Rosemount 0305, 0304 Specifications

Rosemount™ Manifold Solutions

Product Data Sheet

January 2019

00813-0100-4733, Rev RA

Factory assembled, leak-tested, and calibrated

Full breadth offering including integral, in-line, and conventional styles

Integral design enables “flangeless” connection to instrument reducing weight, space, and leak points

Block-and-bleed, 2-, 3-, and 5-valve configurations

Compact, lightweight design

Easy in-process calibration

Direct-mount capability

Available in NACE

Available with Pressure-Lock

®

-compliant materials of construction

™

Valve

Rosemount Manifolds

Rosemount

R305 three-valve manifold

Rosemount 3051S assembled

to R305 five-valve manifold

Rosemount R306 two-valve

manifold

Rosemount 3051S assembled

to 306 two-valve manifold

Selection guide

Rosemount 305 Coplanar Style

Standard features

Assembled directly to transmitter, eliminating the need for flange

Factory leak tested and calibrated

Two, three, and five-valve configurations

Available with female NPT process connections

No exposed bolt configuration enhances reliability

50 percent fewer leak points than conventional transmitter to flange to manifold interface

Special cleaning options available

Rosemount 305 available with five-valve natural gas metering pattern

Rosemount R305 exclusive features

Pressure-Lock Valve with two-piece stem design

Large internal process bore to resist plugging

January 2019

Rosemount 306 In-line Style

(1)

Standard features

Assembled directly to transmitter or Rosemount Pressure Gauge

Factory leak tested and calibrated

Block-and-bleed and two-valve configurations

Available with female NPT process connections

Special cleaning options available

(1)

Rosemount R306 exclusive features

Pressure-Lock Valve with two-piece stem design

Large internal process bore to resist plugging

1. Rosemount R306 manifold only available with two-valve configuration.

2

Emerson.com/Rosemount

January 2019

Rosemount 304

three-valve conventional

manifold

Rosemount 304 conventional

manifold - wafer style

Rosemount 304 Conventional Style

Standard features

Attaches to transmitter flange

Two, three, and five-valve configuration

Traditional (flange x flange, flange x NPT) and wafer styles

Available with five-valve natural gas metering pattern

Factory assembled, seal-tested, and calibrated

Rosemount Manifolds

Rosemount Pressure-Lock Valve

Exclusively featured on the Rosemount R305 and R306 manifolds

Pressure-Lock Valve, reference detailed design on page 27

Simplified operation

Two-piece valve stem design provides easier handle turn operation

Increased operator safety

Needle tip safety back seating ensures operator safety during process blowout events

Enhanced reliability

Process isolated stem threads increase overall valve life

Contents

Valve configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Emerson.com/Rosemount

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Dimensional drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

3

Rosemount Manifolds

Isolate

Transmitter

Bleed screw

Process

Transmitter

Vent

Isolate

Process

Transmitter

Equalize

Process

IsolateIsolate

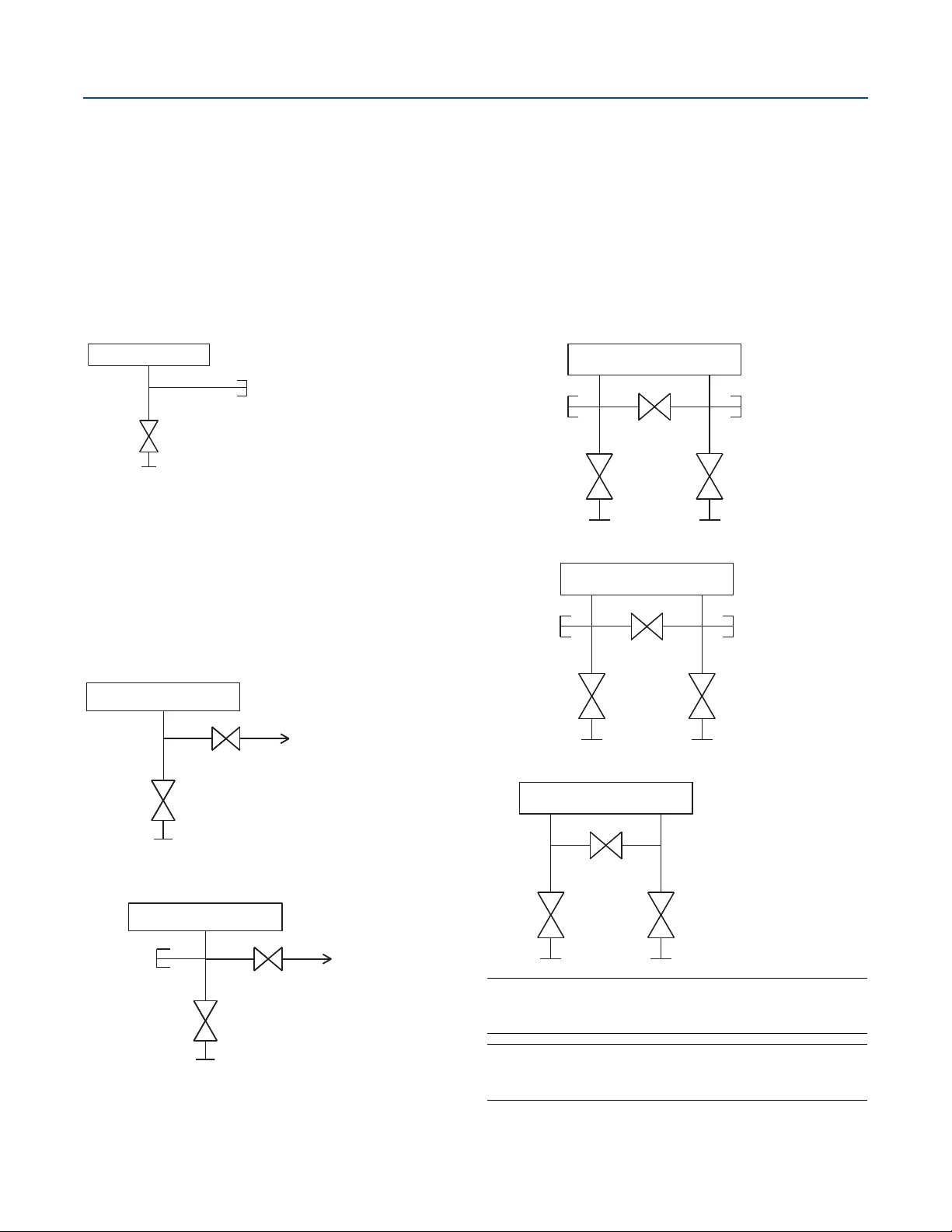

Valve configuration

January 2019

Block-and-bleed

The block-and-bleed configuration is available on the

Rosemount R306/306 Manifolds for use with in-line gage and

absolute pressure transmitters. A single isolate valve provides

instrument isolation and a bleed screw provides drain/vent

capabilities.

Rosemount 306 Manifold

Two-valve

The two valve configuration is available on Rosemount

R305/305, R306/306, and 304 Manifolds for use with absolute

and gage pressure transmitters. An isolate valve provides

instrument isolation and a drain/vent valve allows venting,

draining, or calibration.

Rosemount R305/305 and R306/306 Manifolds

Three-valve

The three valve configuration is available on Rosemount

R305/305 and 304 Manifolds for use with differential pressure

and multi-variable transmitters. Two isolate valves provide

instrument isolation, and one equalize valve is positioned

between the high and low process connections.

Rosemount R305/305 Manifolds

Transmitter

Drain/vent

Equalize

Isolate

Process

Rosemount 304 (traditional) Manifold

Transmitter

(plugged)

Equalize

Drain/vent

Isolate

(plugged)

Rosemount 304 Manifold

Transmitter

Isolate

Process

Isolate

Process

Isolate

Rosemount 304 (wafer) Manifold

Vent(plugged)

Note

Vent ports receive plastic caps to protect threaded connections

unless otherwise noted.

Note

Plugged connections receive

noted.

1

/4-in. NPT plugs unless otherwise

4

Emerson.com/Rosemount

January 2019

Transmitter

Vent

Vent

Equalize

Process

IsolateIsolate

Transmitter

Equalize

Process

Equalize

Process

IsolateIsolate

(plugged)(plugged)

Vent

(closed)

Rosemount Manifolds

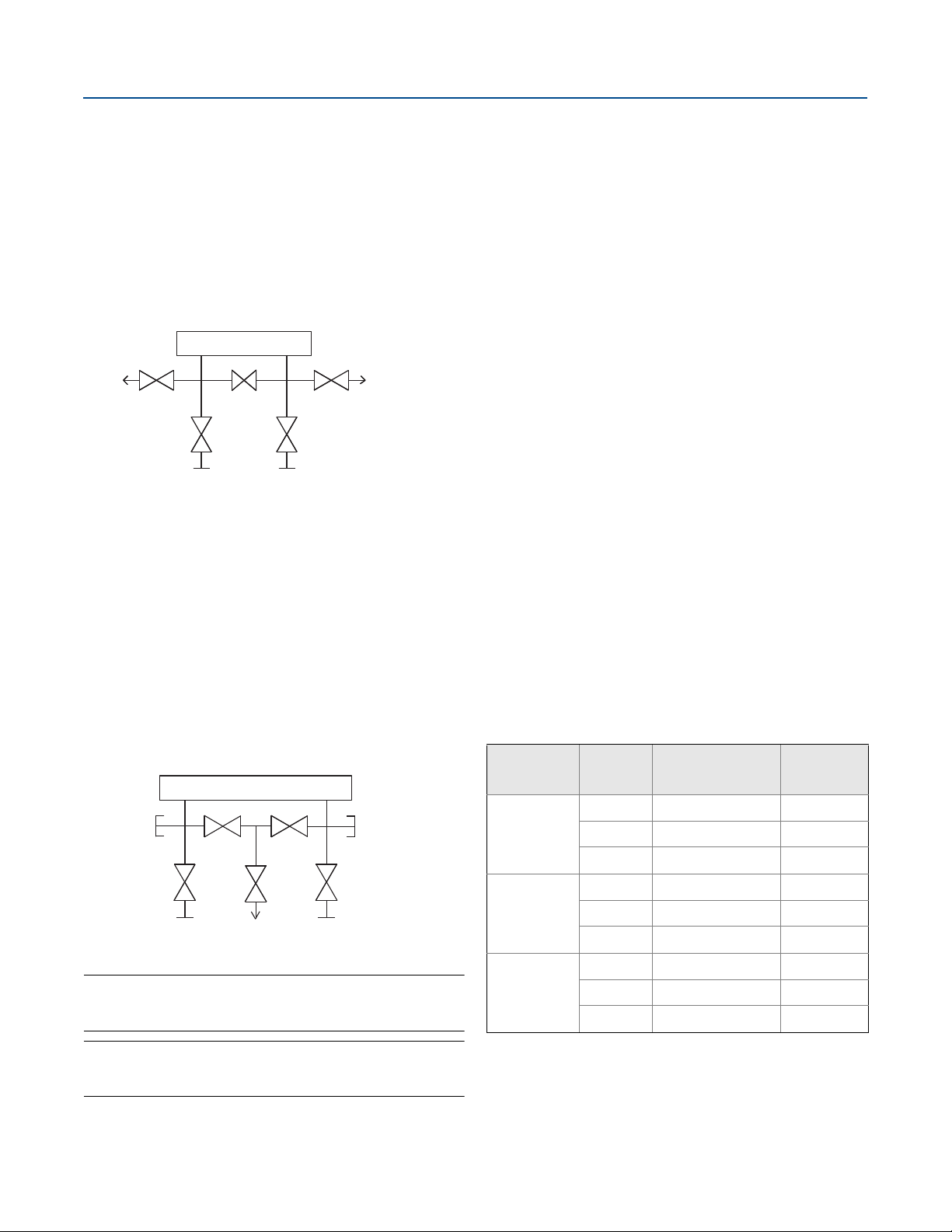

Five-valve

The five valve configuration is available on Rosemount R305/305

and 304 Manifolds for use with differential pressure and

multi-variable transmitters. Two isolate valves provide

instrument isolation and one equalize valve is positioned

between the high and low process connections. In addition, two

drain/vent valves allow for controlled venting, 100 percent

capture of vented or drained process, and simplified in-process

calibration capability.

Rosemount R305/305 Manifolds and 304 (wafer)

Five-valve natural gas

The five valve natural gas configuration is available on the

Rosemount 305 and 304 Manifolds for use with differential

pressure and multi-variable transmitters. Two isolate valves

provide instrument isolation and a single drain/vent valve allows

for controlled venting, 100 percent capture of vented or drained

process, and simplified in-process calibration capability. In

addition, two equalize valves provide extra protection from

leaking to ensure DP signal integrity.

“NG” option includes wide handle pattern and soft seats for

ease of use as well as a larger bore to reduce plugging

Ordering information

Rosemount Manifolds can be ordered as a stand-alone product

or as an integrated assembly attached to a transmitter.

Stand-alone manifold

1. Reference the “Selection guide” on page 2 for assistance

on choosing the type of manifold.

2. Specify a completed model number by referencing the

applicable ordering table for the selected manifold type:

Rosemount 305 Integral Manifold, see page 6.

Rosemount 306 In-line Manifold, see page 11.

Rosemount 304 Conventional Manifold, see page 15.

Transmitter/manifold assembly

1. Specify a completed Rosemount transmitter model

number by referencing the applicable product data sheet.

2. Specify a completed manifold model number by

referencing the applicable ordering table for the selected

manifold type:

Rosemount 305 Integral Manifold, see page 6.

Rosemount 306 In-line Manifold, see page 11

Rosemount 304 Conventional Manifold, see page 15.

3. Verify the transmitter model number contains the correct

“Process Connection” code or “Manifold Option” code for

the desired transmitter manifold assembly (see Tabl e 1).

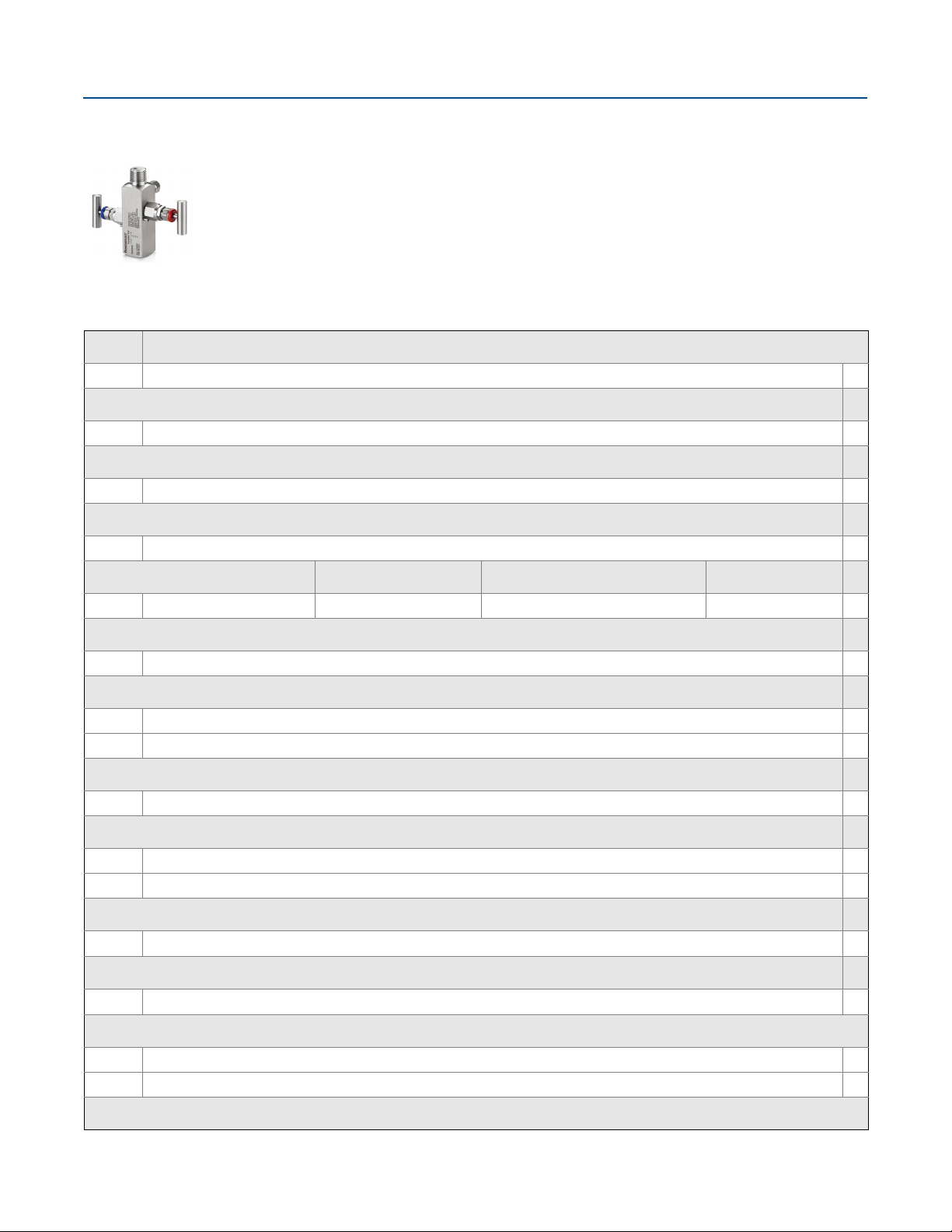

Table 1. Ordering Codes for a Transmitter/Manifold

Assembly

Rosemount 305 Manifolds and 304 (traditional)

Note

Vent ports receive plastic caps to protect threaded connections

unless otherwise noted.

Note

Plugged connections receive 1/4-in. NPT plugs unless otherwise

noted.

Emerson.com/Rosemount

Tra ns mit te r

Rosemount

3051S

Rosemount

3051/2051

Rosemount

2088

Manifold

R305/305 A11 N/A

R306/306 A11 N/A

304 A12 N/A

R305/305 N/A S5

R306/306 N/A S5

304 N/A S6

R305/305 N/A N/A

R306/306 N/A S5

304 N/A N/A

Process

connection code

“Manifold”

option code

5

Rosemount Manifolds

January 2019

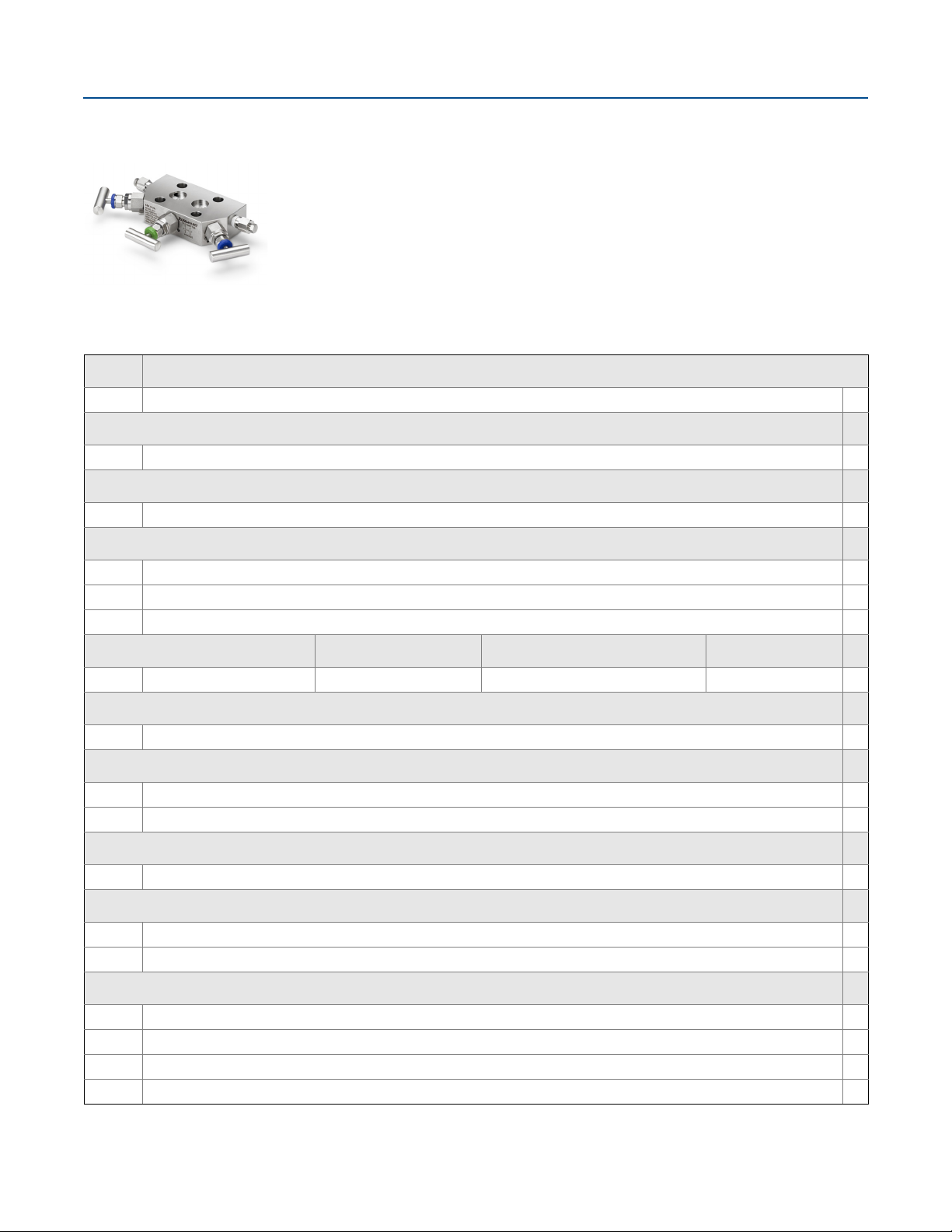

Rosemount 305 Coplanar Manifolds

Rosemount Coplanar manifolds provide a leak checked and pressure tested single point solution

when assembled to Rosemount pressure transmitters. The coplanar platform reduces potential leak

paths by 50 percent over conventional style process connections while also reducing overall

connection system weight.

Specification and selection of product materials, options, or components must be made by the

purchaser of the equipment. See page 18 for more information on material selection.

Table 2. Rosemount R305 Integral Manifold Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

Model Product description

R305 Integral manifold

Design class

E Enhanced ★

Manifold style

C Coplanar ★

Manifold type

2 Two valve ★

3 Three valve ★

5 Five valve ★

(1)

Body

2 316 stainless steel (SST) 316 SST 316 SST 316 SST ★

Bonnet Stem and tip Drain/vent

Process connection

B

1

/2–14 NPT female ★

Packing material

(2)

1

(3)

2

PTFE ★

Graphite-based

Valve seat

1 Integral ★

Extended product warranty

WR3 3-year limited product warranty

WR5 5-year limited product warranty

Mounting bracket

B4 316 SST mounting bracket for 2-in. pipe mount with series 300 SST bolts

BE 316 SST bracket for 2-in pipe mount with 316 SST bolts

BF Carbon steel (CS) panel mount bracket

BG 316 Series SST panel mount bracket

6

Emerson.com/Rosemount

January 2019

Rosemount Manifolds

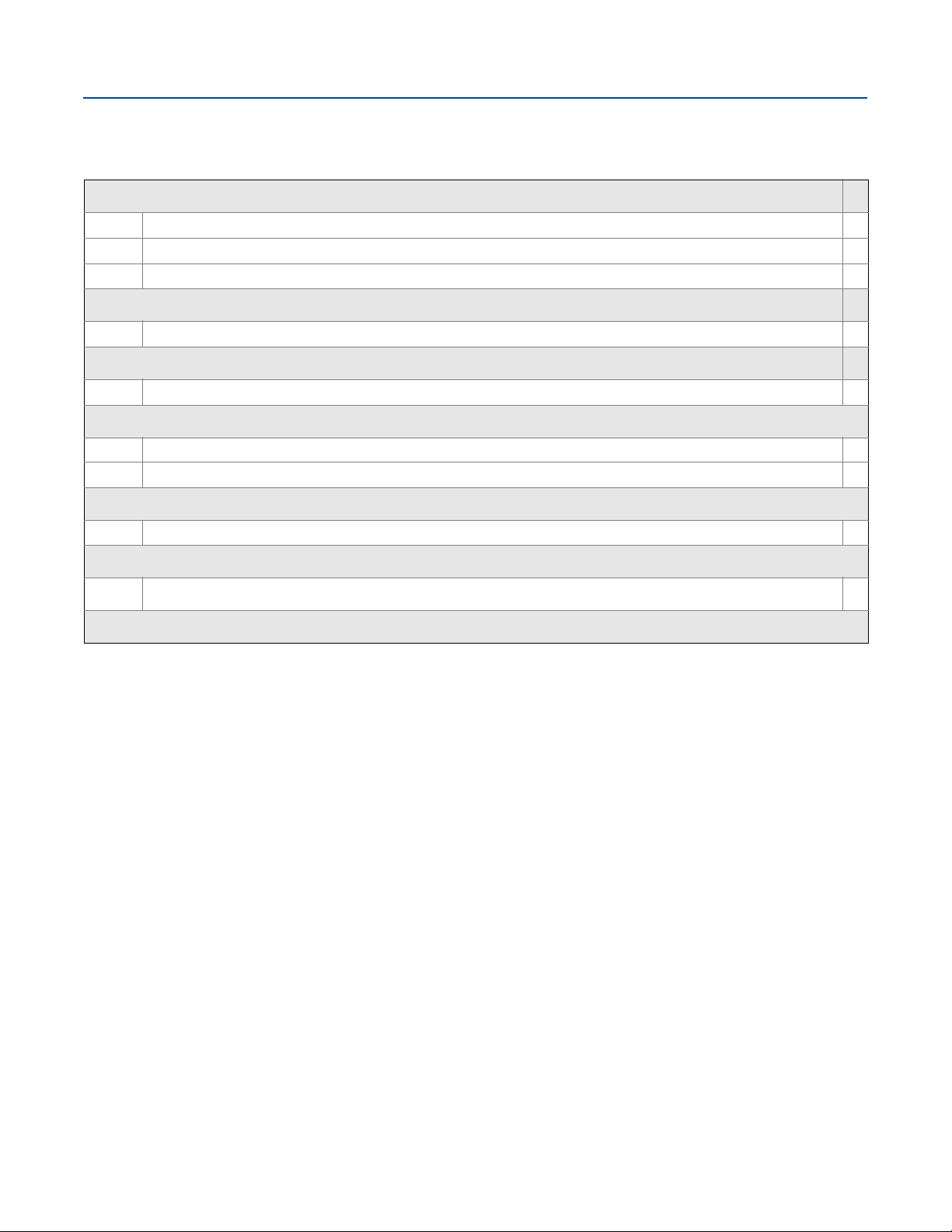

Table 2. Rosemount R305 Integral Manifold Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

Bolting Materials

L4

Austenitic 316 SST bolts

L5 ASTM A 193 B7M bolts

L8 ASTM A 193,Class 2, Grade B8M bolts

Cleaning

P2

Material recommendation for NACE

SG

(4)

Cleaning for special services

(5)

Sour gas (meets NACE MR 0175/ISO 15156, MR 0103)

NACE Certificate

Q15 Certificate of Compliance to NACE MR0175/ISO 15156 for wetted materials ★

Q25 Certificate of Compliance to NACE MR0103 for wetted materials ★

Additional options

DS Drain vent screen ★

Bolts

TD

For assembly to Rosemount 3051D

Typical coplanar integral manifold model number: R305EC32B11B4

1. Refer to page 18 for additional detail on process wetted materials of construction.

2. Includes PTFE tape on drain/vent valves and plugs.

3. Includes graphite tape on drain/vent valves and plugs.

4. Not available with graphite-based packing material code 2 .

5. Valve stem tip material is C-276.

★

Emerson.com/Rosemount

7

Rosemount Manifolds

January 2019

Specification and selection of product materials, options, or components must be made by the purchaser of the equipment.

See page 18 for more information on material selection.

Table 3. Rosemount 305 Integral Manifold Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

Model Product description

0305 Integral manifold

Manufacturer

R Rosemount ★

Manifold style

C Coplanar ★

T Traditional ★

M Traditional (DIN-compliant flange) ★

Manifold type

2 Two valve ★

3 Three valve ★

(1)

5

(2)

6

(2)(3)

7

(2)(3)

8

(2)(3)

9

Body

Five valve ★

Five valve natural gas metering pattern ★

Two valve (per ASME B31.1 [ANSI] power and piping code)

Three valve (per ASME B31.1 [ANSI] power and piping code)

Five valve (per ASME B31.1 [ANSI] power and piping code)

(4)

Bonnet Stem and tip/ball

2 316 SST/316L SST 316 SST 316 SST ★

(5)

3

4

8

9

(5)(6)

(7)

(7)

Alloy C-276 Alloy C-276 Alloy C-276

Alloy 400 Alloy 400 Alloy 400

Alloy 625 Alloy 625 Alloy 625

All super duplex SST (UNS S32760)

Process connection style

(8)

A

(9)

B

1

/4–18 NPT female ★

1

/2–14 NPT female ★

Packing material

(10)

1

(11)

2

PTFE ★

Graphite-based

Valve seat

1 Integral ★

5 Soft POM (only available with natural gas metering pattern) ★

8

Emerson.com/Rosemount

January 2019

Rosemount Manifolds

Table 3. Rosemount 305 Integral Manifold Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

Options

Extended product warranty

WR3 3-year limited warranty ★

WR5 5-year limited warranty

Mounting brackets

B1 Bracket for 2-in. pipe mounting, CS bolts ★

(12)

B3

B4 SST mounting bracket for 2-in. pipe mounting, 300 SST bolts ★

B7 B1 bracket with 316 SST bolts ★

B9

BA 316 SST B1 bracket with 316 SST bolts ★

BC

BE 316 SST B4 bracket with 316 SST bolts ★

BF CS panel mount bracket ★

BG 316 SST panel mount bracket ★

Flat bracket for 2-in. pipe mounting, CS bolts ★

(12)

B3 bracket with 316 SST bolts ★

(12)

316 SST B3 bracket with 316 SST bolts ★

★

Bolt materials

(13)

L4

Austenitic 316 SST bolts ★

L5 ASTM A193, Grade B7M bolts ★

L8 ASTM A193, Class 2, Grade B8M bolts ★

Cleaning

(14)

P2 Cleaning for special services ★

Material recommendations for NACE

(5)(15)

SG Sour gas (meets NACE MR0175/ISO 15156, MR0103/ISO 17495) ★

Adapters

DF

(16)

1

/2–14 NPT female flange adapter ★

DQ 12 mm ferrule tube flange adapter

Cold temperature

(17)

CW1 –67 °F (–55 °C) cold temperature operation

Process flow meter configuration

PF Relocated equalize valve for 9295 process flow meter

Process flange bolting connection

HK 10 mm (M10) process flange bolting connection ★

HL 12 mm (M12) process flange bolting connection ★

(18)

Typical coplanar integral manifold model number: 305 R C 3 2 B 1 1 B4

1. Not available with traditional manifold style T.

Emerson.com/Rosemount

9

Rosemount Manifolds

2. Only available with coplanar manifold style code C.

3. Only available with 316 SST materials of construction code 2 and graphite-based packing code 2.

4. Refer to page 25 for additional detail on process wetted materials of construction.

5. Materials of construction comply with recommendations per NACE MR0175/ISO 15156 for sour oil field production environments. Environmental limits apply to

certain materials. Consult latest standard for details. Selected materials also conform to NACE MR0103/ISO 17495 for sour refining environments.

6. Includes Alloy C - 276 drain vents.

7. Only available with two, three and five-valve manifold type.

8. Only available with traditio nal manifold style codes T and M.

9. Not available with traditional manifold style code M. Manifold style code T does not include mounting holes on process flange.

10. Includes PTFE tape on drain/vent valves and plugs.

11. Includes graphite tape on drain/vent valves and plugs.

12. Not compatible with the Rosemount 3095 Transmitter.

13. Not available with ASME B31.1 manifold type codes 7, 8, and 9.

14. Not available with graphite-based packing material code 2.

15. Only allowed with material of construction code 2.

16. Only allowed with traditional manifold style codes T and M. Not allowed with graphite-based packing code 2.

17. Only available with two, three, and five- valve manifold type, 316SST or Alloy C-276 materials of construction and integral valve seat.

18. Only available with traditional manifold style code M.

January 2019

10

Emerson.com/Rosemount

January 2019

Rosemount Manifolds

Rosemount 306 In-line Manifolds

Rosemount In-Line manifolds provide a leak checked and pressure tested single point solution when

assembled to Rosemount pressure transmitters. The in-line, compact design is available with a lightweight

block and bleed or two-valve configurations.

Specification and selection of product materials, options, or components must be made by the purchaser

of the equipment. See page 18 for more information on material selection.

Table 4. Rosemount R306 Integral Manifold Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

Model Product description

R306 Integral manifold

Design class

E Enhanced ★

Manifold style

T Threaded ★

Manifold type

2 2-valve ★

Body Bonnet Stem and tip Drain/vent

2 316 SST 316 SST 316 SST 316 SST ★

Process connection

BA

1

/2–14 female ANPT process connection for in-line transmitter ★

Packing material

(1)

1

(2)

2

PTFE ★

Graphite-based

Valve seat

1 Integral ★

Extended product warranty

WR3 3-year limited product warranty

WR5 5-year limited product warranty

Cleaning

P2

Material recommendation for NACE

(3)

Cleaning for special services

(4)

SG

Sour gas (meets NACE MR MR 0175/ISO 15156, MR 0103)

NACE Certificate

Q15 Certificate of Compliance to NACE MR0175/ISO 15156 for wetted materials ★

Q25 Certificate of Compliance to NACE MR0103 for wetted materials

Typical coplanar integral manifold model number: R306ET22BA11

Emerson.com/Rosemount

★

11

Rosemount Manifolds

1. Includes PTFE tape on drain/vent valves and plugs.

2. Includes graphite tape on drain/vent valves and plugs.

3. Not available with graphite-based packing material code 2 .

4. Valve stem tip material is C-276.

January 2019

12

Emerson.com/Rosemount

January 2019

Rosemount Manifolds

Specification and selection of product materials, options, or components must be made by the purchaser of the equipment.

See page 18 for more information on material selection.

Table 5. Rosemount 306 Pressure Manifold Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

Model Product description

0306 Pressure manifold

Manufacturer

R Rosemount ★

Manifold style

T Threaded ★

Manifold type

1 Block-and-bleed ★

2 Two valve ★

(1)

3

Body

(2)

Two valve (per ASME B31.1 power piping code)

Bonnet Stem and tip/ball

2 316/316L SST 316 SST 316 SST ★

(3)(4)

3

(3)

4

(3)

8

(3)

9

Alloy C-276 Alloy C-276 Alloy C-276

Alloy 400 Alloy 400 Alloy 400/K-500

Alloy 625 Alloy 625 Alloy 625

All super duplex SST (UNS S32760)

Process connection

AA

AW

BA

BW

(3)

1

/2–14 male NPT process connection for in-line transmitter ★

1

/2–14 male NPT process connection for Rosemount Wireless Pressure Gauge ★

1

/2–14 female NPT process connection for in-line transmitter ★

1

/2–14 female NPT process connection for Rosemount Wireless Pressure Gauge ★

Packing material

(5)

1

(6)

2

PTFE ★

Graphite-based

Valve seat

1 Integral ★

Options

Extended product warranty

WR3 3-year limited warranty ★

WR5 5-year limited warranty

Emerson.com/Rosemount

★

13

Rosemount Manifolds

January 2019

Table 5. Rosemount 306 Pressure Manifold Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

Cleaning

(7)

P2 Cleaning for special services

Cold temperature

(8)

CW1 –67 °F (–55 °C)

(4)(9)

Material recommendations for NACE

SG Sour gas (meets NACE MR0175/ISO 15156, MR0103/ISO 17495) ★

Typical integral manifold model number: 306 R T 2 2 BA 1 1

1. Only available with 316 SST materials of construction and graphite-based packing.

2. Refer to page 25 for additional detail on process wetted materials of construction.

3. Not available with block-and-bleed manifold type.

4. Materials of Construction comply with recommendations per NACE MR0175/ISO 15156 for sour oil field production environments. Environmental limits apply to

certain materials. Consult latest standard for details. Selected materials also conform to NACE MR0103/ISO 17495 for sour refining environments.

5. Includes PTFE tape on drain/vent valves and plugs.

6. Includes graphite tape on plugs.

7. Not available with graphite-based packing material code 2 .

8. Only available with two-valve manifold type, 316SST or Alloy C-276 materials of construction,

transmitters and integral valve seat.

9. Only allowed with material of construction code 2.

1

/2–14 male and female NPT process connection for in-line

14

Emerson.com/Rosemount

Loading...

Loading...