Page 1

Advanced Calibration

The purpose of this document is to assist users of the Roland MDX-540

fine tune the accuracy of their machine when using the 4th-axis option

(ZCL-540) – The following steps will assist users who observe any shifts

or offsets when performing double sided milling. We will cover two

sections:

• Section 1 - Setting Origins

• Section 2 – Manual Adjustments

Page 2

Section 1

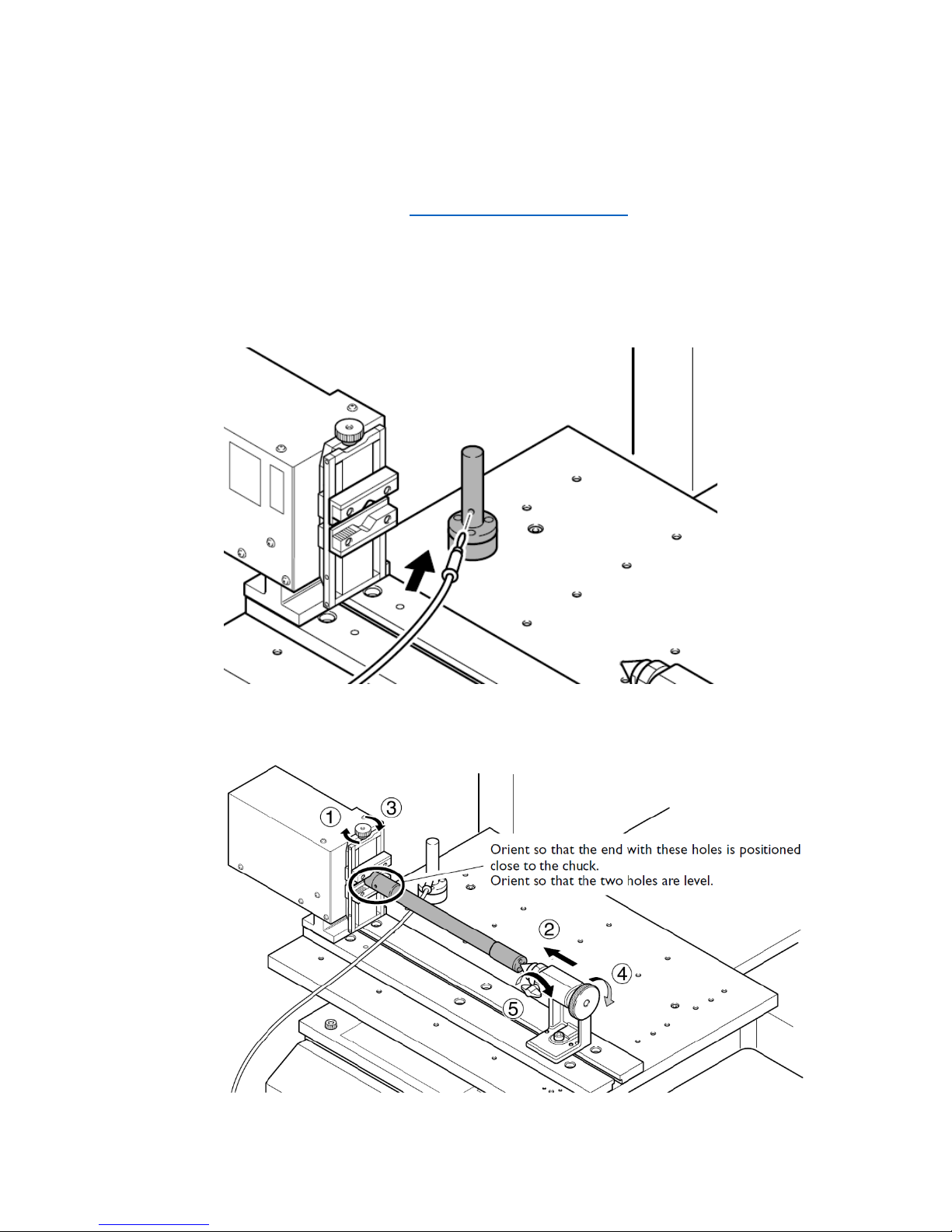

• Make sure to have your ZCL-540 user manual

• Begin the Y-origin sensor detection process. (pg 43-46)

o Connect the sensor cable to the Z-origin sensor. (p g 43 )

handy.

o Install Y-origin sensor bar. (pg 44)

Page 3

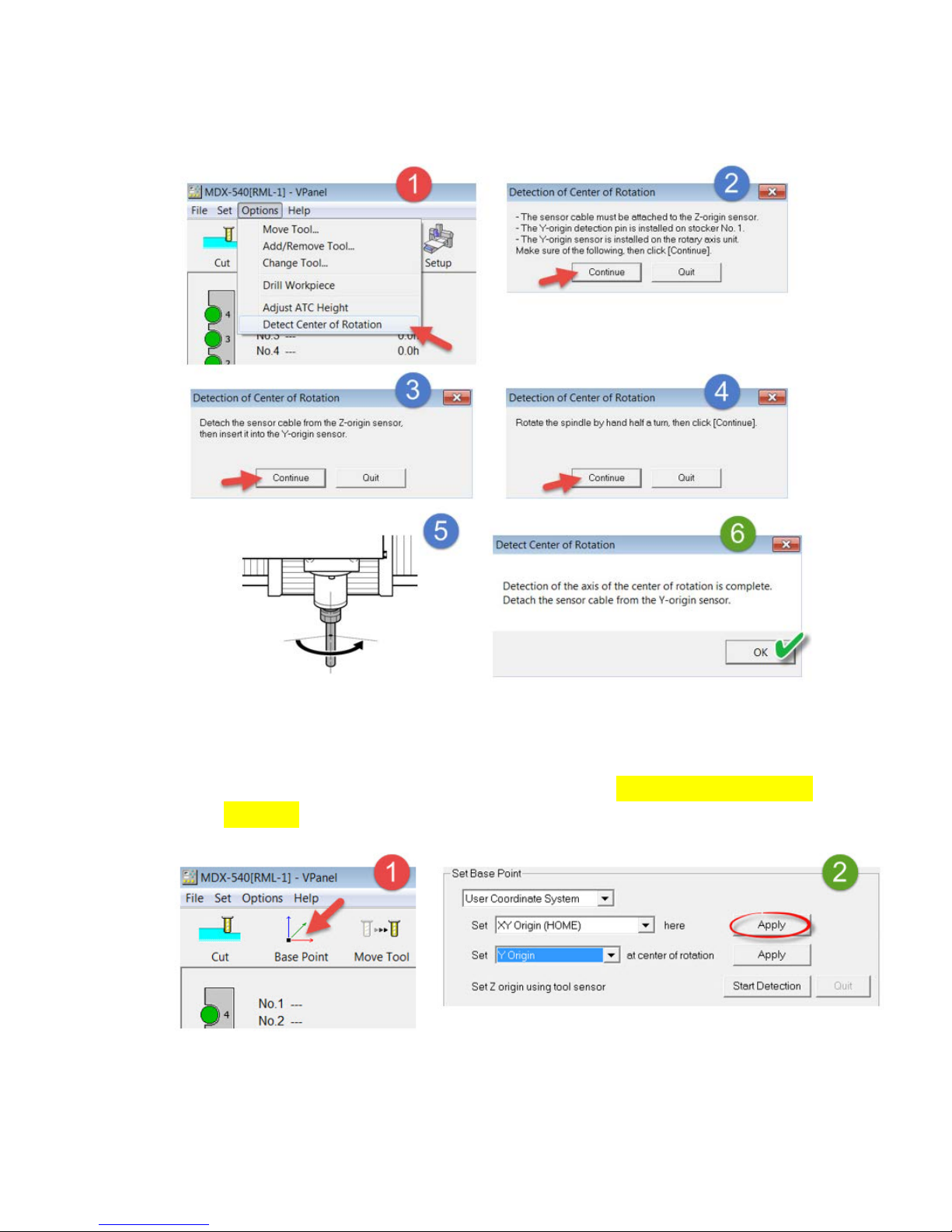

o Begin the “Detect Center of Rotation” process. (pg 45-46)

• Set your Y and Z origins at the center of the A axis. (pg 47-49)

o Open Base Point settings and use the “Set ___ at center of

rotation” drop down menu to set the Y-origin. (pg 47)

Page 4

o Connect the sensor cable to the Z-origin sensor an d inst all a

tool. (pg 48)

o Open Base Point settings and use the “Set ___ at center of

rotation” drop down menu to set the Z-origin. (pg 49)

Page 5

• Set your X and A axis origins. (pg 50- 51)

o Move your tool to the right of your work piece along the X-

axis and set your X-origin using the “Set ___ her e” d ro p do w n

menu. (pg 50)

o Move you’re Axis to a zero degree position and use the “Set

___ here” drop down menu to set the A-origin. (pg 51)

Page 6

Section 2

• Once you have milled out your part using double index milling,

check the “seam” of the part to find any adjustment values. (pg 53)

• Observe what direction this shift occurs to determine what type of

adjustment value you will use. For example, if the “top” of the part

looks like it shifted upwards the Y direction, then your adjustment

value will be negative. (pg 53)

Page 7

• Divide your adjustment value by two and use “Set Base Point” in

VPanel to correct your Y origin position. For example, if you had a

measured adjustment value of 2mm then you would change the

location of your Y origin by 1mm only. (pg 53)

• Check your part in the Z direction for any similar adjustment

values. (pg 53)

Page 8

• Divide your Z adjustment value by two and use “Set Base Point” in

VPanel to correct your Z origin position. Again, if you measure an

offset of 2mm, your adjustment will be 1mm. (pg 53)

• Re-cut your part under these new origin settings to double check

that your adjustments were correct. If you continue to have issues

return to Section 2 and repeat the calibration process. You can

also visit our product support page to do w nlo a d a 20mm cubic test

file (ZCL-540_Calibration_Cube) to help with this process.

Loading...

Loading...