Page 1

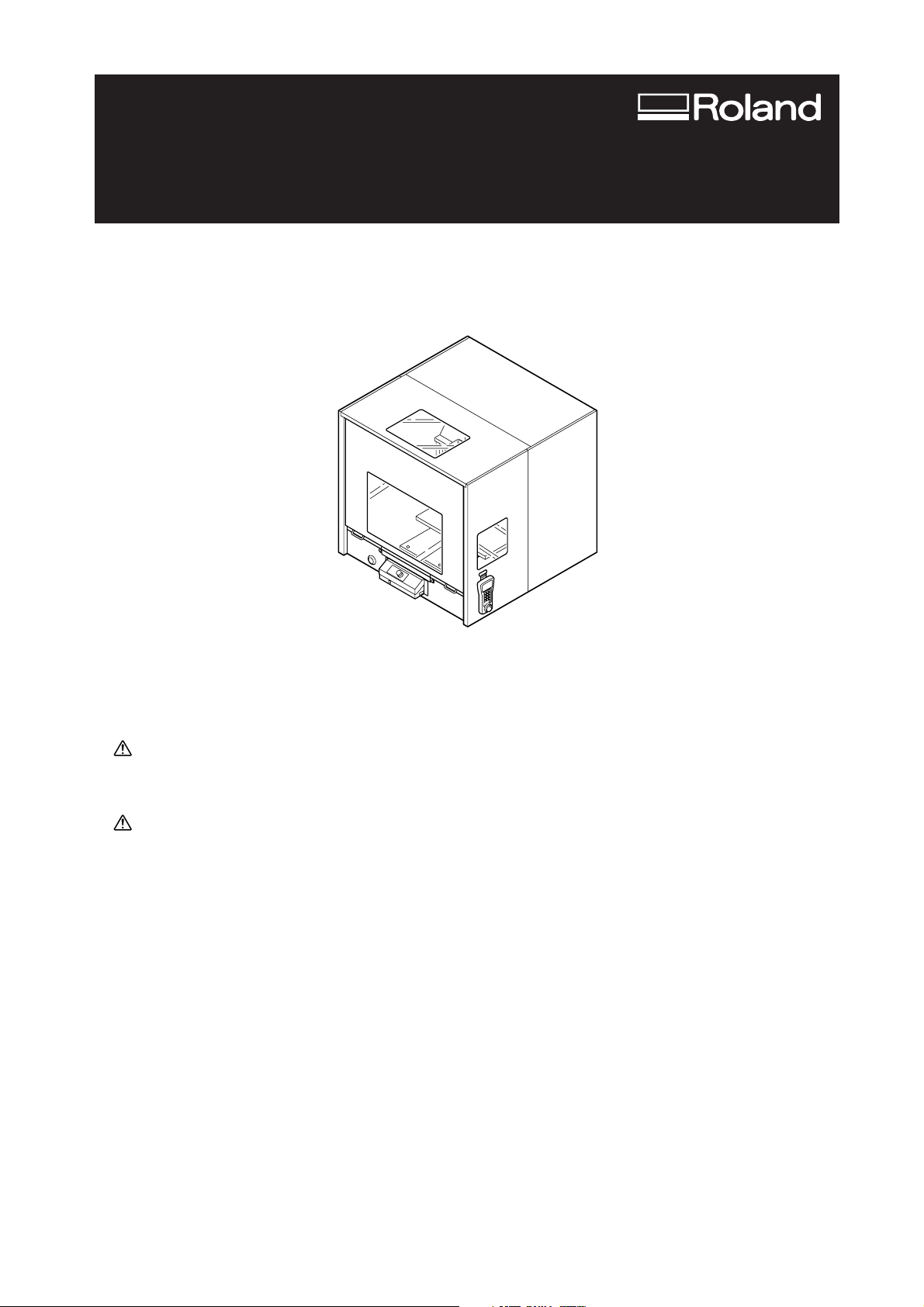

ZBX-540E Safety Cover

Assembly Instructions

This document provides instructions for service personnel. These procedures should not be

performed by the end user.

————————— Important Notes on Assembly Operations —————————

WARNING

WARNING

➢ Before attempting these operations, read through this manual and familiarize yourself with the installation loca-

tion and orientation of each part.

➢ Assembly operations are to be performed by two or more persons.

➢ To prevent injury, wear gloves when performing these operations.

➢ Be sure to use some means to secure the emplacement base and safety cover.

Supported model

MODELA Pro II MDX-540

External dimensions

W x D x H: 1,042 x 1,030 x 978 mm (41 x 40.6 x 38.5 in.)

Weight

68 kg (150 lb.)

Before attempting these operations, unplug the power cord for the modeling machine. Failure to do so may result in danger of electrical shock, electrocution, or entanglement.

After completing the operations, be sure to verify the operation of the interlock switch,

and never use the machine if the switch does not operate correctly.

1

Page 2

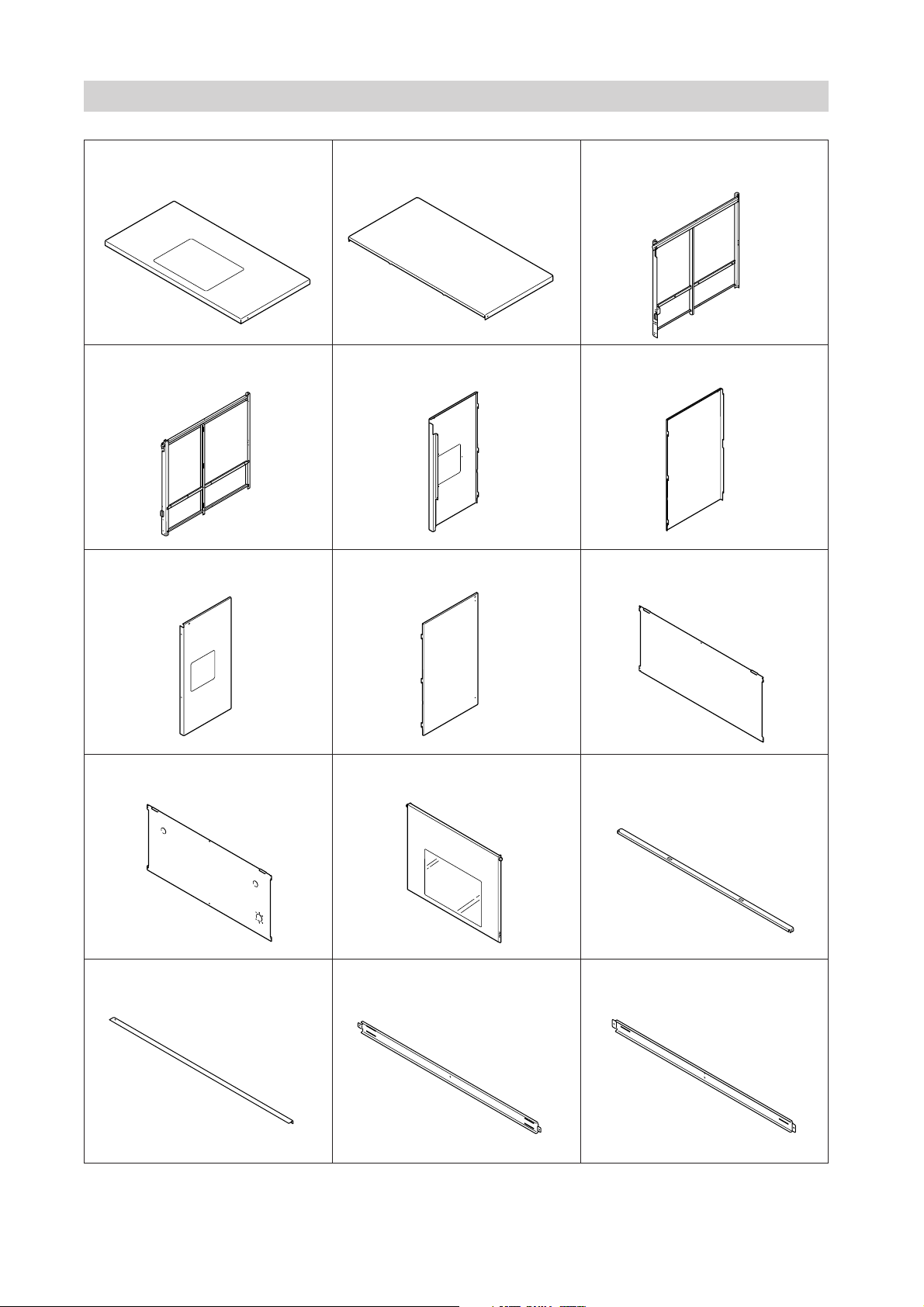

Part List

Top panel A x 1 Top panel B x 1 Left side frame x 1

Right side frame x 1 Left side panel A x 1 Left side panel B x 1

Right side panel A x 1 Back panel A x 1

Back panel B x 1 Hatch panel x 1 Top frame A x 1

Top frame B x 1 Back frame A x 1 Back frame B x 1

Right side panel B x 1

2

Page 3

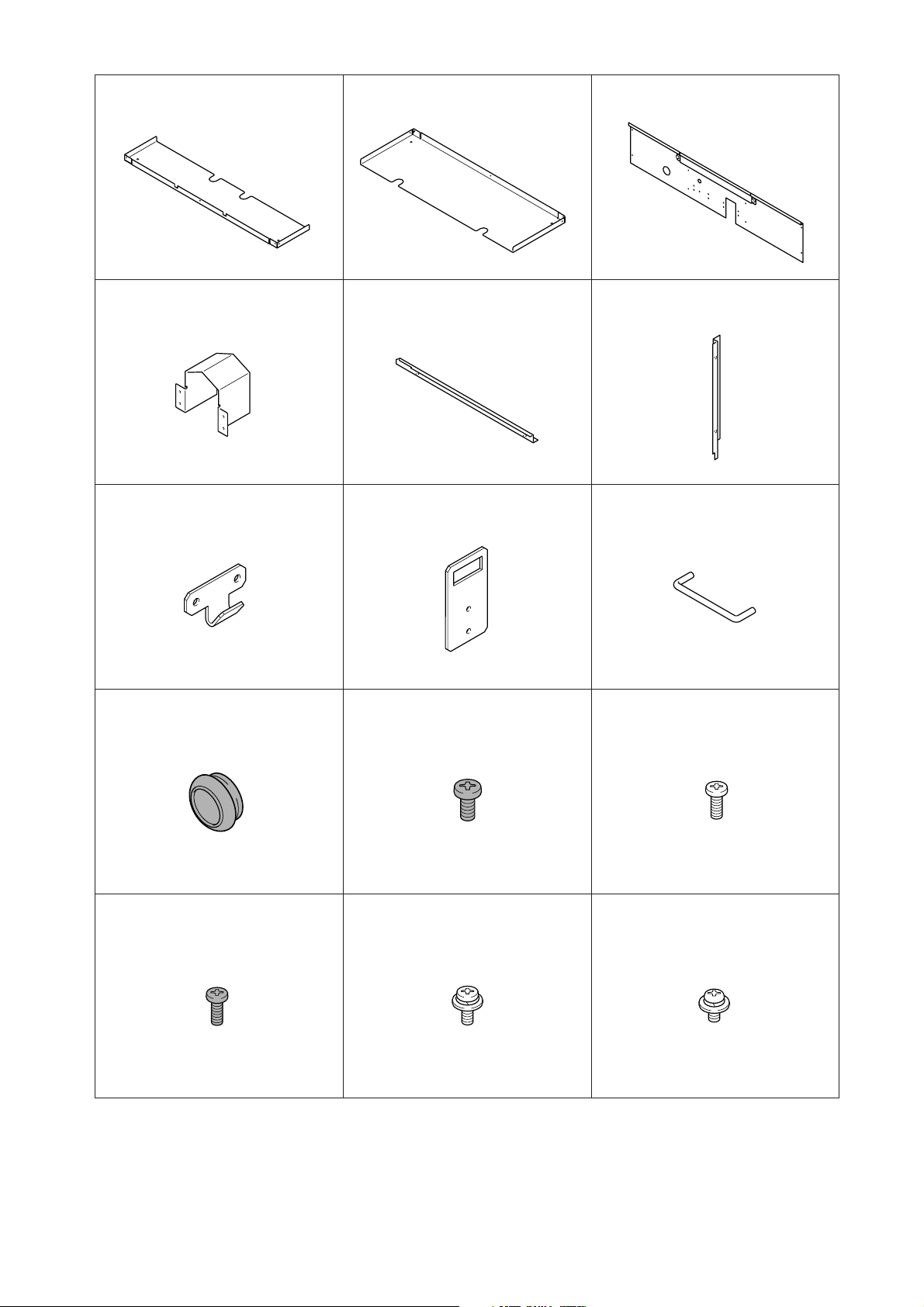

Bottom stay A x 1 Bottom stay B x 1 Front cover x 1

Wiring covers A x 2 Wiring cover B x 1 Wiring cover C x 1

Handy-panel bracket x 1 Handy-panel hanger x 1 Handles x 2

Rubber caps x 3 Screws (M5 x 8 mm) x 4 Screws (silver, M4 x 8 mm) x 52

Screws (black, M4 x 8 mm) x 4 Screws, with washer

(M4 x 8 mm) x 2

Screws, with washer

(M4 x 6 mm) x 2

3

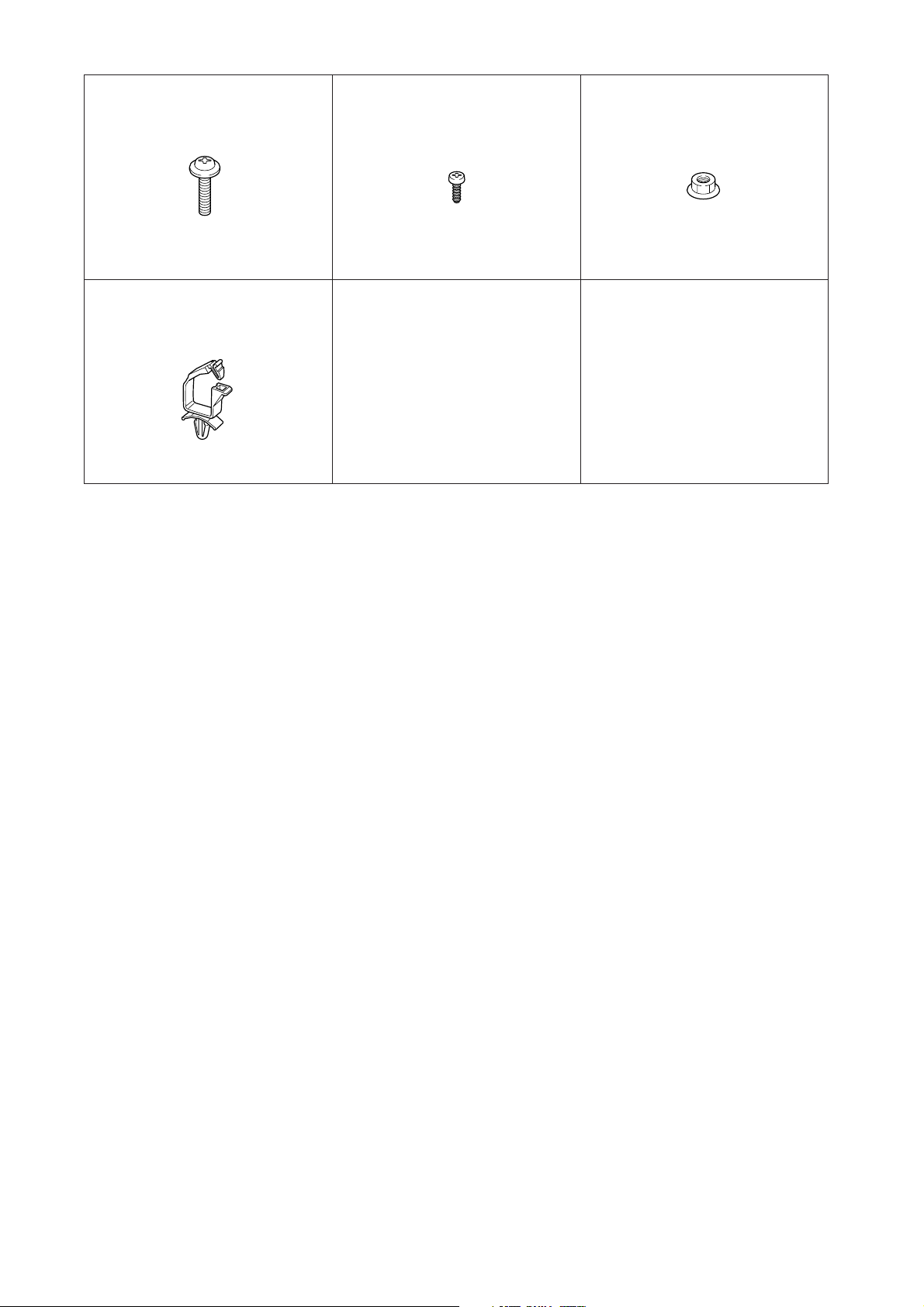

Page 4

Screws, with flange

(M4 x 14 mm) x 4

Cable retainer x 1

Tapping screws (M3 x 8 mm) x 2 Nuts, with flange (M4 mm) x 2

4

Page 5

Assembly

➊

Switch box

➀ Place the modeling machine at the installation loca-

tion.

➁ Remove the switch box from the modeling machine (4

screws). Pull out the wiring from the switch box.

Note: Place the removed switch box on the modeling

machine's table or base cover.

➋

Bottom stay A

➌

Left side frame

Top flame A

Bottom stay B

➀ Line up bottom stays A and B with the modeling

machine's rubber feet and perform positioning of the

safety cover.

Note: After the safety cover has been installed, the modeling machine cannot be relocated. Be sure to perform

emplacement of the modeling machine before attaching the safety cover.

Back flame A

Back flame B

Back flame

Right side frame

Screws: silver, M4 x 8 mm

➀ Attach the left side frame.

➁ Attach the right side frame.

➂ Attach the top frame A.

➃ Attach the back frames A and B.

Side frame

Top flame A

Side frame

5

Page 6

➍

Screws

M5 x 8 mm

Handle

Hatch panel

➀ Attach the handles to the hatch panel.

➎

Top flame B

Top panelA

Screws

M5 x 8 mm

Handle

Top panel B

Hatch panel

Screws:

➀ Attach the hatch panel. Spread the side frames open

➁ Attach the top frame B.

➂ Attach the top panels A and B.

silver, M4x8mm

slightly and fit the rollers onto the rails.

Roller

Rail

Top panel

Top flameA

6

Page 7

➏

Interlock switch

The interlock wiring is along

in the frame.

➀ Attach the wiring covers B and C.

Wiring cover C

Screws

silver, M4x8mm

Screws, with washer

M4x6mm

Wiring cover B

Note: When installing the wiring covers B and C and

the switch box, be especially careful to keep the interlock wiring from being pinched.

➐

Rubber cap

Screws

silver, M4x8mm

➀ Attach the wiring covers A to the front cover.

➁ Attach the cable retainer.

➂ Attach the rubber cap.

Cable retainer

Front cover

Note: Using a cutter, make a cross-shaped cut in the

center of the rubber cap for the front cover as required.

This cut is used when you want to pass the sensor cable

or the like through.

Wiring covers A

7

Page 8

➑

Cable retainer

Interlock wiring

Screws

black, M4x8mm

Screws

black, M4x8mm

➀ Pass the interlock wiring through the cable retainer and

the hole in the front cover.

➁ Attach the front cover.

➒

Front cover

Interlock wiring

Front cover

Switch box

Dummy connector

➀ Remove the dummy connector from the switch box.

➁ Connect the interlock wiring to the switch box and at-

tach the switch box to the front cover. When doing

this, press in any excess wiring into the switch box.

Press in any excess wiring

into the switch box.

8

Page 9

➓

Hatch panel

Front coverMagnet

Hole

Switch

Push plate

Screws

Hatch panel

Push plate

Adjusting the Interlock Switch

Make sure the push plate is positioned at the center of the

hole for the interlock switch when the hatch panel is

closed. If it is misaligned, then it must be adjusted by loosening the screws for the front cover and tilting the side

frames slightly to the left or right, with the hatch panel

kept closed.

Make sure the interlock switch is pressed down fully when

Left side panel B

Left side panel A

The screws are loosened.

the hatch panel is closed. If the switch is not pressed,

loosen the screws for the push plate and adjust the positioning.

How to Close the Hatch Panel

Lower the hatch panel, lift the handles slightly, and position so that the bottom edge of the hatch panel straddles

the protrusion at the top of the front panel.

Side panel

Side frame

Screws:

➀ Attach the left side panels A and B.

➁ Attach the right side panels A and B.

silver, M4x8mm

Right side panel B

Right side panel A

9

Page 10

Handy-panel bracket

Screws, with washer

M4x8mm

Nuts,

with flange

➀ Attach the handy-panel bracket.

➁ Mount the handy-panel hanger on the handy panel.

Handy-panel

hanger

Tapping screws

M3x8mm

Handy panel

➀ Remove the ventilation-duct filter.

Note: Perform attachment and detachment of the ventilation-duct filter while turning it clockwise. When doing this, grasp the hose at a location a short distance

away from its end.

Hose

Ventilation-duct filter

10

Page 11

➀ Attach the back panel B.

Back flame B

Back panel B

Back panel B

Screws

silver, M4x8mm

Screws, with flange

M4x14mm

Hose

➀ Connect the ventilation-duct filter to the hose and at-

tach it to the back panel B.

Back panel B

Ventilation-duct filter

Note: Perform attachment and detachment of the ventilation-duct filter while turning it clockwise. When doing this, grasp the hose at a location a short distance

away from its end.

Note: Insert the hose securely, as far as it will go. If it is

difficult to insert, apply a small amount of water or alcohol to the inside of the hose.

11

Page 12

Rubber cap

Rubber cap

➀ Attach the rubber caps.

➁ Pass the power cord and other necessary cables through

the rubber caps and connect them to the modeling

machine.

Note: Use a cutter to make a cross-shaped cut in the

centers of the rubber caps to match the thickness of

the cables.

Back flame A

Back panel A

Screws

silver, M4 x 8 mm

Back panel A

➀ Attach the back panel A.

➀ Make sure the hatch panel opens and closes

➁ Close the hatch panel and start the modeling

➂ Make sure that the interlock feature is actu-

12

smoothly.

machine. Make sure that cutting operation is

possible when the hatch panel is closed.

ated and cutting operation is restricted when

the hatch panel is opened.

Note: If the interlock feature is not actuated correctly,

repeat the adjustment in step 10.

DOC-0596 R1-060621

Loading...

Loading...