Page 1

Quick Start Guide

00825-0100-2521, Rev AA

October 2019

Rosemount™ 2521 Solids Level Switch

Vibrating Fork

Page 2

Quick Start Guide October 2019

Contents

Introduction.................................................................................................................................3

Mechanical installation.................................................................................................................9

Electrical installation.................................................................................................................. 14

Configuration.............................................................................................................................18

Operation...................................................................................................................................21

Maintenance.............................................................................................................................. 22

Product certifications................................................................................................................. 24

2 Quick Start Guide

Page 3

October 2019 Quick Start Guide

1 Introduction

The level switch detects the presence and absence of a process media at its

installation point, and reports it as a switched electrical output.

Note

Other language versions of this Quick Start Guide can be found at

Emerson.com/Rosemount.

1.1 Safety messages

NOTICE

Read this manual before working with the product. For personal and system

safety, and for optimum product performance, ensure you thoroughly

understand the contents before installing, using, or maintaining this

product.

For technical assistance, contacts are listed below:

Customer Central

Technical support, quoting, and order-related questions.

• United States - 1-800-999-9307 (7:00 am to 7:00 pm CST)

• Asia Pacific- 65 777 8211

North American Response Center

Equipment service needs.

• 1-800-654-7768 (24 hours a day — includes Canada)

• Outside of these areas, contact your local Emerson representative.

WARNING

Physical access

Unauthorized personnel may potentially cause significant damage to and/or

misconfiguration of end users’ equipment. This could be intentional or

unintentional and needs to be protected against.

Physical security is an important part of any security program and

fundamental to protecting your system. Restrict physical access by

unauthorized personnel to protect end users’ assets. This is true for all

systems used within the facility.

Quick Start Guide 3

Page 4

Quick Start Guide October 2019

WARNING

Failure to follow safe installation and servicing guidelines could result in

death or serious injury.

• Ensure the level switch is installed by qualified personnel and in

accordance with applicable code of practice.

• Use the level switch only as specified in this manual. Failure to do so may

impair the protection provided by the level switch.

Explosions could result in death or serious injury.

• The level switch must only be installed and operated in non-hazardous

(ordinary) locations.

Electrical shock could cause death or serious injury.

• Avoid contact with the leads and terminals. High voltage that may be

present on leads can cause electrical shock.

• Ensure the power to the level switch is off, and the lines to any other

external power source are disconnected or not powered while wiring the

level switch.

• Ensure the wiring is suitable for the electrical current and the insulation is

suitable for the voltage, temperature, and environment.

Process leaks could result in death or serious injury.

• Ensure the level switch is handled carefully. If the process seal is

damaged, gas or dust might escape from the silo (or other vessel)

Any substitution of non-recognized parts may jeopardize safety. Repair,

e.g. substitution of components, etc. may also jeopardize safety and is

under no circumstances allowed.

• Unauthorized changes to the product are strictly prohibited as they may

unintentionally and unpredictably alter performance and jeopardize

safety. Unauthorized changes that interfere with the integrity of the

welds or flanges, such as making additional perforations, compromise

product integrity and safety. Equipment ratings and certifications are no

longer valid on any products that have been damaged or modified

without the prior written permission of Emerson. Any continued use of

product that has been damaged or modified without the written

authorization is at the customer’s sole risk and expense.

4 Quick Start Guide

Page 5

October 2019 Quick Start Guide

CAUTION

The products described in this document are NOT designed for nuclearqualified applications.

• Using non-nuclear qualified products in applications that require

nuclear-qualified hardware or products may cause inaccurate readings.

• For information on Rosemount nuclear-qualified products, contact your

local Emerson Sales Representative.

Individuals who handle products exposed to a hazardous substance can

avoid injury if they are informed of and understand the hazard.

• If the product being returned was exposed to a hazardous substance as

defined by Occupational Safety and Health Administration (OSHA), a

copy of the required Safety Data Sheet (SDS) for each hazardous

substance identified must be included with the returned level switch.

1.2 Applications

A Rosemount™ 2521 Solids Level Switch is used for monitoring the level of

bulk materials in all types of containers and silos.

The level switch can be used with all powdery and granulated bulk materials

that do not show a strong tendency to form crusts or deposits. The

detection of solids in a liquid is also possible

Typical applications are:

• Building materials

— Lime, extruded polystyrene foam (XPS), molding sand, etc.

• Food and beverage

— Milk powder, flour, salt, etc.

• Plastics

— Plastic granulates, etc.

• Timber

• Chemicals

The level switch has a threaded, flanged, or Tri Clamp process connection for

mounting it onto a silo (or other vessel). You can mount it on a side wall of

the silo, so that it is level with the filling limit to be monitored. Alternatively,

if it has an extended length, mount it vertically on top of a silo to monitor the

maximum filling limit.

The length of the fork can be up to 157.5 in. (4 m) with an extension tube.

Quick Start Guide 5

Page 6

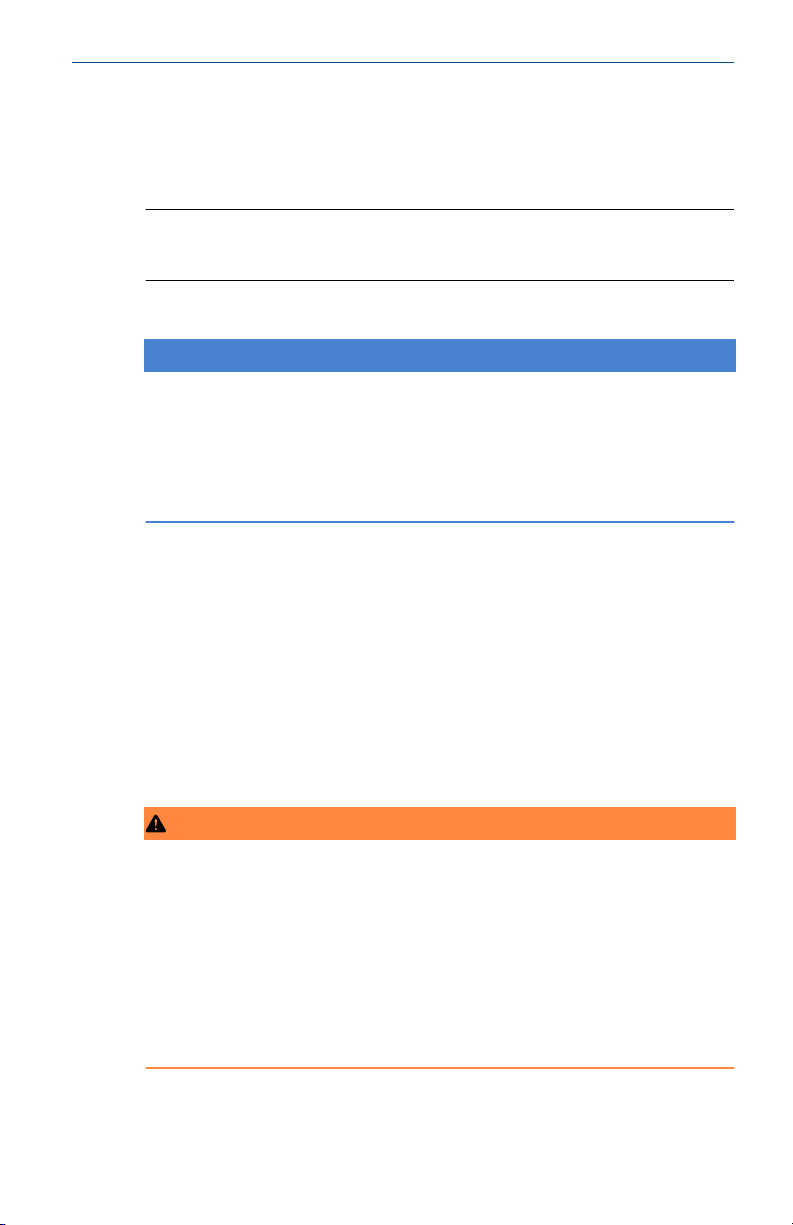

A

B

C

C

C

D

Quick Start Guide October 2019

The use of a sliding sleeve is recommended so that the switching point can

be changed easily during the live operation of the level switch.

Figure 1-1: Typical Installation Examples

A. Rosemount 2521 with the cable-extended fork length

B. Rosemount 2521 with the tube-extended fork length and thermal tube-

extension

C. Rosemount 2521 with the standard length fork

D. Optional sliding sleeve

6 Quick Start Guide

Page 7

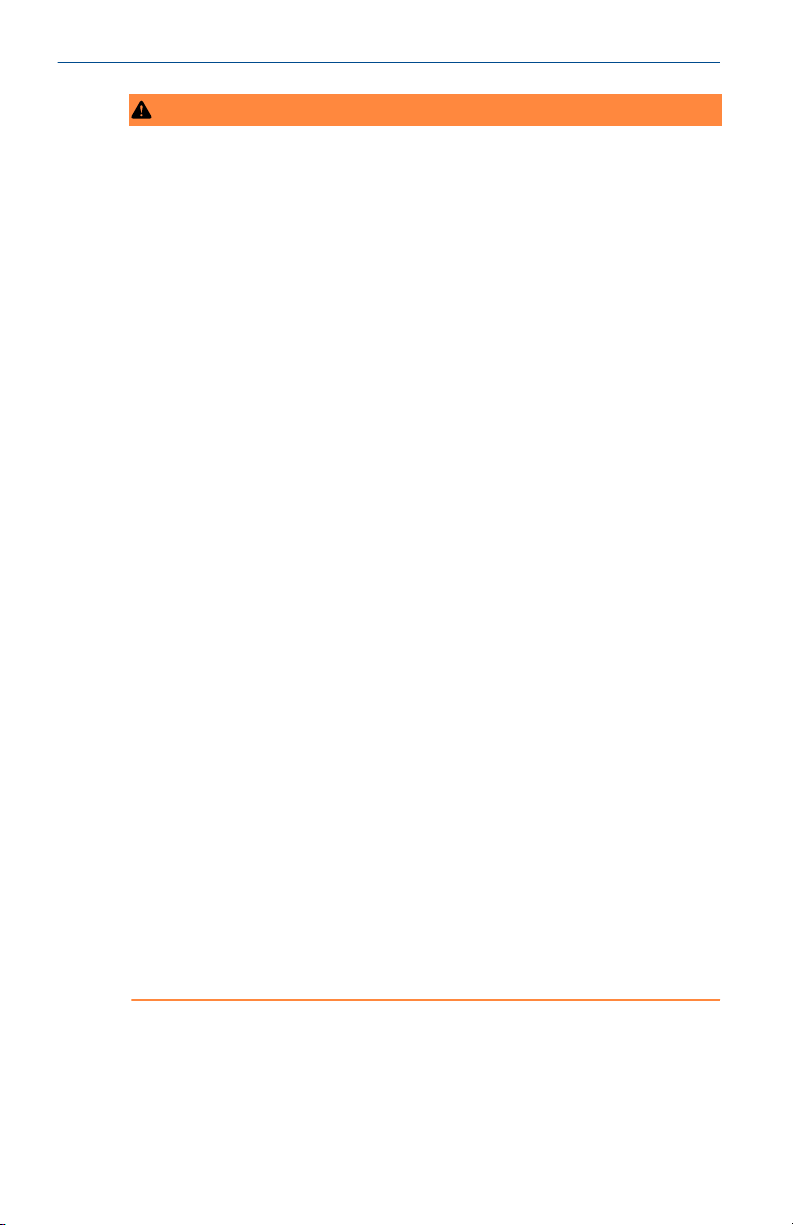

A

C

D

B

B

B

October 2019 Quick Start Guide

Figure 1-2: Detection of solids in water

A. Rosemount 2521 with the tube-extended fork length and thermal tube-

extension

1.3

B. Rosemount 2521 with the standard length fork

C. Optional sliding sleeve

D. Solids in water

Measurement principles

Using the principle of a tuning fork, a piezo-electric crystal oscillates the

forks at their natural frequency. Changes to the oscillation frequency are

continuously monitored by electronics which varies depending on whether

the fork is covered or uncovered by a solids medium.

When the solids medium in the vessel (silo) falls away from the fork, it causes

a change of oscillation frequency that is detected by the electronics and the

output switches to indicate an 'uncovered' state.

Quick Start Guide 7

Page 8

Quick Start Guide October 2019

When the solids medium in the vessel (silo) rises and covers the fork, it

causes a change of oscillation frequency that is detected by the electronics

and the output switches to indicate a 'covered' state.

The electrical output will vary depending on the electronics selected when

the Rosemount 2521 was ordered.

8 Quick Start Guide

Page 9

October 2019 Quick Start Guide

2 Mechanical installation

2.1 Mounting considerations

Before mounting the level switch on a silo (or other vessel), review the safety

and pre-mounting sections.

2.1.1 Safety

General safety

1. Installation of this equipment shall be carried out by suitably trained

personnel, in accordance with the applicable code of practice.

2. If equipment is likely to come into contact with aggressive

substances, it is the user’s responsibility to take suitable precautions

that prevent it from being adversely affected, thus ensuring the type

of protection is not compromised.

a. Aggressive substances: e.g. acidic liquids or gases that may

attack metals or solvents that may affect polymeric materials.

b. Suitable precautions: e.g. regular checks as part of routine

inspections or establishing from a material's data sheet that it

is resistant to specific chemicals.

3. It is the responsibility of the installer to:

a. Take protective measures, such as fitting an angled shield

(reverse V shape) to the silo or selecting an extension tube

option, when there are high mechanical forces.

b. Ensure that the process connection is tightened by the

correct amount of torque and sealed to prevent process

leaks.

4. Technical data

a. The Rosemount 2521 Product Data Sheet has all the technical

specifications. See Emerson.com/Rosemount for other

language versions.

Quick Start Guide 9

Page 10

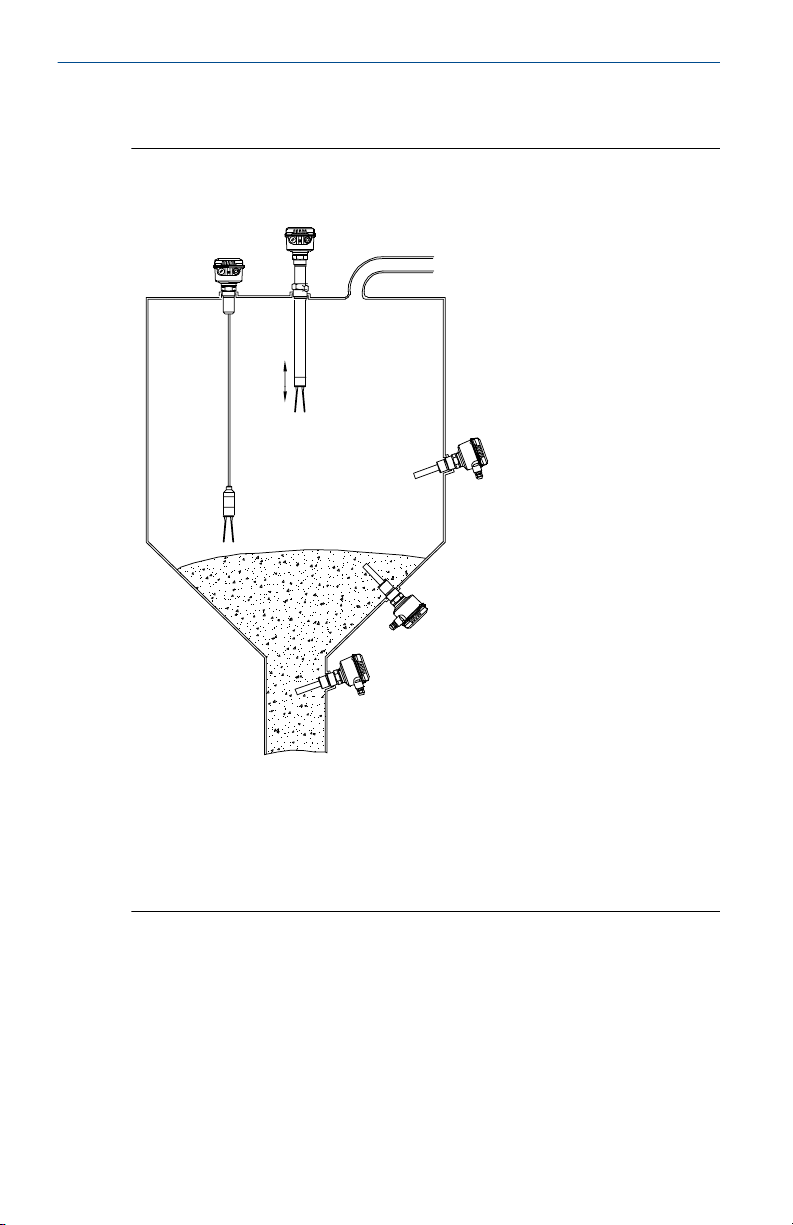

B

A

Quick Start Guide October 2019

2.1.2 Solids in Water

The detection of solids in water is supported by the Rosemount 2521S only.

An installation example can be seen in Figure 1-2.

2.1.3 Mechanical load

The load at the mounting point must not exceed 300 Nm (Rosemount 2521

with an extended length fork).

Figure 2-1: Maximum Mechanical Load

A. Mounting point

B. Mechanical load

2.1.4 Vertical installations

Table 2-1 provides the maximum fork lengths and the corresponding

maximum deviations from a normal vertical installation.

Table 2-1: Maximum Vertical Deviation

Maximum deviation Maximum fork length

5° 157.5 in. (4000 mm)

45° 47.24 in. (1200 mm)

> 45° 23.62 in. (600 mm)

10 Quick Start Guide

Page 11

A

October 2019 Quick Start Guide

2.1.5 Mounting location

Take time to assess a suitable mounting location. Avoid mounting the level

switch near the filling point, internal structures, and walls of a silo (or other

vessel). When mounting the extended length versions of the level switch, it

is especially important to consider internal structures. Forcing the level

switch into a small or congested space risks damage to the sensor and could

impair the protection it provides.

2.1.6 Sliding sleeve

Tighten both M8 screws with a torque of 20 Nm to establish a seal and

maintain the process pressure. See Figure 2-2.

Figure 2-2: Sliding Sleeve, M8 Screws

A. Two off M8 screws

2.1.7 Flange mounting

A suitable gasket must be fitted to provide a seal when the flanges are

tightened.

2.1.8 Tightening threaded process connections

When tightening the threaded process connection of a Rosemount 2521:

• Use an open-ended wrench on the hexagonal boss of the level switch or

the sliding sleeve.

• Never tighten by using the housing.

• Do not exceed the maximum torque of 80 Nm.

2.1.9 Hygienic applications

The food-grade materials are suitable for use under normal and predictable

hygienic applications (according to directive 1935/2004 Art.3). There are

currently no hygienic certifications for the Rosemount 2521.

2.1.10 Vibrating forks

Bending, shortening, or extending the forks will damage the level switch.

Quick Start Guide 11

Page 12

A

C

B

Quick Start Guide October 2019

2.1.11 Rotatable housing and fork orientation mark

The housing of the level switch can be rotated against the threaded

connection after mounting.

Figure 2-3: Housing Rotation and Fork Orientation Mark

A. Threaded process connection

B. Housing

C. Fork orientation mark on hexagonal boss (or sliding sleeve if fitted)

2.1.12 Orientation of cable glands

When the level switch is mounted horizontally, ensure the cable glands are

pointed downwards to avoid water getting inside the housing. Unused

conduit entries must be completely sealed with a suitably rated stopping

(blanking) plug.

2.1.13 Seals

Apply PTFE tape to the threaded process connection. This is required for a

silo (or other vessel) to maintain the process pressure.

2.1.14 Future maintenance

It is advisable to grease the screws of the housing cover (lid) when a

corrosive atmosphere is present. This will help prevent difficulties when the

cover needs to be removed during future maintenance tasks.

2.1.15 Switching point

Heavy bulk materials

The signal output switches over when the forks of the level switch are

covered a few millimeters.

Light bulk materials

The signal output switches over when the forks of the level switch are

covered a few centimeters.

12 Quick Start Guide

Page 13

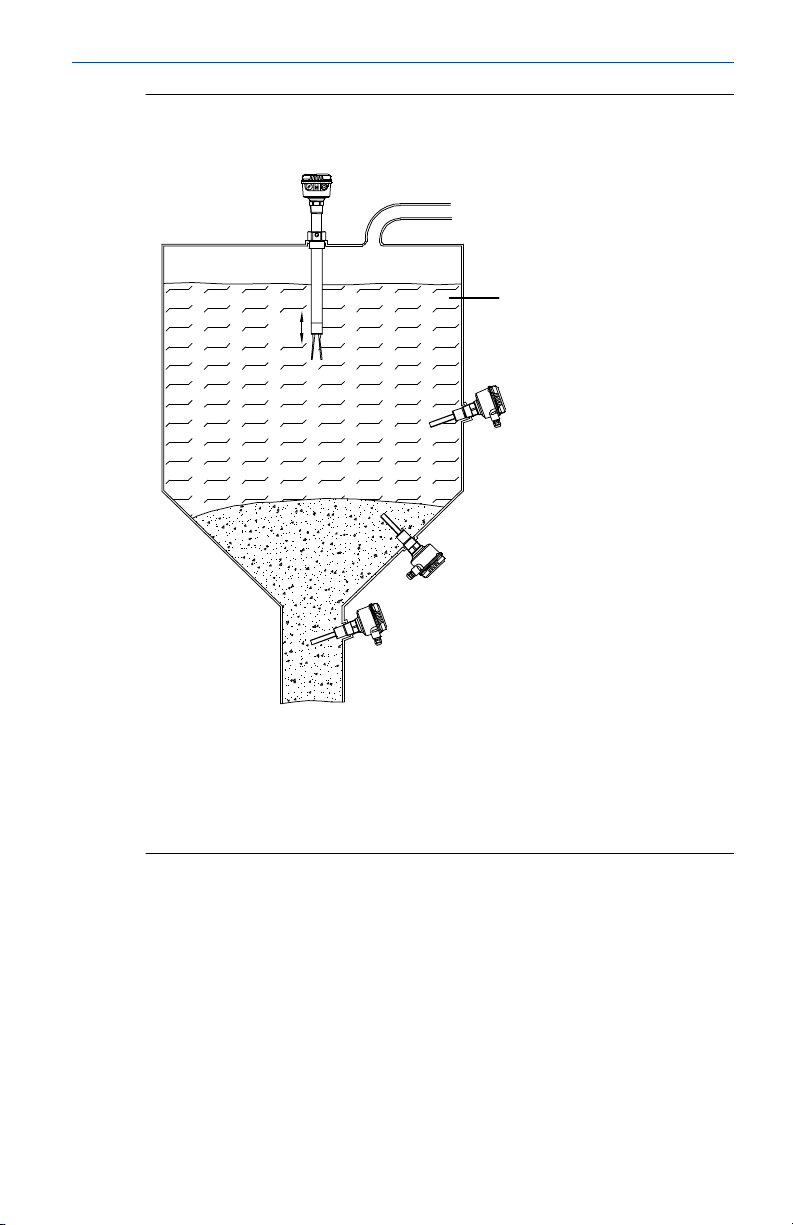

A

B

A

B

C

E

F

G

D

OK

OK

H

October 2019 Quick Start Guide

2.2 Mounting the level switch

Figure 2-4 shows how the level switch should be mounted.

Figure 2-4: Correct and Incorrect Mounting

A. Full-silo detection using the cable-extended fork length option

B. Empty-silo detection using the cable-extended or tube-extended fork

length option

C. Sliding sleeve option

D. Bulk solids slide downwards more easily when the device is mounted at

an angle (recommended)

E. Steel protection shield

F. Installation in the conical part is only suitable for solids material

(powder) that will not build-up on the forks

G. Incorrect installation - the fork orientation is not allowing solids material

to pass between the forks. Check the orientation mark on the hexagon is

either facing upwards or downwards

H. Incorrect installation - the socket is too long and allows the solids

material to easily accumulate inside it. The forks must protrude into the

silo sufficiently to correctly detect the level

Quick Start Guide 13

Page 14

Quick Start Guide October 2019

3 Electrical installation

3.1 Safety messages

WARNING

Failure to follow safe installation and servicing guidelines could result in

death or serious injury.

• Ensure the level switch is installed by qualified personnel and in

accordance with applicable code of practice.

• Use the level switch only as specified in this manual. Failure to do so may

impair the protection provided by the level switch.

Explosions could result in death or serious injury.

• The level switch must only be installed and operated in non-hazardous

(ordinary) locations.

Electrical shock could cause death or serious injury.

• Avoid contact with the leads and terminals. High voltage that may be

present on leads can cause electrical shock.

• Ensure the power to the level switch is off, and the lines to any other

external power source are disconnected or not powered while wiring the

level switch.

• Ensure the wiring is suitable for the electrical current and the insulation is

suitable for the voltage, temperature, and environment.

3.2

Wiring considerations

Note

See the Rosemount 2521 Product Data Sheet for the full electrical

specifications.

3.2.1 Handling

In cases of improper handling or handling malpractice, the electrical safety

of the device cannot be guaranteed.

3.2.2 Installation regulations

Local regulations or VDE 0100 (Regulations of German Electrotechnical

Engineers) must be observed.

When using 24 V supply voltage, an approved power supply with reinforced

insulation to mains is required.

14 Quick Start Guide

Page 15

October 2019 Quick Start Guide

3.2.3 Fuse

Use a fuse as stated in the connection diagrams.

3.2.4 Residual Current Circuit Breaker (RCCB) protection

In case of a defect, the distribution voltage must automatically be cut-off by

an RCCB protection switch to protect against indirect contact with

dangerous voltages.

3.2.5 Power supply

Power supply switch

A voltage disconnection switch must be provided near the device.

Supply voltage

Compare the supply voltage applied with the specifications given on the

electronic module and nameplate before switching on the device.

3.2.6 Wiring

Field wiring cables

The diameter has to match the clamping range of the used cable gland.

The cross-section has to match the clamping range of the connection

terminals and the maximum current must be considered.

All field wiring must have insulation suitable for at least 250 Vac.

The temperature rating must be at least 194 °F (90 °C).

Use a shielded cable when there are electrical interferences present that are

higher than stated in the EMC standards. Otherwise, an unshielded

instrumentation cable can be used.

Wiring diagram

The electrical connections are made in accordance with the wiring diagram.

Guiding the cables in the terminal box

The field wiring cables must be cut to a length to be able to properly fit them

into the terminal box.

3.2.7 Cable glands

Ensure the screwed cable gland safely seals the cable and is tight enough to

prevent water ingress. Unused conduit or cable entries must be sealed with a

stopping (blanking) plug.

Quick Start Guide 15

Page 16

12

3 4 5

A

B

C

Quick Start Guide October 2019

3.2.8 Conduit system

When a threaded conduit system is used instead of a cable gland, the

regulations of the country must be observed. The conduit must have a ½-in.

NPT tapered thread to match a NPT threaded conduit entry of the level

switch and comply with ANSI B 1.20.1. Unused conduit entries must be

closed tightly with a metal stopping (blanking) plug.

3.2.9 Connection terminals

When preparing cable wires for connection to terminals, the wire insulation

must be stripped to show no more than 0.31 in. (8 mm) of the copper

strands. Always check that the power supply is disconnected or switched-off

to avoid coming into contact with dangerous live parts.

3.2.10 Relay and transistor protection

Provide protection for relay contacts and output transistors to protect the

device against inductive load surges.

3.2.11 Static charging

The Rosemount 2521 must be grounded to avoid a static electrical build-up.

This is particularly important for applications with pneumatic conveying and

non-metallic containers.

3.3 Wiring the level switch

Figure 3-1: Connection Overview

A. Internal ground terminal - electronics connected to housing

B. Connection terminals

C. Protective conductor terminal - Protective Earth (PE)

16 Quick Start Guide

Page 17

1

2 3 4 5

PE + -

L N

October 2019 Quick Start Guide

Wiring the SPDT relay

Power supply:

• 19 to 230 Vac (50/60 Hz) +10% 8 VA

• 19 to 55 Vdc +10% 1.5 W

Signal output (floating SPDT relay):

• Maximum 250 Vac, 8 A, non-inductive

• Maximum 30 Vdc, 5 A, non-inductive

Fuse on signal output: maximum 10 A, slow or fast, HBC, 250 V

Figure 3-2: Power supply and Signal Output Connections

Quick Start Guide 17

Page 18

A

C

B

Quick Start Guide October 2019

4 Configuration

4.1 Adjustment of the signal output

FSH signal output

When the level switch is used to indicate full-silo, set to Fail Safe High. A

power failure or line break is regarded as full-silo signal (as protection

against overfilling).

FSL signal output

When the level switch is used to indicate empty load, set to Fail Safe Low. A

power failure or line break is regarded as empty-silo signal (as protection

against running dry).

Figure 4-1: FSL and FSH Settings

A. Electronic module

B. FSL setting (switch position up)

C. FSH setting (switch position down)

18 Quick Start Guide

Page 19

C

A

B

October 2019 Quick Start Guide

4.2 Sensitivity

The level switch is factory-set to high sensitivity (switch position B) and

normally does not need to be changed. However, if the bulk solids material

has a frequent tendency to cake or deposit, the setting switch can be set to

position A to decrease the sensitivity of the probe .

Figure 4-2: Sensitivity Settings

A. Low sensitivity setting A (switch position down)

B. High sensitivity setting B (switch position up) - factory default

C. Electronics PCB

Table 4-1: Approximate minimum bulk density on setting

A

Low sensitivity

Rosemount 2521S 9 lb/ft3 (150 g/l) 3 lb/ft3 (50 g/l)

Rosemount 2521H 4.5 lb/ft3 (75 g/l) 1.2 lb/ft3 (20 g/l)

Rosemount 2521H with enhanced

sensitivity

1.2 lb/ft3 (20 g/l) 0.3 lb/ft3 (5 g/l)

B

High sensitivity

Rosemount 2521S:

For measurement of solids in water, setting A is recommended. Sensitivity

adjustments to the electronics can also be made using the potentiometer.

Option of interface measurement (sensitivity adjustable with the

potentiometer)

Turn potentiometer to Min: Vibrating fork gets less sensitive.

Turn potentiometer to Max: Vibrating fork gets more sensitive.

Quick Start Guide 19

Page 20

A

B C

D

Quick Start Guide October 2019

Figure 4-3: Sensitivity Settings with Potentiometer

A. Potentiometer for adjusting the sensitivity

B. Minimum sensitivity

C. Maximum sensitivity

D. Sensitivity setting is not possible

20 Quick Start Guide

Page 21

A

B

FSL FSH FSL FSH

3 4 53 4 5

345345

A

October 2019 Quick Start Guide

5 Operation

5.1 Signal output (switching logic)

Figure 5-1: Switching Logic (All Versions)

A. Fail Safe High or Low setting

B. Signal output

Note

See Adjustment of the signal output for how to select a FSH or FSL setting.

5.2

Quick Start Guide 21

LED signal output

Figure 5-2: LED Visible On PCB

A. LED

Page 22

Quick Start Guide October 2019

6 Maintenance

6.1 Opening the lid (cover)

Before opening the lid for maintenance reasons, consider the following:

• Do not remove the lid while circuits are live.

• Ensure that no dust deposits or airborne dusts are present.

• Ensure that rain does not enter the housing.

6.2 Regular checks for safety

To ensure robust safety in hazardous locations and with electrical safety, the

following items must be regularly checked depending on the application:

• Mechanical damage or corrosion of the field wiring cables or any other

components (housing side and sensor side).

• Tight sealing of the process connection, cable glands, and enclosure lid.

• Properly connected external PE cable (if present).

6.3 Cleaning

If cleaning is required by the application, following must be observed:

• Cleaning agent must comply with the materials of the unit (chemical

resistance). Mainly the shaft sealing, lid sealing, cable gland and the

surface of the unit must be considered.

The cleaning process must be done in a way, that:

• The cleaning agent cannot enter into the unit through the shaft sealing,

lid sealing or cable gland.

• No mechanical damage of the shaft sealing, lid sealing, cable gland or

other parts can happen.

6.4

22 Quick Start Guide

Function test

A frequent function test may be required depending on the application.

Observe all relevant safety precautions related to work safety (e.g. electrical

safety, process pressure, etc).

This test does not prove if the level switch is sensitive enough to measure

the material of the application.

Function tests are done by covering the forks with a suitable solids material

and monitoring if a correct change of the signal output from uncovered to

covered happens.

Page 23

October 2019 Quick Start Guide

6.5 Production date

The production year is shown on the nameplate.

6.6 Spare parts

Refer to the Rosemount 2521 Product Data Sheet for all spare parts.

Quick Start Guide 23

Page 24

Quick Start Guide October 2019

7 Product certifications

7.1 EU Declaration of Conformity

Figure 7-1: EU Declaration of Conformity (Page 1)

24 Quick Start Guide

Page 25

October 2019 Quick Start Guide

Figure 7-2: EU Declaration of Conformity (Page 2)

Quick Start Guide 25

Page 26

含含有有

China RoHS

管管控控物物质质超超过过最最大大浓浓度度限限值值的的部部件件型型号号列列表表

Rosemount 2521

List of Rosemount 2521 Parts with China RoHS Concent ration above MCVs

部部件件 名名称称

Part Name

有有害害 物物质质 / Hazardous Substances

铅铅

Lead

(Pb)

汞汞

Mercury

(Hg)

镉镉

Cadmium

(Cd)

六六价价 铬铬

Hexavalent

Chromium

(Cr +6)

多多溴溴 联联苯苯

Polybrominated

biphenyls

(PBB)

多多溴溴 联联苯苯醚醚

Polybrominated

diphenyl ethers

(PBDE)

电子组件

Electronics

Assembly

OOO

O

壳体组件

Housing

Assembly

OOOOO

XXOOOOO

本表格系依据

SJ/T11364

的规定而制作.

This table is proposed in accordance with the provision of SJ/T11364.

O:

意为该部件的所有均质材料中该有害物质的含量均低于

GB/T 26572

所规定的限量要求.

O: Indicate that said hazardous substance in all of the homogeneous materials for this part is below the limit requirement of

GB/T 26572.

X:

意为在该部件所使用的所有均质材料里,至少有一类均质材料中该有害物质的含量高于

GB/T 26572

所规定的限量要求.

X: Indicate that said hazardous substance contained in at least one of the homogeneous materials used for this part is above

the limit requirement of GB/T 26572.

X

X X

Process Connection /

Extension

过程连接/扩展部件

Quick Start Guide October 2019

7.2 European Union directive information

The most recent revision of the EU Declaration of Conformity can be found

at Emerson.com/Rosemount.

7.3 China RoHS

26 Quick Start Guide

Page 27

October 2019 Quick Start Guide

Quick Start Guide 27

Page 28

*00825-0100-2521*

00825-0100-2521, Rev. AA

Quick Start Guide

October 2019

Global Headquarters

Emerson Automation Solutions

6021 Innovation Blvd.

Shakopee, MN 55379, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 204 8889

RFQ.RMD-RCC@Emerson.com

Latin America Regional Office

Emerson Automation Solutions

1300 Concord Terrace, Suite 400

Sunrise, FL 33323, USA

+1 954 846 5030

+1 954 846 5121

RFQ.RMD-RCC@Emerson.com

Asia Pacific Regional Office

Emerson Automation Solutions

1 Pandan Crescent

Singapore 128461

+65 6777 8211

+65 6777 0947

Enquiries@AP.Emerson.com

North America Regional Office

Emerson Automation Solutions

8200 Market Blvd.

Chanhassen, MN 55317, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 204 8889

RMT-NA.RCCRFQ@Emerson.com

Europe Regional Office

Emerson Automation Solutions Europe

GmbH

Neuhofstrasse 19a P.O. Box 1046

CH 6340 Baar

Switzerland

+41 (0) 41 768 6111

+41 (0) 41 768 6300

RFQ.RMD-RCC@Emerson.com

Middle East and Africa Regional Office

Emerson Automation Solutions

Emerson FZE P.O. Box 17033

Jebel Ali Free Zone - South 2

Dubai, United Arab Emirates

+971 4 8118100

+971 4 8865465

RFQ.RMTMEA@Emerson.com

Linkedin.com/company/Emerson-

Automation-Solutions

Twitter.com/Rosemount_News

Facebook.com/Rosemount

Youtube.com/user/

RosemountMeasurement

©

2019 Emerson. All rights reserved.

Emerson Terms and Conditions of Sale are

available upon request. The Emerson logo is a

trademark and service mark of Emerson Electric

Co. Rosemount is a mark of one of the Emerson

family of companies. All other marks are the

property of their respective owners.

Loading...

Loading...