Page 1

WPC Qi-compliant Wireless Power Series

NFC-compatible Wireless Power Transmitter

for Automotive Applications

BD57121MUF-M Evaluation Board

BD57121MUF-EVK-001

Page 2

Notice

<High Voltage Safety Precautions>

◇ Read all safety precautions before use

Please note that this document covers only the BD57121MUF-M evaluation board

(BD57121MUF-EVK-001) and its functions. For additional information, please refer to

the datasheet.

To ensure safe operation, please carefully read all precautions before

handling the evaluation board

Depending on the configuration of the board and voltages used,

Potentially lethal voltages may be generated.

Therefore, please make sure to read and observe all safety precautions described in

the red box below.

Before Use

[1] Verify that the parts/components are not damaged or missing (i.e. due to the drops).

[2] Check that there are no conductive foreign objects on the board.

[3] Be careful when performing soldering on the module and/or evaluation board to ensure that solder

splash does not occur.

[4] Check that there is no condensation or water droplets on the circuit board.

During Use

[5] Be careful to not allow conductive objects to come into contact with the board.

[6] Brief accidental contact or even bringing your hand close to the board may result in

discharge and lead to severe injury or death.

Therefore, DO NOT touch the board with your bare hands or bring them too close to the board.

In addition, as mentioned above please exercise extreme caution when using conductive tools such as

tweezers and screwdrivers.

[7] If used under conditions beyond its rated voltage, it may cause defects such as short-circuit or,

depending on the circumstances, explosion or other permanent damages.

[8] Be sure to wear insulated gloves when handling is required during operation.

After Use

[9] The ROHM Evaluation Board contains the circuits which store the high voltage. Since it stores the

charges even after the connected power circuits are cut, please discharge the electricity after using

it, and please deal with it after confirming such electric discharge.

[10] Protect against electric shocks by wearing insulated gloves when handling.

This evaluation board is intended for use only in research and development facilities and

should by handled only by qualified personnel familiar with all safety and operating

procedures.

We recommend carrying out operation in a safe environment that includes the use of high

voltage signage at all entrances, safety interlocks, and protective glasses.

www.rohm.com HVA01E

© 2018 ROHM Co., Ltd. All rights reserved.

Page 3

© 2017 ROHM Co., Ltd.

No. 60AP001E Rev.001

2017.4

© 2019 ROHM Co., Ltd.

No. 61UG042E Rev.001

JAN.2019

User’s Guide

Parameter

Min

Typ

Max

Units

Conditions

Input voltage

11.0

12.0

13.0

V

Output voltage

(receiver side)

-

12.0

-

V

Using BD57015GWL-EVK-002

Rx board

Output current

(receiver side)

0 - 1.25

A

Using BD57015GWL-EVK-002

Rx board

Dark current

- 0 5

μA

SW1=OFF

Operating frequency

(Wireless power)

-

127.8

-

kHz

WPC Qi-compliant Wireless Power Series

NFC-compatible Wireless Power Transmitter

for Automotive Applications

BD57121MUF-M E valuation Board

BD57121MUF-EVK-001

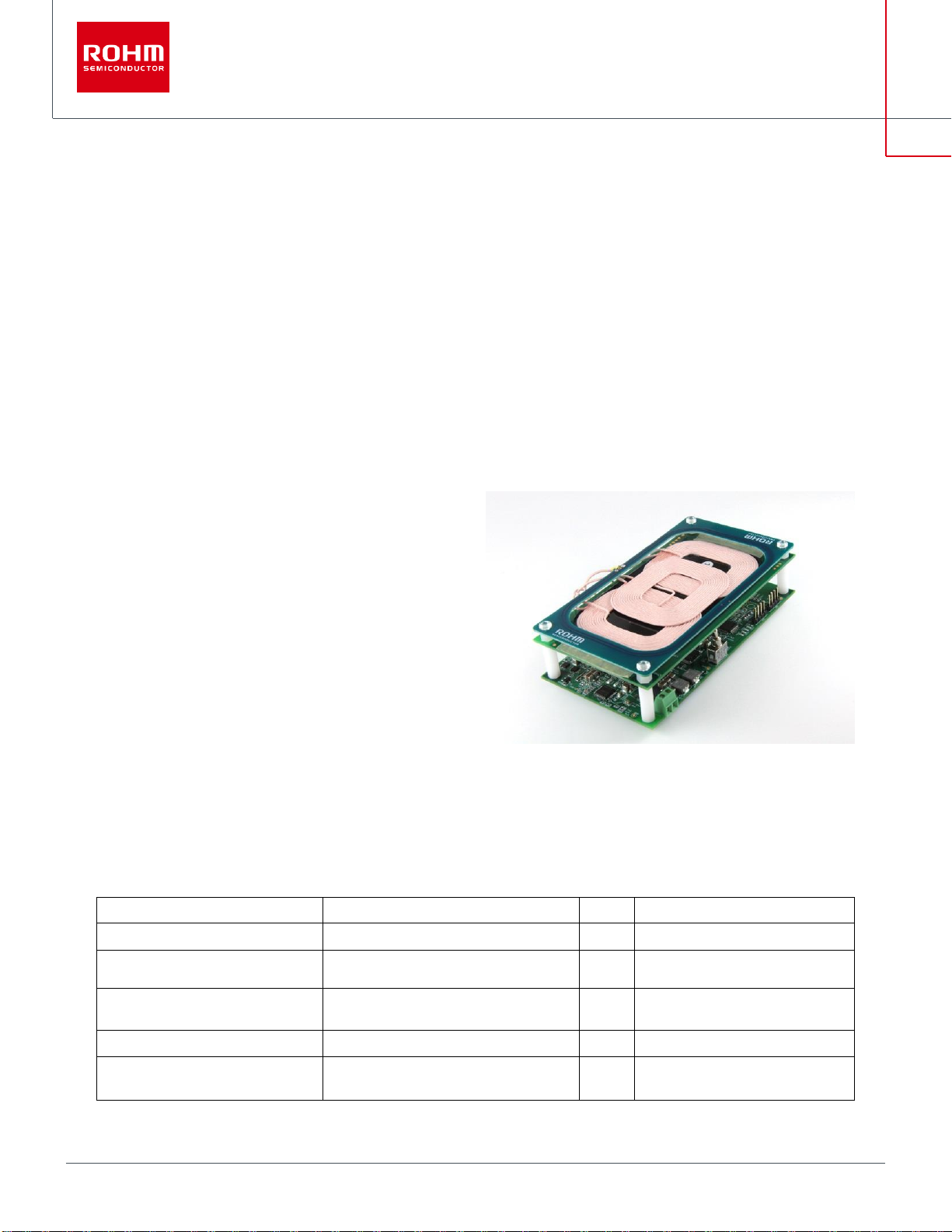

BD57121MUF-EVK-001 Evaluation Board is based on the BD57121MUF-M Automotive-grade wireless power transmitter IC. This board

integrates the ST25R3914 NFC reader/writer IC from ST Microelectronics to detect the presence of any NFC cards or tags and to prevent

damaging of the NFC antennae by the wireless power transfer system. Wireless power transfer is compliant with WPC Qi ver1.2.4 and can supply

power up to 15 W (output in receiver). Detection and identification of NFC Type A, B, F and V are possible.

Features

・Compliance to WPC Qi ver1.2.4

・Support of Multiple coils to increase charging area

(Qi MP-A13 coil type)

・Power control using fixed frequency and variable voltage

・NFC card / tag detection of Type A, B, F, V

・Housing size: 120 mm x 65 mm x 30 mm

Figure 1. BD57121MUF-EVK-001 Evaluation Board

Performance specification

These are only representative values, and they do not represent guaranteed values of the product characteristics.

VIN = 12 V, unless otherwise specified.

1/13

Page 4

User’s Guide

BD57121MUF-EVK-001

© 2019 ROHM Co., Ltd.

No. 61UG042E Rev.001

JAN.2019

Rectification

Mod/DeMod

LDO

Qi packet

Controller

Load

Predriver

Transmitter(Tx) : BD57121MUF-EVK-001

Qi Receiver(Rx)

Voltage

&

Current

Sensing

Power

BD57015GWL

Data

Data

Half/Full

Bridge

Demodulator

Tx

Controller

Voltage

&

Current

Sensing

MCU

BD57121MUF-M

NFC Reader/Writer

NFC

Card/TAG

Data

Data

NFC listener

Manufacturer

Product

Part Number

ROHM Semiconductor

Wireless Power Transmitter IC

BD57121MUF-M

ROHM Semiconductor

Low Dropout Regulator IC

BD00C0AWFP-C

Infineon Technologies

Buck-Boost DC/DC controller IC

TLD5190QV

ST Microelectronics

NFC Reader/Writer IC

ST25R3914

ST Microelectronics

Microcontroller

STM8AF62A8

TDK

Qi Transmitter Coil

WT1005690-12F2-A6-G1

ROHM Semiconductor

NFC Antenna

- (PCB pattern)

Evaluation Board

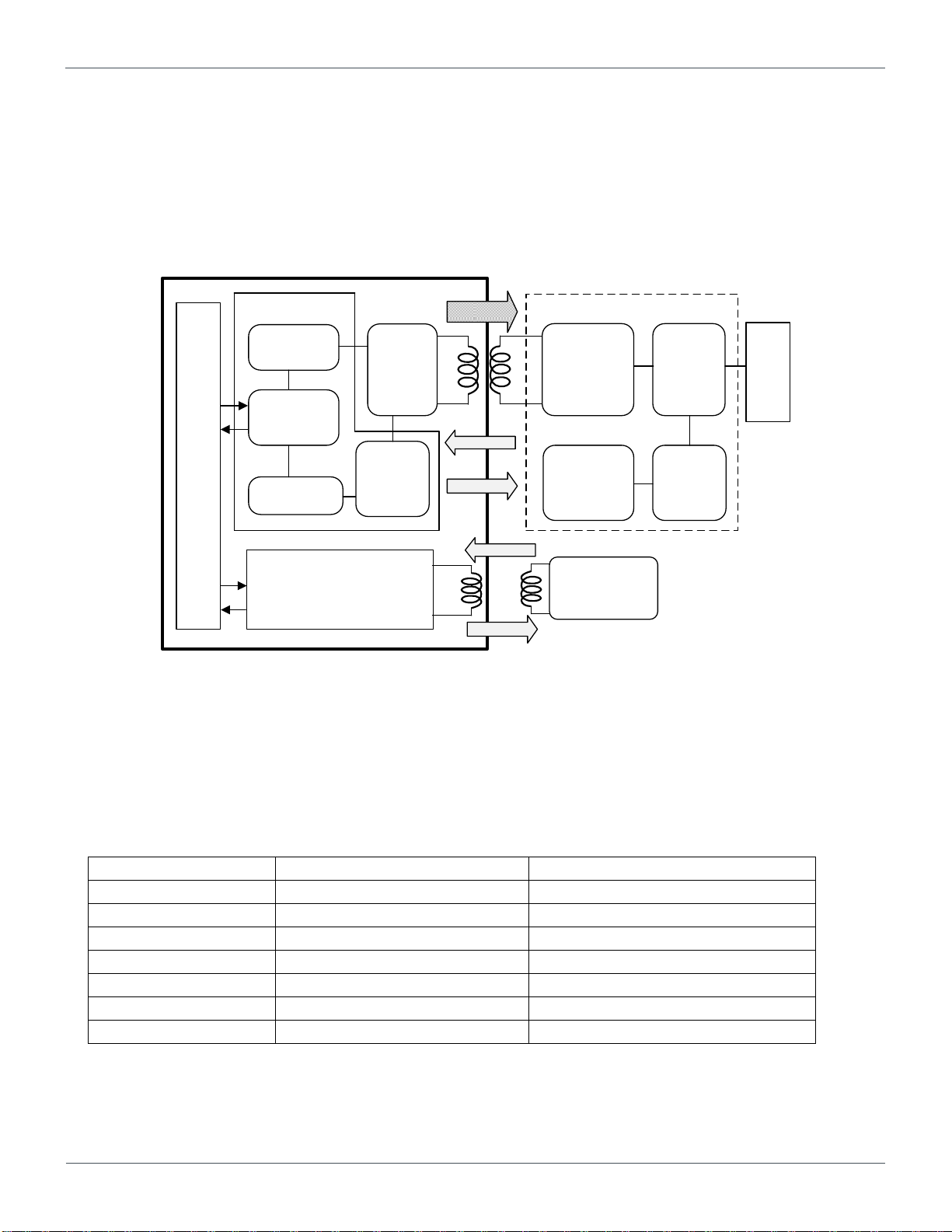

1. System configuration for wireless power transfer and NFC

Wireless power transfer system consists of a two-way power transmission and communication system using a transmitter and a

receiver, and the NFC system also communicates between the reader (= transmitter) and the listener. A single Microcontroller (MCU)

controls both wireless power transmission and NFC reader, so it is possible to have seamless operation between each other.

Figure 2. System configuration for wireless power transfer and NFC

2. Key components

The purpose of this EVK is to evaluate and verify key components needed for wireless power transfer and NFC detection. For more

information, refer to the Web site for each product.

2/13

Page 5

User’s Guide

BD57121MUF-EVK-001

© 2019 ROHM Co., Ltd.

No. 61UG042E Rev.001

JAN.2019

CAR Battery

LDO

Buck-Boost

DC/DC

5.4V/1A

Temperature

Sensing Circuits

(option)

Coil Selector

COIL1 COIL2 COIL3

Full Bridge

Qi Resonant Tank

ROHM WPT

BD57121MUF-M

ST Micro MCU

STM8AF

ST Micro

ST25R3914

DAC

V-

monitor

Pre-

drive

I-

monitor

FET FET

FET FET

LDO

I2C

(3.3V)

SPI

(3.3V)

3.3V/0.15A

12V/3A

Enable SW

Load SW

VDDMCU

VDDA

PI filter

VDDA

VDDMCU

VBUS54

VDDMCU

VBUS54

VDDMCU

VBUS54

NFC Antenna

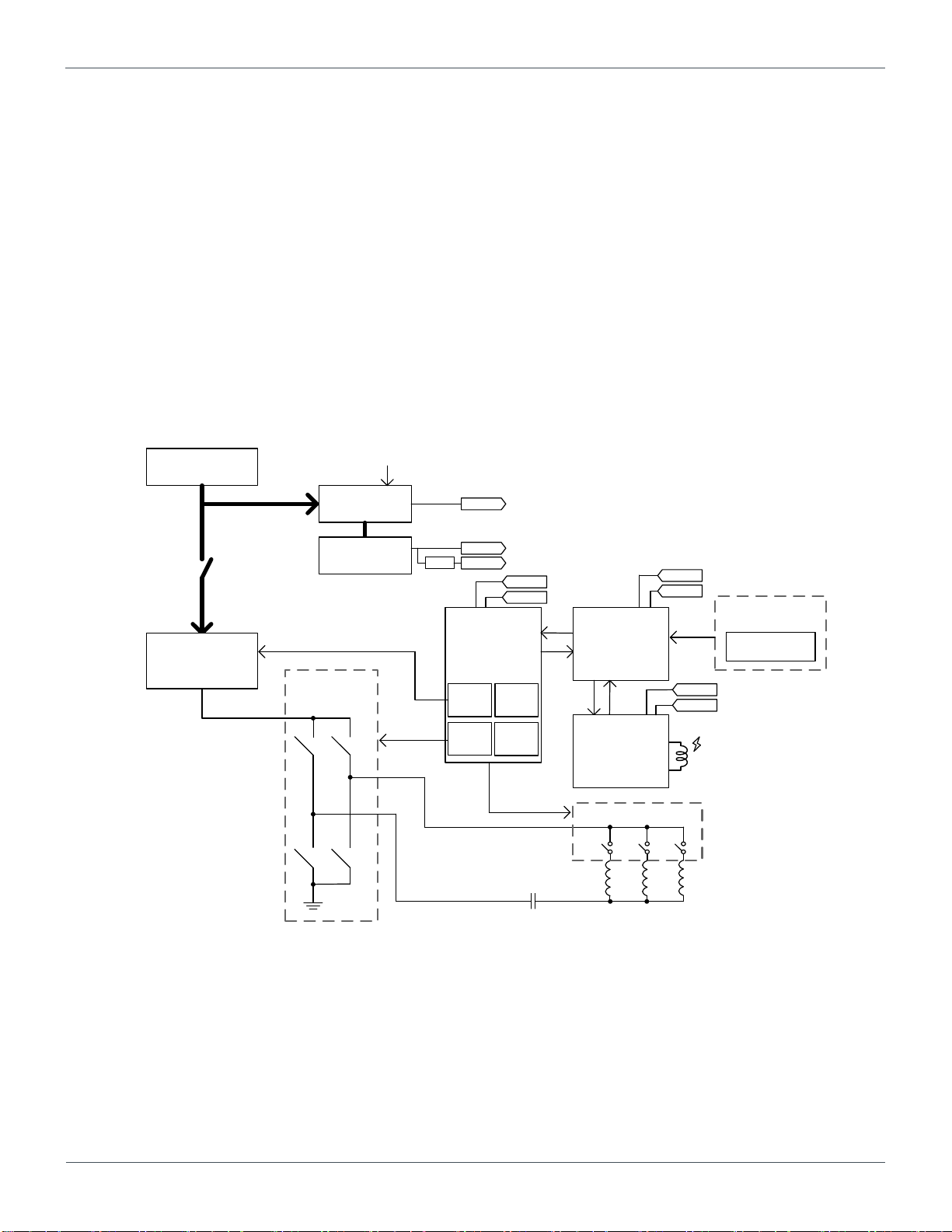

3. Block diagram of the transmitter

BD57121MUF-M operates with a 5.4 V power supply. NFC reader IC ST25R3914 operates with a main power supply of 5.4 V

and a sub of 3.3 V. The STM8AF MCU operates with a main power supply of 3.3 V. The peripheral voltage of the MCU is 3.3 V.

The MCU communicates with the BD57121MUF-M via I2C bus, and with the ST25R3914 via SPI bus.

BD57121MUF-M functions as the analog front-end for wireless power transfer that is compliant to Qi ver 1.2.4, and it includes a

D / A converter for voltage control, a pre-driver for driving the inverter bridge, an analog sensing circuit, and a selector circuit for

multiple coils.

ST25R3914 is a high-sensitivity and high-power NFC / HF analog front-end that supports ISO14443A / B, ISO15693, FeliCa™

and ISO 18092 (NFCIP-1) active P2P. This IC directly drives the NFC antenna. Please contact ST Microelectronics regarding

details of this IC.

Figure 3. BD57121MUF-EVK-001 Block diagram

3/13

Page 6

User’s Guide

BD57121MUF-EVK-001

© 2019 ROHM Co., Ltd.

No. 61UG042E Rev.001

JAN.2019

DC Power

Supply

+ -

SW1

Left : ON

Center: OFF

Right : OFF

LED indicators

Qi Coil

NFC Antenna

GNDADPVADPV

Operation Procedures

1. Required equipment

(1) 12V, 3A DC power supply

(2) BD57121MUF-EVK-001 Evaluation board (this EVK)

(3) Qi compliant receivers (Qi compliant Smartphone / Rohm's EVK receiver: BD57015GWL-EVK-002)

(4) Load (Electronic load or resistor is prepared as a load on the receiver side, if necessary)

(5) DC voltage meter

(6) NFC card / tag

2. Connecting the equipment

(1) Set the DC power supply to 12V and turn off the power supply output.

(2) Confirm that SW1 on the EVK is on the OFF side.

(3) Connect the positive terminal of the power supply to the ADPV terminal and the negative terminal of the power supply to the

GNDADPV terminal with a pair of wires.

(4) Turn on the DC power supply output.

(5) Set SW1 to ON, then LED4 lights on green.

Figure 4. Connection

4/13

Page 7

User’s Guide

BD57121MUF-EVK-001

© 2019 ROHM Co., Ltd.

No. 61UG042E Rev.001

JAN.2019

Tx Status

LED1(Green)

LED2(Green)

LED3(Red)

LED4(Green)

Disable (SW1=OFF)

OFF

OFF

OFF

OFF

Stand by(Idle)

OFF

OFF

OFF

ON

Qi BPP

(*1)

charging

ON

OFF

OFF

ON

Qi EPP

(*2)

charging

ON

ON

OFF

ON

During NFC detection

(*3)

OFF

OFF

ON

ON

During Error detection

(*4)

OFF

OFF

Blinking

ON

3. Operation of Wireless power transmission

(1) Put Qi compliant receiver directly on top of the Qi coil of the transmitter.

(2) When communication with the receiver is established, LED1 and LED2 light up in green according to the power profile of the

receiver.

(3) Connect the load.

4. Operation of NFC detection

(1) Place the NFC card / tag near the NFC antenna (approx. at 5 cm distance).

(2) LED3 lights on red during detection.

5. LED indicators

(*1) BPP (Baseline Power Profile): Capable wireless power supply up to 5W

(*2) EPP (Extended Power Profile): Capable wireless power supply up to 15W

(*3) LED3 also lights up when EVK protection circuit is activated.

Check whether there is abnormal heating on the board or overcurrent of the input power supply.

(*4) There are two types of error detection status.

・ Foreign Object Detection

Make sure that no foreign objects are caught between the transmitter and receiver.

In addition, due to position gap of the coil, foreign object may be detected. Therefore, please align the center of the

receiver coil with the center of Qi coil of the transmitter.

・ End of Power Transfer

The transmitter has stopped transferring power because it has received a stop signal from the receiver that is in use.

Please check using another receiver if the same phenomenon occurs.

5/13

Page 8

BD57121MUF-EVK-001

1

User’s Guide

Circuit Diagram 1

Figure 5. BD57121MUF-EVK-001 Circuit Diagram (1/2)

© 2019 ROHM Co., Ltd.

6/13

No. 61UG042E Rev.00

JAN.2019

Page 9

BD57121MUF-EVK-001

1

Circuit Diagram 2

User’s Guide

Figure 6. BD57121MUF-EVK-001 Circuit Diagram (2/2)

© 2019 ROHM Co., Ltd.

7/13

No. 61UG042E Rev.00

JAN.2019

Page 10

User’s Guide

BD57121MUF-EVK-001

© 2019 ROHM Co., Ltd.

No. 61UG042E Rev.001

JAN.2019

Instance Name

Value

Description

Size

Part Number/Series

Manufacturer

Quantity

U1

-

IC, WIRELESS TRANSMITTER

48VQFN

BD57121MUF-M

ROHM

1

U2

-

IC,IC LED DRVR DCDC CTRLR

48VQFN

TLD5190QV

INFINEON 1 U3

-

IC,IC REG LINEAR POS ADJ 1A

TO252-5

BD00C0AWFP-C

ROHM

1

U4

-

IC,IC MCU 8BIT 128KB FLASH

48LQFP

STM8AF62A8

STMICRO 1 U5

-

IC,IC REG LINEAR 3.3V 150MA

SOT23-5

TC1185-3.3VVCT713

MICROCHIP 1 U200

-

IC,NFC Initiator / HF Reader IC

QFN32

ST25R3914

STMICRO

1

Q_H1, Q_H2, Q_L1, Q_L2, Q5, Q13, Q14,

Q15, Q16

-

MOSFET Nch 40V 30A

HSMT8

RQ3G150GNMHSTB

ROHM

9

Q1

-

MOSFET Pch 30V 7A

TSTM8

RQ1E070RPFRATR

ROHM 1 Q2, Q12

-

MOSFET Nch 100V 1A

TSMT3

RSR010N10FHATL

ROHM 2 Q6, Q7, Q8

-

MOSFET Pch 60V 1.5A

TSMT3

RSR015P06FRATL

ROHM 3 Q9, Q10, Q11

-

MOSFET 2N-CH

8TDSON

IPG20N10S4L-35

INFINEON 3 D1

-

Diode,ZENER DIODES

EMD2

EDZVFHT2R36B

ROHM

1

D2, D4, D5, D6, D7, D8, D9, D13, D14

-

Diode,DIODE SCHOTTKY 100V

D_PMDU

RB578VYM100FHTR

ROHM 9 D10, D11, D12

-

Not mount

D_PMDU - - - LED1, LED2, LED4

-

LED, GREEN-YELLOW CLEAR

1006

SML-P11MTT86RG

ROHM

3

LED3

-

LED, RED CLEAR

1006

SML-P11VTT86RH

ROHM

1

L1

11.5 μH

Inductor, Qi Wireless 3 array coil

-

WT1005690-12F2-A6-G1

TDK

1

L2, L3

1 μH

Inductor 17.3A

-

ETQ-P4M1R0KVK

PANASONIC 2 L4

10 μH

Inductor, 7.6A

-

ETQ-P4M100KVC

PANASONIC 1 L5, L6

3.3 μH

Inductor, 6.1A

-

ETQ-P3M3R3KVN

PANASONIC 2 COM-CH1

700Ω

Inductor,CMC 5A 2LN

-

ACM90V-701-2PL-TL00

TDK 1 L7, L100, L101, L200

470Ω

Inductor, FERRITE BEAD

-

BLM18EG471SH1D

MURATA 4 L300, L301

180 nH

Inductor, 310mA, 1.65Ω

-

LQW18ANR18G8ZD

MURATA 2 RS1, RS2

0.1Ω

Resistor, Chip, 1/3W

1608

UCR10EVHFLR100

ROHM 2 RH1, RH2, RL1, RL2

10Ω

Resistor, Chip, 1/16W

1005

MCR01MZPD10R0

ROHM

4

RHD1, RHD2, RLD1, RLD2, RIN1, RIN2, R51,

R65, R91, R92, R93

100 kΩ

Resistor, Chip, 1/16W

1005

MCR01MZPD1003

ROHM

11

RTX

-

Not mount

1005 - - - RINVV, RINVI

22Ω

Resistor, Chip, 1/16W

1005

MCR01MZPD22R0

ROHM

2

RPK1

47 kΩ

Resistor, Chip, 1/10W

1608

MCR03EZPD4702

ROHM

1

RPK2

4.7 kΩ

Resistor, Chip, 1/10W

1608

MCR03EZPD4701

ROHM 1 RPUINTB, RPUSCL, RPUSDA

3.3 kΩ

Resistor, Chip, 1/16W

1005

MCR01MZPD3301

ROHM

3

RPUVAR, R21, R22, R23, RIN3, R74, R75

20 kΩ

Resistor, Chip, 1/16W

1005

MCR01MZPD2002

ROHM 7 R24, R25, R26

5.1 kΩ

Resistor, Chip, 1/16W

1005

MCR01MZPD5101

ROHM 3 R27, R28, R29, R55, R56

51 kΩ

Resistor, Chip, 1/16W

1005

MCR01MZPD5102

ROHM

5

R33, R34, R35

51Ω

Resistor, Chip, 1/10W

1608

MCR03EZPD51R0

ROHM

3

R41, R42

16 mΩ

Resistor, Chip, 1/3W

1608

UCR10PVHXFSR016

ROHM

2

R43

51Ω

Resistor, Chip, 1/16W

1005

MCR01MZPD51R0

ROHM 1 R44, R45

20 mΩ

Resistor, Chip, 1/3W

1608

UCR10PVHXFSR020

ROHM

2

R46

10 kΩ

Resistor, Chip, 1/16W

1005

MCR01MZPD1002

ROHM

1

R47

30 kΩ

Resistor, Chip, 1/16W

1005

MCR01MZPD3002

ROHM

1

RLSGD1, RLSGD2, RHSGD1, RHSGD2

0Ω

Resistor, Chip, 1/16W

1005

MCR01MZPJ000

ROHM

4

R52, R68, R97, R98, R99, RLED3, RLED4

1 kΩ

Resistor, Chip, 1/16W

1005

MCR01MZPD1001

ROHM

7

R53

3 kΩ

Resistor, Chip, 1/16W

1005

MCR01MZPD3001

ROHM

1

R54

24 kΩ

Resistor, Chip, 1/16W

1005

MCR01MZPD2402

ROHM 1 R58, RCLMP

100 kΩ

Resistor, Chip, 1/10W

1608

MCR03EZPD1003

ROHM

2

R59

510Ω

Resistor, Chip, 1/10W

1608

MCR03EZPD5100

ROHM

1

R61

62 kΩ

Resistor, Chip, 1/16W

1005

MCR01MZPD6202

ROHM

1

R62

10 kΩ

Resistor, Chip, 1/16W

1005

MCR01MZPD1002

ROHM

1

R66

2.4 kΩ

Resistor, Chip, 1/10W

1608

MCR03EZPD2401

ROHM

1

R67

330 kΩ

Resistor, Chip, 1/10W

1608

MCR01MZPD3303

ROHM

1

R68

22 kΩ

Resistor, Chip, 1/16W

1005

MCR01MZPD2202

ROHM

1

R71

100Ω

Resistor, Chip, 1/10W

1005

MCR01MZPD1000

ROHM

1

R76

47 kΩ

Resistor, Chip, 1/16W

1005

MCR01MZPD4702

ROHM

1

R77

6.8 kΩ

Resistor, Chip, 1/16W

1005

MCR01MZPD6801

ROHM

1

R82

10 kΩ

Resistor, Chip, 1/10W

1608

MCR03EZPD1002

ROHM 1 ROSC11

1 MΩ

Resistor, Chip, 1/16W

1005

MCR01MZPD1004

ROHM 1 ROSC12

15Ω

Resistor, Chip, 1/16W

1005

MCR01MZPD15R0

ROHM 1 ROSC21

10 MΩ

Resistor, Chip, 1/10W

1608

MCR03EZPFX1005

ROHM 1 ROSC22

15Ω

Resistor, Chip, 1/10W

1608

MCR03EZPD15R0

ROHM 1 RLED1, RLED2

680Ω

Resistor, Chip, 1/16W

1608

MCR03EZPD6800

ROHM 2 RADP1

120 kΩ

Resistor, Chip, 1/16W

1005

MCR01MZPD1203

ROHM 1 RADP2

18 kΩ

Resistor, Chip, 1/16W

1005

MCR01MZPD1802

ROHM 1 R200, R201, R202, R203, R204

220Ω

Resistor, Chip, 1/16W

1005

MCR01MZPD2200

ROHM 5 R205, R206

1 kΩ

Resistor, Chip, 1/16W

1005

MCR01MZPD1001

ROHM 2 R300_NFCF, R301_NFCF

2Ω

Resistor, Chip, 1/10W

1608

MCR03EZPD2R00

ROHM

2

R300, R301

1 Ω

Resistor, Chip, 1/10W

1608

MCR03EZPD1R00

ROHM

2

Bill of materials

8/13

Page 11

User’s Guide

BD57121MUF-EVK-001

© 2019 ROHM Co., Ltd.

No. 61UG042E Rev.001

JAN.2019

Instance Name

Value

Description

Size

Part Number/Series

Manufacturer

Quantity

CPIF1, CVRAIL1, C42, C45, C48

20 μF

Capacitor, Chip, 25V

3126

GCM32EC71E226KE36L

MURATA

5

CPIF2, CPIF3, CADP1, CADP2, CVIN, C61

10 μF

Capacitor, Chip, 35V

3126

GCM32EC7YA106KA03L

MURATA 6 CIN1, C43, C46, C55, C63, C67

1.0 μF

Capacitor, Chip, 25V

1608

GCM188R71E105KA64D

MURATA 6 CLVAR, CLDO50, CLDO33

4.7 μF

Capacitor, Chip, 25V

2012

GCM21BC71E475KE36L

MURATA

3

CBOOT1, CBOOT2, C47, C51, C52, C56,

C64, C65, C91, C92, C93, CNRST

0.1 μF

Capacitor, Chip, 50V

1005

GRT155R71E104KE01#

MURATA

12

CCOILV2, C24, C25, C26

1000 pF

Capacitor, Chip, 250V

2012

GCM21A5C2E102JX01#

MURATA

4

CVREF33, CVREF41, CRS, C44, C50

2.2 μF

Capacitor, Chip, 25V

2012

GCM21BR71E225KA73L

MURATA 5 CVDDIO, CVDD

1.0 μF

Capacitor, Chip, 25V

1608

GCM188R71E105KA64D

MURATA 2 CVRAIL2, CVRAIL3, CISEN

0.1 μF

Capacitor, Chip, 50V

1005

GRT155R71E104KE01#

MURATA

3

CSER11, CSER12, CP1, CP2, CP3, CP4

0.1 μF

Capacitor, Chip, 450V

3216

GC332DD72W104KX01L

MURATA 6 CSR13, CSR14

-

Not mount

3216 - - - CVDAC, C21, C22, C23, C202

-

Not mount

1005 - - - CSW1, CSW2

-

Not mount

1608 - -

-

C53, C54

0.022 μF

Capacitor, Chip, 50V

1005

GRT155R71H223KE01D

MURATA 2 CLS1, CLS2, CHS1, CHS2

100 pF

Capacitor, Chip, 50V

1005

GRT1555C1H101JA02#

MURATA 4 C66

470 pF

Capacitor, Chip, 50V

1005

GRT1555C1H471JA02#

MURATA 1 C68

2200 pF

Capacitor, Chip, 50V

1608

GRT1885C1H222JA02#

MURATA 1 C69

0.022 μF

Capacitor, Chip, 50V

1005

GRT155R71H223KE01D

MURATA 1 C70

680 pF

Capacitor, Chip, 50V

1005

GRT1555C1H681JA02#

MURATA 1 C81, C82

0.47 μF

Capacitor, Chip, 10V

1005

GRT155R71A474ME01#

MURATA 2 COSC11, COSC12

10 pF

Capacitor, Chip, 100V

1005

GRT1555C2A100JA02D

MURATA 2 COSC21, COSC22

3.3 pF

Capacitor, Chip, 100V

1005

GRT1555C2A3R3CA02D

MURATA 2 C100

100 pF

Capacitor, Chip, 50V

1005

GRT1555C1H101JA02#

MURATA 1 C101, C208, C209, C210, C211

0.01 μF

Capacitor, Chip, 25V

1005

GRT155R71E103KE01#

MURATA 5 C102, C212, C213, C214

2.2 μF

Capacitor, Chip, 10V

1005

GRT155C71A225KE13D

MURATA 4 C200, C215

1.0 μF

Capacitor, Chip, 25V

1608

GCM188R71E105KA64D

MURATA 2 C201, C203

0.1 μF

Capacitor, Chip, 50V

1005

GRT155R71E104KE01#

MURATA 2 C204, C205, C316, C317

12 pF

Capacitor, Chip, 50V

1005

GRT1555C1H120JA02#

MURATA 4 C206, C207

8.2 pF

Capacitor, Chip, 50V

1005

GCM1555C1H8R2DA16D

MURATA 2 C300, C311

150 pF

Capacitor, Chip, 50V

1608

GRT1885C1H151JA02#

MURATA 2 C301, C310

10 pF

Capacitor, Chip, 100V

1005

GRT1555C2A100JA02#

MURATA 2 C302, C309

220 pF

Capacitor, Chip, 50V

1005

GRT1555C1H221JA02#

MURATA 2 C302_NFCF, C309_NFCF

120 pF

Capacitor, Chip, 50V

1005

GRT1555C1H121JA02#

MURATA 2 C304, C308

1200 pF

Capacitor, Chip, 50V

1608

GRT1885C1H122JA02#

MURATA 2 C303, C306

39 pF

Capacitor, Chip, 50V

1608

GRT1885C1H390JA02#

MURATA 2 C305, C307

39 pF

Capacitor, Chip, 50V

1608

GRT1885C1H390JA02#

MURATA 2 C314, C315

5.6 pF

Capacitor, Chip, 50V

1005

GCM1555C1H5R6BA16D

MURATA 2 C318, C319

27 pF

Capacitor, Chip, 50V

1005

GRT1555C1H270JA02#

MURATA 2 C320, C321

56 pF

Capacitor, Chip, 50V

1005

GRT1555C1H560JA02#

MURATA

2

OSC1

48 MHz

Oscillator, CRYSTAL, 8PF

3225

NX3225GA

EXS00A-CG07369

NDK

1

OSC2

-

Not mount

3225 - -

1

Y100

27.12 MHz

Oscillator, CRYSTAL, 6PF

2016

XRCGB27M120F3A00R0

MURATA

1

RVDDIO, ROSC10, ROSC20, CSER21,

CSER22, CSER23, CSER24

-

Jumper, SOLDER SHORT

JUMPER

- - -

-

J302, J303

0Ω

Resistor, Chip, 1/16W

1005

MCR01MZPJ000

ROHM

2

9/13

Page 12

User’s Guide

BD57121MUF-EVK-001

© 2019 ROHM Co., Ltd.

No. 61UG042E Rev.001

JAN.2019

Layout 1

Figure 7. Top silk screen, layout (Top View)

Figure 8. Bottom silk screen, layout (Top View)

Figure 9. TOP Layer layout (Top View)

10/13

Page 13

User’s Guide

BD57121MUF-EVK-001

© 2019 ROHM Co., Ltd.

No. 61UG042E Rev.001

JAN.2019

Layout 2

Figure 10. Middle Layer 1 layout (Top View)

Figure 11. Middle Layer 2 layout (Top View)

Figure 12. Bottom Layer layout (Top View)

11/13

Page 14

User’s Guide

BD57121MUF-EVK-001

© 2019 ROHM Co., Ltd.

No. 61UG042E Rev.001

JAN.2019

0

10

20

30

40

50

60

70

80

0 5 10 15

System Efficiency [%]

Output Power at Rx [W]

0

10

20

30

40

50

60

70

80

0 1 2 3 4 5

System Efficiency [%]

Output Power at Rx [W]

Reference Application data

Figure 13. System Efficiency vs POUT (EPP)

Rx: BD57015GWL-EVK-002(ROHM), 12V output

Figure 14. System Efficiency vs POUT (BPP)

Rx: BD57011AGWL (ROHM), 5V output

12/13

Page 15

© 2019 ROHM Co., Ltd.

No. 61UG042E Rev.001

JAN.2019

User’s Guide

BD57121MUF-EVK-001

date

Revision

Changes

16. Jan. 2019

001

New release

Revision history

13/13

Page 16

Notes

The information contained herein is subject to change without notice.

1)

Before you use our Products, please contact our sales representative

2)

tions :

Although ROHM is continuously working to improve product reliability and quality, semicon-

3)

ductors can break down and malfunction due to various factors.

Therefore, in order to prevent personal injury or fire arising from failure, please take safety

measures such as complying with the derating characteristics, implementing redundant and

fire prevention designs, and utilizing backups and fail-safe procedures. ROHM shall have no

responsibility for any damages arising out of the use of our Poducts beyond the rating specified by

ROHM.

Examples of application circuits, circuit constants and any other information contained herein are

4)

provided only to illustrate the standard usage and operations of the Products. The peripheral

conditions must be taken into account when designing circuits for mass production.

The technical information specified herein is intended only to show the typical functions of and

5)

examples of application circuits for the Products. ROHM does not grant you, explicitly or implicitly,

any license to use or exercise intellectual property or other rights held by ROHM or any other

parties. ROHM shall have no responsibility whatsoever for any dispute arising out of the use of

such technical information.

The Products specified in this document are not designed to be radiation tolerant.

6)

For use of our Products in applications requiring a high degree of reliability (as exemplified

7)

below), please contact and consult with a ROHM representative : transportation equipment (i.e.

cars, ships, trains), primary communication equipment, traffic lights, fire/crime prevention, safety

equipment, medical systems, servers, solar cells, and power transmission systems.

Do not use our Products in applications requiring extremely high reliability, such as aerospace

8)

equipment, nuclear power control systems, and submarine repeaters.

ROHM shall have no responsibility for any damages or injury arising from non-compliance with

9)

the recommended usage conditions and specifications contained herein.

ROHM has used reasonable care to ensurH the accuracy of the information contained in this

10)

document. However, ROHM does not warrants that such information is error-free, and ROHM

shall have no responsibility for any damages arising from any inaccuracy or misprint of such

information.

Please use the Products in accordance with any applicable environmental laws and regulations,

11)

such as the RoHS Directive. For more details, including RoHS compatibility, please contact a

ROHM sales office. ROHM shall have no responsibility for any damages or losses resulting

non-compliance with any applicable laws or regulations.

When providing our Products and technologies contained in this document to other countries,

12)

you must abide by the procedures and provisions stipulated in all applicable export laws and

regulations, including without limitation the US Export Administration Regulations and the Foreign

Exchange and Foreign Trade Act.

This document, in part or in whole, may not be reprinted or reproduced without prior consent of

13)

ROHM.

and verify the latest specifica-

Notice

ZZZURKPFRP

652+0&R/WG$OOULJKWVUHVHUYHG

Thank you for your accessing to ROHM product informations.

More detail product informations and catalogs are available, please contact us.

ROHM Customer Support System

http://www.rohm.com/contact/

5

%

Loading...

Loading...