Page 1

Product Data Sheet

January 2018

00813-0100-4825, Rev LB

Rosemount™ 248 Temperature Transmitter

Basic temperature transmitter offers a reliable solution for temperature monitoring points.

Standard transmitter design provides flexible and reliable performance in process environments.

Experience lower over-all installation costs when compared to wiring sensor directly, reducing the need for

expensive extension wires and multiplexers.

Explore the benefits of a Complete Point Solution

™

from Rosemount Temperature.

Page 2

Rosemount 248

January 2018

Rosemount 248 Temperature Transmitter

Basic temperature transmitter offers a cost effective solution for temperature monitoring points

DIN B style head mount transmitter

Variet y of DIN B enclosure options

Rail mount

HART

Single sensor capability with universal sensor inputs (RTD, T/C, mV, ohms)

Standard transmitter design provides flexible and reliable performance in process environments

Offers improved measurement accuracy and reliability over direct-wiring a sensor to the digital control system for a lower overall

installation cost

One-year stability rating reduces maintenance costs

Open/short sensor diagnostics assist with detecting issues in the sensor loop

Compensation for ambient temperatures enhances transmitter performance

®

/4–20 mA Protocol

Explore the benefits of a Complete Point Solution from Rosemount Temperature Measurement

An “Assemble to Sensor” option enables Emerson

temperature solution, delivering an installation-ready transmitter and sensor

assembly

Emerson offers a selection of RTDs, thermocouples, and thermowells that bring

superior durability and Rosemount reliability to temperature sensing, complementing

the Rosemount Transmitter portfolio

™

to provide a complete point

Experience global consistency and local support from numerous worldwide Rosemount Temperature manufacturing sites

World-class manufacturing provides globally consistent

product from every factory and the capacity to fulfill the

needs of any project, large or small

Experienced Instrumentation Consultants help select the right

product for any temperature application and advise on best

installation practices

An extensive global network of Emerson service and support

personnel can be on-site when and where they are needed

Contents

Rosemount 248 Temperature Transmitter . . . . . . page 3

Transmitter Specifications . . . . . . . . . . . . . . . . . . . . page 8

Product Certifications . . . . . . . . . . . . . . . . . . . . . . . page 12

2

Dimensional Drawings . . . . . . . . . . . . . . . . . . . . . . . page 17

Configuration Interface Specifications . . . . . . . . . page 18

Emerson.com/Rosemount

Page 3

January 2018

Rosemount 248

Rosemount 248 Temperature Transmitter

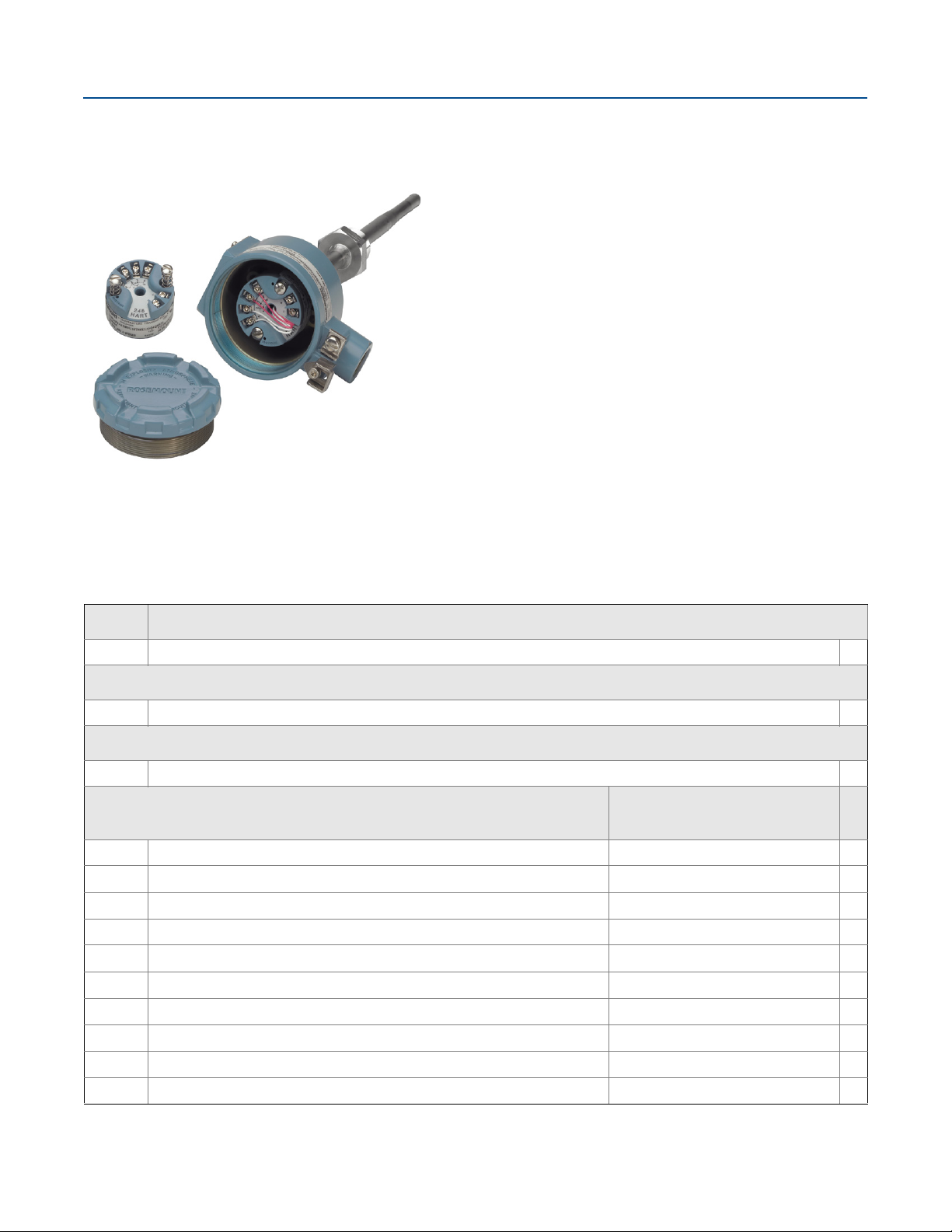

Rosemount 248 Head Mount Temperature Transmitter

The Rosemount 248 has a standard transmitter design that

provides flexible and reliable performance in process

environments.

Transmitter features include:

HART/4–20 mA Communication Protocol

DIN B style head mount and rail mount transmitter types

Variety of DIN B enclosure options

Sanitary Connection Heads available (option code F and S)

Three-Point Calibration Certificate (option code Q4)

Assemble to Sensor options (option code XA)

Specification and selection of product materials, options, or

components must be made by the purchaser of the equipment.

See page 9 for more information on material selection.

Table 1. Rosemount 248 Head Mount Temperature Transmitter

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

Model Product description

248 Temperature transmitter

Transmitter type

H DIN B Head Mount ★

Transmitter output

A 4–20 mA with digital signal based on HART Protocol ★

Product certifications

E5 FM Explosion-Proof A, U, G, H ★

I5 FM Intrinsic Safety and Class I, Division 2 A, B, U, N, G, S, H ★

K5 FM Intrinsic Safety, Explosion-Proof, and Class I, Division 2 A, U, G, H ★

I6 CSA Intrinsic Safety and Class I, Division 2 A, B, U, N, G, H ★

K6 CSA Intrinsic Safety, Explosion-Proof, and Class I, Division 2 A, U, G, H ★

E1 ATE X Flam epr oof A, U, G, H ★

I1 ATEX Intrinsic Safety A, B, U, N,C, G, S, H ★

ND ATE X Dust A, U, G, H ★

N1 ATEX Type n A, U, G, H ★

(1)

NC

ATEX Type n Component N ★

Enclosure option codes

permitted

Emerson.com/Rosemount

3

Page 4

Rosemount 248

Table 1. Rosemount 248 Head Mount Temperature Transmitter

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

E7 IECEx Flameproof and Dust A, U, G, H ★

I7 IECEx Intrinsic Safety All options ★

N7 IECEx Type n A, U, G, H ★

NG IECEx Type n Component N ★

KM Technical Regulations Customs Union (EAC) Flameproof, Intrinsic Safety A, U, G, H ★

IM Technical Regulations Customs Union (EAC) Intrinsic Safety All options ★

EM Technical Regulations Customs Union (EAC) Flameproof A, U, G, H ★

E3 China Flameproof A, G, H, N ★

I3 China Intrinsic Safety A, G, H, N ★

N3 China Type n A, U, G, H ★

NA No Approval All options ★

January 2018

Enclosure Material IP rating

A Connection head Aluminum IP66/68 ★

B BUZ head Aluminum IP65 ★

C BUZ head Polypropylene IP65 ★

G Connection head SST IP66/IP68 ★

H Universal head (junction box) SST IP66/IP68 ★

U Universal head (junction box) Aluminum IP66/IP68 ★

N No enclosure N/A N/A ★

F Sanitary connection head, DIN A Polished SST IP66/IP68

S Sanitary connection head, DIN B Polished SST IP66/IP68

Conduit entry size

(3)

1

2

0 No enclosure ★

M20 1.5 (CM20) ★

1

/2-in. NPT ★

(2)

Assemble to options

XA Sensor specified separately and assembled to transmitter ★

NS No sensor ★

Options (include with selected model number)

Alarm level configuration

A1 NAMUR alarm and saturation levels, high alarm ★

CN NAMUR alarm and saturation levels, low alarm ★

5-point calibration

C4 5-point calibration (requires the Q4 option code to generate a calibration certificate) ★

4

Emerson.com/Rosemount

Page 5

January 2018

Rosemount 248

Table 1. Rosemount 248 Head Mount Temperature Transmitter

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

Calibration certificate

Q4 Calibration certificate (3-point calibration) ★

External ground

G1 External ground lug assembly ★

Line filter

F6 60 Hz line voltage filter ★

Conduit electrical connector

(2)(4)

GE

GM

M12, 4 pin, male connector (eurofast®) ★

(2)(4)

A-size mini, 4 pin, male connector (minifast®) ★

External label

EL External label for ATEX Intrinsic Safety ★

Cover chain option

G3 Cover chain ★

Software configuration

C1 Custom configuration of date, descriptor and message (requires CDS with order) ★

Extended product warranty

WR3 3-year warranty ★

WR5 5-year warranty ★

Typical model number: 248H A I1 A 1 DR N080 T08 EL U250 CN

1. The Rosemount 248H with ATE X Type n Component Approval is not approved as a stand alone unit, additional system certification is required. Transmitter must be

installed so it is protected to at least the requirements of IP54.

2. All process connection threads are

3. For enclosures H and U with the XA option specified, a

4. Available with Intrinsically Safe approvals only for FM Intrinsically Safe or Non-Incendive approval (Option Code I5). To maintain NE MA

according to Rosemount Drawing 03151-1009.

1

/2-in. NPT, except for Enclosure Codes H and U with Conduit Entry Code 1 and Sensor Type Code NS.

1

/2-in. NPT to M20 1.5 thread adapter is used.

®

4X r ati ng, i t mu st be ins tal led

Emerson.com/Rosemount

5

Page 6

Rosemount 248

January 2018

Rosemount 248R Rail Mount Transmitter

The Rosemount 248 has a standard transmitter design that provides

flexible and reliable performance in process environments.

Transmitter features include:

HART/4–20 mA communication protocol

Rail mount transmitter type

3-Point Calibration Certificate (Option Code Q4)

Custom Configuration of Software Parameters (Option Code C1)

Table 2. Rosemount 248R Rail Mount Transmitter

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

Model Product description

248R Rail mount temperature transmitter

Output protocol

A 4–20 mA with digital signal based on HART Protocol ★

Product certifications

I5 FM Intrinsically Safe and Class I, Division 2 ★

I6 CSA Intrinsically Safe and Class I, Division 2 ★

I1 ATEX Intrinsic Safety ★

NC ATEX Type n Component ★

(1)

I7

IM GOST (Russia) Intrinsically Safe ★

NA No Approvals ★

IECEx Intrinsic Safety ★

Options (include with selected model number)

Software configuration

C1 Custom configuration of enters date, descriptor and message (CDS required with order) ★

Alarm level configuration

A1 NAMUR alarm and saturation levels, high alarm ★

CN NAMUR alarm and saturation levels, low alarm ★

5-point calibration

C4 5-point calibration (requires the Q4 option code to generate a calibration certificate) ★

Calibration certificate

Q4 Calibration certificate (3-point calibration) ★

Line filter

F6 60 Hz line voltage filter ★

6

Emerson.com/Rosemount

Page 7

January 2018

Table 2. Rosemount 248R Rail Mount Transmitter

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

Rosemount 248

Mounting style

GR G-rail mounting ★

Extended product warranty

WR3 3-year warranty ★

WR5 5-year warranty ★

Typical model number: 248R A I1 Q4

1. Consult factor y for availability.

Emerson.com/Rosemount

7

Page 8

Rosemount 248

4–20 mA dc

1322

1100

1000

750

500

250

0

1012.0 20

30

40

42.4

Load (Ohms)

Supply Voltage (Vdc)

Operating

Region

Transmitter Specifications

January 2018

Functional specifications

Inputs

User-selectable; sensor terminals rates to 42.4 Vdc. See

“Transmitter accuracy and ambient temperature effects” on

page 10 for sensor options.

Output

Two- wire 4–20 mA, linear with temperature or input; digital

output signal superimposed on 4–20 mA signal, available for a

Field Communicator or control system interface.

Isolation

Input/output isolation tested to 500 Vac rms (707 Vdc) at

50/60 Hz.

Power supply

An external power supply is required for HART devices. The

transmitter operates on 12.0 to 42.4 Vdc transmitter terminal

voltage with load resistance between 250 and 1100 ohms. A

minimum of 17.75 Vdc power supply is required with a load of

250 ohms. Transmitter power terminals are rated to 42.4 Vdc.

Figure 1. Maximum Load = 40.8 (Supply Voltage – 12.0)

Transient protection

The optional Rosemount 470 Transient Protector prevents

damage from transients induced by lightning, welding, heavy

electrical equipment, or switch gears. Refer to the

Rosemount 470 Product Data Sheet

for more information.

Temperature limits

Operating limit

–40 to 185 °F (–40 to 85 °C)

Storage limit

–58 to 248 °F (–50 to 120 °C)

Turn-on time

Performance within specifications in less than five seconds after

power is applied to transmitter, when damping value is set to

zero seconds.

Update rate

Less than 0.5 seconds

Damping

32 seconds maximum; five seconds default

Custom alarm and saturation levels

Custom factory configuration of alarm and saturation levels is

available with option code C1 for valid values. These values can

also be configured in the field using a Field Communicator.

Recommended minimum measuring span

10 K

Software detected failure mode

The values at which the transmitter drives its output in failure

mode depends on whether it is configured to standard, custom,

Humidity limits

0–99 percent relative humidity, non-condensing

NAMUR recommendations

The Rosemount 248 meets the following NAMUR

recommendations:

NE 21 – Electromagnetic compatibility (EMC) for Process and

Laboratory Apparatus

NE 43 – Standard of the signal level breakdown information of

digital transmitters

NE 89 – Standard of temperature transmitters with digital

signal processing

8

or NAMUR-compliant (NAMUR recommendation NE 43)

operation. The values for standard and NAMUR-compliant

operation are as follows:

Table 3. Operation Parameters

Standard

Linear output 3.9 ≤ I ≤ 20.5 3.8 ≤ I ≤ 20.5

Fail high 21 ≤ I ≤ 23 (default) 21 ≤ I ≤ 23 (default)

Fail low I ≤ 3.75 I ≤ 3.6

1. Measured in milliamperes.

Certain hardware failures, such as microprocessor failures, will

always drive the output to greater than 23 mA.

(1)

NAMUR NE43-

compliant

(1)

Emerson.com/Rosemount

Page 9

January 2018

Rosemount 248

Physical specifications

Material selection

Emerson provides a variety of Rosemount product with various

product options and configurations including materials of

construction that can be expected to perform well in a wide

range of applications. The Rosemount product information

presented is intended as a guide for the purchaser to make an

appropriate selection for the application. It is the purchaser’s

sole responsibility to make a careful analysis of all process

parameters (such as all chemical components, temperature,

pressure, flow rate, abrasives, contaminants, etc.), when

specifying product, materials, options and components for the

particular application. Emerson is not in a position to evaluate or

guarantee the compatibility of the process fluid or other process

parameters with the product, options, configuration or

materials of construction selected.

Conformance to specification (±3σ [Sigma])

Technology leadership, advanced manufacturing techniques,

and statistical process control ensure specification conformance

to at least ±3σ.

Field Communicator connections

Communication terminal: clips permanently fixed to the

terminals

Weight

Code Options Weight

248H Headmount transmitter 42 g (1.5 oz)

248R Railmount transmitter 250 g (8.8 oz)

U Universal head 520 g (18.4 oz)

B BUZ head 240 g (8.5 oz)

C Polypropylene head 90 g (3.2 oz.)

A Rosemount connection head 524 g (18.5 oz)

S

G

H Universal head (SST) 1700 g (60 oz)

Polished stainless steel (SST)

head

Rosemount connection head

(SST)

537 g (18.9 oz)

1700 g (60 oz)

Enclosure ratings

The Universal (option code U) and Rosemount Connection

(option code A) Heads are NEMA 4X, IP66, and IP68. The

Universal Head with 1/2 NPT threads is CSA Enclosure Type 4X.

The BUZ head (option code B) is NEMA 4 and IP65.

Materials of construction

Electronics housing

Reinforced GE polyphenylene oxide glass

Universal (option code U and H) and Rosemount connection

(option code A and G) heads

Housing: Low-copper aluminum (option codes U and A)

Stainless Steel (option codes G and H)

Paint: Polyurethane

Cover O-Ring: Buna–N

BUZ head (option code B)

Housing: Aluminum

Paint: Aluminum lacquer

O-Ring Seal: Rubber

Mounting

The Rosemount 248R attaches directly to a wall or a DIN rail. The

Rosemount 248H installs in a connection head or universal head

mounted directly on a sensor assembly or apart from a sensor

assembly using a universal head. The Rosemount 248H can also

mount to a DIN rail using an optional mounting clip

(see Table 7 on page -19).

Performance specifications

Electromagnetic compatibility (EMC)

NAMUR NE21 Standard

The Rosemount 248 meets the requirements for NAMUR NE21

Rating.

Susceptibility Parameter Influence

ESD

Radiated •80–1000 MHz at 10 V/m AM None

Burst •1 kV for I.O. None

Surge

Conducted • 150 kHz to 80 MHz at 10 V None

CE mark

The Rosemount 248 meets the requirements listed in IEC

61326-1:2006 and IEC 61326-2-3:2006.

Power supply effect

Less than ±0.005 percent of span per volt

•6 kV contact discharge

•8 kV air discharge

•0.5 kV line–line

•1 kV line–ground (I.O. tool)

None

None

Emerson.com/Rosemount

9

Page 10

Rosemount 248

1 234 4 4 4333222111

+

_

January 2018

Vibration effect

Tested to the following with no effect on performance per IEC

60770-1, 1999:

Sensor connections

Figure 2. Rosemount 248 Sensor Connections

Frequency Vibration

10 to 60 Hz 0.21 mm displacement

60 to 2000 Hz 3 g peak acceleration

Stability

For RTD and thermocouple inputs the transmitter will have a

stability of ±0.1percent of reading or 0.1 °C (whichever is

greater) for 12 months.

Self calibration

The analog-to-digital measurement circuitry automatically

self-calibrates for each temperature update by comparing the

dynamic measurement to extremely stable and accurate

internal reference elements.

2-wire

RTD and V

1. Rosemount provides four-wire sensors for all single element RTDs. These

RTDs can be used in three-wire configurations by leaving the unneeded

leads disconnected and insulated with electrical tape.

3-wire

RTD and V

(1)

4-wire

RTD and V

Transmitter accuracy and ambient temperature effects

Note

The accuracy and ambient temperature effect is the greater of the fixed and percent of span values (see example).

Table 4. Input Options, Accuracy, and Ambient Temperature Effects

Sensor options

Sensor

reference

Input ranges

Recommended

min. span

(1)

Digital

accuracy

(2)

T/C

and mV

D/A

accuracy

(3)

2-, 3-, 4-wire RTDs °C °F °C °F °C °F

Pt 100 (α = 0.00385) IEC 751 –200 to 850 –328 to 1562 10 18 ± 0.15 ± 0.27 ±0.03% of span

Pt 200 (α = 0.00385) IEC 751 –200 to 850 –328 to 1562 10 18 ± 0.15 ± 0.27 ±0.03% of span

Pt 500 (α = 0.00385) IEC 751 –200 to 850 –328 to 1562 10 18 ± 0.19 ± 0.34 ±0.03% of span

Pt 1000 (α = 0.00385) IEC 751 –200 to 300 –328 to 572 10 18 ± 0.19 ± 0.34 ±0.03% of span

Pt 100 (α = 0.003916) JIS 1604 –200 to 645 –328 to 1193 10 18 ± 0.15 ± 0.27 ±0.03% of span

Pt 200 (α = 0.003916) JIS 1604 –200 to 645 –328 to 1193 10 18 ± 0.27 ± 0.49 ±0.03% of span

Ni 120 Edison Cur ve No. 7 –70 to 300 –94 to 572 10 18 ± 0.15 ± 0.27 ±0.03% of span

Cu 10

Pt 50 (α = 0.00391) GOST 6651-94 –200 to 550 –328 to 1022 10 18 ± 0.30 ± 0.54 ±0.03% of span

Pt 100 (α = 0.00391) GOST 6651-94 –200 to 550 –328 to 1022 10 18 ± 0.15 ± 0.27 ±0.03% of span

Cu 50 (α = 0.00426) GOST 6651-94 –50 to 200 –58 to 392 10 18 ±1.34 ± 2.41 ±0.03% of span

Cu 50 (α = 0.00428) GOST 6651-94 –185 to 200 –301 to 392 10 18 ±1.34 ± 2.41 ±0.03% of span

Cu 100 (α = 0.00426) GOST 6651-94 –50 to 200 –58 to 392 10 18 ±0.67 ± 1.20 ±0.03% of span

Cu 100 (α = 0.00428) GOST 6651-94 –185 to 200 –301 to 392 10 18 ±0.67 ± 1.20 ±0.03% of span

Edison Copper

Winding No. 15

–50 to 250 –58 to 482 10 18 ±1.40 ± 2.52 ±0.03% of span

10

Emerson.com/Rosemount

Page 11

January 2018

0.220.06

2

+0.21° C=

Rosemount 248

Table 4. Input Options, Accuracy, and Ambient Temperature Effects

Sensor options

Thermocouples

(5)

Typ e B

Typ e E

Typ e J

(6)

Typ e K

Typ e N

Typ e R

Typ e S

Typ e T

DIN Type L DIN 43710 –200 to 900 –328 to 1652 25 45 ± 0.35 ± 0.63 ±0.03% of span

DIN Type U DIN 43710 –200 to –600 –328 to 1112 25 45 ± 0.35 ± 0.63 ±0.03% of span

Typ e W5Re /W2 6Re ASTM E 988-96 0 to 2000 32 to 3632 25 45 ± 0.70 ± 1.26 ±0.03% of span

GOST Type L

Sensor

reference

(4)

NIST Monograph

175, IEC 584

NIST Monograph

175, IEC 584

NIST Monograph

175, IEC 584

NIST Monograph

175, IEC 584

NIST Monograph

175, IEC 584

NIST Monograph

175, IEC 584

NIST Monograph

175, IEC 584

NIST Monograph

175, IEC 584

GOST R

8.585-2001

Input ranges

100 to 1820 212 to 3308 25 45 ± 0.77 ± 1.39 ±0.03% of span

–200 to 1000 –328 to 1832 25 45 ± 0.20 ± 0.36 ±0.03% of span

–180 to 760 –292 to 1400 25 45 ± 0.35 ± 0.63 ±0.03% of span

–180 to 1372 –292 to 2501 25 45 ± 0.50 ± 0.90 ±0.03% of span

–200 to 1300 –328 to 2372 25 45 ± 0.50 ± 0.90 ±0.03% of span

0 to 1768 32 to 3214 25 45 ± 0.75 ± 1.35 ±0.03% of span

0 to 1768 32 to 3214 25 45 ± 0.70 ± 1.26 ±0.03% of span

–200 to 400 –328 to 752 25 45 ± 0.35 ± 0.63 ±0.03% of span

–200 to 800 –328 to 1472 25 45 ± 1.00 ± 1.26 ±0.03% of span

Recommended

min. span

(1)

Digital

accuracy

(2)

D/A

accuracy

Other input types

Millivolt Input –10 to 100 mV ±0.015 mV ±0.03% of span

2-, 3-, 4-wire Ohm Input 0 to 2000 ohms ±0.45 ohm ±0.03% of span

(3)

1. No minimum or maximum span restrictions within the input ranges. Recommended minimum span will hold noise within

accuracy specification with damping at zero seconds.

2. The published digital accuracy applies over the entire sensor input range. Digital output can be accessed by HART or FOUNDATION

Fieldbus Communications or Rosemount control system.

3. Total analog accuracy is the sum of digital and D/A accuracies. This is not applicable for F

OUNDATION Fieldbus.

4. Total digital accuracy for thermocouple measurement: sum of digital accuracy +0.5 °C. (cold junction accuracy).

5. Digital accuracy for NIST Type B T/C is ±3.0 °C (±5.4 °F) from 100 to 300 °C (212 to 572 °F).

6. Digital accuracy for NIST Type K T/C is ±0.70 °C (±1.26 °F) from –180 to –90 °C (–292 to –130 °F).

Transmitter accuracy example

When using a Pt 100 (a = 0.00385) sensor input with a 0 to 100 °C span, use the greater of the two calculated values. In this case, the

accuracy would be ±0.2 °C.

Transmitter temperature effects example

Transmitters can be installed in locations where the ambient temperature is between –40 and 185 °F (–40 and 85 °C). In order to

maintain excellent accuracy performance, each transmitter is individually characterized over this ambient temperature range at the

factory.

When using a Pt 100 (a = 0.00385) sensor input with a 0–100 °C span at 30 °C ambient temperature:

Temperature Effects: 0.006 °C (30 – 20) = 0.06 °C

Total transmitter error

Worst Case Transmitter Error: Accuracy + Temperature Effects = 0.2 °C + 0.06 °C = 0.26 °C

Total Probable Transmitter Error:

Emerson.com/Rosemount

11

Page 12

Rosemount 248

Product Certifications

Rev 1.20

January 2018

European Directive Information

A copy of the EU Declaration of Conformity can be found at the

end of the Quick Start Guide. The most recent revision of the EU

Declaration of Conformity can be found at

Emerson.com/Rosemount

.

Ordinary Location Certification

As standard, the transmitter has been examined and tested to

determine that the design meets the basic electrical,

mechanical, and fire protection requirements by a nationally

recognized test laboratory (NRTL) as accredited by the Federal

Occupational Safety and Health Administration (OSHA).

North America

The US National Electrical Code® (NEC) and the Canadian

Electrical Code (CEC) permit the use of Division marked

equipment in Zones and Zone marked equipment in Divisions.

The markings must be suitable for the area classification, gas,

and temperature class. This information is clearly defined in the

respective codes.

Canada

I6 Canada Intrinsically Safe

Certificate: 1091070

Standards: CAN/CSA C22.2 No. 0-10, CSA Std. C22.2 No.

25-1966, CAN/CSA C22.2 No. 94-M91,

CAN/CSA C22.2 No. 157-92, CSA C22.2 No.

213-M1987, C22.2 No 60529-05

Markings: IS CL I, DIV 1 GP A, B, C, D when installed per

Rosemount drawing 00248-1056; CL I DIV 2 GP

A, B, C, D; Type 4X, IP66/68

K6 CSA Intrinsically Safe, Explosionproof, and Class 1,

Division 2

Certificate: 1091070

Standards: CAN/CSA C22.2 No. 0-10, CSA Std. C22.2 No.

25-1966, CSA Std. C22.2 No. 30-M1986,

CAN/CSA C22.2 No. 94-M91, CSA Std. C22.2

No.142-M1987, CAN/CSA C22.2 No. 157-92,

CSA C22.2 No. 213-M1987, C22.2 No 60529-05

Markings: XP CL I/II/III, DIV 1, GP B, C, D, E, F, G when

installed per Rosemount drawing 00248-1066;

IS CL I, DIV 1 GP A, B, C, D when installed per

Rosemount drawing 00248-1056; CL I DIV 2 GP

A, B, C, D; Type 4X, IP66/68 Conduit Seal not

required.

USA

E5 USA Explosionproof

Certificate: 3016555

Standards: FM Class 3600:2011, FM Class 3611:2004, FM

Class 3615:2006, FM Class 3810:2005, ANSI/ISA

60079-0:2009, ANSI/ISA 60079-11:2009, IEC

60529: 2004, NEMA – 250: 1991

Markings: XP CL I, DIV 1, GP B, C, D; DIP CL II/III, DIV 1, GP

E, F, G); NI CL1, DIV 2, GP A, B, C, D when

installed per Rosemount drawing 00248-1065;

Typ e 4;

I5 FM Intrinsic Safety

Certificate: 3016555

Standards: FM Class 3600:2011, FM Class 3610:2010, FM

Class 3611:2004, FM Class 3810:2005, ANSI/ISA

60079-0:2009, ANSI/ISA 60079-11:2009, IEC

60529: 2004, NEMA – 250: 1991

Markings: IS CL I/II/III, DIV 1, GP A, B, C, D, E, F, G; NI CL1,

DIV 2, GP A, B, C, D when installed per

Rosemount drawing 00248-1055; Type 4X;

IP66/68

Europe

E1 ATEX Flam epr oof

Certificate: FM12ATEX0065X

Standards: EN 60079-0: 2012+A11:2013, EN 60079-1:

2014, EN 60529:1991 +A1:2000+A2:2013

Markings: II 2 G Ex db IIC T6…T1 Gb, T6(–50 °C ≤ T

+40 °C), T5…T1(–50 °C ≤ T

See Table 5 at the end of the Product Certifications section

for process temperatures.

Specific Conditions of Use (X):

1. See certificate for ambient temperature range.

2. The non-metallic label may store an electrostatic charge

and become a source of ignition in Group III environments.

3. Guard the LCD display cover against impact energies

greater than 4 joules.

4. Flameproof joints are not intended for repair.

5. A suitable certified Ex d or Ex tb enclosure is required to be

connected to temperature probes with Enclosure option

“N”.

≤ +60 °C)

a

≤

a

12

Emerson.com/Rosemount

Page 13

January 2018

Rosemount 248

a

6. Care shall be taken by the end user to ensure that the

external surface temperature on the equipment and the

neck of DIN Style Sensor probe does not exceed 130 °C.

7. Non-Standard Paint options may cause risk from

electrostatic discharge. Avoid installations that cause

electrostatic build-up on painted surfaces, and only clean

the painted surfaces with a damp cloth. If paint is ordered

through a special option code, contact the manufacturer

for more information.

I1 ATEX Intrinsic Safety

Certificate: Baseefa03ATEX0030X

Standards: EN 60079-0: 2012, EN 60079-11: 2012

Markings: II 1 G Ex ia IIC T5/T6 Ga, T5(–60 °C ≤ T

+80 °C), T6(–60 °C ≤ T

≤ +60 °C)

a

≤

a

See Table 6 at the end of the Product Certifications section

for entity parameters.

Special Condition for Safe Use (X):

1. The apparatus must be installed in an enclosure which

affords it a degree of protection of at least IP20.

Non-metallic enclosures must have a surface resistance of

less than 1 GΩ; light allow or zirconium enclosures must be

protected from impact and friction when installed.

N1 ATEX Type n – with enclosure

Certificate: BAS00ATEX3145

Standards: EN 60079-0:2012+A11:2013, EN

60079-15:2010

Markings: II 3 G Ex nA IIC T5 Gc (–40 °C ≤ T

≤ +70 °C)

a

NC ATEX Type n – without enclosure

Certificate: Baseefa13ATEX0045X

Standards: EN 60079-0:2012, EN 60079-15:2010

Markings: II 3 G Ex nA IIC T5/T6 Gc,T5(-60 °C ≤ T

a

+80 °C),T6(-60°C ≤ Ta ≤ +70 °C)

Special Condition for Safe Use (X):

1. The Model 248 Temperature Transmitter must be installed

in a suitably certified enclosure such that it is afforded a

degree of protection of at least IP54 in accordance with IEC

60529 and EN 60079-15.

ND ATEX Dus t

Certificate: FM12ATEX0065X

Standards: EN 60079-0: 2012+A11:2013, EN

60079-31:2014, EN 60529:1991 +A1:2000

+A2:2013

Markings: II 2 D Ex tb IIIC T130 °C Db, (–40 °C ≤ T

a

+70 °C); IP66

See Table 5 at the end of the Product Certifications section

for process temperatures.

≤

≤

Specific Conditions of Use (X):

1. See certificate for ambient temperature range.

2. The non-metallic label may store an electrostatic charge

and become a source of ignition in Group III environments.

3. Guard the LCD display cover against impact energies

greater than 4 joules.

4. Flameproof joints are not intended for repair.

5. A suitable certified Ex d or Ex tb enclosure is required to be

connected to temperature probes with Enclosure option

“N”.

6. Care shall be taken by the end user to ensure that the

external surface temperature on the equipment and the

neck of DIN Style Sensor probe does not exceed 130 °C.

7. Non-Standard Paint options may cause risk from

electrostatic discharge. Avoid installations that cause

electrostatic build-up on painted surfaces, and only clean

the painted surfaces with a damp cloth. If paint is ordered

through a special option code, contact the manufacturer

for more information.

International

E7 ECEx Flameproof

Certificate: IECEx FMG 12.0022X

Standards: IEC 60079-0:2011, IEC 60079-1:2014-06,

60079-31:2013

Markings: Ex db IIC T6…T1 Gb, T6(–50 °C ≤ T

T5…T1(–50 °C ≤ Ta ≤ +60 °C);Ex tb III C T130C

= –40 °C to +70 °C; IP66

Db T

a

See Table 5 at the end of the Product Certifications section

for process temperatures.

Specific Conditions of Use (X):

1. See certificate for ambient temperature range.

2. The non-metallic label may store an electrostatic charge

and become a source of ignition in Group III environments.

3. Guard the LCD display cover against impact energies

greater than 4 joules.

4. Flameproof joints are not intended for repair.

5. A suitable certified Ex d or Ex tb enclosure is required to be

connected to temperature probes with Enclosure option

“N”.

6. Care shall be taken by the end user to ensure that the

external surface temperature on the equipment and the

neck of DIN Style Sensor probe does not exceed 130 °C.

7. Non-Standard Paint options may cause risk from

electrostatic discharge. Avoid installations that cause

electrostatic build-up on painted surfaces, and only clean

the painted surfaces with a damp cloth. If paint is ordered

through a special option code, contact the manufacturer

for more information.

≤ +40 °C),

a

Emerson.com/Rosemount

13

Page 14

Rosemount 248

January 2018

I7 ECEx Intrinsic Safety

Certificate: IECEx BAS 07.0086X

Standards: IEC 60079-0:2011, IEC 60079-11:2011

Markings: Ex ia IIC T5/T6 Ga, T5(–60 °C ≤ T

≤ +80 °C),

a

T6(–60 °C ≤ Ta ≤ +60 °C)

See Table 6 at the end of the Product Certifications section

for entity parameters.

Special Condition for Safe Use (X):

1. The apparatus must be installed in an enclosure which

affords it a degree of protection of at least IP20.

Non-metallic enclosures must have a surface resistance of

less than 1 GΩ; light allow or zirconium enclosures must be

protected from impact and friction when installed.

N7 IECEx Type n – with enclosure

Certificate: IECEx BAS 07.0055

Standards: IEC 60079-0:2011, IEC 60079-15:2010

Markings: Ex nA IIC T5 Gc; T5(–40 °C ≤ T

≤ +70 °C)

a

NG IECEx Type n – without enclosure

Certificate: IECEx BAS 13.0029X

Standards: IEC 60079-0:2011, IEC 60079-15:2010

Markings: Ex nA IIC T5/T6 Gc; T5(–60 °C ≤ T

≤ +80 °C),

a

T6(–60 °C ≤ Ta ≤ +60 °C)

Special Condition for Safe Use (X):

1. The Model 248 Temperature Transmitter must be installed

in a suitably certified enclosure such that it is afforded a

degree of protection of at least IP54 in accordance with IEC

60529 and IEC 60079-15.

China

E3 NEPSI Flameproof

Certificate: GYJ16.1335X

Standards: GB3836.1-2010, GB3836.2-2010

Markings: Ex d IIC T6

T5…T1 (–50 °C ≤ T

+60 °C)

Special Conditions for Safe Use (X):

1. Ambient temperature range is: T6…T1(–50 °C ≤ T

+40 °C) T5…T1 (–50 °C ≤ T

2. The earth connection facility in the enclosure should be

connected reliably.

3. During installation, there should be no mixture harmful to

flameproof housing.

4. During installation in hazardous location, cable glands,

conduits and blanking plugs, certified by state-appointed

inspection bodies with Ex d IIC Gb degree, should be used.

T1 Gb: T6…T1(–50 °C ≤ Ta ≤ +40 °C)

~

≤

a

≤ +60 °C).

a

≤

a

5. During installation, use and maintenance in explosive gas

atmospheres, observe the warning “Do not open when

energized”.

6. End user is not permitted to change any components

inside, but to settle the problem in conjunction with

manufacturer to avoid damage to the product.

7. When installation, use and maintenance of this product,

observe the following standards:

GB3836.13-2013 “Electrical apparatus for explosive gas

atmospheres Part 13: Repair and overhaul for apparatus

used in explosive gas atmospheres”.

GB3836.15-2000 “Electrical apparatus for explosive gas

atmospheres Part 15: Electrical installations in hazardous

area (other than mines)”.

GB3836.16-2006 “Electrical apparatus for explosive gas

atmospheres Part 16: Inspection and maintenance of

electrical installation (other than mines).

GB50257-2015 “Code for construction and acceptance of

electric device for explosion atmospheres and fire hazard

electrical equipment installation engineering”.

I3 NEPSI Intrinsic Safety

Certificate: GYJ16.1334X

Standards: GB3836.1-2010, GB3836.4-2010,

GB3836.20-2010

Markings: Ex ia IIC T5/T6 Ga; T5(–60 °C ≤ T

≤ +80 °C),

a

T6(–60 °C ≤ Ta ≤ +60 °C)

See Table 6 at the end of the Product Certifications section

for entity parameters.

Special Conditions for Safe Use (X):

1. Symbol “X” is used to denote specific conditions of use:

a. The enclosure may contain light metal, attention

should be taken to avoid ignition hazard due to impact

or friction.

b. The apparatus must be installed in an enclosure which

affords it a degree of protection of at least IP20.

Non-metallic enclosures must have a surface

resistance of less than 1 GΩ.

2. The relation between T code and ambient temperature

range is:

T code Temperature range

T6 –60 °C ≤ T

T5 –60 °C ≤ T

≤ +60 °C

a

≤ +80 °C

a

14

Emerson.com/Rosemount

Page 15

January 2018

Rosemount 248

3. Intrinsically Safe parameters:

HART loop terminals (+ and –)

Maximum

Maximu

m input

voltage

U

(V)

i

30 130 1.0 3.6 0

The above supply must be derived from a linear supply.

Sensor terminals (1 to 4)

Maximu

m input

current

I

(mA)

i

Maximu

m input

power: P

(W)

internal

parameters

i

Ci

(nF)

Li

(mH)

Maximum

Maximu

m output

voltage

U

(V)

o

45 26 290 2.1 0

Sensor terminals (1 to 4)

Maximu

m output

current I

(mA)

Maximu

m output

power: P

o

(mW)

internal

parameters

o

Ci

(nF)

Li

(mH)

Maximum external

Group

parameters

Co (nF) Lo (mH)

IIC 23.8 23.8

IIB 237.9 87.4

IIA 727.9 184.5

4. The product should be used with Ex-certified associated

apparatus to establish explosion protection system that

can be used in explosive gas atmospheres. Wiring and

terminals should comply with the instruction manual of

the product and associated apparatus.

5. The cables between this product and associated apparatus

should be shielded cables (the cables must have insulated

shield). The shielded has to be grounded reliably in

non-hazardous area.

6. End user is not permitted to change any components

inside, but to settle the problem in conjunction with

manufacturer to avoid damage to the product.

7. When installation, use and maintenance of this product,

observe the following standards:

GB3836.13-1997 “Electrical apparatus for explosive gas

atmospheres Part 13: Repair and overhaul for apparatus

used in explosive gas atmospheres”.

GB3836.15-2000 “Electrical apparatus for explosive gas

atmospheres Part 15: Electrical installations in hazardous

area (other than mines)”.

GB3836.16-2006 “Electrical apparatus for explosive gas

atmospheres Part 16: Inspection and maintenance of

electrical installation (other than mines)”.

GB50257-1996 “Code for construction and acceptance of

electrical device for explosion atmospheres and fire hazard

electrical equipment installation engineering.

N3 NEPSI Type n

Certificate: GYJ15.1089

Standards: GB3836.1-2010, GB3836.8-2003

Markings: Ex nA nL II C T5 Gc (–40 °C ≤ T

Special Condition for Safe Use (X):

1. See certificate for special conditions.

≤+70 °C)

a

EAC

EM Technical Regulation Customs Union (EAC) Flameproof

Certificate: TC RU C-US.AA87.B.00057

Markings: 1Ex d IIC T6…T1 Gb X, T6(–50 °C ≤ T

T5…T1(–50 °C ≤ Ta ≤

+60 °C); IP66/IP67

Special Condition for Safe Use (X):

1. See certificate for special conditions.

IM Technical Regulation Customs Union (EAC) Intrinsic Safety

Certificate: TC RU C-US.AA87.B.00057

Markings: 0Ex ia IIC T5,T6 Ga X, T6(–60 °C ≤ Ta ≤ +60 °C),

T5(–60 °C ≤ Ta ≤ +80 °C); IP66/IP67

Special Condition for Safe Use (X):

1. See certificate for special conditions.

≤ +40 °C),

a

Korea

EP Korea Explosionproof/Flameproof

Certificate: 13-KB4BO-0208X

Markings: Ex d IIC T6; T6(–40 °C ≤ T

Special Condition for Safe Use (X):

1. See certificate for special conditions.

≤ +65 °C)

amb

Combinations

K5 Combination of E5 and I5

KM Combination of EM and IM

Emerson.com/Rosemount

15

Page 16

Rosemount 248

Table 5. Process Temperatures

Temperature class Ambient temperature

T6 –50 °C to +40 °C 55 55 60 65

T5 –50 °C to +60 °C 70 70 70 75

T4 –50 °C to +60 °C 100 110 120 130

T3 –50 °C to +60 °C 170 190 200 200

T2 –50 °C to +60 °C 280 300 300 300

T1 –50 °C to +60 °C 440 450 450 450

January 2018

Process temperature without LCD display cover (°C)

No ext. 3-in. 6-in. 9-in.

Table 6. Entity Parameters

HART loop

Parameters

terminals + and

–

Voltage Ui 30 V 45 V

Current Ii 130 mA 26 mA

Power Pi 1 W 290 mW

Capacitance Ci 3.6 nF 2.1 nF

Inductance Li 0 mH 0 μH

Sensor

terminals

1 to 4

Additional Certifications (Rosemount 248 Head Mount only)

SBS American Bureau of Shipping (ABS) Type Approval

Certificate: 11-HS771994B-1-PDA

Intended Use: Measurement of temperature for marine

and offshore applications.

SBV Bureau Veritas (BV) Type Approval

Certificate: 26325

Requirements: Bureau Veritas Rules for the Classification

of Steel Ships

Application: Class notations: AUT-UMS, AUT-CCS,

AUT-PORT and AUT-IMS; Temperature

transmitter cannot be installed on diesel

engines.

Application:

Location classes

Tem p er at u re D

Humidity B

Vibration A

EMC A

Enclosure

SLL Lloyds Register (LR) Type Approval

Certificate: 11/60002

Application: Environmental categories ENV1, ENV2,

ENV3, and ENV5

B/IP66 Al,

C/IP66: SST

SDN Det Norske Veritas (DNV) Type Approval

Certificate: A-14187

Intended Use: Det Norske Veritas’ Rules for Classification

of Ships, High Speed & Light Craft and Det

Norske Veritas’ Offshore Standards.

16

Emerson.com/Rosemount

Page 17

January 2018

44 (1.7)

33 (1.3)

12.9 (0.51)

24.5

(0.97)

123.5 (4.86)

95.25

(3.75)

25.9

(1.02)

48.77

(1.92)

104

(4.09)

100

(3.93)

78

(3.07)

A

84 (3.331)

118 (4.65)

95.35 (3.75)

72 (2.84)

95

(3.74)

96 (3.76)

112 (4.41)

B

A

75

(2.93)

Dimensional Drawings

Figure 3. Transmitters

Rosemount 248R Railmount Rosemount 248H Headmount (enlarged)

Dimensions are in millimeters (inches).

Rosemount 248

Figure 4. Enclosures

Connection head

A. Approval label

B. SST “U” bolt mounting, 2-in. pipe

Dimensions are in millimeters (inches).

1. If ordering the transmitter with a DIN style sensor, it is recommended the enclosure be ordered within the sensor model (see Rosemount D IN-Style Product Data Sheet)

2. A “U” Bolt is shipped with each universal head unless a sensor is ordered assembled to the enclosure. However, since the head can be integrally mounted to the sensor, it

Emerson.com/Rosemount

rather than within the transmitter model, in order to drive necessary parts.

may not need to be used.

(1)

BUZ and polypropylene heads (option codes B and C)

and Mini SST head (option code S)

Universal head

(option codes H and U)

(2)

17

Page 18

Rosemount 248

Configuration Interface Specifications

January 2018

Configuration software

(1)

The Rosemount 248 PC-based configuration software for the

Rosemount 248 allows comprehensive configuration of the

transmitters. Used in conjunction with various Rosemount or

user-supplied hardware modems, the software provides the

tools necessary to configure the Rosemount 248 Transmitters

including the following parameters:

Process variable

Sensor type

Number of wires

Engineering units

Transmitter tag information

Damping

Alarming parameters

Configuration hardware

The Rosemount 248 Configuration Interface has three hardware

options as follows:

Software only

Part number: 00248-1603-0002

Customer must provide appropriate communications hardware

(e.g. modem, power supply).

Serial HART modem and software

Part number: 00248-1603-0004

Serial HART modem

Customer must provide separate loop power supply and

resistor.

Requires PC serial port

Suitable for use with powered loops

USB HART modem and software

Part number: 00248-1603-0003

USB (Universal Serial Bus) HART modem

Customer must provide separate loop power supply and

resistor.

Requires PC with USB port

Suitable for use with powered loops

1. The Rosemount configuration software is compatible with Windows™ XP, Windows 7 32-bit and Windows 7 64-bit. It is not compatible with Windows NT and

Windows 2000.

18

Emerson.com/Rosemount

Page 19

January 2018

B

A

C

Rosemount 248

Table 7. Transmitter Accessories

A. Mounting hardware

B. Transmitter

C. Rail clip

Part description

Aluminum Alloy Universal Head – M20 Entries 00644-4420-0002

Aluminum Alloy Universal Head – 1/2 NPT Entries 00644-4420-0001

Aluminum Alloy Rosemount Connection Head – M20 Conduit Entry, M24 Instrument

Entry

Aluminum Alloy Rosemount Connection Head – 1/2 NPT Conduit Entry and M24

Instrument Entry

Aluminum Alloy BUZ Head – M20 Conduit Entry, M24 Instrument Entry 00644-4196-0023

Aluminum Alloy BUZ Head – M20 Conduit Entry and 1/2 NPT Instrument Entry 00644-4196-0021

Aluminum Alloy BUZ Head – 1/2 NPT Conduit Entry 00644-4196-0011

External Ground Screw Assembly Kit 00644-4431-0001

Kit, Hardware for Mounting a Rosemount 248 to a DIN Rail (see left picture-top hat

rail, symmetric)

Standard Cover for Universal or Rosemount Connection Heads 03031-0292-0001

Snap Rings Kit (used for assembly to DIN Plate Style sensor) 00644-4432-0001

Rosemount 248 Programming Software (CD) 00248-1603-0002

Rosemount 248 Programming Kit - Serial connection 00248-1603-0004

Rosemount 248 Programming Kit - USB connection 00248-1603-0003

Part number

00644-4410-0023

00644-4410-0013

00248-1601-0001

Hardware tag

20 characters maximum

Transmitter enclosure, sensor, and thermowell if applicable

will be tagged in accordance with customer requirements

Software tag

The transmitter can store up to eight characters. If no

characters are specified, the first eight characters of the

hardware tag are the default.

Configuration

When ordering a transmitter and sensor assembly in one model

number, the transmitter will be configured for the sensor that is

ordered.

When a transmitter is ordered alone, the transmitter will be

shipped as follows (unless specified):

Sensor type

4 mA value

20 mA value

Damping

Output

Failure mode

Line voltage filter

Ta g

RTD, Pt 100 (α=0.00385, 4-wire)

0 °C

100 °C

5 seconds

Linear with temperature

High/Upscale

50 Hz

See Hardware tag

Emerson.com/Rosemount

19

Page 20

Rosemount 248

Options

The following table lists the requirements necessary to specify a

custom configuration.

Option code Requirements/specification

Date: day/month/year

C1: Factory Configuration Data (CDS required)

A1: NAMUR-Compliant, High Alarm See Figure 3 on page 8.

CN: NAMUR-Compliant, Low Alarm See Figure 3 on page 8.

Q4: Calibration Certificate

Descriptor: 16 alphanumeric characters

Message: 32 alphanumeric character

Analog Output: Alarm and saturation levels

Will include 3-point calibration at 0, 50, and 100% analog and digital output

points.

.

January 2018

C4: Five Point Calibration

F6: 60 Hz Line Filter Calibrated to a 60 Hz line voltage filter instead of 50 Hz filter

Will include 5-point calibration at 0, 25, 50, 75, and 100% analog and digital

output points. Use with Calibration Certificate Q4.

20

Emerson.com/Rosemount

Page 21

January 2018

Rosemount 248

Emerson.com/Rosemount

21

Page 22

Rosemount 248

00813-0100-4825, Rev LB

Global Headquarters

Emerson Automation Solutions

6021 Innovation Blvd.

Shakopee, MN 55379, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RFQ.RMD-RCC@Emerson.com

North America Regional Office

Emerson Automation Solutions

8200 Market Blvd.

Chanhassen, MN 55317, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RMT-NA.RCCRFQ@Emerson.com

Latin America Regional Office

Emerson Automation Solutions

1300 Concord Terrace, Suite 400

Sunrise, FL 33323, USA

+1 954 846 5030

+1 954 846 5121

RFQ.RMD-RCC@Emerson.com

Product Data Sheet

January 2018

Europe Regional Office

Emerson Automation Solutions Europe GmbH

Neuhofstrasse 19a P.O. Box 1046

CH 6340 Baar

Switzerland

+41 (0) 41 768 6111

+41 (0) 41 768 6300

RFQ.RMD-RCC@Emerson.com

Asia Pacific Regional Office

Emerson Automation Solutions Asia Pacific Pte Ltd

1 Pandan Crescent

Singapore 128461

+65 6777 8211

+65 6777 0947

Enquiries@AP.Emerson.com

Middle East and Africa Regional Office

Emerson Automation Solutions

Emerson FZE P.O. Box 17033

Jebel Ali Free Zone - South 2

Dubai, United Arab Emirates

+971 4 8118100

+971 4 8865465

RFQ.RMTMEA@Emerson.com

Linkedin.com/company/Emerson-Automation-Solutions

Twitter.com/Rosemount_News

Facebook.com/Rosemount

Youtube.com/user/RosemountMeasurement

Google.com/+RosemountMeasurement

Standard Terms and Conditions of Sale can be found on the Terms and

Conditions of Sale page.

The Emerson logo is a trademark and service mark of Emerson Electric Co.

Complete Point Solutions, Rosemount, and Rosemount logotype are

trademarks of Emerson.

eurofast and minifast are registered trademarks of TURCK.

HART is a registered trademark of the FieldComm Group.

NEMA is a registered trademark and service mark of the National

Electrical Manufacturers Association.

National Electrical Code is a registered trademark of National Fire

Protection Association, Inc.

Windows is a trademark of Microsoft Corporation in the United States and

other countries.

All other marks are the property of their respective owners.

© 2018 Emerson. All rights reserved.

Loading...

Loading...