the transmitter could result.

Maximum Load = 43.5 3 (Supply Voltage – 12.0)

1322

1100

1000

750

500

Load (Ohms)

250

0

10

4–20 mA dc

Operating

Region

20 30 40 42.4

12.0

Supply Voltage (V dc)

2-3

Page 12

Rosemount Model 3144 and 3244MV Smart Temperature Transmitters

Field Wiring All power to the transmitter is supplied over the signal wiring. Signal

wiring does not need to be shielded, but twisted pairs should be used for

the best results. Do not run unshielded signal wiring in conduit or open

trays with power wiring, or near heavy electrical equipment. High

voltage may be present on the leads and may cause electrical shock.

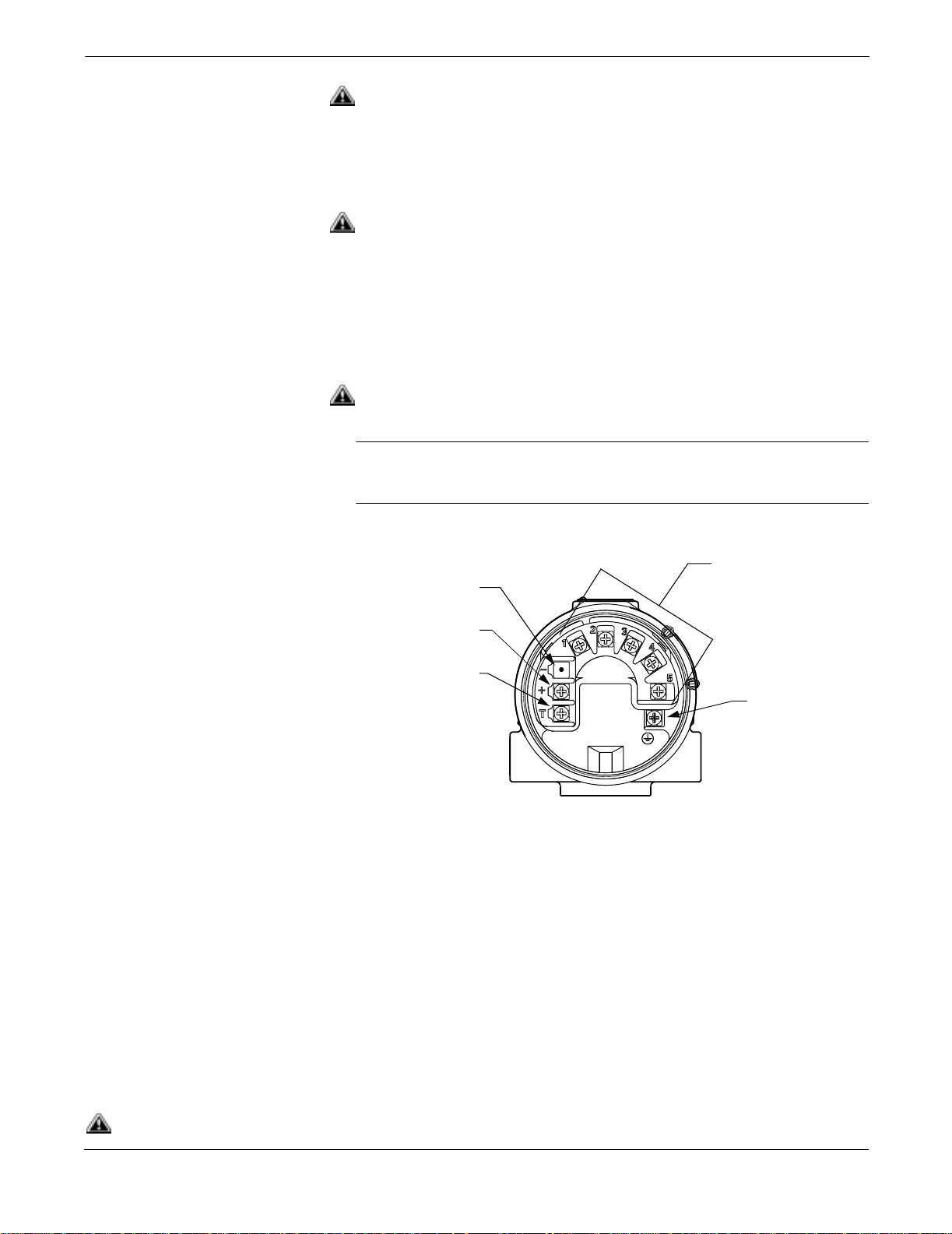

To power the transmitter, follow the steps below.

1. Remove the transmitter covers. Do not remove the transmitter

covers in an explosive atmosphere when the circuit is alive.

2. Connect the positive power lead to the terminal marked “+” and

the negative power lead to the terminal marked “–” as shown in

Figure 2-3. When wiring to screw terminals, the use of crimped

lugs is recommended.

3. Tighten the terminal screws to ensure that good contact is made.

No additional power wiring is required.

4. Replace the transmitter covers. Both transmitter covers must be

fully engaged to meet explosion-proof requirements.

NOTE

Do not apply high voltage (e.g., ac line voltage) to the transmitter

terminals. Abnormally high voltage can damage the unit.

Figure 2-3. Transmitter Ter minal Block.

Power/Current Loop

Connections

Sensor Terminals

Negative Terminal

Positive Terminal

Test Terminal

Ground Term inal

3144-0200E01D

Use ordinary copper wire of sufficient size to ensure that the voltage

across the transmitter power terminals does not go below 12.0 V dc.

1. Connect the current signal leads as shown in Figure 2-4.

2. Recheck the polarity and correctness of connections.

3. Turn the power ON.

For information about multichannel installations, refer to page 2-6. For

information about intrinsically safe installations, refer to page 2-13.

See “Safety Messages” on page 2-1 for complete war ning informatio n.

2-4

Page 13

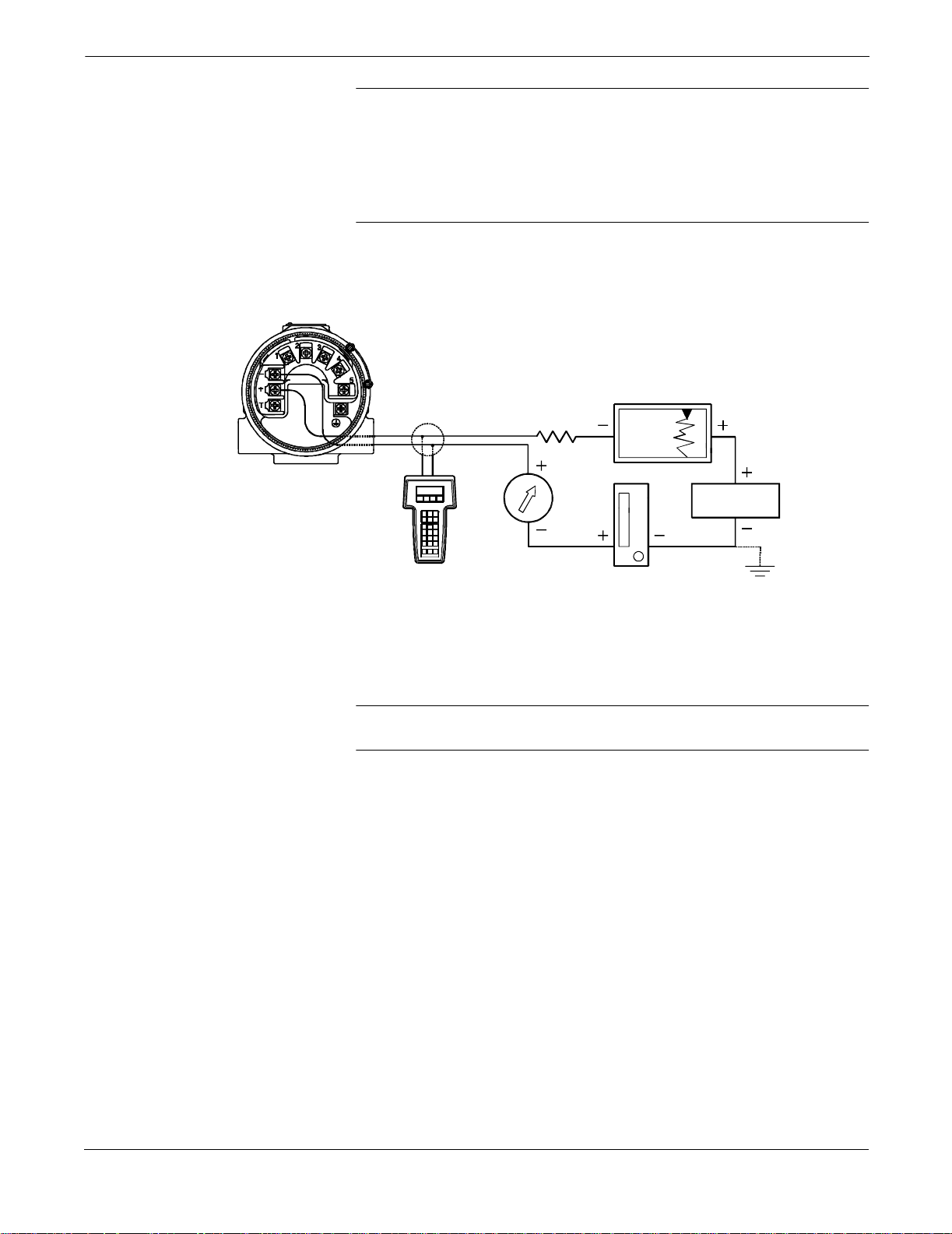

Figure 2-4. Connecting a

Communicator to a Transmitter Loop.

Power/Signal

Terminals

Installation

NOTE

Do not connect the power/signal wiring to the test terminals.

The voltage present on the power/signal leads may burn out the

reverse-polarity protection diode that is built in to the test terminal. If

the test terminals’ reverse polarity protection diode is burned out by the

power/signal wiring, the transmitter can still be operated by jumping

the current from one test terminal to the other.

The signal loop may be grounded at any

point or left ungrounded.

≤RL≤1100 V

250 V

A HART communicator may be

connected at any termination

point in thesignal loop. The

signal loop must have between

250 and 1100 ohms load for

communications.

Power

Supply

Grounding Transmitters are electrically isolated to 500 V ac rms. You can ground

the signal wiring at any single point, if desired. When using a grounded

thermocouple, the grounded junction serves as this point.

NOTE

Do not ground the signal wire at both ends.

Shielded Wire Recommended grounding techniques for shielded wire usually call for a

single grounding point for each shielded wire to avoid grounding the

loop. The following two examples employ the single point grounding

technique:

Example 1

Connect the shield for the signal wiring to the shield for the sensor

wiring. Make sure that the two shields are tied together and

electrically isolated from the transmitter housing. Ground the shield

at the power supply end.

3144-0000A04A

Example 2

Connect the shield for the sensor wiring to the ground terminal

inside of the terminal compartment of the transmitter housing. The

shield for the signal wiring should be cut and isolated from the

transmitter housing. This shield should be grounded only at the

power supply end. Never connect the shield for the signal wiring to

the ground terminal inside the transmitter housing.

2-5

Page 14

Rosemount Model 3144 and 3244MV Smart Temperature Transmitters

Transmitter Housing Ground the transmitter housing in accordance with local electrical

requirements. An internal ground terminal is standard. An optional

external ground lug assembly (Option Code G1) can also be ordered if

needed. Ordering certain hazardous approvals automatically includes

an external ground lug (see table on page 5-9). External grounding is

recommended when using the optional transient protector (Option

Code T1).

Surges/Transients The transmitter will withstand electrical transients of the energy level

usually encountered in static discharges or induced switching.

However, high-energy transients, such as those induced in wiring from

nearby lightning strikes, can damage both the transmitter and the

sensor.

To protect against high-energy transients, install either the integral

transient protection board (Option Code T1) or the Rosemount Model

470 Transient Protector. The integral transient protection board is

available as an ordered option or as an accessory. Refer to “Transient

Protection (Option Code T1)” on page 6-4 for more information. The

Model 470 transient protector is available only as an accessory. Refer to

the Model 470 Transient Protector Product Data Sheet (Rosemount

publication no. 00813-0100-4191) for more information.

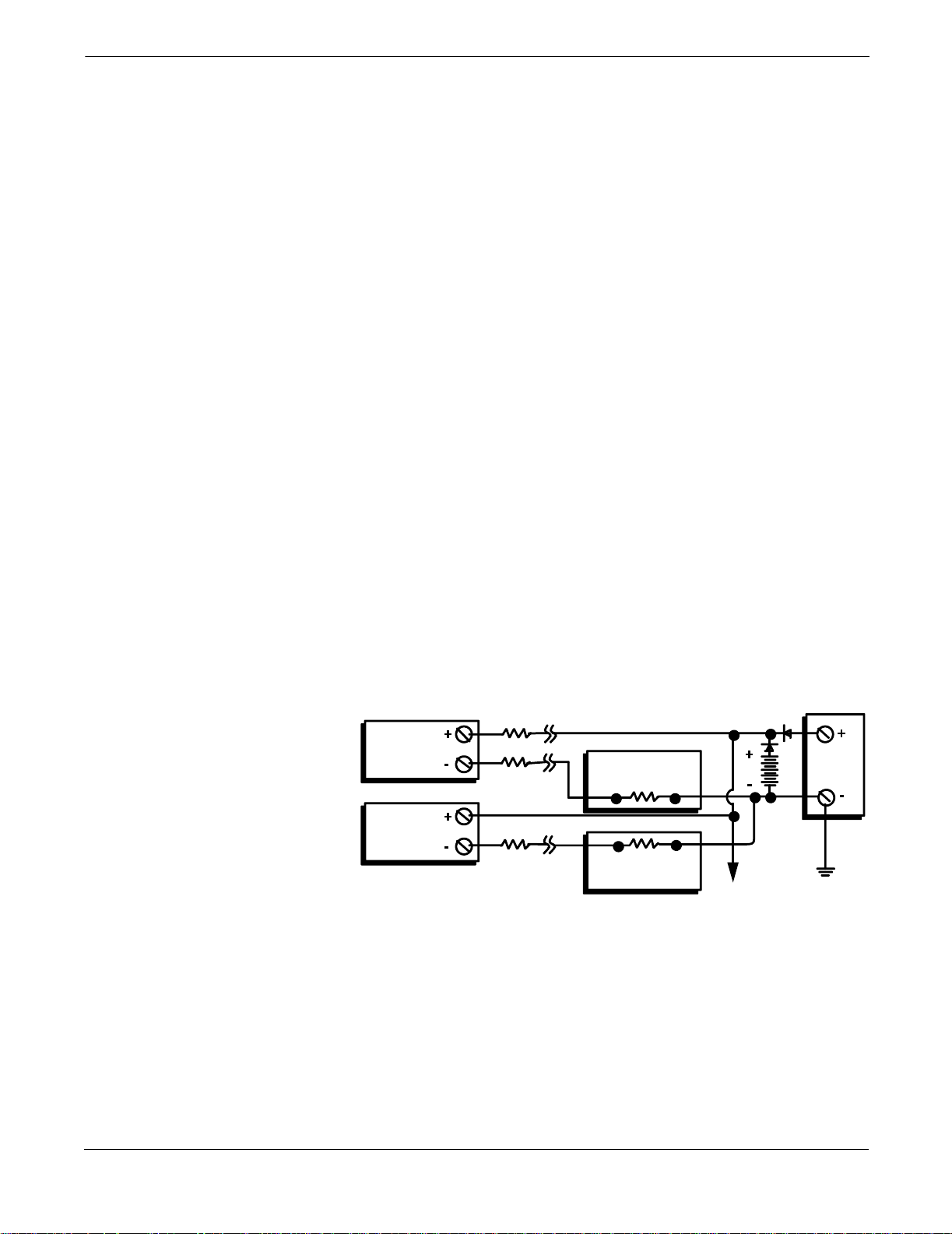

Multichannel Installations You can connect several transmitters to a single master power supply,

as shown in Figure 2-5. In this case, the system may be grounded only

at the negative power supply terminal. In multichannel installations

where several transmitters depend on one power supply, and the loss of

all transmitters would cause operational problems, consider an

uninterruptible power supply or a back-up battery. The diodes shown in

Figure 2-5 prevent unwanted charging or discharging of the back-up

battery.

Figure 2-5. Multichannel Installations.

Battery

Backup

dc

Power

Supply

To Additional

Transmitters

Transmitter

No. 1

Transmitter

No. 2

R

R

R

Lead

Lead

Lead

Readout or

Controller No. 1

Readout or

Controller No. 2

Between 250 and

1100 Ω If No Load

Resistor

3044-0131A

2-6

Page 15

Installation

FAILURE MODE AND SECURITY JUMPERS

Failure Mode Jumper The transmitter monitors itself during normal operation with an

automatic diagnostic routine. If the diagnostic routine detects a sensor

failure or a failure in the transmitter electronics, the transmitter goes

into alarm (high or low, depending on the position of the failure mode

jumper).

The analog alarm and saturation values that the transmitter uses

depend on whether it is factory configured to standard or

NAMUR-compliant operation. The values for each are as follows:

Standard Operation

Fail High 21.0 mA ≥ I ≥ 23.0 mA

High Saturation I ≥ 20.5 mA

Low Saturation I ≤ 3.90 mA

Fail Low I ≤ 3.75 mA

NAMUR-Compliant Operation

Fail High 21.0 mA ≥ I ≥ 23.0 mA

High Saturation I ≥ 20.5 mA

Low Saturation I ≤ 3.8 mA

Fail Low I ≤ 3.6 mA

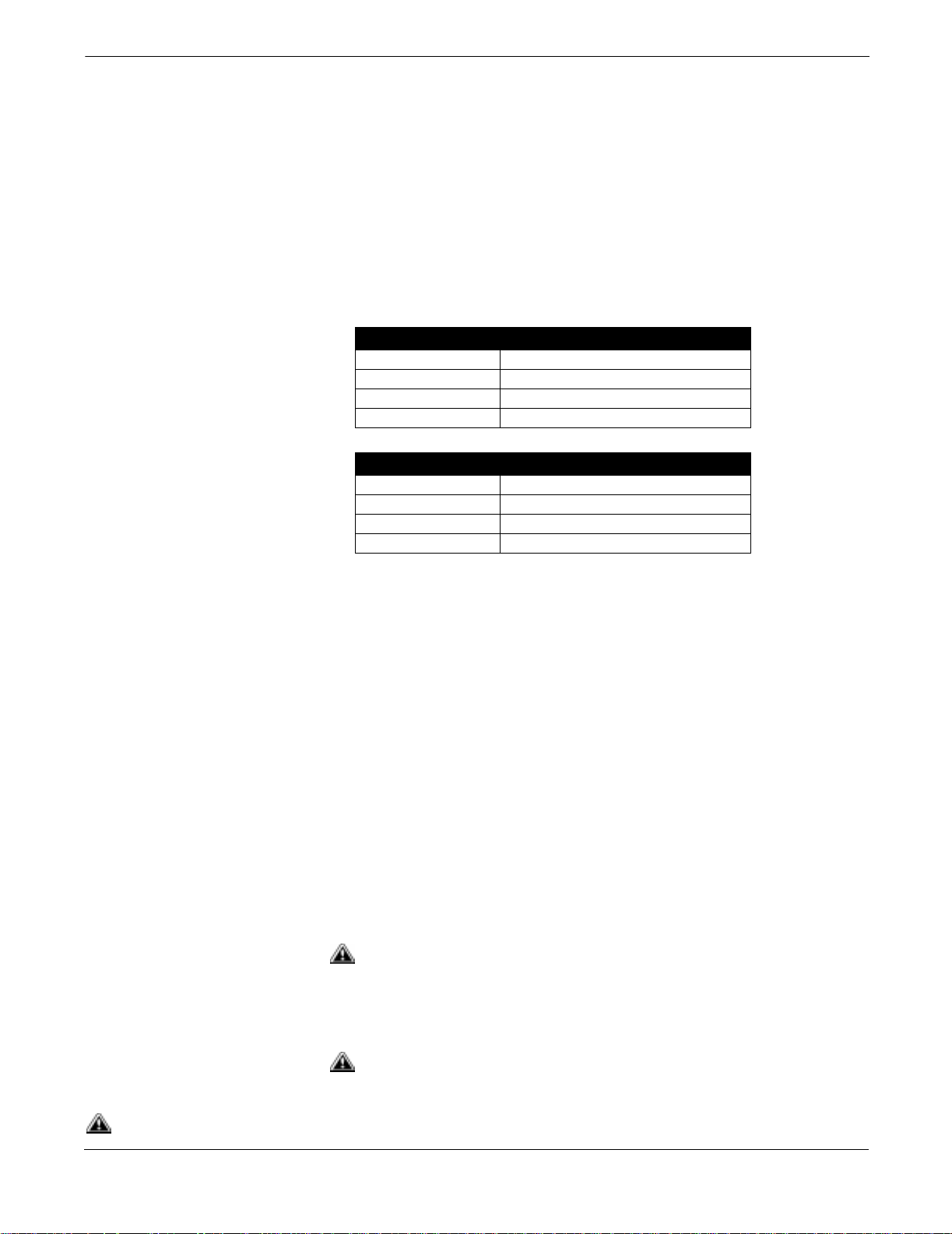

Failure Mode Jumper Locations Without a meter installed:

The failure mode jumper is located on the front side of the

electronics module on the electronics side of the transmitter

housing, and is labeled FAIL MODE (see Figure 2-6 on page 2-8).

With a meter installed:

The failure mode jumper is located on the LCD faceplate on the

electronics module side of the transmitter housing, and is labeled

FAIL MODE (see Figure 2-6 on page 2-8).

Transmitter Security

Jumper

The transmitter is equipped with a write-protect jumper that can be

positioned to prevent the accidental or deliberate change of

configuration data. The security jumper is located on the front side of

the electronics module and is labeled XMTR SECURITY (see Figure 2-6

on page 2-8).

Changing the Position of

the Failure Mode or

Security Jumper

To change the position of the failure mode or security jumper, follow the

steps below.

1. If the transmitter is installed, set the loop to manual.

2. Remove the housing cover on the electronics side. Do not remove

the transmitter cover in explosive atmospheres when the circuit

is alive.

3. Set the jumper(s) to the desired position. See Figure 2-6 on

page 2-8.

4. Replace the transmitter cover. Both transmitter covers must be

fully engaged to meet explosion-proof requirements.

See “Safety Messages” on page 2-1 for complete warning information.

2-7

Page 16

Rosemount Model 3144 and 3244MV Smart Temperature Transmitters

Figure 2-6. Transmitter Jumper

Locations.

Security Jumper

Failure Mode Jumper

(without a Meter Installed)

Failure Mode Jumper

(with a Meter Installed)

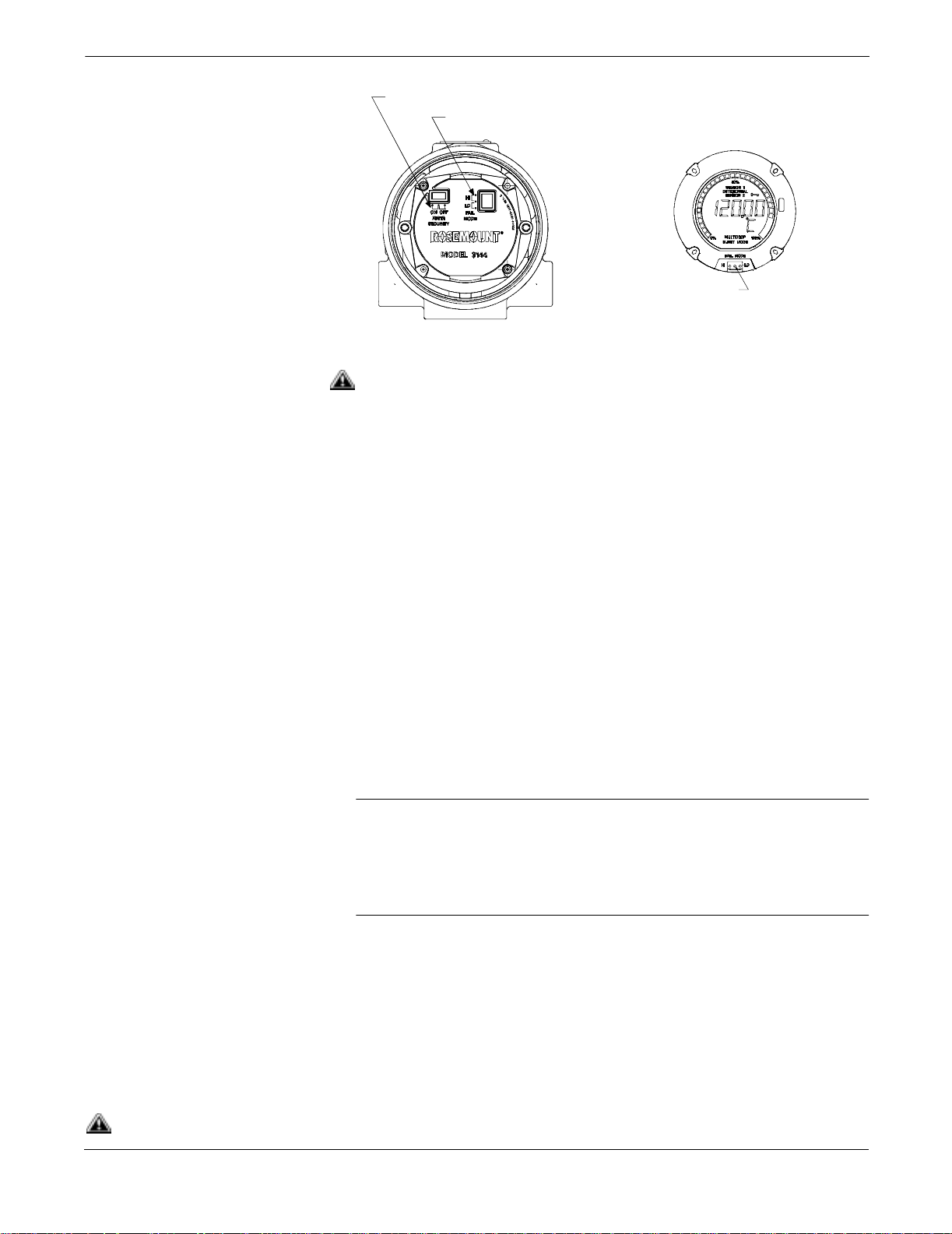

SENSOR CONNECTIONS Figure 2-7 on page 2-9 shows the correct input connections to the

sensor terminals on the transmitter. To ensure an adequate sensor

connection, anchor the sensor lead wires beneath the flat washer on the

terminal screw. Do not remove the transmitter cover in explosive

atmospheres when the circuit is alive. Both transmitter covers must be

fully engaged to meet explosion-proof requirements. Use extreme

caution when making contact with the leads and terminals.

RTD or Ohm Inputs If the transmitter is mounted remotely from a 3- or 4-wire RTD, it will

operate within specifications, without recalibration, for lead wire

resistances of up to 10 ohms per lead (equivalent to 1,000 feet of 20

AWG wire). In this case, the leads between the RTD and transmitter

should be shielded. If using only two leads (or a compensation loop lead

wire configuration), both RTD leads are in series with the sensor

element, so significant errors can occur if the lead lengths exceed one

foot of 20 AWG wire. For longer runs, attach a third or fourth lead as

described above.

3144-0200G01A, 2352A01D

Thermocouple or Milliv olt

Inputs

For direct-mount applications, connect the thermocouple directly to the

transmitter. If mounting the transmitter remotely from the sensor, use

appropriate thermocouple extension wire. Make connections for

millivolt inputs with copper wire. Use shielding for long runs of wire.

NOTE

The use of two grounded thermocouples with a Model 3244MV

transmitter is not recommended. For applications in which the use of

two thermocouples is desired, connect either two ungrounded

thermocouples, one grounded and one ungrounded thermocouple, or one

dual element thermocouple.

See “Safety Messages” on page 2-1 for complete warning information.

2-8

Page 17

Figure 2-7. Sensor Wiring Diagram.

Installation

MODEL 3144 SENSOR CONNECTIONS

2-wire RTD

2-wire RTD

2-wire RTD

and Ohms**

and Ohms**

and Ohms

3-wire RTD

3-wire RTD

3-wire RTD

and Ohms**

and Ohms**

and Ohms**

4-wireRTD

and Ohms

T/Cs and Millivolts RTD with

Compensation Loop*

MODEL 3244MV SENSOR CONNECTIONS

2-wire RTD

2-wire RTD

and Ohms**

and Ohms

***

Hot Backup/Dual Sensor with

* Transmitter must be configured for a 3-wireRTD in order to recognize an RTD with a compensation loop.

** Rosemount provides 4-wire sensors for all single-element RTDs. Y oucan use these RTDs in 3-wire configurations by leaving

*** Typicalwiring config uration of a Rosemountdual-elementRTD is shown (R=Red,W=White, G=Green,B=Black).

W

R

Avg. Temp/DT/

the unneeded leads disconnected and insulated with electrical tape.

W&G

G

B

2RTDs**

MECHANICAL CONSIDERATIONS

3-wire RTD

and Ohms**

Avg. Temp/DT/

Hot Backup/Dual Sensor with

2 thermocouples

Use the following information when preparing the installation site and

selecting transmitter options.

4-wire RTD

and Ohms

Avg. Temp/DT/

Hot Backup/Dual Sensor with

RTDs/thermocouples**

T/Cs and Millivolts

Avg. Temp/DT/

Hot Backup/Dual Sensor with

RTDs/thermocouples**

Compensation Loop*

Hot Backup/Dual Sensor

with2RTDswith

Compensation Loop**

The transmitter may be mounted directly to or remotely from the

sensor. Using optional mounting brackets, the transmitter may be

mounted to a flat surface or to a two-inch diameter pipe (see Figure 2-8

on page 2-10).

RTD with

Avg. Temp/∆T/

3144-0000E05A, F05A, A04A

Mounting The transmitter may require supplementary support under

high-vibration conditions, particularly if used with extensive

thermowell lagging or long extension fittings. Pipe-stand mounting,

using one of the optional mounting brackets, is recommended for use in

high-vibration conditions.

Access Requirements Take into account the need for access to the transmitter when choosing

an installation location and position.

Housing Rotation You may rotate the electronics housing up to 90 degrees in either

direction to improve field access to the two compartments.

Terminal Side of Electronics

Housing

Mount the transmitter so the terminal side is accessible. Be sure to

allow adequate clearance for cover removal. Make wiring connections

through the conduit openings on the bottom of the housing.

2-9

Page 18

Rosemount Model 3144 and 3244MV Smart Temperature Transmitters

Circuit S ide of Electronics

Housing

Figure 2-8. Option Code B4 Mounting

Bracket.

PANEL MOU NT

3.65 ±0.06

(2)5/16-inch Bolts not provided

Mount the transmitter so that the circuit side is accessible. Be sure to

provide adequate clearance for cover removal. Also, be sure to account

for extra room if an LCD meter is installed. Refer to Section 6: Options

for more information on the LCD meter option.

PIPE M OUNT

1.04 (26)

1.55

(39.4)

1.0

(25.4)

2.81 ±0.03

NOTE

Dimensions are in inches (millimeters).

Figure 2-9. Option Code B5 Mounting

Bracket.

6.4 (163)

(71.4)

2.0 ± 0.03

(50.8)

0.41 (10.4)

Diameter

0.375 (9.5)

Diameter

2-inch

Pipestand

3144-3144A14A, 0000A01A; 3044-2101A01A; 3144-1081A01B

1.0 (25)

7.2 (182

2-10

3144-0427B, 0427C

Page 19

Installation

ENVIRONMENTAL CONSIDERATIONS

Temperature Effects The transmitter will operate within specifications for ambient

temperatures between –40 and 185 °F (–40 and 85 °C). Heat from the

process is transferred from the thermowell to the transmitter housing.

If the expected process temperature is near or beyond specification

limits, consider the use of additional thermowell lagging, an extension

nipple, or a remote mounting configuration to isolate the transmitter

from the process. Figure 2-11 describes the relationship between

transmitter housing temperature rise and extension length.

Figure 2-10. Model 3144/3244MV

Transmitter Housing Temperature Rise

versus ExtensionLength for a Test

Installation.

HOUSING TEMPERATURE RISE

ABOVE AMBIENT °C (°F)

22

60 (108)

50 (90)

40 (72)

30 (54)

20 (36)

10 (18)

Transmitter Housing

Temperature Risevs.

8

1

5

°

C

(

1

,

5

0

0

°

C

0°

°

F

)

O

(

1

,

0

0

0

°

F)

O

C

(

4

8

2

°

F

)

5

4

0

2

5

Extension Length for a

Test Installation

v

e

n

T

e

mp

e

r

a

v

en

T

e

m

p

e

r

O

v

e

n

T

e

m

p

t

u

r

e

a

t

u

r

e

e

r

a

t

u

r

e

0

3 4 5 6 7 8 9

3.6

EXTENSION LENGTH (IN.)

EXAMPLE:

The maximum permissible housing temperature rise (T) can be

calculated by subtracting the maximum ambient temperature (A)

from the transmitter’s ambient temperature specification limit (S).

For instance, suppose A = 40 °C.

TSA–=

T 85 °C 40 °C–=

T 45 °C=

For a process temperature of 540 °C (see Figure 2-10), an extension

length of 3.6 inches yields a housing temperature rise (R) of 22 °C,

which provides a safety margin of 23 °C. A six-inch extension length

(R = 10 °C) would offer a higher safety margin (35 °C) and would

reduce temperature-effect errors but would probably require extra

support for the transmitter. Gauge the requirements for individual

applications along this scale. If a thermowell with lagging is used,

the extension length may be reduced by the length of the lagging.

3044-0123A

2-11

Page 20

Rosemount Model 3144 and 3244MV Smart Temperature Transmitters

Moist or Corrosive

Environments

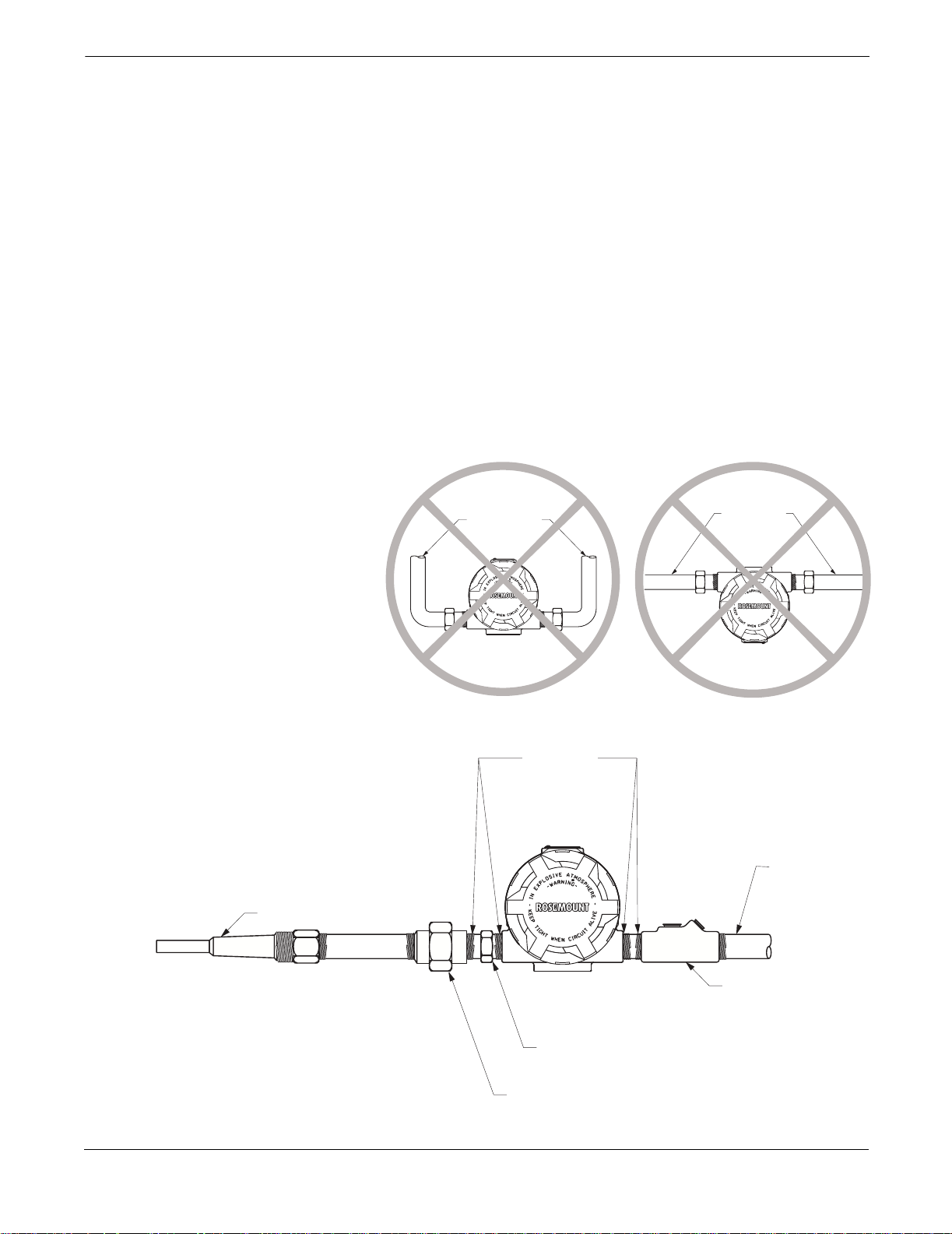

Figure 2-11. Incorrect Conduit

Installation.

The Model 3144 and 3244MV transmitters have a highly reliable

dual compartment housing designed to resist attack by moisture and

corrosives. The sealed electronics module is mounted in a

compartment that is isolated from the terminal side conduit entries.

O-ring seals protect the interior when the covers are installed. In

humid environments, however, it is possible for moisture to

accumulate in conduit lines and drain into the housing.

Proper transmitter installation can ensure optimal operation and

service life and prevent moisture from accumulating in the housing.

Refer to Figure 2-11, and Figure 2-12 before mounting a transmitter.

Mount the transmitter at a high point in the conduit run, if possible,

so that moisture from the conduits will not drain into the housing. If

the transmitter is mounted at a low point in the conduit run, the

terminal compartment could fill with water. In some instances, the

installation of a poured conduit seal, such as the one pictured in

Figure 2-12, is advisable. Remove the terminal compartment cover

periodically and inspect the transmitter for moisture and corrosion.

Conduit

Lines

Conduit

Lines

Figure 2-12. Recommended Mounting

with Drain Seal.

Thermowe ll

Sealing

Compound

Sensor Hex

Union Coupling

with Exten sio n

3144-0429A, 04 29B

Conduit for

Field Wiring

Poured ConduitSeal

(Where R equired)

3144-0430B

2-12

Page 21

Installation

Hazardous Locations

Installations

INSTALLATION PROCEDURE

The transmitter is designed with explosion-proof housings and circuitry

suitable for intrinsically safe and non-incendive operation. Each

transmitter is clearly marked with a tag indicating the approvals

carried. To maintain certified ratings for installed transmitters, install

in accordance with all applicable installation codes and approval

drawings. Verify that the operating atmosphere of the transmitter is

consistent with the appropriate hazardous locations certifications. Both

transmitter covers must be fully engaged to meet explosion proof

requirements. Refer to Appendix D: Hazardous Area Approval

Installation Drawings for transmitter installation drawings.

IMPORTANT

Once a device labeled with multiple approval types is installed, it

should not be reinstalled using any of the other labeled approval types.

To ensure this, the approval label should be permanently marked to

distinguish the used from the unused approval type(s).

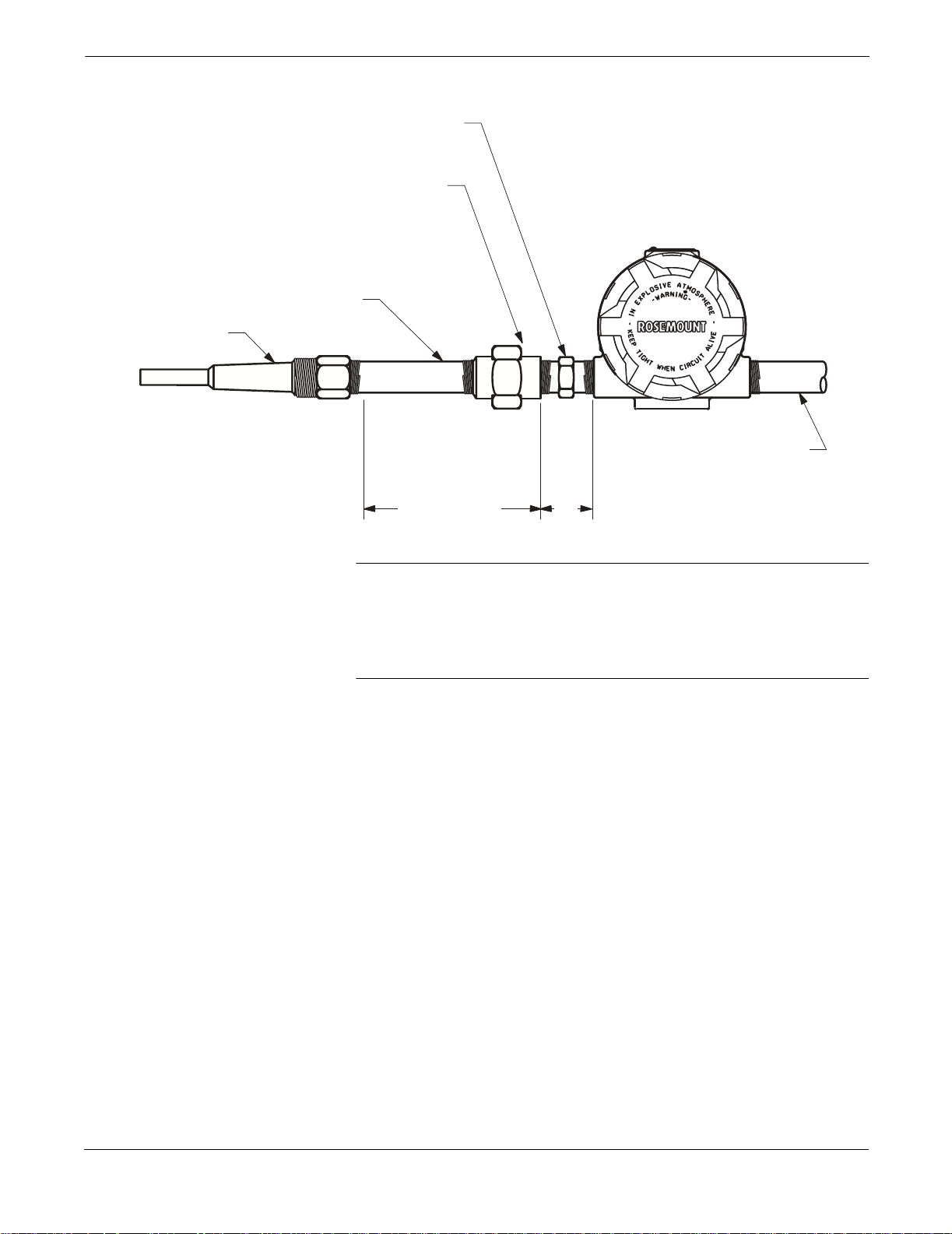

Installation consists of mounting the transmitter and sensor and

making electrical connections. If you are mounting the transmitter

directly to the sensor assembly, use the process shown in Figure 2-13. If

you are mounting the transmitter apart from the sensor assembly, use

conduit between the sensor and transmitter. The transmitter accepts

male conduit fittings with

(PG 11), or JIS G

perform the installation.

1

/2 threads. Make sure only qualified personnel

1

/2–14 NPT, M20 × 1.5 (CM 20), PG 13.5

Typical North American

Configuration

1. Mount the thermowell to the pipe or process container wall. Be

sure to install and tighten thermowells and sensors. Perform a

leak check before starting the process.

2. Attach any necessary unions, couplings, and extension fittings.

Be sure to seal the fitting threads with silicone or tape (if

required).

3. Screw the sensor into the thermowell.

4. Verify all sealing requirements for severe environments or to

satisfy code requirements.

5. Attach the transmitter to the thermowell assembly. Be sure to

seal all threads with silicone or tape (if required).

6. Pull sensor leads through the extensions, unions, or couplings

into the terminal side of the transmitter housing.

7. Install conduit for field wiring to the remaining conduit entry of

the transmitter.

8. Pull the field wiring leads into the terminal side of the

transmitter housing. Avoid contact with the leads and terminals.

9. Attach the sensor leads to the transmitter sensor terminals.

Attach the power leads to the transmitter power terminals. Avoid

contact with the leads and terminals.

10. Attach and tighten both transmitter covers. Both transmitter

covers must be fully engaged to meet explosion-proof

requirements.

See “Safety Messages” on page 2-1 for complete warning information.

2-13

Page 22

Rosemount Model 3144 and 3244MV Smart Temperature Transmitters

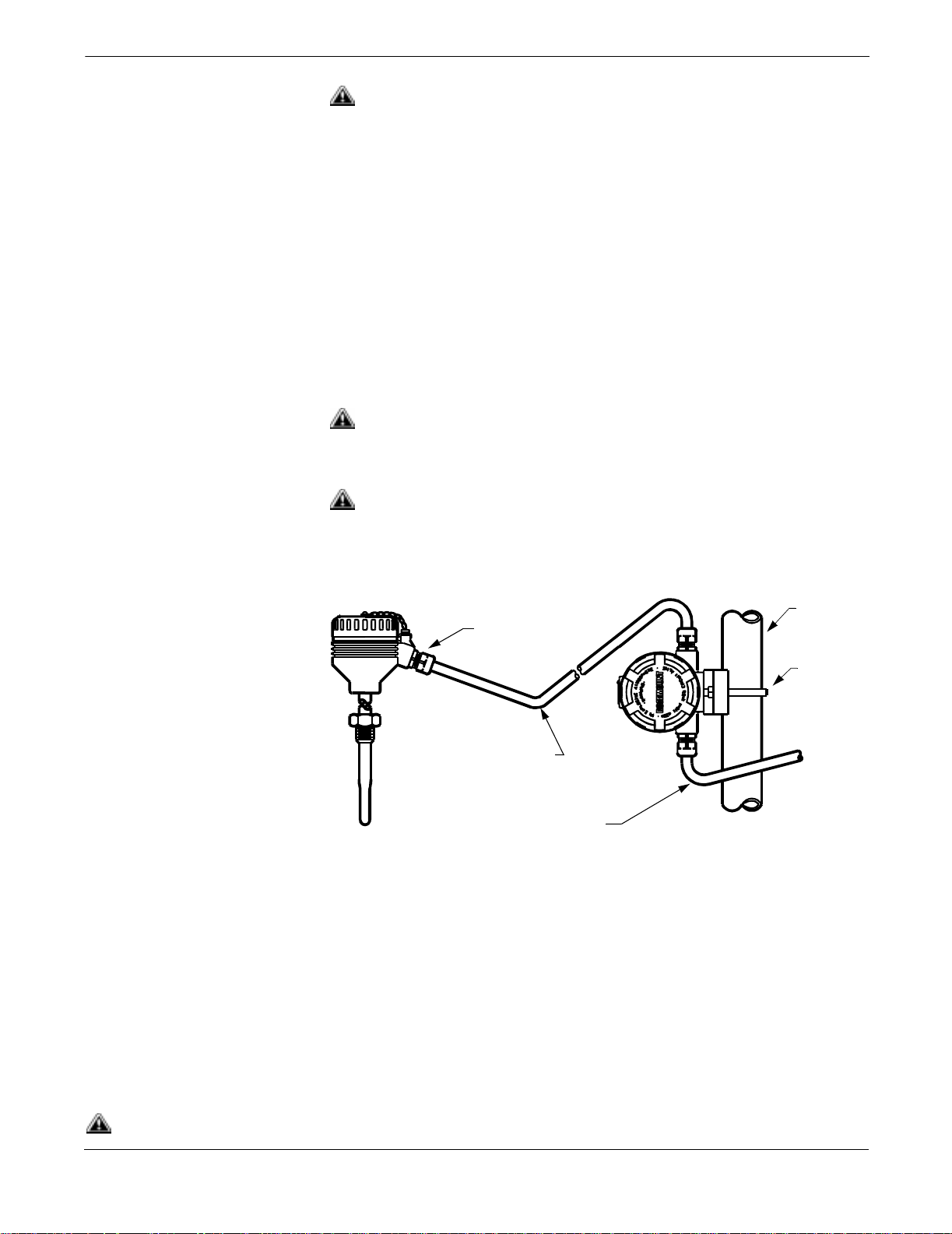

Figure 2-13. Typical North American

Mounting Configuration.

Sensor Hex

Union o r

Coupling

Extension

Thermowell

Conduit for

Field Wiring

(dc power)

NOTE

Dimensions are in inches (millim eters).

Extension Fitting

Length

3.2

(81)

NOTE

The National Electrical Code requires that a barrier or seal be used in

addition to the primary (sensor) seal to prevent process fluid from

entering the electrical conduit and continuing to the control room.

Professional safety assistance is recommended for installations in

potentially hazardous processes.

3144-0433B

2-14

Page 23

Installation

Typical European

Configuration

1. Mount the thermowell to the pipe or the process container wall.

Install and tighten thermowells and sensors. Perform a leak

check before starting the process.

2. Attach a connection head to the thermowell.

3. Insert the sensor into the thermowell and attach it to the

connection head.

4. Mount the transmitter to a 2-inch pipe or a suitable panel using

one of the optional mounting brackets. The B4 bracket is shown

in Figure 2-14.

5. Attach cable glands to the shielded cable running from the

connection head to the transmitter and from the transmitter to

the control room.

6. Insert the shielded cable leads into the connection head and the

transmitter through the cable entries. Connect and tighten the

cable glands.

7. Connect the shielded cable leads to the sensor wiring leads inside

of the connection head, and the sensor wiring terminals inside of

the transmitter housing. Avoid contact with the leads and the

terminals.

8. Connect the shielded cable leads to the transmitter power

terminals. Avoid contact with the leads and the terminals.

Figure2-14.TypicalEuropeanProcess

Mounting Configuration.

Cable Gland

Shielded Cable from

Sensor to Transmitter

Shielded Cable

from Transmitter

to Control Room

2-inch

Pipe

B4

Mounting

Bracket

644-0000B05B

See “Safety Messages” on page 2-1 for complete warning information.

2-15

Page 24

Rosemount Model 3144 and 3244MV Smart Temperature Transmitters

INSTALLATION IN

CONJUNCTION WITH A

MODEL 333 HART

TRI-LOOP

HART-TO-ANALOG

SIGNAL CONVERTER

Figure2-15.HARTTri-Loop Installation

Flowchart.

START

HERE

Unpack the

Tri-Loop

Use the Model 3244MV transmitter in operation with two sensors in

conjunction with a Model 333 HART Tri-Loop

®

HART-to-Analog Signal

Converter to acquire an independent 4–20 mA analog output signal for

each sensor input. During normal operation, the Model 3244MV

transmitter outputs four out of the five following digital process

variables: sensor 1, sensor 2, differential temperature, average

temperature, and transmitter terminal temperature. The HART

Tri-Loop divides the digital signal and outputs any or all of these

variables into as many as three separate 4–20 mA analog channels.

Refer to Figure 2-15 for basic installation information. Refer to the

Model 333 HART Tri-Loop HART-to-Analog Signal Converter Product

Manual (Rosemount publication number 00809-0100-4754) for

complete installation information.

INSTALL THE

TRI-LOOP

COMMISSION

THE TRI-LOOP

No

Install the

Model 3244MV

(see page 2-2)

Review the

Tri-Loop

Product Manual

Model 3244MV

Installed?

Yes

Set theModel

3244MV Burst

Command

Order

Set theModel

3244M V to

Burst HART

Command3

ReviewTri-Loop

Installation

Conside r ations

Mount the

Tri-Loop to a

DIN Rail

RunWiresfrom

Model 3244MV

to Burst Input

Terminals

Install Channel 1

Wires fro m

Tri-Loop to

Control Room

OPTIONAL:

Install Channel 2

Wires fro m

Tri-Loop to

Control Room

Configure the

Tri-Loop to

Receive Model

3244MVBurst

Commands

Pass System

Test?

Yes

DONE

No

Refer to th e

HART Tri-Loop

Product Manual

2-16

OPTIONAL:

Install Channel 3

Wires fro m

Tri-Loop to

Control Room

Page 25

Installation

COMMISSIONING THE TRANSMITTER FOR USE WITH THE HART TRI-LOOP

Set the Transmitter to Burst

Mode

To prepare the Model 3244MV transmitter for use with a Model 333

HART Tri-Loop, you must configure the transmitter to Burst Mode and

set the process variable output order. In Burst Mode, the transmitter

provides digital information for the analog current in mA to the HART

Tri-Loop. The HART Tri-Loop divides the signal into separate 4–20 mA

loops for the primary (PV), secondary (SV), tertiary (TV), and

quaternary (QV) variables. When using the Model 3244MV transmitter

in conjunction with the HART Tri-Loop, you must also consider the

configuration of the differential temperature and Hot Backup features,

if used.

NOTE

These procedures assume that the sensors and the transmitter are

connected, powered, and functioning properly, and that a Model 275

HART Communicator is connected to the transmitter control loop and

is communicating successfully. For communicator usage instructions,

see Appendix B: Model 275 HART Communicator.

To set the transmitter to burst mode, follow the steps below.

1. From the Home screen, select 1 Device setup, 4 Detailed setup,

3 Output condition, 2HART output, 4 Burst option to prepare to

set the transmitter to burst command 3. The communicator

displays the Burst option screen.

Set Process Variable Output

Order

2. Select Process vars/crnt. The communicator returns to the HART

output screen.

3. Select 3Burst mode to prepare to enable Burst Mode. The

communicator displays the Burst Mode screen.

4. Select On to enable Burst Mode. The communicator returns to

the HART output screen.

5. Select Send to download the new configuration information to

the transmitter.

To set the process variable output order, follow the steps below.

1. From the Home screen, select 1 Device setup, 1 Process variables,

7 Variable re-map. Select OK to set the control loop to manual.

The communicator displays the Primary Variable screen.

2. Select the item you wish to set as the primary variable at the

Select PV prompt.

3. Repeat step 2 for the SV, TV, and QV. The communicator displays

the Variable mapping screen.

4. Select OK to accept the order to which the variables are mapped,

or Abort to abort the entire procedure.

NOTE

Take careful note of the process variable output order. You must

configure the HART Tri-Loop to read the variables in the same order.

5. Select OK to return the control loop to automatic control.

2-17

Page 26

Rosemount Model 3144 and 3244MV Smart Temperature Transmitters

Special Considerations To initiate operation between a Model 3244MV transmitter and the

HART Tri-Loop, you must consider the configuration of both the

differential temperature and the Hot Backup features, if used.

Differential Temperature Measurement

To enable the differential temperature measurement feature of a

Model 3244MV transmitter operating in conjunction with the HART

Tri-Loop, adjust the range end points of the corresponding channel

on the HART Tri-Loop to include zero. For example, if you wish the

secondary variable of the transmitter to report differential

temperature, configure the transmitter accordingly (see “Set Process

Variable Output Order” on page 2-17), and adjust the corresponding

channel of the HART Tri-Loop so one range end point is negative

and the other is positive.

Hot Backup

To enable the Hot Backup feature of a Model 3244MV transmitter

operating in conjunction with the HART Tri-Loop, ensure that the

output units of the sensors are the same as the units of the HART

Tri-Loop. You may use any combination of RTDs or thermocouples

as long as the units of both match the units of the HART Tri-Loop.

For more information on configuring the transmitter for Hot

Backup, see page 3-10. See ”Using the Tri-Loop to Detect Sensor

Failures and Sensor Drift” for information on how to use the

Tri-Loop to detect sensor failure and sensor drift.

Using the Tri-Loop to Detect

Sensor Failures and Senso r Drift

The Model 3244MV transmitter outputs a digital HART signal

whenever a sensor failure occurs. If an analog warning is required, the

HART Tri-Loop can be configured to produce an analog signal that can

be interpreted by the control system as a sensor failure.

To set up the HART Tri-Loop to transmit sensor failure alerts, follow

the steps below.

1. Configure the Model 3244MV transmitter variable map as shown

in the table.

Variable Mapping

PV Sensor1 or Sensor Average

SV Sensor2

TV Differential Temperature

QV As Desired

2. Configure Channel 1 of the HART Tri-Loop as TV (differential

temperature). If either sensor should fail, the differential

temperature output will be +9999 or –9999 (high or low

saturation), depending on the position of the Failure Mode

Jumper (see “Failure Mode and Security Jumpers” on page 2-7).

3. Select temperature units for Channel 1 that match the

differential temperature units of the transmitter.

2-18

Page 27

Figure 2-16. Tracking Sensor Drift and

Sensor Failure with Differential

Temperature.

Installation

4. Specify a range for the TV such as –100 to 100 °C. If the range is

large, then a sensor drift of a few degrees will represent only a

small percent of range. If Sensor 1 or Sensor 2 fails, the TV will

be +9999 (high saturation) or –9999 (low saturation). In this

example, zero is the midpoint of the TV range. If a ∆T of zero is

set as the lower range limit (4 mA), then the output could

saturate low if the reading from Sensor 2 exceeds the reading

from Sensor 1. By placing zero in the middle of the range, the

output will normally stay near 12 mA, and the problem will be

avoided.

5. Configure the DCS so that TV < –100 °C or TV > 100 °C indicates

a sensor failure and, for example, TV ≤ –3 °C or TV ≥ 3°C

indicates a drift alert. See Figure 2-16.

Sensor Failure

(Failure Mode Jumper HI)

100 °C

Sensor Drift

3°C

0°C

–3 ° C

DIFFERENTIAL TEMPERATURE

–100 °C

Sensor Drift

Sensor Failure

(Failure Mode Jum per LO)

2-19

Page 28

Rosemount Model 3144 and 3244MV Smart Temperature Transmitters

2-20

Page 29

Section

3 On-line Operations

OVERVIEW This section contains information needed to configure and format the

Model 3144 and 3244MV Smart Temperature Transmitters. The

transmitters can be configured either on-line or off-line. During on-line

configuration, the transmitter is connected to a HART communicator.

Data are entered in the working register of the communicator and sent

directly to the transmitter. Off-line configuration consists of storing

configuration data in a HART communicator while it is not connected to

a transmitter. Data is stored in nonvolatile memory and can be

downloaded to the transmitter at a later time.

NOTE

The information in this section applies to the use of a Model 275 HART

Communicator to communicate with a Model 3144 or 3244MV Smart

Temperature Transmitter. For information regarding the use of a Model

268 Communicator, refer to Appendix C: Model 268 SMART FAMILY

Interface.

SAFETY MESSAGES Instructions and procedures in this section may require special

precautions to ensure the safety of the personnel performing the

operations. Information that raises potential safety issues is indicated

by a warning symbol ( ). Please refer to the following safety messages

before performing an operation preceded by this symbol.

Warnings

Explosions may result in death or serious injury.

• Do not remove the instrument cover in explosive atmospheres when the circuit

is alive.

• Before connecting a HART communicator in an explosive atmosphere, make

sure the instruments in the loop are installed in accordance with intrinsically

safe or non-incendive field wiring practices.

• Bothtransmitter covers must be fully engaged to meet explosion proof

requirements.

Electrical shock could cause death or serious injury. If the sensor is installed in a

high-voltage environment and a fault or installation error occurs, high voltage may

be present on transmitter leads and terminals.

• Use extreme caution when making contact with the leads and terminals.

3-1

Page 30

Rosemount Model 3144 and 3244MV Smart Temperature Transmitters

Setting the Loop to Manual Whenever you are preparing to send or request data that would disrupt

the loop or change the output of the transmitter, you must set your

process application loop to manual. Both the Model 275 HART

Communicator and the Rosemount Model 268 SMART FAMILY

Interface will prompt you to set the loop to manual when necessary.

Keep in mind that acknowledging this prompt does not set the loop to

manual. The prompt is only a reminder; you have to set the loop to

manual yourself, as a separate operation.

REVIEW CONFIGURATION DATA

Review all of the factory-set configuration data to ensure that it reflects

the current application before operating the Model 3144 or 3244MV

transmitters in an actual installation.

Review Review the transmitter configuration parameters set at the factory to

HART Fast Keys 1, 5

ensure accuracy and compatibility with your particular application.

After activating the Review function, scroll through the data list to

check each variable. Refer to “Basic Setup” on page 3-5 if a change to

the transmitter configuration data is necessary.

CHECK OUTPUT Before performing other transmitter on-line operations, review the

digital output parameters to ensure that the transmitter is operating

properly and is configured to the appropriate process variables.

Proces s V ariab les The process variables for the Model 3144 and 3244MV transmitters

HART Fast Keys 1, 1

provide the transmitter output. The Process Variable menu displays

process variables and allows for remapping of the values shown. These

process variables are continuously updated. Select Variable Re-map to

change the sequencing of the process variables. With the Model 3144,

two screens follow that allow you to select the primary variable (PV)

and the secondary variable (SV). From each screen you can choose

either sensor 1 or terminal temperature. With the Model 3244MV, four

screens follow that allow you to select the primary variable (PV),

secondary variable (SV), tertiary variable (TV), and quaternary

variable (QV). Primary variable choices include sensor 1, sensor 2,

differential temperature, average temperature, and transmitter

terminal temperature. The primary variable is the 4–20 mA analog

signal.

3-2

See Tables 3-1, 3-2, and 3-3 for a list of interaction rules for varying

transmitter configurations.

Page 31

TABLE 3-1. Valid Options/Outputs Using Sensor 1 (Model 3144 and 3244MV).

On-line Operations

Diff

Primary

Variable

Any Y Y/N Y/N Y/N Y/N Invalid

Any Y/N Y Y/N Y/N Y/N Invalid

Sensor 2 Y/N Y/N Y/N Y/N Y/N Invalid

Differential N N Y/N N Y/N Differential None ±9999 Normal Normal 9999 ±9999

Any N N Y/N Y Y/N Alarm Sensor1Fail ±9999 Normal ±9999 9999 ±9999

Term Temp N N Y/N N Y/N Term Temp None ±9999 Normal Normal 9999 ±9999

Sensor 1 N N Y/N N Y/N Sensor 1 None ±9999 Normal Normal 9999 ±9999

Average N N Y/N N Y/N Average None ±9999 Normal Normal 9999 ±9999

Hot Backup

Enabled

Drift Alert

Activated

Drift Alarm

Mode On

Sensor 1 Fail

Analog

Output

Sensor 2 Fail

Digital

Status

Temp

Value

Term

Temp

Value

Sensor

1

Value

Sensor

2

Value

Average

Temp

Value

NOTE: If alarm value is set to low, the valuewill be –9999, and if set to high the value will be +9999.

NOTE: If a hardware error occurs, alloutputs will go to ±9999.

TABLE 3-2. Valid Options/Outputs Using Sensor 2 (Model 3244MV Only).

Primary

Variable

Any Y Y/N Y/N Y/N Y/N Invalid

Any Y/N Y Y/N Y/N Y/N Invalid

Sensor 1 Y/N Y/N Y/N Y/N Y/N Invalid

Differential N N Y/N Y/N N Differential None ±9999 Normal 9999 Normal ±9999

Any N N Y/N Y/N Y Alarm Sensor 1 Fail ±9999 Normal 9999 ±9999 ±9999

Term Temp N N Y/N Y/N N Term Temp None ±9999 Normal 9999 Normal ±9999

Sensor 2 N N Y/N Y/N N Sensor 2 None ±9999 Normal 9999 Normal ±9999

Average N N Y/N Y/N N Average None ±9999 Normal 9999 Normal ±9999

Hot Backup

Enabled

Drift Alert

Activated

Drift Alarm

Mode On

Sensor 1 Fail

Analog

Output

Sensor 2 Fail

Digital

Status

Diff

Temp

Value

NOTE: If alarm value is set to low, the valuewill be –9999, and if set to high the value will be +9999.

NOTE: If a hardware error occurs, alloutputs will go to ±9999.

Term

Temp

Value

Sensor

1

Value

Sensor

2

Value

Average

Temp

Value

3-3

Page 32

Rosemount Model 3144 and 3244MV Smart Temperature Transmitters

TABLE 3-3. Valid Options/Outputs Using Both Sensor 1 and Sensor 2 (Model 3244MV Only).

Primary

Variable

Diff

Analog

Hot Backup

Enabled

Drift Alert

Activated

Drift Alarm

Mode On

Sensor 1 Fail

Output

Sensor 2 Fail

Digital

Status

Temp

Value

Term

Temp

Value

Sensor

1

Value

Sensor

2

Value

Average

Temp

Value

Differential Y Y/N Y/N Y/N Y/N Invalid

Term Temp Y Y/ N Y /N Y/N Y/N Invali d

Sensor 2 Y Y/N Y/N Y/N Y/N Invalid

Any N N Y/N N Y Alarm Sensor 2 Fail ±9999 Normal Normal ±9999 ±9999

Any N N Y/N Y N Alarm Sensor 1 Fail ±9999 Normal ±9999 Normal ±9999

Any N N Y/N Y Y Alarm Sensor 1/Sensor 2 Fail ±9999 Normal ±9999 ±9999 ±9999

Any N Y N N Y Alarm Drift Alert/Sensor 2 Fail ±9999 Normal Normal ±9999 ±9999

Any N Y N Y N Alarm Drift Alert/Sensor 1 Fail ±9999 Normal ±9999 Normal ±9999

Any N Y N Y Y Alarm Sensor 1/Sensor 2 Fail ±9999 Normal ±9999 ±9999 ±9999

Any N Y Y N N Alarm Drift Alert Normal Normal Normal Normal Normal

Any N Y Y N Y Alarm DriftAlert/Sensor 2 Fail ±9999 Normal Normal ±9999 ±9999

Any NYYYN Alarm DriftAlert/Sensor1Fail±9999Normal±9999Normal±9999

Any N Y Y Y Y Alarm Sensor 1/Sensor 2 Fail ±9999 Normal ±9999 ±9999 ±9999

Differential N N Y/N N N Differential None Normal Normal Normal Normal Normal

Differential N Y N N N Differential Drift Alert Normal Normal Normal Normal Normal

Term Temp N N Y/N N N Term Temp None Normal Normal Normal Normal Normal

Term Temp N Y N N N Term Temp Drift Alert Normal Normal Normal Normal Normal

Sensor1 N N Y/N N N Sensor1 None Normal Normal Normal Normal Normal

Sensor1 N Y N N N Sensor 1 Drift Alert Normal Normal Normal Normal Normal

Sensor1 Y N Y/N N N Sensor 1 None Normal Normal Normal Normal Normal

Sensor1 Y N Y/N N Y Sensor 1 Sensor2Fail ±9999 Normal Normal ±9999 Sens 1

Sensor 1

Sensor 1

(1)

Y N Y/N Y N Sensor 2 Hot BU/Sensor 1 Fail ±9999 Normal ±9999 Normal Sens 2

(1)

Y N Y/N Y Y Alarm HotBU/Sensor 1/Sensor

±9999 Normal ±9999 ±9999 ±9999

2Fail

Sensor1 Y Y N N N Sensor 1 Drift Alert Normal Normal Normal Normal Normal

Sensor 1 Y Y N N Y Sensor 1 Drift Alert/Sensor 2 Fail ±9999 Normal Normal ±9999 Sens 1

Sensor 1

Sensor 1

(1)

Y Y N Y N Sensor 2 DriftAlert/HotBU/Sensor

(1)

Y Y N Y Y Alarm HotBU/Sensor 1/Sensor

1Fail

±9999 Normal ±9999 Normal Sens 2

±9999 Normal ±9999 ±9999 ±9999

2Fail

Any Y Y Y Y/N Y/N Invalid

(2)

Sensor2 N N Y/N N N Sensor2 None Normal Normal Normal Normal Normal

Sensor2 N Y N N N Sensor 2 Drift Alert Normal Normal Normal Normal Normal

Average N N Y/N N N Average None Normal Normal Normal Normal Normal

Average N Y N N N Average Drift Alert Normal Normal Normal Normal Normal

Average Y N Y/N N N Average None Normal Normal Normal Normal Normal

Average Y N Y/N N Y Average Sensor 2 Fail ±9999 Normal Normal ±9999 Sens 1

(1)

Average

Average

Y N Y/N Y N Sensor 2 Hot BU/Sensor 1 Fail ±9999 Normal ±9999 Normal Sens 2

(1)

Y N Y/N Y Y Alarm HotBU/Sensor 1/Sensor

±9999 Normal ±9999 ±9999 ±9999

2Fail

Average Y Y N N N Average Drift Alert Normal Normal Normal Normal Normal

Average Y Y N N Y Average Drift Alert/Sensor 2 Fail ±9999 Normal Normal ±9999 Sens 1

(1)

Average

Average

Y Y N Y N Sensor 2 DriftAlert/HotBU/Sensor

(1)

Y Y N Y Y Alarm HotBU/Sensor 1/Sensor

1Fail

±9999 Normal ±9999 Normal Sens 2

±9999 Normal ±9999 ±9999 ±9999

2Fail

Any N N Y/N N Y Alarm Sensor 2 Fail ±9999 Normal Normal ±9999 ±9999

NOTE: If alarm value is set to low, the valuewill be –9999, and if set to high the value will be +9999.

NOTE: If a hardware error occurs, alloutputs will go to ±9999.

(1) Remapping occurs in thissituation.

(2) Hot Backup and Drift Alarm mode can not be used simultaneosly.

3-4

Page 33

On-line Operations

BASIC SETUP The transmitters must be configured for certain basic variables in order

to be operational. In many cases, all of these variables are

pre-configured at the factory. Configuration may be required if your

transmitter is not configured or if the configuration variables need

revision.

Select Senso r Type The Sensor 1 Conn and Sensor 2 Conn commands designate, for the

HART Fast Keys 1, 3, (5 or 7)

transmitter, the sensor type and the number of wires to be connected.

Note that differential and average temperature measurements can only

be made with 2- or 3-wire sensors. The Sensor 2 Conn command

pertains only to the Model 3244MV transmitter. Select from the

following sensor types:

• 2-, 3-, or 4-wire Pt 100, Pt 200, Pt 500, or Pt 1000 (α = 0.00385)

(1)

platinum RTDs

(1)

• 2-, 3-, or 4-wire Pt 100 α = 0.003916

platinum RTD

• 2-, 3-, or 4-wire Ni 120 nickel RTDs

• 2-, 3-, or 4-wire Cu 10 copper RTDs

• Type B, E, J, K, N, R, S, and T thermocouples

• NIST Type C thermocouple

• –10 to 100 millivolts

• 2-, 3-, or 4-wire 0 to 2000 ohms

• Special RTD or T/C calibration schedules

Set Output Units The PV Unit command sets the desired primary variable units. Set the

HART Fast Keys 1, 3, 2

transmitter output to one of the following engineering units:

• Degrees Celsius

• Degrees Fahrenheit

• Degrees Rankine

• Kelvin

•Ohms

• Millivolts

NOTE

After changing units, press SEND (F2) so the microprocessor will

recalculate the associated variables (4–20 mA points, for example).

Both models recalculate all variables that depend on units. After the

transmitter recalculates the variables, you may change any of the

remaining parameters.

(1) Pt 1000

α =

0.00385 and Pt 100

in previous versions of the Model 3144 and 3244MV transmitters.

α =

0.003916 RTD sensor input types are not available

3-5

Page 34

Rosemount Model 3144 and 3244MV Smart Temperature Transmitters

Rerange The Range Values command sets the 4 and 20 mA points or the lower

HART Fast Keys 1, 3, 3

and upper range values. Setting the range values to the limits of

expected readings maximizes transmitter performance; the transmitter

is most accurate when operated within the expected temperature

ranges for your application. The range of expected readings is defined

by the Lower Range Value (LRV) and the Upper Range Value (URV).

Refer to Table 5-1 on page 5-10 for unit and range limits. You can reset

the transmitter range values as often as necessary to reflect changing

process conditions.

DETAILED SETUP

50/60 Hz Filter The 50/60 Hz filter command sets the transmitter electronic filter to

HART Fast Keys 1,4,1,3

match the frequency of the ac power supply in your plant, which

reduces or eliminates electronic noise within the measurement loop.

Terminal Temperature

Settings

HART Fast Keys 1,4,1,2

The Ter m Te m p S e n s o r command sets the terminal temperature units

to indicate the ambient temperature of the transmitter.

Signal Conditio n The Signal Condition command allows you to view or change primary

HART Fast Keys 1,4,2

variable lower and upper range values, sensor percent range, and

sensor damping.

Analog Output The Analog Output command allows you to view the analog output

HART Fast Keys 1,4,3,1

signal and alarm setting (high or low). With this command you can also

initiate a loop test or make digital trim changes.

Disable Special Sensor The Dis Spec Snsr command disables sensor matching or any other

HART Fast Keys 1,4,1,1,4, (1 or 2), 5

special sensor configuration, and returns the transmitter to either the

factory or user trim setting, whichever was used previously. After

disabling the sp eci al sensor,make certain the trans mitter engineering

units default co rrectly be fore retu rni ng th e transmitter to servi ce .

HART Output The HART Output command allows you to make changes to the

HART Fast Keys 1,4,3,2

multidrop address, specify the number of requested preambles, initiate

burst mode, and make changes to the burst options.

Meter Settings The Meter Settings command sets meter options including engineering

HART Fast Keys 1,4,3,3

units, decimal point, and bar graph features. Transmitters without

meters are shipped set to “UNUSED.” Change the meter settings to

reflect necessary configuration parameters when adding a meter or

re-configuring the transmitter.

3-6

To customize the variables that the meter displays, follow the steps

below.

1. Select 1 Device setup, 4 Detailed setup, 3 Output condition,

3Meter Options, 1Meter typ to prepare to customize the meter

display.

2. Select the appropriate variable configuration from the Meter

Type screen.

Page 35

On-line Operations

NOTE

Selecting Not Used from the Meter Type screen will disable the meter.

3. Select Send to download the new meter configuration to the

transmitter.

For a more detailed description of the meter features and diagnostic

messages, refer to “LCD Meter (Option Code M5)” on page 6-6.

Alarm Values

HART Fast Keys 1,4,3,4

(1)

The Alarm Values command allows the high and low alarm and

saturation values to be viewed. Transmitters are factory configured for

either Rosemount standard or NAMUR-compliant output levels and

cannot be changed in the field. Use the failure mode jumper (see

“Failure Mode and Security Jumpers” on page 2-7) to set whether the

output will be driven to high alarm or low alarm in the case of failure.

Process Variable Damping The PV Damp command changes the response time of the transmitter

HART Fast Keys 1,3,3

to smooth variations in output readings caused by rapid changes in

input. Determine the appropriate damping setting based on the

necessary response time, signal stability, and other requirements of the

loop dynamics of your system. The default damping value is 5.0 seconds

and can be reset to any value between 0 and 32 seconds.

The value chosen for damping affects the response time of the

transmitter. When set to zero (i.e., disabled), the damping function is off

and the transmitter output reacts to changes in input as quickly as the

intermittent sensor algorithm allows (refer to “Intermittent Sensor

Algorithm” on page 5-14). Increasing the damping value increases

transmitter response time.

With damping enabled, if the temperature change is within 2 percent of

the output range, the transmitter measures the change in input every

500 milliseconds and outputs values according to the following

relationship:

2TU–

Damped Value P N–()

P =previous damped value

N =new sensor value

T = damping time constant

U =update rate

× N+=

------------------

2TU+

At the value to which the damping time constant is set, the transmitter

output is at 63 percent of the input change; it continues to approach the

input according to the damping equation above.

For example, as illustrated in Figure 3-1, if the temperature undergoes

a step change—within 2 percent of the output range—from 100 degrees

to 110 degrees, and the damping is set to 5.0 seconds, the transmitter

calculates and reports a new reading every 500 milliseconds using the

damping equation. At 5.0 seconds, the transmitter outputs 106.3

degrees, or 63 percent of the input change, and the output continues to

approach the input curve according to the equation above.

For information regarding the damping function when the input change

is greater than 2 percent of the output range, refer to “Intermittent

Sensor Algorithm” on page 5-14.

(1) This commandis not available in previous versions of the Model 3144 and 3244MVtransmitters.

3-7

Page 36

Rosemount Model 3144 and 3244MV Smart Temperature Transmitters

Figure 3-1. Change in Input versus

Change in Output with Damping

Enabled.

яяюэю

ÿþýþ

ÿþýþ

ÿþýþ

ÿþýþ

ÿþýþ

ÿþýþ

Temperature

ÿþýþ

ÿþýþ

яюяэю

яююэю

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0 7.5 8.0 8.5 9.0 9.5 10.0

Time (Seconds)

InputValue

OutputValue

Differential Temperature The Model 3244MV transmitter can accept any two inputs and display

Model 3244MV

HART Fast Keys 1,1,8,1

the differential temperature between them. Use the following

procedure to configure the transmitter to measure differential

temperature.

NOTE

This procedure assumes that you wish to report differential

temperature as the primary variable analog signal. If this is not the

case, assign differential temperature to the secondary, tertiary, or

quaternary variable.

1. From the HOME screen, select 1Device Setup, 1 Process

Variable, 8 Variable Re-Map, to prepare to set the transmitter to

display differential temperature. Select OK after you set the

control loop to manual.

2. Select 1 Diff from the Primary Variable (PV) menu.

3-8

3. Select 3Snsr 1 or 4Snsr 2 from the Secondary Variable (SV)

menu.

4. Select the remaining sensor from the Tertiary Variable (TV)

menu.

Page 37

On-line Operations

NOTE

The transmitter determines differential temperature by subtracting

Sensor 2 from Sensor 1 (S1 – S2). Ensure that this order of subtraction

is consistent with the desired reading for your application. Refer to

Figure 2-7 on page 2-9, or inside the transmitter terminal-side cover for

sensor wiring diagrams.

5. Select 2 Term temp (terminal temperature), 5 Sensor Average, or

6Not Used from the Quaternary Variable (QV) menu.

6. Select OK after verifying the variable settings from the variable

mapping menu.

7. Select OK to return the control loop to automatic control.

8. Select HOME to return to the On-line menu.