Product Data Sheet

00813-0100-2555, Rev AB

Rosemount™ 2555 Solids Level Switch

Capacitance Probe

January 2020

■

Very high sensitivity (dielectric constant, DK >= 1.5)

■

Supports high mechanical loads of up to 10 kN

■

Simple to install and set-up

■

Robust version for overpressure up to 363 psi (25 bar)

■

Temperature from -40 to 932 °F (-40 to 500 °C)

Rosemount 2555 January 2020

Introduction

Measurement principles

The Rosemount™ 2555 Solids Level Switch uses the principle of measuring capacitance through RF (Radio Frequency) to detect the

presence or absence of a solids medium and monitors the change in capacitance between the probe and the silo wall.

When the solids medium in the vessel (silo) falls away from the probe level, it causes an increase in capacitance that is detected by

the electronics and the output switches to indicate an 'uncovered' state.

When the solids medium in the vessel (silo) rises and covers the rod, it causes a decrease of capacitance that is detected by the

electronics and the output switches to indicate a 'covered' state.

The electrical output will vary depending on the electronics selected.

Key features and benefits

■

Flexible, robust solids switch - suitable for point level measurement of nearly all types of bulk materials

■

Reliable measurement of materials with low dielectric constants (DK from 1.5)

■

Designed for operation in high temperatures and pressures of up to 932 °F (500 °C) and 363 psi (25 bar)

■

Simple and quick automatic calibration for easy commissioning

■

Special probe design with high resistance to material build-up for safe maintenance-free operation

■

Continuous self-checking diagnostics for condition monitoring with easy-to-read display and push buttons

■

Approvals for hazardous locations (gas and dust)

■

Versatile installation options:

rod version: vertical, horizontal, and angled installation

—

— cable version: vertical installation

Note

A listing of dielectric (DK) values for solids materials can be in the Dielectric Values (DK Values) Data Sheet on-line document.

Contents

Introduction...................................................................................................................................................................................... 2

Ordering information........................................................................................................................................................................ 4

Spares and accessories...................................................................................................................................................................... 8

Specifications.................................................................................................................................................................................. 10

Product certifications...................................................................................................................................................................... 15

Dimensional drawings..................................................................................................................................................................... 19

2 Emerson.com/Rosemount

January 2020 Rosemount 2555

Applications

■

Level measurements of most bulk solids materials, including:

Flour, grains, sugar, cement, granulate, carbon black, and materials with coating properties

—

■

All types of vessel from small process silos to large storage silos

■

Extreme-temperature and high-pressure applications

■

Environments with heavy vibration

■

High-reliability and high-safety

■

Approvals for hazardous and explosive environments

Emerson.com/Rosemount 3

Rosemount 2555 January 2020

Ordering information

The specification and selection of product materials, options, or components must be made by the purchaser of the equipment.

See Materials selection for more information.

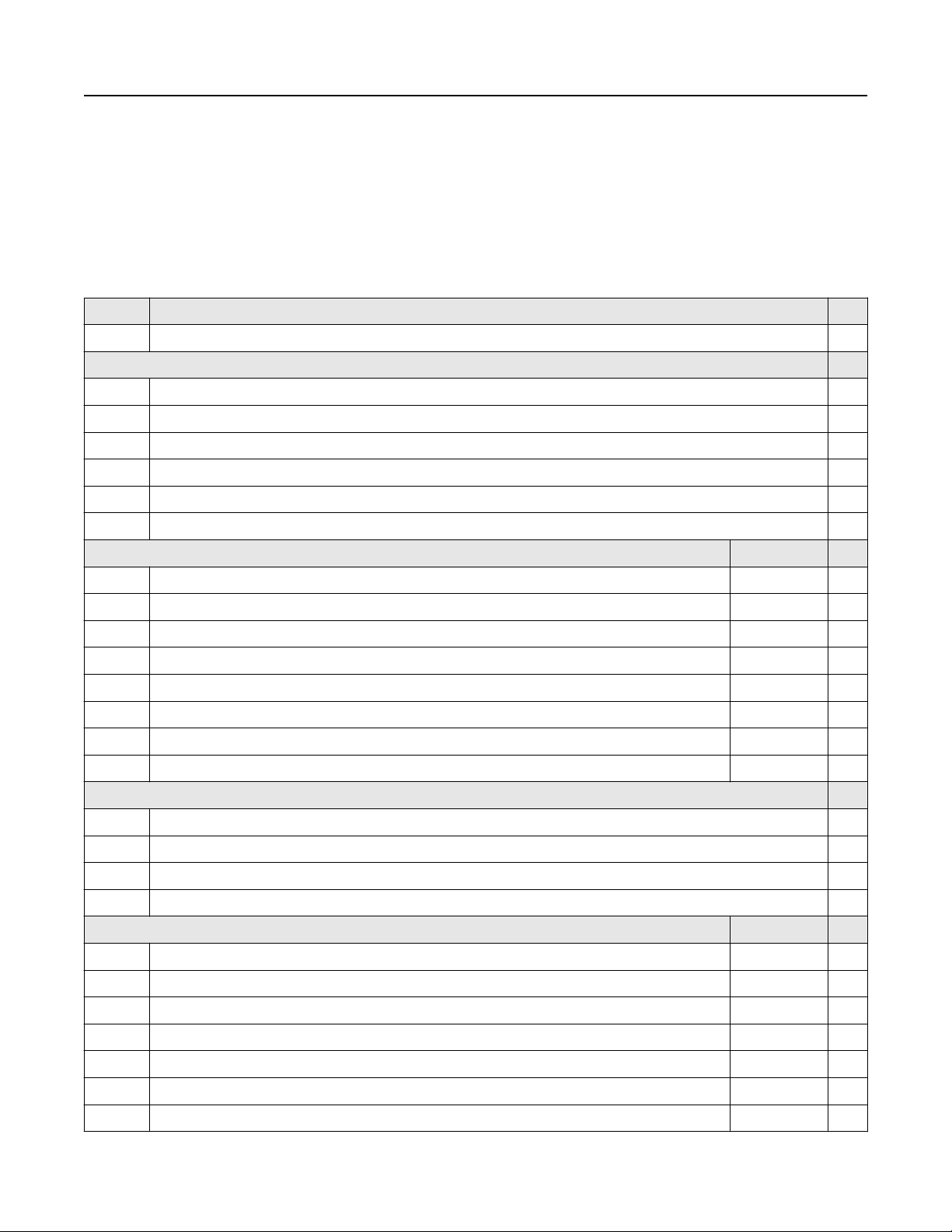

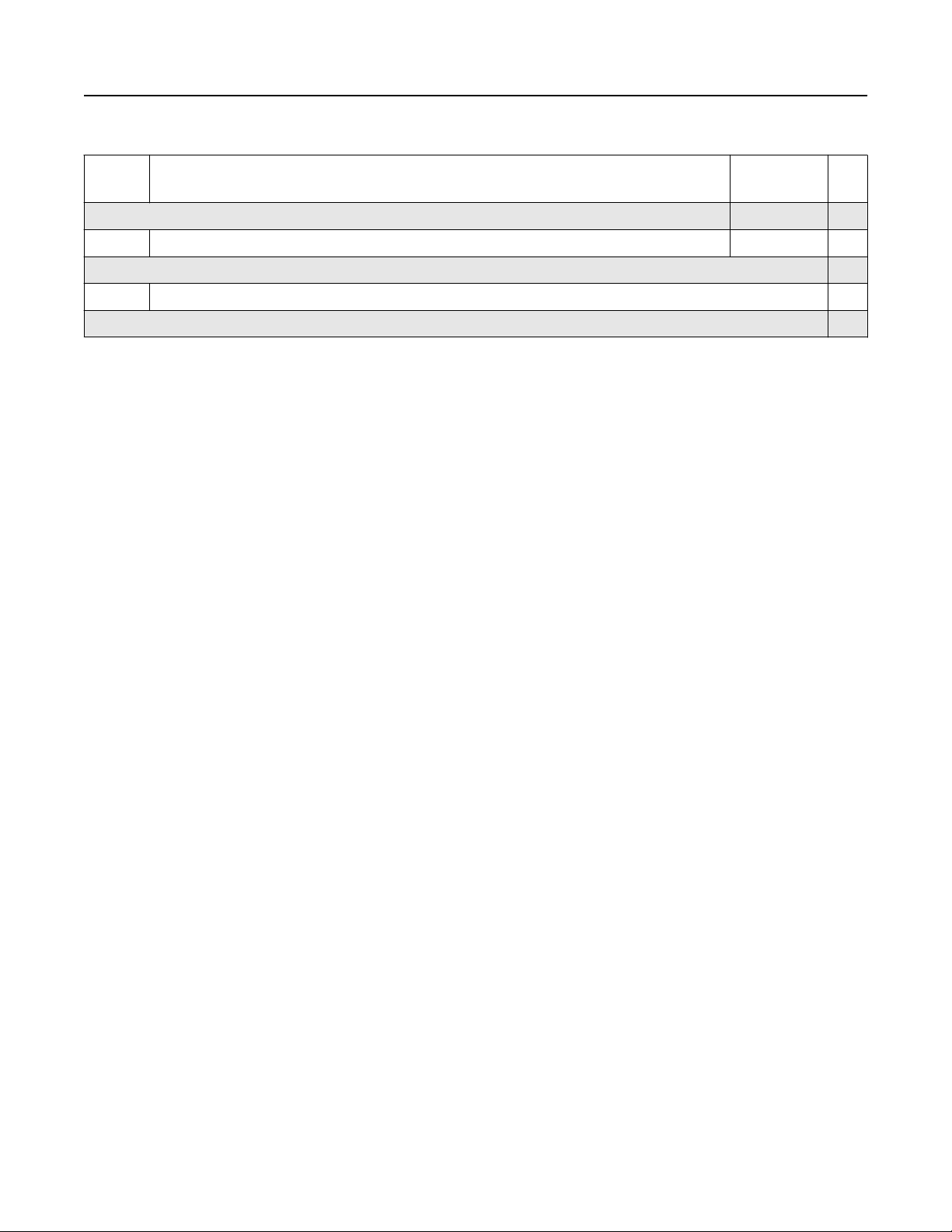

Table 1: Rosemount 2555 Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings

are subject to additional delivery lead time.

Model Product description

2555 Rosemount Solids Level Switch - Capacitance Probe ★

Probe thermal profile

S Standard 10-mm diameter probe (T

M Medium 22-mm diameter probe (T

E Extreme 22-mm diameter probe (T

R Standard 4-mm diameter rope (T

P Medium 8-mm diameter rope (T

V Extreme 8-mm diameter rope (T

process

process

process

= -40 to +464 °F (-40 to +240 °C), Pop -14.5 to 363 psi (-1 to +25 bar)) ★

process

= -40 to +464 °F (-40 to +240 °C), Pop -14.5 to 363 psi (-1 to +25 bar)) ★

process

= -40 to +932 °F (-40 to +500 °C), Pop -14.5 to 145 psi (-1 to +10 bar)) ★

process

= -40 to +464 °F (-40 to +240 °C), Pop -14.5 to 363 psi (-1 to +25 bar)) ★

= -40 to +464 °F (-40 to +240 °C), Pop -14.5 to 363 psi (-1 to +25 bar)) ★

= -40 to +932 °F (-40 to +500 °C), Pop -14.5 to 145 psi (-1 to +10 bar)) ★

Materials of construction: process connection/active probe and inactive extension rod Profiles

D 303/304/321 Stainless steel (1.4301/1.4305/1.4541) All ★

E 303/304/321 Stainless steel (1.4301/1.4305/1.4541), PFA coating to active probe only S ★

F 303/304/321 Stainless steel (1.4301/1.4305/1.4541), PFA coating to rope only R ★

G 303/304/321 Stainless steel (1.4301/1.4305/1.4541), PFA coating S ★

S 316/316L Stainless steel (1.4404/1.4401) All ★

T 316/316L Stainless steel (1.4404/1.4401), PFA coating to active probe only S ★

U 316/316L Stainless steel (1.4404/1.4401), PFA coating to rope only R ★

V 316/316L Stainless steel (1.4404/1.4401), PFA coating S ★

Conduit entry / cable threads

1 M20 x 1.5, 1 off screwed cable gland + 1 off blind plug for CE, ATEX, and IECEx ★

2 M20 x 1.5, 2 off screwed cable glands ★

3 M20 x 1.5, 1 off screwed cable gland + 1 off blind plug for FM ★

4 NPT ½-in. tapered ANSI B1.20.1 (1 off conduit + 1 off Ex-d blind plug) ★

Process connection size Profiles

(1)

9

(1)

1

(1)

A

¾-in./19 mm (DN25)/25A S and R ★

1-in./25 mm (DN25)/25A S and R ★

1.25-in./32 mm All ★

5 1.5 in./(DN38)/40A All ★

(1)

2

(1)

3

(1)

4

2 in./50 mm (DN50)/50A All ★

3 in./80 mm (DN80)/80A All ★

4 in./100 mm (DN100)/100A All ★

4 Emerson.com/Rosemount

January 2020 Rosemount 2555

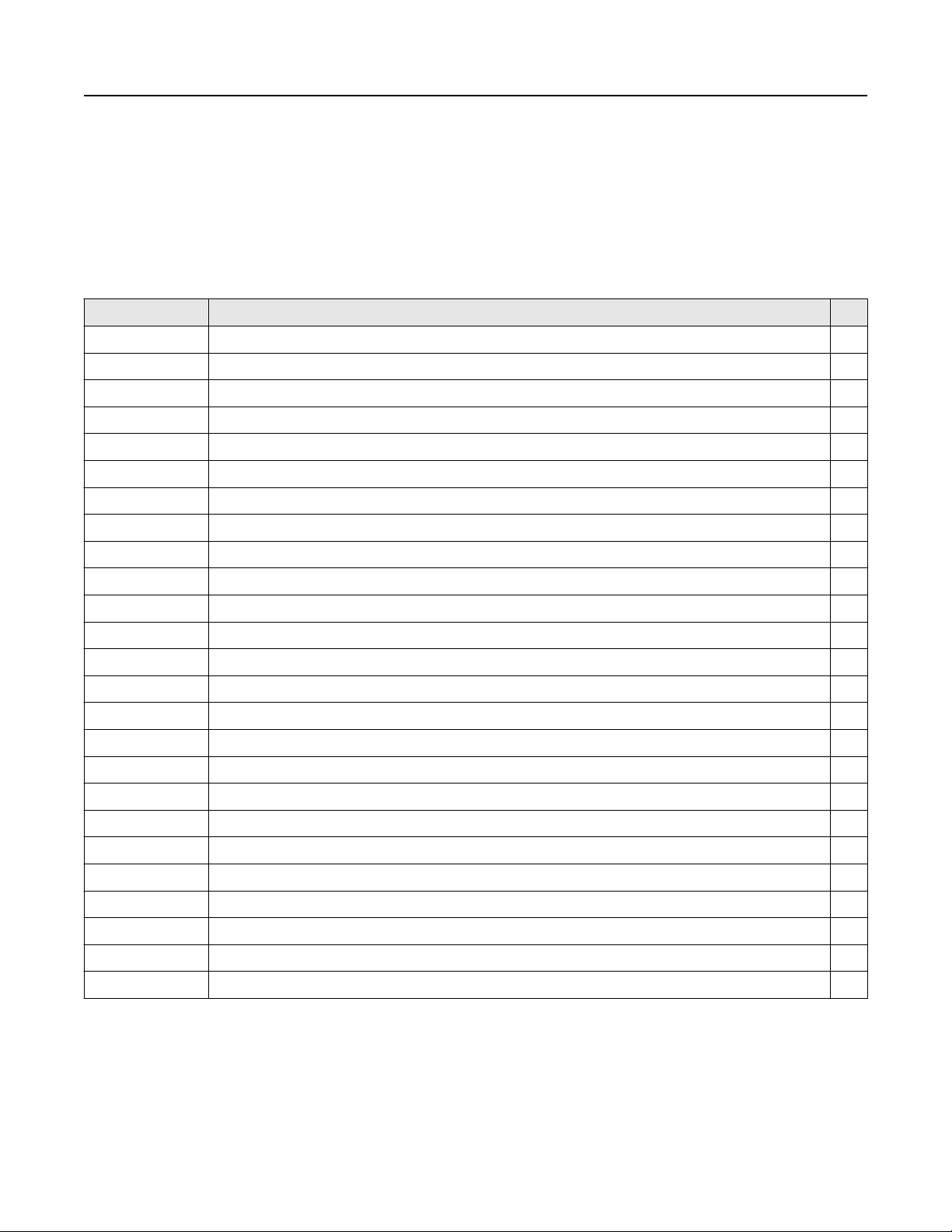

Table 1: Rosemount 2555 Ordering Information (continued)

(1)

B

(1)

C

Process connection rating Sizes

AA ASME B16.5 Class 150 flange 2, 3, and 4 ★

DZ EN 1092-1 PN6 flange 4 ★

DA EN 1092-1 PN16 flange 4 ★

M30 x 1.5 mm S and R ★

M32 x 1.5 mm S and R ★

NN For use with non-flange process connection type All except 3

and 4

Process connection type Ratings

F Flat-face flange DZ and DA ★

R Raised-face flange AA ★

G BSPP (G) thread NN ★

N NPT thread NN ★

M Metric thread NN ★

C Tri Clamp (ISO 2852) NN ★

Electronic type

V Relay DPDT 21 to 230 Vac/Vdc ★

Active probe length Profiles

(2)

A

(2)

B

(2)

C

Standard length 3.94-in. (100 mm) S, M, and E ★

Standard length 7.87-in. (200 mm) S, M, and E ★

Standard length 11.8-in. (300 mm) S, M, and E ★

E Extended, customer-specified length in tenths of inches All ★

M Extended, customer-specified length in millimeters All ★

Specific extended active probe length All

★

00000 Factory default length (only if active probe length A, B, or C is selected) ★

XXXXX Specific customer-specified length in tenths of inches (XXXX.X inches) or millimeters (XXXXX mm) ★

Inactive extension length

(3)

A

No inactive extension ★

E Inactive extension, customer-specified length in tenths of inches ★

M Inactive extension, customer-specified length in millimeters ★

Specific inactive extension length

0000 Factory default length (only if inactive extension length A is selected) ★

XXXX Specific customer-specified length in tenths of inches (XXX.X inches) or millimeters (XXXX mm) ★

Product certifications Conduit entry

NA No hazardous locations certifications 1, 2, and 4 ★

(4)

ND

ATEX, Dust Certification 1, 2, and 4 ★

Emerson.com/Rosemount 5

Rosemount 2555 January 2020

Table 1: Rosemount 2555 Ordering Information (continued)

(4)

NK

(4)

NL

(4)(5)

E5

(4)(5)

E7

(4)(5)

E8

EM

(4)(5)

K1

(4)(5)

K7

KM

(4)(5)

KY

KZ American and Canadian Ordinary Location (unclassified, safe area) 2, 3, and 4 ★

Options (include with selected model number)

Calibration data certification

Q4 Certificate of functional test ★

IECEx, Dust Certification 1, 2, and 4 ★

American, DIP 2, 3, and 4 ★

American, Flameproof/Dust certification 4

IECEx, Flameproof/Dust certification 4

ATEX, Flameproof/Dust certification 4

(4)(5)

Technical Regulations Customs Union (EAC), Dust Certification 1, 2, and 4

ATEX, Flameproof/Increased Safety/Dust Certification 1, 2, and 4

IECEx, Flameproof/Increased Safety/Dust Certification 1, 2, and 4

(4)(5)

Technical Regulations Customs Union (EAC), Flameproof/Increased Safety/Dust certification 1, 2, and 4

American, Flameproof/Dust certification 4

Weather protection

P2 Weather protection cover ★

Electronics sensitivity configuration

V1 Calibrate to 0.5 pF ★

V2 Calibrate to 1 pF ★

V3 Calibrate to 4 pF ★

V4 Calibrate to 10 pF ★

Active probe extension Profiles

R0 Rigid, 316L (1.4404) stainless steel, 15.7 in. (400 mm) long, ø10-mm probe S ★

R1 Rigid, 316L (1.4404) stainless steel, 15.7 in. (400 mm) long, ø10-mm probe, includes fixing hole S ★

R2 Rigid, 316L (1.4404) stainless steel, 15.7 in. (400 mm), ø22-mm probe M, E, P, V ★

R3 Flexible, 304/303 (1.4301/1.4305) stainless steel, 39.4 in. (1000 mm) long, ø10-mm probe S ★

R4 Flexible, 304/303 (1.4301/1.4305) stainless steel, 39.4 in. (1000 mm) long,

S ★

ø10-mm probe, includes fixing hole

R5 Rope, 304/303 (1.4301/1.4305) stainless steel, 78.7 in. (2000 mm) long,

S ★

ø10-mm probe and ø4-mm rope

R6 Rope, 304/303 (1.4301/1.4305) stainless steel, 78.7 in. (2000 mm) long,

S ★

ø10-mm probe, includes fixing hole and ø4-mm rope

R7 Rope, 316L/316 (1.4404/1.4401) stainless steel, 78.7 in. (2000 mm) long,

S ★

ø10-mm probe and ø4-mm rope

R8 Rope, 316L/316 (1.4404/1.4401) stainless steel, 78.7 in. (2000 mm) long,

S ★

ø10-mm probe, includes fixing hole and ø4-mm rope

6 Emerson.com/Rosemount

January 2020 Rosemount 2555

Table 1: Rosemount 2555 Ordering Information (continued)

R9 Rope, 316L/316 (1.4404/1.4401) stainless steel, 78.7 in. (2000 mm) long,

M, E, P, V ★

ø22-mm probe, ø8-mm rope

Sliding sleeve

(6)

Profiles

S1 Sliding sleeve S, M, R, P ★

Extended product warranty

WR5 5-year limited warranty ★

Typical model number: 2555 S D 1 5 NN G V A 00000 A 0000 NA

(1)

This process connection size is not available when Materials of Construction codes G or V is selected.

(2)

This active probe length is not available when Materials of Construction codes F or U are selected.

(3)

The No Inactive Extension option is not available when Materials of Construction codes G or V is selected.

(4)

This product certification is available when Materials of Construction codes D or S are selected.

(5)

Contact your local Emerson representative for the availability of this option code.

(6)

The Sliding Sleeve option is not available when Materials of Construction codes G or V are selected.

Emerson.com/Rosemount 7

Rosemount 2555 January 2020

Spares and accessories

The specification and selection of product materials, options, or components must be made by the purchaser of the equipment.

See Materials selection for more information.

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings

are subject to additional delivery lead time.

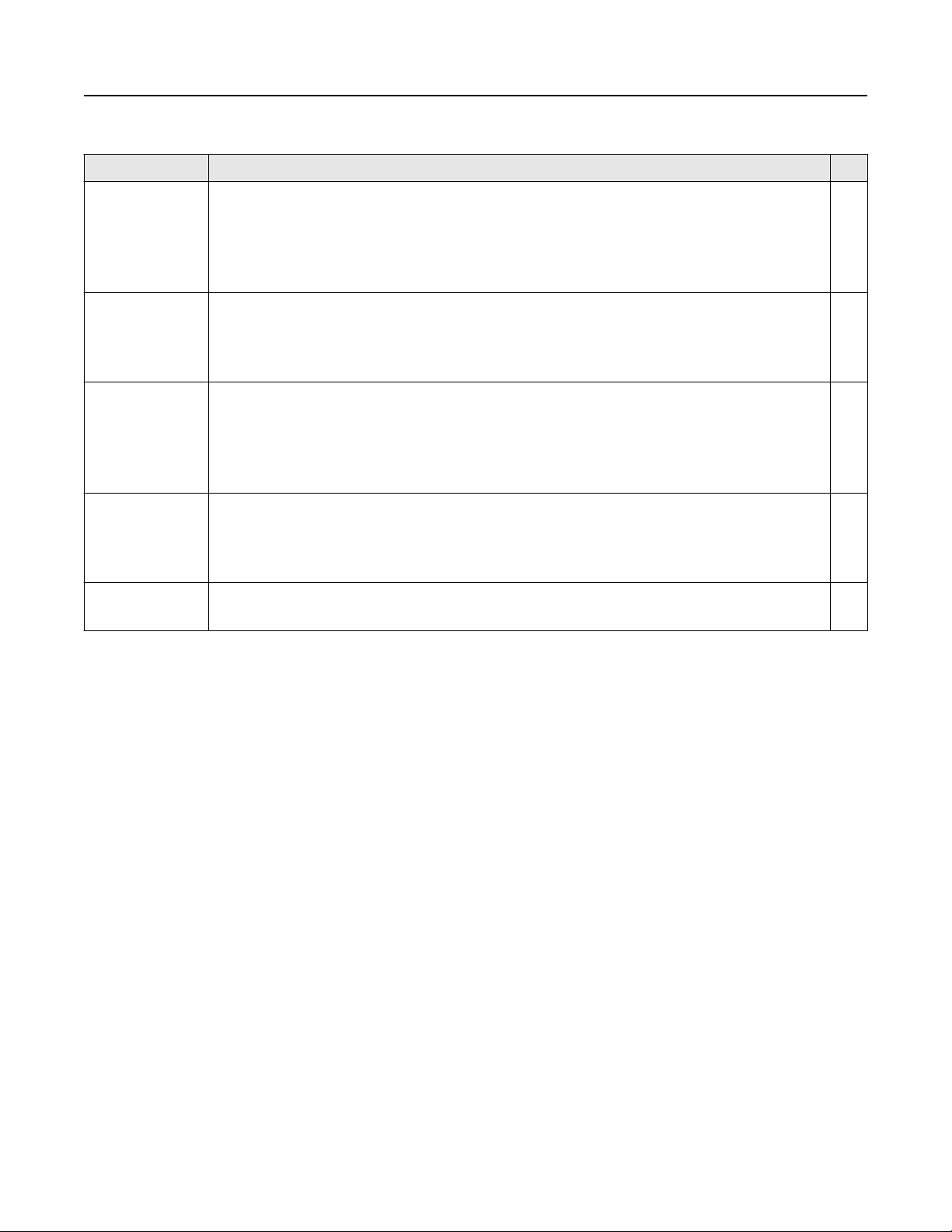

Table 2: Spares

Part number Description

02500-1000-0106 Electronics board: Relay DPDT, universal voltage ★

02500-7000-0001 Extension: Rigid 316L SST (1.4404), 15.7 in. (400 mm) long, Ø10 mm probe ★

02500-7000-0002 Extension: Rigid 316L SST (1.4404), 15.7 in. (400 mm) long, Ø22 mm probe ★

02500-7000-0003 Extension: Flexible 304/303 SST (1.4301/14305), 39.4 in. (1000 mm) long, Ø10 mm probe ★

02500-7000-0004 Extension: Rope 304/303 SST (1.4301/14305), 78.7 in. (2000 mm) long, Ø10 mm probe, Ø4 mm rope ★

02500-7000-0005 Extension: Rope 316L SST (1.4404), 78.7 in. (2000 mm) long, Ø10 mm probe, Ø4 mm rope ★

02500-7000-0006 Extension: Rope 316L SST (1.4404), 78.7 in. (2000 mm) long, Ø10 mm probe, Ø8 mm rope ★

02500-1000-0109 Standard Ø4 mm rope, 316 SST (1.4401), not coated, price per 39.4 in, (1000 mm) ★

02500-1000-0110 Standard Ø4 mm rope, 316 SST (1.4401), coated, price per 39.4 in, (1000 mm) ★

02500-1000-0111 Weight Ø22 mm for 4 mm rope, 304/303 SST (1.4301/14305), including fixings ★

02500-1000-0112 Weight Ø22 mm for 4 mm rope, 316L SST (1.4404), including fixings ★

02500-1000-0113 Rope holder Ø22 mm for 4 mm rope, 304/303 SST (1.4301/14305), including fixings ★

02500-1000-0114 Rope holder Ø22 mm for 4 mm rope, 316L SST (1.4404), including fixings ★

02500-1000-0115 Medium Ø8 mm rope, 316 SST (1.4401), not coated, price per 39.4 in, (1000 mm) ★

02500-1000-0116 Weight Ø35 mm for 8 mm rope, 304/303 SST (1.4301/14305), including fixings ★

02500-1000-0117 Weight Ø35 mm for 8 mm rope, 316L SST (1.4404), including fixings ★

02500-1000-0118 Rope holder Ø22 mm for 8 mm rope, 304/303 SST (1.4301/14305), including fixings ★

02500-1000-0119 Rope holder Ø22 mm for 8 mm rope, 316L SST (1.4404), including fixings ★

02500-1000-0056 1 off M32 x 1½ mm hexagon nut (kit), 303 SST (1.4305), ★

02500-1000-0121 1 off ¾-in. BSPP hexagon nut (kit), 303 SST (1.4305) ★

02500-1000-0058 1 off 1-in. BSPP hexagon nut (kit), 303 SST (1.4305) ★

02500-1000-0060 1 off M30 x 1½ mm hexagon nut (kit), 303 SST (1.4305) ★

02500-1000-0063 1 off 1½ in. BSPP hexagon nut (kit), 303 SST (1.4305) ★

02500-1000-0064 1 off 1¼ in. BSPP hexagon nut (kit), 303 SST (1.4305) ★

02500-1000-0126 Weather protection for housing ★

8 Emerson.com/Rosemount

January 2020 Rosemount 2555

Table 3: Accessories

Part number Description

02500-7500-0003 Mounting kit 1 for DN100 PN6 and EN1092-1 flange with ø18 mm holes, containing:

4 off M16 x 60 mm screws (304-grade stainless steel)

4 off M16 nuts

4 off washers

1 off seal (non-food grade) for up to 464 °F (240 °C)

02500-7500-0006 Mounting kit 2 for DN100 PN6 and EN1092-1 flange with M16 threaded holes, containing:

4 off M16 x 40 mm screws (A2-grade stainless steel)

4 off M16 washers (A2-grade stainless steel)

1 off seal (non-food grade) for up to 464 °F (240 °C)

02500-7500-0009 Mounting kit 3 for DN100 PN16 and EN1092-1 flange with ø18 mm holes, containing:

8 off M16 x 60 mm screws (A2-grade stainless steel)

8 off M16 nuts (A2-grade stainless steel)

8 off M16 washers (A2-grade stainless steel)

1 off seal (non-food grade) for up to 464 °F (240 °C)

02500-7500-0012 Mounting kit 4 for DN100 PN16 and EN1092-1 flange with M16 threaded holes, containing:

8 off M16 x 40 mm screws (A2-grade stainless steel)

8 off M16 washers (A2-grade stainless steel)

1 off seal (non-food grade) for up to 464 °F (240 °C)

02500-7501-0001 Flat sealing gasket for 1-in. threaded process connection

Maximum operating temperature of 464 °F (240 °C)

★

★

★

★

★

Emerson.com/Rosemount 9

Rosemount 2555 January 2020

Specifications

Electrical data

Connection terminals

Cable entry

Signal output delay

Safety operation (FSL or FSH)

Operation frequency

Overvoltage category

Pollution degree

Electronics

Power supply

Maximum ripple of power

supply

Maximum installed load

Signal output

Display

Status indication

Data storage

Isolation

Protection class

0.14 - 2.5 mm2 (AWG 26-14)

M20 × 1.5 screwed cable gland

½-in. NPT conduit connection

Clamping range (diameter) of the factory provided cable glands:

0.24 to 0.47-in. (6 to 12 mm) for M20 × 1.5

Configurable from 0.5 to 60 seconds.

Configurable switches for each signal output. Select Fail Safe High (FSH) or Fail Safe Low (FSL)

depending on application.

100 kHz

II

2 (inside housing)

Universal voltage Relay DPDT

21 to 230 Vac (50/60 Hz) or Vdc ±10%

*

includes ±10% from EN 61010

7 Vss for dc supply

1.5 VA or 1.5 W

Floating relay DPDT

Maximum 250 Vac, 8 A (non-inductive)

Maximum 30 Vdc, 5 A (non-inductive)

Four digit LCD

Displays actual measured capacitance, signal output state, and self diagnostics

Lowest operating temperature: -22 °F (-30 °C)

Tri-color built-in LED (according to NE44): Power on, signal output, failure/maintenance

Non-volatile EPROM for configuration settings and calibration data.

Power supply to signal output: 2225 Vrms

Signal output to signal output: 2225 Vrms

I

*

10 Emerson.com/Rosemount

January 2020 Rosemount 2555

Mechanical data

Housing

Ingress protection

Process connection/probes

Maximum noise level

Overall weight

(approximated)

Aluminum housing, powder coated

Seal between housing and lid: NBR

Seal between housing and process connection: NBR

Nameplate: polyester film

IP67 (EN 60529), NEMA® Type 4X

Rosemount 2555S and 2555R

Materials:

Stainless steel 303/304 (1.4301/1.4305) or 316/316L (1.4401/1.4404) for rope

Reinforced-PPS probe isolation

FKM or FFKM probe gaskets

PFA coating of probe/rope (optional)

Thread: G (¾-in., 1-in., 1¼-in., or 1½-in.) DIN 228; M30 x 1.5, M32 x 1.5; NPT (¾-in. 1-in., 1¼-in.,

or 1½-in.) tapered ANSI B 1.20.1

Tri Clamp: 1-in. (DN25), 1½-in. (DN40), or 2-in. (DN50) ISO 2852

Rosemount 2555M and 2555P

Materials:

Stainless steel 303/304 (1.4301/1.4305) or 316/316L (1.4401/1.4404) for rope

Reinforced-PPS probe isolation

FKM or FFKM probe gaskets

Thread: G (1¼-in. or 1½-in.) DIN 228; NPT (1¼-in. or 1½-in.) tapered ANSI B 1.20.1

Rosemount 2555E and 2555V

Materials:

Stainless steel 303/304 (1.4301/1.4305) or 316/316L (1.4401/1.4404) for rope

Ceramic probe isolation

Graphite probe gaskets

Thread: G (1¼-in. or 1½-in.) DIN 228; NPT (1¼-in. or 1½-in.) tapered ANSI B 1.20.1

Other:

Flanges according to selection, stainless steel 321 (1.4541) or 316L (1.4404)

All materials are food grade.

40 dBA

See Table 4.

Table 4: Overall Weight (Approximated)

Total weight = Basic weight + active probe length L1 + inactive length L2.

All weights with 1¼-in. NPT process connection and without flanges.

Standard housing

(1)

Active probe length:

(2)

L1

1.37 lbs per 39.3 in.

(+0.62 kg per m)

Inactive length:

(2)

L2

2.65 lbs per 39.3 in.

(+1.2 kg per m)

Rosemount 2555S

rod version

Basic weight

3.7 lbs

(1.7 kg)

Emerson.com/Rosemount 11

-40 °F

(-40 °C)

-40 °F

(-40 °C)

104 °F

(40 °C)

158 °F

(70 °C)

158° F

(70 °C)

464 °F

(240 °C)

Tamb

Tp

932/833 °F

(500/445 °C)

Rosemount 2555 January 2020

Table 4: Overall Weight (Approximated) (continued)

Standard housing

Basic weight

(1)

Active probe length:

(2)

L1

Inactive length:

(2)

L2

Rosemount 2555R

rope version

Rosemount 2555M

rod version

Rosemount 2555P

rope version

Rosemount 2555E

rod version

Rosemount 2555V

rope version

(1)

Rod version with shortest length L1=3.9 in. (100 mm), and rope version without rope.

(2)

See Dimensional drawings.

5.1 lbs

(2.3 kg)

6.2 lbs

(2.8 kg)

8.8 lbs

(4.0 kg)

8.0 lbs

(3.6 kg)

11 lbs

(4.8 kg)

Operating conditions

Ambient

temperature

(housing)

Process

temperature

-40 to +158 °F (-40 to +70 °C)

Rosemount 2555S,

2555R, 2555M and

2555P:

Rosemount 2555E or

2555V:

-40 to +464 °F (-40 to +240 °C)

-40 to +932 °F (-40 to +500 °C); versions with Ex-approvals: +833 °F (+445 °C)

0.13 lbs per 39.3 in.

(+0.06 kg per m)

6.61 lbs per 39.3 in.

(+3.0 kg per m)

0.57 lbs per 39.3 in.

(+0.26 kg per m)

6.61 lbs per 39.3 in.

(+3.0 kg per m)

0.57 lbs per 39.3 in.

(+0.26 kg per m)

2.65 lbs per 39.3 in.

(+1.2 kg per m)

7.19 lbs per 39.3 in.

(+3.26 kg per m)

7.19 lbs per 39.3 in.

(+3.26 kg per m)

7.19 lbs per 39.3 in.

(+3.26 kg per m)

7.19 lbs per 39.3 in.

(+3.26 kg per m)

Ventilation

Maximum range

and sensitivity

Spark protection

12 Emerson.com/Rosemount

Ventilation is not required.

3 to 100 pF, 0.5 pF

3 to 400 pF, 2 pF

Robust built-in protection against static-electricity discharge from the bulk materials.

For versions with Ex-approvals: see also Product Certifications.

A

B

217psi

(15 bar)

363psi

(25 bar)

248 °F

(120 °C)

464 °F

(240 °C)

P

Tp

932 °F

(500 °C)

-14.5 psi

(-1 bar)

-40 °F

(-40 °C)

14.5 psi

(1 bar)

January 2020 Rosemount 2555

Bulk material

restrictions

Maximum

mechanical load

Maximum process

pressure

Dielectric constants (DK values) > 1.5

Note

All ratings are for 104 °F (40 °C).

Rosemount 2555S

Rosemount 2555R

Rosemount 2555M

Rosemount 2555P

Rosemount 2555E

Rosemount 2555V

Rod version:

Rope version:

Rod version:

Rope version:

Rod version:

Rope version:

A: 125 Nm

4 kN tensile load

A: 525 Nm

40 kN tensile load

A: 525 Nm

10 kN tensile load

B: 20 Nm

B: 90 Nm

B: 20 Nm

The maximum process pressure may be reduced when flanges are used. Refer to the flange standards for

pressure ratings and pressure de-ratings with higher temperatures.

For versions with Ex-approvals: see also Product Certifications.

Vibration

Relative Humidity

Maximum altitude

Expected product

lifetime

Emerson.com/Rosemount 13

1.5 (m/s2)2/ Hz according to EN 60068-2-64

0 to 100%, suitable for outdoor use

6562 ft. (2000 m)

The following parameters have a negative influence on the expected product lifetime:

High ambient- and process temperatures, corrosive environments, high plant vibrations, and high flow rate

of abrasive bulk.

Rosemount 2555 January 2020

Transport and storage

Transport

Storage

Refer to the instructions as stated on the transport packaging, otherwise the products may get

damaged.

Transport temperature: -40 to +176 °F (-40 to +80 °C)

Transport humidity: 20 to 85%

Always inspect the received goods for any damage occurred during shipment from the factory. Notify

Emerson of damaged goods as soon as possible.

Products must be stored at a dry and clean place. They must be protected from influence of corrosive

environments, vibrations, and exposure to direct sunlight.

Storage temperature: -40 to +176 °F (-40 to +80 °C)

Storage humidity: 20 to 85%

14 Emerson.com/Rosemount

January 2020 Rosemount 2555

Product certifications

European Union directive information

A copy of the EU Declaration of Conformity can be found at the end of the Rosemount 2555 Product Certifications document. The

most recent revision of the EU Declaration of Conformity can be found at Emerson.com/Rosemount.

Ordinary location certification

As standard, the level switch has been examined and tested to determine that the design meets the basic electrical, mechanical,

and fire protection requirements by a nationally recognized test laboratory (NRTL) as accredited by the Federal Occupational Safety

and Health Administration (OSHA).

Installing equipment in North America

The US National Electrical Code® (NEC) and the Canadian Electrical Code (CEC) permit the use of Division marked equipment in

Zones and Zone marked equipment in Divisions. The markings must be suitable for the area classification, gas, and temperature

class. This information is clearly defined in the respective codes.

U.S.A.

U.S.A. Dust certification

NL

Summary of product certification

Protection

Project ID

Standards

Markings

Dust-ignition proof

3053298

FM Class 3600:2011

FM Class 3616:2011

FM Class 3810:2005

ANSI/ISA 61010:2012

ANSI/ISA 60079-0:2013

ANSI/ISA 60079-11:2013

ANSI/NEMA® 250:1991

ANSI/IEC 60529:2004

DIP-IS Class II,III Division 1 Groups E, F, G T4A

T

= -40 °C to +70 °C

(amb)

Enclosure IP67, Type 4 or Type 4X

Emerson.com/Rosemount 15

Rosemount 2555 January 2020

U.S.A. Ordinary Location certification

KZ

Summary of product certification:

Protection

Project ID

Standards

Markings

Ordinary location (unclassified, safe area)

3053298

FM Class 3810:2005

ANSI/ISA 61010:2012

ANSI/ISA 60079-11:2013

ANSI/NEMA® 250:1991

ANSI/IEC 60529:2004

Type 4/4X, IP67

Canada

Canada Ordinary Location certification

KZ

Summary of product certification

Protection

Project ID

Standards

Markings

Europe

ATEX Dust certification

ND

Summary of product certification

Protection

Certificate

Standards

Markings

Temperature

Ordinary location (unclassified, safe area)

3053298

CSA-C22.2 No. 94:R2011

CSA-C22.2 No. 60529:R2010

CSA-C22.2 No. 61010-1:2012

Type 4/4X, IP67

By enclosure

BVS 19 ATEX E 073

EN60079-0:2012/A11:2013

EN 60079-11:2012

EN 60079-31:2014

II 1/2 D Ex ia/tb IIIC T* Da/Db

See Table 5

16 Emerson.com/Rosemount

January 2020 Rosemount 2555

Table 5: Thermal data

Maximum ambient temperature Maximum process temperature Maximum surface temperature

70 °C <= 80 °C 120 °C

<= 120 °C

<= 240 °C

<= 445 °C

(1)

Maximum surface temperature is identical to the maximum process temperature.

(2)

Available only when Probe Thermal Profile code E is selected.

(2) (1)

Permitted ambient temperature at the electronics enclosure:

■

-40 °C <= T

<= +70 °C

Amb

The maximum surface temperature is limited to 120 °C by a thermal fuse.

Permitted temperature at sensor extension, process connection:

■

-40 to 240 °C (when Probe Thermal Profile code S, M, R or P is selected.)

■

-40 to 445 °C (when Probe Thermal Profile code E or V is selected.)

(1)

(1)

International

IECEx Dust certification

NK

Summary of product certification

Protection

Certificate

Standards

Markings

Temperature

Table 6: Thermal data

Maximum ambient temperature Maximum process temperature Maximum surface temperature

70 °C <= 80 °C 120 °C

<= 120 °C

<= 240 °C

<= 445 °C

By enclosure

IECEx BVS 19.0069

IEC 60079-0:2011

EN 60079-11:2011

IEC 60079-31:2013

IEC Ex ia/tb IIIC T* Da/Db

See Table 6

(1)

(1)

(2) (1)

(1)

Maximum surface temperature is identical to the maximum process temperature.

(2)

Available only when Probe Thermal Profile code E is in the model number.

The maximum surface temperature is limited to 120 °C by a thermal fuse.

Permitted temperature at sensor extension, process connection:

Emerson.com/Rosemount 17

Rosemount 2555 January 2020

■

-40 to 240 °C (when Probe Thermal Profile code S, M, R or P is selected.)

■

-40 to 445 °C (when Probe Thermal Profile code E or V is selected.)

18 Emerson.com/Rosemount

3.23 (82) 3.23 (82) 3.94 (100)

2.76

(70)

3.94

(100)

L

3.94

(100)

L

L2

2.76

(70)

H

C C D

Ø0.87

(Ø22)

3.15

(80)

L1

Ø0.39

(Ø10)

0.79

(20)

0.79

(20)

G

A

B

E

F

L1

Ø0.39

(Ø10)

3.15

(80)

3.94

(100)

L+0.28

(L+7)

January 2020 Rosemount 2555

Dimensional drawings

Figure 1: Rosemount 2555 Capacitance Probe Level Switch (Thermal Profile code S)

A. Rod version, inactive extension

B. Rod version, shortest length

G¾-in. or ¾-in. NPT threaded process connection

C.

D. G1½-in., G1¼-in., G1-in., M32x1.5, M30x1.5, 1½-in. NPT, 1¼-in. NPT, 1-in. NPT threaded process connection

E. 1-in. or 2-in. Tri Clamp process connection

F. Flanged process connections - various sizes

G. Active shield

H. Aluminum housing with M20 or ½-in. conduit/cable entries

Dimensions are in inches (millimeters).

See Table 7 for L, L1, and L2 dimensions.

Emerson.com/Rosemount 19

Rosemount 2555 January 2020

Table 7: Dimensions L1 and L2 for Rosemount 2555 with Thermal Profile code S

L1: Active probe

(standard length)

3.94 in. (100 mm) 1.97 in. (50 mm) 78.74 in. (2000 mm) 1.97 in. (50 mm) 94.49 in. (2400 mm) - L1

7.87 in. (200 mm)

11.81 in. (300 mm)

Note

Length L = L1 + L2 + 3.94-in. (100 mm)

Minimum L length is 5.91-in. (150 mm)

Maximum L length is 98.4-in. (2500 mm)

Inactive extension: the active probe shall have at least 1.97 in. (50 mm) distance to the silo wall.

L1: Active probe (customer length) L2: Inactive extension length

Minimum Maximum Minimum Maximum

20 Emerson.com/Rosemount

3.23 (82)

2.76

(70)

3.94

(100)

0.79

(20)

0.79

(20)

L

L2

3.15

(80)

L1

G

A

Ø0.87

(Ø22)

Ø0.87

(Ø22)

Ø0.16

(Ø4)

3.94 (100)

H

D

E

F

3.94

(100)

L+0.28

(L+7)

Ø0.87

(Ø22)

Ø0.87

(Ø22)

Ø0.16

(Ø4)

B

3.23 (82)

2.76

(70)

3.94

(100)

L

L1

3.15

(80)

G

C C

January 2020 Rosemount 2555

Figure 2: Rosemount 2555 Capacitance Probe Level Switch (Thermal Profile code R)

A. Rope version, inactive extension

B. Rope version, shortest length

G¾-in. or ¾-in. NPT threaded process connection

C.

D. G1½-in., G1¼-in., G1-in., M32x1.5, M30x1.5, 1½-in. NPT, 1¼-in. NPT, 1-in. NPT threaded process connection

E. 1-in. or 2-in. Tri Clamp process connection

F. Flanged process connections - various sizes

G. Active shield

H. Aluminum housing with M20 or ½-in. conduit/cable entries

Dimensions are in inches (millimeters). See Table 8 for L, L1, and L2 dimensions.

Emerson.com/Rosemount 21

Rosemount 2555 January 2020

Table 8: Dimensions L1 and L2 for Rosemount 2555 with Thermal Profile code R

L1: Active probe (customer length) L2: Inactive extension length

Minimum Maximum Minimum Maximum

13.77 in. (350 mm) 787.4 in. (20000 mm) 1.97 in. (50 mm) 74.8 in. (1900 mm)

Note

Length L = L1 + L2 + 3.94-in. (100 mm)

Minimum L length is 17.7-in. (450 mm)

Maximum L length is 866.1-in. (22000 mm)

Inactive extension: the active probe shall have at least 1.97 in. (50 mm) distance to the silo wall.

22 Emerson.com/Rosemount

3.23 (82)

2.76

(70)

2.76

(70)

3.23 (82)

3.94 (100)

F

5.91

(150)

5.91

(150)

0.98

(25)

C

C

3.15

(80)

0.98

(25)

L2

Ø1.3

(Ø33)

Ø1.3

(Ø33)

Ø1.5

(Ø38)

3.74

(95)

3.15

(80)

L

L

L1

E

E

L1

A

B

5.91

(150)

L

D

Ø1.5

(Ø38)

Ø0.87

(Ø22)

Ø0.87

(Ø22)

3.74

(95)

January 2020 Rosemount 2555

Figure 3: Rosemount 2555 Capacitance Probe Level Switch (Thermal Profile code M)

A. Rod version, inactive extension

B. Rod version, shortest length

G1½-in., G1¼-in.,1½-in. NPT or 1¼-in. NPT threaded process connection

C.

D. Flanged process connections - various sizes

E. Active shield

F. Aluminum housing with M20 or ½-in. conduit/cable entries

Dimensions are in inches (millimeters). See Table 9 for L, L1, and L2 dimensions.

Emerson.com/Rosemount 23

Rosemount 2555 January 2020

Table 9: Dimensions L1 and L2 for Rosemount 2555 with Thermal Profile code M

L1: Active probe

(standard length)

3.94 in. (100 mm) 3.94 in. (100 mm) 78.74 in. (2000 mm) 3.94 in. (100 mm) 90.55 in. (2300 mm) - L1

7.87 in. (200 mm)

11.81 in. (300 mm)

Note

Length L = L1 + L2 + 7.87-in. (200 mm)

Minimum L length is 11.81-in. (300 mm)

Maximum L length is 98.4-in. (2500 mm)

Inactive extension: the active probe shall have at least 1.97 in. (50 mm) distance to the silo wall.

L1: Active probe (customer length) L2: Inactive extension length

Minimum Maximum Minimum Maximum

24 Emerson.com/Rosemount

2.76

(70)

3.23 (82)

3.94 (100)

E

3.23 (82)

5.91

(150)

0.98

(25)

L2

Ø1.3

(Ø33)

Ø1.5

(Ø38)

3.74

(95)

L

3.15

(80)

L1

Ø0.31

(Ø8)

C

A

B

C

3.15

(80)

2.76

(70)

0.98

(25)

5.91

(150)

3.7

(94)

Ø1.5

(Ø38)

L

L1

Ø0.31

(Ø8)

5.91

(150)

L

D

Ø1.18

(Ø30)

Ø1.18

(Ø30)

January 2020 Rosemount 2555

Figure 4: Rosemount 2555 Capacitance Probe Level Switch (Thermal Profile code P)

A. Rope version, inactive extension

B. Rope version, shortest length

C.

G1½-in., G1¼-in.,1½-in. NPT or 1¼-in. NPT threaded process connection

D. Flanged process connections - various sizes

E. Aluminum housing with M20 or ½-in. conduit/cable entries

Dimensions are in inches (millimeters). See Table 10 for L, L1, and L2 dimensions.

Emerson.com/Rosemount 25

Rosemount 2555 January 2020

Table 10: Dimensions L1 and L2 for Rosemount 2555 with Thermal Profile code P

L1: Active probe (customer length) L2: Inactive extension length

Minimum Maximum Minimum Maximum

13.78 in. (350 mm) 787.4 in. (20000 mm) 3.94 in. (100 mm) 70.87 in. (1800 mm)

Note

Length L = L1 + L2 + 7.87-in. (200 mm)

Minimum L length is 21.65-in. (550 mm)

Maximum L length is 866.1-in. (22000 mm)

Inactive extension: the active probe shall have at least 1.97 in. (50 mm) distance to the silo wall.

Maximum process temperature for Ex-approved versions is limited to 445 °C.

26 Emerson.com/Rosemount

2.17

(55)

2.76

(70)

3.23 (82)

11.81

(300)

Ø1.31

(Ø33.4)

C

0.98

(25)

L2

Ø1.3

(Ø33)

2.17

(55)

E

5.51

(140)

L1

L

Ø0.87

(Ø22)

A

B

Ø1.5

(Ø38)

3.94 (100)

3.23 (82)

Ø1.31

(Ø33.4)

0.98

(25)

2.76

(70)

11.81

(300)

L

5.51

(140)

L1

Ø0.87

(Ø22)

E

11.81

(300)

L

D

C

F

Ø1.5

(Ø38)

January 2020 Rosemount 2555

Figure 5: Rosemount 2555 Capacitance Probe Level Switch (Thermal Profile code E)

A. Rod version, inactive extension

B. Rod version, shortest length

C.

G1½-in., G1¼-in.,1½-in. NPT or 1¼-in. NPT threaded process connection

D. Flanged process connections - various sizes

E. Active shield

F. Aluminum housing with M20 or ½-in. conduit/cable entries

Dimensions are in inches (millimeters). See Table 11 for L, L1, and L2 dimensions.

Emerson.com/Rosemount 27

Rosemount 2555 January 2020

Table 11: Dimensions L1 and L2 for Rosemount 2555 with Thermal Profile code E

L1: Active probe

(standard length)

3.94 in. (100 mm) 3.94 in. (100 mm) 39.7 in. (1000 mm) 3.94 in. (100 mm) 90.55 in. (2300 mm) - L1

7.87 in. (200 mm)

11.81 in. (300 mm)

Note

Length L = L1 + L2 + 8.66-in. (220 mm)

Minimum L length is 12.6-in. (320 mm)

Maximum L length is 99.2-in. (2520 mm)

Inactive extension: the active probe shall have at least 1.97 in. (50 mm) distance to the silo wall.

Maximum process temperature for Ex-approved versions is limited to 445 °C.

L1: Active probe (customer length) L2: Inactive extension length

Minimum Maximum Minimum Maximum

28 Emerson.com/Rosemount

2.76

(70)

3.23 (82)

3.23 (82)

11.81

(300)

0.98

(25)

Ø1.31

(Ø33.4)

Ø1.3

(Ø33)

L2

2.17

(55)

Ø1.5

(Ø38)

E

5.51

(140)

L

L1

Ø0.31

(Ø8)

Ø1.18

(Ø30)

A

B

D

11.81

(300)

L

F

3.94 (100)

2.76

(70)

11.81

(300)

0.98

(25)

Ø1.31

(Ø33.4)

Ø1.18

(Ø30)

Ø0.31

(Ø8)

E

5.51

(140)

L1

L

2.17

(55)

Ø1.5

(Ø38)

C

C

January 2020 Rosemount 2555

Figure 6: Rosemount 2555 Capacitance Probe Level Switch (Thermal Profile code V)

A. Rope version, inactive extension

B. Rope version, shortest length

C.

G1½-in., G1¼-in.,1½-in. NPT or 1¼-in. NPT threaded process connection

D. Flanged process connections - various sizes

E. Aluminum housing with M20 or ½-in. conduit/cable entries

Dimensions are in inches (millimeters). See Table 12 for L, L1, and L2 dimensions.

Emerson.com/Rosemount 29

X

Rosemount 2555 January 2020

Table 12: Dimensions L1 and L2 for Rosemount 2555 with Thermal Profile code V

L1: Active probe (customer length) L2: Inactive extension length

Minimum Maximum Minimum Maximum

13.78 in. (350 mm) 787.4 in. (20000 mm) 3.94 in. (100 mm) 70.87 in. (1800 mm)

Note

Length L = L1 + L2 + 8.66-in. (220 mm)

Minimum L length is 22.4-in. (570 mm)

Maximum L length is 886.9-in. (22020 mm)

Inactive extension: the active probe shall have at least 1.97 in. (50 mm) distance to the silo wall.

Maximum process temperature for Ex-approved versions is limited to 445 °C.

Selecting active probe length

The correct selection of an active probe length (L1) is necessary to get a satisfactory change of capacitance between an uncovered

and covered probe (see recommendations in Table 13). If these recommendations are observed, the standard sensitivity of 2 pF can

be achieved in most cases.

Figure 7: Level Switch Switchpoint

Table 13: Active Probe Length Recommendations

DK Length L1 (horizontal mounting)

(1)

Switchpoint X

(2)

<1.5 n.a. n.a.

≥1.6 ≥11.8 in. (300 mm) ≤11.8 in. (300 mm)

≥1.8 ≥7.9 in. (200 mm) ≤7.9 in. (200 mm)

≥2.2 ≥3.9 in. (100 mm) ≤3.9 in. (100 mm)

≥10 ≥2.0 in. (50 mm) ≤2.0 in. (50 mm)

(1)

With stated L1 the unit works with factory set sensitivity (2 pF).

(2)

The table states the switchpoint with factory set sensitivity (2 pF).

30 Emerson.com/Rosemount

January 2020 Rosemount 2555

Emerson.com/Rosemount 31

00813-0100-2555

Rev. AB

January 2020

Global Headquarters

Emerson Automation Solutions

6021 Innovation Blvd.

Shakopee, MN 55379, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 204 8889

RFQ.RMD-RCC@Emerson.com

Latin America Regional Office

Emerson Automation Solutions

1300 Concord Terrace, Suite 400

Sunrise, FL 33323, USA

+1 954 846 5030

+1 954 846 5121

RFQ.RMD-RCC@Emerson.com

Asia Pacific Regional Office

Emerson Automation Solutions

1 Pandan Crescent

Singapore 128461

+65 6777 8211

+65 6777 0947

Enquiries@AP.Emerson.com

North America Regional Office

Emerson Automation Solutions

8200 Market Blvd.

Chanhassen, MN 55317, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 204 8889

RMT-NA.RCCRFQ@Emerson.com

Europe Regional Office

Emerson Automation Solutions Europe

GmbH

Neuhofstrasse 19a P.O. Box 1046

CH 6340 Baar

Switzerland

+41 (0) 41 768 6111

+41 (0) 41 768 6300

RFQ.RMD-RCC@Emerson.com

Middle East and Africa Regional Office

Emerson Automation Solutions

Emerson FZE P.O. Box 17033

Jebel Ali Free Zone - South 2

Dubai, United Arab Emirates

+971 4 8118100

+971 4 8865465

RFQ.RMTMEA@Emerson.com

Linkedin.com/company/Emerson-Automation-Solutions

Twitter.com/Rosemount_News

Facebook.com/Rosemount

Youtube.com/user/RosemountMeasurement

©

2020 Emerson. All rights reserved.

Emerson Terms and Conditions of Sale are available upon request. The Emerson logo is a

trademark and service mark of Emerson Electric Co. Rosemount is a mark of one of the

Emerson family of companies. All other marks are the property of their respective owners.

Loading...

Loading...