Page 1

00813-0100-4952, Rev GC

Rosemount™ 0085 Pipe Clamp Sensor

Product Data Sheet

July 2017

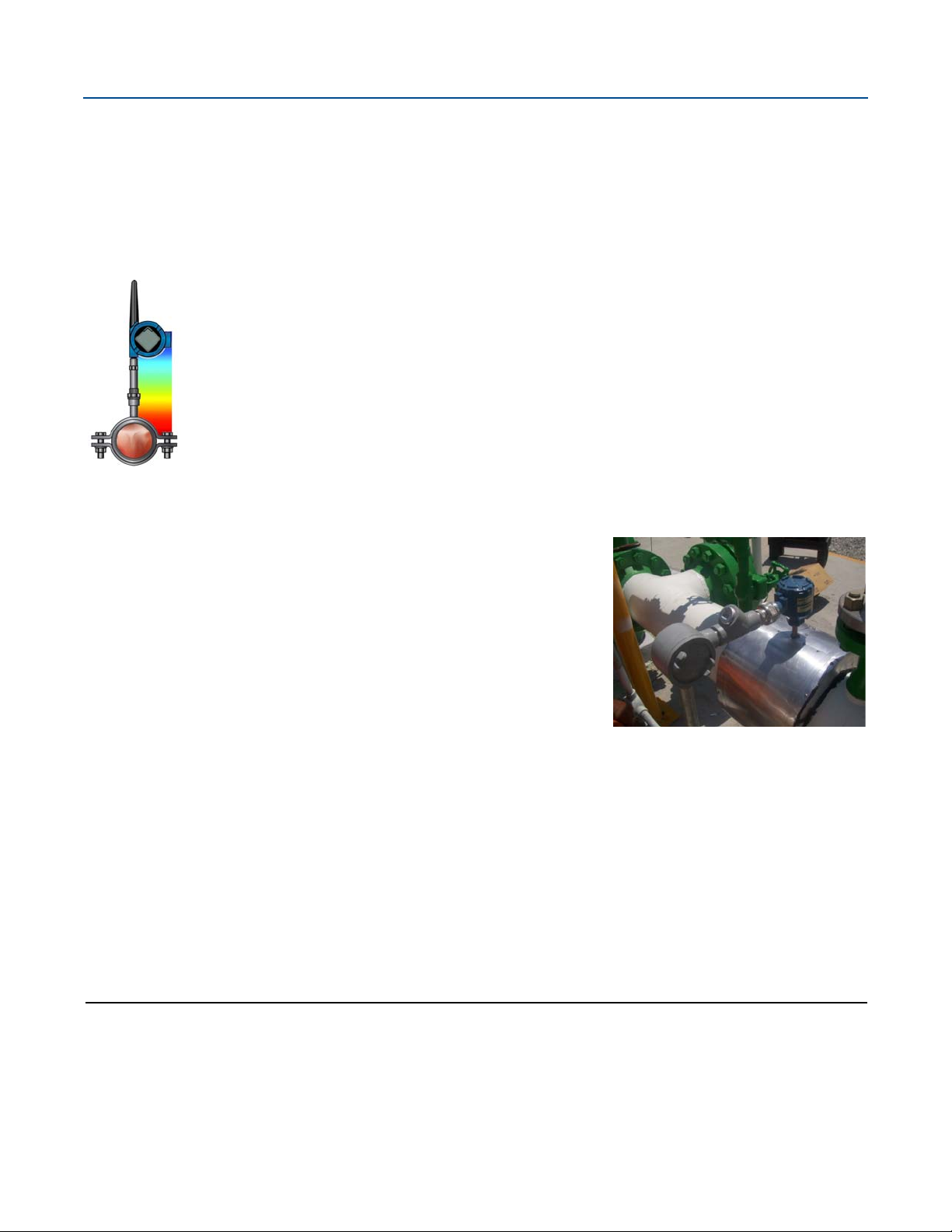

Direct mount assembly with Rosemount 3144P Temperature transmitter or Rosemount 648 Wireless

Temperature transmitter with Rosemount X-well

without the requirement of a thermowell or process penetration

Non-intrusive design for fast and easy temperature measurement in piping applications

Platinum RTD temperature sensors with silver or nickel tip

Integrated temperature assemblies provide time and cost savings

™

Technology provides accurate process temperature

Page 2

Rosemount 0085 Pipe Clamp Sensor

Rosemount 0085 Pipe Clamp Sensor

Rosemount X-well Technology provides a Complete Point Solutions™ for accurately measuring process temperature without the requirement of a thermowell or process penetration.

Simplify temperature measurement point specification, installation and maintenance, and eliminate possible

leak points

Calculates a repeatable and accurate process temperature measurement via an in-transmitter thermal

conductivity algorithm

Measures pipe surface and ambient temperature, and utilizes the thermal conductivity properties of the

installation and process piping in order to provide an accurate process measurement

Proven pipe clamp sensors deliver excellent performance and reliability

July 2017

Superior accuracy and stability

Improved response time with silver and nickel tip

Easy implementation and installation in existing application

Available in a wide variety of pipe sizes and material

Installation with only two bolts – no welding needed

Optimized surface contact by spring loaded sensor design

Minimized risk of sensor failure and unplanned shutdowns

Avoids stresses related to flow, pressure, chemical contact, abrasion, vibration, and bending

Maintenance of sensor without shutdown of process

Achieve optimal efficiency with Rosemount wireless transmitter offering

Measure your temperature anywhere

Contents

Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

How to order Rosemount X-well Technology . . . . . . . . . 8

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2

Dimensional Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Product Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Emerson.com/Rosemount

Page 3

July 2017

Rosemount 0085 Pipe Clamp Sensor

Explore the benefits of Complete Point Solutions from Rosemount Temperature Measurement

An “Assemble to Transmitter” option enables Emerson

temperature solution, delivering an installation-ready transmitter and sensor assembly

Emerson has a complete portfolio of single point, high density and wireless

temperature measurement solutions, allowing you to effectively measure and control

your processes with the reliability you trust from Rosemount products

™

to provide a complete point

Experience global consistency and local support from numerous worldwide Rosemount Temperature sites

Experienced Instrumentation Consultants help select

the right product for any temperature application and

advise on best installation practices

An extensive global network of Emerson service and support

personnel can be on-site when and where they are needed

Emerson.com/Rosemount

3

Page 4

Rosemount 0085 Pipe Clamp Sensor

July 2017

Ordering information

The Rosemount 0085 Pipe Clamp Sensor is designed for fast and easy non-intrusive surface temperature

measurements in piping applications.

Features include:

Temperature range of -50 to 300 °C (-58 to 572 °F) for silver tip, -200 to 300 °C (-328 to 572 °F) for nickel tip

Suitable for pipe sizes

Single or Dual Element Class A Sensor

Assemble to Transmitter Option

Specification and selection of product materials, options, or components must be made by the purchaser of

the equipment.

See page 10 for more information on material selection.

Table 1. Rosemount Pipe Clamp Sensor Ordering Information

The starred offerings (H) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

Model Product description

0085 Non Intrusive Pipe Clamp Sensor

Code Connection head IP rating Conduit entry

1

/2-in. to 48-in. (22 mm to 1219 mm)

C Connection head Rosemount, aluminum 68 M20 x 1.5 H

D Connection head Rosemount, aluminum 68

1

/2-in. NPT H

G Connection head Rosemount, stainless steel 68 M20 x 1.5 H

H Connection head Rosemount, stainless steel 68

1

/2-in. NPT H

N No connection head N/A N/A H

1 Connection head Rosemount, aluminum with LCD display cover 68 M20 x 1.5 H

2 Connection head Rosemount, aluminum with LCD display cover 68

1

/2-in. NPT H

3 Connection head Rosemount, stainless steel with LCD display cover 68 M20 x 1.5 H

4 Connection head Rosemount, stainless steel with LCD display cover 68

1

/2-in.NPT H

Sensor connection

3 Spring loaded adapter H

5 Spring loaded adapter with terminal block H

Sensor type Temperature range

P1 RTD, single element, 4-wire, silver tip -50 to 300 °C (-58 to 572 °F) H

P2 RTD, dual element, 3-wire, silver tip -50 to 300 °C (-58 to 572 °F) H

P3 RTD, single element, 4-wire, nickel tip -200 to 300 °C (-328 to 572 °F) H

P4 RTD, dual element, 3-wire, nickel tip -200 to 300 °C (-328 to 572 °F) H

Extension type Head connection

J Nipple -Union None

N No extension (sensor only option) H

Instrument

connection

1

/2-in. NPT Stainless steel H

Material

4

Emerson.com/Rosemount

Page 5

July 2017

Table 1. Rosemount Pipe Clamp Sensor Ordering Information

The starred offerings (H) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

Rosemount 0085 Pipe Clamp Sensor

Extension length (N)

0080 80 mm H

0150 150 mm H

XXXX Non standard lengths 200–500 mm (available in 50 mm increments)

Pipe clamp material

N No clamp (sensor only option) H

P ASTM 304 SST (1.4301) H

B Duplex F51 (1.4462)

C Carbon steel (1.0037)

S ASTM 316 SST (1.4401)

Nonstandard pipe

sizes

Millimeters

Clamp/bolt

dimensions

Inner diameter (D)

Standard pipe sizes

(1)

Inches DIN

Min. OD Max. OD

0022 22 mm

0027 27 mm

0030 30 mm N/A DN25 27 31 30 x 5 mm, M10

0034 34 mm 1 DN25 31 35 30 x 5 mm, M10 H

0043 43 mm 11/4 DN32 40 46 30 x 5 mm, M10

0049 49 mm 11/2 DN40 46 50 30 x 5 mm, M10 H

0061 61 mm 2 DN50 58 68 40 x 6 mm, M12 H

0077 77 mm 21/2 DN65 74 86 40 x 6 mm, M12

0089 89 mm 3 DN80 86 96 40 x 6 mm, M12 H

0115 115 mm 4 DN100 112 120 50 x 8 mm, M16 H

0140 140 mm 5 DN135 137 144 50 x 8 mm, M16 H

0159 159 mm N/A DN150 156 162 50 x 8 mm, M16

0169 169 mm 6 DN150 166 172 50 x 8 mm, M16 H

0220 220 mm 8 DN200 217 223 50 x 8 mm, M16 H

0273 273 mm 10 DN250 269 278 60 x 8 mm, M20

0306 306 mm N/A N/A 302 311 60 x 8 mm, M20

0324 324 mm 12 DN300 320 329 60 x 8 mm, M20

0356 356 mm 14 DN350 352 361 60 x 8 mm, M20

0368 368 mm N/A DN350 364 373 60 x 8 mm, M20

0407 407 mm 16 DN400 401 417 70 x 10 mm, M24

0458 458 mm 18 DN450 452 468 70 x 10 mm, M24

0508 508 mm 20 DN500 502 518 70 x 10 mm, M24

0521 521 mm N/A DN500 515 531 70 x 10 mm, M24

1

/2 DN15 19 24 30 x 5 mm, M10 H

3

/4 DN20 24 27 30 x 5 mm, M10 H

Emerson.com/Rosemount

5

Page 6

Rosemount 0085 Pipe Clamp Sensor

Table 1. Rosemount Pipe Clamp Sensor Ordering Information

The starred offerings (H) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

0610 610 mm 24 DN600 604 620 70 x 10 mm, M24

0660 660 mm 26 N/A 654 670 70 x 10 mm, M24

0720 720 mm N/A N/A 714 730 70 x 10 mm, M24

0762 762 mm 30 N/A 756 772 70 x 10 mm, M24

0813 813 mm 32 DN790 807 823 70 x 10 mm, M24

0915 915 mm 36 DN900 909 925 70 x 10 mm, M24

1016 1016 mm 40 DN1000 1010 1026 70 x 10 mm, M24

1070 1070 mm 42 N/A 1064 1064 70 x 10 mm, M24

1219 1219 mm 48 N/A 1213 1229 70 x 10 mm, M24

July 2017

Corrosion protection inlay

N None H

A Material NBR

Options (include with selected model number)

316SST material options

M1 316SST Wire-on tag H

M2 316SST Components H

Sensor options

A1 Single element Class A sensor from -50 to 300 °C (-58 to 572 °F) H

(2)

A2

Dual element Class A sensor from -50 to 300 °C (-58 to 572 °F) H

Assemble to option

XA Assemble sensor to specific temperature transmitter H

Cable gland options

G2 Cable gland, Ex d, brass, 7.5–11.9 mm H

G7 Cable gland, M20 x 1.5, Ex e, blue, Polyamide, diam 5–9 mm H

Product certifications

E1 ATEX Flamep roo f H

I1 ATEX Intrinsic Safety H

E7 IECEx Flameproof and Dust H

E5 FM Explosion-Proof H

E6 CSA Explosion-Proof H

EM Technical Regulations Customs Union (EAC) Flameproof H

IM Technical Regulations Customs Union (EAC) Intrinsic Safety H

Cover chain option

G3 Cover chain (only available with Rosemount connection head material codes C, D, G, and H) H

6

Emerson.com/Rosemount

Page 7

July 2017

Table 1. Rosemount Pipe Clamp Sensor Ordering Information

The starred offerings (H) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

Rosemount 0085 Pipe Clamp Sensor

Product certifications

LT Special material to meet extended temperature range of -51 °C H

Q8 Material Traceability Certification per EN 10204 3.1B H

Typical pipe clamp model number: 0085 C 3 P 1 J 0080 P 0061 N

Replacement sensor only model

number:

1. When selecting this option in regards to Rosemount X-well Technology, refer to “How to order Rosemount X-well Technology” on page 8.

2. The sensor option code A2 is not available with sensor type P4.

0085 N3 P 1 N 0080 N 0061 N

Emerson.com/Rosemount

7

Page 8

Rosemount 0085 Pipe Clamp Sensor

July 2017

How to order Rosemount X-well Technology

Rosemount X-well Technology is for temperature monitoring applications and is not intended for control or safety applications. It is

available in the Rosemount 3144P Transmitter and 648 Wireless Transmitter in a factory assembled direct mount configuration with

a Rosemount 0085 Pipe Clamp Sensor. It cannot be used in a remote mount configuration. Rosemount X-well Technology will only

work as specified with factory supplied and assembled Rosemount 0085 Sensor silver tipped single element sensor with an 80 mm

extension length. It will not work as specified if used with other sensors.

Tra ns mi tt er

The Rosemount 3144P option code requirements are:

Code Description

D1-D4 Aluminum field mount housing

PT Temperature measurement assembled with Rosemount X-well Technology

A 4-20 mA with digital signal based on HART protocol

XA Sensor specified separately and assembled to transmitter

C1 Custom configuration of date, descriptor, message, and wireless parameters (requires CDS with order)

HR7 Configured for HART Revision 7

The Rosemount 648 Wireless option code requirements are:

Code Description

PT Temperature measurement assembled with Rosemount X-well Technology

XA Sensor specified separately and assembled to transmitter

C1 Custom configuration of date, descriptor, message, and wireless parameters (requires CDS with order)

The Rosemount 0085 Pipe Clamp Sensor option code requirements are:

Code Description

N No connection head

3 Sensor connection

P1 Sensor type

J Extension type

0080 Extension length

XA Assemble sensor to specific temperature transmitter

Rosemount X-well assemblies are available in most Rosemount 0085 Pipe Clamp sensor diameter sizes.

Rosemount 3144P and 0085

3144P D 1A 1 NA M5 PT C1 HR7 XA

0085 N 3 P1 J 0080 C 0169 N XA

Typical model number of the assembly:

Rosemount 648 Wireless and 0085

648 D X 1 D NA WA3 WK1 M5 PT C1 XA

0085 N 3 P1 J 0080 C 0169 N XA

8

Emerson.com/Rosemount

Page 9

July 2017

60

50

40

30

20

10

0

135 160 185 210

815

˚C

process

process

process

temperature

temperature

temperature

235 260 285

Uninsulated distance from the process (mm)

Housing rise above ambient ( ˚C)

540

˚C

250

˚C

Overview

Rosemount 0085 Pipe Clamp Sensor

Rosemount Pipe Clamp overview

Emerson offers a range of RTDs alone, or as integrated

temperature assemblies including Rosemount Temperature

Transmitters and connection heads.

Rosemount Pipe Clamp Platinum RTD Sensors are highly linear

and have a stable resistance versus temperature relationship.

They are used primarily in industrial environments where high

accuracy, durability, and long-term stability are required, and

are designed to meet the most critical parameters of

international standards: DIN EN 60751/IEC 751 1983

incorporating Amendments 1 and 2.

(1)

Rosemount Pipe Clamp Sensors are available in single and dual

element types.

Selecting the extension length for a pipe clamp sensor

A direct mounting configuration allows heat from the process,

aside from ambient temperature variations, to transfer from the

pipe clamp to the transmitter housing. If the expected pipe

surface temperature is near or above the transmitter

specification limits, consider using additional extension length

or a remote mounting configuration to isolate the transmitter.

Figure 1 provides an example of the relationship between

transmitter housing temperature rise and distance from the

process.

Example

The rated ambient temperature specification for the transmitter

is 85 °C. If the maximum ambient temperature is 40 °C and the

temperature to be measured is 540 °C, the maximum allowable

housing temperature rise is the rated temperature specification

limit minus the existing ambient temperature (85 – 40), or

45 °C.

As shown in Figure 1, an uninsulated distance from the process

of 90 mm will result in a housing temperature rise of 22 °C.

Therefore, 100 mm would be the minimum recommended

distance from the process providing a safety factor of about

25 °C. A longer length, such as 150 mm, is desired to reduce

errors caused by transmitter temperature effect, although in

that case the transmitter may require extra support.

Sensor tip material configuration

The pipe clamp sensor tip is constructed from silver or nickel for

better thermal conductivity and to reduce the thermal response

time. The silver tip has a slightly faster response time while the

nickel tip has a larger temperature range, which allows for

cryogenic applications. The silver tip temperature range is -50 to

300 °C (-58 to 572 °F), and the nickel tip temperature range is

-200 to 300 °C (-328 to 572 °F).

Figure 1. Transmitter Housing Temperature Rise vs.

Uninsulated Distance from the Process

1. 100 Ω at 0 °C, α = 0.00385 Ω x °C/Ω.

Emerson.com/Rosemount

9

Page 10

Rosemount 0085 Pipe Clamp Sensor

Black

Red

Red

Green

Blue

Blue

1

2

3

4

5

6

Blue

Red

Red

Blue

Green

Black

Specifications

July 2017

Material selection

Emerson provides a variety of Rosemount product with various

product options and configurations including materials of

construction that can be expected to perform well in a wide

range of applications. The Rosemount product information

presented is intended as a guide for the purchaser to make an

appropriate selection for the application. It is the purchaser’s

sole responsibility to make a careful analysis of all process

parameters (such as all chemical components, temperature,

pressure, flow rate, abrasives, contaminants, etc.), when

specifying product, materials, options and components for the

particular application. Emerson is not in a position to evaluate or

guarantee the compatibility of the process fluid or other process

parameters with the product, options, configuration or

materials of construction selected.

Rosemount Pipe Clamp Platinum RTD

Nominal resistance

In accordance with DIN EN 60751/IEC 751 1983 incorporating

Amendments 1 and 2, the nominal resistance is defined:

100 Ω RTD at 0 °C

α = 0.00385 Ω x °C/Ω., averaged between 0 and 100 °C

Lead wires

PTFE insulated, silver-coated copper wire (Figure 2)

Identification data

The model and serial numbers are engraved directly on the

spring loaded adapter.

Ingress Protection (IP) rating for connection head

IP68 and NEMA® 4X

Figure 2. Sensor Lead Wire Termination - Pipe Clamp RTD

Spring Loaded

Single element 4-wire Dual element 3-wire

Red

Red

White

White

Limit deviations

Tolerance Class B, as standard t = ±(0.3 + 0.005 x [t]);

temperature range -200 to 300 °C (-328 to 572 °F)

Tolerance Class A, as option t = ±(0.15 + 0.002 x [t]);

temperature range -50 to 300 °C (-58 to 572 °F)

Process temperature range

-200 to 300 °C (-328 to 572 °F)

Ambient temperature range

-40 to 85 °C (-40 to 185 °F)

Self-heating

0.15 K/mW when measured as defined in DIN EN 60751; 1996

Insulation resistance (RTD)

1,000 MΩ minimum insulation resistance when measured at

500 V dc at room temperature

Sheath material

321 SST with mineral insulated cable construction and silver or

nickel tip

White

1

6

5

4

White

2

Red

3

Red

10

Emerson.com/Rosemount

Page 11

July 2017

L

11± 2

68 N

D

Dimensional Drawings

Figure 3. 1/2-in. ANPT Spring Loaded Adapter

Rosemount 0085 Pipe Clamp Sensor

Figure 4. Pipe Clamp Sensor Assembly with Rosemount 3144P

Dimensions are in millimeters.

Emerson.com/Rosemount

11

Page 12

Rosemount 0085 Pipe Clamp Sensor

68

N

D

Figure 5. Pipe Clamp Sensor Assembly with Rosemount Connection Head

68 N

July 2017

D

Figure 6. Pipe Clamp Sensor Assembly with Rosemount 648 Wireless Transmitter

Dimensions are in millimeters.

12

Emerson.com/Rosemount

Page 13

July 2017

Rosemount 0085 Pipe Clamp Sensor

Accessories

Table 2. Connection Head

Part number Model/material

IP rating

00644-4410-0011 Rosemount, aluminum 68

00644-4410-0021 Rosemount, aluminum 68 M20 x 1.5

00644-4410-0111 Rosemount, aluminum with LCD display cover 68

00644-4410-0121 Rosemount, aluminum with LCD display cover 68 M20 x 1.5

00644-4411-0011 Rosemount, stainless steel 68

00644-4411-0021 Rosemount, stainless steel 68 M20 x 1.5

00644-4411-0111 Rosemount, stainless steel with LCD display cover 68

00644-4411-0121 Rosemount, stainless steel with LCD display cover 68 M20 x 1.5

Figure 7. Connection Head

With LCD display cover With standard cover

Conduit

connection

1

/2-in. NPT

1

/2-in. NPT

1

/2-in. NPT

1

/2-in. NPT

Process

connection

1

/2-in. NPT

1

/2-in. NPT

1

/2-in. NPT

1

/2-in. NPT

1

/2-in. NPT

1

/2-in. NPT

1

/2-in. NPT

1

/2-in. NPT

A. LCD display

Dimensions are in millimeters.

78

104

A

128

78

128

104

100

Emerson.com/Rosemount

13

Page 14

Rosemount 0085 Pipe Clamp Sensor

Product Certifications

Rev 1.8

July 2017

European Directive Information

A copy of the EU Declaration of Conformity can be found at the

end of the Quick Start Guide. The most recent revision of the EU

Declaration of Conformity can be found at

Emerson.com/Rosemount

.

Ordinary Location Certification

As standard, the transmitter has been examined and tested to

determine that the design meets the basic electrical,

mechanical, and fire protection requirements by a nationally

recognized test laboratory (NRTL) as accredited by the Federal

Occupational Safety and Health Administration (OSHA).

North America

The US National Electrical Code® (NEC) and the Canadian

Electrical Code (CEC) permit the use of Division marked

equipment in Zones and Zone marked equipment in Divisions.

The markings must be suitable for the area classification, gas,

and temperature class. This information is clearly defined in the

respective codes.

North America

E5 FM Explosionproof and Dust-Ignitionproof

Certificate: 0R7A2.AE

Standards: FM Class 3600- 2011, FM Class 3615-2006, FM Class

3810-2005, ANSI/NEMA 250-1991

Markings: XP CL I, DIV 1, GP B, C, D, T6; DIP CL II/III, DIV 1, GP E,

F, G, T6; Type 4X; Installed per 00068-0013;

E6 CSA Explosionproof, Dust-Ignitionproof

Certificate: 1063635

Standards: CAN/CSA C22.2 No. 0-M91, CSA Std. C22.2 No.

25-1966, CSA Std. C22.2 No. 30-M1986, CSA

Std. C22.2 No.94-M91, CSA Std. C22.2 No.

142-M1987, CSA Std. C22.2 No. 213-M1987

Markings: XP Class I Groups B, C, and D; DIP Class II Groups E, F,

G; Class III; Class I Div. 2 Groups A, B, C, D; Class I

Zone 1 Group IIB+H2; Class I Zone 2 Group IIC;

Installed per 00068-0033;

Special Conditions for Safe Use (X):

1. See certificate for ambient temperature range

2. The non-metallic label may store an electrostatic charge

and become a source of ignition in Group III environments

3. Guard the LCD cover against impact energies greater than

4 joules

4. Flameproof joints are not intended for repair

5. A suitable certified Ex d or Ex tb enclosure is required to be

connected to temperature probes with Enclosure option

"N".

6. Care shall be taken by the end user to ensure that the

external surface temperature on the equipment and the

neck of DIN Style Sensor probe does not exceed 130 °C.

7. Non-Standard Paint options may cause risk from

electrostatic discharge. Avoid installations that cause

electrostatic build-up on painted surfaces, and only clean

the painted surfaces with a damp cloth. If paint is ordered

through a special option code, contact the manufacturer

for more information

I1 ATEX Intrinsic Safety

Certificate: Baseefa16ATEX0101X

Standards: EN 60079-0:2012+A11:2013, EN

60079-11:2012

Markings: II 1 G Ex ia IIC T5/T6 Ga SEE CERTIFICATE FOR

SCHEDULE

Thermocouples; Pi = 500mW T6 60 °C ≤ Ta ≤ +70 °C

RTDs; Pi = 192mW T6 60 °C ≤ Ta ≤ +70 °C

RTDs; Pi = 290mW

Special Conditions of Use (X):

1. The equipment must be installed in an enclosure which

affords it a degree of ingress protection of at least IP20

T6 60 °C

T5 60 °C

≤ Ta ≤ +60 °C

≤ Ta ≤ +70 °C

International

E7 IECEx Flameproof

Certificate: IECEx FMG 12.0022X

Standards: IEC60079-0:2011, IEC60079-1:2007

Markings: Ex d IIC T6…T1 Gb

Europe

E1 ATE X Flameproof

Certificate: FM12ATEX0065X

Standards: EN60079-0:2012, EN60079-1:2007

Markings: II 2 G Ex d IIC T6…T1 Gb

14

Emerson.com/Rosemount

Page 15

July 2017

Special Conditions for Safe Use (X):

1. See certificate for ambient temperature range

2. The non-metallic label may store an electrostatic charge

and become a source of ignition in Group III environments

3. Guard the LCD cover against impact energies greater than

4 joules

4. Flameproof joints are not intended for repair

5. A suitable certified Ex d or Ex tb enclosure is required to be

connected to temperature probes with Enclosure option

"N".

6. Care shall be taken by the end user to ensure that the

external surface temperature on the equipment and the

neck of DIN Style Sensor probe does not exceed 130 °C.

7. Non-Standard Paint options may cause risk from

electrostatic discharge. Avoid installations that cause

electrostatic build-up on painted surfaces, and only clean

the painted surfaces with a damp cloth. If paint is ordered

through a special option code, contact the manufacturer

for more information

EAC

EM Explosionproof/ Flameproof

Markings: 1Ex db IIC T6..T1 Gb X; T6 (-50°C to 40°C); T5..T1

(-50°C to 60°C); IP66/IP167

Rosemount 0085 Pipe Clamp Sensor

Special Conditions for Safe Use (X):

1. See Certificate

IM Intrinsic Safety

Markings: 0Ex ia IIC T5/T6 Ga X; T5, Pi = 0.29W, (-60°C to +70°C);

T6, Pi = 0.29W, (-60°C to +60°C); T6, Pi =

0.192W, (-60° to +70°C);

Special Conditions for Safe Use (X):

1. See Certificate

KM Combination of EM, IM, and Dust-Ignitionproof

Markings: Ex tb IIIC T130°C Db X (-60°C to +70°C);

Markings for both EM and IM above are included

with this option.

Special Conditions for Safe Use (X):

1. See Certificate

Emerson.com/Rosemount

15

Page 16

Rosemount 0085 Pipe Clamp Sensor

00813-0100-4952, Rev GC

Global Headquarters

Emerson Automation Solutions

6021 Innovation Blvd.

Shakopee, MN 55379, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RFQ.RMD-RCC@Emerson.com

North America Regional Office

Emerson Automation Solutions

8200 Market Blvd.

Chanhassen, MN 55317, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RMT-NA.RCCRFQ@Emerson.com

Latin America Regional Office

Emerson Automation Solutions

1300 Concord Terrace, Suite 400

Sunrise, FL 33323, USA

+1 954 846 5030

+1 954 846 5121

RFQ.RMD-RCC@Emerson.com

Product Data Sheet

July 2017

Europe Regional Office

Emerson Automation Solutions Europe GmbH

Neuhofstrasse 19a P.O. Box 1046

CH 6340 Baar

Switzerland

+41 (0) 41 768 6111

+41 (0) 41 768 6300

RFQ.RMD-RCC@Emerson.com

Asia Pacific Regional Office

Emerson Automation Solutions Asia Pacific Pte Ltd

1 Pandan Crescent

Singapore 128461

+65 6777 8211

+65 6777 0947

Enquiries@AP.Emerson.com

Middle East and Africa Regional Office

Emerson Automation Solutions

Emerson FZE P.O. Box 17033

Jebel Ali Free Zone - South 2

Dubai, United Arab Emirates

+971 4 8118100

+971 4 8865465

RFQ.RMTMEA@Emerson.com

Linkedin.com/company/Emerson-Automation-Solutions

Twitter.com/Rosemount_News

Facebook.com/Rosemount

Youtube.com/user/RosemountMeasurement

Google.com/+RosemountMeasurement

Standard Terms and Conditions of Sale can be found on the Ter ms a nd

Conditions of Sale page.

The Emerson logo is a trademark and service mark of Emerson Electric

Co.

Complete Point Solution, Rosemount X-well Technology, Rosemount,

and Rosemount logotype are trademarks of Emerson.

National Electrical Code is a registered trademark of National Fire Protection Association, Inc.

NEMA is a registered trademark and service mark of the National Electrical Manufacturers Association.

All other marks are the property of their respective owners.

© 2017 Emerson. All rights reserved.

Loading...

Loading...