Page 1

Rosemount 3101, 3102, and 3105

Ultrasonic Liquid Level Transmitters

Reference Manual

00809-0100-4840, Rev CB

February 2015

Page 2

Page 3

Reference Manual

00809-0100-4840, Rev CB

Rosemount 3101, 3102, and 3105

Ultrasonic Liquid Level Transmitters

Title Page

February 2015

Read this manual before working with the product. For personal and system

safety, and for optimum product performance, make sure you thoroughly

understand the contents before installing, using, or maintaining this

product.

Within the United States, Rosemount Inc. has two toll-free assistance

numbers.

Customer Central: 1-800-999-9307(7:00 a.m. to 7:00 p.m. CST)

Technical support, quoting, and order-related questions.

North American Response Center:

Equipment service needs.

1-800-654-7768 (24 hours a day – Includes Canada)

For equipment service or support needs outside the United States, contact

your local Rosemount representative.

The products described in this document are NOT designed for

nuclear-qualified applications.

Using non-nuclear qualified products in applications that require

nuclear-qualified hardware or products may cause inaccurate readings.

For information on Rosemount nuclear-qualified products, contact your

local Rosemount Sales Representative.

This device complies with part 15 of the FCC rules. Operation is subject to

the following two conditions: (1) This device may not cause harmful

interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

i

Page 4

Title Page

February 2015

Reference Manual

00809-0100-4840, Rev CB

ii

Page 5

Reference Manual

00809-0100-4840, Rev CB

Contents

1Section 1: Introduction

2Section 2: Transmitter Overview

Contents

February 2015

1.1 Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Manual overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3 Service support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.4 Product recycling/disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.1 The Rosemount 3101, 3102, and 3105 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1.1 Theory of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2.2 Components of the transmitter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3 System architecture. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3Section 3: Installation

3.1 Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Considerations before installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2.1 Safety considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3.2.2 Environmental considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.3 Mechanical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.3.1 Mounting considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.3.2 Consider liquid surface conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.3.3 Consider in-tank effects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.3.4 Mounting the transmitter above the liquid surface . . . . . . . . . . . . . . . . . 12

3.3.5 Open channel flow installations (the 3102/3105) . . . . . . . . . . . . . . . . . . 14

3.4 Electrical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.4.1 Connecting the cable(s) to the transmitter. . . . . . . . . . . . . . . . . . . . . . . . 16

3.4.2 Connecting the cable wires to the Rosemount 3101 . . . . . . . . . . . . . . . 17

3.4.3 Connecting the cable wires to the Rosemount 3102 . . . . . . . . . . . . . . . 18

3.4.4 Connecting the cable wires to the Rosemount 3105 . . . . . . . . . . . . . . . 19

3.4.5 Remote temperature sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.4.6 Wiring to allow HART communications . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.4.7 Lightning / surge protection and other loop devices. . . . . . . . . . . . . . . . 21

Contents

iii

Page 6

Contents

February 2015

Reference Manual

00809-0100-4840, Rev CB

4Section 4: Starting up

4.1 Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.2 Programming the Rosemount 3101, 3102, and 3105 Transmitters. . . . . . . . . . 24

4.2.1 Integral display and buttons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.2.2 What happens when powering up the transmitter . . . . . . . . . . . . . . . . . 25

4.2.3 Considerations before starting the programming . . . . . . . . . . . . . . . . . . 25

4.3 Programming the 3101 using the integral display and buttons . . . . . . . . . . . . . 26

4.3.1 Display units (on the 3101) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.3.2 First measurements (on the 3101) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.3.3 Setting the bottom reference (on the 3101) . . . . . . . . . . . . . . . . . . . . . . 28

4.3.4 Setting 4 mA and 20 mA levels (on the 3101). . . . . . . . . . . . . . . . . . . . . . 28

4.3.5 Setting the output damping (on the 3101). . . . . . . . . . . . . . . . . . . . . . . . 30

4.3.6 Selecting the Lost Echo action (on the 3101) . . . . . . . . . . . . . . . . . . . . . . 31

4.3.7 Setting 4 mA and 20 mA levels using ranging (on the 3101) . . . . . . . . . 32

4.3.8 Learn about echoes from false targets (on the 3101) . . . . . . . . . . . . . . . 33

4.3.9 Do final checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.3.10 What happens when a power failure occurs . . . . . . . . . . . . . . . . . . . . . . . 34

4.4 Programming the 3102 and 3105 using the integral display and buttons . . . . 35

4.4.1 Overview of programming the 3102 or the 3105 . . . . . . . . . . . . . . . . . . 35

4.4.2 Selecting the duty (on the 3102/3105) . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.4.3 Selecting the units of measurement (on the 3102/3105) . . . . . . . . . . . 36

4.4.4 Setting the correct bottom reference (on the 3102/3105) . . . . . . . . . . 38

4.4.5 Selecting a profile (on the 3102/3105) . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.4.6 Power factor for the flow law (on the 3102/3105). . . . . . . . . . . . . . . . . . 43

4.4.7 Setting the scaling factor (on the 3102/3105) . . . . . . . . . . . . . . . . . . . . . 44

4.4.8 Maximum level entry (on the 3102/3105). . . . . . . . . . . . . . . . . . . . . . . . . 45

4.4.9 Maximum flow entry (on the 3102/3105) . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.4.10 Maximum contents (volume) entry (on the 3102/3105) . . . . . . . . . . . . 47

4.4.11 Setting the 4 mA point (on the 3102/3105) . . . . . . . . . . . . . . . . . . . . . . . 48

4.4.12 Setting the 20 mA point (on the 3102/3105) . . . . . . . . . . . . . . . . . . . . . . 49

4.4.13 Setting the output damping (on the 3102/3105) . . . . . . . . . . . . . . . . . . 50

4.4.14 Selecting the Lost Echo action (on the 3102/3105). . . . . . . . . . . . . . . . . 51

4.4.15 Setting the relay on and off points (on the 3102). . . . . . . . . . . . . . . . . . . 52

4.4.16 Setting the 4 and 20 mA levels using ranging (on the 3102/3105) . . . 54

4.4.17 Do final checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4.4.18 What happens when a power failure occurs . . . . . . . . . . . . . . . . . . . . . . . 55

iv

Contents

Page 7

Reference Manual

00809-0100-4840, Rev CB

5Section 5: Service and Troubleshooting

Contents

February 2015

5.1 Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5.2 Servicing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.3 Diagnostics for the 3101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.3.1 General troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.3.2 Error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.4 Diagnostics for the 3102 and the 3105 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

5.4.1 General troubleshooting (on the 3102/3105) . . . . . . . . . . . . . . . . . . . . . 59

5.4.2 Fault and alarms (on the 3102/3105). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

5.4.3 Diagnostic data (on the 3102/3105) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

5.4.4 Loop test (on the 3102/3105) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

5.5 Engineering menu for the 3102 and 3105. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

5.5.1 Accessing the engineering menu (on the 3102/3105) . . . . . . . . . . . . . . 62

5.5.2 Setting the threshold (on the 3102/3105) . . . . . . . . . . . . . . . . . . . . . . . . 63

5.5.3 Setting lost echo time (on the 3102/3105). . . . . . . . . . . . . . . . . . . . . . . . 64

5.5.4 Setting the dead band (on the 3102/3105) . . . . . . . . . . . . . . . . . . . . . . . 65

5.5.5 Setting the frequency (on the 3102/3105) . . . . . . . . . . . . . . . . . . . . . . . . 66

5.5.6 Setting the pulse repetition frequency (on the 3102/3105) . . . . . . . . . 67

5.5.7 Setting valid echo count (on the 3102/3105). . . . . . . . . . . . . . . . . . . . . . 68

5.5.8 Setting spike rejection (on the 3102/3105) . . . . . . . . . . . . . . . . . . . . . . . 69

5.5.9 Learn about echoes from false targets (on the 3102/3105). . . . . . . . . . 69

5.5.10 Setting the ambient temperature (on the 3102/3105) . . . . . . . . . . . . . 71

5.5.11 Temperature calibration (on the 3102/3105). . . . . . . . . . . . . . . . . . . . . . 72

5.5.12 Loading factory default values (on the 3102/3105) . . . . . . . . . . . . . . . . 73

5.5.13 Changing the base units (on the 3102/3105). . . . . . . . . . . . . . . . . . . . . . 74

5.6 False echoes under certain ambient operating conditions

(on the 3102/3105) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

AAppendix A: Reference Data

A.1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

A.1.1 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

A.1.2 Measuring performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

A.1.3 Display and configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

A.1.4 Electrical. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Contents

A.1.5 Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

A.1.6 Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

A.1.7 Measuring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

A.1.8 Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

v

Page 8

Contents

February 2015

Reference Manual

00809-0100-4840, Rev CB

A.1.9 Temperature and pressure ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

A.1.10 Load limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

A.2 Dimension drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

A.3 Ordering information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

A.3.1 Rosemount 3101 ordering information. . . . . . . . . . . . . . . . . . . . . . . . . . . 87

A.3.2 Rosemount 3102 ordering information. . . . . . . . . . . . . . . . . . . . . . . . . . . 88

A.3.3 The Rosemount 3105 level transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

A.4 Spare parts and accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

A.4.1 Spare parts and accessories for the 3101/3102/3105. . . . . . . . . . . . . . . 90

BAppendix B: Product Certifications

B.1 Manufacturing location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

B.2 European Union directive information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

B.3 Non-hazardous location certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

B.3.1 American and Canadian certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

B.4 Hazardous locations certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

B.4.1 American and Canadian certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

B.4.2 European certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

B.4.3 International certifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

B.5 Approval drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

CAppendix C: Integrated Display Menus

C.1 Menus on the 3101 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

C.2 Menus on the 3102 and the 3105 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

DAppendix D: Rosemount 3490 Series Menus

D.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

D.2 Menus and parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

EAppendix E: Field Communicator Menus

E.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

E.2 Menus and parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

FAppendix F: Programming the 3102 and 3105 using HART

F. 1 Overview of programming the 3102 and 3105 . . . . . . . . . . . . . . . . . . . . . . . . . . 117

F. 1. 1 Using a Rosemount 3490 Series Control Unit. . . . . . . . . . . . . . . . . . . . . 117

F. 1. 2 Using a Field Communicator or AMS Device Manager . . . . . . . . . . . . . 117

vi

Contents

Page 9

Reference Manual

00809-0100-4840, Rev CB

Contents

February 2015

F. 2 Command parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

F. 2. 1 Base units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

F. 2. 2 Set as empty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

F. 2. 3 Present depth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

F. 2. 4 Learn false echo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

F. 2. 5 Auto tank map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

F. 2. 6 Simulation of PV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

F. 2. 7 Restart device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

F. 2. 8 Load defaults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

F. 2. 9 Simulate current output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

F.2.10 Trim 4 mA / trim 20 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

F. 3 Configuration parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

F. 3. 1 Message (P000) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

F. 3. 2 Tag (P001) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

F. 3. 3 Descriptor (P002). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

F. 3. 4 Final assembly number (P004). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

F. 3. 5 Serial number (P005). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

F. 3. 6 Bottom reference (P010) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

F. 3. 7 Upper blanking (P023) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

F. 3. 8 Lower blanking (P063) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

F. 3. 9 Distance offset (P060). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

F.3.10 Level offset (P069) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

F.3.11 Tank shape / non-linear profile (P011) . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

F.3.12 Contents (volume) measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

F.3.13 Flow measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

F.3.14 Primary variable units (P012) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

F.3.15 Scale factor / k-factor (P013) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

F.3.16 Profile height / power factor (P014) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

F.3.17 Profile points 1 to 10 (P030 to P039) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

F.3.18 Upper range value (P015). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

F.3.19 Lower range value (P016) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

F.3.20 Damping (P020) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

F.3.21 Relay 1 mode (P070) on the Rosemount 3102. . . . . . . . . . . . . . . . . . . . 163

F.3.22 RL1 PV on point (P071) on the Rosemount 3102 . . . . . . . . . . . . . . . . . . 165

Contents

F.3.23 RL1 PV off point (P072) on the Rosemount 3102. . . . . . . . . . . . . . . . . . 166

F.3.24 Relay 2 mode (P073) on the Rosemount 3102. . . . . . . . . . . . . . . . . . . . 167

F.3.25 RL2 PV on point (P074) on the Rosemount 3102 . . . . . . . . . . . . . . . . . . 168

F.3.26 RL2 PV off point (P075) on the Rosemount 3102. . . . . . . . . . . . . . . . . . 169

vii

Page 10

Contents

February 2015

Reference Manual

00809-0100-4840, Rev CB

F.3.27 Lost echo delay (P021) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

F.3.28 Lost echo action (P022). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

F.3.29 Speed of sound (P024) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

F.3.30 Temperature (P025) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

F.3.31 Set threshold (P026) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

F.3.32 Transmit power control (P040) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

F.3.33 Pulse repeat (P041) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

F.3.34 Echoes needed (P042). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

F.3.35 Threshold 1 time (P043) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

F.3.36 Threshold 1 size (P048). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

F.3.37 Target pulses (P044) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

F.3.38 Target frequency (P045). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

F.3.39 Spike rejection (P049) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

F.3.40 False echo data (P081 to P088) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

F.3.41 Clear false echoes (P089) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

F.3.42 Transducer material (P970) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

F.3.43 Poll address (D951) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

F.3.44 Maximum temperature (P046) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

F.3.45 Minimum temperature (P047) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

F.3.46 Date (P003) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

F. 4 Monitoring and diagnostic parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

F. 4. 1 Process value / primary variable (PV) (D900) . . . . . . . . . . . . . . . . . . . . . 193

F. 4. 2 Level / Secondary Variable (SV) (D901) . . . . . . . . . . . . . . . . . . . . . . . . . . 194

F. 4. 3 Distance / tertiary variable (TV) (D902) . . . . . . . . . . . . . . . . . . . . . . . . . . 195

F. 4. 4 Temperature / fourth variable (FV) (D903) . . . . . . . . . . . . . . . . . . . . . . . 196

F. 4. 5 % of current output (D905) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

F. 4. 6 Current output (D906) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

F. 4. 7 Distance (D910) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

F. 4. 8 Echo size (D911). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

F. 4. 9 Echo success (D912) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

F.4.10 Target echoes (D913) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

F.4.11 Speed of sound (D914) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

F.4.12 Temperature for SoS calculation (D915) . . . . . . . . . . . . . . . . . . . . . . . . . 204

F.4.13 Frequency (D916) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

viii

F.4.14 Threshold in use (D917) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

F.4.15 Pulses in use (D918). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

F.4.16 Transmit power (D919). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

F.4.17 Model code (D949) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Contents

Page 11

Reference Manual

00809-0100-4840, Rev CB

Contents

February 2015

F.4.18 Hardware rev. (D952) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

F.4.19 Software revision (D953) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

F.4.20 Manufacturer (D960). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

F.4.21 Unique device ID (D961). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

F.4.22 HART revision (D962) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

F.4.23 Transmitter specific command revision (D963). . . . . . . . . . . . . . . . . . . 215

F.4.24 Preambles (D964) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

F.4.25 Transmitter flags (D965). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

F.4.26 Primary variable trend . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

F.4.27 Temperature Trend . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

F.4.28 Distance and Echo Size Trend . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Contents

ix

Page 12

Contents

February 2015

Reference Manual

00809-0100-4840, Rev CB

x

Contents

Page 13

Reference Manual

00809-0100-4840, Rev CB

Section 1 Introduction

1.1 Safety messages

Procedures and instructions in this section may require special precautions to ensure the safety

of the personnel performing the operation. Information that raises potential safety issues is

indicated by a warning symbol ( ). Refer to the following safety messages before performing

an operation preceded by this symbol.

Failure to follow these installation guidelines could result in death or serious injury.

Make sure only qualified personnel perform the installation.

Use the equipment only as specified in this manual. Failure to do so may impair the

protection provided by the equipment.

Explosions could result in death or serious injury.

Verify that the operating environment of the transmitter is consistent with the

appropriate hazardous locations certifications.

Before connecting a HART

sure the instruments in the loop are installed in accordance with intrinsically safe or

non-incendive field wiring practices.

Electrical shock could cause death or serious injury.

Use extreme caution when making contact with the leads and terminals.

®

-based communicator in an explosive atmosphere, make

Section 1: Introduction

February 2015

Any substitution of non-recognized parts may jeopardize safety. Repair, e.g. substitution of

components etc., may also jeopardize safety and is under no circumstances allowed.

1.2 Manual overview

This manual provides installation, configuration and maintenance information for the

Rosemount 3101, 3102, and 3105 Ultrasonic Liquid Level Transmitters.

Section 2: Transmitter Overview

Section 3: Installation

Section 4: Starting up

Section 5: Service and Troubleshooting

Appendix A: Reference Data

Appendix B: Product Certifications

Introduction

1

Page 14

Section 1: Introduction

February 2015

Appendix C: Integrated Display Menus

Appendix D: Rosemount 3490 Series Menus

Appendix E: Field Communicator Menus

Appendix F: Programming the 3102 and 3105 using HART

1.3 Service support

To expedite the return process outside of the United States, contact the nearest Emerson

Process Management representative.

Within the United States, call the Emerson Process Management Instrument and Valves

Response Center using the 1 800 654 7768 toll-free number. This center, available 24 hours a

day, will assist you with any needed information or materials.

The center will ask for product model and serial numbers, and will provide a Return Material

Authorization (RMA) number. The center will also ask for the process material to which the

product was last exposed.

Reference Manual

00809-0100-4840, Rev CB

Individuals who handle products exposed to a hazardous substance can avoid injury if they

are informed of, and understand, the hazard. If the product being returned was exposed to

a hazardous substance as defined by OSHA, a copy of the required Material Safety Data

Sheet (MSDS) for each hazardous substance identified must be included with the returned

goods.

1.4 Product recycling/disposal

Recycling of equipment and packaging should be taken into consideration. The product and

packaging should be disposed of in accordance with local and national legislation.

2

Introduction

Page 15

Reference Manual

B

A

G

EE

20mA

4mA

F

DD

C

00809-0100-4840, Rev CB

Section 2: Transmitter Overview

Section 2 Transmitter Overview

The Rosemount 3101, 3102, and 3105 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3

Components of the transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4

System architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 6

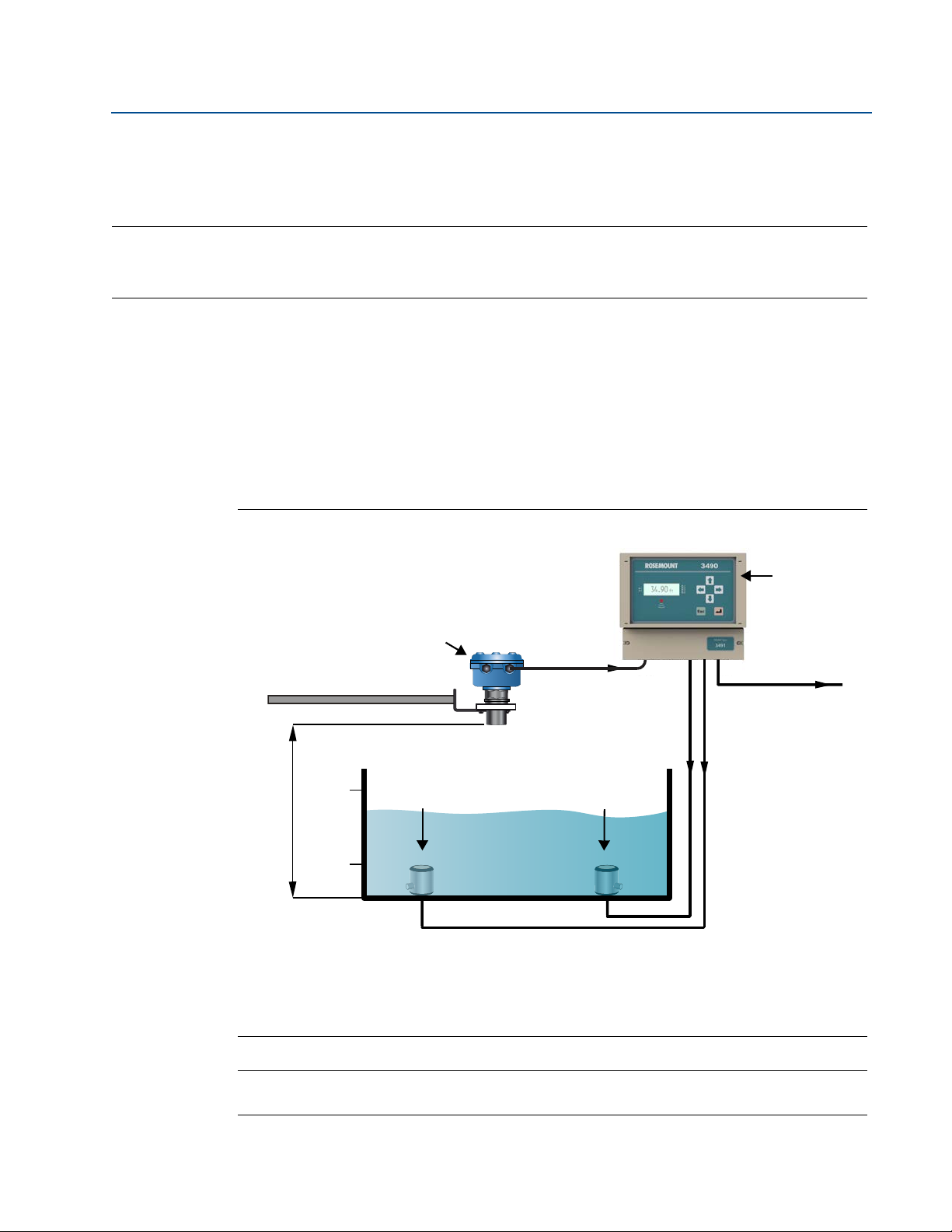

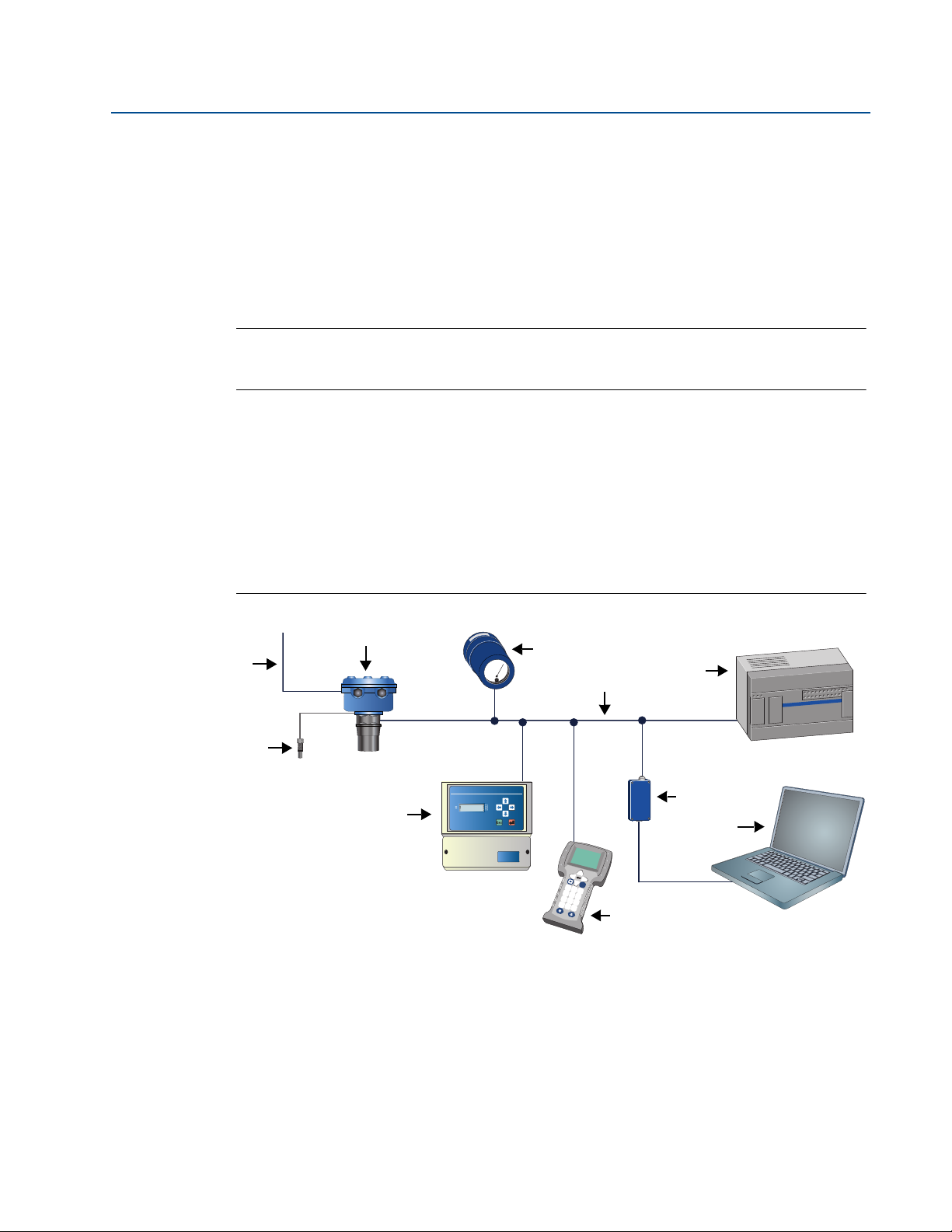

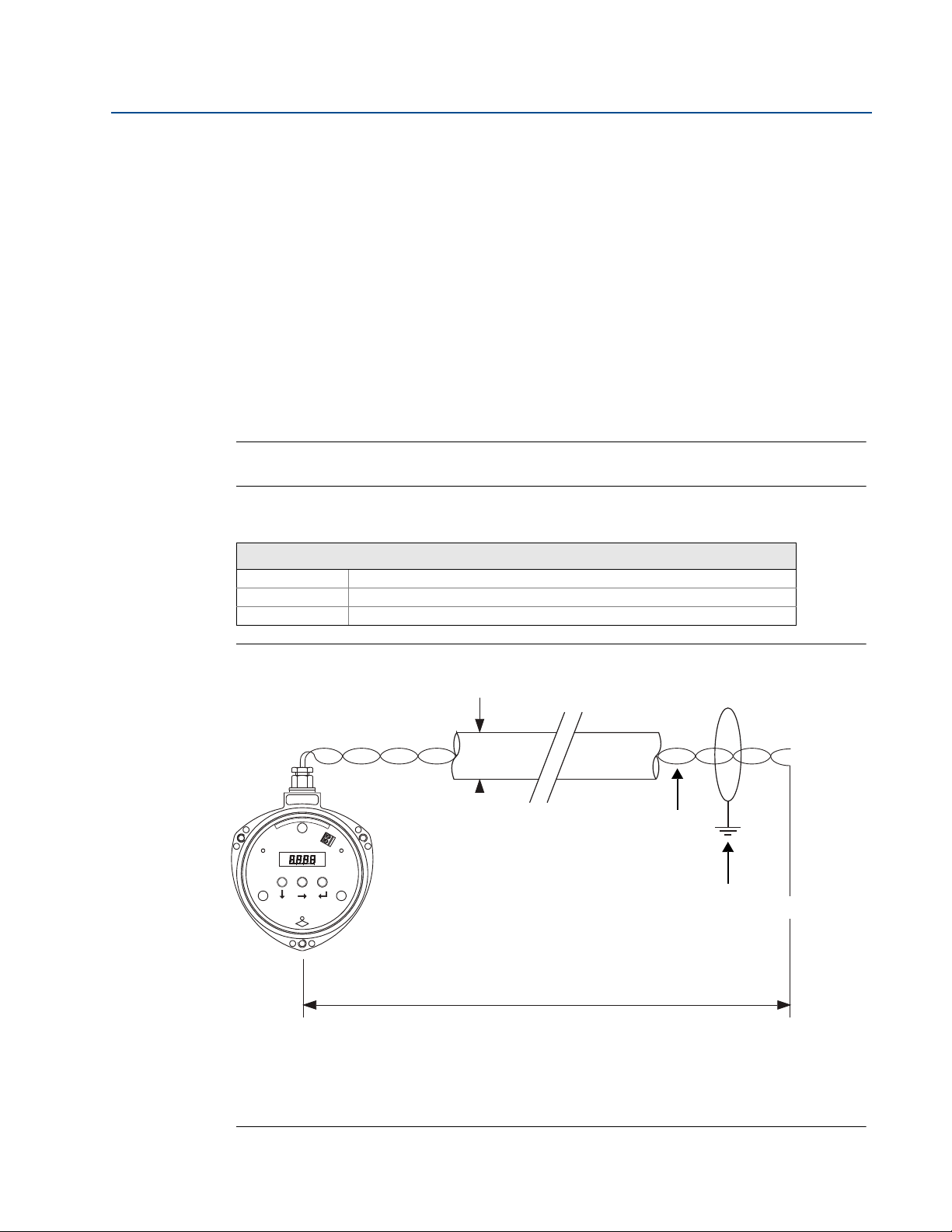

2.1 The Rosemount 3101, 3102, and 3105

The 3101, 3102, and 3105 are 4–20 mA loop-powered level transmitters designed for

continuous liquid level measurements in tanks or open channel flows.

The transmitters can be connected directly to a plant control system, or used with a Rosemount

3490 Series Control Unit for programmable control functionality. The Rosemount 3105 may be

mounted in a hazardous area if powered from a protected power supply.

February 2015

Figure 2-1. Typical Application using a Rosemount 3100 Series Transmitter

A. Rosemount 3100 Series Transmitter E. Pump

B. Rosemount 3490 Series Control Unit F. Transmitter Bottom Reference

C. 4–20 mA Signal G. 4–20 mA and HART Signal

D. Relay

Note

HART is available on the Rosemount 3102 and Rosemount 3105.

Transmitter Overview

3

Page 16

Section 2: Transmitter Overview

February 2015

2.1.1 Theory of operation

The Rosemount 3101, 3102, and 3105 transmitters are designed to be mounted above a liquid

and use ultrasonic pulses to continuously measure the distance to the liquid surface.

The microprocessor-controlled electronics calculate the distance to the liquid level from the

time delay between the transmitting and receiving of the signals.

When programmed with the bottom reference of the application, usually the tank bottom

(Figure 2.2), the transmitter calculates the liquid depth (level) and outputs the level as a

4–20 mA signal (and a digital HART

The 3101 calculates the level only and then outputs the result as a 4–20 mA signal.

The 3102 and 3105 can calculate level, contents (volume), or open channel flow, and then

output the result as a 4–20 mA signal and a digital HART signal.

A LCD screen inside the enclosure displays the selected measurement. Programming is achieved

using integral buttons inside the enclosure (all models), or by remote communication using

HART (on the 3102 and the 3105 only).

®

signal on the 3102 and 3105).

Reference Manual

00809-0100-4840, Rev CB

2.2 Components of the transmitter

The Rosemount 3101, 3102, and 3105 transmitters have a housing containing advanced

electronics for signal processing, and terminals for connecting the external power supply.

The electronics produces an ultrasonic signal from the transmitter face.

A comprehensive specification for the Rosemount 3101, 3102, and 3105 is in the section

“Specifications” on page 77.

4

Transm itter Over view

Page 17

Reference Manual

D

C

B

A

Glass-filled nylon

housing

Aluminum Housing

F

B

A

E

E

C

00809-0100-4840, Rev CB

Figure 2-2. The 3101, 3102, and 3105 Components

Section 2: Transmitter Overview

February 2015

A. Electronics Housing

B. 2-in. Mounting Thread

C. Transmitter Face

1

/2–14 NPT Conduit Threads (1/2–14 NPT to M20 x 1.5 adaptors are available when ordering. See page 90)

D.

E. Housing Cover (opened by un-doing three screws)

F. M20 x 1.5 Conduit Threads (supplied with one IP66/67 nylon compression cable gland and one M20 plug)

Transmitter Overview

5

Page 18

Section 2: Transmitter Overview

3490

Fn

1

2

3

4

5

6

7

8

9

0

-

.

3491

Model type:

B

D

F

I

G

A

E

C

H

J

February 2015

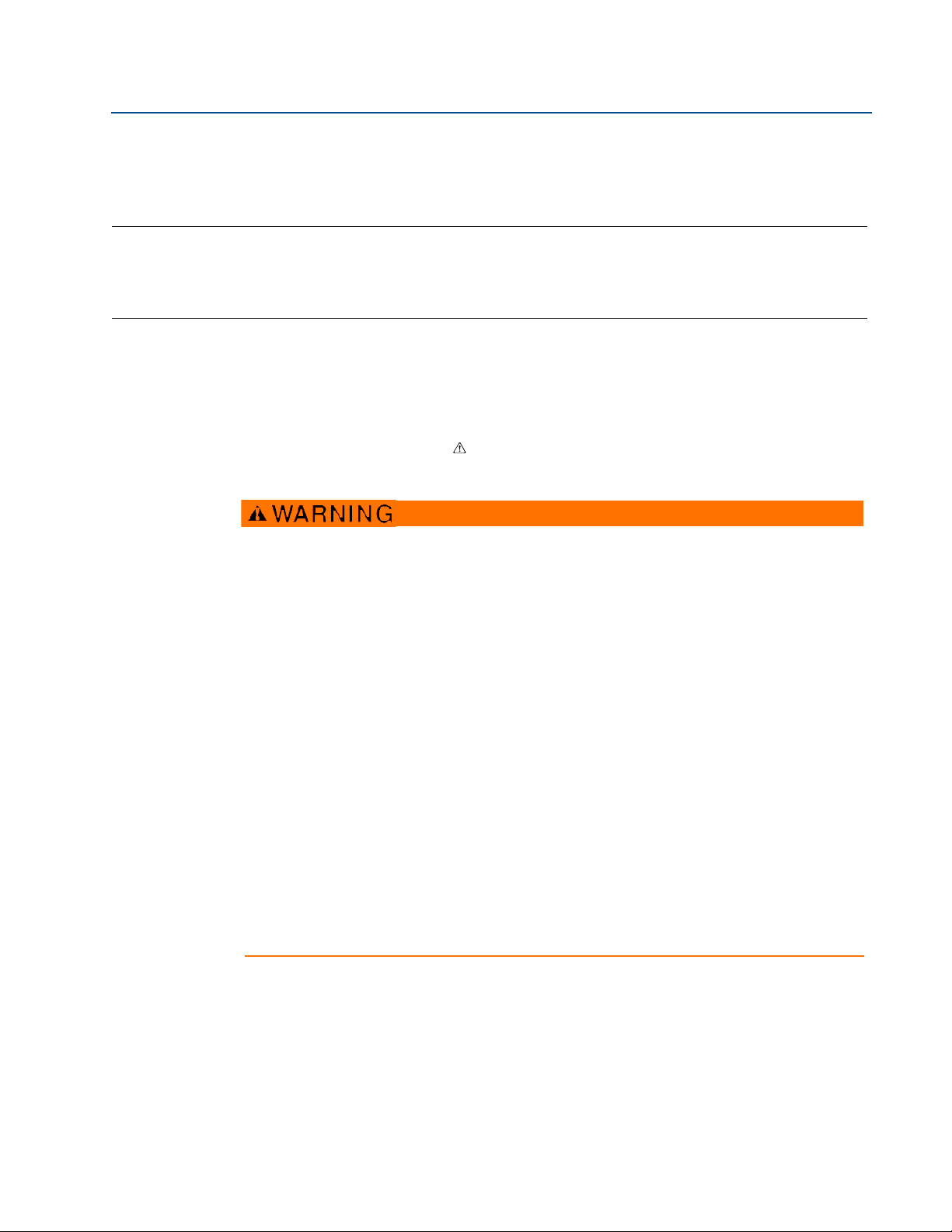

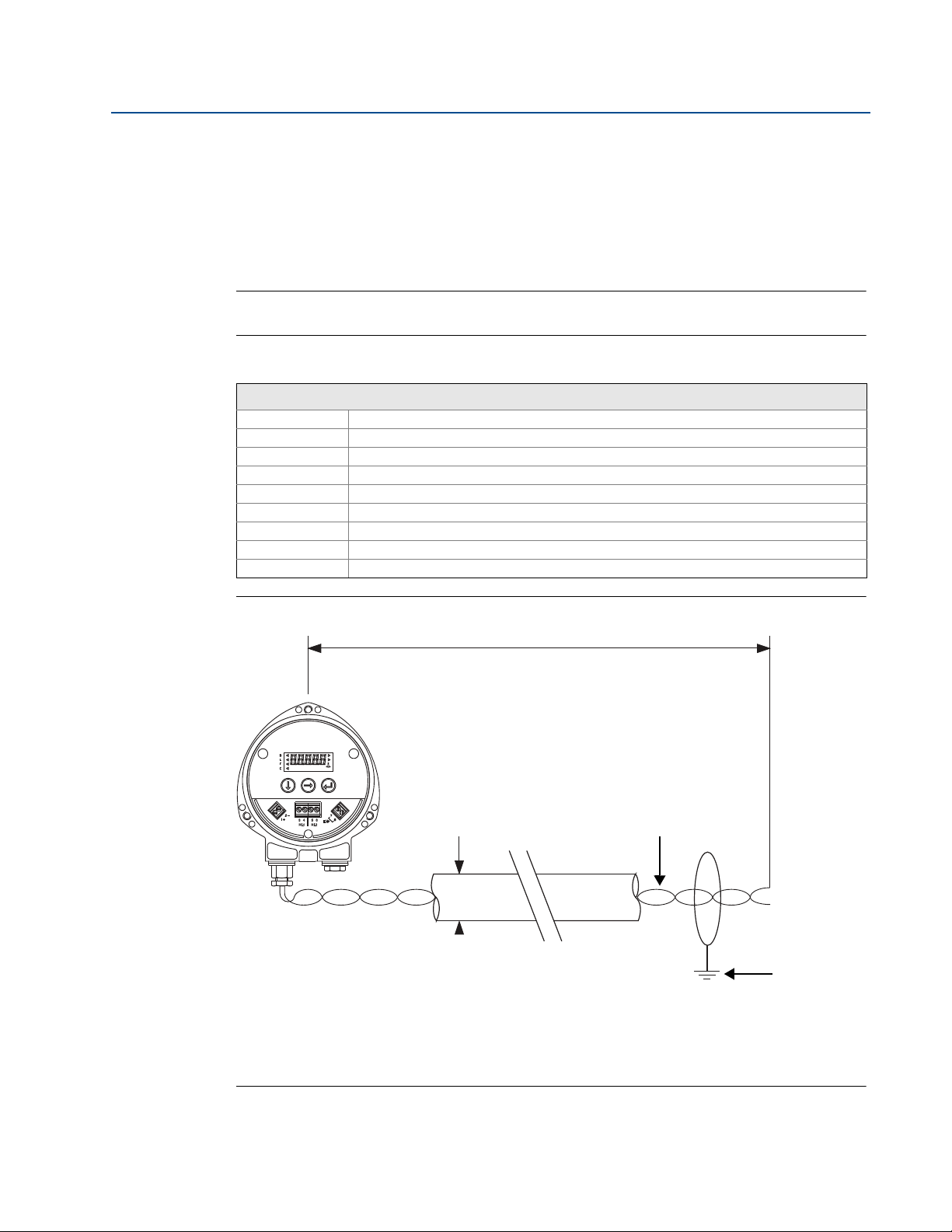

2.3 System architecture

The Rosemount 3101, 3102, and 3105 are two-wire 24 Vdc loop-powered transmitters and can

be connected to a direct current (dc) power source using two-core, shielded cable.

On The Rosemount 3101, the output is a 4–20 mA analog signal.

On The Rosemount 3102 and Rosemount 3105, the output can be a 4–20 mA analog signal and

a digital HART signal.

Note

It is possible to use the multi-drop function with the HART protocol (Figure 2-3). In this case,

communication is restricted to digital since the current is fixed to 4 mA

Each transmitter can be configured locally using the push-buttons (3101) or

membrane-buttons (3102/3105) which are revealed after removing the housing cover.

The 3102 and 3105 transmitters can be easily configured remotely by using a Rosemount 3490

Series Control Unit. Alternatively, a Field Communicator, or a PC with AMS Suite: Intelligent

Device Manager software can be used to configure each transmitter.

Reference Manual

00809-0100-4840, Rev CB

A comprehensive specification for the Rosemount 3101, 3102, and 3105 is in the section

“Specifications” on page 77.

Figure 2-3. System Architecture

A. Rosemount 3102 or 3105 Transmitter

B. Two Relay Outputs from Transmitter (Rosemount 3102 only)

C. Remote Temperature Sensor (Optional Accessory for Rosemount 3102 and Rosemount 3105 Transmitters)

D. 751 Display

E. 4–20 mA signal / HART communications

F. Co nt rol Sys te m

G. Rosemount 3490 Series Control Unit

H. HART Modem

I. Field Communicator

J. AMS Suite: Intelligent Device Manager

6

Transm itter Over view

Page 19

Reference Manual

00809-0100-4840, Rev CB

Section 3 Installation

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 7

Considerations before installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 8

Mechanical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 10

Electrical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 16

3.1 Safety messages

Procedures and instructions in this section may require special precautions to ensure the safety

of the personnel performing the operation. Information that raises potential safety issues is

indicated by a warning symbol ( ). Refer to the following safety messages before performing

an operation preceded by this symbol.

Section 3: Installation

February 2015

Explosions could result in death or serious injury.

Verify that the operating environment of the transmitter is consistent with the

appropriate hazardous locations certifications.

Before connecting a HART

®

-based communicator in an explosive atmosphere, make

sure the instruments in the loop are installed in accordance with intrinsically safe or

non-incendive field wiring practices.

Do not remove the housing cover in explosive atmospheres when the circuit is alive.

Failure to follow safe installation and servicing guidelines could result in death or

serious injury.

Make sure only qualified personnel perform the installation.

Use the equipment only as specified in this manual. Failure to do so may impair the

protection provided by the equipment.

Do not perform any service other than those contained in this manual unless you are

qualified.

Process leaks could result in death or serious injury.

Make sure that the transmitter is handled carefully.

High voltage that may be present on leads could cause electrical shock.

Avoid contact with leads and terminals

Make sure the main power to the transmitter is off and the lines to any other external

power source are disconnected or not powered while wiring.

Installation

7

Page 20

Section 3: Installation

February 2015

3.2 Considerations before installation

The Rosemount 3100 Series may be used for level and volume measurement in open- or closedtanks, or open channel flow measurement.

The glass-filled nylon housing version of the transmitter must be installed in a location where it

is protected from ultraviolet radiation to prevent long term degradation of the plastics used

e.g. shrouded from direct sunlight.

It is important to correctly position the transmitter for reliable ultrasonic level measurement.

For maximum accuracy and stability of the level measurement reading, the transmitter should

be shrouded from direct sunlight and radiated heat.

The transmitter may be site-tuned to deal with most application conditions, but it is

recommended that the following guidelines be adopted where relevant.

Note

The Rosemount 3100 Series is designed to be mounted in a non-metallic fitting or flange.

The use of metallic fittings/flanges is not recommended.

Please see “Spare parts and accessories for the 3101/3102/3105” on page 90.

Reference Manual

00809-0100-4840, Rev CB

3.2.1 Safety considerations

Installation must be carried out by suitably trained personnel in accordance with the

applicable code of practice.

If the equipment is likely to come into contact with aggressive substances, it is the

responsibility of the user to take suitable precautions that prevent it from being

adversely affected, thus ensuring that the type of protection is not compromised.

Aggressive substances are acidic liquids or gases that may attack metals or solvents that

may affect polymeric materials.

Suitable precautions are regular checks as part of routine inspections, or establishing,

from the material's datasheet, that it is resistant to specific chemicals.

The equipment must only be cleaned with a damp cloth; do not use solvents.

The equipment is not intended to be repaired by the user and is to be replaced by an

equivalent certified unit. Repairs should only be carried out by the manufacturer or

approved repairer.

The transmitter is Double Insulated, and therefore Protective Earthing is not required.

However, the cable shield/screen should be connected to a suitable ground (earth) at

one end only (see “Connecting the cable(s) to the transmitter” on page 16).

Note that if the equipment is used in a manner not specified by the manufacturer, the

protection afforded by the equipment may be impaired.

To ensure electro-magnetic compatibility in any European member state, it should not

be installed in a residential area.

Note

It is not advisable to mount the transmitter in close proximity to a source of electrical noise such

as a variable-speed drive or other high-powered electrical device.

8

Installation

Page 21

Reference Manual

OKOK OK

00809-0100-4840, Rev CB

3.2.2 Environmental considerations

The Rosemount 3105 Transmitter is Intrinsically Safe (IS) approved for hazardous area

installations.

The Rosemount 3101, 3102, and 3105 Transmitters are designed for open- or closed-

tank installation. They are weatherproof and protected against the ingress of dust.

Avoid installing the transmitters near heat sources.

Figure 3-1. Environmental Considerations

Section 3: Installation

February 2015

Installation

9

Page 22

Section 3: Installation

February 2015

3.3 Mechanical installation

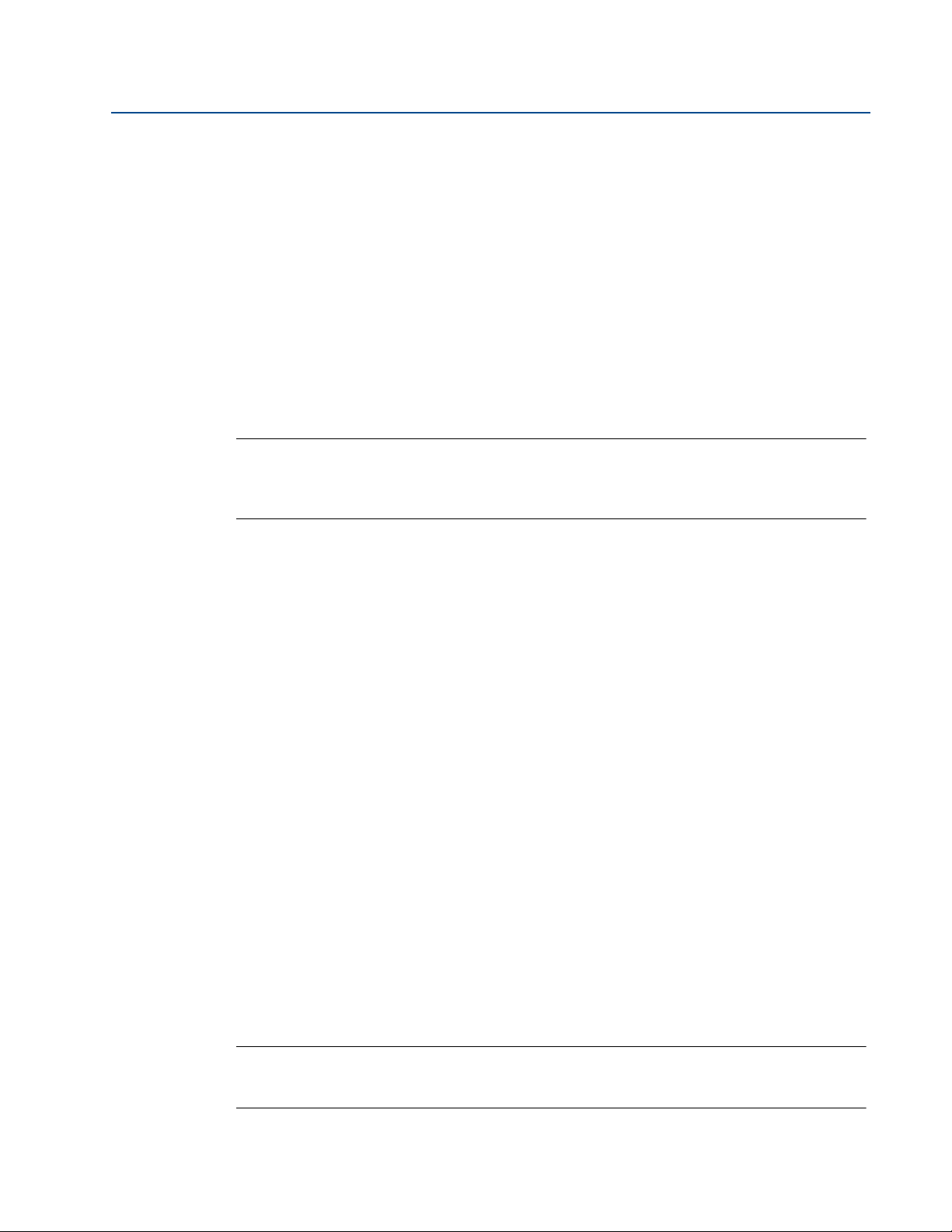

3.3.1 Mounting considerations

Mount the transmitter above the liquid using the 2-in. thread provided, but no closer

than 12 in. (0,3 m) to the surface. The transmitter does not detect any liquid surface

closer than 12 in. (0,3 m) to the transmitter face. (See “Mounting the transmitter above

the liquid surface” on page 12).

Optional flanges and bracket kits are available to help mounting

(see “Spare parts and accessories for the 3101/3102/3105” on page 90).

The transmitter should be mounted vertically to ensure a good echo from the liquid

surface. The transmitter beam half angle is 6 degrees (see Figure 3-2 on page 11).

Obstructions in the tank, or well, may generate echoes which can be confused with the

real liquid surface echo. Obstructions within the beam angle generate strong false

echoes. Wherever possible, the transmitter should be positioned to avoid false echoes.

To avoid detecting unwanted objects in the tank or well, it is advisable to maintain a

distance sideways of at least 1.3 in. from the center line of the transmitter for ever y foot

(11 cm per meter) range to the obstruction (see Figure 3-2 on page 11).

No false echoes are generated if the transmitter is located near the side of the tank or

well, and the wall is smooth and free of protrusions. However, there will still be a

reduction in the echo size. It is recommended that the transmitter be mounted no

closer than 12 in. (0,3 m) to the wall to avoid a large reduction in the echo size.

If the transmitter is mounted in an enclosed tank with a domed top, avoid mounting

the transmitter in the center of the tank roof because this could act as a parabolic

reflector and create unwanted echoes.

Reference Manual

00809-0100-4840, Rev CB

Avoid applications where heavy condensation could form on the transmitter face.

If the transmitter is mounted in a stand-off or nozzle, the transmitter face should

protrude at least 0.2 in. (5 mm) into the tank. If this is not possible, see “Mounting the

transmitter above the liquid surface” on page 12).

If the transmitter is used in environments where direct sunlight can cause high

temperatures on exposed surfaces, a sun-shade is recommended.

Check that the maximum liquid level will not enter the 12-in. (0,3 m) blanking zone of

the transmitter.

3.3.2 Consider liquid surface conditions

Foaming liquids can reduce the size of the returned echo because foam is a poor

ultrasonic reflector.

Mount an ultrasonic transmitter over an area of clear liquid, such as near the inlet to a

tank or well. In extreme conditions, or where this is not possible, the transmitter may

be mounted in a vented stilling tube provided that the inside measurement of the

stilling tube is at least 4 in. (100 mm) and is smooth and free from joints or protrusions.

It is important that the bottom of the stilling tube stays covered to prevent the ingress

of foam.

10

Installation

Page 23

Reference Manual

A

D

B

C

00809-0100-4840, Rev CB

Avoid mounting the transmitter directly over any inlet stream.

Liquid surface turbulence is not normally a problem unless it is excessive. The effects of

turbulence are minor, but excessive turbulence can be dealt with by fine-tuning the

transmitter on site, if necessary.

3.3.3 Consider in-tank effects

Stirrers or agitators can cause a vortex. Mount the transmitter off-center of any vortex

to maximize the return echo.

If stirrer blades become uncovered, they create echoes as they pass through the

ultrasonic beam. The transmitter can learn to ignore these false echoes (see page 69 or

page 122).

In tanks with rounded or conical bottoms, mount the transmitter off-center. If needed,

a perforated reflector plate can be installed on the tank bottom directly under the

transmitter center line to ensure a satisfactory return echo.

Avoid detecting pump casings, as the liquid falls away, by not mounting the transmitter

directly above pumps. If this is not possible, fine-tuning of the transmitter on-site may

be required.

Section 3: Installation

February 2015

Figure 3-2. Tank Installation Considerations

A. Transmitter is Mounted Vertically (Maximum Deviation of 3°)

B. Use Non-metallic Fitting or Flange

C. 6° Beam Half Angle

D. 1.3 in./ft. (11 cm/m). Minimum of 12 in. (0,3 m)

Installation

11

Page 24

Section 3: Installation

B

C

A

February 2015

Reference Manual

00809-0100-4840, Rev CB

3.3.4 Mounting the transmitter above the liquid surface

A 2-in. thread is provided to mount the transmitter. The thread form is either 2-in. BSPT or NPT,

and is clearly marked on the hexagon of the transmitter body.

To help installation, flange accessories and bracket kits are available from Emerson Process

Management. The accessory flanges supplied are manufactured from PVC and are a full face

design. Care must be taken when installing to raised face mating flanges on the tank or vessel to

prevent distortion of the PVC flange by over-tightening the bolts. See “Spare parts and

accessories for the 3101/3102/3105” on page 90 for ordering information.

Note

The Rosemount 3101, 3102, and 3105 Transmitters are designed to be mounted in a

non-metallic fitting or flange. The use of metallic fittings/flanges is not recommended

Bracket mounting

The bracket kit contains a stainless steel angle bracket and PVC threaded disc, which may be

used to mount the transmitter on a support over the liquid surface.

The bracket and disc dimensions are in Figure A-5 on page 86. The combined weight of bracket

and disc is 16 oz (0,5 kg). For transmitter weight, see “Specifications” on page 77.

Installation instructions

1. Attach bracket to the disc using the three screws provided.

2. Attach the assembled bracket and disc to a rigid support over the liquid surface.

The bracket may be bolted to a suitable crossmember (structural section of steel).

Ensure the transmitter is perpendicular to the surface to maximize the return echo size.

3. Use PTFE tape on the screw thread of the transmitter (Figure 3-4 on page 13).

4. Insert the transmitter into the disc.

5. Tighten to a torque of 1.5 ft-lb (2 N-m) using the transmitter’s hexagon.

Do not use the transmitter housing to tighten.

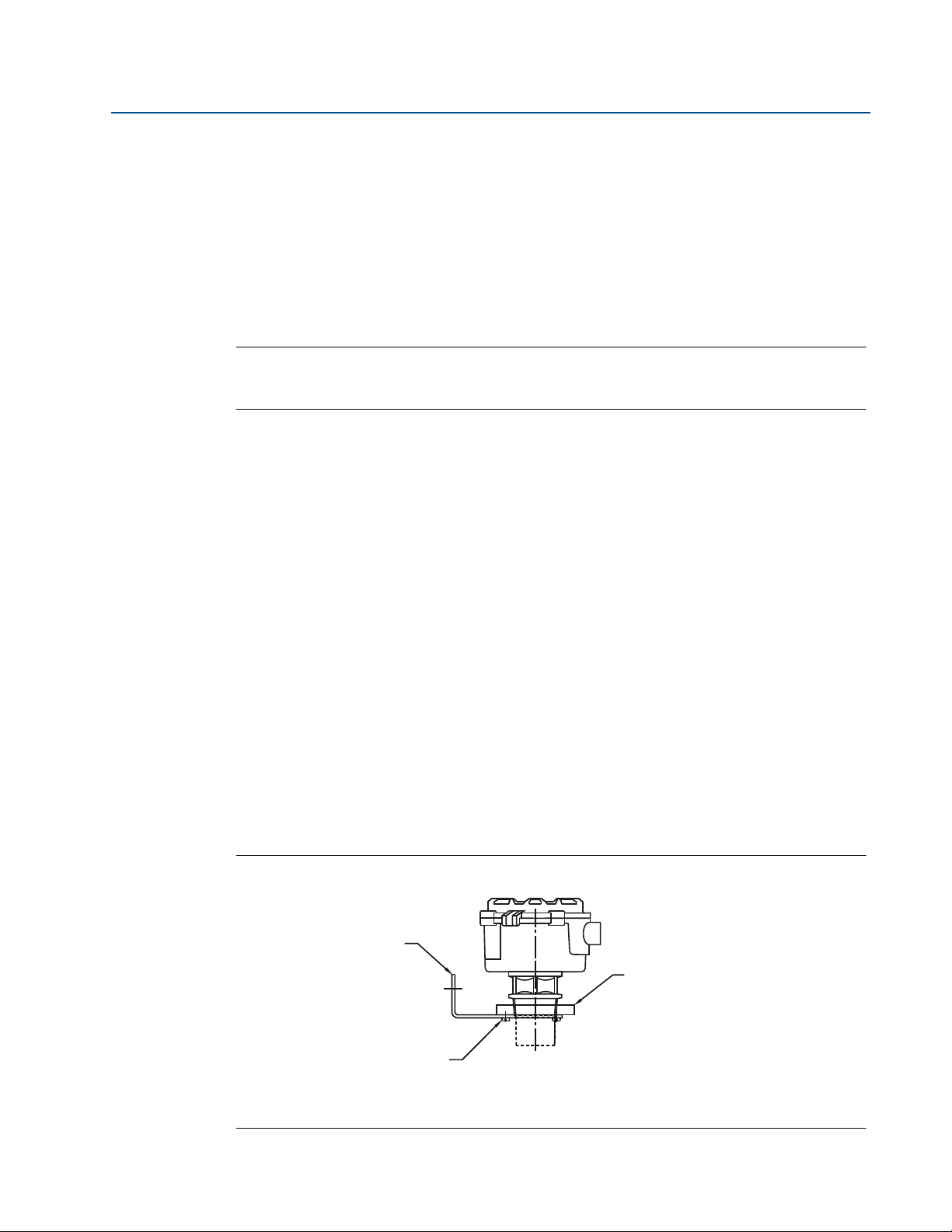

Figure 3-3. Bracket Kit Mounting

12

A. Stainless Steel Bracket

B. No. 4X 13 Long Self Tap Screw (3 Positions) Carbon Steel (Zinc Plated)

C. PVC Disc

Installation

Page 25

Reference Manual

PTFE

L

D

Tighten to a torque of 1.5 lbf.ft

(2 Nm) using the hexagon. Do

not use the housing to tighten

Use non-metallic

fitting / flange

00809-0100-4840, Rev CB

Installing in a tank with a nozzle or stand-off

Installation instructions

1. Use PTFE tape on the screw thread of the transmitter (Figure 3-4 on page 13).

2. If the tank has a flanged nozzle or stand-off:

Section 3: Installation

February 2015

a. Attach the transmitter to a non-metal instrument flange using the threaded

connection. Tighten to a torque of 1.5 lb-ft (2 N-m) using the transmitter’s hexagon.

b. The instrument (accessory) flanges supplied by Emerson Process Management are

manufactured from PVC and are a full face design. Care must be taken when installing

to a raised face mating flange on the tank or vessel to prevent distortion of the PVC

flange by over-tightening the bolts.

c. Ensure the gasket is sitting correctly on the nozzle/tank flange.

d. Lower the assembled transmitter and instrument flange onto the tank flange, and

secure with appropriate bolting to a suitable torque for the flanges.

If mating to a raised face flange (RF) on the tank nozzle or stand-off, tighten to a

maximum torque of 10 lb-ft (13.6 N-m).

3. If the tank has a threaded nozzle or stand-off:

a. Attach the transmitter to the nozzle/stand-off using the threaded connection.

b. Tighten to a torque of 1.5 lb-ft (2 N-m) using the transmitter’s hexagon.

Note

If the transmitter face does not protrude into the vessel, note the dimensions in Tab l e 3 -1 for

Figure 3-4, and always ensure that the nozzle/vessel weld is smooth and free from internal weld

beads or other projections.

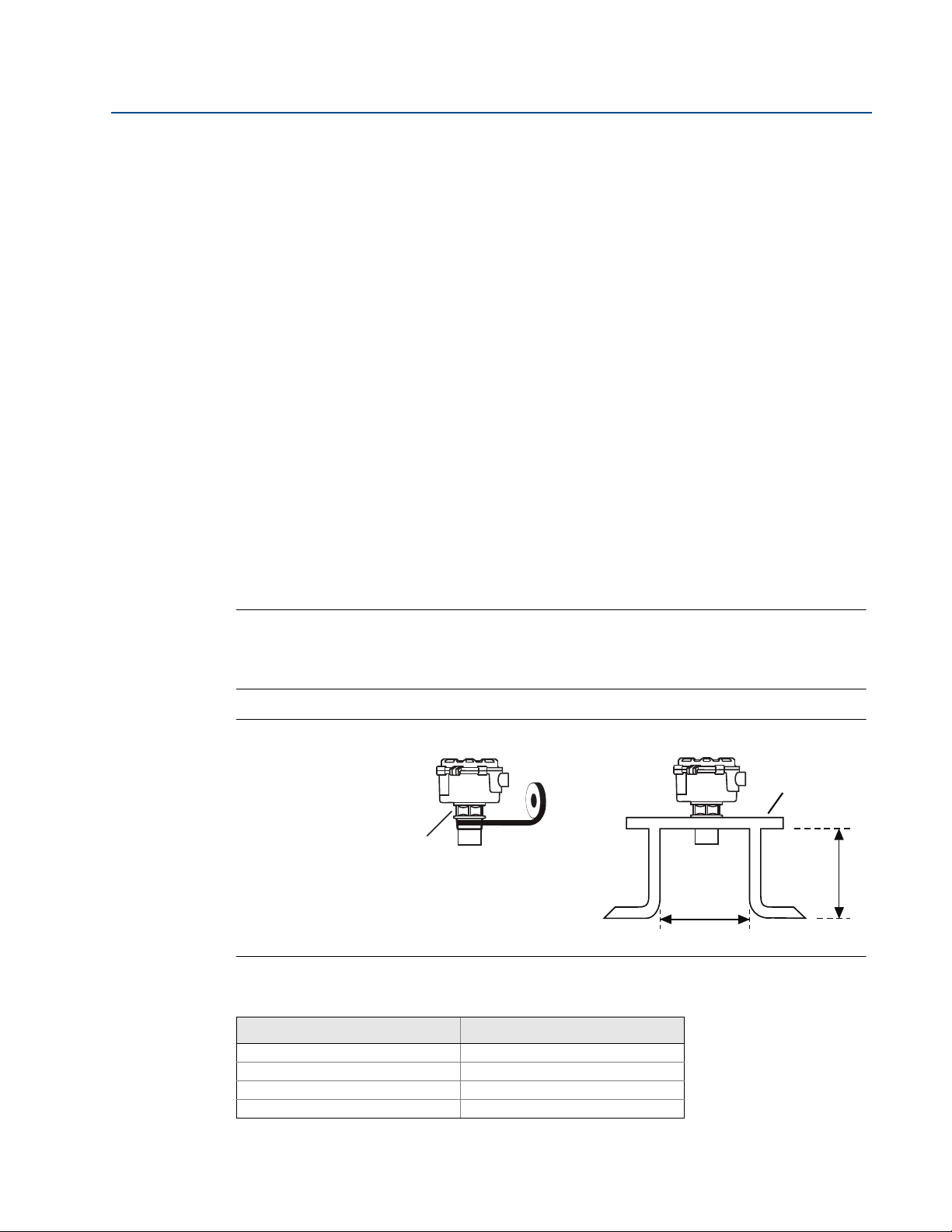

Figure 3-4. Mounting the Transmitter using a Nozzle/Stand-off

Installation

Table 3-1. Nozzle diameter size (D) and maximum length (L)

Nozzle Diameter Size (D) Maximum Nozzle Length (L)

DN50 (2 in.) 4 in. (100 mm)

DN80 (3 in.) 6.3 in. (160 mm)

DN100 (4 in.) 6.3 in. (160 mm)

DN125 (5 in.) 11.8 in. (300 mm)

13

Page 26

Section 3: Installation

A

B

C

D

A

B

C

February 2015

00809-0100-4840, Rev CB

3.3.5 Open channel flow installations (the 3102/3105)

There are normally two distinct parts to an open channel flow measurement system; the

primary element (flow structure) and the secondary element (Head measurement instrumentation). For accurate open channel flow measurement, both parts of the system must be

correctly installed. This section explains the important parts of installing the transmitter

(secondary element). The flow structure (primary element) installation can be referenced in the

British (BS3680) or ISO International standards.

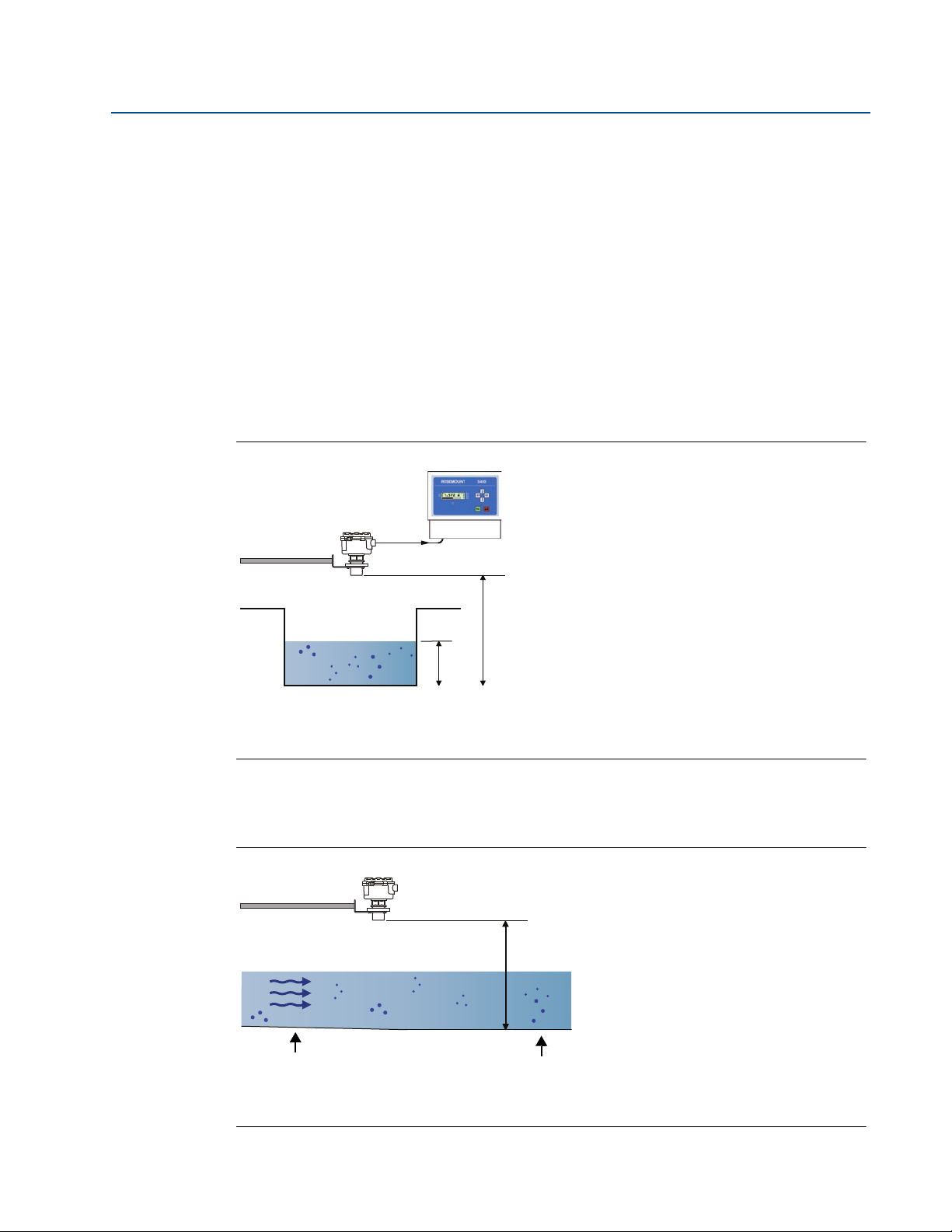

Positioning of the transmitter is critical, and should be the correct distance upstream from the

flow structure as stated in the relevant standard for your country. For example, in the ISO

standards, the distance should be four to five times the maximum height of the water (Hmax)

for a thin plate weir, or three to four times Hmax for a flume. For optimum accuracy, position the

transmitter’s front face at a height equal to the sum of the maximum flow depth plus the

transmitter deadband of 12.2 in. (300 mm) plus an extra 2 in. (50 mm).

Figure 3-5. Choosing the Height Position above a Flow

Reference Manual

A. Transmitter Front Face

B. Hmax

C. Transmitter Bottom Reference = Hmax + 12.2 in. (300 mm) + 2 in. (50 mm)

It is important that the bottom reference of the transmitter should be related to the datum of

the primary measuring device (see Figure 3-6).

Figure 3-6. Transmitter Bottom Reference for a Flume or Weir

A. Transmitter Bottom Reference C. Approach Channel

B. Primary Element (e.g. Flume, Weir) Invert D. Flow

14

Installation

Page 27

Reference Manual

A

B

00809-0100-4840, Rev CB

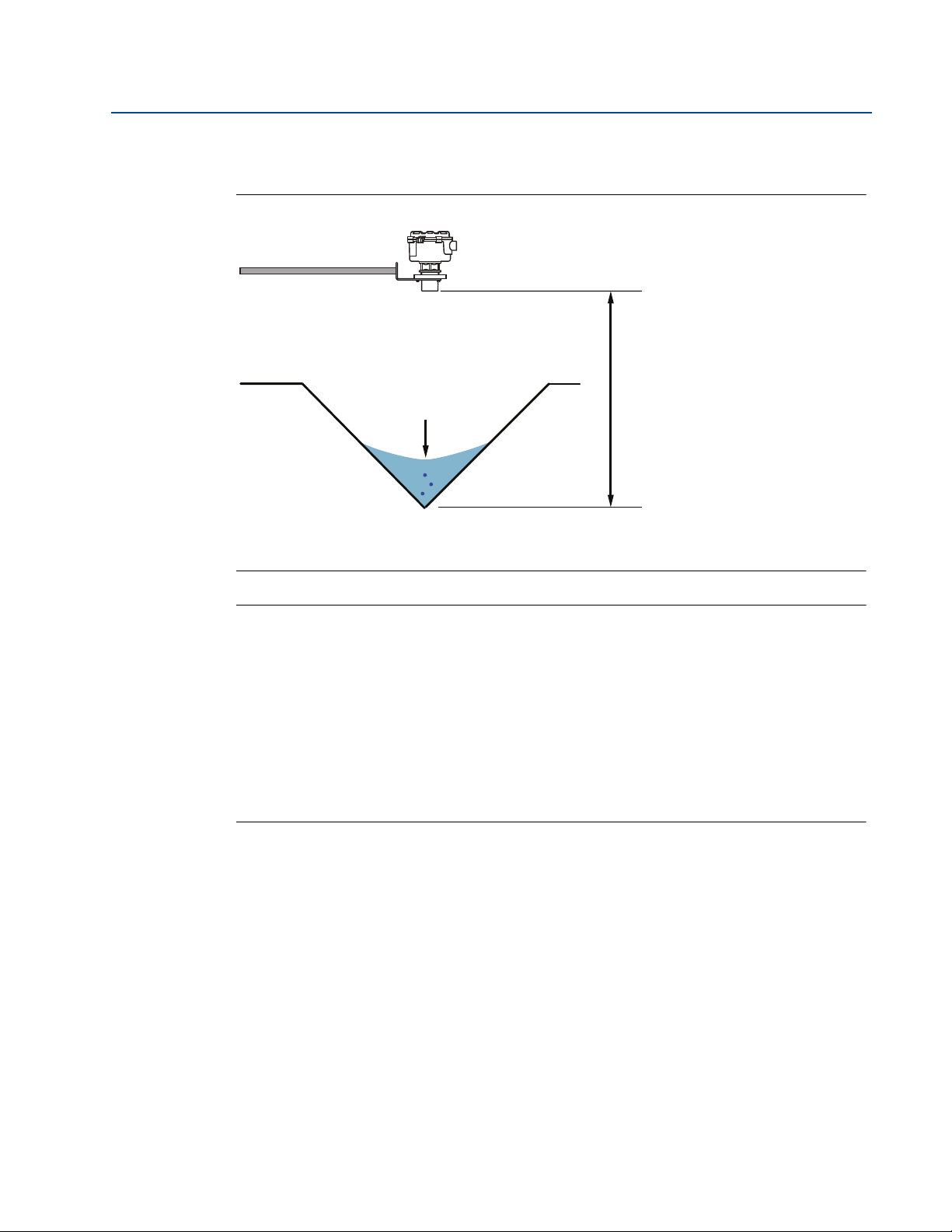

When setting the bottom reference on a ‘V’ notch weir, it is important the true invert is used and

not the meniscus level (Figure 3-7).

Figure 3-7. Bottom reference of a ‘V’-notch weir

Section 3: Installation

February 2015

A. Transmitter Bottom Reference (i.e. True Invert)

B. Meniscus Level

Note

The transmitter should be free from a situation where it is likely to 'drown' (refer to relevant

Standard for further information)

The Rosemount 3102 and Rosemount 3105 have the option of a Remote Temperature Sensor

(RTS) for temperature compensation (see page 21). The temperature sensor should be

mounted in a location where it can get an accurate air temperature measurement and is

protected from sunlight. (See Quick Installation Guide 00825-0100-4842 for further RTS

installation information)

If the flow structure permits, mount the transmitter within the flow channel or chamber.

Shroud the transmitter from direct sunlight for maximum accuracy and stability

Installation

15

Page 28

Section 3: Installation

February 2015

3.4 Electrical installation

3.4.1 Connecting the cable(s) to the transmitter

The Rosemount 3100 Series is a two-wire loop-powered transmitter accepting power supplies

as follows:

The 3101: 12 to 30 Vdc

The 3102: 12 to 40 Vdc

The 3105: 12 to 40 Vdc (non-hazardous), 12 to 30 Vdc (hazardous).

Note

To comply with the CSA approval requirements, the 3101 and the 3102 must be powered from a

Rosemount 3490 Series Control Unit or a class 2 separate extra-low voltage (SELV) source

Other devices may reset if connecting the transmitter to a multi-drop system while the loop is

powered. De-energize the loop to avoid devices being reset

Each transmitter is supplied with two cable entries. A suitable conduit system or cable gland

must be used to maintain the weather-proof rating and hazardous area protection. Any unused

entry must be sealed with a suitably rated blanking plug.

Reference Manual

00809-0100-4840, Rev CB

A two-core, shielded/screened cable is required for external power supply and output signal

connections. The cable is not supplied.

Connect the cable(s) to the transmitter

1. Make sure that the power supply is disconnected.

2. Undo the three cover screws and then lift the transmitter housing cover.

The cover on the metal housing can rest on the hinge. Place an object under the cover

to avoid the transmitter toppling over.

3. Pass the cable through the cable gland/conduit.

4. Connect the cable wires:

a. For The Rosemount 3101, connect wires according to the section

“Connecting the cable wires to the Rosemount 3101” on page 17.

b. For The Rosemount 3102, connect wires according to the section

“Connecting the cable wires to the Rosemount 3102” on page 18.

c. For The Rosemount 3105, connect wires according to the section

“Connecting the cable wires to the Rosemount 3105” on page 19.

5. Connect the cable shield/screen to a suitable ground (earth) at one end only.

6. Replace the cover, tighten the cable gland, and connect the power supply.

16

Installation

Page 29

Reference Manual

E

C

12 to 30 Vdc

0 Vdc

B

A

D

00809-0100-4840, Rev CB

Section 3: Installation

What to do after completing the cabling

To maintain the weather-proof rating and hazardous area protection of the transmitter, ensure

all cable glands, blanking plugs, and seals are in good condition.

Check that the cover seal is in good condition, and not twisted or misaligned in the seal location

groove. When replacing the cover, tighten the three cover screws evenly to exert uniform

pressure on the cover seal.

3.4.2 Connecting the cable wires to the Rosemount 3101

The Rosemount 3101 is not intrinsically safe, and is for use in non-hazardous (ordinary location)

installations only.

Wire the transmitter as shown in Figure 3-8.

Important

Make sure that the power supply is off when connecting the transmitter

February 2015

Table 3-2. Terminal Connections on the Rosemount 3101

Connections

Ter min al 1 24 Vdc

Ter min al 2 0 Vdc

Earth Screen Connect the cable shield/screen to ground (earth) in the control room

Figure 3-8. Wiring Diagram for the Rosemount 3101

Installation

A. Maximum cable length is 9750 ft. (3000 m)

B. Connect the cable shield/screen to ground (earth) in the control room

C. Cable thickness: Ø0.15 to 0.31 in. (Ø4 to 8 mm)

D. Twisted-pair, screened wires. Minimum size: 0.22 mm2 (24 SWG / 23 AWG); Maximum: 1.5 mm2 (16 SWG / 18 AWG)

E. Minimum of 12 Vdc is required at the transmitter for it to operate

17

Page 30

Section 3: Installation

E

CD

0 Vdc

12 to 40 Vdc

B

A

February 2015

Reference Manual

00809-0100-4840, Rev CB

3.4.3 Connecting the cable wires to the Rosemount 3102

The Rosemount 3102 is not intrinsically safe, and is for use in non-hazardous (Ordinary Location)

installations only.

Wire the transmitter as shown in Figure 3-9. If HART digital communications is required, see

also “Wiring to allow HART communications” on page 21.

Important

Make sure the power supply is off when connecting the transmitter

Table 3-3. Terminal Connections on the Rosemount 3102

Connections

Ter min al 1 24 Vdc

Ter min al 2 0 Vdc

Ter min al 3 RL1 (SPST) - see “Relays” on page 19

Ter min al 4 RL1 (SPST) - see “Relays” on page 19

Ter min al 5 RL2 (SPST) - see “Relays” on page 19

Ter min al 6 RL2 (SPST) - see “Relays” on page 19

Ter min al 7 Remote temperature sensor (if used) - see “Remote temperature sensor” on page 21

Ter min al 8 Remote temperature sensor (if used) - see “Remote temperature sensor” on page 21

Earth Screen Connect the cable shield/screen to ground (earth) in the control room

Figure 3-9. Wiring Diagram for the Rosemount 3102

A. Maximum cable length is 9750 ft. (3000 m)

B. Connect the cable shield/screen to ground (earth) in the control room

C. Cable thickness: Ø0.15 to 0.31 in. (Ø4 to 8 mm)

D. Twisted-pair, screened wires. Minimum size: 0.22 mm2 (24 SWG / 23 AWG); Maximum: 1.5 mm2 (16 SWG / 18 AWG)

E. Minimum of 12 Vdc is required at the transmitter for it to operate

18

Installation

Page 31

Reference Manual

00809-0100-4840, Rev CB

Section 3: Installation

Relays

The 3102 has two integral relays which may be used for fault indication or control purposes.

These relays are for light duty and should be used as signal relays only, with control functions

being performed by external control relays.

Relay number 2 is defaulted as a 'fault' relay - normally energized - but may be re-configured

on-site as a set-point relay if required.

Relay status indicators are on the LCD inside the housing (see “Integral display and buttons” on

page 24).

3.4.4 Connecting the cable wires to the Rosemount 3105

The Rosemount 3105 is for intrinsically safe installations. See Appendix B: Product Certifications

for the safety approvals and control drawings.

Important

Make sure the power supply is off when connecting the transmitter

February 2015

Installation in a non-hazardous (ordinary location) area

Wire the transmitter as shown in Figure 3-10 on page 20.

Installation in a hazardous area

When the 3105 is powered by a Rosemount 3490 Series Control Unit, no safety barriers are

required as the output from the control unit is Intrinsically Safe.

If powering the transmitter from any other power supply, ensure a suitable Intrinsically Safe

barrier is fitted in the non-hazardous (safe) area.

The barrier must be chosen such that its output parameters Uo, Io and Po are less than Ui, Ii and

Pi of the transmitter (see Appendix B: Product Certifications).

The sum of the capacitance and the inductance of the transmitter and the connecting cable

fitted must not exceed the maximum specified for the barrier chosen.

Note

Make sure that the instruments in the loop are installed according to intrinsically-safe field

wiring practices and control drawings, when applicable

If HART digital communications is required, see also “Wiring to allow HART communications”

on page 21.

Installation

19

Page 32

Section 3: Installation

E

D

0 Vdc

12 to 40 Vdc

(non I.S. application)

or

12 to 30 Vdc from

protective barrier

(I.S. application.)

C

B

A

February 2015

Table 3-4. Terminal Connections on the Rosemount 3105

Connections

Ter min al 1 24 Vdc

Ter min al 2 0 Vdc

Ter min al 7 Remote temperature sensor (if used) - see “Remote temperature sensor” on page 21

Ter min al 8 Remote temperature sensor (if used) - see “Remote temperature sensor” on page 21

Earth Screen Connect the cable shield/screen to ground (earth) in the control room

Figure 3-10. Wiring Diagram for the Rosemount 3105

Reference Manual

00809-0100-4840, Rev CB

A. Maximum cable length is 9750 ft. (3000 m)

B. Connect the cable shield/screen to ground (earth) in the control room

C. Cable thickness: Ø0.15 to 0.31 in. (Ø4 to 8 mm)

D. Twisted-pair, screened wires. Minimum size: 0.22 mm2 (24 SWG / 23 AWG); Maximum: 1.5 mm2 (16 SWG / 18 AWG)

E. Minimum of 12 Vdc is required at the transmitter for it to operate

20

Installation

Page 33

Reference Manual

00809-0100-4840, Rev CB

3.4.5 Remote temperature sensor

The Rosemount 3102 and Rosemount 3105 accept input from a Rosemount Remote

Temperature Sensor (see “Spare parts and accessories for the 3101/3102/3105” on page 90).

This is a thermistor-based temperature sensor designed for use with the 3102 and 3105.

Full installation instructions are supplied with the temperature sensor, but it should be mounted

out of direct sunlight in a position so that it can give a representative reading of the air

temperature between the liquid surface and the transmitter.

Note

Do not connect any other temperature sensor to the Rosemount 3102 or 3105 Transmitters.

3.4.6 Wiring to allow HART communications

If HART communications is required (available on the 3102 and 3105 only), a 250 Ohm

(minimum), 0.25 W load resistor must be installed in the loop.

Section 3: Installation

February 2015

Note

When the transmitter is used with a Rosemount 3490 Series Control Unit, there is no need to

install an external load resistor in the loop because a suitable resistor is built in to the control

unit (see “Load limitations” on page 83).

If the transmitter is being supplied through a safety barrier, ensure the type chosen will pass

HART information.

After the load resistor is installed, a Field Communicator can be connected across the load

resistor. It is the responsibility of the installer to ensure that any Field Communicator used

in the hazardous area is suitably certified.

Note

Make sure that the instruments in the loop are installed according to intrinsically-safe field

wiring practices and control drawings, when applicable.

3.4.7 Lightning / surge protection and other loop devices

If the area is prone to lightning strikes or voltage surges, a suppressor device may be installed

between the transmitter and the control unit.

If an additional loop-powered device or separately powered device is included in the two-wire

loop, ensure the transmitter receives a minimum voltage of 12 Vdc.

(See “Load limitations” on page 83).

Installation

21

Page 34

Section 3: Installation

February 2015

Reference Manual

00809-0100-4840, Rev CB

22

Installation

Page 35

Reference Manual

00809-0100-4840, Rev CB

Section 4 Starting up

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 23

Programming the Rosemount 3101, 3102, and 3105 Transmitters . . . . . . . . . . . . . . . .page 24

Programming the 3101 using the integral display and buttons . . . . . . . . . . . . . . . . . . . page 26

Programming the 3102 and 3105 using the integral display and buttons . . . . . . . . . . .page 35

4.1 Safety messages

Procedures and instructions in this section may require special precautions to ensure the safety

of the personnel performing the operation. Information that raises potential safety issues is

indicated by a warning symbol ( ). Refer to the following safety messages before performing

an operation preceded by this symbol.

Section 4: Starting up

February 2015

Explosions could result in death or serious injury.

Verify that the operating environment of the gauge is consistent with the appropriate

hazardous locations certifications.

Before connecting a HART

®

-based communicator in an explosive atmosphere, make

sure the instruments in the loop are installed in accordance with intrinsically safe or

non-incendive field wiring practices.

Do not remove the gauge cover in explosive atmospheres when the circuit

is alive.

Failure to follow safe installation and servicing guidelines could result in death or serious

injury.

Make sure only qualified personnel perform the installation.

Use the equipment only as specified in this manual. Failure to do so may impair the

protection provided by the equipment.

Do not perform any service other than those contained in this manual unless you are

qualified.

Starting up

23

Page 36

Section 4: Starting up

Green

Button

Red

Button

Blue

Button

Alarm

Faul t

D

L

F

C

February 2015

Reference Manual

00809-0100-4840, Rev CB

4.2 Programming the Rosemount 3101, 3102, and 3105 Transmitters

Rosemount 3101, 3102, and 3105 Transmitters are operated from a menu of parameters, each

held in a specific memory location within the transmitter. The memory locations may be

pictured as a matrix, and are navigated for programming the instrument using

Each transmitter is pre-programmed at the factory with a value in each parameter location so

that when the power is first applied, the transmitter gives a sensible reading.

This section details the programming using the buttons provided inside the transmitter.

The Integral Display menu structure is shown in Appendix C: Integrated Display Menus.

Note

The 3102 and 3105 are HART-enabled, allowing remote communications with the instrument.

For remote programming information, refer to Appendix F: Programming the 3102 and 3105

using HART

and steps.

4.2.1 Integral display and buttons

The integral display allows up to five characters. In the normal running mode, the display shows

a measurement termed the Process Value (PV) of the transmitter. In programming mode, on

the display is data to assist with programming.

To the left of the main display are four arrow icons (3102/3105 only); one of which will be

illuminated to indicate the duty chosen by the user: Distance-to-surface (D), Level (L), Flow (F),

or Contents (C).

To the right of the PV display on the Rosemount 3102 are two arrow icons that indicate the

status of the transmitter relays. When illuminated, they indicate the relay contact is closed.

Under the PV display is a text string indicating the units of measurement. The transmitter will

illuminate only those characters applicable to the units of measurement chosen.

To the right of the text string is an echo received icon. It is made up of three arc segments that

continuously indicate the strength of the echo received (minimum, average, and good).

Figure 4-1. Integral Display and the Green/Blue/Red Buttons

24

Starting up

Page 37

Reference Manual

00809-0100-4840, Rev CB

Section 4: Starting up

4.2.2 What happens when powering up the transmitter

When the power is turned on, the transmitter takes several seconds to initialize. The display will

run through a set-up routine, first illuminating all display characters, and then showing the

software revision number. Finally, a full set of zeros is displayed while the microprocessor

identifies the correct return echo. After these checks are complete, the display indicates the live

measurement based upon the factory default values in memory.

When a new transmitter is aimed at a good target, the level reading is calculated using the

default value for the bottom reference.

On the Rosemount 3102 and Rosemount 3105, the duty chosen icon next to letter L (Level)

(and the RL2 icon on the 3102) will be illuminated. The RL1 icon on the 3102 may be

illuminated, depending on the level calculated by the transmitter at this time.

The transmitter is now ready to be programmed with details of the application. It may be

programmed on-site or prior to installation. All programmed data is retained in the transmitter

memory after the power is turned off.

4.2.3 Considerations before starting the programming

February 2015

Important notes to help you program the transmitter

Do not allow rain or water to enter the transmitter during programming or the circuit

boards may be damaged.

The step-by-step instructions through is chapter show how to use the integral buttons

to navigate through the programming menu and select or enter application data.

Push the buttons firmly, but not too hard to avoid damaging the circuit boards. Also, to

avoid entering incorrect data, do not push the buttons too fast.

The 3102 and 3105 transmitters have a “load default values” routine that restores the

transmitter memory with factory default values. This will clear the memory of all

previous selected or entered data.

Starting up

25

Page 38

Section 4: Starting up

February 2015

Reference Manual

00809-0100-4840, Rev CB

4.3 Programming the 3101 using the integral display and buttons

Note

The Integral Display menu is shown in full in Appendix C: Integrated Display Menus.

4.3.1 Display units (on the 3101)

The display units are indicated by the position of the decimal point in the displayed PV value:

Units Display

m8.000

ft. 26.24

in. 314.9

Default values are as follows:

3101****SC**: m

3101****RC**: ft.

Note

See Figure C-1 on page 102 for a map of the programming menu structure showing how to

access all the menu options and return to the PV display.

To change the display units

1. Start from the PV display (see the note above).

2. Hold down the blue button

3. The display units will then change according to the following sequence:

3101****SC**: Metres to Feet, Feet to Inches, and Inches to Metres

3101****RC**: Feet to Inches, Inches to Metres, and Metres to Feet

4. Continue to hold down the blue button

above sequence after every three seconds.

5. Confirm the display units by releasing the blue button

The same units must be used when programming in the bottom reference and the 4 and 20 mA

points. The 4–20 mA output may be set to operate over all or just a part of the total measuring

range. There is no limit on the minimum span of the current output, although a span below 4 in.

(100 mm) is not recommended. The 4 mA level may be set above or below the 20 mA level to

suit the monitoring or control equipment.

for 10 seconds, but do not release it yet.

to change to the next display unit in the

.

26

Note

The Rosemount 3101 measures and calculates in meters. The display units are derived as a last

operation using a pre-programmed conversion factor

Starting up

Page 39

Reference Manual

B

C

A

00809-0100-4840, Rev CB

4.3.2 First measurements (on the 3101)

With the transmitter installed and display units selected, the display will show what the

instrument calculates as the liquid depth (level). This value is calculated by the microprocessor

as being the difference between the distance-to-target being measured and the default value

for the datum or bottom reference (b.rEF).

Figure 4-2. Transmitter Bottom Reference

Section 4: Starting up

February 2015

A. Transmitter Bottom Reference

B. Distance-to-target

C. Depth (Level)

Before changing any of the default values, press the blue button to change the PV display to

indicate distance-to-target, as measured by the transmitter from the transmitter face.

This value is shown alternately with the text “diSt” to indicate the display is in distance mode.

The calculation can be checked against a manual measurement if required.

Note

A useful feature at this stage is that the transmitter can be used as an electronic tape measure.

With an empty tank or vessel, the transmitter will read the distance to the bottom of the tank.

This distance can be noted and later used when setting b.rEF.

Press the blue button

again to get to the echo size. This is a scale of 0 to 100. (It is possible to

record a value greater than 100). With the display in this mode, the central “:” cursor will flash

once for every echo received, which under normal circumstances will be once per second.

Note

It is useful at this point to check that the maximum echo size available is being received.

Adjust the position of the instrument until the highest echo size is continually shown.

In most applications, the signal strength will vary over a wide range: 20 to 80.

Starting up

Press the blue button

again to return to the original level reading and start the set-up routine,

beginning with setting the bottom reference of the transmitter.

Note

The output of the transmitter will vary during programming, as the various default values are

changed. The display will automatically revert to the level reading from any other display after a

period of four minutes.

27

Page 40

Section 4: Starting up

February 2015

4.3.3 Setting the bottom reference (on the 3101)

Screen display: b.rEF

Defaults: 8.000 (m), 26.24 (ft.), 314.9 (in.)

Note

See Figure C-1 on page 102 for a map of the programming menu structure and how to access all

the menu options.

To change the bottom reference (b.rEF) setting

1. If entering the menu system from the PV display, press the green button to indicate

the “b.rEF” menu option (see the above note).

Reference Manual

00809-0100-4840, Rev CB

2. Press the blue button

b.rEF value.

3. If this value is correct, press the red button

to the next menu option. Otherwise, continue with step (4).

4. Press the blue button

edited.

5. Press the green button

6. Press the blue button

edited.

7. Repeat steps (5) and (6) until the last digit is flashing, and edited as required.

8. Press the blue button

be flashing.

9. Press the red button

not save. Afterwards, depending on the button pressed, either the “b.rEF” menu or the

next menu appears.

to enter the menu for b.rEF. The display indicates the present

and then press the green button to get

to start editing. The first digit flashes to indicate it can be

repeatedly to edit the flashing digit.

to move to the next digit. The digit flashes to indicate it can be

to confirm the new b.rEF value. None of the digits should now

to save the new value if it is correct, or press the blue button to

4.3.4 Setting 4 mA and 20 mA levels (on the 3101)

Screen display: 4 and 20

4 mA level defaults: 0.000 (m), 00.00 (ft.), 000.0 (in.)

20 mA level defaults: 7.500 (m), 24.60 (ft.), 295.2 (in.)

28

The 4 mA level may be set above or below the 20 mA level to suit the monitoring or control

equipment.

Note