3611- 4722 GHB and BHB

Supplement to G12-209

G12-436

04/08/04

®

OWNERS MANUAL

SAFETY INSTRUCTIONS

This is an industrial component. Only a qualified systems integrator should be allowed to

design it into a system. The integrator must determine proper plumbing, mounting, driveline

and guard components.

Improper installation or use could lead to a serious, even fatal, accident. The system

integrator must communicate all safe operation procedures to the end user(s).

Before operation, fully understand and follow the instructions shown in this manual and any

instructions communicated by the system integrator. No one should be allowed to operate or

maintain this pump who has not been fully trained to work safely according to the

configuration of the pump system and in accordance with all applicable government and

industry regulations.

Roper Pump Company

P.O. Box 269

Commerce, GA 30529 USA

Telephone: (706) 335-5551

TeleFAX: (706) 335-5490

Email: sales@roperpumps.com

www.roperpumps.com

Good Practice

NOTE: These are general guidelines and do not cover all possible situations.

It is the responsibility of the system integrator to apply this product properly.

Plumbing

1. The inlet pipe should be as short and straight as possible to minimize

suction pressure losses. Excessive restrictions at the inlet can cause

cavitation resulting in poor performance, noise, vibration, or pump

damage.

2. Slope the inlet plumbing appropriately to avoid air pockets.

3. Plumbing weight, misalignment with the ports or thermal expansion can

exert excessive force on the pump. Plumbing must be properly

supported and aligned with expansion joints, if required, to minimize

these forces.

4. To prevent over pressure situations, install a relief valve as close to the

pump outlet as possible. Install the relief valve before any shut-off

valves.

____________________________________________________________

Separate Pump and Drive Assemblies

Driveline Guards

1. Assure adequate guards have been installed to prevent personnel

contacting moving components.

2. Follow all OSHA, Federal, state and local codes.

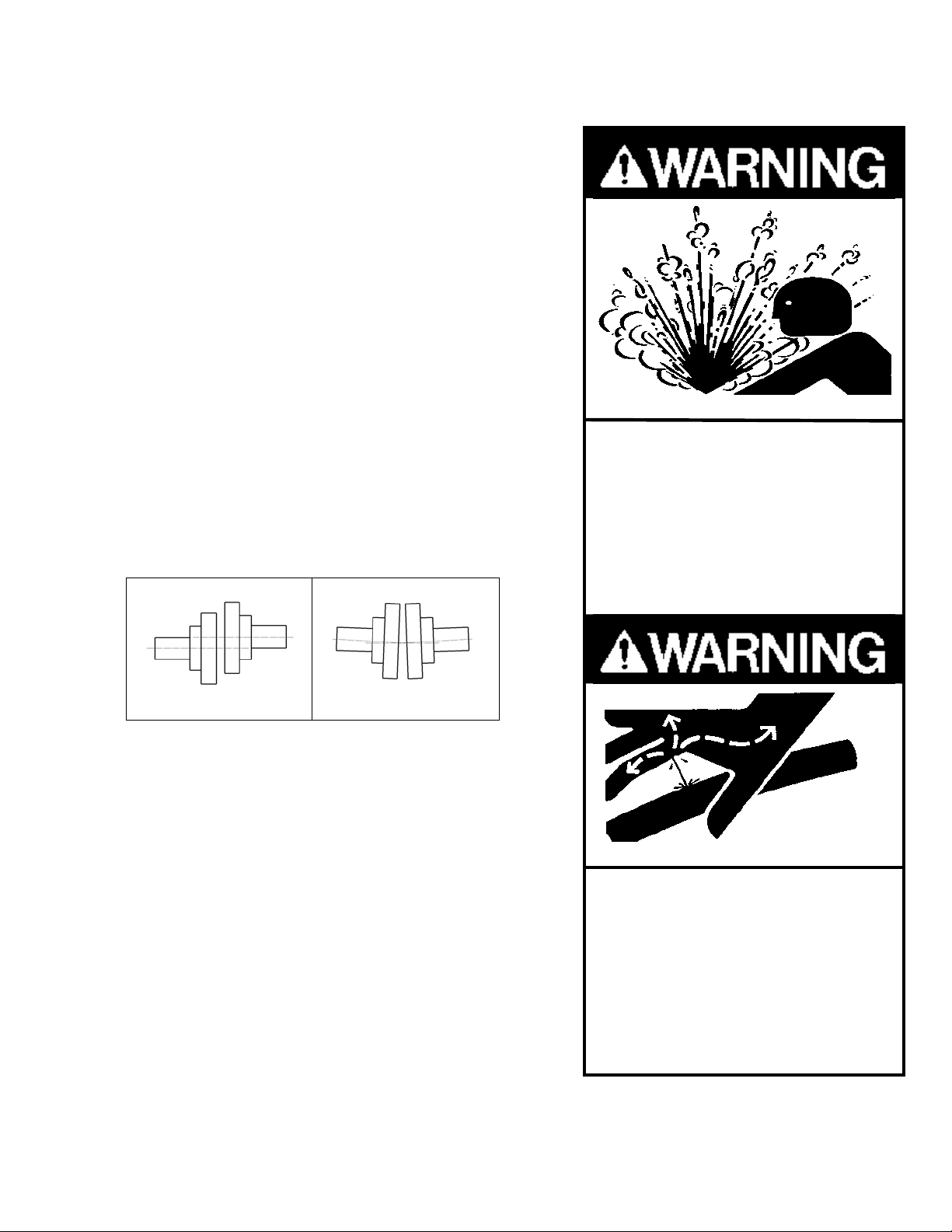

Check Alignment of Pump to Driveline

Excessive misalignment can overload the pump input shaft and cause

premature failure. The figures below show parallel and angular

misalignments.

Parallel Angular

Mounting Base

1. Mount the unit on a rigid, heavy base to provide support and absorb

shock. Bases should be designed for high rigidity, not just strength.

2. The pump feet were not designed for mounting to concrete and do not

have enough contact area to prevent concrete from failing. When

mounting to cement or concrete, use a steel base plate (supplied by

others) to distribute the mounting stress over an area large enough to

prevent the cement from failing. The base plate should be at least as

thick as the pump feet. Grout it in place.

___________________________________________________________

Roper Pumps’ Close Coupled Drives

Hydraulic drive units where the drive mounts directly to the pump

• Driveline is not exposed and does not require guards.

• Alignment between pump and drive line is maintained by the assembly.

• Because the assembly absorbs reaction forces of the driveline, the

mounting base does not need to be as robust. The level of rigidity and

strength is determined by the piping stresses from the system.

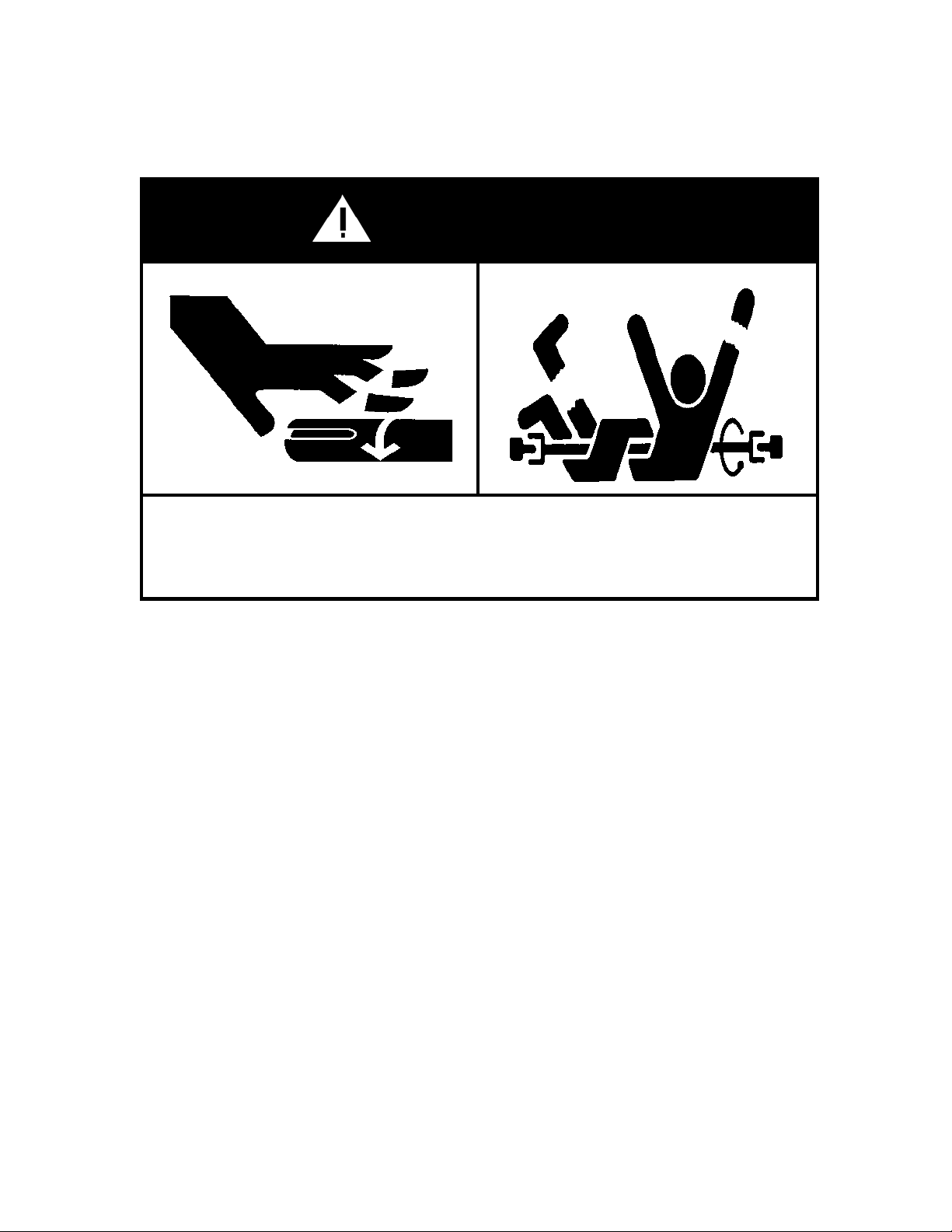

Over-pressure may burst pump or

system components. Always include

a relief valve in installation. Do not

over pressurize pump or block

discharge line while running.

Injection Hazard: Do not try to

stop a leak with your hand! Avoid

any close contact with hydraulic

fluid jets. Escaping fluid can

penetrate skin, causing serious

injury. In case of accident, see a

doctor immediately for removal of

fluid.

2

WARNING

Operating without guards could result in serious injury or death.

Machinery in operation can grab, crush, cut, mangle and dismember.

Do not operate without adequate guards in place.

3

INSTALLATION

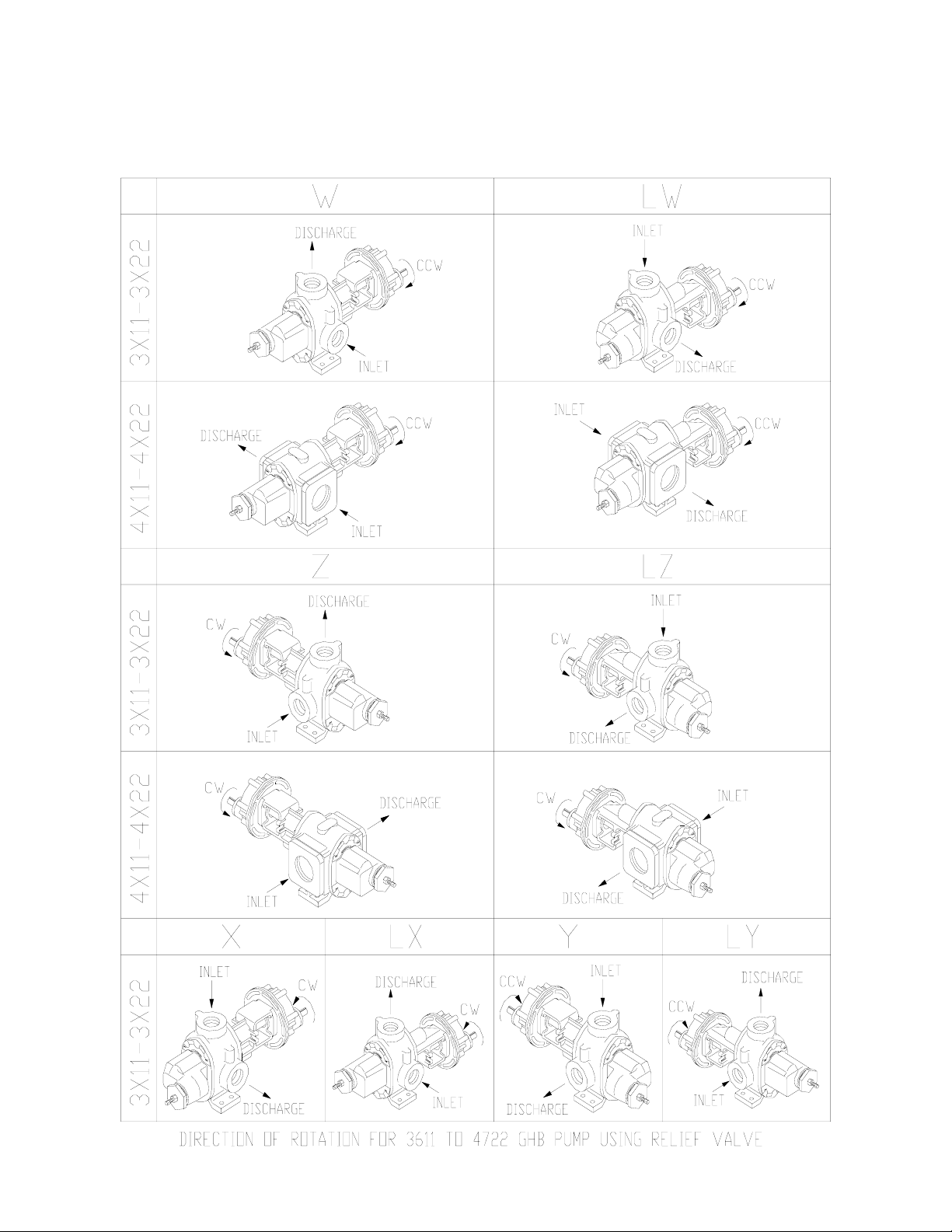

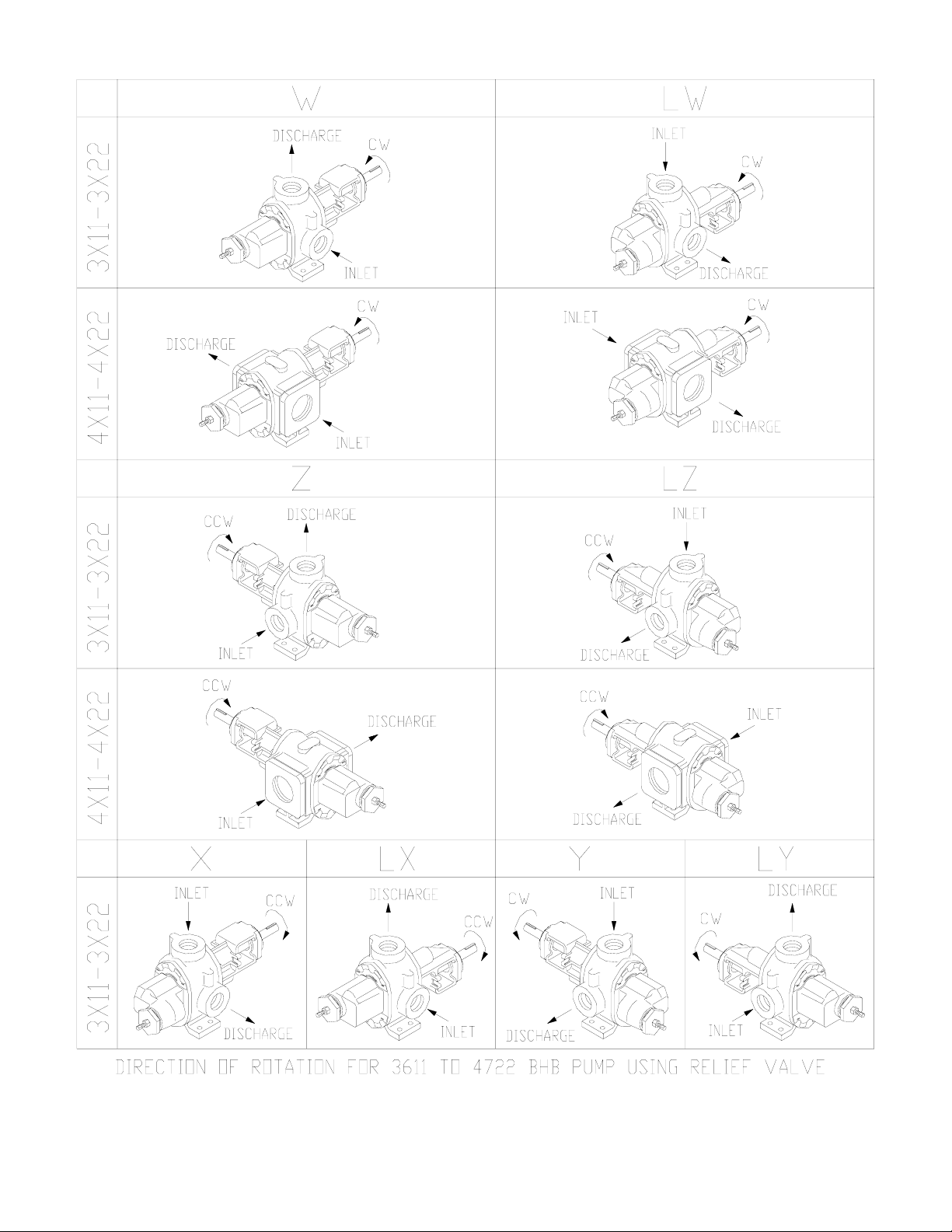

Check Ports Versus Rotation:

Make sure the inlet and discharge ports have been correctly plumbed corresponding to the direction of rotation and the

relief valve, if present, is properly positioned.

See following drawings for various configurations.

Figure A

4

Figure B

5

1. RECOMMENDED TOOL LIST

NOTE: Tools not furnished with pump.

Tools for all Pumps:

(1) Safety Glasses

(1) 9/16” Combination Wrench

(1) ¾” Combination Wrench

(1) 6” Adjustable Wrench

(1) CG-45 Snap-On

(1) 6” to 10” Three Square File

(1) Pliers

Additional Tools for GHB Pumps:

(1) ½” Combination Wrench

Additional Tools for Pumps with an RV Type Relief Valve:

(1) 7/16” Combination Wrench

(1) 18” Pipe Wrench

Additional Tools for Pumps with Flanges:

(2) 15/16” Combination Wrench

Additional Tools for Pumps with Shaft Packing:

Packing Hook for .34” square packing rings

Additional Tools for Pumps with Mechanical Seals:

(1) 0400 External Retaining Ring Pliers

Additional Tools for BHB and BH Pumps:

(1) 5/16” Hex Key

Snap-On is a registered trademark of Snap-On Tool Corporation

Tool Bearing Puller

6

2. INSTRUCTIONS FOR PUMP DISASSEMBLY

Refer to PUMP SECTIONAL DRAWINGS, (Figures 7.1 and 7.2)

1. Read WARNINGS before starting to disassemble pump. While disassembling pump, always inspect

disassembled parts and adjacent parts to see if further disassembly is needed. Replace worn or damaged parts

as required.

2. If you do not know which pump arrangement you have, collect nameplate data and refer to the Owners Manual for

3611-22 (G12-209), to determine what you have. Consult a Roper distributor or Roper Pump Company if you

have any questions.

3. When cleaning or lubricating, use only cleaning solutions and lubricants that are compatible with products being

pumped and with sealing elastomers. DO NOT use petroleum base products with seals with EPR elastomers.

Use a nonpetroleum base lubricant with EPR elastomers.

4. Turn off pump and lock out energy source to driver. DO NOT proceed further with disassembly of pump if there is

the slightest possibility that driver may be started.

5. If used, turn off and disconnect flush from mechanical seal.

6. Close inlet and discharge valves.

7. Remove guard and disconnect coupling between driver and pump.

8. Drain inlet and discharge lines. Disconnect lines from pump inlet and discharge.

9. Follow the procedure in the Owners Manual for 3611-22 (G12-209), INSTRUCTIONS FOR DRAINING PUMP.

10. A.) For 3600/4600 “GHBO” pumps, follow steps 11 – 20.

B.) For 3600/4600 “BHB” pumps, go to Section 4, INSTRUCTIONS FOR DISASSEMBLY OF A TYPE “BHB”

HYDRAULIC DRIVE. After disassembling hydraulic drive, return to this section and follow steps 11 – 20.

C.) For 3600/4600 “GHB” pumps, follow steps 21 – 32.

D.) For 3700/4700 “GHBO” pumps, follow steps 11 – 20.

E.) For 3700/4700 “BHB” pumps, go to Section 4, INSTRUCTIONS FOR DISASSEMBLY OF A TYPE “BHB”

HYDRAULIC DRIVE. After disassembling hydraulic drive, return to this section and follow steps 11 – 20.

F.) For 3700/4700 “GHB” pumps, follow steps 42 – 53.

11. Remove two washer head cap screws (K) and eight hex head cap screws (L) securing faceplate (23A, B, C) to

case (19A, B, C, D). Remove faceplate (23A, B, C).

12. Remove two dowel pins (J) from case.

13. Remove case gaskets (20).

14. On “BHB” and “GHBO” pumps, remove drive gear (34) and key (B) from drive shaft (32).

15. Remove idler gear (35) and key (B) from idler shaft (33). Remove idler shaft.

16. Remove two washer head cap screws (K) and eight hex head cap screws (L) securing backplate (6A, B) to case

(19A, B, C, D). Separate parts.

17. Remove case gaskets (20) from opposite side of case (19A, B, C, D).

18. Remove two dowel pins (J) from opposite side of case (19A, B, C, D).

19. Remove drive key (A) from drive shaft (32).

20. A.) For 3600/4600 “GHB” gear reduction unit, follow steps 21 – 32.

B.) For 3600/4600 “GHBO” and “BHB” pumps, follow steps 33 – 41.

C.) For 3700/4700 “GHB” gear reduction unit, follow steps 42 – 53.

7

D.) For 3700/4700 “GHBO” and “BHB” pumps, follow steps 54 – 61.

3600/4600 ‘GHB” Gear Reduction Unit (See Figures 7.1 and 7.2)

21. Drain oil from gear reduction unit.

22. Remove drive key (A). Remove four hex head cap screws (U) and slide seal retainer (37) assembled with lip

seal (39) off end of pinion shaft (42).

23. Remove seal retainer gasket (38) between seal retainer (37) and gear case (44).

24. Remove pinion shaft (42) assembly with ball bearing (41) and retaining ring (40).

25. Remove six hex head cap screws (W), twelve flat washers (X), and six lockwashers (Y).

26. Remove gear case (44). Remove gear case gasket (48).

27. Remove needle bearing (43). This bearing is installed with a press fit.

28. Remove retaining ring (45).

29. Remove drive gear (46). A gear puller may be necessary in removing gear, as a close fit is maintained between

gear and shaft.

30. Remove drive gear key (Z).

31. Remove four socket head cap screws (AD) securing cover (49) to backplate (6A, B). Remove cover gasket (50).

32. Remove spacer (47).

3600/4600 “GHBO” and “BHB” Pumps (See Figure 7.1)

33. Remove retaining ring (3) securing ball bearing (2) in place.

34. Remove two locknuts (F) from square head bolts (G) securing packing gland (14) in place. Remove packing gland

clip (13), packing gland (14), spring clip (15), and two square head bolts (G).

35. Remove packing rings (16) and packing washer (18). Remove lantern ring (17) if used. Packing hooks are

commercially available to assist in removal of packing.

36. Remove drive shaft (32) along with ball bearing (2) and retaining ring (4) from backplate (6A, B).

37. Remove ball bearing (2) from drive shaft (32).

38. Remove retaining ring (4) from drive shaft (32).

39. Remove lip seal (5) from backplate (6A, B) and discard. It will be damaged during disassembly.

40. Clean drive shaft and adjacent parts. Examine shaft. Replace drive shaft if excessively worn or scored.

41. Visually inspect all parts. Replace all worn or damaged parts before reassembling pump. It is recommended that

new gaskets (20, 22, 25, if applicable, 38, 48, 50) and new lip seals (5, 39) be installed each time the pump is

disassembled and reassembled.

3700/4700 “GHB” Gear Reduction Unit (See Figures 7.1 and 7.2)

42. Drain oil from gear reduction unit.

43. Remove drive key (A). Remove four hex head cap screws (U) and slide seal retainer (37) assembled with lip

seal (39) off end of pinion shaft (42).

44. Remove seal retainer gasket (38) between seal retainer (37) and gear case (44).

45. Remove pinion shaft (42) assembly with ball bearing (41) and retaining ring (40).

46. Remove six hex head cap screws (W), twelve flat washers (X), and six lockwashers (Y).

47. Remove gear case (44). Remove gear case gasket (48).

48. Remove needle bearing (43). This bearing is installed with a press fit.

49. Remove retaining ring (45).

8

50. Remove drive gear (46). A gear puller may be necessary in removing gear, as a close fit is maintained between

gear and shaft.

51. Remove drive gear key (Z).

52. Remove four socket head cap screws (AD) securing cover (49) to backplate (6A, B). Remove cover gasket (50).

53. Remove spacer (47).

3700/4700 “GHBO” and “BHB” Pumps (See Figure 7.1)

54. Remove retaining ring (3) securing ball bearing (2) in place.

55. Remove drive shaft (32) along with ball bearing (2) and retaining ring (4) from backplate (6A, B).

56. Remove ball bearing (2) from drive shaft (32).

57. Remove retaining ring (4) from drive shaft (32).

58. If lip seal (5) is damaged or worn, remove from backplate (6A, B) and discard.

59. Remove two locknuts (F) from square head bolts (G) securing seal retainer (9) to backplate (6A, B). Remove seal

retainer (9).

60. When removing following type of single seals (John Crane

Sealol

Type 43), clean and lubricate drive shaft (32) prior to removing mechanical seal making sure that drive

Type 21, Type 8-1, Type 9; Pac-Seal Type 21;

shaft is smooth and free from all burrs. Loosen setscrew (if present) on mechanical seal. Remove mechanical

seal (11). Inspect sealing surfaces of stationary seal face and inspect rotating element. Replace as required.

Remove retaining ring (12) from drive shaft (32), if applicable.

61. Visually inspect all parts. Replace all worn or damaged parts before reassembling pump. It is recommended that

new gaskets (20, 22, 25, if applicable) and new lip seals (5, 39) be installed each time pump is disassembled and

reassembled.

John Crane is a registered trademark of John Crane Inc.

Pac-Seal

Sealol

is a registered trademark of Pac-Seal Inc.

is a registered trademark of EG & G Sealol.

3. INSTRUCTIONS FOR PUMP ASSEMBLY

Refer to Section 7, PARTS LIST, (Figures 7.1 and 7.2).

Refer to Section titled “Check Ports Versus Rotation” (Figures A and B) to assure proper configuration for pump rotation,

port location, and relief valve position prior to assembling pump.

1. Visually inspect all parts during assembly. Replace all worn or damaged parts. Although they may appear

reusable, it is recommended that new gaskets (20, 22, 25, if applicable, 38, 48, 50) and lip seals (5, 39) be

installed when pump is being reassembled.

• WARNING! Only use genuine Roper gaskets. Gasket thickness determines proper clearances. Always check

quantity of gaskets removed and replace with exact quantity. Proper material must be used based on application.

2. When cleaning or lubricating, only use products that are compatible with product being pumped and elastomers

within pump. DO NOT use petroleum base products with seals with EPR elastomers. Clean and lubricate parts

with light oil unless EPR elastomers are used. Use a nonpetroleum base lubricant with EPR elastomers.

3. Mechanical seals are precision pieces of equipment. Use extreme care not to damage seal faces or elastomers

during assembly.

4. Install two hollow dowel pins (J) on each side of case (19A, B, C, D). Place appropriate number of case gaskets

(20) on faceplate side of case. Align faceplate (23A, B, C) on hollow dowel pins (J). Secure faceplate to case

using two washer head cap screws (K) and eight hex head cap screws (L).

5. Place idler gear (35) into case bore. Install key (B) in keyway on idler shaft (33). Slide idler shaft into I.D. of idler

gear.

9

Loading...

Loading...