Page 1

Product Data Sheet

00813-0100-2521, Rev AB

Rosemount™ 2521 Solids Level Switch

Vibrating Fork

January 2020

■

Very high sensitivity (<5 g/l)

■

High quality 316 stainless steel material for the process

■

Suitable for process pressures up to 232 psi (16 bar)

■

Temperature range from -40 to 302 °F (-40 to 150 °C)

■

Extremely robust short-fork versions

Page 2

Rosemount 2521 January 2020

Introduction

Measurement principles

The Rosemount™ 2521 Solids Level Switch uses the principle of a tuning fork and a piezo-electric crystal to oscillate the forks at their

natural frequency. Changes to the oscillation frequency are continuously monitored by electronics which varies depending on

whether the fork is covered or uncovered by a solids medium.

When the solids medium in the vessel (silo) falls away from the fork, it causes a change of oscillation frequency that is detected by

the electronics and the output switches to indicate an 'uncovered' state.

When the solids medium in the vessel (silo) rises and covers the fork, it causes a change of oscillation frequency that is detected by

the electronics and the output switches to indicate a 'covered' state.

The electrical output will vary depending on the electronics selected.

Key features and benefits

■

Enhanced version of the vibrating fork with extra sensitivity options

■

Available as a standard fork length and tube/cable extended fork lengths

■

Ideal for use on bulk solids - particularly suitable for use in fine-grained and powdered materials

■

Suitable for hygienic applications - polished forks and wetted parts made from stainless steel

■

Short fork design allows mounting in small pipes or process vessels with very limited space

■

Versatile installation, may be installed in vertical, horizontal, or angled positions

■

Modular and simple design

■

Available with separate electronic housing

■

Reliable, simple, and maintenance-free measurement principle

■

Robust aluminum die-cast housing with IP66 protection

■

Adjustable signal output time delay

Contents

Introduction...................................................................................................................................................................................... 2

Ordering information........................................................................................................................................................................ 4

Spares and accessories...................................................................................................................................................................... 7

Specifications.................................................................................................................................................................................... 8

Product certifications...................................................................................................................................................................... 11

Dimensional drawings..................................................................................................................................................................... 12

2 Emerson.com/Rosemount

Page 3

January 2020 Rosemount 2521

Applications

■

Applications with high mechanical loading

■

Materials with very light product density

■

Applications requiring pneumatic filling

■

Silos/vessels with limited space

■

Vibration within the vessel

■

High reliability requirements

Emerson.com/Rosemount 3

Page 4

Rosemount 2521 January 2020

Ordering information

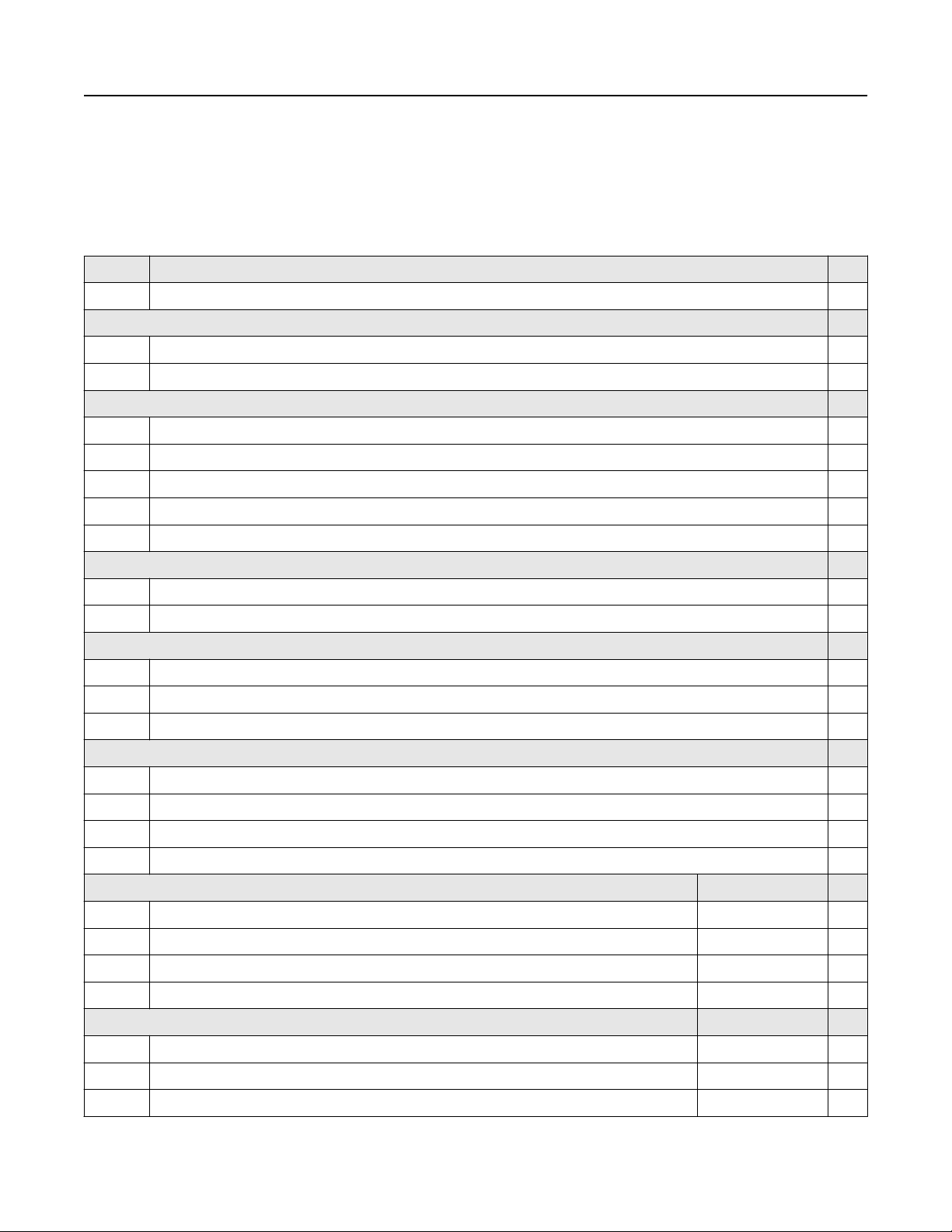

Table 1: Rosemount 2521 Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings

are subject to additional delivery lead time.

Model Product description

2521 Level Switch - Enhanced Vibrating Fork ★

Fork profile

S Standard sensitivity, 3 lb/ft3 (50 g/l), dry and wet applications ★

H High sensitivity, 1.2 lb/3 (20 g/l) ★

Thermal profile

(1)

M Without extension tube (up to T

(2)

E

(2)

R

(2)

S

C With cable extension (T

With extension tube (up to T

With remote housing cable 59-in. (1500 mm) long (up to T

With remote housing cable 157-in. (4000 mm) long (up to T

: -13 to 176 °F (-25 to 80 °C), T

proc

= 302 °F (150 °C) at T

proc

= 302 °F (150 °C) at T

proc

<= 104 °F (40 °C)) ★

amb

> 104 °F (40 °C)) ★

amb

= 302 °F (150 °C) ★

proc

= 302 °F (150 °C) ★

proc

: -13 to 140 °F (-25 to 60 °C)) ★

amb

Materials of construction: process connection/process extension tube

D 304/321 Stainless steel (1.4301/1.4541) ★

(3)

S

316L Stainless steel (1.4404) ★

Conduit entry/cable threads

1 M20 x 1.5, 1 off screwed cable gland for CE, ATEX, and IECEx ★

2 M20 x 1.5, 2 off screwed cable glands ★

4 ½-in. NPT tapered ANSI B1.20.1 (1 off conduit + 1 off Ex-d blind plug) ★

Process connection size

5 1½ in./40 mm (DN40)/40A ★

2 2 in./50 mm (DN50)/50A ★

3 3 in./80 mm (DN80)/80A ★

4 4 in./100 mm (DN100)/100A ★

Process connection rating Sizes

AA ASME B16.5 Class 150 flange All except 5 ★

DZ EN 1092-1 PN6 flange 4 ★

DA EN 1092-1 PN16 flange 4 ★

NN For use with non-flange process connection type 2 and 5 ★

Process connection type Ratings

F Flat-face flange DZ and DA ★

R Raised-face flange AA ★

B BSPT (R) thread NN ★

4 Emerson.com/Rosemount

Page 5

January 2020 Rosemount 2521

Table 1: Rosemount 2521 Ordering Information (continued)

G BSPP (G) thread NN ★

N NPT thread NN ★

(3)

C

Electronic type

E Relay SPDT 19 to 230 Vac / 19 to 55 Vdc ★

Fork length Fork profiles

(3)

A

(3)

B

(3)

E

(3)

M

(4)

F

(4)

N

Specific extended fork length

00000 Factory default length (only if fork length A or B is selected) ★

Tri Clamp NN ★

Standard length 6.47 in. (165 mm) S ★

Standard length 9.25 in. (235 mm), or 10.24-in (260 mm) for Fork Sensitivity V1/V2/V3 H ★

Extended tube, customer-specified length in tenths of inches All ★

Extended tube, customer-specified length in millimeters All ★

Extended cable, customer-specified length in tenths of inches All ★

Extended cable, customer-specified length in millimeters All ★

XXXXX Specific customer-specified tube/cable length in tenths of inches (XXXX.X inches) or millimeters (XXXXX mm) ★

Product certifications Conduit entry

NA No hazardous locations certifications All ★

(5)

ND

NK

E2

E7

E8

EM

I1

I2

I7

IM

K1

K2

K5

K7

KB

KM

KY

KZ

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

ATEX, dust certification All

IECEx, dust certification All

INMETRO Flameproof 4

IECEx Flameproof/Dust certification 4

ATEX Flameproof/Dust certification 4

(5)

Technical Regulations Customs Union (EAC), dust certification All

ATEX Intrinsic Safety and Dust certification All

INMETRO Intrinsic Safety All

IECEx Intrinsic Safety and Dust certification All

Technical Regulations Customs Union (EAC), Intrinsic Safety All

ATEX Flameproof/Increased Safety/Dust certification All

INMETRO Intrinsic Safety, Flameproof All

American Intrinsically Safe and Explosion-proof 4

IECEx Flameproof/Increased Safety/Dust certification All

American and Canadian, DIP 4

(5)

Technical Regulations Customs Union (EAC), Flameproof/Increased Safety/Dust All

American and Canadian Flameproof/Dust certification 4

American and Canadian Ordinary Location (Unclassified, safe area) certification 4

Emerson.com/Rosemount 5

Page 6

Rosemount 2521 January 2020

Table 1: Rosemount 2521 Ordering Information (continued)

Options (include with selected model number)

Calibration data certification

Q4 Certificate of functional test ★

Weather protection

P2 Weather protection cover ★

Fork sensitivity Thermal profiles

(6)

V1

V2

(6)

V3

(8)

V4

Sliding sleeve

(9)

S2

Extended product warranty

WR5 5-year limited warranty ★

Enhanced (> 0.3 lb/ft3 (5 g/l) M, E, and C ★

(6)(7)

Enhanced (< 0.3 lb/ft3 (5 g/l) with increased vibrating surface (aluminum) M, E, and C ★

Enhanced (< 0.3 lb/ft3 (5 g/l) M, E, and C ★

Adjustable sensitivity for interface applications M, E, and C ★

Sliding sleeve, maximum 232 psi (16 bar), maximum 302 °F (150 °C) ★

Typical model number: 2521 S M D 1 5 NN B E A 00000 NA

(1)

There are two adjustable settings, A and B on the electronics board. See Operating conditions for how the minimum density requirements are

affected by the Fork Profile option codes.

(2)

A thermal extension cable or tube (temperature-extended shaft) moves the electronics further away from high process temperatures. Select this

extension when ambient temperatures are greater than 104 °F (40 °C). See Operating conditions and Dimensional drawings for further

information.

(3)

Not available when Thermal Profile code C is selected.

(4)

Available only when Thermal Profile code C is selected.

(5)

Please contact your local Emerson representative for the availability of this option.

(6)

Available only when Fork Profile code H is selected (for high sensitivity).

(7)

This option requires a 4-in. flanged process connection to be selected.

(8)

Available only when Fork Profile code S is selected (for standard sensitivity in wet and dry applications) and Product Certification code NA is

selected. The potentiometer on the electronics board may then be used to fine-tune the sensitivity.

(9)

The sliding sleeve option requires an extended fork length.

6 Emerson.com/Rosemount

Page 7

January 2020 Rosemount 2521

Spares and accessories

The specification and selection of product materials, options, or components must be made by the purchaser of the equipment.

See Materials selection for more information.

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings

are subject to additional delivery lead time.

Table 2: Spares

Part number Description

02500-1000-0069 Electronics board: Relay SPDT 19 to 230 Vac, 19 to 55 Vdc, Fork Profile code S ★

02500-1000-0080 Electronics board: Relay SPDT 19 to 230 Vac, 19 to 55 Vdc, Fork Profile code H ★

02500-1000-0081 Electronics board: Relay SPDT 19 to 230 Vac, 19 to 55 Vdc, Fork Sensitivity code V1 ★

02500-1000-0082 Electronics board: Relay SPDT 19 to 230 Vac, 19 to 55 Vdc, Fork Sensitivity code V3 ★

02500-1000-0083 Electronics board: Relay SPDT 19 to 230 Vac, 19 to 55 Vdc, Fork Sensitivity code V2 ★

Table 3: Accessories

Part number Description

02500-7500-0002 Mounting kit 1 for DN100 PN6 and EN1092-1 flange with ø18 mm holes, containing:

4 off M16 x 60 mm screws (A2-grade stainless steel)

4 off M16 nuts

4 off washers

1 off seal (non-food grade) for up to 464 °F (240 °C)

02500-7500-0005 Mounting kit 2 for DN100 PN6 and EN1092-1 flange with M16 threaded holes, containing:

4 off M16 x 40 mm screws (A2-grade stainless steel)

4 off washers

1 off seal (non-food grade) for up to 464 °F (240 °C)

02500-7500-0008 Mounting kit 3 for DN100 PN16 and EN1092-1 flange with ø18 mm holes, containing:

8 off M16 x 60 mm screws (A2-grade stainless steel)

8 off M16 nuts

8 off washers

1 off seal (non-food grade) for up to 464 °F (240 °C)

02500-7500-0011 Mounting kit 4 for DN100 PN16 and EN1092-1 flange with M16 threaded holes, containing:

8 off M16 x 40 mm screws (A2-grade stainless steel)

8 off washers

1 off seal (non-food grade) for up to 464 °F (240 °C)

★

★

★

★

Emerson.com/Rosemount 7

Page 8

Rosemount 2521 January 2020

Specifications

Electrical data

Connection terminals

Cable entry options

Signal output delay

Safety operation (FSL,FSH)

Sensitivity

Vibration frequency

Installation category

Pollution degree

Electronics

Power supply

Maximum ripple of power

supply

Maximum installed load

Signal output

Intrinsically Safe (IS) ratings

Status of signal output

Isolation

Protection class

4 mm2 (AWG 12), maximum

M20 × 1.5 screwed cable gland

½-in. NPT conduit connection

Clamping range (diameter) of the factory provided cable glands:

0.24 to 0.47 in. (6 to 12 mm) for M20 × 1.5

1 second for uncovered-to-covered switchover

1 to 2 seconds for covered-to-uncovered switchover

Configurable switches for each signal output. Select Fail Safe High (FSH) or Fail Safe Low (FSL)

depending on application.

Adjustable, two settings (A or B)

Rosemount 2521S: 350 Hz

Rosemount 2521H: 125 Hz (standard) or 90 Hz (enhanced sensitive options V1 to V3)

II

2 (inside housing)

Universal voltage SPDT relay

19 to 230 Vac 50/60 Hz ±10%

19 to 55 Vdc ±10%

7 Vss at dc

8 VA, 1.5 W

Floating relay SPDT

Maximum 250 Vac, 8 A (non-inductive)

Maximum 30 Vdc, 5 A (non-inductive)

The Rosemount 2521 must only be installed in non-hazardous areas (unclassified locations).

Indicated by a built-in LED

Power supply to signal output:

2225 Vrms

I

8 Emerson.com/Rosemount

Page 9

T

amb

T

process

T

amb

T

process

A

B, C

A

B C

212˚F

(100 ˚C)

302 ˚F

(150˚C)

140 ˚F

(60 ˚C)

104 ˚F

(40 ˚C)

Ø1.97 in.

(Ø50 mm)

7.08 in.

(180 mm)

January 2020 Rosemount 2521

Mechanical data

Housing

Cable of separate housing

Degree of protection

Process connection and

extension

Fork

Maximum noise level

Overall weight

(approximated)

Aluminum housing, powder coated

Seal between housing and lid: NBR

Seal between housing and process connection: NBR

Nameplate: polyester film

Silicone elastomer, ø10 mm (ø0.39 in.), surface resistance < 109 Ohm, UV-resistent, minimum

bend radius of 1.97 in. (50 mm)

NEMA® Type 4X, IP66 (IEC/EN 60529)

Materials:

1.4301/1.4404 stainless steel (304/316L)

Flanges: 1.4541 stainless steel (321)

Extension cable: PUR with black carbon (not food grade)

Thread: R 1½-in. tapered (EN 10226) or 1½-in. NPT tapered (ANSI B 1.20.1)

Tri Clamp: 1.4301/1.4404 stainless steel (304/316L), 2-in. (DN50) ISO 2852

1.4581 stainless steel, food grade

Surface finish: polished, Ra < 0.75 μm; PTFE (on request)

50 dBA

Standard length version: 4.6 lbs (2.1 kg)

Tube/shaft extended length version: 4.6 lbs + 5.5 lbs per 39.3 in. (2.1 kg + 2.5 kg per m)

Cable extended length version: 9.9 lbs + 1.1 lbs per 39.3 in. (4.5 kg + 0.5 kg per m)

Operating conditions

Ambient temperature

(housing)

Process temperature

Emerson.com/Rosemount 9

-40 to +140 °F (-40 to +60 °C) All except cable-extended versions

-13 to +140 °F (-25 to +60 °C) Cable-extended versions

-40 to +302 °F (-40 to +150 °C) All except cable-extended versions

Mounting for process temperature up to 150 °C (302 °F): see graph

-13 to +176 °F (-25 to +80 °C) Cable-extended versions

Page 10

Rosemount 2521 January 2020

Ventilation

Minimum powder

density requirements

Bulk material

requirements

Maximum mechanical

load

Maximum mechanical

torque

Maximum tractive force

Maximum process

pressure

Vibration

Relative Humidity

Maximum altitude

Expected product

lifetime

Ventilation is not required.

Setting B: Setting A:

Rosemount 2521S 3 lb/ft3 (50 g/l) 9 lb/ft3 (150 g/l)

Rosemount 2521H 1.2 lb/ft3 (20 g/l)

0.3 lb/ft3 (5 g/l)

No strong tendency to cake or deposit.

Maximum 0.39 in. (10 mm) grain size.

600 N laterally (on the forks)

Fit a protective angled (reverse-V shaped) shield to the vessel, directly above the level switch, when

mechanical loads are high.

300 Nm Tube/shaft-extended versions

2 kN Cable-extended versions

232 psi (16 bar)

87 psi (6 bar)

The maximum overall process pressure may be reduced, depending on the selected flange. Refer to

the flange standards for pressure ratings and pressure de-ratings at higher temperatures.

1.5 (m/s2)2/Hz according to EN 60068-2-64

0 to 100%, suitable for outdoor use

6562 ft. (2000 m)

The following parameters have a negative influence on the expected product lifetime:

High ambient- and process temperatures, corrosive environments, high plant vibration, and a high

flow rate of abrasive bulk material.

Standard length and tube/shaft extended versions

Cable-extended versions

4.5 lb/ft3 (75 g/l) for standard

sensitivity

1.2 lb/ft3 (20 g/l) for enhanced

sensitivity

Transport and storage

Transport

Storage

10 Emerson.com/Rosemount

Refer to the instructions as stated on the transport packaging, otherwise the products may get

damaged.

Transport temperature: -40 to +176 °F (-40 to +80 °C)

Transport humidity: 20 to 85%

Always inspect the received goods for any damage occurred during shipment from the factory. Notify

Emerson of damaged goods as soon as possible.

Products must be stored at a dry and clean place. They must be protected from influence of corrosive

environments, vibrations, and exposure to direct sunlight.

Storage temperature: -40 to +176 °F (-40 to +80 °C)

Storage humidity: 20 to 85%

Page 11

January 2020 Rosemount 2521

Product certifications

European Union directive information

A copy of the EU Declaration of Conformity can be found at the end of the Rosemount 2521 Quick Start Guide . The most recent

revision of the EU Declaration of Conformity can be found at Emerson.com/Rosemount.

Emerson.com/Rosemount 11

Page 12

6.5

(165)

3.94

(100)

Ø1.65

(Ø42)

A

B

C

5.31 (135)

4.92

(125)

Ø4.72 (Ø120)

6.3

(160)

A

E

Ø0.39

(Ø10)

2.36

(60)

D

F

G

Rosemount 2521 January 2020

Dimensional drawings

Figure 1: Rosemount 2521S Vibrating Fork Level Switch (Standard Length, Standard Fork Sensitivity)

A. Thread

B. Tri Clamp

C. Flange

D. Thermal extension tube (temperature-extended shaft)

E. Separate housing option

F. Conduit/cable entries

G. Aluminum housing

Dimensions are in inches (millimeters).

12 Emerson.com/Rosemount

Page 13

3.94

(100)

Ø1.65

(Ø42)

A

B

C

5.31 (135)

4.92

(125)

E

Ø0.39

(Ø10)

A

2.36

(60)

6.3

(160)

D

Ø4.72 (Ø120)

F

G

11.8 to 157.5

(300 to 4000)

January 2020 Rosemount 2521

Figure 2: Rosemount 2521S Vibrating Fork Level Switch (Tube-extended Length, Standard Fork Sensitivity)

A. Thread

B. Flange

Tri Clamp

C.

D. Thermal extension tube (temperature-extended shaft)

E. Separate housing option

F. Conduit/cable entries

G. Aluminum housing

Dimensions are in inches (millimeters).

Emerson.com/Rosemount 13

Page 14

11.8 to 157.5

(300 to 4000)

11.8 to 157.5

(300 to 4000)

Ø1.65

(Ø42)

Ø1.65

(Ø42)

7.68

(195)

3.94

(100)

3.94

(100)

6.1

(155)

6.1

(155)

Ø1.65

(Ø42)

Ø1.65

(Ø42)

5.31 (135)

4.92

(125)

Ø4.72 (Ø120)

7.68

(195)

B

A

C

D D

Rosemount 2521 January 2020

Figure 3: Rosemount 2521S Vibrating Fork Level Switch (Cable Extension, Standard Fork Sensitivity)

A. Thread

B. Flange

C.

Conduit/cable entries

D. Aluminum housing

Dimensions are in inches (millimeters).

14 Emerson.com/Rosemount

Page 15

H

I

Ø1.65

(Ø42)

B

A

C

A

E

Ø0.39

(Ø10)

D

5.31 (135)

4.92

(125)

Ø4.72 (Ø120)

F

G

6.3

(160)

2.36

(60)

January 2020 Rosemount 2521

Figure 4: Rosemount 2521H Vibrating Fork Level Switch (Standard Length, Enhanced Fork Sensitivity)

A. Thread

B. Flange

C.

Tri Clamp

D. Thermal extension tube (temperature-extended shaft)

E. Separate housing option

F. Conduit/cable entries

G. Aluminum housing

H. Dimension L (see Table 4)

I. Dimension X (see Table 4)

Dimensions are in inches (millimeters).

Table 4: Dimensions L and X

Dimension Fork sensitivity options

Without option Options (V1, V2

L 9.25 in. (235 mm) 10.24 in. (260 mm)

X 6.69 in. (170 mm) 7.68 in. (195 mm)

(1)

Option V2 is only available on a Rosemount 2521 with a 4-in. DN100 flanged process connection.

(1)

and V3)

Emerson.com/Rosemount 15

Page 16

Ø1.65

(Ø42)

H

A

B

C

A

D

E

Ø0.39

(Ø10)

2.36

(60)

5.31 (135)

4.92

(125)

Ø4.72 (Ø120)

6.3

(160)

F

G

11.8 to 157.5

(300 to 4000)

Rosemount 2521 January 2020

Figure 5: Rosemount 2521H Vibrating Fork Level Switch (Tube-extended Length, Enhanced Fork Sensitivity)

A. Thread

B. Flange

C.

Tri Clamp

D. Thermal extension tube (temperature-extended shaft)

E. Separate housing option

F. Conduit/cable entries

G. Aluminum housing

H. Dimension X (see Table 5)

Dimensions are in inches (millimeters).

Table 5: Dimension X

Dimension Fork sensitivity options

Without option Options V1, V2

X 6.69 in. (170 mm) 7.68 in. (195 mm)

(1)

Option V2 is only available on a Rosemount 2521 with a 4-in. DN100 flanged process connection.

(1)

and V3

16 Emerson.com/Rosemount

Page 17

5.31 (135)

4.92

(125)

C

D

Ø4.72 (Ø120)

29.6 to 787

(750 to 20000)

29.6 to 787

(750 to 20000)

7.68

(195)

E

6.1

(155)

7.68

(195)

E

6.1

(155)

Ø1.65

(Ø42)

Ø1.65

(Ø42)

Ø1.65

(Ø42)

Ø1.65

(Ø42)

B

A

January 2020 Rosemount 2521

Figure 6: Rosemount 2521H Vibrating Fork Level Switch (Cable Extension, Enhanced Fork Sensitivity)

A. Thread

B. Flange

Conduit/cable entries

C.

D. Aluminum housing

E. Dimension X (see Table 5)

Dimensions are in inches (millimeters).

Emerson.com/Rosemount 17

Page 18

Rosemount 2521 January 2020

18 Emerson.com/Rosemount

Page 19

January 2020 Rosemount 2521

Emerson.com/Rosemount 19

Page 20

00813-0100-2521

Rev. AB

January 2020

Global Headquarters

Emerson Automation Solutions

6021 Innovation Blvd.

Shakopee, MN 55379, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 204 8889

RFQ.RMD-RCC@Emerson.com

Latin America Regional Office

Emerson Automation Solutions

1300 Concord Terrace, Suite 400

Sunrise, FL 33323, USA

+1 954 846 5030

+1 954 846 5121

RFQ.RMD-RCC@Emerson.com

Asia Pacific Regional Office

Emerson Automation Solutions

1 Pandan Crescent

Singapore 128461

+65 6777 8211

+65 6777 0947

Enquiries@AP.Emerson.com

North America Regional Office

Emerson Automation Solutions

8200 Market Blvd.

Chanhassen, MN 55317, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 204 8889

RMT-NA.RCCRFQ@Emerson.com

Europe Regional Office

Emerson Automation Solutions Europe

GmbH

Neuhofstrasse 19a P.O. Box 1046

CH 6340 Baar

Switzerland

+41 (0) 41 768 6111

+41 (0) 41 768 6300

RFQ.RMD-RCC@Emerson.com

Middle East and Africa Regional Office

Emerson Automation Solutions

Emerson FZE P.O. Box 17033

Jebel Ali Free Zone - South 2

Dubai, United Arab Emirates

+971 4 8118100

+971 4 8865465

RFQ.RMTMEA@Emerson.com

Linkedin.com/company/Emerson-Automation-Solutions

Twitter.com/Rosemount_News

Facebook.com/Rosemount

Youtube.com/user/RosemountMeasurement

©

2020 Emerson. All rights reserved.

Emerson Terms and Conditions of Sale are available upon request. The Emerson logo is a

trademark and service mark of Emerson Electric Co. Rosemount is a mark of one of the

Emerson family of companies. All other marks are the property of their respective owners.

Loading...

Loading...