ROHM LTR10EZPJ Technical data

Table 1

R

t

High Power Chip Resistors

<Wide Terminal type>

LTR10 (2012 size : 1 / 4W)

Features

1) Improved welding strength

The structure of longer electrodes provides the wider welding area than the chip resistors with normal electrodes, and this

enhanced the solder welding strength.

2) Increased surge-resistance

This is achieved by Rohm’s original trimming technology plus resistive element patterning.

3) High-power tolerance

Two times of the rated power is guaranteed than the normal-electrode resistors.

4) ROHM resistors are ISO-9001 & ISO/TS16949 certified.

Design and specifications are subject to change without notice. Carefully check the specification sheet before using or

ordering it.

Applications

Automotive, industrial and power supply.

Ratings

Item Conditions Specifications

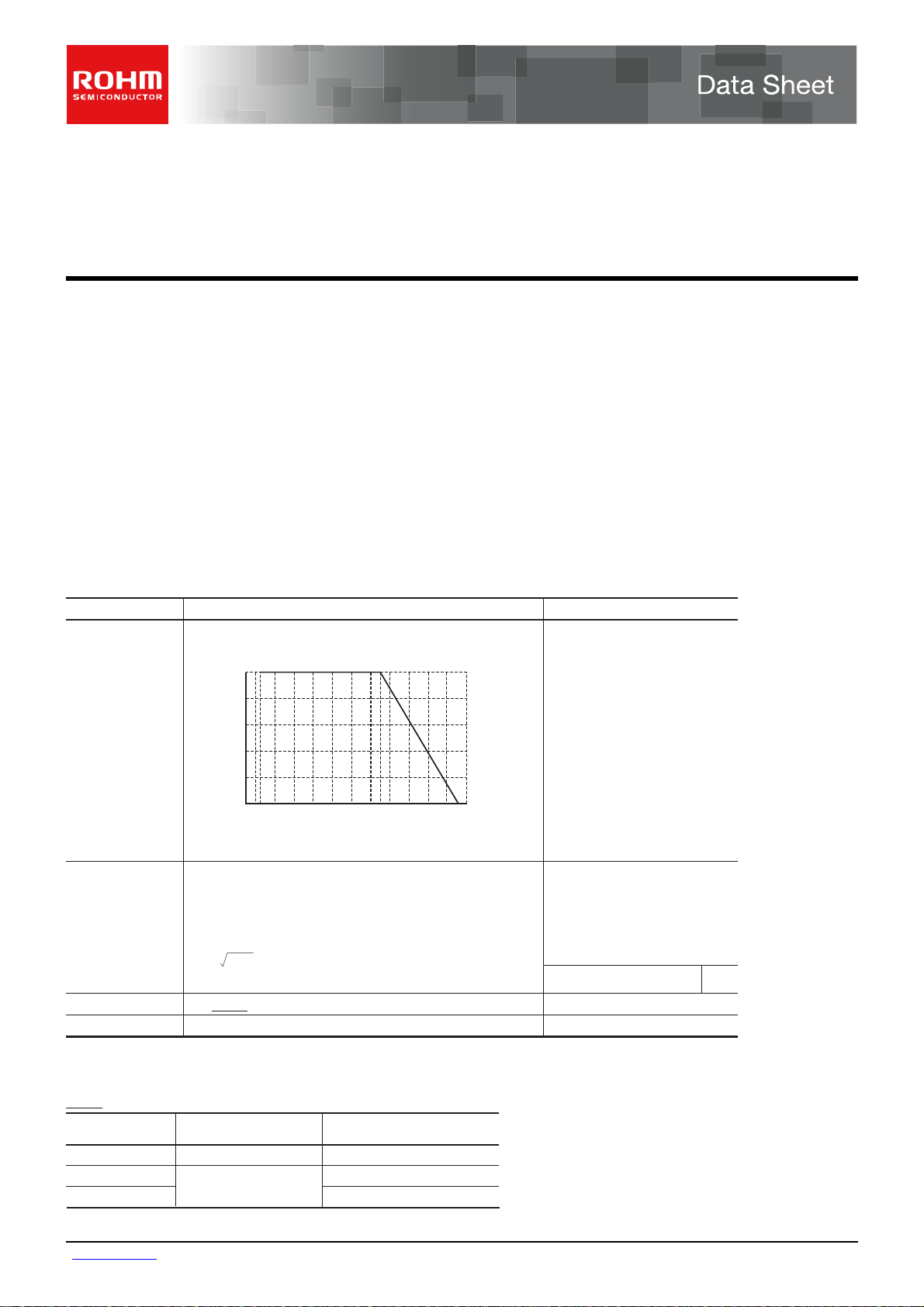

Rated power

Power must be derated according to the power derating curve in

Figure 1 when ambient temperature exceeds 70°

100

80

60

40

POWER LOAD (%)

20

0

−55 0 70 100 155

AMBIENT TEMPERATURE (°C)

Fig.1

C

.

0.25W (1 / 4W)

at 70°C

Rated voltage

Nominal resistance

Operating temperature

The voltage rating is calculated by the following equation.

If the value obtained exceeds the limiting element voltage,

the voltage rating is equal to the maximum operating voltage.

E: Rated voltage (V)

E= P×R

See Table 1.

P: Rated power (W)

R: Nominal resistance (Ω)

Limiting element voltage 150V

C to + 155°C

−55°

esistance tolerance

D (±0.5%)

F (±1%)

J (±5%)

www.rohm.com

1/3

c

○

2010 ROHM Co., Ltd. All rights reserved.

Resistance range

(Ω)

10 to 1M

1 to 1M (E24)

Resistance temperature coefficien

(ppm/°C)

±100

±100

±200

2010.06 - Rev.D

n.

Before using components in circuits where they will be exposed to transients such as pulse loads (short–duration, high– level

loads), be certain to evaluate the component in the mounted state. In addition, the reliability and performance of this component

cannot be guaranteed if it is used with a steady state voltage that is greater than its rated voltage.

Characteristics

Resistance

Variation of resistance

with temperature

Overload

Item Test conditions (JIS C 5201-1)

Guaranteed value

Resistor type

J : ±5%

F : ±1%

D : ±0.5%

See Table.1

± (2.0%+0.1Ω)

JIS C 5201-1 4.5

JIS C 5201-1 4.8

Measurement : −55 / +25 / +125°C

JIS C 5201-1 4.13

Rated voltage (current) ×2.5, 2s.

Maximum overload voltage : 200V

Data Sheet LTR10

Solderability

Resistance to

soldering heat

Rapid change of

temperature

Damp heat, steady state

Endurance at 70°C

Endurance

Resistance to solvent

Bend strength of

the end face plating

Static electric

characteristics

A new uniform coating of minimum of

95% of the surface being immersed

and no soldering damage.

± (1.0%+0.05Ω)

No remarkable abnormality on the appearance.

± (1.0%+0.05Ω)

± (3.0%+0.1Ω)

± (3.0%+0.1Ω)

± (3.0%+0.1Ω)

± (1.0%+0.05Ω)

± (1.0%+0.05Ω)

Without mechanical damage such as breaks.

± (5.0%+0.05Ω)

JIS C 5201-1 4.17

Rosin·Ethanol (25%WT)

Soldering condition : 235±5

Duration of immersion : 2.0±0.5s.

JIS C 5201-1 4.18

Soldering condition : 260±5

Duration of immersion : 10±1s.

JIS C 5201-1 4.19

Test temp. : −55

JIS C 5201-1 4.24

°C, 93%RH

40

Test time : 1,000h to 1,048h

JIS C 5201-1 4.25.1

Rated voltage (current), 70

1.5h : ON − 0.5h : OFF

Test time : 1,000h to 1,048h

JIS C 5201-1 4.25.3

°C

155

Test time : 1,000h to 1,048h

JIS C 5201-1 4.29

23±5

°C

, Immersion cleaning, 5±0.5mi

Solvent : 2-propanol

JIS C 5201-1 4.33

EIAJ ED-4701/300 Test method 304

Voltage : 3kV

C : 100pF

R : 1.5kΩ

Apply cycle : 1 time

°C

to +125°C 5cyc

°C

°C

°C

www.rohm.com

2/3

c

○

2010 ROHM Co., Ltd. All rights reserved.

2010.06 - Rev.D

Loading...

Loading...