Page 1

Reference Manual

00809-0100-4810, Rev DA

September 2007

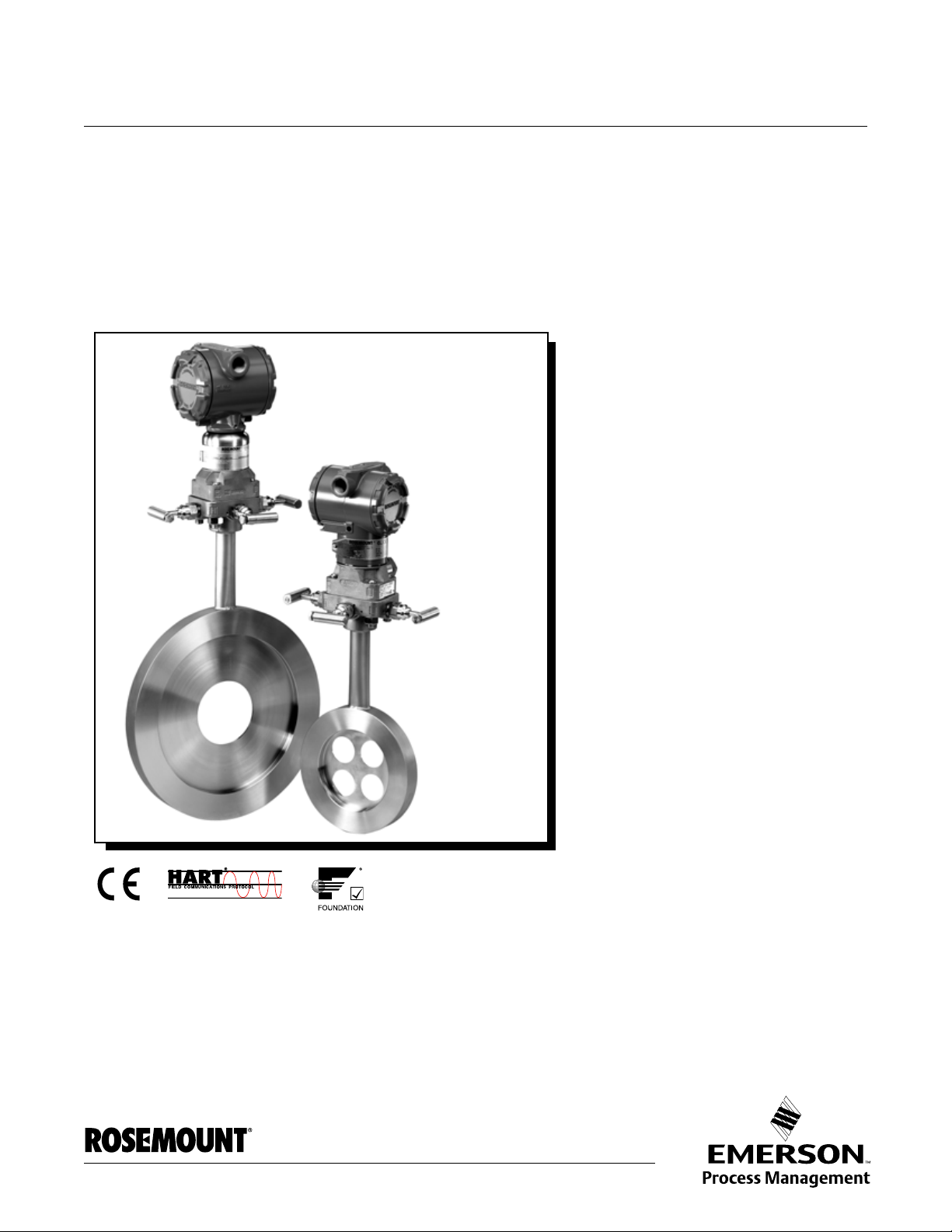

Rosemount Compact Orifice

Flowmeter Series

www.rosemount.com

Page 2

Page 3

Reference Manual

Rosemount Compact Orifice

00809-0100-4810, Rev DA

September 2007

Flowmeter Series

Rosemount Compact Orifice Flowmeter Series

NOTICE

Read this manual before working with the product. For personal and system safety, and for

optimum product performance, make sure you thoroughly understand the contents before

installing, using, or maintaining this product.

The United States has two toll-free assistance numbers and one International number.

Customer Central

1-800-999-9307 (7:00 a.m. to 7:00 P.M. CST)

International

1-(952) 906-8888

National Response Center

1-800-654-7768 (24 hours a day)

Equipment service needs

The products described in this document are NOT designed for nuclear-qualified

applications. Using non-nuclear qualified products in applications that require

nuclear-qualified hardware or products may cause inaccurate readings.

For information on Emerson Process Management nuclear-qualified products, contact your

local Emerson Process Management Sales Representative.

This device is intended for use in temperature monitoring applications and should not be

used in control and safety applications.

www.rosemount.com

Page 4

Page 5

Reference Manual

00809-0100-4810, Rev DA

September 2007

Rosemount Compact Orifice

Flowmeter Series

Table of Contents

SECTION 1

Introduction

SECTION 2

Installation

Transmitter Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Receiving and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Returning the Product. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Functional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Vibration Limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Straight Run Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Bolting a transmitter to the Rosemount 405 . . . . . . . . . . . . . . . . . 2-3

Location and Orientation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Direct Mount Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Gas in Horizontal Pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Liquid or Steam in Horizontal Pipes . . . . . . . . . . . . . . . . . . . . . 2-5

Liquid in Vertical Pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Gas in Vertical Pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Remote Mount Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Gas in Vertical or Horizontal Pipes. . . . . . . . . . . . . . . . . . . . . . 2-6

Liquid or Steam in Vertical or Horizontal Pipes . . . . . . . . . . . . 2-7

Process Connections (Remote Mount Only) . . . . . . . . . . . . . . . . . 2-7

High Temperature Units (Option Code T) . . . . . . . . . . . . . . . . 2-8

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Remote RTD Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

SECTION 3

Commissioning

SECTION 4

Operation and

Maintenance

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Direct Mount Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Liquid Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Gas Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Steam Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Remote Mount Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Liquid Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Gas Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Steam Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Check Flow Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Check Orientation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Check Zero. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Check Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Check Configuration/Scaling . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Check 3095M Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

RTD Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Remote Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

TOC-1

Page 6

Rosemount Compact Orifice

Flowmeter Series

Reference Manual

00809-0100-4810, Rev DA

September 2007

APPENDIX A

Reference Data

Rosemount 3051SFC Compact Orifice Flowmeter . . . . . . . . . . . . A-1

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Functional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Physical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Installation Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-9

Dimensional Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-11

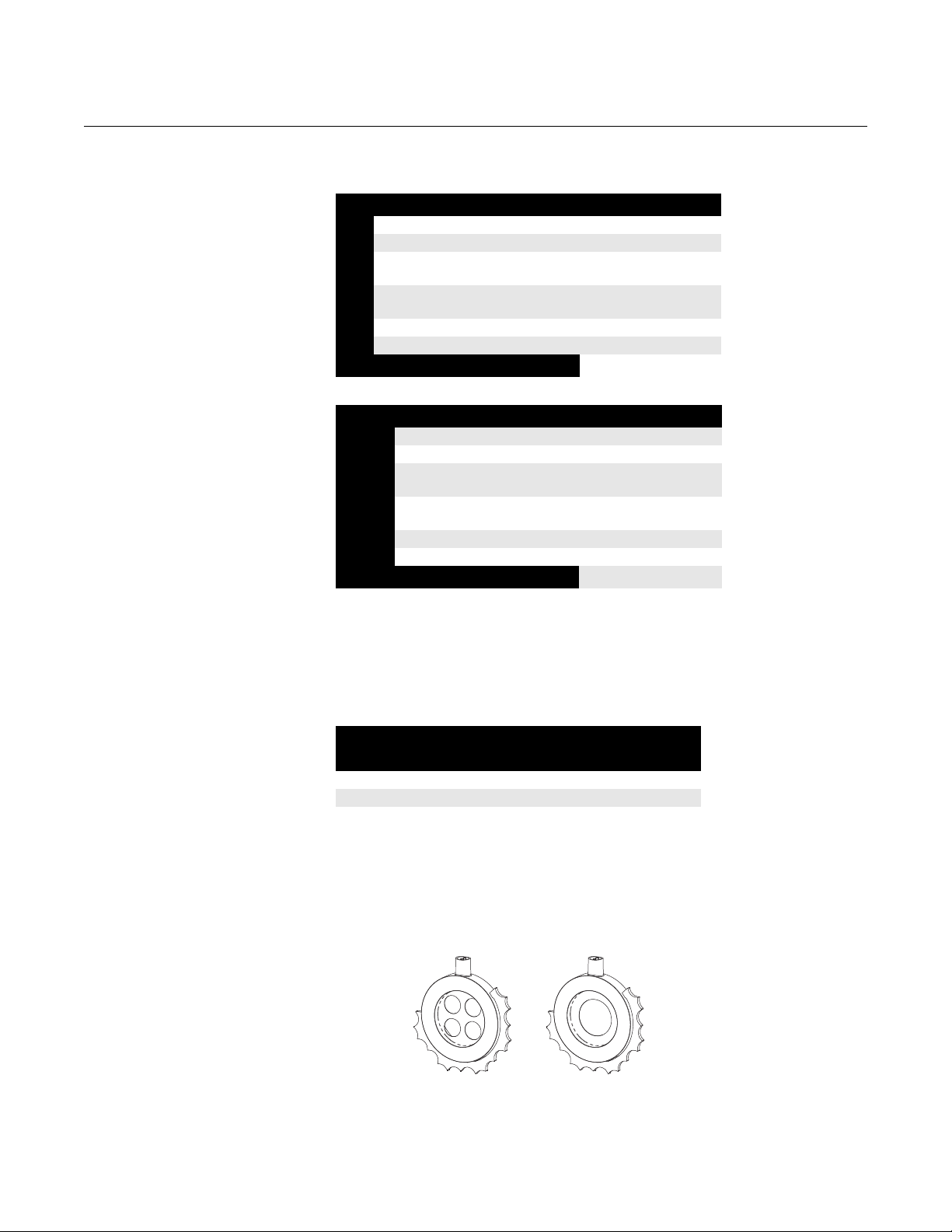

Compact Orifice Plate

(Primary Element Type code P) . . . . . . . . . . . . . . . . . . . . . . . A-11

Conditioning Orifice Plate

(Primary Element Type code C) . . . . . . . . . . . . . . . . . . . . . . .A-11

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-12

Rosemount 3051SFC Compact Orifice

Flowmeter Ordering Information . . . . . . . . . . . . . . . . . . . . . . . A-12

Rosemount 3095MFC Compact Orifice Mass Flowmeter . . . . . .A-16

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-16

Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-16

Functional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-17

Physical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-19

Installation Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-21

Dimensional Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-24

Compact Orifice Plate

(Primary Element Type code P) . . . . . . . . . . . . . . . . . . . . . . . A-24

Conditioning Orifice Plate

(Primary Element Type code C) . . . . . . . . . . . . . . . . . . . . . . .A-24

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-25

Rosemount 3095MFC Compact Orifice Mass

Flowmeter Ordering Information . . . . . . . . . . . . . . . . . . . . . . . A-25

Rosemount 405 Compact Orifice Primary Element . . . . . . . . . . . A-28

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-28

Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-28

Functional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-28

Physical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-29

Installation Consideration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-30

Dimensional Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-33

Compact Orifice Plate

(Primary Element Type code P) . . . . . . . . . . . . . . . . . . . . . . . A-33

Conditioning Orifice Plate

(Primary Element Type code C) . . . . . . . . . . . . . . . . . . . . . . .A-33

Compact Orifice Plate

(Primary Element Type code P) . . . . . . . . . . . . . . . . . . . . . . . A-34

Conditioning Orifice Plate

(Primary Element Type code C) . . . . . . . . . . . . . . . . . . . . . . .A-34

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-35

Rosemount 405 Compact Orifice

Primary Element Ordering Information . . . . . . . . . . . . . . . . . . A-35

Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-37

Mounting Stud and Nut Kits. . . . . . . . . . . . . . . . . . . . . . . . . . . A-37

Gasket Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-37

Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-38

TOC-2

Page 7

Reference Manual

00809-0100-4810, Rev DA

September 2007

Rosemount Compact Orifice

Flowmeter Series

APPENDIX B

Product Certifications

3051SFC Product Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

Approved Manufacturing Locations . . . . . . . . . . . . . . . . . . . . . . . . B-1

European Directive Information . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Ordinary Location Certification for FM . . . . . . . . . . . . . . . . . . . . . . B-2

Hazardous Locations Certifications . . . . . . . . . . . . . . . . . . . . . . . . B-2

North American Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

European Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-2

Australian Certifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

IECEx Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-5

Combinations of Certifications. . . . . . . . . . . . . . . . . . . . . . . . . . B-6

3095MFC Product Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

ATEX Directive (94/9/EC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

European Pressure Equipment Directive (PED) (97/23/EC) . . .B-6

Electro Magnetic Compatibility (EMC) (89/336/EEC) . . . . . . . . B-7

Ordinary Location Certification for Factory Mutual . . . . . . . . . .B-7

Hazardous Locations Certifications . . . . . . . . . . . . . . . . . . . . . . . . B-7

North American Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . B-7

European Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-8

Combinations of Certifications. . . . . . . . . . . . . . . . . . . . . . . . . . B-9

Installation Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-9

TOC-3

Page 8

Rosemount Compact Orifice

Flowmeter Series

Reference Manual

00809-0100-4810, Rev DA

September 2007

TOC-4

Page 9

Reference Manual

00809-0100-4810, Rev DA

September 2007

Rosemount Compact Orifice

Section 1 Introduction

Transmitter Information . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-1

Receiving and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . page 1-1

Returning the Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-1

Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-2

Flowmeter Series

TRANSMITTER

INFORMATION

RECEIVING

AND INSPECTION

RETURNING THE

PRODUCT

If the 405 primary element was ordered assembled to a Rosemount 3051S

transmitter, the new assembly is the Rosemount 3051SFC Compact Orifice

Flowmeter. See the Rosemount 3051S Series Pressure Transmitter reference

manual (document number 00809-0100-4801) for information regarding

transmitter installation, configuration, and operation.

If the 405 primary element was ordered assembled to a Rosemount 3095M

transmitter, the new assembly is the Rosemount 3095MFC Compact Orifice

Mass Flowmeter. See the Rosemount 3095M Mass Flow Transmitter

reference manual (document number 00809-0100-4801) for information

regarding transmitter installation, configuration, and operation.

Flowmeters are available in different models and with different options, so it is

important to inspect and verify that the appropriate model was delivered

before installation.

Upon receipt of the shipment, check the packing list against the material

received and the purchase order. All items are tagged with a model number,

serial number, and customer tag number. Report any damage to the carrier.

To expedite the return process, call the Rosemount National Response

Center toll-free at 800-654-7768. This center, available 24 hours a day, will

assist you with any needed information or materials.

The center will ask for the following information:

• Product model

• Serial numbers

• The last process material to which the product was exposed

www.rosemount.com

The center will provide

• A Return Material Authorization (RMA) number

• Instructions and procedures that are necessary to return goods that

were exposed to hazardous substances

NOTE

If a hazardous substance is identified, a Material Safety Data Sheet (MSDS),

required by law to be available to people exposed to specific hazardous

substances, must be included with the returned materials.

Page 10

Rosemount Compact Orifice

Flowmeter Series

Reference Manual

00809-0100-4810, Rev DA

September 2007

CONSIDERATIONS

Functional The Rosemount 405 produces the most accurate and repeatable

measurement when it is used in single-phase flow or steam flow above the

saturation temperature. Location of the 405 in pulsating flow will cause a

noisy signal. Vibration can also distort the output signal and compromise the

structural limits of the flowmeter.

Mount the 405 in a secure run of pipe as far as possible from pulsation

sources such as check valves, reciprocating compressors or pumps, and

control valves.

Install the 405 in the correct location within the piping branch to prevent

measurement inaccuracies caused by flow disturbances.

Maximum temperature for direct mount applications is 450 °F

(232 °C). Maximum temperature for remote mount applications is 850 °F

(454 °C).

Vibration Limits

Qualified per IEC61298-3 (1998) for field with high vibration level or pipeline

with high vibration level (10-60Hz 0.21mm displacement peak amplitude / 60 500Hz 3g).

The weight and length of the transmitter assembly shall not exceed 5.8 lbs

and 7.75-in.

1-2

Page 11

Reference Manual

00809-0100-4810, Rev DA

September 2007

Rosemount Compact Orifice

Flowmeter Series

Section 2 Installation

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-1

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-1

Location and Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-4

SAFETY MESSAGES Instructions and procedures in this section may require special precautions to

ensure the safety of the personnel performing the operations. Please refer to

the following safety messages before performing any operation in this section.

Explosions could result in death or serious injury:

• Do not remove the transmitter cover in explosive atmospheres when the circuit is

live.

• Before connecting a HART Communicator in an explosive atmosphere, make sure

the instruments in the loop are installed in accordance with intrinsically safe or

non-incendive field wiring practices.

• Verify that the operating atmosphere of the transmitter is consistent with the

appropriate hazardous locations certifications.

• Both transmitter covers must be fully engaged to meet explosion-proof

requirements.

Failure to follow these installation guidelines could result in death or serious injury:

• Make sure only qualified personnel perform the installation.

The product may be hot while in service, potentially causing burns. Handle with care.

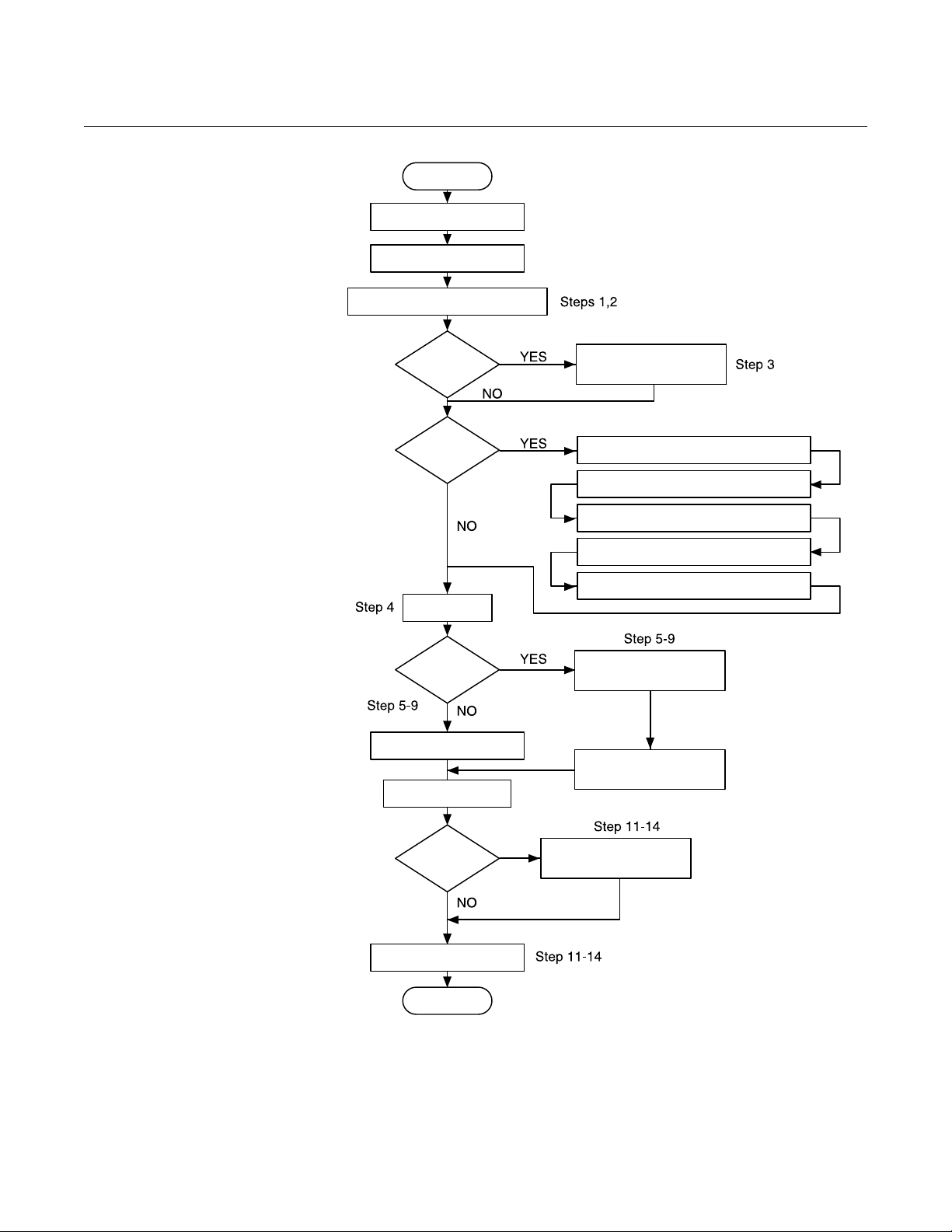

INSTALLATION

Flowchart Installation Chart page 2-2 is an installation flowchart that provides guidance

through the installation process. Following the figure, an installation checklist

has been provided to verify that all critical steps have been taken in the

installation process. The checklist numbers are indicated in the flowchart.

2-1

Page 12

Rosemount Compact Orifice

Start.

Unpack Instrument

Review Product

Manual.

Verify proper location.

Hazardous

Location?

Bench

Configure

Review Appendix B.

Configure write-protect and

failure alarm

Connect the bench power supply

Connect the instrument to a PC

Perform bench configuration tasks

(Optional) Perform bench

calibration tasks

Verify model

Remote

Mounted

Electronics?

Install electronics

Install flowmeter

Wire

Remote

Mounted

Electronics?

Finish.

Commission

Install hardware

Commission

Flowmeter Series

Figure 2-1. Installation Chart

Reference Manual

00809-0100-4810, Rev DA

October 2007

Handling

The product tag is not designed to withstand the weight of the orifice - do not

lift the product by the tag.

Do not lift the product by the orifice holes. Holes have sharp edges that may

cause personal injury. Lift the product by the casting neck.

2-2

Page 13

Reference Manual

00809-0100-4810, Rev DA

September 2007

Straight Run

Requirements

Rosemount Compact Orifice

Flowmeter Series

Table 2-1. 405C Straight Pipe

Requirements

Table 2-2. 405P Straight Pipe

Requirements

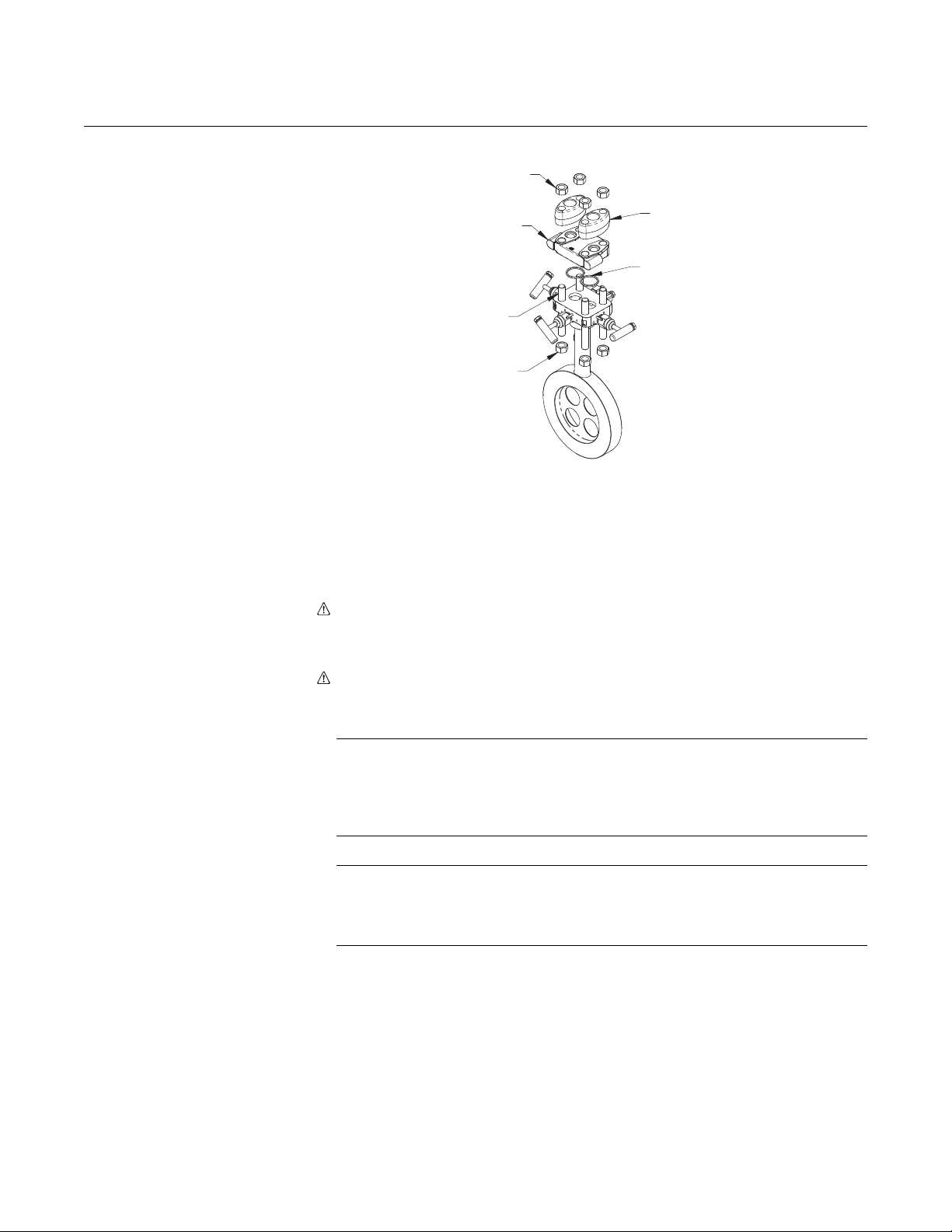

Bolting a transmitter to

the Rosemount 405

(1)

Beta

Single 90° bend or tee 2 2

Two or more 90 ° bends in the same plane 2 2

Two or more 90° bends in different plane 2 2

Up to 10° of swirl

Reducer (1 line size) 2 2

side of primary

Upstream (inlet)

Butterfly valve (75% open) 2 N/A

Downstream (outlet) side of primary

(1) (2) (3)

Beta

Reducer 5 12

Single 90° bend or tee 16 44

Two or more 90 ° bends in the same plane 10 44

Two or more 90° bends in different plane 50 60

Expander 12 28

Ball / Gate valve fully open 12 18

side of primary

Upstream (inlet)

(1) Consult an Emerson Process Management representative if disturbance is not listed.

(2) Recommended lengths represented in pipe diameters per ISO 5167.

(3) Refer to ISO 5167 for recommended lengths when using flow straighteners.

0.40 0.65

22

0.40 0.65

67

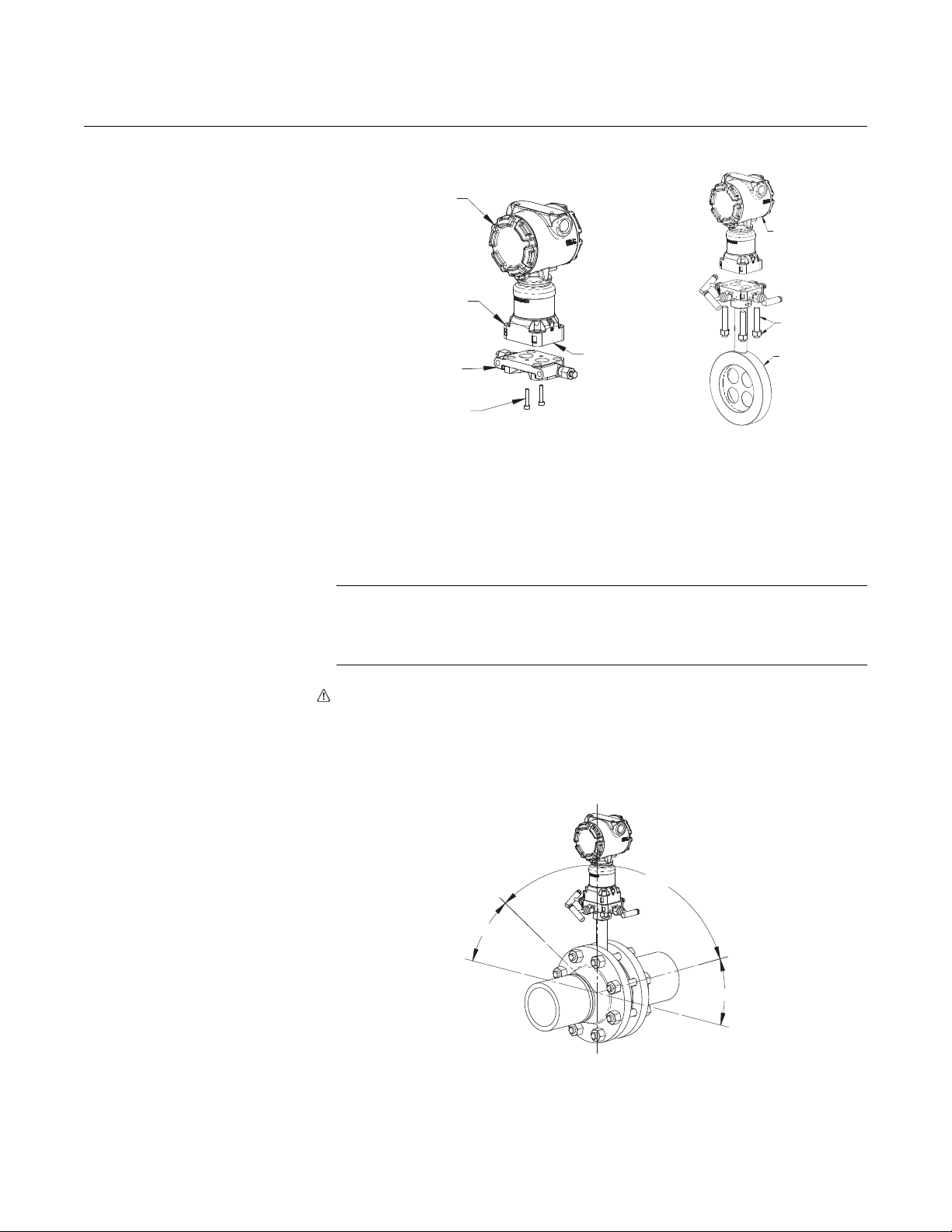

If the 405 is ordered separately from the 3051, or 3095M transmitter and will

be used in a direct mount configuration, it will need to be assembled to the

transmitter. Follow the directions below to assemble the 405 to a transmitter

with a coplanar configuration.

NOTE

Units shipped from the factory direct mounted are pressure tested and

characterized with the primary attached. Factory assembly is recommended

for best performance.

1. Remove the body bolts (4) from the transmitter.

2. Remove the socket head cap screws from the bottom of the coplanar

flange and remove the coplanar flange.

NOTE

Protect the transmitter sensing diaphragms and do not remove the o-rings in

transmitter sensor module.

3. Carefully assemble the 405 to the pressure transmitter sensor making

sure the “H” and “L” on transmitter and primary match.

4. Use studs and nuts supplied with the 405 to connect the transmitter

sensor to the manifold head of the 405.

5. Preload to 150 lbs/in. then final torque at 300 lbs/in.

2-3

Page 14

Rosemount Compact Orifice

FLANGE SCREWS

TRANSMITTER

SENSING MODULE

COPLANAR FLANGE

SENSING

DIAPHRAGMS

AND 0-RINGS

(DO NOT

DISTURB OR

REMOVE)

Flowmeter Series

Figure 2-2. Bolting the 405

to a transmitter

Reference Manual

00809-0100-4810, Rev DA

September 2007

TRANSMITTER

STUDS

AND NUTS

ROSEMOUNT

405

LOCATION AND

ORIENTATION

The 405 has two mounting methods:

• integral mount (or direct mount)

• remote mount.

An integrally mounted 405 may be shipped with the transmitter already bolted

directly to the sensor.

Direct Mount Installation NOTE

The maximum acceptable temperature for direct mounting is 450 °F (232 C°).

Refer to "Location and Orientation" beginning on page 2-4 if the process

could potentially exceed this temperature.

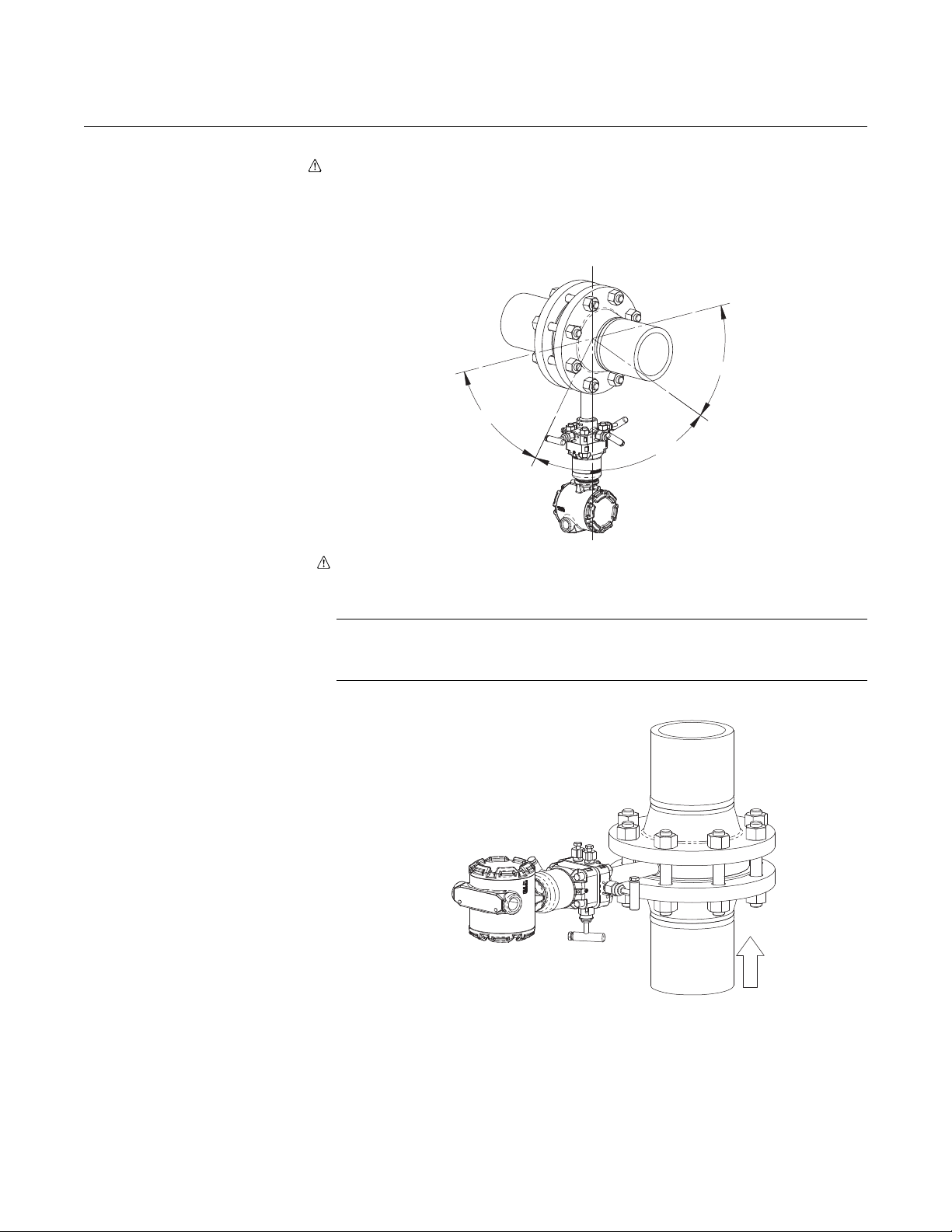

Gas in Horizontal Pipes

The 405 should be mounted above the pipe to ensure that condensate does

not collect on the transmitter sensing diaphragms. Orient the unit within the

120° recommended zone as shown in Figure 2-3.

Figure 2-3. Direct Mount Gas in

Horizontal Pipes

120°

2-4

30°

30°

Page 15

Reference Manual

FLOW

00809-0100-4810, Rev DA

September 2007

Figure 2-4. Direct Mount Liquid

or Steam in Horizontal Pipes

Rosemount Compact Orifice

Flowmeter Series

Liquid or Steam in Horizontal Pipes

The 405 should be mounted below the pipe to ensure that gases do not

collect on the transmitter sensing diaphragms. Orient the unit within the 80°

recommended zone as shown in Figure 2-4.

50°

50°

80°

Figure 2-5. Direct Mount Liquid

in Vertical Pipes

Liquid in Vertical Pipes

The 405 should be mounted with the vents on top to allow gas to be bled off.

NOTE

The 405 should not be used in vertical liquid or steam applications if the fluid

is flowing down.

2-5

Page 16

Rosemount Compact Orifice

FLOW

FLOW

Flowmeter Series

Gas in Vertical Pipes

The 405 should be mounted with vents on bottom to allow condensate

drainage.

NOTE

Due to drain vent orientation, a direct mount 405 should not be used in

vertical gas applications if the fluid is flowing up. Consider remote mounting

the pressure transmitter to facilitate condensate draining.

Figure 2-6. Direct Mount Gas in

Vertical Pipes

Reference Manual

00809-0100-4810, Rev DA

September 2007

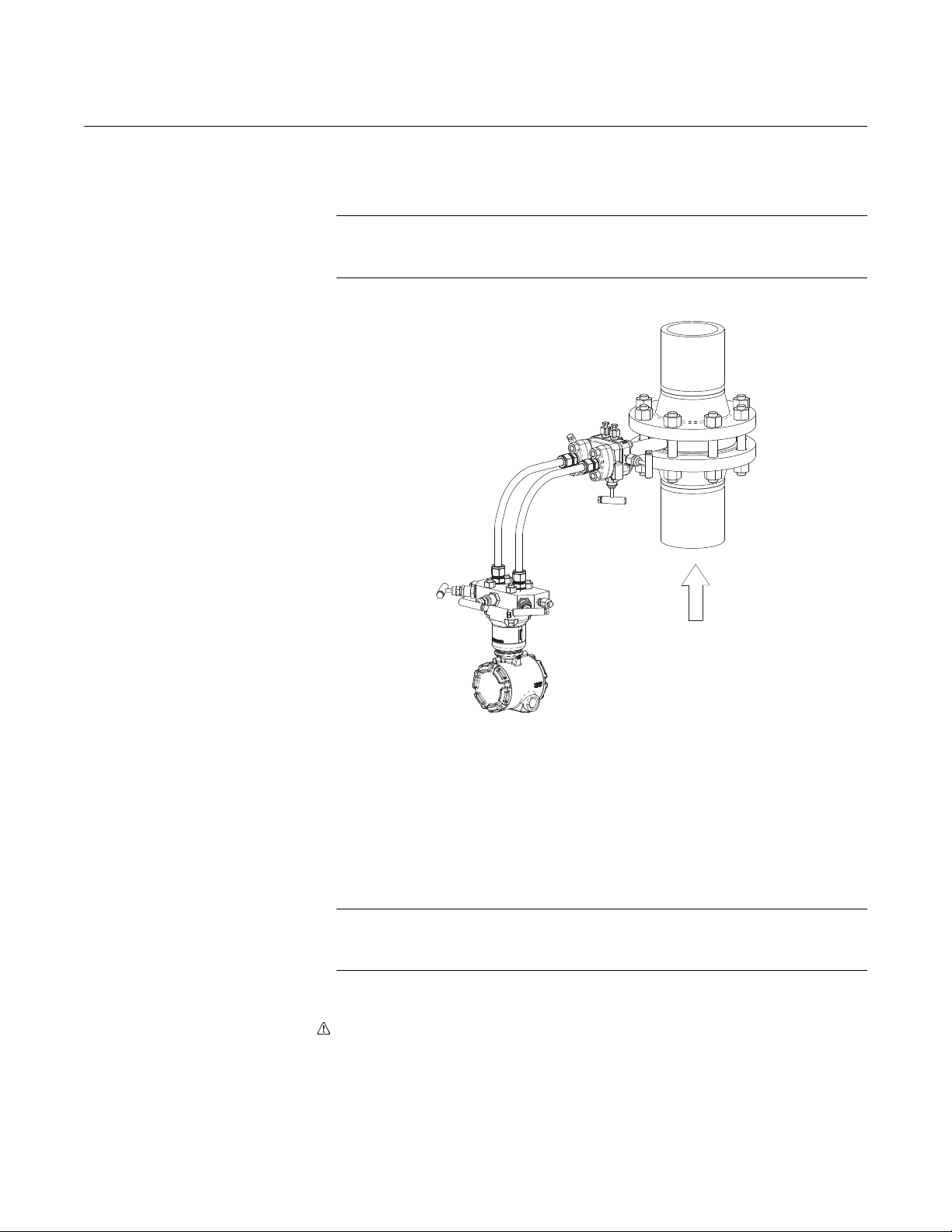

Remote Mount

Installation

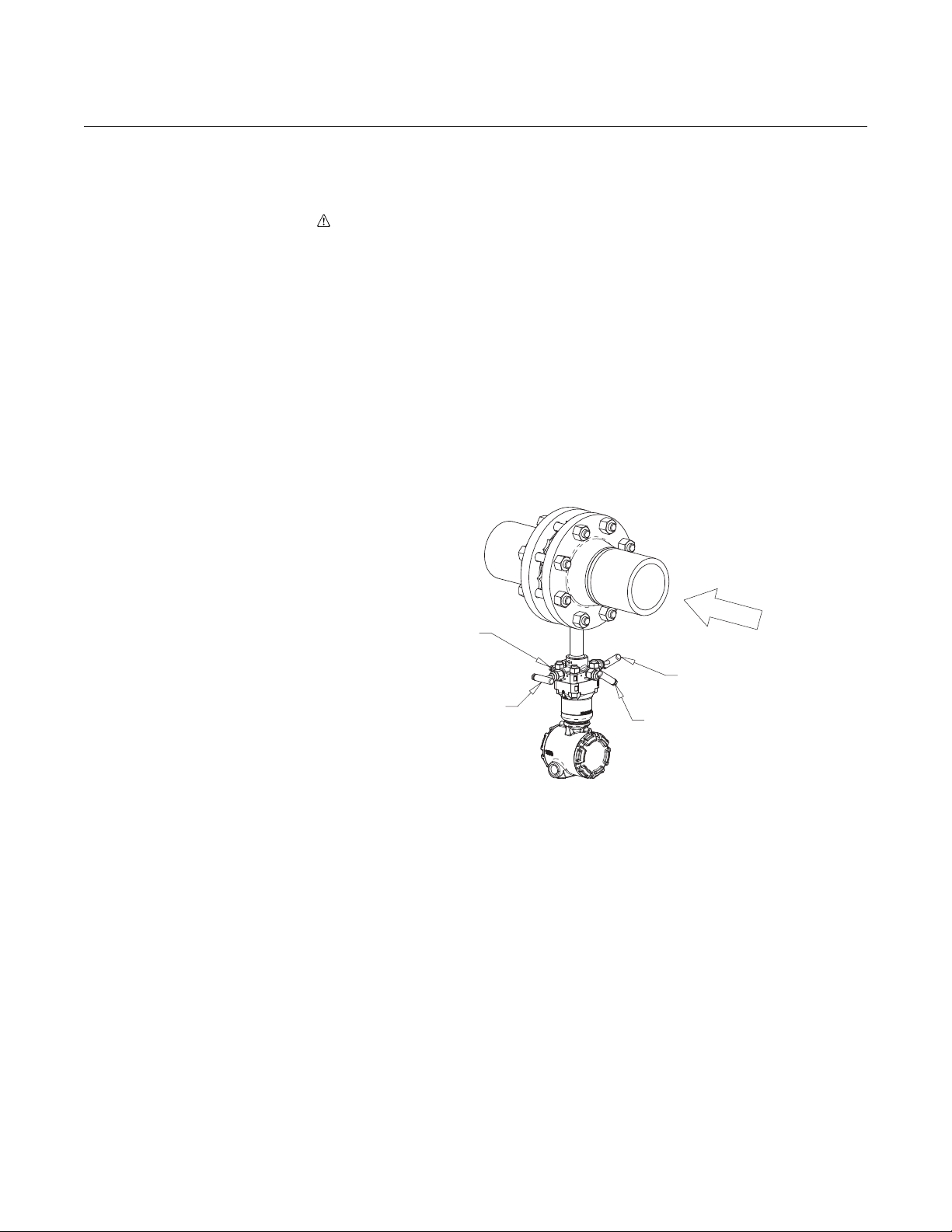

Figure 2-7. Remote Mount Gas

in Vertical or Horizontal Pipes

Gas in Vertical or Horizontal Pipes

Mount the transmitter above the 405 with the instrument lines sloping down.

2-6

Page 17

Reference Manual

00809-0100-4810, Rev DA

September 2007

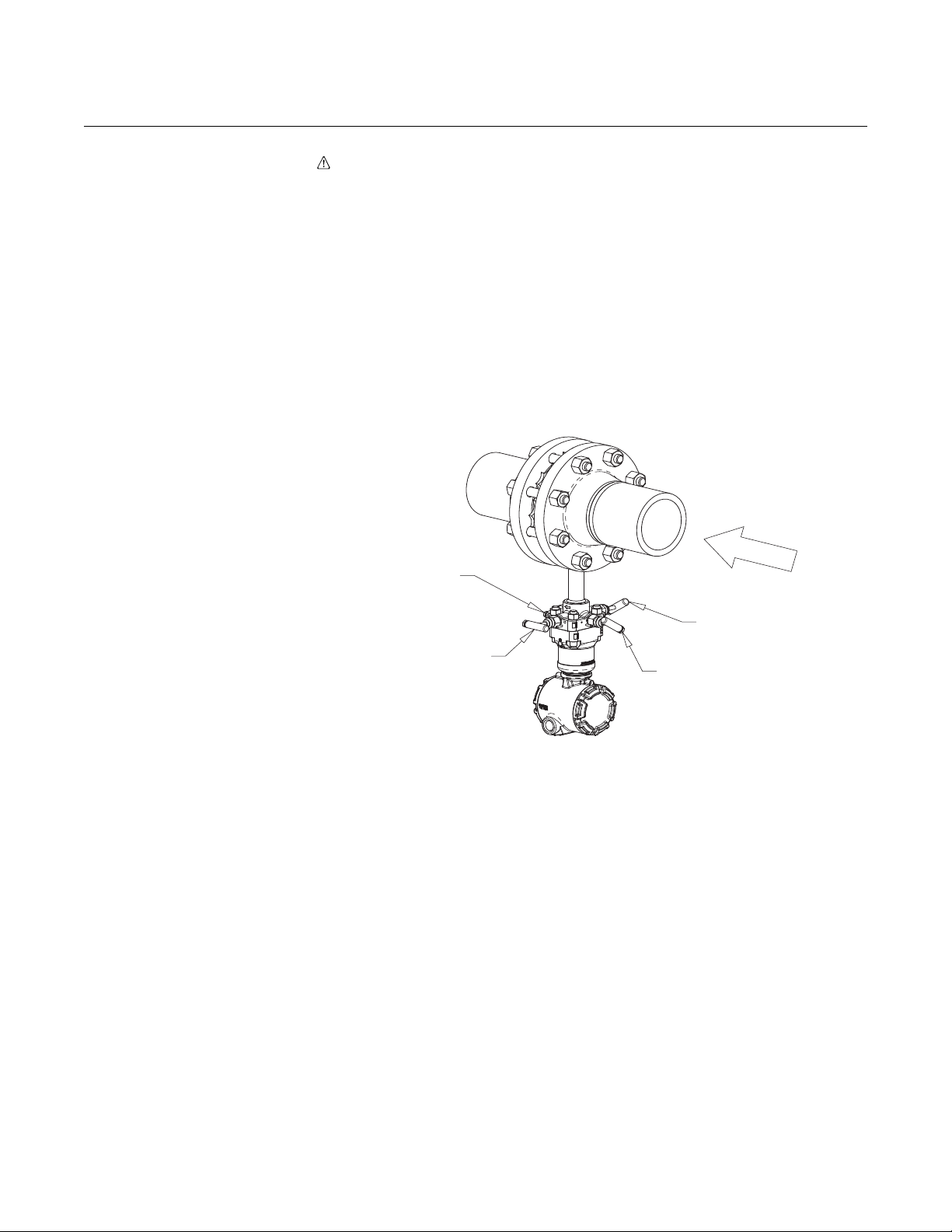

Figure 2-8. Remote Mount

Liquid in Vertical or Horizontal

Pipes

Rosemount Compact Orifice

Flowmeter Series

Liquid or Steam in Vertical or Horizontal Pipes

Mount the transmitter below the 405 with the instrument lines sloping up.

NOTE

The 405 should not be used in vertical liquid or steam applications if the fluid

is flowing down.

Process Connections

(Remote Mount Only)

FLOW

The 405 is available with either ¼-in. – 18 NPT connections (standard) or

½-in. – 14 NPT connections (option code E). The ½-in. connections can be

rotated to attain connection centers of 2-in. (51 mm), 2

¼-in. (57 mm). The threads are Class 2; use a lubricant or sealant when

making the process connections.

Ensure all four flange studs are installed and tightened prior to applying

pressure to prevent process leakage. When properly installed, the flange

studs will protrude through the top of the module housing.

NOTE

Do not attempt to loosen or remove the flange studs while the 405 is in

service.

Perform the following to install flange adapters to the head of the 405.

1. Place o-ring in the groove on bottom of the flange adapter.

2. Position flange adapters over NPT connections on the adapter plate.

3. Insert studs through 405 head, adapter plate, and flange adapters.

4. Thread nuts onto studs. Tighten nuts to 300 in-lbs. (34 N-m).

1

/8-in. (54 mm), or 2

2-7

Page 18

Rosemount Compact Orifice

A

Flowmeter Series

Reference Manual

00809-0100-4810, Rev DA

September 2007

Figure 2-9. Installing the Flange

Adapters to a 405

NUT

FLANGE

DAPTER

PLATE

STUD

NUT

ADAPTER

O-RING

When compressed, PTFE o-rings tend to cold flow, which aids in their sealing

capabilities. When removing adapter plates or adapters, visually inspect the

o-rings. Replace them if there are any signs of damage, such as nicks or cuts.

If they are undamaged, you may reuse them. If you replace the o-rings,

retorque the nuts after installation to compensate for cold flow.

High Temperature Units (Option Code T)

®

Inconel

o-rings should be replaced any time the unit is disassembled.

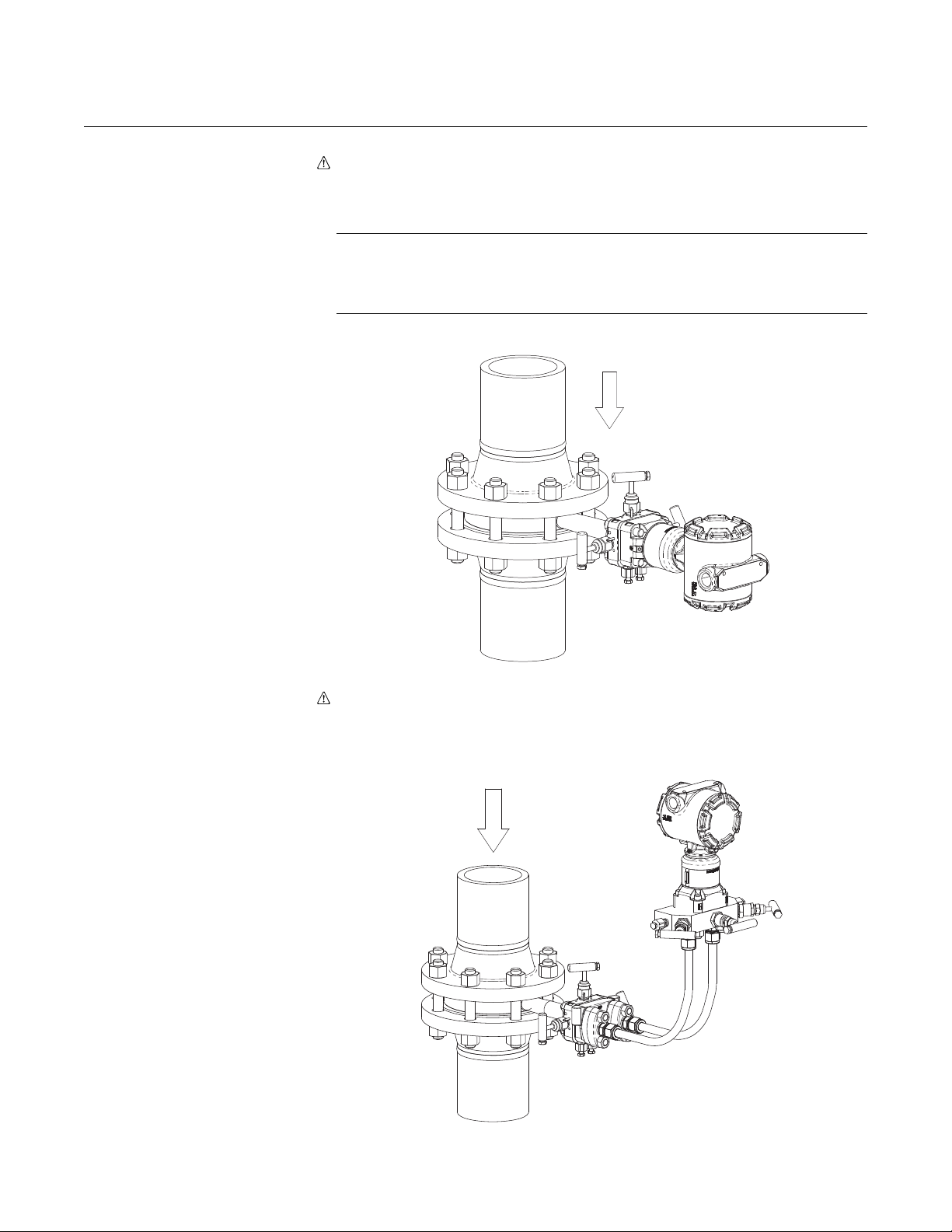

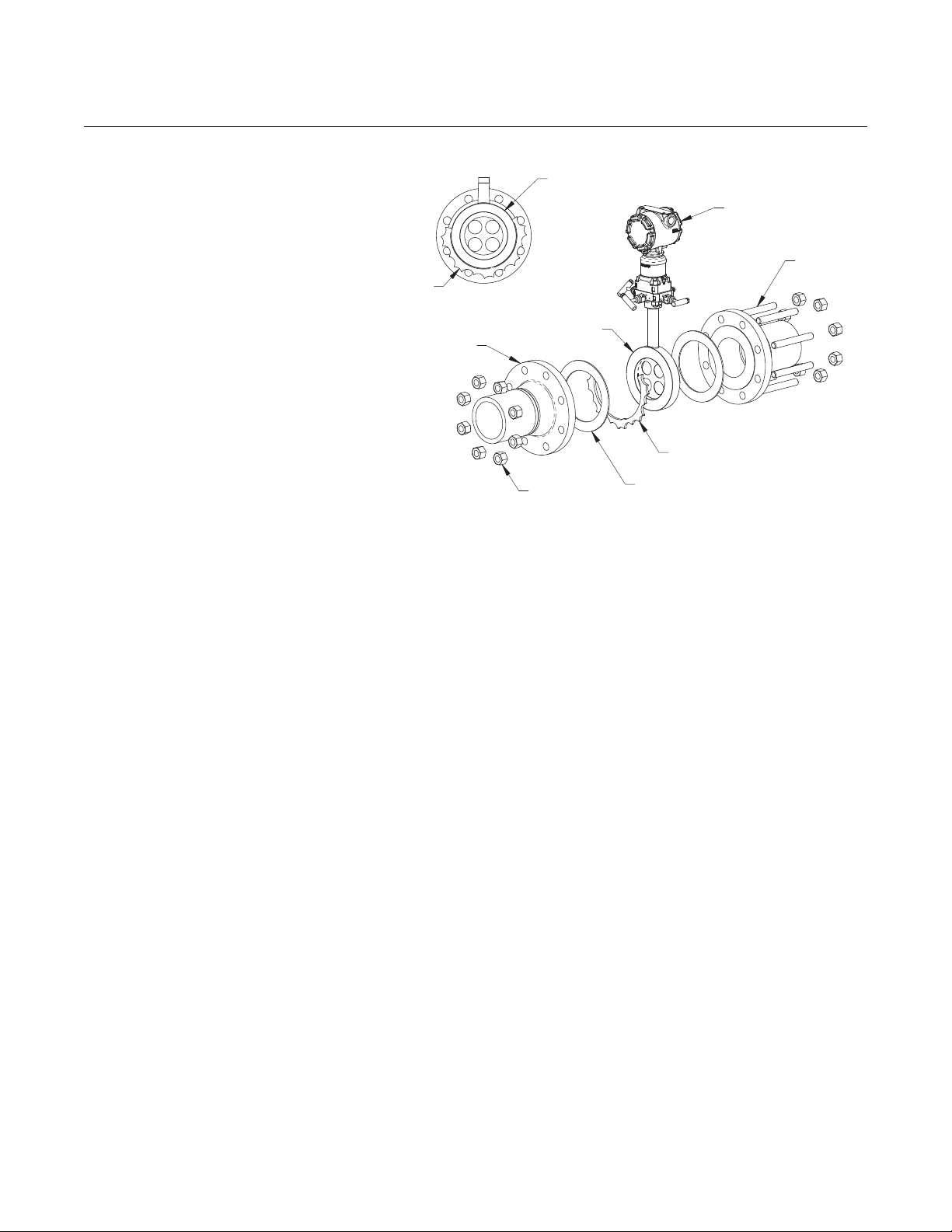

INSTALLATION Install the 405 according to the procedure below.

1. Orient the assembly according to the guidelines provided in "Location

and Orientation" beginning on page 2-4. Ensure that the flow arrow is

pointing in the same direction as the process flow.

NOTE

An ANSI alignment ring is provided standard with the 405. If a DIN or JIS

alignment ring is required, it must be ordered as an option. Contact an

Emerson Process Management sales representative for additional

information.

NOTE

For ease of installation, the gasket may be secured to the flange face with

small pieces of tape. Be sure the gasket and/or tape do not protrude into the

pipe.

2. If using an alignment ring with through holes, proceed to step 9.

3. Insert two studs through the flange holes located opposite the head of

the 405.

2-8

Page 19

Reference Manual

00809-0100-4810, Rev DA

September 2007

Rosemount Compact Orifice

Flowmeter Series

4. Place the alignment ring on the 405 body (see Figure 2-10).

5. Insert gaskets.

6. Insert the 405 between the flanges so that the indentations on the

alignment ring contact the installed studs. The studs must contact the

alignment ring in the indentation marked with the appropriate flange

rating to ensure proper alignment.

7. Install remaining studs and nuts (hand tight). Ensure that three of the

studs are in contact with the alignment ring.

8. Lubricate studs and tighten nuts in a cross pattern to the appropriate

torque per local standards.

Steps 9-12 are for use with alignment rings that have through holes.

9. Place the alignment ring on the 405 body (see Figure 2-10).

10. Insert the 405 between the flanges. Insert one stud through the

flange hole located opposite the 405 head; passing through the

alignment ring through hole and the opposite flange hole. The stud

must contact the alignment ring through the through hole marked with

the appropriate flange rating to ensure proper alignment.

11. Repeat step 10 for a second (2) stud opposite the 405 head.

12. Insert gaskets.

13. Install remaining studs and nuts (hand tight). Ensure that three of the

studs are in contact with the alignment ring.

14. Lubricate studs and tighten nuts in a cross pattern to the appropriate

torque per local standards.

NOTE

Standard

gaskets could potentially caused a bias shift in the measurement.

1

/16-in. gaskets are recommended for use with the 405. Using other

2-9

Page 20

Rosemount Compact Orifice

ALIGNMENT RING

405

(1)

ALIGNMENT RING

(2)

TRANSMITTER

(2) GASKET

ASSEMBLY

WITH FLANGE

NUT

STUD

EXISTING PIPE

405

(1)

(1) This installation drawing applies to both the 405P and 405C.

(2) Applies to both the 3051SFC (uses a 3051S transmitter) and a 3095MFC (uses a 3095M transmitter).

Flowmeter Series

Figure 2-10. 405 Installation

Reference Manual

00809-0100-4810, Rev DA

September 2007

Remote RTD Installation A remote RTD requires that the process piping be modified. Follow site

specific requirements for installation. Install the RTD thermowell in close

proximity downstream

connection cable is 12 ft long. Consult factory for longer lengths.

5

Drill a

/8-in. (16 mm) to 3/4-in. (19 mm) hole at the RTD location and weld on a

customer supplied 1-in. (25mm) tall

thermowell threads into the weld coupling. The thermowell material is 316

1

SST with

/2–14 ANPT threads. When installed It will be inserted 11/2-in. (38

mm) into the pipe internal diameter.

For remote RTD applications with pipe diameters less than 2 inches (50mm)

consult factory.

(1)

of the primary element. The standard supplied RTD

1

/2 inch -14 NPT weld coupling. The RTD

2-10

(1) For the 405P, at least six pipe diameters downstream of the primary element. For the 405C,

two pipe diameters downstream of the primary element.

Page 21

Reference Manual

00809-0100-4810, Rev DA

September 2007

Rosemount Compact Orifice

Flowmeter Series

Section 3 Commissioning

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-1

Direct Mount Applications . . . . . . . . . . . . . . . . . . . . . . . . . page 3-2

Remote Mount Applications . . . . . . . . . . . . . . . . . . . . . . . page 3-5

SAFETY MESSAGES Instructions and procedures in this section may require special precautions to

ensure the safety of the personnel performing the operations. Please refer to

the following safety messages before performing any operation in this section.

Explosions could result in death or serious injury:

• Do not remove the transmitter cover in explosive atmospheres when the circuit is

live.

• Before connecting a HART Communicator in an explosive atmosphere, make sure

the instruments in the loop are installed in accordance with intrinsically safe or

non-incendive field wiring practices.

• Verify that the operating atmosphere of the transmitter is consistent with the

appropriate hazardous locations certifications.

• Both transmitter covers must be fully engaged to meet explosion-proof

requirements.

Failure to follow these installation guidelines could result in death or serious injury:

• Make sure only qualified personnel perform the installation.

• If the line is pressurized, serious injury or death could occur by opening valves.

3-1

Page 22

Rosemount Compact Orifice

LOW VALVE

HIGH VALVE

EQUALIZER

VALVE

(2) VENT

FLOW

Flowmeter Series

DIRECT MOUNT

APPLICATIONS

Liquid Service 1. Pressurize line.

2. Open the equalizer valve.

3. Open the high and low side valves.

4. Bleed drain/vent valves until no gas is apparent in the liquid.

5. Close the vent/drain valves.

6. Close the low side valve.

7. Check the transmitter zero according to the transmitter product

manual so that the output on the test meter reads zero percent of

span.

8. Close the equalizer valve.

9. Open the low side valve. The system is now operational.

Figure 3-1. Direct Mount Liquid

Service

Reference Manual

00809-0100-4810, Rev DA

September 2007

3-2

Page 23

Reference Manual

LOW VALVE

HIGH VALVE

VALVE

EQUALIZER

(2) VENT

FLOW

00809-0100-4810, Rev DA

September 2007

Gas Service 1. Pressurize line.

2. Open the equalizer valve.

3. Open the high and low side valves.

4. Open drain/vent valves to ensure no liquid is present.

5. Close the vent/drain valves.

6. Close the low side valve.

7. Check the transmitter zero according to the transmitter product

manual so that the output on the test meter reads zero percent of

span.

8. Close the equalizer valve.

9. Open the low side valve. The system is now operational.

Figure 3-2. Direct Mount Gas

Service

Rosemount Compact Orifice

Flowmeter Series

3-3

Page 24

Rosemount Compact Orifice

LOW VALVE

HIGH VALVE

EQUALIZER

VALVE

(2) VENT

FLOW

Flowmeter Series

Steam Service 1. Remove pressure from line.

2. Open equalizer, high, and low side valves.

3. Zero electronics.

4. Fill manifold and transmitter with water via drain vents.

5. Close low side valve.

6. Pressurize line.

7. Gently tap electronics body, manifold head, and 405 body with a

small wrench to dislodge any entrapped air.

8. Zero electronics.

9. The system is now operational.

Figure 3-3. Direct Mount

Steam Service

Reference Manual

00809-0100-4810, Rev DA

September 2007

3-4

Page 25

Reference Manual

MANIFOLD

VENT

MANIFOLD

LOW

VALVE

TRANSMITTER

MANIFOLD

TRANSMITTER

405 HIGH VALVE

405 EQUALIZER VALVE

405 LOW VALVE

VENTS

MANIFOLD

HIGH

VALVE

MANIFOLD

EQUALIZER

VALVE

FLOW

Rosemount Compact Orifice

00809-0100-4810, Rev DA

September 2007

REMOTE MOUNT

APPLICATIONS

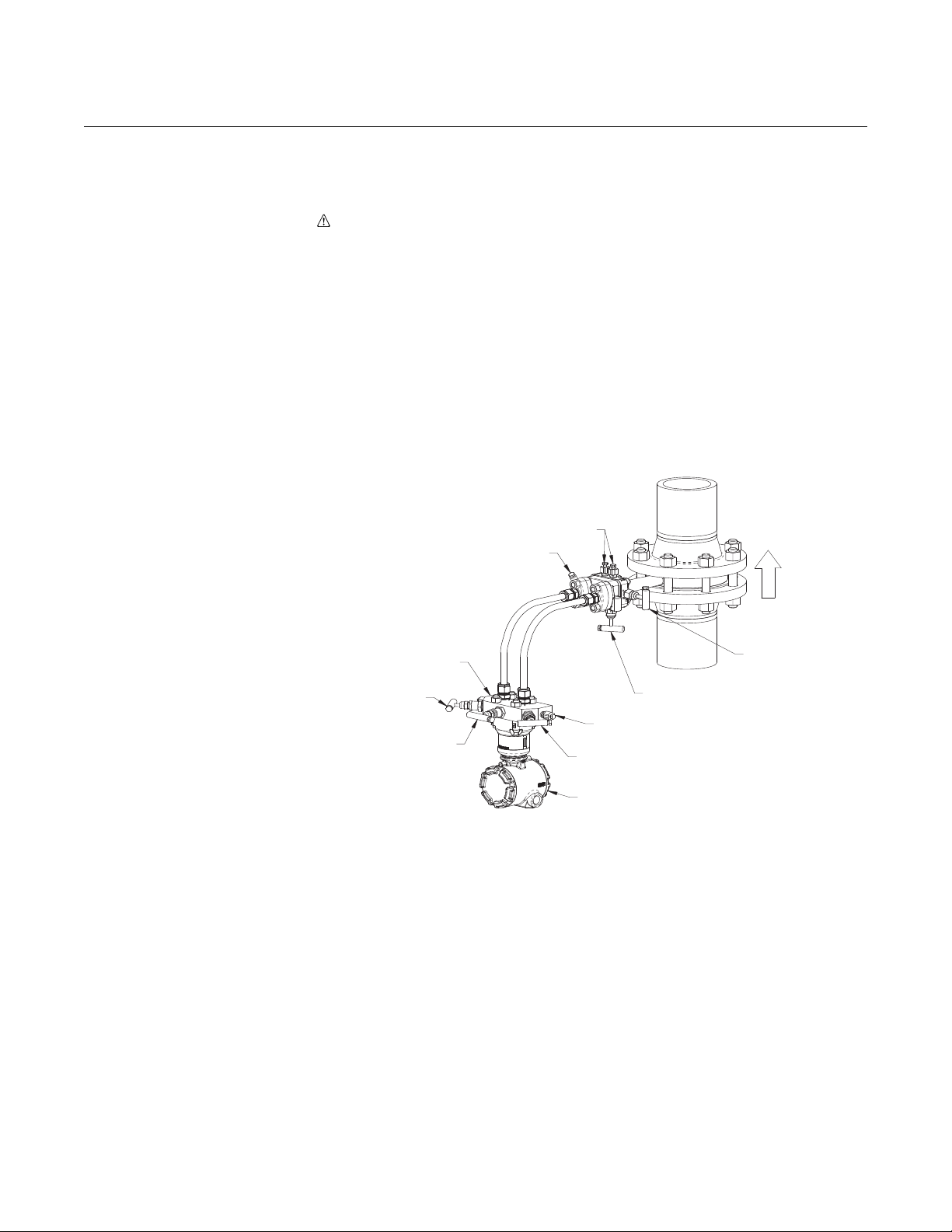

Liquid Service 1. Zero electronics and pressurize line.

2. Open equalizer valves on transmitter manifold and 405.

3. Open high and low side transmitter manifold valves and 405 valves.

4. Bleed drain vent valves on transmitter manifold until no air is present.

5. Close drain vent valves.

6. Close equalizer valve on 405.

7. Check transmitter zero. If transmitter does not read zero repeat steps

1-7.

8. Close equalizer valve on transmitter manifold.

Figure 3-4. Remote Liquid

Service

Flowmeter Series

3-5

Page 26

Rosemount Compact Orifice

R

Flowmeter Series

Gas Service 1. Zero electronics and pressurize line.

2. Open equalizer valves on transmitter manifold and 405.

3. Open high and low side transmitter manifold valves and 405 valves.

4. Open drain/vent valves on transmitter manifold to ensure no liquids

are present.

5. Close drain/vent valves.

6. Close low side transmitter manifold valve.

7. Close 405 equalizer valve.

8. Check transmitter zero. If transmitter does not read zero repeat steps

1-7.

9. Close equalizer on transmitter manifold.

10. Open low side valve on transmitter manifold. The system is now

operational.

Figure 3-5. Remote Gas Service

MANIFOLD

VENT

405 LOW VALVE

405 EQUALIZER VALVE

Reference Manual

00809-0100-4810, Rev DA

September 2007

TRANSMITTER

TRANSMITTE

MANIFOLD

MANIFOLD

LOW

VALVE

FLOW

405 HIGH VALVE

VENTS

MANIFOLD

EQUALIZER

VALVE

MANIFOLD

HIGH

VALVE

3-6

Page 27

Reference Manual

MANIFOLD

VENT

MANIFOLD

LOW

VALVE

TRANSMITTER

MANIFOLD

TRANSMITTER

405 HIGH VALVE

405 EQUALIZER VALVE

405 LOW VALVE

VENTS

MANIFOLD

HIGH

VALVE

MANIFOLD

EQUALIZER

VALVE

FLOW

Rosemount Compact Orifice

00809-0100-4810, Rev DA

September 2007

Steam Service 1. Remove pressure from line.

2. Open equalizer valves, high side valves, and low side valves on both

the 405 and transmitter manifold.

3. Zero electronics.

4. Fill transmitter manifold, instrument lines, and 405 with water via

drain vents on transmitter manifold.

5. Close 405 equalizer valve and transmitter manifold vents.

6. Close low side transmitter manifold valve.

7. Pressurize line.

8. Gently tap electronics body, transmitter manifold, instrument lines,

and 405 with a small wrench to dislodge any trapped air.

9. Check transmitter zero. If transmitter does not read zero repeat steps

4-8.

10. Close the transmitter equalizer and open low side valve on

transmitter manifold. The system is now operational.

Flowmeter Series

Figure 3-6. Remote Steam

Service

3-7

Page 28

Rosemount Compact Orifice

Flowmeter Series

Reference Manual

00809-0100-4810, Rev DA

September 2007

3-8

Page 29

Reference Manual

00809-0100-4810, Rev DA

September 2007

Rosemount Compact Orifice

Flowmeter Series

Section 4 Operation and Maintenance

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4-1

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4-1

RTD Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4-3

SAFETY MESSAGES Procedures and instructions in this section may require special precautions to

ensure the safety of the personnel performing the operations. Information that

raises potential safety issues is indicated by a warning symbol ( ). Refer to

the following safety messages before performing an operation preceded by

this symbol.

Explosions can result in death or serious injury.

• Do not remove the instrument cover in explosive environments when the circuit is

live.

• Both transmitter covers must be fully engaged to meet

explosion-proof requirements.

• Before connecting a communicator in an explosive atmosphere, make sure the

instruments in the loop are installed in accordance with intrinsically safe or

nonincendive field wiring practices.

Electrical shock can result in death or serious injury.

• Avoid contact with the leads and the terminals.

TROUBLESHOOTING If a malfunction is suspected despite the absence of a diagnostic messages

on the communicator display, follow the procedures described below to verify

that the flowmeter hardware and process connections are in good working

order. Always approach the most likely and easiest-to-check conditions first.

4-1

Page 30

Rosemount Compact Orifice

Reference Manual

00809-0100-4810, Rev DA

Flowmeter Series

Symptom Possible Cause Corrective Action

Questionable accuracy or

erroneous flow signal

Spiking flow signal Two-phase flow The flowmeter is a head measurement device and will not accurately

Spiking flow signal (Stream

Service)

Milliamp reading is zero

Electronics not in

communication

Milliamp reading is low or

high

No response to changes in

applied flow

Low reading/high reading

Erratic reading for pressure

variable

Improper installation

System leaks Check for leaks in instrument piping. Repair and seal all leaks.

Contamination/plugging Remove the flowmeter and check for contamination.

Closed valve Verify that both 3095MFC (PH & PL) or (MH & ML) valves are open.

Calibration Is the calibration too high or low for the flow rate?

Connections (remote mount only) Verify that the high side of the electronics is connected to the high

Entrapped air (liquid applications) Are there uneven water legs caused by air entrapment in the

3095MFC misalignment Misalignment of the flowmeter beyond 3 degrees will cause an

Operating conditions Are the operating conditions in compliance with those given at the

Improper insulation (Vertical pipes

only)

Excessive vibration

• Is the flow arrow pointed in the direction of the flow?

• Verify that the cross reservoirs are perfectly level with one another.

• Is there sufficient straight run upstream and downstream of the

flowmeter?

Verify that vent, equalizer, and line valves are properly positioned per

the “start up procedure.”

side of the flowmeter. Check the same for the low side.

instrument connections? If so, bleed air.

erroneous signal.

time the flowmeter was purchased? Check the flow calculation and

the fluid parameters for accuracy. Double-check pipe inside diameter

for proper sizing.

measure a two-phase flow.

Added insulation may be required to ensure that a phase change

occurs at the cross reservoirs.

Check the impulse piping for vibration.

• Check if power polarity is reversed

• Verify voltage across terminals (should be 10–55V dc)

• Check for bad diode in terminal block

• Replace electronics terminal block

• Check power supply voltage at electronics (10.5V minimum)

• Check load resistance (250 ohms minimum)

• Check if unit is addressed properly

• Replace electronics board

• Check pressure variable reading for saturation

• Check if output is in alarm condition

• Perform 4–20 mA output trim

• Replace electronics board

• Check test equipment

• Check impulse piping for blockage

• Check for disabled span adjustment

• Check electronics security switch

• Verify calibration settings (4 and 20 mA points)

• Contact factory for replacement

• Check impulse piping for blockage

• Check test equipment

• Perform full sensor trim (if software revision is 35 or higher)

• Contact factory for replacement

• Check impulse piping for blockage

• Check damping

• Check for EMF interference

• Contact factory for replacement

September 2007

4-2

Page 31

Reference Manual

00809-0100-4810, Rev DA

September 2007

Rosemount Compact Orifice

Flowmeter Series

Check Flow Direction

Check that the flow arrow on the neck of the 405 points in the direction of flow.

If the DP transmitter is remote mounted from the 405, be sure that the impulse

tubing is connected correctly from the 405 to the DP transmitter (high to high

and low to low).

Check Orientation

Improper orientation can result in inaccurate measurements.

Check Zero

The transmitter may read off in the high or low direction if not zeroed properly

at start-up/commissioning. Refer to the appropriate transmitter reference

manual for additional information.

Check Valves

The correct valve setting for flow measurement are; equalizer valve fully

closed, high and low side valves fully open.

Check Configuration/Scaling

Is the 20mA DP URL of the 405 set properly? This may involve sizing the 405

in the Toolkit Software program to confirm.

Confirm the DCS or PLC and transmitter on 405 are scaled consistently.

Is the square root being taken in the DCS or transmitter attached to the 405?

The square root should not be taken in both places.

Check 3095M Configuration

If a Rosemount 3095M transmitter is being used, its enhanced functionality

should be taken into account during configuration and troubleshooting. The

square root should not be taken in the DCS if a 3095M transmitter is being

used.

See the Rosemount 3095M reference manual (document number

00809-0100-4716) for additional information.

RTD MAINTENANCE This section covers RTD maintenance procedures.

Remote Mount

If an RTD needs to be replaced on a remote mount, proceed as follows:

4-3

Page 32

Rosemount Compact Orifice

Rubber Bushing

(Slide stop to edge of armored cable)

3

/4 to 1/2–in. NPT Adapter

(Screws into RTD Connection Head)

Compression Fitting

Connect to

transmitter

Compression

Fitting

Cap

Brushing

Washer

Cap

Flowmeter Series

1. Close instrument valves to ensure that the pressure is disconnected

from the transmitter.

2. Open the bleed valves on the transmitter to remove all pressure.

3. Remove the cap.

4. Remove the RTD wiring only from the terminal.

5. Remove the Terminal Housing from the head.

6. Pull the RTD wire out of the nipple and remove the RTD. The RTD is in

a thermowell, so no live line pressure will be present.

7. Install the new RTD and thread the wires through the nipple.

8. Using the appropriate thread lubricant or tape, install the terminal

housing onto the remote head.

9. Reconnect the RTD wires to the terminal. This diagram is for a typical

RTD transmitter wiring connection.

10.Open the instrument valves.

Reference Manual

00809-0100-4810, Rev DA

September 2007

4-4

Page 33

Reference Manual

Rosemount Compact Orifice

00809-0100-4810, Rev DA

September 2007

Flowmeter Series

Appendix A Reference Data

Rosemount 3051SFC Compact Orifice Flowmeter . . . . . page A-1

Rosemount 3095MFC Compact Orifice Mass Flowmeter page A-16

Rosemount 405 Compact Orifice Primary Element . . . . . page A-28

Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page A-37

Rosemount 3051SFC Compact Orifice Flowmeter

SPECIFICATIONS

Performance System Reference Accuracy

Percent (%) of volumetric flow rate

Table A-1. 3051SFC Compact Orifice Flowmeter

Classic

(8:1 flow

Typ e Beta

3051SFCC 0.4

3051SFCP

3051SFCP

3051SFCP

(1) Line sizes 1/2-in. (15mm)

(2) For 0.65 beta and ReD< 10,000 add an additional 0.5% to the

Discharge Coefficient Uncertainty.

0.65

(1)

0.4

0.65

(1)

0.4

0.65

(1)

0.4

0.65

turndown)

±1.05%

±1.35%

±2.45% ±2.35% ±2.30%

(2)

±2.00% ±1.90% ±1.85%

(2)

±1.55% ±1.45% ±1.40%

(2)

Ultra

(8:1 flow

turndown)

±0.85%

±1.20%

Ultra for

Flow

(14:1 flow

turndown)

±0.80%

±1.15%

Repeatability

±0.1%

Line Sizes

•1/2-in. (15 mm) – not available for the 3051SFCC

• 1-in. (25 mm) – not available or the 3051SFCC

1

/2-in. (40 mm) – not available for the 3051SFCC

•1

• 2-in. (50 mm)

• 3-in. (80 mm)

• 4-in. (100 mm)

• 6-in. (150 mm)

• 8-in. (200 mm)

Performance Statement Assumptions

• Measured pipe I.D

Sizing

Contact an Emerson Process Management representative for assistance. A Configuration Data

Sheet is required prior to order for application verification.

A-1

Page 34

Rosemount Compact Orifice

Voltage (V dc)

Load (Ohms)

Operating

Region

1387

1000

500

0

10.5 20 30

42.4

Voltage (V dc)

Load (Ohms)

Operating

Region

1322

1000

500

0

12.0 20 30

42.4

Flowmeter Series

Functional Service

•Liquid

•Gas

•Steam

4–20 mA/HART

Zero and Span Adjustment

Zero and span values can be set anywhere within the range.

Span must be greater than or equal to the minimum span.

Output

Two-wire 4–20 mA is user-selectable for linear or square root output. Digital process variable

superimposed on 4–20 mA signal, available to any host that conforms to the HART protocol.

Power Supply

External power supply required.

Standard transmitter (4–20 mA): 10.5 to 42.4 V dc with no load

3051S SIS Safety transmitter: 12 to 42 Vdc with no load

3051S HART Diagnostics transmitter: 12 to 42 Vdc with no load

Load Limitations

Maximum loop resistance is determined by the voltage level of the external power supply, as

described by:

Reference Manual

00809-0100-4810, Rev DA

September 2007

Standard Transmitter

Maximum Loop Resistance = 43.5 * (Power Supply Voltage – 10.5)

The HART communicator requires a minimum

loop resistance of 250Ω for communication.

3051S SIS Safety Transmitter (output code B)

3051S HART Diagnostics Transmitter (option code DA1)

Maximum Loop Resistance = 43.5 * (Power Supply Voltage – 12.0)

A-2

The HART communicator requires a minimum

loop resistance of 250Ω for communication.

HART Diagnostics Suite (Option Code DA1)

The 3051S HART Diagnostics Transmitter provides Abnormal Situation Prevention (ASP)

indication, device operating hours, variable logging, and enhanced EDDL graphic displays for

easy visual analysis.

Page 35

Reference Manual

00809-0100-4810, Rev DA

September 2007

Rosemount Compact Orifice

Flowmeter Series

The integral statistical process monitoring (SPM) technology calculates the mean and

standard deviation of the process variable 22 times per second and makes them available to

the user. The 3051S ASP algorithm uses these values and highly flexible configuration

options for customization to detect many user-defined or application specific abnormal

situations (e.g. plugged impulse line detection).

The device operating hours are logged along with the occurrence of diagnostic events to

enable quick troubleshooting of application and installation issues.

FOUNDATION fieldbus

Power Supply

External power supply required; transmitters operate on 9.0 to 32.0 V dc transmitter terminal

voltage.

Current Draw

17.5 mA for all configurations (including LCD display option)

F

OUNDATION fieldbus Parameters

Schedule Entries 14 (max.)

Links 30 (max.)

Virtual Communications Relationships (VCR) 20 (max.)

Standard Function Blocks

Resource Block

• Contains hardware, electronics, and diagnostic information.

Transducer Block

• Contains actual sensor measurement data including the sensor diagnostics and the ability

to trim the pressure sensor or recall factory defaults.

LCD Block

• Configures the local display.

2 Analog Input Blocks

• Processes the measurements for input into other function blocks. The output value is in

engineering or custom units and contains a status indicating measurement quality.

PID Block with Auto-tune

• Contains all logic to perform PID control in the field including cascade and feedforward.

Auto-tune capability allows for superior tuning for optimized control performance.

Backup Link Active Scheduler (LAS)

The transmitter can function as a Link Active Scheduler if the current link master device fails

or is removed from the segment.

Software Upgrade in the Field

Software for the 3051S with F

OUNDATION fieldbus Common Device Software Download procedure.

F

PlantWeb Alerts

Enable the full power of the PlantWeb digital architecture by diagnosing instrumentation

issues, communicating advisory, maintenance, and failure details, and recommending a

solution.

Advanced Control Function Block Suite

(Option Code A01)

Input Selector Block

• Selects between inputs and generates an output using specific selection strategies such as

minimum, maximum, midpoint, average, or first “good.”

Arithmetic Block

• Provides pre-defined application-based equations including flow with partial density

compensation, electronic remote seals, hydrostatic tank gauging, ratio control and others.

Signal Characterizer Block

• Characterizes or approximates any function that defines an input/output relationship by

configuring up to twenty X, Y coordinates. The block interpolates an output value for a

given input value using the curve defined by the configured coordinates.

OUNDATION fieldbus is easy to upgrade in the field using the

A-3

Page 36

Rosemount Compact Orifice

Flowmeter Series

Integrator Bock

• Compares the integrated or accumulated value from one or two variables to pre-trip and

trip limits and generates discrete output signals when the limits are reached. This block is

useful for calculating total flow, total mass, or volume over time.

Output Splitter Block

• Splits the output of one PID or other control block so that the PID will control two valves or

other actuators.

Control Selector Block

• Selects one of up to three inputs (highest, middle, or lowest) that are normally connected to

the outputs of PID or other control function blocks.

Block Execution Time

Resource Transducer LCD Block Analog Input 1, 2 20 milliseconds

PID with Auto-tune 25 milliseconds

Input Selector 20 milliseconds

Arithmetic 20 milliseconds

Signal Characterizer 20 milliseconds

Integrator 20 milliseconds

Output Splitter 20 milliseconds

Control Selector 20 milliseconds

Fully Compensated Mass Flow Block (Option Code H01)

Calculates fully compensated mass flow based on differential pressure with external process

pressure and temperature measurements over the fieldbus segment. Configuration for the

mass flow calculation is easily accomplished using the Rosemount 3095 Engineering

Assistant.

OUNDATION fieldbus Diagnostics Suite (Option Code D01)

F

3051S F

indication and enhanced EDDL graphic displays for easy visual analysis.

The integral statistical process monitoring (SPM) technology calculates the mean and

standard deviation of the process variable 22 times per second and makes them available to

the user. The 3051S ASP algorithm uses these values and highly flexible configuration

options for customization to detect many user-defined or application specific abnormal

situations (e.g. plugged impulse line detection).

OUNDATION fieldbus Diagnostics provide Abnormal Situation Prevention (ASP)

Reference Manual

00809-0100-4810, Rev DA

September 2007

A-4

Process Temperature Limits

Direct Mount Electronics

• 450 °F (232 °C)

Remote Mount Electronics

• 850 °F (454 °C) – Stainless Steel

Electronics Temperature Limits

Ambient

• –40 to 185 °F (–40 to 85 °C)

• With Integral Mount LCD Display

• With Option Code P0: –4 to 185 °F (–20 to 85 °C)

Storage

• –50 to 230 °F (–46 to 110 °C)

• With Integral Mount LCD Display: –40 to 185 °F (–40 to 85 °C)

• With Wireless Output (Code X): –40 to 185 °F (–40 to 85 °C)

(1) LCD display may not be readable and LCD updates will be slower at temperatures below -4

°F (-20 °C).

(1)

: –40 to 175 °F (–40 to 80 °C)

Page 37

Reference Manual

00809-0100-4810, Rev DA

September 2007

Rosemount Compact Orifice

Flowmeter Series

Differential Pressure Limits

Maximum differential pressure (DP) up to 800 inH2O.

Pressure Limits

Direct Mount Electronics

• Pressure retention per ANSI B16.5 600# or DIN PN

(1)

Static Pressure Limits

• Range 1A: Operates within specification between static line pressures of 0.5 psia to 2000

psig (0.03 to 138 bar)

• Ranges 2A– 3A: Operates within specifications between static line pressures of 0.5 psia and

3626 psig (0.03 bar-A to 250 bar-G)

Vibration Limits

Qualified per IEC61298-3 (1998) for field with high vibration level or pipeline with high vibration

level (10-60Hz 0.21mm displacement peak amplitude / 60 - 500Hz 3g).

The weight and length of the transmitter assembly shall not exceed 5.8 lbs and 7.75-in.

Burst Pressure Limits

Coplanar or traditional process flange

• 10000 psig (689,5 bar).

Overpressure Limits

Flowmeters withstand the following limits without damage:

• Range 1A: 2000 psig (138 bar)

• Ranges 2A–3A: 3626 psig (250 bar)

Table A-2. Overpressure Limits

Standard Type

ANSI/ASME Class 150 285 (20) 275 (19)

ANSI/ASME Class 300 740 (51) 720 (50)

ANSI/ASME Class 600 1480 (102) 1440 (99)

At 100 °F (38 °C), the rating decreases with increasing temperature.

DIN PN 10/40 580 (40) 580 (40)

DIN PN 10/16 232 (16) 232 (16)

DIN PN 25/40 580 (40) 580 (40)

At 248 °F (120 °C), the rating decreases with increasing temperature.

(1) Carbon Steel and Stainless Steel Ratings are measured in

psig (bar).

(1)

Carbon Steel

Rating

Stainless

Steel Rating

Humidity Limits

• 0–100% relative humidity

Turn-On Ti m e

Performance within specifications less than 2 seconds (typical) after power is applied to the

transmitter

Damping

Analog output response to a step input change is user-selectable from 0 to 60 seconds for one

time constant. This software damping is in addition to sensor module response time

Failure Mode Alarm

HART 4-20mA (output option codes A and B)

If self-diagnostics detect a gross transmitter failure, the analog signal will be driven offscale to

alert the user. Rosemount standard (default), NAMUR, and custom alarm levels are available

(see Table A-3).

High or low alarm signal is software-selectable or hardware-selectable via the optional switch

(option D1).

(1) Static pressure selection may effect pressure limitations.

A-5

Page 38

Rosemount Compact Orifice

T

c

T

d

Td = Dead Time

T

c

= Time Constant

Pressure Released

Response Time = Td+T

c

63.2% of Total

Step Change

Time

0%

100%

36.8%

Transmitter Output vs. Time

Flowmeter Series

Table A-3. Alarm Configuration

Default ≥ 21.75 mA ≤ 3.75 mA

NAMUR compliant

Custom levels

(1) Analog output levels are compliant with NAMUR recommendation NE 43, see option codes C4

or C5.

(2) Low alarm must be 0.1 mA less than low saturation and high alarm must be 0.1 mA greater than

high saturation.

(3) Not available with the 3051S SIS Safety Transmitter.

(2) (3)

Reference Manual

00809-0100-4810, Rev DA

September 2007

High Alarm Low Alarm

(1)

≥ 22.5 mA ≤ 3.6 mA

20.2 - 23.0 mA 3.6 - 3.8 mA

Dynamic Performance

Total Response Time (Td + Tc)

Process Variable Response Time

Dead Time (Td)

Update Rate

3051S_C, Ranges 2A - 3A:

3051S SIS, Ranges 2A - 3A:

(4)

(3)

Range 1A:

Range 1A:

3051S

3051S SIS

3051S SIS Safety Transmitter Failure Values

Safety accuracy: 2.0%

(1)

Safety response time: 1.5 seconds

(1) A 2% variation of the transmitter mA output is allowed before

a safety trip. Trip values in the DCS or safety logic solver

should be derated by 2%.

4 - 20 mA (HART®)

(1)

Fieldbus protocol

(2)

:

100 milliseconds

255 milliseconds

220 milliseconds

375 milliseconds

152 milliseconds

307 milliseconds

Not Applicable

Not Applicable

45 milliseconds (nominal) 97 milliseconds

22 times per second

11 times per second

22 times per second

Not Applicable

Typical Transmitter Response Time

A-6

(1) Dead time and update rate apply to all models and ranges; analog output only

(2) Transmitter fieldbus output only, segment macro-cycle not included.

(3) Nominal total response time at 75 °F (24 °C) reference conditions. For option code DA1, add 40 milliseconds (nominal) to 4-20 mA (HART®) total

response time values.

(4) For option code DA1, dead time (Td) is 85 milliseconds (nominal).

Page 39

Reference Manual

Rosemount Compact Orifice

00809-0100-4810, Rev DA

September 2007

Physical Temperature Measurement

Remote RTD

• 100 Ohm platinum with

housing)

Model 0078D21N00A025T32Ex

Connection Head: 00644-4410-0011

• Standard RTD cable is shielded armored cable, length is 12 feet (3.66 m)

Thermowell with Remote RTD

1

/2-in. x 1/2-in. NPT, 316 SST

•

NOTE

Remote temperature measurement is not available for

Electronic Connections for Remote Mount

1

/2–14 NPT, G1/2, and M20 × 1.5 (CM20) conduit. HART interface connections fixed to terminal

block for output code A

Material of Construction

Body/Plate

• 316 SST

• 50 micro-inch Ra surface finish

Manifold Head/Valves

• 316 SST

Flange Studs and Nuts

• Customer supplied

• Available as a spare part

Transmitter Connection Studs and Nuts

• Studs– A193 Grade B8M.

• Nuts– A194 Grade 8M.

Gasket and O-rings

• Gaskets are customer supplied.

• Durlon 8500 fiber gaskets are recommended. Consult an Emerson Process Management

representative for use with other gaskets.

• Available as a spare part

NOTE

Gaskets and O-rings must be replaced when the 405 is disassembled.

1

/2-in. NPT nipple and union (078 series with Rosemount 644

Flowmeter Series

1

/2-in., 1-in., and 11/2-in. sizes.

Transmitter Connections

Remote Mount

• Available with

Orifice Type

• Square edged

• Corner tapped

• Concentric

• Wafer-style

1

/4-in. (standard) or 1/2-in. (option code E) connections

Process Connections

Mounts between the following flange configurations:

ASME B16.5

(ANSI)

Class 150

Class 300

Class 600

ANSI alignment ring is included as standard when ordering.

DIN JIS

PN16 (option code G)

PN40 (option code H)

PN100 (option code H)

10k (option code B)

20k (option code R)

40k (option code S)

A-7

Page 40

Rosemount Compact Orifice

Flowmeter Series

Typical Orifice Hole Sizes (For 3051SFCC)

Beta is calculated by: (β) = dC / Pipe ID, where the calculated bore is equal to 2 x typical orifice

hole size (d

Table A-4. β = 0.4

Line Size 3051SFCC 3051SFCP

1

/2-in. (15 mm) Not Available 0.249 (6.325)

1-in. (25 mm) Not Available 0.420 (10.668)

1

/2-in. (40 mm) Not Available 0.644 (16.358)

1

2-in. (50 mm) 0.413 (10.490) 0.827 (21.006)

3-in. (80 mm) 0.614 (15.596) 1.227 (31.166)

4-in. (100 mm) 0.805 (20.447) 1.610 (40.894)

6-in. (150 mm) 1.213 (30.810) 2.426 (61.620)

8-in. (200 mm) 1.596 (40.538) 3.192 (81.077)

Table A-5. β = 0.65

Line Size 3051SFCC 3051SFCP

1

/2-in. (15 mm) Not Available 0.404 (10.262)

1-in. (25 mm) Not Available 0.682 (17.323)

1

1

/2-in. (40 mm) Not Available 1.047 (26.594)

2-in. (50 mm) 0.620 (15.748)

3-in. (80 mm) 0.997 (25.324) 1.994 (50.648)

4-in. (100 mm) 1.308 (33.223) 2.617 (66.472)

6-in. (150 mm) 1.971 (50.063) 3.942 (100.127)

8-in. (200 mm) 2.594 (65.888) 5.188 (131.775)

(1) Measurement is in inches (millimeters)

(2) Tolerance = ±0.002-in.

(3) Beta (β) = 0.60-in. (15.24 mm) for 2-in. line size only.

= 2d). The table below shows the diameter of each of the four typical orifice holes.

C

(1)(2)

(1)(2)

Reference Manual

00809-0100-4810, Rev DA

September 2007

(3)

1.344 (34.138)

Weight

Line Size Direct Mount (D3)

1

/2-in. (15 mm) 11.20 (5.08) 8.0 (3.63)

1-in. (25 mm) 11.70 (5.31) 8.5 (3.86)

1

1

/2-in. (40 mm) 12.45 (5.65) 9.25 (4.20)

2-in. (50 mm) 13.20 (5.99) 10.0 (4.54)

3-in. (80 mm) 13.95 (6.32) 11.75 (5.33)

4-in. (100 mm) 14.95 (6.78) 13.5 (6.12)

6-in. (150 mm) 20.45 (9.28) 17.25 (7.83)

8-in. (200 mm) 24.95 (11.32) 21.75 (9.87)

(1) Measurement in lb (kg).

(1)

Remote Mount (R3)

(1)

A-8

Page 41

Reference Manual

Upstream (inlet)

side of primary

3051SFCDP

Compact

Orifice

3051SFCDC

Conditioning

Orifice

00809-0100-4810, Rev DA

September 2007

Rosemount Compact Orifice

Flowmeter Series

Installation

Considerations

Straight Run Requirements

Table A-6. 3051SFCC Straight Pipe Requirements

Beta 0.40 0.65

Reducer (1 line size) 2 2

Single 90° bend or tee 2 2

Two or more 90 ° bends

in the same plane

Two or more 90° bends in different

plane

side of primary

Up to 10° of swirl 2 2

Upstream (inlet)

Butterfly valve (75% to 100% open) 2 N/A

Downstream (outlet) side of primary

2 2

2 2

22

Table A-7. 3051SFCP Straight Pipe Requirements

Beta 0.40 0.65

Reducer (1 line size) 5 12

Single 90° bend or tee 16 44

Two or more 90 ° bends

in the same plane

Two or more 90° bends

in different plane

Expander 12 28

Ball / Gate valve fully open 12 18

Downstream (outlet) side of primary

(1) Consult an Emerson Process Management representative if

disturbance is not listed.

(2) Recommended lengths represented in pipe diameters per ISO 5167.

(3) Refer to ISO 5167 for recommended lengths when using flow

straighteners.

10 44

50 60

6 7

(1)

(1)(2)(3)

Pipe Orientation

Pipe orientation for both 3051SFCC Compact Conditioning and standard 3051SFCP Compact

Orifice.

Process

Orientation/ Flow Direction

Horizontal D/R D/R D/R

Verti cal Up R D/R R

Vertical Down D/R NR NR

(1) D = Direct mount acceptable (recommended)

R = Remote mount acceptable

NR = Not recommended

Gas Liquid Steam

(1)

Pipe Centering

Improper centering of any orifice type device can cause an error of up to ±5% in small line sizes.

A centering mechanism (centering ring) independent of flange rating comes standard with the

405 Compact Orifice Series.

A-9

Page 42

Rosemount Compact Orifice

30°

120°

30°

360°

FLOW

Flowmeter Series

Flowmeter Orientation

Flowmeter orientation for both 3051SFC Conditioning Compact Orifice and standard Compact

Orifice.

Reference Manual

00809-0100-4810, Rev DA

September 2007

Gas (Horizontal)

Liquid and Steam (Horizontal)

50°

50°

80°

Gas (Vertical)

Liquid (Vertical)

360°

FLOW

A-10

Page 43

Reference Manual

1.0 (25.4)

C

A

B

1.0 (25.4)

C

00809-0100-4810, Rev DA

September 2007

DIMENSIONAL DRAWINGS

Rosemount 3051SFC Compact Orifice Flowmeter

Orifice Plate Front View Orifice Plate Side View Orifice Plate Top View

B

A

Compact Orifice Plate

(Primary Element Type code P)

Rosemount Compact Orifice

Flowmeter Series

D

D

(Primary Element Type code C)

Conditioning Orifice Plate

Table A-8. Dimensional Drawings

Plate Type A B Transmitter Height C D

Type P and C 5.50 (140) Transmitter Height + A 7.75 (197) 7.75 (197) - closed

(1) Measurement in inches (millimeters).

(1)

8.25 (210) - open

6.00 (152) - closed

6.25 (159) - open

A-11

Page 44

Rosemount Compact Orifice

Reference Manual

00809-0100-4810, Rev DA

Flowmeter Series

September 2007

ORDERING INFORMATION

Rosemount 3051SFC Compact Orifice Flowmeter Ordering Information

Model Product Description

3051SFC Compact Orifice Flowmeter

Code Measurement Type

D Differential Pressure

Code Primary Element Type

C Conditioning Orifice Plate

P Orifice Plate

Code Material Type

S 316 Stainless Steel (SST)

Code Line Size

(1) 1

005

(1)

010

(1)

015

020 2-in. (50 mm)

030 3-in. (80 mm)

040 4-in. (100 mm)

060 6-in. (150 mm)

080 8-in. (200 mm)

Code Primary Element Style

N Square Edged

Code Beta Ratio

040 0.40 Beta Ratio (β)

(2)

065

Code Temperature Measurement

R Remote Thermowell and RTD

0 No Temperature Sensor

Code Electronics Connection Platform

3 Direct-mount, 3-valve integral manifold, SST

7 Remote-mount, 1/4-in. NPT connections

9 Special

Code Differential Pressure Range

1 0 to 25 in H2O (0 to 62.2 mbar)

2 0 to 250 in H2O (0 to 623 mbar)

3 0 to 1000 in H2O (0 to 2.5 bar)

Code Static Pressure Range

A None

D Absolute 0 to 800 psia (0 to 55.2 bar)

E Absolute 0 to 3626 psia (0 to 250 bar)

J Gage -14.7 to 800 psig (-1 to 55.2 bar)

K Gage -14.7 to 3626 psig (-1 to 250 bar)

Code Output Protocol

A 4–20 mA with digital signal based on HART protocol

(3)

F

X Wireless

Code Electronics Housing Style Material Conduit Entry Size

01 Assemble to Rosemount 753R Web-based Monitoring Indicator

1A PlantWeb Housing Aluminum

1B PlantWeb Housing Aluminum M20 x 1.5 (CM20)

1C PlantWeb Housing Aluminum G

1J PlantWeb Housing 316L SST

1K PlantWeb Housing 316L SST M20 x 1.5 (CM20)

1L PlantWeb Housing 316L SST G1/2

/2-in. (15 mm)

1-in. (25 mm)

11/2-in. (40 mm)

0.65 Beta Ratio (β)

FOUNDATION fieldbus protocol

1

/2-14 NPT

1

/2

1

/2-14 NPT

A-12

Page 45

Reference Manual

00809-0100-4810, Rev DA

September 2007

Rosemount Compact Orifice

Flowmeter Series

Rosemount 3051SFC Compact Orifice Flowmeter Ordering Information

2A Junction Box Housing Aluminum

2B Junction Box Housing Aluminum M20 x 1.5 (CM20)

2C Junction Box Housing Aluminum G

2E Junction Box housing with output for remote display and interface Aluminum

2F Junction Box housing with output for remote display and interface Aluminum M20 x 1.5 (CM20)

2G Junction Box housing with output for remote display and interface Aluminum G1/2

2J Junction Box Housing 316L SST

2M Junction Box housing with output for remote display and interface 316L SST

5A Wireless PlantWeb housing Aluminum M20 x 1.5 (CM20)

(4)

7J

Code Electronics Performance Class for Flow

(5)

1

2 Classic: up to ± 1.05% flow rate accuracy, 8:1 flow turndown, 5-year stability

(5)

3

5 Classic 2: 0.xx% flow rate accuracy, 8:1 flow turndown, 5-year stability

Code Options

Installation Accessories

G DIN alignment ring (PN 16)

H DIN alignment ring (PN 40, PN 100)

B JIS Alignment Ring 10K

R JIS Alignment Ring 20K

S JIS Alignment Ring 40K

Remote Adapters

E Flange adapters 316 SST (1/2-in. NPT)

High Temperature Applications

T Graphite valve packing (Tmax = 850 °F)

Flow Calibration

(6)

WC

(6)

WD

Pressure Testing

P1 Hydrostatic testing with certificate

Special Cleaning

P2 Cleaning for special processes

PA Cleaning per ASTM G93 Level D (section 11.4)

Special Inspection

QC1 Visual and dimensional inspection with certificate

QC7 Inspection and performance certificate

Transmitter Calibration Certification

Q4 Calibration Data Certificate for Transmitter

Safety Certification

QS Certificate of FMEDA data

QT Safety Certified to IEC 61508 with certificate of FMEDA data

Material Traceability Certifications

Q8 Material Cert per ISO 10474 3.1.B and EN 10204 3.1.B

Code Conformance

J2 ANSI B31.1

J3 ANSI B31.3

J4 ANSI B31.8

(7)

J5

Country Certification

J1 Canadian Registration

Product Certifications

E1 ATEX Flameproof

I1 ATEX Intrinsically Safe

(8)

IA

N1 ATEX Type n

Quick Connect (A size Mini, 4-pin male termination)

Ultra: up to ± 0.85% flow rate accuracy, 8:1 flow turndown, 10-year stability, limited 12-year warranty

Ultra for Flow: up to ± 0.75% flow rate accuracy, 14:1 flow turndown, 10-year stability. limited 12-year warranty

Discharge coefficient verification (3 point)

Discharge coefficient verification (full 10 point)

NACE MR-0175 / ISO 15156

ATEX FISCO Intrinsically Safe; for FOUNDATION fieldbus protocol only

1

/2-14 NPT

1

/2

1

/2-14 NPT

1

/2-14 NPT

1

/2-14 NPT

A-13

Page 46

Rosemount Compact Orifice

Reference Manual

00809-0100-4810, Rev DA

Flowmeter Series

September 2007

Rosemount 3051SFC Compact Orifice Flowmeter Ordering Information

ND ATEX Dust

K1 ATEX Flameproof, Intrinsically Safe, Type n, Dust (combination of E1, I1, N1, and ND)

E4 TIIS Flameproof

E5 FM Explosion-proof

I5 FM Intrinsically Safe, Non-incendive

K5 FM Explosion-proof, Intrinsically Safe, Non-incendive (combination of E5 and I5)

E6 CSA Explosion-proof, Division 2

I6 CSA Intrinsically Safe

K6 CSA Explosion-proof, Intrinsically Safe, Division 2 (combination of E6 and I6)

(8)

E7

I7 IECEx Intrinsically Safe

N7 IECEx Type n

K7 SAA Flameproof, Dust Ignition-proof, IECEx Intrinsically Safe, and Type n (combination of E7, I7, and N7)

KA ATEX and CSA Flameproof, Intrinsically Safe (combination of E1, I1, E6, and I6)

KB FM and CSA Explosion-proof, Intrinsically Safe, Division 2 (combination of E5, E6, I5, and I6)

KC FM and ATEX Explosion-proof, Intrinsically Safe, Non-incendive (combination of E5, E1, I5, and I1)

KD FM, CSA, and ATEX Explosion-proof, Intrinsically Safe (combination of E5, I5, E6, I6, E1, and I1)

Alternative Transmitter Material of Construction

L1 Inert Sensor Fill Fluid (not available with Differential Pressure range code 1A)

L2 Graphite-filled Teflon® (PTFE) o-ring

LA Inert sensor fill fluid and graphite-filled Teflon (PTFE) o-ring

Display

M5 PlantWeb LCD display

(5)(10)

M8

(5)(10)

M9

Terminal Blocks

(9)

T1

(11)

T2

(11)

T3

Manifold for Remote Mount Option

F2 3-Valve Manifold, SST

F6 5-Valve Manifold, SST

PlantWeb Control Functionality

(12)

A01

PlantWeb Diagnostic Functionality

(12)

D01

(13)

DA1

Wireless Transmit Rate, Operating Frequency and Protocol

WA1 HART, Self Organizing Network - 2.4 GHz

WA2 User Configurable Transmit Rate, 900 MHz FHSS, HART

Antenna and SmartPower Options

WK1 Integral, Omnidirectional Antenna, Long-life Battery Pack

Cold Temperature Procedure

BRR -60 °F (-51 °C) Temperature Soak with Power Cycle

Special Configuration (Software)

(14)

C4

(1) Not available for Primary Element Type code C.

(2) For 2-in. (50.8 mm) line sizes the Beta Ratio is 0.6 for Primary Element Type code C.

(3) Requires PlantWeb housing.

(4) Available with output code A only. Available approvals are FM Intrinsically Safe, Non-incendive (option code I5) or ATEX Instrinsically Safe (option code I1).

SAA Flameproof, Dust Ignition-proof

Note: Only available on Housing Style codes 1A, 1J, 2A, 2J, 2E, or 2M.

Note: Only available on Housing Style codes 1A, 1J, 2A, 2J, 2E, or 2M.