Page 1

USER'S MANUAL

Thank you very much for purchasing this product.

➢ To ensure correct and safe usage with a full understanding of this product's performance, please be

sure to read through this manual completely and store it in a safe location.

➢ Unauthorized copying or transferral, in whole or in part, of this manual is prohibited.

➢ The contents of this operation manual and the specifications of this product are subject to change

without notice.

➢ The operation manual and the product have been prepared and tested as much as possible. If you

find any misprint or error, please inform us.

➢ Roland DG Corp. assumes no responsibility for any direct or indirect loss or damage which may

occur through use of this product, regardless of any failure to perform on the part of this product.

➢ Roland DG Corp. assumes no responsibility for any direct or indirect loss or damage which may

occur with respect to any article made using this product.

Page 2

For the USA

FEDERAL COMMUNICATIONS COMMISSION

RADIO FREQUENCY INTERFERENCE

STATEMENT

This equipment has been tested and found to comply with the

limits for a Class A digital device, pursuant to Part 15 of the

FCC Rules.

These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated

in a commercial environment.

This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance

with the instruction manual, may cause harmful interference

to radio communications.

Operation of this equipment in a residential area is likely to

cause harmful interference in which case the user will be

required to correct the interference at his own expense.

Unauthorized changes or modification to this system can void

the users authority to operate this equipment.

NOTICE

Grounding Instructions

Do not modify the plug provided - if it will not fit the outlet,

have the proper outlet installed by a qualified electrician.

Check with qualified electrician or service personnel if the

grounding instructions are not completely understood, or if in

doubt as to whether the tool is properly grounded.

Use only 3-wire extension cords that have 3-prong

grounding plugs and 3-pole receptacles that accept the tool’s

plug.

Repair or replace damaged or worn out cord immediately.

For Canada

CLASS A NOTICE

This Class A digital apparatus meets all requirements of the

Canadian Interference-Causing Equipment Regulations.

CLASSE A AVIS

Cet appareil numérique de la classe A respecte toutes les

exigences du Règlement sur le matériel brouilleur du

Canada.

ROLAND DG CORPORATION

1-6-4 Shinmiyakoda, Hamamatsu-shi, Shizuoka-ken, JAPAN 431-2103

MODEL NAME : See the MODEL given on the rating plate.

RELEVANT DIRECTIVE : EC LOW VOLTAGE DIRECTIVE (73/23/EEC)

EC ELECTROMAGNETIC COMPATIBILITY DIRECTIVE (89/336/EEC)

WARNING

This is a Class A product. In a domestic environment this product may cause radio interference in which

case the user may be required to take adequate measures.

As an ENERGY STAR® Partner, Roland DG Corp. has determined that this product meets the ENERGY

STAR® guidelines for energy efficiency.

The International ENERGY STAR® Office Equipment Program is an international program that

promotes energy saving through the penetration of energy efficient computers and other office

equipment. The program backs the development and dissemination of products with functions that

participate voluntarily. The targeted products are office equipment such as computers, monitors, printers, facsimiles,

copiers, scanners, and multifunction devices. Their standards and logos are uniform among participating nations.

effectively reduce energy consumption. It is an open system in which business proprietors can

Page 3

Contents

To Ensure Safe Use ........................................................................................................................ 4

Pour utiliser en toute sécurité.................................................................................................. 10

Important Notes on Handling and Use ........................................................................................... 16

Printer unit .................................................................................................................................................................... 16

Ink cartridges................................................................................................................................................................ 16

Chapter 1 Introduction ..................................................................................................................... 17

1-1 Machine Features ................................................................................................................................................. 18

1-2 Part Names and Functions ................................................................................................................................ 19

Printer Unit and Dryer........................................................................................................... 19

Printer Control Panel ............................................................................................................. 21

Media Take-up and Feed Systems .......................................................................................... 22

Chapter 2 Operation ......................................................................................................................... 23

2-1 Switching the Power On and Off.................................................................................................................... 24

Switching the Power On and Off........................................................................................... 24

The Power-saving Feature ...................................................................................................... 25

2-2 Loading and Cutting Off Media ........................................................................................................................ 26

How to Load Media .............................................................................................................. 26

How to Cut Off Media .......................................................................................................... 39

2-3 Settings of Preheater, Print Heater and Dryer ............................................................................................. 40

What Are the Preheater, Print Heater and Dryer? .................................................................. 40

Temperature Settings for the Preheater and Print Heater ....................................................... 41

Temperature Setting for the Dryer.......................................................................................... 41

General Guide for the Preset Temperatures ........................................................................... 42

2-4 Starting Printing.................................................................................................................................................... 43

Getting Ready to Receive Data from a Computer .................................................................. 43

Printing Tests and Cleaning ................................................................................................... 44

2-5 If Ink Runs Out ..................................................................................................................................................... 45

Checking for Remaining Ink .................................................................................................. 45

If Ink Runs Out ...................................................................................................................... 46

Chapter 3 Maintenance and Adjustment ........................................................................................49

3-1 Daily Care and Maintenance ............................................................................................................................. 50

Disposing of Discharged Ink ................................................................................................. 50

Cleaning ................................................................................................................................ 51

Care and Maintenance of the Print Heads ............................................................................. 52

3-2 When Head Cleaning Is Not Effective ............................................................................................................ 53

Performing More Powerful Cleaning ..................................................................................... 53

When Powerful Cleaning Is Not Effective .............................................................................. 54

3-3 Cleaning the Heads Using the Cleaning Kit .................................................................................................. 55

When the Cleaning Kit Becomes Necessary .......................................................................... 55

How to Perform Cleaning...................................................................................................... 55

3-4 Replacing Consumable Parts ............................................................................................................................. 59

Replacing the Wipers ............................................................................................................59

3-5 When Not in Use for a Prolonged Period ..................................................................................................... 61

Keep Performing Maintenance .............................................................................................. 61

Alarm Feature........................................................................................................................ 61

Chapter 4 Feature Reference........................................................................................................... 63

4-1 Pausing or Canceling Printing ........................................................................................................................... 64

Canceling Printing Before It Finishes ..................................................................................... 64

1

Page 4

Contents

4-2 Setting the Printing Position and Margins ...................................................................................................... 65

Shifting the Print-start Position to the Rear ............................................................................ 65

Shifting the Printing Position to the Left................................................................................. 65

Changing the Left and Right Margins .................................................................................... 66

4-3 Optimizing Printing to Match Media Thickness ............................................................................................ 68

Adjusting Head Height to Match Media Thickness ................................................................ 68

Correcting for Misalignment in Bidirectional Printing ........................................................... 69

Saving Bidirectional Correction Values .................................................................................. 72

Loading Bidirectional Correction Values ............................................................................... 72

Performing Feed Correction to Alleviate Horizontal Bands and the Like ............................... 73

4-4 Accommodating Various Kinds of Media ........................................................................................................ 75

Using Transparent Media....................................................................................................... 75

Printing Hard-to-dry Media ................................................................................................... 75

Speeding Up Printing for Narrow Media ............................................................................... 76

Preventing Media from Coming Loose .................................................................................. 77

Keeping Media from Being Soiled by Ink Drips ..................................................................... 77

4-5 Changing How the Printer Operates.............................................................................................................. 79

Determining What Happens When Ink Runs Out.................................................................. 79

Setting the Interval until Activation of the Sleep Mode .......................................................... 79

Deactivating the Sleep Mode ................................................................................................ 80

Changing the Menu Language and the Units of Measurement .............................................. 80

Returning All Settings to Their Initial Values .......................................................................... 81

Printing a System Report ....................................................................................................... 81

4-6 Changing How the Preheater, Print Heater and Dryer Operate............................................................. 82

Switching the Dryer On and Off ........................................................................................... 82

Switching Off the Preheater and Print Heater ........................................................................ 82

Determining How the Preheater, Print Heater, and Dryer Operate ........................................ 83

4-7 Menu List ............................................................................................................................................................... 84

Main menu............................................................................................................................ 84

Language and Unit Menu ...................................................................................................... 88

Cleaning and Maintenance Menu ......................................................................................... 88

Heater Configuration Menu .................................................................................................. 88

Chapter 5 What to Do If ................................................................................................................... 89

5-1 The Machine Doesn't Run .................................................................................................................................. 90

The Printer Unit Doesn't Run ................................................................................................ 90

The Media Take-up or Feed System Doesn't Run ................................................................... 90

The Dryer Doesn't Warm Up................................................................................................. 90

The Preheater and Print Heater Don't Warm Up ................................................................... 90

5-2 Attractive Printing Is Impossible ....................................................................................................................... 91

Printed Results Are Coarse or Contain Horizontal Stripes...................................................... 91

Colors Are Unstable or Uneven............................................................................................. 91

The Media Becomes Soiled When Printed ............................................................................ 92

5-3 The Media Jams ..................................................................................................................................................... 93

The Media Jams..................................................................................................................... 93

5-4 The Media Cannot Be Taken Up Smoothly .................................................................................................... 94

The Media Cannot Be Taken Up Smoothly ............................................................................ 94

5-5 Media Wrinkles or Shrinks, or Feed Is Unstable.......................................................................................... 95

Media Wrinkles or Shrinks .................................................................................................... 95

The Media Is Not Straight ...................................................................................................... 95

Media Feed Is Not Smooth .................................................................................................... 95

5-6 The Print Heads Stopped Moving .................................................................................................................... 96

What to Do First .................................................................................................................... 96

If the Heads Still Do Not Move ............................................................................................. 96

5-7 If a Message Appears ........................................................................................................................................... 97

5-8 If an Error Message Appears ............................................................................................................................. 98

2

Page 5

Contents

Chapter 6 Specifications ................................................................................................................. 101

6-1 Usable Media ....................................................................................................................................................... 102

Conditions for Usable Media .............................................................................................. 102

6-2 Printing Area........................................................................................................................................................ 103

Printing Area and Margins ................................................................................................... 103

6-3 Locations of the Power Rating and Serial Number Labels.....................................................................104

6-4 Specifications ....................................................................................................................................................... 105

Company names and product names are trademarks or registered trademarks of their respective holders.

Copyright © 2004 Roland DG Corporation http://www.rolanddg.com/

3

Page 6

To Ensure Safe Use

Incorrect operation may cause injury

Improper handling or operation of this machine may result in injury or damage to property. Points which

must be observed to prevent such injury or damage are described as follows.

About WARNING and CAUTION Notices

Used for instructions intended to alert the user to the risk of death or se-

WARNING

CAUTION

About the Symbols

vere injury should the unit be used improperly.

Used for instructions intended to alert the user to the risk of injury or material damage should the unit be used improperly.

* Material damage refers to damage or other adverse effects caused with

respect to the home and all its furnishings, as well to domestic animals

or pets.

The symbol alerts the user to important instructions or warnings. The specific meaning of the symbol is determined by the design contained within the triangle. The symbol

at left means "danger of electrocution."

The symbol alerts the user to items that must never be carried out (are forbidden).

The specific thing that must not be done is indicated by the design contained within the

circle. The symbol at left means the unit must never be disassembled.

The symbol alerts the user to things that must be carried out. The specific thing that

must be done is indicated by the design contained within the circle. The symbol at left

means the power-cord plug must be unplugged from the outlet.

WARNING

Be sure to follow the operation procedures described in this manual.

Failure to follow the procedures may cause

sudden operation or the like of the machine,

which may result in unexpected injury.

Never allow anyone unfamiliar with

the usage or handling of the machine

to touch the machine.

Touching a dangerous location may cause sudden operation or the like of the machine, which

may lead to an unexpected accident.

Never allow children near the machine.

The machine includes locations and components that pose a danger to children, and major accident, including injury, blindness, or

choking, may occur.

Do not disassemble, repair, or modify.

Doing so may lead to fire or abnormal operation resulting in injury.

4

Page 7

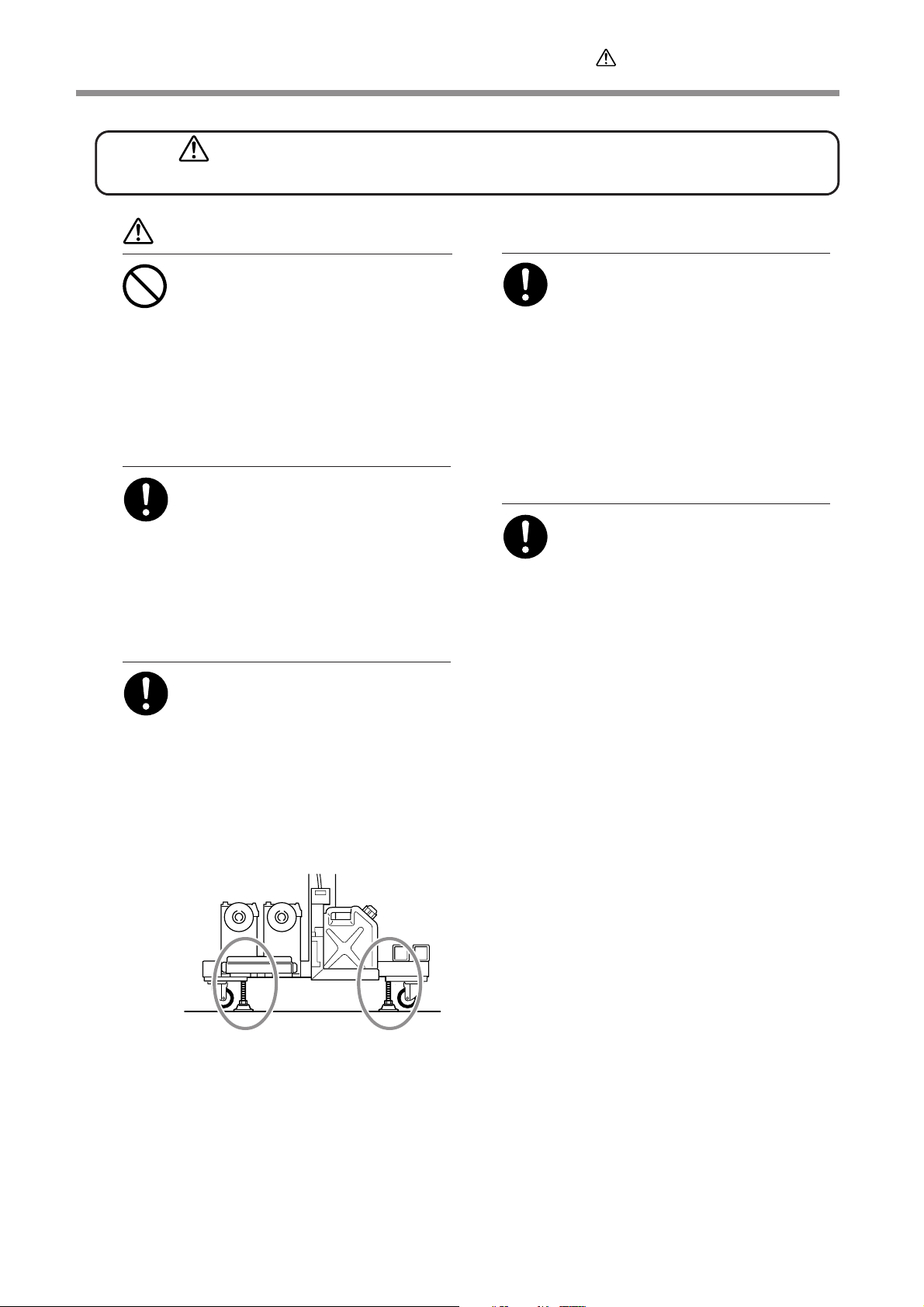

This machine weighs 600 kg (1350 lb.). Media weighs 100 kg (220 lb.)

WARNING

To Ensure Safe Use

Never attempt to perform operations

such as installation or relocation yourself.

This machine weighs approx. 455 kg (up to

approx. 600 kg (1350 lb.), including media and

the like), and moving it requires special equipment and training. Performing operations in

an unreasonable manner may result in a major

accident.

Install the machine in a location that

is level, stable, and able to bear the

weight of the machine.

This machine weighs approx. 455 kg (up to

approx. 600 kg (1350 lb.), including media and

the like). Installation in an unsuitable location

may cause a major accident, including tipover,

fall, or collapse.

After installation, keep the stand secured in place using the adjusters.

This machine weighs approximately 455 kg (up

to approx. 600 kg (1350 lb.), including media

and the like). If the machine should begin to

topple, the tipover cannot be stopped with

human strength, and a major accident may result, including crushing of the appendages or

the body.

When loading or moving roll media,

be sure to use load-handling equipment such as a lifter and carry out

operations with care to prevent falls

or other accidents.

Some roll media may weigh about 100 kg (220

lb.). Attempting manual lifting operations that

tax your strength may cause physical injury.

Also, if dropped, such items may cause unexpected injury, such as crushing of the feet.

When storing roll media, implement

adequate safety measures to ensure

that the stored media will not roll, fall,

or topple over.

Some roll media may weigh about 100 kg (220

lb.), and becoming pinned under such media

may cause major injury.

5

Page 8

To Ensure Safe Use

Danger of electrical short, shock, electrocution, or fire

This machine carries a high current of a maximum of approximately 10 amperes. This can cause situations

that could not occur with low-power equipment; use caution.

WARNING

Do not use with any electrical power

supply that does not meet the ratings

displayed on the unit.

Use with any other power supply may lead to

fire or electrocution.

Never operate the machine or insert

or remove its power plug with wet

hands.

Doing so may result in electrical shock or electrocution.

Never allow the machine to get wet,

or apply gasoline, thinner, or any other

flammable material to it.

Current leakage may cause electrical shock,

electrocution, or combustion and fire.

Never allow hairpins, coins, matches,

or any other object to get inside the

machine through the ventilation ports.

Doing so may cause and electrical short, resulting in shock or electrocution, or the inserted object may catch fire.

Never place gasoline, alcohol, thinner,

or any other flammable material near

the machine, or use an aerosol spray

close to the machine.

Doing so may cause fire.

Never use the machine with the power

cord bound into a bundle or roll.

The cord carries a high current of approximately 10 amperes. If the cord is in a bundle

or roll, it may grow hot and cause fire.

Never use any power cord other than

the power cord included with the machine. Also, never use a power strip or

extension cord.

The cord carries a high current of approximately 10 amperes. The power strip or extension cord may grow hot and cause fire.

Do not use with a damaged power cord

or plug, or with a loose electrical outlet.

Doing so may lead to fire, electrical shock, or

electrocution.

When unplugging the electrical power

cord from the power outlet, grasp the

plug, not the cord.

Unplugging by pulling the cord may damage it,

leading to fire, electrical shock, or electrocution.

Ground the unit with the ground wire.

Failure to do so may result in risk of electrocution in the event of a mechanical problem.

Never damage the power cord or pull

it with force.

Doing so may tear the cord's insulation, causing an electrical short and resulting in electrical shock, electrocution, or fire.

Never place any object on the power

cord, bend the power cord using ex-

In the event of an abnormal state (such

as smoke or sparks, odor or burning

or unusual noise), immediately unplug

the power cord.

Failure to do so may result in fire, electrical

shock, or electrocution. Immediately disconnect the power cord and contact your Roland DG Corp. service center.

cessive force, or allow the power cord

to become deformed.

The cord carries a high current of approximately 10 amperes. If it becomes deformed, the

deformed location may grow hot and cause fire.

6

Page 9

To Ensure Safe Use

Ink, cleaning liquid, and discharged fluid are flammable and toxic

WARNING

Never operate in locations such as

those near an open flame or heater, or

where sparking or static electricity

may occur.

Ink or the like may ignite and cause fire.

Never place ink, cleaning liquid, or discharged fluid in any of the following

locations.

➢ Near open flame

➢ In a hot location, such as near a

heater or on the machine's platen

or dryer

➢ Near bleach, chemicals, explosives,

or the like

Doing so may cause fire.

CAUTION

Ensure adequate ventilation for the

work area.

Odor from ink and the like may cause physical

distress, or may cause to fire.

Never drink or sniff ink, cleaning liquid, or discharged fluid, or allow them

to come in contact with the eyes or

skin.

Doing so may be hazardous to your health.

Store ink cartridges in a location out

of the reach of children.

In the Event of Ingestion or Physical Distress

➢ In the event of contact with the eyes, immediately flush with running water for at least 15 minutes. If eye irritation

continues, seek treatment by a physician.

➢ In the event of contact with skin, immediately wash with soap. If irritation or inflammation occur, seek treatment

by a physician.

➢ In the event of ingestion, do not induce vomiting, and immediately seek treatment by a physician. Forcibly inducing

vomiting may lead to danger of choking.

➢ If odor leads to physical distress, move to a well-ventilated location and rest quietly. If dizziness or nausea persists,

seek treatment by a physician.

7

Page 10

To Ensure Safe Use

Danger of fire, burns, or toxic gas emissions

Important Notes Regarding Operators and the Work Area

WARNING

This machine has high-temperature

areas (platen and dryer). Exercise caution to avoid fire or burns.

Never leave media loaded in the machine when printing is not being performed.

The continued application of heat at a single

location may cause fire or produce toxic gases.

When printing is not being performed, switch

off the power or remove any loaded media.

Never use media that cannot withstand the heat.

Doing so may result in fire or the release of

toxic gases, or may degrade the media.

Never use the platen or dryer for any

purpose for which they are not intended, such as to dry clothing.

Doing so may cause overheating, resulting in

fire or accident.

WARNING CAUTION

Never operate the machine when tired

or after ingesting alcohol or medications.

Operation requires lifting heavy objects and

unimpaired judgment, and unexpected injury

may result.

Never attempt operation while wearing a necktie, necklace, loose clothing,

or the like. Bind long hair securely.

Such items may become caught in the media

take-up system or other areas, resulting in injury.

Conduct operations in a clean, brightly

lit location.

Working in a location that is dark or cluttered

can be hazardous. Operations in such locations may cause an accident, such as tripping

and becoming pinned under the roll media.

Never climb or lean on the machine.

The machine is not made to support a person.

Climbing or leaning on the machine may move

away components and cause in a slip or fall,

resulting in injury.

8

Page 11

To Ensure Safe Use

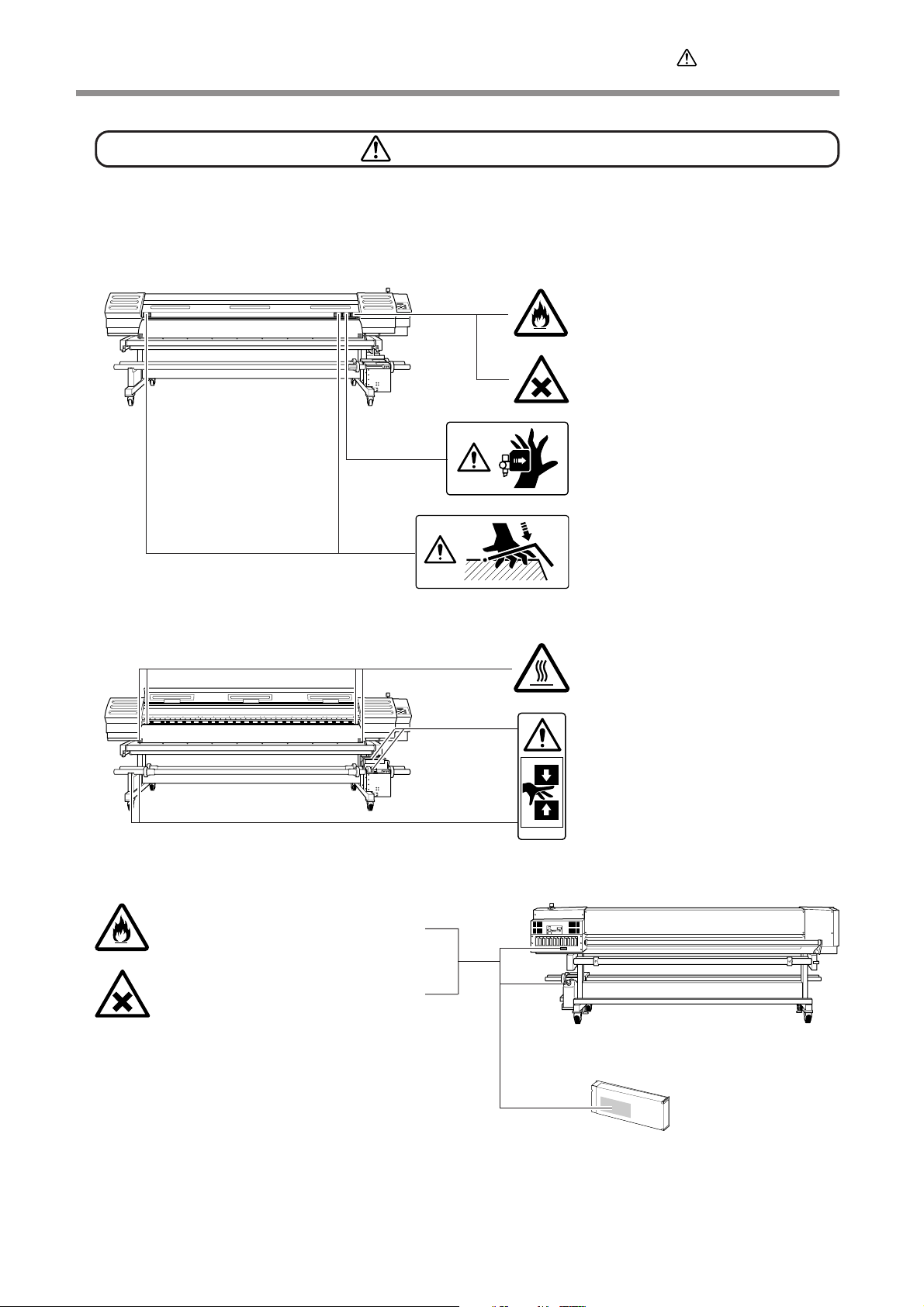

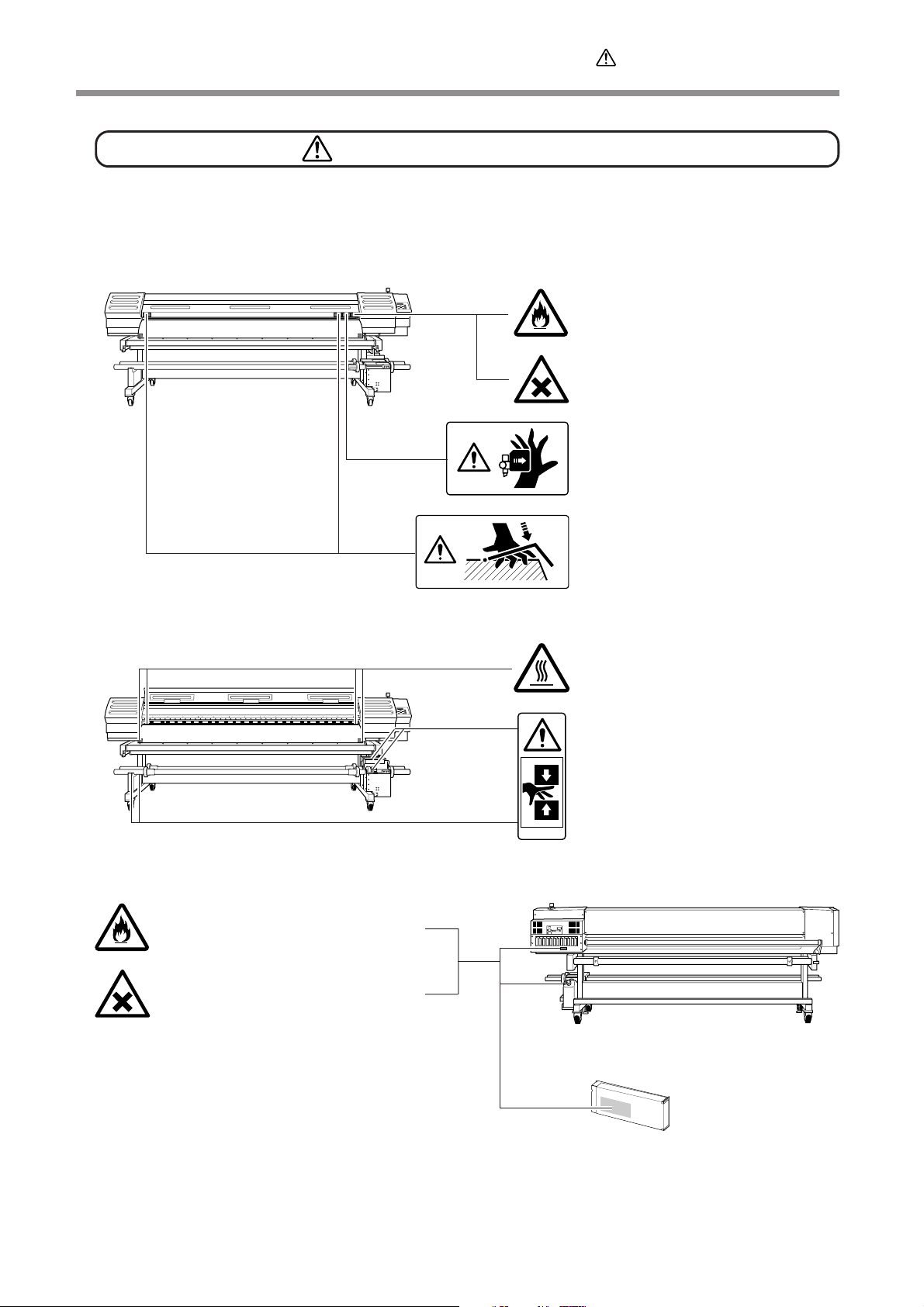

Warning Labels

Warning labels are affixed to make areas of danger immediately clear. The meanings of these labels are as

follows. Be sure to heed their warnings.

Also, never remove the labels or allow them to become obscured.

Flammable

Ink and discharged fluid are flammable.

Keep away from open flame.

Ink Is Toxic

Ink and discharged fluid are toxic. Avoid

contact with the body. Use only in a wellventilated area.

Caution: Moving Print Heads

The print heads inside the cover move at

high speed and pose a hazard. Never

insert the hand or fingers into the gap.

Flammable

Ink and discharged fluid are flammable.

Keep away from open flame.

Caution: Pinching Hazard

Be careful not to allow the fingers to

become pinched when closing the cover.

Caution: High Temperature

The platen and dryer become hot.

Exercise caution to avoid fire or burns.

Caution: Pinching Hazard

Be careful not to allow the fingers to

become pinched when loading media or

closing covers.

Ink Is Toxic

Ink and discharged fluid are toxic. Avoid

contact with the body. Use only in a wellventilated area.

Ink cartridge

9

Page 12

Pour utiliser en toute sécurité

L'utilisation incorrecte peut causer des blessures

La manipulation ou l'utilisation inadéquates de cet appareil peuvent causer des blessures ou des dommages

matériels. Les précautions à prendre pour prévenir les blessures ou les dommages sont décrites ci-dessous.

Avis sur les avertissements

ATTENTION

PRUDENCE

Utilisé pour avertir l'utilisateur d'un risque de décès ou de blessure grave

en cas de mauvaise utilisation de l'appareil.

Utilisé pour avertir l'utilisateur d'un risque de blessure ou de dommage

matériel en cas de mauvaise utilisation de l'appareil.

* Par dommage matériel, il est entendu dommage ou tout autre effet

indésirable sur la maison, tous les meubles et même les animaux

domestiques.

À propos des symboles

Le symbole attire l'attention de l'utilisateur sur les instructions importantes ou les

avertissements. Le sens précis du symbole est déterminé par le dessin à l'intérieur du

triangle. Le symbole à gauche signifie "danger d'électrocution".

Le symbole avertit l'utilisateur de ce qu'il ne doit pas faire, ce qui est interdit. La

chose spécifique à ne pas faire est indiquée par le dessin à l'intérieur du cercle. Le

symbole à gauche signifie que l'appareil ne doit jamais être démonté.

Le symbole prévient l'utilisateur sur ce qu'il doit faire. La chose spécifique à faire est

indiquée par le dessin à l'intérieur du cercle. Le symbole à gauche signifie que le fil

électrique doit être débranché de la prise.

10

ATTENTION

S'assurer de suivre les procédures

d'utilisation décrites dans ce manuel.

Si les procédures indiquées ne sont pas suivies,

le fonctionnement de l'appareil peut être

déclenché soudainement, ce qui risque de

causer des blessures.

Ne jamais permettre à quiconque de

toucher l'appareil s'il ou si elle n'en

connaçò pas le fonctionnement ou la

manutention.

Toucher l'appareil à certains points dangereux

peut en déclencher le fonctionnement, ce qui

risque de causer un accident imprévu.

Ne jamais laisser d'enfants s'approcher

de l'appareil.

Des éléments et des surfaces de l'appareil

présentent des risques pour les enfants. Il

pourrait se produire un accident grave qui

causerait des blessures, ou créerait un risque

de cécité ou de suffocation.

Ne pas démonter, réparer ni modifier.

Démonter, réparer ou modifier l'appareil risque de provoquer un incendie ou de causer

un fonctionnement anormal entraînant des

blessures.

Page 13

Le poids de cet appareil est de 600 kg (1350 lb.)

Le poids du support est de 100 kg (220 lb.)

ATTENTION

Pour utiliser en toute sécurité

Ne jamais tenter de procéder seul à

des opérations comme l'installation ou

le déplacement de l'appareil.

Le poids de cet appareil est d'environ 455 kg

(jusqu'à environ 600 kg (1350 lb.), y compris

le support et d'autres éléments); il faut une

formation et de l'équipement spéciaux pour

déplacer l'appareil. Tenter de procéder à ces

opérations de manière intempestive peut

provoquer un accident grave.

Installer l'appareil à un endroit stable

et plat et capable de supporter son

poids.

Le poids de cet appareil est d'environ 455 kg

(jusqu'à environ 600 kg (1350 lb.), y compris

le support et d'autres éléments). Installer

l'appareil à un endroit inapproprié peut

provoquer un accident grave comme le

renversement, la chute ou l'écrasement.

Une fois l'appareil installé, solidifier la

base à l'aide des éléments de réglage

ajustables.

Le poids de cet appareil est d'environ 455 kg

(jusqu'à environ 600 kg (1350 lb.), y compris

le support et d'autres éléments). Si l'appareil

commence à basculer, aucune force humaine

ne peut l'empêcher de se renverser; il

s'ensuivrait un accident grave, par exemple

l'écrasement d'un membre ou du corps.

Lors du chargement ou du

déplacement du support en rouleau,

utiliser de l'équipement de levage

comme et prendre des précautions

pour éviter les chutes et autres accidents.

Le poids de certains supports en rouleaux peut

être de quelque 100 kg (220 lb.). Tenter de

soulever manuellement des objets trop lourds

peut causer des blessures. En outre, si ces

objets sont échappés, ils peuvent causer des

blessures, par exemple écraser les pieds.

Il faut prendre les mesures de sécurité

adéquates pour l'entreposage des rouleaux de support pour s'assurer qu'ils

ne rouleront pas, ne tomberont pas et

ne se renverseront pas.

Certains rouleaux de support pèsent quelque

100 kg (220 lb.), et rester coincé sous un rouleau peut causer des blessures graves.

11

Page 14

Pour utiliser en toute sécurité

Risque de décharge ou de choc électrique,

d'électrocution ou d'incendie

Cet appareil transmet une tension élevée (maximum d'environ 10 ampères). Cela peut créer des situations qui ne se produisent pas avec de l'équipement à basse tension. La prudence est de mise.

ATTENTION

Ne pas utiliser avec une source

d'alimentation électrique non

conforme à la norme indiquée sur

l'appareil.

Utiliser l'appareil avec une autre source

d'alimentation risque de provoquer un incendie

ou de causer une électrocution.

Ne jamais utiliser l’appareil, insérer la

prise dans le réceptacle ou l’en enlever

si on a les mains mouillées.

Il y a risque de décharge électrique ou

d'électrocution.

Ne jamais permettre que l'appareil

soit mouillé; ne jamais y appliquer

d'essence, de diluant ni aucun matériau

inflammable.

Une fuite de courant peut causer un choc

électrique, l'électrocution ou la combustion et

un incendie.

Ne jamais laisser des épingles à

cheveux, des pièces de monnaie, des

allumettes ni aucun autre objet

pénétrer dans l'appareil par les orifices

de ventilation.

Cela crée un risque de décharge électrique

ou d'électrocution. En outre, les objets peuvent

prendre feu.

Ne jamais placer de l'essence, du

diluant ni aucun matériau inflammable

près de l'appareil; ne jamais utiliser de

produits en aérosol près de l'appareil.

Cela crée un risque d'incendie.

Ne jamais endommager le câble

d'alimentation ni le tirer vigoureusement.

Cela risque de déchirer l'isolant du câble et

de causer un court-circuit, ce qui aurait comme

résultat un choc électrique, l'électrocution ou

un incendie.

Ne jamais placer d'objets sur le cordon d'alimentation, plier le câble

d'alimentation en utilisant une force

excessive ni laisser le câble

d'alimentation se déformer.

Le câble transmet un courant de forte intensité,

soit environ 10 ampères. Si le câble se déforme,

la section affectée peut surchauffer et causer

un incendie.

Ne jamais utiliser l'appareil si le câble

d'alimentation est attaché ou enroulé.

Le câble transmet un courant de forte intensité,

soit environ 10 ampères. S'il est attaché ou

enroulé, il peut surchauffer et causer un

incendie.

Ne jamais utiliser un cordon

d'alimentation autre que celui qui est

fourni avec l'appareil. Ne jamais non

plus utiliser de bande d'alimentation

électrique ni de rallonge.

Le câble transmet un courant de tension élevée

(environ 10 ampères). La bande d'alimentation

ou la rallonge peuvent surchauffer et causer

un incendie.

Ne pas utiliser si le fil ou la fiche

électriques sont endommagés; ne pas

brancher dans une prise mal fixée.

Négliger de suivre cette consigne risque de

provoquer un incendie ou decauser une

décharge électrique ou une électrocution.

Pour débrancher l'appareil, saisir la

fiche et non le fil électrique.

Tirer sur le fil peut l'endommager, ce qui risque de provoquer un incendie ou de causer

une décharge électrique ou une électrocution.

12

Page 15

L'encre, les liquides nettoyants et les liquides

usées sont inflammables et toxiques

ATTENTION

Pour utiliser en toute sécurité

Mettre l'appareil à la terre avec le fil

de mise à la terre.

Ne pas respecter cette consigne peut créer

un risque d'électrocution en cas de panne

mécanique.

ATTENTION

Ne jamais utiliser l'appareil près d'une

flamme nue ou d'un appareil de

chauffage ou dans des endroits où la

production d'étincelles ou d'électricité

statique peut survenir.

L'encre ou les autres produits combustibles

peuvent s'enflammer et causer un incendie.

Ne jamais placer d'encre, de liquide de

nettoyage ou des liquides usés dans les

endroits suivants :

➢ près d'une flamme nue

➢ dans un endroit chaud, par exemple

près d'un appareil de chauffage, sur

la platine ou la surface de séchage

de l'appareil;

➢ près de javellisants, de produits

chimiques, d'explosifs ou d'autres

produits semblables

Cela crée un risque d'incendie.

S'il se produit quoi que ce soit

d'anormal (fumée, étincelles, odeur,

combustion ou bruit inhabituel),

débrancher immédiatement le câble

d'alimentation.

Le défaut de ce faire peut entraîner un

incendie, un choc électrique ou l'électrocution.

Débrancher immédiatement le câble

d'alimentation et communiquer avec le Centre de services Roland DG.

PRUDENCE

S'assurer que le lieu de travail est bien

aéré.

L'odeur de l'encre et des autres produits peut

causer es troubles physique ou provoquer un

incendie.

Ne jamais boire l'encre, le liquide de

nettoyage ni les liquides usés, ne pas

en respirer les vapeurs et ne pas laisser

les produits entrer en contact avec les

yeux ou la peau.

Cela est dangereux pour la santé.

Entreposer les cartouches dans un

endroit hors de la portée des enfants.

En cas d'ingestion ou de trouble physique

➢ En cas de contact avec les yeux, rincer immédiatement et abondamment à l'eau courante pendant au moins 15

minutes. Si les yeux sont toujours irrités, consulter un médecin.

➢ En cas de contact avec la peau, laver immédiatement à l'eau et au savon Si la peau devient irritée ou inflammée,

consulter un médecin.

➢ En cas d'ingestion, ne pas provoquer le vomissement et demander immédiatement l'aide d'un médecin. Provoquer

le vomissement peut créer un risque de suffocation.

➢ Si l'odeur cause un trouble physique, amener la personne dans un endroit bien aéré et la faire se reposer. Si

l'étourdissement ou les nausées persistent, consulter un médecin.

13

Page 16

Pour utiliser en toute sécurité

Risque d'incendie, de brûlures ou d'émissions de gaz toxiques

Remarques importantes sur les opérateurs et le lieu de travail

ATTENTION

Certaines surfaces de cet appareil

atteignent des températures élevées

(platine et surface de séchage). Prendre des précautions pour éviter un

incendie ou des brûlures.

Ne jamais laisser de support dans

l'appareil quand aucune impression

n'est en cours.

L'application continue de chaleur au même

endroit peut provoquer un incendie ou

l'émission de gaz toxiques. Quand l'appareil

n'est pas utilisé, couper l'alimentation ou retirer

les supports qui y sont chargés.

Ne jamais utiliser un support qui ne

peut pas supporter la chaleur.

L'utilisation de supports qui ne supportent pas

la chaleur peut causer un incendie, provoquer

l'émission de gaz toxiques ou affecter le support.

Ne jamais utiliser la platine et la surface de séchage à des fins autres que

celles pour lesquelles ils sont conçus,

par exemple, ne pas les utiliser sécher

des vêtements.

L'utilisation à ces fins risque de causer une

surchauffe et de provoquer un incendie ou un

accident.

ATTENTION PRUDENCE

Ne jamais faire fonctionner l'appareil

en état de fatigue, ni après avoir

consommé de l'alcool ou des

médicaments.

L'utilisation de l'appareil exige que l'opérateur

soulève des objets lourds; par conséquent,

l'opérateur peut se blesser s'il n'est pas en

possession de tous ses moyens.

Utiliser l'appareil dans un endroit

propre et bien éclairé.

Travailler dans un endroit sombre ou

encombré peut créer des risques. Utiliser

l'appareil dans de tels endroits risque de causer

un accident, par exemple un faux pas, une chute

et rester coincé sous le rouleau de support.

Ne jamais faire fonctionner l'appareil

si on porte une cravate, un collier, des

vêtements amples ou autres du même

genre. Bien attacher les cheveux longs.

Les cravates, colliers, vêtements amples ou

cheveux peuvent être entraînés dans le

système d'alimentation du support ou par

d'autres éléments, ce qui risque de causer des

blessures.

Ne jamais grimper ni s'appuyer sur

l'appareil.

L'appareil n'est pas conçu pour supporter le

poids d'une personne. Grimper ou s'appuyer

sur la machine peut déplacer des éléments et

causer un faux pas ou une chute, ce qui

causerait des blessures.

14

Page 17

Pour utiliser en toute sécurité

Vignettes d'avertissement

Des vignettes d'avertissement sont apposées pour qu'il soit facile de repérer les zones dangereuses. La

signification des vignettes est donnée ci-dessous. Respecter les avertissements.

Ne jamais retirer les vignettes et ne pas les laisser s'encrasser.

Inflammable

L'encre et les liquides usés sont

inflammables. Les garder loin de toute

flamme nue.

L'encre est toxique

L'encre et les liquides usés sont toxiques.

Éviter tout contact avec le corps. Utiliser

uniquement dans un endroit bien aéré.

Attention : Têtes d'impression mobiles

Les têtes d'impression sous le couvercle

se déplacent à haute vitesse et

représentent un danger. Ne jamais insérer

la main ou les doigts dans l'ouverture.

Inflammable

L'encre et les liquides usés sont

inflammables. Les garder loin de toute

flamme nue.

Attention : Risque de pincement

Faire attention de ne pas coincer les

doigts lors de la fermeture du couvercle.

Attention : Température élevée

La platine et la surface de séchage

chauffent. Être prudent pour éviter un

incendie ou des brûlures.

Attention : Risque de pincement

Faire attention de ne pas coincer les

doigts pendant le chargement du support

ou lors de la fermeture du couvercle.

L'encre est toxique

L'encre et les liquides usés sont toxiques.

Éviter tout contact avec le corps. Utiliser

uniquement dans un endroit bien aéré.

La cartouche d'encre

15

Page 18

Important Notes on Handling and Use

This machine is a precision device. To ensure the full performance of this machine, be sure to observe the

following important points. Failure to observe these may not only result in loss of performance, but may also

cause malfunction or breakdown.

Printer unit

This Machine Is a Precision Device

➢ Handle carefully, and never subject the machine to impact or excessive force.

➢ Never needlessly put your hand or fingers inside the cover, the ink-cartridge ports, or other internal areas of the

machine.

Install in a Suitable Location

➢ Install in a location having the specified temperature and relative humidity.

➢ Install in a quiet, stable location offering good operating conditions.

The Print Heads Are Delicate

➢ Never needlessly touch or allow media to scrape them. Failure to handle with care may cause damage.

➢ The print heads may be damaged if allowed to dry out. The machine prevents desiccation automatically, but im-

proper operation may render this feature inoperative. Operate properly, as specified in this manual.

➢ Never allow the machine to stand with an ink cartridge removed. Remaining ink in the printer may harden and clog

the print heads.

➢ The print heads are components that wear out. Periodic replacement is required, with the frequency of replacement

depending on use.

This Machine Becomes Hot

➢ Never cover the ventilation holes with cloth, tape, or anything else.

When Moving the Machine

➢ Special preparations are required when moving the machine. Please check with your authorized Roland DG Corp.

dealer or Roland DG Corp. service center ahead of time.

Ink cartridges

Ink Cartridges Come in Various Types

➢ Use a type that is compatible with the printer. Also, be sure to use only genuine items from Roland DG Corp.

Never Subject to Impact or Attempt to Disassemble

➢ Never drop or shake forcefully. The impact may rupture the internal pouch and cause the ink to leak.

➢ Never attempt to disassemble.

➢ Never attempt to refill the ink.

➢ If ink gets on your hands or clothing, wash it off as soon as possible. Removal may become difficult if allowed to

stand.

Storage

➢ Store unopened in a well-ventilated location at a temperature of -20 to 40˚C (-4 to 104˚F).

16

Page 19

Chapter 1

Introduction

17

Page 20

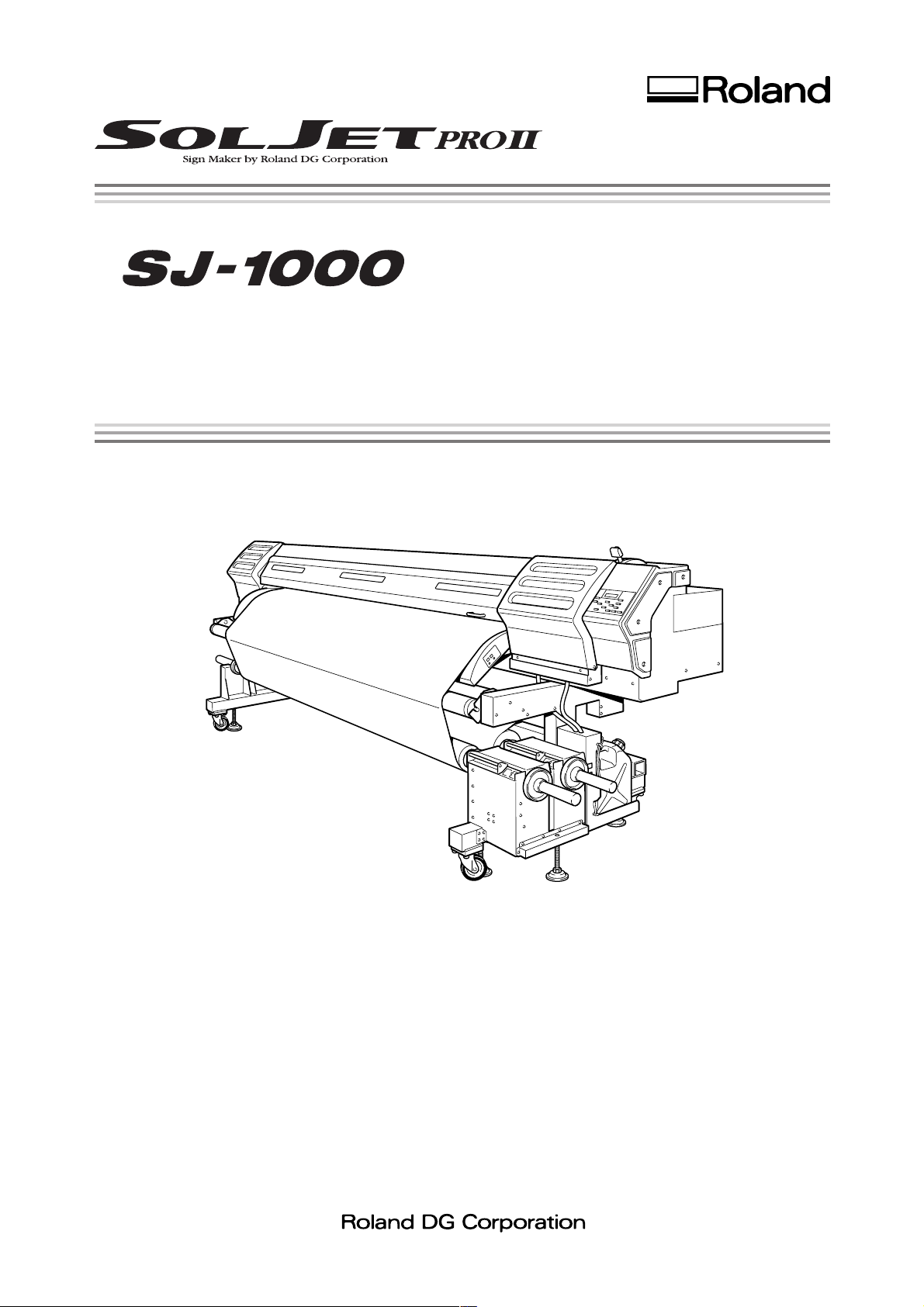

1-1 Machine Features

This machine is a high-speed, large-format printer compatible with media having a width of 100 inches. It

provides ample image quality for large outdoor signs and the like even in its fastest mode, demonstrating high

practicality and productivity. It is provided with the necessary features for high-speed, high-volume printing,

including a media feed and take-up systems and media dryer.

Also, despite being an ink-jet printer, it achieves output of high weatherability thanks to the use of ECO-SOL

inks.

18

Chapter 1 Introduction

Page 21

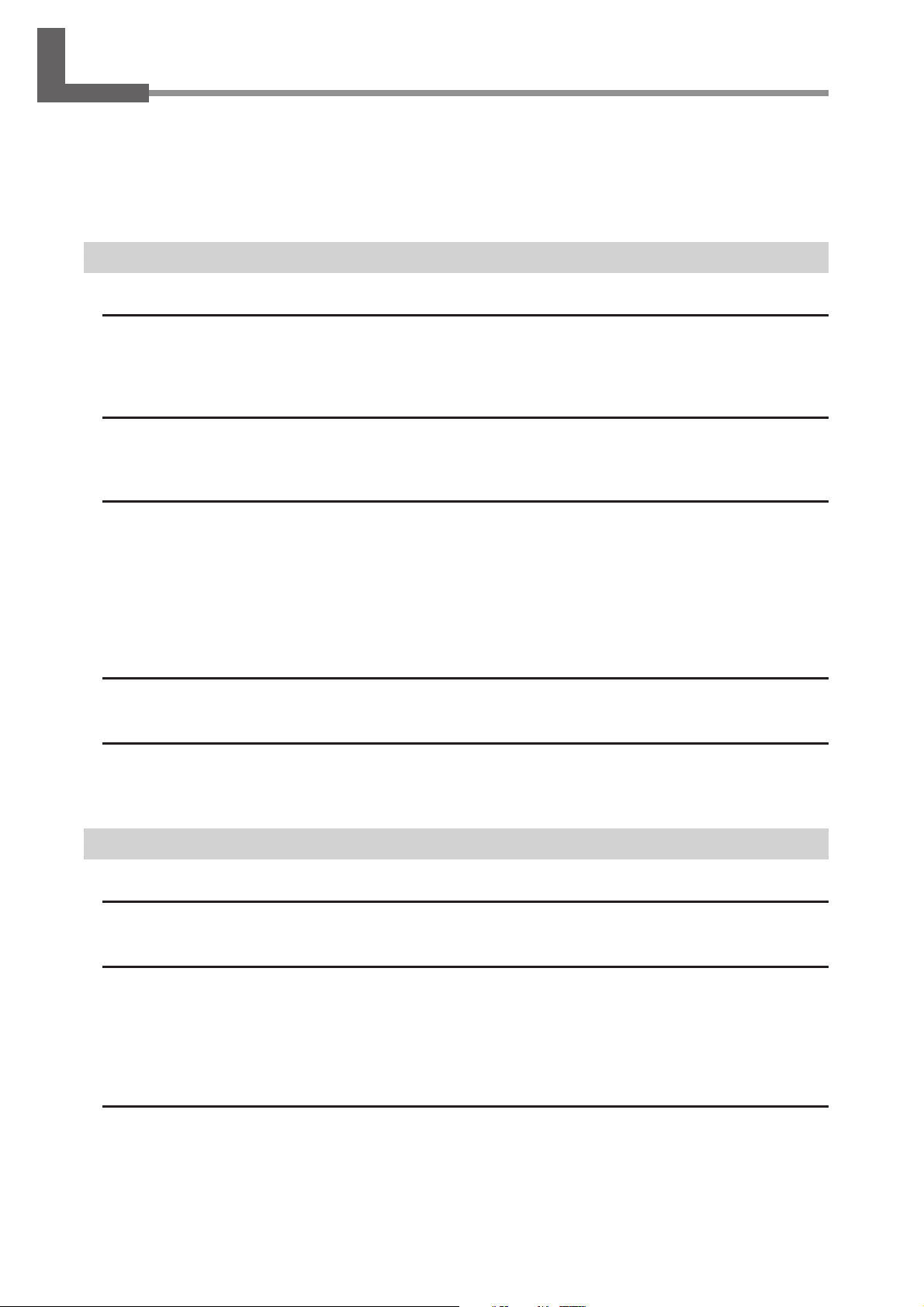

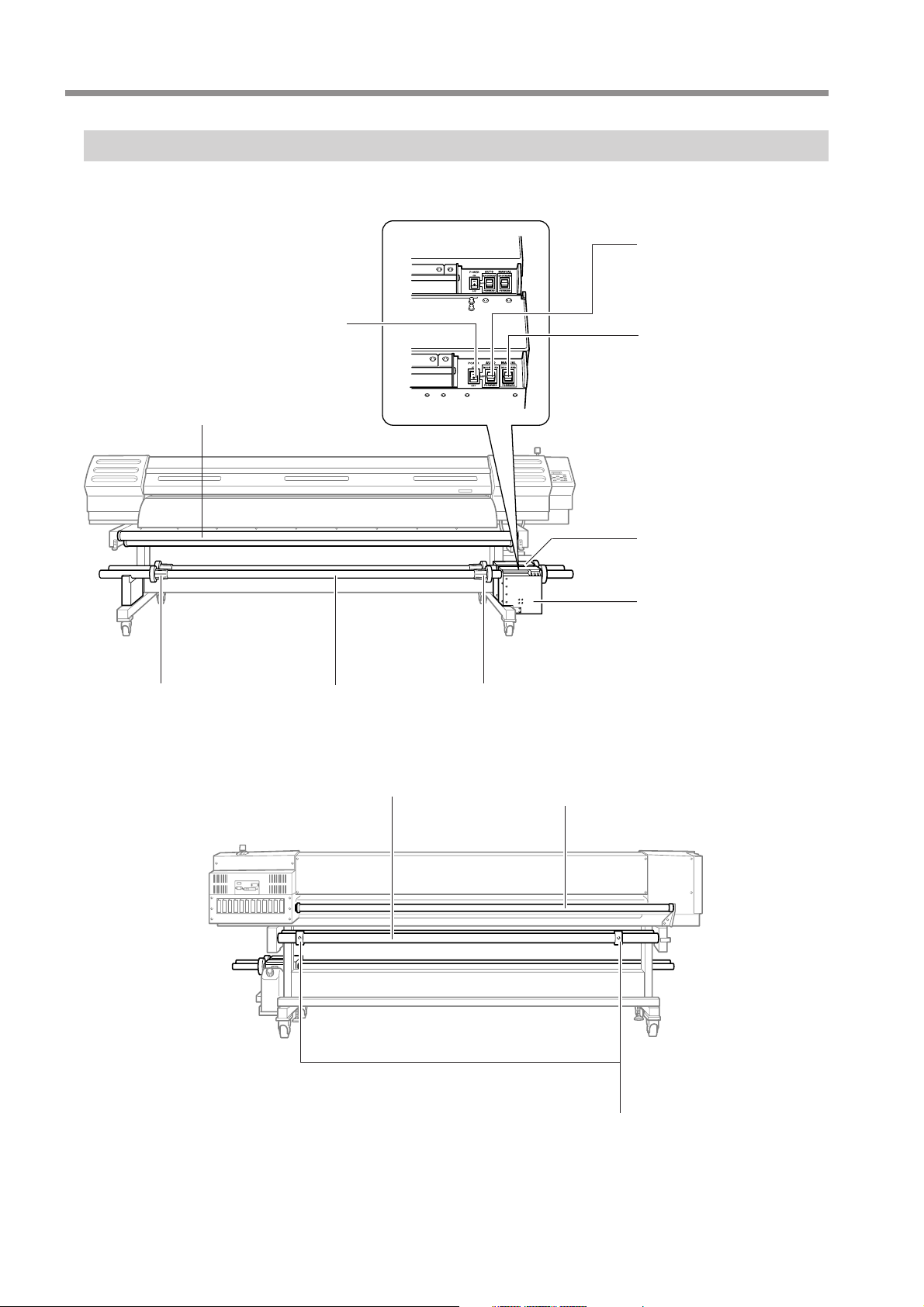

1-2 Part Names and Functions

Printer Unit and Dryer

Front Cover

Be sure to close this when you

perform printing.

Left Side Cover

You remove this when you

perform maintenance.

Loading Lever

You operate this when you

load media.

Dryer

This heats the media to hasten ink-drying.

Operation Panel

You use this to perform various operations.

☞ p 21 "Printer Control Panel"

Right Side Cover

You remove this when you

perform maintenance.

Cartridge Slots

This is where ink cartridges

are installed.

Printer Main Power Switch

This is the main power switch for the printer unit.

Ethernet Connector

This is used to connect the printer to a network.

Power-cord Connector

This supplies power to the printer unit, dryer, and

media take-up and feed systems. A 200 to 240 V

electrical outlet is required.

Drain Bottle

This collects drained ink and other such fluids.

Discard any collected fluid before it overflows.

Chapter 1 Introduction

19

Page 22

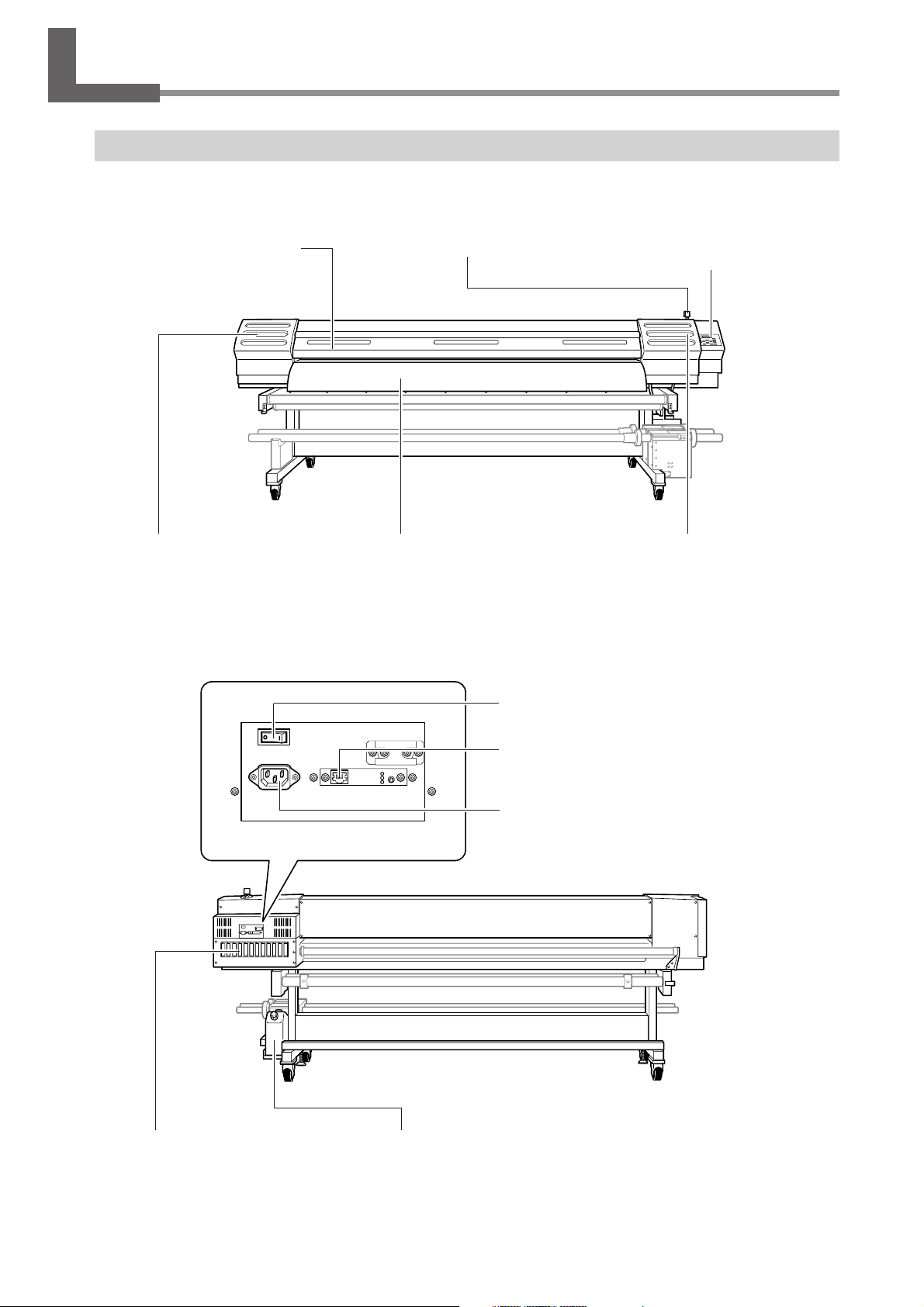

1-2 Part Names and Functions

Platen

This is the path over which

the media passes. A suction

fan that keeps the media

from coming loose and a

preheater and print heater

that help fix the ink are

built in.

Media Clamps

These keep the media from

coming loose and prevent

fuzz on the cut edge of the

media from touching the

print heads.

Pinch Rollers

These clamp the media

when the loading lever is

pulled back toward you.

Grit Rollers

These rollers feed out media toward the front of the

machine.

Knife Guide

The media can be cut off

with a straight edge by inserting a retractable knife

into this groove.

Print-head Carriage

The print heads are inside

this.

Guide Line

This line serves as a guide

for positioning the right

edge of the media.

Actual Temperature

This displays the current

temperature of the dryer.

Preset Temperature

This displays the preset

temperature.

Temperature Setting

keys

These set the temperature

for the dryer.

Dryer Main Power Switch

This is the main power

switch for the dryer. It shares

the power-cord connector

with the printer unit.

20

Chapter 1 Introduction

Page 23

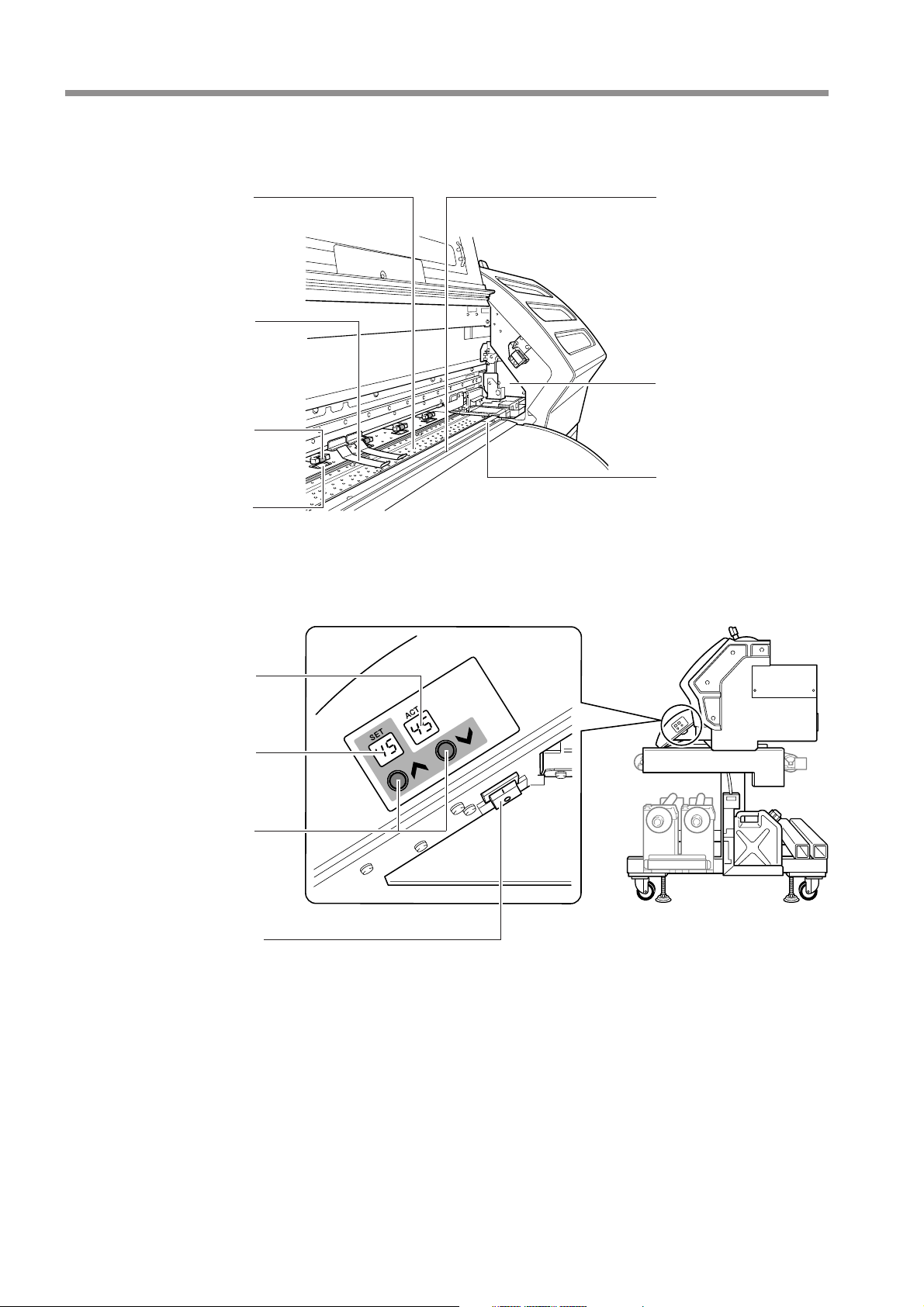

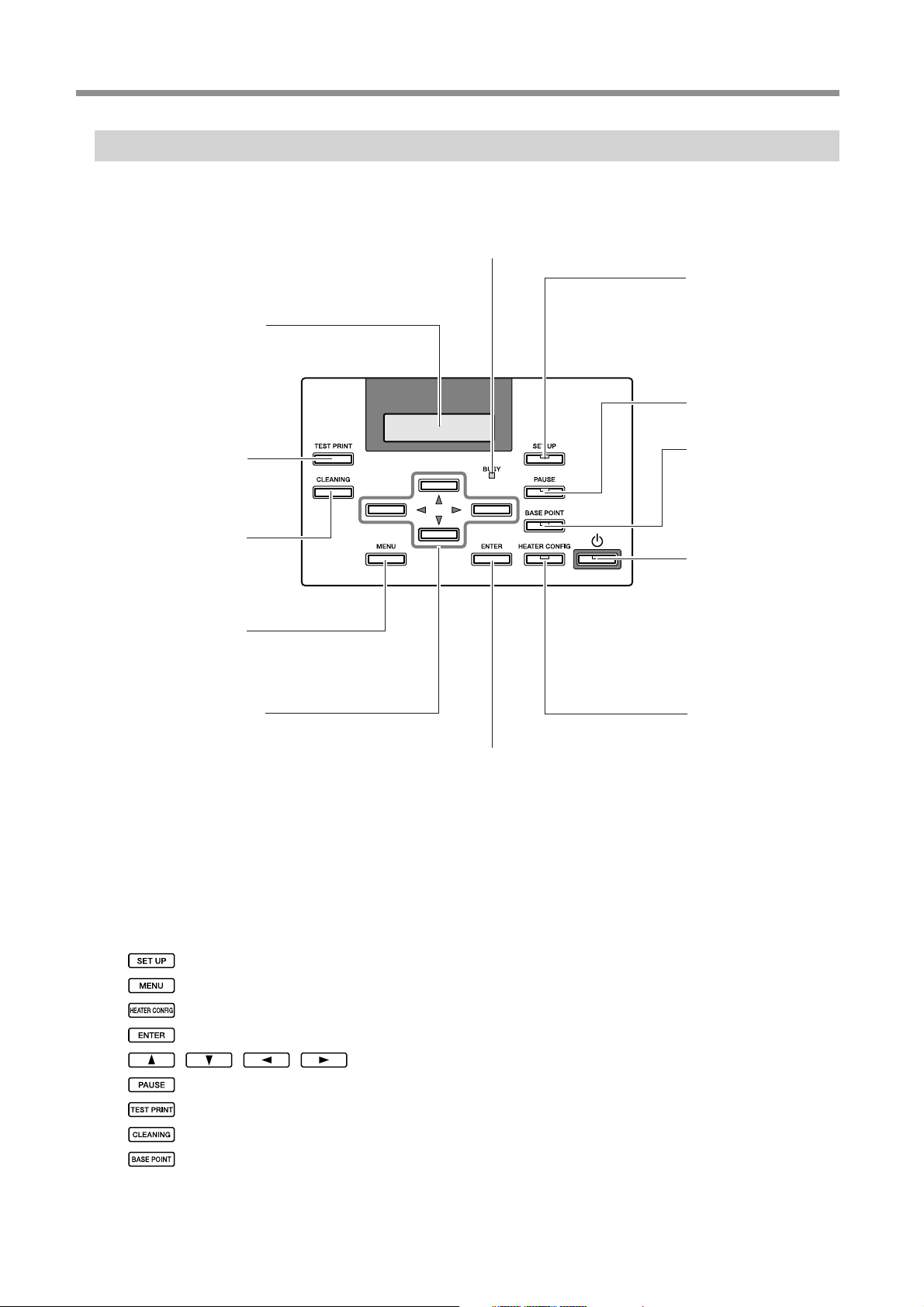

Printer Control Panel

Display Screen

This displays various setting menus and other information.

TEST PRINT Key

Holding this down for

one second or longer

performs a printing test.

CLEANING Key

You use this to perform

cleaning of the print

heads.

MENU Key

You press this to enter

the menus for various

settings.

Cursor Keys

You use these to select settings for menu items, to

move the media, and for

other such operations.

BUSY Light

This lights up during printing

and other such operations.

ENTER Key

You use this for such tasks

as enabling setting values.

1-2 Part Names and Functions

SETUP Key/Light

You press this when you

load media. The light

comes on when media

is loaded and the machine is ready to perform printing.

PAUSE Key/Light

This pauses printing.

BASE POINT Key/Light

You use this when you

want to set the printstart position. The light

comes on when the set

has been made.

Sub Power Switch/Light

This switches the printer

on and off. (To switch

the printer off, you hold

down the switch for one

second or longer). The

light flashes slowly

when the machine is in

the sleep mode.

HEATER CONFIG Key/Light

You press this when you

make temperature settings for the preheater

and print heater. The light

flashes while heating up

is in progress, and remains steadily lighted

when the preset temperature is reached.

Panel Notation

In this document, the keys and lights on the control panel are indicated by the following images.

SETUP Key/Light

MENU Key

HEATER CONFIG Key/Light

ENTER Keys

Cursor Keys

PAUSE Key/Light

TEST PRINT Key

CLEANING Key

BASE POINT Key/Light

Chapter 1 Introduction

21

Page 24

1-2 Part Names and Functions

Media Take-up and Feed Systems

Power Switch

This switches take-up and feed

units on and off.

Take-up Dancer Roller

This maintains uniform tension for take-up media.

AUTO Switch

This makes the direction of

rotation for take-up and feed

during printing change automatically.

MANUAL Switch

You use this when you want

to operate the take-up and

feed units manually.

Roll ShaftsEnd Caps

Feed Dancer Rollers

This maintains uniform tension for the feed media.

End Caps

Feed Unit

This rotates roll media to feed

it to the printer.

Take-up Unit

This rotates the roll shaft to

take up media.

Guide Roller

22

Balance Weights

This weight balances the feed

dancer roller to keep it level.

Chapter 1 Introduction

Page 25

Chapter 2

Operation

23

Page 26

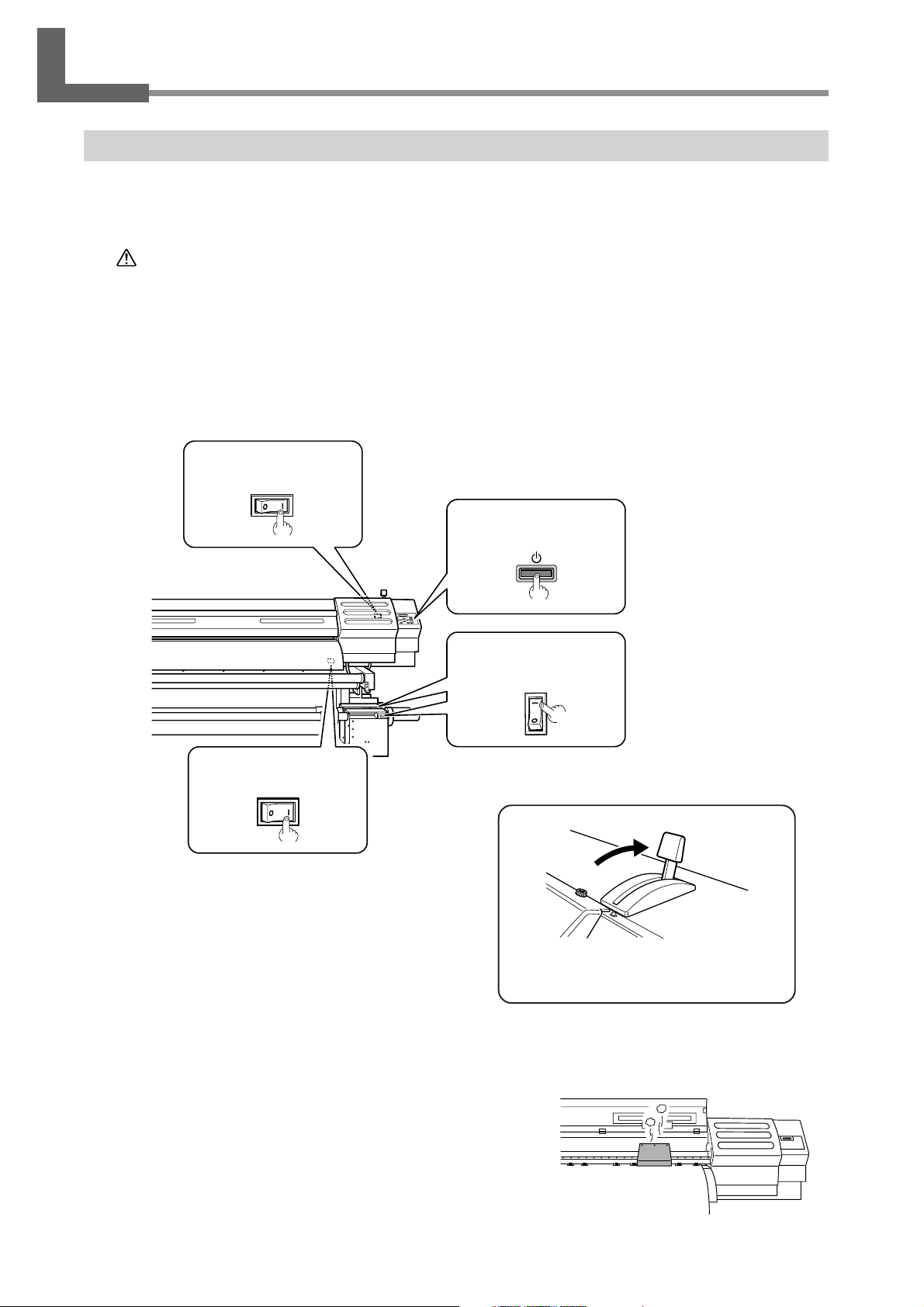

2-1 Switching the Power On and Off

Switching the Power On and Off

This machine has four power switches. You switch on all four when using the machine.

When you finish printing, you turn off switches 2, 3, and 4 as required. You also flip down the loading lever to the

rear of the machine.

WARNING

We recommend leaving this switched on at all times during ordinary

day-to-day operation. (The machine monitors the dryness of the print

heads which this switch is on.)

➀ Main power switch

for the printer

When leaving the printer unattended after completing operation, be sure to turn

off the power to the machine.

Failure to do so may lead to overheating of the platen or dryer, resulting to fire. Also, inadvertent contact by someone other than the operator may result in sudden operation of the machine, leading to injury or burns.

➁ Sub power switch

for the printer

➂ Power switches for

the media take-up

and feed systems

Turn this switch on after

closing the front cover. To

turn it off, hold down the

switch for one second or

longer.

➃ Main power switch

for the dryer

This switch lights up when it

is on.

Important Note on Switching Off the Power

Never switch off the printer's main power or unplug the power cord

suddenly while operation is in progress. Doing so may damage the

print heads. Be sure to first switch off the sub power.

If the main power is accidental switched off, immediately turn the

main power and sub power back on.

Flip the loading lever down to

the rear when not in use.

24

Chapter 2 Operation

Page 27

2-1 Switching the Power On and Off

The Power-saving Feature

This machine is provided with a power-saving feature that switches to a low-power "sleep mode" when a fixed

interval passes with no operation. The factory default for the time after which the machine switches to the sleep

mode is 30 minutes.

You can change the setting for the time of the shift to the sleep mode. You can also switch off the power-saving

feature.

☞ p 79 "Setting the Interval until Activation of the Sleep Mode"

☞ p 80 "Deactivating the Sleep Mode"

When the machine is in the sleep mode, the POWER light flashes slowly and the heating devices stop.

Using the control panel or performing operations such as sending printing data from the computer (when media

is loaded) restore the machine to its normal mode.

To reduce power consumption and prevent problems such as overheating, we recommend leaving the powersaving feature on and setting the activation time for the sleep mode to 30 minutes or less.

Chapter 2 Operation

25

Page 28

2-2 Loading and Cutting Off Media

How to Load Media

WARNING

WARNING

CAUTION

When loading or moving roll media, be sure to use load-handling equipment such

as a lifter and carry out operations with care to prevent falls or other accidents.

Some roll media may weigh about 100 kg (220 lb.). Attempting manual lifting operations that

tax your strength may cause physical injury. Also, if dropped, such items may cause unexpected

injury, such as crushing of the feet.

Never use media less than 1,220 mm (48 inches) in width.

The platen may overheat, resulting in fire or the release of toxic gases.

Be sure to perform operations as specified by these instructions, and never touch

any area not specified in the instructions.

Sudden movement of the machine may cause injury.

26

Chapter 2 Operation

Page 29

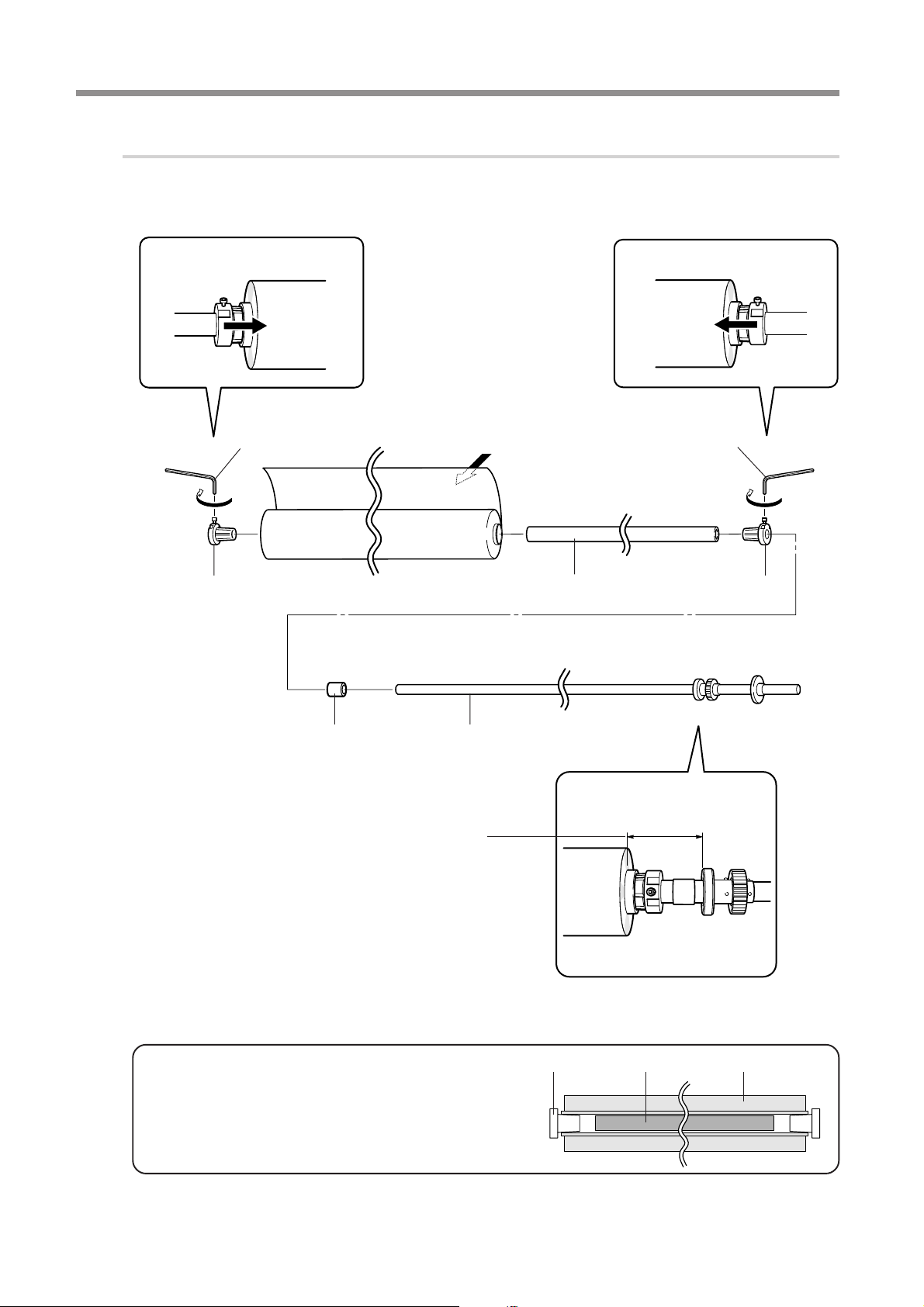

Load the media onto the roll shaft.

1.

■ Media having an outward curl

Press in to fit on securely. Press in to fit on securely.

2-2 Loading and Cutting Off Media

Hexagonal wrench

(large)

Roll media

End cap

Spacer

Adjust the end cap to a position of 110 to 130 mm

(4.3 to 5 in.).

* When using media having a width of 2,540 mm

(100 inches) or more, be sure to position the

media at 110 mm.

* The scale on the media gauge is useful for ad-

justing the position.

Printed surface

Roll shaft

Hexagonal wrench

(large)

Reinforcement pipe End cap

110 to 130 mm (4.3 to 5 in.)

Reinforcement pipe

Use this when loading media that has a width of 1,880

mm (74 inches) or wider. It reduces sagging of the

roll media.

Reinforcement pipe MediaEnd cap

Chapter 2 Operation

27

Page 30

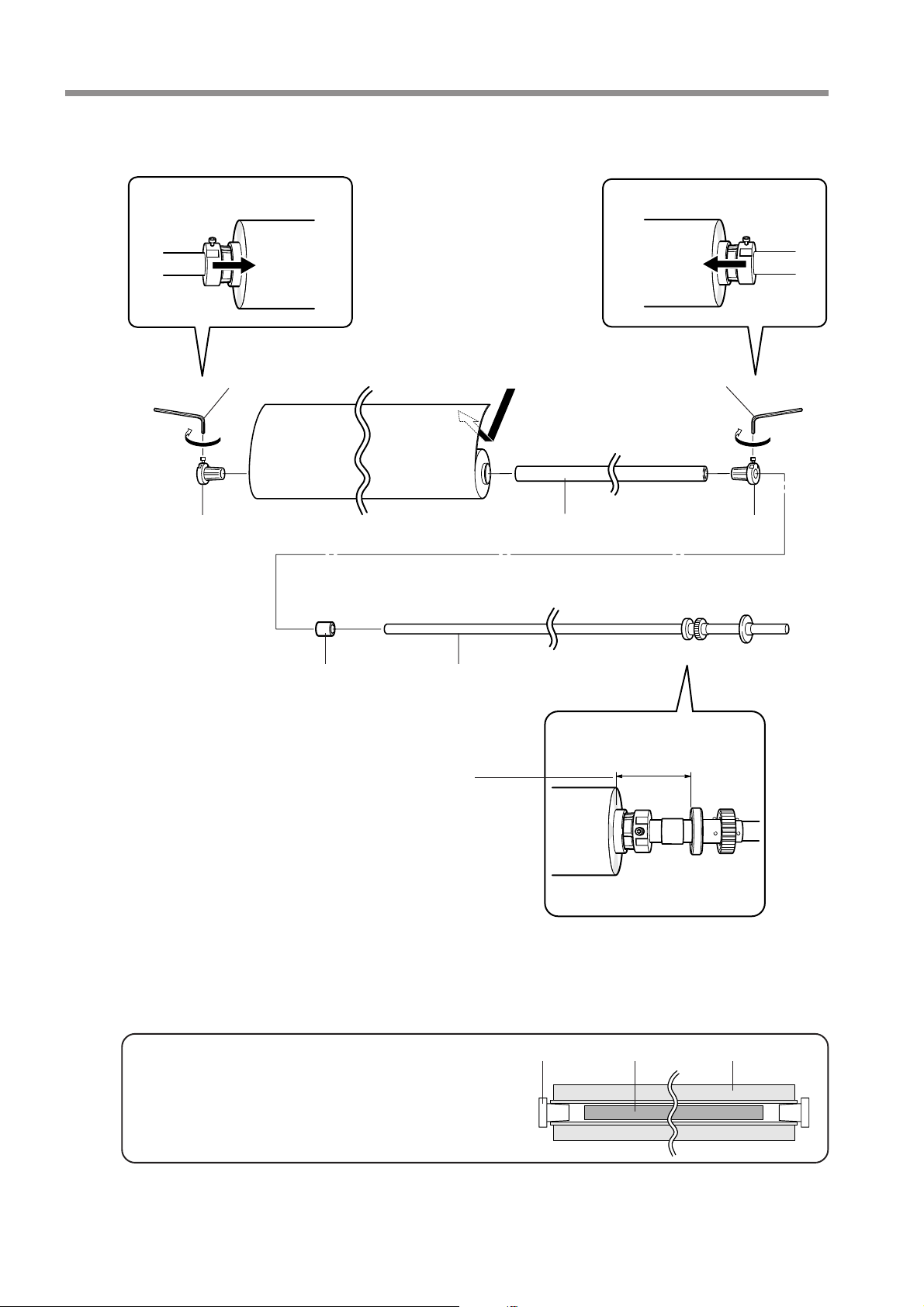

2-2 Loading and Cutting Off Media

■ Media having an inward curl

Press in to fit on securely. Press in to fit on securely.

Hexagonal wrench

(large)

Roll media

End cap

Spacer

Adjust the end cap to a position of 110 to 130 mm

(4.3 to 5 in.).

* When using media having a width of 2,540 mm

(100 inches) or more, be sure to position the

media at 110 mm.

* The scale on the media gauge is useful for ad-

justing the position.

Roll shaft

Printed surface

Reinforcement pipe End cap

110 to 130 mm (4.3 to 5 in.)

Hexagonal wrench

(large)

28

Reinforcement pipe

Use this when loading media that has a width of 1,880

mm (74 inches) or wider. It reduces sagging of the

roll media.

Chapter 2 Operation

Reinforcement pipe MediaEnd cap

Page 31

Mount the roll shaft in the paper pipe.

2.

Press in to fit on securely. Press in to fit on securely.

2-2 Loading and Cutting Off Media

Hexagonal wrench

(large)

End cap End cap

Spacer

Adjust the end cap to a position of 75 to 100 mm

(3 to 4 in.).

* When using media having a width of 2,540 mm

(100 inches) or more, be sure to position the

media at 100 mm.

* The scale on the media gauge is useful for ad-

justing the position.

Paper pipe

Roll shaft

75 to 100 mm (3 to 4 in.)

Hexagonal wrench

(large)

Chapter 2 Operation

29

Page 32

2-2 Loading and Cutting Off Media

Mount the media and paper pipe on the take-up and feed units.

3.

➊

➋

➌

Roll media

Place on the feed unit

(interior).

Power switch

for feed unit

Power switch

for take-up unit

Switch off the power.

Open the cover.

Mount the roll shaft.

Paper pipe

Place on the take-up

unit (toward the front

of the machine).

Fit the bearing for the roll

shaft into place here.

Bearing

30

Chapter 2 Operation

Page 33

2-2 Loading and Cutting Off Media

Pass the media through the printer and adjust the balance weights.

4.

➊

Before you pass the media through, move the balance weights to match the width of the media.

➋

When 1220 to 1372 mm

(48 to 54 inches)

When 1373 to 2032 mm

(54 to 80 inches)

When 2033 to 2641 mm

(80 to 104 inches)

Pass the media through the rollers until its end reaches the

platen.

Work from the back of the printer.

Tighten

Loosen

Balance weight

➌

Pull back the loading lever to keep the threaded media

from slipping and falling off.

Chapter 2 Operation

31

Page 34

2-2 Loading and Cutting Off Media

➍

Adjust the position of the balance weights to match the width of the media.

When 1220 to 1372 mm

(48 to 54 inches)

When 1373 to 1625 mm

(54 to 64 inches)

When 1626 to 2032 mm (64 to 80 inches)

When 2033 to 2641 mm (80 to 104 inches)

Tighten

Loosen

32

Balance weight

Chapter 2 Operation

Page 35

Fasten the media to the paper pipe.

5.

2-2 Loading and Cutting Off Media

➊

➋

➌

➀ Go to the front of the printer.

➁ While holding down the media by hand to

keep it from slipping out of place, flip the loading lever to the rear.

➂ Pull the media to a position next to the pa-

per pipe.

Close the cover.

➀ Set the AUTO switch off.

➁ Switch on the power.

➍

Feed unit

While pulling the media to keep it taut, adjust

the position of the end of the media.

Position so that the end of the media reaches

the paper pipe (that is, so that it reaches a position where it can be taped in place).

Chapter 2 Operation

33

Page 36

2-2 Loading and Cutting Off Media

➎

While pulling the media to keep it taut, adjust the position of the end of the media.

Position so that the end of the media reaches the paper pipe (that is, so that it reaches a position where it

can be taped in place).

Bring this surface into

contact with the side of

the roll.

Media gauge

As shown in the figure, place on the feed-side roll

media and use as a guide for positioning the media on the take-up side.

As you position the left and right edges, follow the

➏

procedure

media in place.

on the following page to tape the

34

Chapter 2 Operation

Page 37

➏

Use adhesive tape to fasten the media securely to the paper pipe.

Apply the adhesive tape at intervals of about 20 to 30 cm (10 inches).

■ Take-up with outward curl

Paper pipe Adhesive tape

20 to 30 cm

(approx. 10 in.)

2-2 Loading and Cutting Off Media

10 mm (0.4 in)

or lager

■ Take-up with inward curl

Paper pipe Adhesive tape

20 to 30 cm

(approx. 10 in.)

10 mm (0.4 in)

or lager

When this is 10 mm (0.4 in.) or

less, go back to Step 1 and readjust the location of the end

cap.

10 mm (0.4 in)

or lager

10 mm (0.4 in)

or lager

When this is 10 mm (0.4 in.) or

less, go back to Step 1 and readjust the location of the end

cap.

Chapter 2 Operation

35

Page 38

2-2 Loading and Cutting Off Media

Set the orientation for automatic feed and automatic take-up.

6.

➊

Make the setting for the AUTO switch on the feed unit.

➋

Operate the MANUAL switch to take up the media and pull it taut.

Take up the media for one turn or more.

Feed side

Media having an inward curl

Media having an outward curl

■ Take-up with outward curl

Ensure there is

no slack.

take up one turn

or more.

■ Take-up with inward curl

Ensure there is

no slack.

Take-up side

Take-up side

36

take up one turn

or more.

When you begin take-up, take care to ensure that the end of the media does not become

rolled or creased.

Chapter 2 Operation

Page 39

➌

Make the setting for the AUTO switch on the take-up unit.

Take-up side

Take-up with inward

curl

Take-up with outward

curl

➍

Pull back the loading lever to secure the media in place.

2-2 Loading and Cutting Off Media

Chapter 2 Operation

37

Page 40

2-2 Loading and Cutting Off Media

Install the media clamps.

7.

The media clamps are magnetic.

Media clamp

Line up the hole with the

end of the media.

How to install correctly

Important Notes on the Media Take-up and Feed Systems

Never attempt any operation that pulls the media with excessive force, like the ones shown below.

➢ Never operate the MANUAL switch when the loading lever has been pulled back.

➢ Never use

to feed the media in reverse.

38

CAUTION

Chapter 2 Operation

Never needlessly touch loaded media, rollers, or the like.

Sudden movement of the media take-up or feed system may cause fingers, clothing or the like

to become caught, resulting in injury.

Page 41

How to Cut Off Media

2-2 Loading and Cutting Off Media

CAUTION

Cut off the media along the knife guide, using a retractable knife or the like.

The cutter knife used here is sharp and poses a hazard. Carry out operations with

caution to avoid injury.

Knife guide

Chapter 2 Operation

39

Page 42

2-3 Settings of Preheater, Print Heater and Dryer

What Are the Preheater, Print Heater and Dryer?

This machine is equipped with three devices for heating media. You use these mainly to improve ink adhesion

and dry the ink. You can adjust the temperature settings to match the type of media and printing speed.

Preheater

This device warms the media before

printing.

Print heater

This device is used mainly to improve

ink adhesion.

Dryer

You use this to speed up drying of the

ink.

WARNING

WARNING

WARNING

The platen and dryer become hot. Exercise caution to avoid fire or burns.

Never leave media loaded in the machine when printing is not being performed.

The continued application of heat at a single location may cause fire or produce toxic gases.

When printing is not being performed, switch off the power or remove any loaded media.

Never use media that cannot withstand the heat.

Doing so may result in fire or the release of toxic gases, or may degrade the media.

40

Chapter 2 Operation

Page 43

2-3 Settings of Preheater, Print Heater and Dryer

Temperature Settings for the Preheater and Print Heater

Procedure

➊

PRE 45 45

PRINT 45 45

Preset

temp.

W 2600 mm

➋

SETUP SHEET

At first, the preheater and preheater do not warm up to the preset temperature. (This is the factory-default setting.) Pressing

Actual

temp.

to make the light come on makes them to warm up to the preset temperature.

Press .

Use

Use

Press

Press .

Press

to select the preheater or print heater.

to make the setting.

to enable the setting.

to go back to the original screen.

Temperature Setting for the Dryer

Actual temp. (˚C)

Preset temp. (˚C)

Press the keys to set

the temperature.

Turn on the main power switch for the dryer.

This switch lights up when it is on.

Chapter 2 Operation

41

Page 44

2-3 Settings of Preheater, Print Heater and Dryer

General Guide for the Preset Temperatures

The optimal temperature settings vary according to the type of media, differences in the print mode, and other

factors. Use the following as a general guide and adjust accordingly.

General Guide for Adjustment

Preheater

Set this to a temperature that is the same as or lower than the temperature of the print heater.

You use the preheater mainly to heat media gradually. This is because media becomes more likely to shrink or

wrinkle if heated suddenly.

Print heater

You use this mainly to improve ink adhesion and inhibit smudging.

If the ink forms lumps or smudges, raise the temperature. Note, however, that a temperature that is too high may

degrade the media or cause it to wrinkle.

Dryer

When ink drying is poor, raise the temperature. Note, however, that a temperature that is too high may degrade

the media or cause it to wrinkle.

The relationship between the print mode and temperature

If smudging or poor drying occur even after raising the temperature, try using a print mode offering higher image

quality. Conversely, when you want to use a faster print mode, raise the temperature.

Amount of ink

When you change the amount of ink using the settings for your RIP program, adjusting this may yield better

results. If problems such as smudging persist even after raising the temperature, try reducing the amount of ink.

Examples of Preset Temperatures

Media

Type: Scrim banner (PVC)

Thickness: 300 to 400 µm (12 to 16 mil)

Type: Marking film (PVC, with adhesive)

Thickness: 60 to 100 µm (2.5 to 4 mil, not including backing paper)

➢ These are only rough estimates. Make adjustments to match the media you're using.

➢ Using the heating devices does not necessarily make it possible to apply ink to every kind of media. Be sure to test

in advance.

➢ Results may vary greatly depending on the print mode and other factors. Make settings suited to the media.

➢ When suggested settings for temperature, print mode, and other values are given, use the suggested settings.

Temperature

Preheater: 45˚C (112˚F)

Print heater: 45˚C (112˚F)

Dryer: 50˚C (122˚F)

Preheater: 40˚C (104˚F)

Print heater: 40˚C (104˚F)

Dryer: 45˚C (112˚F)

42

Chapter 2 Operation

Page 45

2-4 Starting Printing

Getting Ready to Receive Data from a Computer

When you have finished loading media and making the temperature settings for the heating devices, then follow

the steps below. This procedure enables the machine to receive data from the computer and perform printing.

Procedure

➊

Close the front cover.

➋

Press (making the light come on).

➌

Wait until the light stops flashing and stays steadily lit.

➍

Wait for the dryer to warm up.

➎

Make sure you are at the top menu.

If you are not at the top menu, press , then press .

Top menu

W 2600 mm

Flashing

Steadily lighted

Printing Is Not Possible in These Situations

➢ The machine does not run when the front cover is open. Also, never open it when printing is in progress.

Doing so interrupts printing.

➢ Data from the computer is not accepted when

➢

➢ Printing does not start until

➢ Data from the computer is not accepted when you are not at the top menu.

light does not come on when media is loaded incorrectly.

light comes on.

light is dark.

Steadily lighted

Chapter 2 Operation

43

Page 46

2-4 Starting Printing

Printing Tests and Cleaning

We recommend performing a printing test to check for problems such as dot drop-out before you carry out

actual printing. If problems such as dot drop-out are found, clean the print heads.

How to Perform a Printing Test

Hold down for one second

or longer.

Printing test

Dot drop-out

Holding down for one second or longer prints a test

pattern.

You can print the test pattern where you want by

using

then pressing

movement, but be sure to close it before you press

. The front cover may be open during

to move the print heads,

.

44

How to Perform Cleaning

Hold down for one second

or longer.

Chapter 2 Operation

Closing the front cover and holding down for one second or longer

performs cleaning for the heads. When the operation ends, press

then

It may be a good idea to perform a printing test again to make sure the dot

drop-out has been corrected. If the problem persists, try performing cleaning a second time. If the problem doesn't go away even after performing

cleaning two or three times, then try cleaning using a different method.

to go back to the initial screen.

☞ p 53 "When Head Cleaning Is Not Effective"

,

Page 47

2-5 If Ink Runs Out

Checking for Remaining Ink

Procedure

➊

MENU

INK REMAINING

➋

1 ■■ 2 ■■ 3

5 ■■ 6 ■■ 7

➌

9 ■■ 10 ■■ 11

W 2600 mm

➍

SETUP SHEET

Cartridge slot number

■■

■■

■■

Press .

Press

4

8

12

■■

■■

■■

Press .

Press .

Press .

Press

1 ■■ 2 ■■ 3 ■■ 4

5 ■■ 6 ■■ 7

9 ■■ 10 ■■ 11

several times.

to go back to the original screen.

Amount of ink remaining

■■

■■

8

■■

■■

12

■■

Much

Little

The display shows an approximate guide to the amount of remaining ink, which may differ somewhat from the actual

amount remaining. Also, the displayed information may differ greatly from the actual amount remaining if you insert a

partly used ink cartridge or change cartridges while the power is off.

Chapter 2 Operation

45

Page 48

2-5 If Ink Runs Out

If Ink Runs Out

When ink runs out, a warning beep sounds and printing pauses (unless the default settings have been changed).

Pull out the empty cartridge and insert a new one. Printing resumes.

Procedure

➊

1 _ 2 ■ 3 ■ 4 ■ 5 ■ 6 ■

7 ■ 8 ■ 9 ■ 10 ■ 11 ■ 12 ■

➋

➌

Pull out the empty cartridge and immediately insert the new one.

➢ Keep the labeled side face up.

➢ Insert and remove slowly, one at a time.

➢ Insert firmly, as far as it will go.

The slot number for the empty cartridge flashes.

Gently shake the new cartridge.

Replace with an item of identical type and color.

46

Chapter 2 Operation

Page 49

2-5 If Ink Runs Out

Important Notes on Replacing Cartridges

➢ Be sure to replace with an item of identical type. Never mix items of different types.

➢ Never allow the machine to stand with an ink cartridge removed. The print heads may become clogged.

➢ Never insert or remove a partially used ink cartridge.

➢ Never remove an ink cartridge suddenly while the printer is in operation.

WARNING

Never place ink, cleaning liquid, or discharged fluid in any of the following locations.

➢ Near open flame

➢ In a hot location, such as near a heater or on the machine's platen or dryer

➢ Near bleach, chemicals, explosives, or the like

Doing so may cause fire.

Chapter 2 Operation

47

Page 50

48

Page 51

Chapter 3

Maintenance and

Adjustment

49

Page 52

3-1 Daily Care and Maintenance