Roland DJ-808 Service Manual

Oct. 2016 DJ-808

SERVICE NOTES

Issued by RJA

Table of Contents

Cautionary Notes ..............................................................2

Specifications .....................................................................3

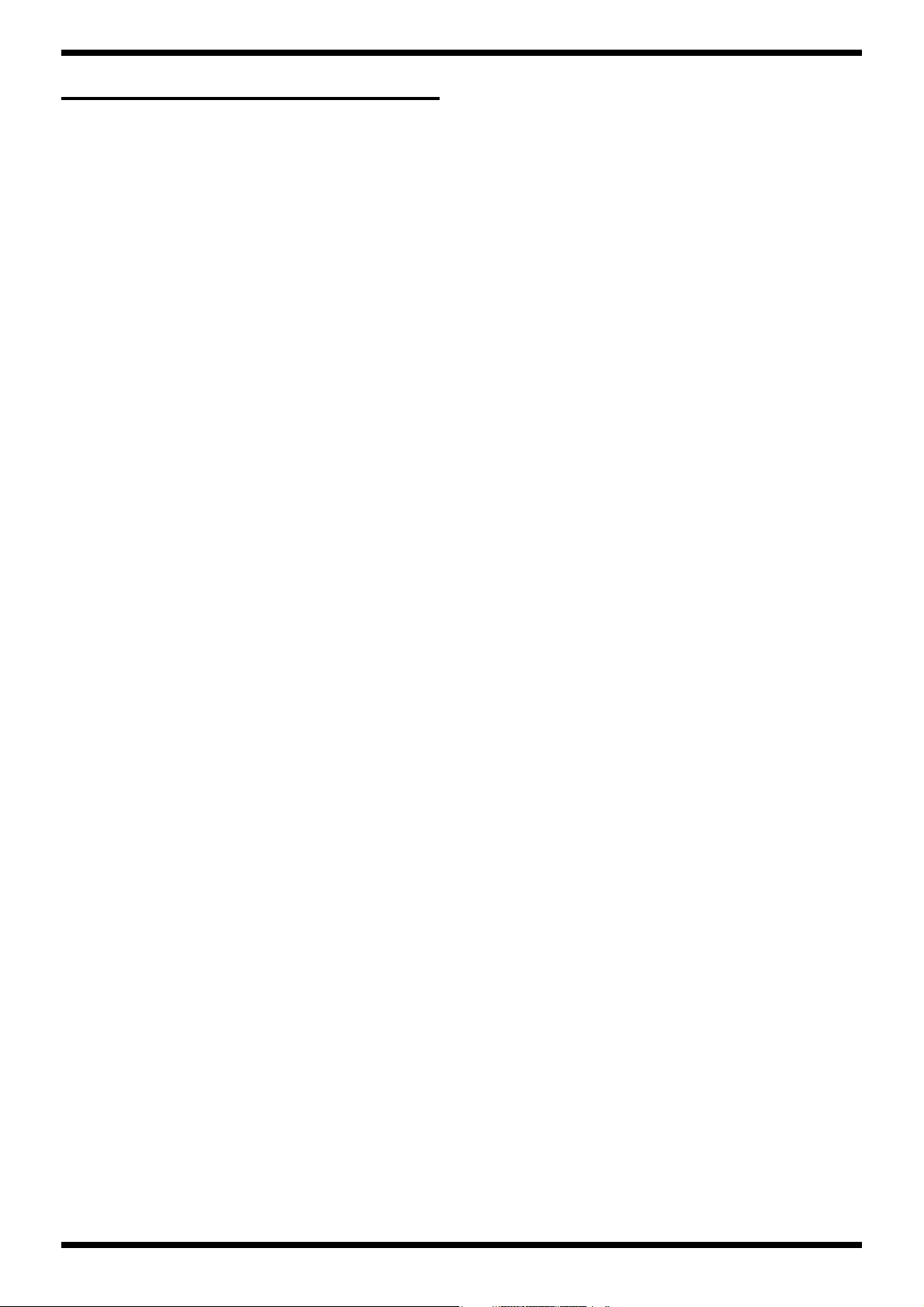

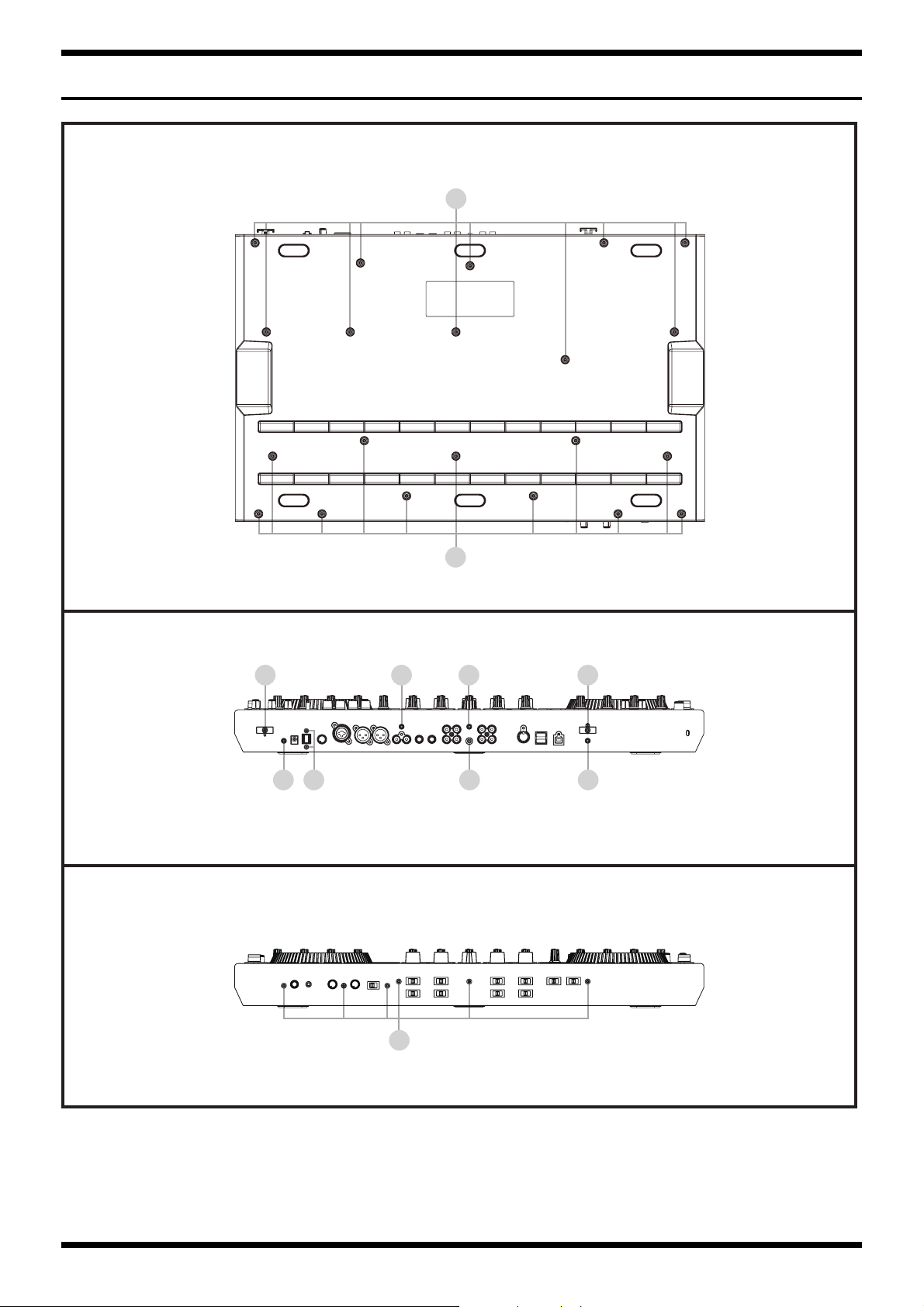

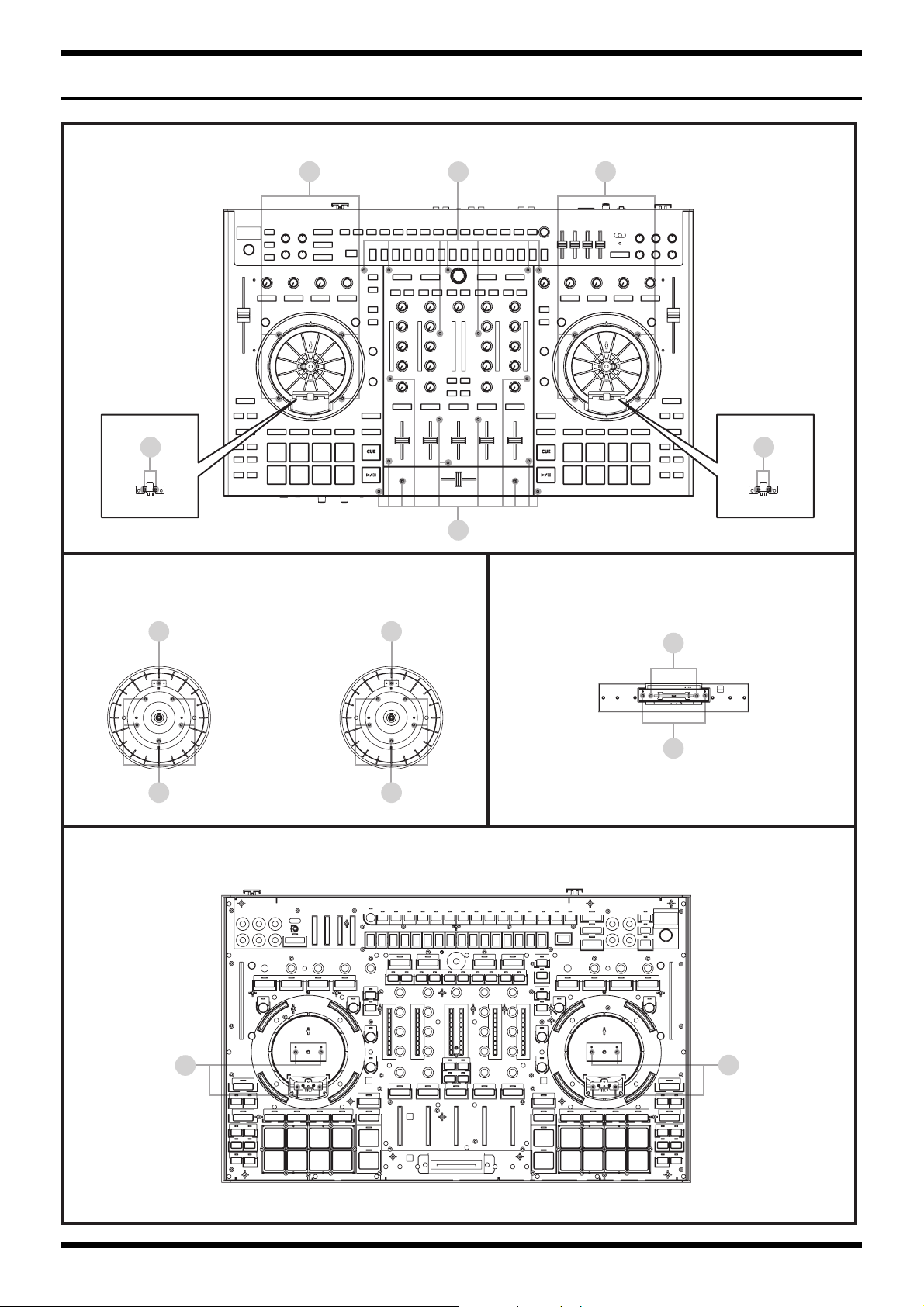

Location of Controls (Top A)...........................................4

Location of Controls (Top A) Parts List.........................5

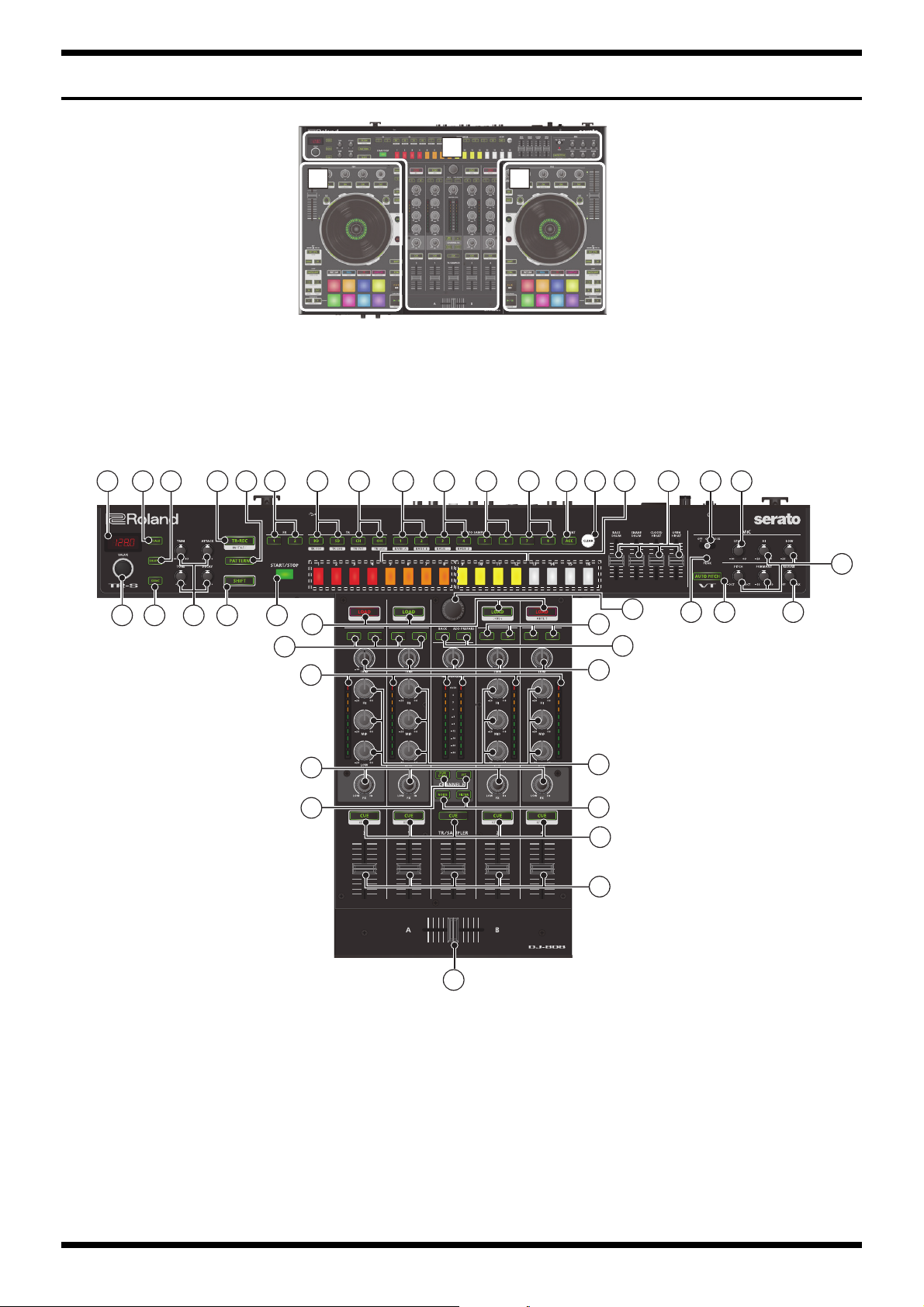

Location of Controls (Top B) ...........................................6

Location of Controls (Top B) Parts List..........................7

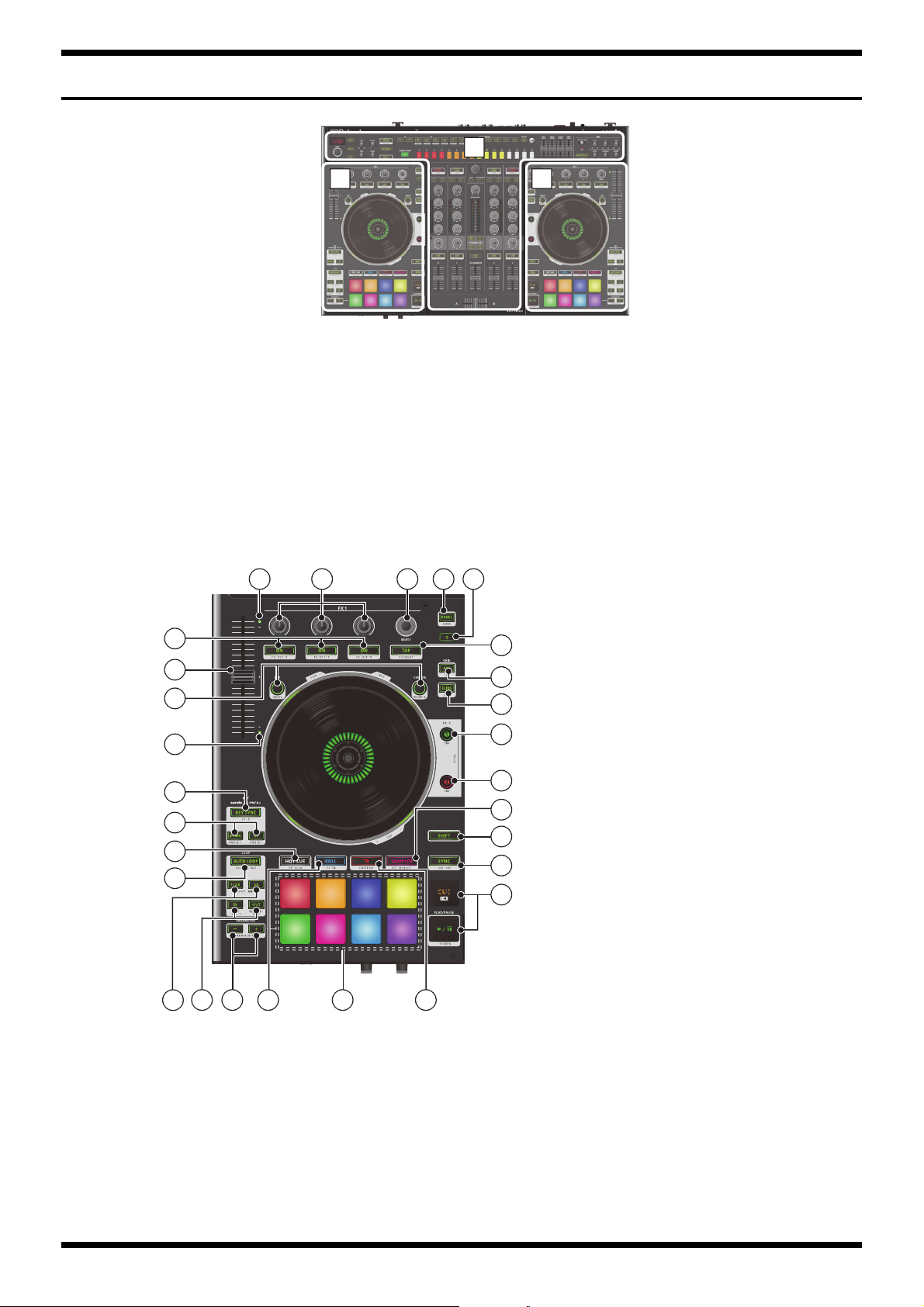

Location of Controls (Top C)...........................................8

Location of Controls (Top C) Parts List .........................9

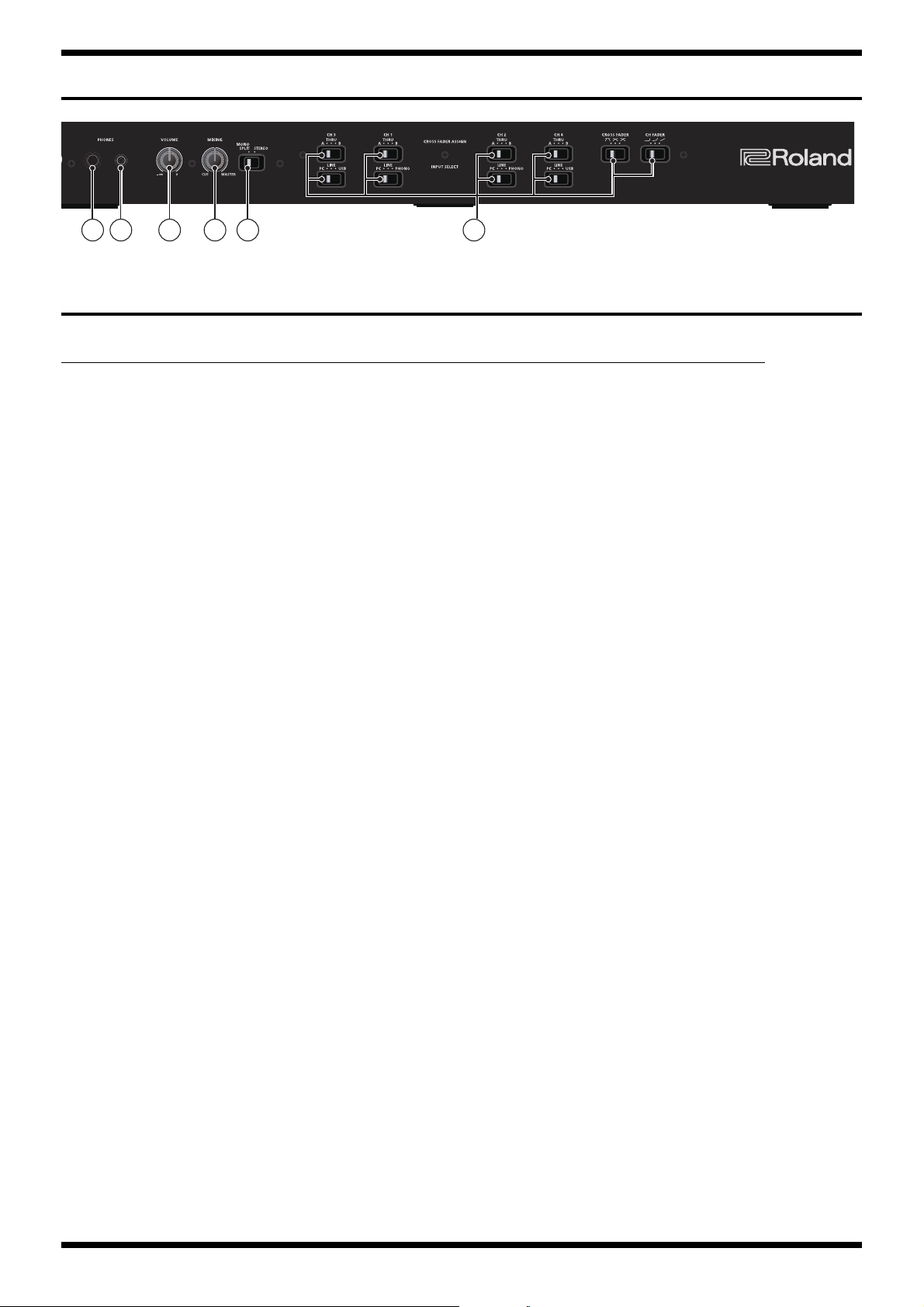

Location of Controls (Front) ..........................................10

Location of Controls (Front) Parts List.........................10

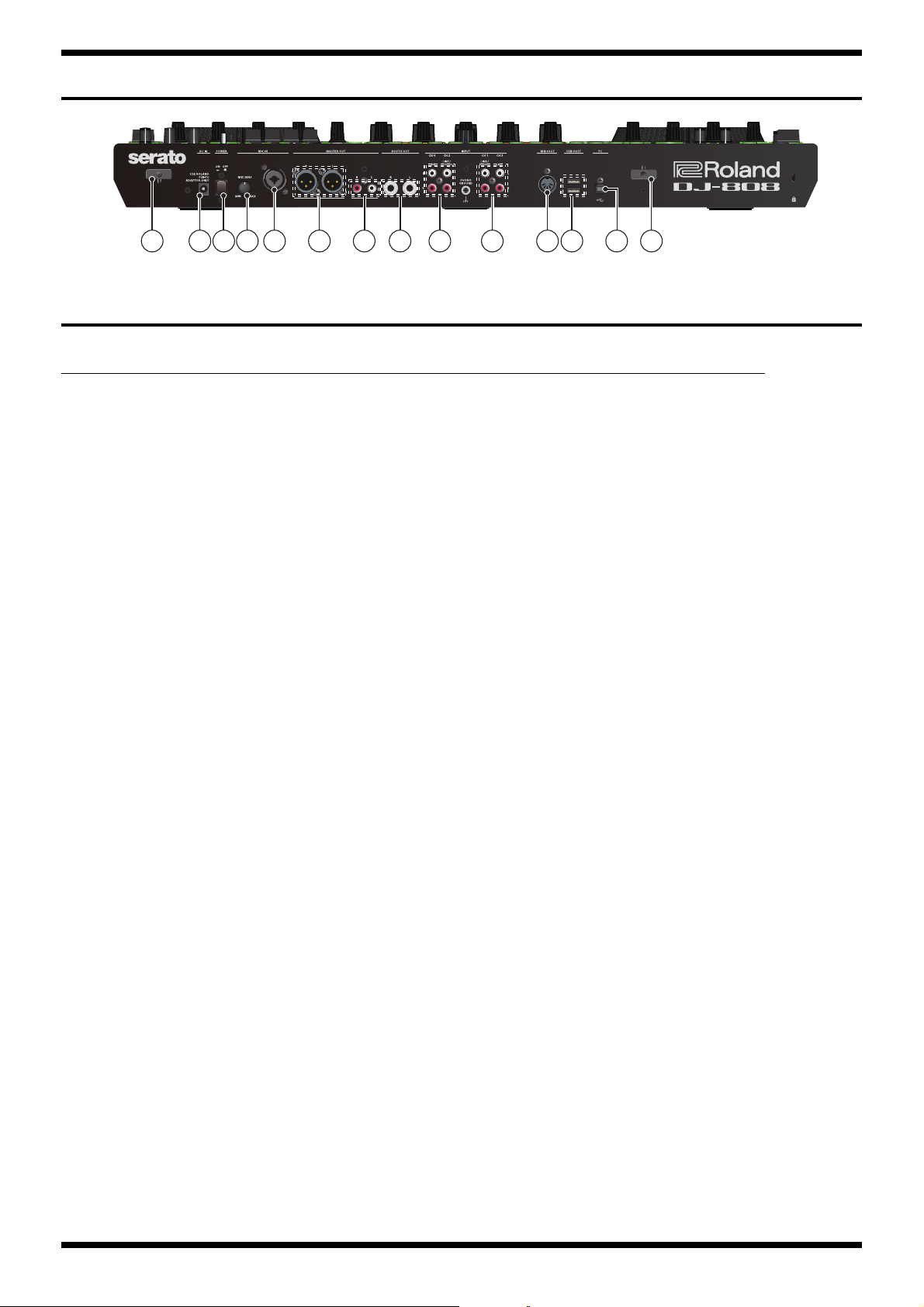

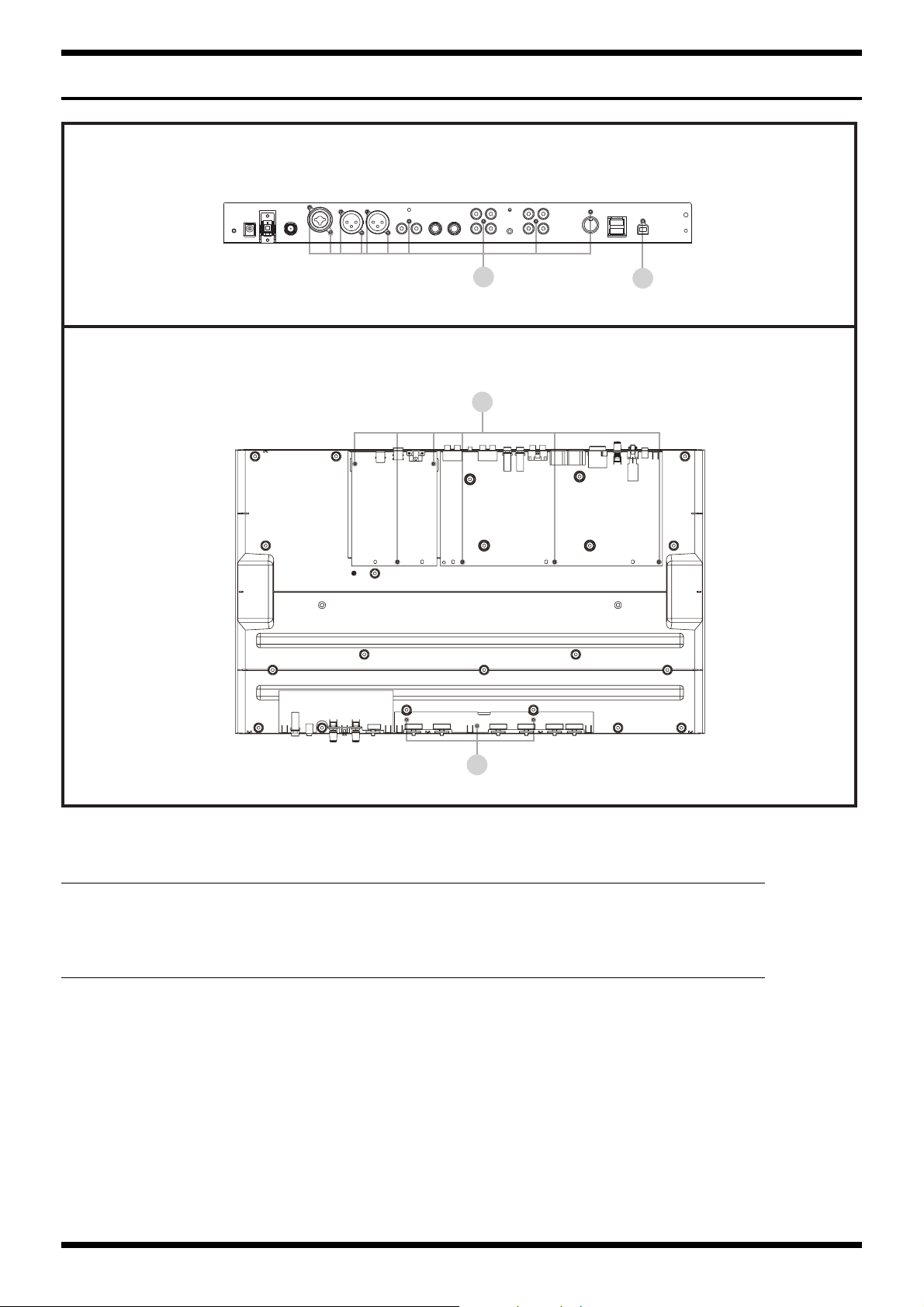

Location of Controls (Rear)............................................11

Location of Controls (Rear) Parts List ..........................11

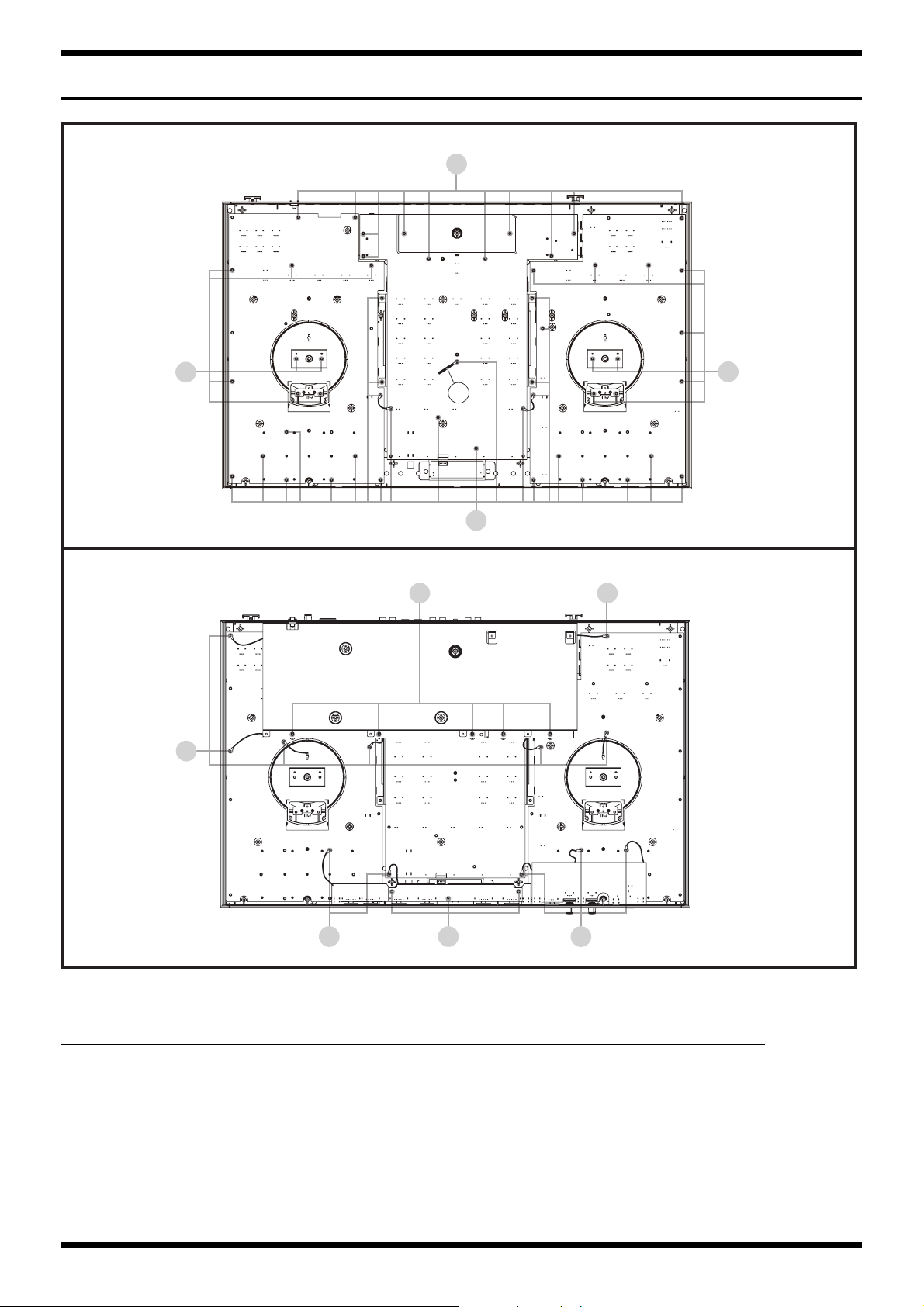

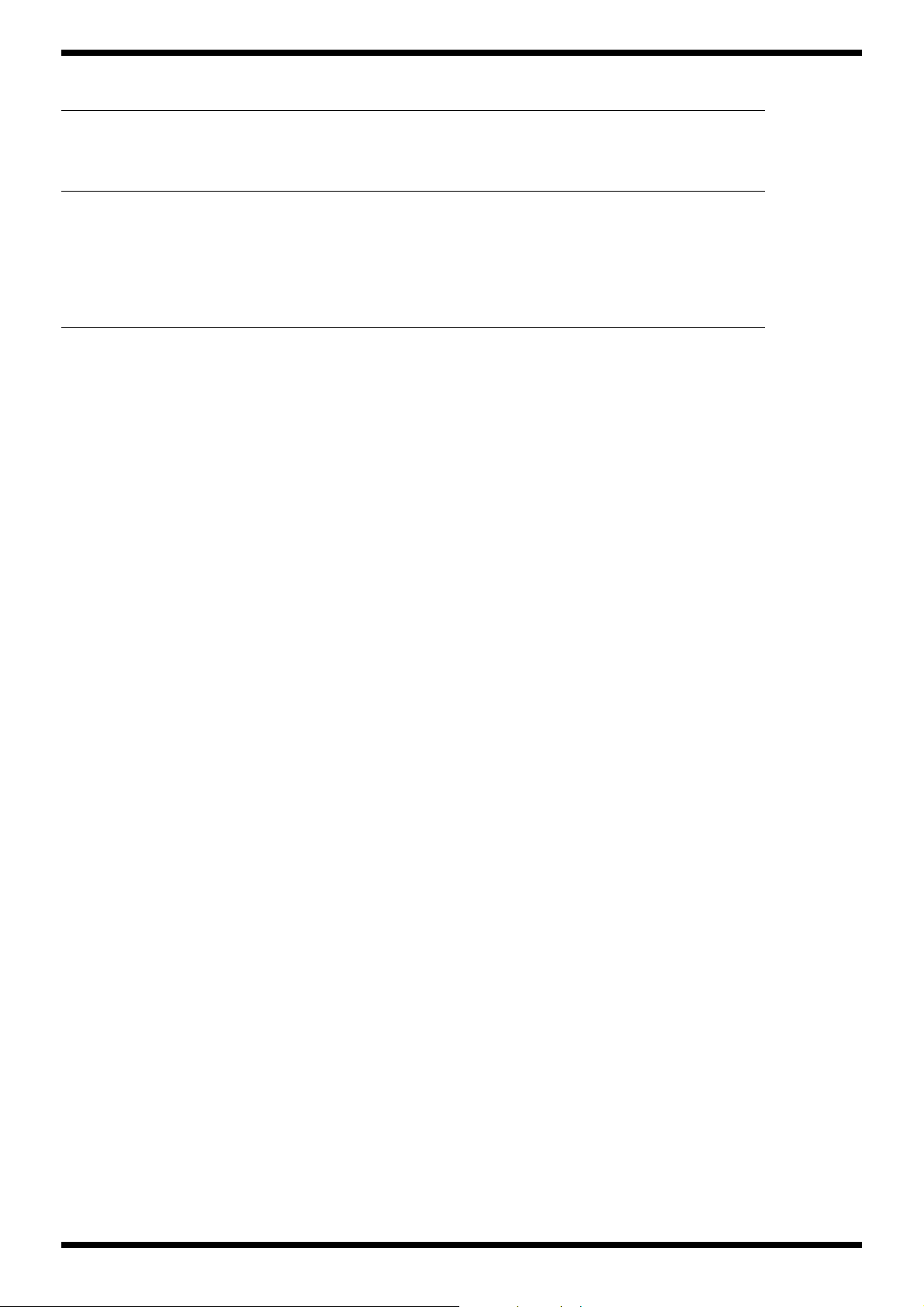

Exploded View (1)...........................................................12

Exploded View Parts List (1).........................................13

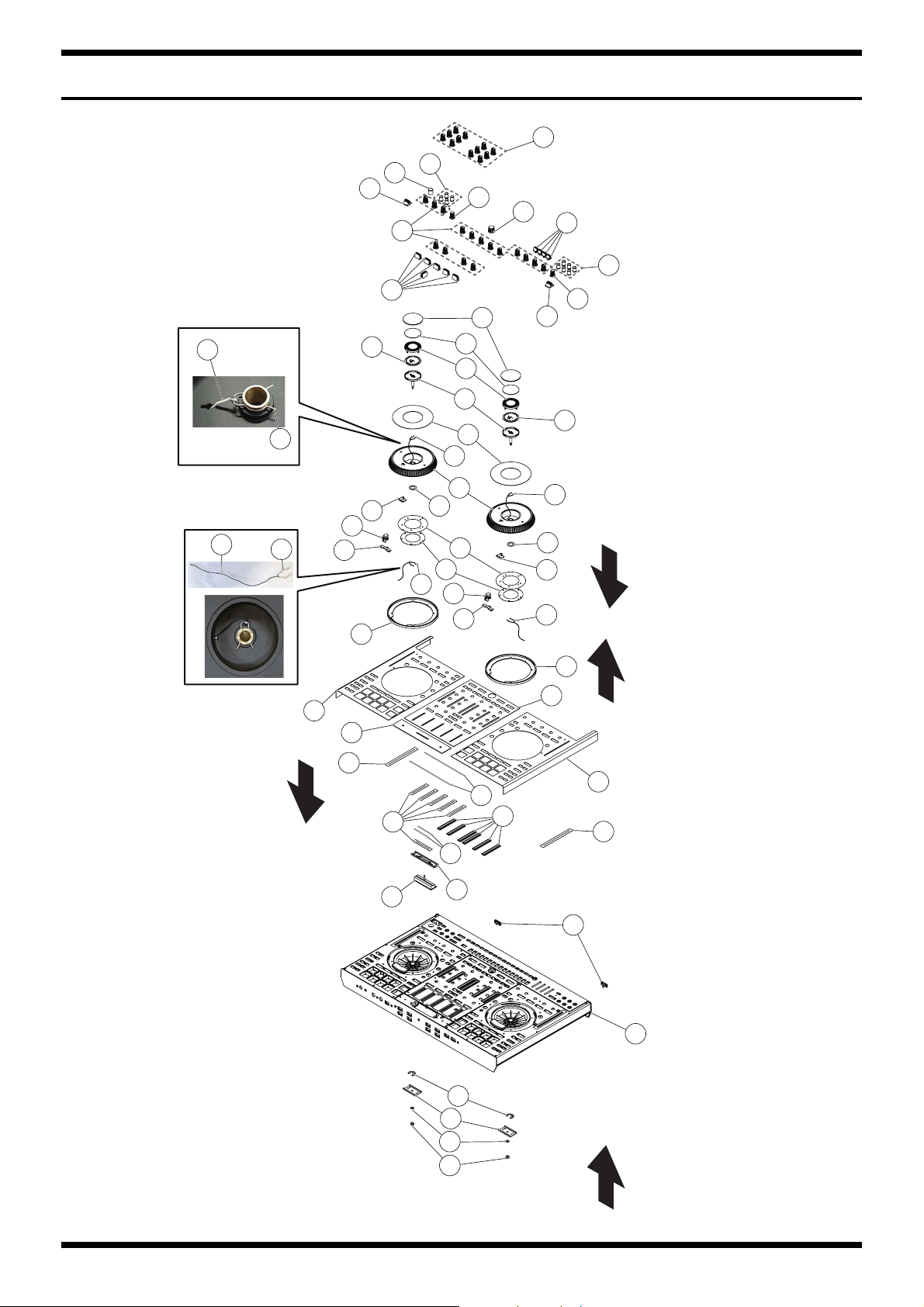

Plain View (1)...................................................................14

Plain View (2)...................................................................15

Plain View (3)...................................................................16

Exploded View (Fig. A)..................................................18

Exploded View Parts List (Fig. A) ................................19

Plain View (Fig. A) (1) ....................................................20

Disassembly Procedure ..................................................22

Assembling the Platter ...................................................22

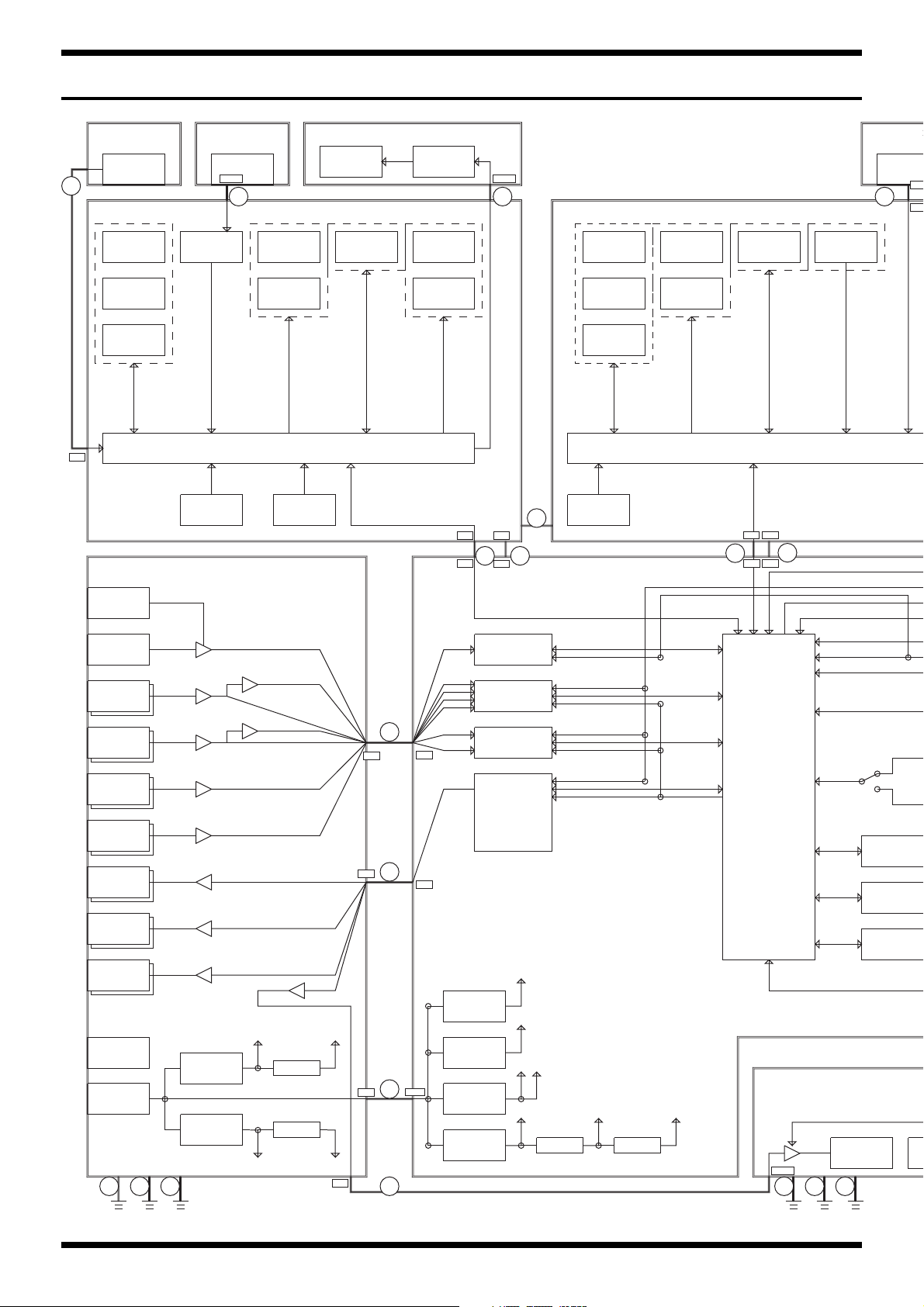

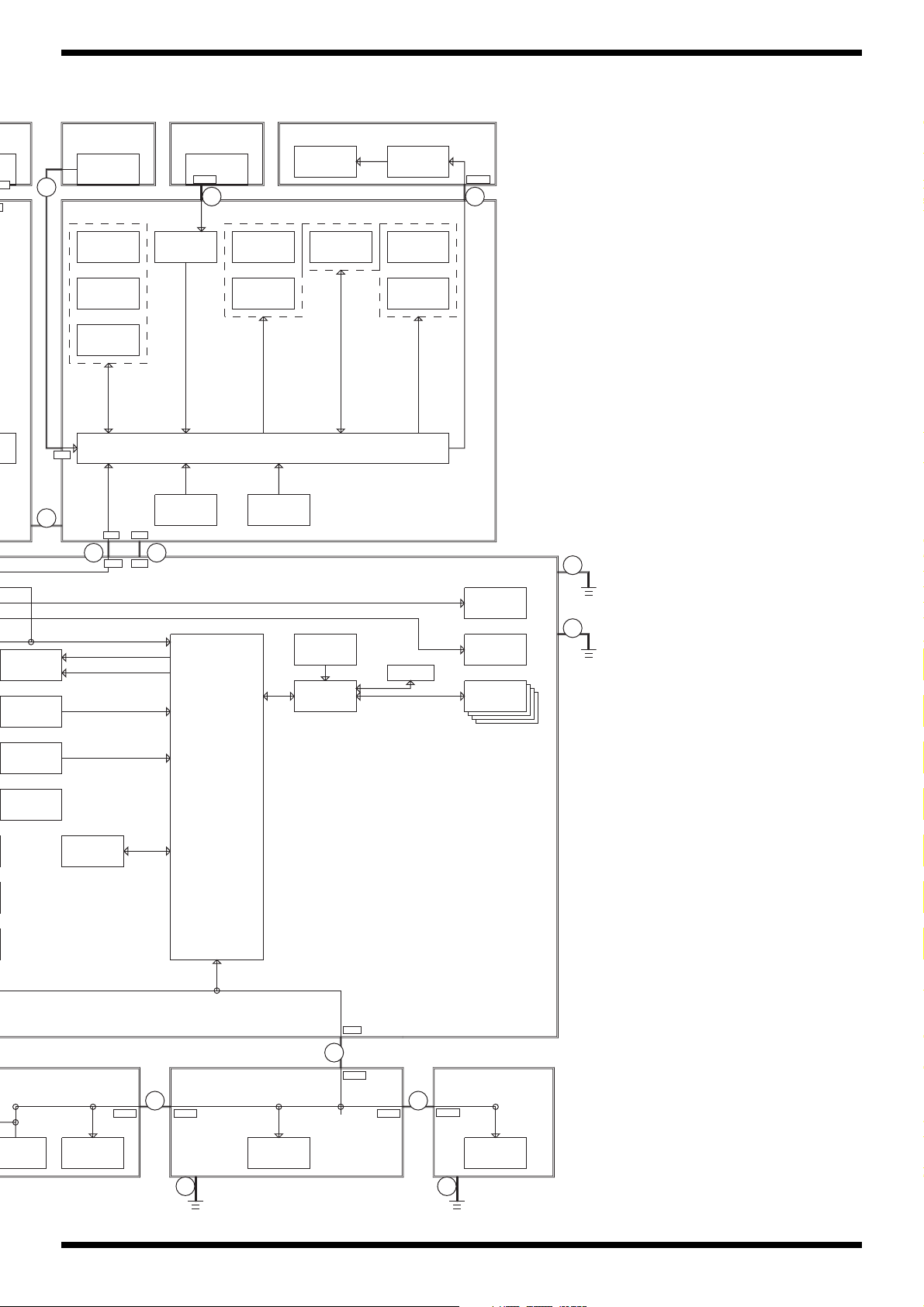

Wiring Diagram/Block Diagram..................................26

Parts List ...........................................................................29

The locations of the buttons using the operation .......33

Verifying the Version......................................................33

Data Backup and Restore Operations ..........................33

Updating the System ......................................................34

Performing a Factory Reset............................................35

Test Mode.........................................................................35

Copyright © 2016 Roland Corporation

All rights reserved. No part of this publication may be reproduced in any form without the written permission

of Roland Corporation.

CC-KWS17057052E0

Oct. 2016 DJ-808

Cautionary Notes

Before beginning the procedure, please read

through this document. The matters described may

differ according to the model.

Back Up User Data!

User data may be lost during the course of the procedure. Refer to Data

Backup and Restore Operations (p. 33) in the Service Notes and save the

data. After completing the procedure, restore the backed-up data to the

product.

Part Replacement

When replacing components near the power-supply circuit or a heatgenerating circuit (such as a circuit provided with a heat sink or including a

cement resistor), carry out the procedure according to the instructions with

respect to the part number, direction, and attachment position (mounting so as

to leave an air gap between the component and the circuit board, etc.).

Parts List

A component whose part code is ******** will not be supplied as a service part

because one of the following reasons applies.

• Because it is supplied as an assembled part (under a different part code).

• Because a number of circuit boards are grouped together and supplied as

a single circuit board (under a different part code).

• Because supply is prohibited due to copyright restrictions.

• Because reissuance is restricted.

• Because the part is made to order (at current market price).

• Because it is carried in electronic data on the Roland web site.

• Because it is a package or an accessory irrelevant to the function

maintenance of the main body.

• Because it can be replaced with an article on the market. (battery or etc.)

Circuit Diagram

In the circuit diagram, “NIU” is an abbreviation for “Not in Use,” and

“UnPop” is an abbreviation for “Unpopulated.” They both mean non-mounted

components. The circuit board and circuit board diagram show silk-screened

indications, but no components are mounted.

Roland Japan Warranty

Please send the problem report with followings when the defect occurred

within one year from production and within one month from the first

customer’s purchase.

• Model name:

• Serial number:

•Version:

• Purchase date by the first customer: yyyy/mm/dd

•Symptom:

• Frequency: always, sometimes or seldom

• Confirmed the symptom at your service dept: Yes/No

Please send the problem report to rjasc@roland.co.jp.

2

Oct. 2016 DJ-808

Specifications

Roland DJ-808: DJ Controller

Signal processing

Sampling Frequency = 96 kHz, 48 kHz, 44.1 kHz

A/D conversion: 24 bits

D/A conversion: 32 bits

Nominal input level

INPUT (1--4) (RCA phono type, LINE): -12 dBu

INPUT (1, 2) (RCA phono type, PHONO): -39 dBu

MIC IN (Combo type): -60 dBu

Nominal output level

MASTER OUT 1: +6 dBu (balanced)

MASTER OUT 2: +0 dBu

BOOTH OUT: +6 dBu (balanced)

Head room

18 dB

Input impedance

INPUT (1--4) (RCA phono type): 47 kΩ or greater

MIC IN (Combo type): 7 kΩ or greater

Output impedance

MASTER OUT 1: 600 Ω (balanced)

MASTER OUT 2: 1 kΩ (unbalanced)

BOOTH OUT: 600 Ω (balanced)

PHONES: 44 Ω

Frequency response

96.0 kHz: 20 Hz--40 kHz (+0/-2 dB)

48.0 kHz: 20 Hz--22 kHz (+0/-2 dB)

44.1 kHz: 20 Hz--20 kHz (+0/-2 dB)

Residual noise level

INPUT (1--4) --> MASTER OUTPUT 1: 83 dBu typ.

(GAIN knob: min., input terminated with 1 kΩ, channel fader: max., IHF-A,

typ.)

Dynamic range

MASTER OUT: 115 dB

BOOTH OUT: 115 dB

PHONES: 115 dB

Connectors

INPUT (1--4) jacks: RCA phono type

MIC IN jack: Combo type (XLR, 1/4 inch TRS phone (balanced))

MASTER OUT 1 jacks: XLR type (balanced)

MASTER OUT 2 jacks: RCA phono type

BOOTH OUT jacks: TRS phone type (balanced)

PHONES jacks: stereo 1/4 inch phone type, miniature phone type

USB Host ports: USB type A

PC port: USB type B

MIDI OUT connector

DC IN jack

PHONO GROUND terminal

Power supply

AC adaptor

Current draw

2,000 mA

Dimensions

668 (W) x 427 (D) x 84 (H) mm

26-5/16 (W) x 16-13/16 (D) x 3-5/16 (H) inches

Weight

6.8 kg (excluding AC adaptor)

15 lbs

Accessories

AC adaptor (#5100012293, #5100000692, #5100000564, #5100039367,

#5100018086, #05017301, #5100029122)

Power cord (#04236101)

Startup guide (#5100051467)

USB cable (#5100009897)

serato P’NT DJ EXPANSION PACK VOUCHER card (#********)

* 0dBu = 0.775Vrms

* Printed matters will not be supplied after the end of the production. Then,

download the electronic file from the Roland web site.

* In the interest of product improvement, the specifications and/or appearance of

this unit are subject to change without prior notice.

3

Oct. 2016 DJ-808

1 16 19

23 19

17

22

32

35

31

27

28

6

6 7 8 6 9 10 11 12 1332 4 14 15

6

26

25

33

A

18 19 20 21

29

30

24

5

36

34

A

B

C

Location of Controls (Top A)

fig.panel-top2.eps

4

Oct. 2016 DJ-808

Location of Controls (Top A) Parts List

No. Part Code Part Name Description Q’ty

1 5100052116 7SEG COVER 1

5100036722 LED A-364SRD 1

40122534 DOUBLE-FACED TAPE #500 W3MM 20M 136P -

2 5100052394 S-KEYTOP SX1H CLR SCALE 1

02891789 TACT SWITCH SKRGADD010 H=5.0 1

3 5100052396 S-KEYTOP SX1H CLR SHUFFLE 1

02891789 TACT SWITCH SKRGADD010 H=5.0 1

4 5100052423 S-KEYTOP LX1H CLR TR-REC 1

02891789 TACT SWITCH SKRGADD010 H=5.0 1

5 5100052424 S-KEYTOP LX1H CLR PATTERN 1

02891789 TACT SWITCH SKRGADD010 H=5.0 1

6 5100052410 S-KEYTOP SX2H CLR 1-2 6

02891789 TACT SWITCH SKRGADD010 H=5.0 12

7 5100052421 S-KEYTOP SX2H CLR BD-SD 1

02891789 TACT SWITCH SKRGADD010 H=5.0 1

8 5100052422 S-KEYTOP SX2H CLR CH-OH 1

02891789 TACT SWITCH SKRGADD010 H=5.0 1

9 5100052411 S-KEYTOP SX2H CLR 3-4 1

02891789 TACT SWITCH SKRGADD010 H=5.0 1

10 5100052412 S-KEYTOP SX2H CLR 5-6 1

02891789 TACT SWITCH SKRGADD010 H=5.0 1

11 5100052413 S-KEYTOP SX2H CLR 7-8 1

02891789 TACT SWITCH SKRGADD010 H=5.0 1

12 5100052400 S-KEYTOP SX1H CLR ACC 1

02891789 TACT SWITCH SKRGADD010 H=5.0 1

13 5100052438 C-KEYTOP MX1H CLR CLEAR 1

02891789 TACT SWITCH SKRGADD010 H=5.0 1

14 5100044011 KEY CAP CLR 16

5100052092 RUBBER SWITCH 8P 2

15 5100037191 J S-KNOB M BLK/LCG 4

5100052310 SLIDE POTENTIOMETER C3080G1AV1B103BF10BF 4

16 5100047832 SWITCH SL10020F-0203-15PA-SN 1

5100052452 DUST COVER S 1

17 5100044342 M R-KNOB LF-ELA BLK 1

5100051141 ENCODER XRE0125PVB20FINB1-2-24PCE/I 1

18 5100052398 S-KEYTOP SX1H CLR SYNC 1

02891789 TACT SWITCH SKRGADD010 H=5.0 1

19 5100009822 M R-KNOB(716-10014-01-00) MF-ELA-A BLK/LCG 6

5100041032 ROTARY POTENTIOMETER XV09223NPV25F972Z10K/I 6

20 5100052425 S-KEYTOP LX1H CLR SHIFT 1

02891789 TACT SWITCH SKRGADD010 H=5.0 1

21 5100044011 KEY CAP CLR 1

5100052093 RUBBER SWITCH 1P 1

22 5100052095 LED LENS A 1

23 5100052426 S-KEYTOP LX1H CLR AUTO PITCH 1

02891789 TACT SWITCH SKRGADD010 H=5.0 1

24 5100052446 R-KNOB KF-ELA BLK 1

5100038727 ENCODER RE111F-41B3-15F-20P-105 1

25 5100052436 S-KEYTOP LX1H CLR LOAD 4

02891789 TACT SWITCH SKRGADD010 H=5.0 4

26 5100052414 S-KEYTOP SX2H CLR BLK-BLK 1

02891789 TACT SWITCH SKRGADD010 H=5.0 2

27 5100052447 J R-KNOB MF-ELA BLK/LCG 5

5100048077 ROTARY POTENTIOMETER RK09L1140A2U 5

28 5100052102 LED COVER 6

29 5100052419 S-KEYTOP SX2H CLR DUB ECHO-JET 1

02891789 TACT SWITCH SKRGADD010 H=5.0 2

30 5100052420 S-KEYTOP SX2H CLR NOISE-FILTER 1

02891789 TACT SWITCH SKRGADD010 H=5.0 2

31 5100052437 S-KEYTOP LX1H CLR CUE 5

02891789 TACT SWITCH SKRGADD010 H=5.0 5

32 5100052449 J S-KNOB BLK 5

5100052877 SLIDE POTENTIOMETER C4591NOFV1B103BL0021 5

5100052453 DUST COVER M 5

33 5100053558 J R-KNOB MF-ELA MCG/LCG 12

5100048076 ROTARY POTENTIOMETER RK09L114001T 12

34 5100009822 M R-KNOB(716-10014-01-00) MF-ELA-A BLK/LCG 4

5100041031 ROTARY POTENTIOMETER XV09223NPV25F972Z10KCC/I 4

35 5100052449 J S-KNOB BLK 1

5100047833 SLIDE POTENTIOMETER RA45D1LF-211-20C1-B10K 1

5100052453 DUST COVER M 1

36 5100052447 J R-KNOB MF-ELA BLK/LCG 4

5100048076 ROTARY POTENTIOMETER RK09L114001T 4

5

Oct. 2016 DJ-808

Location of Controls (Top B)

fig.panel-top3.eps

A

B

B

2 45316

C

16

17

18

19

20

21

1

6

7

25242322

27

26

8

9

10

11

12

13

14

15

6

Oct. 2016 DJ-808

Location of Controls (Top B) Parts List

No. Part Code Part Name Description Q’ty

1 5100052428 S-KEYTOP LX1H CLR ON 3

02891789 TACT SWITCH SKRGADD010 H=5.0 3

2 5100052447 J R-KNOB MF-ELA BLK/LCG 3

5100048077 ROTARY POTENTIOMETER RK09L1140A2U 3

3 5100052448 J R-KNOB MF-ELA BLK 1

5100038727 ENCODER RE111F-41B3-15F-20P-105 1

4 5100052395 S-KEYTOP SX1H CLR Q 1

02891789 TACT SWITCH SKRGADD010 H=5.0 1

5 5100052393 S-KEYTOP SX1H CLR PANEL 1

02891789 TACT SWITCH SKRGADD010 H=5.0 1

6 5100052450 S-KNOB BLK 1

5100052775 SLIDE POTENTIOMETER RFA0N12K6505 1

7 5100052443 C-KEYTOP MX1H CLR BLK 2

02891789 TACT SWITCH SKRGADD010 H=5.0 2

8 5100052397 S-KEYTOP SX1H CLR ADJ 1

02891789 TACT SWITCH SKRGADD010 H=5.0 1

9 5100052399 S-KEYTOP SX1H CLR SLIDE 1

02891789 TACT SWITCH SKRGADD010 H=5.0 1

10 5100052439 C-KEYTOP MX1H CLR 1 1

02891789 TACT SWITCH SKRGADD010 H=5.0 1

11 5100052441 C-KEYTOP MX1H CLR 3 1

02891789 TACT SWITCH SKRGADD010 H=5.0 1

12 5100052434 S-KEYTOP LX1H CLR SAMPLER 1

02891789 TACT SWITCH SKRGADD010 H=5.0 1

13 5100052425 S-KEYTOP LX1H CLR SHIFT 1

02891789 TACT SWITCH SKRGADD010 H=5.0 1

14 5100052435 S-KEYTOP LX1H CLR SYNC 1

02891789 TACT SWITCH SKRGADD010 H=5.0 1

15 5100052445 KEYTOP UNIT CUE & PLAY/PAUSE 1

02891789 TACT SWITCH SKRGADD010 H=5.0 2

16 5100052096 LED LENS B 2

17 5100052429 S-KEYTOP LX1H CLR KEY SYNC 1

02891789 TACT SWITCH SKRGADD010 H=5.0 1

18 5100052415 S-KEYTOP SX2H CLR DOWN-UP 1

02891789 TACT SWITCH SKRGADD010 H=5.0 2

19 5100052431 S-KEYTOP LX1H CLR HOT CUE 1

02891789 TACT SWITCH SKRGADD010 H=5.0 1

20 5100052430 S-KEYTOP LX1H CLR AUTO LOOP 1

02891789 TACT SWITCH SKRGADD010 H=5.0 1

21 5100052416 S-KEYTOP SX2H CLR 1/2X-2X 1

02891789 TACT SWITCH SKRGADD010 H=5.0 2

22 5100052417 S-KEYTOP SX2H CLR IN-OUT 1

02891789 TACT SWITCH SKRGADD010 H=5.0 2

23 5100052418 S-KEYTOP SX2H CLR -/+ 1

02891789 TACT SWITCH SKRGADD010 H=5.0 2

24 5100052432 S-KEYTOP LX1H CLR ROLL 1

02891789 TACT SWITCH SKRGADD010 H=5.0 1

25 5100052091 RUBBER SWITCH 4X2P 1

5100052090 PRESSURE SHEET SENSOR 1

26 5100052427 S-KEYTOP LX1H CLR TAP 1

02891789 TACT SWITCH SKRGADD010 H=5.0 1

27 5100052433 S-KEYTOP LX1H CLR TR 1

02891789 TACT SWITCH SKRGADD010 H=5.0 1

7

Oct. 2016 DJ-808

Location of Controls (Top C)

fig.panel-top4.eps

A

B

C

C

2 1 13

10

11

12

4

5

6

7

8

9

14

3

25

24

13

23

22

21

20

18 19171615

8

Oct. 2016 DJ-808

Location of Controls (Top C) Parts List

No. Part Code Part Name Description Q’ty

1 5100052448 J R-KNOB MF-ELA BLK 1

5100048077 ENCODER RE111F-41B3-15F-20P-105 1

2 5100052447 J R-KNOB MF-ELA BLK/LCG 4

5100048077 ROTARY POTENTIOMETER RK09L1140A2U 4

3 5100052427 S-KEYTOP LX1H CLR TAP 1

02891789 TACT SWITCH SKRGADD010 H=5.0 1

4 5100052428 S-KEYTOP LX1H CLR ON 3

02891789 TACT SWITCH SKRGADD010 H=5.0 3

5 5100052397 S-KEYTOP SX1H CLR ADJ 1

02891789 TACT SWITCH SKRGADD010 H=5.0 1

6 5100052399 S-KEYTOP SX1H CLR SLIDE 1

02891789 TACT SWITCH SKRGADD010 H=5.0 1

7 5100052440 C-KEYTOP MX1H CLR 2 1

02891789 TACT SWITCH SKRGADD010 H=5.0 1

8 5100052442 C-KEYTOP MX1H CLR 4 1

02891789 TACT SWITCH SKRGADD010 H=5.0 1

9 5100052431 S-KEYTOP LX1H CLR HOT CUE 1

02891789 TACT SWITCH SKRGADD010 H=5.0 1

10 5100052425 S-KEYTOP LX1H CLR SHIFT 1

02891789 TACT SWITCH SKRGADD010 H=5.0 1

11 5100052435 S-KEYTOP LX1H CLR SYNC 1

02891789 TACT SWITCH SKRGADD010 H=5.0 1

12 5100052445 KEYTOP UNIT CUE & PLAY/PAUSE 1

02891789 TACT SWITCH SKRGADD010 H=5.0 2

13 5100052096 LED LENS B 2

14 5100052432 S-KEYTOP LX1H CLR ROLL 1

02891789 TACT SWITCH SKRGADD010 H=5.0 1

15 5100052091 RUBBER SWITCH 4X2P 1

5100052090 PRESSURE SHEET SENSOR 1

16 5100052433 S-KEYTOP LX1H CLR TR 1

02891789 TACT SWITCH SKRGADD010 H=5.0 1

17 5100052418 S-KEYTOP SX2H CLR -/+ 1

02891789 TACT SWITCH SKRGADD010 H=5.0 2

18 5100052417 S-KEYTOP SX2H CLR IN-OUT 1

02891789 TACT SWITCH SKRGADD010 H=5.0 2

19 5100052416 S-KEYTOP SX2H CLR 1/2X-2X 1

02891789 TACT SWITCH SKRGADD010 H=5.0 2

20 5100052430 S-KEYTOP LX1H CLR AUTO LOOP 1

02891789 TACT SWITCH SKRGADD010 H=5.0 1

21 5100052434 S-KEYTOP LX1H CLR SAMPLER 1

02891789 TACT SWITCH SKRGADD010 H=5.0 1

22 5100052415 S-KEYTOP SX2H CLR DOWN-UP 1

02891789 TACT SWITCH SKRGADD010 H=5.0 2

23 5100052429 S-KEYTOP LX1H CLR KEY SYNC 1

02891789 TACT SWITCH SKRGADD010 H=5.0 1

24 5100052443 C-KEYTOP MX1H CLR BLK 2

02891789 TACT SWITCH SKRGADD010 H=5.0 2

25 5100052450 S-KNOB BLK 1

5100052775 SLIDE POTENTIOMETER RFA0N12K6505 1

9

Oct. 2016 DJ-808

Location of Controls (Front)

fig.panel-front.eps

1 2 3 4 5 6

Location of Controls (Front) Parts List

No. Part Code Part Name Description Q’ty

1 13449275 6.5MM JACK YKB21-5074 1

2 02456390 3.5MM JACK STEREO YKB21-5290 1

3 5100009822 M R-KNOB(716-10014-01-00) MF-ELA-A BLK/LCG 1

02125778 9M/M ROTARY POTENTIOMETER RK09L12B0 1

4 5100009822 M R-KNOB(716-10014-01-00) MF-ELA-A BLK/LCG 1

03560512 ROTARY POTENTIOMETER RK09L112003P 1

5 5100052089 S-KNOB 1

5100051485 SWITCH SKV-22F01-G6-TA 1

6 5100052089 S-KNOB 10

5100051488 SWITCH SKV-23F01-G6-TA 10

10

Oct. 2016 DJ-808

Location of Controls (Rear)

fig.panel-rear.eps

1 2 3 4 10 15 126 7 8 9 9 11

Location of Controls (Rear) Parts List

No. Part Code Part Name Description Q’ty

1 5100027106 CORD HOOK 40516-014 2

2 02341634 DC JACK HTJ-020-05A 1

3 5100037825 G S-BUTTON BLK (710-12058-15-00) 1

5100052451 POWER SWITCH ESCUTCHEON 1

04904123 PUSH SWITCH AC POWER SUPPLY 400-07040-01-00(PWL-2P2T-6SBP 1

4 5100009822 M R-KNOB(716-10014-01-00) MF-ELA-A BLK/LCG 1

13289231 POTENTIOMETER RK09L1120A14 1

5 5100013062 CANNON CONNECTOR CT/PJ-02-07EP 1

6 5100030795 CANNON CONNECTOR CT3-05M-01-EP(F3439960R0) 2

7 03234590 RCA(PIN) JACK YKC21-3503 1

8 13449275 6.5MM JACK YKB21-5074 2

9 03345778 JACK YKC21-3473 2

10 13429672 MIDI JACK YKF51-5047 1

11 5100007091 USB CONNECTOR UAR62-8K5J00(F3439907R0) 1

12 02781101 USB CONNECTOR B TYPE FEMALE YKF45-0020N 1

11

Oct. 2016 DJ-808

27

26

14

25

24

16

20

19

7

8

10

22

18

17

15

9

13

11

12

23

23

21

21

28

a

b

a

a

a

b

b

b

View 1

View 2

View 5

View 4

View 3

View 6

View 7

RR

Refer to Location of Controls (Top A) (p. 4).

Refer to Location of Controls (Top C) (p. 8).

Refer to Location of Controls (Top B) (p. 6).

Refer to Exploded View (Fig. A) (p. 18).

Exploded View (1)

fig.bunkai-2-e.eps

12

Oct. 2016 DJ-808

Exploded View Parts List (1)

No. Part Code Part Name Description Q’ty

7 5100052098 VOLUME HOLDER 1

5100050272 PANEL C SHEET ASSY 1

8 ******** PANEL C BOARD 1

15 ******** FRONT U BOARD 1

16 ******** FRONT L BOARD 1

11 ******** PANEL L SPACER 1

12 ******** PANEL R SPACER 1

18 ******** PHONES SPACER 1

9 ******** PANEL L BOARD 1

10 ******** PANEL R BOARD 1

* This unit includes the following parts.

******** CROSSFADER BOARD Refer to Exploded View (Fig. A) (p. 18). 1

5100050281 PANEL L SHEET ASSY 1

* This unit includes the following parts.

******** ENCODER BOARD Refer to Exploded View (Fig. A) (p. 18). 1

******** LEAF BOARD Refer to Exploded View (Fig. A) (p. 18). 1

******** LED BOARD Refer to Exploded View (Fig. A) (p. 18). 1

5100050290 PANEL R SHEET ASSY 1

* This unit includes the following parts.

******** ENCODER BOARD Refer to Exploded View (Fig. A) (p. 18). 1

******** LEAF BOARD Refer to Exploded View (Fig. A) (p. 18). 1

******** LED BOARD Refer to Exploded View (Fig. A) (p. 18). 1

13 5100050270 MAIN BOARD ASSY 1

5100050265 JACK SHEET ASSY 1

14 ******** JACK BOARD 1

17 ******** PHONES BOARD 1

19 5100052455 SHIELD SHEET 1

20 5100052452 DUST COVER S 1

21 5100052089 S-KNOB 11

22 02124112 STANDOFF M3 L16C 3

23 5100009822 M R-KNOB(716-10014-01-00) MF-ELA-A BLK/LCG 3

24 5100037825 G S-BUTTON BLK (710-12058-15-00) 1

25 5100052451 POWER SWITCH ESCUTCHEON 1

26 5100052097 PWB CHASSIS 1

27 5100051448 BOTTOM CASE 1

28 5100052118 FOOT 6

a ******** NUT attached to Rotary Potentiometer 30

b ******** WASHER attached to Rotary Potentiometer 30

* This unit includes the following parts.

13

Oct. 2016 DJ-808

Plain View (1)

fig.heimen2-1.eps

View 1

View 2

b

b

b

31

b

b b

b

db

b

View 1

No. Part Code Part Name Description Q’ty

b 40011312 SCREW 3X8 BINDING TAPTITE P FE BZC 54

31 40120967 COATING CLIP CS-3 1

View 2

No. Part Code Part Name Description Q’ty

b 40011312 SCREW 3X8 BINDING TAPTITE P FE BZC 17

d 40237101 SCREW M3X8 PAN MACHINE W/SW+SMALL PW BZC 3

14

Oct. 2016 DJ-808

Plain View (2)

fig.heimen2-2.eps

View 3

View 4

b

i

d

d

View 3

No. Part Code Part Name Description Q’ty

b 40011312 SCREW 3X8 BINDING TAPTITE P FE BZC 10

d 40237101 SCREW M3X8 PAN MACHINE W/SW+SMALL PW BZC 1

View 4

No. Part Code Part Name Description Q’ty

d 40237101 SCREW M3X8 PAN MACHINE W/SW+SMALL PW BZC 3

i 40011090 SCREW 3X6 BINDING TAPTITE B BZC 6

15

Oct. 2016 DJ-808

Plain View (3)

fig.heimen2-3.eps

View 5

b

View 6

View 7

b

b d d

ad dh

b

16

e

Oct. 2016 DJ-808

View 5

No. Part Code Part Name Description Q’ty

b 40011312 SCREW 3X8 BINDING TAPTITE P FE BZC 21

View 6

No. Part Code Part Name Description Q’ty

a 5100052875 SCREW 2.6X10 FLAT TAPTITE P BZC 2

b 40011312 SCREW 3X8 BINDING TAPTITE P FE BZC 2

d 40237101 SCREW M3X8 PAN MACHINE W/SW+SMALL PW BZC 4

h 5100053890 SCREW M3X15 FOR GND 1

5100054060 PLAIN WASHER 3X10X1 NI 1

View 7

No. Part Code Part Name Description Q’ty

e 40010512 SCREW M3X8 FLAT MACHINE BZC 6

17

Oct. 2016 DJ-808

38

36

39

35

40

33

30

28

20

14

24

27

27

24

14

41

42

26

26

26

18

7

7

2

5

5

4

3

1

8

1

20

15

15

19

21

21

23

22

17

18

18

16

13

12

11

6

9

33

29

31

32

34

37

View 2View 4

View 1

View 3

44

45

46

43

Exploded View (Fig. A)

fig.bunkai-1.eps

18

Oct. 2016 DJ-808

Exploded View Parts List (Fig. A)

No. Part Code Part Name Description Q’ty

1 5100052448 J R-KNOB MF-ELA BLK 2

2 5100052446 R-KNOB KF-ELA BLK 1

3 5100053558 J R-KNOB MF-ELA MCG/LCG 12

4 5100044342 M R-KNOB LF-ELA BLK 1

5 5100009822 M R-KNOB(716-10014-01-00) MF-ELA-A BLK/LCG 10

6 5100037191 J S-KNOB M BLK/LCG 4

7 5100052450 S-KNOB BLK 2

8 5100052447 J R-KNOB MF-ELA BLK/LCG 16

9 5100052449 J S-KNOB BLK 6

11 5100052104 PLATTER COVER 2

12 5100052103 LED SHEET 2

13 5100052082 LED ESCUTCHEON TOP 2

5100050281 PANEL L SHEET ASSY 1

14 ******** LED BOARD C 1

15 ******** ENCODER BOARD A 1

20 ******** LEAF BOARD B 1

14 ******** LED BOARD The same part as C mentioned above 1

15 ******** ENCODER BOARD The same part as A mentioned above 1

20 ******** LEAF BOARD The same part as B mentioned above 1

* This unit includes the following parts.

******** PANEL L BOARD Refer to Exploded View (1) (p. 12). 1

5100050290 PANEL R SHEET ASSY 1

* This unit includes the following parts.

******** PANEL R BOARD Refer to Exploded View (1) (p. 12). 1

16 5100052083 LED ESCUTCHEON BOTTOM 2

17 5100052088 PLATTER SHEET 2

18 5100052115 CLIP S 2

19 5100052081 PLATTER 2

21 5100052105 PLATTER SPACER 2

22 5100052099 WHEEL PLATE 2

23 5100052456 CODE WHEEL 2

24 5100052100 ENCODER HOLDER 2

26 5100052114 CLIP L 2

27 5100052094 RING 2

28 5100052086 TOP PANEL C 1

29 5100052084 TOP PANEL L 1

30 5100052085 TOP PANEL R 1

31 5100052087 FADER PANEL 1

32 5100052102 LED COVER 6

33 5100052454 DUST COVER L 2

34 5100052453 DUST COVER M 6

35 5100052117 FADER HOLDER 1

5100050272 PANEL C SHEET ASSY 1

36 ******** CROSSFADER BOARD 1

37 5100027106 CORD HOOK 40516-014 2

38 5100051447 TOP CASE 1

39 40122534 DOUBLE-FACED TAPE #500 W3MM 20M 136P 40 40122490 DOUBLE-FACED TAPE #500 W5MM 20M 40P 41 5100052990 WIRING J-2 2

42 5100052989 WIRING J-1 2

43 5100052984 E-RING 24X12X1 2

44 5100052101 PLATTER ANGLE 2

45 5100052983 PLAIN WASHER 5X10X1 ZC 2

46 40129890 HEX NUT M5 ZC 2

* This unit includes the following parts.

******** FRONT L BOARD Refer to Exploded View (1) (p. 12). 1

******** FRONT U BOARD Refer to Exploded View (1) (p. 12). 1

******** PANEL C BOARD Refer to Exploded View (1) (p. 12). 1

* When attaching the Top Panel L (29) and the Top Panel R (30) to the Top Case (38), apply a load enough not to peel off even if time has passed.

Because especially the area around the buttons and outer circumference are raised easily, press it firmly.

A rough indication: apply a load of 2 kg or more per square centimeter for 3 seconds or longer.

19

Oct. 2016 DJ-808

Plain View (Fig. A) (1)

fig.heimen1-1.eps

View 1

View 2

a

c c

a

bb

View 3

View 4

f

b

b

f

b

g

b

b

20

Oct. 2016 DJ-808

View 1

No. Part Code Part Name Description Q’ty

a 5100052875 SCREW 2.6X10 FLAT TAPTITE P BZC 18

b 40011312 SCREW 3X8 BINDING TAPTITE P FE BZC 8

c 40235134 SCREW 2X6 PAN MACHINE W/SW+PW ZC 4

View 2

No. Part Code Part Name Description Q’ty

b 40011312 SCREW 3X8 BINDING TAPTITE P FE BZC 10

f 5100038406 SCREW 2.6X6 BINDING TAPTITE P BZC 2

View 3

No. Part Code Part Name Description Q’ty

b 40011312 SCREW 3X8 BINDING TAPTITE P FE BZC 2

g 40342712 SCREW M3X6 PAN MACHINE W/SW+SMALL PW BZC 2

View 4

No. Part Code Part Name Description Q’ty

b 40011312 SCREW 3X8 BINDING TAPTITE P FE BZC 8

21

Oct. 2016 DJ-808

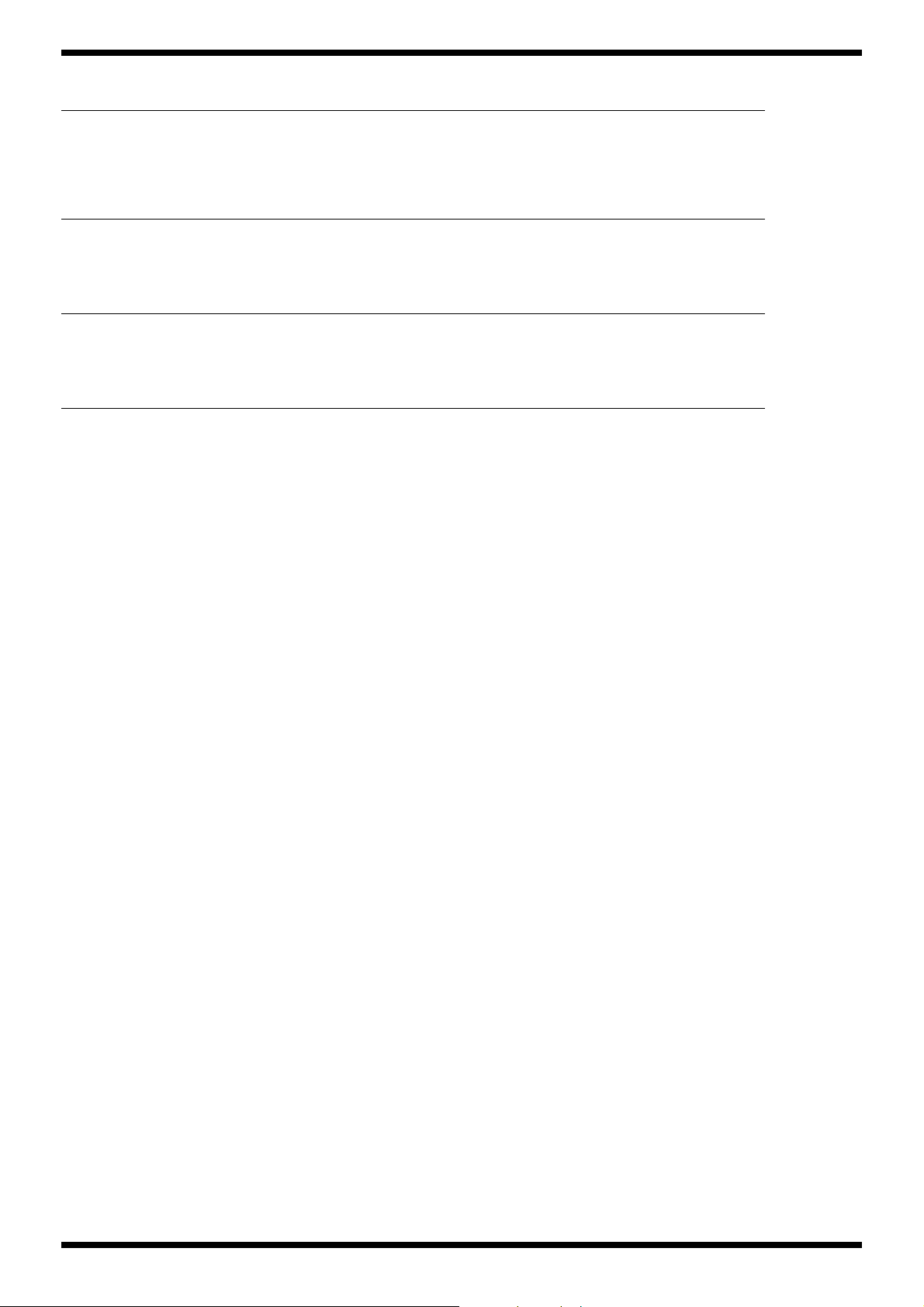

Gray

Red

Orange

Yellow

Green

White

Polish

Disassembly Procedure

Detaching the Bottom Case

* Each part number written in parenthesis corresponds to the number in

Exploded View (1) (p. 12).

1. Remove the screws b (x 21) securing the Bottom Case (27). (Plain View

(3) (p. 16), View 5)

2. Detach the Bottom Case.

Detaching the Circuit Board

* Each part number written in parenthesis corresponds to the number in

Exploded View (1) (p. 12).

1. Remove the screw h (x 1), the washers h (x 1) and d (x 4) securing the

PWB Chassis (26) from the rear side. (Plain View (3) (p. 16), View 6)

2. Remove the screws b (x 5) securing the Main Board (13) and the Jack

Board (14) to the Bottom Case (27) and remove the screws b (x 5)

securing the GND wire around these circuit boards. (Plain View (1) (p.

14), View 2)

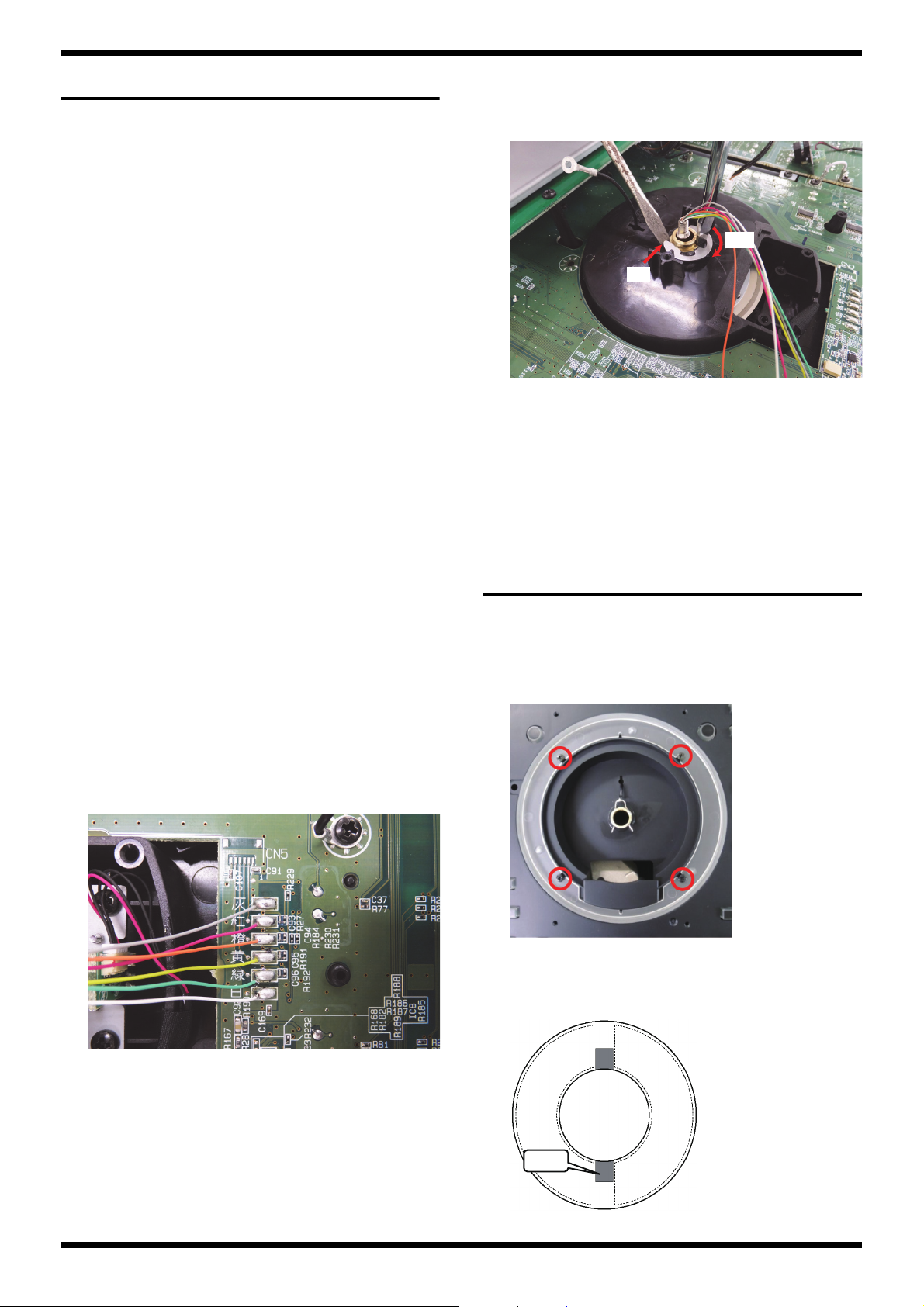

3. Lift the PWB Chassis gently and disconnect the connectors around the

circuit board.

* The number of pins of CN5, CN6 and CN8 on the Main Board are the same.

Correct connections are as shown below. However, the product is not corrupted

even if the connections are incorrect because the currents of the same voltage are

supplied.

Main Board CN5 -> Panel-R Board CN2

Main Board CN6 -> Panel-C Board CN2

Main Board CN8 -> Panel-L Board CN2

4. Detach the Sub Chassis.

* When detaching the Panel C Board (8), the Panel L Board (9) and the Panel R

Board (10), remove the corresponding knobs on the panel, the Front U Board

(15), the Front L Board (16) and the Phones Board (17) first.

Detaching the Platter

* Each part number written in parenthesis corresponds to the number in

Exploded View (Fig. A) (p. 18).

1. Peel off the acetate tape on the wirings coming out from the center of the

Platter (19) and soldered to the Panel L and R Board, and then remove the

solder.

* When assembling, connect (solder) each wirings as shown below.

fig.assemble-platter-24.eps

4. Remove the E-Ring (43).

Fix the edge of the E-Ring with a flathead screwdriver and insert the

another flathead screwdriver into the hole of the E-Ring, and turn it 90

degrees (in case of the figure, to the clockwise direction).

fig.bunkai-tejun-1-e.eps

Turn

Fix

Fix the flathead screwdriver that you turned as it is, insert the flathead

screwdriver that fixed the edge of the E-Ring into another hole and turn

to the opposite direction (in case of the figure, to the counterclockwise

direction) to remove.

* If the pipe of the Platter has a large damage, to remove from the Top Case may be

difficult. Be careful not to damage it.

* Never reuse the E-Ring which has been removed once, replace it with new one.

5. Hold down the pip of the Platter and press out toward to the Top Case,

then detach it.

Assembling the Platter

* Each part number written in parenthesis corresponds to the number in

Exploded View (Fig. A) (p. 18).

Attaching the Ring

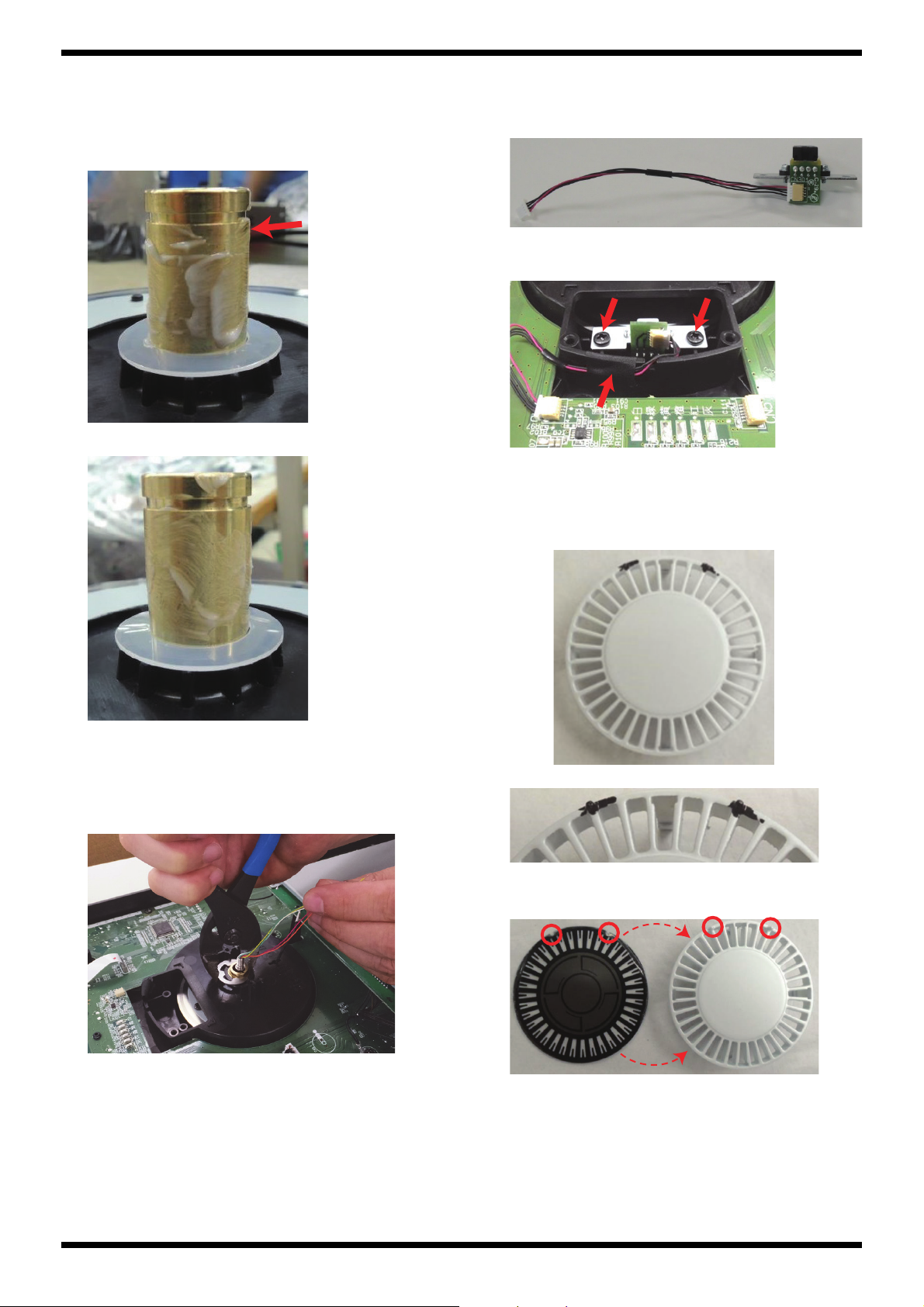

1. Attach the Ring (27) to the Top Case.

fig.assemble-platter-16.eps

Gray

Red

Orange

Yellow

Green

White

2. Remove the nut (46), the washer (45) and the screw and remove the

Platter Angle (44).

3. Remove the Encoder Board (15) and the Encoder Holder (24).

22

Platter Sheet

2. To keep the conductive property of the Platter Sheet (17), polish lightly a

masking area on the back with a sandpaper and remove an oxide film.

fig.assemble-platter-1.eps

from

bottom View

Oct. 2016 DJ-808

3. Affix the Platter Sheet to the Platter (19). At this time, align the masking

area of the Patter Sheet with the hole of the Platter.

fig.assemble-platter-2.eps

* When affixing, apply a load enough not to peel off even if time has passed.

A rough indication: apply a load of 2 kg or more per square centimeter for 3

seconds or longer.

Attaching the Leaf Board

4. Attach the Leaf Board (20) to the Platter.

* Verify that the Leaf is not deformed.

fig.assemble-platter-3.eps

7. Turn the Clip S to set the position as shown in the figure.

* Be careful to ensure that the wiring does not have slack.

fig.assemble-platter-6.eps

Attaching the Code Wheel and the Platter

Spacer

8. Align the holes (arrows in the figure) of the Code Wheel (23) with the

protrusion on the Platter and place it.

fig.assemble-platter-7.eps

Attaching the Clip S

5. After passing the Wiring J-2 (41) through the hole of the Platter, solder

the Clip S (18) to the tip of the wiring.

* To avoid the interference with the Platter, orient the Clip S as shown in the

figure and solder it.

fig.assemble-platter-4.eps

6. Fit the Clip S into the groove of the pipe at the center of the Platter.

fig.assemble-platter-5.eps

9. Place the Wheel Plate (22) and fix it with the screws.

fig.assemble-platter-8.eps

10. Pass the Platter Spacer (21) through the pipe of the Platter.

fig.assemble-platter-9.eps

23

Oct. 2016 DJ-808

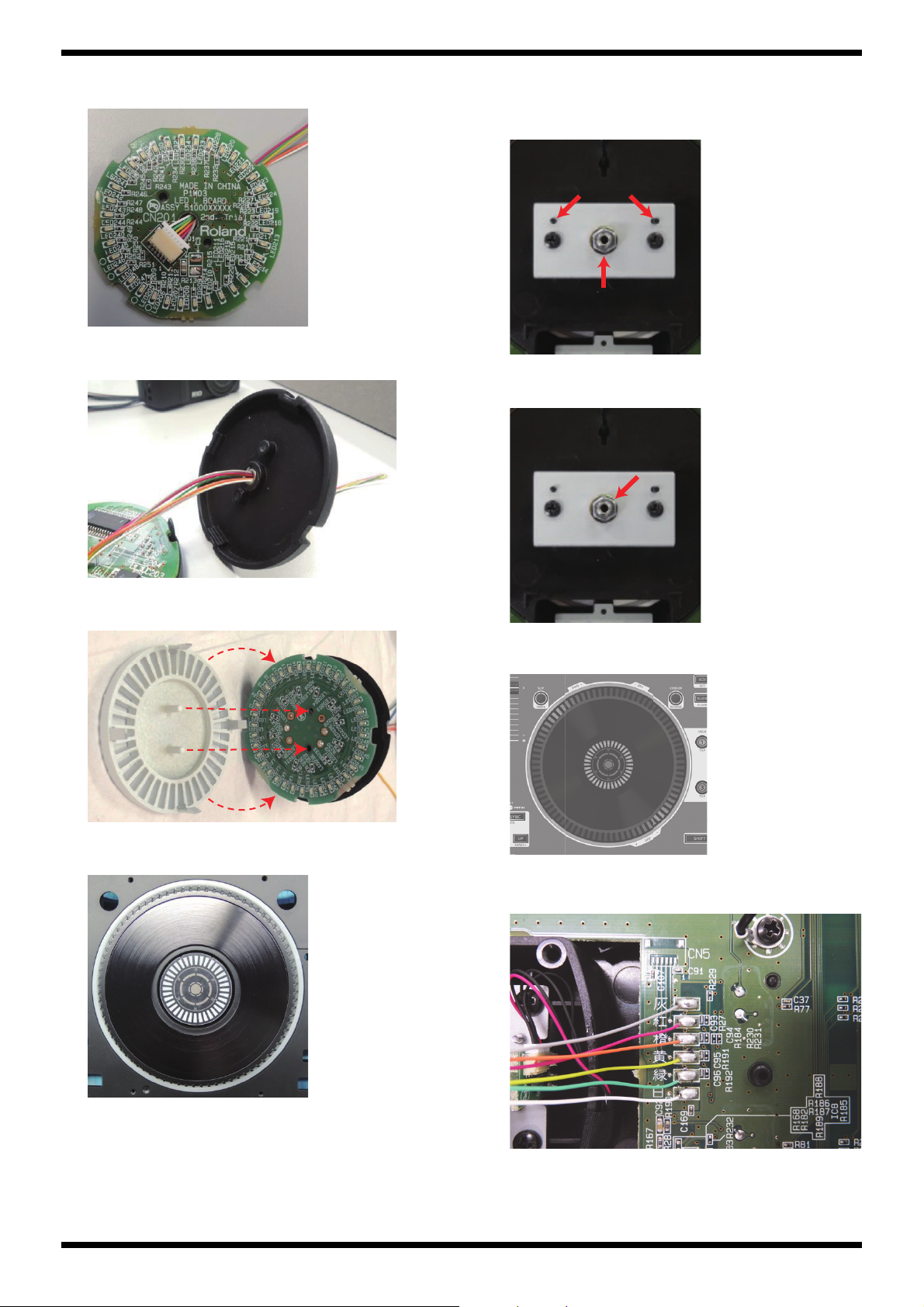

Application of grease

11. Apply grease to the pipe of the Platter.

Apply it to the lower part of the groove (arrows in the figure). As a result

of this, grease spreads entirely when assembling. Refer to the following

figure for the amount of coating.

fig.assemble-platter-10.eps

OK

fig.assemble-platter-11.eps

Attaching the Encoder Board

13. Connect the WIRING 3302#32 4X100-SHR-SHR-F (#5100052977) to the

Encoder Board (15) and attach it to the Encoder Holder (24).

fig.assemble-platter-18.eps

14. Attach the unit described above to the Top Case and secure the wirings

with the acetate tape.

fig.assemble-platter-19.eps

Attaching the LED Board and the LED

Escutcheon

15. Paint the protrusions on the Escutcheon Top (13) black with a felt-tip pen.

fig.assemble-platter-13.eps

Not enough

Attaching the Platter and the E-Ring

12. Pass the assembled Platter unit through the hole of the Top Case and fit

the E-Ring (43) into the groove on the pipe of the Platter.

fig.assemble-platter-17.eps

* In the example of this picture, the LED Board is already attached. In this case, be

careful not to scratch the wirings.

* Originally, we recommend the following method—grasp the inside of the pipe of

the Platter and the E-Ring with needle nose pliers and fit the E-Ring into the

groove before attaching the LED Board. This makes the outer surface of the pipe

avoid to damage itself.

* Never reuse the E-Ring which has been removed once, replace it with new one.

16. Peel off the backing paper of the LED Sheet (12) and align the notches of

the LED Sheet to the protrusions on the Escutcheon Top.

fig.assemble-platter-15.eps

17. Peel off the protective sheet on the surface of the LED Sheet.

24

Oct. 2016 DJ-808

GrayGray

RedRed

OrangeOrange

YellowYellow

GreenGreen

WhiteWhite

18. Pass the WIRING 3302#32 6X160-SHR (#5100052978) through the hole of

the LED Board (14) and connect it to the connector.

fig.assemble-platter-12.eps

19. Pass the wirings described above through the hole of the LED Escutcheon

Bottom.

fig.assemble-platter-25.eps

22. Align the holes of the Platter Angle (44) with the protrusions on the Top

Case and align the notch of the pipe of the LED Escutcheon Bottom with

the notch of the hole of the Platter Angle further and secure it with

screws.

fig.assemble-platter-20-e.eps

Align them with the protrusions

on the Top Case.

Align the notch.

23. Secure the pipe of the LED Escutcheon Bottom with the washer (45) and

the nut (46).

fig.assemble-platter-21.eps

20. Put the LED Board between the LED Escutcheon Top and the LED

Escutcheon Bottom and assemble them.

fig.assemble-platter-14.eps

21. Put the unit described above in the center of the Platter from the upper

side of the Top Case.

fig.assemble-platter-23.eps

* At this time, align the rotation angle of the Platter Sheet on the surface as shown

in the figure and tighten the nut.

fig.assemble-platter-26.eps

24. Apply the thread-locking fluid to the nut.

25. Solder the wirings as shown in the figure and affix the acetate tape.

fig.assemble-platter-24.eps

25

Oct. 2016 DJ-808

Rotary

Volume

Slide

Volume

PAD

STM32F100V

PANEL CPU

LED IC

BU2090

LED

3color

LED

Light

ENC

Rotary

ENC

Tact

Switch

Rotary

Volume

Slide

Volume

Rotary

Enc

Swtich

LED

Multi

plex

BU2090

LED IC

DC IN

PSB-1U

POWER

SW

M.OUT

XLR

M.OUT

PIN

B.OUT

TS

IN CH4

PIN

IN CH3

PIN

IN CH2

PIN

IN CH1

PIN

MIC

COMBO

TLC

LED IC

STM32F100V

PANEL CPU

LT3580

DC/DC

A+15V

AK5357

ADC

PCM

AK4458

DAC

ESC2

MASTER

SDRAM

SYSTEM

SDRAM

EFFECT

FLASH

24MHz

X'tal

PCM1865

ADC

PCM1865

ADC

AT42QT

TOUCH

24MHz

X'tal

I2C

UART

20MHz

20MHz

Phono

Phono

I2S

Bus

Bus

SFI

Select

48MHz

USB

UART

UART

PANEL L BOARD PANEL C BOARD

JACK BOARD

MAIN

BOARD

I2C

MIC

VR

A-15V

LT3580

DC/DC

Reg

A+7V

Reg

A-7V

UART

UART

I2S/TDM

MCK/BCK/LRCK

MCK/BCK/LRCK

MCK/BCK/LRCK

MCK/BCK/LRCK

MCLK LRCK BCK

I2S x 4

I2C

I2C

I2C

I2S/TDM

I2S/TDM

LED BOARD

Reg

D+1.2V

R1240N

DC/DC

A+3.3V

R1240N

DC/DC

D+3.3V

A+5.0VA+5.5V

D+5.0V

Reg

LED5.0V

R1240N

DC/DC

R1242S

DC/DC

Phones

Ro

Vo

PHONES BOARD

LED

BU2151

LED IC

ENCORDER

BOARD

LEAF

BOARD

LEAF

Slide

Volum

CROSSFAD

BOARD

13

14 15 16

4

5

6

18

3

1

1

2

1017 17 17 17 17 17

CN10

CN5

CN4

CN2

CN4

CN3

CN9

CN3

CN2

CN3

CN7

CN2

CN4

CN9

CN401 CN201

CN501

CN6

CN4

CN8

CN1

Wiring Diagram/Block Diagram

fig.block.eps@L

26

Oct. 2016 DJ-808

MIDI

OUT

USB

LINK

USB

PC

AK4128

SRC

X'tal

ESC2

SLAVE

X'tal

X'tal

48MHz

18.432MHz

16.9344MHz

SDRAM

SYSTEM

USB2514

HUB IC

UART

24MHz

X'tal

HS SW

Bus

18.432MHz

48MHz

I2S x 4

USB

UART

USB USB

MCLK LRCK BCK

Slide

Switch

Slide

Switch

FRONT U BOARD FRONT L BOARD

Slide

Switch

TOUCH

AT42QT

24MHz

X'tal

I2C

20MHz

TLC

TOUCH

LED

BU2151

LED IC

Slide

Volume

PAD

STM32F100V

PANEL CPU

ENCORDER

BOARD

LEAF

BOARD

LEAF

LED BOARD

PANEL R BOARD

Rotary

Volume

BU2090

LED IC

LED

3color

LED

Light

ENC

Rotary

ENC

Tact

Switch

13

14 15

7 8

18

17

11 12

9

17

17

17

CN4

CN401 CN201

CN501

CN503CN502CN502

CN601

CN3

CN11

CN12

CN2

CN5

fig.block.eps@R

27

Oct. 2016 DJ-808

No. Part Code Part Name Description Q’ty

1 5100052976 WIRING 1061#28 16X60-PHR-PHR-F 2

2 5100052973 WIRING 1061#28 8X490-PHR-PHR-F 1

3 5100052985 FLAT CABLE SML2CD-8X260-BDX8(BL)-P1.0-S5 1

4 5100052970 WIRING 1061#28 6X120-PHR-PHR-F 1

5 5100052987 FLAT CABLE SML2CD-12X250-BDX8(BL)-P1.0-S 1

6 5100052971 WIRING 1061#28 6X300-PHR-PHR-F 1

7 5100052986 FLAT CABLE SML2CD-10X600-BDX8(BL)-P1.0-S 1

8 5100052972 WIRING 1061#28 6X400-PHR-PHR-F 1

9 5100052988 FLAT CABLE SML2CD-16X290-BDX8(BL)-P1.0-S 1

10 5100052975 WIRING 1061#28 10X350-PHR-PHR-F 1

11 5100045471 WIRING 1061#28 4X100-PHR-PHR-F 1

12 5100052974 WIRING 1061#28 10X60-PHR-PHR-F 1

13 5100052977 WIRING 3302#32 4X100-SHR-SHR-F 2

14 5100052989 WIRING J-1 2

5100052990 WIRING J-2 2

15 5100052978 WIRING 3302#32 6X160-SHR 2

16 5100052979 WIRING 1007#22 3X50-XHP-XHP-F 1

17 05012067 WIRING J-1 Refer to Exploded View (Fig. A) (p. 18). 10

18 05012456 WIRING J-2 Refer to Exploded View (Fig. A) (p. 18). 2

28

Oct. 2016 DJ-808

Parts List

fig.-part1-e.eps

Safety Precautions:

The parts marked have

safety-related characteristics. Use

only listed parts for replacement.

Note: The parts marked # are new. (initial parts) The description “Q’ty” means a necessary number of the parts per one product.

CASING

# 5100051447 TOP CASE 1

# 5100052084 TOP PANEL L 1

# 5100052086 TOP PANEL C 1

# 5100052085 TOP PANEL R 1

# 5100052087 FADER PANEL 1

# 5100052081 PLATTER 2

# 5100052088 PLATTER SHEET 2

# 5100051448 BOTTOM CASE 1

CHASSIS

# 5100052100 ENCODER HOLDER 2

# 5100052117 FADER HOLDER 1

# 5100052101 PLATTER ANGLE 2

# 5100052097 PWB CHASSIS 1

# 5100052098 VOLUME HOLDER 1

# 5100052099 WHEEL PLATE 2

KNOB, BUTTON

# 5100052448 J R-KNOB MF-ELA BLK 2

# 5100052447 J R-KNOB MF-ELA BLK/LCG 16

# 5100053558 J R-KNOB MF-ELA MCG/LCG 12

# 5100052449 J S-KNOB BLK 6

# 5100052446 R-KNOB KF-ELA BLK 1

# 5100052450 S-KNOB BLK 2

# 5100052089 S-KNOB 11

# 5100052439 C-KEYTOP MX1H CLR 1 1

# 5100052440 C-KEYTOP MX1H CLR 2 1

# 5100052441 C-KEYTOP MX1H CLR 3 1

# 5100052442 C-KEYTOP MX1H CLR 4 1

# 5100052443 C-KEYTOP MX1H CLR BLK 4

# 5100052438 C-KEYTOP MX1H CLR CLEAR 1

# 5100052093 RUBBER SWITCH 1P 1

# 5100052092 RUBBER SWITCH 8P 2

# 5100052091 RUBBER SWITCH 4X2P 2

# 5100052445 KEYTOP UNIT CUE & PLAY/PAUSE 2

# 5100052430 S-KEYTOP LX1H CLR AUTO LOOP 2

# 5100052426 S-KEYTOP LX1H CLR AUTO PITCH 1

# 5100052437 S-KEYTOP LX1H CLR CUE 5

# 5100052431 S-KEYTOP LX1H CLR HOT CUE 2

# 5100052429 S-KEYTOP LX1H CLR KEY SYNC 2

# 5100052436 S-KEYTOP LX1H CLR LOAD 4

# 5100052428 S-KEYTOP LX1H CLR ON 6

# 5100052424 S-KEYTOP LX1H CLR PATTERN 1

# 5100052432 S-KEYTOP LX1H CLR ROLL 2

# 5100052434 S-KEYTOP LX1H CLR SAMPLER 2

# 5100052425 S-KEYTOP LX1H CLR SHIFT 3

# 5100052435 S-KEYTOP LX1H CLR SYNC 2

# 5100052427 S-KEYTOP LX1H CLR TAP 2

# 5100052433 S-KEYTOP LX1H CLR TR 2

# 5100052423 S-KEYTOP LX1H CLR TR-REC 1

# 5100052400 S-KEYTOP SX1H CLR ACC 1

# 5100052397 S-KEYTOP SX1H CLR ADJ 2

# 5100052393 S-KEYTOP SX1H CLR PANEL 1

# 5100052395 S-KEYTOP SX1H CLR Q 1

# 5100052394 S-KEYTOP SX1H CLR SCALE 1

# 5100052396 S-KEYTOP SX1H CLR SHUFFLE 1

# 5100052399 S-KEYTOP SX1H CLR SLIDE 2

# 5100052398 S-KEYTOP SX1H CLR SYNC 1

# 5100052418 S-KEYTOP SX2H CLR -/+ 2

5100037191 J S-KNOB M BLK/LCG 4

5100044342 M R-KNOB LF-ELA BLK 1

5100009822 M R-KNOB(716-10014-01-00) MF-ELA-A BLK/LCG 13

5100037825 G S-BUTTON BLK (710-12058-15-00) 1

5100044011 KEY CAP CLR 17

Due to one or more of the following reasons, parts with parts code ******** cannot be supplied

as service parts.

• Supply is prohibited due to copyright restrictions.

• It is carried in electronic data on the Roland web site.

• The part is made to order (at current market price).

• It can be replaced with an article on the market. (battery or etc.)

• It is a package or an accessory irrelevant to the function maintenance of the main body.

• A number of circuit boards are grouped together and supplied as a single circuit board (under a different part code).

• Reissuance is restricted.

• It is supplied as an assembled part

(under a different part code).

29

Oct. 2016 DJ-808

KNOB, BUTTON

# 5100052416 S-KEYTOP SX2H CLR 1/2X-2X 2

# 5100052410 S-KEYTOP SX2H CLR 1-2 6

# 5100052411 S-KEYTOP SX2H CLR 3-4 1

# 5100052412 S-KEYTOP SX2H CLR 5-6 1

# 5100052413 S-KEYTOP SX2H CLR 7-8 1

# 5100052421 S-KEYTOP SX2H CLR BD-SD 1

# 5100052414 S-KEYTOP SX2H CLR BLK-BLK 1

# 5100052422 S-KEYTOP SX2H CLR CH-OH 1

# 5100052415 S-KEYTOP SX2H CLR DOWN-UP 2

# 5100052419 S-KEYTOP SX2H CLR DUB ECHO-JET 1

# 5100052417 S-KEYTOP SX2H CLR IN-OUT 2

# 5100052420 S-KEYTOP SX2H CLR NOISE-FILTER 1

SWITCH

# 5100047832 SWITCH SL10020F-0203-15PA-SN 1

# 5100051488 SWITCH SKV-23F01-G6-TA 10

# 5100051485 SWITCH SKV-22F01-G6-TA 1

JACK, EXT TERMINAL

PWB ASSY

# 5100050270 MAIN BOARD ASSY 1

# 5100050265 JACK SHEET ASSY 1

# 5100050272 PANEL C SHEET ASSY 1

04904123 PUSH SWITCH AC POWER SUPPLY 400-07040-01-00(PWL-2P2T-6SBP 1

02891789 TACT SWITCH SKRGADD010 H=5.0 104

02456390 3.5MM JACK STEREO YKB21-5290 1

13449275 6.5MM JACK YKB21-5074 3

5100030795 CANNON CONNECTOR CT3-05M-01-EP(F3439960R0) 2

5100013062 CANNON CONNECTOR CT/PJ-02-07EP 1

02341634 DC JACK HTJ-020-05A 1

03345778 JACK YKC21-3473 2

13429672 MIDI JACK YKF51-5047 1

03234590 RCA(PIN) JACK YKC21-3503 1

5100007091 USB CONNECTOR UAR62-8K5J00(F3439907R0) 1

02781101 USB CONNECTOR B TYPE FEMALE YKF45-0020N 1

* This unit includes the following parts.

******** JACK BOARD 1

******** PHONES BOARD 1

* This unit includes the following parts.

******** CROSSFADER BOARD 1

******** FRONT L BOARD 1

******** FRONT U BOARD 1

******** PANEL C BOARD 1

# 5100050281 PANEL L SHEET ASSY 1

# 5100050290 PANEL R SHEET ASSY 1

DIODE

POTENTIOMETER

# 5100048076 ROTARY POTENTIOMETER RK09L114001T 16

# 5100048077 ROTARY POTENTIOMETER RK09L1140A2U 12

# 5100052310 SLIDE POTENTIOMETER C3080G1AV1B103BF10BF 4

# 5100052877 SLIDE POTENTIOMETER C4591NOFV1B103BL0021 5

# 5100047833 SLIDE POTENTIOMETER RA45D1LF-211-20C1-B10K 1

# 5100052775 SLIDE POTENTIOMETER RFA0N12K6505 2

* This unit includes the following parts.

******** ENCODER BOARD A 1

******** LEAF BOARD B 1

******** LED BOARD C 1

******** PANEL L BOARD 1

* This unit includes the following parts.

******** ENCODER BOARD The same part as A mentioned above 1

******** LEAF BOARD The same part as B mentioned above 1

******** LED BOARD The same part as C mentioned above 1

******** PANEL R BOARD 1

5100036722 LED A-364SRD 1

02125778 9M/M ROTARY POTENTIOMETER RK09L12B0 1

13289231 POTENTIOMETER RK09L1120A14 1

5100041032 ROTARY POTENTIOMETER XV09223NPV25F972Z10K/I 6

5100041031 ROTARY POTENTIOMETER XV09223NPV25F972Z10KCC/I 4

03560512 ROTARY POTENTIOMETER RK09L112003P 1

30

Loading...

Loading...