Rosemount 1199 Product Manual

Model 1199

Diaphragm Seal

Systems Manual

00809-0100-4002

English

Rev. AD

Product Manual

NOTICE

Read this m anual before wor k ing with the product. For personal an d system

safety, and for optimum product performance, make sure you thoroughly

understand the contents before installing, using, or maintaining this product.

Within the United States, Rosemount Inc. has two toll-free assistance numbers.

Customer Central: 1-800-999-9307 (

Technical support, quoting, and order-related questions.

North American 1-800-654-7768 (

Response Center: Equipment service needs.

For equipment s ervice or support needs outsid e the United States, contact y our

local Rosemount representative.

The products described in this document are NOT designed for nuclearqualified applications.

Using non-nuclear qualified products in applications that require nuclearqualified hardware or products may cause inaccurate readings.

For information on Rosemount nuclear-qualified products, contact your local

Rosemount Sales Representative.

7:00 a.m. to 7:00 p.m. CST)

24 hours a day – Includes Canada)

For Western Europe, please contact:

Fisher- Rosemount

Diaphragm Seal Support

Heath Place

Bognor Regis

West Sussex PO229SH

United Kingdom

Tel+441243863121

Fax+441243845354

For Central and Eastern Europe, please

contact:

Fisher-Rosemount GmbH & Co.

Diaphragm Seal Support

Argelsrieder Feld 7

D-82234 Wessling

Germany

Tel (+49) (0) 8153 27-0

Fax (+49) (0) 8153 27-172

For Asia-Pacific, please contact your local

Fisher Rosemount Representative

Rosemount Inc.

8200 Market Boulevard

Chanhassen, MN 55317 USA

Tel 1-800-999-9307

Telex 4310012

Fax (612) 949-7001

© 1997 Rosemount, Inc.

http://www.rosemount.com

T

N

I

E

D

R

P

IN

U.

A.

S.

The Model 3051C Pressure Transmitter may be protected by one or more of the following U.S. Pat. No.:

4,370,890: 4,612,812; 4,791,352; 4,798,089; 4,818,994; 4,833,922; 4,866,435; 4,926,340; 4,988,990;

5,028,746. MEXICO PATENTADO NO. 154,961. May Depend on Model. Other U.S. and Foreign Patents

Issued and Pending.

The Model 1151 Pressure Transmitter may be protected by one or more of the following U.S. Patent Nos.

3,854,039; 3,975,719; 4,339,750; and Re. 30, 603. Mexico Patentado No. 136,497. May depend on model.

Other foreign patents issued and pending.

The Model 2088 Pressure Transmitter may be protected by the following U.S. Patent Nos.: 4,970,898 and 5,

083,091. May depend on Model. Other U.S. and Foreign Patents Issued and Pending.

Rosemount, the Rosemount logotype, and Alphaline are registered trademarks of Rosemount Inc.

HART is a registered trademark of the HART Communication Foundation.

Tri-Clamp is a registered trademark of Tri-Clover Inc. of the Alfa-Laval Group.

The 3-A symbol is a registered trademark of the 3-A Sanitary Standards Symbol Council.

Grafoil is a trademark of Union Carbide Corp.

Teflon is a registered trademark of E.I. du Pont de Nemours & Co.

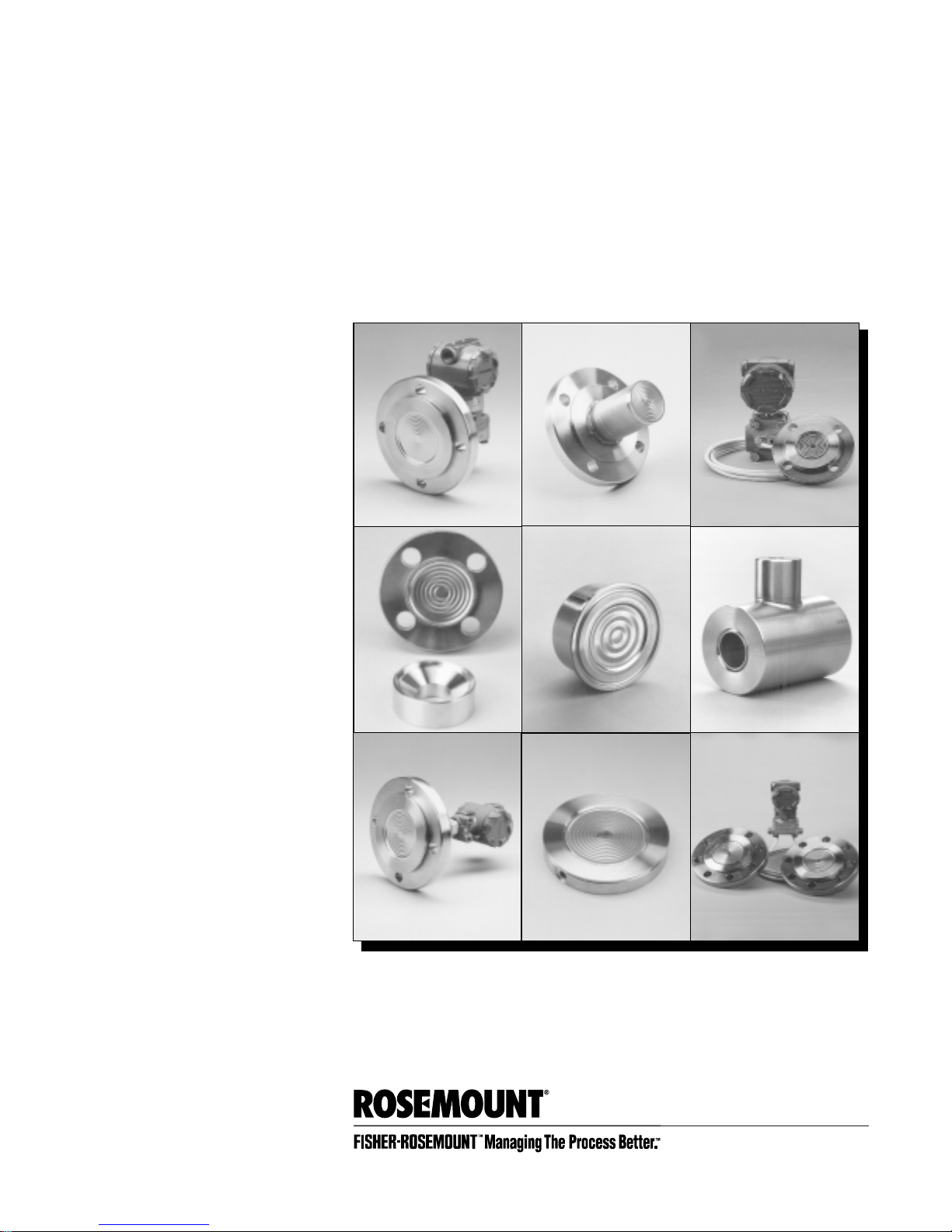

Cover Photos: 1199-039AB, 034AB, 051AB, 041AB, 077AB, 074AB, 038AB, 042AB, 063AB.

Fisher-Rosemount satisfies all obligations coming from legislation

to harmonize product requirements in the European Union.

Table of Contents

SECTION 1

Introduction

SECTION 2

Installation

SECTION 3

Calibration

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Seals Handling and Installation Considerations . . . . . . . . . . . 2-1

Tagging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Flanged Type Seals: Flush or Extended Diaphragm . . . . . . . . 2-2

Pancake Type Seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Threaded Type Seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Saddle Type Seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

In-line Flow-Through Seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Sanitary Tank Spud Seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Sanitary Flanged Tank Spud Seals . . . . . . . . . . . . . . . . . . . . . . 2-6

Sanitary Tri-Clamp

Sanitary Threaded Type Seals . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Application Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Zero Suppression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Zero Elevation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Maximum Span Calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Electronics Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Maximum Span . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Calibrating a One Seal System with Suppressed Zero

(Transmitter Mounted Below the High Side Tap) . . . . . . . . . . 3-3

Calibrating a One-Seal System with Elevated Zero

(Transmitter Mounted Above the High Side Tap) . . . . . . . . . . 3-4

Calibrating a Two-Seal System with Elevated Zero

(Transmitter Mounted Level with, Above, or Below

the High Pressure Tap) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

®

Seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

SECTION 4

Maintenance and

Troubleshooting

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Return of Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

iii

iv

Section

1 Introduction

Introduction

A diaphragm seal system consists of a pressure transmit te r, a

diaphragm seal, a fill fluid, and either a direct mount or capillary style

connection.

During operation, the thin, flexible diaphragm and fill fluid separate

the pressure sensitive element of the transmitter from the process

medium. The capillary tubing or direct mount flange connects the

diaphragm to the transmitter.

When process pressure is applied, the diaphragm is displaced,

transferring the measured pressure through the filled system, by way

of the capillary tubing, to the transmitter element. This transferred

pressure displaces the s ensing diaphragm in the pressure-sensitive

element of the transmitter. This displacement is proportional to the

process pressure and is converted electronically to an appropriate

current, voltage, or digital HART

Transducer) output signal.

This manual is designed to assist in installing, operating, and

maintaining the Rosemount Model 1199 Filled Systems for Pressure

Transmitters. The manual contains supplemental information about

the transmitter/seal system that is not covered in the correlative

transmitter manual.

The information is organized into the following categories:

• Installation

• Calibration

• Maintenance/Troubleshooting

See Product Data Sheets 00813-0100-4016 in North America or

00813-0201-4016 in Europe for more detailed information on specific

Rosemount diaphragm seals.

(Highway Addressable Remote

1-1

Model 1199 Diaphragm Seal Systems Manual

1-2

Loading...

Loading...